Flexible hitting-rod assembly structure for squeezing type breeding-peanut shelling machine

An extrusion type and shelling machine technology, applied in the direction of shelling, application, pod removal, etc., can solve the problems of large workload of disassembly and re-tightening of bolts, difficulty in ensuring the quality of shelling, and difficulty in hitting the outer end face of the rod, etc. To achieve the effect of improving the removal rate, reducing damage and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

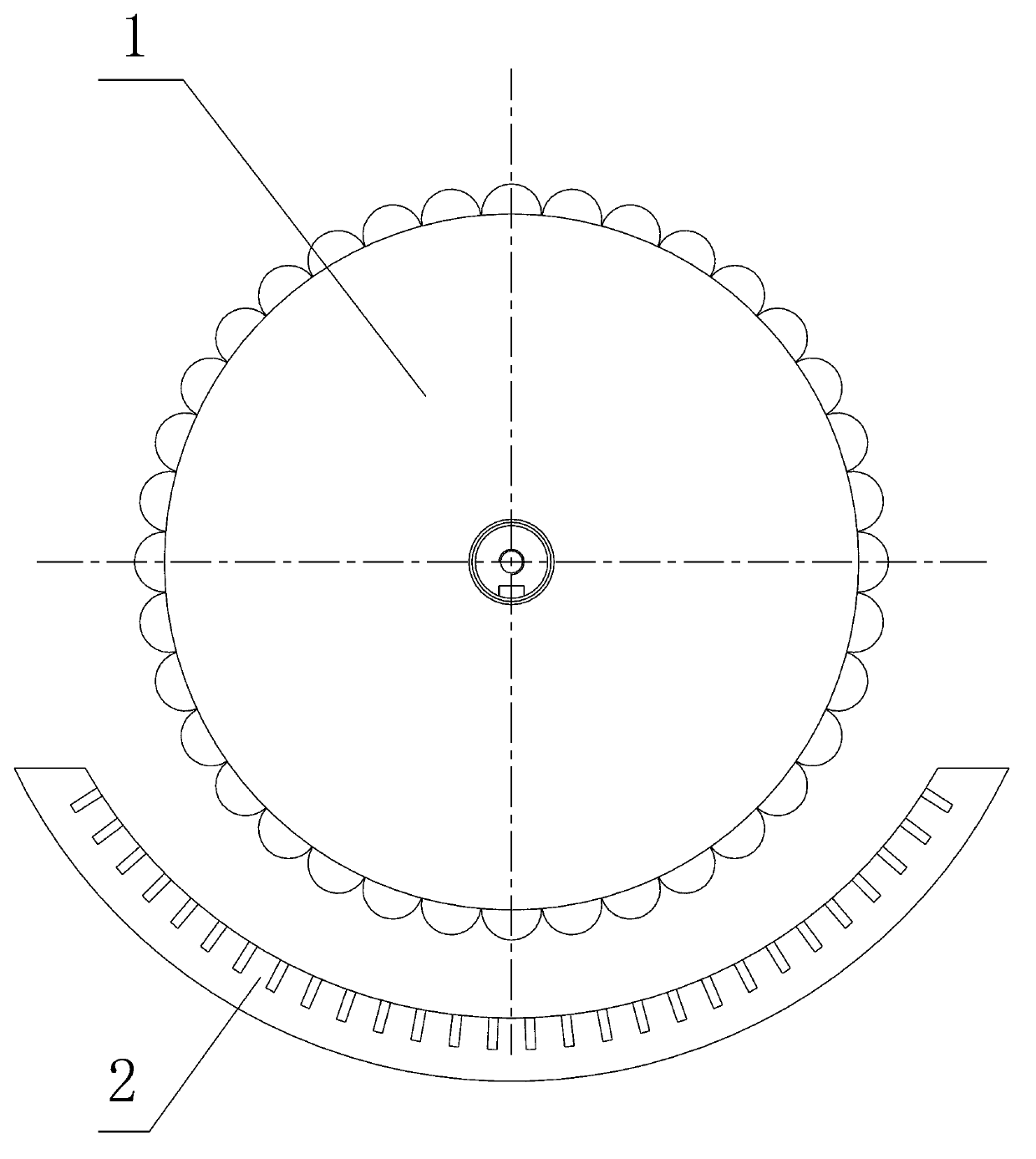

[0033] An extruded type peanut shelling machine beater rod assembly structure is characterized in that:

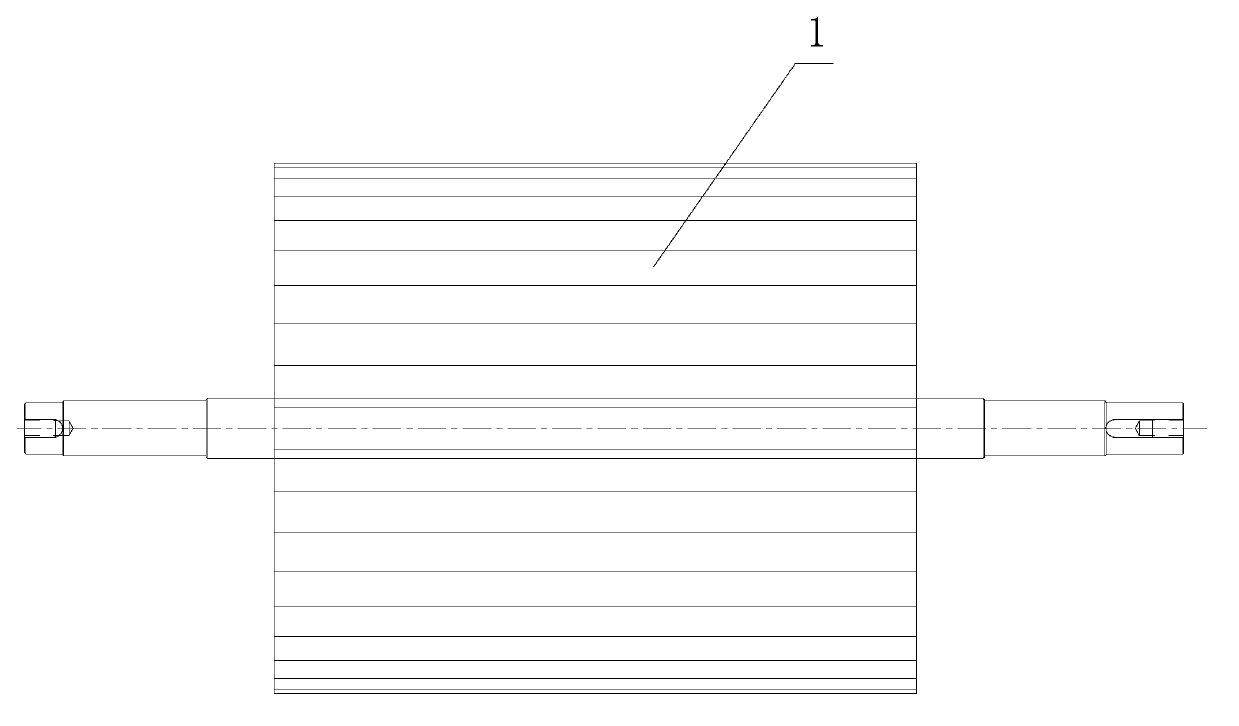

[0034] The rod beating cylinder 1 in the rod beating assembly is a cylindrical soft elastic body, and the middle of the cylinder is a rotating shaft;

[0035] The cylindrical body of the rod-beating drum 1 is surrounded by a large number of semicircular convex lines parallel to the axis of the cylindrical body, that is, its cross section is in the shape of a disk, the middle is a circle, and the periphery of the circle is a large number of semicircular convex pieces protruding outward. The radius of the piece is 1-2 cm;

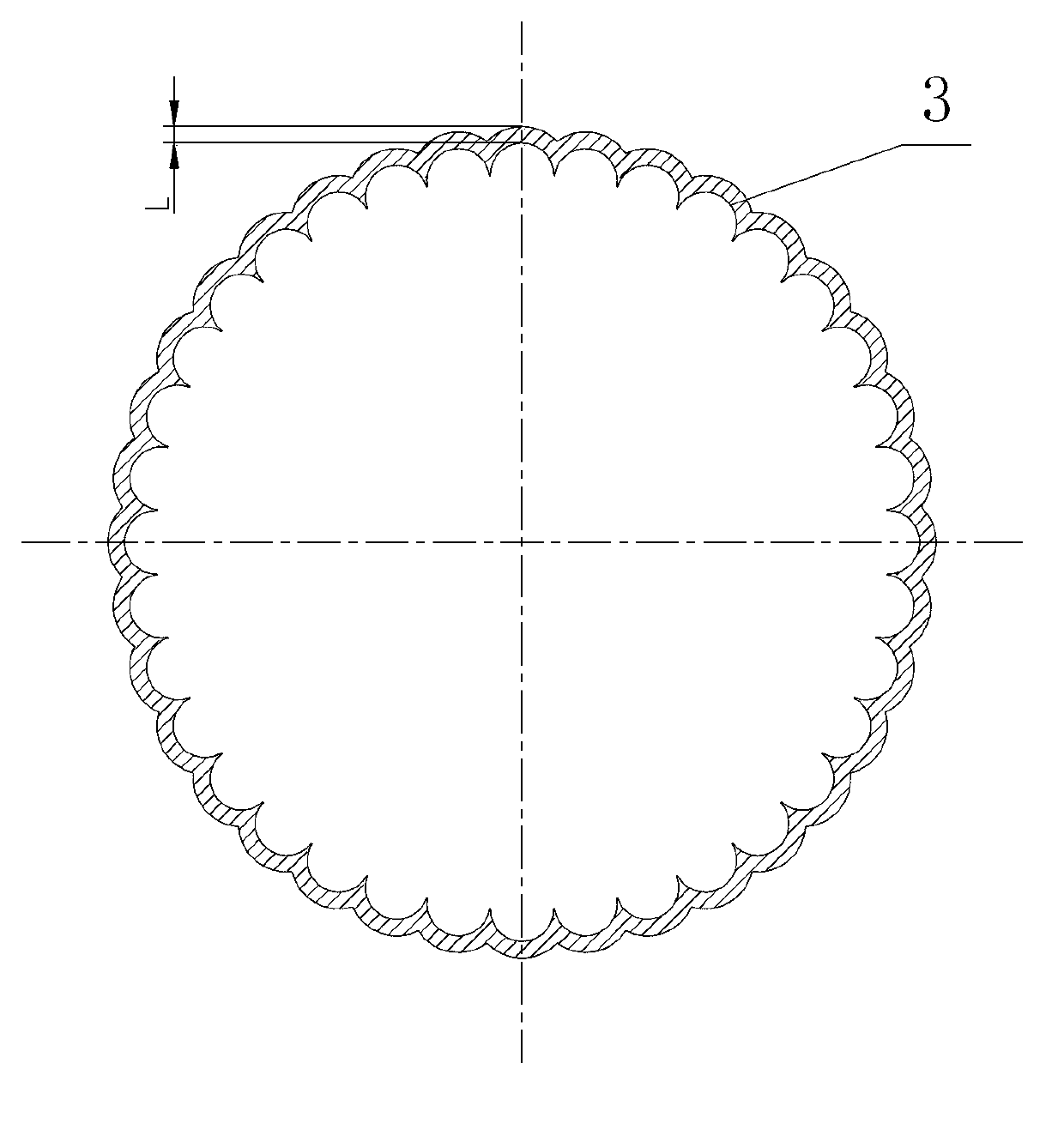

[0036] Depending on the size of the peanut pods used for planting, the rod adjustment sleeve 3 can be used or not;

[0037] The rod adjustment sleeve 3 is an annular ring of soft elastic body with different thicknesses...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com