Plastic fan coil

A fan coil and plastic technology, applied in the direction of mechanical equipment, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of prone to bacteria breeding, accumulation of foreign matter on the surface of the filter, and difficult equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

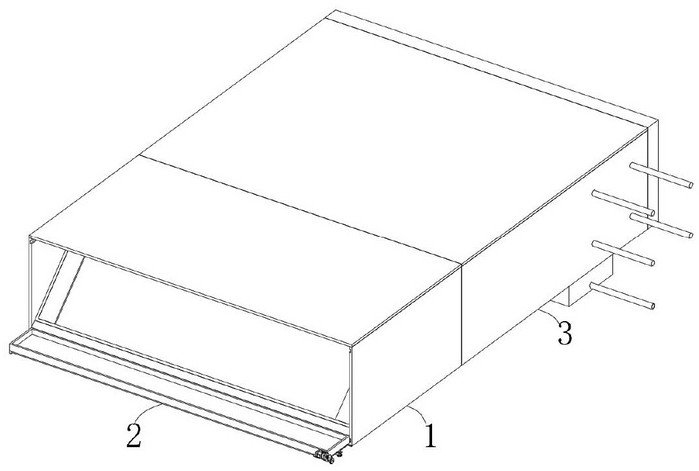

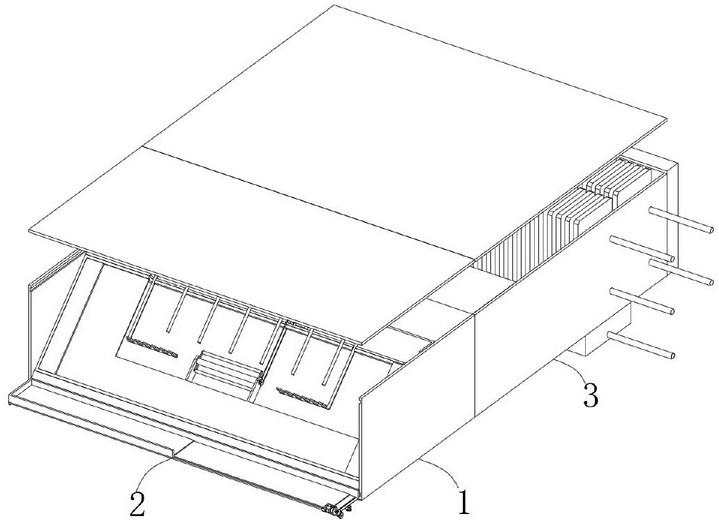

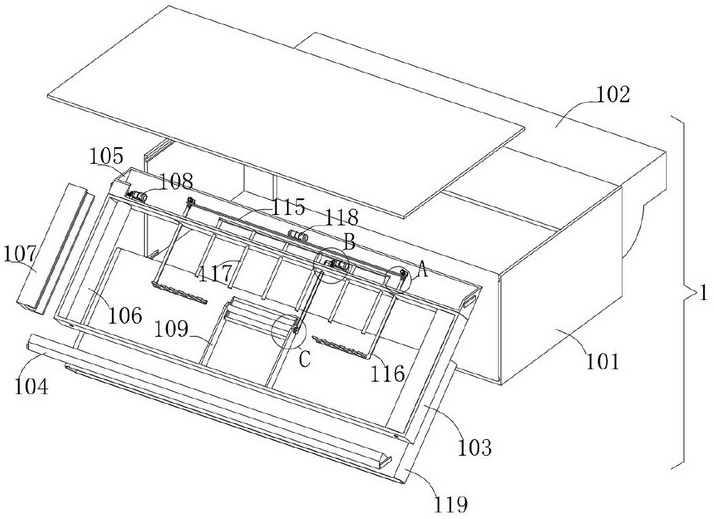

[0031] refer to Figure 1-Figure 9: Plastic fan coil unit, including: filter mechanism 1, storage mechanism 2 and functional mechanism 3, filter mechanism 1 includes bottom frame 101 and cleaning parts, the establishment of bottom frame 101 provides the installation basis for setting other functional parts of the equipment, and at the same time can Effective protection of other functional components of the equipment, the inner surface walls on both sides of the bottom frame 101 are provided with a first chute, which facilitates the installation of the top frame 105 through the establishment of the first chute. A top frame 105 is slidably embedded between the top frame 105, and the installation of other functional components of the equipment is facilitated by the establishment of the top frame 105. The inner surface walls on both sides of the bottom frame 101 are provided with a second chute, which is convenient for the establishment of the second chute. For the installation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com