Device for manufacturing chopped fiber bundle and method for manufacturing same

A technology of chopped fiber and manufacturing equipment, which is applied in the direction of fiber bundles into fiber sliver/yarn, manufacturing tools, glass manufacturing equipment, etc., which can solve the problems of difficulty in continuous introduction at a constant introduction angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, embodiments of the present invention will be described with reference to the drawings.

[0039]

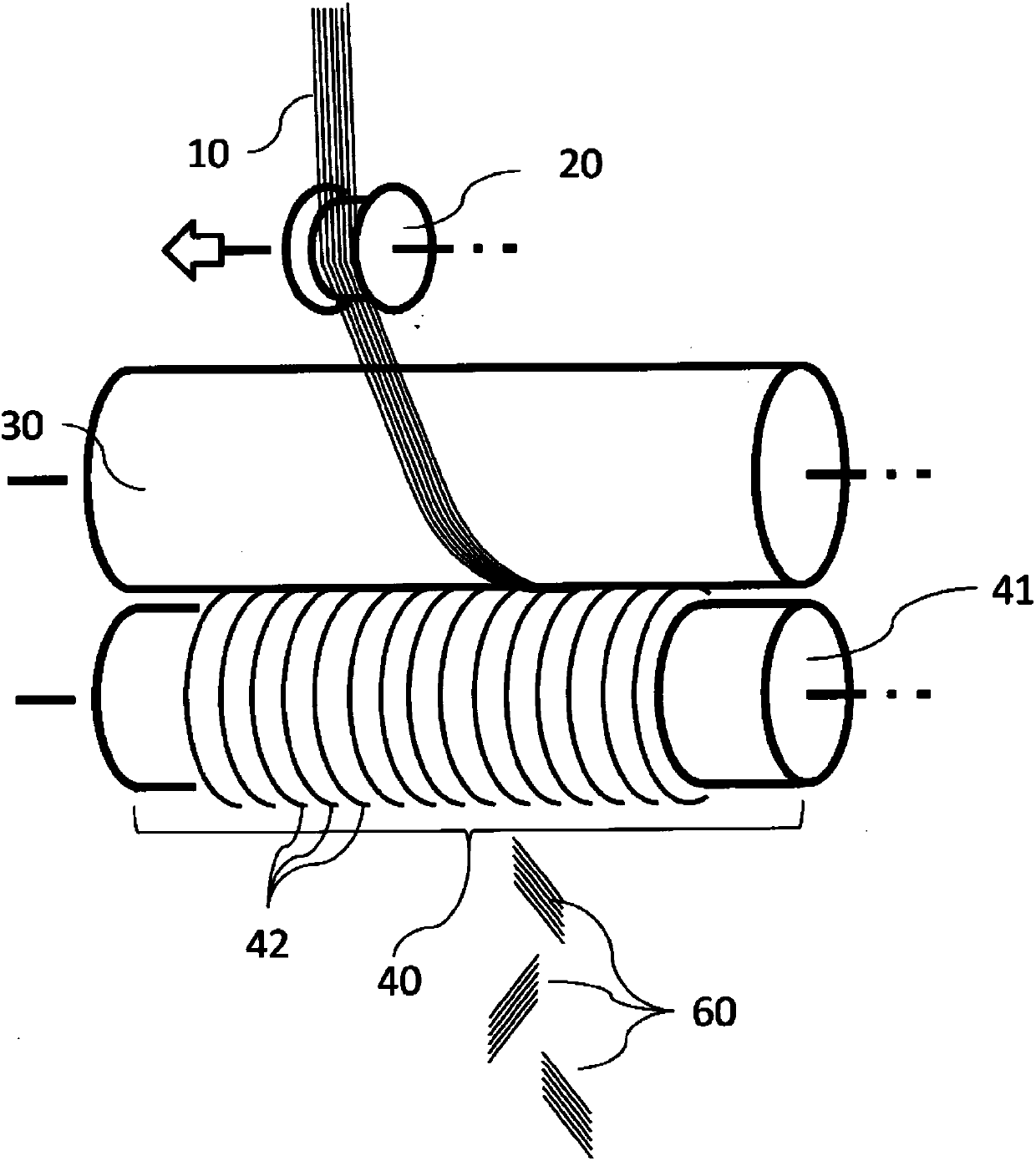

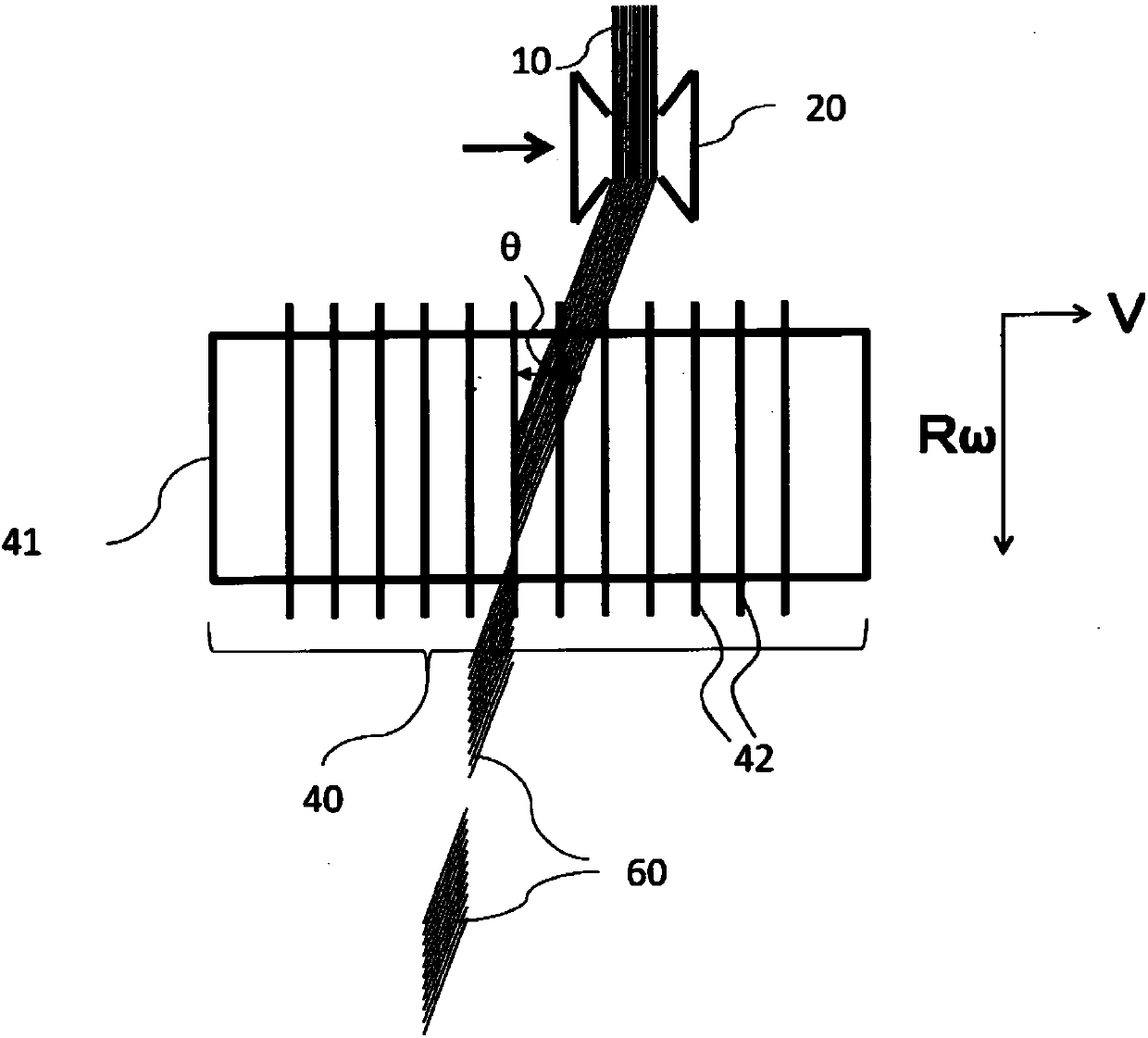

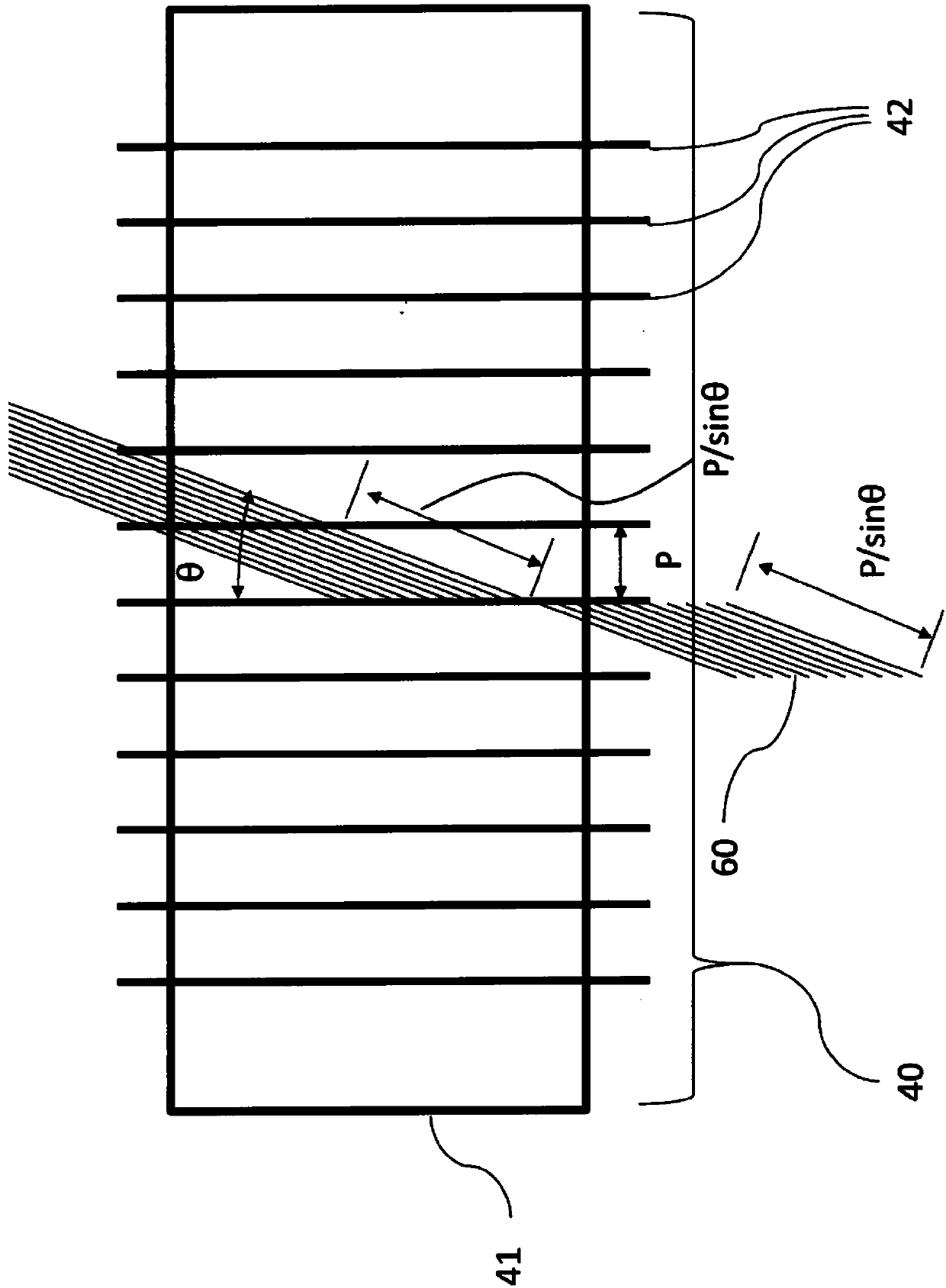

[0040] The manufacturing apparatus for manufacturing chopped fiber bundles according to the present invention is shown in figure 1 . The manufacturing apparatus used in the present invention has at least a cutting roller 40 formed by mounting one or more disc cutters 42 on the outer periphery of the roller body 41 so that the rotation axis of the roller body 41 coincides with the central axis, and the roller body 41 The pinch rollers 30 are arranged parallel to the direction of the rotation axis. In addition, in order to continuously feed the reinforcing fiber sliver 10 between the nip roller 30 and the cutting roller 40 and continuously cut them, a rotation drive mechanism (not shown) that rotates the cutting roller 40 is provided. In addition, it has (a) a reciprocating drive mechanism (not shown) that reciprocates the cutting roller 40 in the direction of the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com