Water delivery pipe with antibacterial inner layer

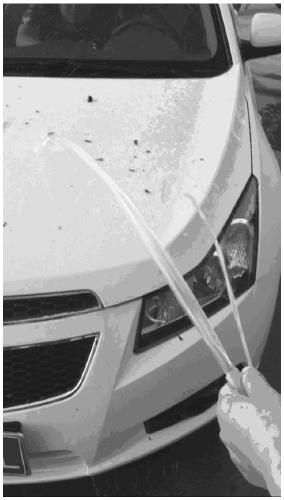

A technology of water delivery pipes and inner layers, applied in the field of hoses, can solve the problems such as the hygienic conditions that bacteria on the inner walls of the delivery hoses are easy to breed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

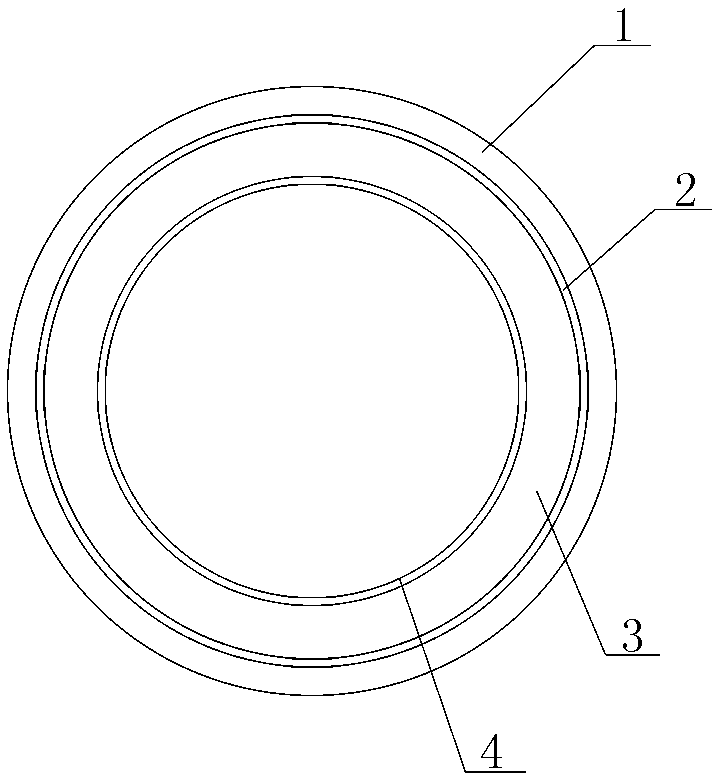

[0033] refer to Figure 1 to Figure 4 , the present invention comprises a wear-resistant outer layer 1;

[0034] The inner wall of the wear-resistant outer layer 1 is provided with a pressure-resistant light-shielding layer 3, and a network cable pressure-resistant layer 2 is arranged between the wear-resistant outer layer 1 and the pressure-resistant light-shielding layer 3;

[0035] The inner wall of the pressure-resistant light-shielding layer 3 is provided with an antibacterial inner layer 4;

[0036] The wear-resistant outer layer 1, the network cable pressure-resistant layer 2, the pressure-resistant light-shielding layer 3 and the antibacterial inner layer 4 are co-extruded into a composite integrated structure through a co-extrusion machine.

[0037] Further, the thickness of the wear-resistant outer layer 1 is 0.8-1.1 mm, and the wear-resistant outer layer is made of PVC plastic.

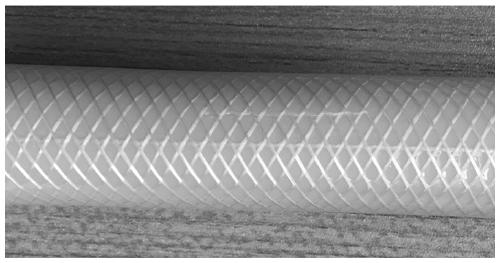

[0038] Further, the mesh wire pressure-resistant layer 2 is made of synthetic polyest...

Embodiment 2

[0044] The antibacterial inner layer of the present invention is prepared according to the following process:

[0045] 1) Methyl methacrylate-butadiene-styrene copolymer, polyvinyl chloride, polyvinyl acetate, polyvinyl alcohol, trioctyl trimellitate, carbon black and glass fiber are mixed according to the ratio of 50:10:8 : Mix evenly with a mass ratio of 5:2:1:1, add to a banbury mixer, banbury time is 8min, banbury temperature is 80°C, and the main ingredient is obtained;

[0046] 2) Mix nano-titanium dioxide and nano-silver uniformly at a mass ratio of 1:1 to obtain a mixture, then add it to 1,3-butanediol of the same weight, stir at 500 rpm for 3 minutes, and then let stand for 30 minutes to obtain a composite nanomaterial;

[0047] 3) Put the main material and composite nanomaterials into the centrifuge in sequence according to the mass ratio of 10:1, and centrifuge at 1000rpm for 8 minutes. After mixing evenly, enter the twin-screw extruder to extrude into a molten stat...

Embodiment 3

[0049] Performance test of the antibacterial inner layer of the present invention.

[0050] 1. Set up a control group, control group 1: do not add nano-titanium dioxide, the rest is the same as the present invention; control group 2: do not add nano-silver, the rest is the same as the present invention; control group 3: do not add nano-titanium dioxide and nano-silver, the rest is the same as the present invention .

[0051]The control group and the test materials of the present invention are all placed in a petri dish, and the bacteria liquid or algae liquid is dropped on a sterile plate, cultivated in an incubator for 240min, then taken out, and counted under a microscope. The strength of the inhibitory ability was judged by the number of colonies. The lower the number of microorganisms, the stronger the inhibitory ability. Take Escherichia coli, Staphylococcus aureus and green algae as examples, see Table / 1 for details:

[0052] Table 1

[0053] group

Viabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com