Method for assembling a blade to a cylinder body, blade, cylinder body and cutting device

A cylinder and blade technology, applied in textiles and papermaking, textile material cutting, metal processing, etc., to achieve the effect of reducing costs and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

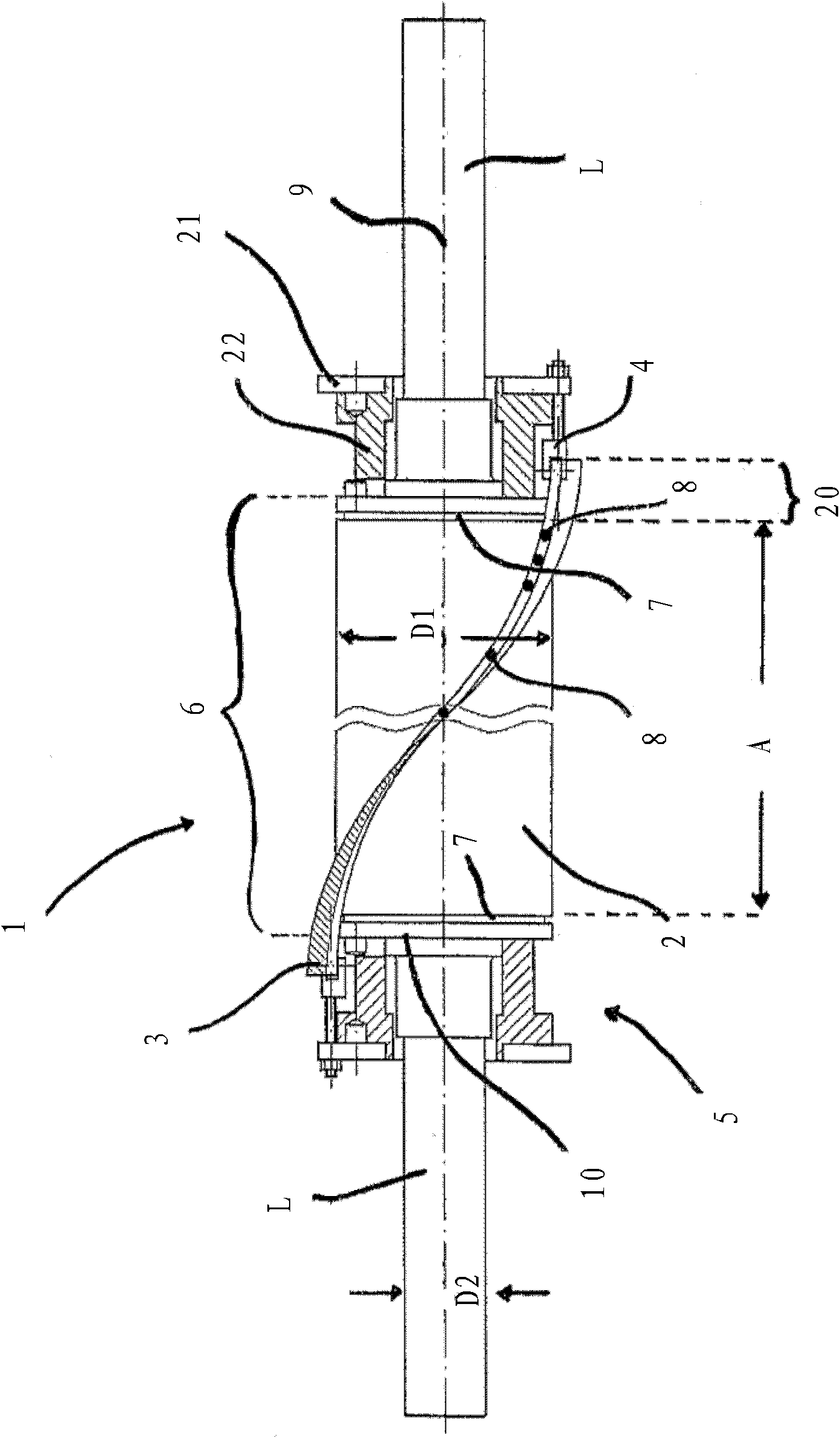

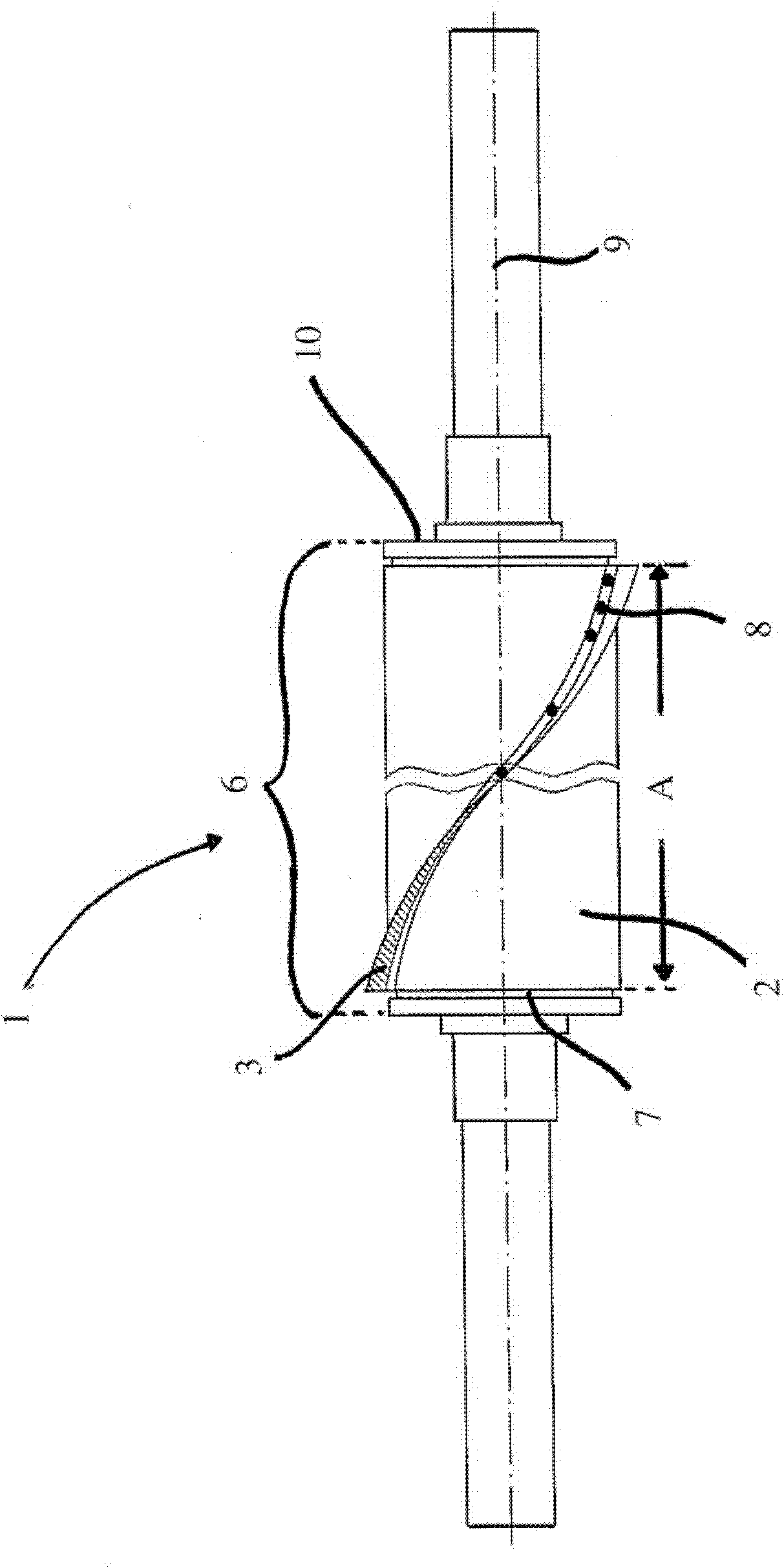

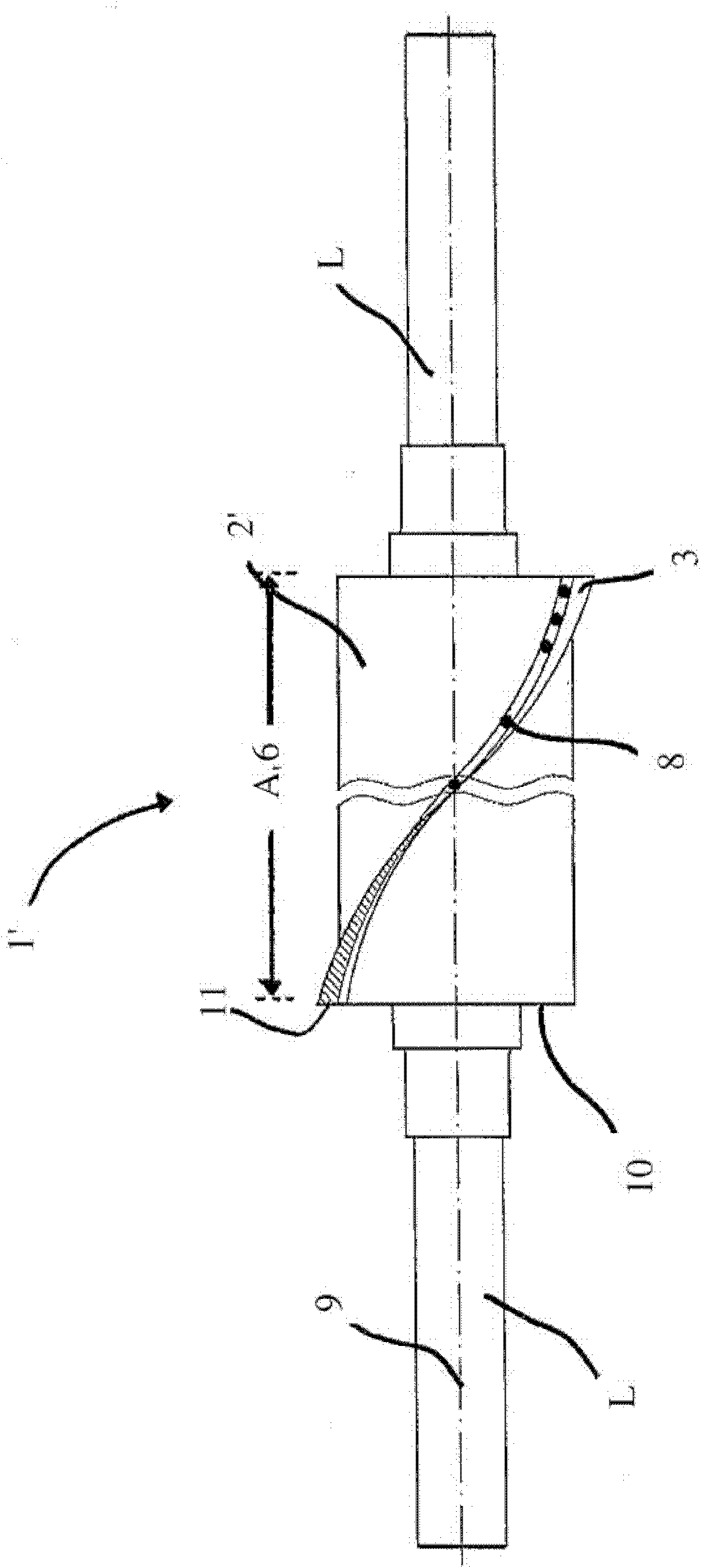

[0050] figure 1 Denotes a cutting device 1, which has a cylinder 2 and a blade 3. As already explained above, a complete set of blades is usually installed, so the steps described here are intended for the parallel implementation of several blades 3 . Of course, for some applications, only one blade 3 can be installed on the cylinder 2 as well. The method used is described here with the cutting device 1 as an example. Although it has a plurality of blades 3 in the working state, only a single blade 3 is used to illustrate the assembly process here for the sake of simplicity.

[0051] The two ends of the blade 3 are respectively provided with traction parts 4 in the tension section. The traction member 4 connects the blade 3 and the supporting body 5 respectively. The carrier body 5 shown here itself has a side plate 22 and an adapter 23 . The cylinder 2 is composed of a region 6 in which the cylinder 2 has a larger diameter D1 and two regions respectively arranged at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com