Valve seat of double-clip type butterfly valve for coal cinder pipeline

A technology of cinder and valve seat, which is applied in the field of valve seat of butterfly valve for clip-on cinder pipeline, which can solve the problems of tearing, rubber-lined sealing layer falling off, short life, etc., and achieves increased corrosion resistance and wear resistance, and is not easy to tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

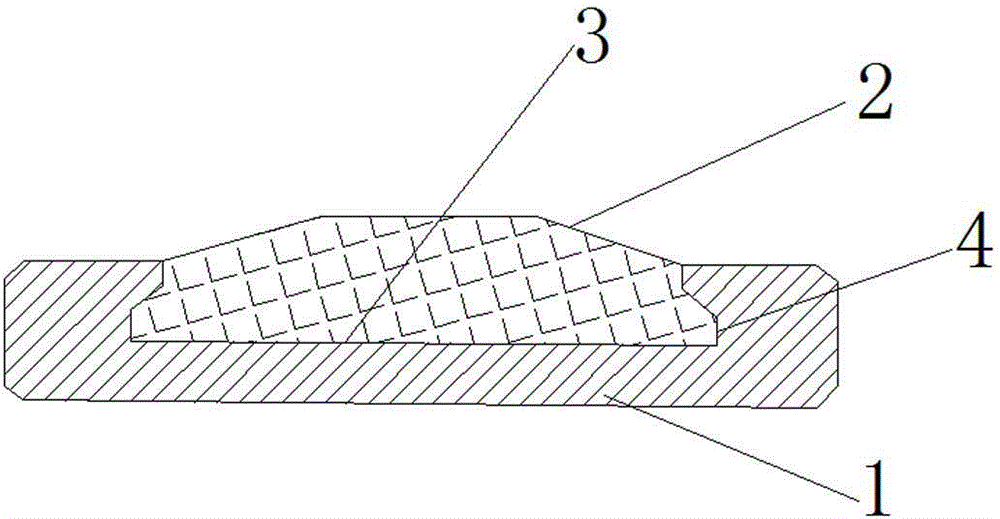

[0011] The invention discloses a valve seat of a butterfly valve for a clip-on coal slag pipeline. The valve seat includes a skeleton 1 made of 153 alloy cast iron with excellent corrosion resistance and wear resistance and a rubber lining 2 made of wear-resistant rubber with high rubber content. , one side of the skeleton 1 is a horizontal plane, and the other side is provided with a concave hole 3, a groove 4 is arranged around the periphery of the concave hole 3, and the rubber lining 2 is located inside the concave hole 3 and passes through the groove 4. Fix it on the skeleton 1. This design makes it difficult for the rubber lining 2 to fall off from the skeleton 1, and the use of wear-resistant rubber material with high rubber content makes the rubber lining 2 difficult to tear. The service life of the valve seat is extended, the overall sealing performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com