Special graphite carbon sleeved roller for corrosion-resistant and abrasion-resistant continuous annealing line and manufacturing process thereof

A manufacturing process, graphite carbon technology, applied in the field of special graphite carbon sleeve rollers for anti-corrosion and wear-resistant continuous annealing lines and its manufacturing process, can solve the problems of high cost, poor anti-corrosion and wear resistance, etc., to reduce production costs, enhance Anti-corrosion and wear resistance, the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

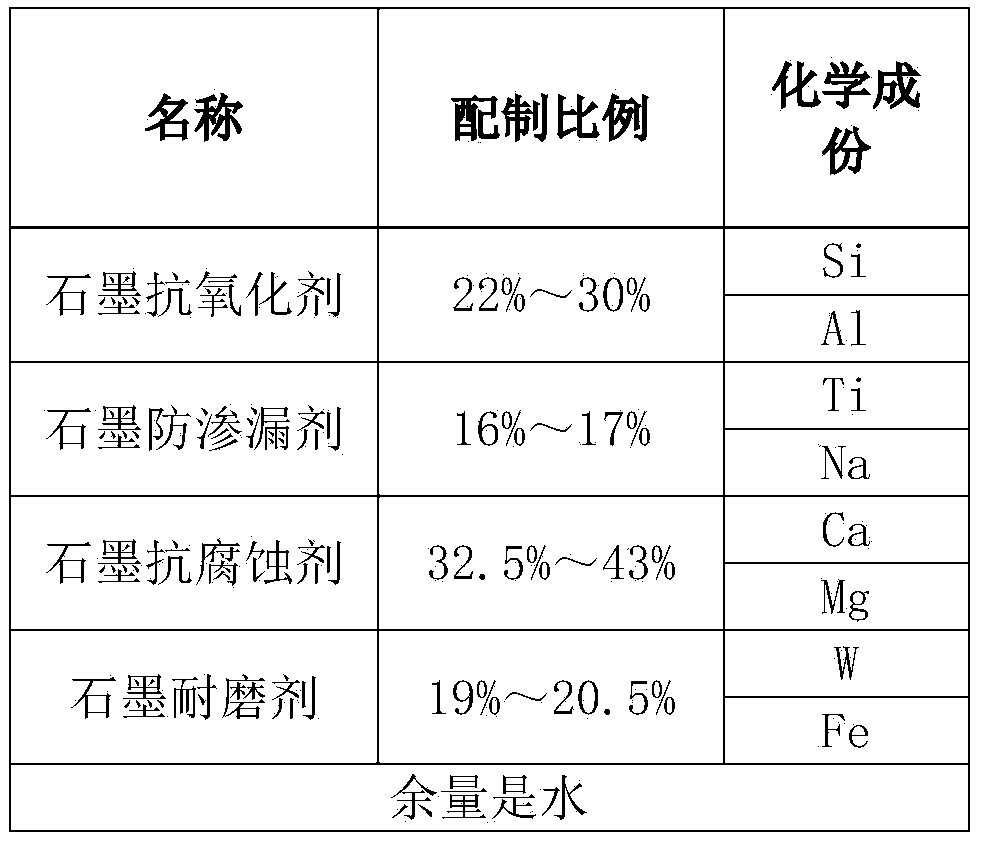

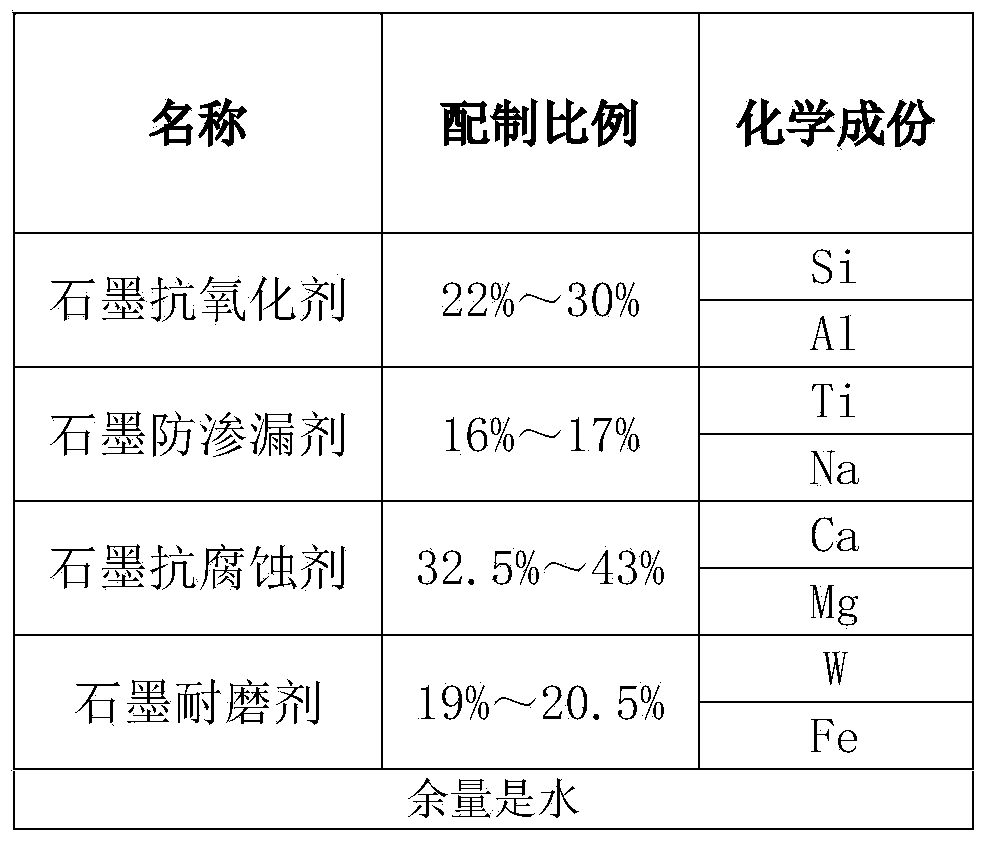

[0033] A special graphite carbon sleeve roll for anti-corrosion and wear-resistant continuous annealing line, the graphite carbon sleeve roll includes: C87.8%; Al1%; Si1.2%; Ti0.4%; Mg2.5%; Ca1.8%; Fe1.8%; Na1.2%; W2.3%.

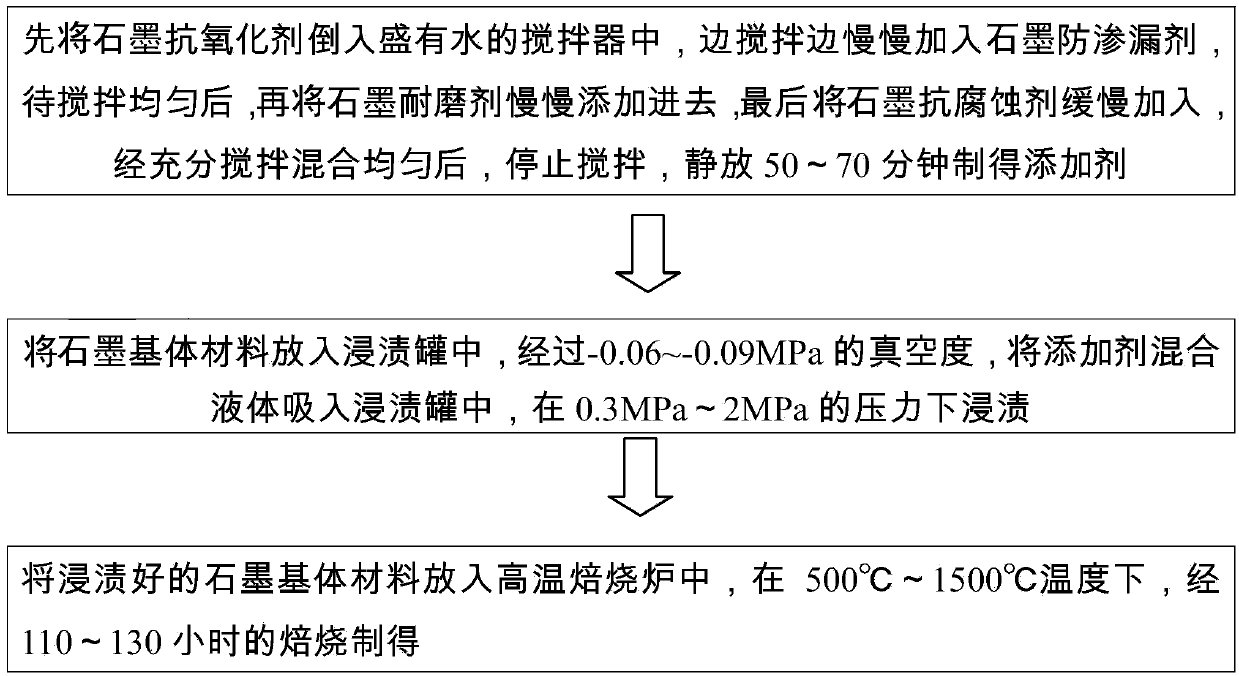

[0034] The manufacturing process of above-mentioned graphite carbon cover roller, comprises the steps:

[0035] First pour 22% graphite antioxidant in mass percentage into a stirrer filled with 9% water, slowly add 16% graphite anti-leakage agent while stirring, and then add 32.5% graphite anti-leakage agent Slowly add in, and finally slowly add 20.5% graphite anti-corrosion agent, after fully stirring and mixing, stop stirring, and let stand for 50 minutes to prepare the additive.

[0036] Put the above-mentioned graphite base material into the impregnation tank, through the vacuum degree of -0.09MPa, suck the mixed liquid of antioxidant, anti-leakage agent, anti-corrosion agent and wear-resistant agent into the impregnation tank, and complete the impregna...

Embodiment 2

[0039] A special graphite carbon sleeve roll for anti-corrosion and wear-resistant continuous annealing line, the graphite carbon sleeve roll includes: C88.2%; Al1%; Si1.2%; Ti1.3%; Mg2.5%; Ca1.8%; Fe0.9%; Na2.1%; W1%.

[0040] The manufacturing process of above-mentioned graphite carbon cover roller, comprises the steps:

[0041] First pour 22% graphite antioxidant in mass percentage into a stirrer filled with 9.5% water, slowly add 17% graphite anti-leakage agent while stirring, and then add 32.5% graphite anti-leakage agent Slowly add in, and finally slowly add 19% graphite anti-corrosion agent, after fully stirring and mixing, stop stirring, and let stand for 55 minutes to prepare the additive.

[0042]Put the above-mentioned graphite matrix material into the impregnation tank, through the vacuum of -0.08MPa, suck the mixed liquid of antioxidant, anti-leakage agent, anti-corrosion agent and wear-resistant agent into the impregnation tank, and complete the impregnation und...

Embodiment 3

[0045] A special graphite carbon sleeve roll for anti-corrosion and wear-resistant continuous annealing line, the graphite carbon sleeve roll includes: C87%; Al2%; Si2.1%; Ti0.4%; Mg3%; Ca2.4% ; Fe0.9%; Na1.2%; W1%.

[0046] The manufacturing process of above-mentioned graphite carbon cover roller, comprises the steps:

[0047] First pour 26% graphite antioxidant in mass percentage into a stirrer filled with 1.25% water, slowly add 16% graphite anti-leakage agent while stirring, and then add 37.75% graphite anti-leakage agent Slowly add in, and finally slowly add 19% graphite anti-corrosion agent, after fully stirring and mixing, stop stirring, and let stand for 60 minutes to prepare the additive.

[0048] Put the above-mentioned graphite matrix material into the impregnation tank, through the vacuum degree of -0.07Pa, suck the mixed liquid of antioxidant, anti-leakage agent, anti-corrosion agent and wear-resistant agent into the impregnation tank, and complete the impregnati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com