Corrosion-resistant and wear-resistant roll wrapper

A foreskin and wear-resistant technology, applied in the direction of coating, etc., can solve the problems of easy delamination and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

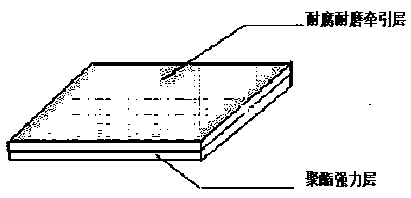

[0020] A corrosion-resistant and wear-resistant roller cover, including a traction layer and a polyester strength layer, with a total thickness of 1.6mm, wherein the thickness ratio of the traction layer to the strength layer is 1.7:1. The traction layer is composed of main material, reinforcement system, vulcanization system, anti-aging system and plasticizer in a mass ratio of 100:50:8:2:15, and the polyester tension layer is activated and modified.

[0021] The main material is hydroxynitrile butadiene rubber, the reinforcement system is composed of white carbon black, nano-aluminum silicate, and calcium silicate in a mass ratio of 40:8:2, and the vulcanization system is sulfur-80 and zinc oxide-80, and melamine resin in accordance with The mass ratio is 1:3:4, the anti-aging system is phenol MB (2-mercaptobenzimidazole) and amine RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer) according to the mass ratio The composition is 1:1, and the plasticizer is compounded with TP75...

Embodiment 2

[0024] A corrosion-resistant and wear-resistant roller cover, including a two-layer structure of a traction layer and a polyester strength layer, with a total thickness of 1.8mm, wherein the thickness ratio of the traction layer to the strength layer is 1.9:1. The traction layer is composed of main material, reinforcement system, vulcanization system, anti-aging system and plasticizer in a mass ratio of 100:55:9:2.5:18, and the polyester strength layer is activated and modified.

[0025] The main material is hydroxynitrile rubber, the reinforcement system is composed of white carbon black, nano-aluminum silicate, and calcium silicate in a mass ratio of 40:10:5, and the vulcanization system is sulfur-80, zinc oxide-80, and melamine resin in accordance with The mass ratio is 1:4:4, the anti-aging system is phenol MB (2-mercaptobenzimidazole) and amine RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer) according to the mass ratio 1.5:1 composition, the plasticizer is compounded by...

Embodiment 3

[0028] A corrosion-resistant and wear-resistant roller covering, including a two-layer structure of a traction layer and a polyester strength layer, with a total thickness of 2.0mm, wherein the thickness ratio of the traction layer to the strength layer is 2.5:1. The traction layer is composed of main material, reinforcement system, vulcanization system, anti-aging system and plasticizer in a mass ratio of 100:60:10:3:20, and the polyester tension layer is activated and modified.

[0029] The main material is hydroxynitrile rubber, the reinforcement system is composed of white carbon black, nano-aluminum silicate, and calcium silicate in a mass ratio of 40:15:5, and the vulcanization system is sulfur-80, zinc oxide-80, and melamine resin in accordance with The mass ratio is 1:5:4, the anti-aging system is phenol MB (2-mercaptobenzimidazole) and amine RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer) according to the mass ratio The composition is 1.5:1.5, and the plasticizer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com