High-strength yarn made through stretch breaking and process for producing the same

A manufacturing method and high-strength technology, applied in the direction of yarn, textile and papermaking, fiber bundles into fiber strips/yarns, etc., can solve problems such as increased strength deviation, increased single yarn length variation, entanglement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3、 comparative example 1-3

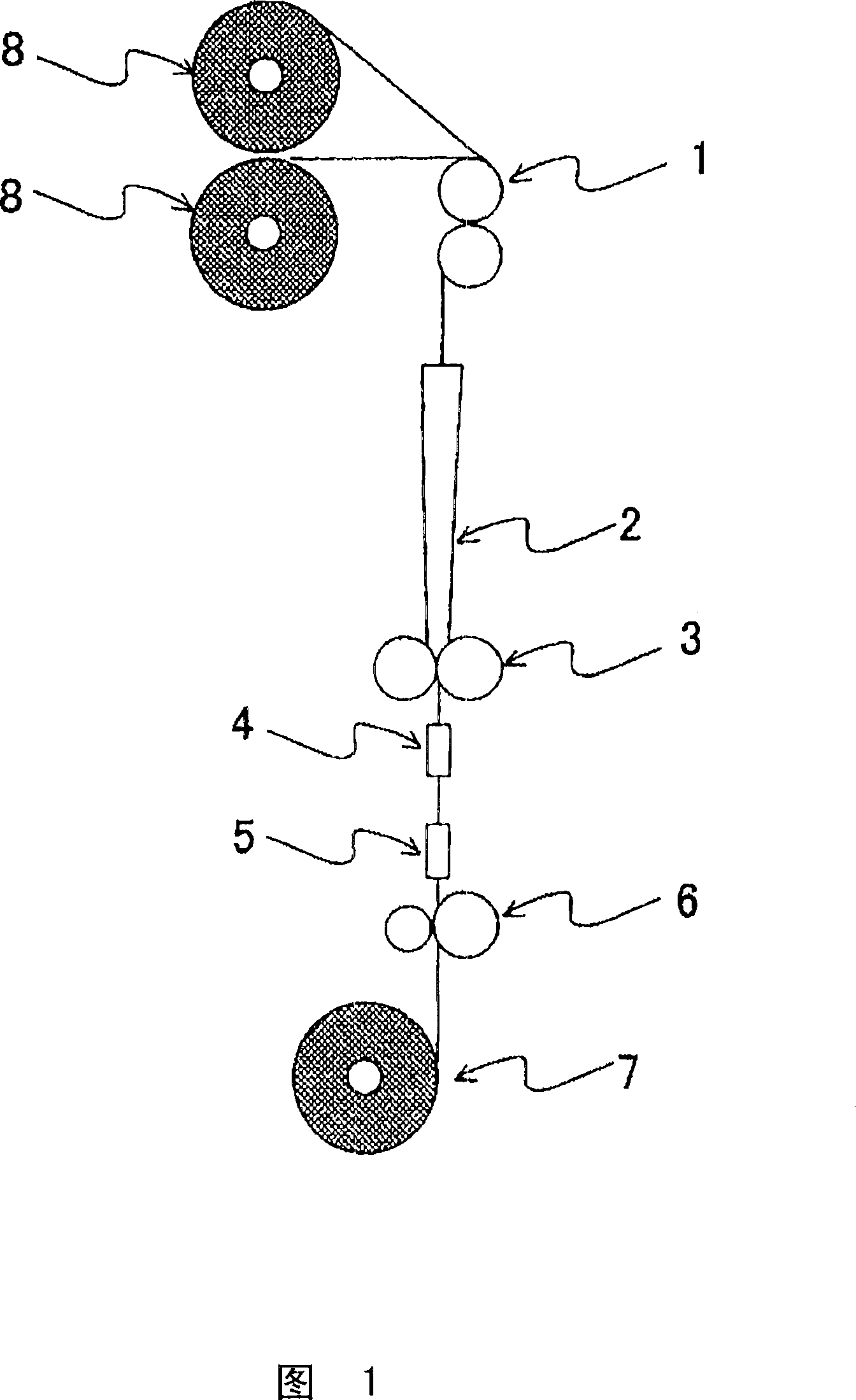

[0038] Using the device shown in Fig. 1, two poly-p-phenylene terephthalamide fibers (トイジントイントラロン: テイジントラロン) with the single yarn fineness and oil agent adhesion of Table 1, a total fineness of 1100dtex, and a strength of 21cN / dtex were used. Manufacturing) doubling, the distance between the rollers (stretching length) and the humidity of the moist air are changed as shown in Table 1, and the moist air is given between the feed nip roll, the spray box, and the stretch nip roll. One side is broken at a speed of 300m / min, and the stretching ratio is about 10 times to make short fiber bundles.

[0039] Next, under the condition that the speed ratio of the nip roll and the delivery roll is 100:99.5, it is passed through an attractive air nozzle and an entangling nozzle with swirling flow, so that the fiber bundle is entangled, and at the same time, the short fiber is randomly wrapped. Hairiness, get about 220dtex stretch-cut processed yarn. The physical properties of the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Torsion | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com