Ultra-high molecular weight PE yarn and processing method thereof

An ultra-high molecular weight, polyethylene yarn technology, applied in the field of yarn processing, can solve the problems of low breaking rate, difficult drawing and cutting, and difficult to draw and cut spinning method spinning, etc., to achieve simple process and avoid damage to needles. cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

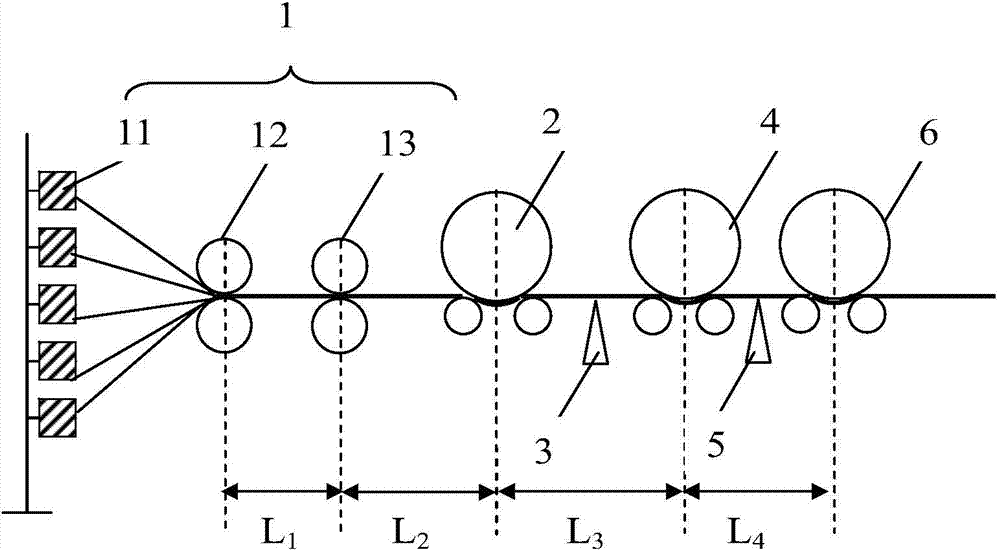

[0040] use figure 1 The shown stretching device is implemented, wherein in the stretching device, the distance L between the first bundle roller and the second bundle roller 1 400mm, distance L between the second roller and the drafting roller 2 400mm, distance L between drafting roller and pre-stretching roller 3 250mm, the distance L between the pre-stretch roller and the stretch roller 4 is 160mm.

[0041] Use 1800D / 1380F ultra-high molecular weight polyethylene filaments as raw materials, use 20 filament tubes for doubling, and then use the first roller to apply pressure P 1 , the pressure P applied by the second roller 2 Carry out bundle treatment to form filaments; use drafting roller to apply pressure P 3 Drafting of the sliver; application of pressure P with pre-drawing rollers 4 , to pre-stretch the stretched filaments; use the stretching roller to apply pressure P 5 , the pre-stretch-cut silk sliver is stretched to obtain fiber strips, the drafting ratio of th...

Embodiment 2

[0044] use figure 1 The shown stretching device is implemented, wherein in the stretching device, the distance L between the first bundle roller and the second bundle roller 1 400mm, distance L between the second roller and the drafting roller 2 400mm, distance L between drafting roller and pre-stretching roller 3 250mm, the distance L between the pre-stretch roller and the stretch roller 4 is 200mm.

[0045] Use 1800D / 1380F ultra-high molecular weight polyethylene filaments as raw materials, use 20 filament tubes for doubling, and then use the first roller to apply pressure P 1 , the pressure P applied by the second roller 2 Carry out bundle treatment to form filaments; use drafting roller to apply pressure P 3 Drafting of the sliver; application of pressure P with pre-drawing rollers 4 , to pre-stretch the stretched filaments; adopt the pressure P applied by the stretching roller 5 , the pre-stretch-cut silk sliver is stretched to obtain a fiber strip, the drafting ra...

Embodiment 3

[0048] use figure 1 The shown stretching device is implemented, wherein in the stretching device, the distance L between the first bundle roller and the second bundle roller 1 400mm, distance L between the second roller and the drafting roller 2 400mm, distance L between drafting roller and pre-stretching roller 3 250mm, the distance L between the pre-stretch roller and the stretch roller 4 150mm.

[0049] Use 1800D / 1380F ultra-high molecular weight polyethylene filaments as raw materials, use 20 filament tubes for doubling, and then use the first roller to apply pressure P 1 , the pressure P applied by the second roller 2 Carry out bundle treatment to form filaments; use drafting roller to apply pressure P 3 Drafting of the sliver; application of pressure P with pre-drawing rollers 4 , to pre-stretch the stretched filaments; adopt the pressure P applied by the stretching roller 5 , the pre-stretch-cut silk sliver is stretched to obtain fiber strips. The drafting ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com