Copper sleeve structure with an integrated sleeve base

An integrated, sleeve technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of shortening the service life of copper sleeves, inconvenient installation, time-consuming and labor-consuming, etc., to improve corrosion resistance and wear resistance, The effect of prolonging the service life and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

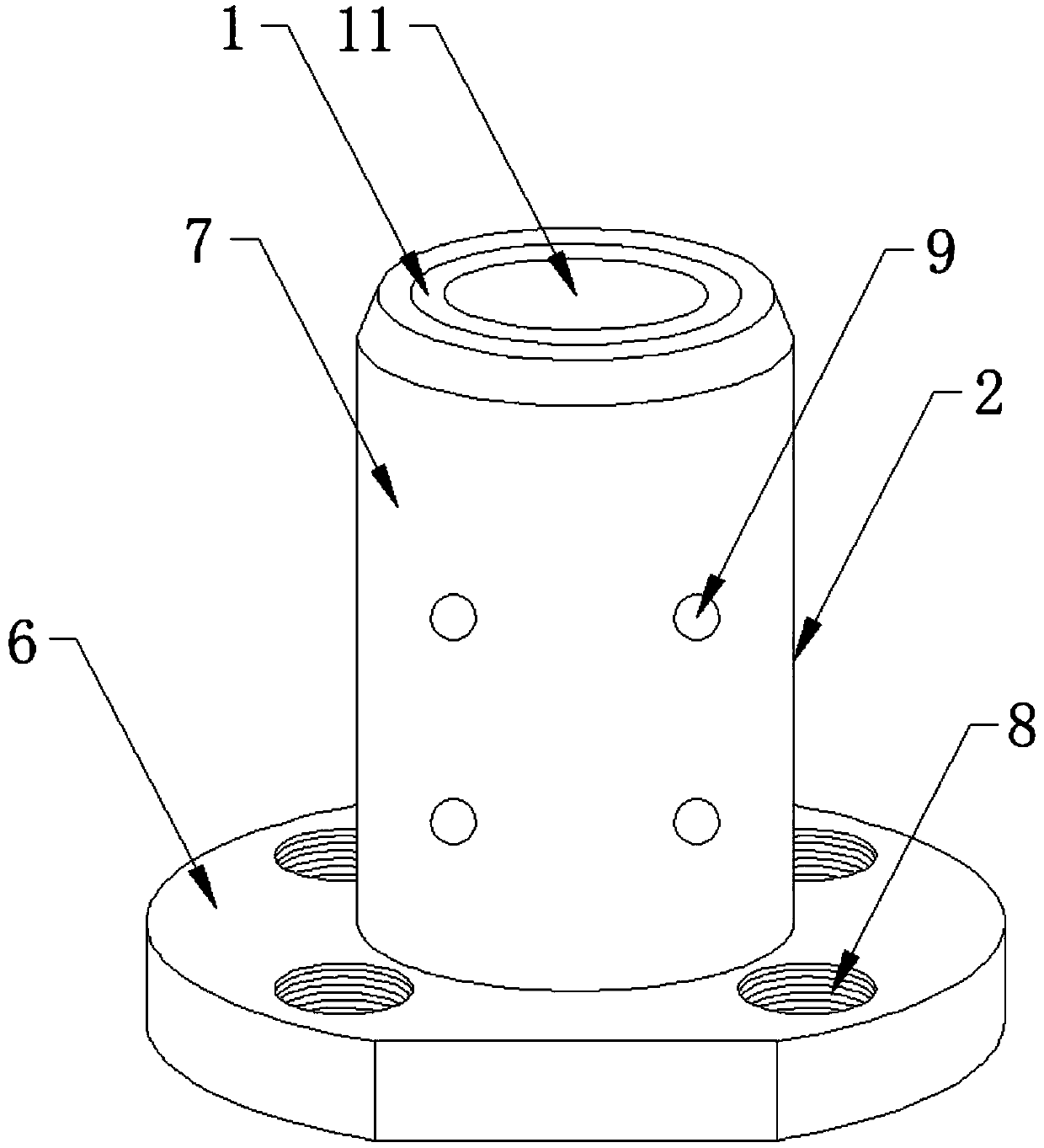

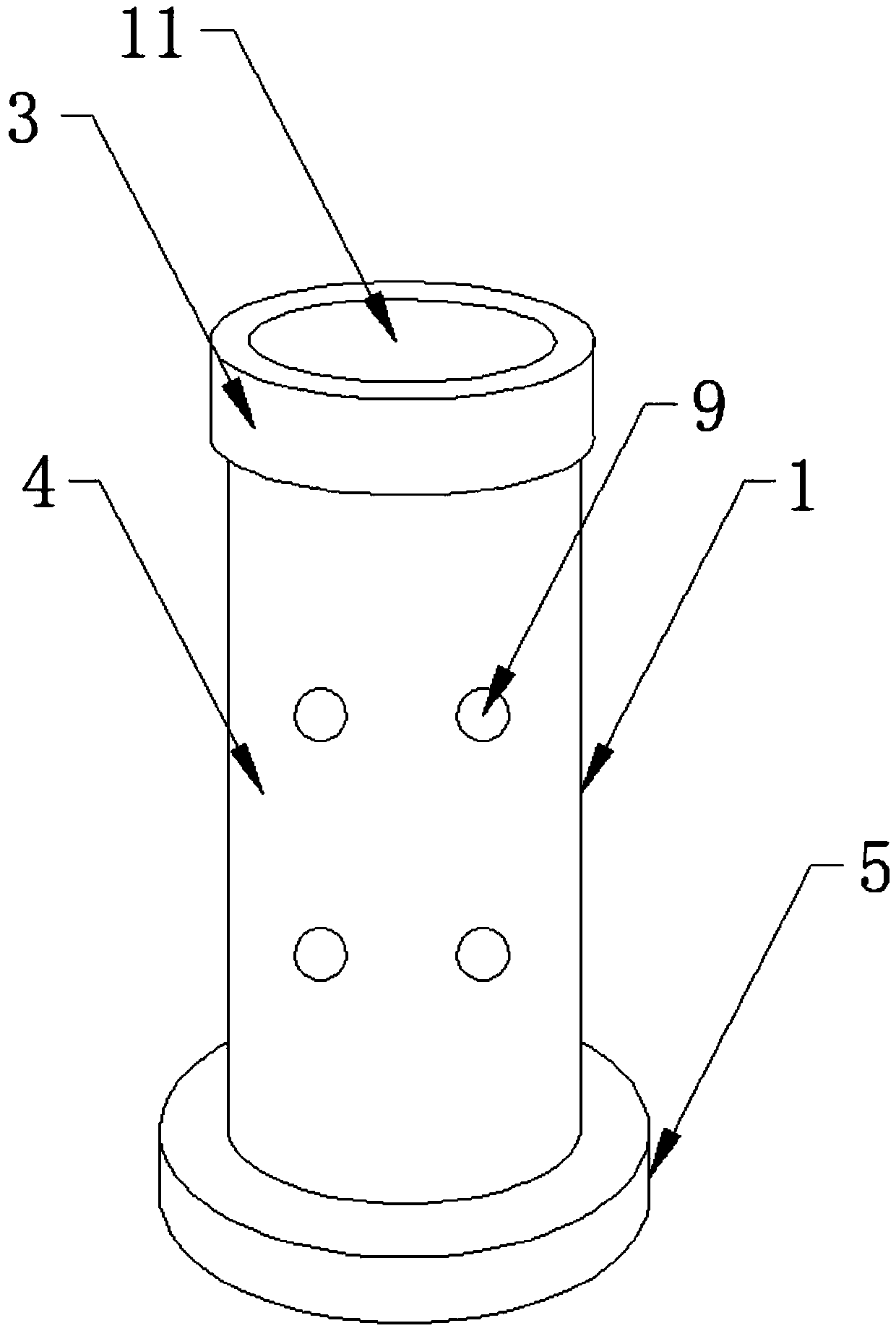

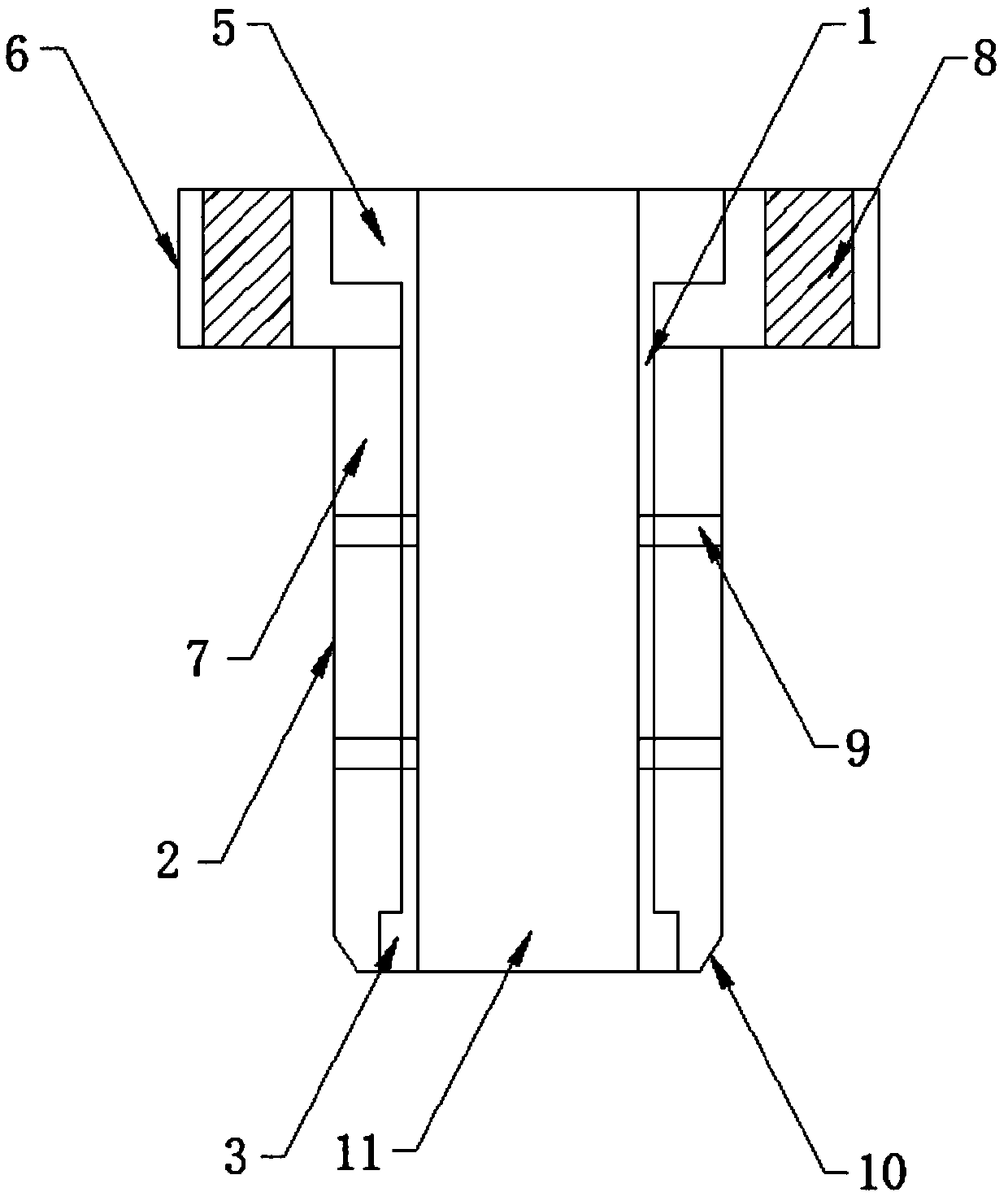

[0026] Such as Figure 1-5 As shown, the present invention provides a copper sleeve structure with an integrated sleeve, including an inner sleeve 1 and an outer sleeve 2, the inner sleeve 1 includes an upper sleeve 3, a middle shaft sleeve 4 and a lower sleeve 5, and the outer end sleeve of the inner sleeve 1 The outer sleeve 2 is connected, and the outer sleeve 2 includes a flange base 6 and an outer sleeve 7. The bottom end of the outer sleeve 7 is provided with a flange base 6, and the four corners of the flange base 6 are provided with mounting screw holes 8. The cylinder 7 and the flange base 6 are of an integrated structure, which is convenient for installation and saves costs.

[0027] The outer ends of the outer sleeve 7 and the middle shaft sleeve 4 are provided with a number of oil injection holes 9 to facilitate the injection of lubricant.

[0028] The jacket 2 is made of 440C stainless steel with extremely high hardness and good wear resistance and corrosion resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com