Patents

Literature

107results about "Tows to slivers/yarns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

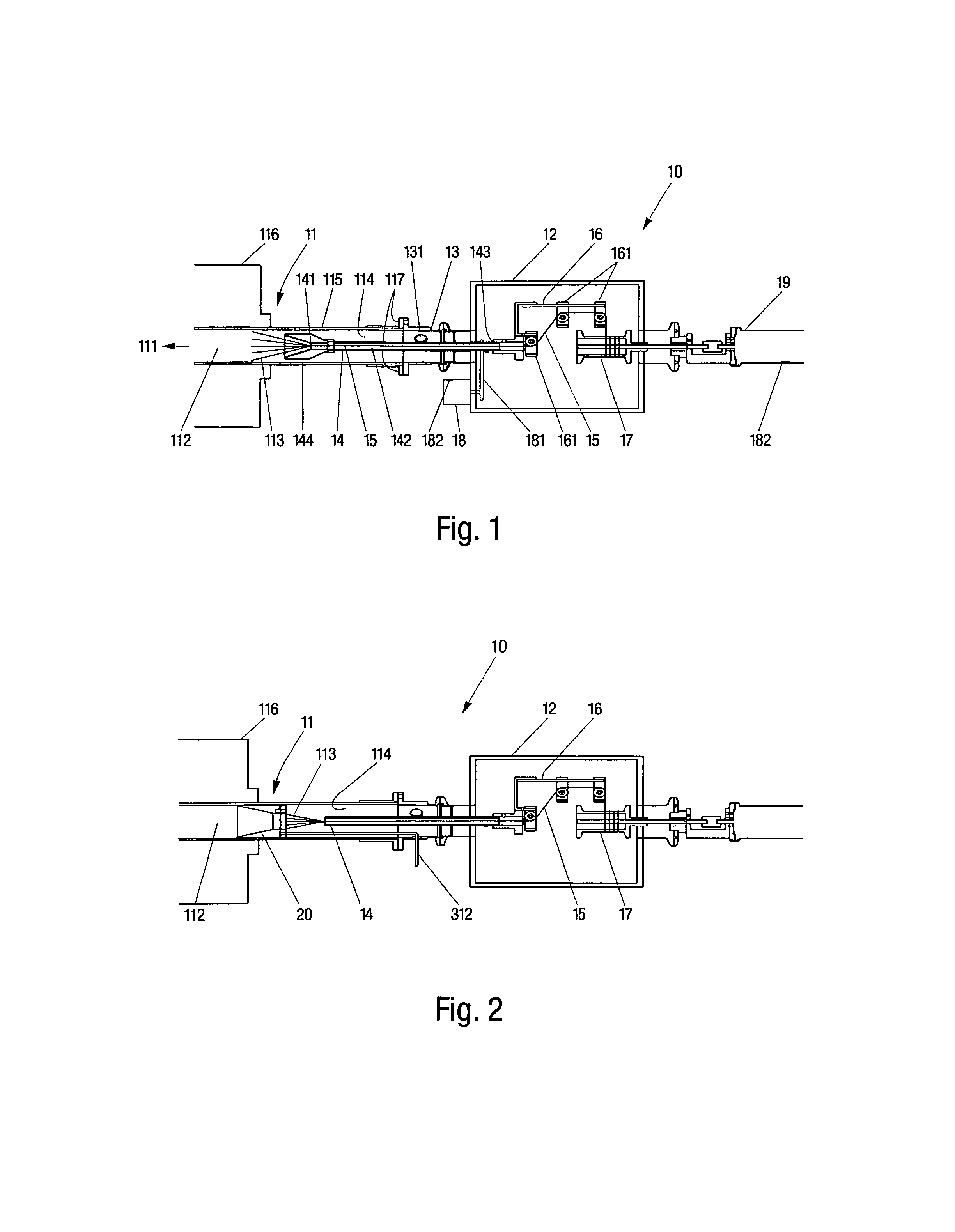

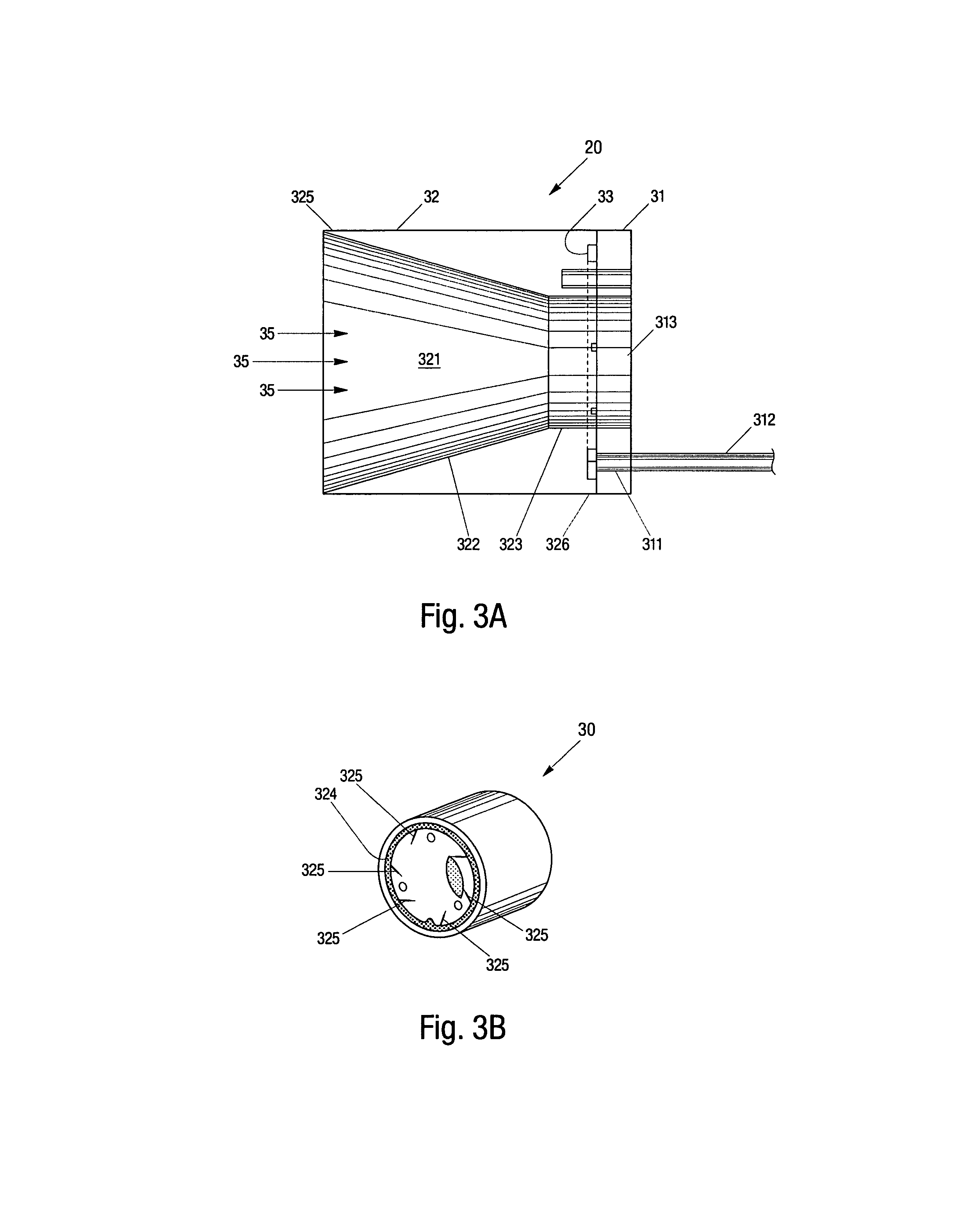

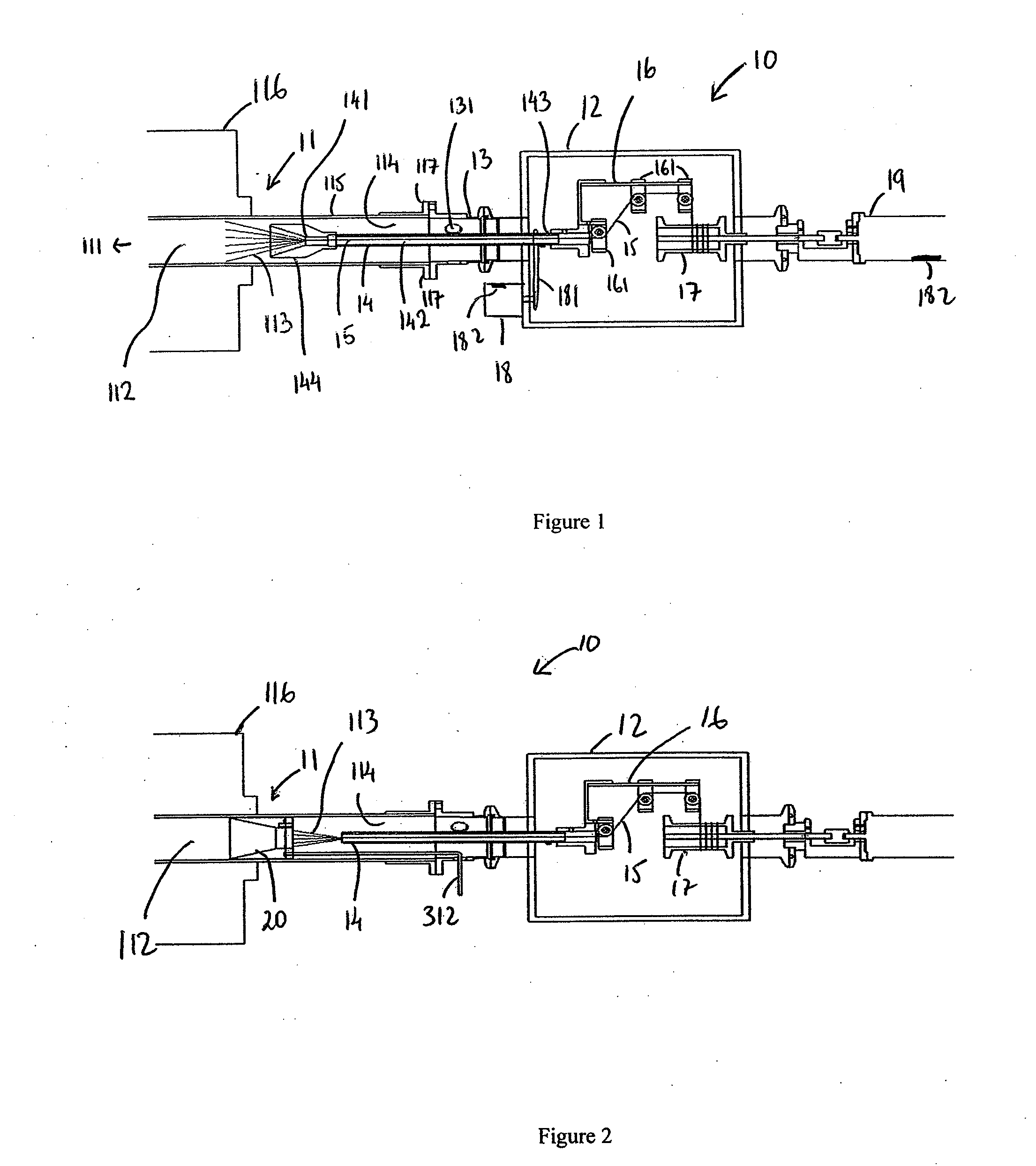

Systems and methods for formation and harvesting of nanofibrous materials

ActiveUS20070036709A1Minimize bondingHinder integrityMaterial nanotechnologyTransportation and packagingFiberYarn

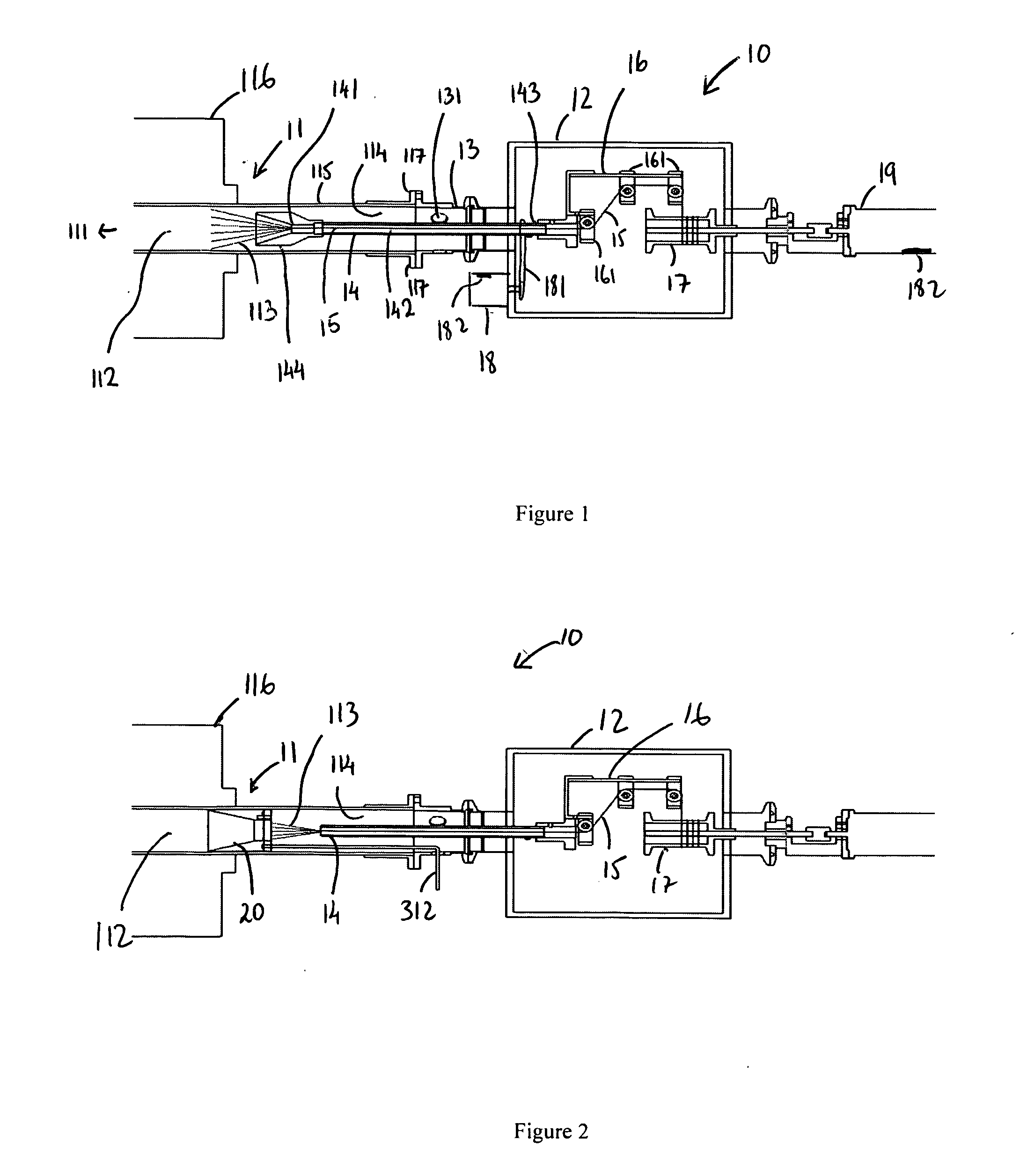

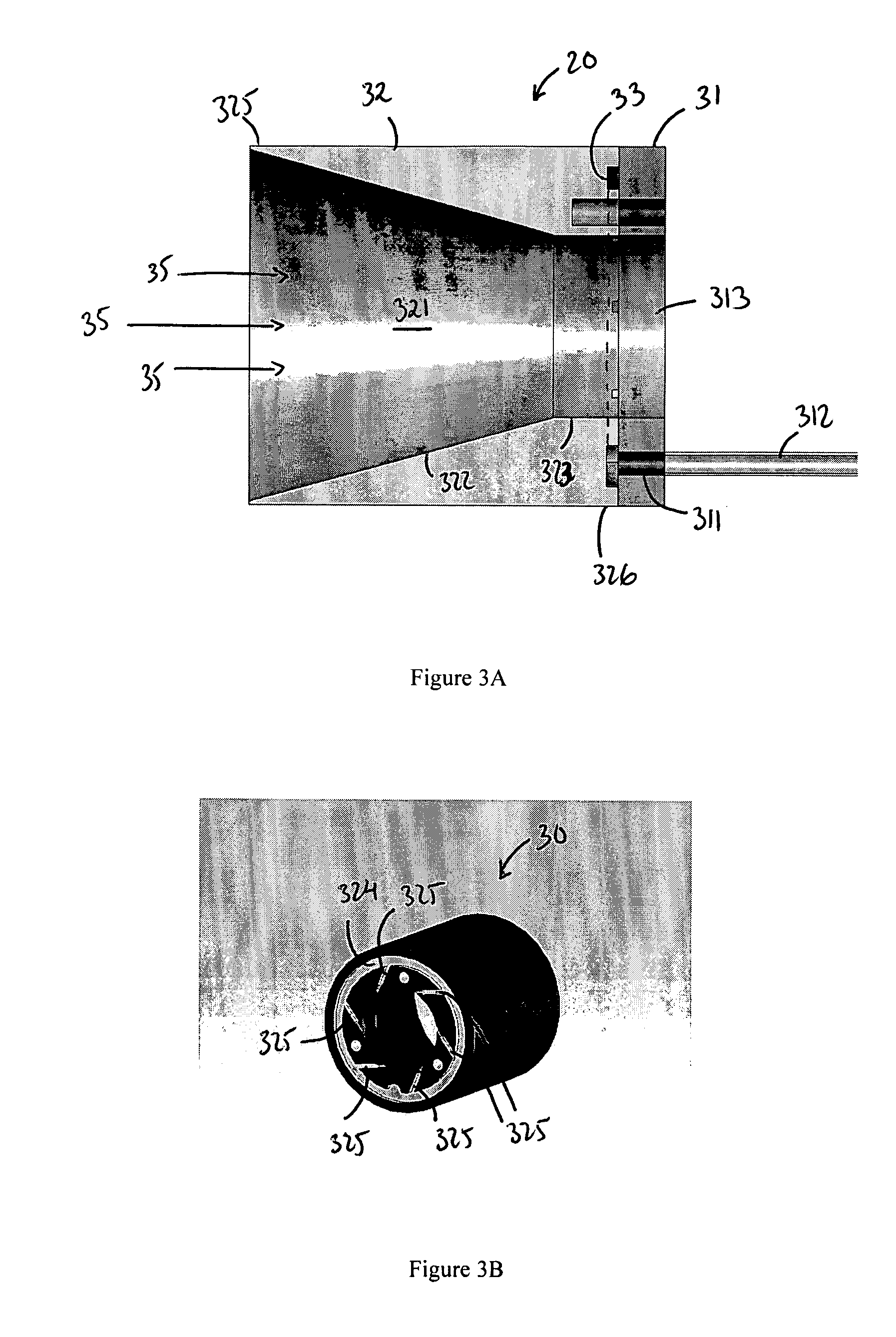

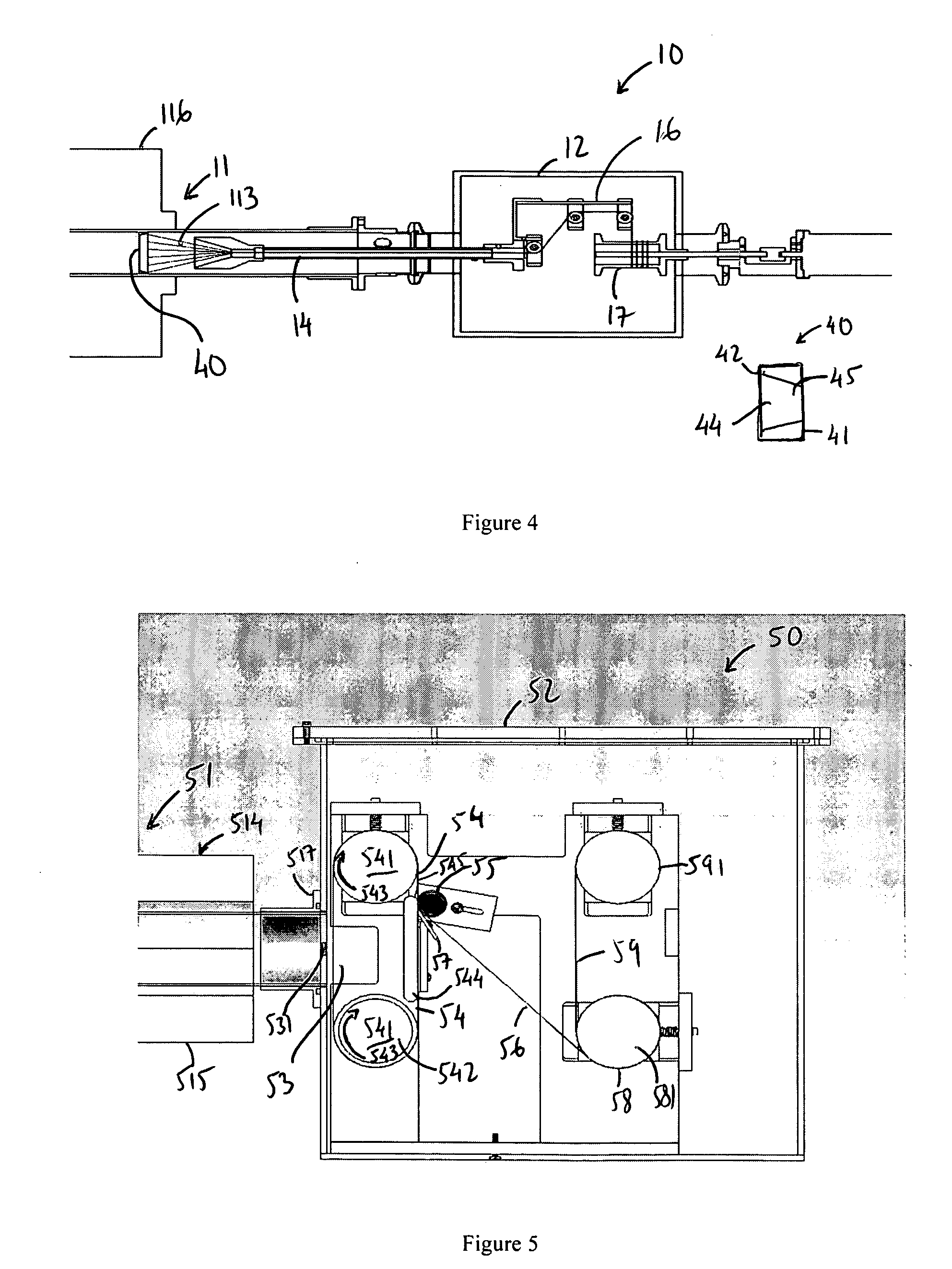

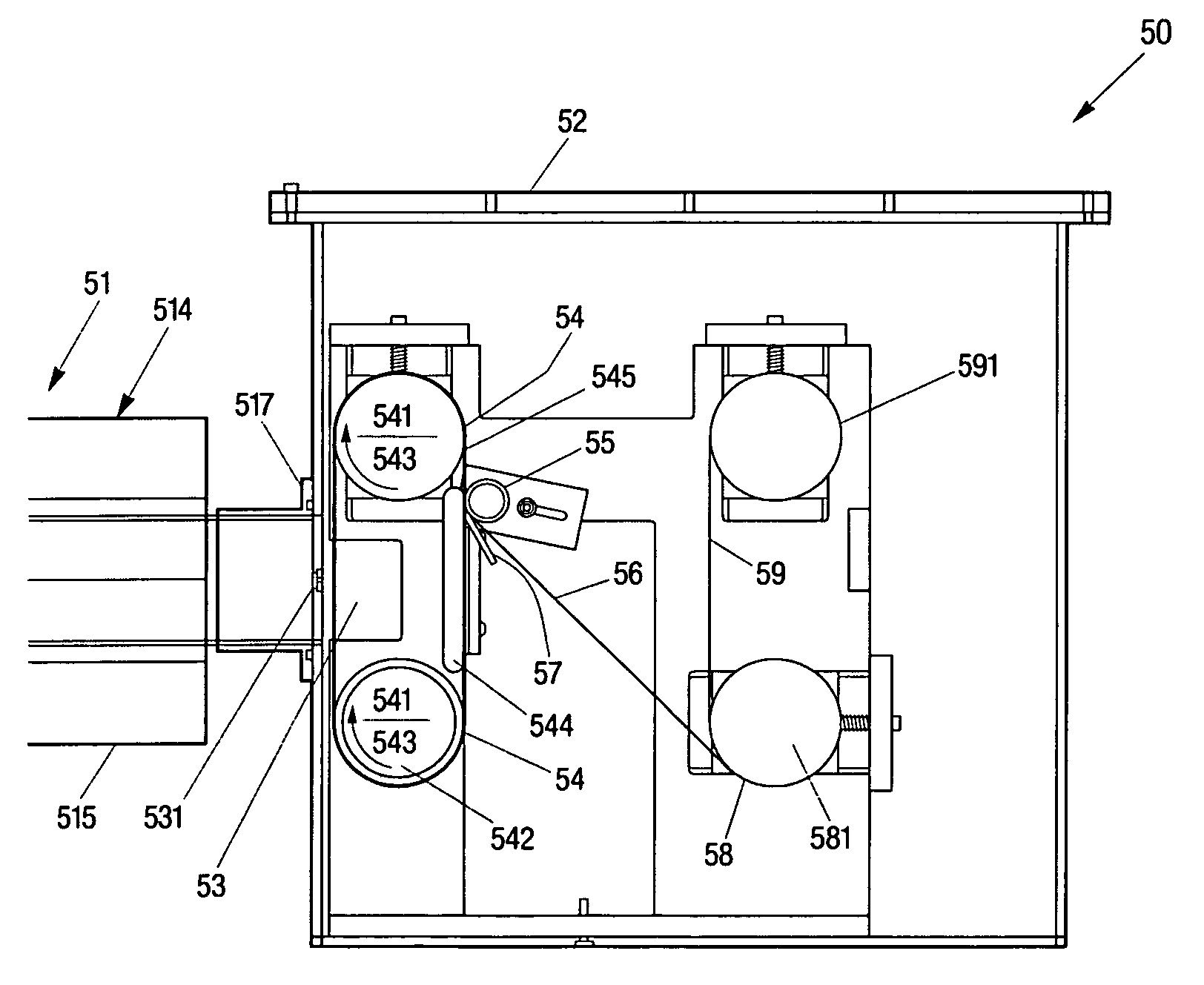

A system that receives nanomaterials, forms nanofibrous materials therefrom, and collects these nanofibrous materials for subsequent applications. The system is coupled to a chamber that generates nanomaterials, typically carbon nanotubes produced from chemical vapor deposition, and includes a mechanism for spinning the nanotubes into yarns or tows. Alternatively, the system includes a mechanism for forming non-woven sheets from the nanotubes. The system also includes components for collecting the formed nanofibrous materials. Methods for forming and collecting the nanofibrous materials are also provided.

Owner:NANCOMP TECHNOLOGIES INC

Systems and methods for formation and harvesting of nanofibrous materials

ActiveUS7993620B2Minimize bondingHinder integrityMaterial nanotechnologyTransportation and packagingFiberYarn

Owner:NANCOMP TECHNOLOGIES INC

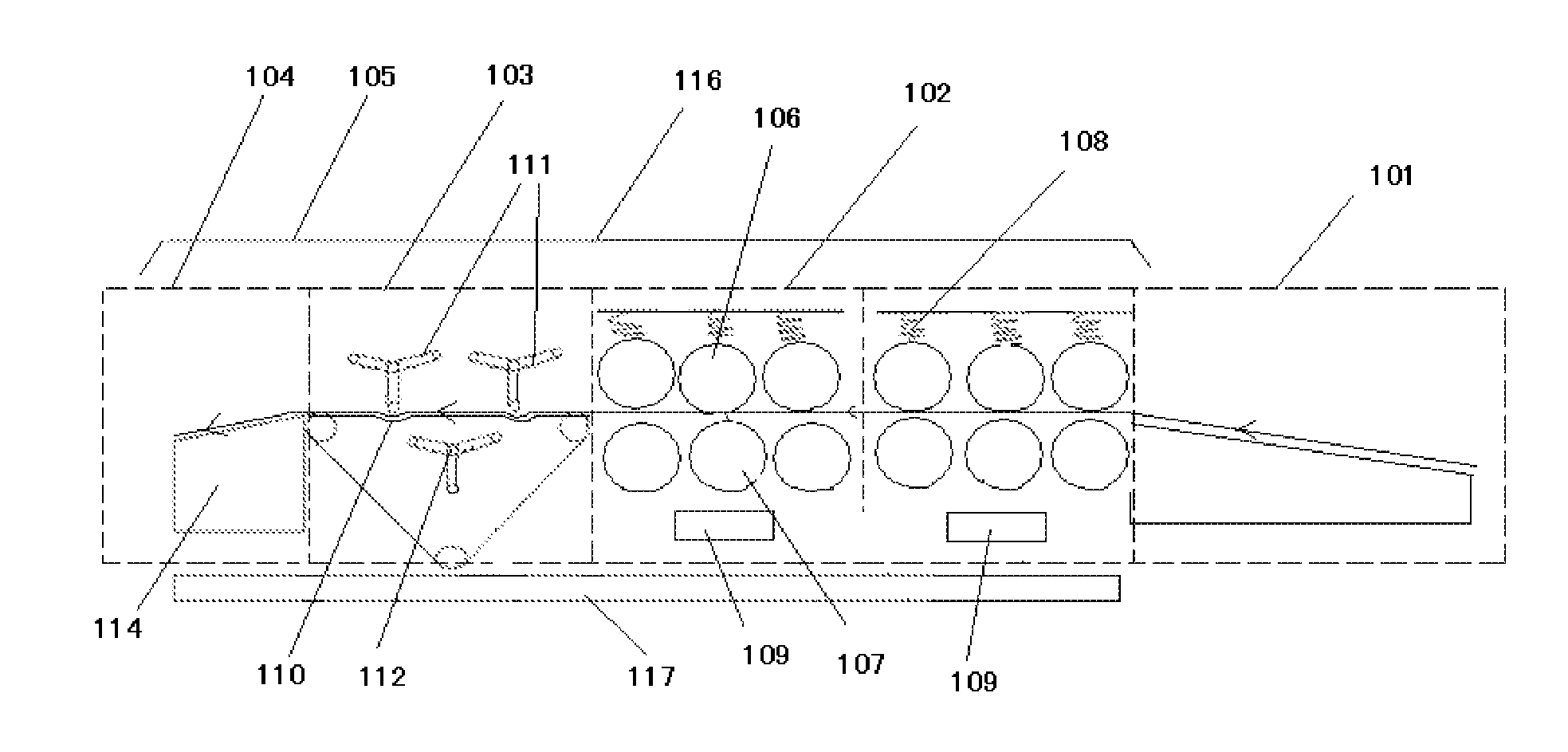

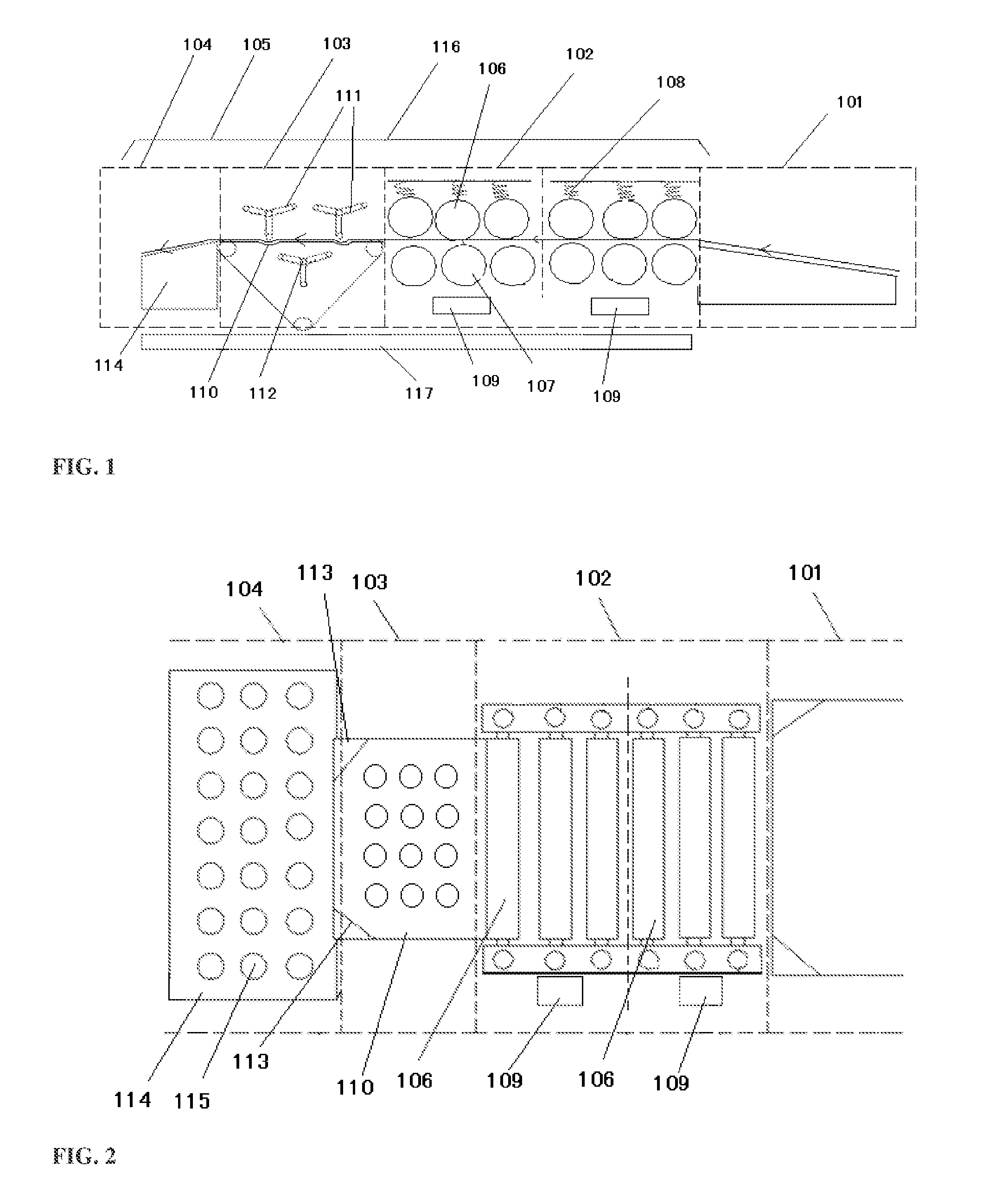

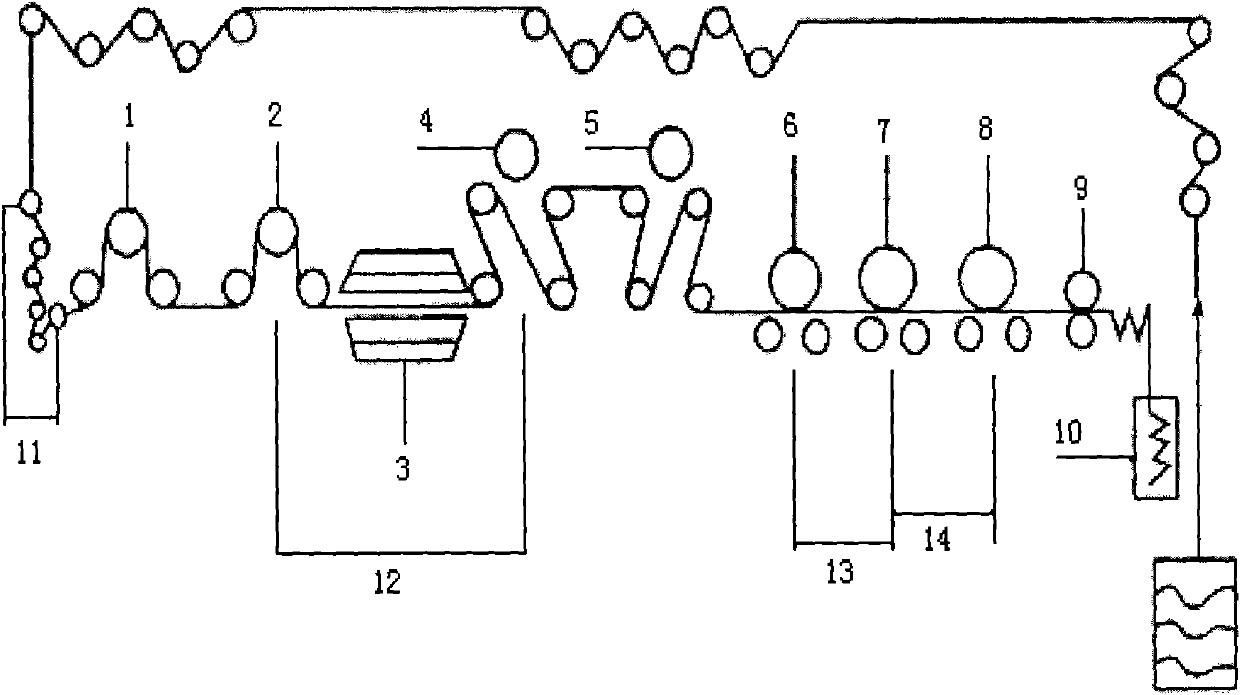

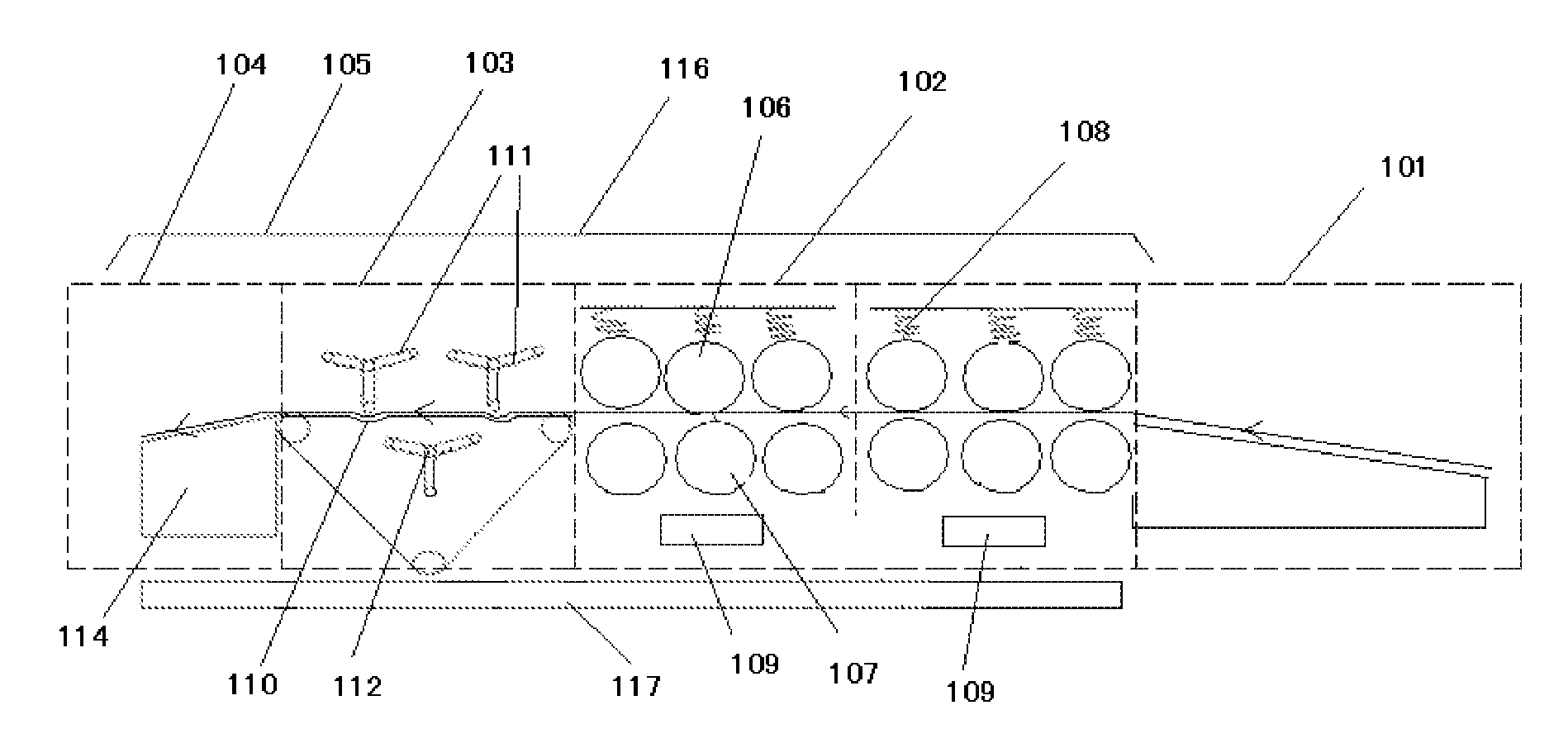

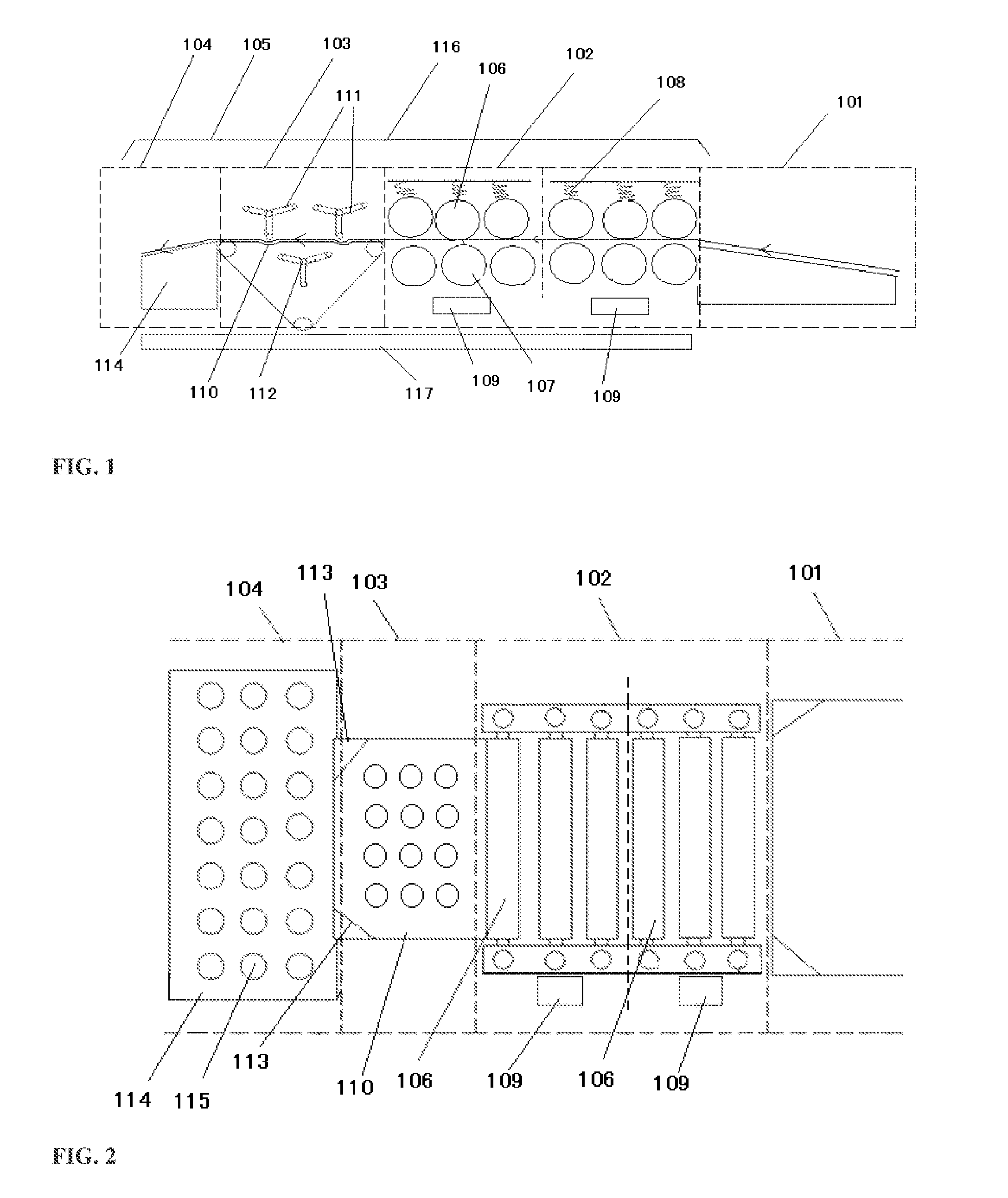

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

Systems And Methods For Formation And Harvesting of Nanofibrous Materials

InactiveUS20090215344A1Minimize bondingHinder integrityMaterial nanotechnologyTransportation and packagingFiberYarn

A system that receives nanomaterials, forms nanofibrous materials therefrom, and collects these nanofibrous materials for subsequent applications. The system is coupled to a chamber that generates nanomaterials, typically carbon nanotubes produced from chemical vapor deposition, and includes a mechanism for spinning the nanotubes into yarns or tows. Alternatively, the system includes a mechanism for forming non-woven sheets from the nanotubes. The system also includes components for collecting the formed nanofibrous materials. Methods for forming and collecting the nanofibrous materials are also provided.

Owner:NANCOMP TECHNOLOGIES INC

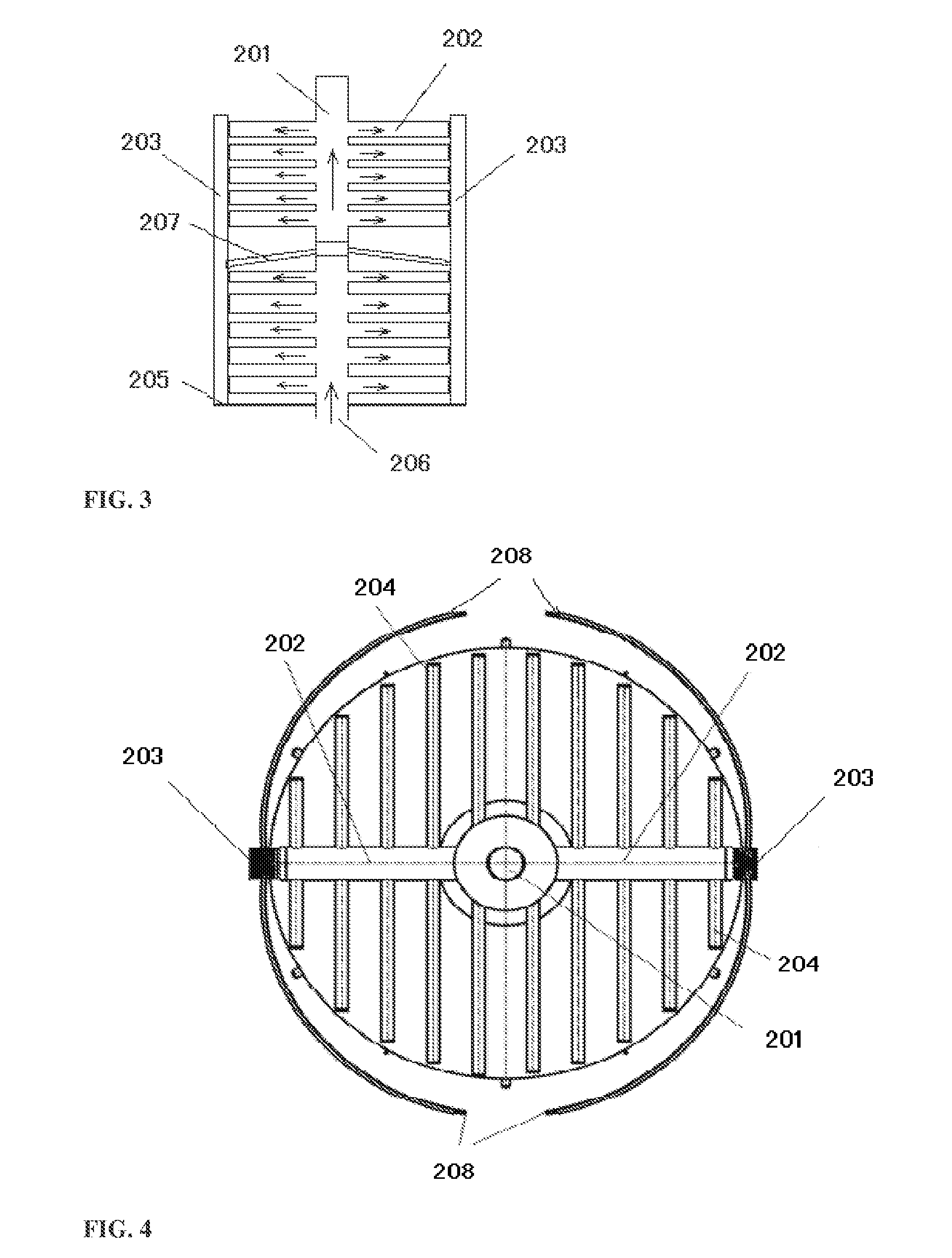

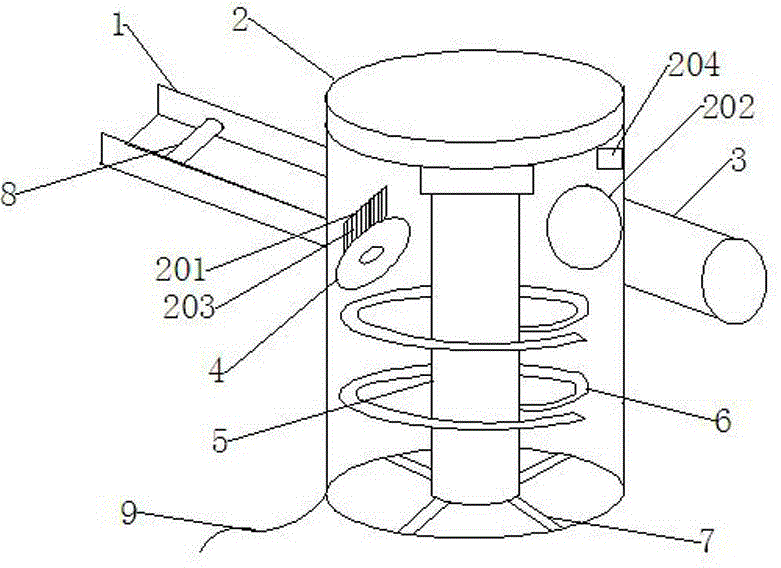

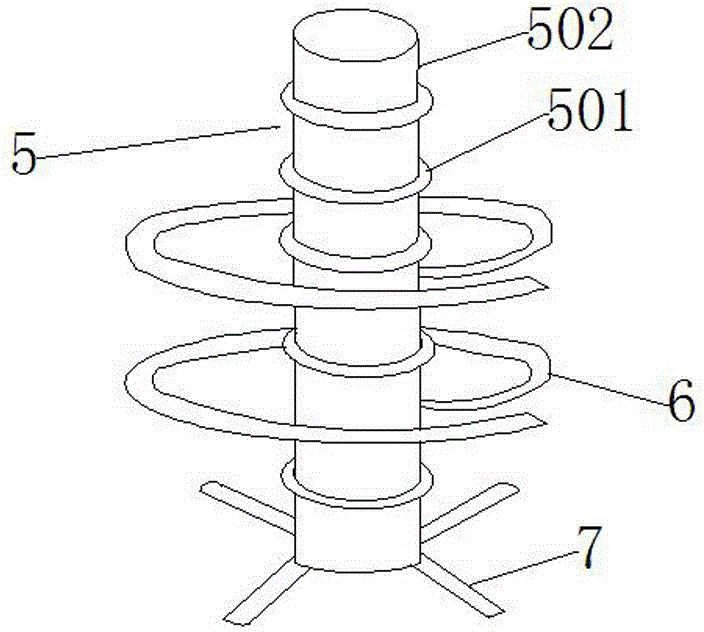

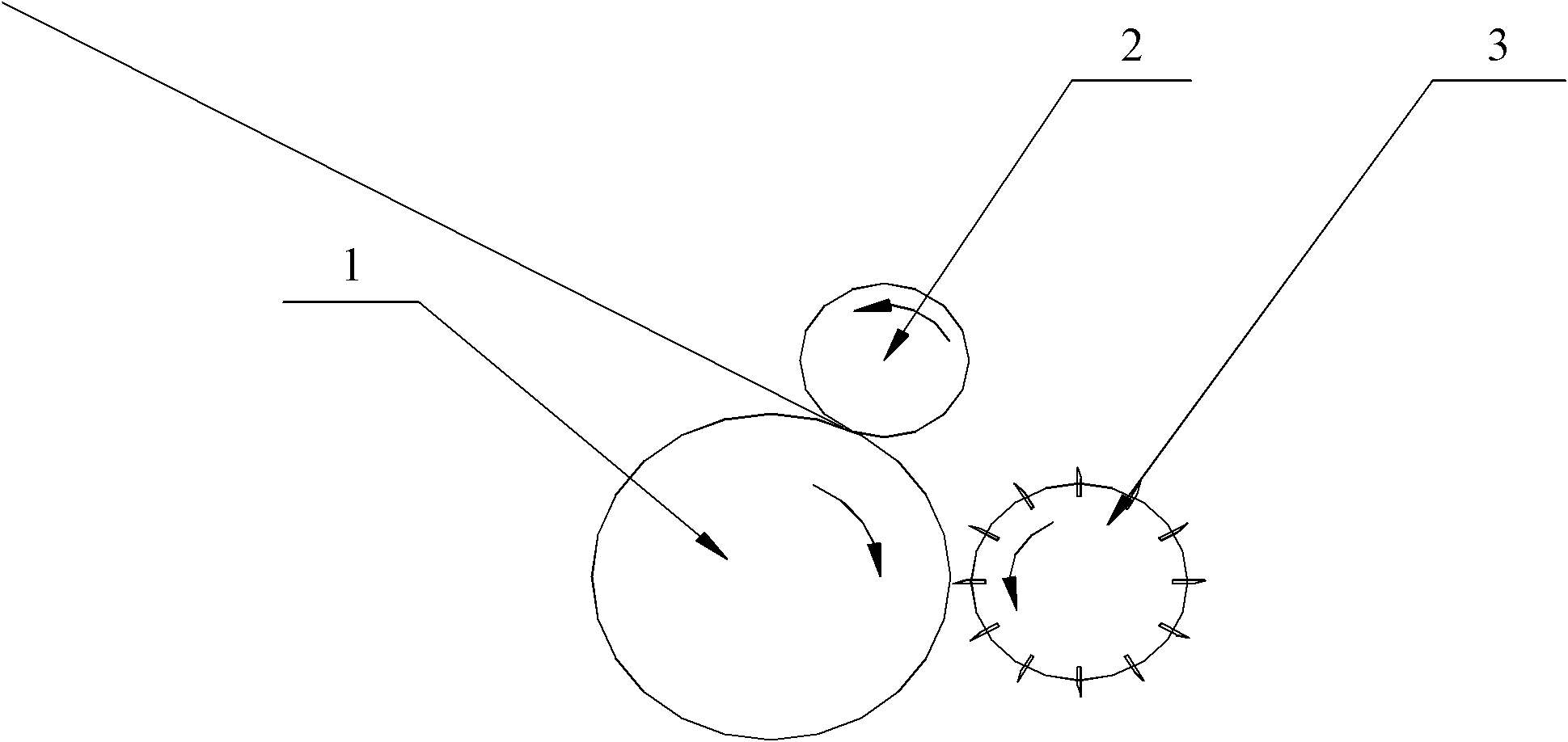

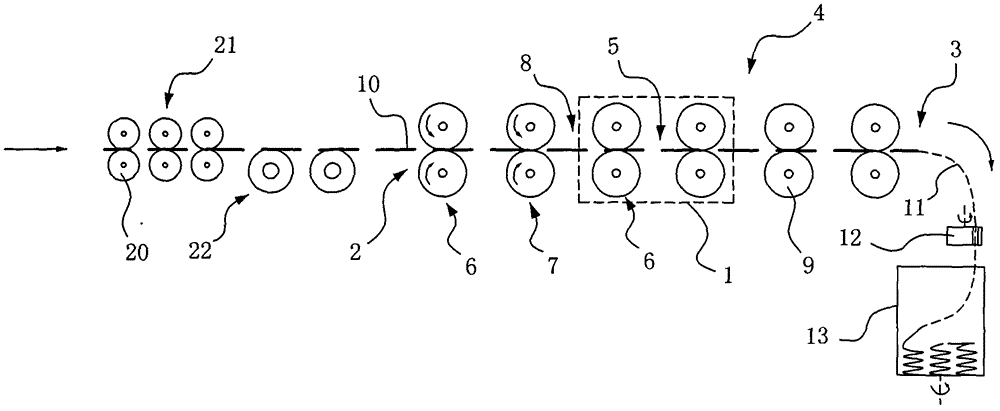

Double-cutter cotton-escape preventing fiber cutting machine

InactiveCN104153045AExcellent resistance to moisture absorptionStrong acid and alkali corrosion resistanceTows to slivers/yarnsTextile disintegration and recoveryFiberEngineering

The invention discloses a double-cutter cotton-escape preventing fiber cutting machine. The double-cutter cotton-escape preventing fiber cutting machine comprises a feed inlet cutter set (4) and a rolling cutter set (5), the feed inlet cutter set (4) is arranged below a feed inlet (201), the feed inlet cutter set (4) is driven by a first motor through a transmission mechanism, the rolling cutter set (5) is driven by a second motor through the transmission mechanism, a plurality of stirring racks are fixedly arranged on the rolling cutter set (5), a plurality of bottom stirring rods (7) are arranged at the bottom end of the rolling cutter set (5), the bottom surfaces of the bottom stirring rods (7) contact with the bottom surface of a box body (2), a cotton stop brush (203) is arranged at the position of the feed inlet (201), and a humidifier (204) is arranged on the box body (2); the box body (2) is connected with an earth lead (9). Cotton fibers can be effectively prevented from escaping out of the box body, and cotton fiber content in the environment is reduced. Meanwhile, fiber products are uniformly and finely cut.

Owner:扬中市金德纺织机械设备厂

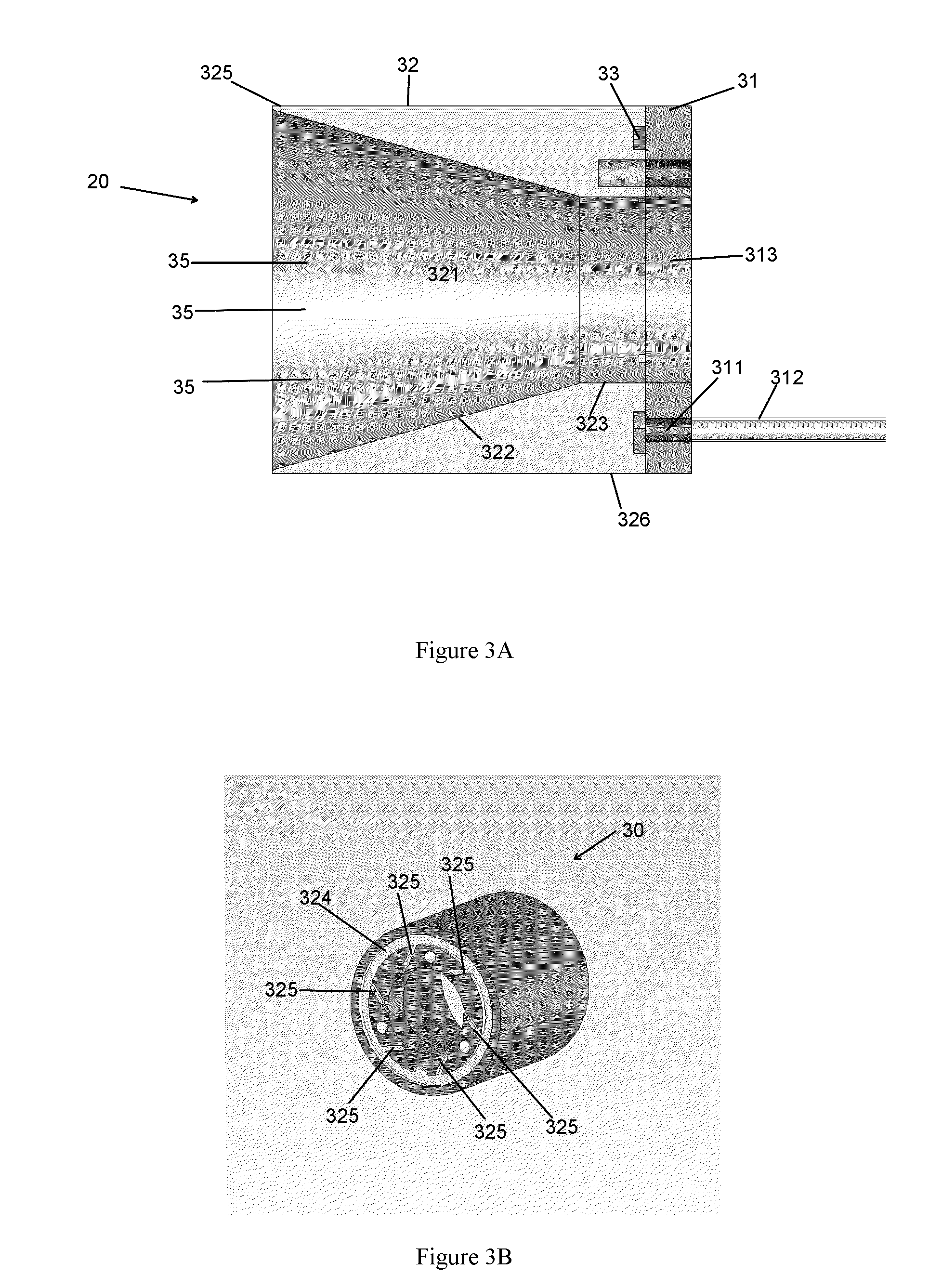

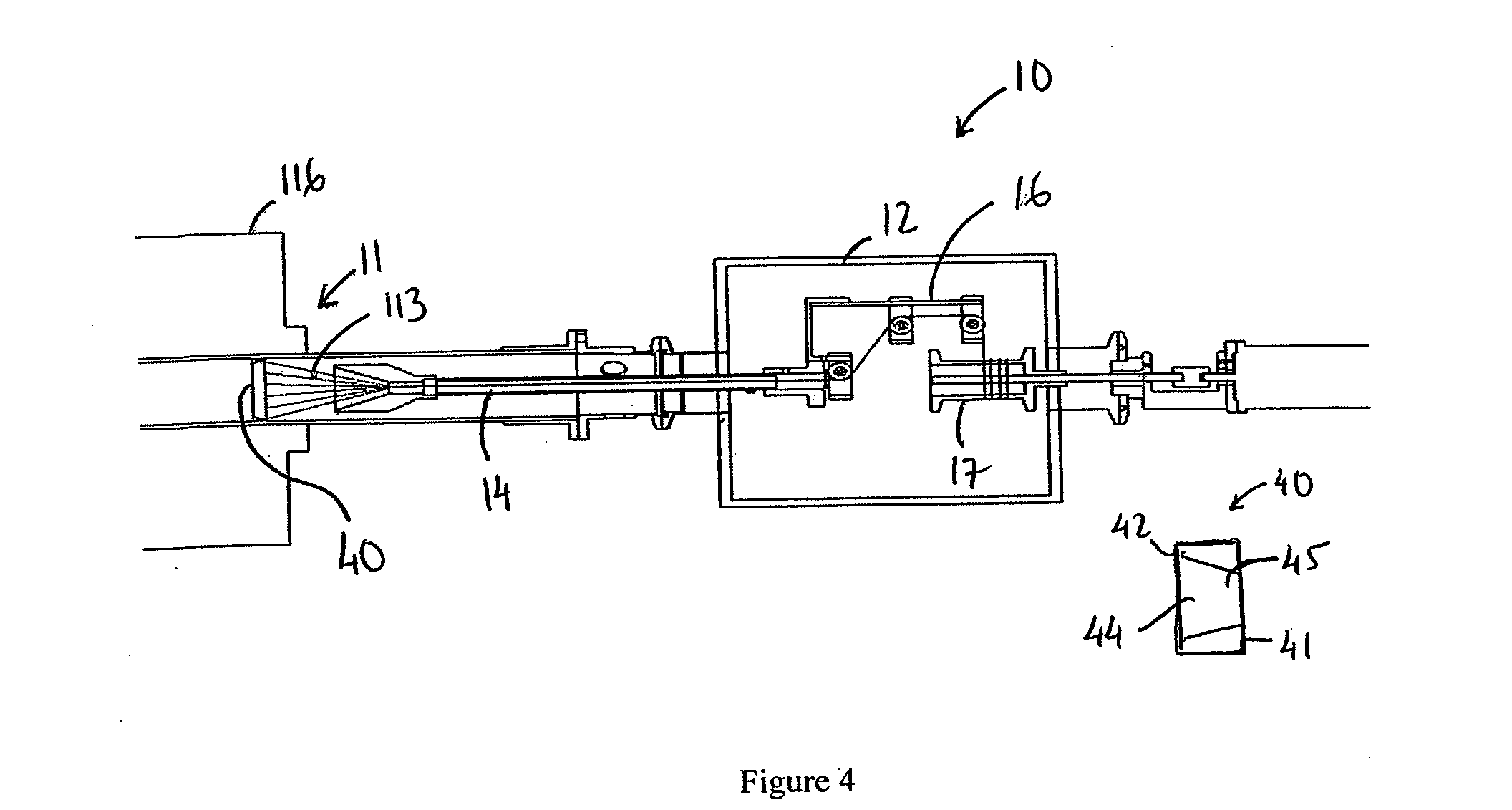

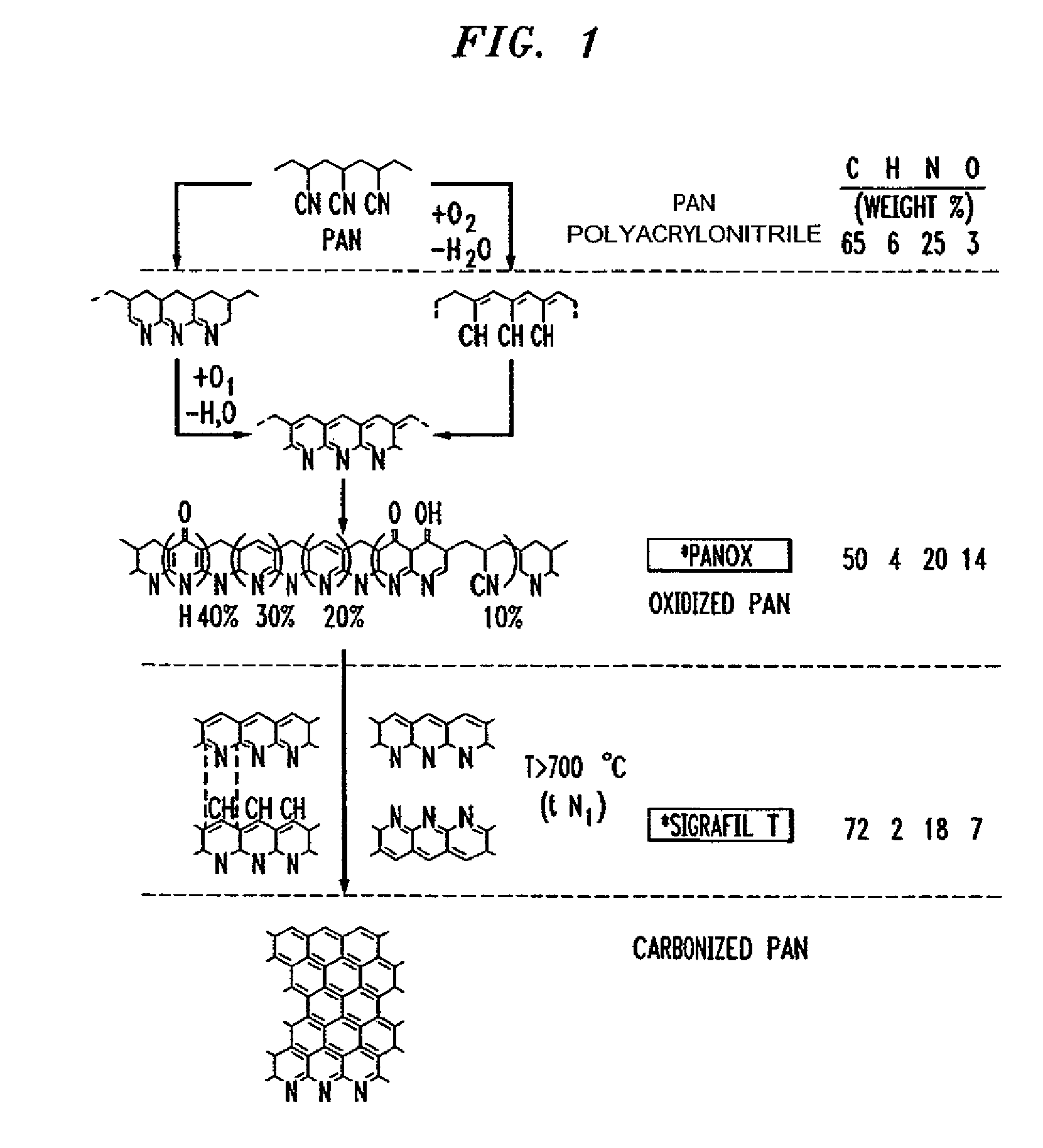

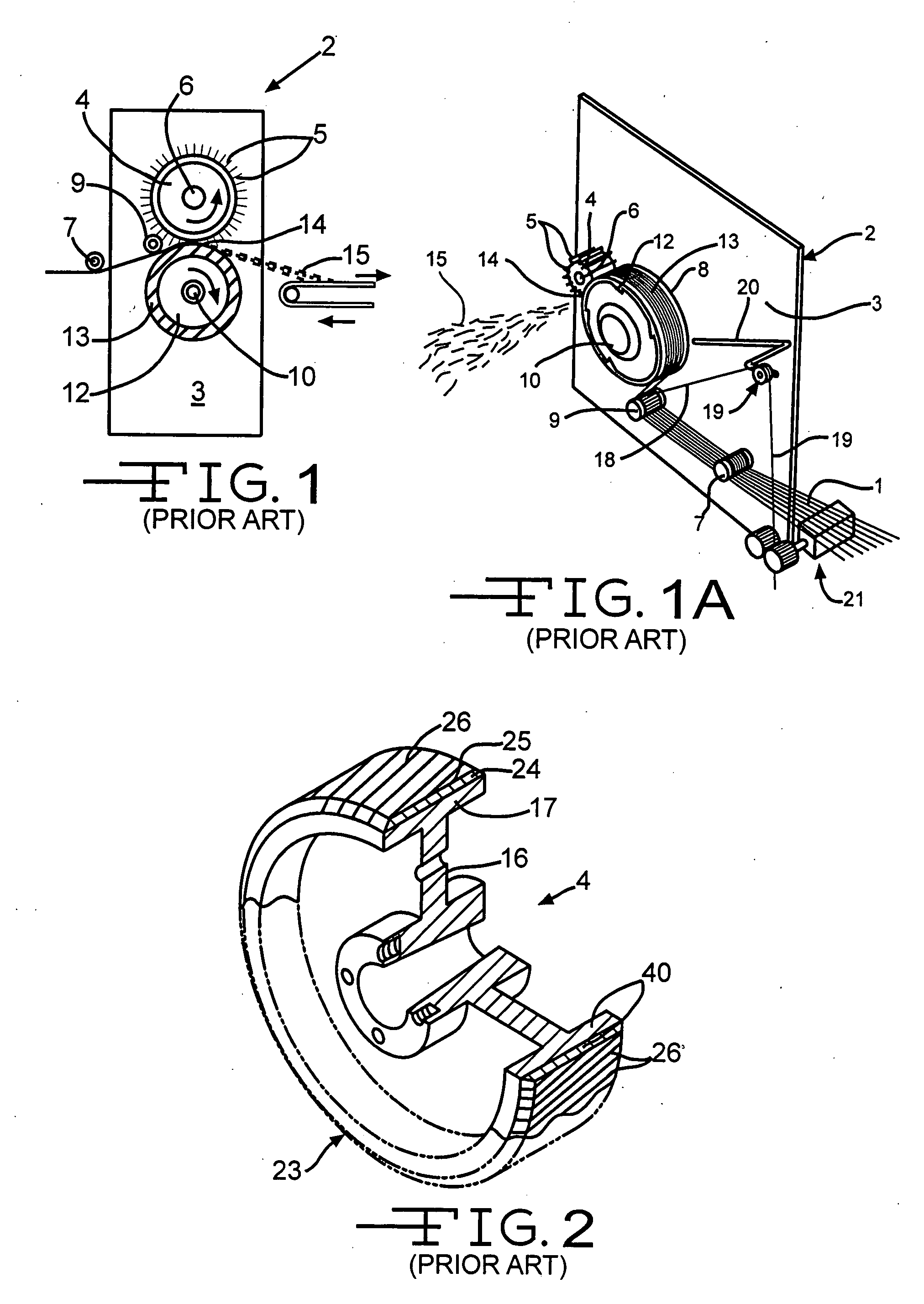

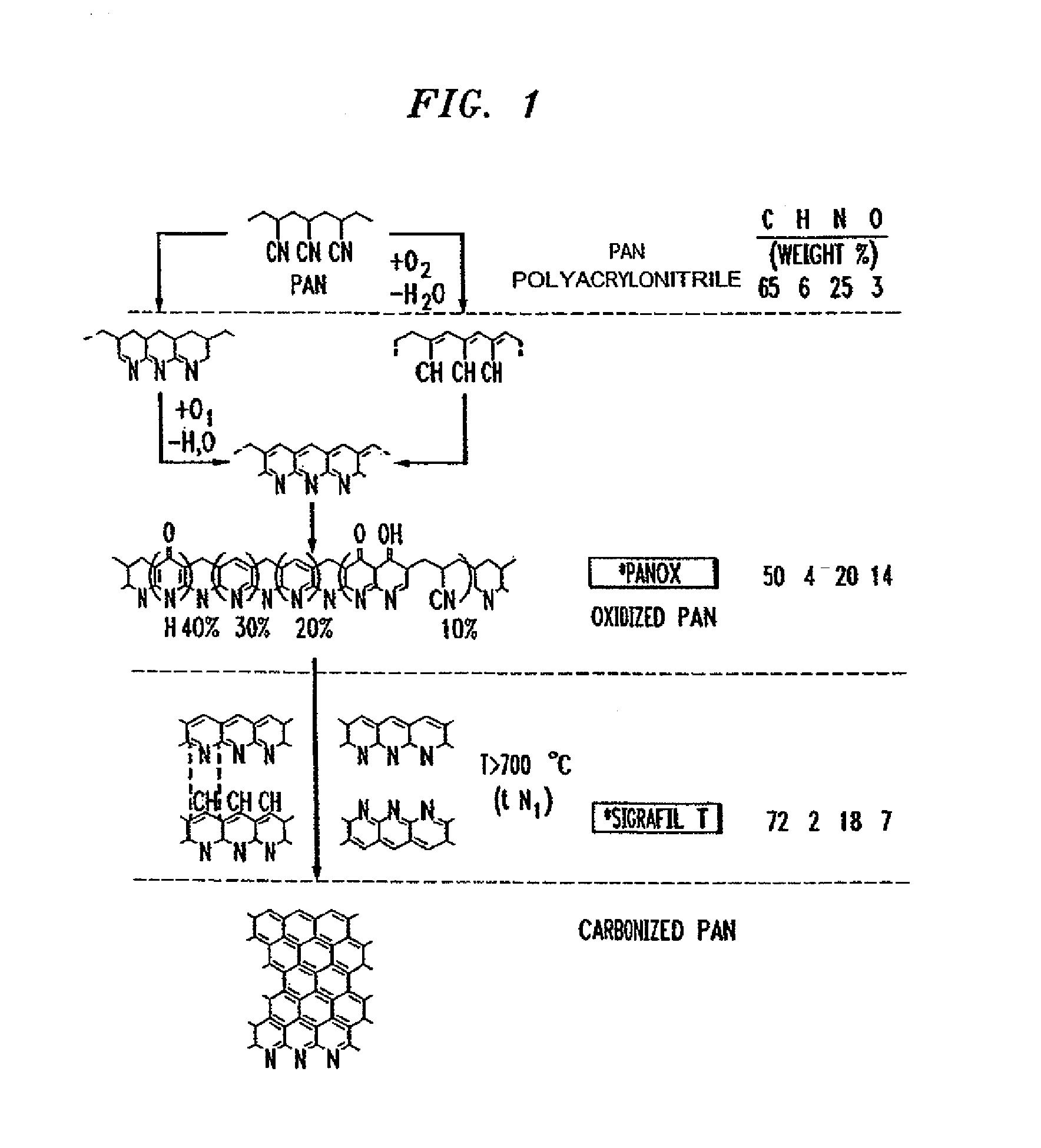

Fire retardant compositions and methods and apparatuses for making the same

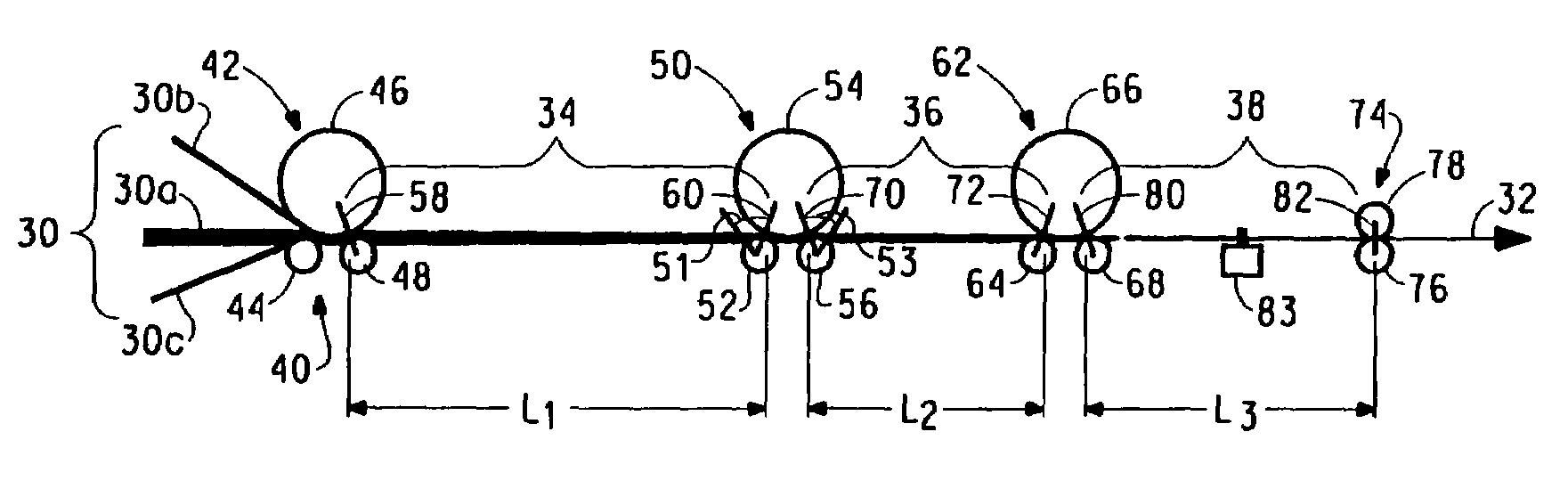

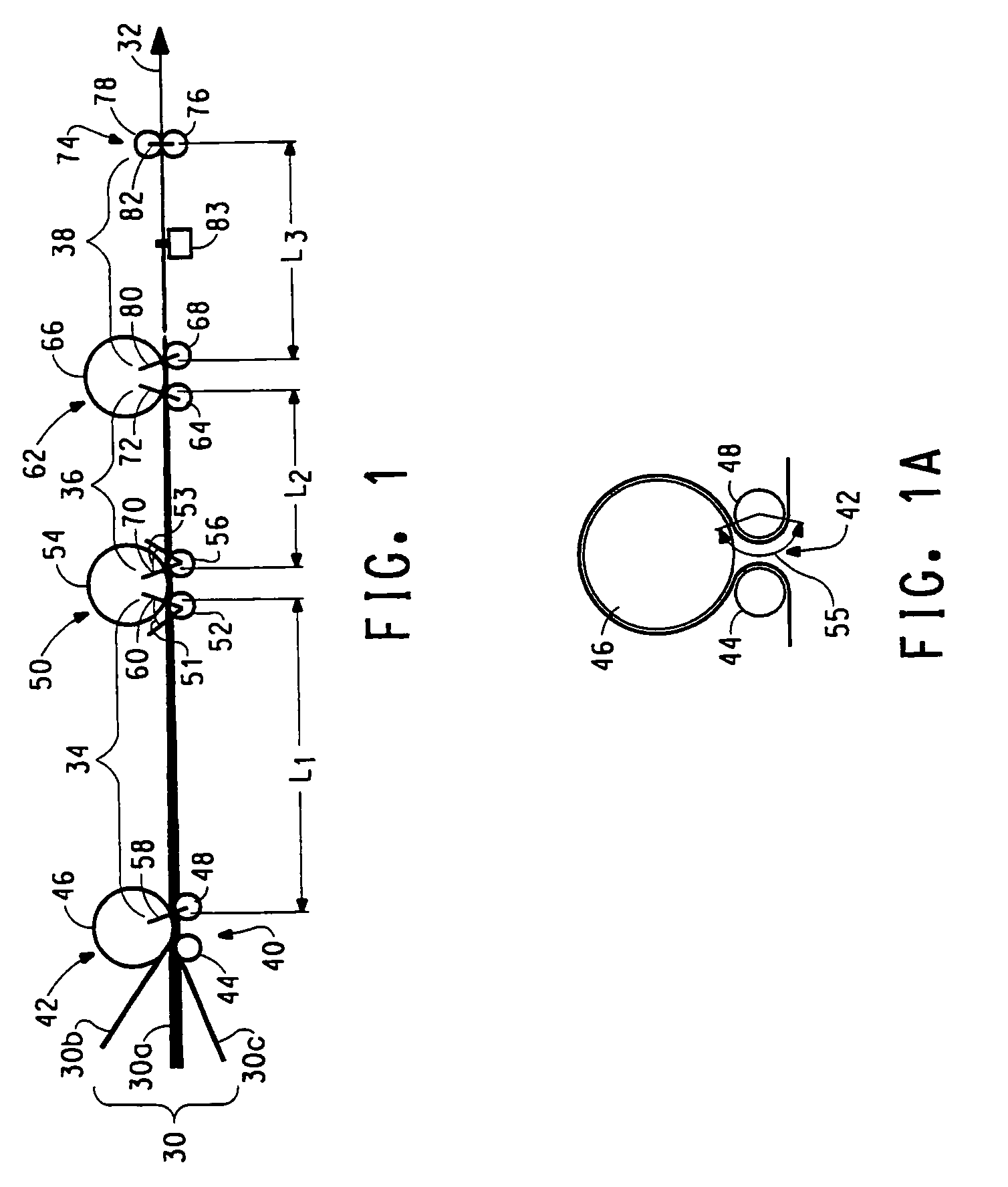

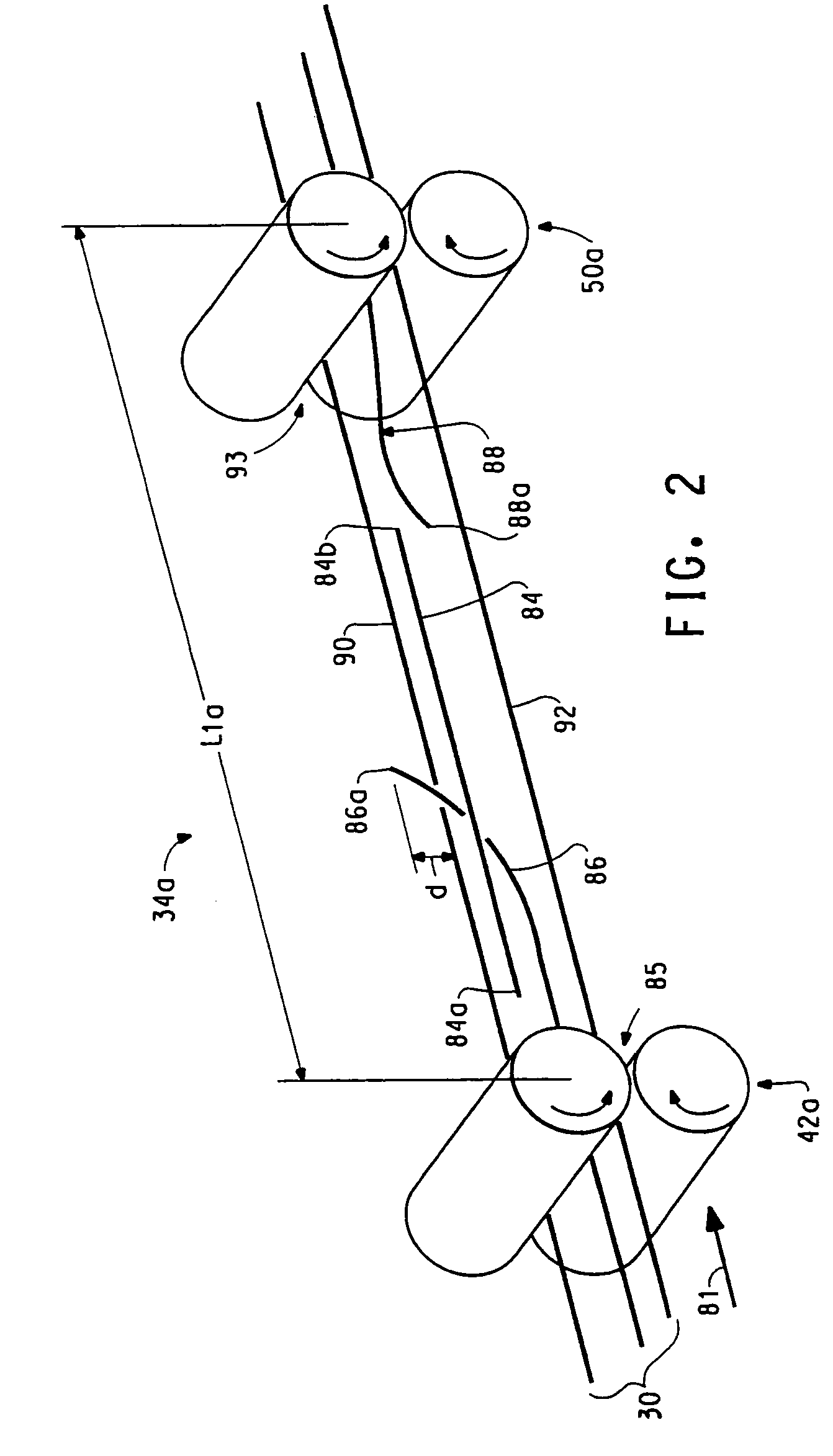

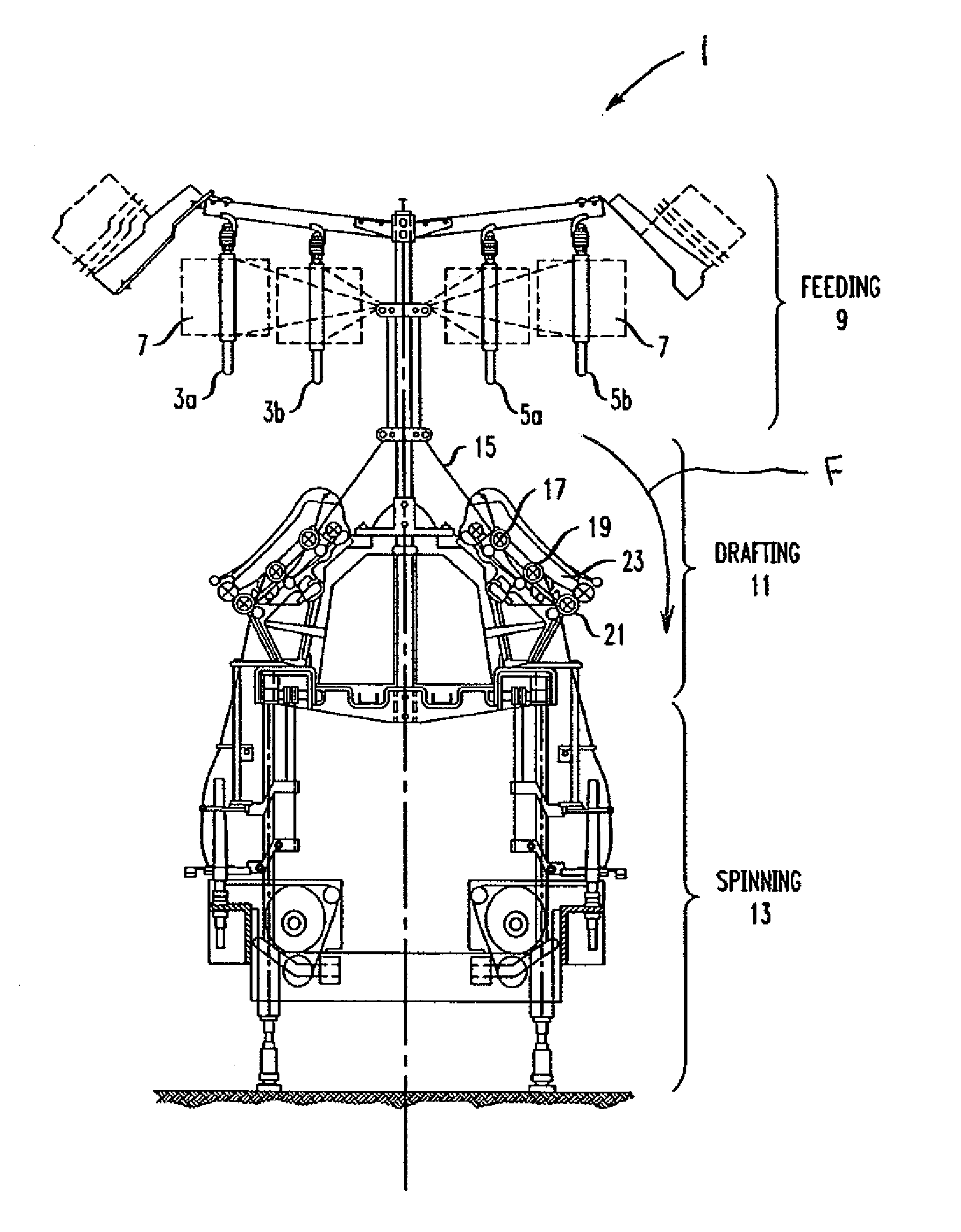

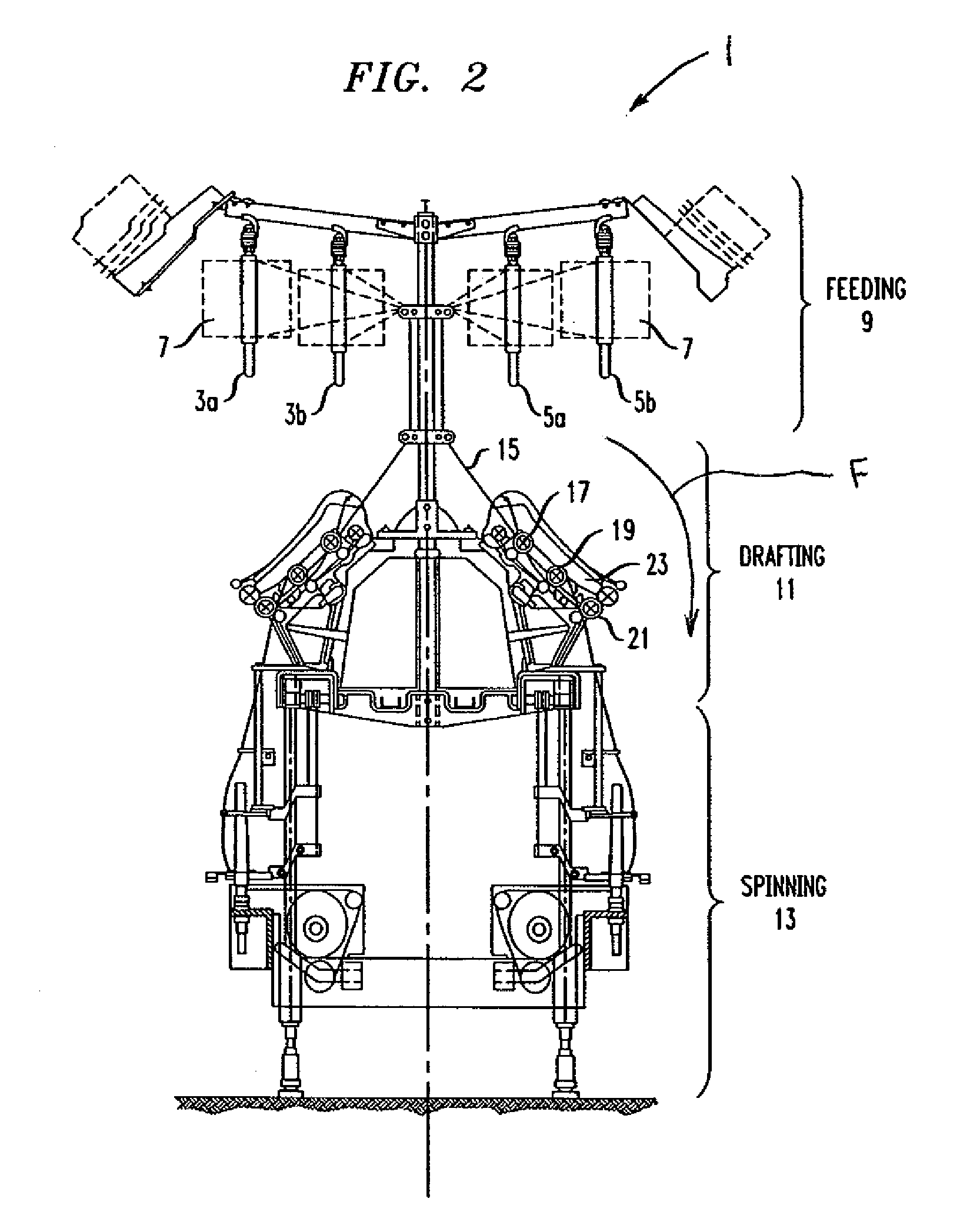

A method for forming yarn provides for forming an intermediate product being a fire retardant and heat resistant cohesive elongated network of fibers in a single operation by stretching and breaking filaments of a ribbon like tow starting material of longitudinally aligned filaments. The intermediate product may be wool-like with wavy and randomly oriented fibers formed by from the fragmented filaments. The single drafting operation includes directing the tow through first and second pairs of rollers, the second pair rotating faster than the first. The intermediate product may be spun directly into yarn in one spinning / twisting operation. The fire retardant and heat resistant yarn so produced may include 100% oxidized polyacrylonitrile fibers having an average length greater than about 15 cm. The yarn may be knitted or otherwise formed into fire-retardant and heat resistant fabrics or other products used in various applications.

Owner:LORICA INT

Ultra-high molecular weight PE yarn and processing method thereof

ActiveCN104120525ASimple processAvoid problems such as damage to card clothingNew-spun product collectionArtificial thread manufacturing machinesFiberYarn

The invention provides ultra-high molecular weight PE yarn and a processing method of the ultra-high molecular weight PE yarn. The processing method includes the steps that firstly, ultra-high molecular weight PE filaments are bundled and processed, and filament rods are obtained; secondly, crush cutting is conducted on the filament rods, auxiliary cutting is conducted on the filament rods in the crush cutting process so that part of the filament rods can be cut off, and fiber rods are formed; thirdly, drawing, roving, spinning and stranding are sequentially conducted on the fiber rods, and the ultra-high molecular weight PE yarn is obtained. Due to the fact that in the crush cutting process, auxiliary cutting is conducted on the filament rods, part of the filament rods are cut off to obtain short ultra-high molecular weight PE fibers, and the ultra-high molecular weight PE yarn is obtained through the subsequent third step. According to the processing method, the ultra-high molecular weight PE filaments are directly made into the fiber rods, the technology is simple and convenient to conduct, and the problem that card clothing is damaged by traditional short ultra-high molecular weight fibers in the carding process is solved.

Owner:CHINESE TEXTILE ACAD

Method for chopping unwound items and coated chopper blades

InactiveUS20080210066A1Prolong lifeExtend blade lifeSevering to form staple fibresTows to slivers/yarnsYarnFiber

A method for separating long, unwound items like fiber, fiber strands, yarn, etc. having a liquid chemical sizing on the surfaces into short lengths by chopping is disclosed.Improved chopping life is achieved by using blades, or at least blade edges of cemented tungsten carbide, and selecting the liquid chemical sizings having a pH of about 7 or greater to apply to the surfaces of the items being chopped. Also disclosed are blades having at least the sharp edges of the chopping blades coated with various materials including a material selected from a group consisting of tungsten carbide, titanium nitride, diamond like carbon, polycrystalline diamond, polycrystalline cubic boron nitride, cemented tungsten carbide, or mixture of two or more of these materials. These coated blades can be used to separate items having both neutral, basic and acidic sizings thereon

Owner:JOHNS MANVILLE CORP

Method and apparatus for cutting stainless steel fibre bundle

ActiveCN1644773ASuitable for spinning process requirementsImprove uniformityDrafting machinesTows to slivers/yarnsMetallurgyStainless steel fiber

A method for draft-breaking the stainless steel fibre tow used for weaving the stainless steel fibre fabric features that the stainless steel fibres and drafted for breaking them to obtain the fibres with the proper length distribution suitable for spinning technology. It is possible that the broken stainless steel fibres are wrapped by conventional ribbon. Its apparatus is the reformed double.

Owner:TEXTILE INST JIANGSU PROVINCE

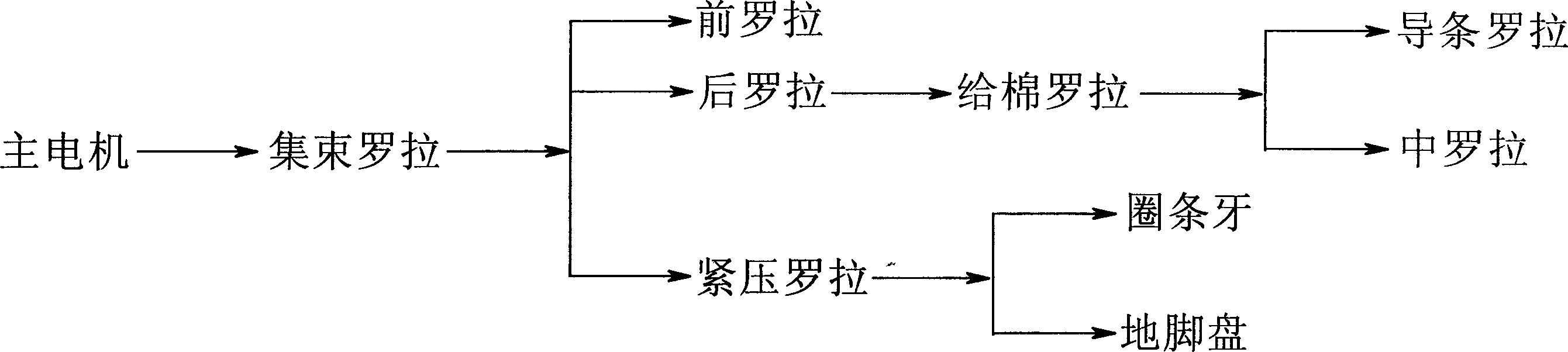

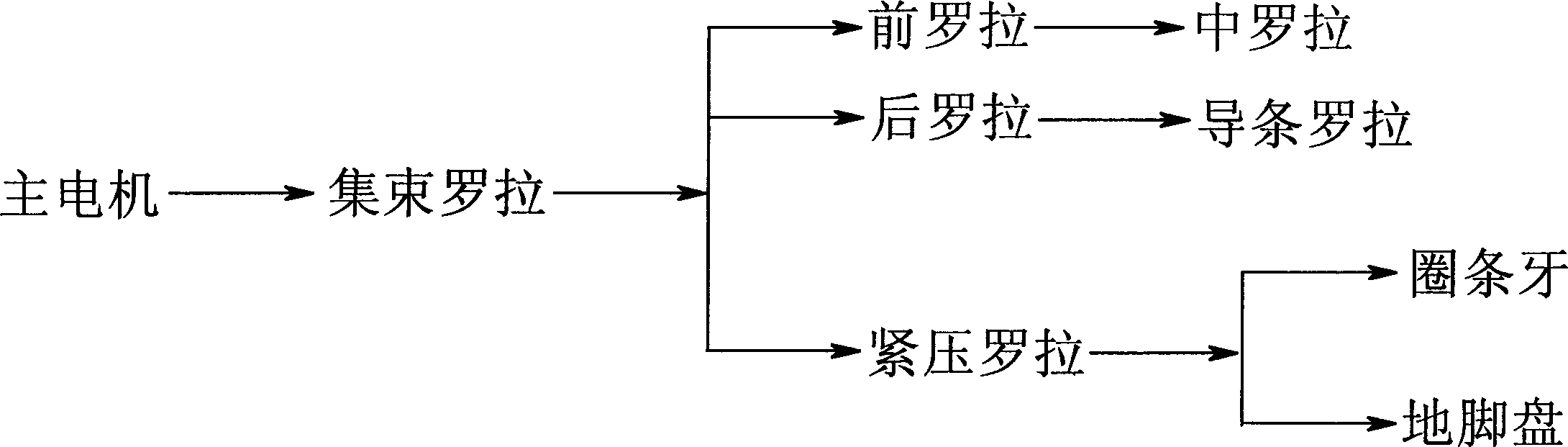

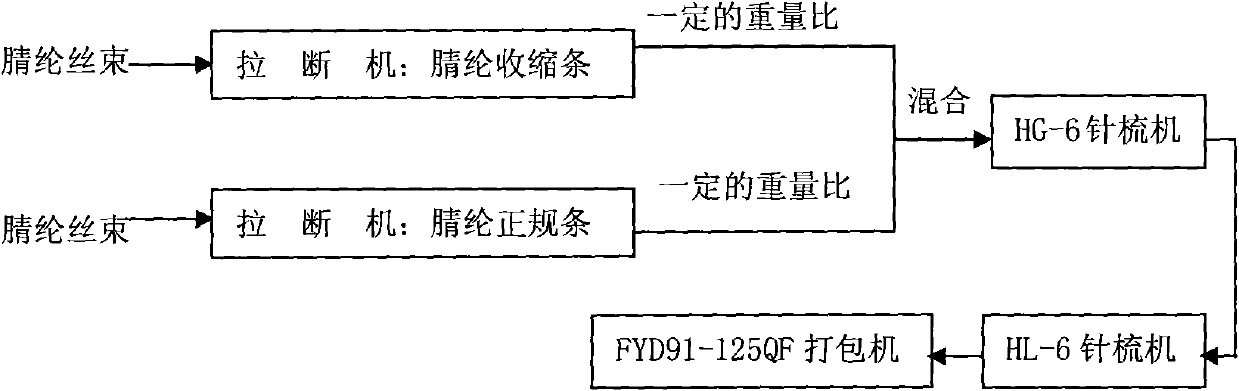

Method for producing fine denier acrylic tops

ActiveCN102021679ASuitable for productionImprove evenness qualityDrafting machinesTows to slivers/yarnsSteam pressureBiochemical engineering

The invention relates to a method for producing fine denier acrylic tops. 0.44-1.11dtex fine denier acrylic tows are taken as raw materials, and the method comprises the following steps of: manufacturing the tops by using a breaking machine, wherein the total draw ratio is 6.05-6.27, the space of rebreaking areas is 5mm greater than the conventional space, the pressure of a pressing plate in a crimping box is 1-2 buckles greater than the conventional pressure, and the steaming pressure is 0.15-0.3MPa; and manufacturing the tops by using a gilling machine, wherein the needle plate number of a comb box is NO.6-8, the draft multiple in a coiling area is 1.15-1.3, the draft multiple in a feeding area of the comb box is 0.98, the main draft multiple is 6-8, and the front roller space is 35-45mm. The quality indexes of the fine denier acrylic tops produced by the method meet the qualified product standard, and partial indexes meet the high-class product standard.

Owner:PETROCHINA CO LTD

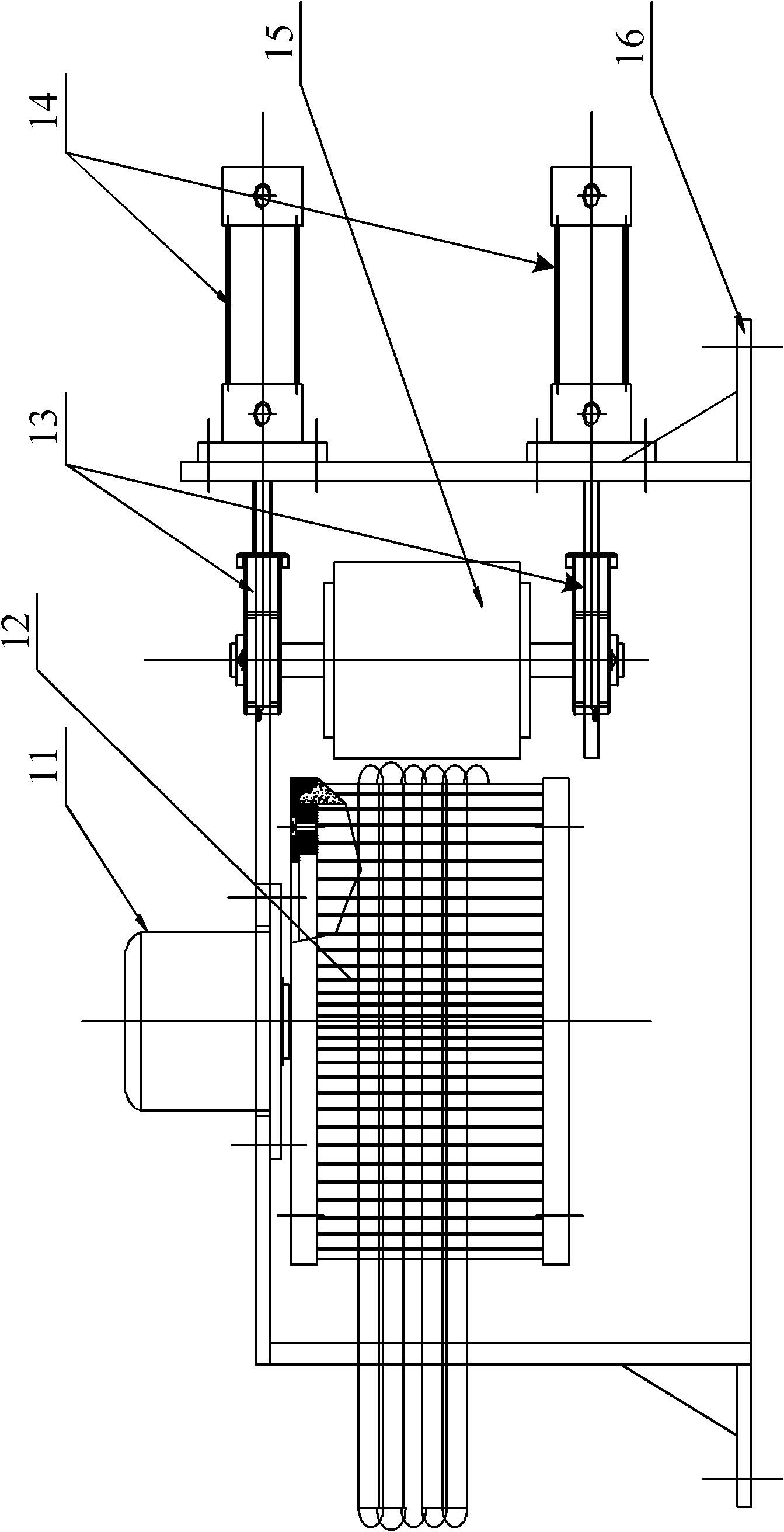

Fiber chopping machine

InactiveCN102094263ASolve the problem of increasing production costsTows to slivers/yarnsFiberEngineering

The invention discloses a chopping machine which comprises a stand, a vertical motor, a knife wheel, two cylinders and a pressing roll, wherein the vertical motor is installed on the stand; the knife wheel is rotatably arranged on the output shaft of the vertical motor, and knife blades the edges of which are outward are arranged at preset intervals on the knife wheel; the two cylinders are installed up and down on the stand; the two ends of the pressing roll are respectively installed on the stand through bearings with seats and are respectively connected with the two cylinders; and the pressing roll can move close to or far from the knife wheel in accordance with the movement of the cylinders.

Owner:CHONGQING POLYCOMP INT

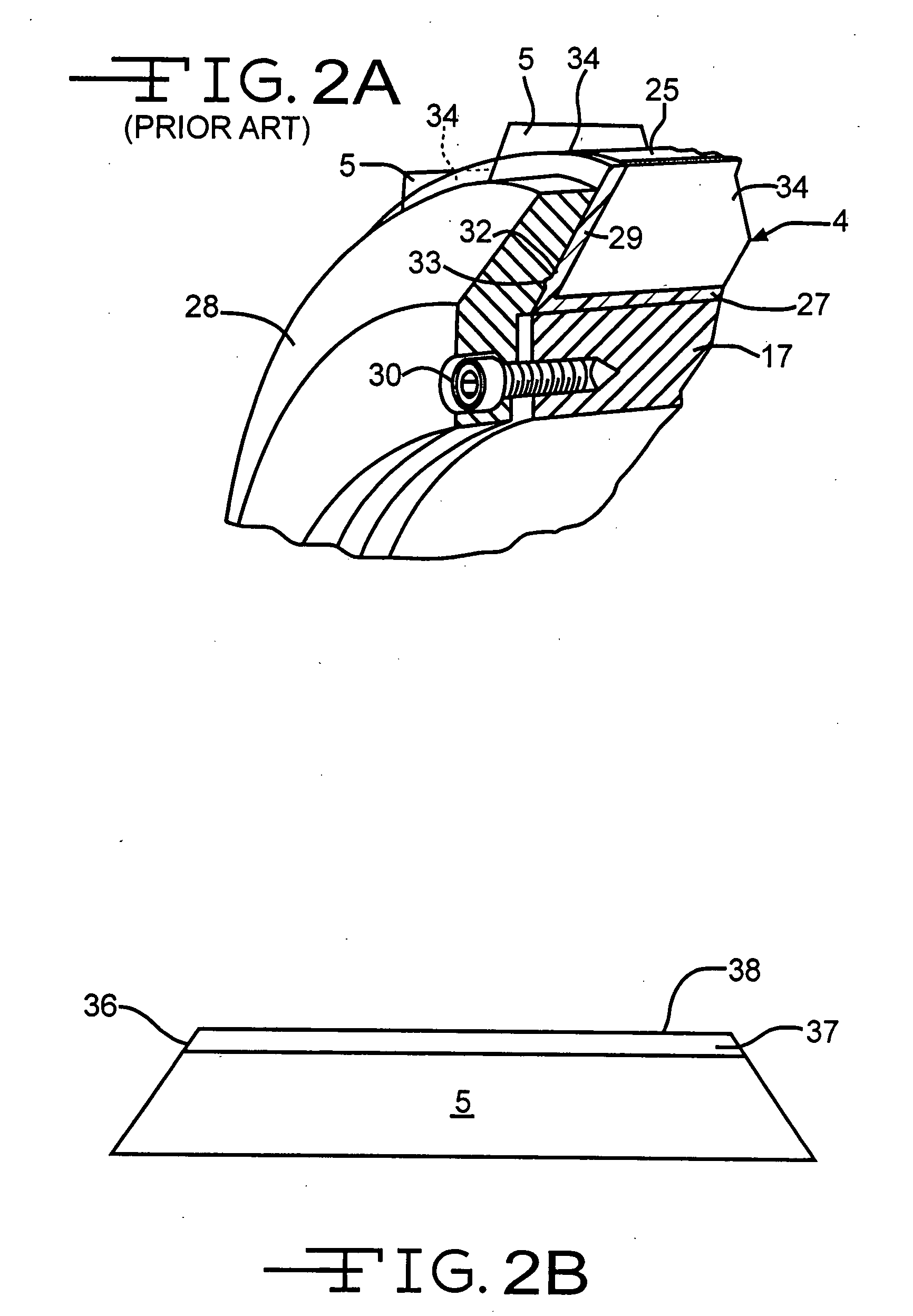

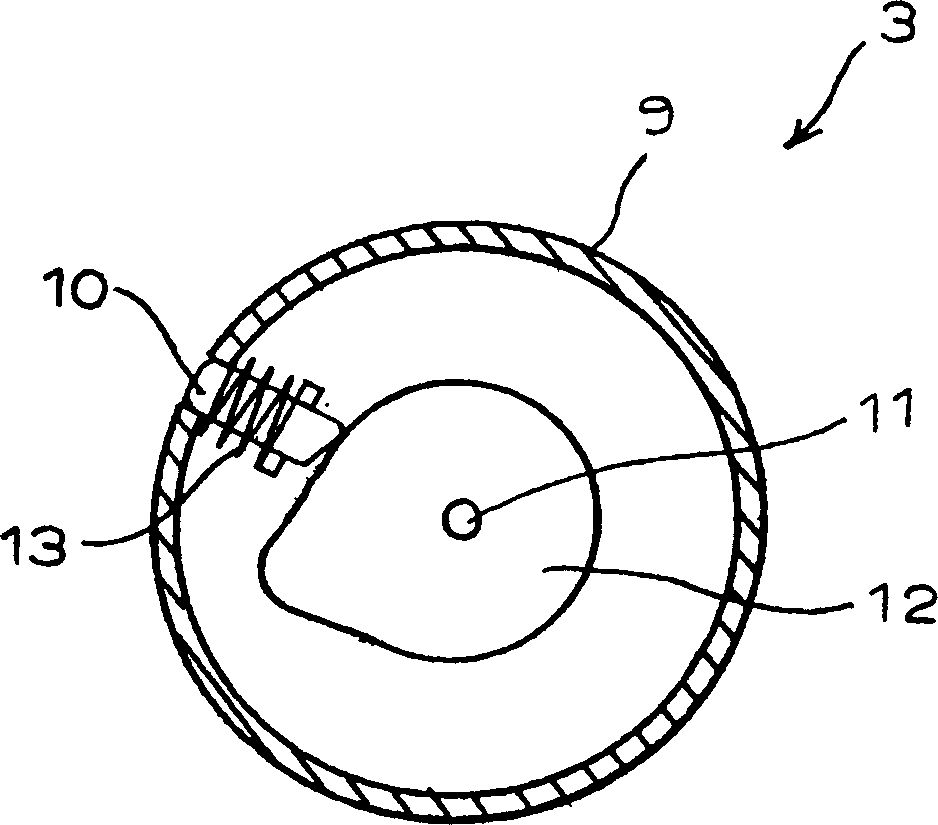

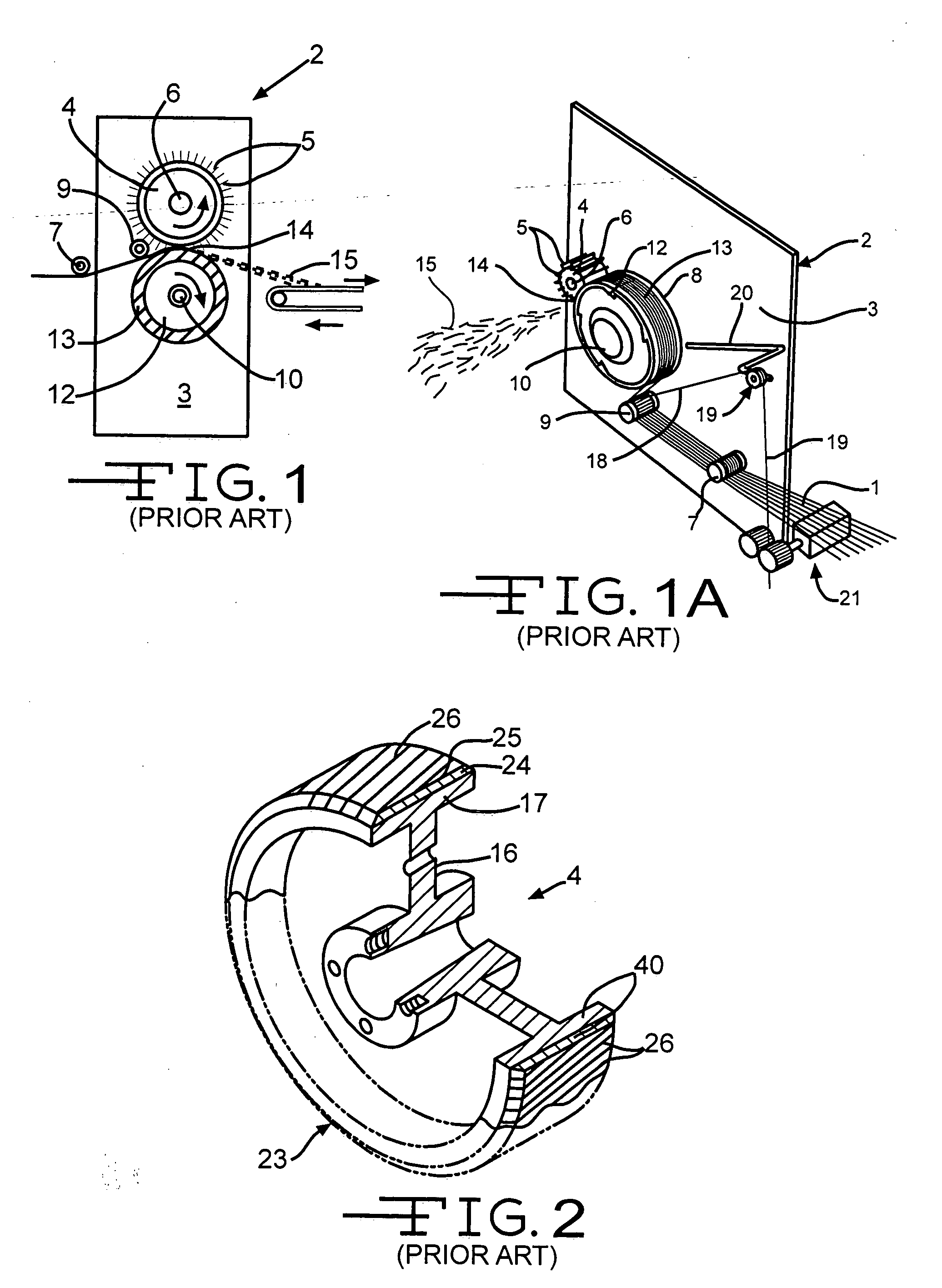

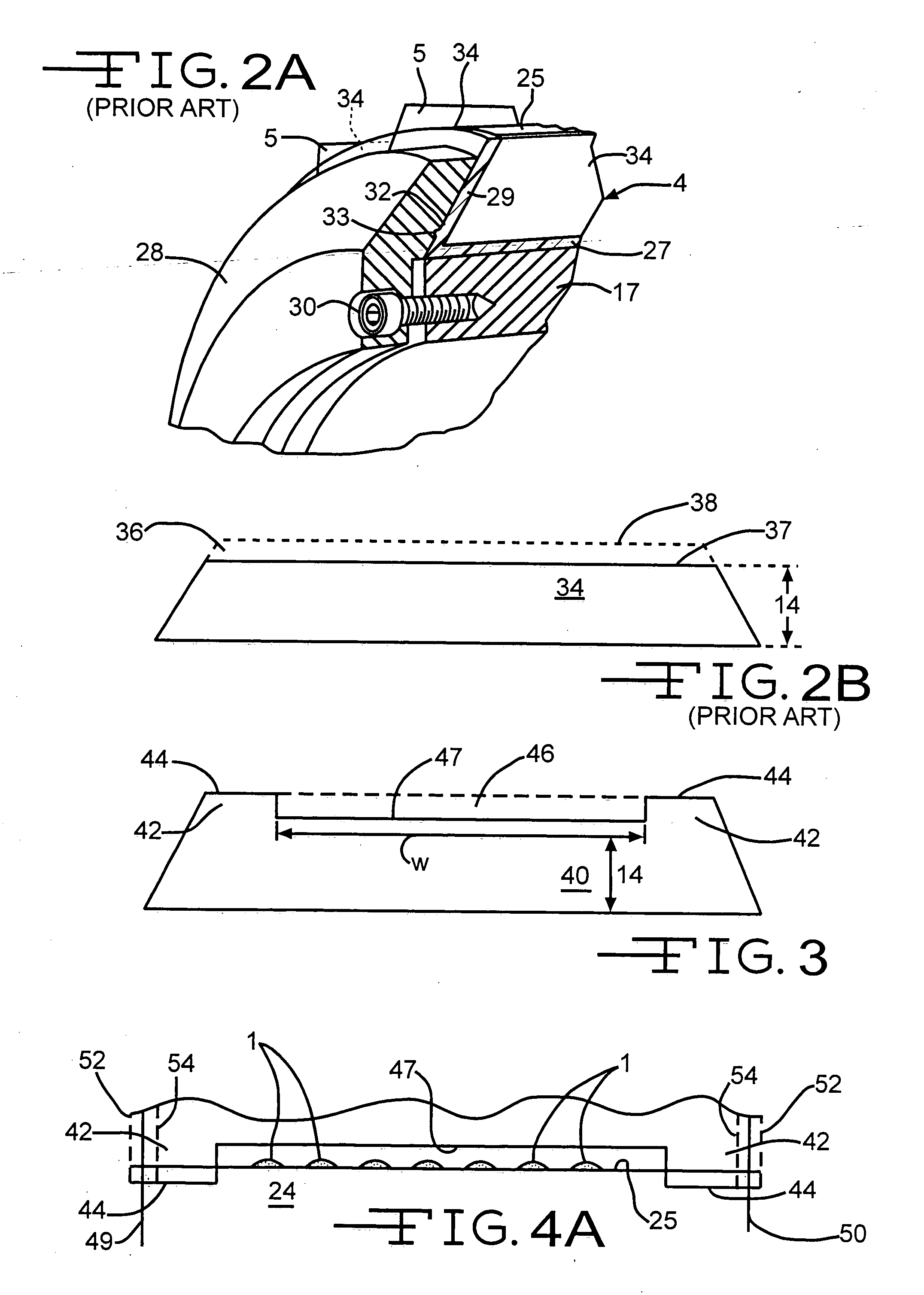

Cutter blade head for fiber roving chopper

A blade cartridge for a fiber roving chopper comprises an annular support and a plurality of blade holders. Each of the plurality of blade holders comprises a main body portion, a first end, a second end, and a blade. The first end of the main body portion is connected to the annular support. The second end of the main body portion is opposite the first end such that the main body portion is cantilevered from the annular support. The blade is integrally seated in the main body portion and extends between the first end and the second end. In a further embodiment of the invention, the main body portion of the blade holder includes first and second end notches that extend through the main body portion and the blade.

Owner:GRACO INC

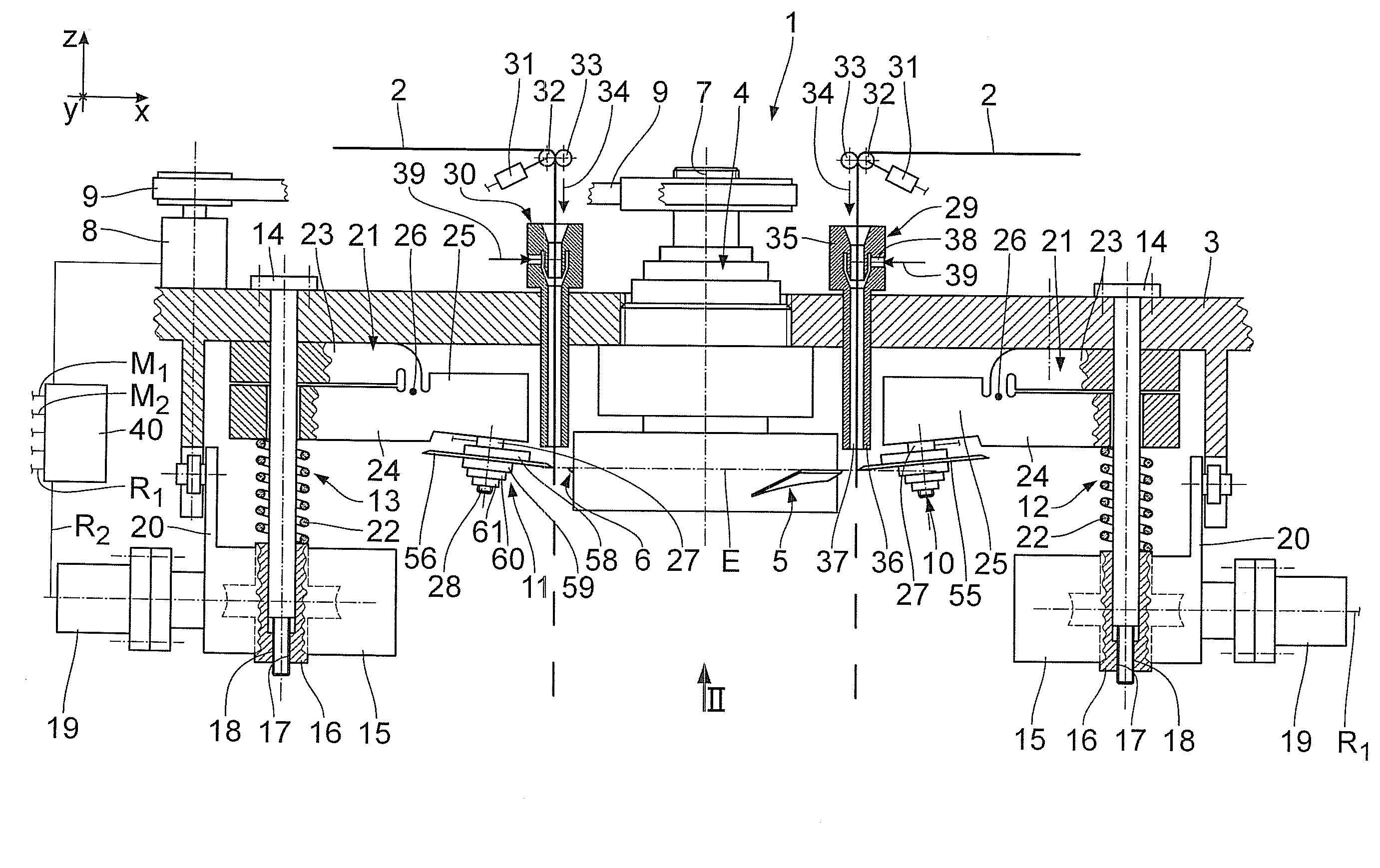

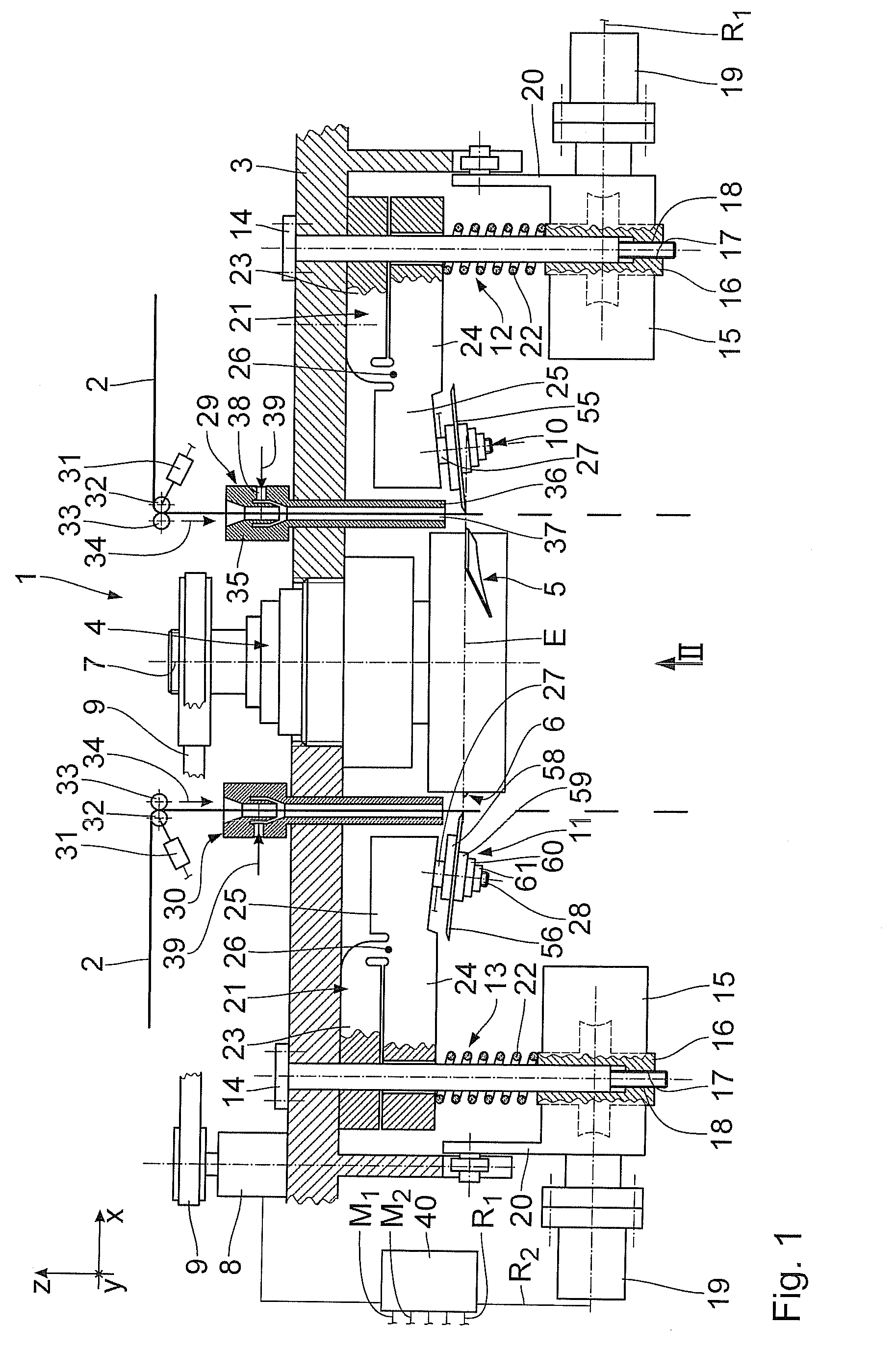

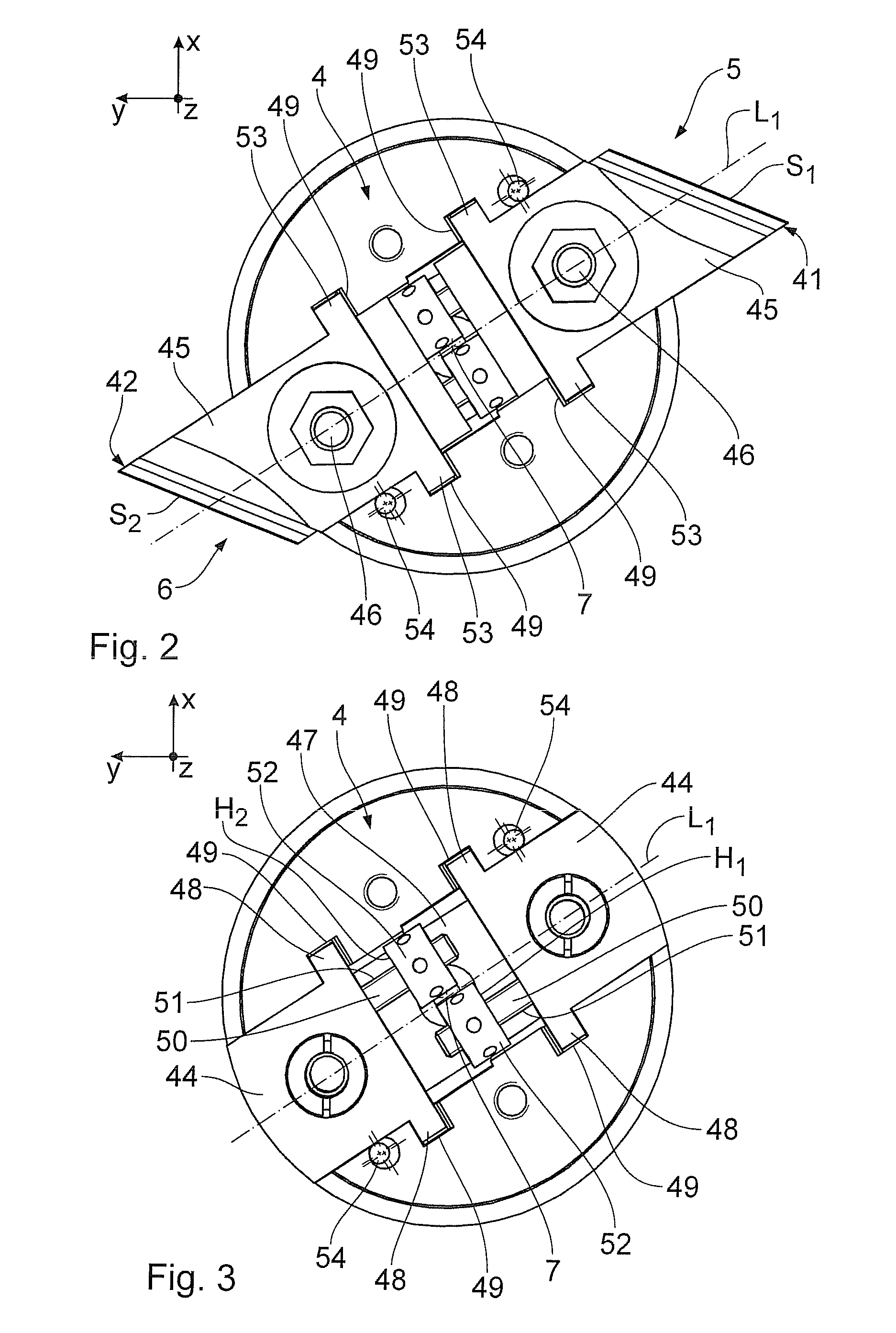

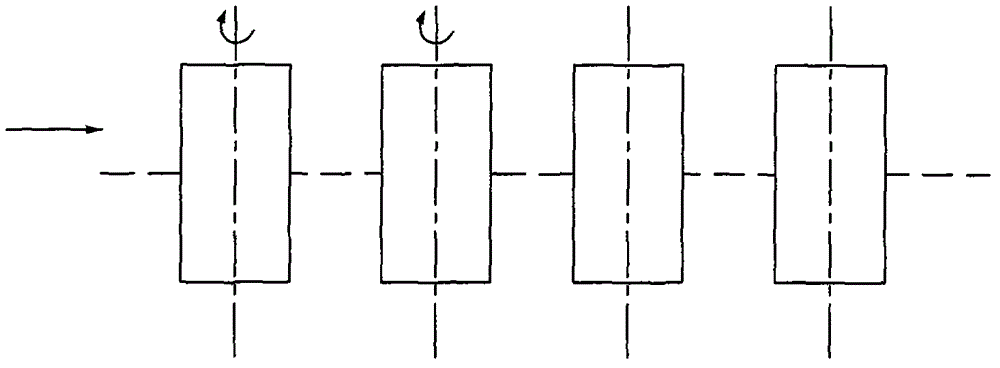

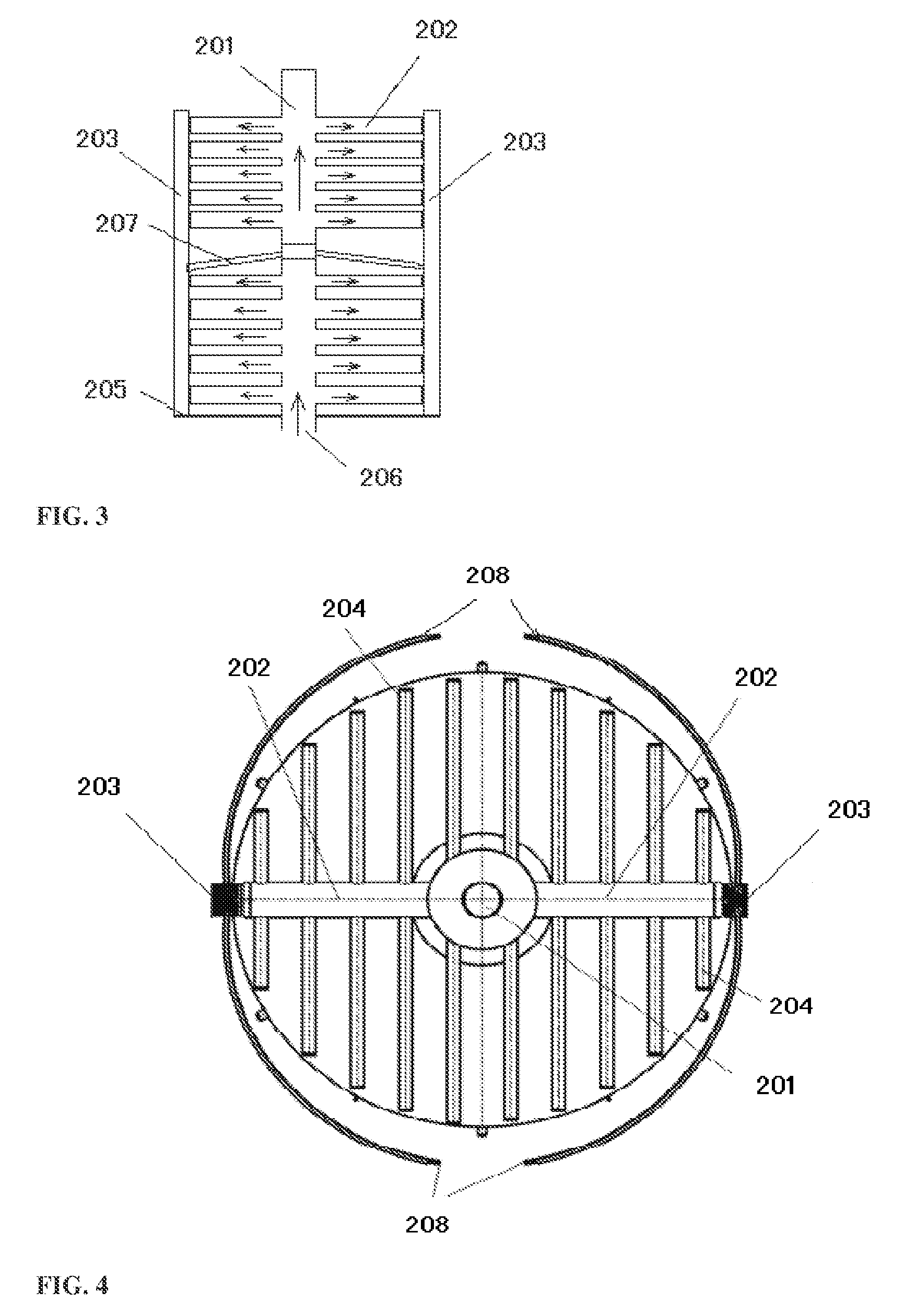

Cutting device for shear-cutting of fibre strands

InactiveUS20110203433A1Improve cut qualityImprove throughputAutomatic control devicesSevering to form staple fibresEngineeringMechanical engineering

A cutting device for shear-cutting of fibre strands comprises at least two cutting units which are rotatably drivable about an axis of rotation and two counter cutting units which are rigidly mounted relative to a base frame. The cutting edges of the cutting units as well as the counter cutting edges of the counter cutting units are positionable relative to a common cutting plane independently of each other. The forces acting on the counter cutting edges are measured during a cutting process by means of corresponding measuring sensors, allowing the position of the counter cutting edges to be controlled by means of a control unit via electrically driven displacement devices.

Owner:SCHMIDT & HEINZMANN

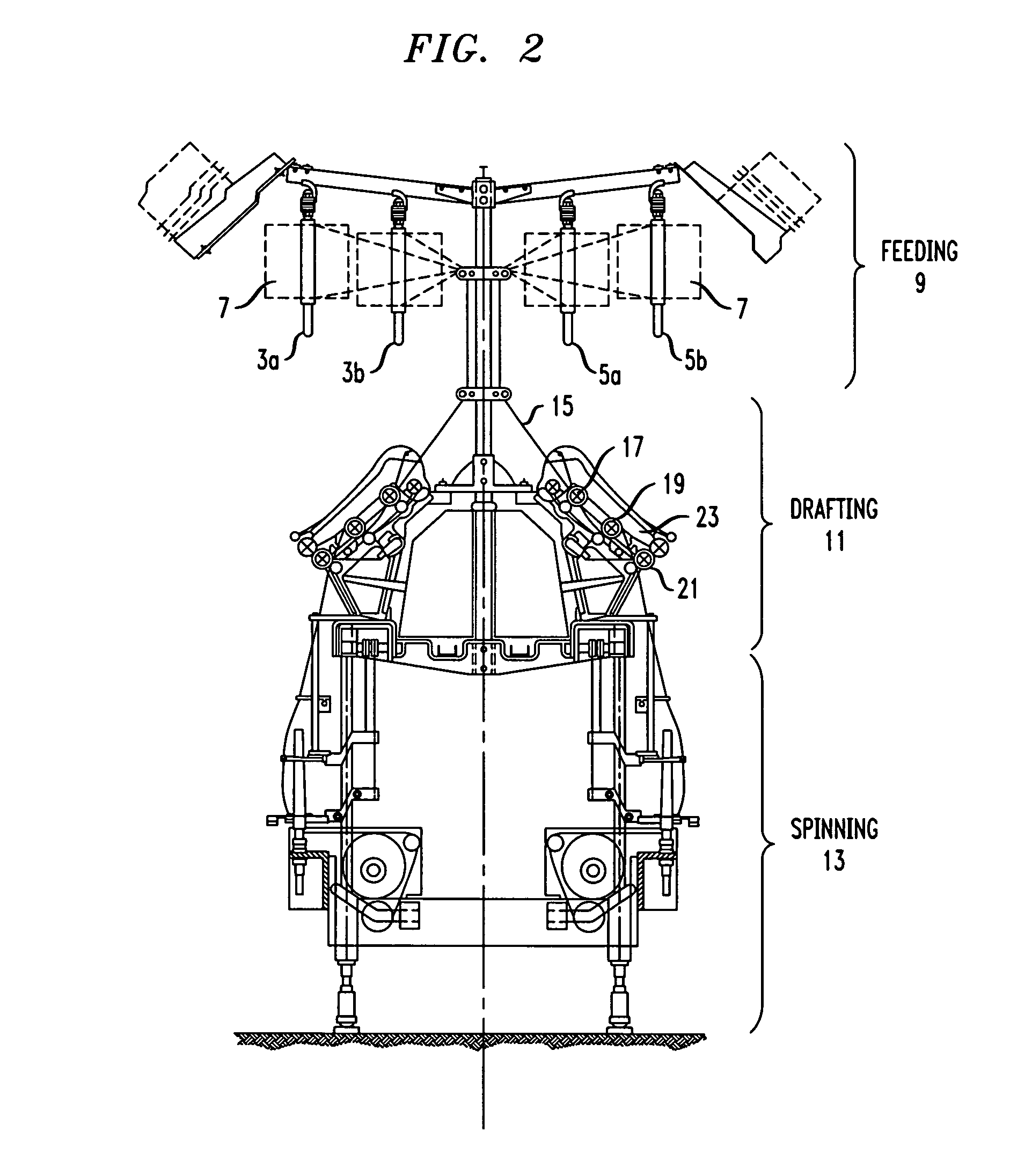

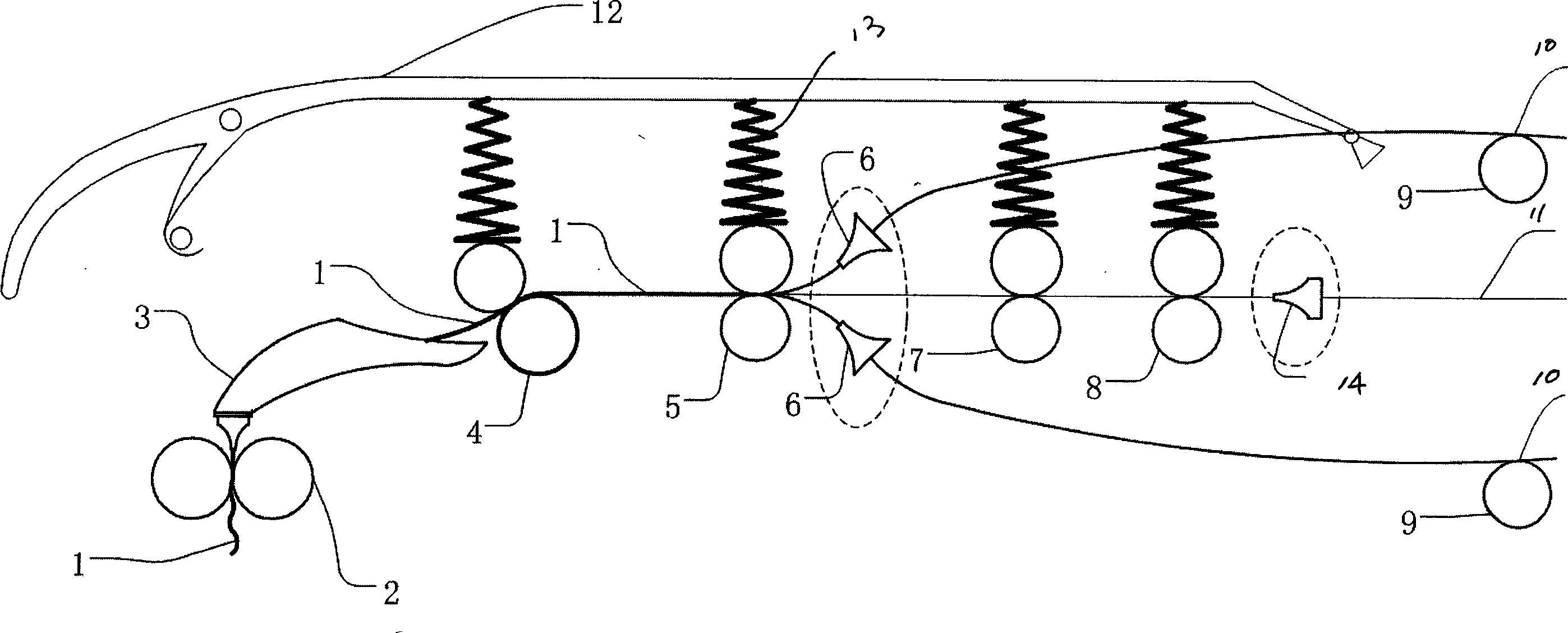

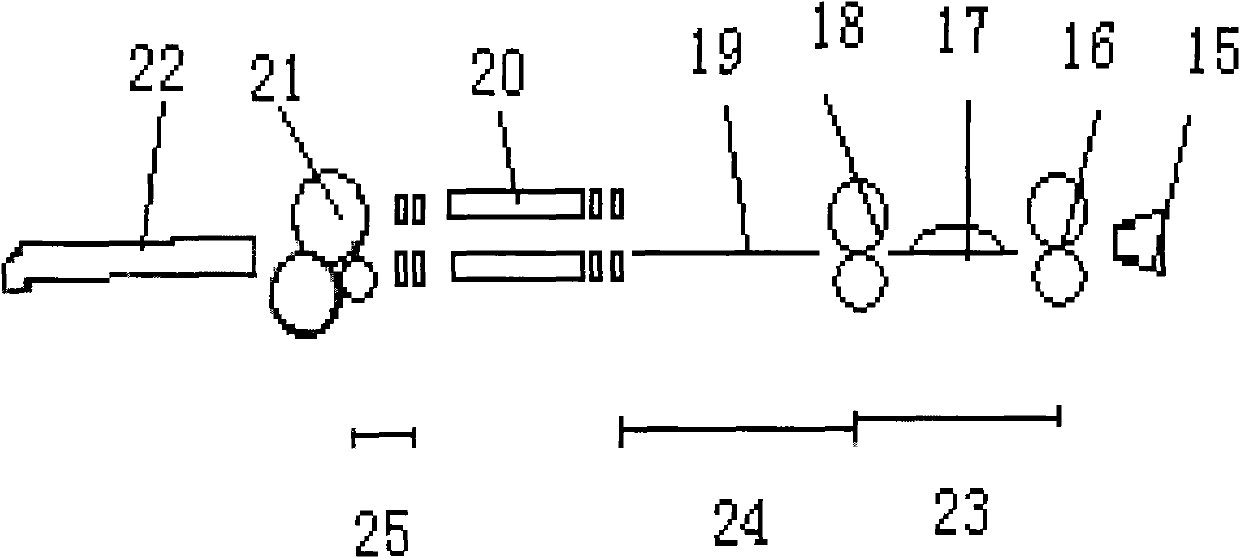

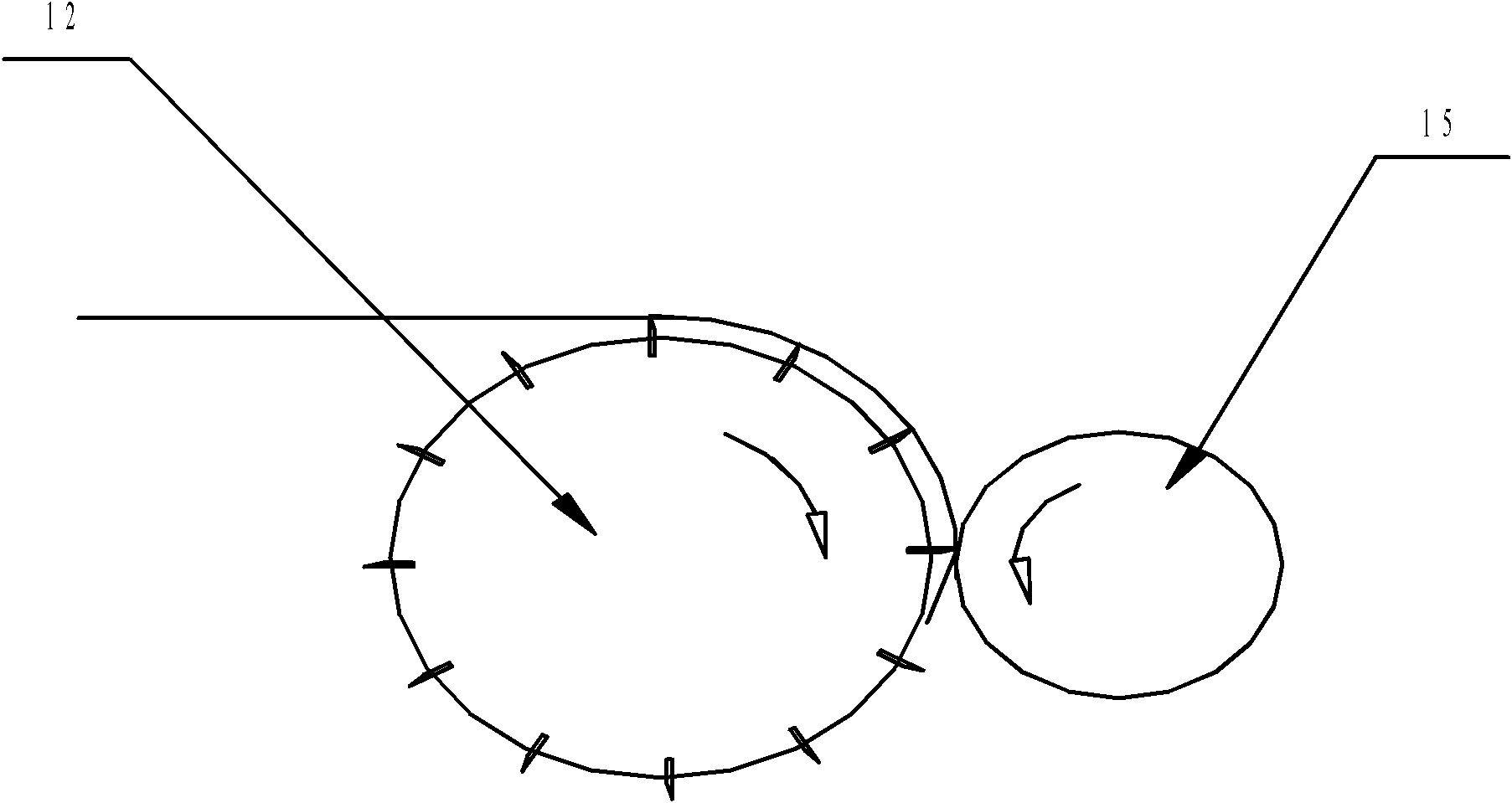

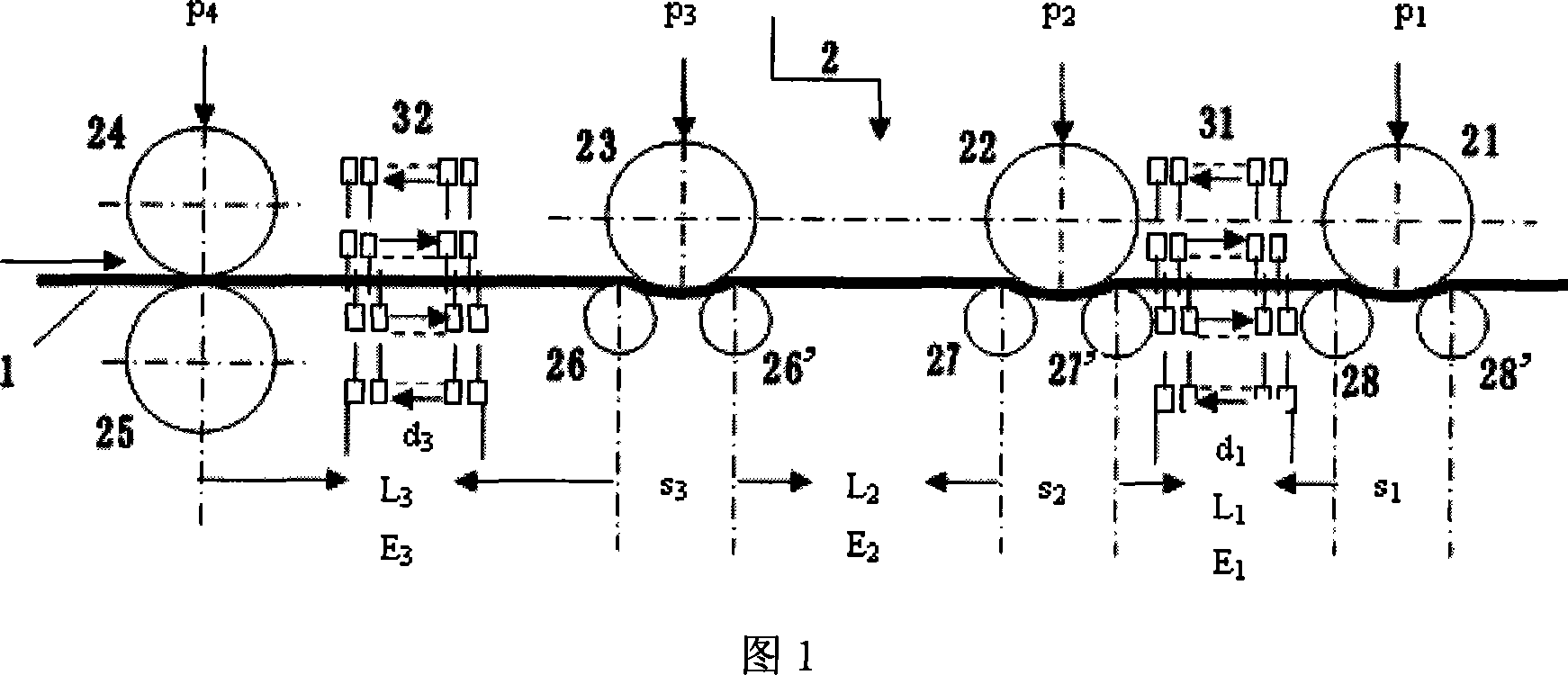

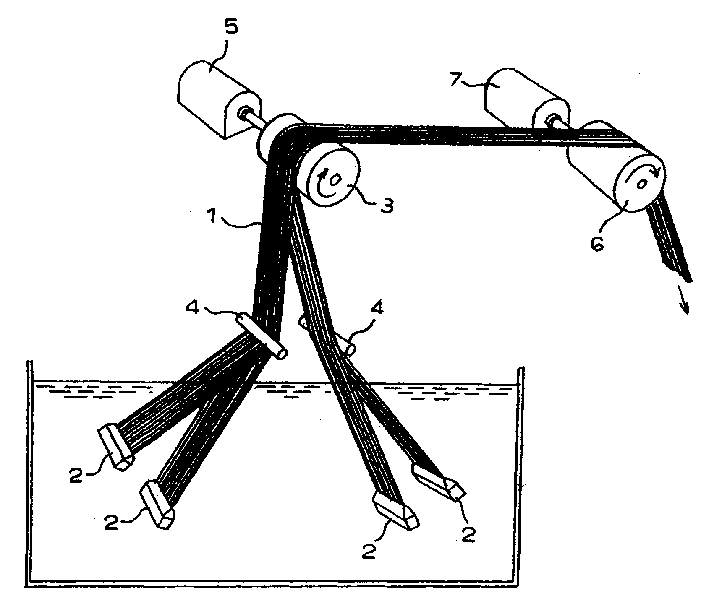

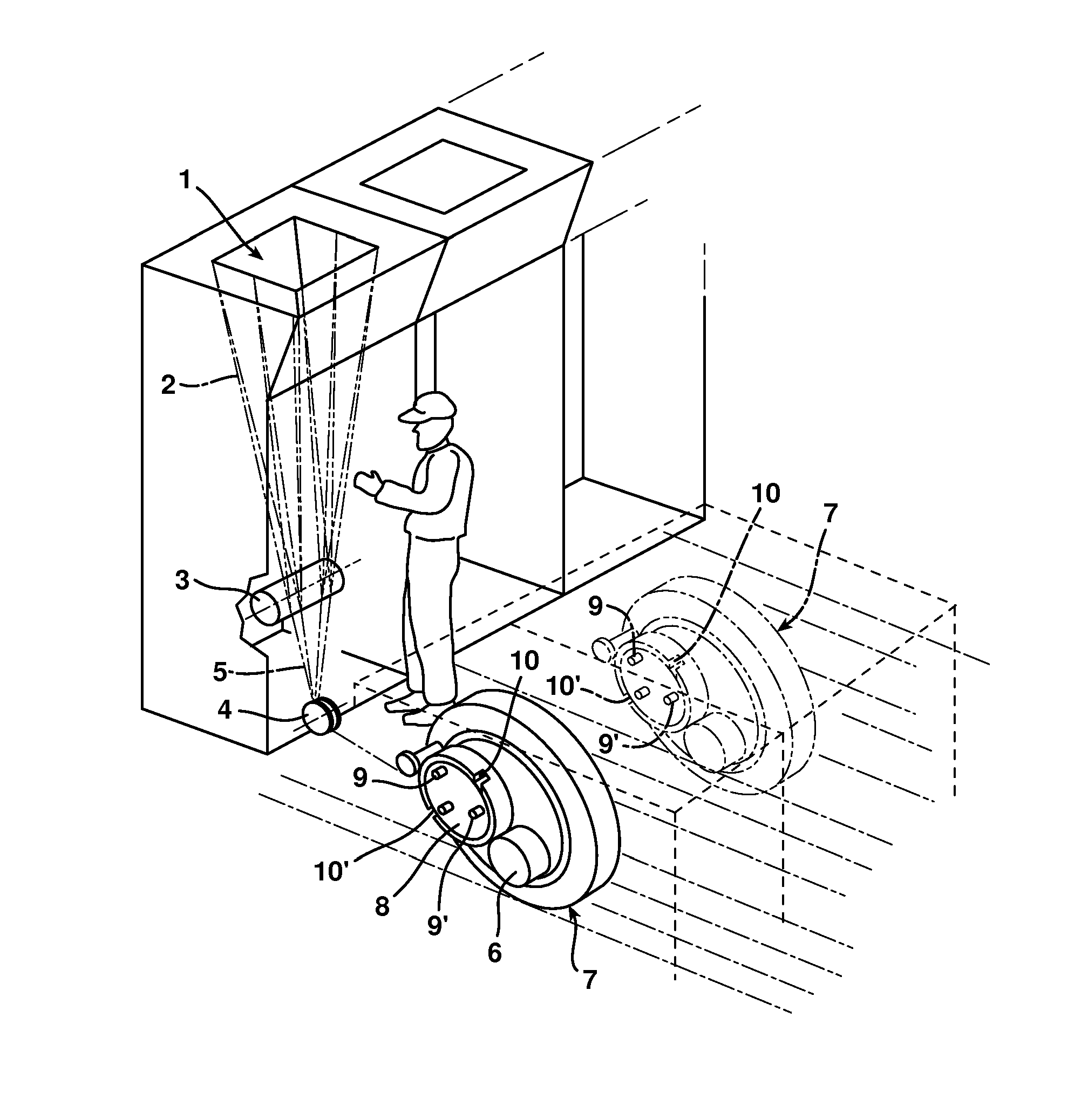

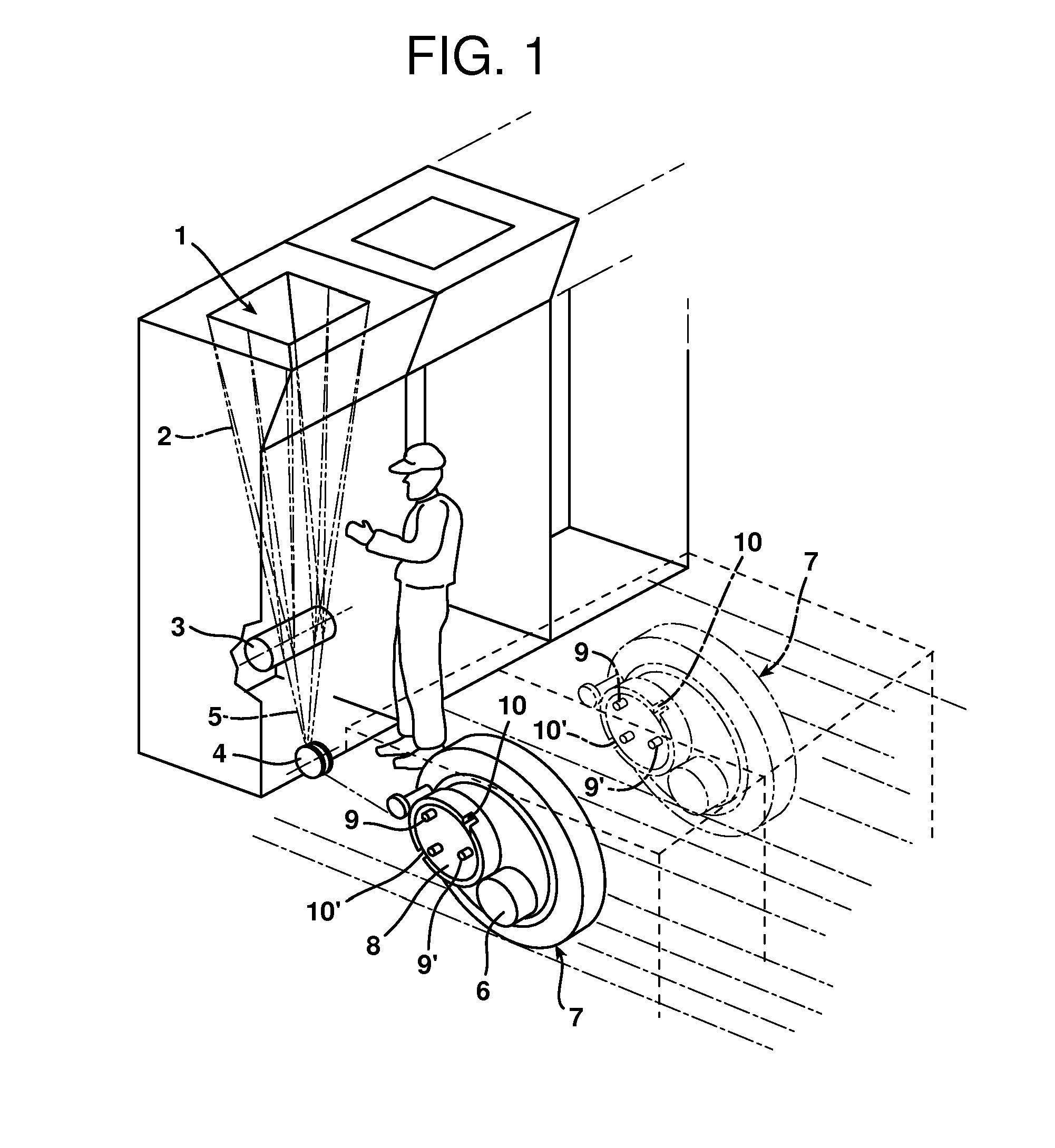

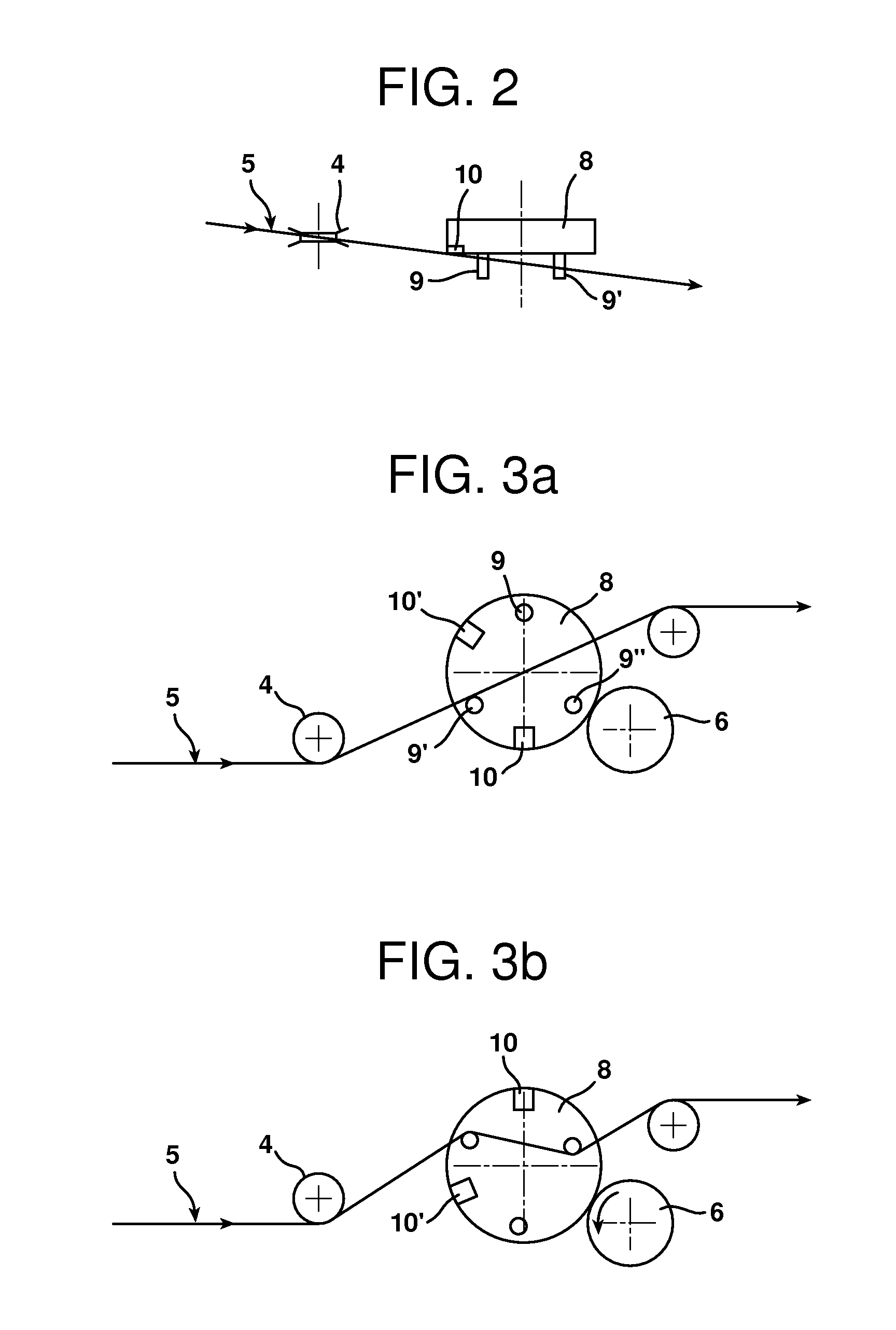

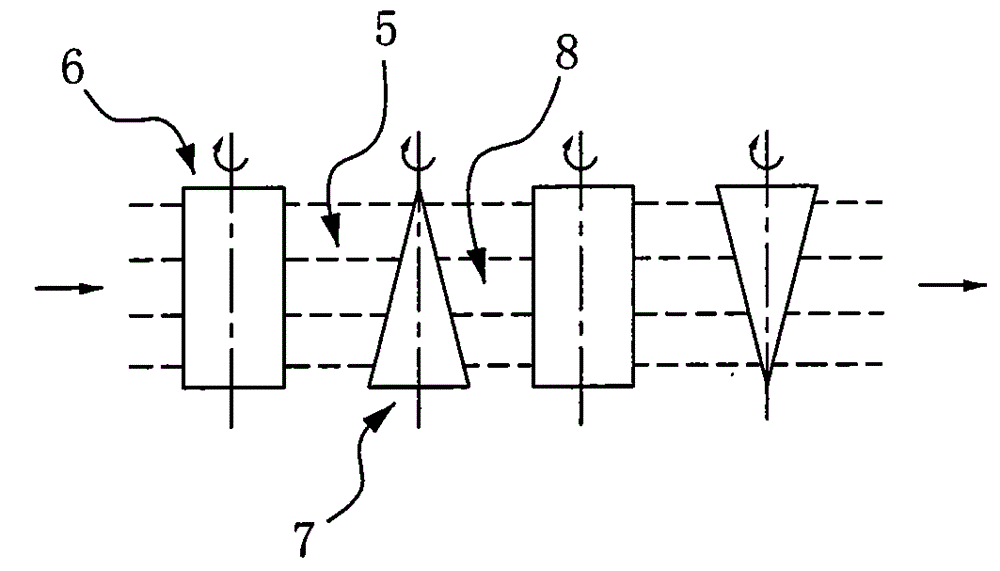

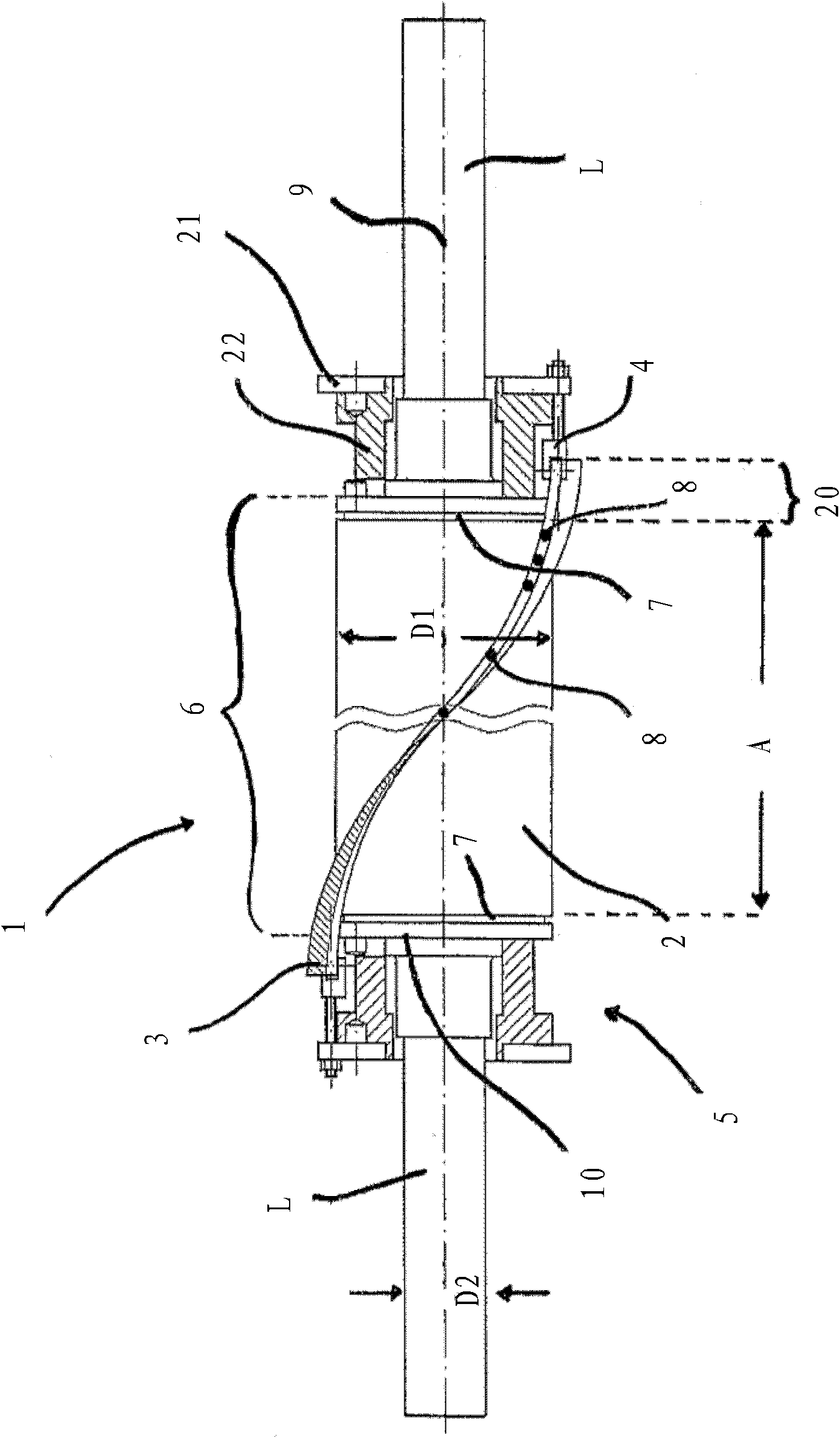

Double-needle plate roller hybrid type stretch breaking spinning device

InactiveCN101215740AGuaranteed to straightenReduce parallel wireDrafting machinesTows to slivers/yarnsHybrid typeFiber bundle

The invention relates to a double needle plate roller composite draft-cut spinning device, which comprises a roller type draft-cut device (2) and two needle plat devices (3) which are fixed on the rack, wherein the roller type draft-cut device (2) comprises three draft-cut areas which are formed by four rubber rollers and four pairs of rollers, and the needle plat devices (3) are respectively arranged on the first and the third draft-cur areas. The invention can distinctively reduce doubling, and guarantee that bend fiber bundles which are shorter than the first and the third draft-cut gauge can be straightened under the control of needle bar.

Owner:DONGHUA UNIV

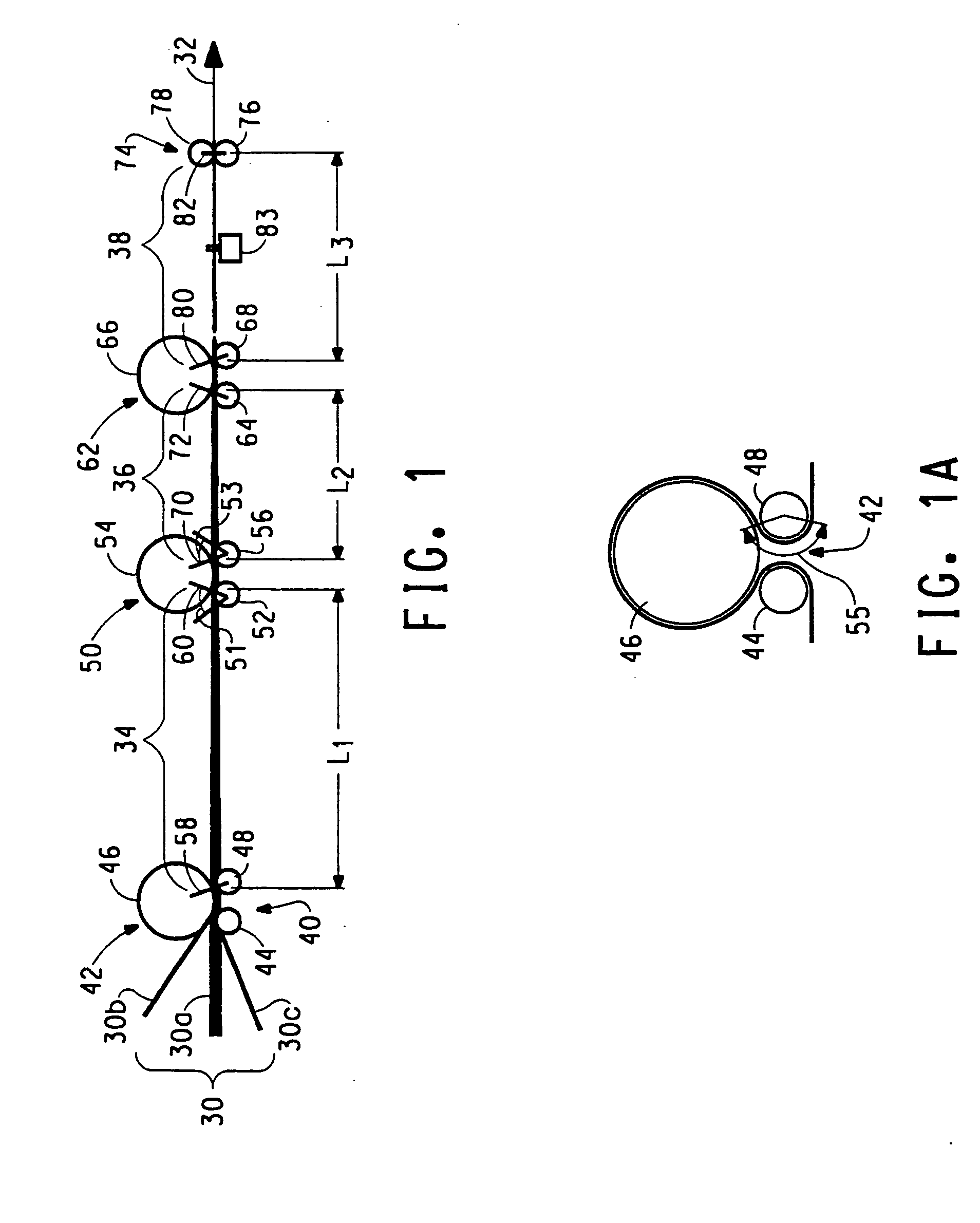

Stretch break method and product

InactiveUS7083853B2Minimize wrappingMinimize static buildupTows to slivers/yarnsMonocomponent synthetic polymer artificial filamentYarnProcess engineering

Owner:EI DU PONT DE NEMOURS & CO

Stretch break method and product

InactiveUS20050147815A1Minimize static buildupMinimize wrappingTows to slivers/yarnsNatural mineral layered productsYarnProcess engineering

Owner:EI DU PONT DE NEMOURS & CO

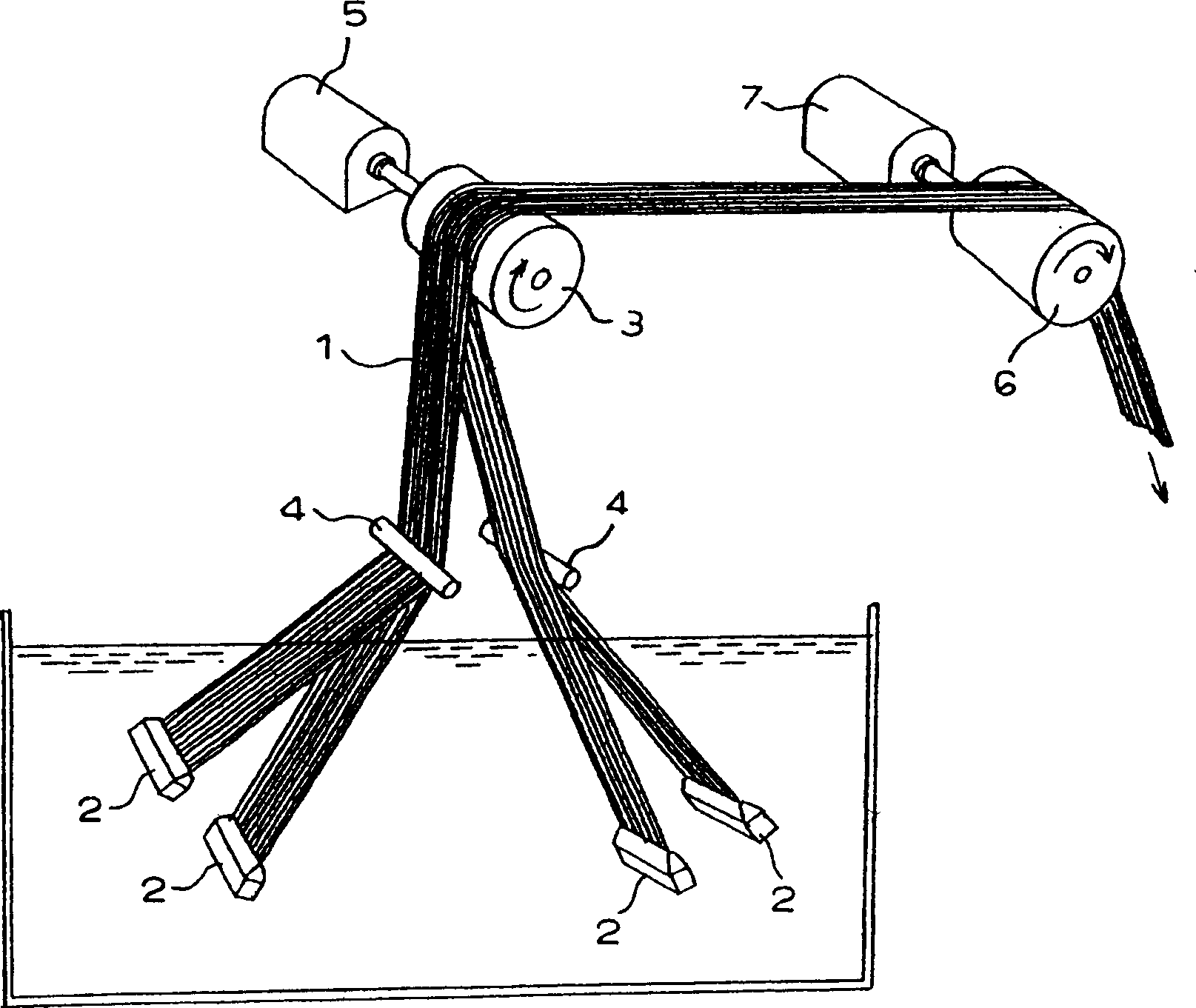

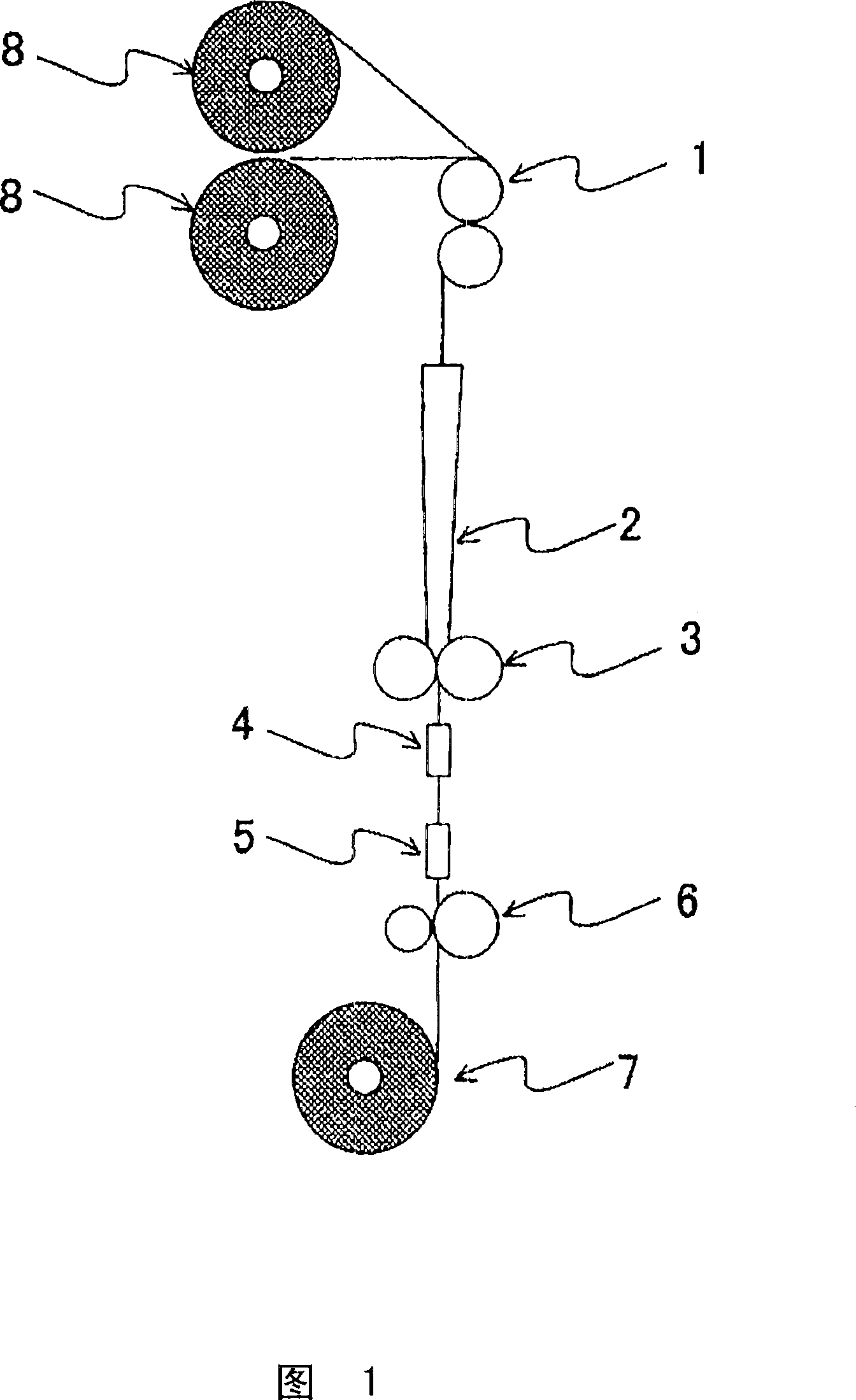

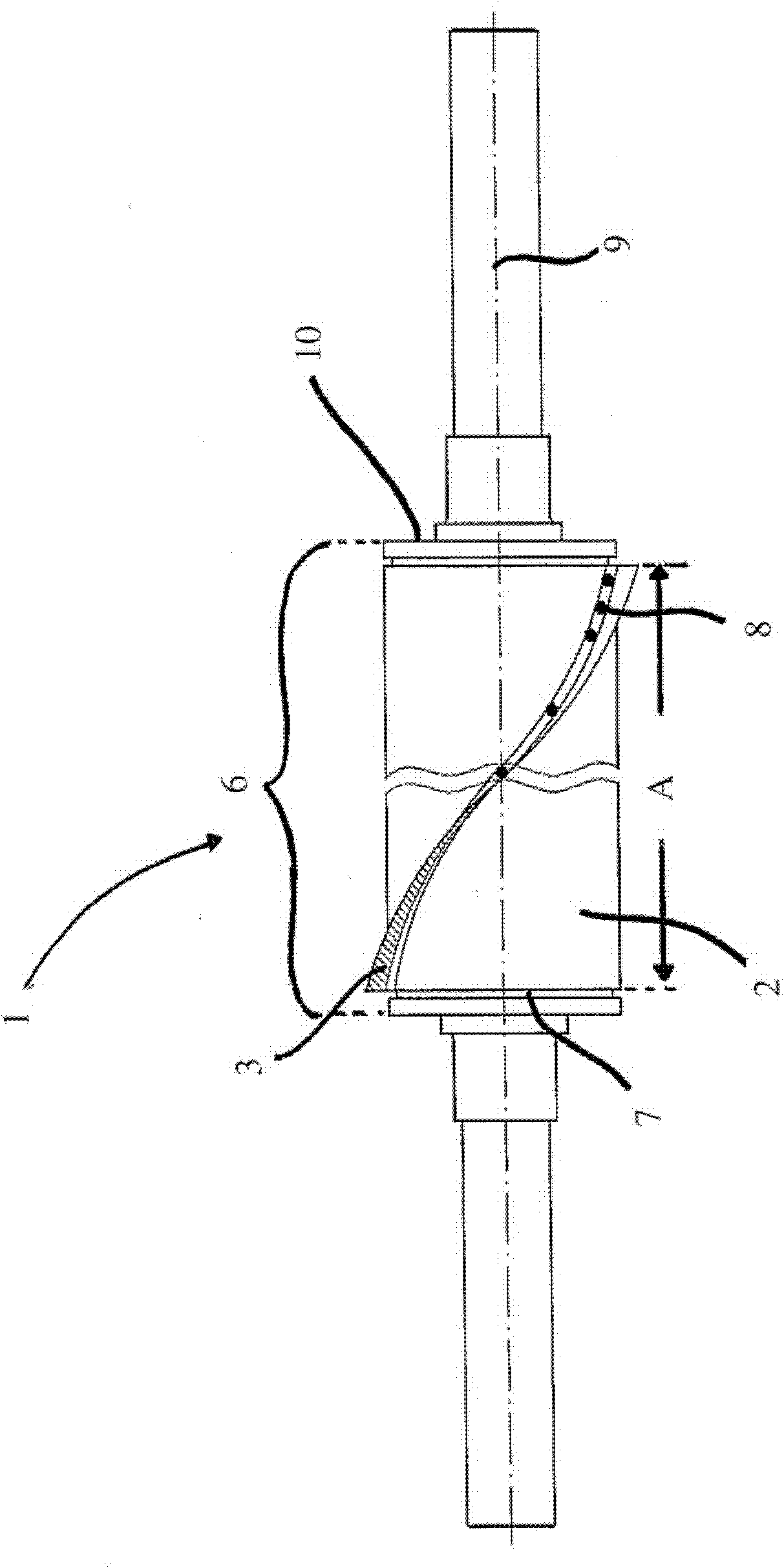

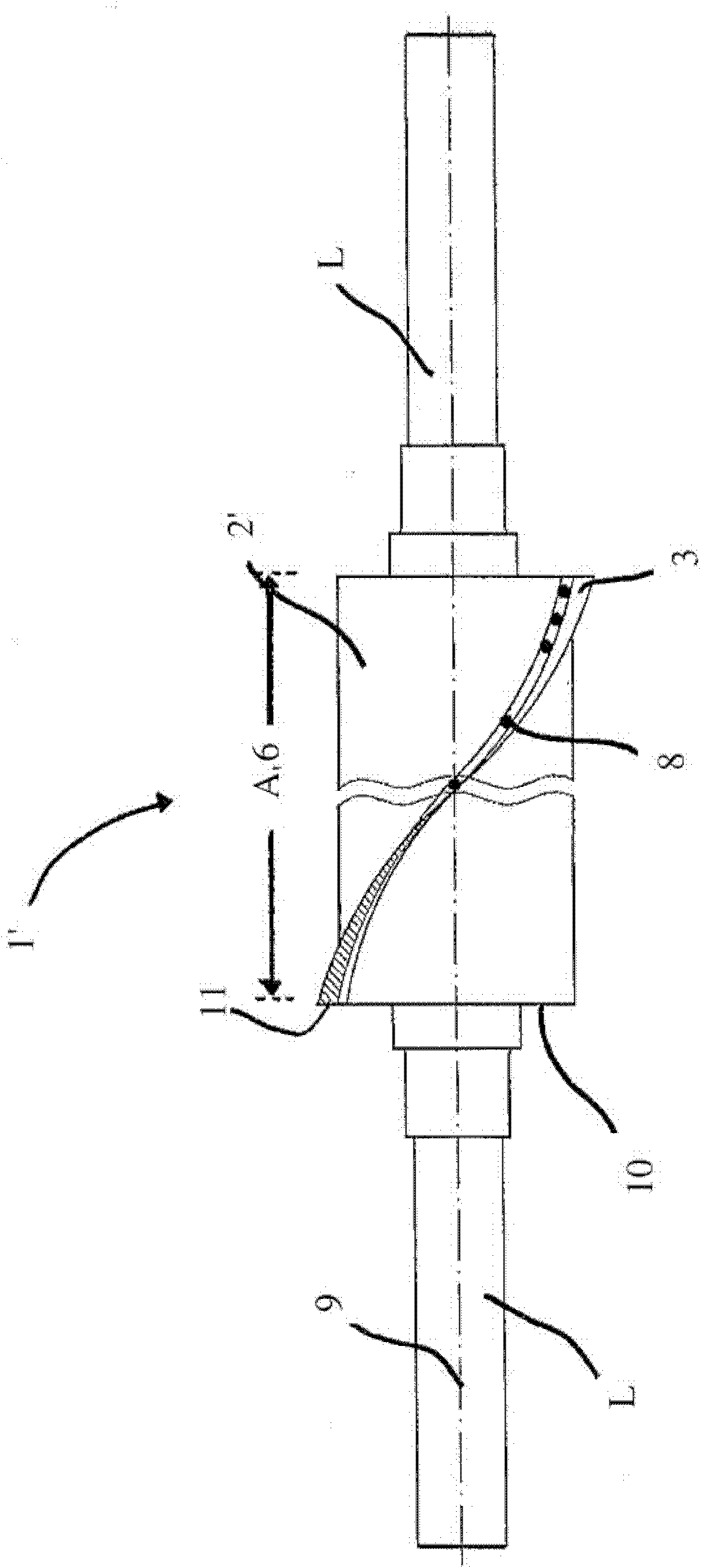

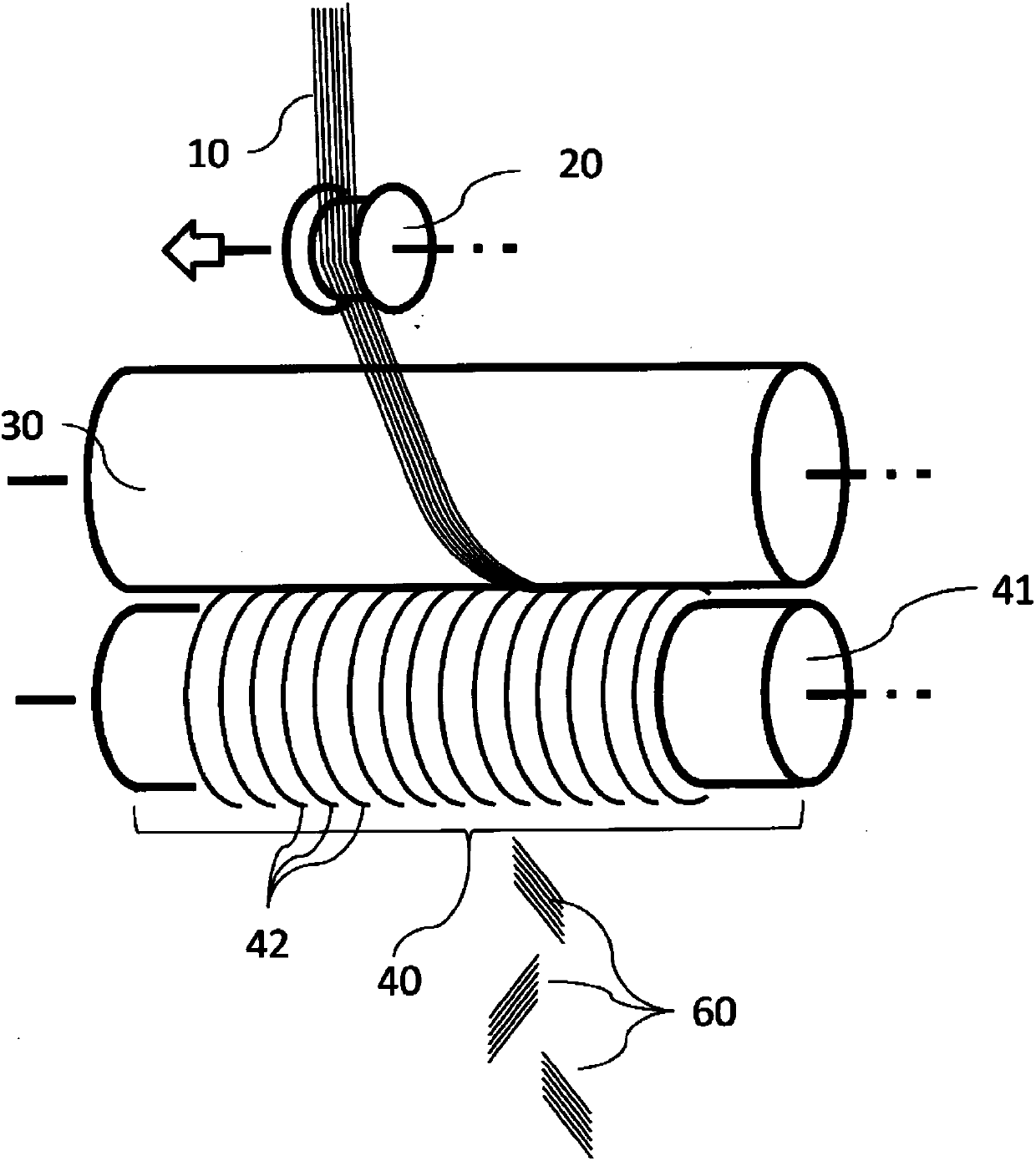

Fiber, method and apparatus for making said fiber

InactiveCN1455032ATows to slivers/yarnsMonocomponent synthetic polymer artificial filamentNarrow rangeFiber

The invention provides a fiber to form a sliver having a cut length distribution of a staple diagram falling within a narrow range and produced by the stretch breaking of the fiber with a tow converter, etc., under a specific extension of the fiber and provides an apparatus for producing the fiber and a production method of the fiber. Fibers extruded from a nozzle 2 are taken up with a take-up roll 6 while periodically varying the peripheral velocity of an inversion roll 3 placed between the nozzle 2 and the take-up roll 6 to form constricted parts along the fiber axis of the fiber 1 at nearly equal intervals. The interval of the constricted parts is set to the length nearly equal to the predetermined cut length or the length taking consideration of the elongation in the stretch breaking of the fiber.

Owner:MITSUBISHI CHEM CORP

High-strength yarn made through stretch breaking and process for producing the same

A spanized yarn constituted by a high strength short fiber containing at least one polymer selected from the group consisting of poly-p-phenylene terephthalamide, poly-p-phenylene benzoxazole, polyethylene, polyvinyl alcohol and wholly aromatic polyester and having a strength of 14 cN / dtex or more, and the high strength short fiber has an average single yarn length of from 50 to 90 cm and a coefficient of variation (CV) in average single yarn length of 50% or less.

Owner:TEIJIN TECHNO PRODUCTS LTD

Chopper and method of chopping unwound items

A method and apparatus for separating long, unwound items like fiber, fiber strands, yarn, etc. into short lengths is disclosed. The apparatus has a backup roll, a blade roll that uses novel dummy blade slot fillers between each pair of chopping blades on the blade roll to eliminate or substantially reduce vibration normally encountered when making longer chopped lengths of chopped product.

Owner:JOHNS MANVILLE CORP

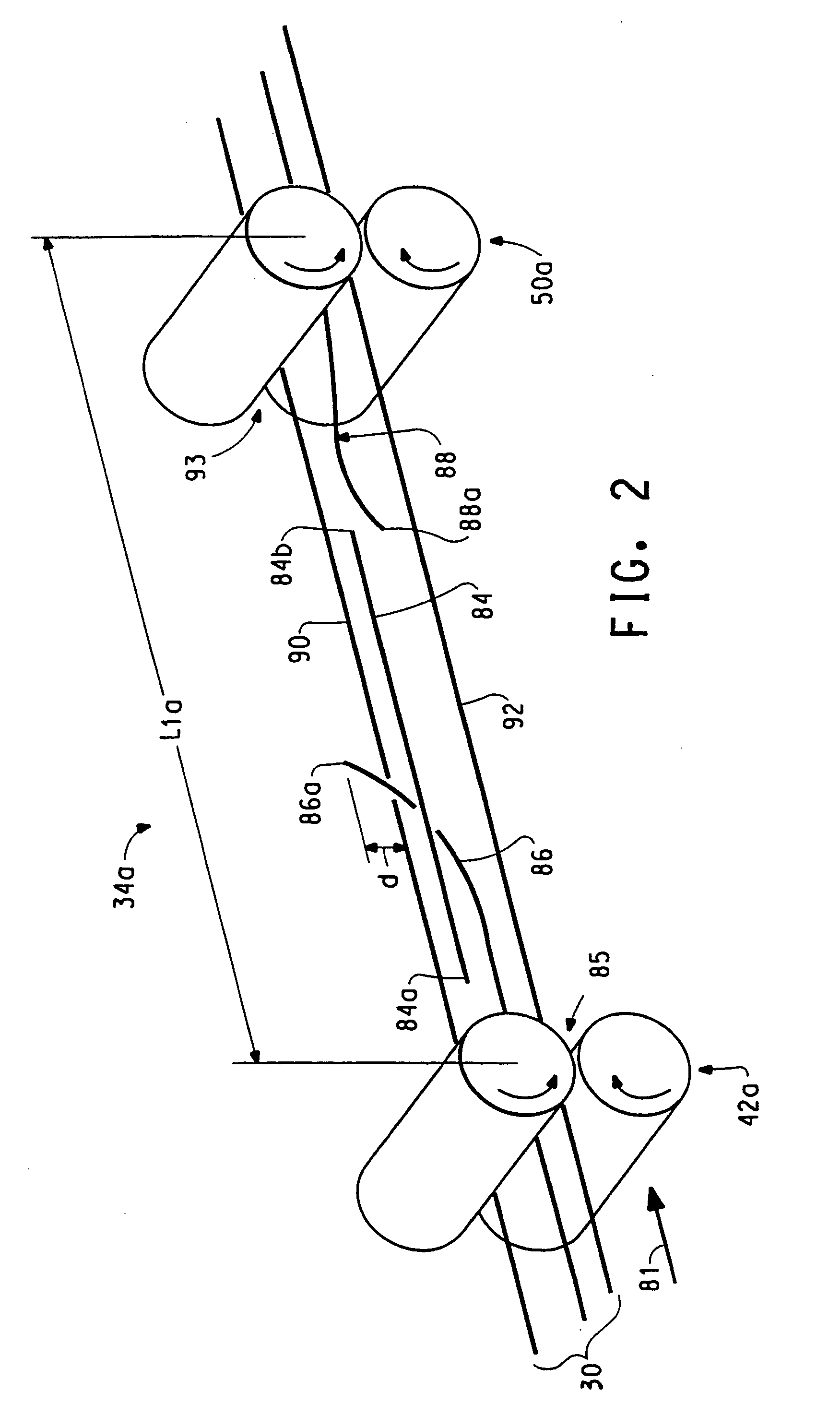

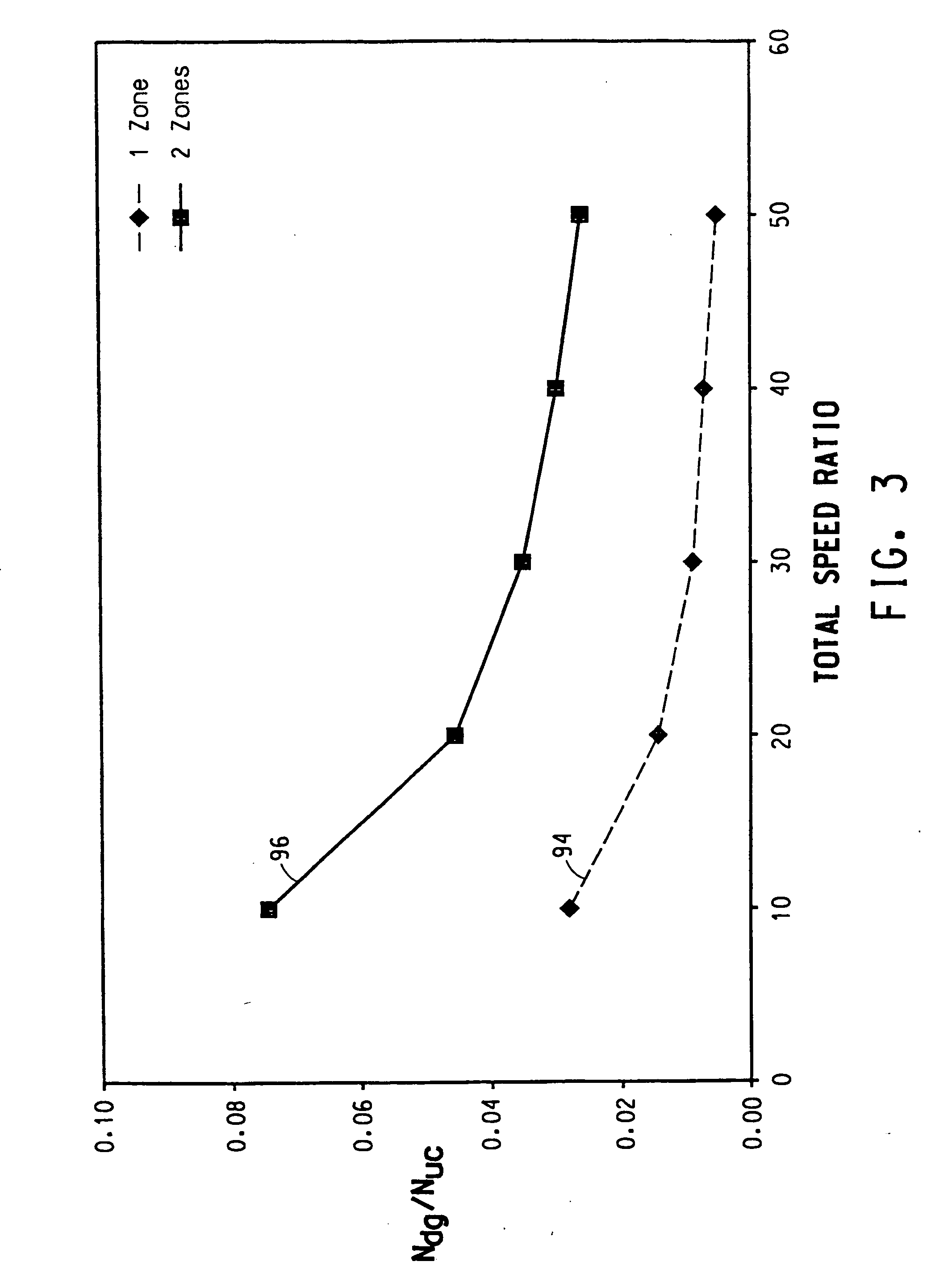

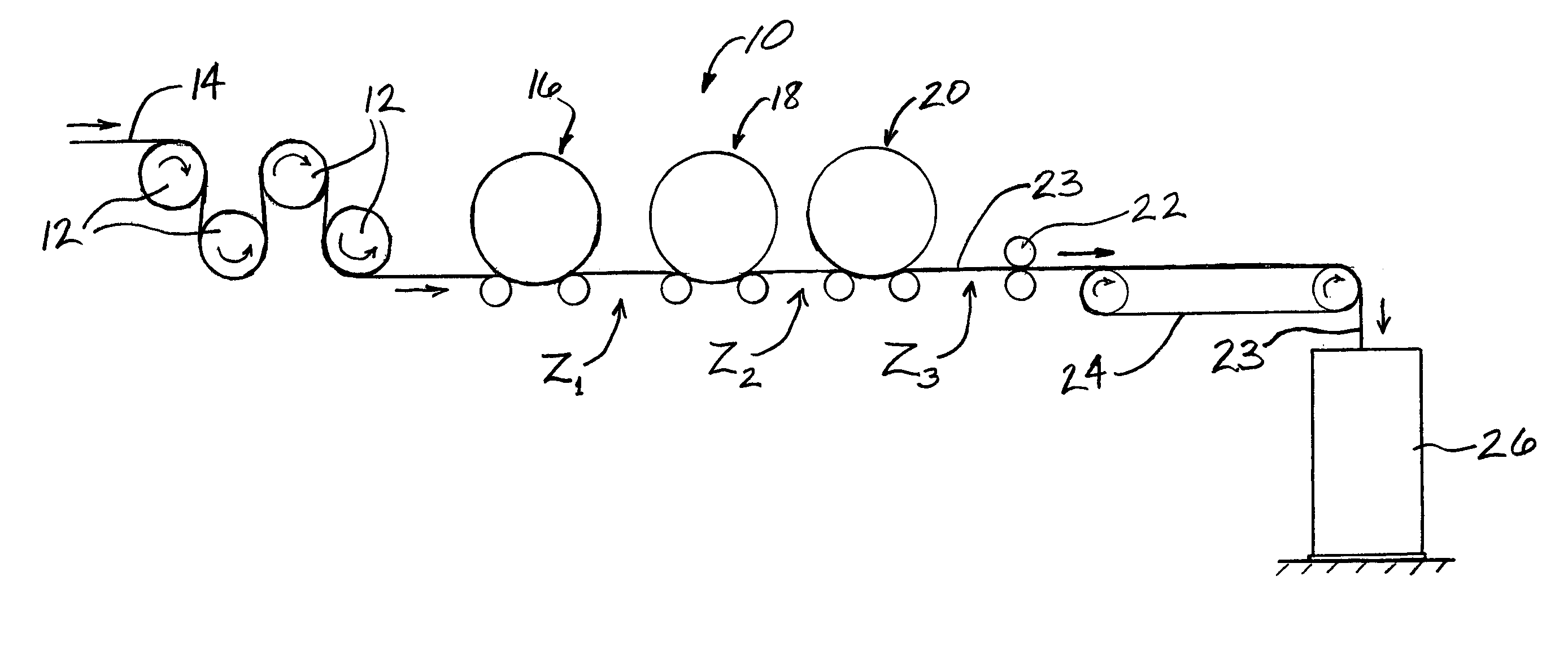

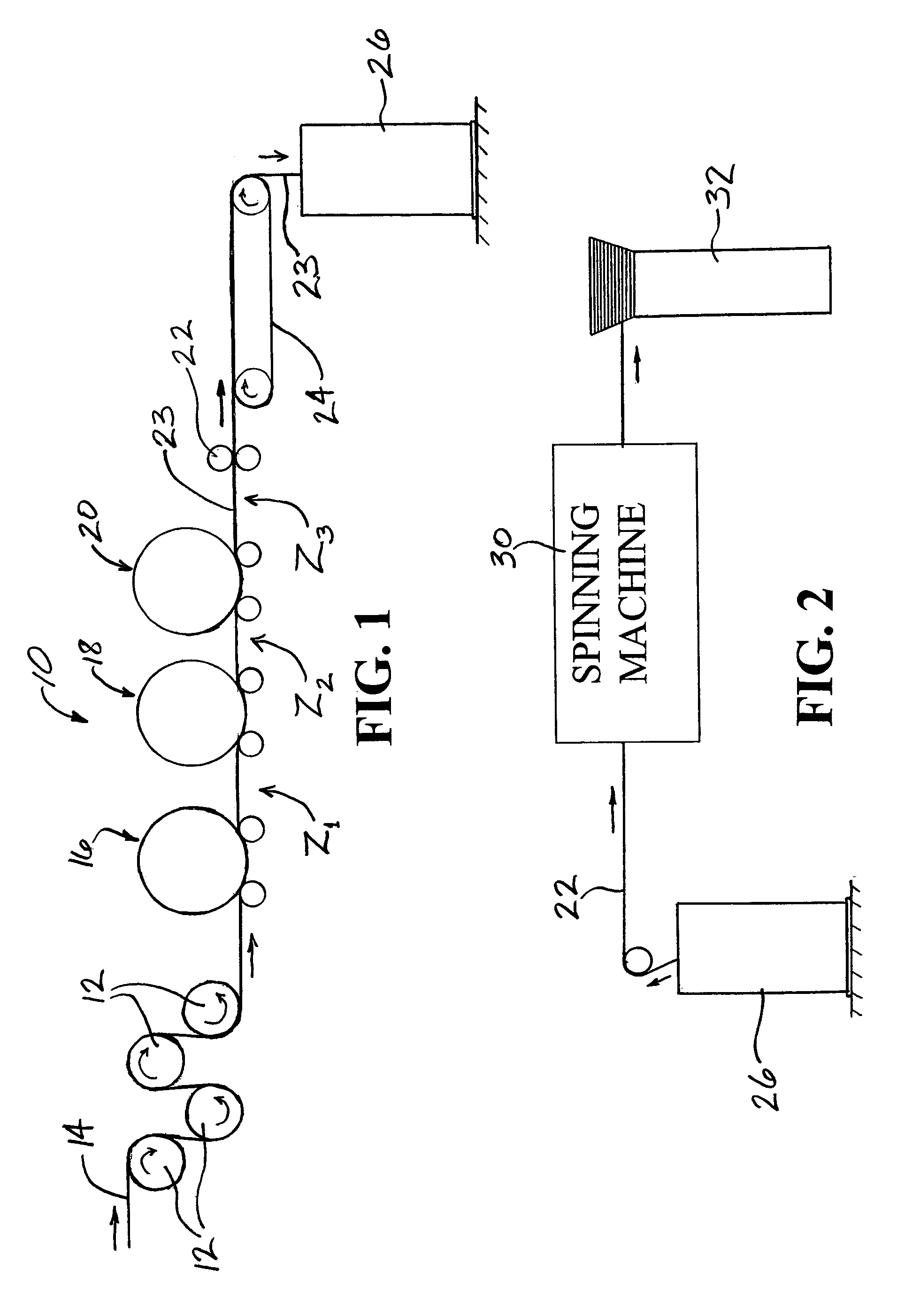

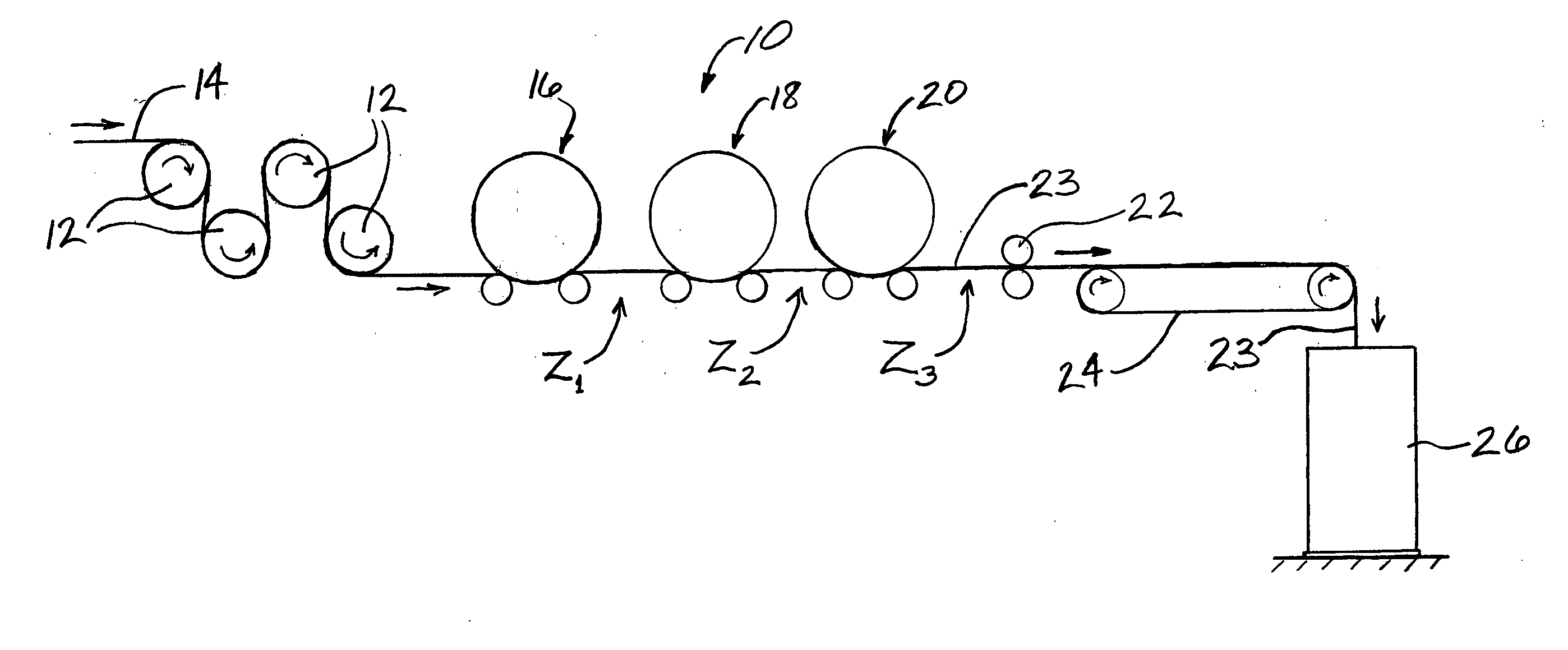

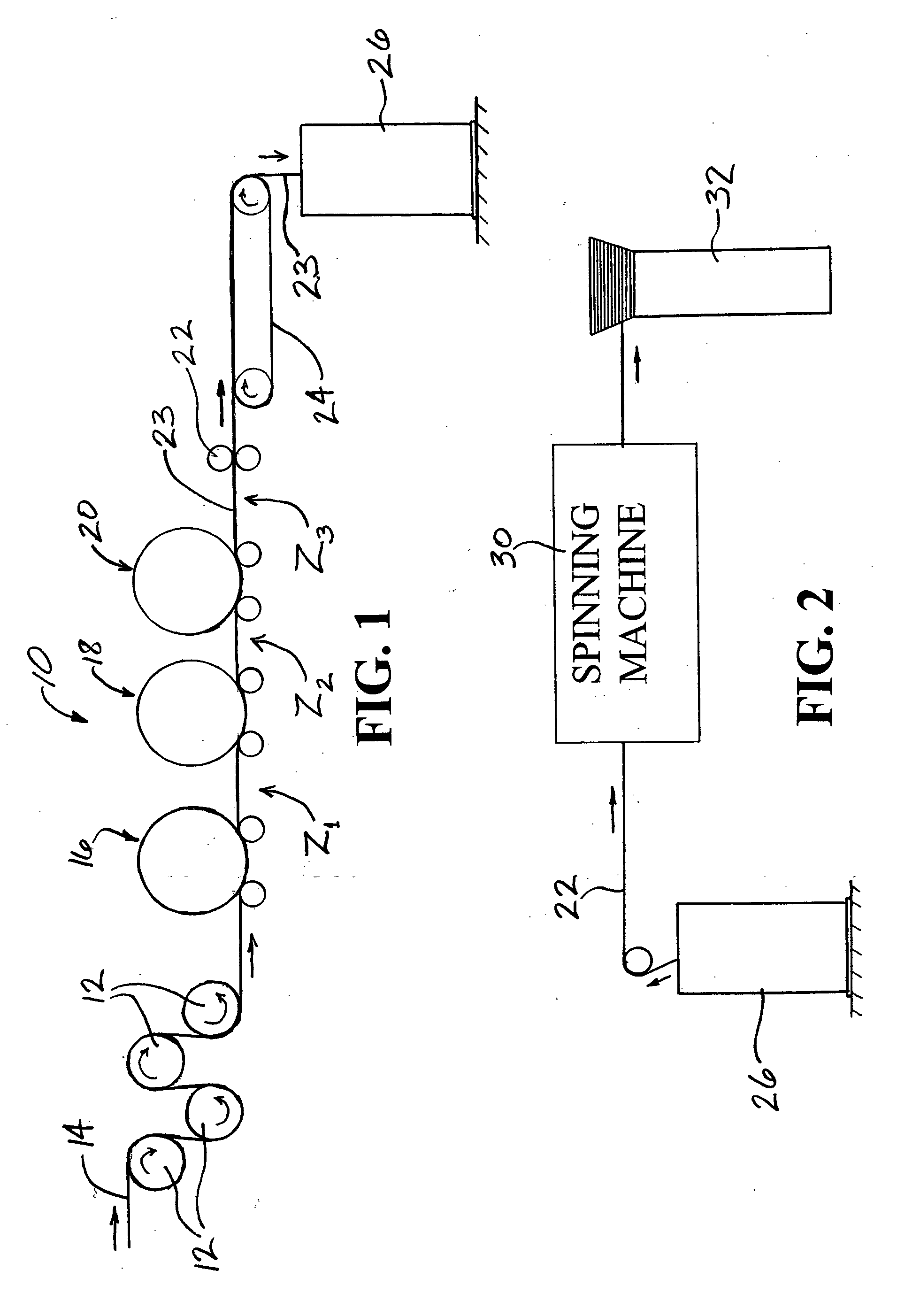

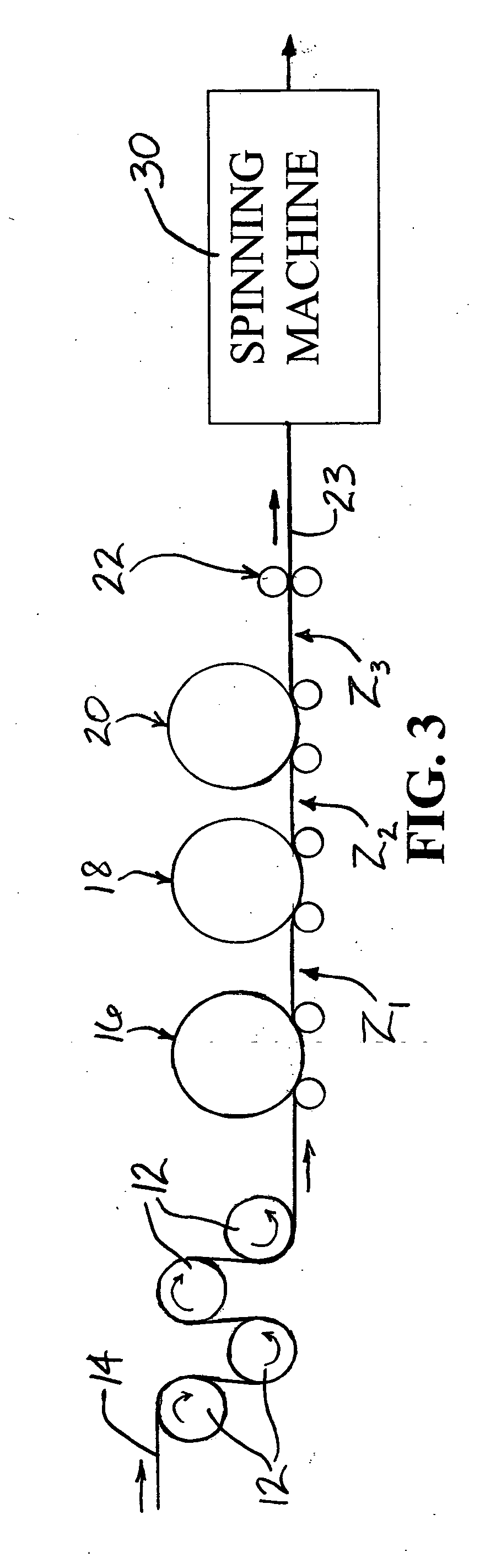

High-strength spun yarn produced from continuous high-modulus filaments, and process for making same

ActiveUS7188462B2Minimizing damageImprove throughputTows to slivers/yarnsYarnHigh intensityMaterials science

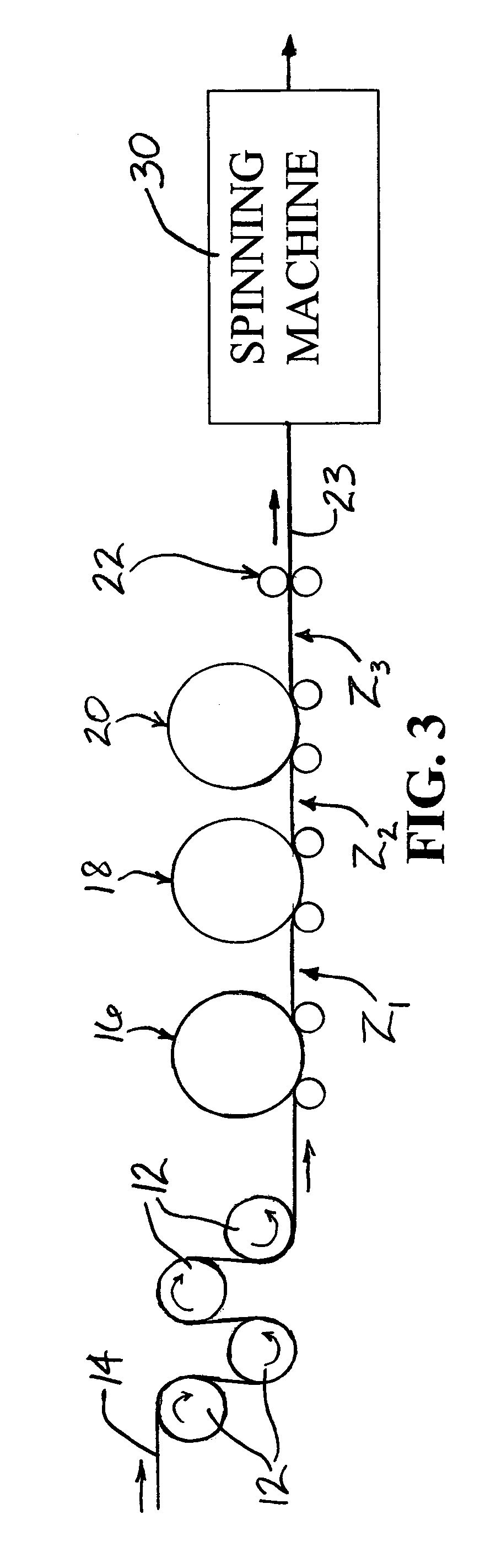

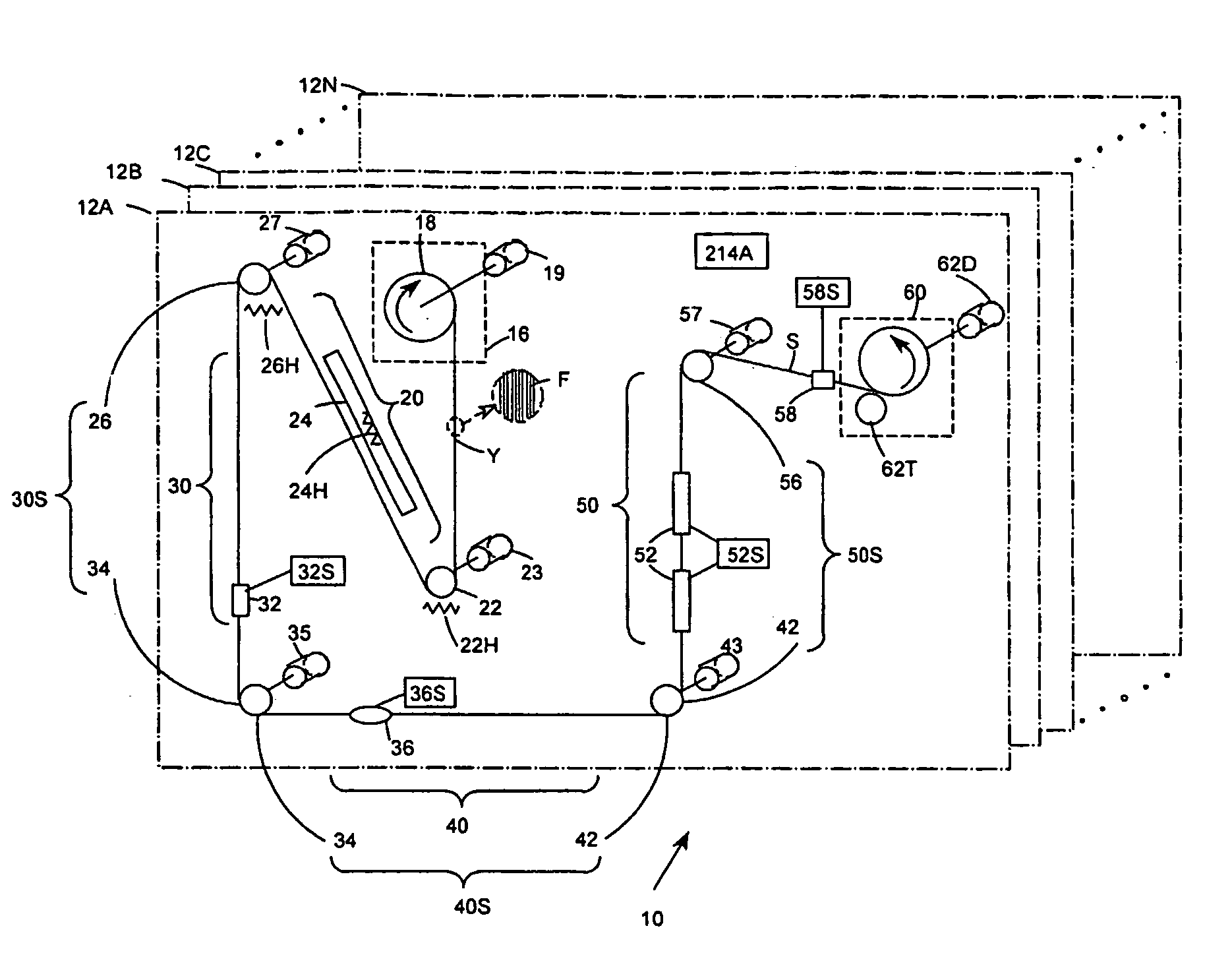

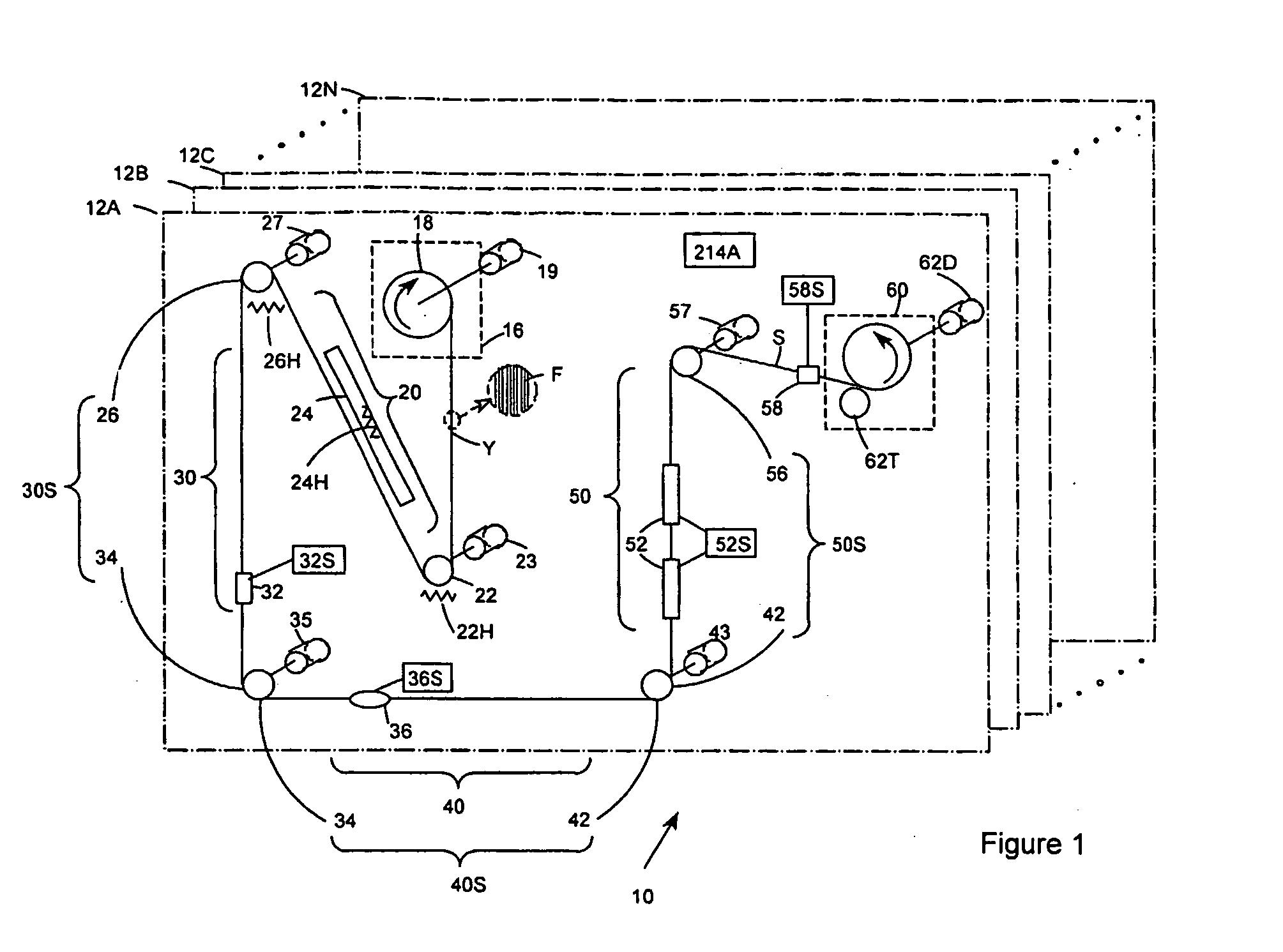

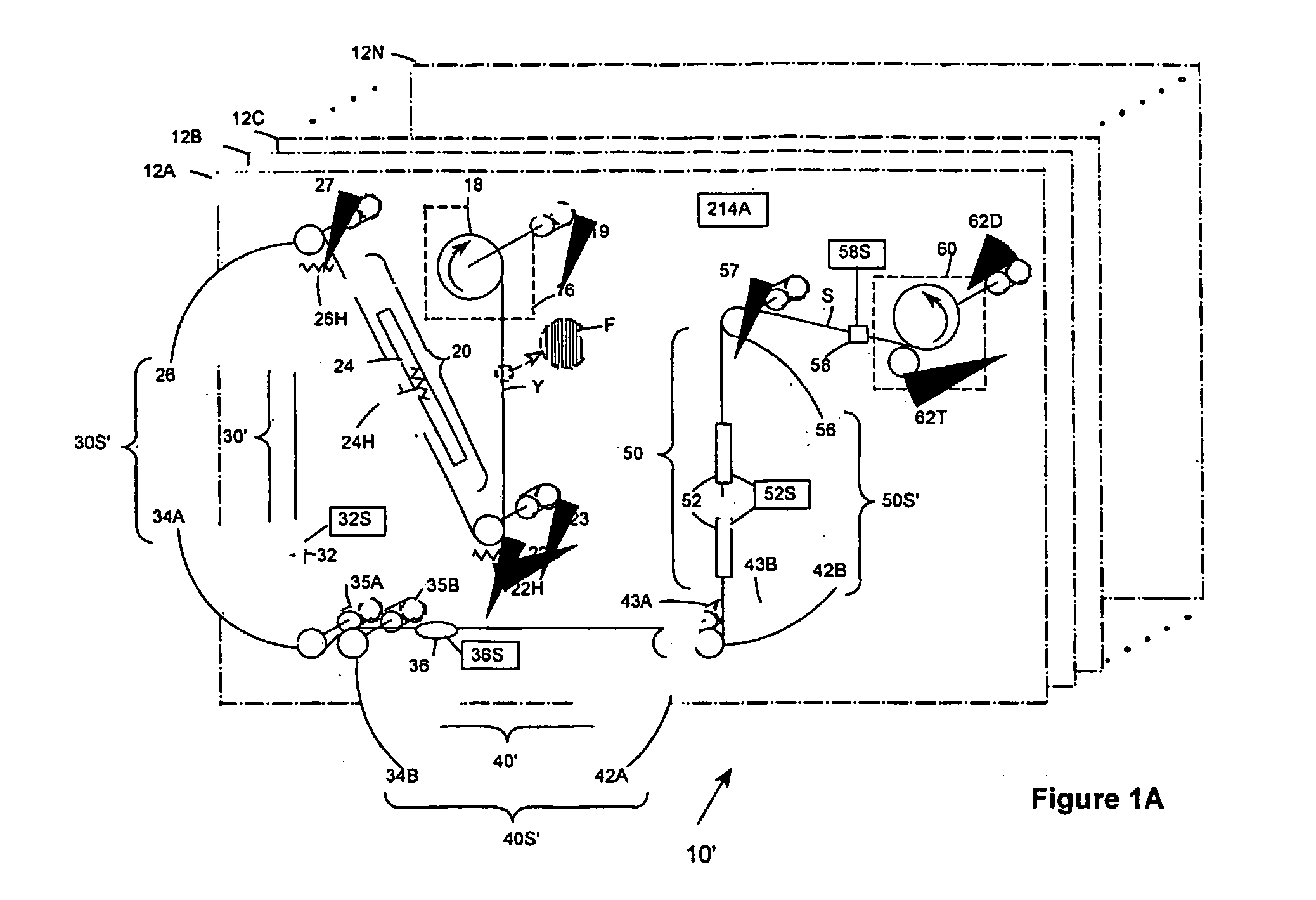

A process for making a high-strength spun yarn begins by feeding one or more tows of substantially uncrimped continuous filaments of high-modulus material having a tensile modulus exceeding about 20×106 psi through a high-speed stretch-breaking apparatus operating at low total draft ratio (preferably about 2.0) to break the filaments into high-modulus staple fibers having an average length in the range of about 5 to 6 inches. The tows advantageously are heavy, for example, having a denier of about 25,000 to about 500,000. Following the stretch-breaking step, the staple fibers are collected in sliver cans, and the staple fibers are advanced from the sliver cans to a spinning machine, where the fibers are spun into yarn. An important aspect of the invention is that no intermediate processes are performed between the stretch-breaking and spinning processes, which minimizes disruption of the alignment of and damage to the staple fibers.

Owner:STOWE PHARR MILLS

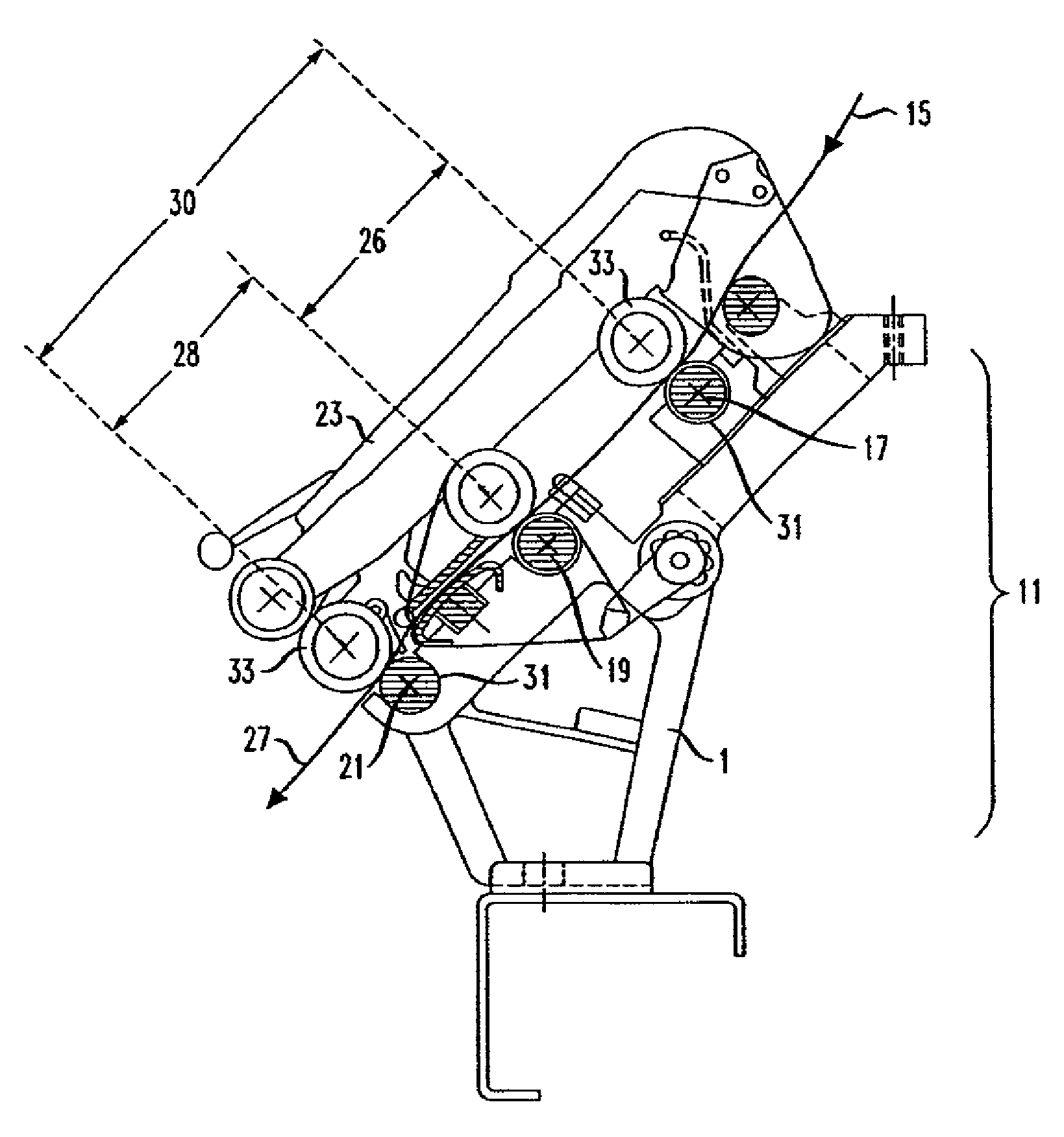

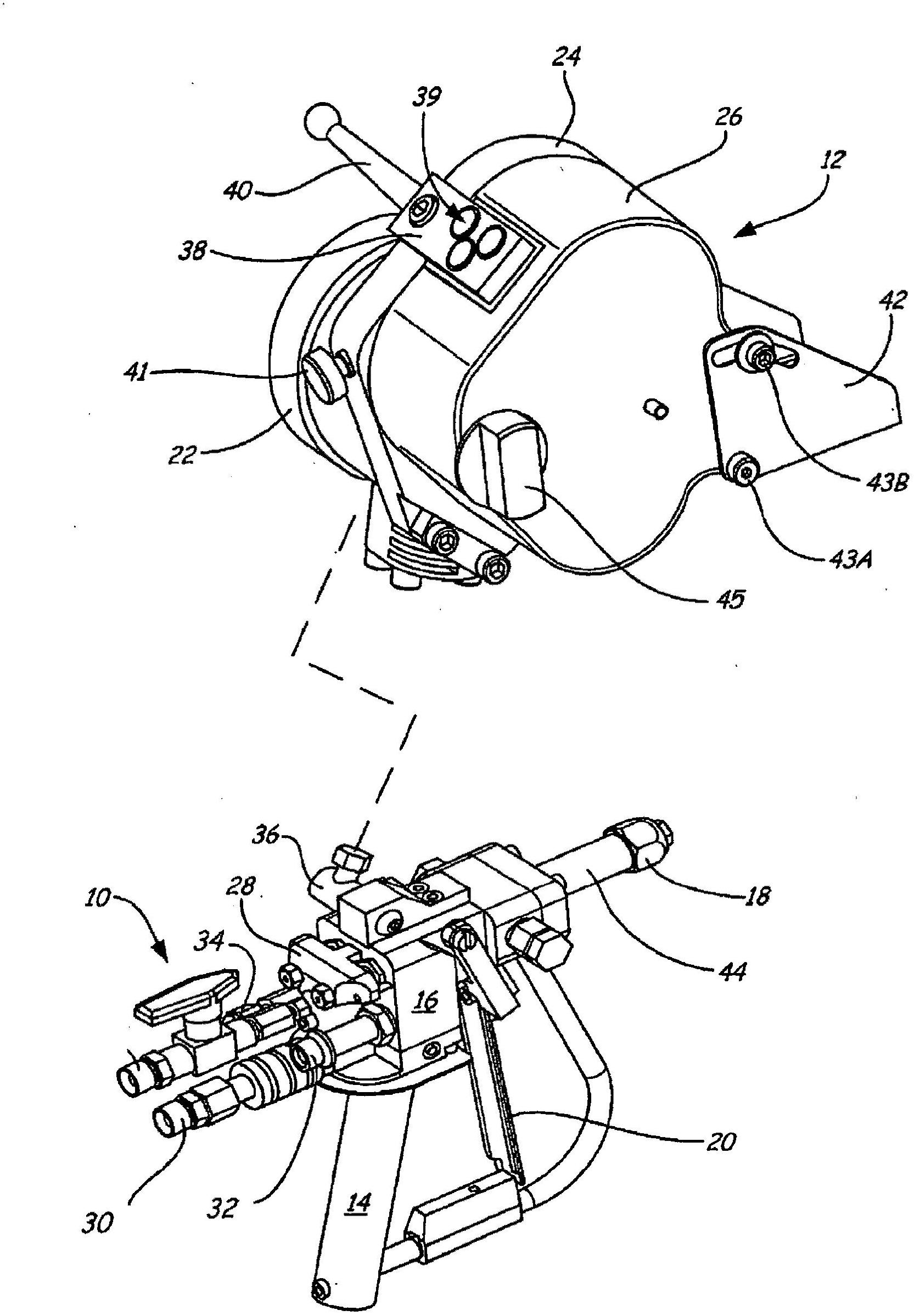

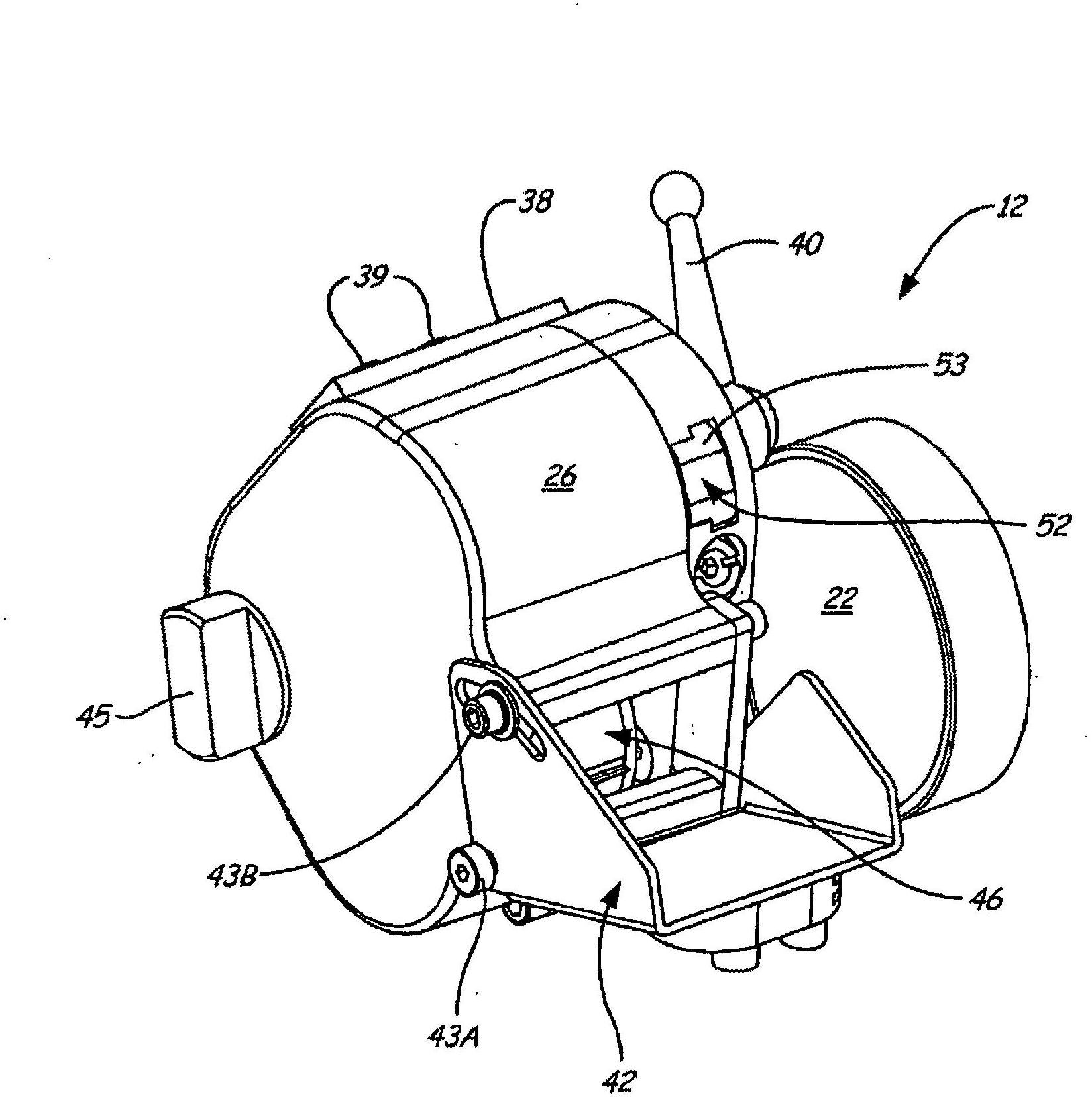

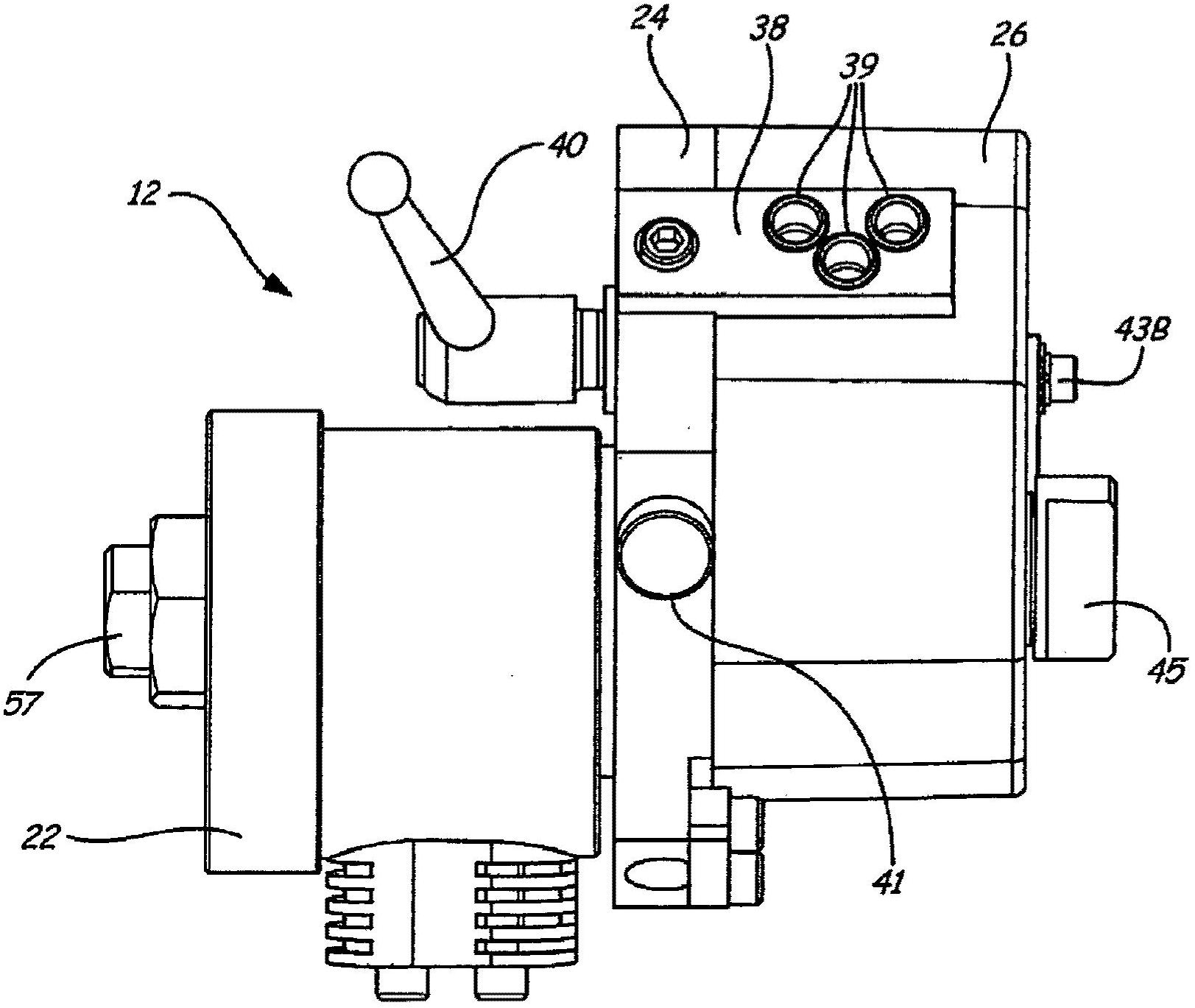

Method for control of yarn processing equipment

InactiveUS20060009873A1Completely processedMinimize breakageProgramme controlTows to slivers/yarnsYarnProcess engineering

A method for starting or stopping each of at least two separately controllable roll-sets (22, 26, 34, 56) used for processing a yarn (Y) in a stretch-break process, each roll-set comrpising at least two rolls, the method is characterized by the step of each roll-set, changing the speed of each roll from an initial condition to a steady state condition in accordance with a predetermined sequence and in coordination with a change in speed of at least one of the other rolls, such that simultaneous complete breakage of a yarn (Y) being processed in a stretch-break process is minimized.

Owner:EI DU PONT DE NEMOURS & CO

System for the manufactur of chopped strands made of thermoplastic material

InactiveUS20110008482A1Improve productivityLow production costMouldsConfectioneryPlastic materialsEngineering

A chopping machine chops strands of thermoplastic material coming from a single die into sections having a predetermined length. The machine has a substantially cylindrical chopping wheel provided on its periphery with a number of uniformly distributed blades oriented about an axis of rotation. An anvil wheel wrapped in a plastic material is located adjacent the chopping wheel. The anvil wheel has a device for routing strands between the wheels, thereby drawing out and chopping the strands into sections. The device has two or more pins that project laterally from a face of the anvil wheel. The pins may be movable with respect to the face. A restart process using the chopping machine is also provided.

Owner:OCV INTELLECTUAL CAPITAL LLC

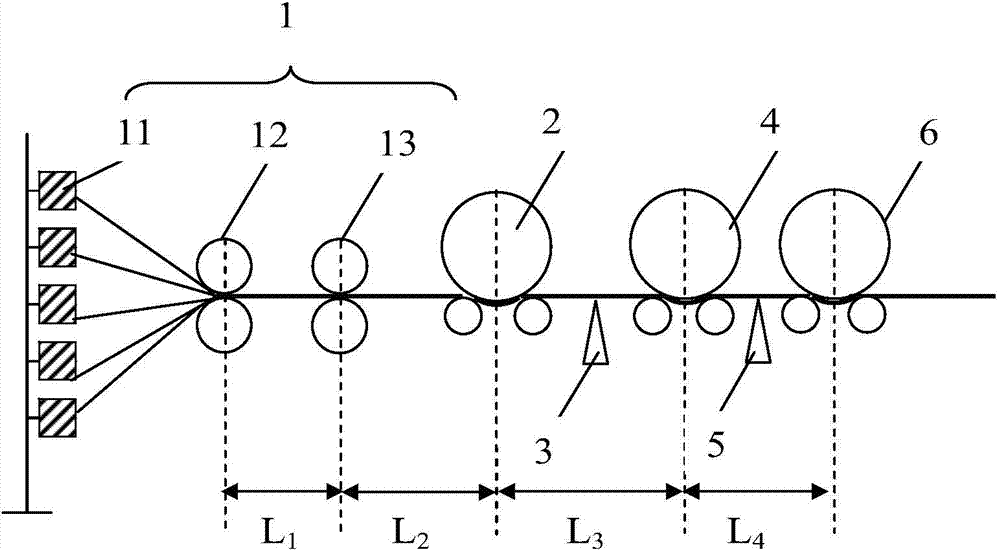

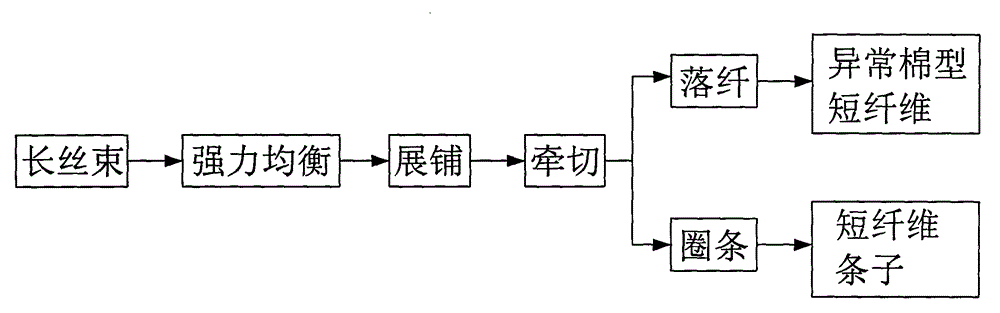

Cotton type fiber stretch-breaking strip making method

The invention discloses a cotton type fiber stretch-breaking strip making method, which comprises the following steps that (1) tows requiring stretch-breaking strip making are prepared; (2) stretch-breaking strip making treatment is carried out: 1) the tows led out from a tow box are fed into a stretch-breaking device provided with four stretching regions and four groups of stretch-breaking rollers, and first-time stretch-breaking processing is firstly carried out through a first stretch-breaking region; 2) the tows subjected to the first-time stretch-breaking processing enter a second stretching region for second stretch-breaking processing; 3) the tows subjected to the second stretch-breaking processing enter a third stretching region for third stretch-breaking processing; 4) the tows subjected to the third stretch-breaking processing enter a fourth stretching region for fourth stretch-breaking processing; (3) coiling processing is carried out. The method has the advantages that cotton type short fiber strips can be directly manufactured, and the severe carding effect of a cotton carding machine can be avoided, and the cotton type short fiber strips can be directly mixed with other fiber strips in the drawing work procedure.

Owner:湖北立天生物工程有限公司

Low-strength fiber stretch-breaking and slivering device

The invention discloses a low-strength fiber stretch-breaking and slivering device. The low-strength fiber stretch-breaking and slivering device comprises a stretch-breaking device which is composed of multiple sets of stretch-breaking roller set and provided with a feeding end and a discharging end, a stretch-breaking area is formed between each set of the stretch-breaking roller set, each set of the stretch-breaking roller set is composed of a pair of stretching rollers and a pair of stretch-breaking rollers which are meshed with each other respectively, a stretch-breaking transition area is formed by the stretching roller and the stretch-breaking roller which are located between adjacent stretch-breaking roller sets, the stretching roller and the stretch-breaking roller are both composed of two roller bodies, and the size of the horizontal distance between the stretching roller and the stretch-breaking roller in the axial direction of the roller body in each stretch-breaking area is changeable. Through arranging tapered or trapezoid structure, the tractive force of the stretch-breaking areas is greatly reduced, the diameters of the stretch-breaking rollers are decreased, the distance of the stretch-breaking areas formed by the stretch-breaking roller sets is shortened, the distance between the stretching roller and the stretch-breaking roller can be set to be small enough, stretch-breaking can be conducted on short fiber with smaller cotton fiber level, and the production efficiency is greatly improved. The low-strength fiber stretch-breaking and slivering device has the advantages that the structure is simple and compact, the occupied area is small, the cost is low, and popularization and application are applicable.

Owner:QINGDAO UNIV

Processing line of bast fiber

ActiveUS8650717B2Easy to collectEasy to processContinuous processingFibre cleaning/openingCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

High-strength spun yarn produced from continuous high-modulus filaments, and process for making same

A process for making a high-strength spun yarn begins by feeding one or more tows of substantially uncrimped continuous filaments of high-modulus material having a tensile modulus exceeding about 20×106 psi through a high-speed stretch-breaking apparatus operating at low total draft ratio (preferably about 2.0) to break the filaments into high-modulus staple fibers having an average length in the range of about 5 to 6 inches. The tows advantageously are heavy, for example, having a denier of about 25,000 to about 500,000. Following the stretch-breaking step, the staple fibers are collected in sliver cans, and the staple fibers are advanced from the sliver cans to a spinning machine, where the fibers are spun into yarn. An important aspect of the invention is that no intermediate processes are performed between the stretch-breaking and spinning processes, which minimizes disruption of the alignment of and damage to the staple fibers.

Owner:STOWE PHARR MILLS

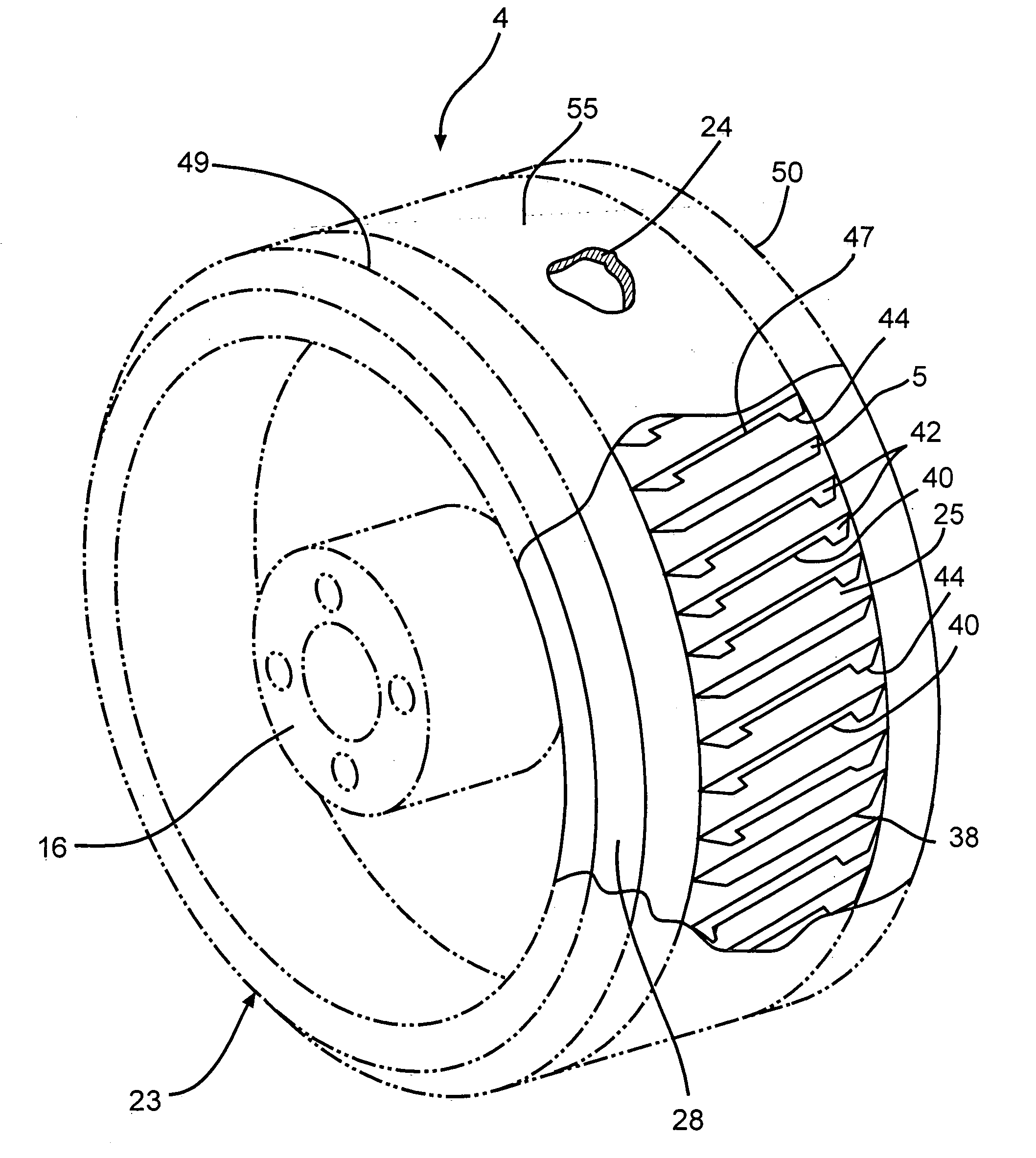

Method for assembling a blade to a cylinder body, blade, cylinder body and cutting device

InactiveCN102644192AEffective frictionLow costSevering textilesTows to slivers/yarnsEngineeringMechanical engineering

The invention relates to a method for assembling a helix blade on the outer surface of a cylinder body. The method comprises the following steps of making a blade having a base and a cutting edge equipped angularly relative to the base and having a blade turning back to the base equipped on the outer surface of the cylinder body through the base; and tightening the blade along the longitudinal axis of the cylinder body through at least one traction member. The traction member is respectively connected with the blade inside a tightening section in a force transmission manner. Therefore, not only the at least one traction member but also the blade ends without the traction member are respectively supported on an anchoring point. The at least traction member exerts force on one end of the blade along the helix direction. Then the blade makes the base contact face pressed and abut on the outer surface of the cylinder body. The blade is then fixed on the cylinder body through screws penetrating the base. According to the invention, the end sections (20) with traction members (4) are all cut from the blade (3); and at leat one cut end section (20) and related traction members (4) are removed.

Owner:好使有限责任公司和两合公司

Preparation method of polylactic acid staple fibers

PendingCN109234820AEasy to control the lengthImprove performanceSpinning solution de-aeratingFilament forming substance formingFiberYarn

The invention provides a preparation method of polylactic acid staple fibers. The method adopts fiber-grade polylactic acid (PLA) as a raw material, and the polylactic acid (PLA) staple fibers are prepared through vacuum drying, screw extrusion melting, spraying, cooling, bundling, drawing, heat treatment, tow crimping and cutting and other technological processes. The process route of the methodis simple, the prepared polylactic acid (PLA) staple fibers obtained after batched industrialization have excellent performance, the linear density of the staple fibers is 0.56-6.67 dtex, the demandsof knitting and weaving yarn for comprehensive indexes are fully met, and a high market application value is achieved.

Owner:安徽丰原生物纤维股份有限公司

Fire retardant fabrics and methods for making the same

A fire retardant fabric is manufactured from oxidized polyacrylonitrile fibers having a fineness of about 0.5 to about 1.5 denier per fiber.

Owner:LORICA INT

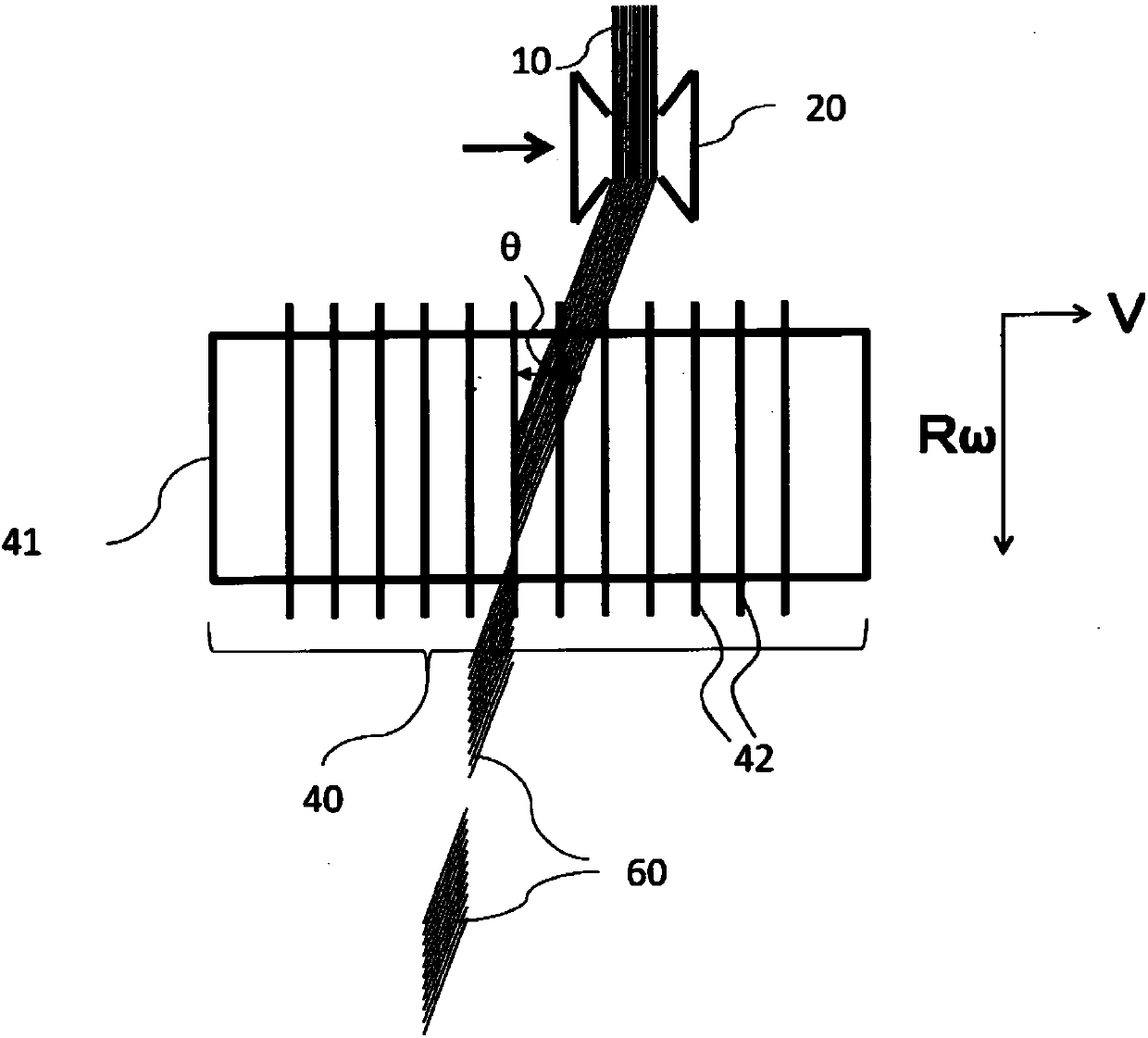

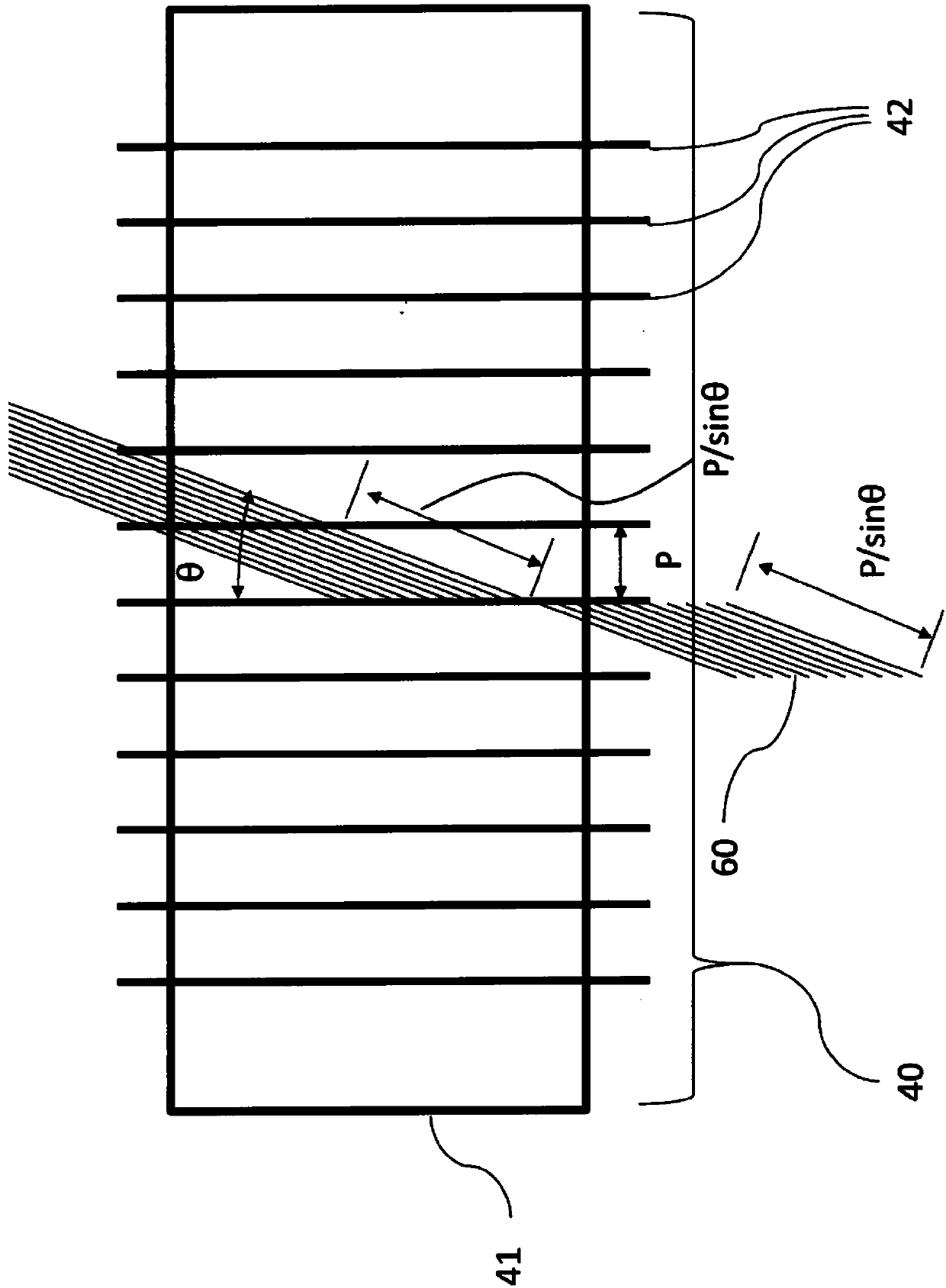

Device for manufacturing chopped fiber bundle and method for manufacturing same

Provided is a device for manufacturing a chopped fiber bundle that is provided with a cutter roll obtained by attaching one or a plurality of disc blades on the outer circumferential surface of a rollmain body such that the axis of rotation of the roll main body matches the center axis, and a nip roll disposed parallel to the direction of the axis of rotation of the roll main body, and that feedsreinforcing fiber yarn between the nip roll and cutter roll and continuously cuts the same, wherein the device is characterized by being provided with at least a rotary drive mechanism for rotating the cutter roll, and also being provided with a back and forth drive mechanism for back and forth drive of the cutter roll in the direction of the axis of rotation of the cutter roll, and / or a traverseguide for traversing the reinforcing fiber yarn in the direction of the axis of rotation of the roll main body. The present invention provides a device for manufacturing a chopped fiber bundle that can, by means of a simple device, continuously cut the reinforcing fiber yarn obliquely, and further, that is provided with a traverse guide that makes oblique cutting at a small angle possible, and provides a method for manufacturing a chopped fiber bundle.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com