Method and apparatus for cutting stainless steel fibre bundle

A fiber tow, stainless steel technology, applied in the direction of fiber bundles into fiber sliver/yarn, drafting equipment, textiles and papermaking, etc. problems, to achieve the effect of avoiding scattered loss, less broken ends, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

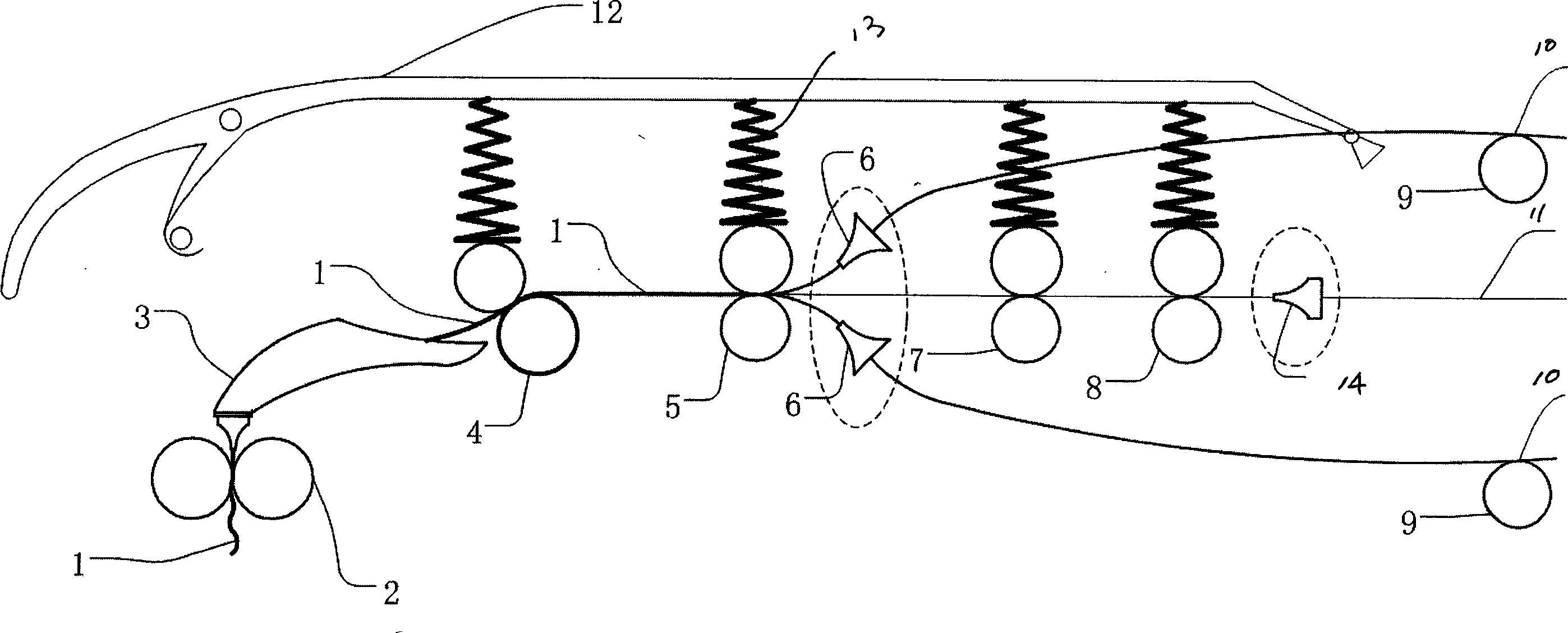

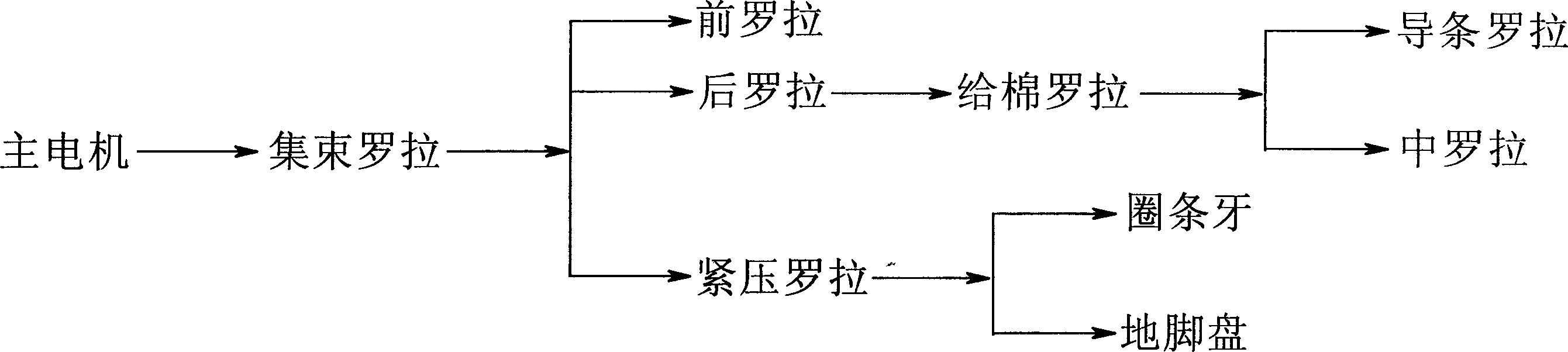

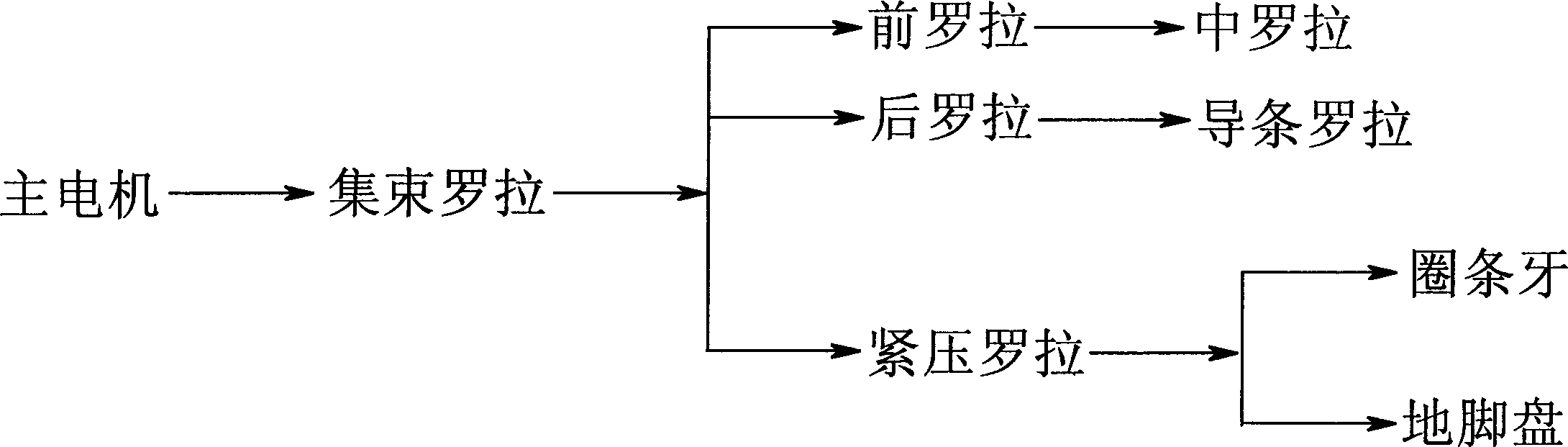

Method used

Image

Examples

Embodiment 1

[0030] Raw materials used: the conventional fiber strips are polyester strips, with a basis weight of 1.47 g / m; the selection and technical indicators of metal fibers are shown in Table 1. When the draft change gear K=39 T , the drafting multiples and calculations are as follows, and the quality of the core-spun strips after drawing is shown in Table 2.

[0031] Single fiber average equivalent diameter / μm

6

Tow weight / gm -1

3

Number of tows / root·bundle -1

12500

[0032] Main draft ratio (middle roller to rear roller): 39 84 · 95 25 · 31 28 · 28 28 = 1.9533 Formula 1

[0033] Tension draft ratio (converging rollers to front rollers): 40 35 · 28 31 ...

Embodiment 2

[0037] Raw material usage: the conventional fiber slivers are cotton slivers with a basis weight of 2.24 g / m; the selection and technical indicators of metal fibers are shown in Table 3. When the draft change gear K=36 T , the main drafting ratio is 1.8031 times, the tension drafting ratio is 1.0323 times, and the total drafting ratio is 1.8613 times.

[0038] Single fiber average equivalent diameter / μm

[0039] composition

Embodiment 3

[0041] Raw materials used: the conventional fiber strips are polyester strips, with a basis weight of 2.24 g / m; the selection and technical indicators of metal fibers are shown in Table 5. Conventional fiber strips, quantitatively 2.5 g / m; when the drafting conversion gear K=47 T , the main draft ratio is 2.3540 times, the tension draft ratio is 1.0323 times, and the total draft ratio is 2.4300 times.

[0042] Single fiber average equivalent diameter / μm

[0043] composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com