Centrifugal pump low in failure rate

A centrifugal pump, failure rate technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of parts being easily damaged by corrosion, unstable performance, and high operating noise, etc., to achieve The effect of prolonging service life, reducing failure rate and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

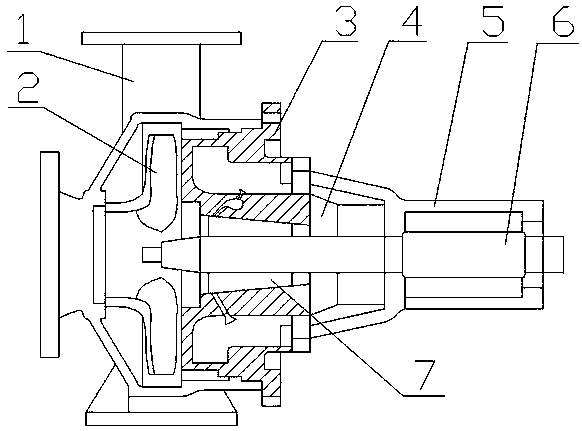

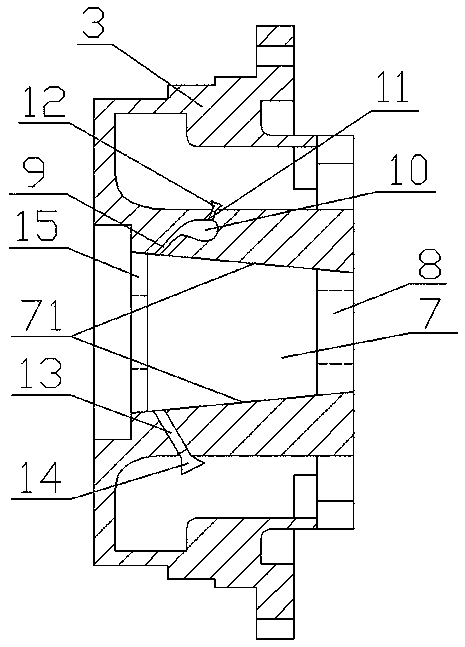

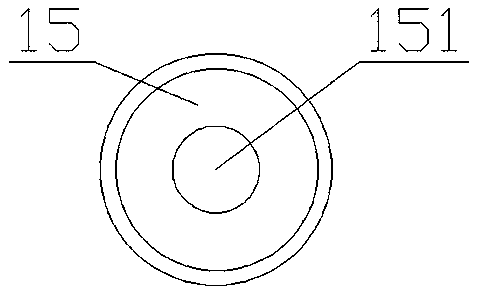

[0026] A centrifugal pump with stable use and long service life, including a pump body 1, an impeller 2, a pump cover 3, a mechanical seal gland 4, a suspension 5 and a rotating shaft 6, the pump cover 3 is fixed on one side of the pump body 1, The pump chamber for installing the impeller 2 is formed between the pump cover 3 and the pump body 1, the suspension 5 is fixed on one side of the pump cover 3, the rotating shaft 6 is supported in the suspension 5 through a bearing, and one end of the rotating shaft 6 extends into the pump chamber , the impeller 2 is placed in the pump cavity of the pump body 1 and fixed on the end of the shaft 6, a mechanical seal cavity 7 for installing a mechanical seal is provided between the pump cover 3 and the shaft 6, and a positioning mechanical seal is installed on the outside of the pump cover 3 The mechanical seal gland 4, the pump cover 3 is provided with a central through hole 8, the mechanical seal chamber 7 is located on the side of the...

Embodiment 2

[0040] A centrifugal pump with a low failure rate, including a pump body, an impeller, a pump cover, a mechanical seal gland, a suspension and a rotating shaft, the pump cover is fixed on one side of the pump body, and an impeller is formed between the pump cover and the pump body The pump chamber, the suspension is fixed on one side of the pump cover, the rotating shaft is supported in the suspension by the bearing, and one end of the rotating shaft extends into the pump chamber, the impeller is placed in the pump chamber of the pump body and fixed on the end of the rotating shaft, A mechanical seal chamber for installing a mechanical seal is provided between the pump cover and the rotating shaft, and a mechanical seal gland for positioning the mechanical seal is installed on the outside of the pump cover. The through hole faces one side of the pump body of the centrifugal pump and is connected with the central through hole. The mechanical seal chamber is in the shape of a tru...

Embodiment 3

[0054] A centrifugal pump with a low failure rate, including a pump body, an impeller, a pump cover, a mechanical seal gland, a suspension and a rotating shaft, the pump cover is fixed on one side of the pump body, and an impeller is formed between the pump cover and the pump body The pump chamber, the suspension is fixed on one side of the pump cover, the rotating shaft is supported in the suspension by the bearing, and one end of the rotating shaft extends into the pump chamber, the impeller is placed in the pump chamber of the pump body and fixed on the end of the rotating shaft, A mechanical seal chamber for installing a mechanical seal is provided between the pump cover and the rotating shaft, and a mechanical seal gland for positioning the mechanical seal is installed on the outside of the pump cover. The through hole faces one side of the pump body of the centrifugal pump and is connected with the central through hole. The mechanical seal chamber is in the shape of a tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com