Anti-slip cable saddle structure of a suspension bridge

A suspension bridge and anti-skid technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor safety and reliability, limited friction coefficient, poor practicability, etc., and achieve the effect of improving the overall rigidity and anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

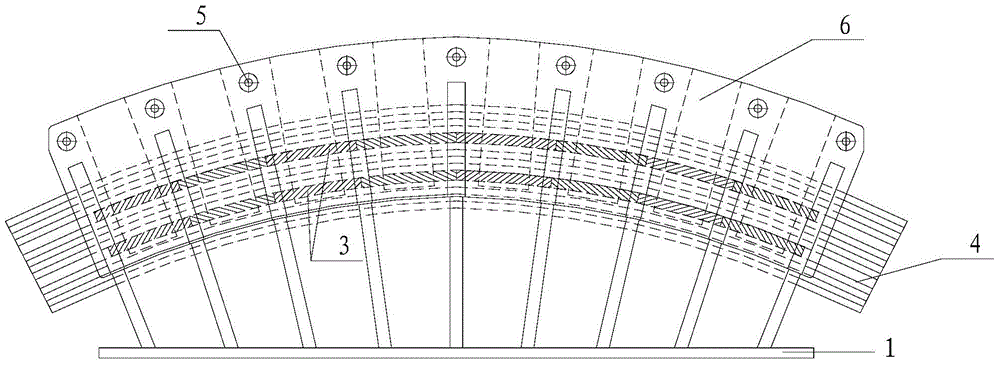

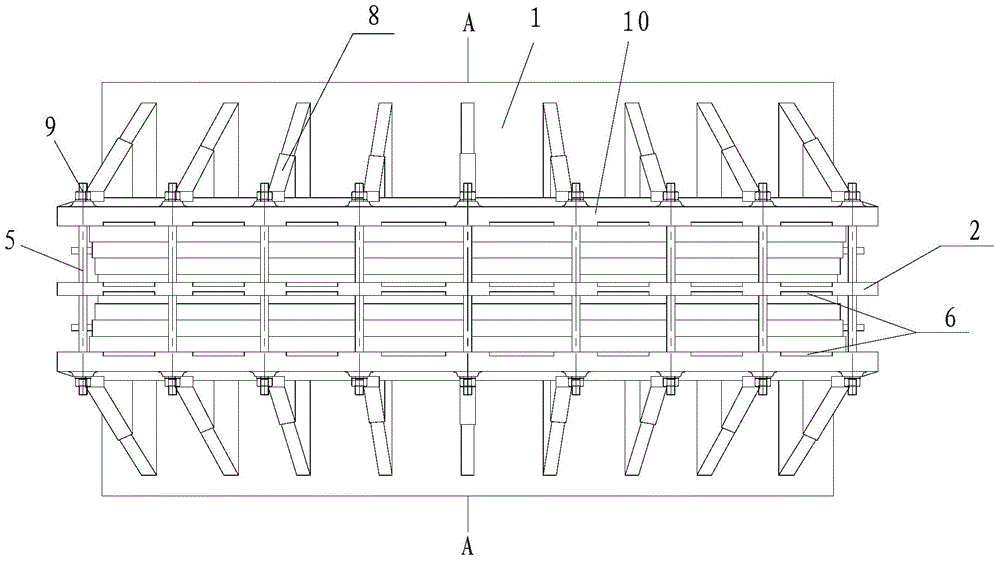

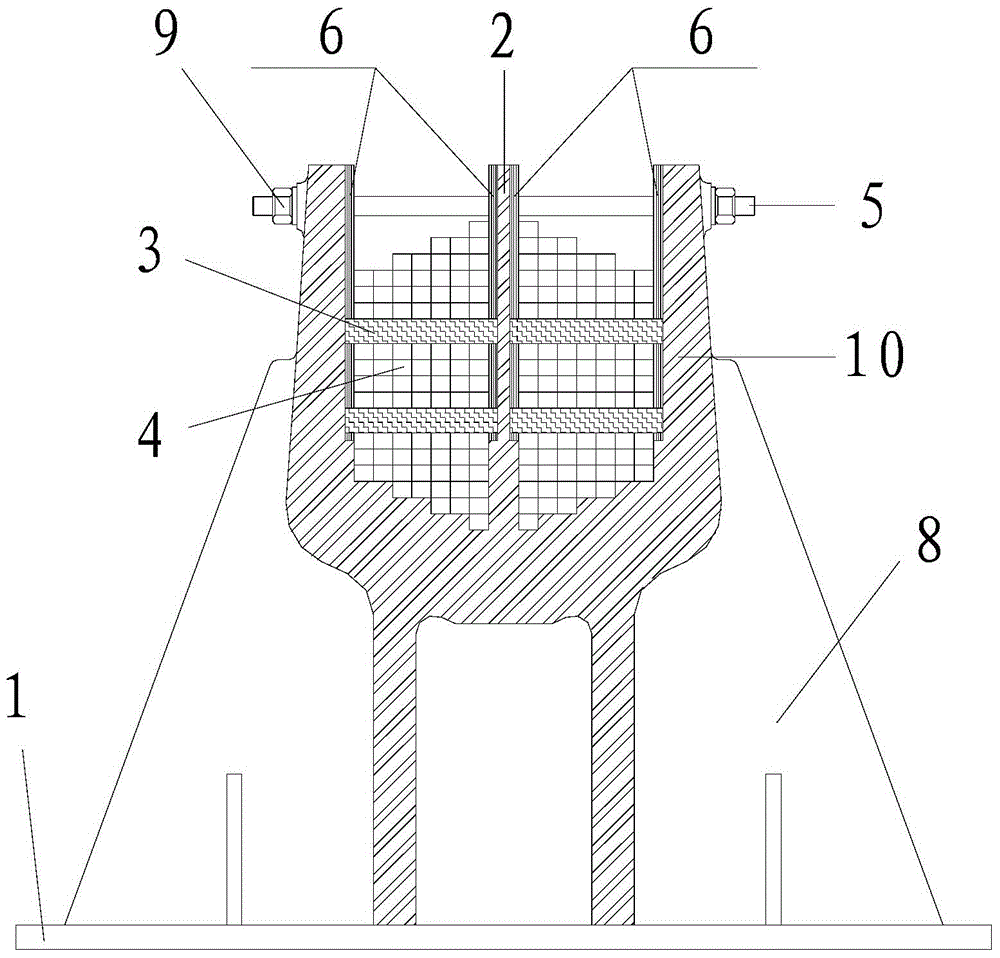

[0018] Such as Figure 1~3 As shown, an anti-skid cable saddle structure of a suspension bridge includes a saddle 1; the bottom of the saddle groove of the saddle 1 is provided with a longitudinal diaphragm 2 parallel to the groove wall 10; There are two layers of discontinuous splints parallel to the arc of the saddle groove, and each layer of discontinuous splints is formed by connecting eight tangential splints 3 in the longitudinal direction; the saddle 1 and the mediastinum 2 are connected as a whole.

[0019] Eight rows of radial chute 6 corresponding to the tangential splint 3 are longitudinally arranged on the inner side of the groove wall 10 and both sides of the longitudinal partition 2; Freely slide from top to bottom.

[0020] Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com