Transition roller cleaning device used in float glass slag box and cleaning method thereof

A float glass and cleaning device technology, applied to glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve problems such as troublesome operation, failure to clean transition rollers, and easy gaps between graphite strips and transition rollers, etc., to achieve Improve cleaning efficiency and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

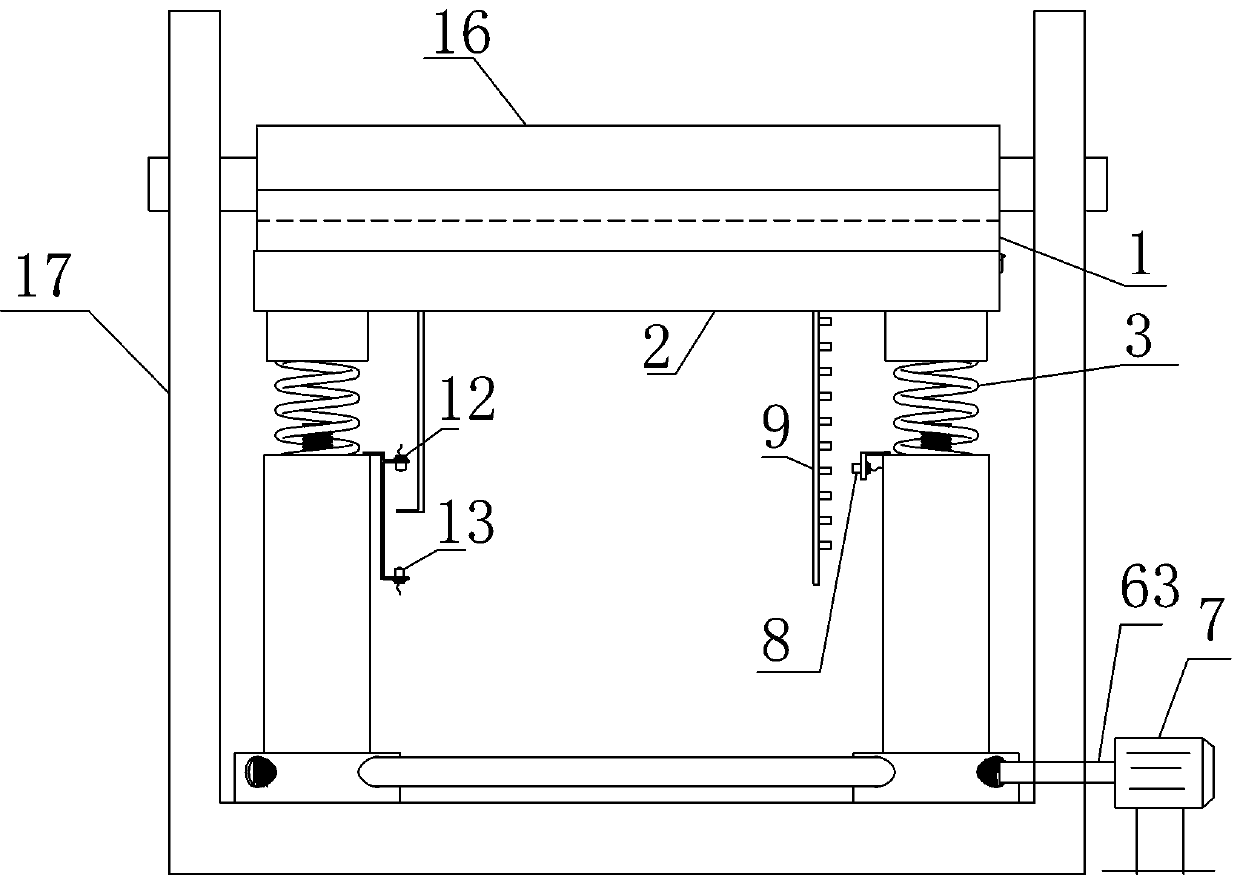

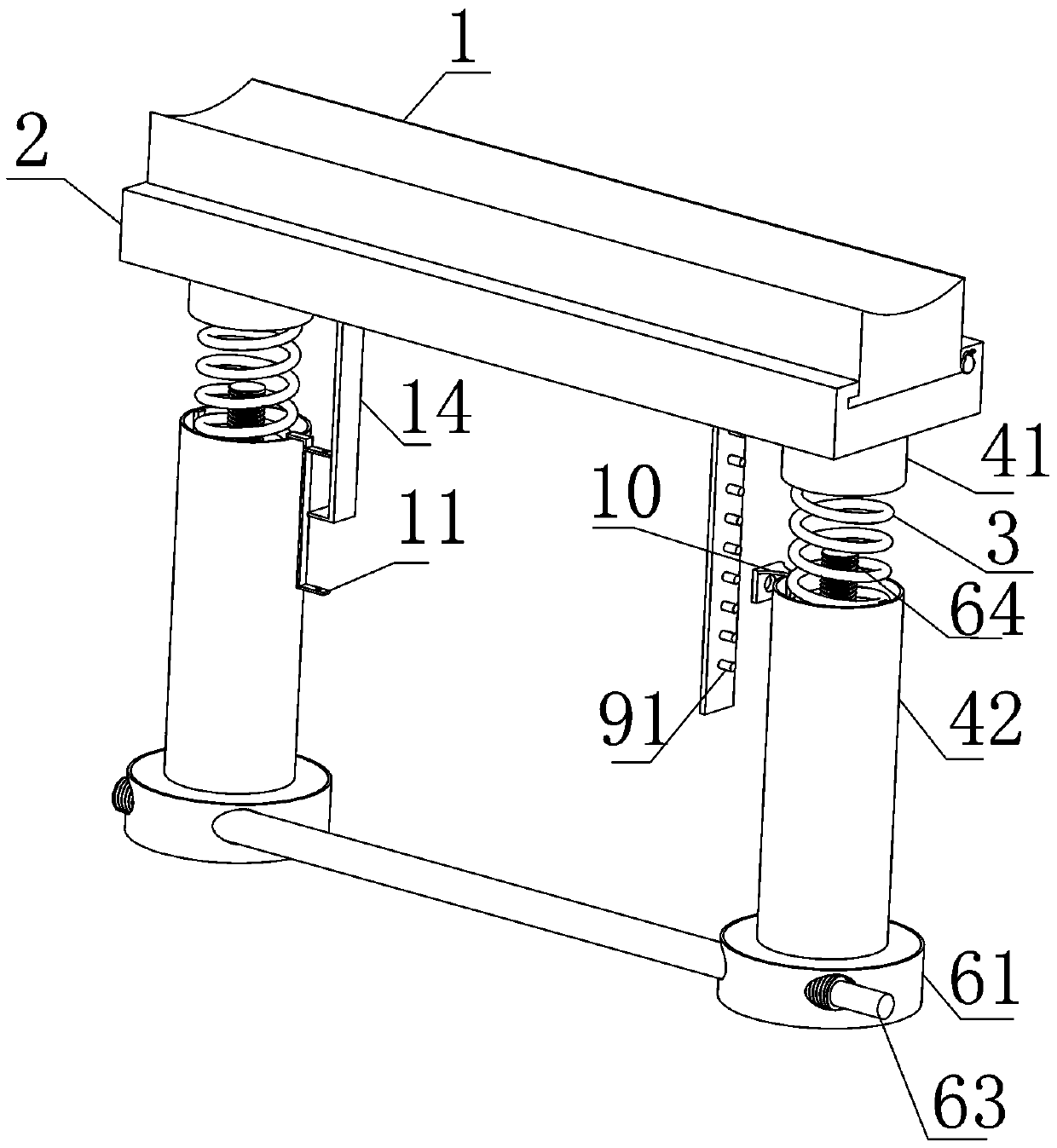

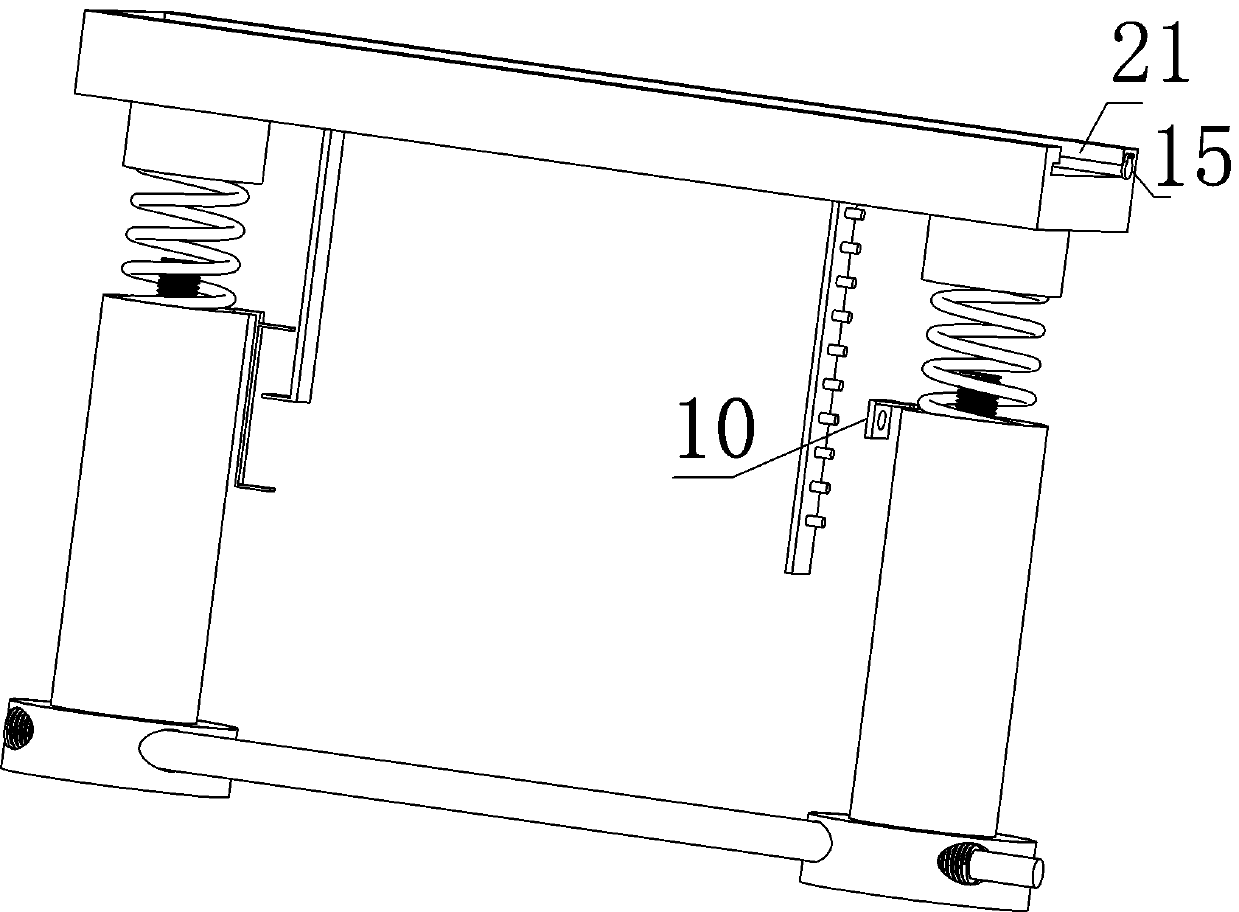

[0032] The preferred solution is as Figure 1~3 as well as Figure 10~11 As shown, a transition roller cleaning device used in a float glass slag box includes a graphite strip 1, which is detachably arranged on a graphite strip fixing seat 2, and the bottom of the graphite strip fixing seat 2 is provided with an elastic device . Because the existing graphite strips are generally fixed by bolts, when the graphite strips are worn out due to friction, it is necessary to install shim irons to increase the height of the graphite strips, so that the graphite strips can effectively frictionally clean the transition rollers. And the design starting point of this technical scheme is to change the bolt fixing into an elastic device, so that there will be a pre-tightening force in the friction between the graphite strip 1 and the transition roller. can effectively contact.

[0033] Such as Figure 10~11 As shown, the elastic device includes a spring 3 for supporting the graphite stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com