Novel arc extinguishing grid type load switch suitable for C4F7N environment-friendly gas

A load switch and grid-type technology, which is applied in the field of new arc-extinguishing grid-type load switches, can solve the problems that the load switch cannot achieve the breaking capacity and the breaking performance is reduced, so as to reduce flying out, increase the voltage drop, The effect of enhancing the breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

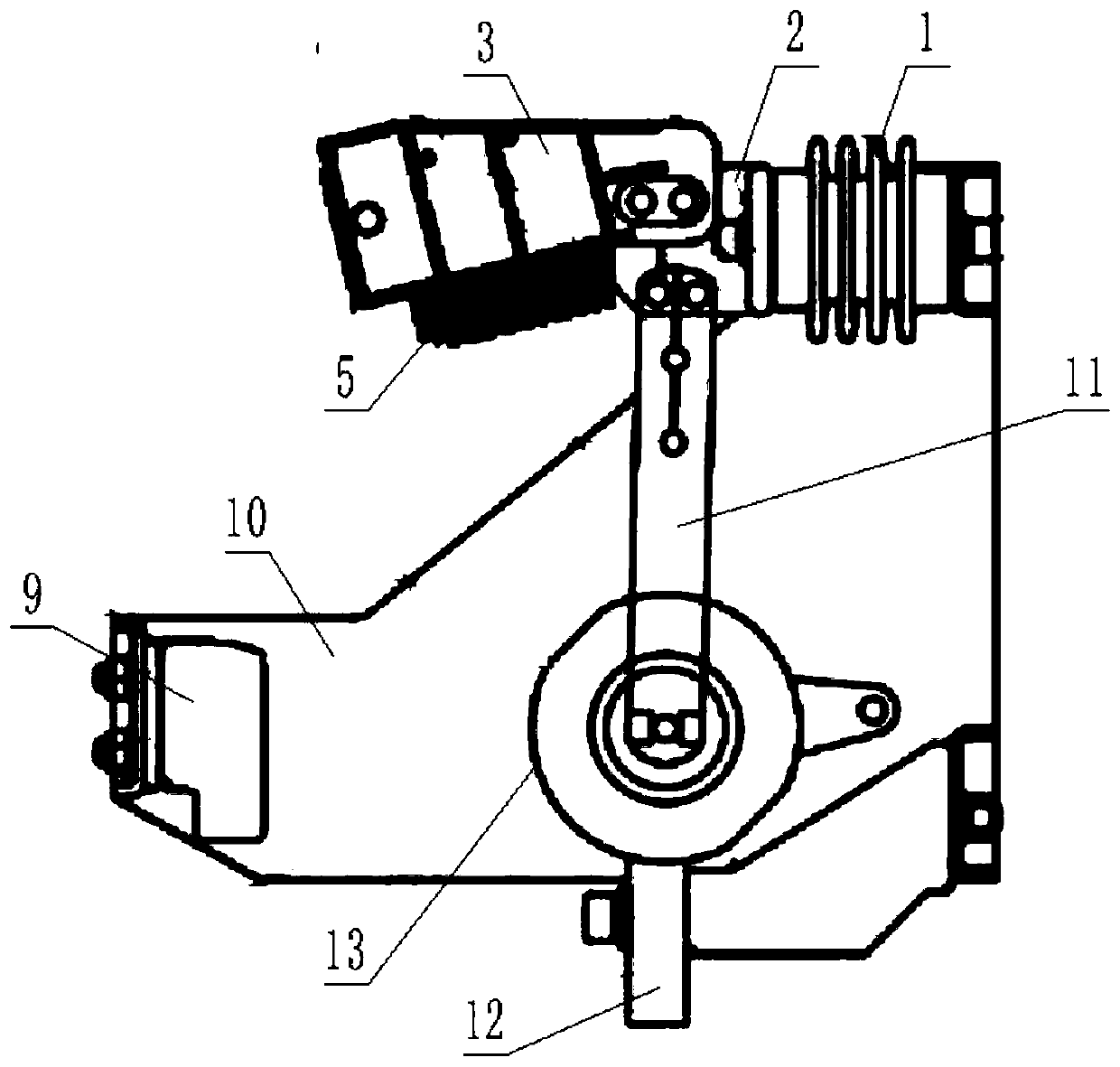

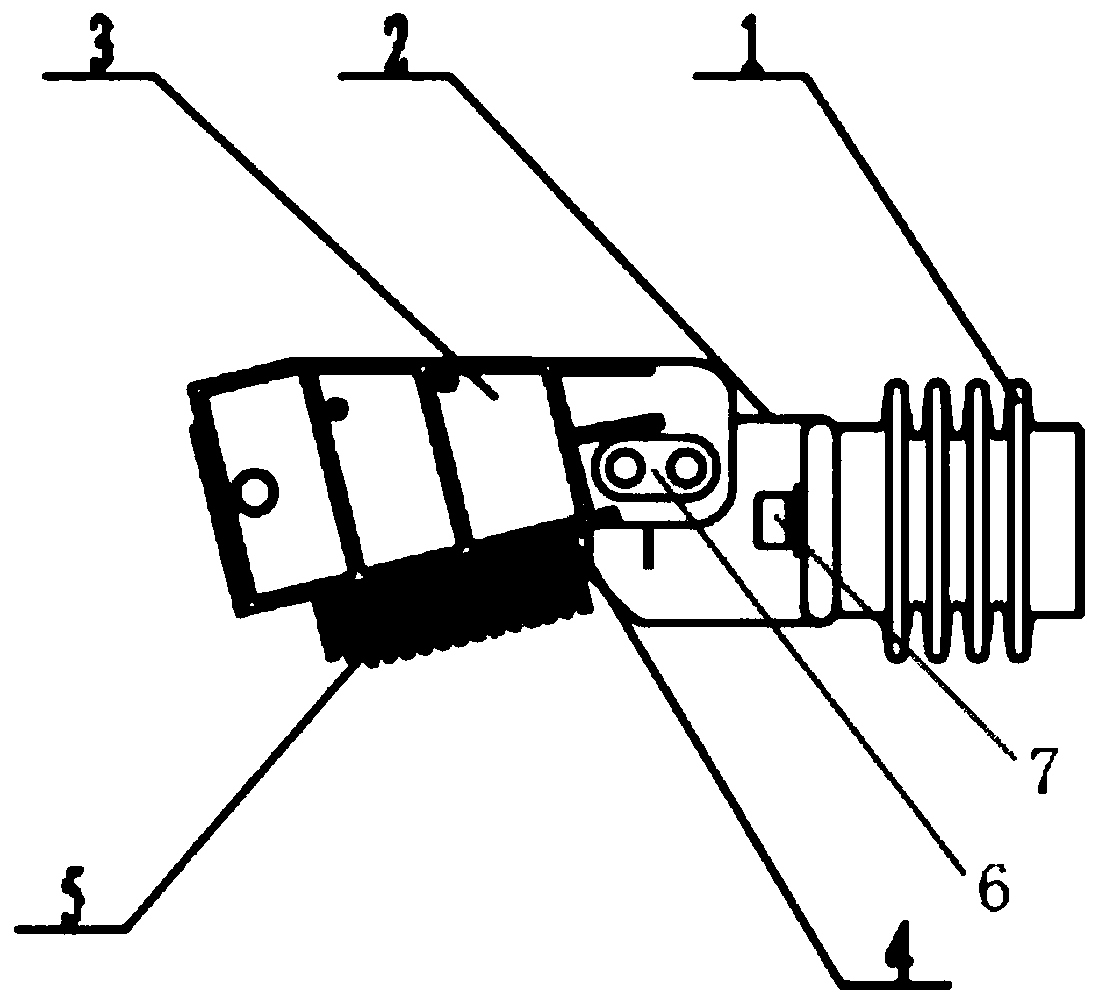

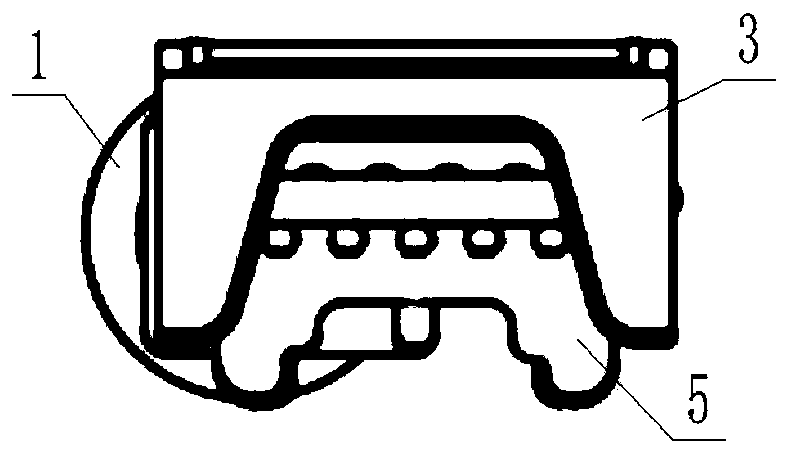

[0029] Such as figure 1 As shown, the present invention includes a mounting base 10 on which an arc extinguishing mechanism and a ground contact base 9 are installed. Such as figure 2 , 3 As shown, the arc extinguishing mechanism includes a supporting insulator 1, a static contact seat 2 and an arc extinguishing chamber, and the arc extinguishing chamber includes an arc extinguishing grid 3 and a plurality of arc extinguishing grids 5 installed on the arc extinguishing grid 3 In this embodiment, the arc extinguishing grid 3 is a semi-closed structure. The static contact base 2 is a right-angle plate, one of the right-angled sides of the static contact base 2 is connected with the arc extinguishing grid 3, the other right-angled side of the static contact base 2 is connected with the supporting insulator 1, and the supporting insulator 1 is connected with the mounting base 10. . The ground contact base 9 and the static contact base 2 form a three-station knife switch through t...

Embodiment 2

[0035] The difference between Embodiment 2 and Embodiment 1 is that the structure of the arc extinguishing grid and the arc extinguishing grid is changed, such as Figure 8 As shown, the arc extinguishing grid is a fully enclosed structure, and the arc extinguishing grid is wrapped in the arc extinguishing grid. The arc extinguishing grid is changed from a semi-closed structure to a fully enclosed structure to protect the interphase arc from breakdown and increase Insulation reliability between phases. Such as Picture 9 Therefore, the groove bottom of the arc extinguishing grid is a straight groove, the groove bottom of the arc extinguishing grid is changed from a stepped groove to a straight groove, and the size of the bottom of the arc extinguishing grid is reduced (the arc movement space size remains unchanged), so that the arc The magnetic field is more concentrated, so that the initial arc enters the arc chute smoothly under the action of the magnetic field. Due to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com