Patents

Literature

51results about How to "Reduce fly-out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

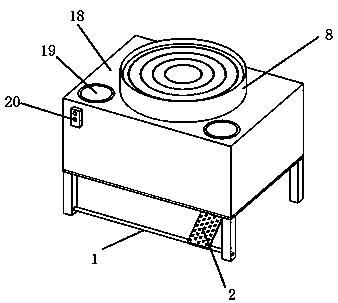

Double-cutter cotton-escape preventing fiber cutting machine

InactiveCN104153045AExcellent resistance to moisture absorptionStrong acid and alkali corrosion resistanceTows to slivers/yarnsTextile disintegration and recoveryFiberEngineering

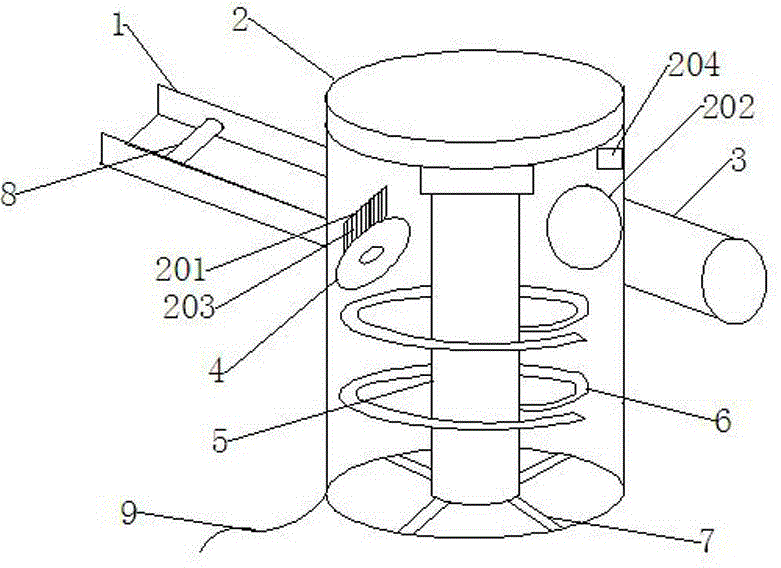

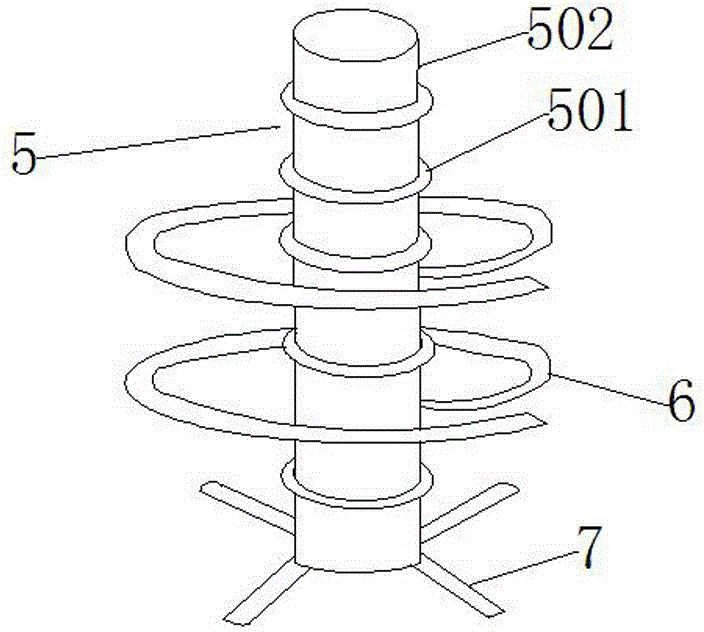

The invention discloses a double-cutter cotton-escape preventing fiber cutting machine. The double-cutter cotton-escape preventing fiber cutting machine comprises a feed inlet cutter set (4) and a rolling cutter set (5), the feed inlet cutter set (4) is arranged below a feed inlet (201), the feed inlet cutter set (4) is driven by a first motor through a transmission mechanism, the rolling cutter set (5) is driven by a second motor through the transmission mechanism, a plurality of stirring racks are fixedly arranged on the rolling cutter set (5), a plurality of bottom stirring rods (7) are arranged at the bottom end of the rolling cutter set (5), the bottom surfaces of the bottom stirring rods (7) contact with the bottom surface of a box body (2), a cotton stop brush (203) is arranged at the position of the feed inlet (201), and a humidifier (204) is arranged on the box body (2); the box body (2) is connected with an earth lead (9). Cotton fibers can be effectively prevented from escaping out of the box body, and cotton fiber content in the environment is reduced. Meanwhile, fiber products are uniformly and finely cut.

Owner:扬中市金德纺织机械设备厂

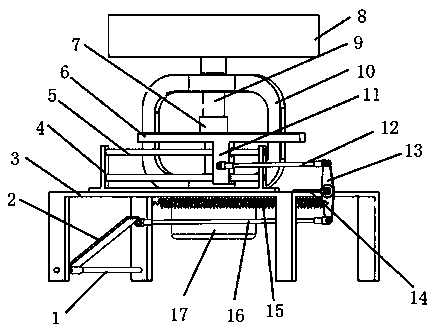

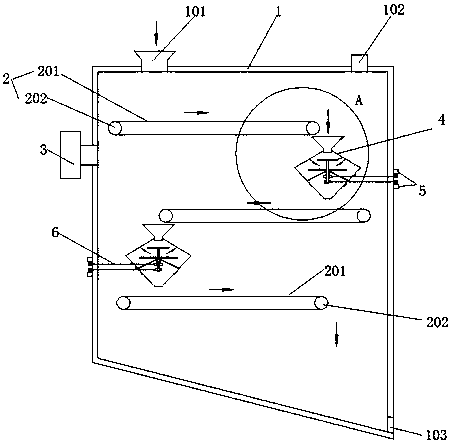

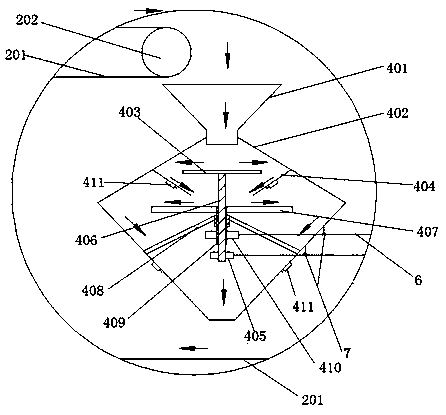

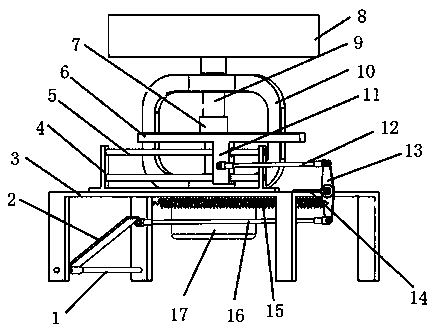

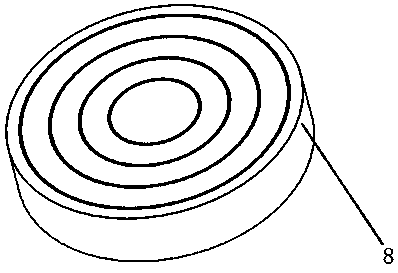

Plastic grinder

InactiveCN103752385AImprove work efficiencyReduce fly-outGrain treatmentsEngineeringCentrifugal force

The invention relates to a grinder, in particular to a plastic grinder. The plastic grinder comprises a grinder body, a moving cutter, a fixed cutter and a screen plate, wherein the moving cutter and the fixed cutter are arranged inside the grinder body; the screen plate is arranged below the moving cutter and the fixed cutter; a shifting wheel cutter is mounted inside the grinder body and in a position above the moving cutter and the fixed cutter, the rotation direction of the shifting wheel cutter is opposite to that of the moving cutter, and the shifting wheel cutter is rotationally occluded with the moving cutter; the grinder body adopts a closed box body structure; a feed inlet with a material splashing prevention device is formed in the upper part of the grinder body; a discharge opening matched with the bag mouth of a packaging bag is formed in the lower part of the grinder body. The plastic grinder solves the problems that a conventional grinder has low working efficiency at a low rotating speed, when the conventional grinder operates at a high rotating speed, ground raw materials fly up under the action of the centrifugal force of the ground materials and a moving cutter and a fixed cutter cannot sufficiently occlude the ground materials so as to waste power. The plastic grinder has high working efficiency; a conventional grinder with the same power only grinds 1 ton of plastics each hour, but the plastic grinder can grind 3 tons of plastics each hour; the plastic grinder adopts the closed structure, so that the phenomenon that dust flies out in the working process of the plastic mill is avoided, and environmental pollution is reduced.

Owner:王国声

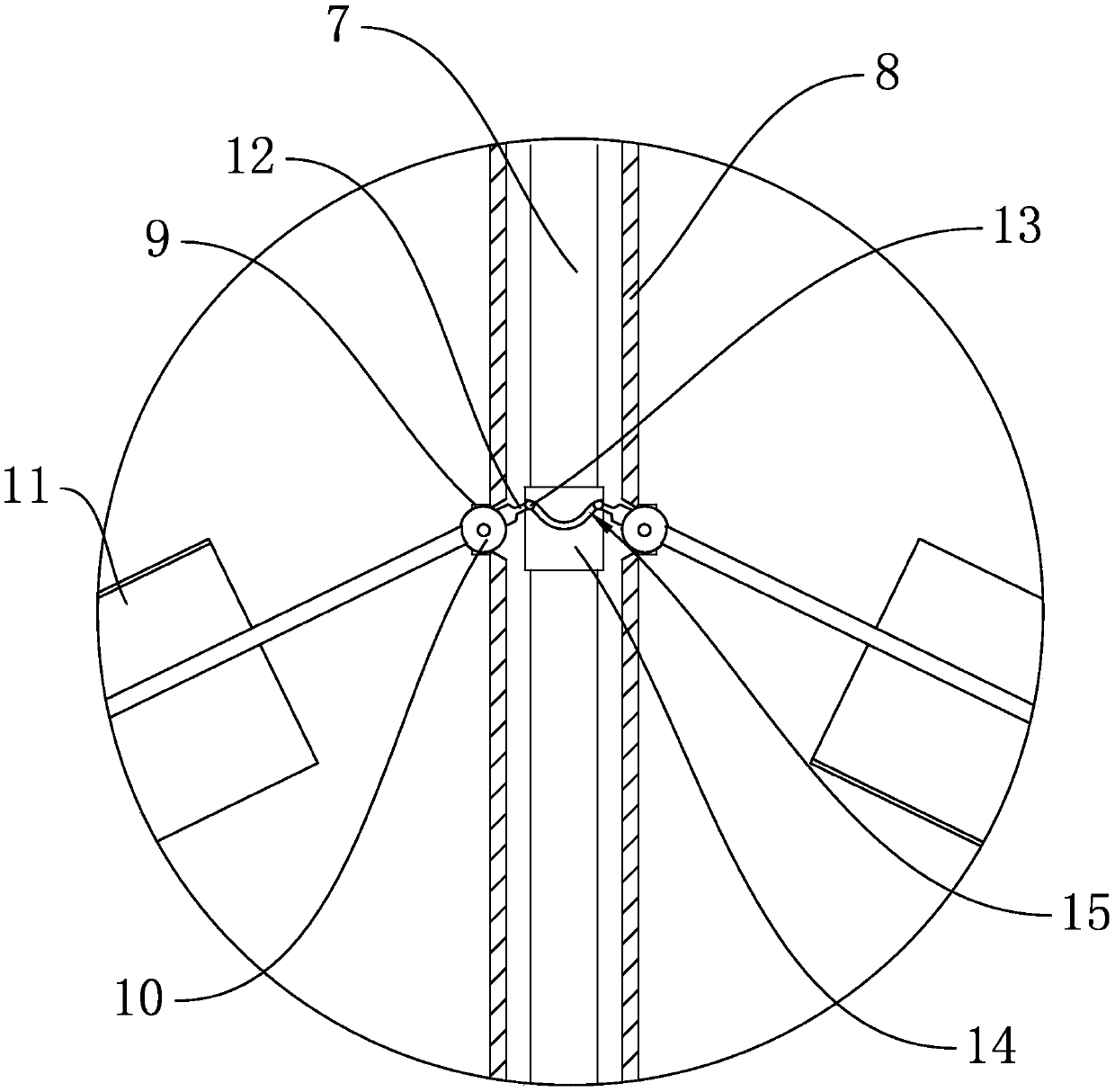

Cement mixer

The invention provides a cement mixer, and belongs to the technical field of buildings. The mixer solves the technical problems of non-uniform mixing, low mixing efficiency and the like. The cement mixer comprises a base, wherein a box body is fixed on the base, a fixing frame is fixedly arranged on the top of the box body, a first motor is fixedly arranged on the fixing frame, an output shaft ofthe first motor is vertically downwards arranged, the end part of the output shaft of the first motor is fixedly provided with a mounting frame, a second motor is fixedly arranged in the mounting frame, an output shaft of the second motor is vertically downwards arranged, the output shaft of the second motor is coaxially provided with a rotary shaft, the rotary shaft is externally sleeved with a rotating cylinder, the upper end of the rotating cylinder is fixedly connected to the mounting frame, a plurality of through holes are formed in the rotating cylinder, mounting blocks are fixedly arranged on the through holes, cylindrical blocks are arranged in the mounting blocks, and the cylindrical blocks can rotate in the mounting blocks. The mixer has the advantages of being uniform in mixingand high in mixing efficiency.

Owner:QUZHOU UNIV

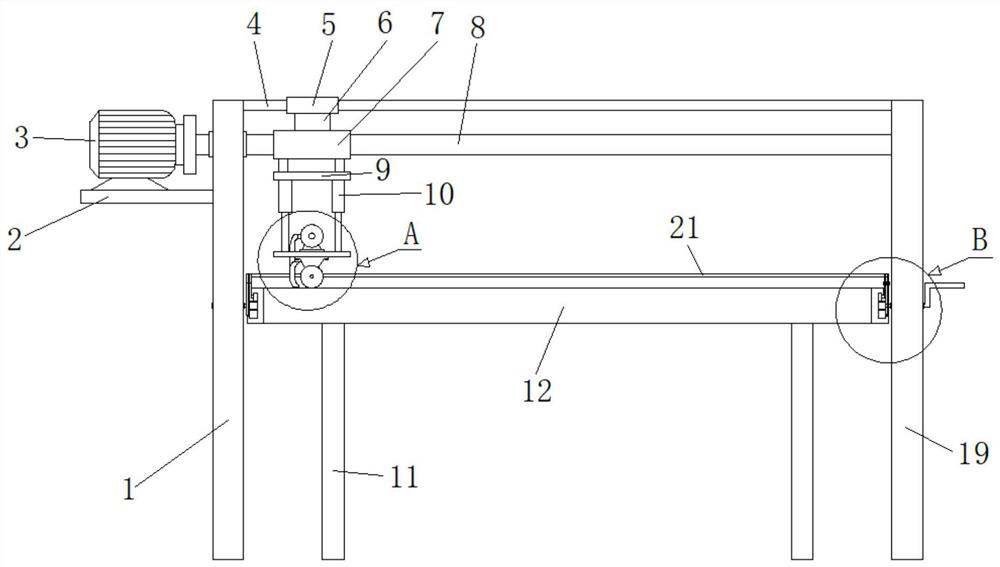

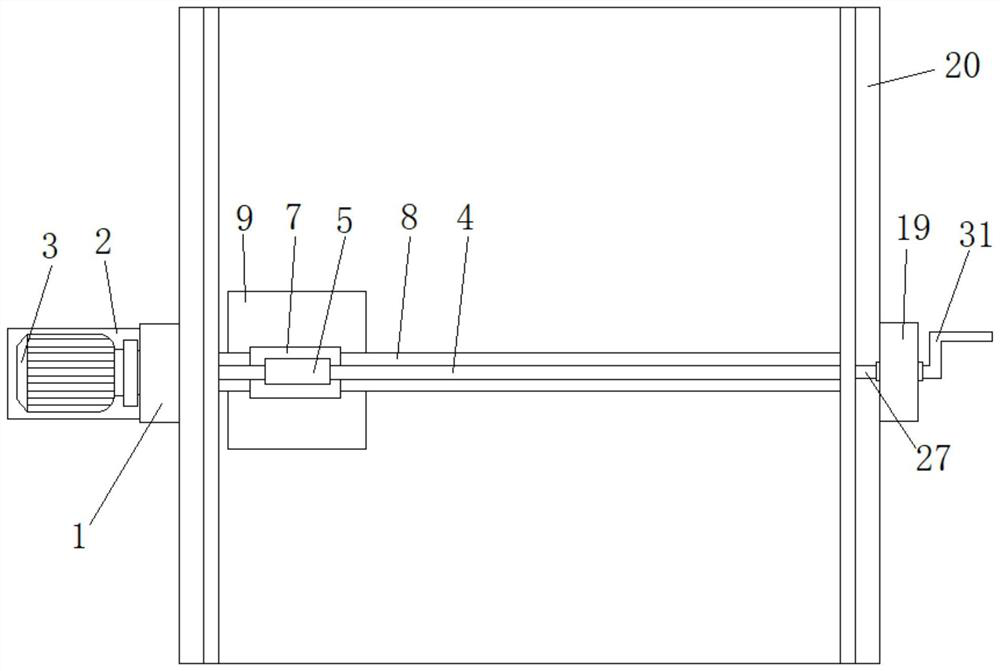

Waste plastic cutting machining equipment

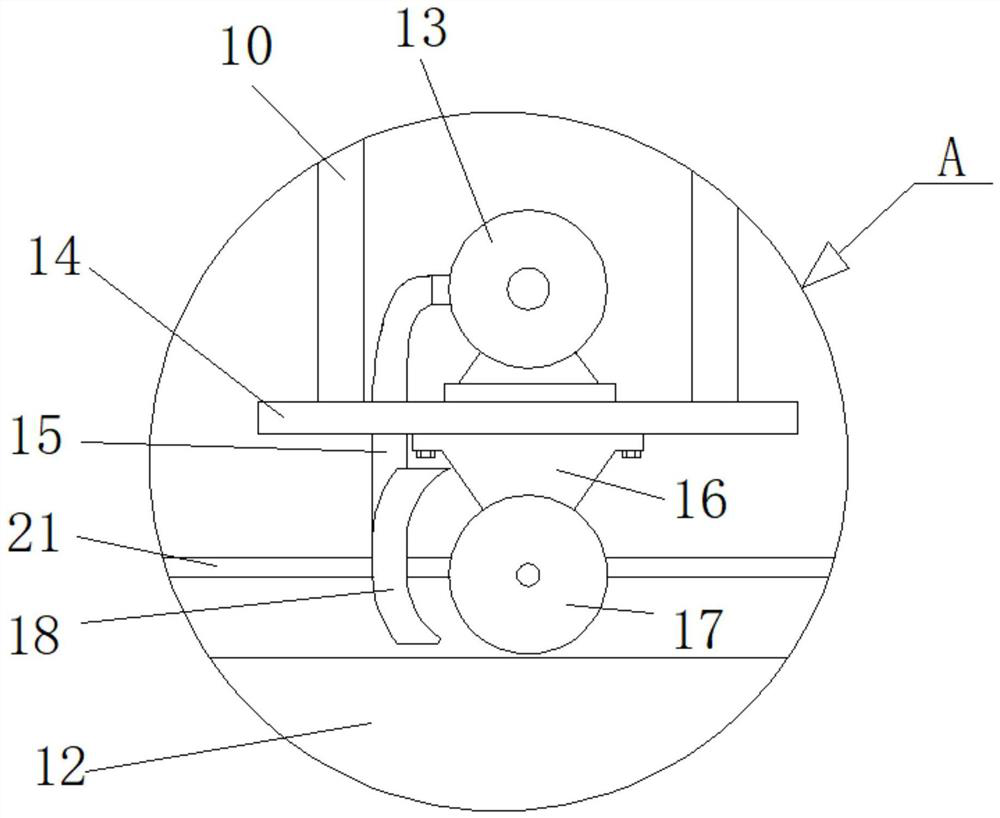

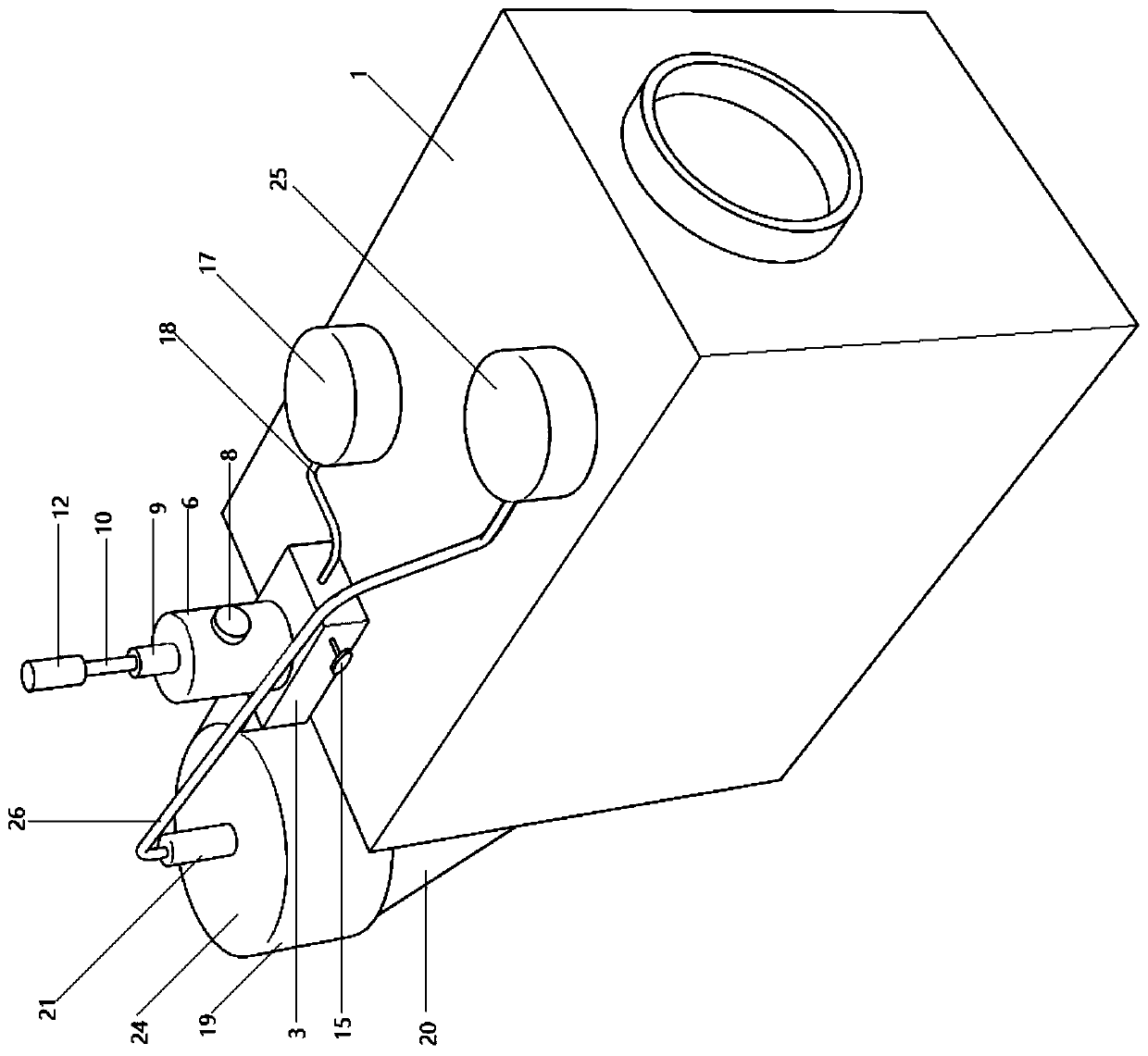

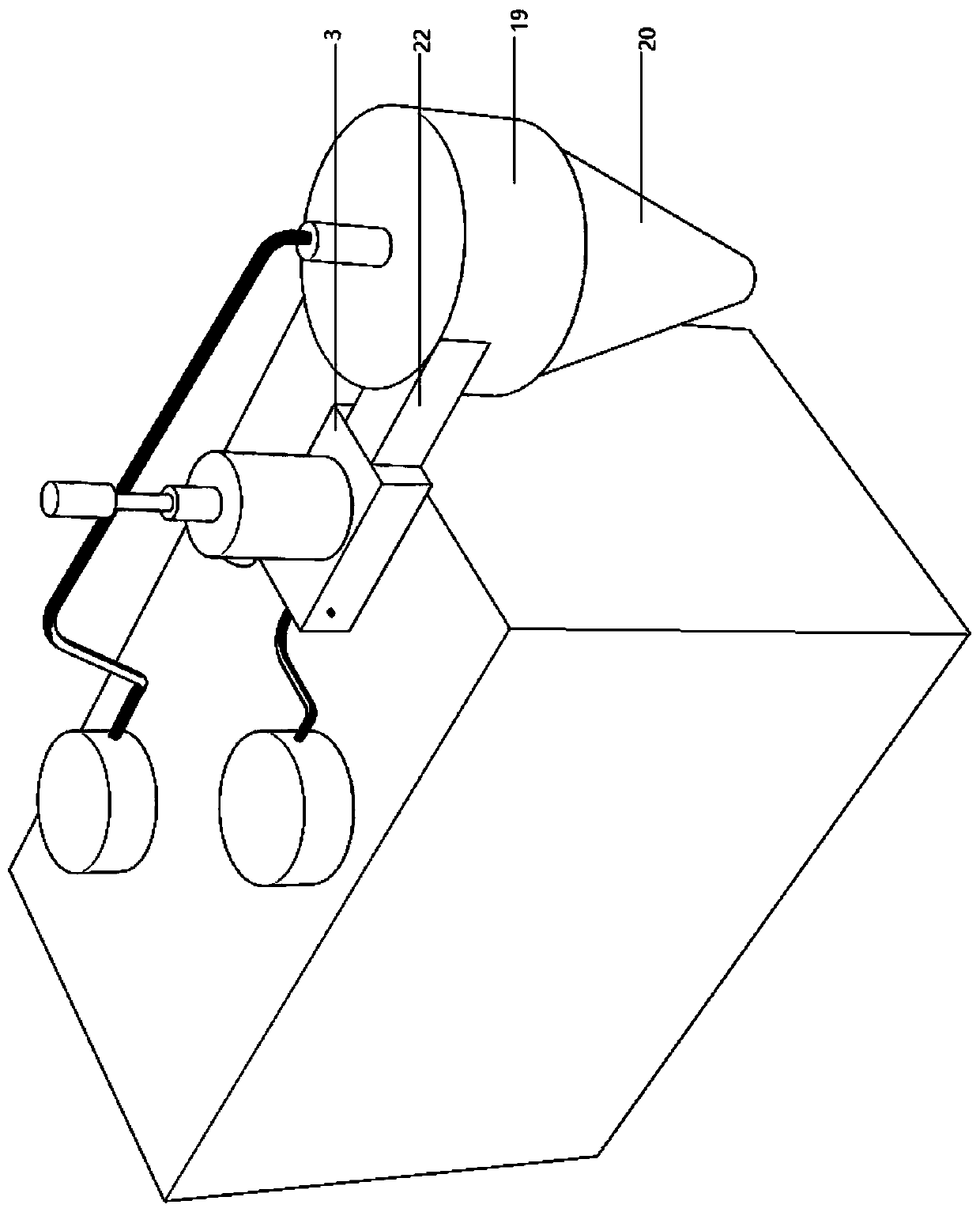

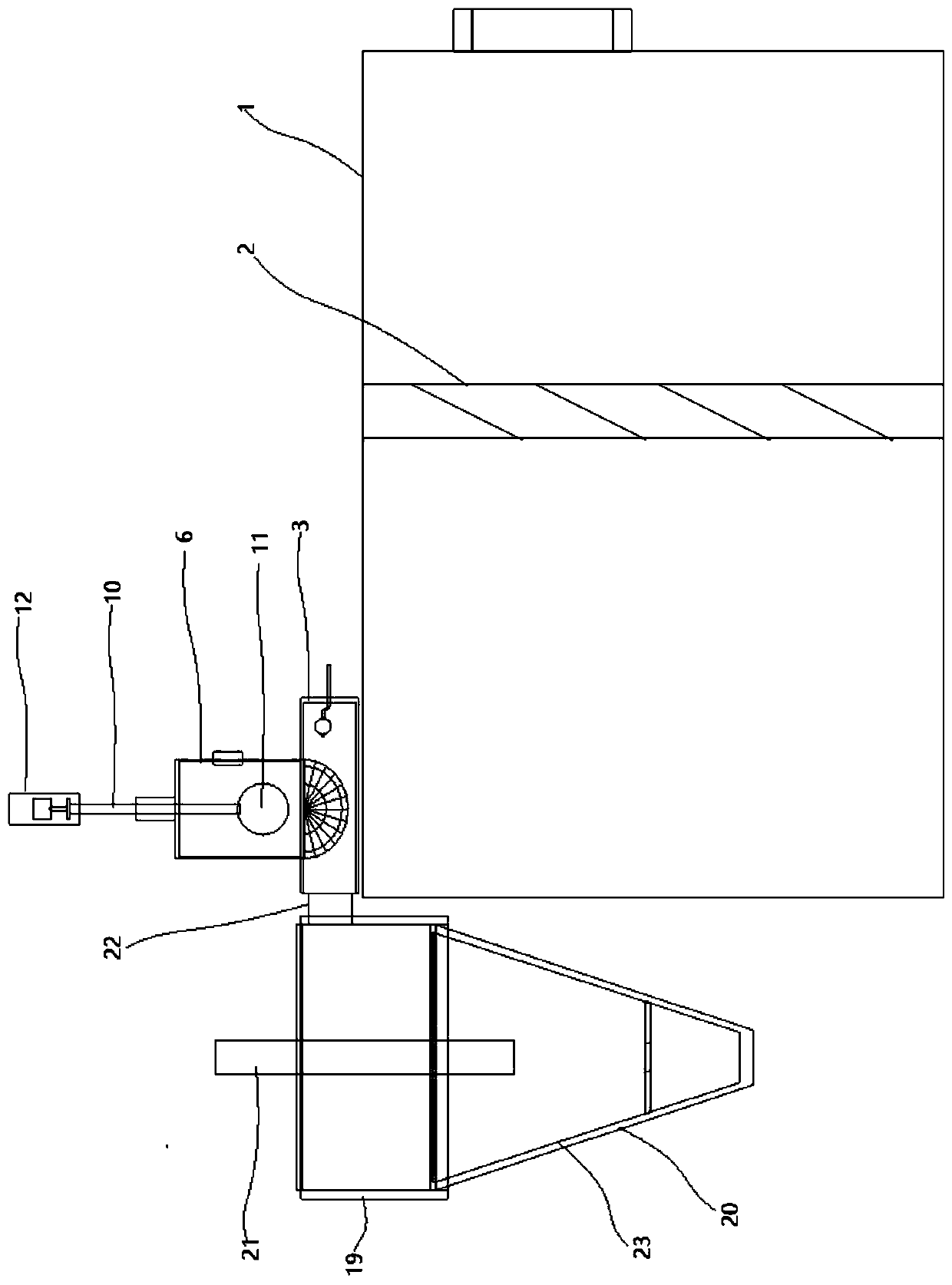

PendingCN107415094AReduce fly-outReduce pollutionPlastic recyclingMechanical material recoveryMachiningElectric motor

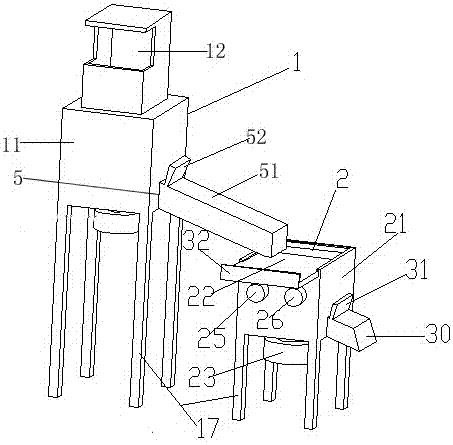

The invention discloses waste plastic cutting machining equipment. The waste plastic cutting machining equipment comprises a first smashing machine and a second smashing machine; the first smashing machine comprises a cutting box, a feeding opening is formed in the upper end of the cutting box, a transverse plate is horizontally arranged in the cutting box, a cutting assembly is arranged between the transverse plate and the top of the cutting box, and the bottom of the cutting box is arranged in an inclined manner; an outlet is formed in one side face of the cutting box, a material via way is connected to one side of the outlet, and the material via way and the cutting box are blocked by a first baffle; the second smashing machine comprises a smashing box, the smashing box is arranged at the lower end of the material via way, the upper end of the smashing box is provided with a push plate, a first motor is installed at the midpoint of the lower end face of the smashing box, and a smashing cutter is installed inside the smashing box and penetrates the bottom face of the smashing box to be connected with the first motor; and a second motor and a third motor are installed on the upper side of the front end of the smashing box, a first rotating shaft and a second rotating shaft are arranged at the upper end of the interior of the smashing box, and chopping knives are installed on the first rotating shaft and the second rotating shaft correspondingly.

Owner:吴江市金鑫塑料厂

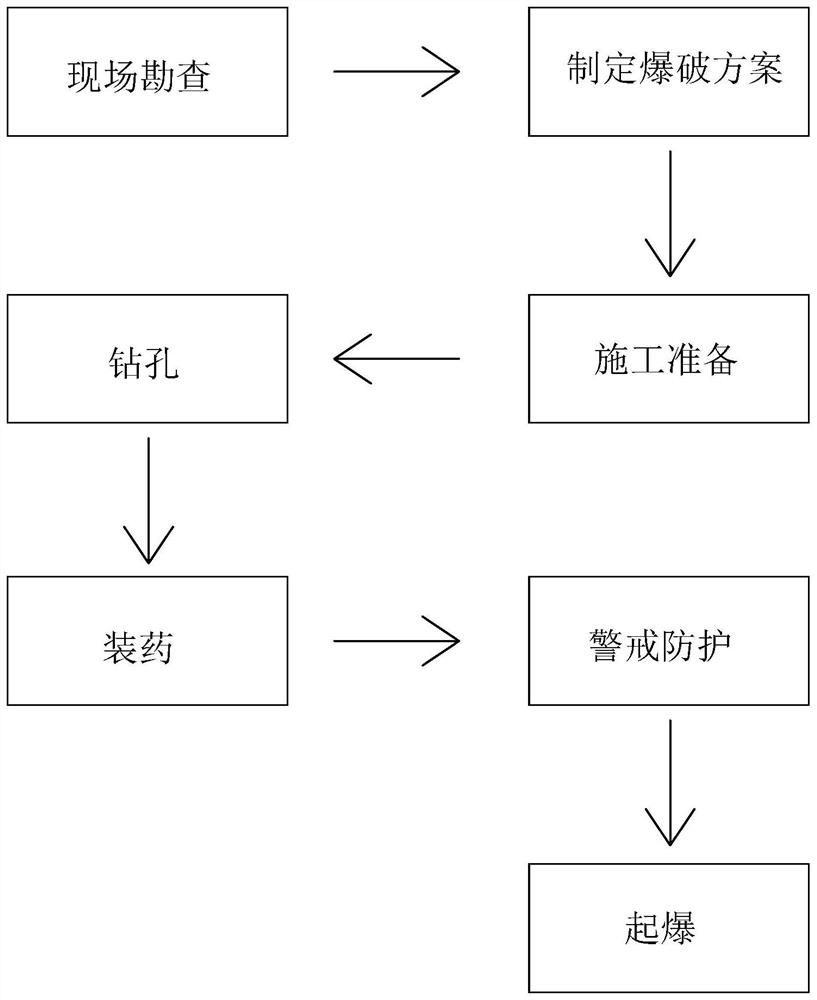

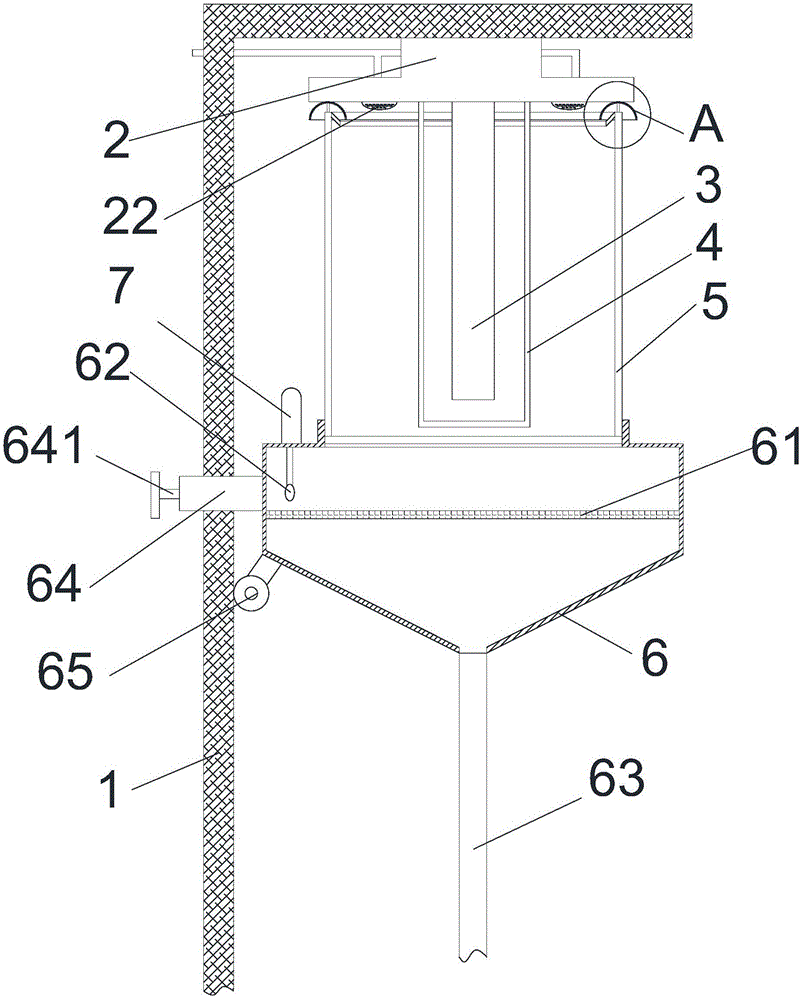

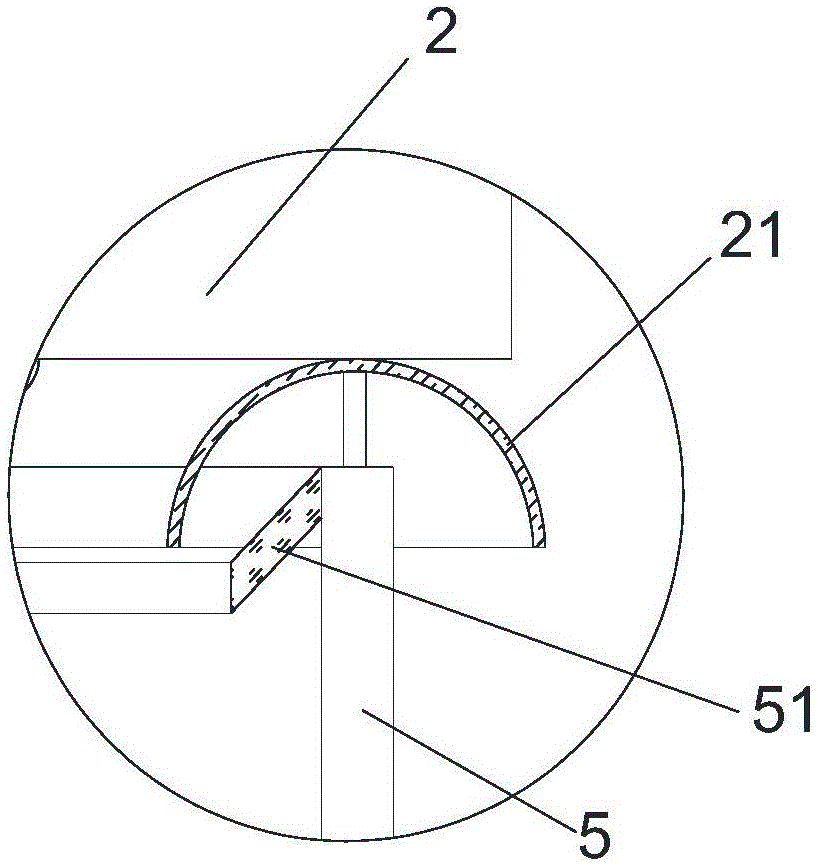

Foundation pit earth-rock excavation blasting method and protective equipment used for blasting

The invention relates to the technical field of foundation pit construction, in particular to a foundation pit earth-rock excavation blasting method. The method comprises following steps: step 1, on-site investigation: a blasting site is investigated; step 2, formulation of a blasting scheme: the blasting scheme is formulated according to the on-site investigation; step 3, construction preparation: personnel allocation is carried out before construction, and blasting materials are transported and prepared simultaneously; step 4, drilling: blast holes are formed in a blasting area through drilling by drilling equipment at equal intervals; step 5, charging: the blast holes are filled with explosives, and detonators are inserted into the blast holes; step 6, guarding protection: the blastingarea is detected to determine that no personnel or equipment exists in the blasting area, meanwhile, the blasting area is guarded, and protective equipment for preventing stone which is blown up fromflying out of the blasting area is arranged; and step 7, detonation: the explosives are detonated. The foundation pit earth-rock excavation blasting method has the effects that the stone which is blown up can be protected, the probability of the stone flying out of the blasting area is reduced, and the probability of causing safety accidents is reduced.

Owner:深圳市蛇口招商港湾工程有限公司

Novel casting equipment easy to demold

InactiveCN106513645AHighly integratedLow costFoundry mouldsMoulding machinesSurface-active agentsWater pipe

Owner:成都嘉新特种精密铸造有限公司

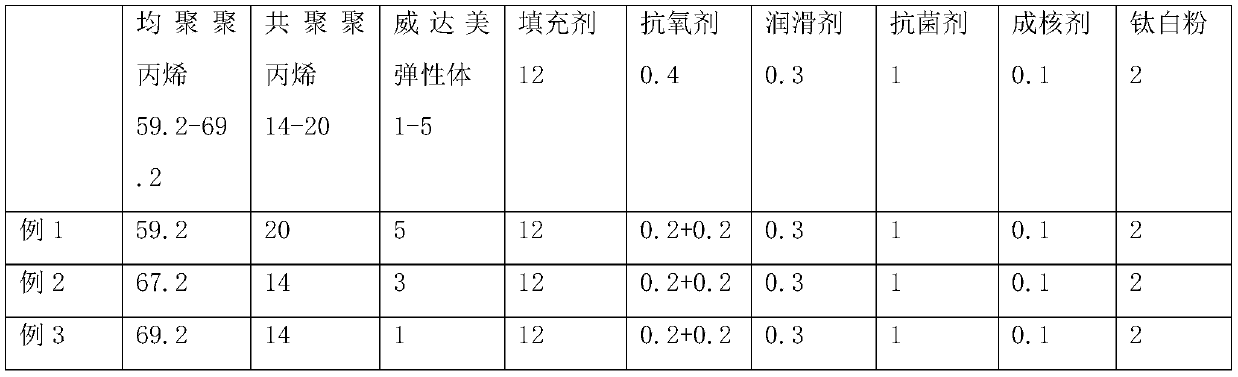

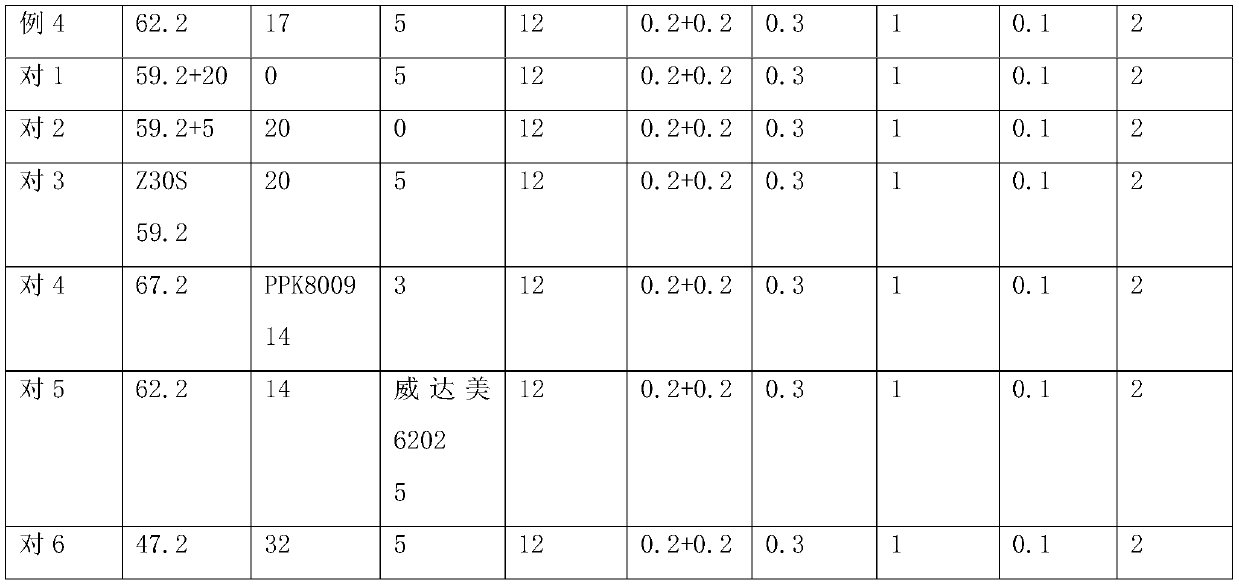

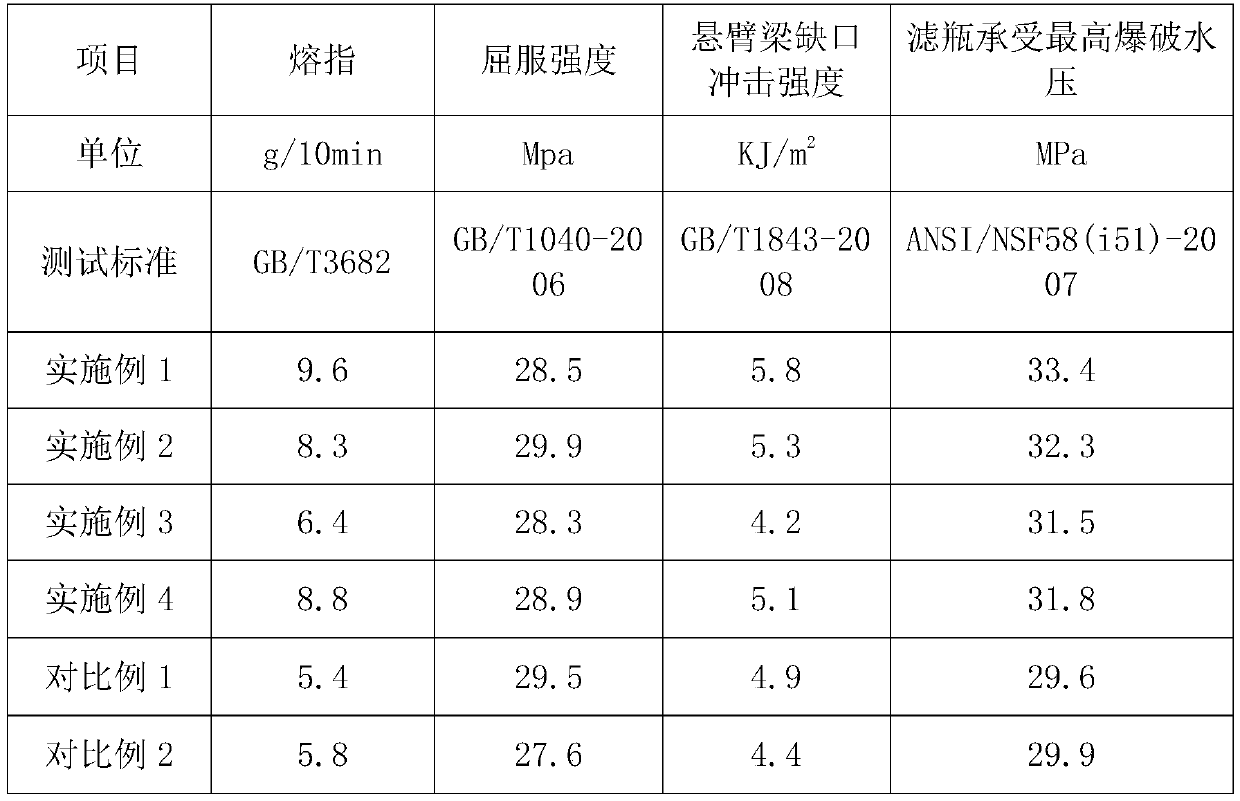

Polypropylene composite material for shell of filter bottle of water purifier, and preparation method and applications thereof

The invention discloses a polypropylene composite material for the shell of the filter bottle of a water purifier. The polypropylene composite material is characterized by comprising homo-polypropylene, co-polypropylene, a Vistamaxx elastomer, a filler, an antioxidant, a lubricant, an antibacterial agent, a nucleating agent, and titanium dioxide according to a ratio of (59.2-69.2):(14-20):(1-3):12:0.4:0.3:1:0.1:2; wherein the isotacticity of homo-polypropylene is not less than 96%, the melting index is not more than 6g / 10min; the melting point of co-polypropylene is not higher than 140 DEG C;and the melt flowing speed of the Vistamaxx elastomer is greater than 500g / 10min. After spinning melting processing, the strength of the fusion face of the composite material is high, and thus the composite material can bear a high circulation water pressure, will not be broken, and can be used to prepare a water purifier filter bottle shell.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Coal smashing device

InactiveCN106345562AKeep healthyEasy to cleanCombination devicesExternal electric electrostatic seperatorPhysical healthCoal

The invention discloses a coal smashing device which comprises a smashing bin, a motor, a coal guide hopper, a coal receiving hopper, a coal conveying pipe, a coal lifting hopper, an electromagnetic valve, a dust collecting pipe, a dust removing device, a fan and a gas outlet pipe. The motor and a feeding barrel are arranged on the top of the smashing bin, the smashing bin is sealed, and the motor is a bi-directional rotary motor; the motor is in drive connection with a spindle, a stirring paddle is arranged on the upper side of the spindle, and a movable cone is arranged below the stirring paddle; movable cutters are arranged on the outer surface of the movable cone, protrusions are arranged on the lower side of the smashing bin and are matched with the movable cone, and fixed cones are arranged on the surfaces of the protrusions; a bin is arranged below the movable cone and the fixed cones; the bin is connected with the coal guide hopper, the coal receiving hopper is connected with the bottom of the coal guide hopper and is connected with the coal lifting hopper by the coal conveying pipe, and the electromagnetic valve is arranged on the coal conveying pipe; the dust collecting pipe is arranged on the top of the coal receiving hopper and is connected with an air inlet of the dust removing device. The coal smashing device has the advantages that the coal smashing device is safe in use, good smashing effect and dust removing effects can be realized, and accordingly the physical health of staffs can be guaranteed.

Owner:合肥智慧殿机械设计有限公司

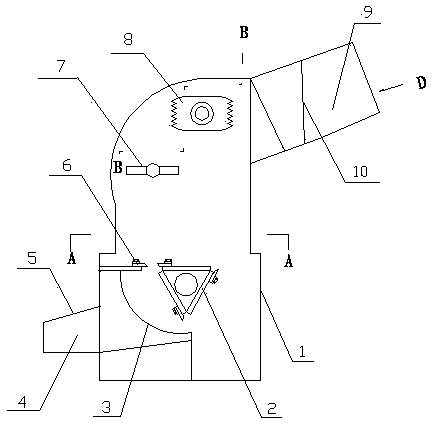

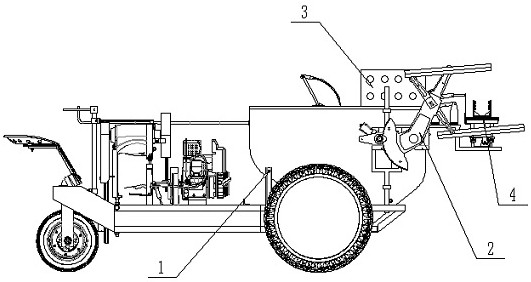

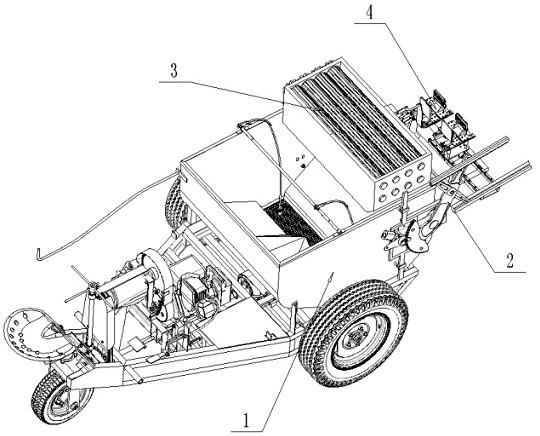

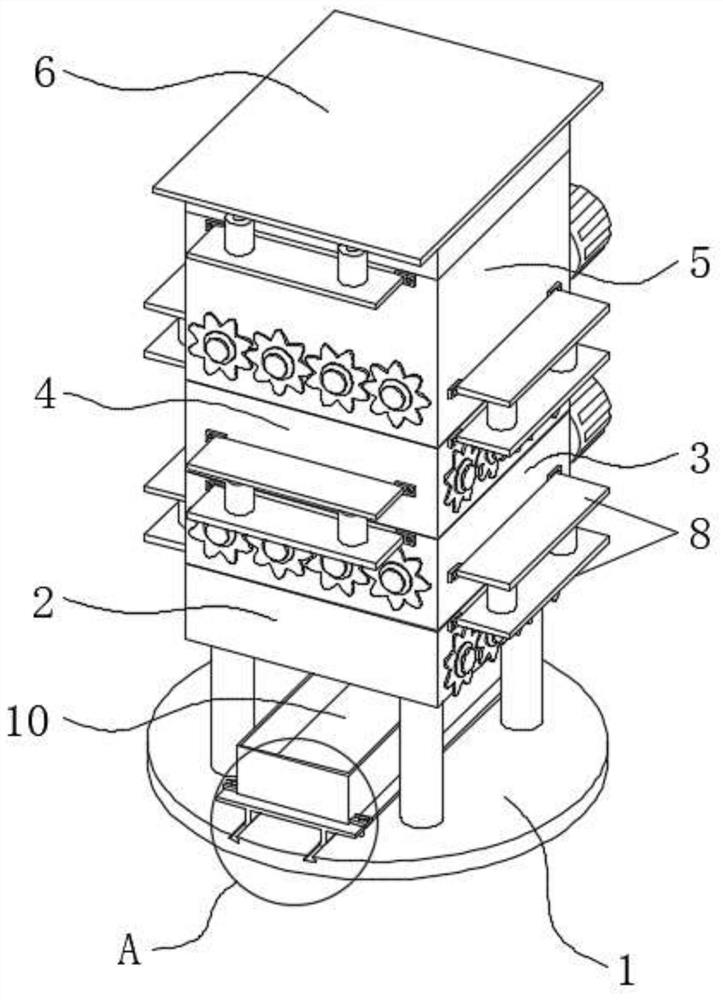

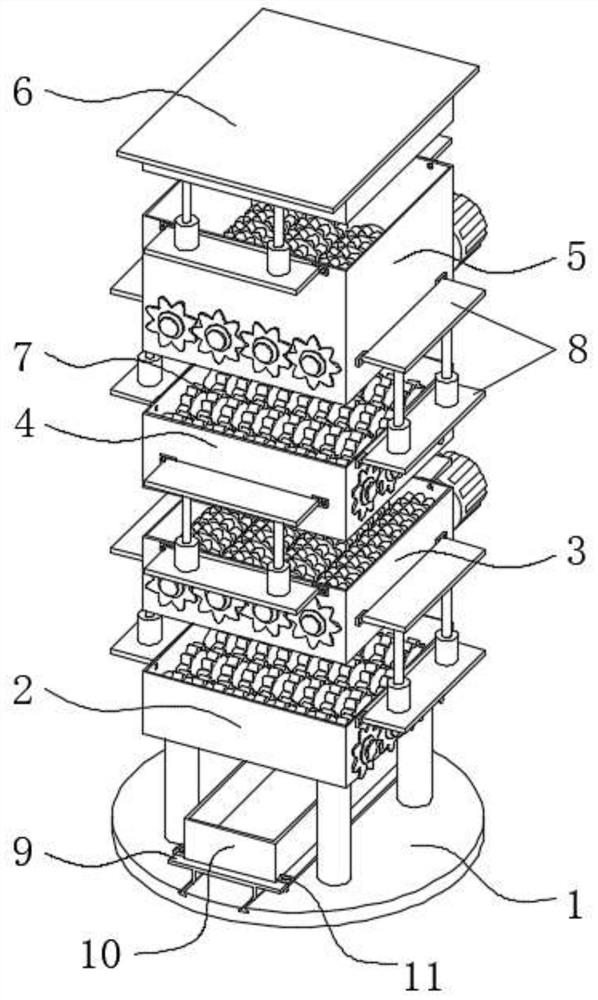

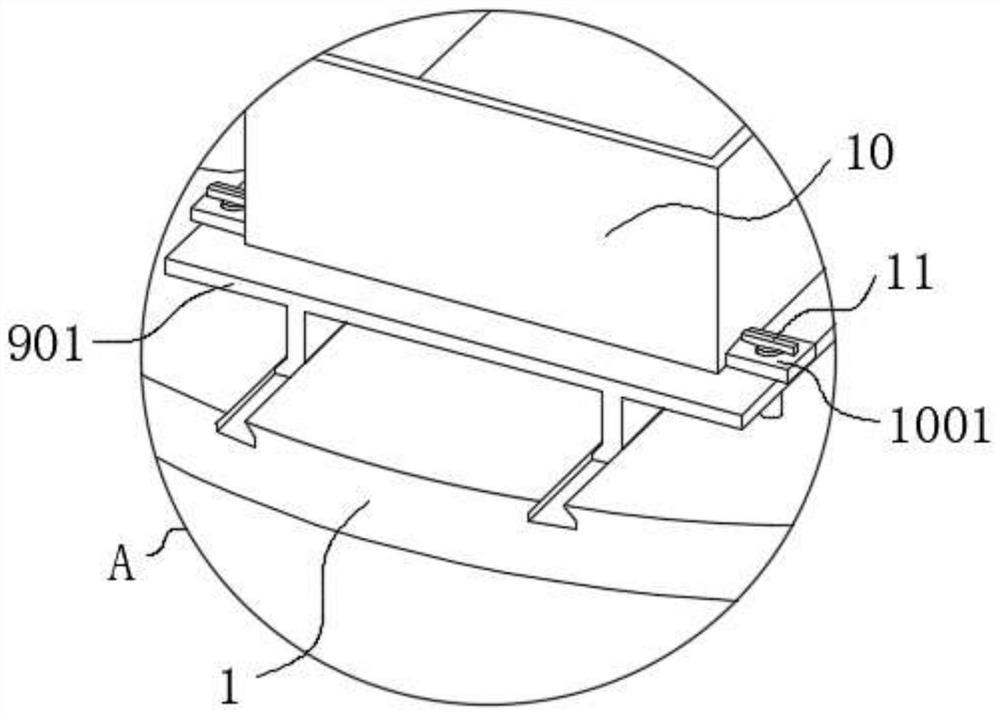

Automatic pruning equipment for long-branch plants outside fence

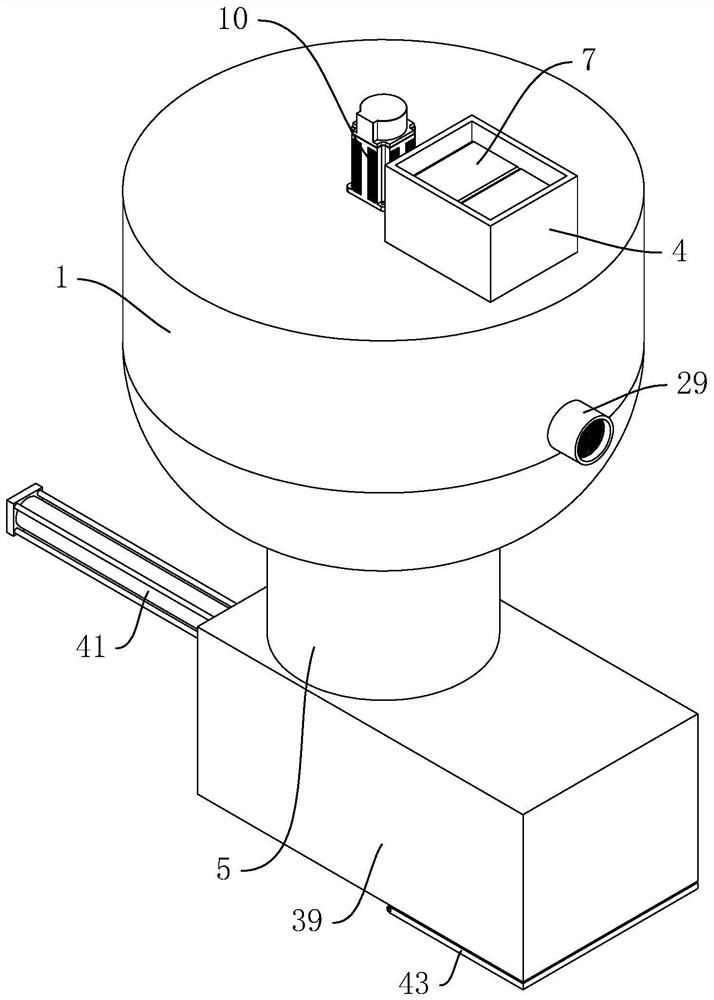

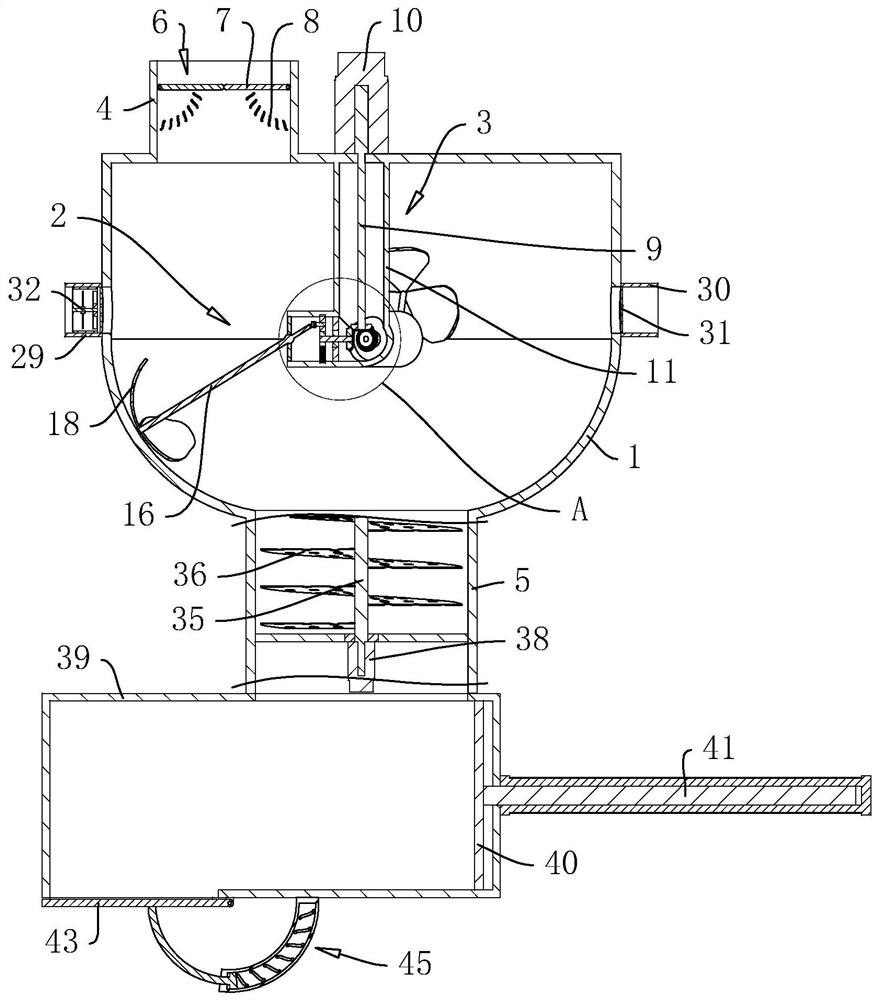

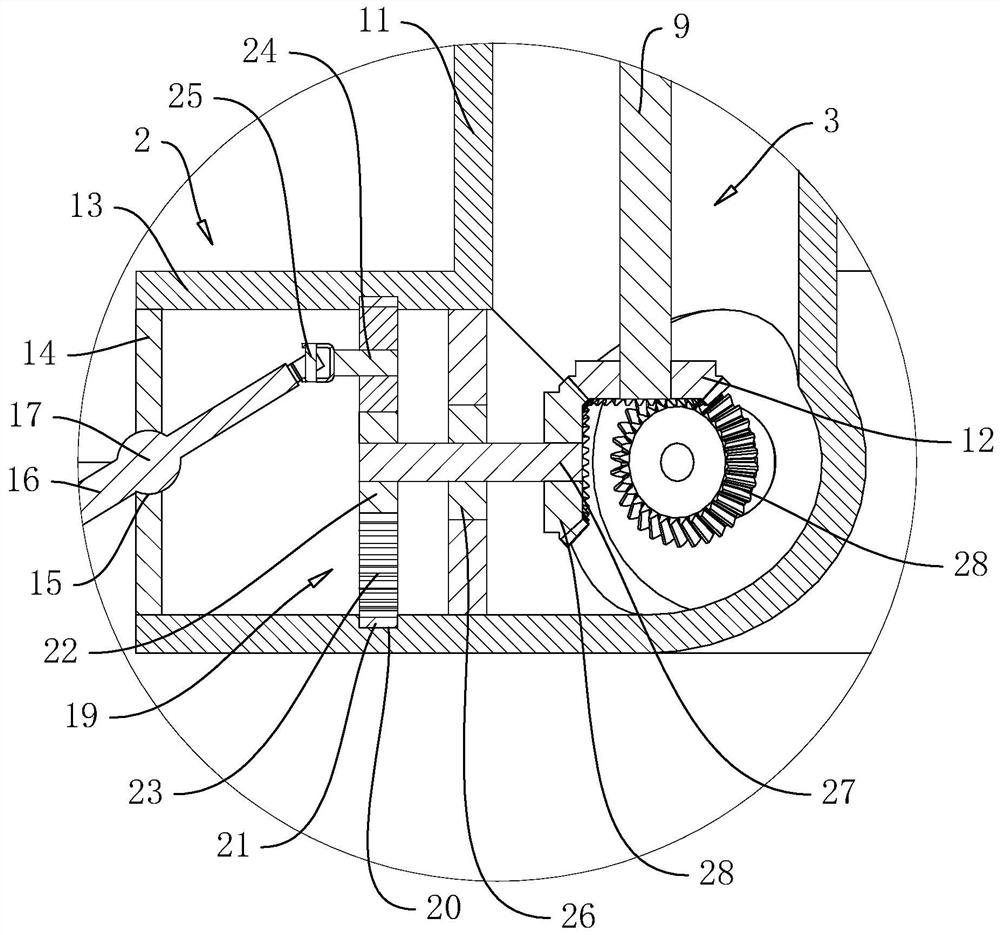

PendingCN112616475AEasy pruningReduce fly-outPlant waste comminutingCuttersRefuse collectionGear wheel

The invention discloses automatic pruning equipment for long-branch plants outside a fence. The automatic pruning equipment comprises a vehicle body, a pruning part, a smashing part and a taking part. During use, firstly, the vehicle body moves close to the fence, a stepping motor drives a lifting frame to move up and down so as to adjust the height of the pruning part, a servo motor drives a rotating bracket to rotate by a certain angle, pruning is conducted through electric scissors, and branches of different heights and angles can be sheared more conveniently; meanwhile, the branches are poured into a twisting-in shaft through the taking part, the branches are extruded into a crushing box through rotation of the twisting-in shaft, a crushing shaft is driven by a crushing gear to rotate to crush the branches, powder is leaked into a garbage collection box, after the powder reaches a specified position, a manual control rod is manually pulled to drive a rotating rod to rotate so as to drive a pull rod to pull an overturning plate upwards to leak the powder, and therefore the space is saved; and meanwhile, the powder can be used as fertilizer, so that integrated pruning, collecting and crushing are realized.

Owner:薛秀菊

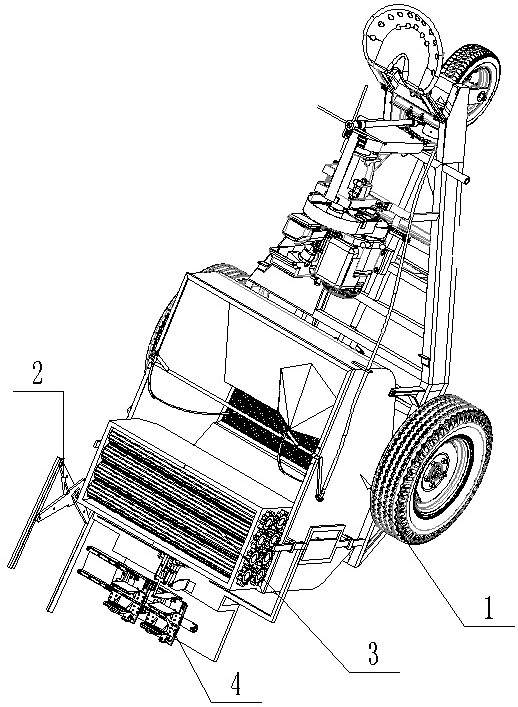

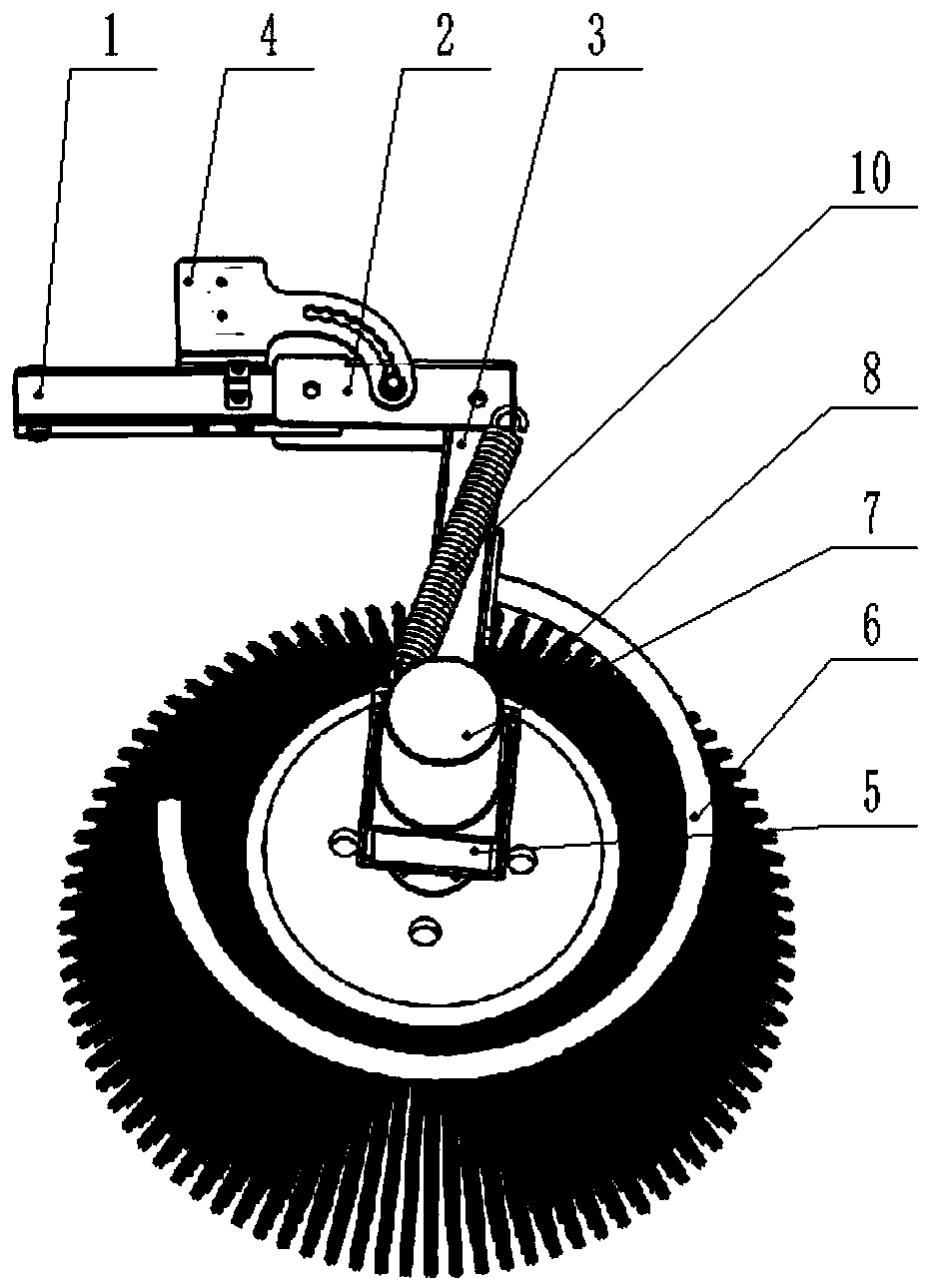

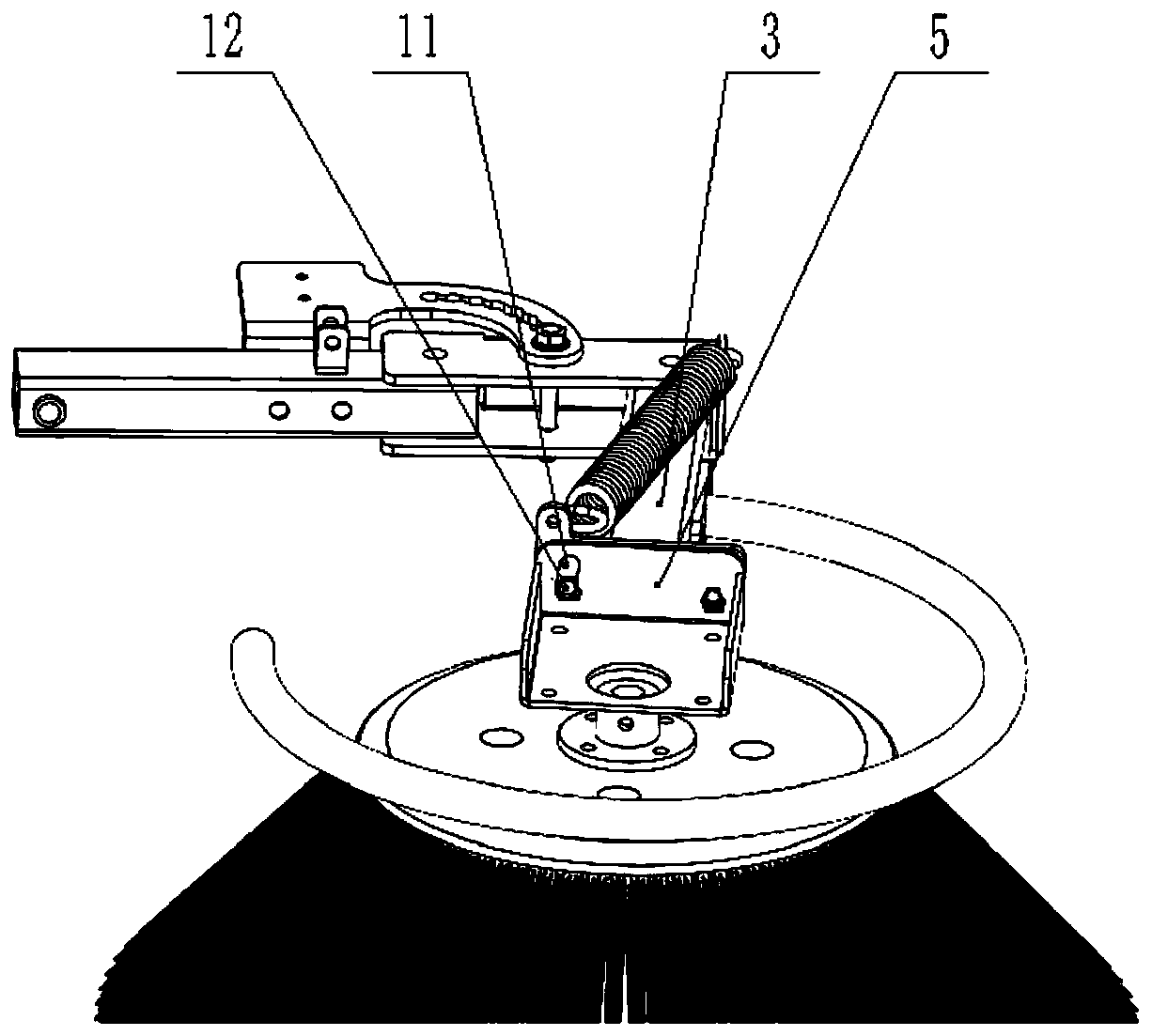

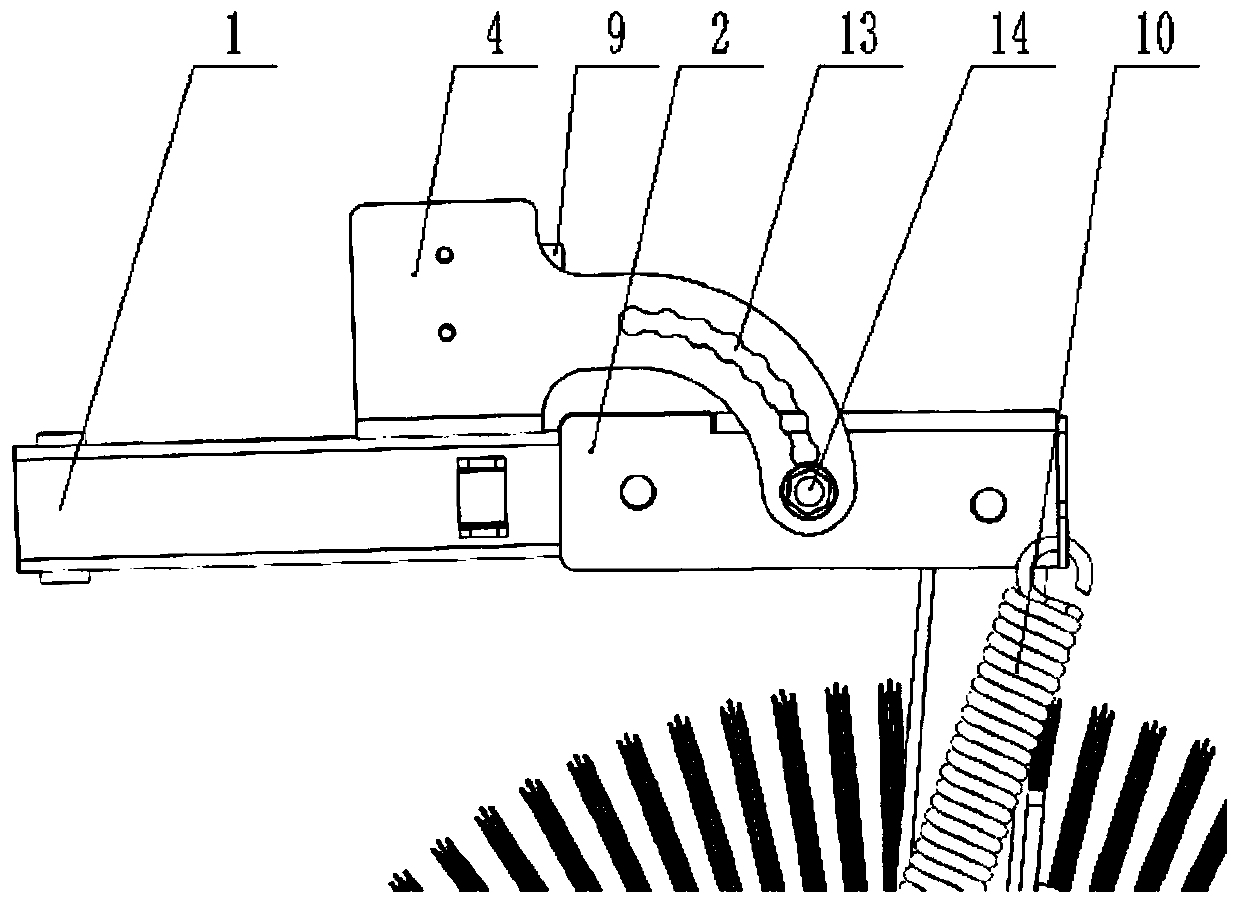

Anti-collision, energy-saving and sweeping width and angle adjustable cleaning mechanism of sweeping vehicle

The invention provides an anti-collision, energy-saving and sweeping width and angle adjustable cleaning mechanism of a sweeping vehicle, which is used for solving the problems that in the prior art,the sweeping mechanism is easy to collide with obstacles, large in maintenance cost, large in energy consumption and unadjustable in sweeping angle. The cleaning mechanism comprises a side brush support, the side brush support is hinged to an side brush swing arm support, the edge brush swing arm support is hinged to a side brush swing arm, the side brush swing arm is connected with a mounting piece of an side brush motor, the side brush motor mounting piece is provided with the side brush motor, the output end of the side brush motor is connected with the sweeping brush, and one end of a tension spring is connected with the side brush swing arm support and the other end of the tension spring is connected with the side brush swing arm. According to the cleaning mechanism, the sweeping brush and the motor can be prevented from being collided to the maximum extent, the sweeping width can be adjusted, the operation is convenient, the passing rate of the sweeping vehicle is greatly improved, the energy is saved, the cleaning mechanism can be used in cooperation with the rear fixing side brush, the cleaning mechanism can be used in multiple stages, the universality is high, and the installation is convenient.

Owner:河南银泰智能专用车有限公司

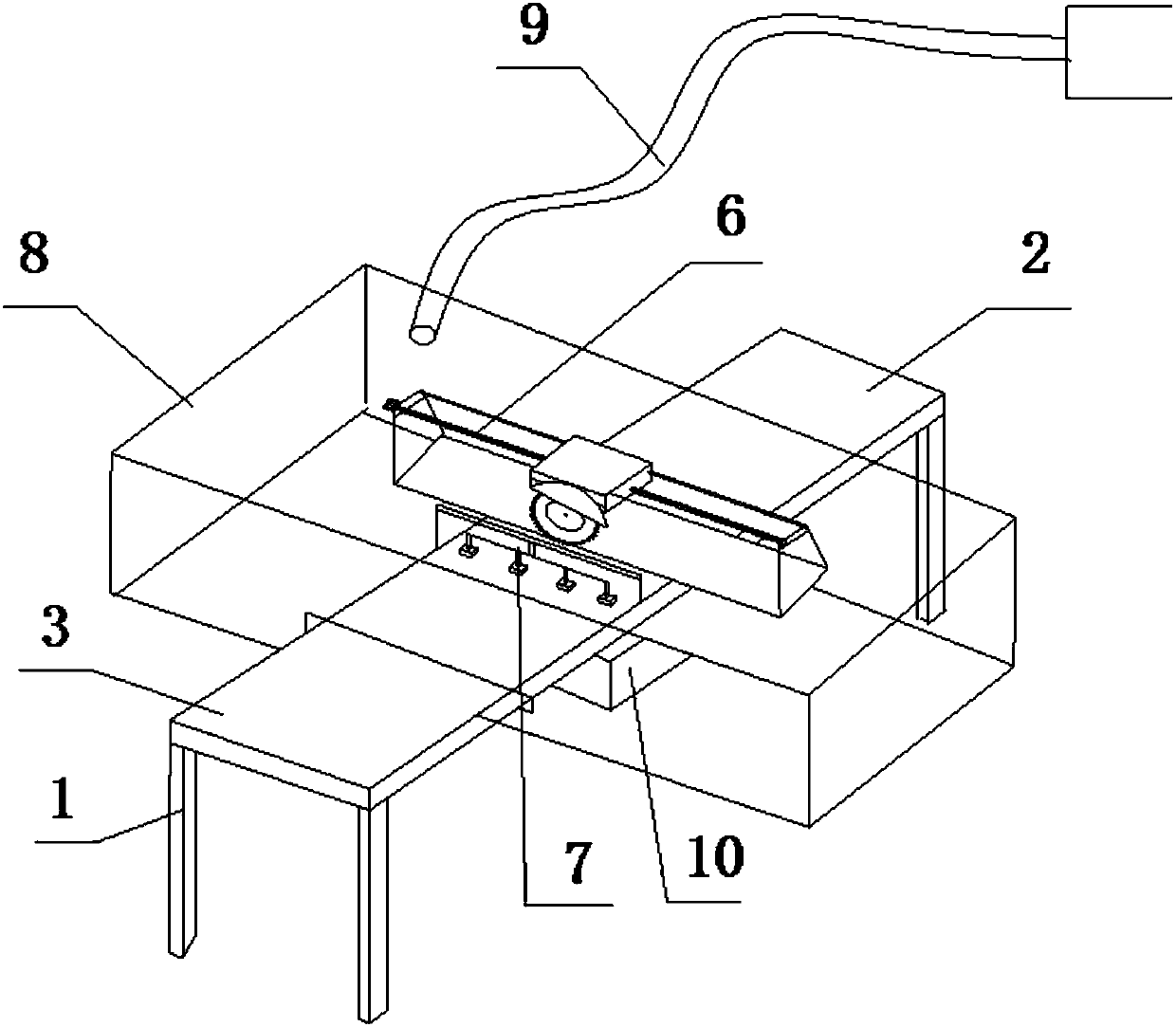

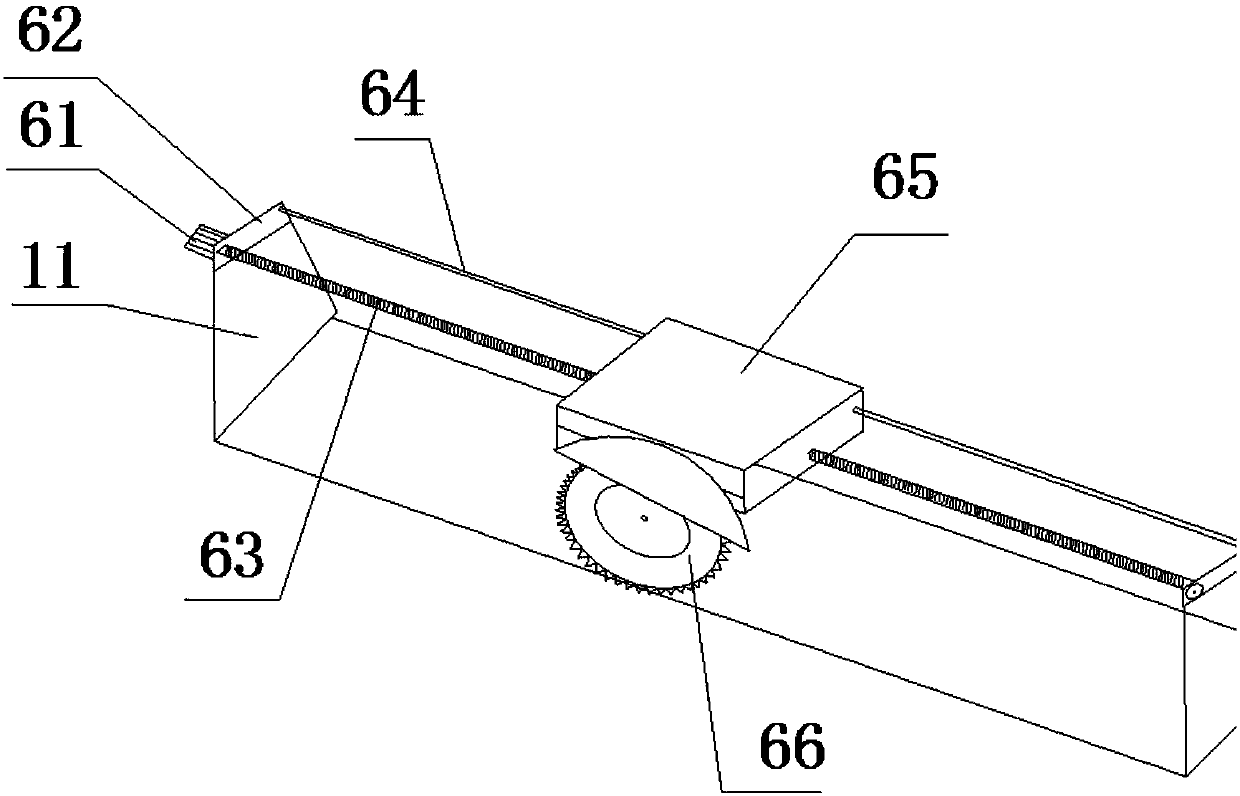

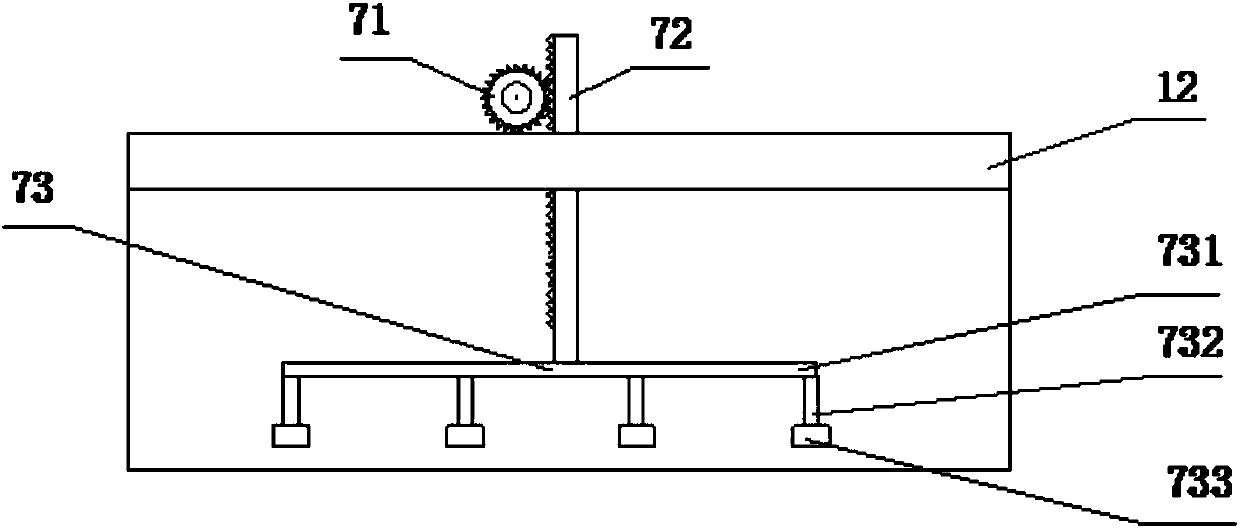

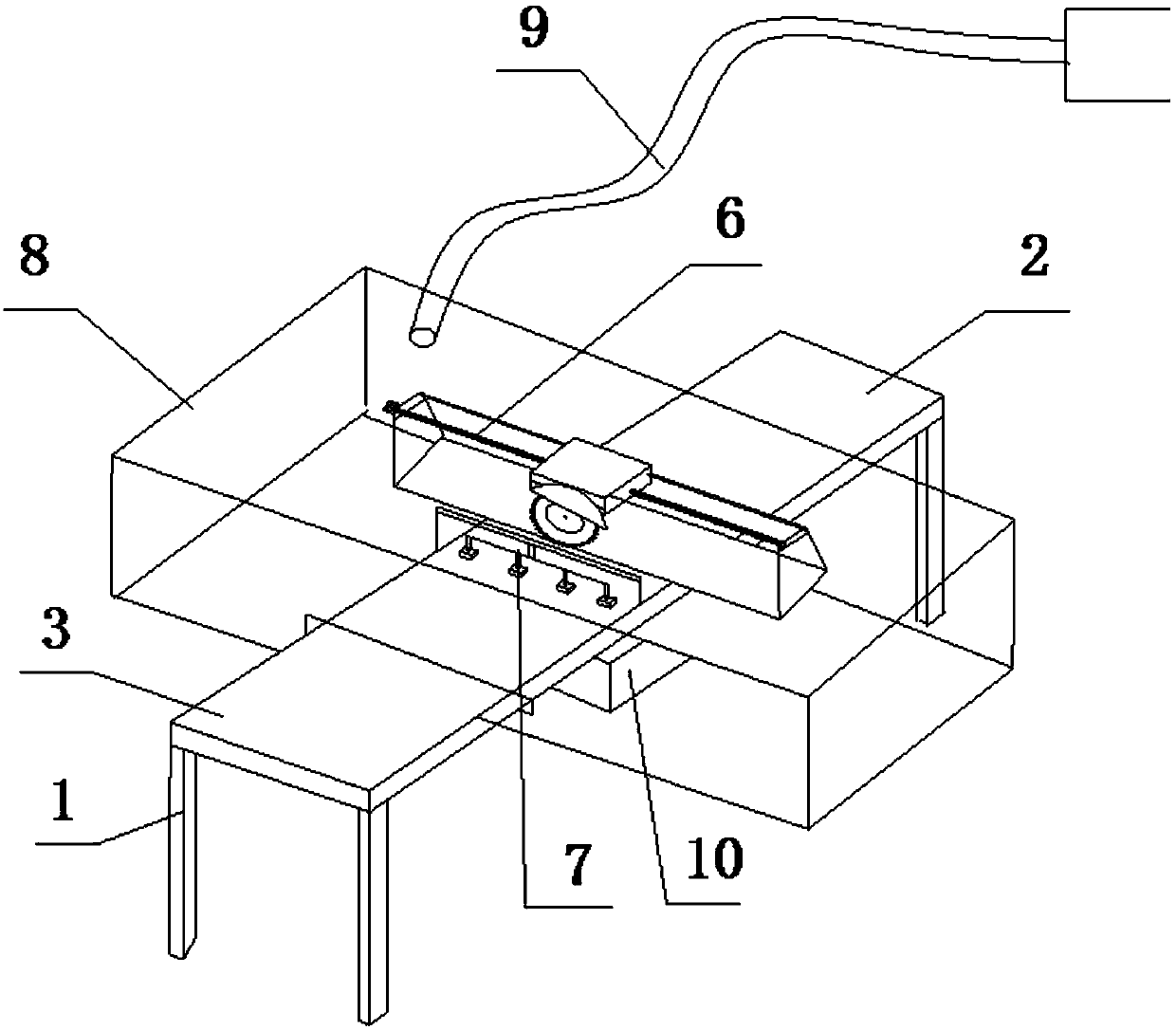

Cutting system for stone panel machining based on Internet of Things

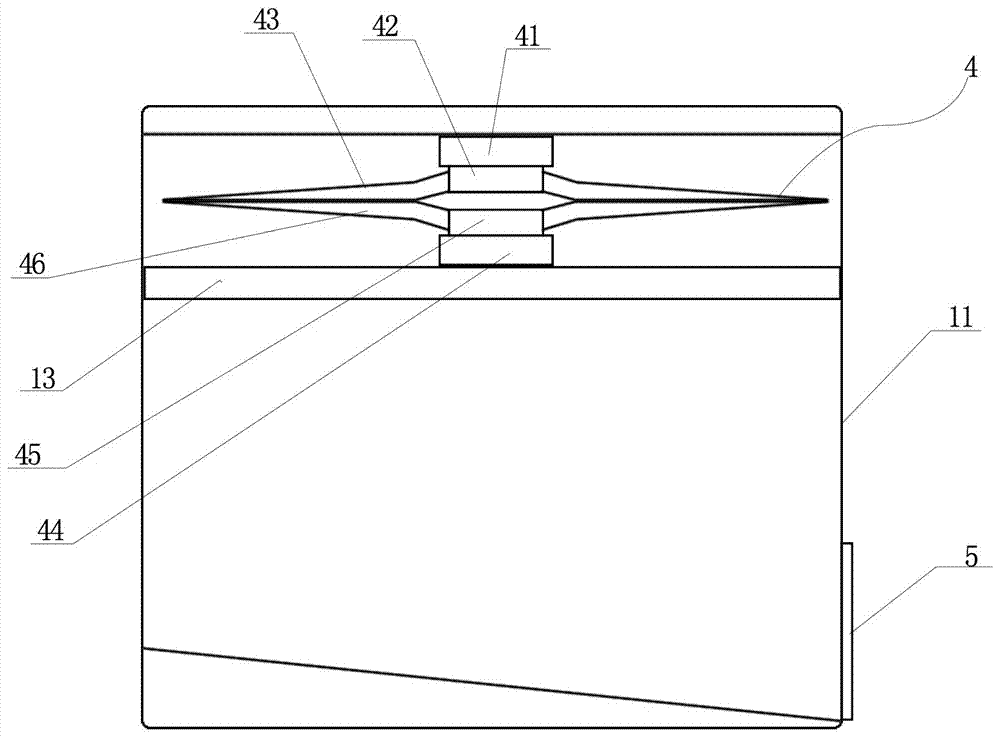

ActiveCN107791401AEven by forceAvoid damage and breakageWorking accessoriesStone-like material working toolsThe InternetPsychological health

The invention discloses a cutting system for a stone panel based on the Internet of Things. A rack is provided with a panel feeding channel and a panel discharging channel, and a gap is formed betweenthe panel feeding channel and the panel discharging channel. A cutting device is fixed to the rack and located above the gap, a panel cutting area is formed, and a cooling device is arranged in the panel cutting area and achieves cooling in the panel cutting process. Panel pressing devices are arranged at the tail end of the panel feeding channel and the front end of the panel discharging channel. The panel cutting area on the rack is covered with a transparent dust stop chamber, and the dust stop chamber is connected with a dust suction device. The cutting device, the cooling device, the panel pressing devices and the dust suction device are connected with an intelligent control system. By adoption of the system for stone panel cutting, the effects that the cutting efficiency is high, the damage rate is low, and influences on physical and psychological health of workers are weak are achieved.

Owner:江苏奇胜石材有限公司

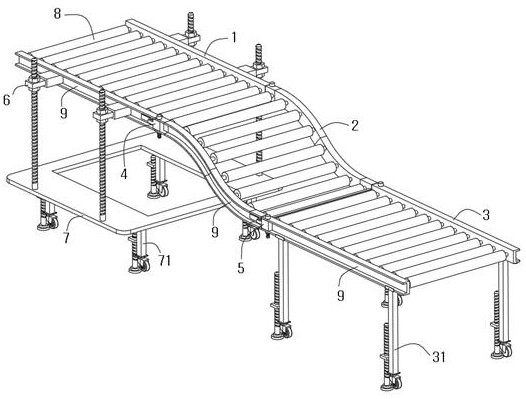

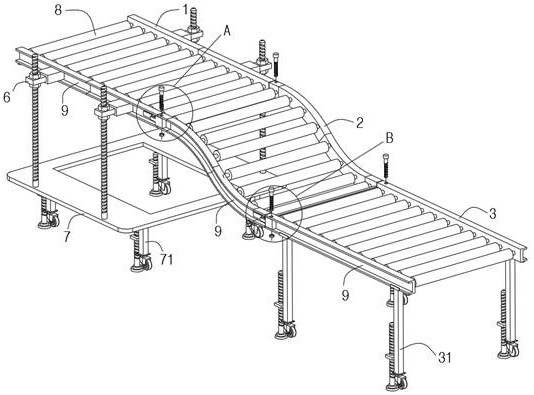

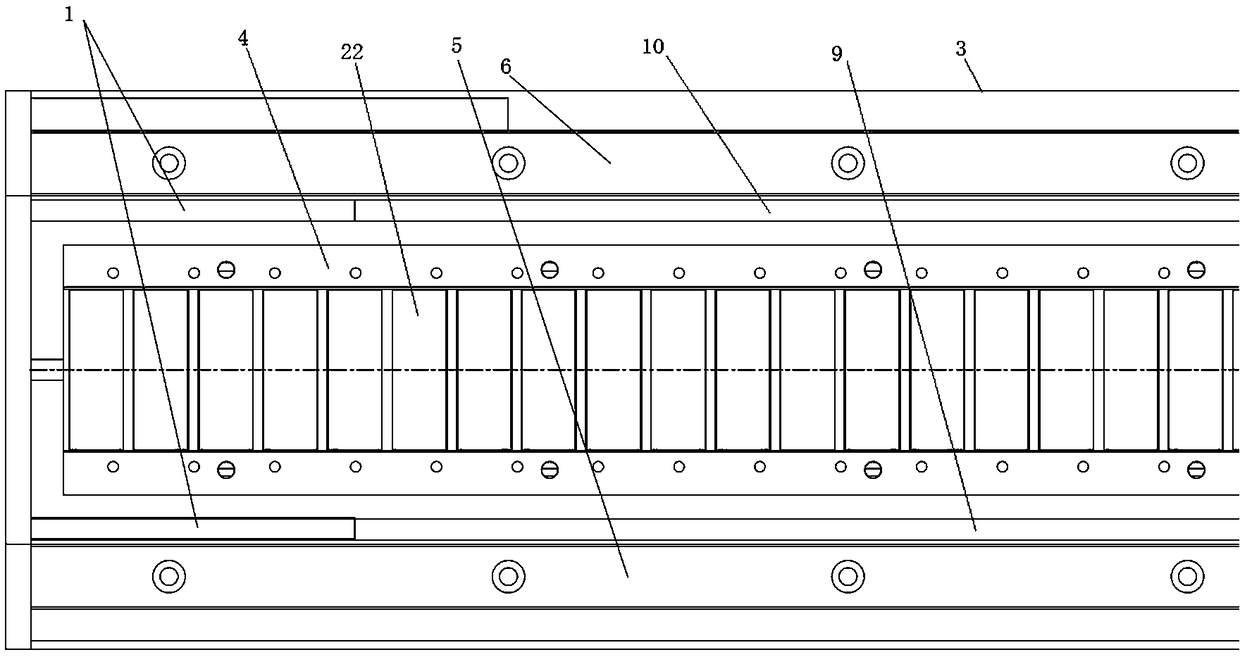

Unpowered roller line

ActiveCN113443333AAchieve accelerationReduce CatonRoller-waysLogistics managementStructural engineering

The invention discloses an unpowered roller line, and relates to the technical field of logistics conveying. The unpowered roller line comprises two parallel first frame plates; a second frame plate is arranged at one end of each first frame plate, and a third frame plate is arranged at the end, away from the corresponding first frame plate, of each second frame plate; a plurality of rollers are rotationally connected between the inner sides of the two first frame plates in the length direction of the first frame plates, between the inner sides of the two second frame plates in the length direction of the second frame plates and between the inner sides of the two third frame plates in the length direction of the third frame plates; each second frame plate is formed by sequentially splicing a straight line section I, an arc section I, an arc section II and a straight line section II; the arc section I is tangent to the linear section I, the arc section II is tangent to the linear section II, and the arc section I is also tangent to the arc section II; and the top and the bottom of the linear section I are flush with the tops and the bottoms of the first frame plates correspondingly. The unpowered roller line has the beneficial effects that objects can be conveyed conveniently, and accumulation, falling and the like of the objects in the conveying process are reduced.

Owner:江苏伊凡诺尔智能科技有限公司

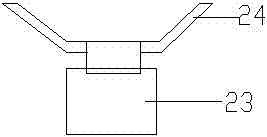

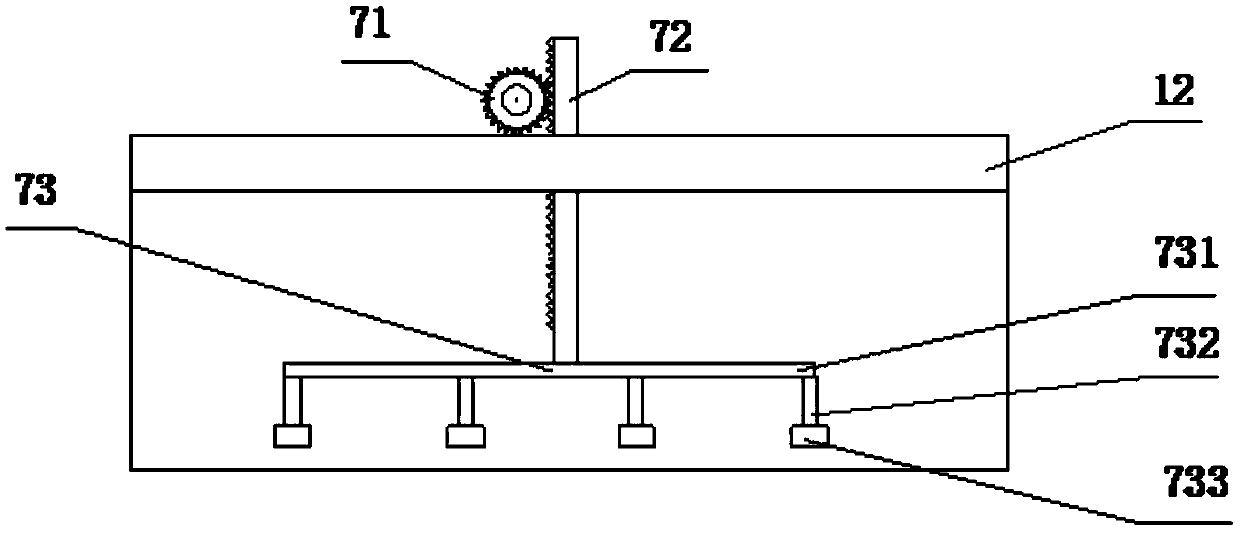

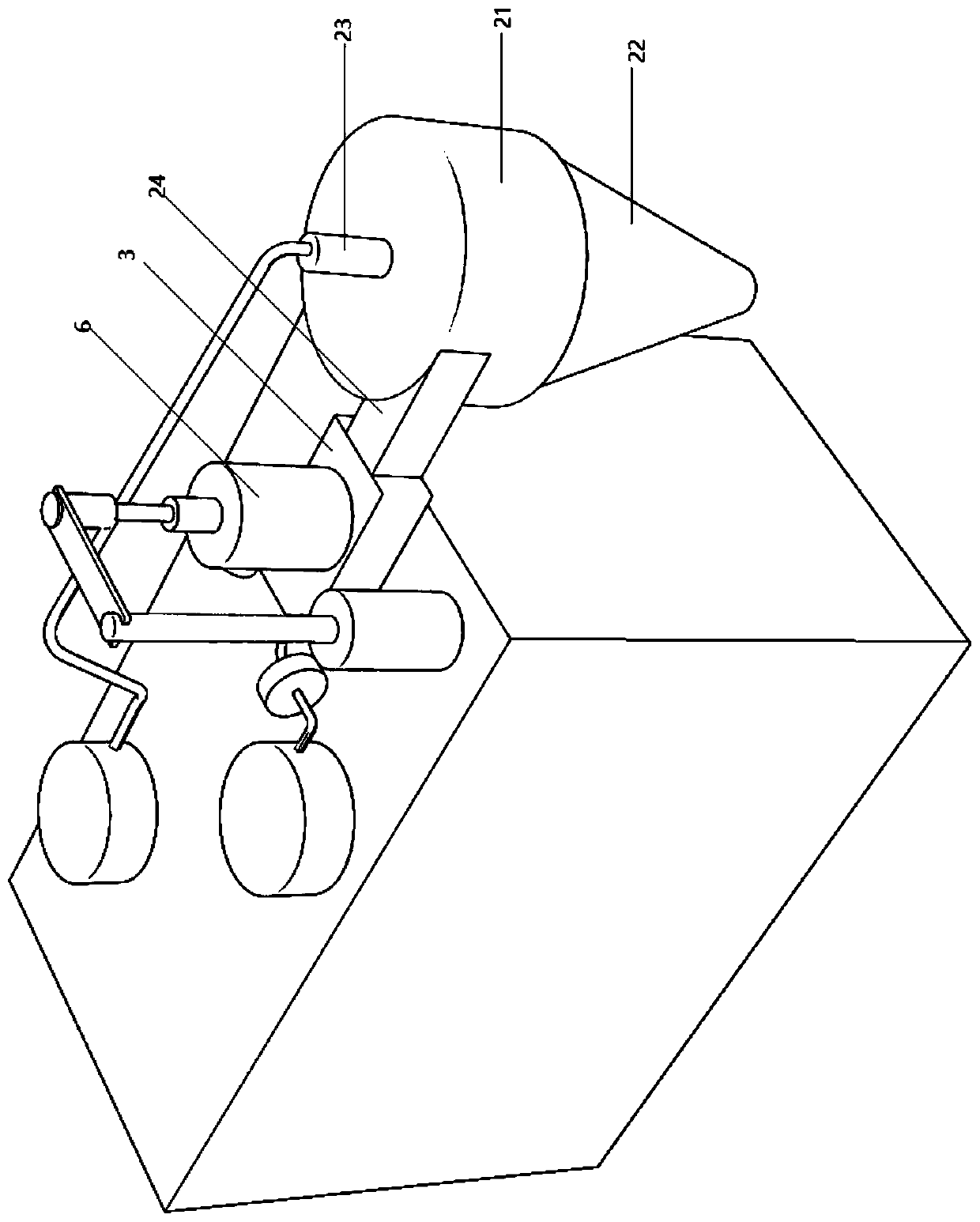

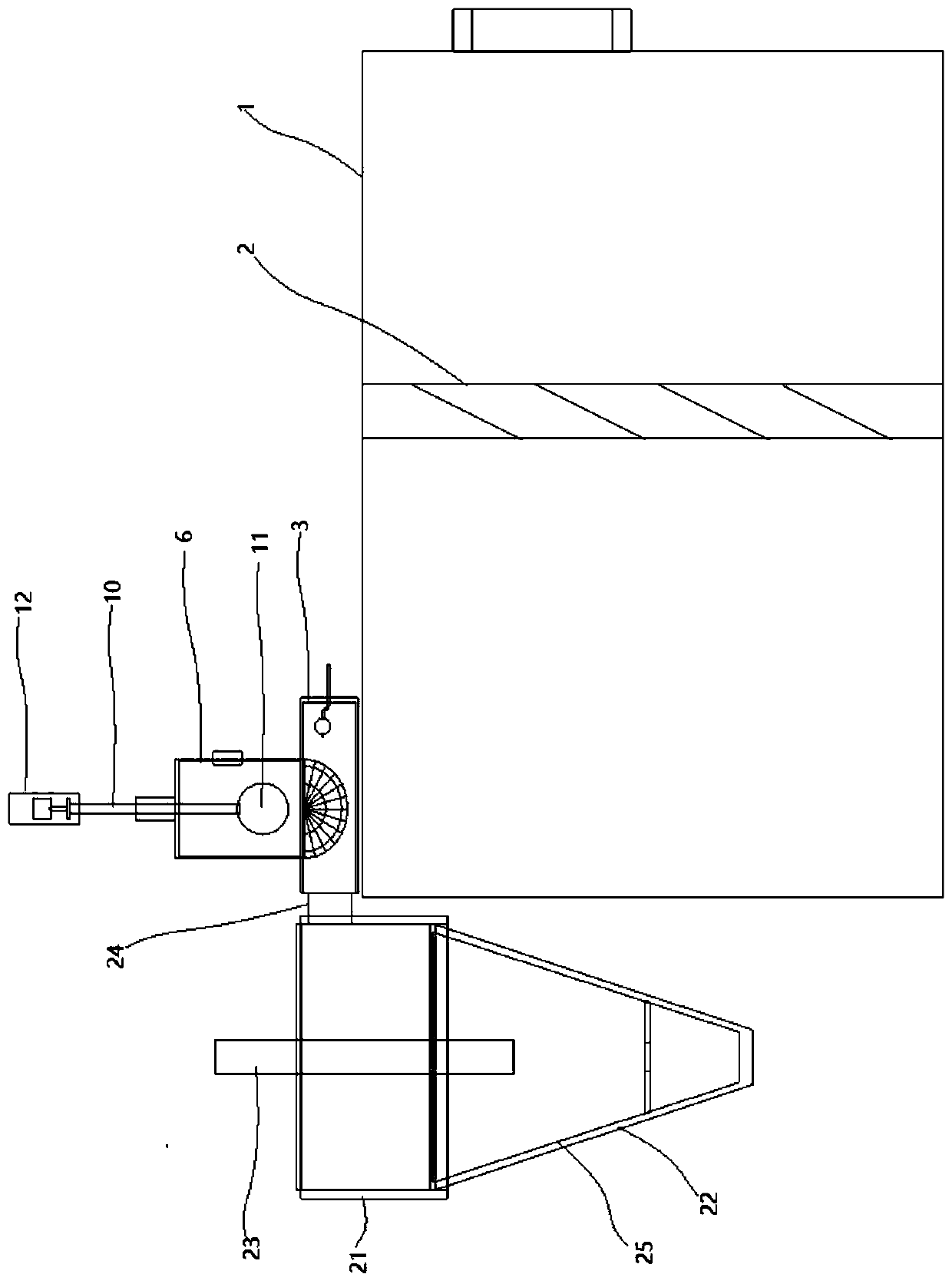

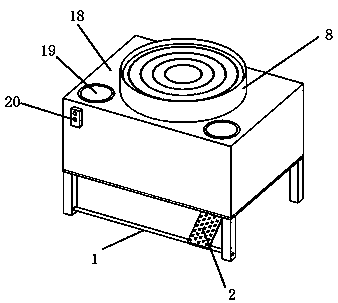

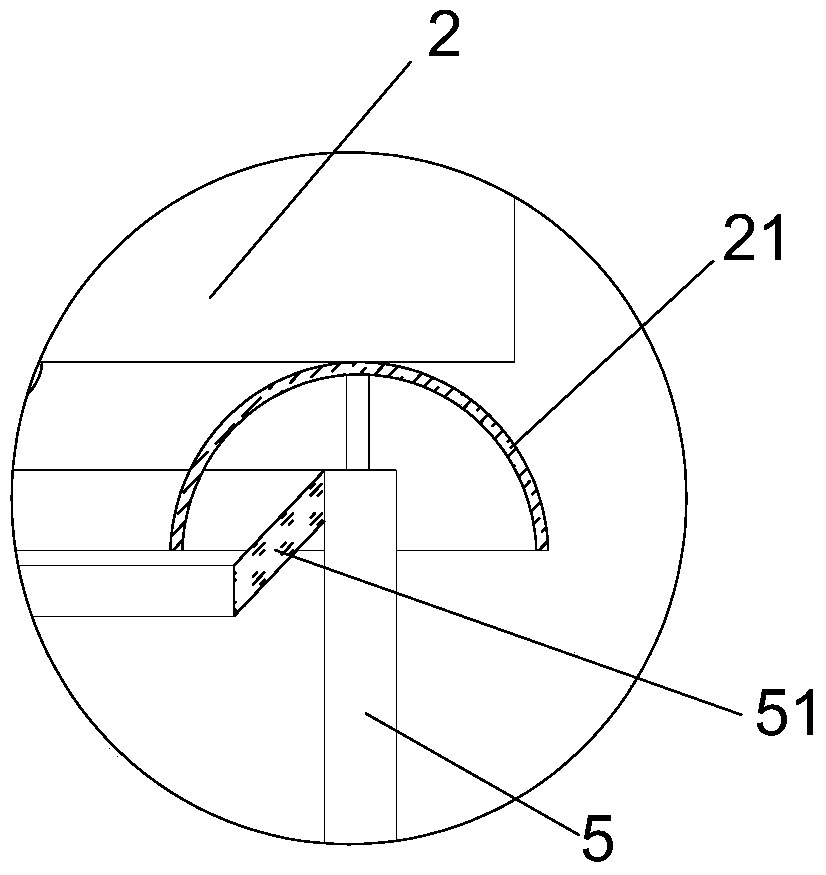

Shaft frame of Jun porcelain blank drawing machine

PendingCN109079960ASimple structureImprove utilization efficiencyCeramic shaping apparatusEngineeringMechanical engineering

The invention provides a shaft frame of a Jun porcelain blank drawing machine. The shaft frame sleeves a rotating shaft, is connected with a base of the Jun ceramic blank drawing machine and comprisesan upper connecting part, a lower connecting part, a left supporting arm and a right supporting arm, wherein the upper connecting part, the lower connecting part, the left supporting arm and the right supporting arm are connected into an integrated square annular structure; first through holes for the rotating shaft to penetrate are formed in the upper connecting part and the lower connecting part respectively, a second through hole for being connected with the base is formed in the lower connecting part, the rotating shaft is connected with the shaft frame through a bearing, a turntable is arranged on the top of the rotating shaft, a manual driving device is arranged below the base and drives the rotating shaft to rotate, and a hood casing is arranged on the base. The shaft frame is simple in structure and is of the square annular structure, the bearing is arranged between the shaft frame and a main shaft to reduce the friction between the main shaft and the shaft frame, and the userequirements for a gear on the main shaft are met.

Owner:禹州市晋家钧窑有限公司

Construction waste recycling and crushing device for construction waste treatment

InactiveCN113145270AImprove crushing qualityImprove the effectGrain treatmentsProcess engineeringRefuse Disposals

Owner:WEIFANG UNIV OF SCI & TECH

Novel efficient casting device capable of achieving easy demoulding

InactiveCN106735130AHighly integratedLow costMoulding machinesMould handling equipmentsFixed frameConfined space

The invention discloses a novel efficient casting device capable of achieving easy demoulding. The novel efficient casting device capable of achieving easy demoulding comprises an upper sand box, a lower sand box, an upper sand box fixing frame and a lower sand box supporting platform. The upper sand box fixing frame comprises four symmetrically arranged stand columns. Hydraulic lifting sliding blocks are installed in the middles of the stand columns and connected with cross arms. One ends of the cross arms are hinged to the hydraulic lifting sliding blocks through hinges, and the other ends of the cross arms are hinged to the upper sand box through hinges. A hydraulic compactor is installed at the tops of the stand columns. The four corners of the bottom of the lower sand box supporting platform are hinged to lifting supporting rods through hinges. Baffles are installed between the stand columns, and one of the baffles is provided with an operation door. A top plate is installed at the tops of the stand columns, and a confined space is formed by the baffles and the top plate. A water mist spraying pipe is installed on the lower surface of the top plate. The inner surfaces of the upper sand box and the lower sand box are both coated with surface active agents. The novel efficient casting device capable of achieving easy demoulding is high in integration degree, convenient to use, low in manufacturing cost, good in moulding quality, high in efficiency, high in casting efficiency and free of environment pollution, and demoulding of the sand boxes is easy.

Owner:成都嘉新特种精密铸造有限公司

A cutting system for stone slab processing based on the Internet of Things

ActiveCN107791401BEfficient cuttingEven by forceWorking accessoriesStationary filtering element filtersThe InternetEngineering

The invention discloses a cutting system for a stone panel based on the Internet of Things. A rack is provided with a panel feeding channel and a panel discharging channel, and a gap is formed betweenthe panel feeding channel and the panel discharging channel. A cutting device is fixed to the rack and located above the gap, a panel cutting area is formed, and a cooling device is arranged in the panel cutting area and achieves cooling in the panel cutting process. Panel pressing devices are arranged at the tail end of the panel feeding channel and the front end of the panel discharging channel. The panel cutting area on the rack is covered with a transparent dust stop chamber, and the dust stop chamber is connected with a dust suction device. The cutting device, the cooling device, the panel pressing devices and the dust suction device are connected with an intelligent control system. By adoption of the system for stone panel cutting, the effects that the cutting efficiency is high, the damage rate is low, and influences on physical and psychological health of workers are weak are achieved.

Owner:江苏奇胜石材有限公司

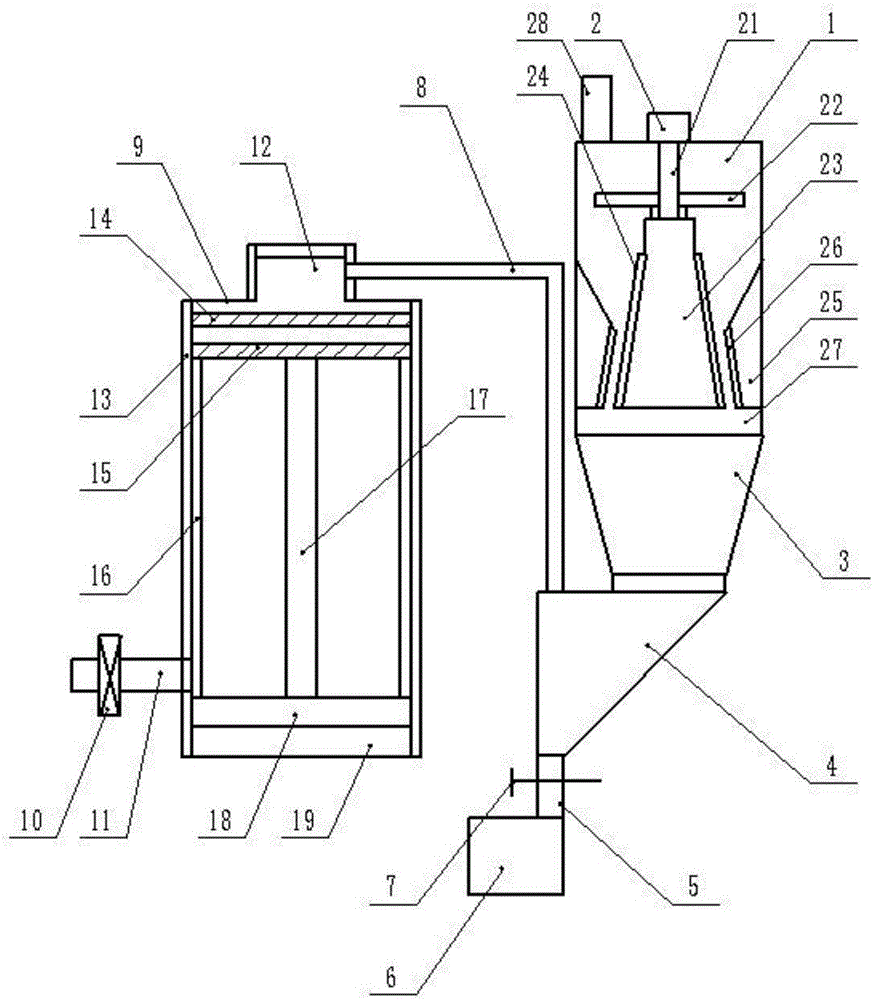

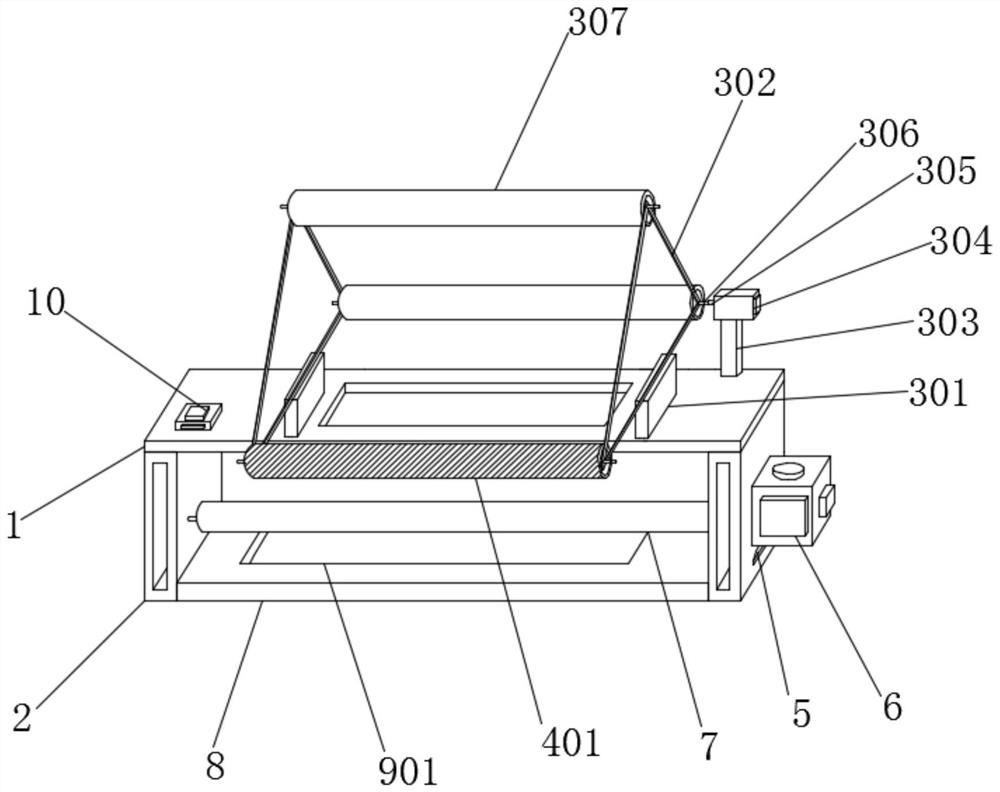

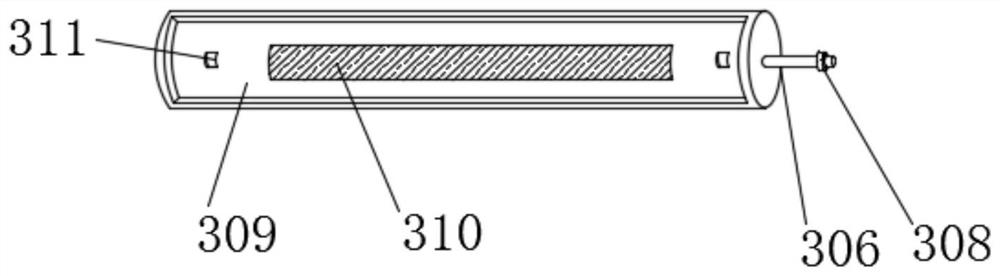

Drying system capable of preventing agglomeration of calcium carbonate powder

PendingCN109341305AQuality assuranceStir wellDrying machines with progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention discloses a drying system capable of preventing agglomeration of calcium carbonate powder. The drying system comprises an oven shell, a feeding unit, and a heat supply unit for providingheat; the oven shell is provided with a feed port, a discharge port and an exhaust port; the feeding unit is formed by joining multiple feeding modules end to end; each feeding module comprises a traction roller, and a conveying belt arranged on the traction roller; the head end of the first feeding module is positioned under the feed port; the tail end of the final feeding module is positioned above the discharge port; a dispersing device is arranged in the oven shell, is mounted in the oven shell, and is positioned under discharge ends of the feeding modules; the dispersing device comprisesa leading plate, an outer shell and a centrifugal device; the leading plate takes the shape of a funnel with large top and small bottom; and a large end of the leading plate is positioned under a discharge end of the conveying belt. The drying system can effectively prevent agglomeration of calcium carbonate during drying, can effectively improves the product quality, and meanwhile, achieves a better drying effect.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

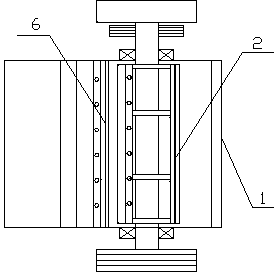

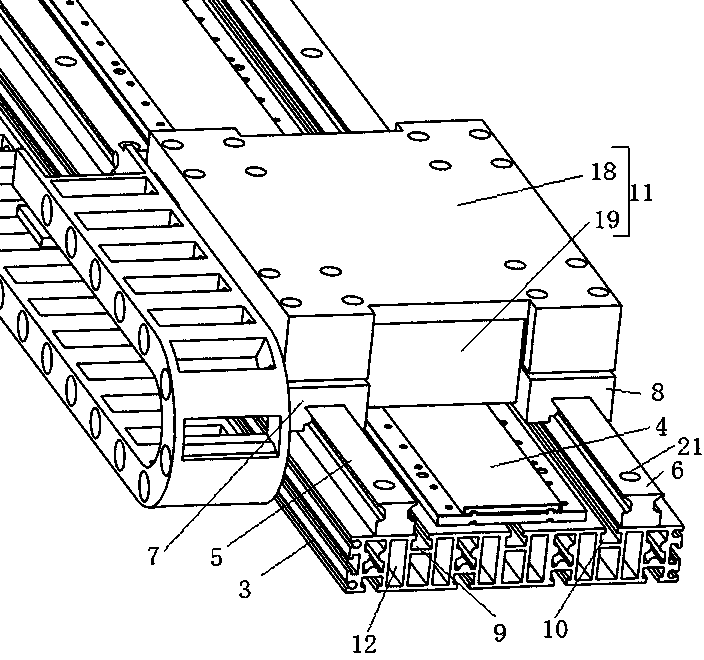

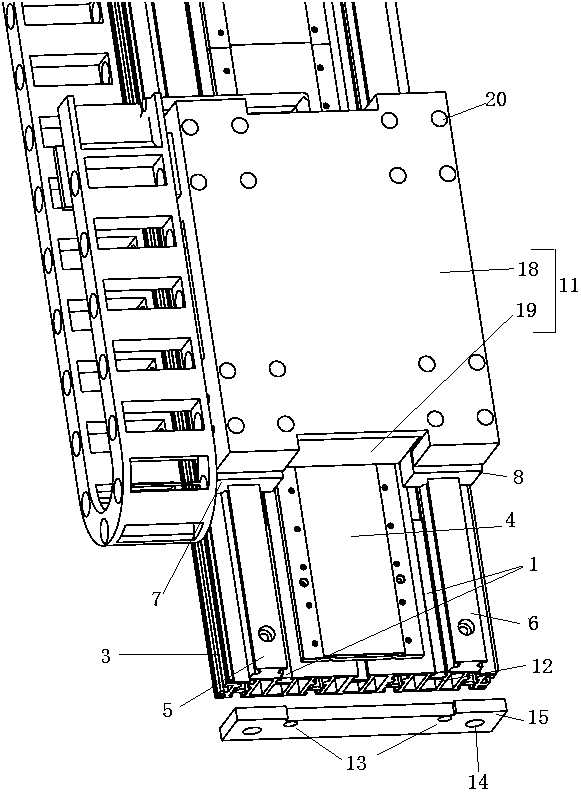

Invisible anti-collision linear motor

ActiveCN108832793AImprove toughnessHigh cushioning factorPropulsion systemsSupports/enclosures/casingsEngineeringLinear motor

The present invention discloses an invisible anti-collision linear motor. The invisible anti-collision linear motor comprises a primary part, a secondary part, a substrate, a first sliding block, a second sliding block, a first guide rail, a second guide rail, invisible mechanical anti-collision devices and end plates, the secondary part is installed on the substrate, the substrate is provided with the first guide rail and the second guide rail, the substrate is provided with a first bar-shaped groove and a second bar-shaped groove, the first sliding block slidingly connected with the first guide rail and the sliding block slidingly connected with the second guide rail are fixed on the primary part, the two ends at the internal portion of the first bar-shaped groove and the two ends of theinternal portion of the second bar-shaped groove are respectively provided with the invisible mechanical anti-collision devices, the two end faces of the substrate are respectively provided with theend plates, a first stop block and a second stop block are fixed on the primary part, the first stop block is slidingly connected with the first bar-shaped groove, and the second stop block is slidingly connected with the second bar-shaped groove. The invisible anti-collision linear motor has function of buffer and mechanical clamping so as to greatly improve the protection of the motor, and is elegant in appearance.

Owner:PHASE MOTION CONTROL NINGBO

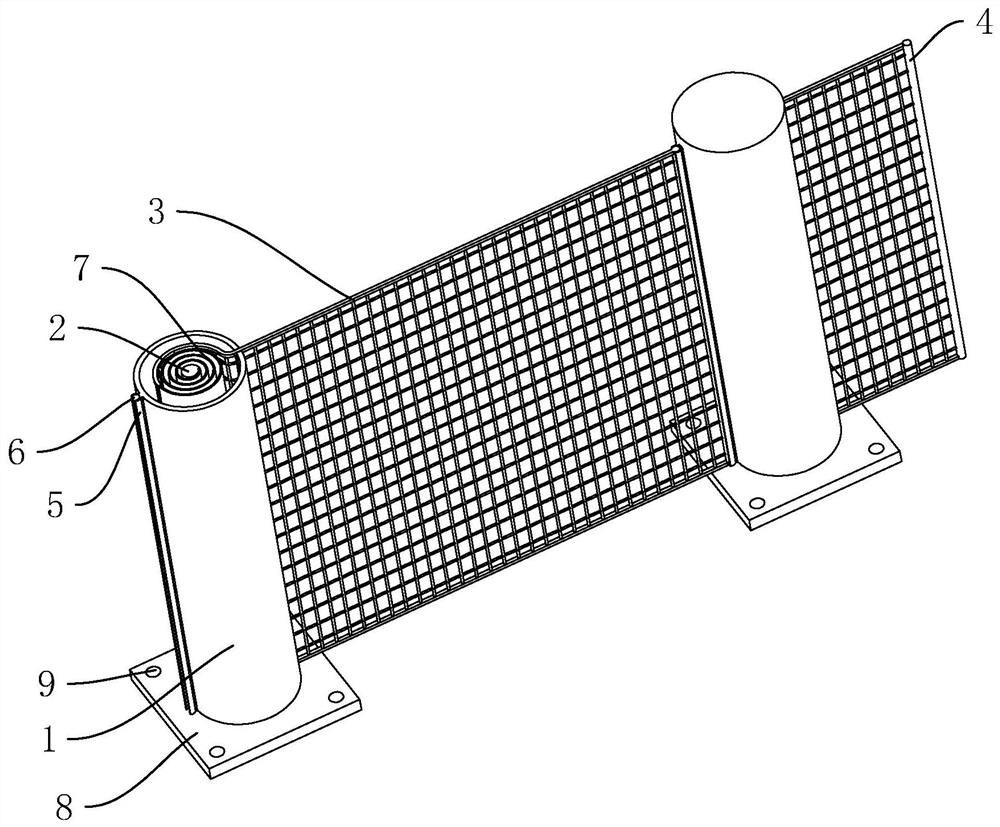

Rapid winding device for thermo-sensitive paper and using method of rapid winding device

The invention discloses a rapid winding device for thermo-sensitive paper and a using method thereof. The device comprises a transverse plate, a winding assembly, a protection assembly and a cooling assembly, wherein the top of the transverse plate is connected with a winding heating assembly, the two sides of the bottom of the transverse plate are detachably connected with supporting plates, a base is detachably connected between the bottoms of the supporting plates, the surface of the base is connected with the cooling assembly, and the interior of the winding heating assembly is cooperatively connected with the winding protection assembly. The cooling assembly comprises a frame, an opening is formed in the frame, a plurality of transverse rods are detachably connected between the interiors of the opening, electric motors are connected to the surfaces of the transverse rods in a matched mode, fan blades are detachably connected to the tops of the electric motors. Flying-out of sundries is reduced through a filter screen. The whole thermal paper winding device has a function of rapidly cooling the surface of the thermal paper during winding and storage, so that the deformation problem during subsequent storage is reduced, and a mode of reducing pollution during winding is provided.

Owner:JIANGSU WANBAO RUIDA HI TECH CO LTD

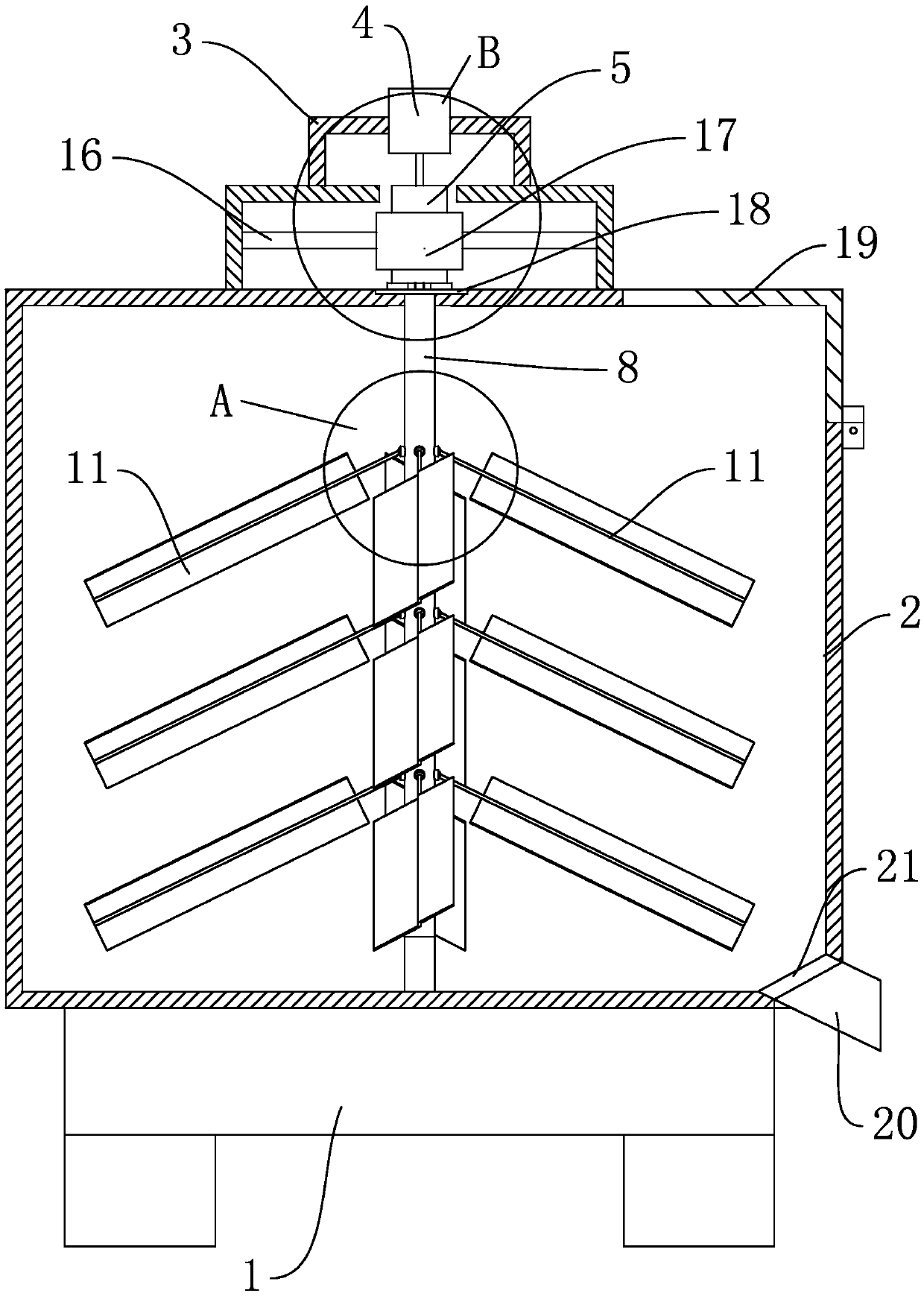

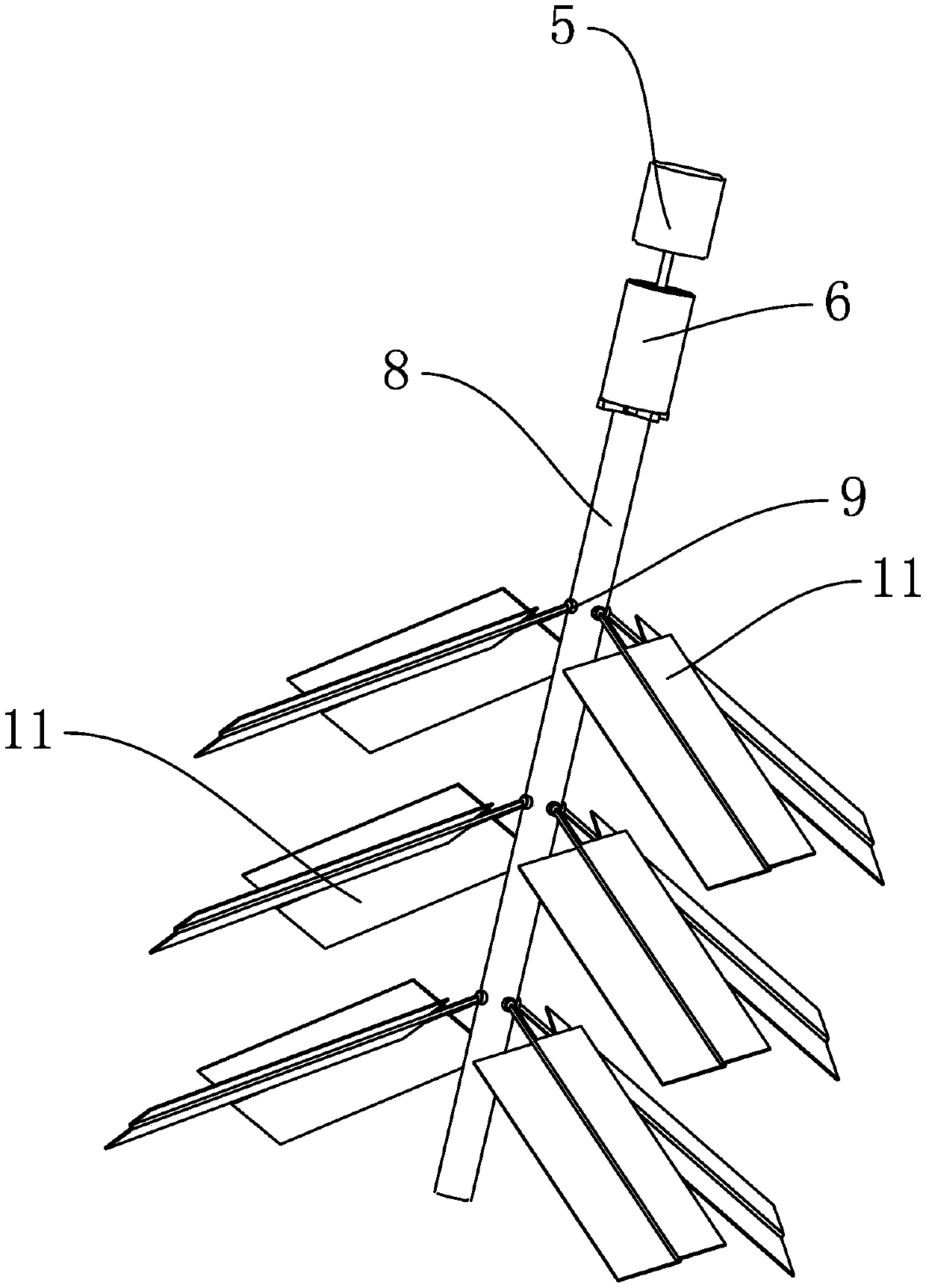

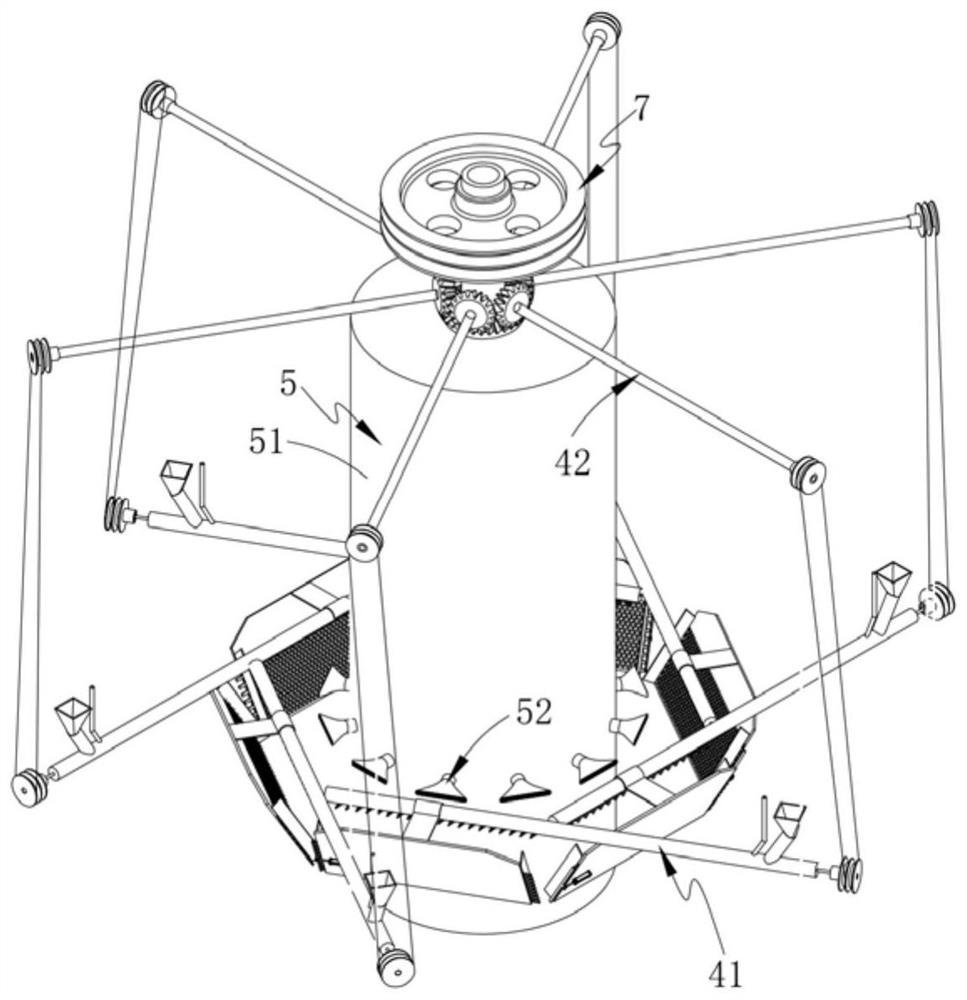

Hay crushing device and working method thereof

InactiveCN113557857AExpand the range of crushingGuaranteed feeding effectDrying gas arrangementsBalingKnife bladesBall joint

The invention relates to the field of smashing devices, in particular to a hay smashing device and a working method thereof. The hay smashing device comprises a smashing box, a plurality of sets of smashing assemblies arranged in the smashing box and annularly and evenly distributed and a driving mechanism used for driving the smashing assemblies, the crushing assembly comprises a mounting sleeve, a mounting plate, a ball groove, a rotating shaft, a rotating ball, a crushing blade and a transmission mechanism, the mounting sleeve is arranged in the crushing box in the horizontal direction and fixedly connected with the crushing box, the mounting plate is fixedly connected to the end of the mounting sleeve, the ball groove penetrates through the mounting plate, the rotating shaft penetrates through the ball groove, wherein one end of the rotating shaft extends into the mounting sleeve, the rotating ball is fixedly connected to the rotating shaft and is in ball joint with the interior of the ball groove, the crushing blade is arranged on the rotating shaft and is positioned outside the mounting sleeve, the transmission mechanism is used for enabling the rotating shaft to rotate and enabling one end, positioned in the mounting sleeve, of the rotating shaft to revolve around a rotating ball, and the driving mechanism is in transmission connection with the transmission mechanism. The hay crushing device has the effect of more uniformly crushing hay.

Owner:于辉 +11

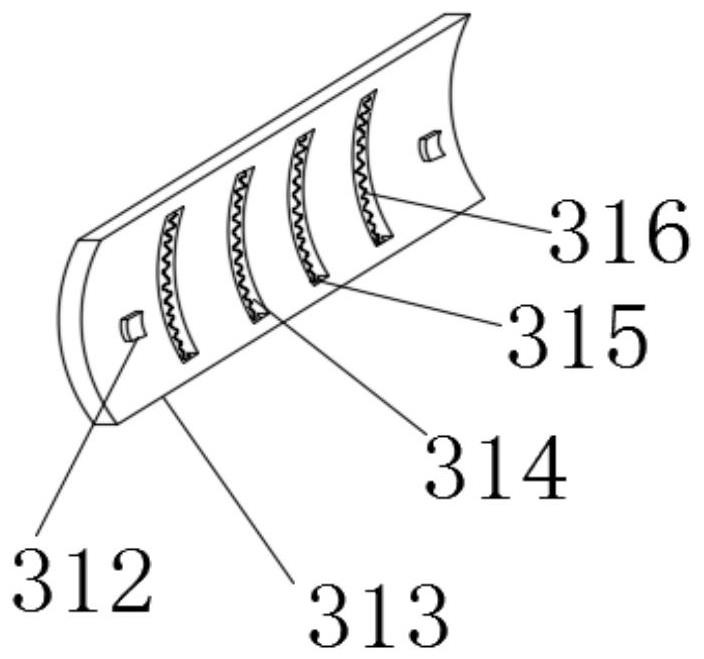

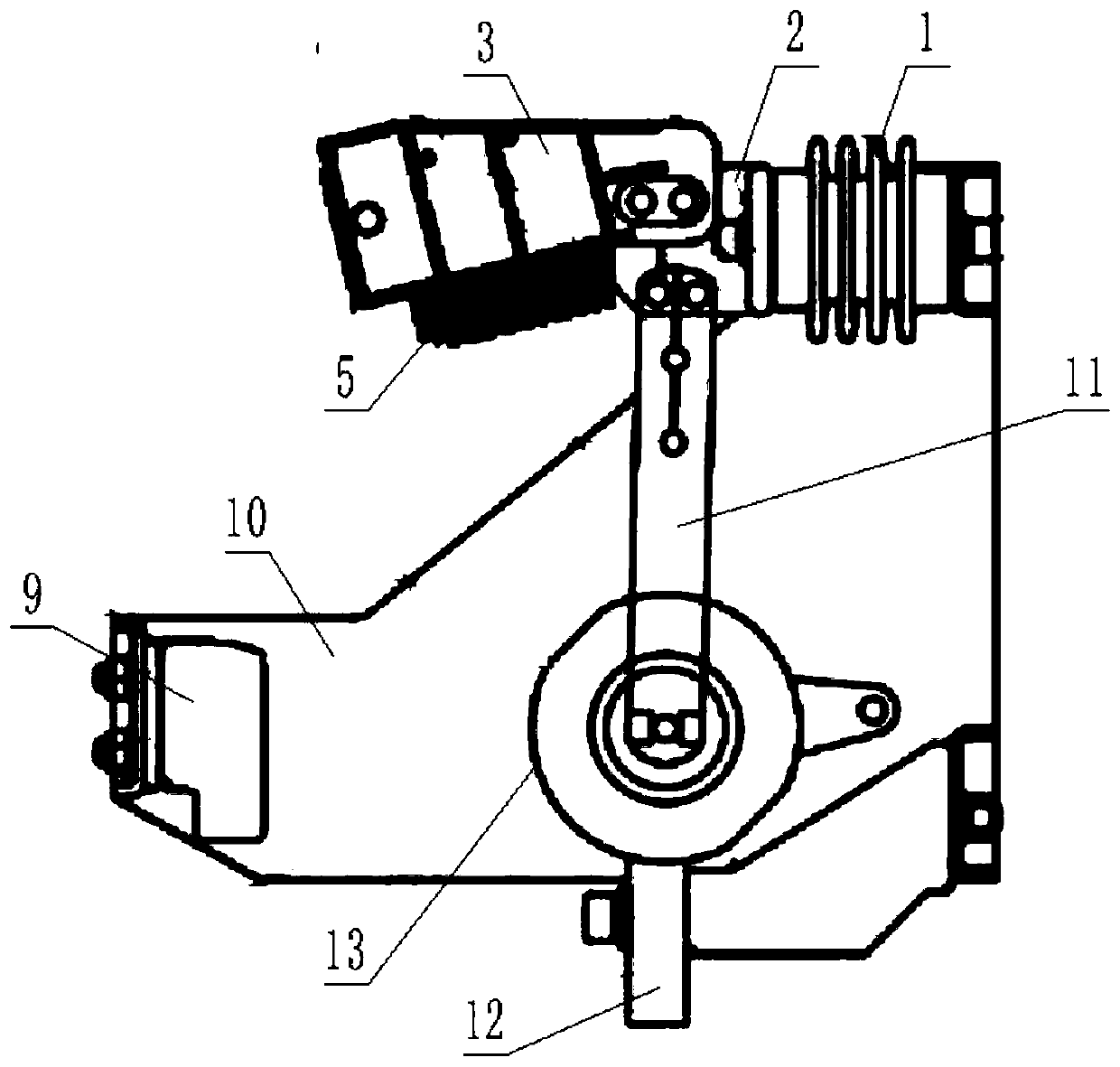

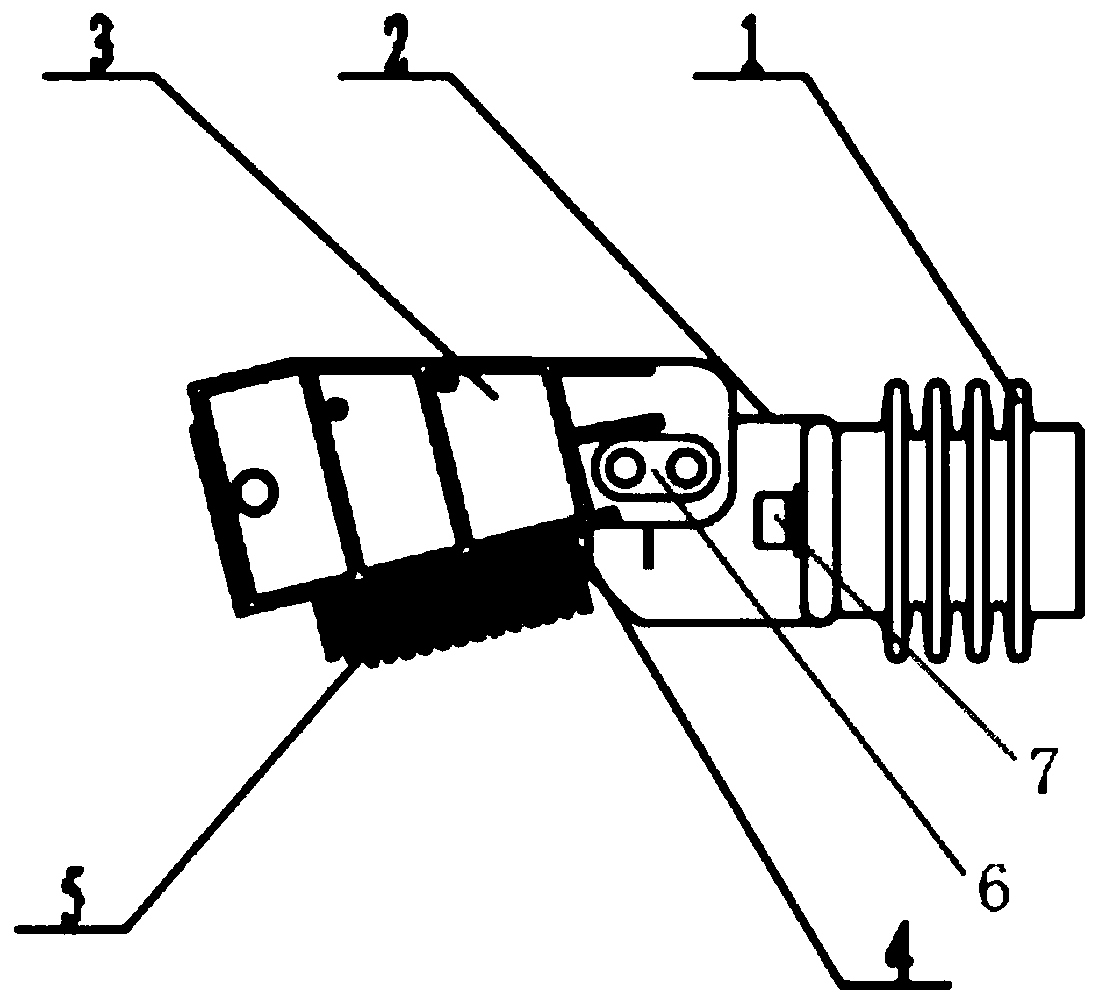

Novel arc extinguishing grid type load switch suitable for C4F7N environment-friendly gas

PendingCN110581042AImprove breaking capacityReduce fly-outHigh-tension/heavy-dress switchesAir-break switchesCopper–tungstenGround contact

The invention relates to a novel arc extinguishing grid type load switch suitable for C4F7N environment-friendly gas. The load switch comprises an installation seat, wherein an arc extinguishing mechanism and a grounding contact seat are installed on the installation seat, the arc extinguishing mechanism comprises a supporting insulator, a static contact seat and an arc extinguishing chamber, thearc extinguishing chamber comprises an arc extinguishing grid frame and a plurality of arc extinguishing grid sheets installed on the arc extinguishing grid frame, the static contact seat is a right-angle plate, one right-angle side of the static contact seat is connected with the arc extinguishing grid frame, the other right-angle side of the static contact seat is connected with the supporting insulator, the supporting insulator is connected with the mounting seat, and a current blocking groove and a copper-tungsten arc contact are arranged on the right-angle side of the static contact seatconnected with the arc extinguishing grid frame. The load switch is advantaged in that the load switch is a special load switch developed for being matched with the novel environment-friendly gas C4F7N, a three-station knife type load switch is adopted, arc extinguishing gate type arc extinguishing is adopted in an arc extinguishing mode, and the requirement for the breaking capacity of the load switch in the C4F7N gas is met by adjusting the structure of the load switch.

Owner:山东泰开电力开关有限公司

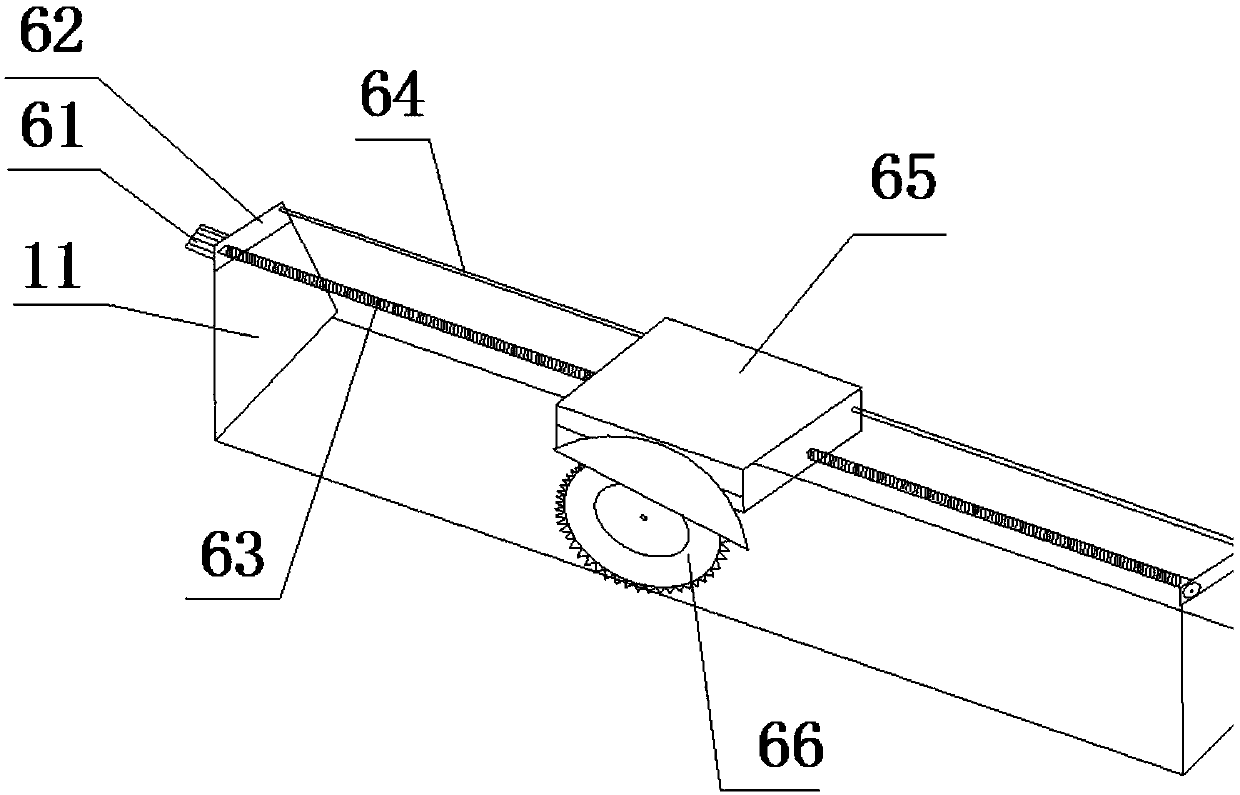

Cutting equipment for reflective fabric preparation

InactiveCN112726182AReduce fly-outAvoid pollutionSevering textilesMetal working apparatusForeign matterEngineering

The invention relates to the technical field of reflective fabrics, and discloses cutting equipment for reflective fabric preparation. The cutting equipment comprises a first support column, a cutting knife, a dust baffle, a dust collector, a rocker, a gear, an upper rack, a lower rack, a short flattening rod, a long flattening rod and other structures, and is characterized in that a dust baffle device is arranged behind the cutting stroke of the cutting knife, so that foreign matter such as chippings and the like generated in the cutting process can be prevented from flying out; the dust collection function of the dust collector is matched, foreign matter cleaning is conducted while the reflective cloth is cut, and foreign matter pollution is reduced; the rocker drives the gear to rotate, and the upper rack and the lower rack are engaged, so that the short flattening rod above the gear and the long flattening rod above the lower rack move towards the two sides; and the length of a first supporting rod and the length of a third supporting rod are matched, the short flattening rod and the long flattening rod make contact with the reflective fabric, so that the function that the reflective fabric is flattened is achieved, operation can be conducted by one person, labor force is reduced, and convenience and quickness are achieved.

Owner:WUHU LE CHUANG ELECTRONICS TECH CO LTD

Drug crushing device for pediatric nursing

InactiveCN110013906APrevents adhesive residueFaster and better separated collectionGrain treatmentsPediatric nursingCyclone

The invention discloses a drug crushing device for pediatric nursing, and relates to the technical field of ceramic medical treatment apparatuses. The device comprises an air handling box, wherein a grinding device is mounted at the front side of the upper end of the air handling box; a pneumatic cyclone separating device is connected to the front side of the grinding device; the grinding device comprises a guide housing which is fixed to the front side of the upper end of the air handling box; a semispherical filtering net is mounted at a through hole in a fitting manner; a grinding ball is fixed to the lower end of a connecting rod; an air outlet tube is rotatably mounted at the inner rear side of the guide housing; the pneumatic cyclone separating device comprises a pneumatic cyclone barrel, a tapered barrel and an air exhausting tube; and tapered edible sweet wrapper is arranged close to the inner sidewall of the tapered barrel. The device has the beneficial effects that air is blown through high pressure in order to remove the surface, so that the waste is reduced, and the next drug crushing operation is conveniently carried out; and meanwhile, the device is matched with the pneumatic cyclone separating device, so that drug particles can be quickly greatly separated and collected; and the edible sweet wrapper is damaged a little and achieves drug collection.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

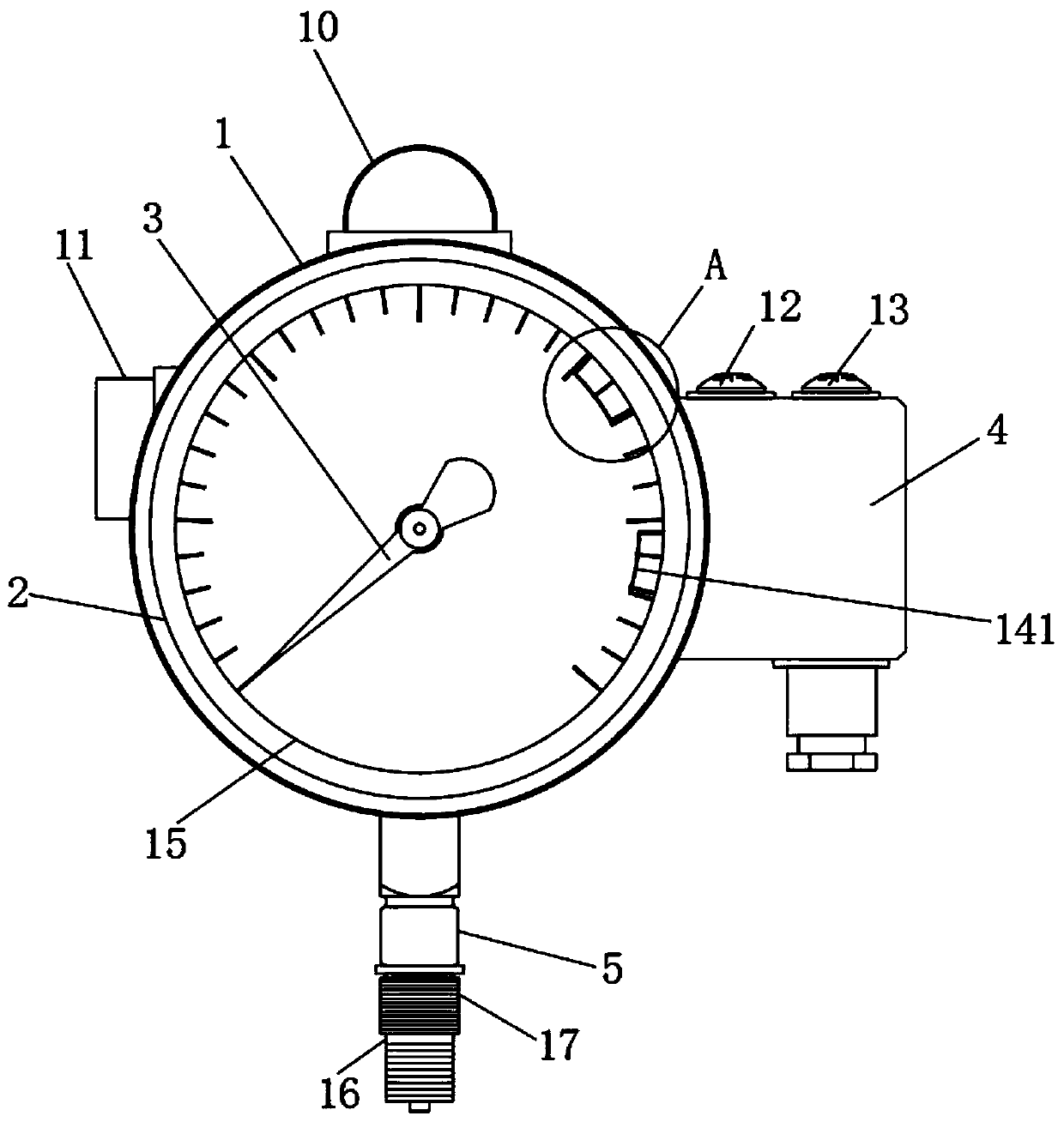

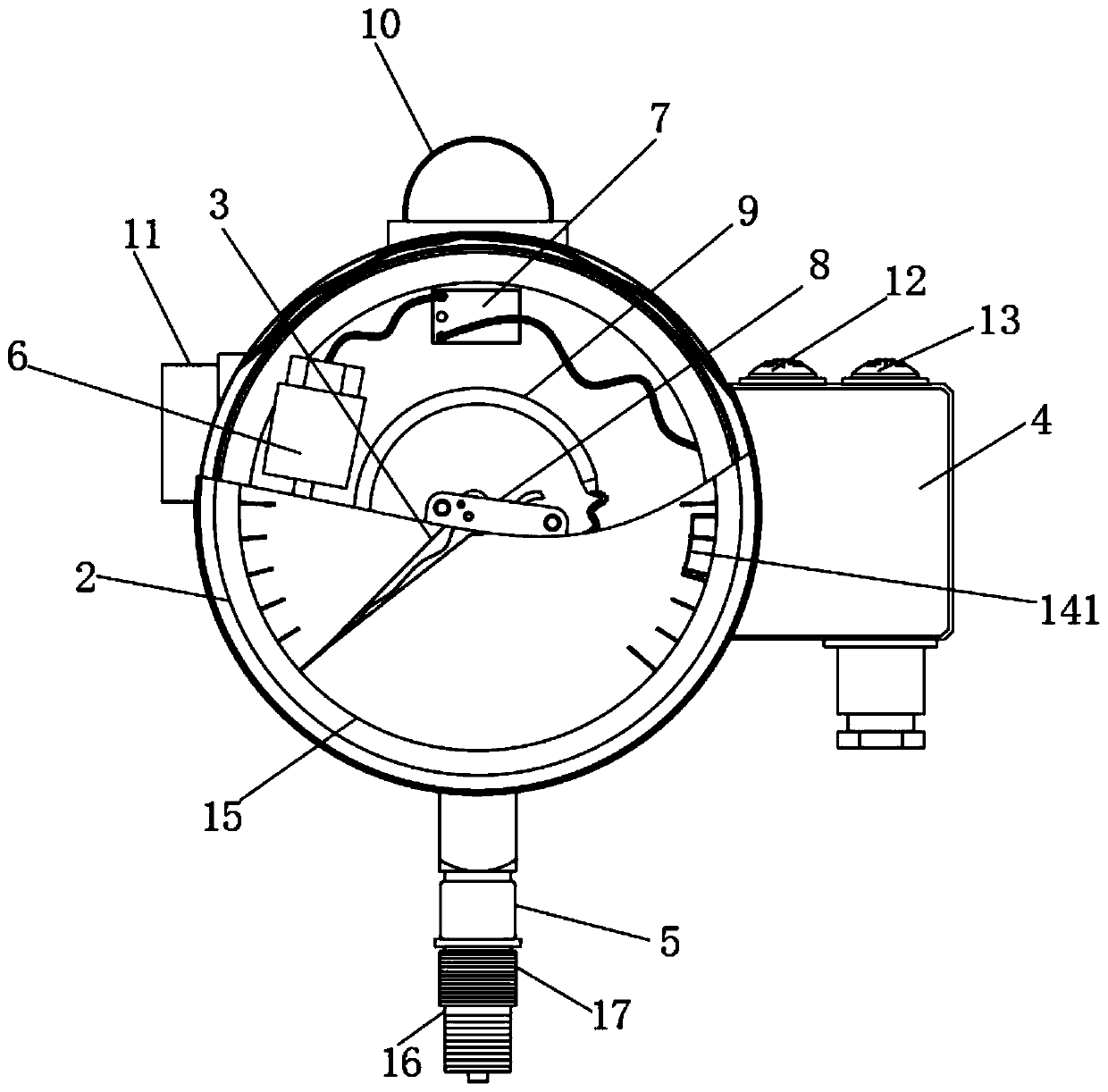

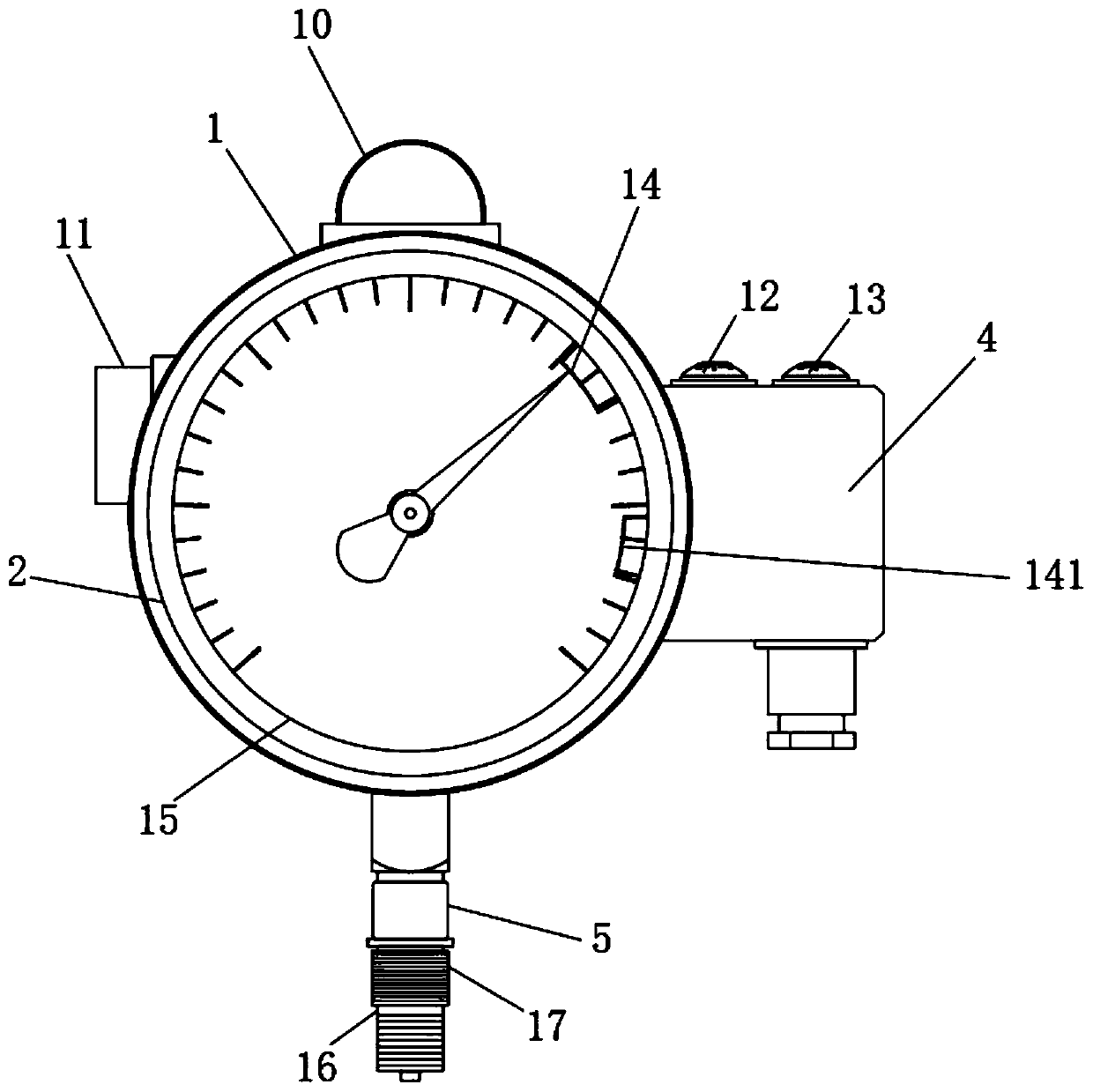

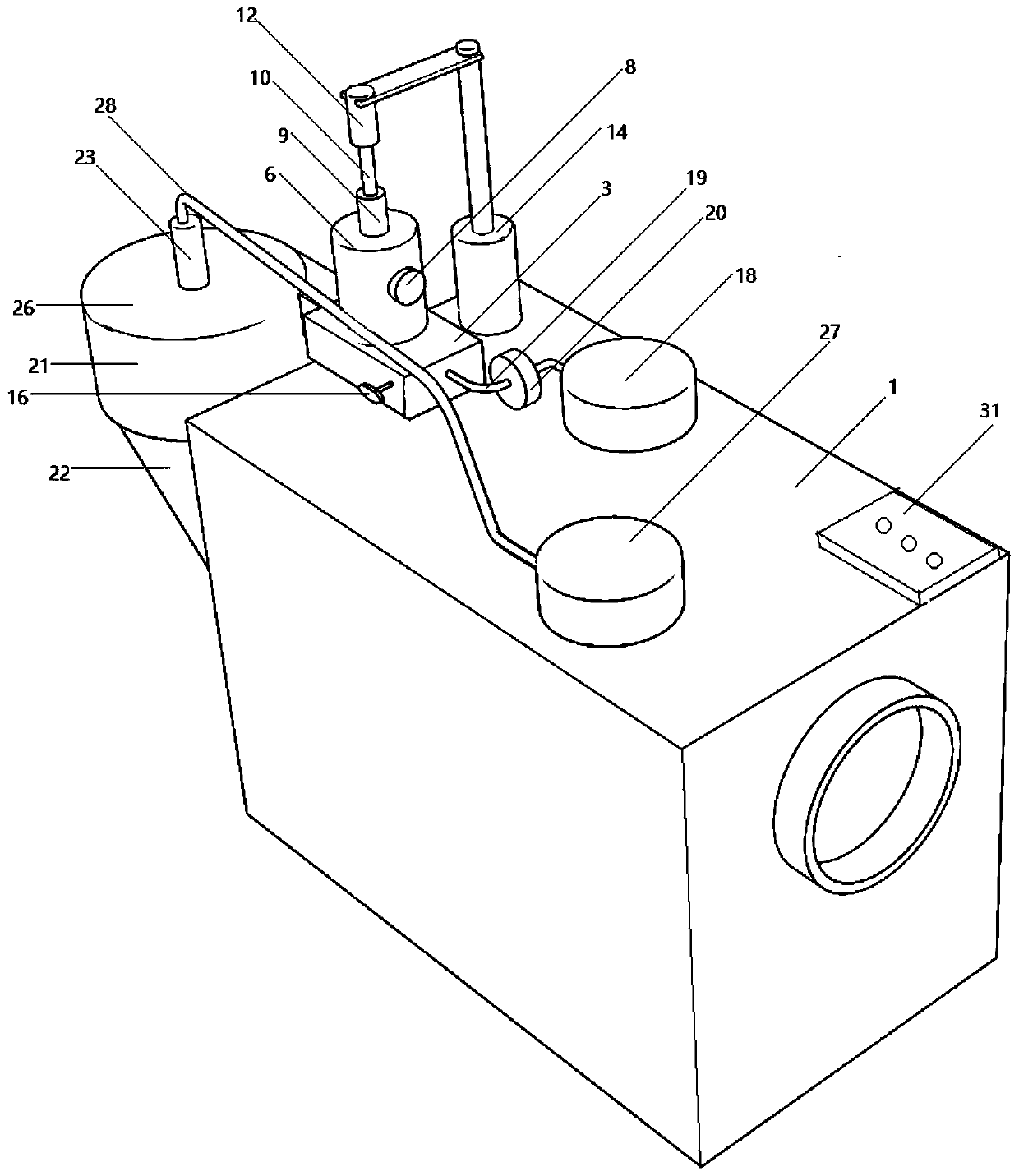

Remote pressure gauge

PendingCN109959483AImprove securityPlay a protective effectFluid pressure measurementComputer moduleEngineering

The invention discloses a remote pressure gauge which comprises a pressure gauge main body, a Hessmann junction box, a pressure sensor, an integrated module, a movement and a spring tube. A dial, tempered glass and a cover are successively arranged in the inner cavity of the pressure gauge main body from the inside out. The cover and the pressure gauge main body are movably clamped. A sealing ringis fixedly connected with the movable clamp joint of the cover and the pressure gauge main body. The tempered glass is fixedly connected between the dial and the cover. The pointed number on the dialgradually increases in a clockwise direction. A first touch panel is fixedly connected with the upper right corner of the front surface of the dial. According to the invention, a pointer, an indicator light, a power supply, a first speaker, a second speaker, the first touch panel and a second touch panel are designed, so that the design scheme has the advantages of simple structure, convenient use and good early warning effect; when the remote pressure gauge is used, the safety of the remote pressure gauge can be effectively improved; and the personal safety of staff can be protected.

Owner:ANHUI TIAN CHANG INSTR FACTORY

Medicine breaking device for pediatric nursing

ActiveCN110013439APrevents adhesive residueFaster and better separated collectionOral administration devicePediatric nursingAir treatment

The present invention discloses a medicine breaking device for pediatric nursing and relates to the technical field of porcelain medical devices. The medicine breaking device comprises an air treatment box; a grinding device is arranged on a front side of an upper end of the air treatment box; a cyclone separation device is connected to a front side of the grinding device; the grinding device comprises a guiding shell fixed on the front side of the upper end of the air treatment box; a hemispherical filter mesh is arranged on a through-hole; a grinding ball is fixed at a lower end of a connecting rod; an air outlet pipe is rotatably arrange an inner rear side of the guiding shell; a pulse valve is arranged on an air guiding pipe; the cyclone separation device comprises a cyclone cylinder,a cone cylinder and an air exhaust pipe; and an inner side wall of the cone cylinder is fitted with cone edible sugar paper. Beneficial effects are as follows: high pressure is used for air blowing toclean surface, waste is reduced, a next medicine breaking operation is facilitated, at the same time the cyclone separation device is cooperated to separate and collect medicine particles faster andbetter, and the medicine breaking device is very small on destroy of the edible sugar paper and realizes use of the edible sugar paper for drug collection.

Owner:周静

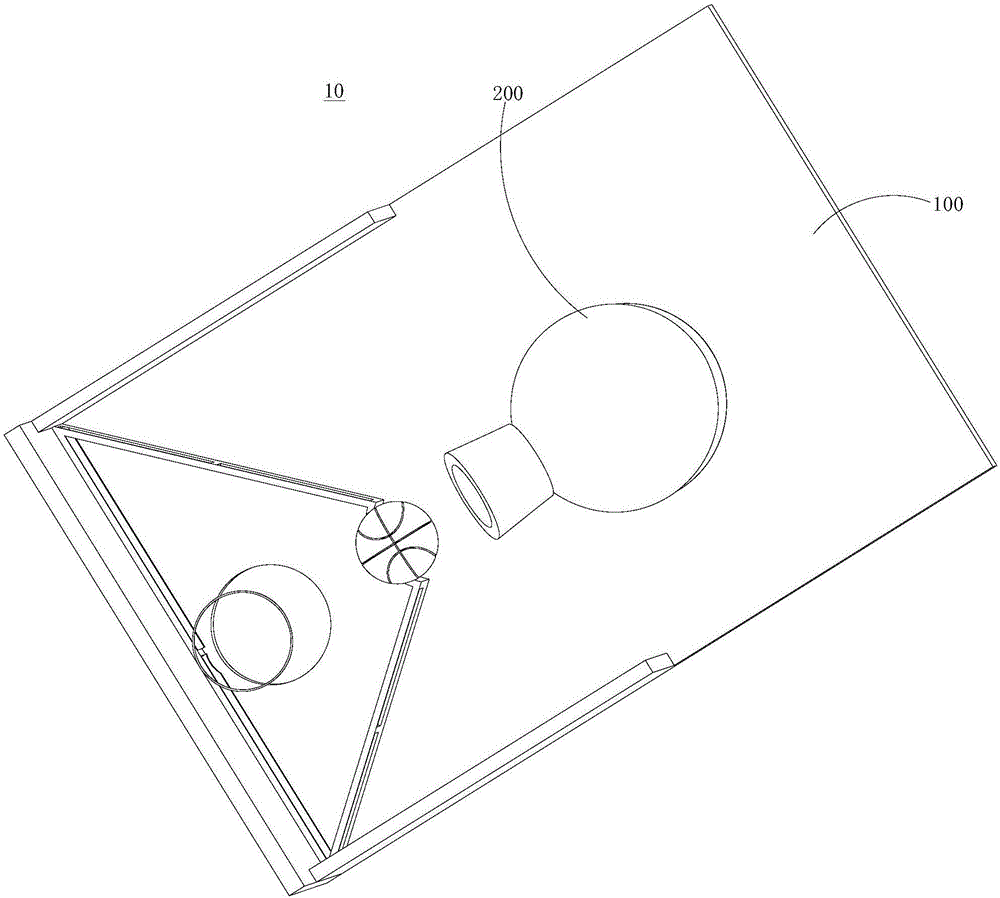

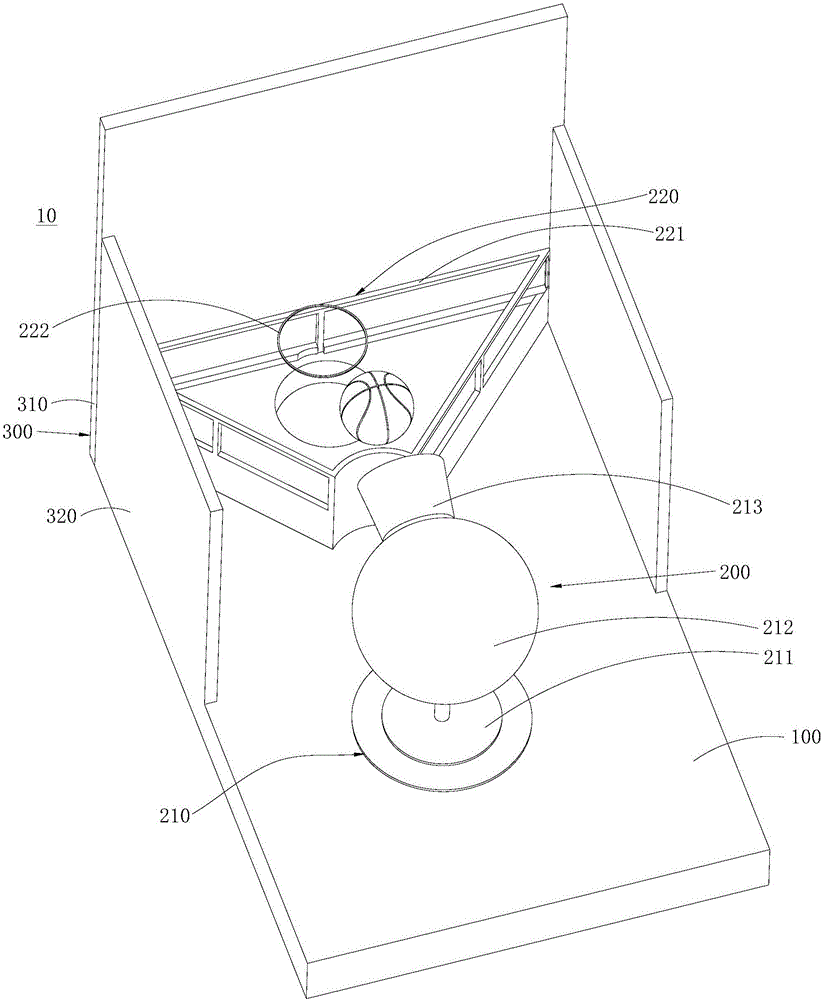

Playground device

A playground device comprises a bottom plate, a basket shooting device and a protection component, wherein the basket shooting device comprises an airflow bloating component and a basket component, the airflow bloating component comprises a support frame, an air blowing ball and a placement drum, the air blowing ball is arranged on the support frame, an air blowing opening is formed in the air blowing ball, the placement drum is arranged on the air blowing ball, a basketball placing area is formed in the placement drum, the basketball placing area is communicated with the air blowing opening, the basket component comprises an installation frame and a basket, the installation frame is arranged on the bottom plate, the basket is arranged on the installation frame, and the placement drum is arranged towards the basket. The protection component comprises a back baffle, a protection screen and two side baffles, and the back baffle is arranged on the bottom plate. The playground device can improve disinfection efficiency and prolong service life of basket balls by arranging the basket shooting device, can decrease occurrence rate of the problem that the basket balls fly out of the playground device well so as to collect the basket balls well, and can further decrease occurrence rate of the problem that the basketballs directly crash into tourists.

Owner:惠州市里斯科技有限公司

Novel insect killing equipment with electric light source

The invention provides novel insect killing equipment with an electric light source. The novel insect killing equipment comprises a lamp support, a lamp cap, the electric light source, an inner lampshade, an outer lampshade and a water diversion box. An insect attracting plate is installed at the position, corresponding to the outer lampshade, below the lamp cap. The insect attracting plate is connected to the upper end of the outer lampshade through a plurality of connecting columns. The cross section of the insect attracting plate is in an arc shape. The insect attracting plate protrudes in the direction away from the outer lampshade. A black non-reflecting layer is arranged on the portion, located on the inner wall of the outer lampshade, of the insect attracting plate, wherein the inner wall is at the side, away from the inner lampshade, of the outer lampshade. A reflecting mirror is arranged on the portion, located on the inner wall of the outer lampshade, of the insect attracting plate, wherein the inner wall is at the side, close to the inner lampshade, of the outer lampshade. A spraying nozzle is arranged on the portion, located between the outer lampshade and the inner lampshade, below the lamp cap. An insect isolating plate is arranged on the upper portion of the inner wall of the outer lampshade in an inclining mode. The height, in the direction away from the inner wall of the outer lampshade, of the insect isolating plate is gradually reduced. A reflecting mirror is arranged on the upper portion of the insect isolating plate. A black non-reflecting layer is arranged on the lower portion of the insect isolating plate. A water inlet is formed in the position, corresponding to the outer lampshade, of the upper portion of the water diversion box. A water outlet is formed in the lower portion of the water diversion box. A filter screen is arranged in the water diversion box. The insect killing equipment is high in insect killing efficiency and has little influence on illumination effect.

Owner:WUHU BEISI SCI & TECH PARK

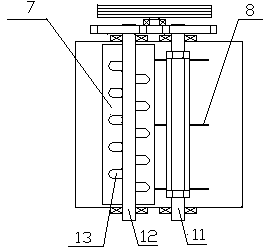

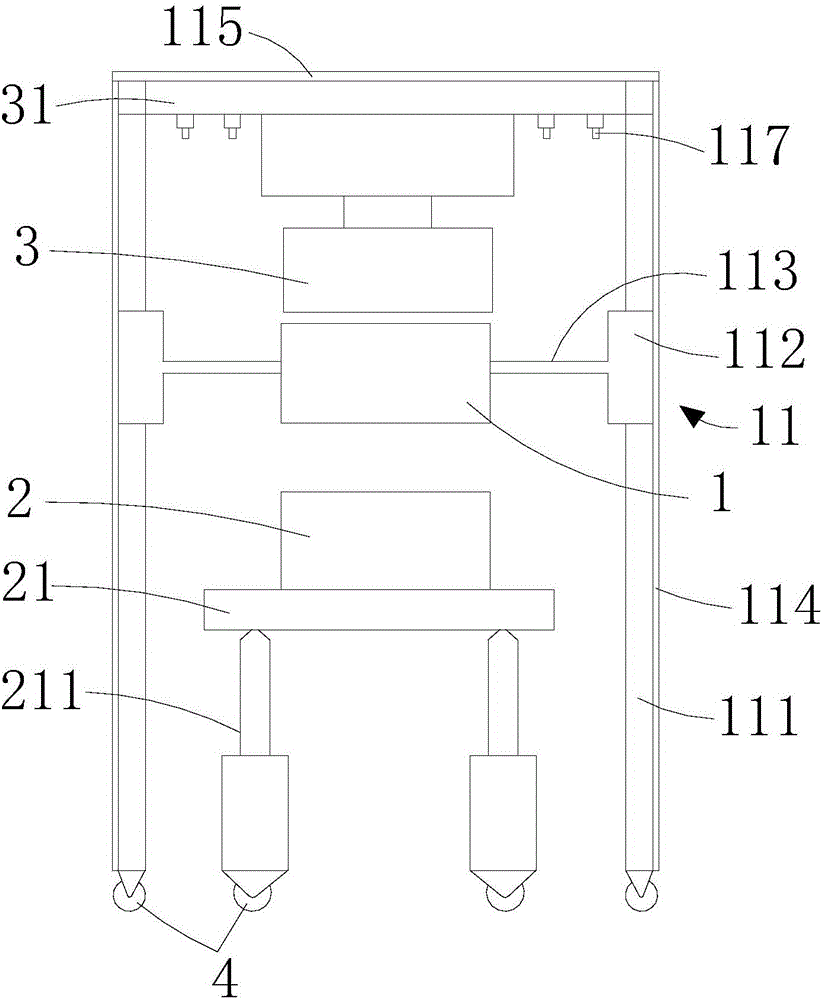

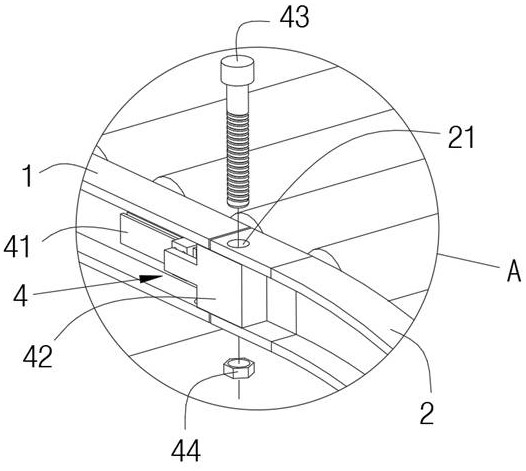

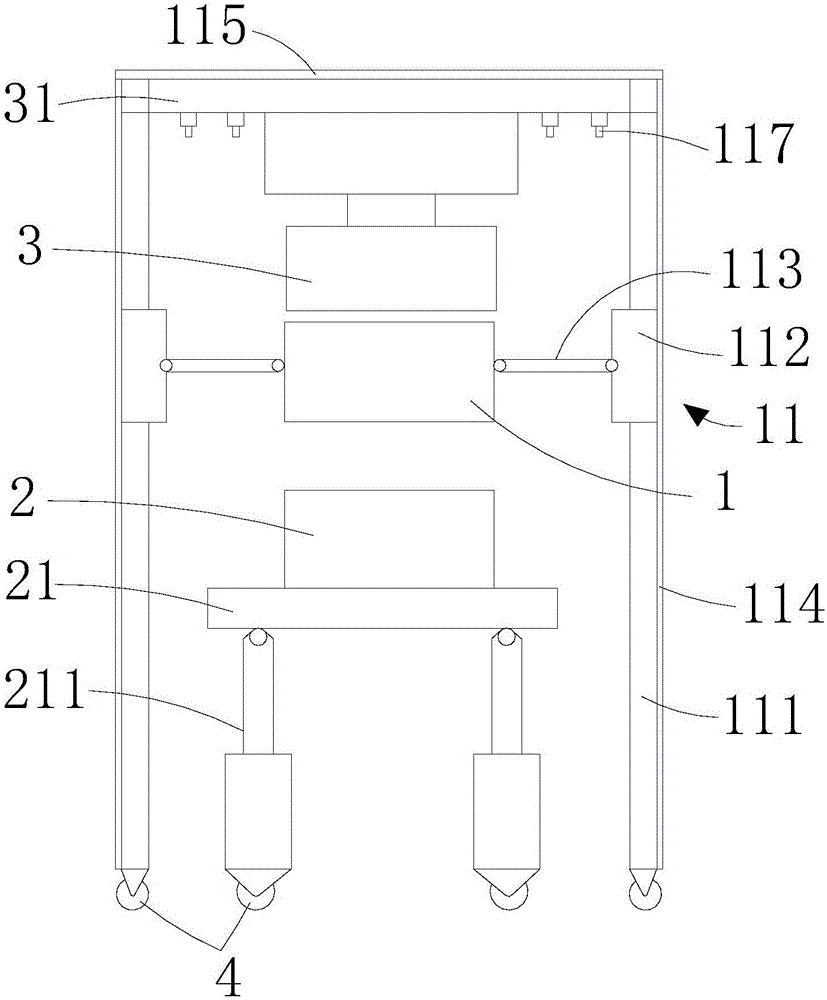

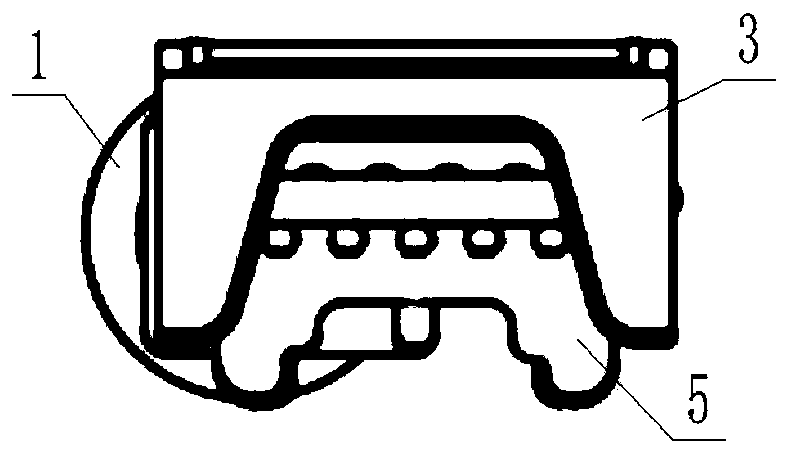

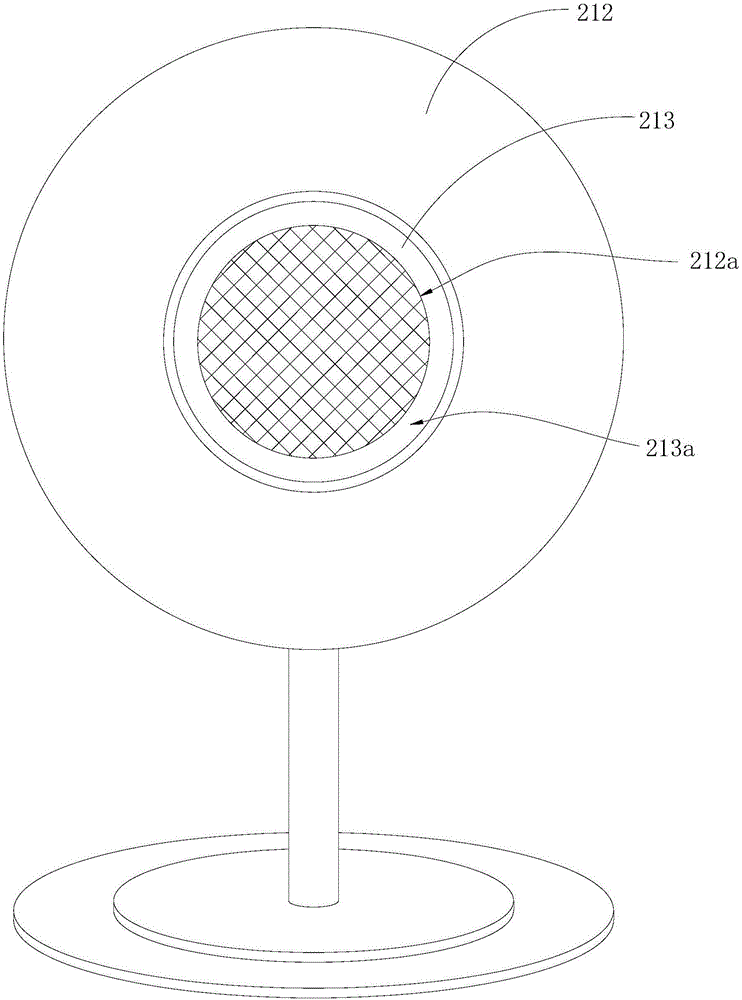

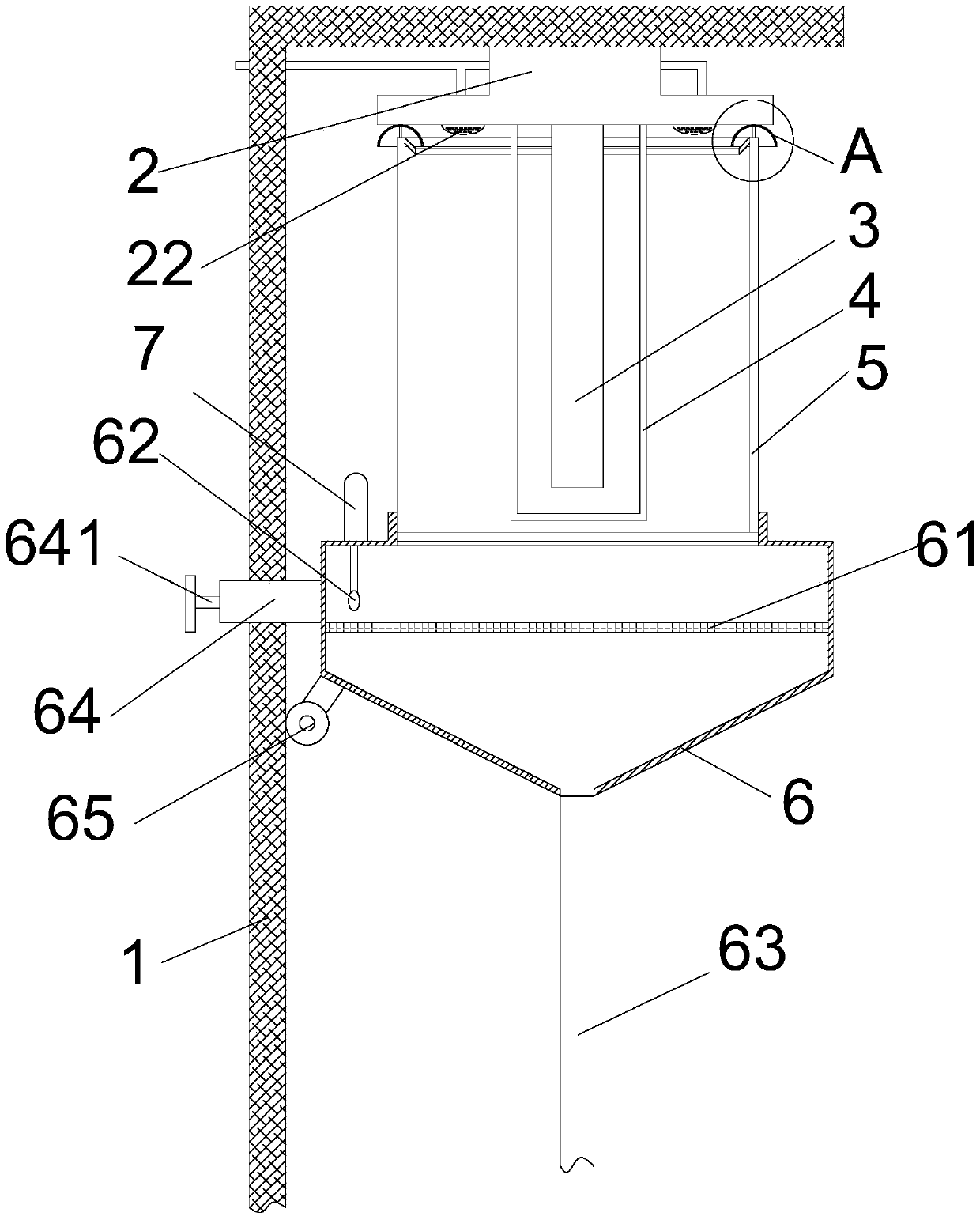

Covering shell of jun porcelain throwing machine

PendingCN109109125ASimple structureImprove utilization efficiencyAuxillary shaping apparatusEngineeringMechanical engineering

The invention provides a covering shell of a jun porcelain throwing machine. The covering shell comprises a base, a motor, a rotating shaft, a shaft bracket, a covering shell body and a manual drivingdevice. Supporting legs are arranged at the lower end of the base. The supporting legs support the base. The motor is arranged on the bottom face of the base. A spindle of the motor is connected withthe lower end of the rotating shaft. A through hole is formed in the base. The rotating shaft penetrates through the through hole. The shaft bracket is arranged at the upper end of the base. The shaft bracket is arranged at the rotating shaft in a sleeving mode and is tightly connected with the base. The rotating shaft is connected with the shaft bracket by a bearing. A rotating disc is arrangedat the top of the rotating shaft. The manual driving device is arranged below the base. The manual driving device drives the rotating shaft to rotate. The covering shell body is arranged at the base.The lower end of the covering shell body is tightly connected with the base. The covering shell body is of a hollow square structure. The lower end of the covering shell body is tightly connected withthe base. The round through hole is formed in the upper end of the covering shell body. The structure is simple. The covering shell is of a hollow square structure, the design requirements are met, and the appearance is attractive.

Owner:禹州市晋家钧窑有限公司

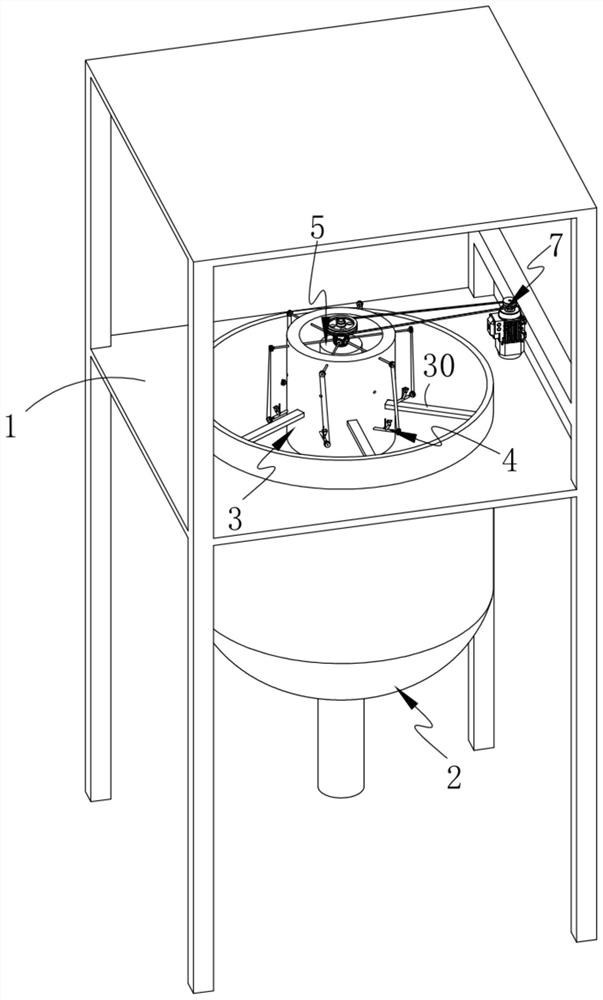

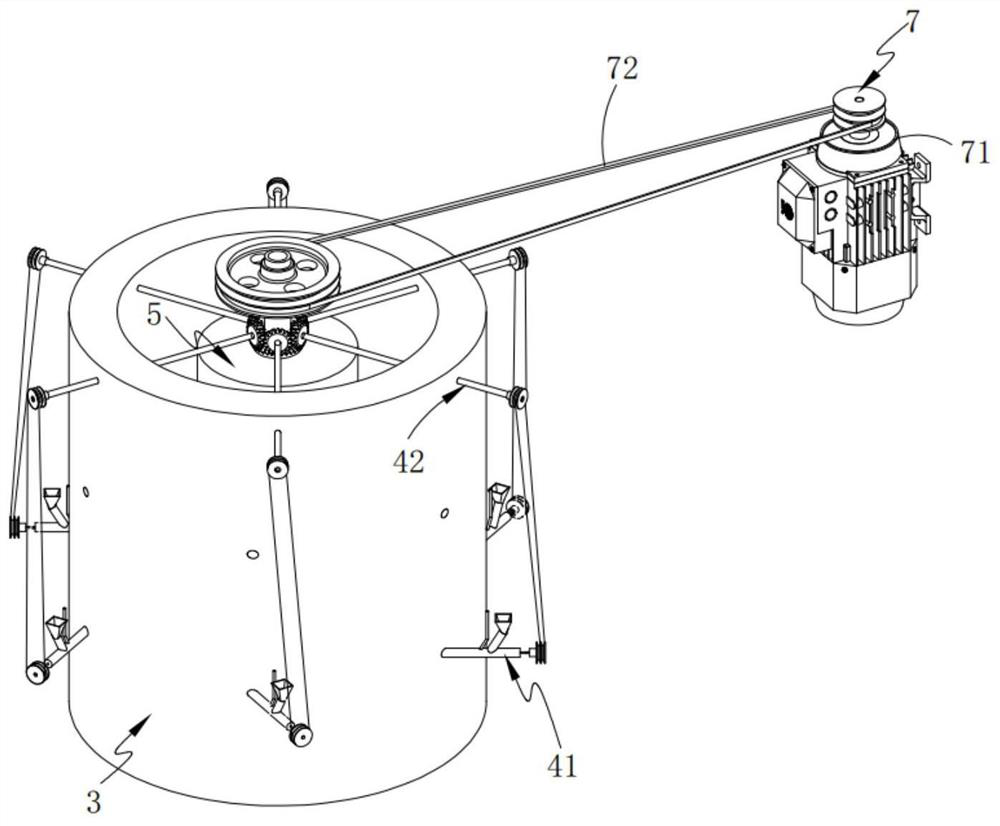

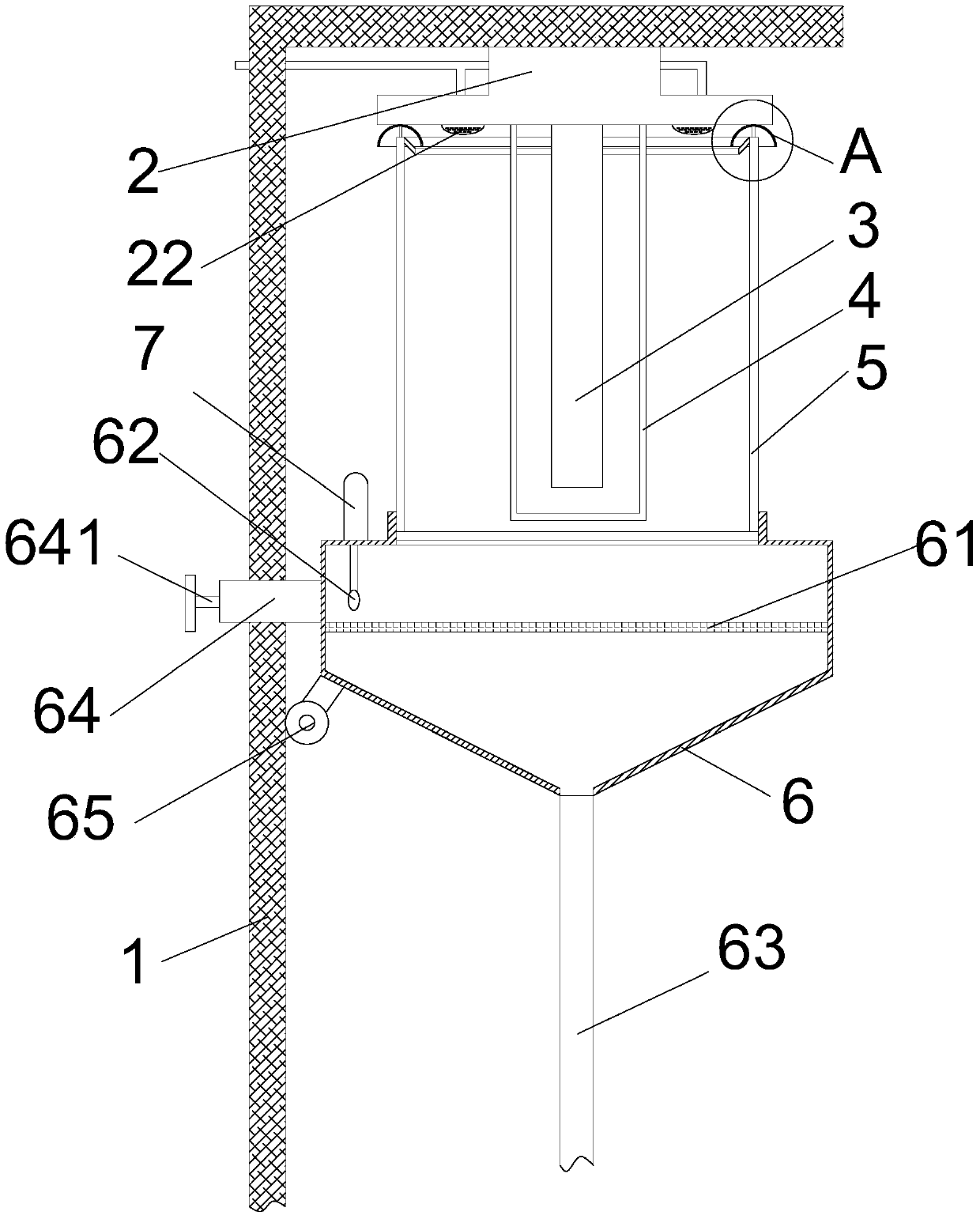

Aerated concrete slab solid waste recovery system

ActiveCN112792989ASolve the technical problem of powder bubble generationShorten mixing timeSolid waste managementCement mixing apparatusProcess engineeringSlurry

The invention provides an aerated concrete slab solid waste recovery system which comprises a stirring bin arranged on an equipment platform, a mixing bin arranged in the stirring bin, a feeding system penetrating through the side wall of the mixing bin, a liquid spraying system arranged in the mixing bin, a defoaming system arranged below the feeding system and connected with the feeding system, and a driving system connected with the liquid spraying system. Powder is sprayed into the mixing bin through the feeding system, liquid in a liquid storage bin is centrifugally sprayed out to form fog drops through cooperation of the liquid spraying system and the driving system, and the powder and the fog drops which move relatively collide with each other, so that the powder is mixed in the air; slurry drops falling onto a material receiving plate are subjected to secondary shearing and crushing through the defoaming system, so that bubbles in the slurry drops are completely removed, the powder and the liquid are mixed more uniformly, the subsequent stirring time is shortened, and the production efficiency is improved; and through continuous powder adding and continuous slurry spraying, continuous automatic production is achieved.

Owner:德阳优博络客新型建材有限公司

An electric light source insecticidal device

Owner:WUHU BEISI SCI & TECH PARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com