Patents

Literature

38results about How to "Extend blade life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

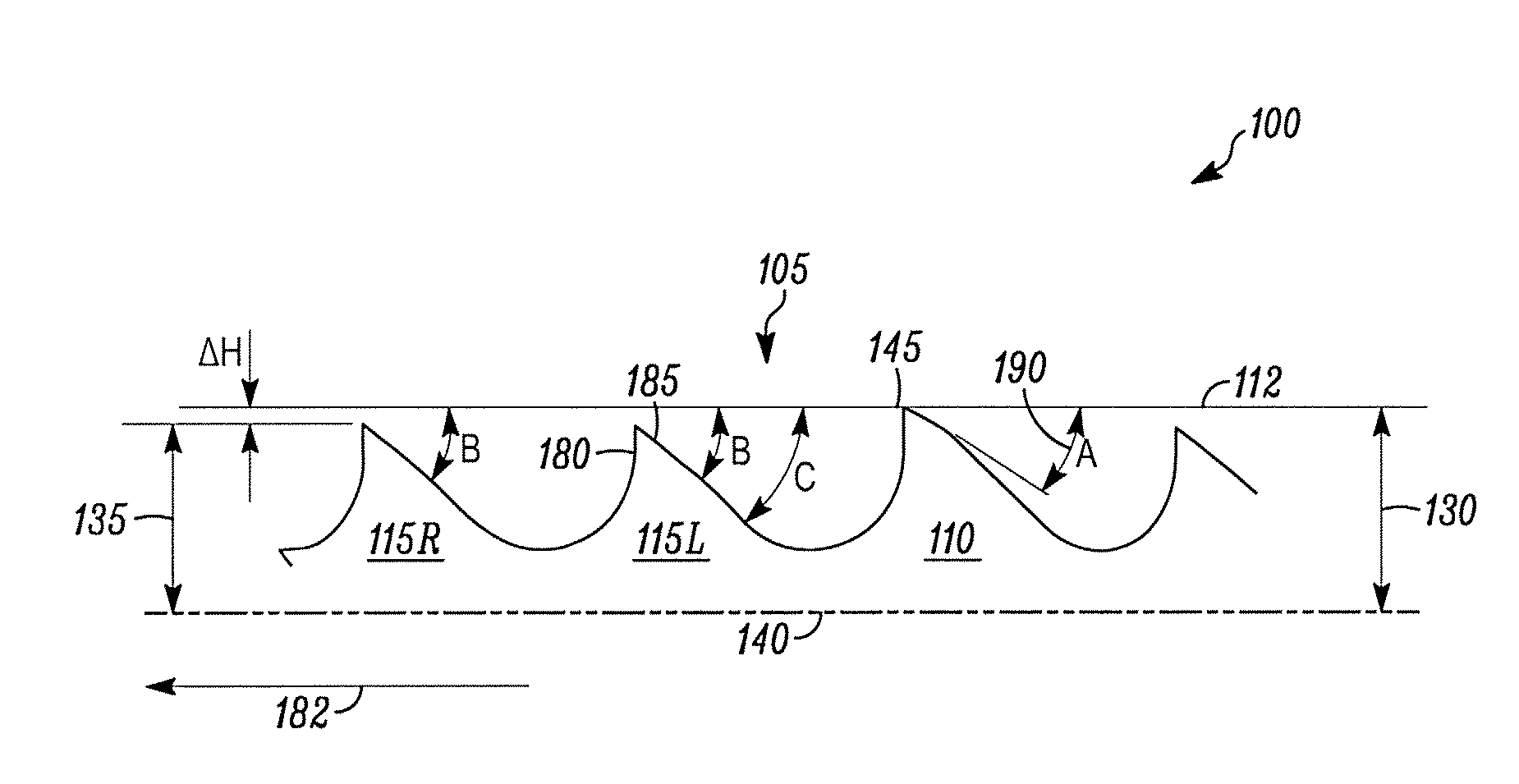

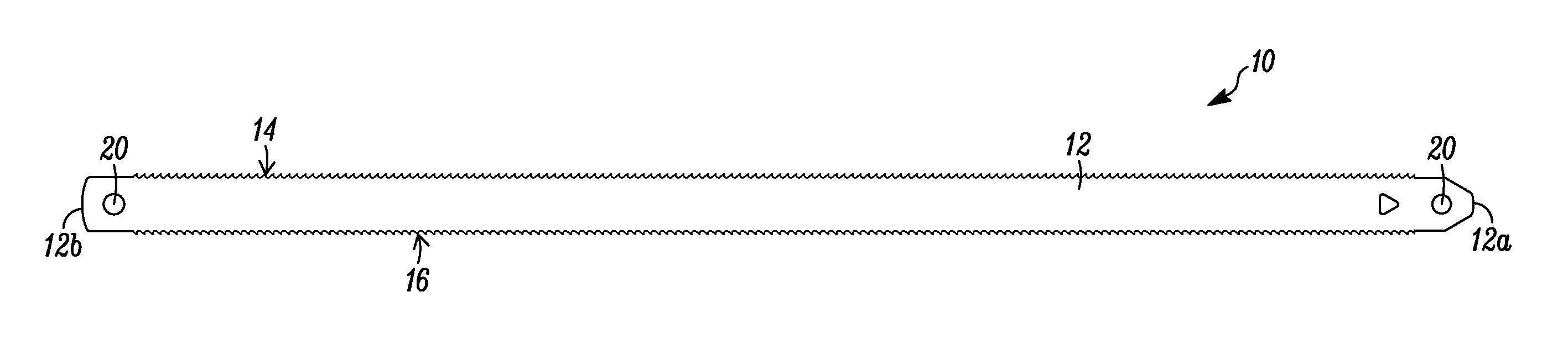

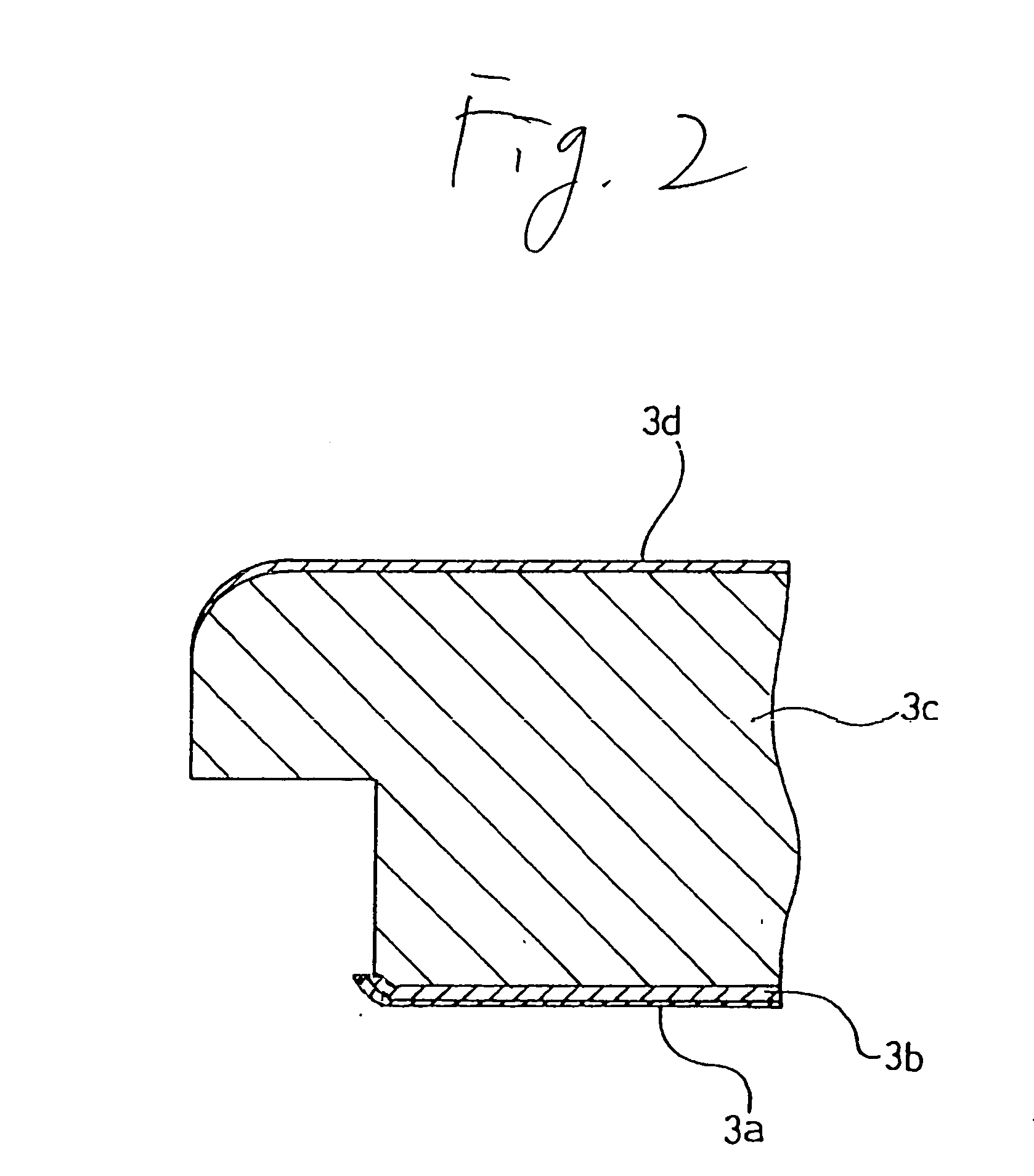

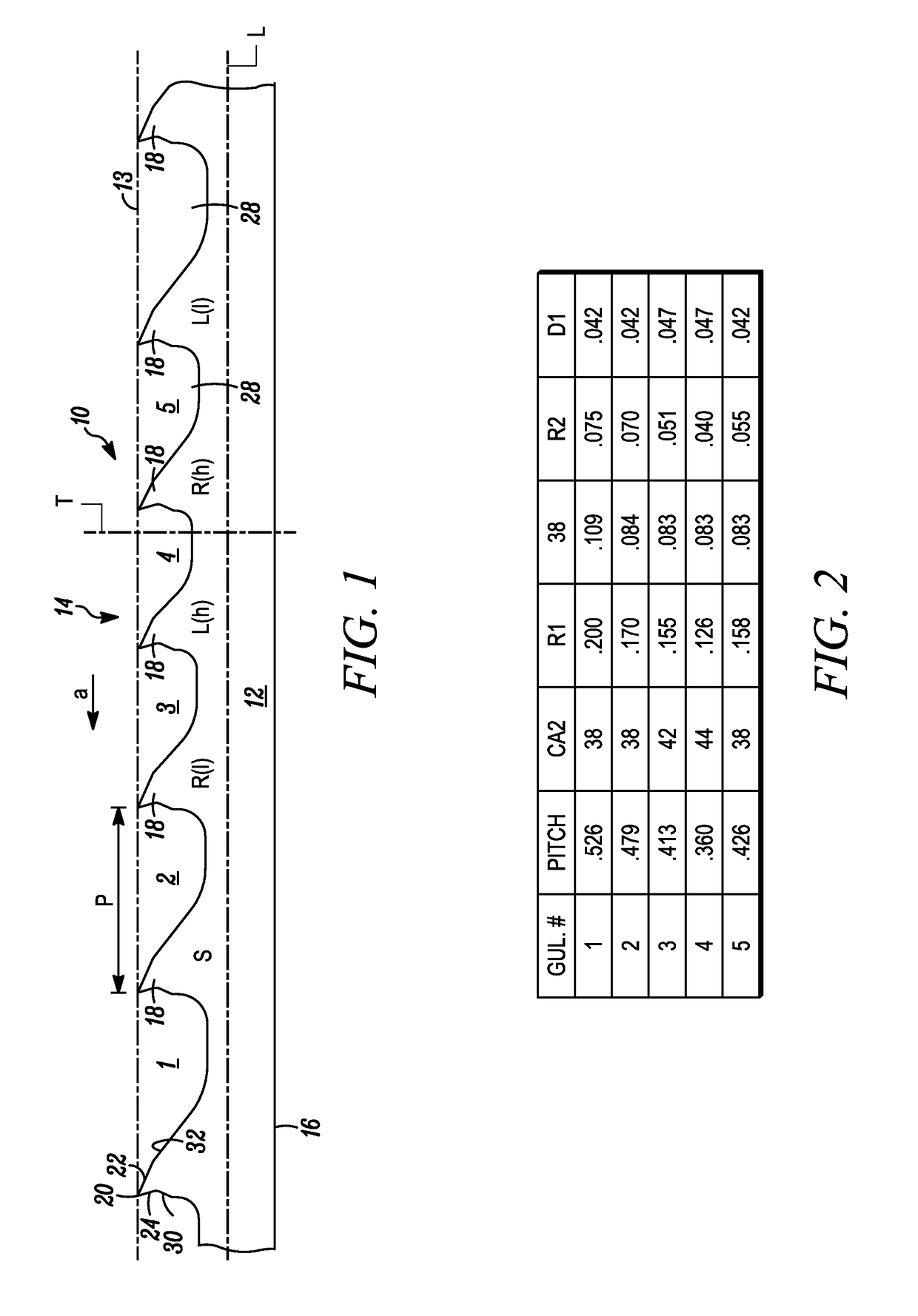

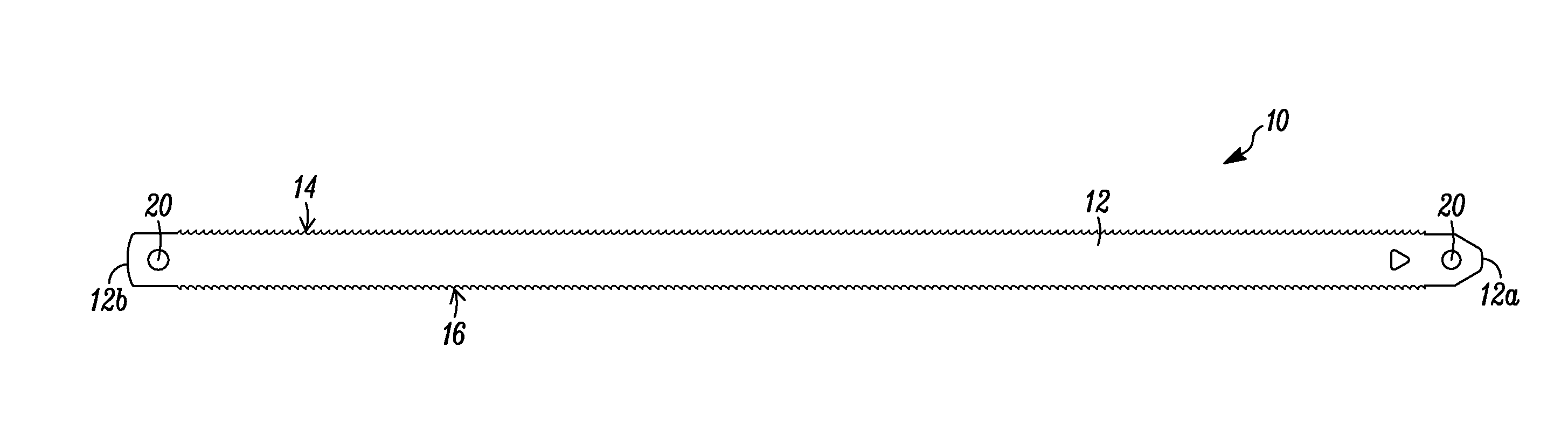

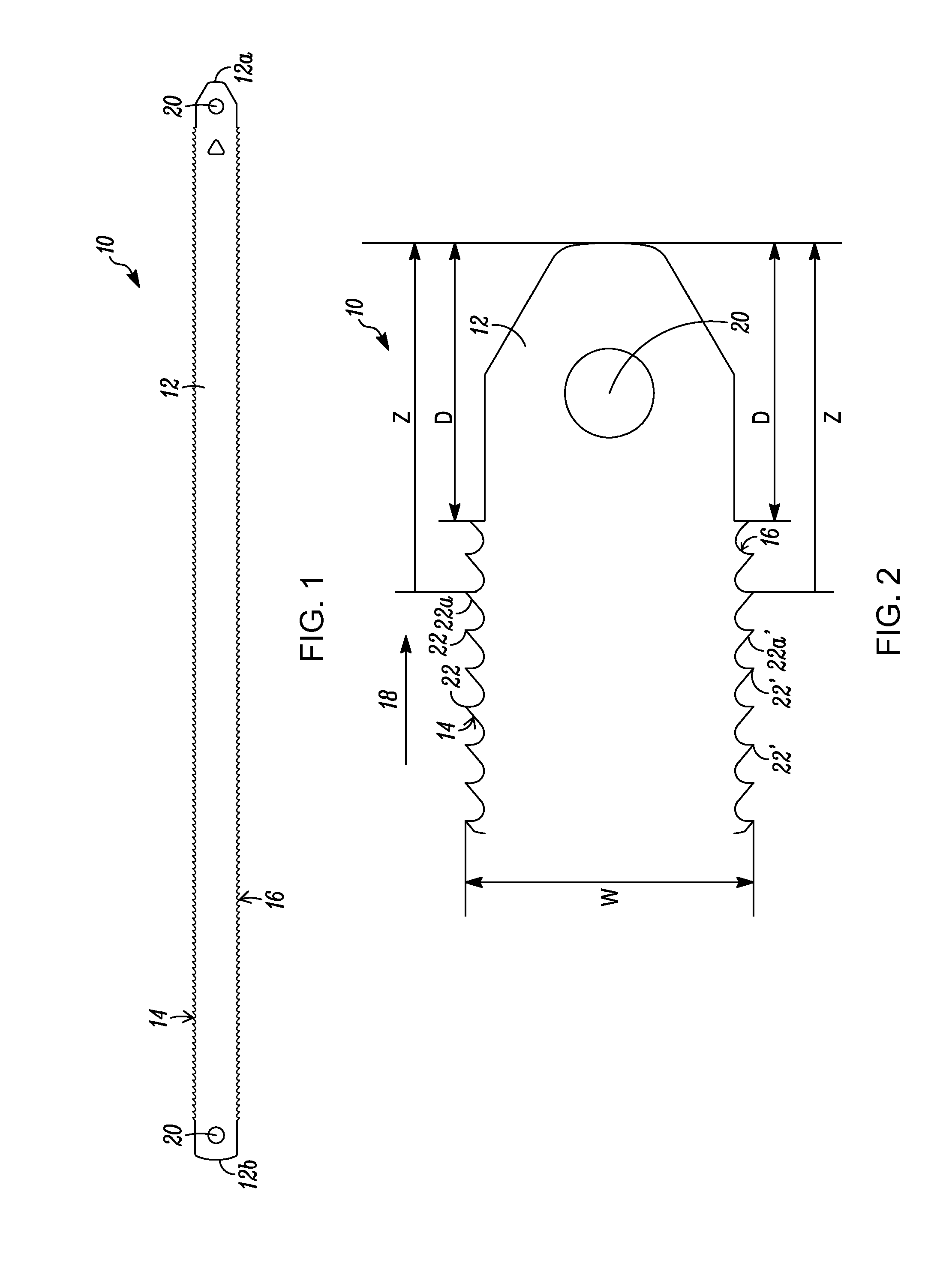

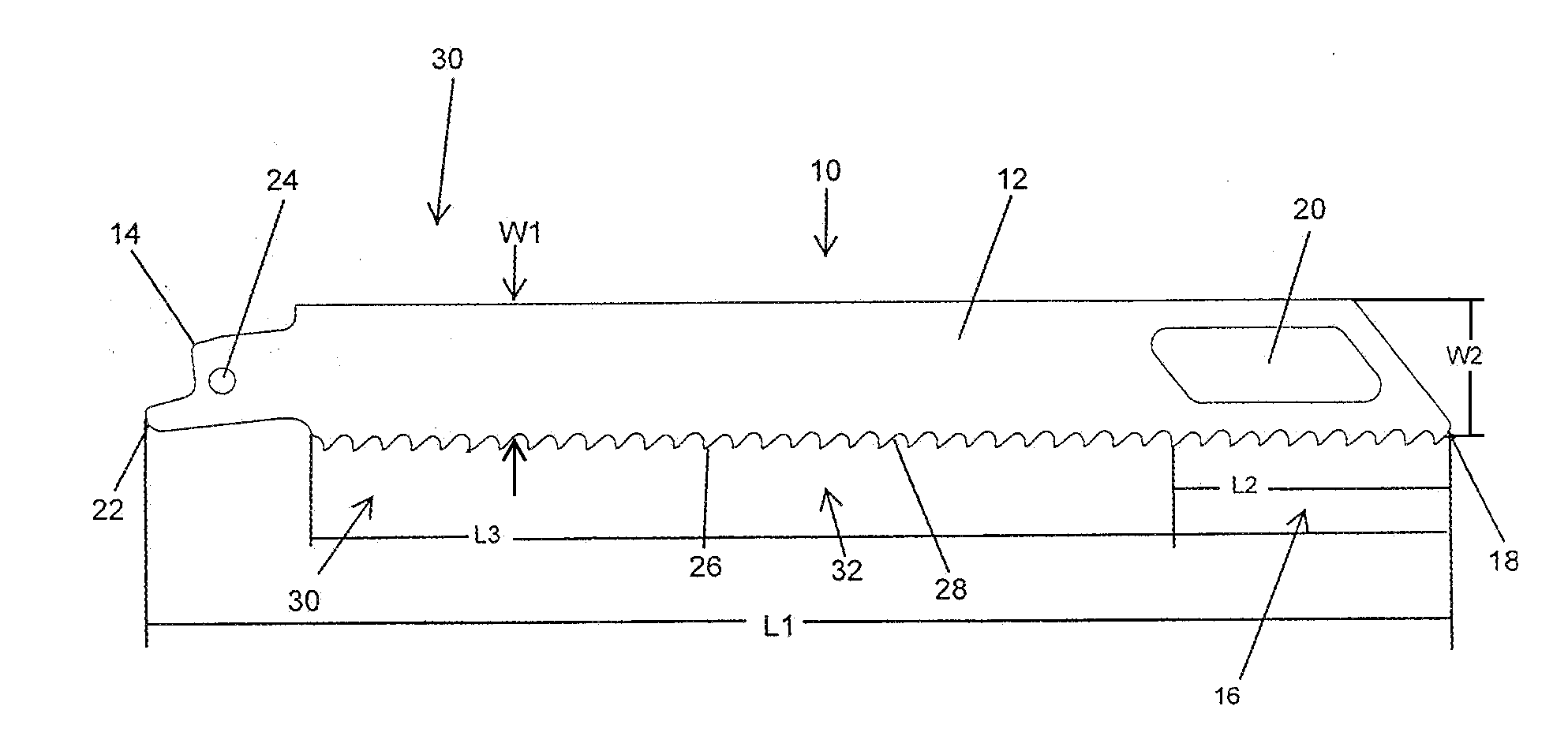

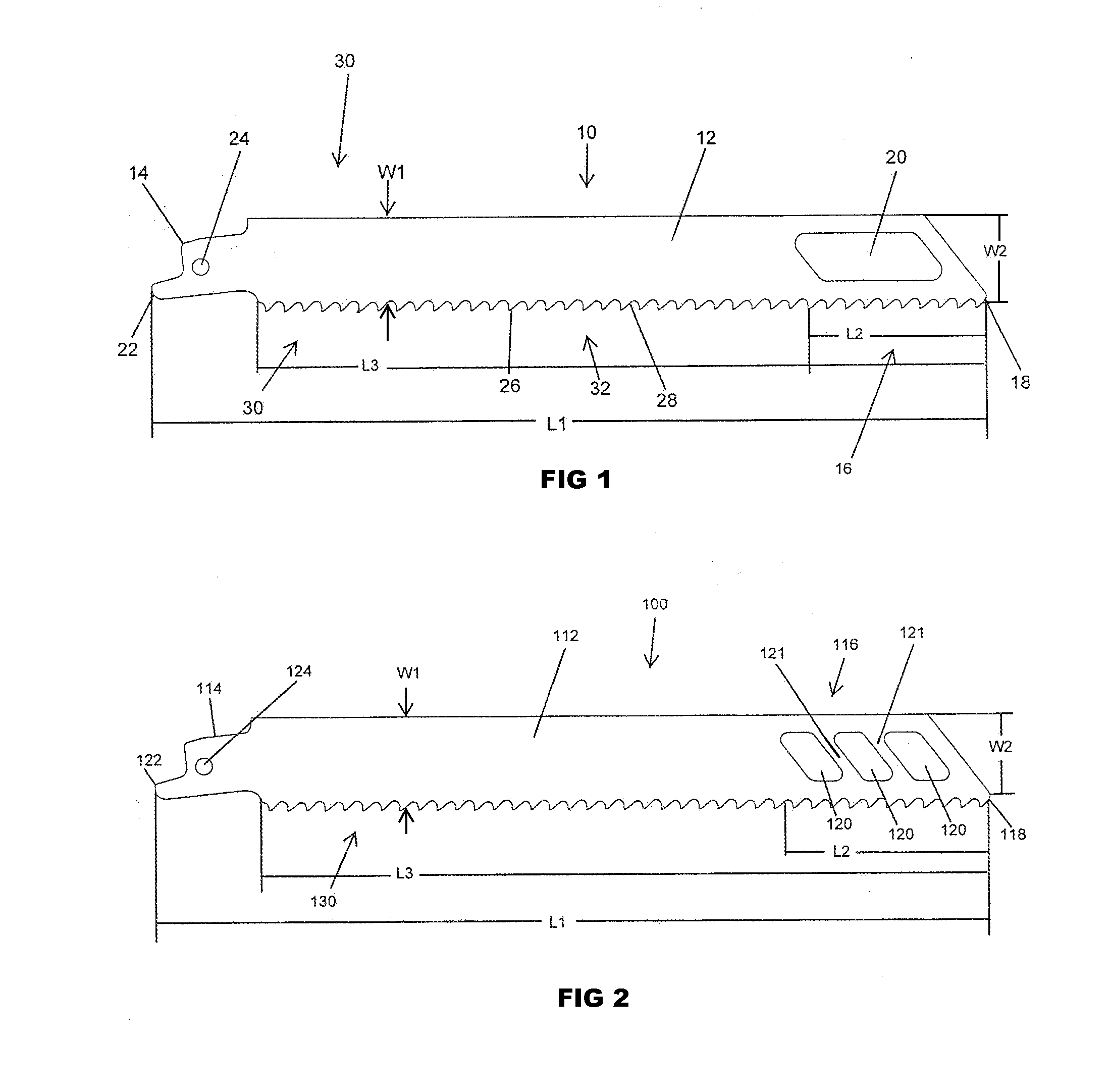

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

Electrostatographic imaging member

InactiveUS6303254B1Improve thickness uniformityReduces undesirable dirtElectrographic process apparatusMicrometerPolymer chemistry

An electrostatographic imaging member including: a flexible supporting substrate; an imaging layer having an optional adjacent ground strip layer coated on one side of the substrate; and an anti-curl backing layer coated on the other side of the substrate which layer is comprised of a film forming polymer binder, an optional adhesion promoting polymer, and a dispersion of polytetrafluoroethylene particles which dispersion has particles with a narrow diameter particle size distribution of from about 0.19 micrometer to about 0.21 micrometer, and an average diameter particle size of about 0.20 micrometer. The optional ground strip layer can include the same dispersion of polytetrafluoroethylene particles as the anti-curl backing layer.

Owner:XEROX CORP

Erosion and corrosion-resistant coating system and process therefor

InactiveUS20090176110A1Improving solid particle and water droplet erosion characteristicImprove corrosion resistanceMolten spray coatingEngine fuctionsThermal sprayingCoating system

A coating system and process capable of providing erosion and corrosion-resistance to a component, particularly a steel compressor blade of an industrial gas turbine. The coating system includes a metallic sacrificial undercoat on a surface of the component substrate, and a ceramic topcoat deposited by thermal spray on the undercoat. The undercoat contains a metal or metal alloy that is more active in the galvanic series than iron, and electrically contacts the surface of the substrate. The ceramic topcoat consists essentially of a ceramic material chosen from the group consisting of mixtures of alumina and titania, mixtures of chromia and silica, mixtures of chromia and titania, mixtures of chromia, silica, and titania, and mixtures of zirconia, titania, and yttria.

Owner:GENERAL ELECTRIC CO

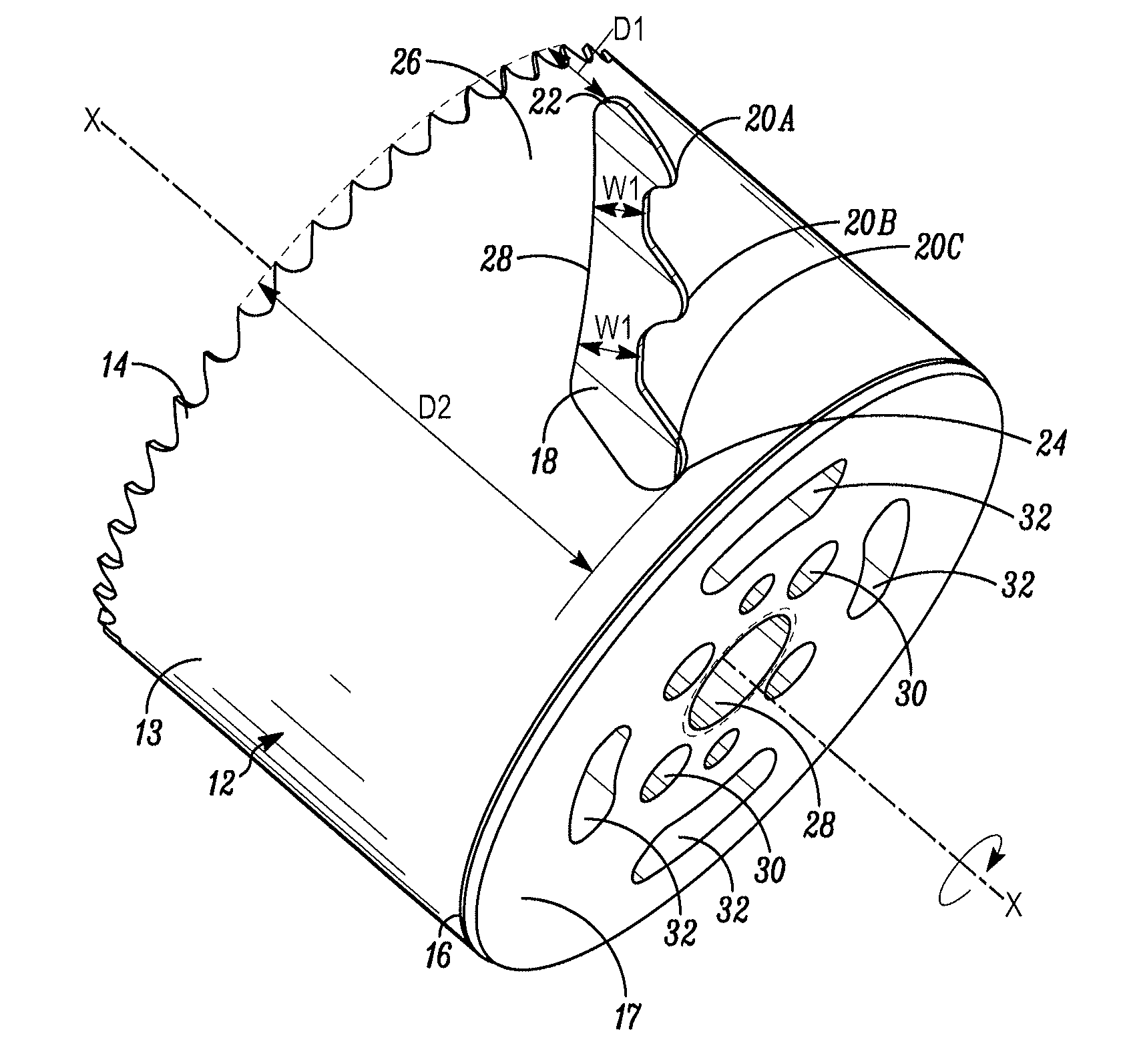

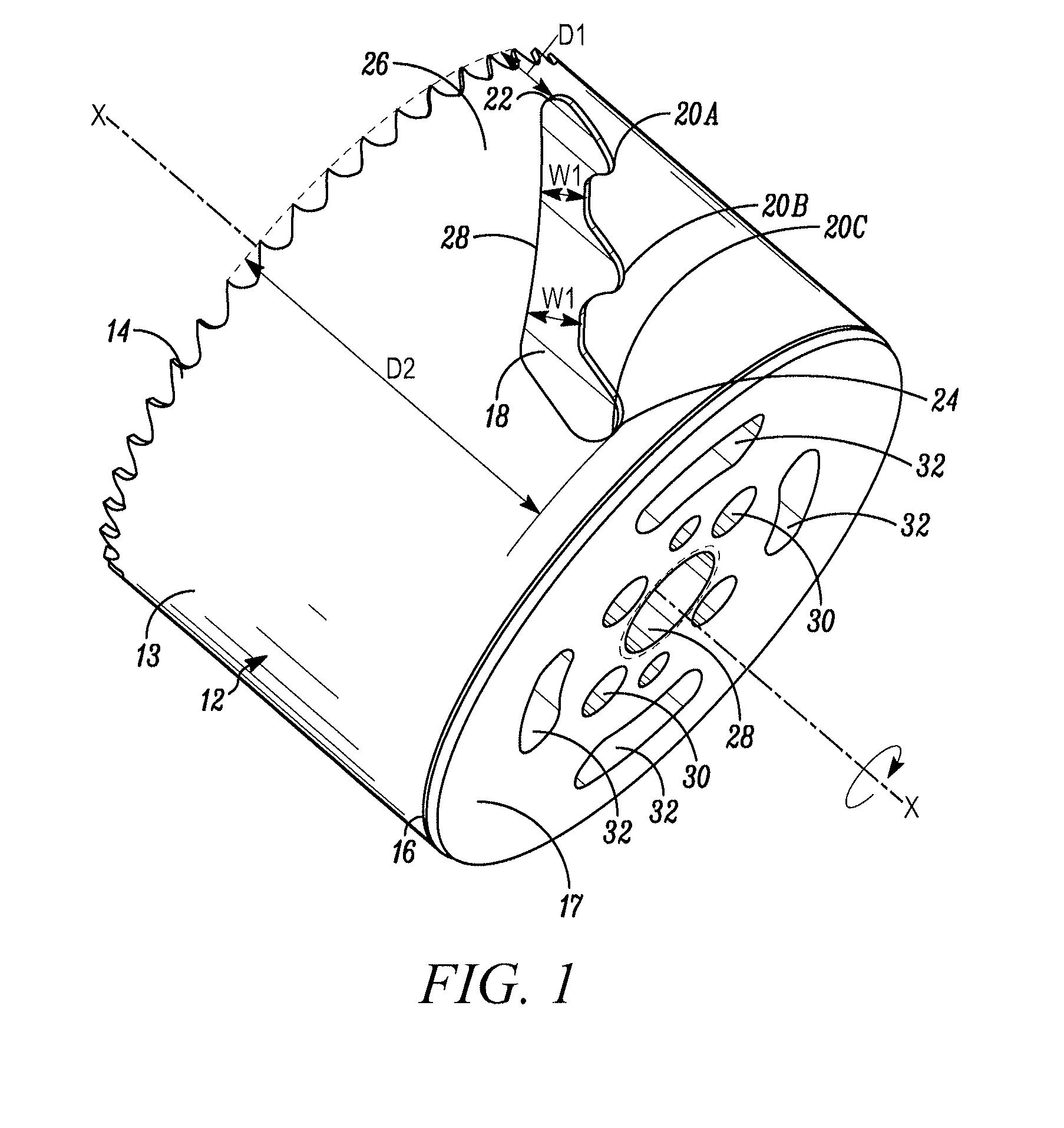

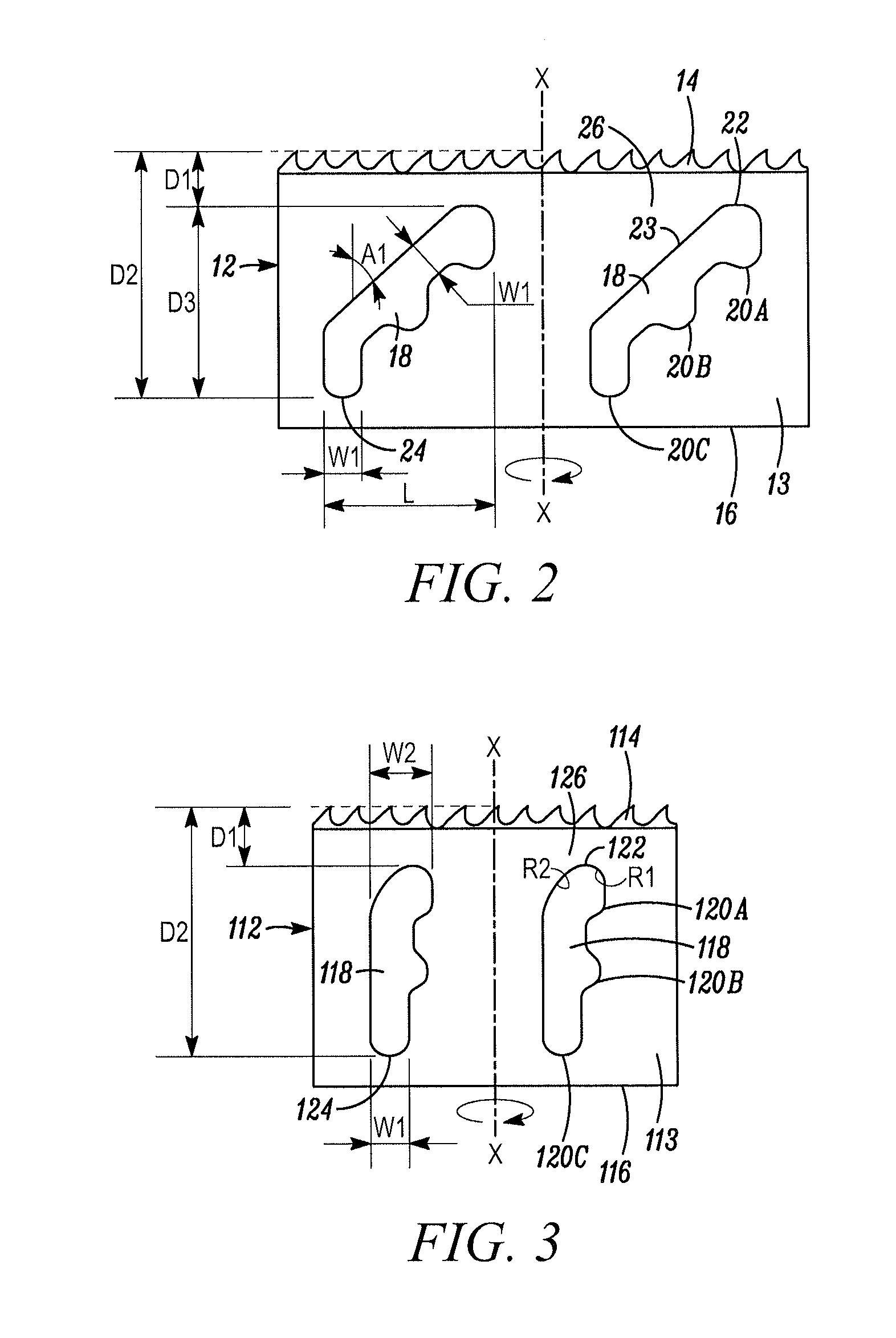

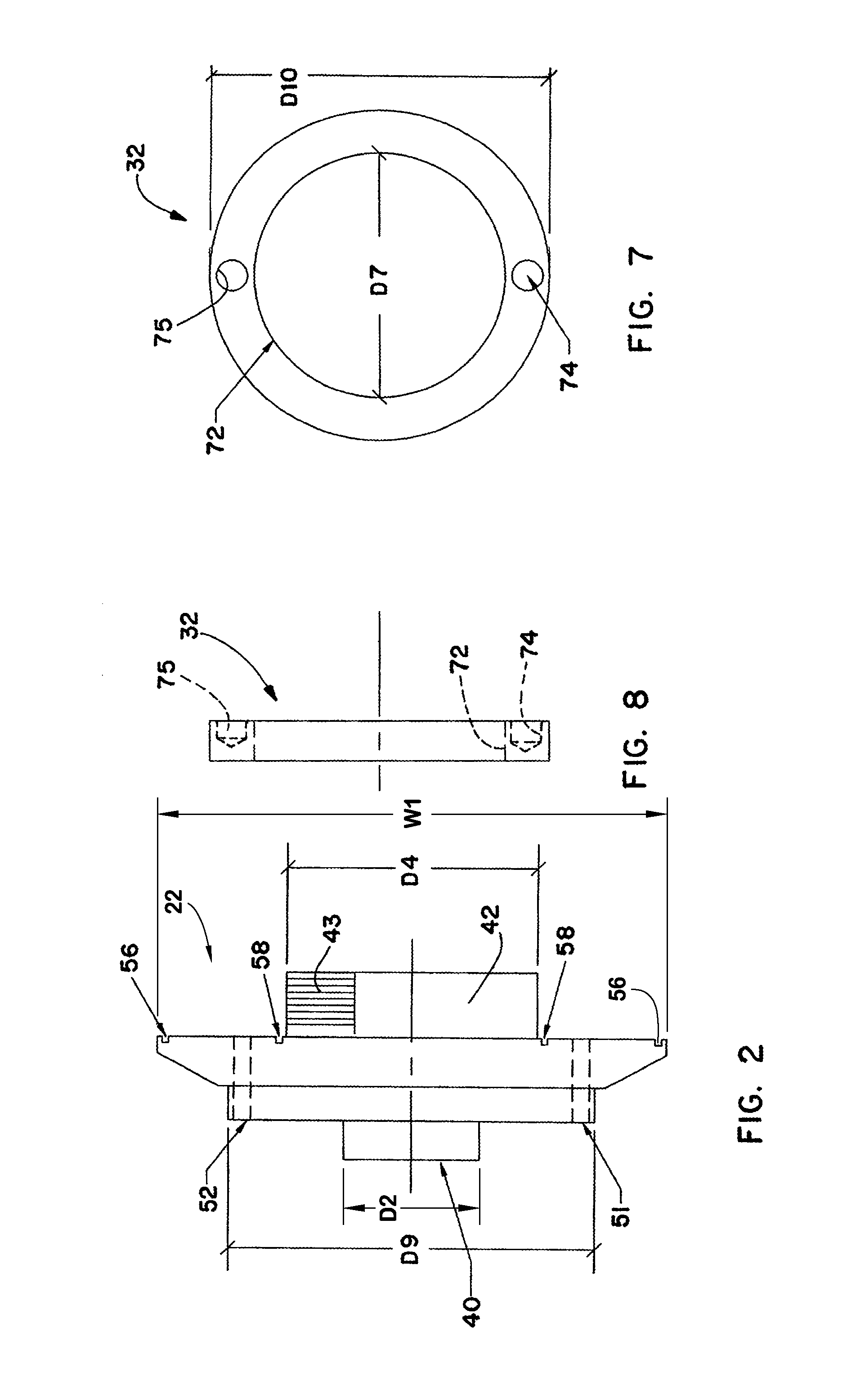

Hole Cutter with Chip Egress Aperture

ActiveUS20110170967A1Easy to moveAvoid collectingTransportation and packagingCircular sawsMechanical engineering

A hole cutter has a substantially cylindrical blade body defining a blade body circumference, a cutting edge formed on one end of the blade body, and an axially-elongated slot formed through the substantially cylindrical blade body. The axially-elongated slot is configured to receive chips flowing from the cutting edge within the interior of the blade body and (i) into the slot, and / or (ii) through the slot, to prevent the collection of such chips within the interior of the blade body and / or at an interface between the blade body and work piece. The axially-elongated slot defines a first end adjacent to the cutting edge, a second end axially spaced further from the cutting edge, and a slot area. The hole cutter further defines a total slot area to blade body circumference ratio within the range of about 0.1 to about 0.3 depending on the size of the hole cutter.

Owner:BLACK & DECKER INC

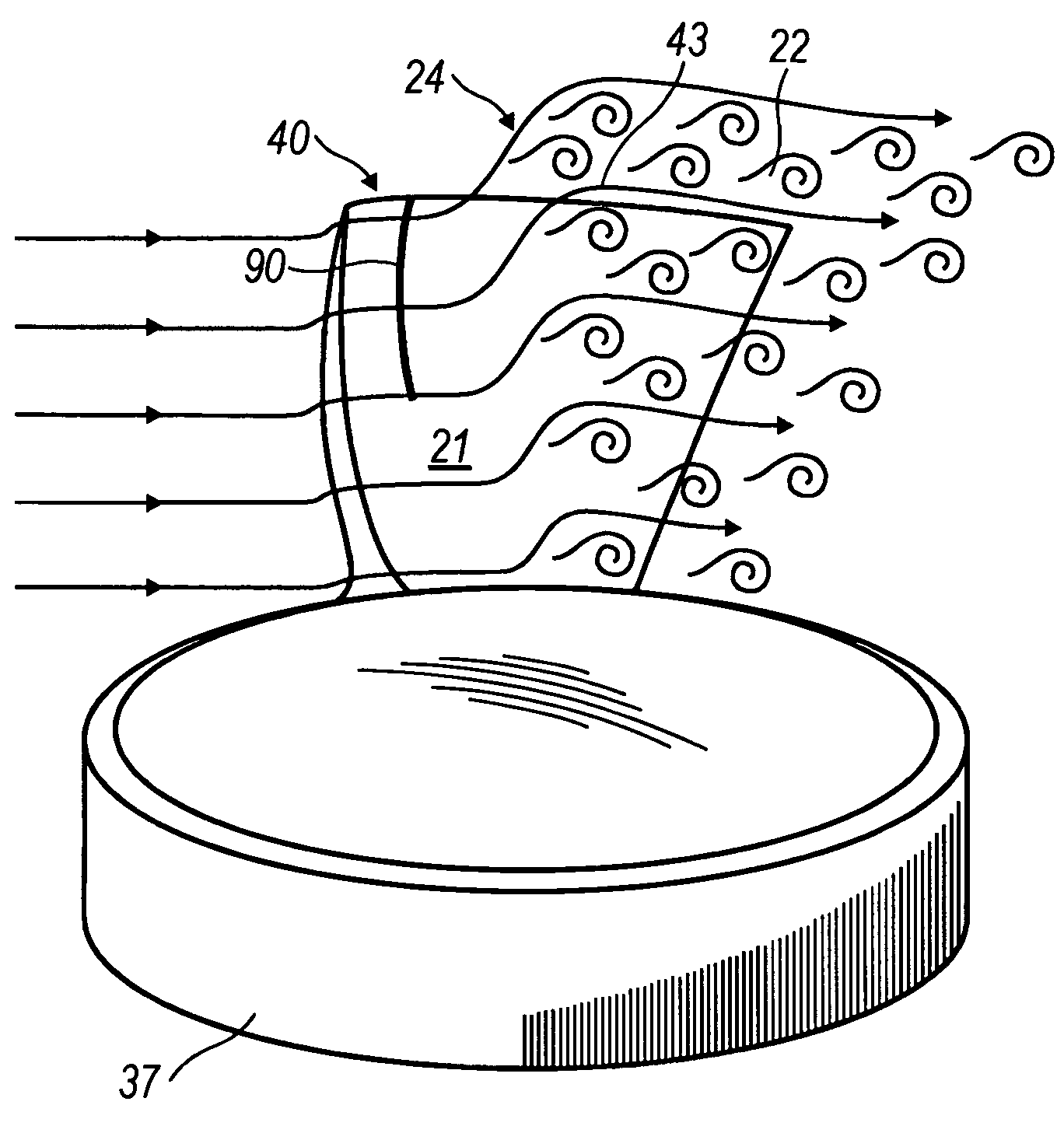

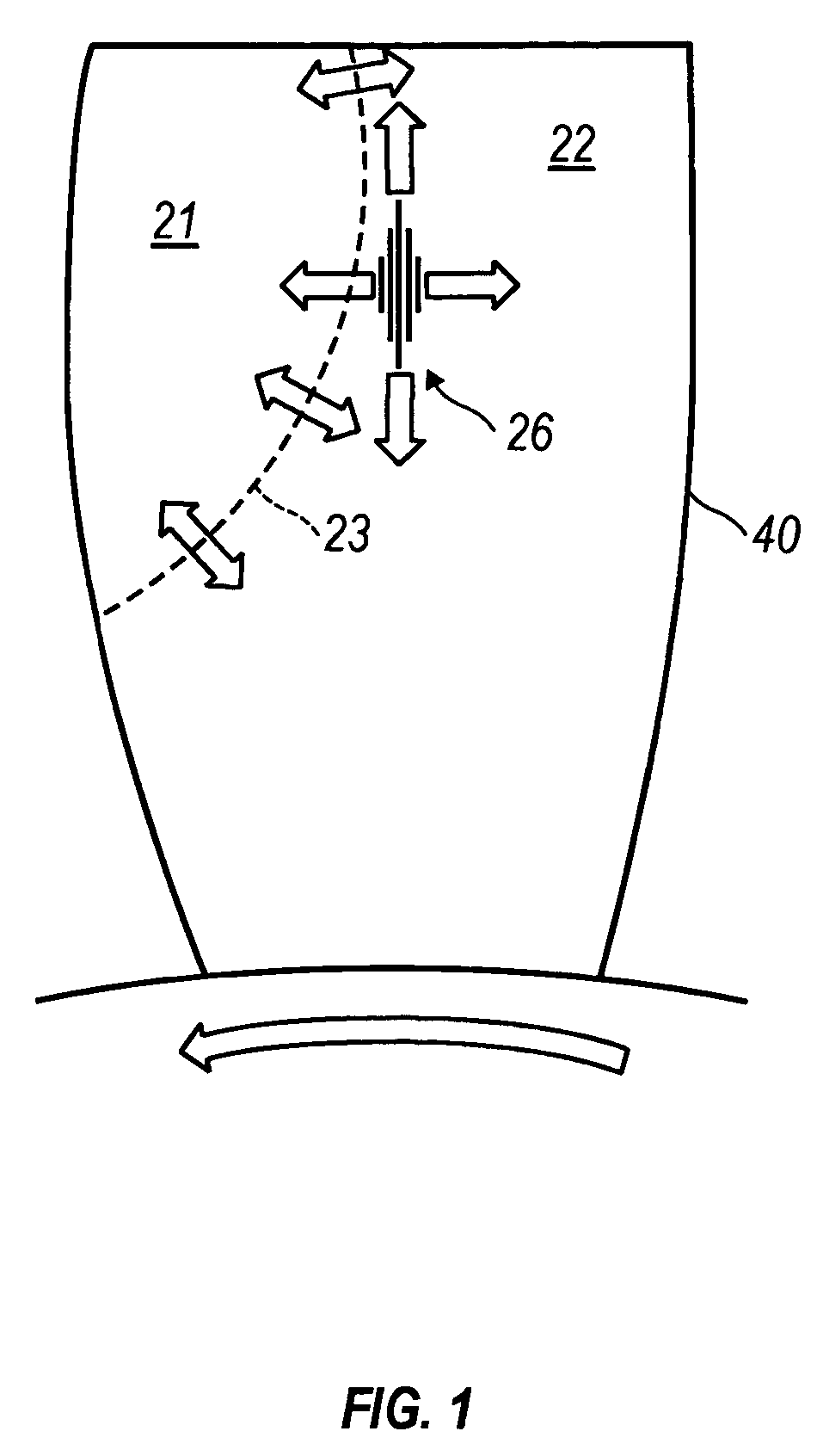

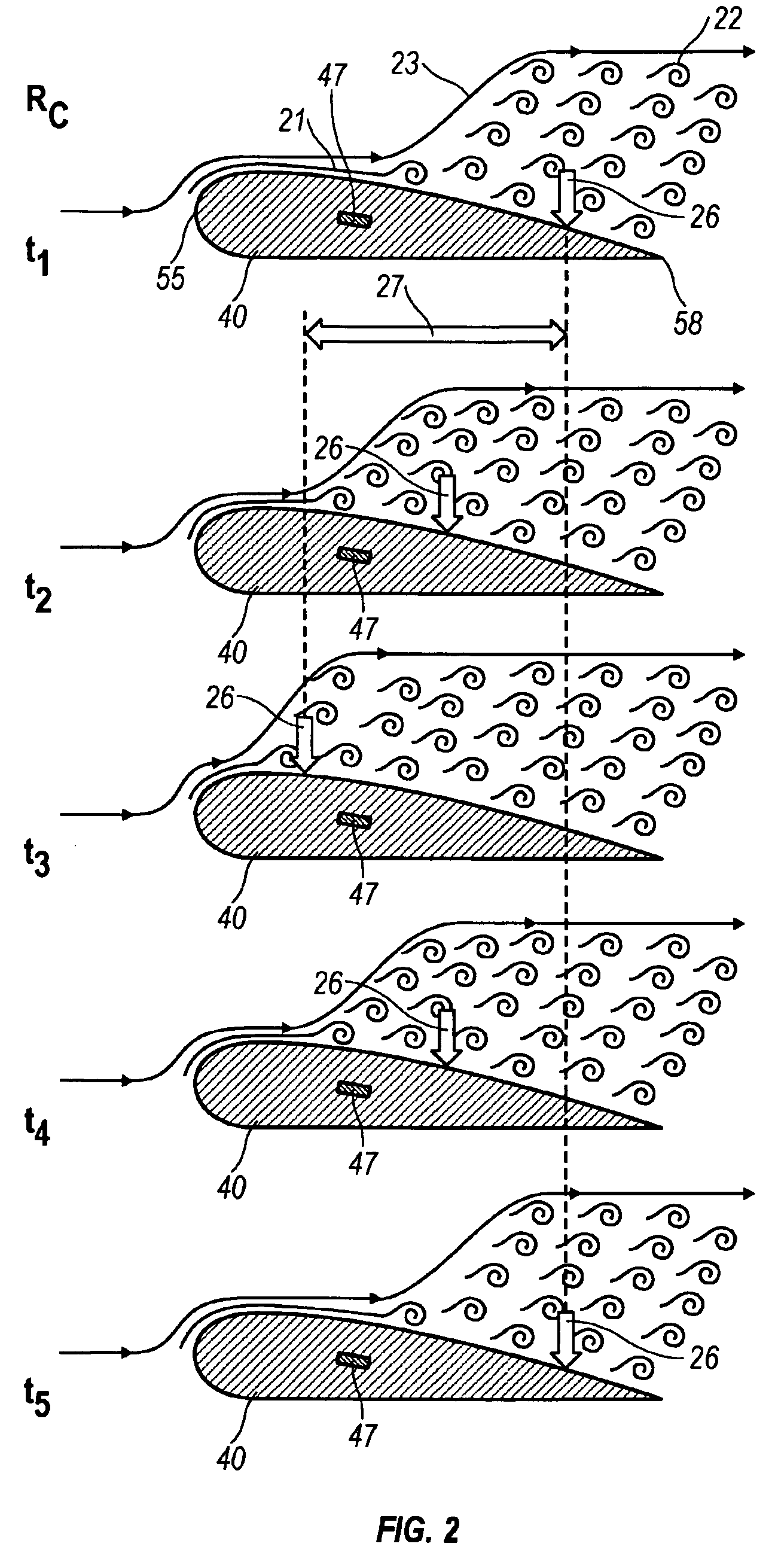

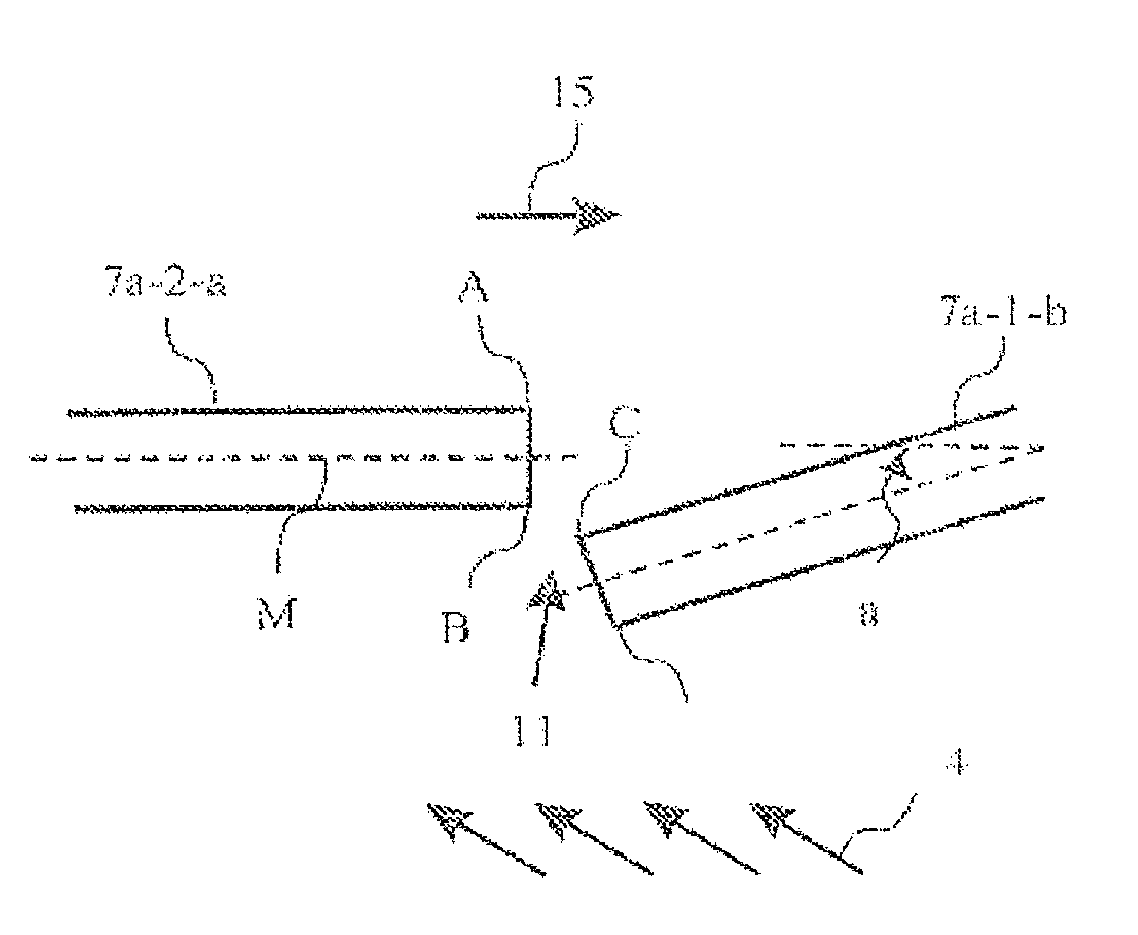

Mitigation of unsteady peak fan blade and disc stresses in turbofan engines through the use of flow control devices to stabilize boundary layer characteristics

ActiveUS7878759B2Direct and powerful and efficientReduce or eliminate unsteady aerodynamic flow effectsPropellersRotary propellersCircular discLeading edge

Method and apparatus for providing a turbofan blade 40 adapted to initiate and control a boundary layer transition at a side surface of the blade 40 during operation as a component in a turbofan assembly 35. The turbofan blade 40 includes a leading edge 55, a trailing edge 58, and two side surfaces including a high-pressure side surface 49 and a low-pressure side surface 52. At least one of the two side surfaces has an essentially smooth surface portion 61 located between the leading and trailing edges, and the essentially smooth surface portion is interrupted by a surface deviation 64. The surface deviation is configured to fix a positionally unstable laminar to turbulent boundary layer transition 24 at a location toward the trailing edge from the surface deviation during operation of the turbofan blade in the turbofan assembly. In this manner, fatigue inducing and / or structurally damaging unsteady aerodynamic forces experienced upon the blade and / or fan disc during operation are controlled, and the resultant fluctuating fan blade and disc peak stresses are mitigated.

Owner:ROLLS ROYCE DEUT LTD & CO KG

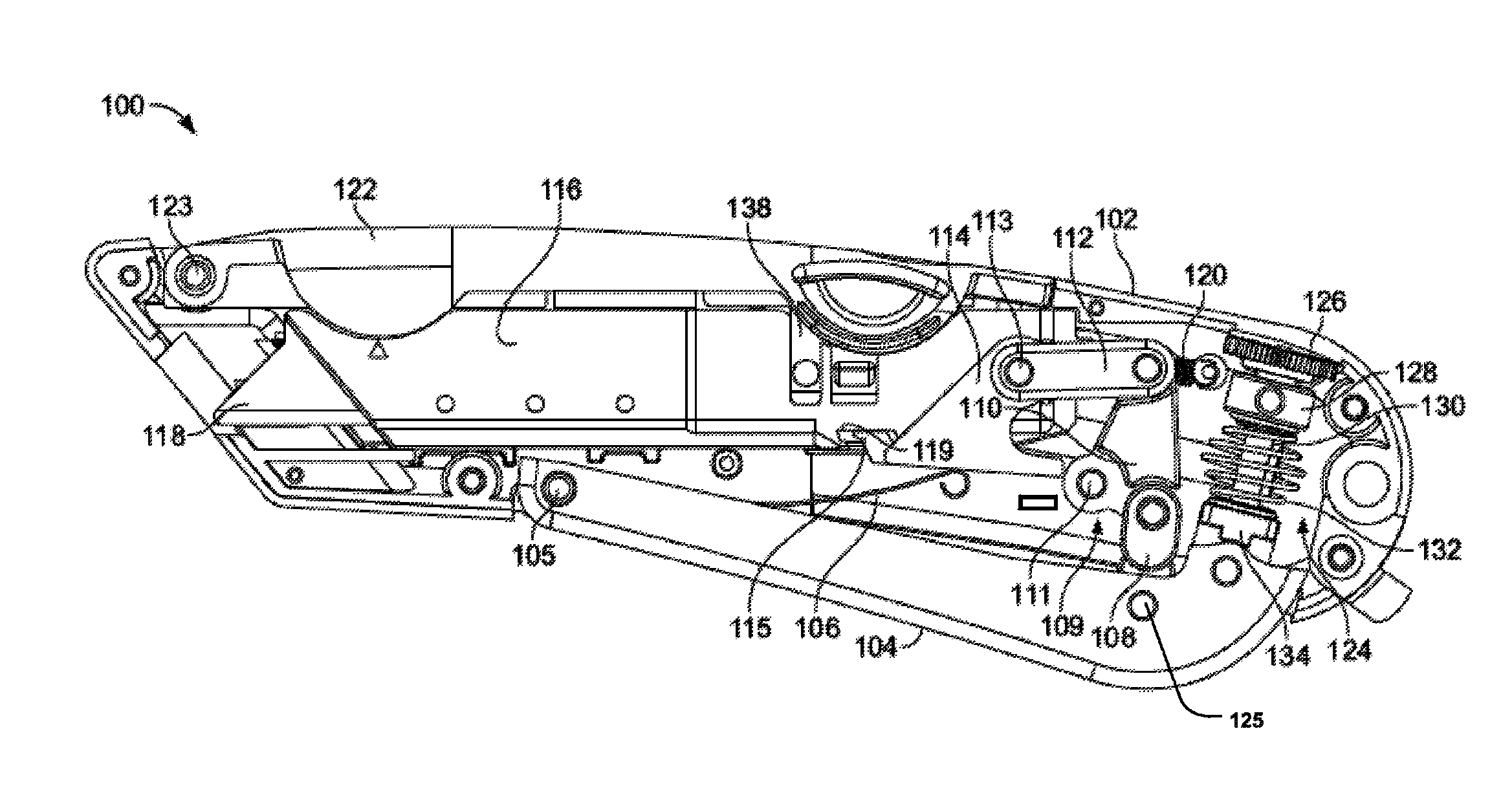

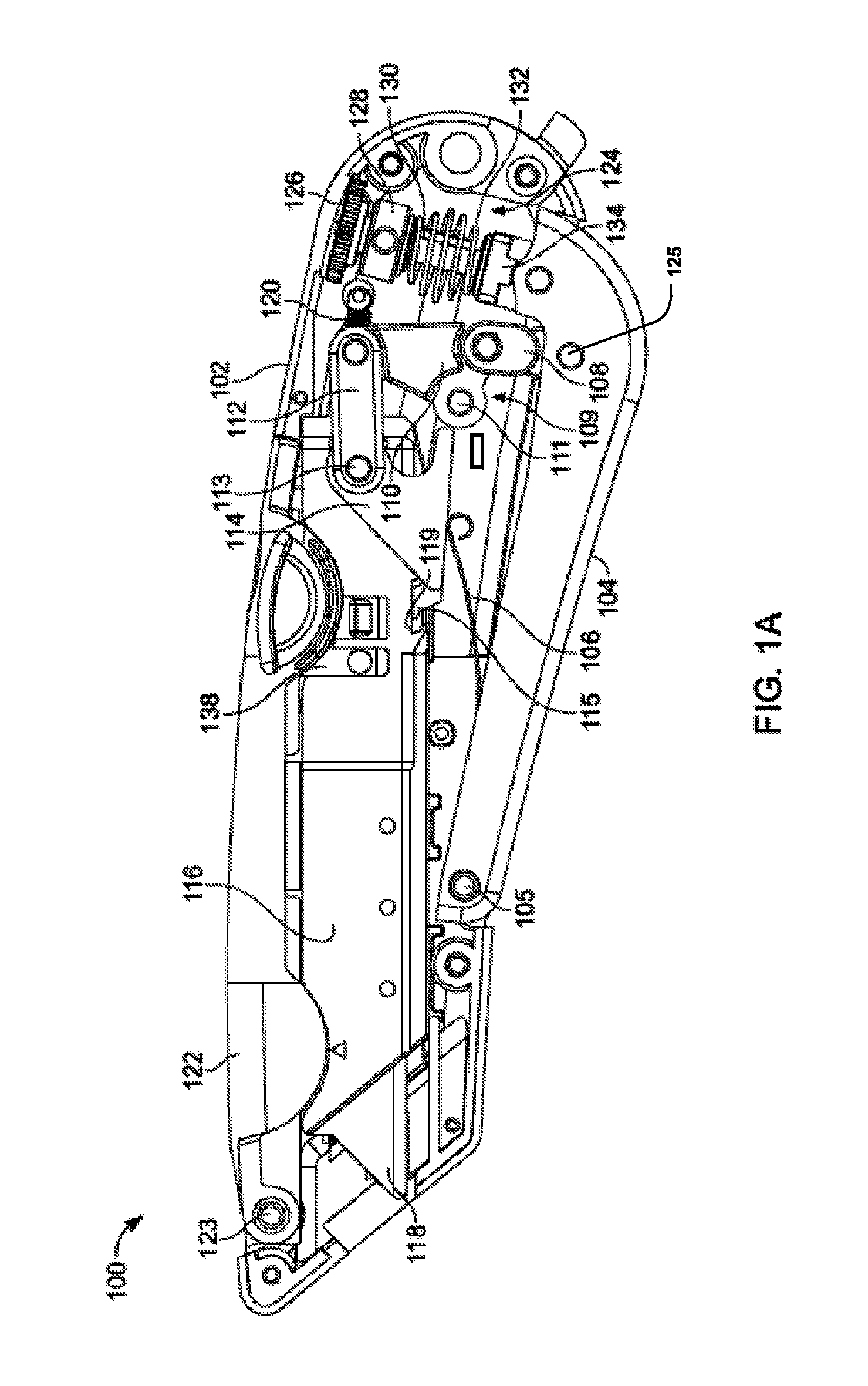

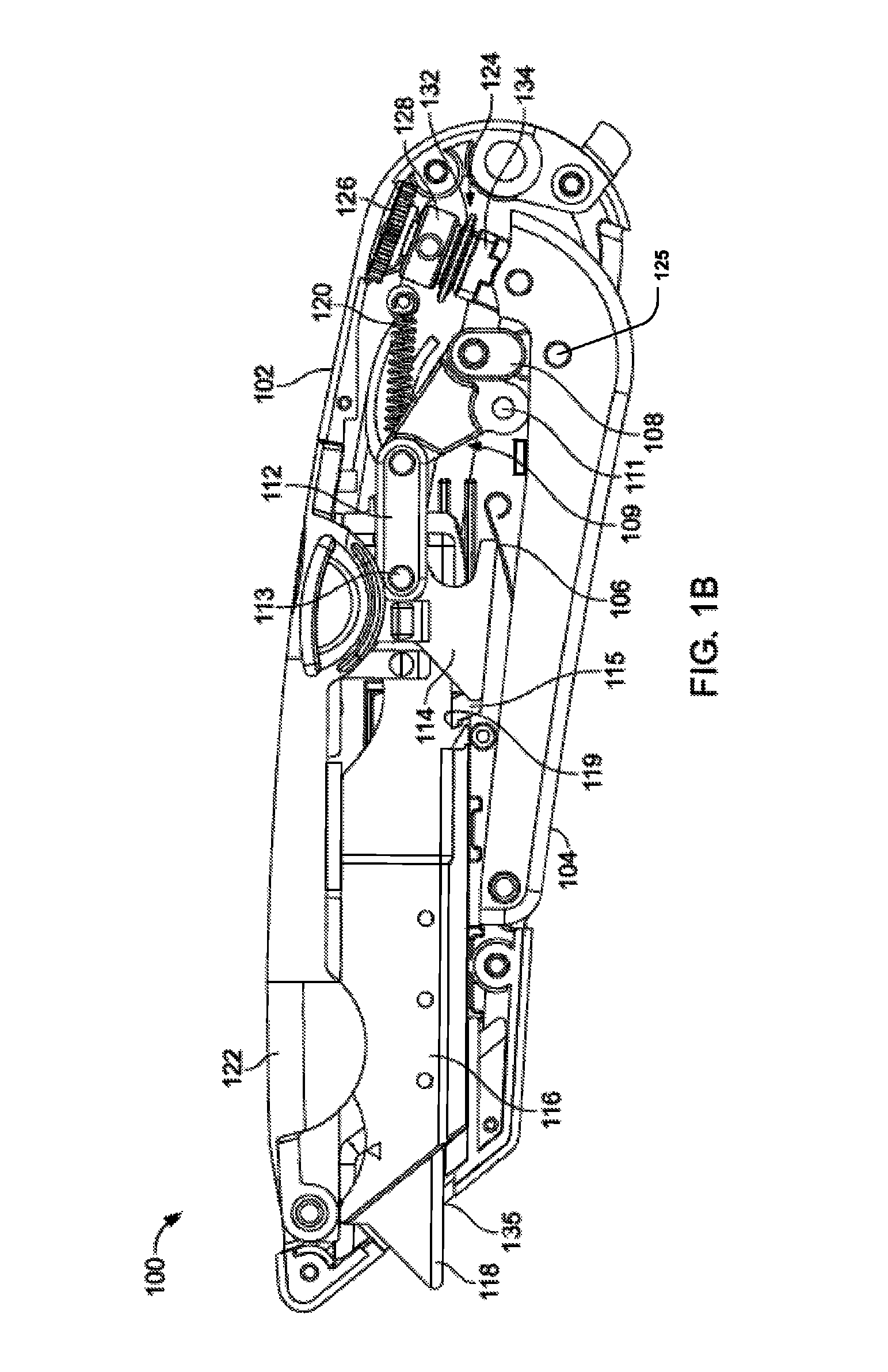

Adjustable utility knife

ActiveUS8250764B2Weaken energyReduce laborThrusting weaponsWeapon componentsRest positionFixed length

Owner:ADCO IND TECH

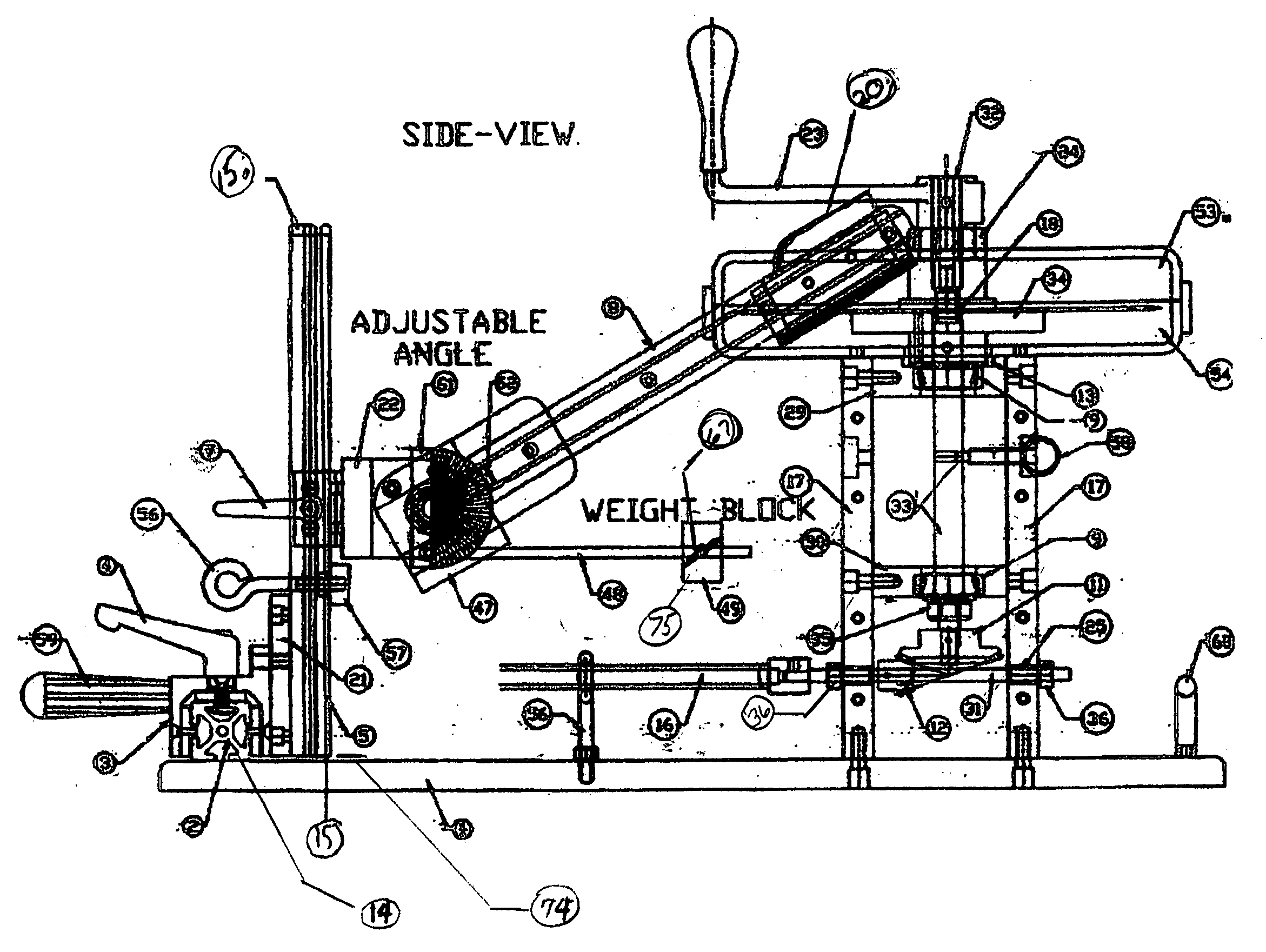

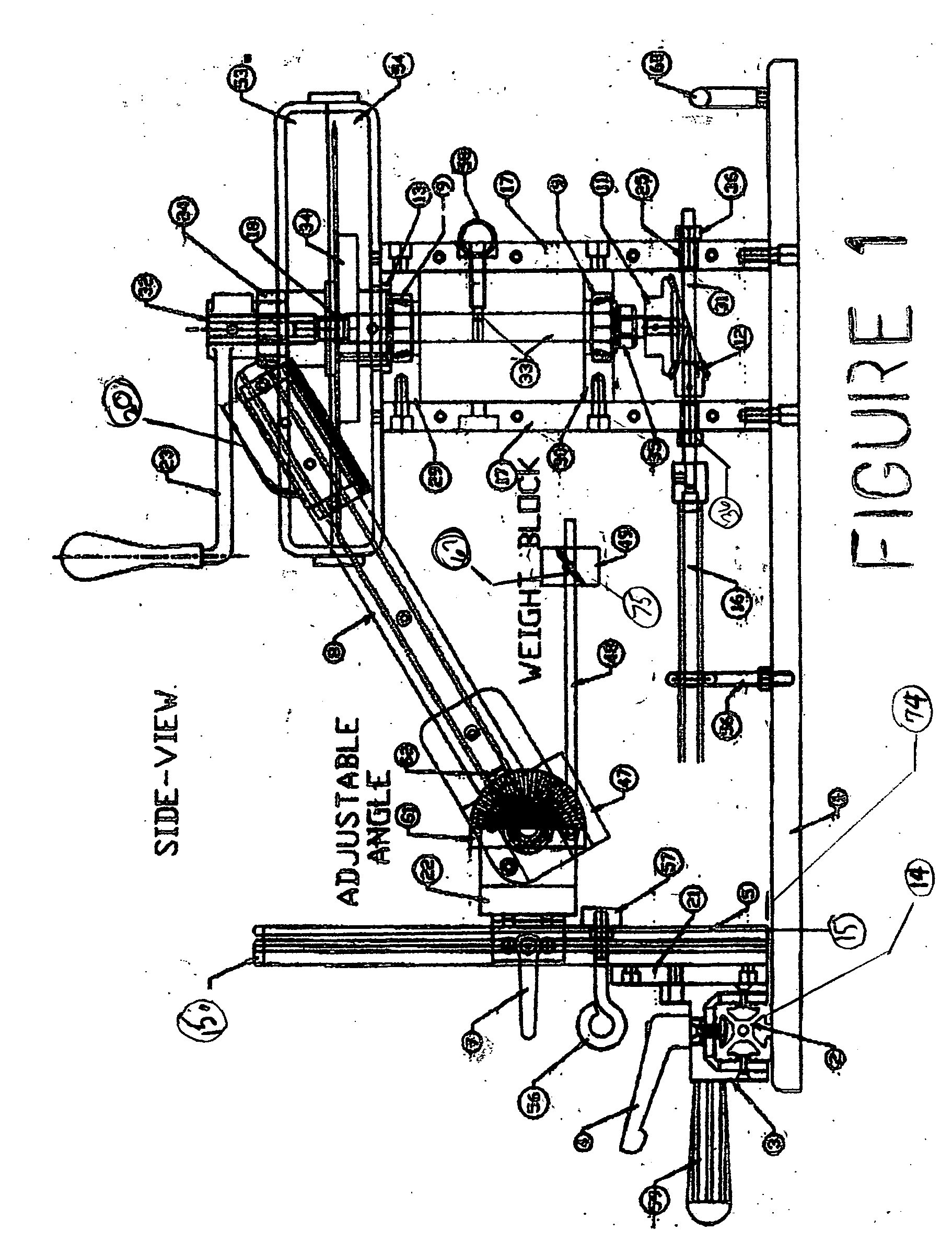

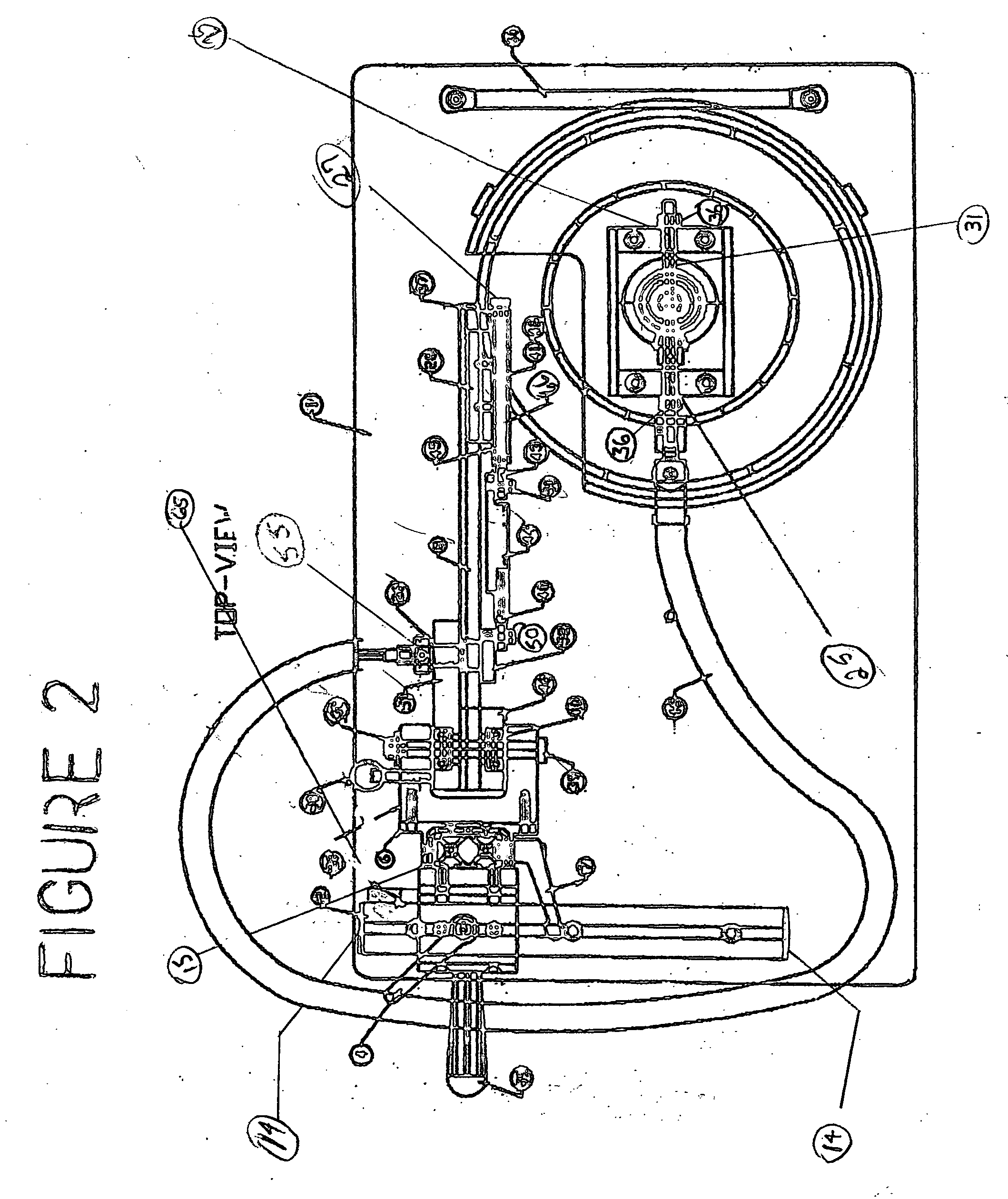

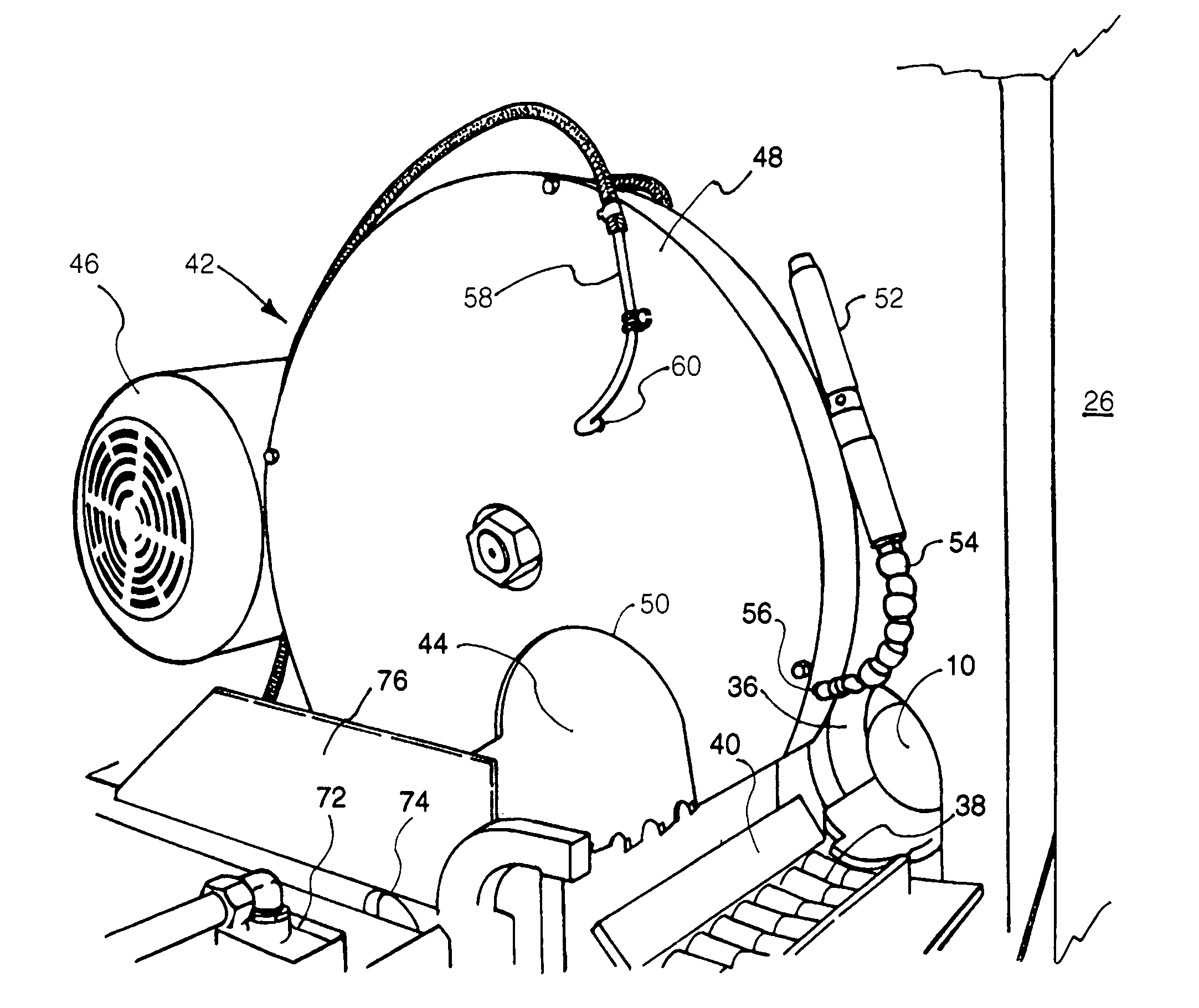

Edge buster series round blade sharpener and the edge tracker sharpener

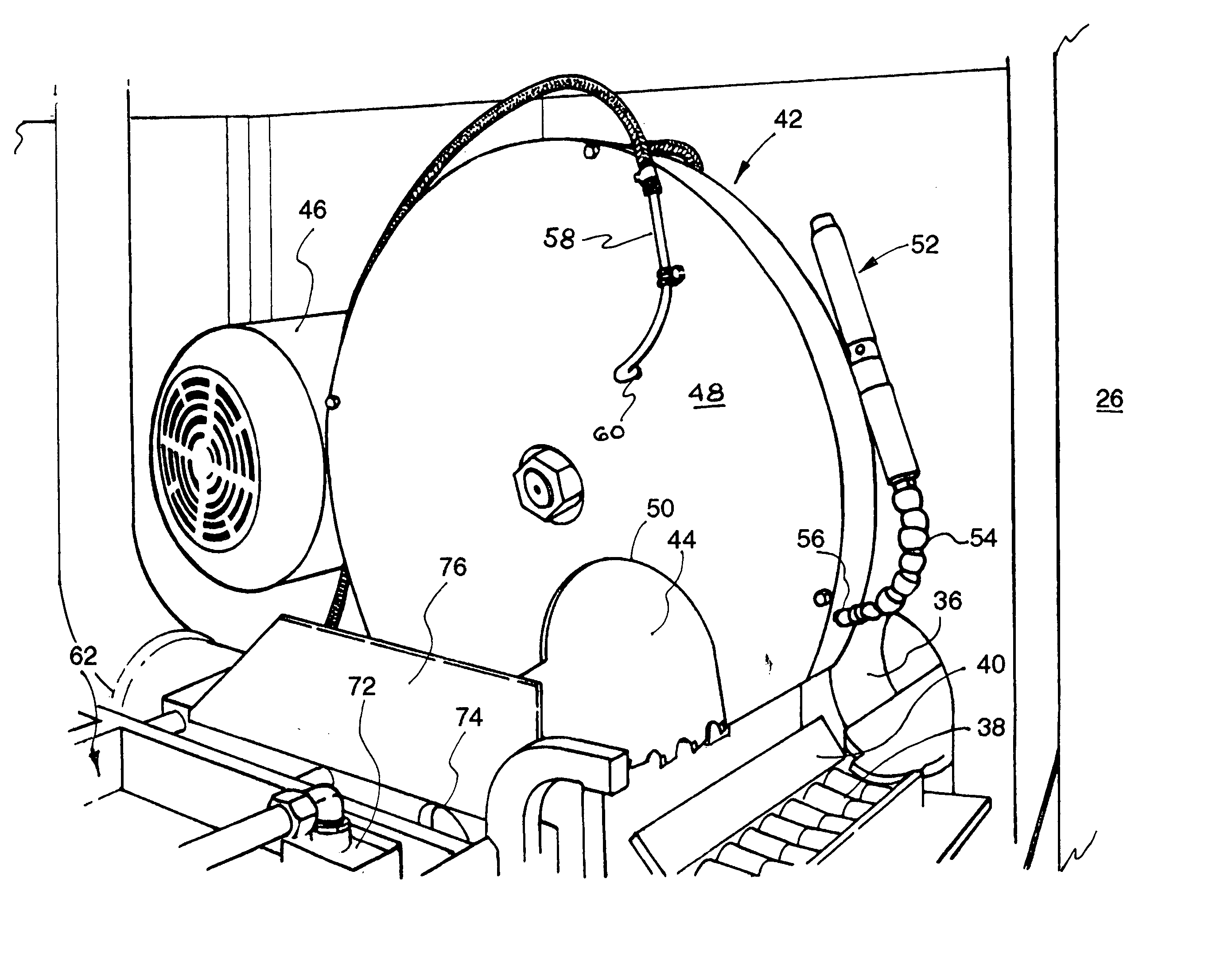

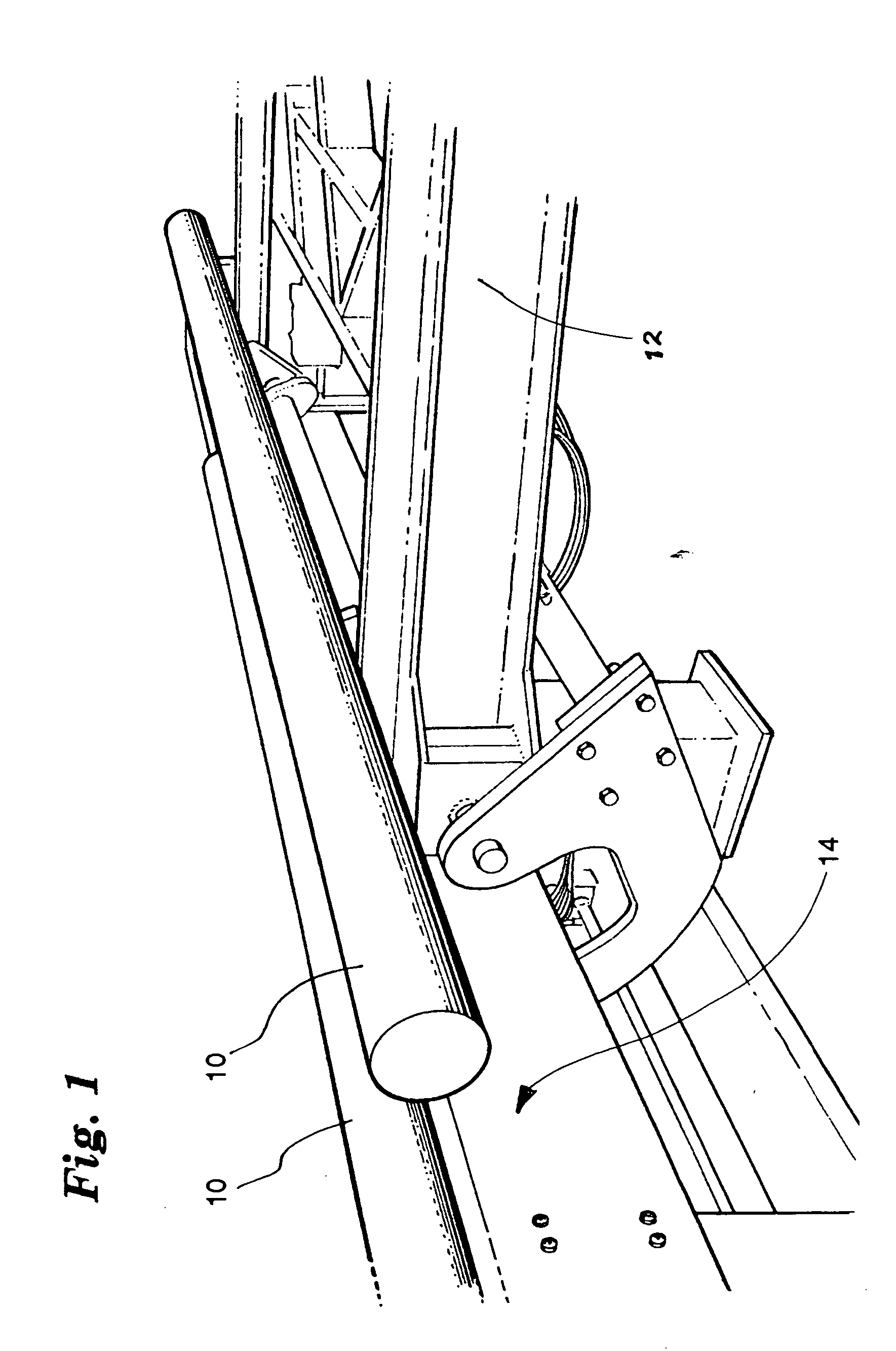

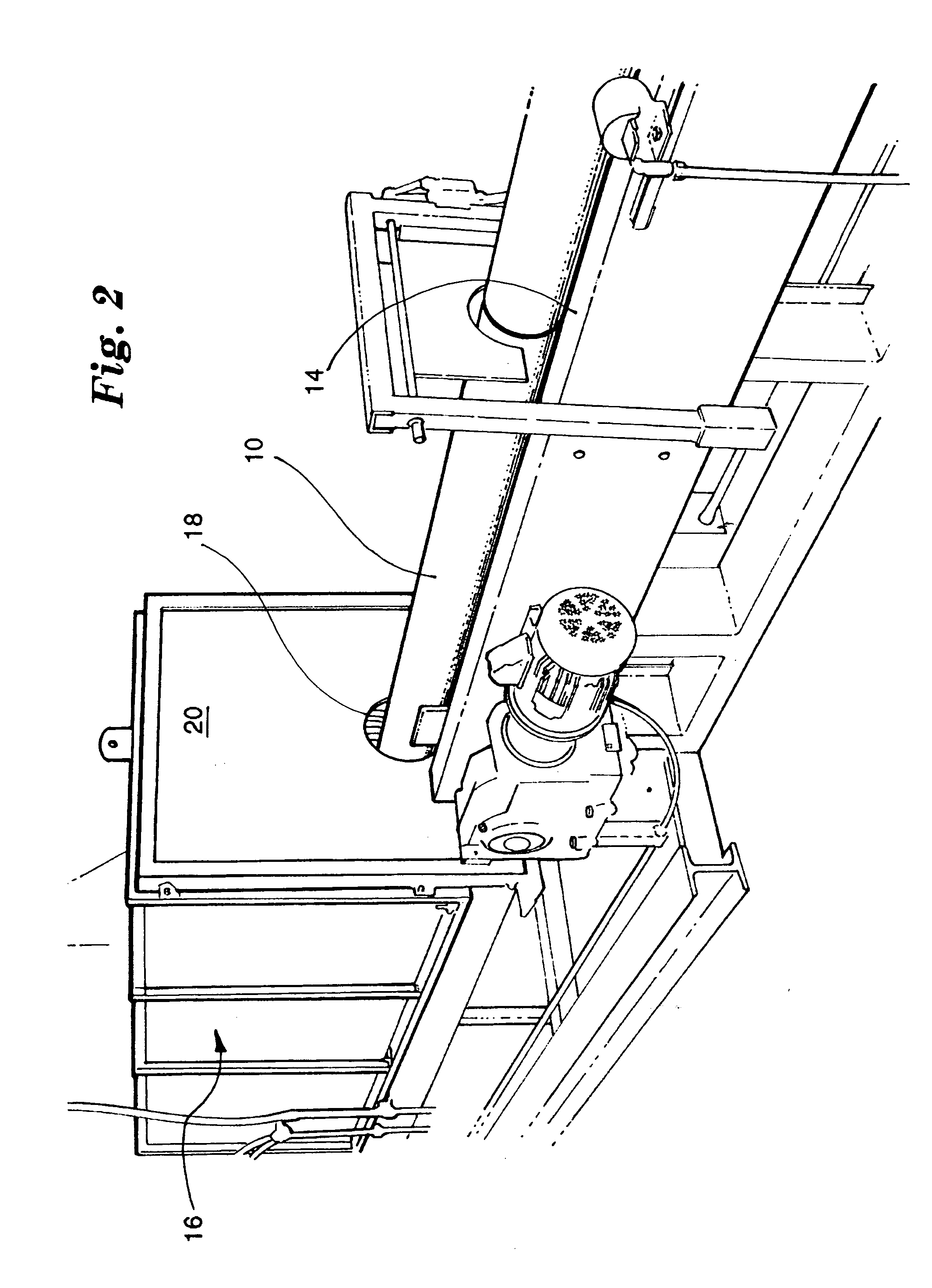

InactiveUS20070026771A1Extend blade lifeDestroying the temper of the bladeOther manufacturing equipments/toolsPlane surface grinding machinesKnife bladesSizing

Apparatus for sharpening, grinding or sizing a cutting edge on a circular blade which has dulled, chipped, or needs re-sizing blades from 2½″ to 48″ diameter. Differs from prior art in that it sharpens, grinds or sizes circular blades and blades with different geometrical shaped blades. Manually or pneumatically externally powered driven. Furthermore, it is necessary to maintain factory blade edge angles when sharpening the edge of the blade allowing the blade life to be greatly extended and maintain a like new cutting edge through out the life of the circular blade. Present invention is also unique in respect to the not heating up of the blade edge using similar devices. The simplest and safest sharpener of its type to operate. Also the Pneumatically Driven Machine incorporates such a design as to sharpen blades which are of different geometric shapes I.e. Scalloped, Wide Slotted

Owner:HARDEN KATHLEEN +1

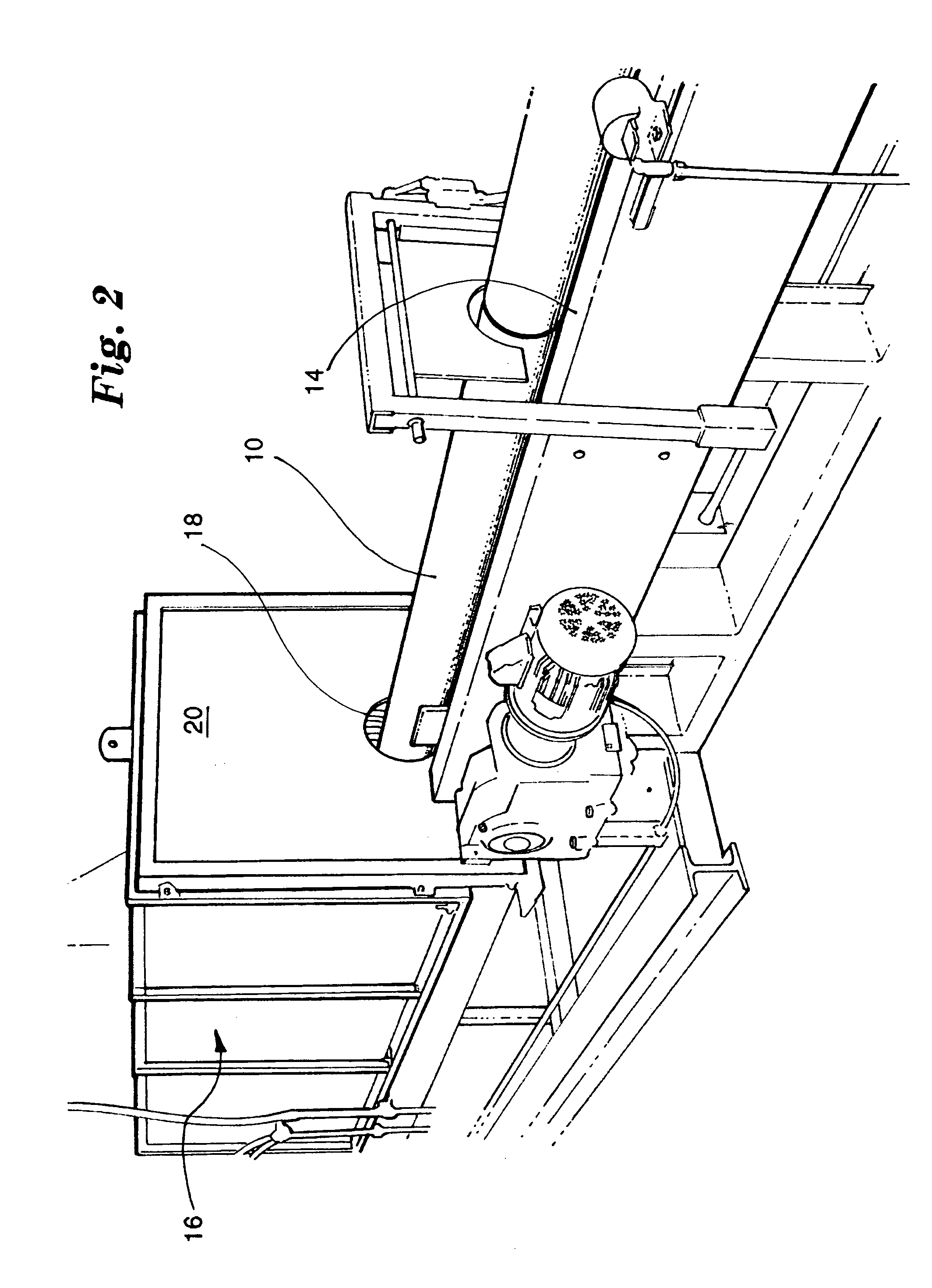

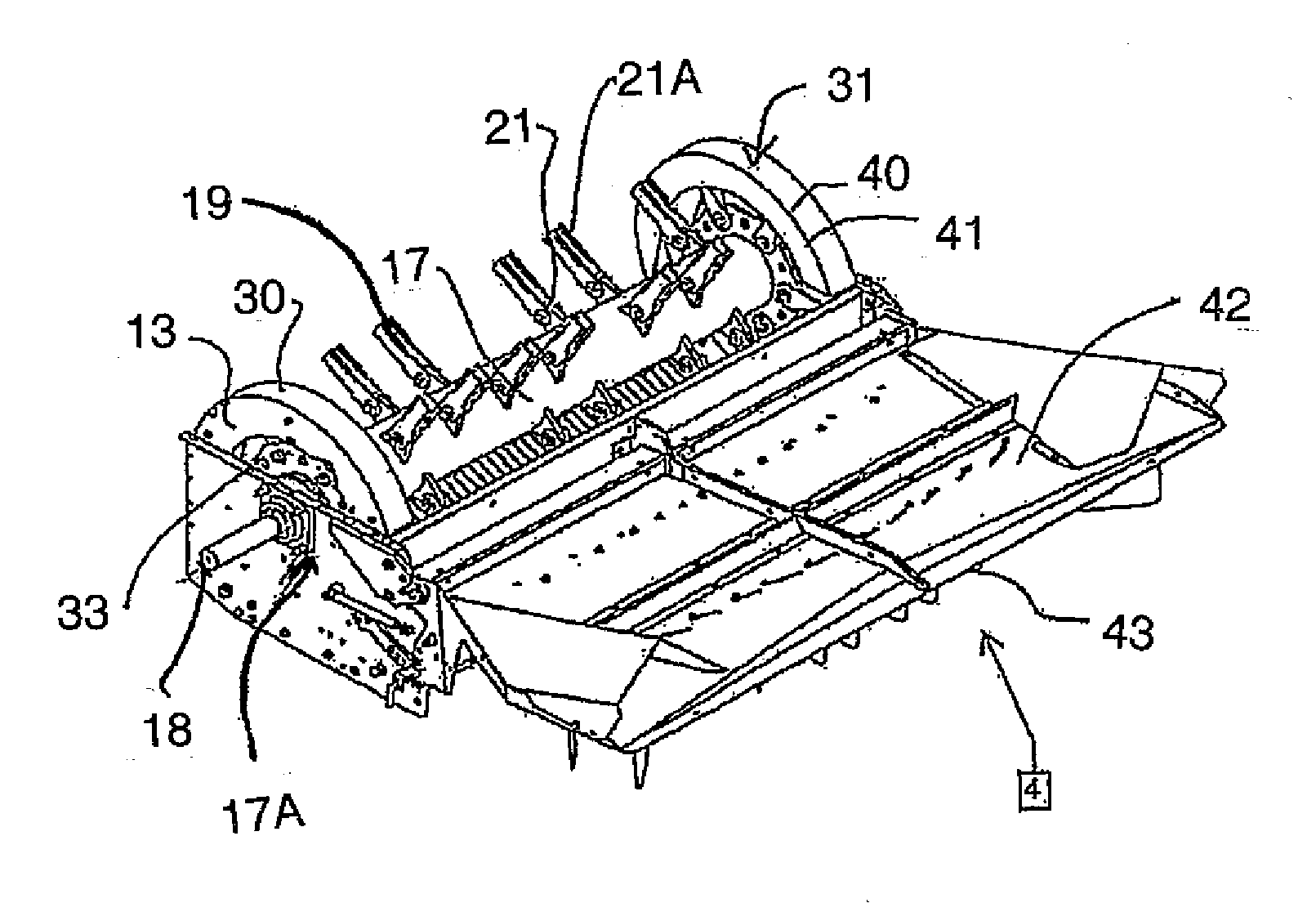

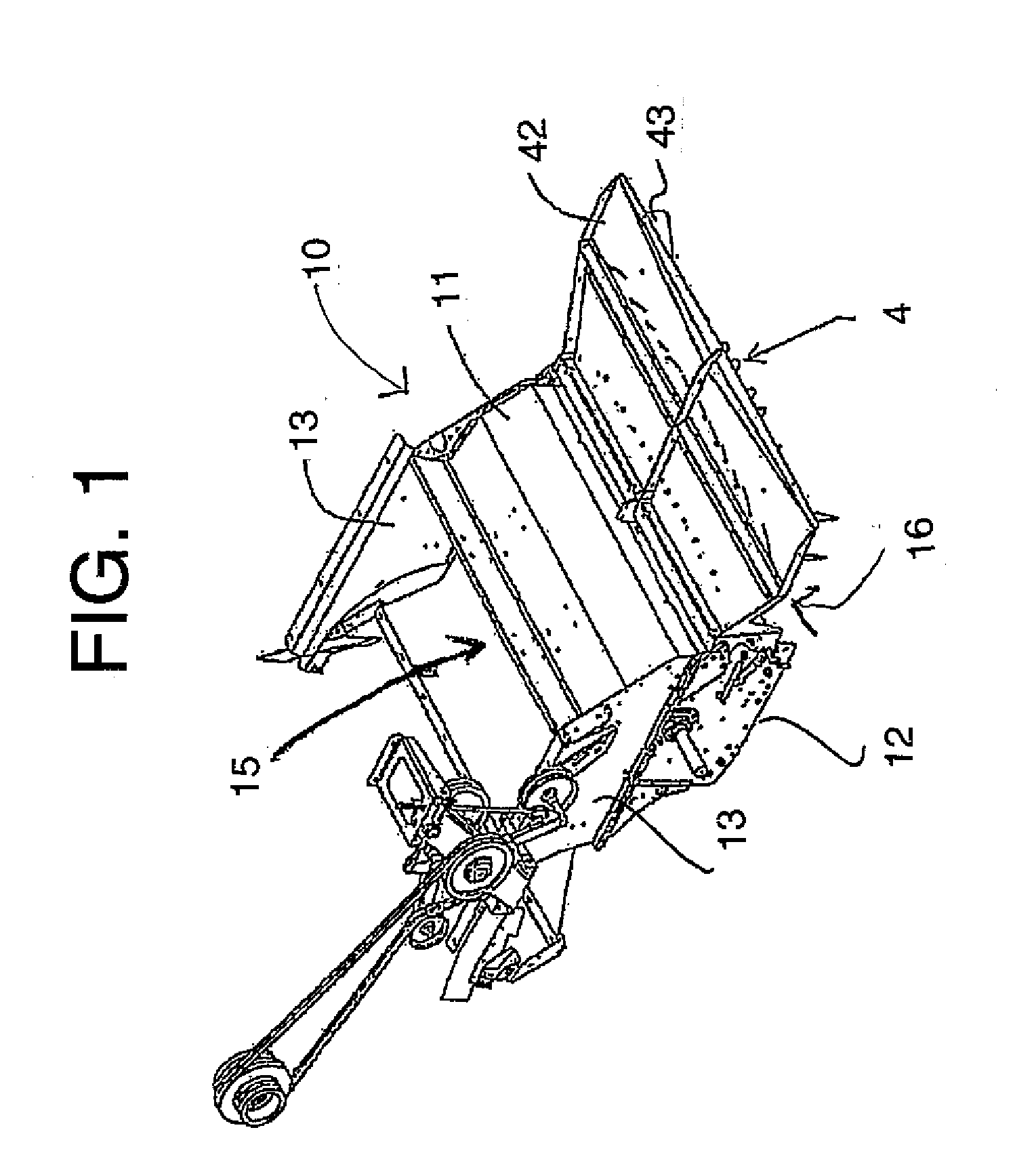

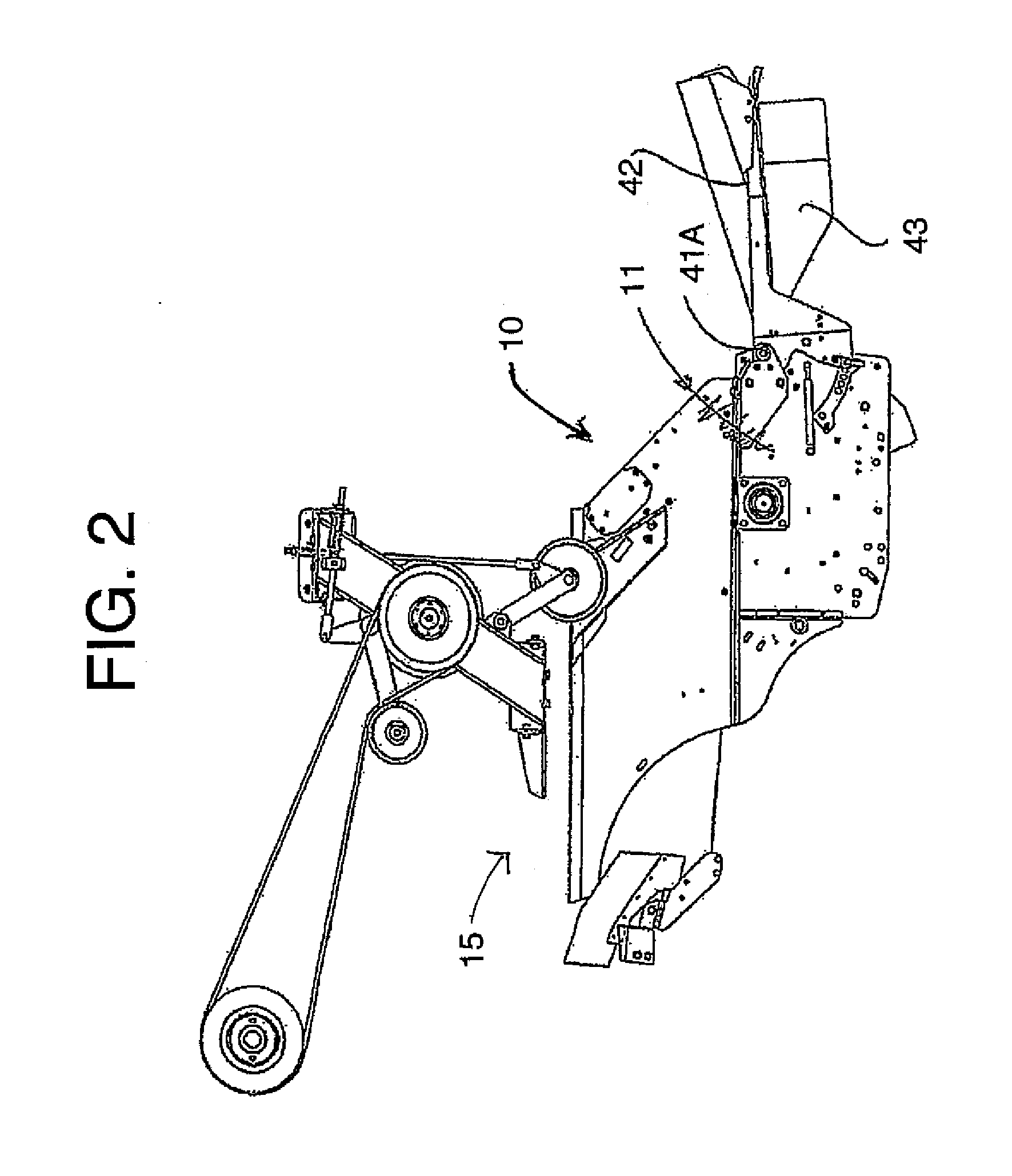

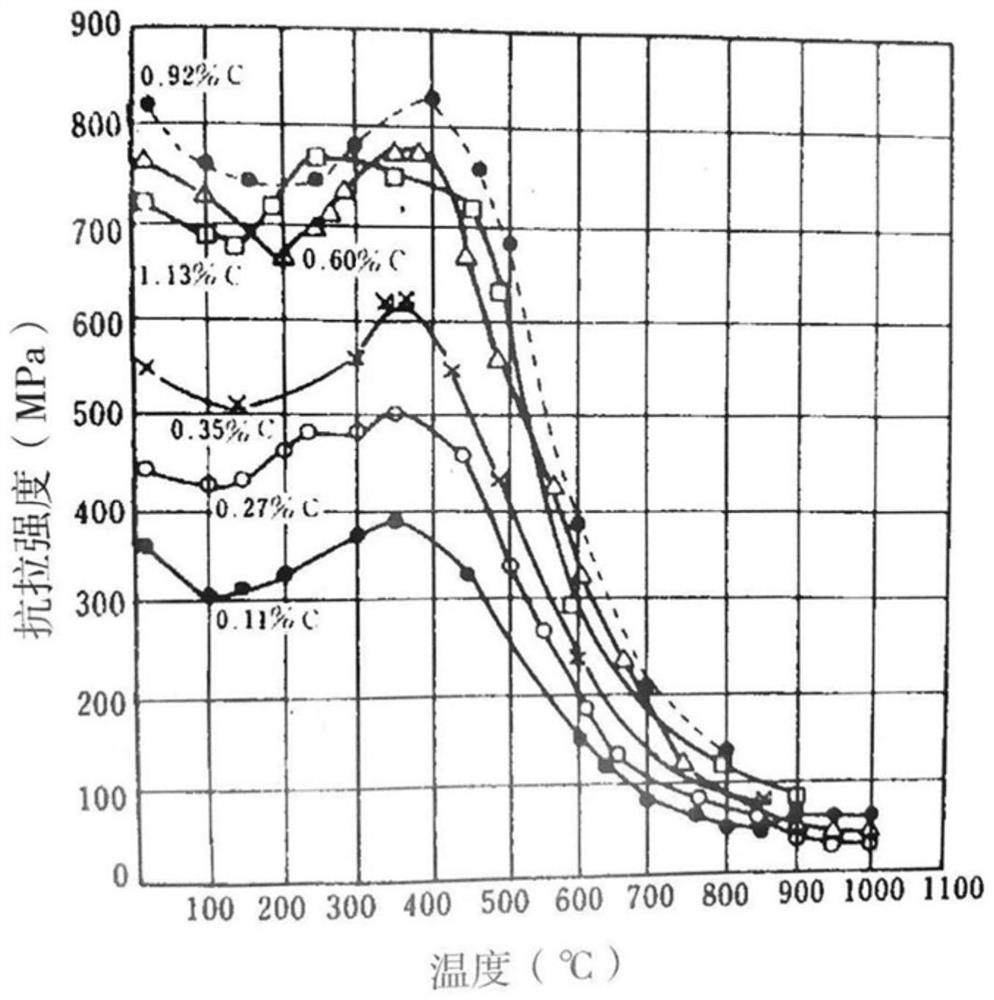

Hot cut aluminum billet saw

ActiveUS20050034502A1Reduce the temperatureLess scrapMetal sawing devicesMetal sawing accessoriesCross cutCircular saw

A process and apparatus for extruding aluminum into products, wherein aluminum logs are first heated to a predetermined temperature in a furnace, then are cut into billets of predetermined lengths, and then the billets, while still hot, are extruded into predetermined products in an extruder. In the process, the logs are cut into billets with a cross cut circular saw immediately after the logs are heated and before the logs are permitted to cool to a temperature below a suitable extruding temperature. The circular saw is cooled and lubricated during the cutting to as to restrain the saw from sticking in the heated aluminum and so as to maintain the temperature of the log at the cut within a predetermined range wherein the aluminum is relatively easy to cut and waste is minimized.

Owner:BELCO INDS

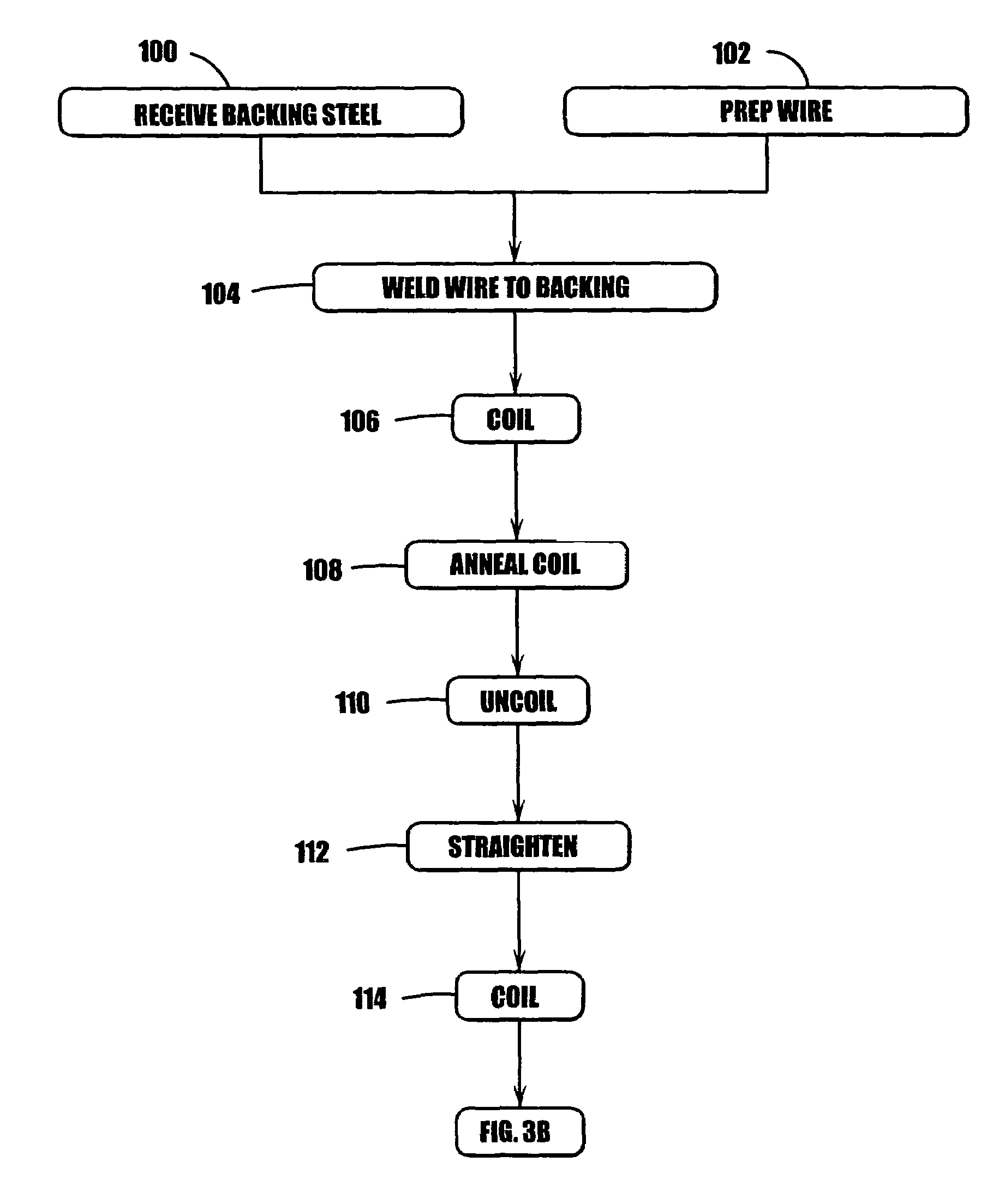

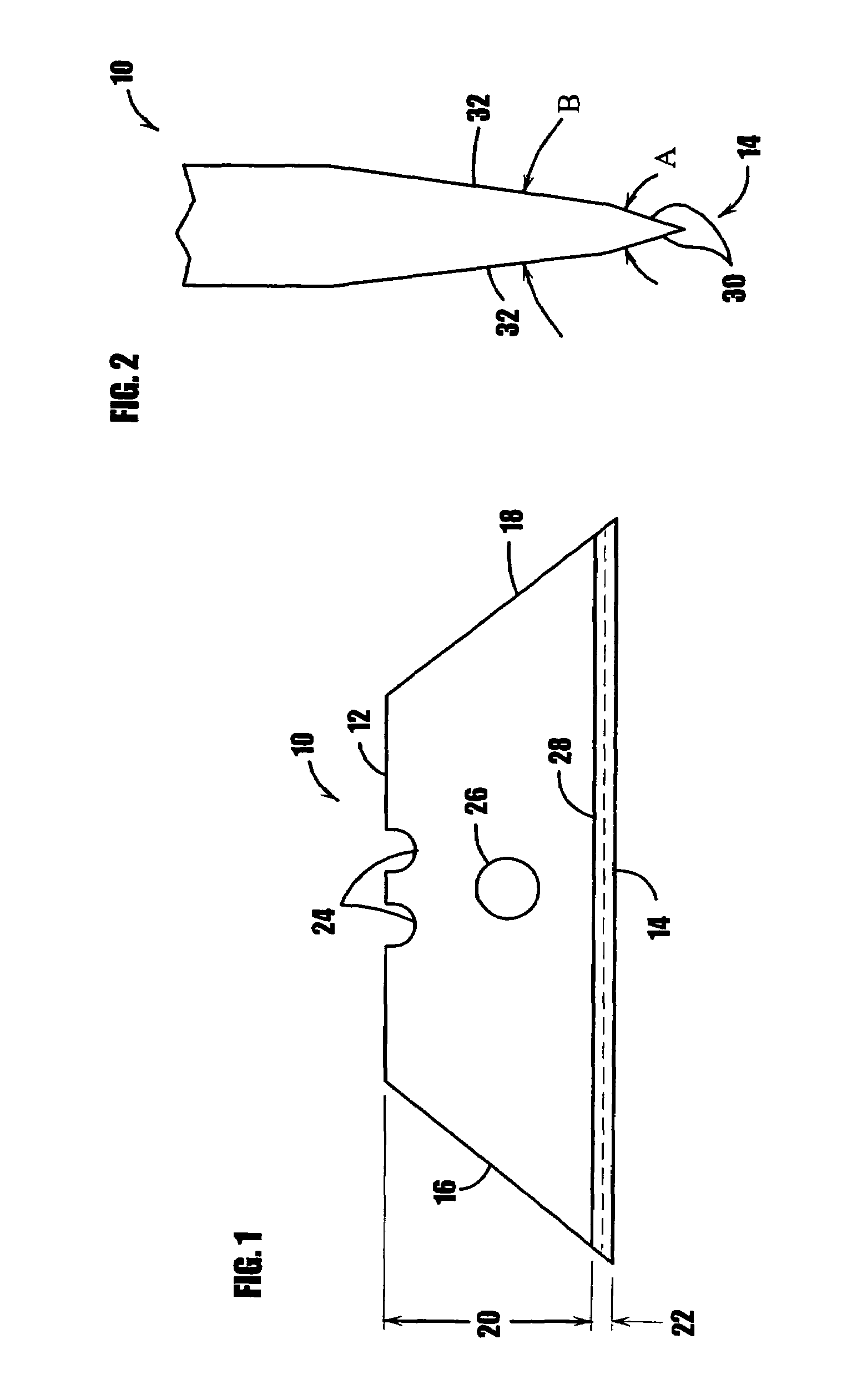

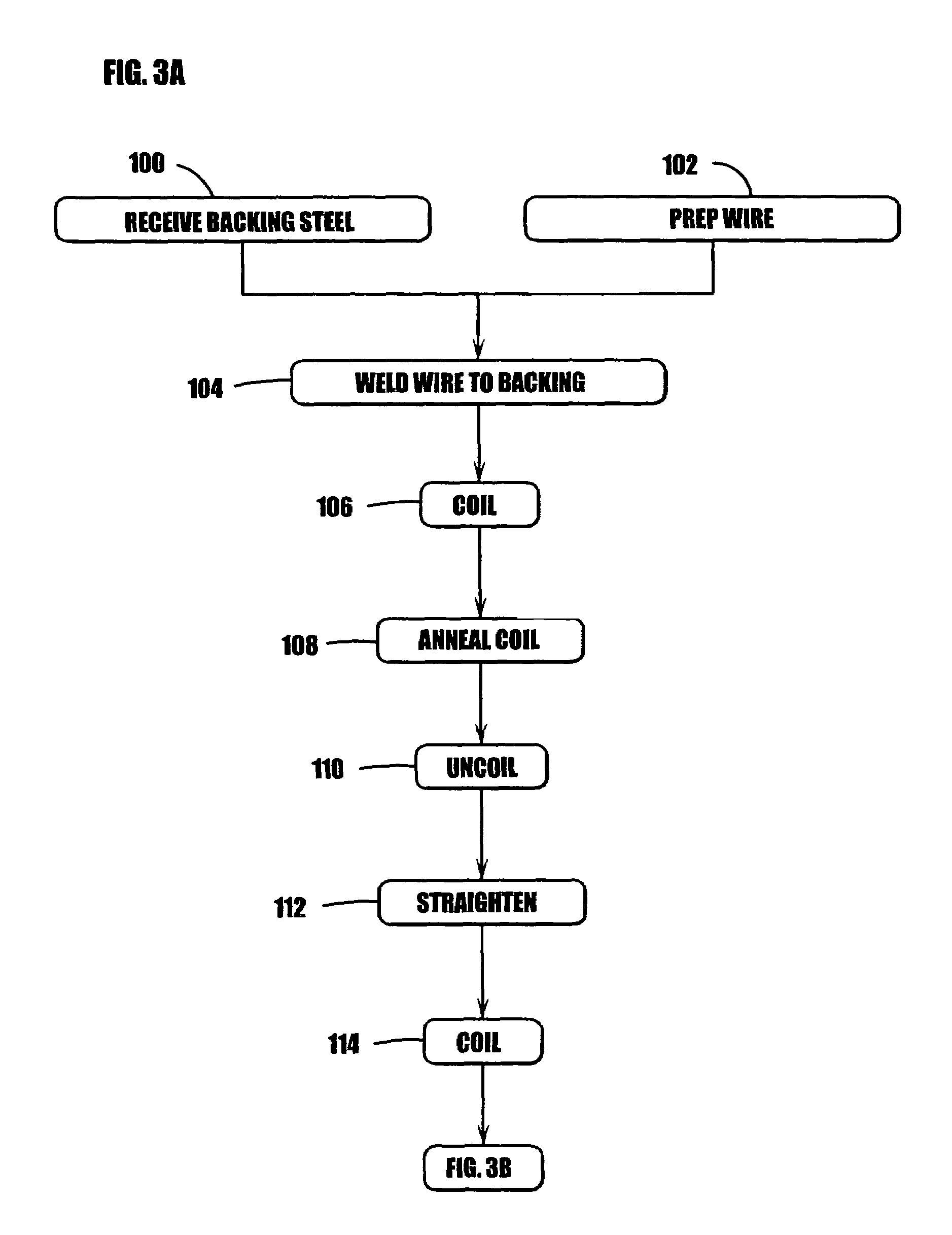

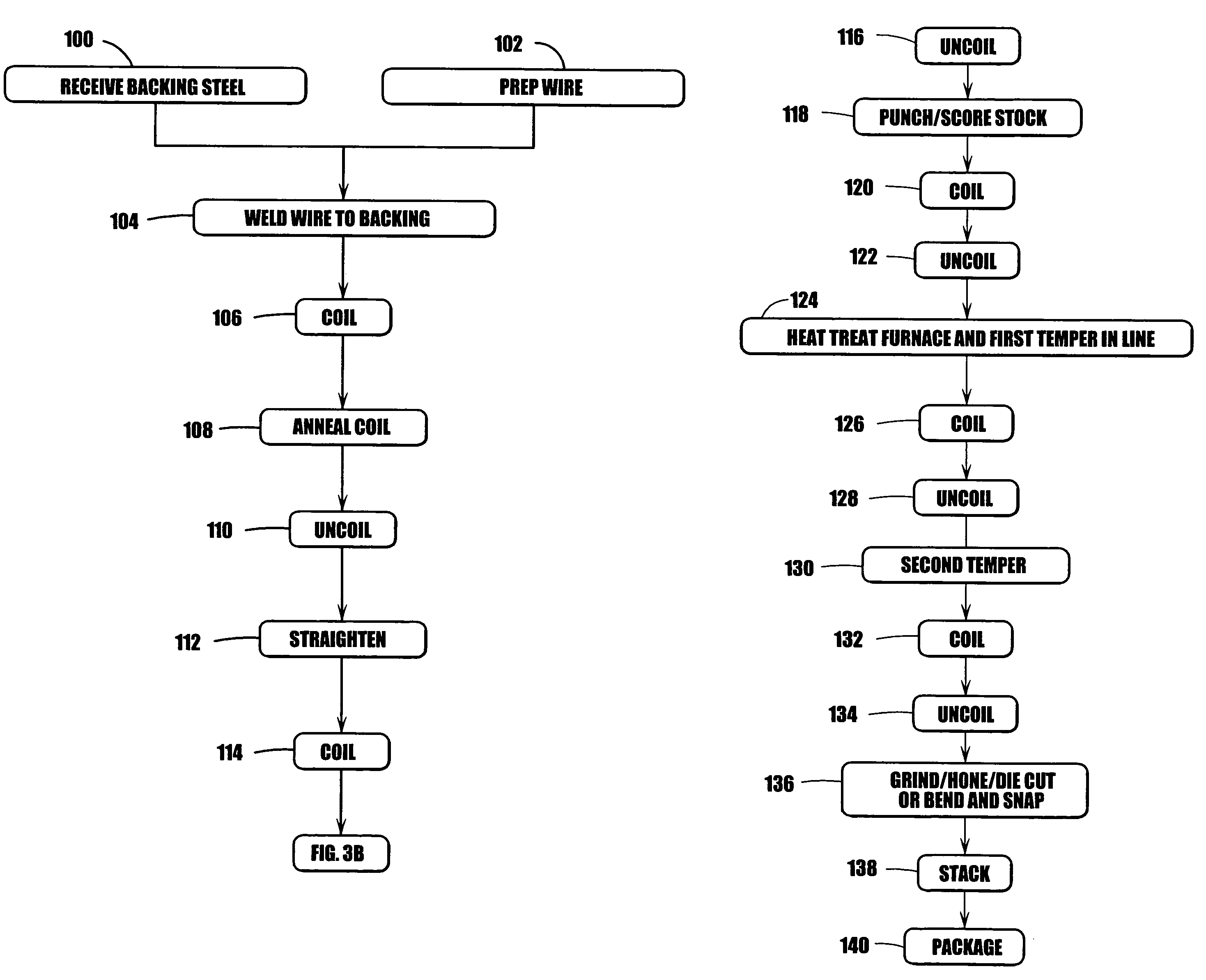

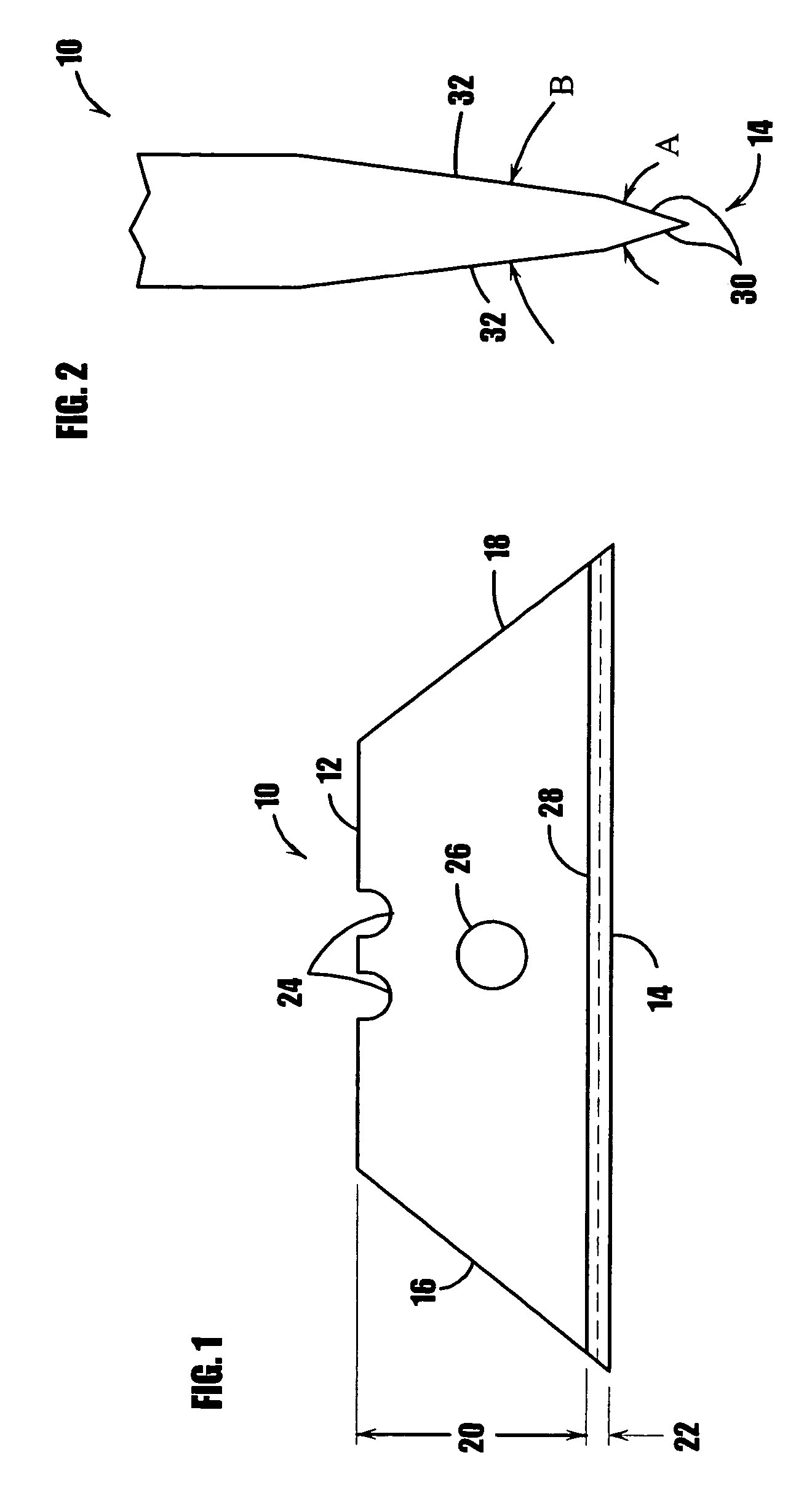

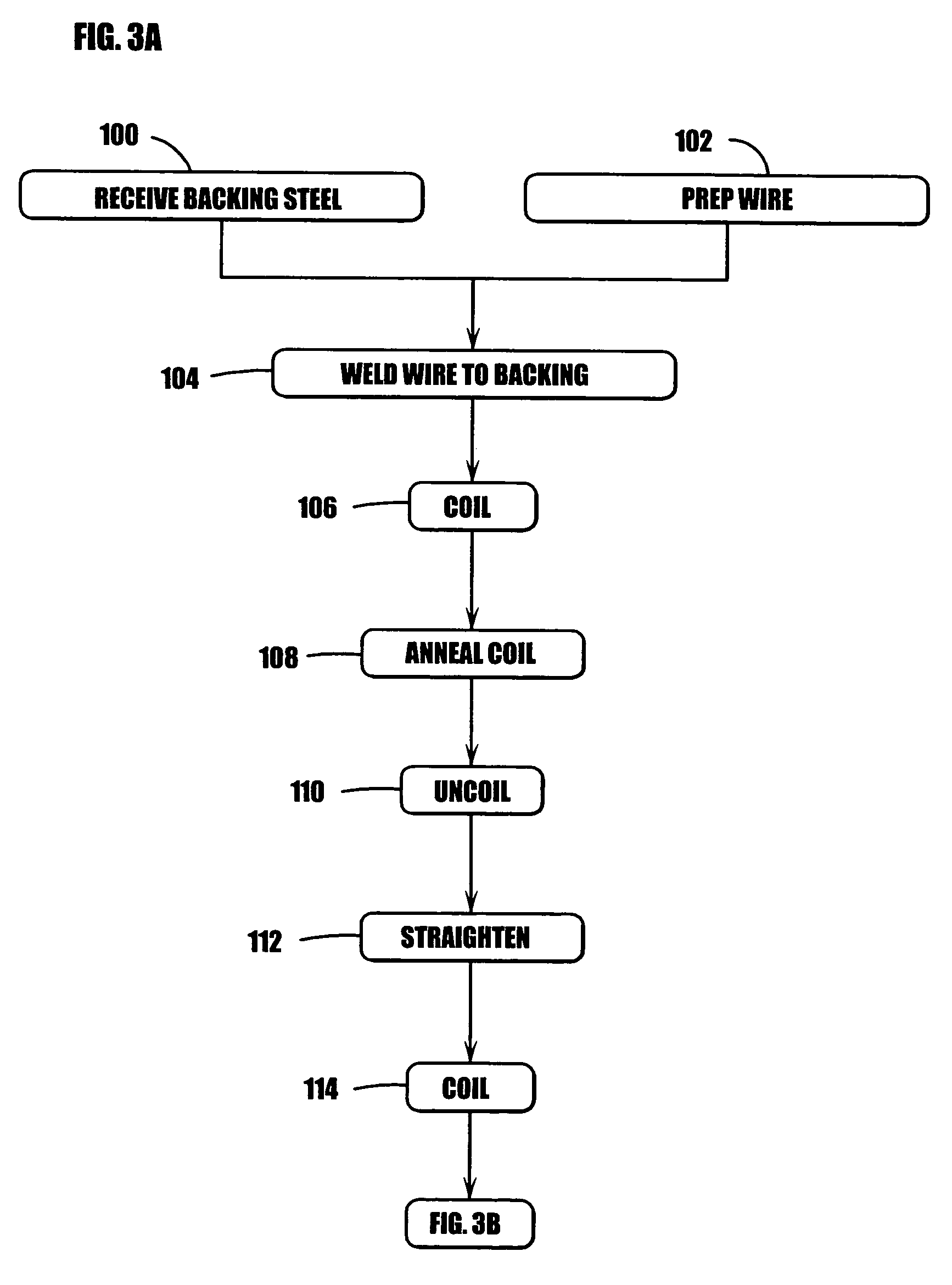

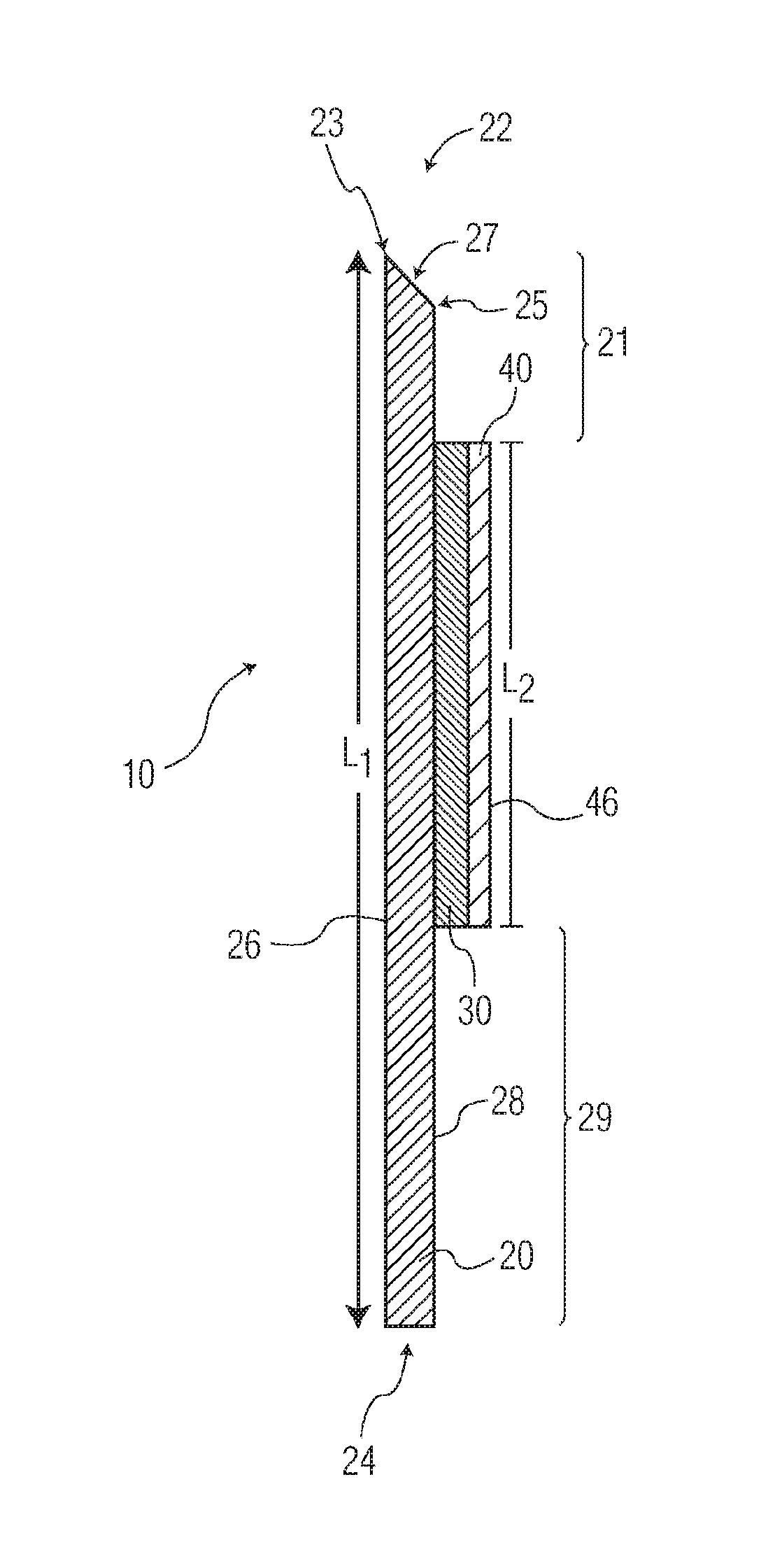

Composite utility blade, and method of making such a blade

InactiveUS7712222B2Hard and wear-resistantExtend blade lifeThin material handlingMetal working apparatusHardnessFront edge

A composite utility blade and method of making such a blade involves butt joining a high speed or tool steel wire to a front edge of an alloy steel backing strip. The wire defines a predetermined cross-sectional shape that substantially corresponds to the cross-sectional shape of the cutting edge of the blade. The wire is electron beam welded to the backing strip to form a composite strip defining a first metal portion formed by the alloy steel backing strip, a second metal portion formed by the high speed or tool steel wire, and a weld region joining the first and second metal portions. The composite strip is then annealed, and the annealed strip is straightened to eliminate any camber therein. The annealed composite strip is then hardened such that the first metal portion defines a first surface hardness and the second metal portion defines a second surface hardness greater than the first surface hardness. The hardened strip is then subjected to tempering and quenching cycles, and facets are formed on the edge of the second metal portion to form a straight, tool steel cutting edge. The composite strip is then scored at axially spaced locations to form a plurality of score lines, and the plurality of score lines define a plurality of blade sections there between. The cutting edge may be coated with AlTiN, TiN, or an inner coating of AlTiN and an outer coating of TiN.

Owner:BLACK & DECKER INC

Method of making a composite utility blade

InactiveUS7658129B2Extend blade lifeImprove cutting performanceFurnace typesMetal working apparatusHardnessFront edge

A composite utility knife blade and method of making such a blade involves butt joining a tool steel wire to a front edge of an alloy steel backing strip. The wire is electron beam welded to the backing strip to form a composite strip defining a first metal portion formed by the alloy steel backing strip, a second metal portion formed by the tool steel wire, and a weld region joining the first and second metal portions. The composite strip is then annealed, and the annealed strip is straightened to eliminate any camber therein. The annealed composite strip is then hardened such that the first metal portion defines a surface hardness within the range of approximately 38 Rc to approximately 52 Rc, and the second metal portion defines a surface hardness within the range of approximately 60 Rc to approximately 57 Rc.

Owner:BLACK & DECKER INC

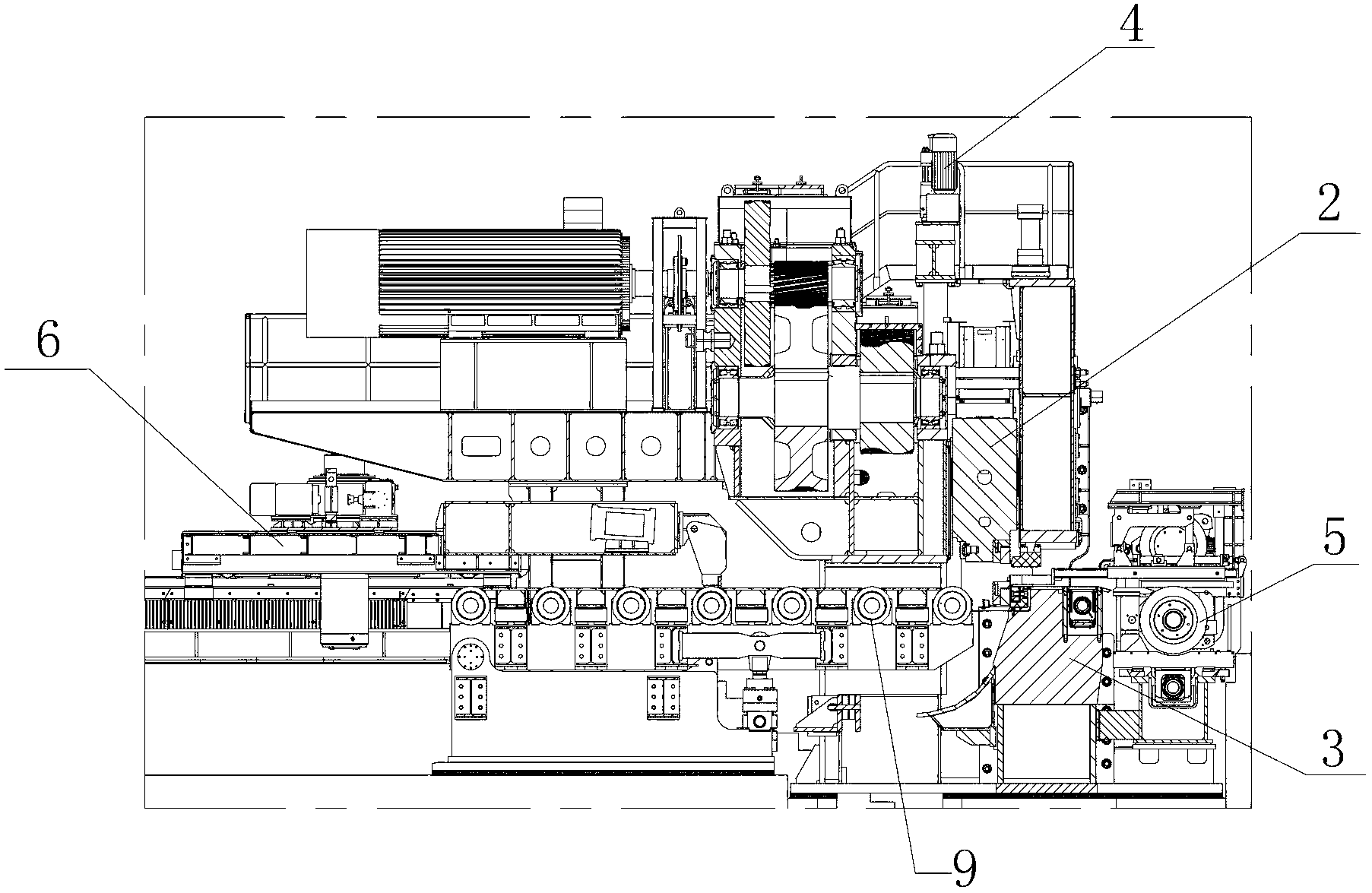

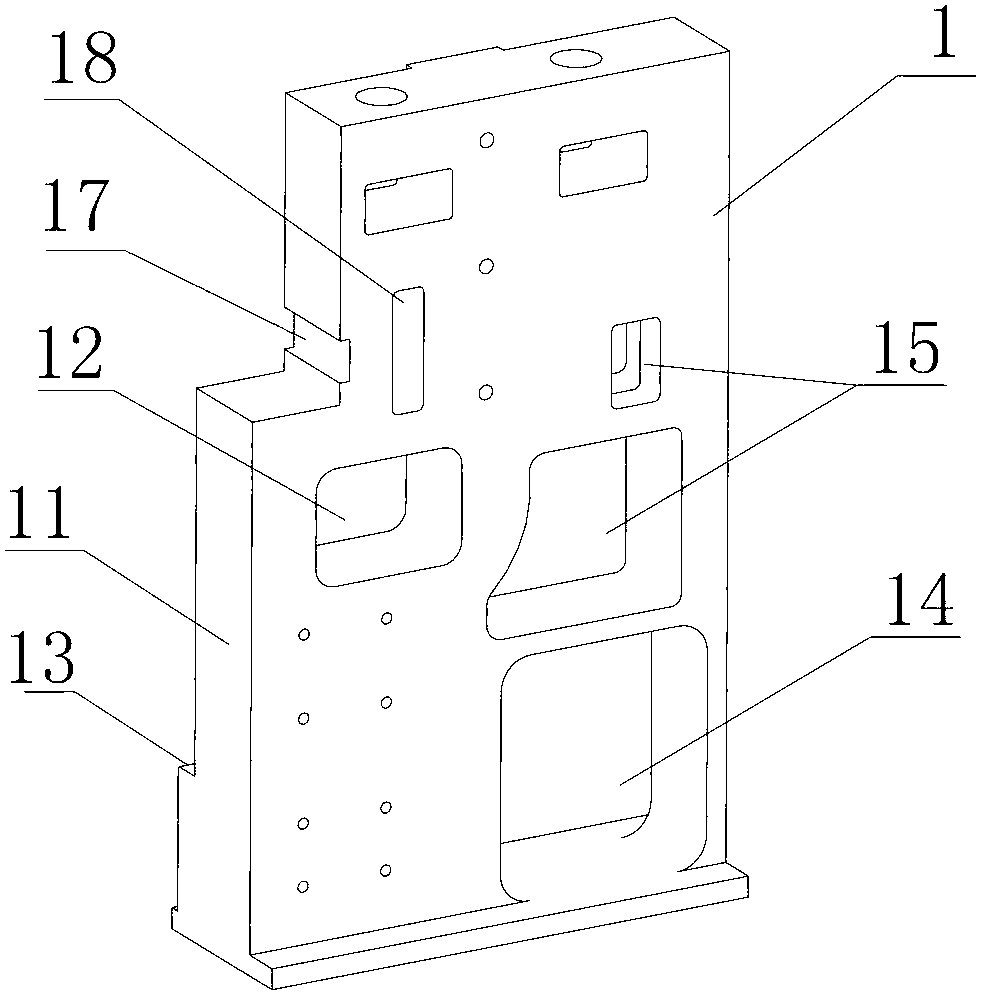

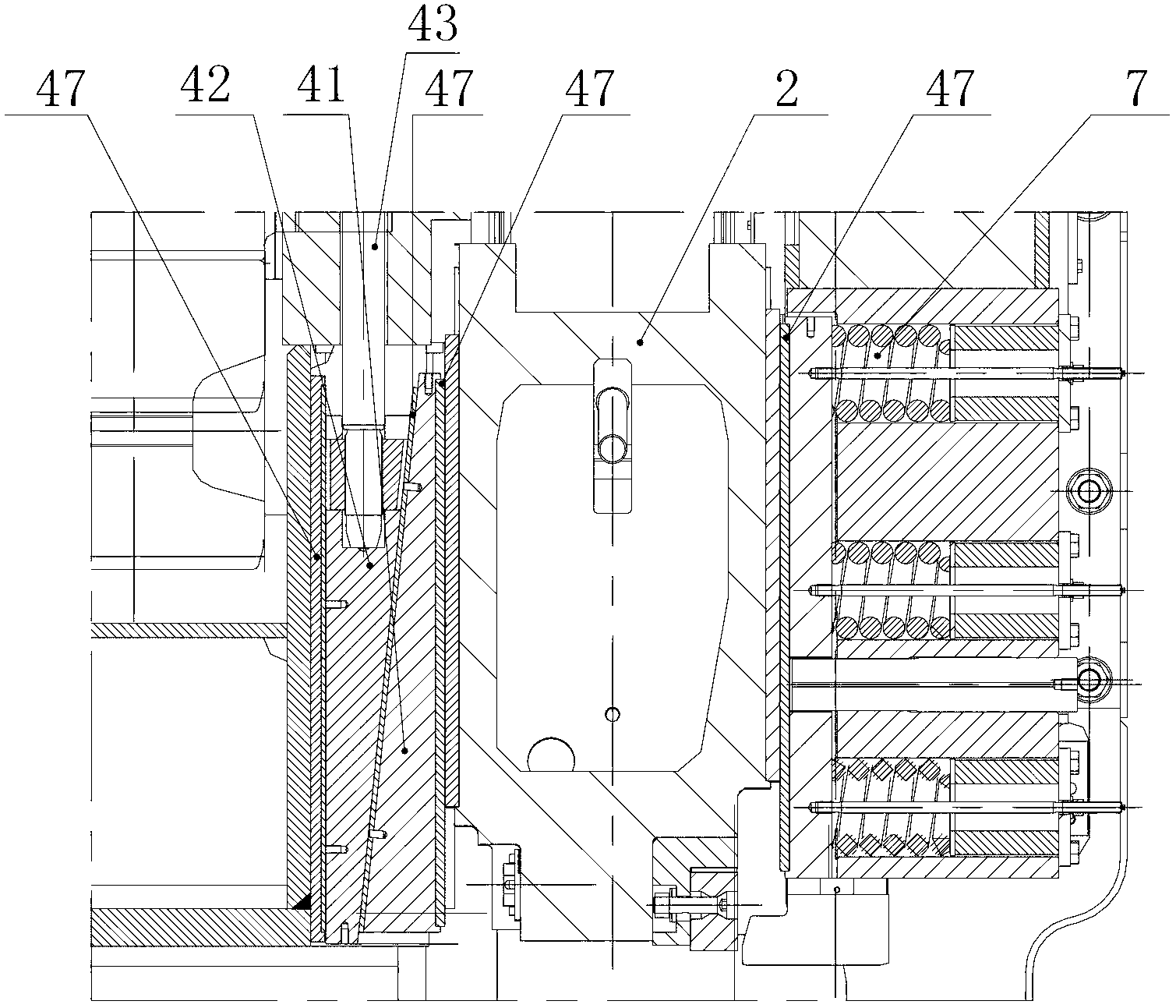

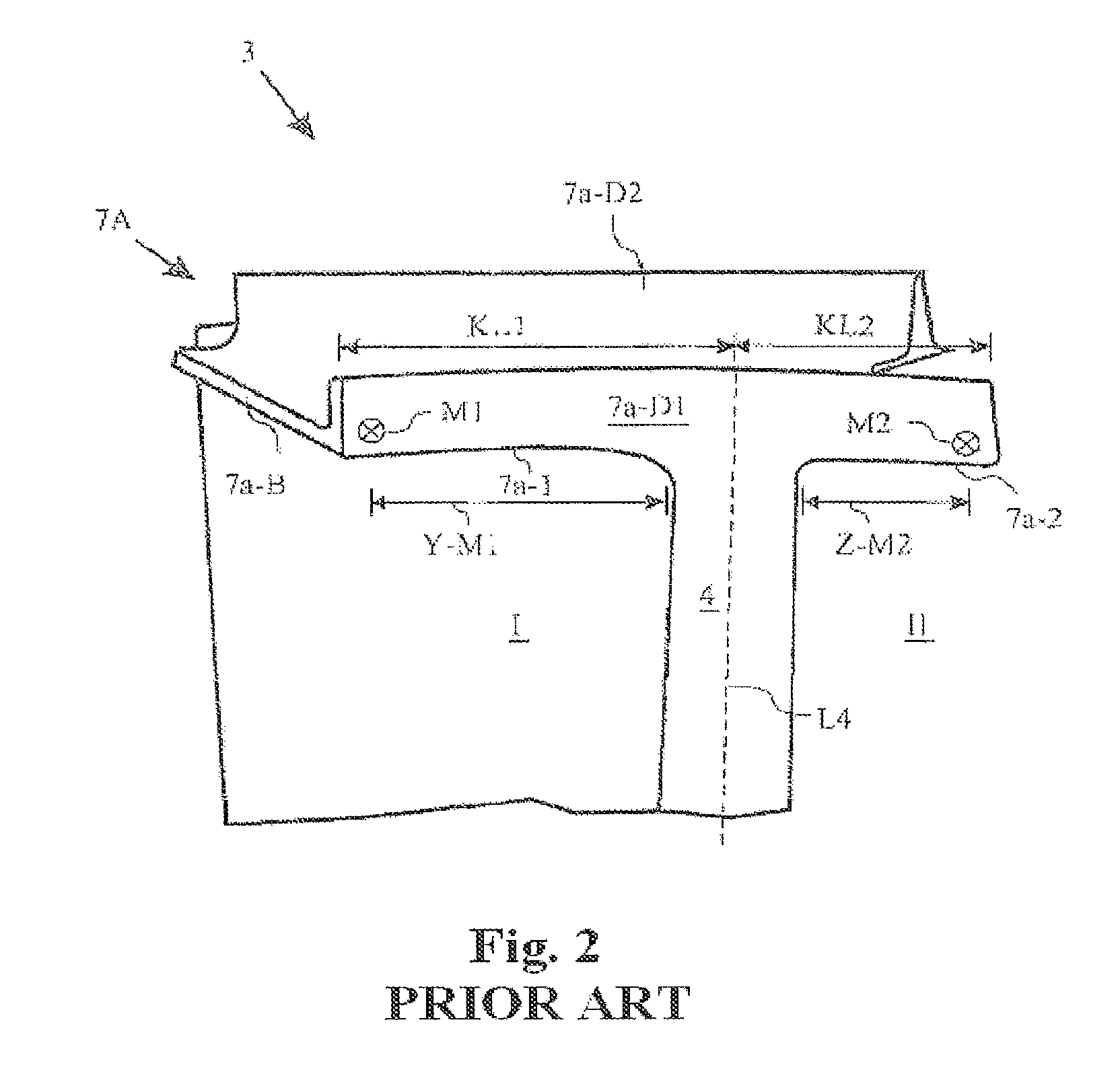

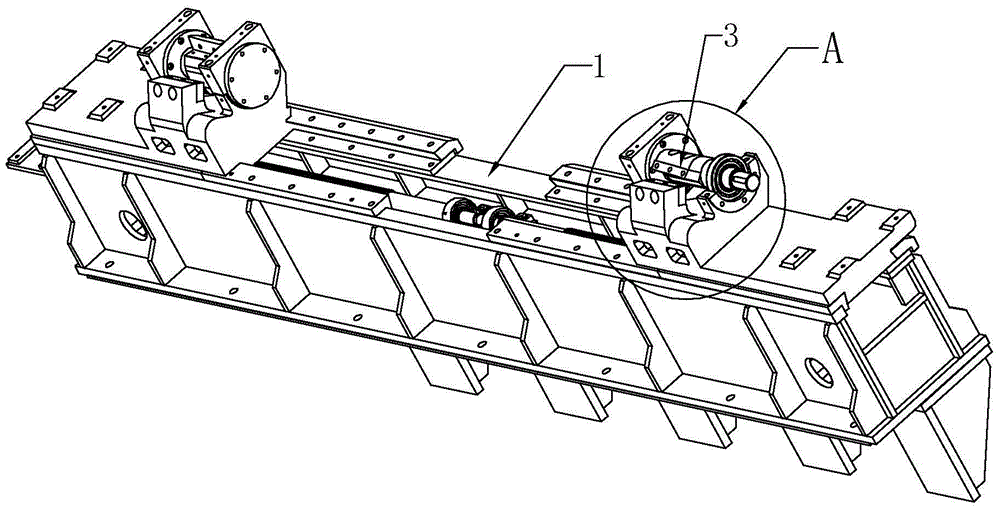

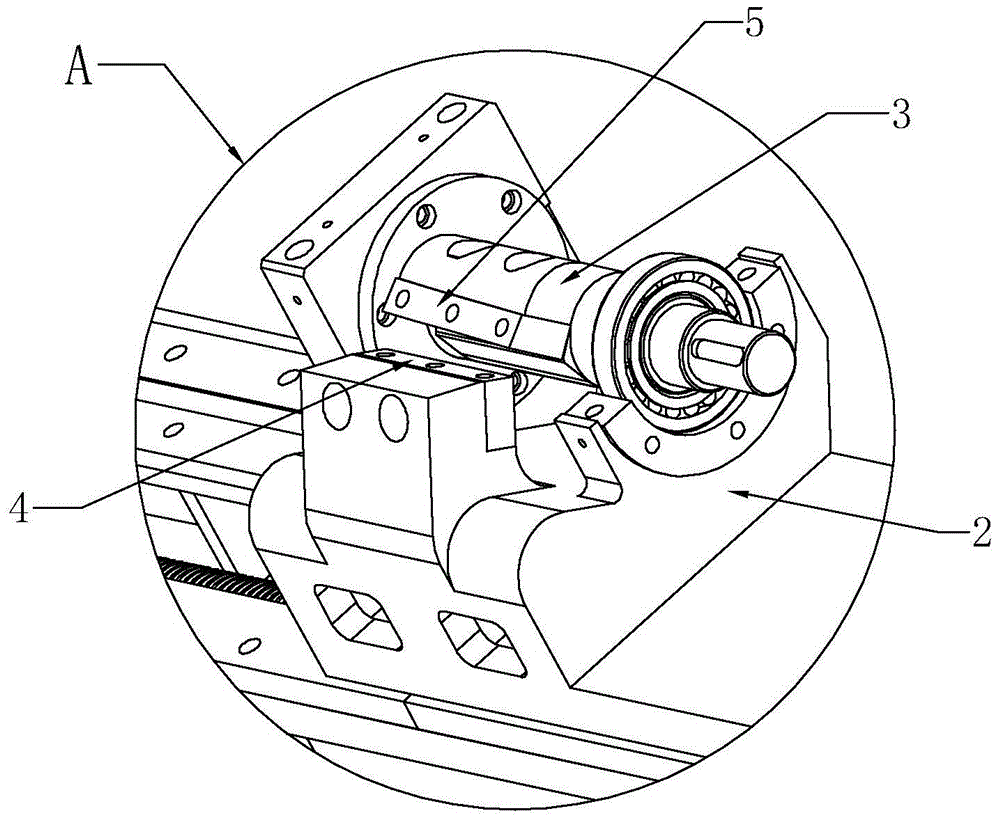

Rotary cutting type cut-to-length device for plate of moderate thickness

ActiveCN102699405AReduce distortionThe amount of overlap does not changeShearing machinesShearing machine accessoriesEngineeringSurface plate

The invention discloses a rotary cutting type cut-to-length device for a plate of moderate thickness. The rotary cutting type cut-to-length device for the plate of moderate thickness at least comprises a frame, a panel, an upper knife rest, a lower knife rest, a shear blade clearance adjusting mechanism, a pinch roll, an over-balanced swinging roller bed mechanism and a shear gauge. The upper and lower knife rests are arranged in the front part of the shear gauge device relatively. The shear gauge is arranged in the rear part of the shear gauge device. The shear blade clearance adjusting mechanism is installed outside the upper knife rest, the upper knife rest can be moveably arranged between the shear blade clearance adjusting mechanism and the frame, the over-balanced swinging roller bed mechanism is arranged close to the lower knife rest, and the frame consists of two integrally cast and formed vertical plates which are oppositely arranged. Tool changing windows which are circumferentially closed are arranged in positions corresponding to an upper blade of the upper knife rest and a lower blade of the lower knife rest on the surface of the vertical plates. The rotary cutting type cut-to-length device for the plate of moderate thickness provided by the invention has the advantages of strong rigidity and small deformation of the frame, high shearing quality, good lubricating effect, avoids mutual shearing of the upper and lower shear blades and can recycle the lubricating oil.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

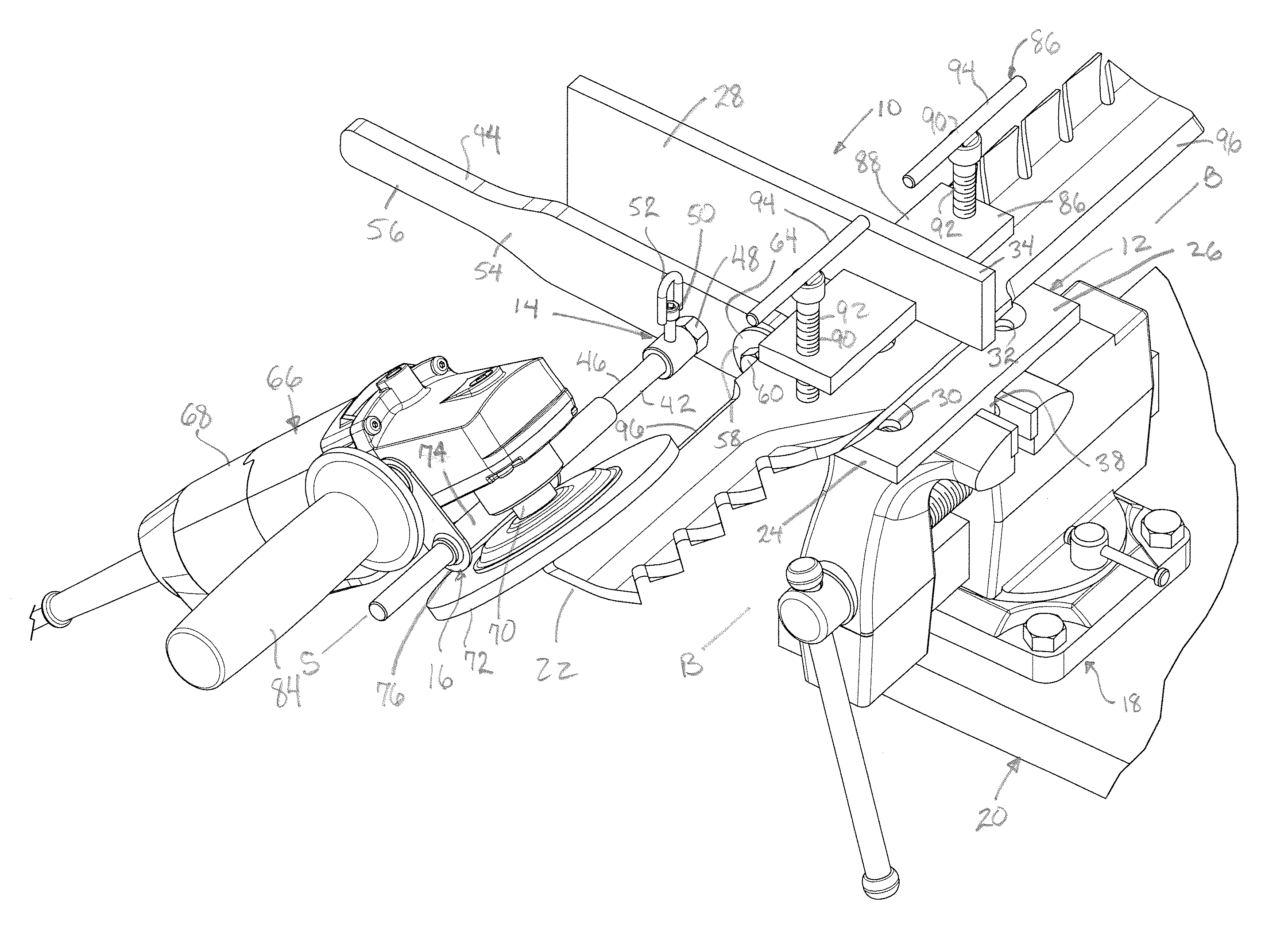

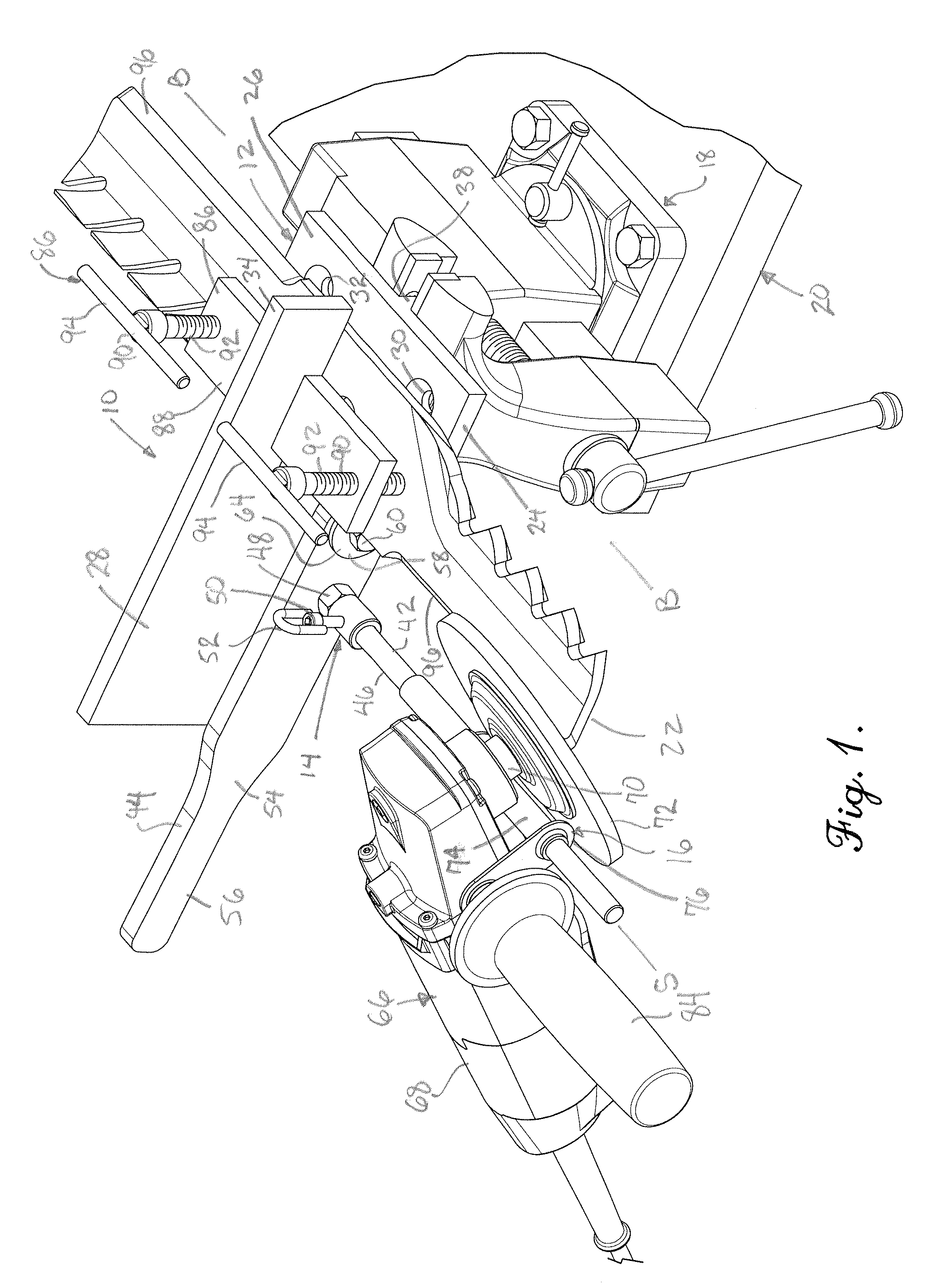

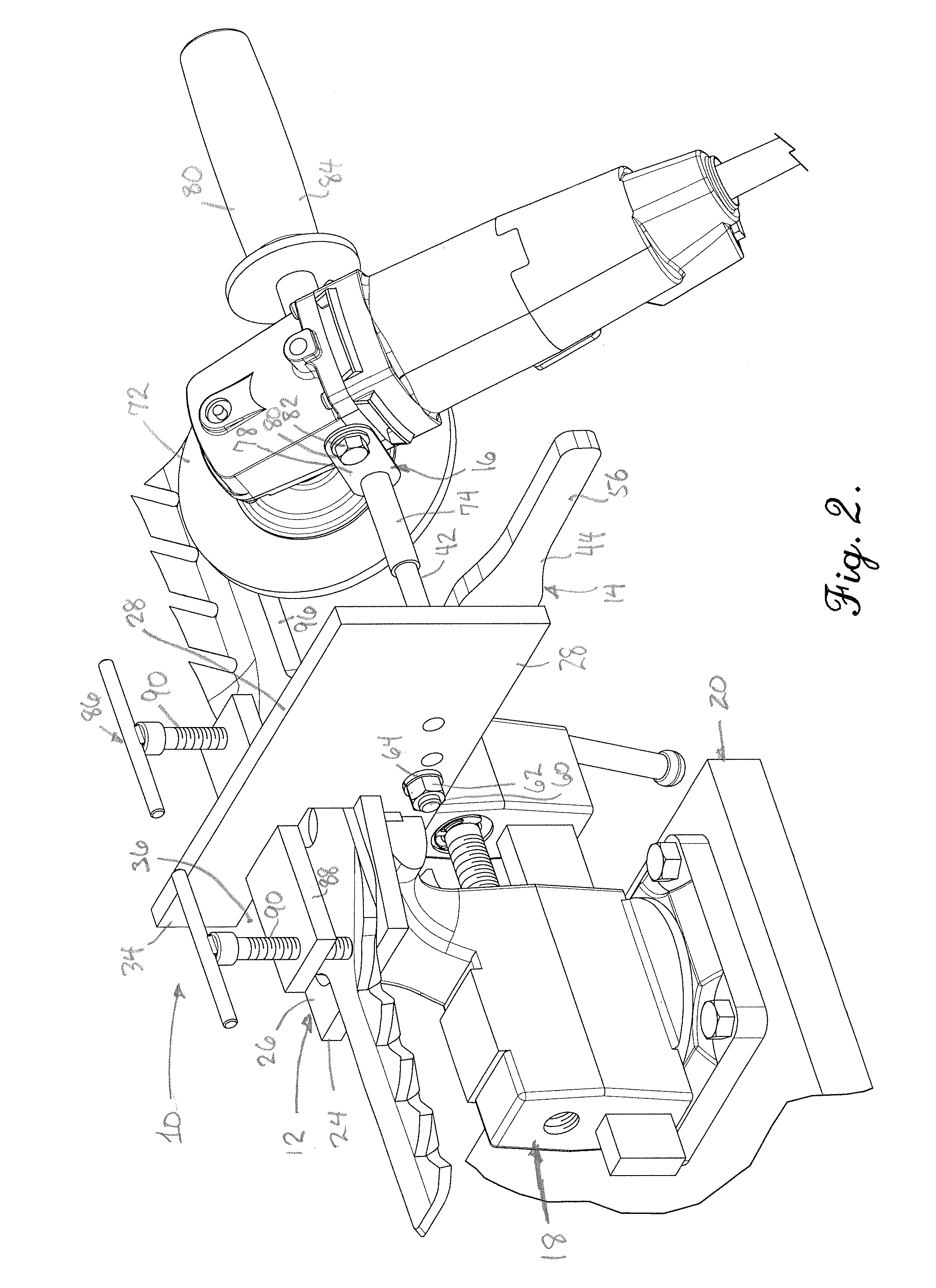

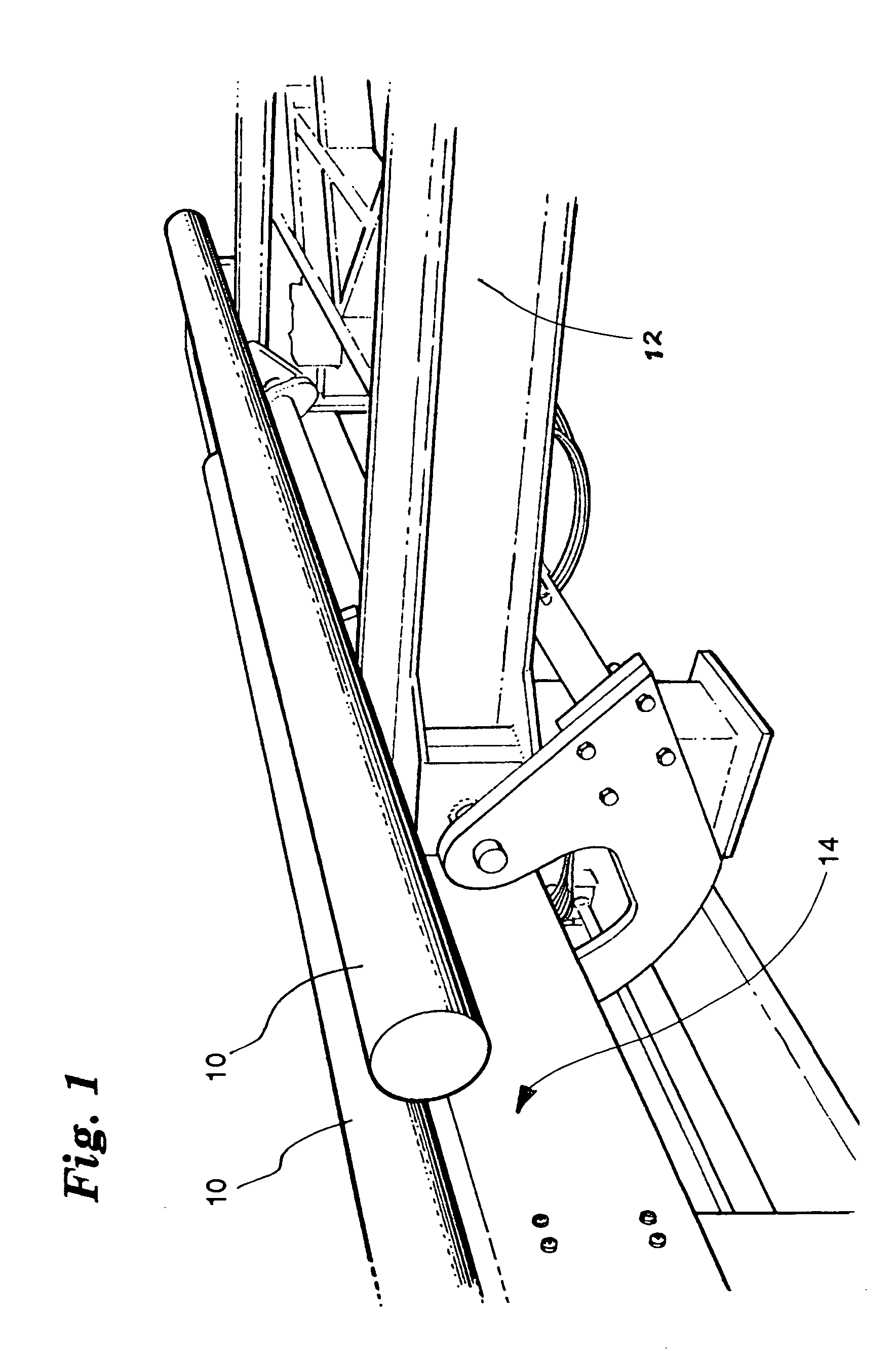

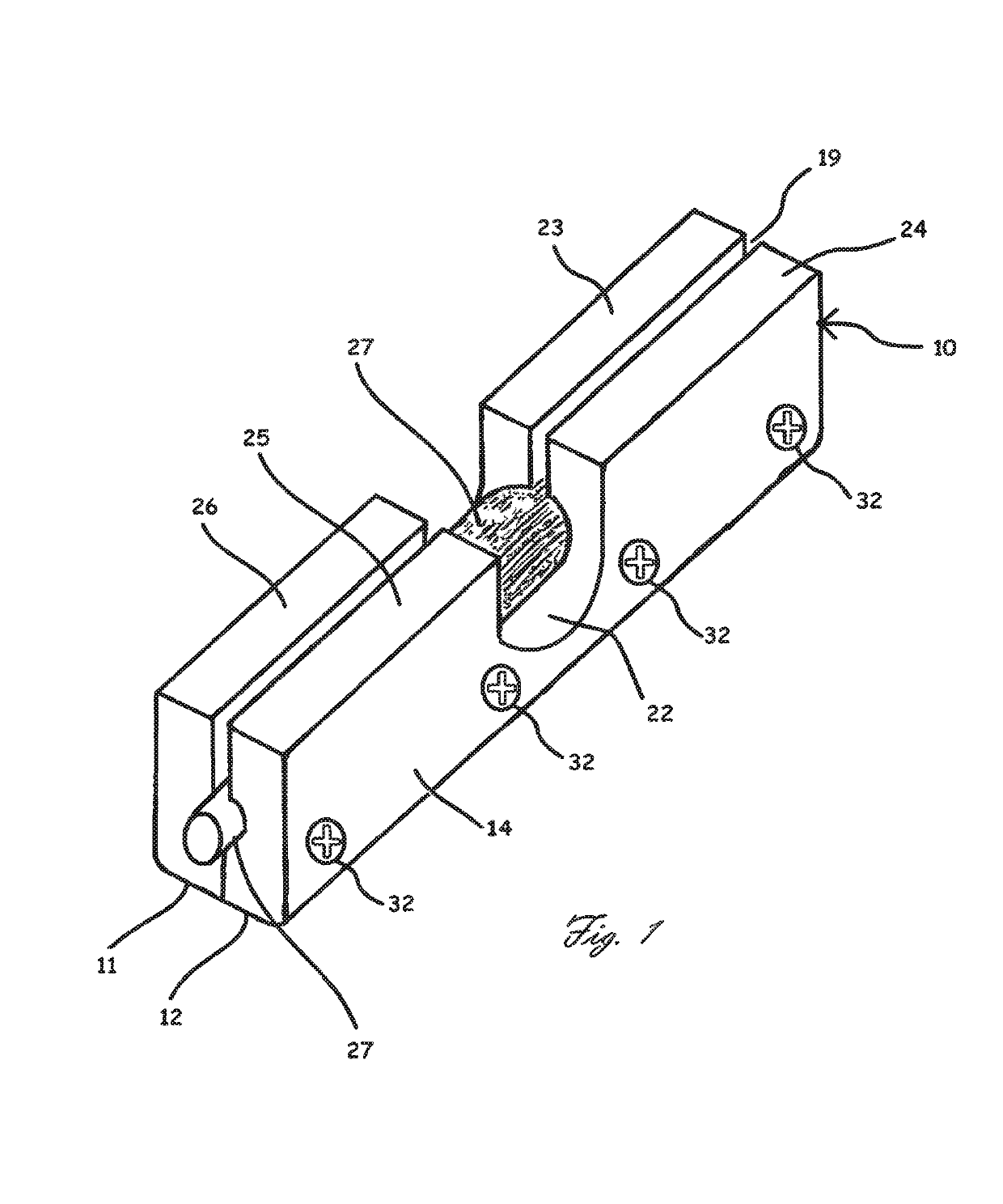

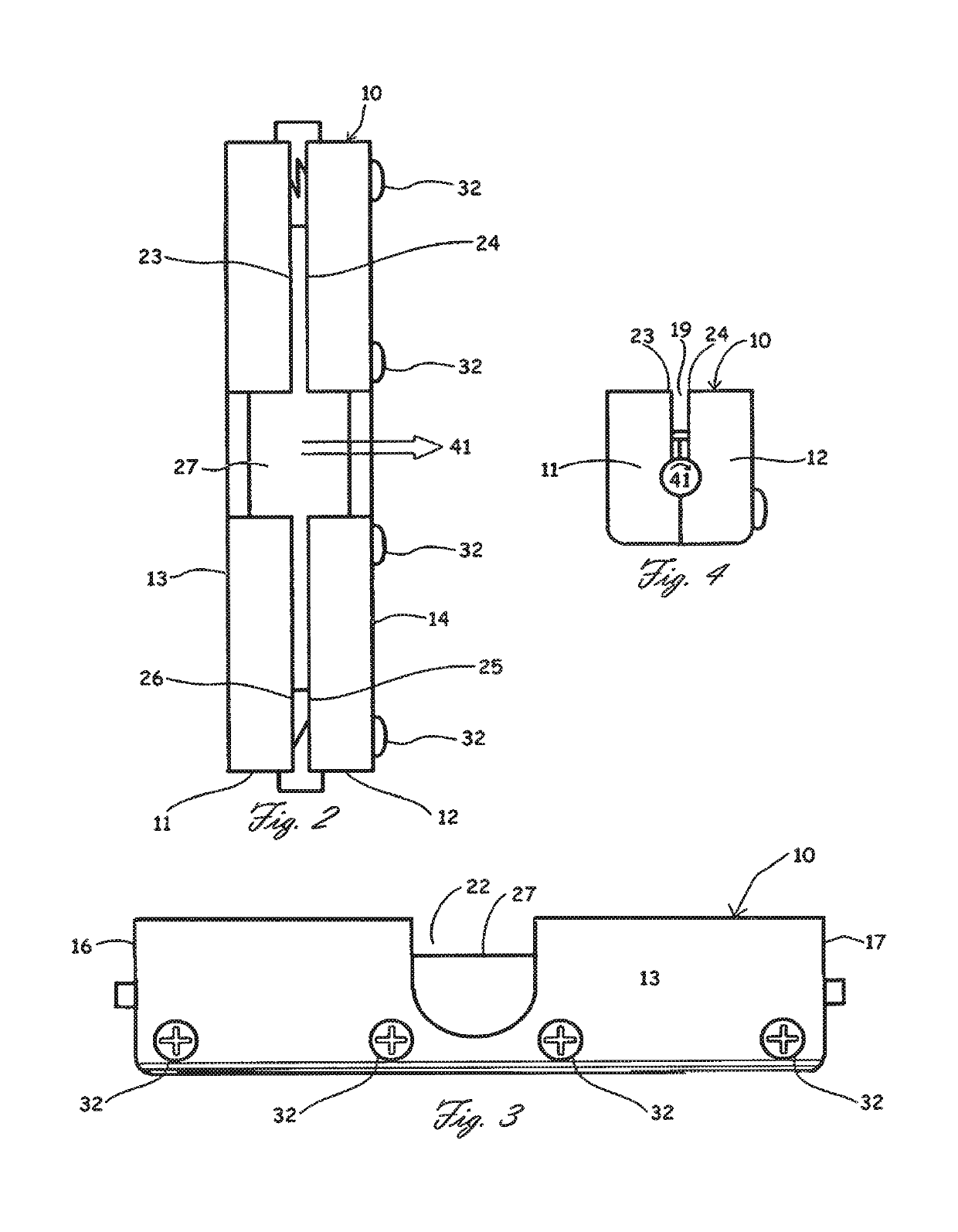

Blade sharpener

InactiveUS7967666B1Stable supportExtend blade lifeCutting toolsPortable grinding machinesEngineeringKnife blades

An apparatus useful for sharpening blades includes a blade support, a sharpener guide mounted to the blade support, and a sharpener mount. The sharpener guide includes an elongated guide member defining a sharpening axis extending substantially parallel to a blade axis defined by the blade support. The sharpener mount includes a pivot connector coupled to and complementally configured with the elongated guide member for enabling pivotal movement of the sharpener mount about the sharpening axis and translational movement along the elongated guide member. The sharpener mount may be coupled to a rotary grinder having a grinding wheel, such that the sharpener mount and the grinder may pivot to provide a desired sharpening angle on the blade and move the grinder along the blade while the blade remains in place on the blade support.

Owner:MESSNER MARVIN

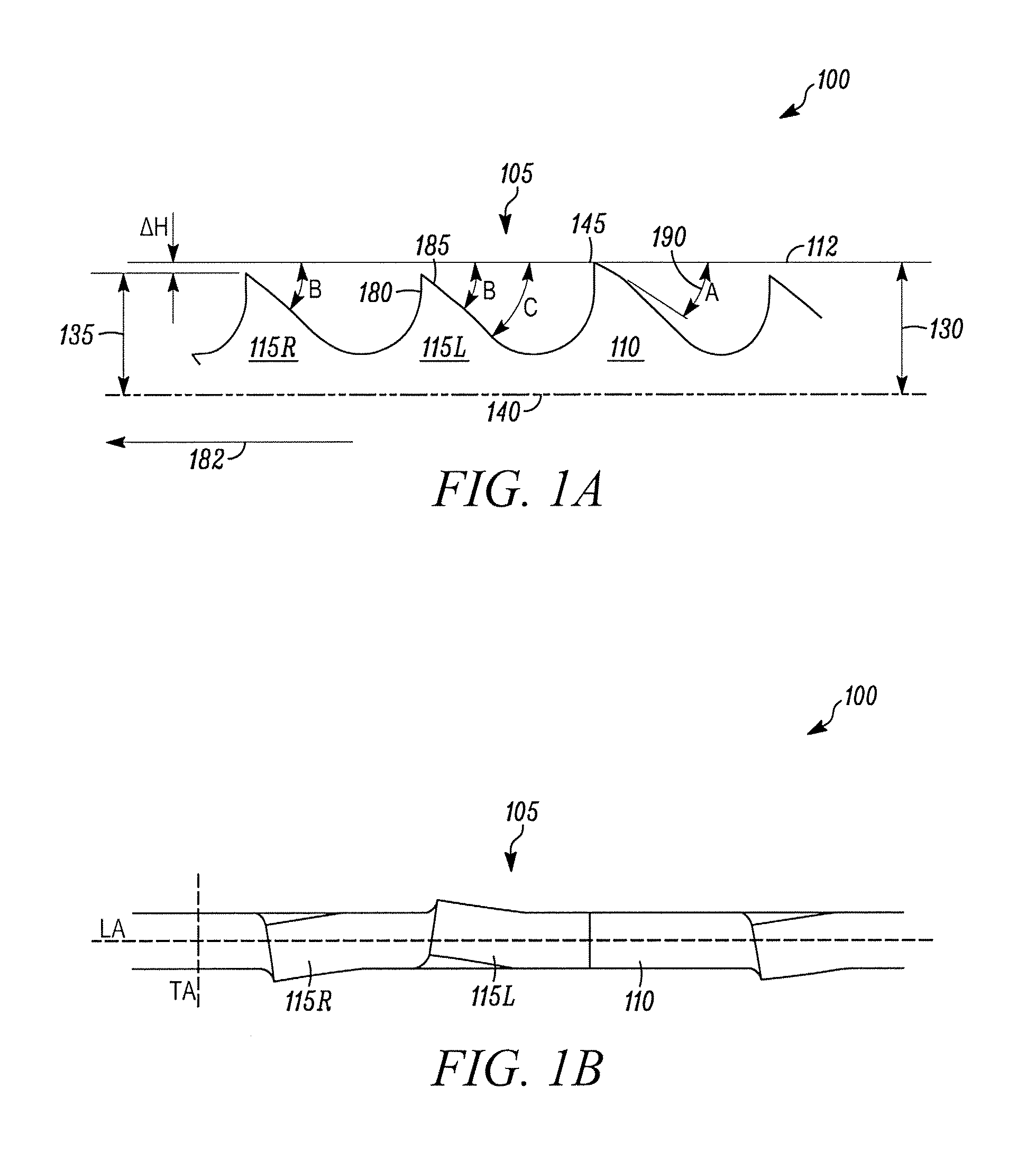

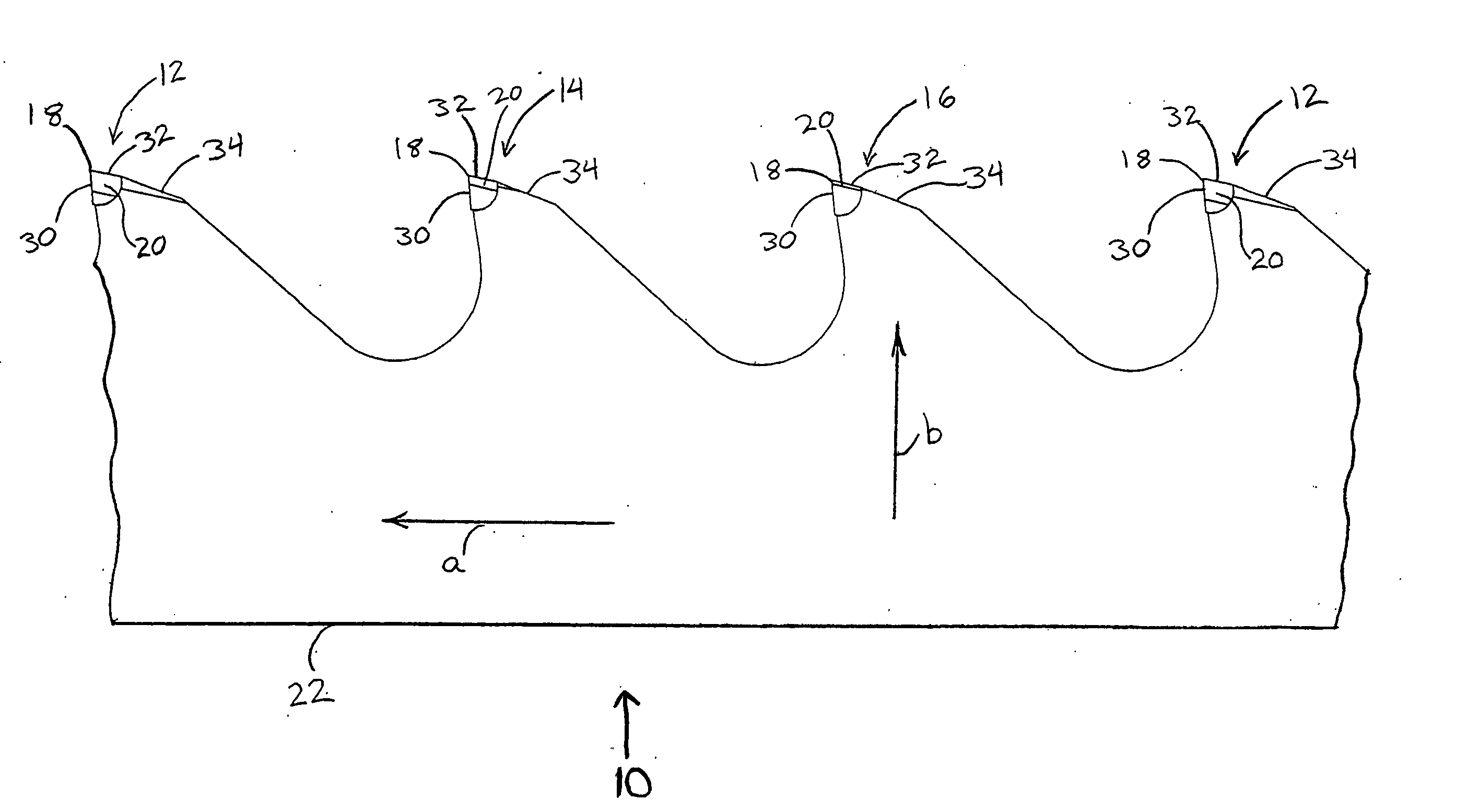

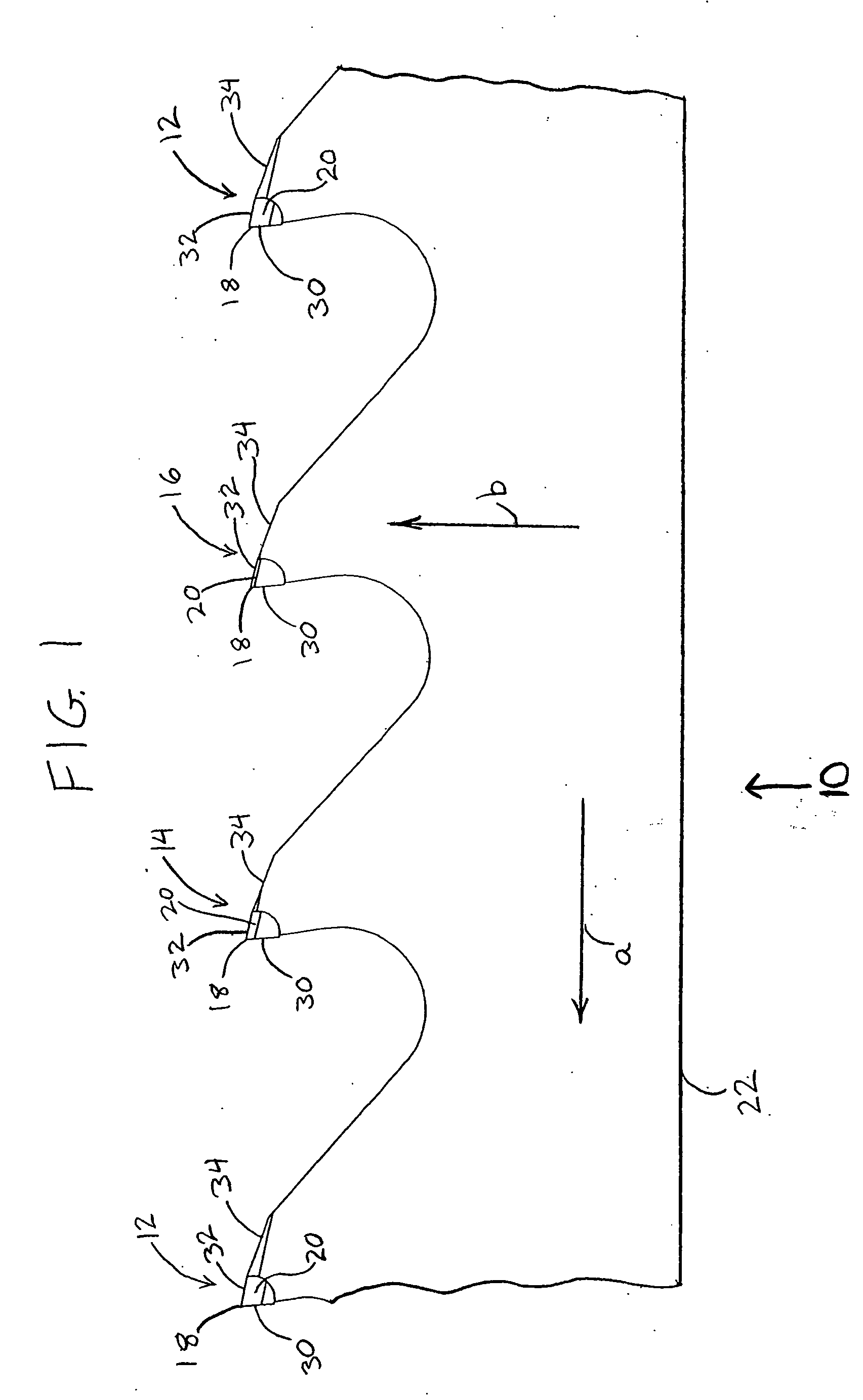

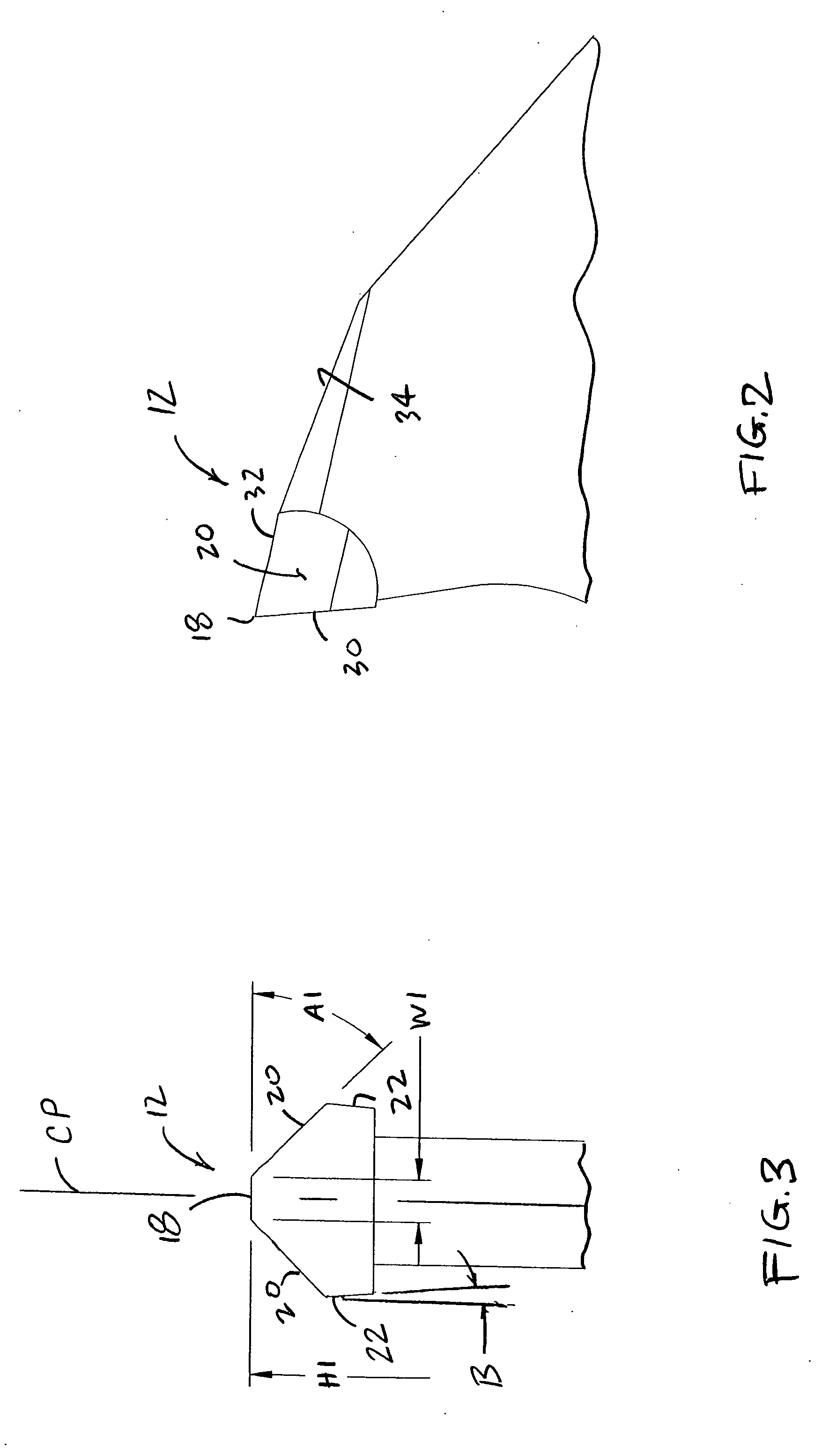

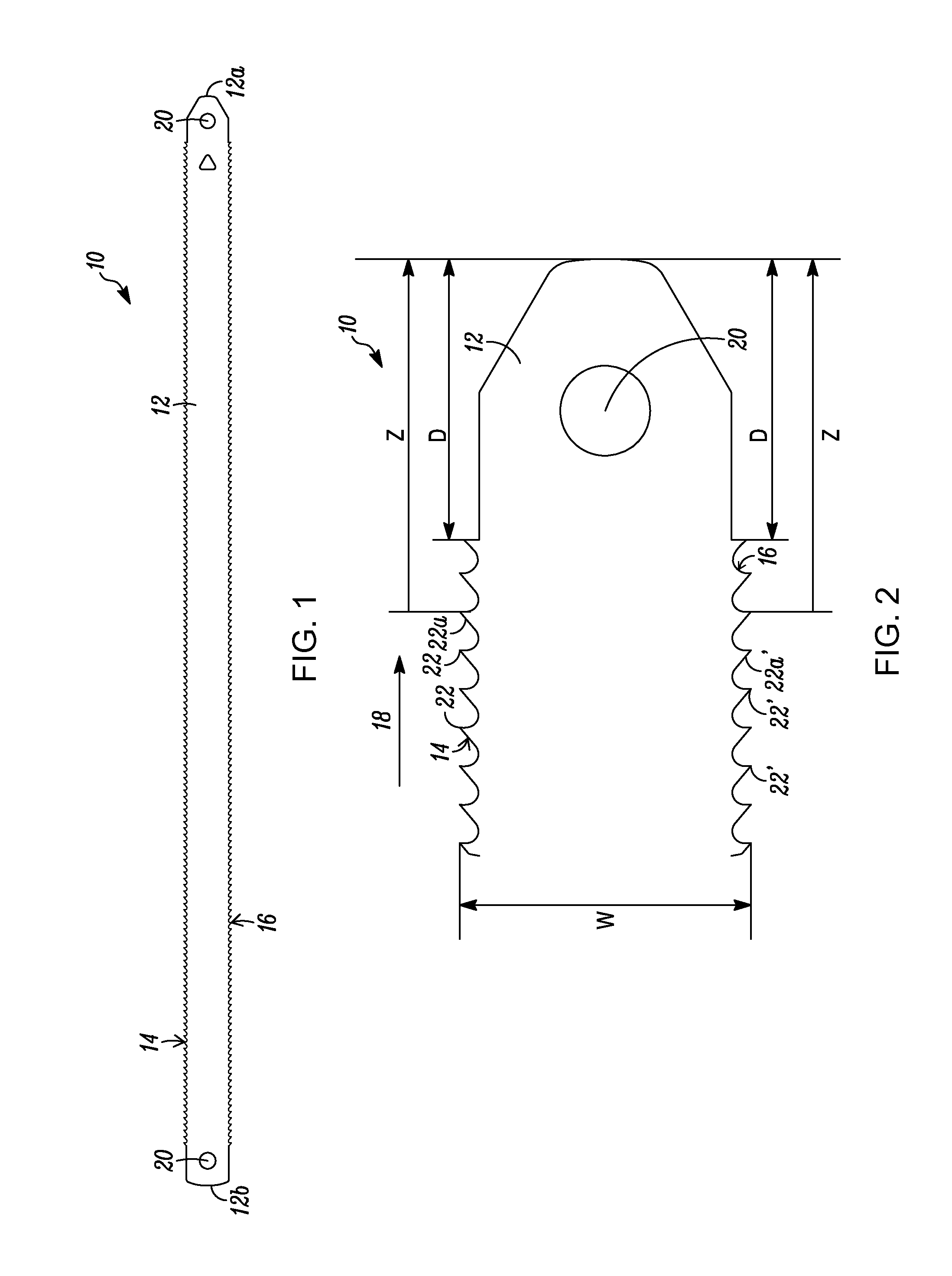

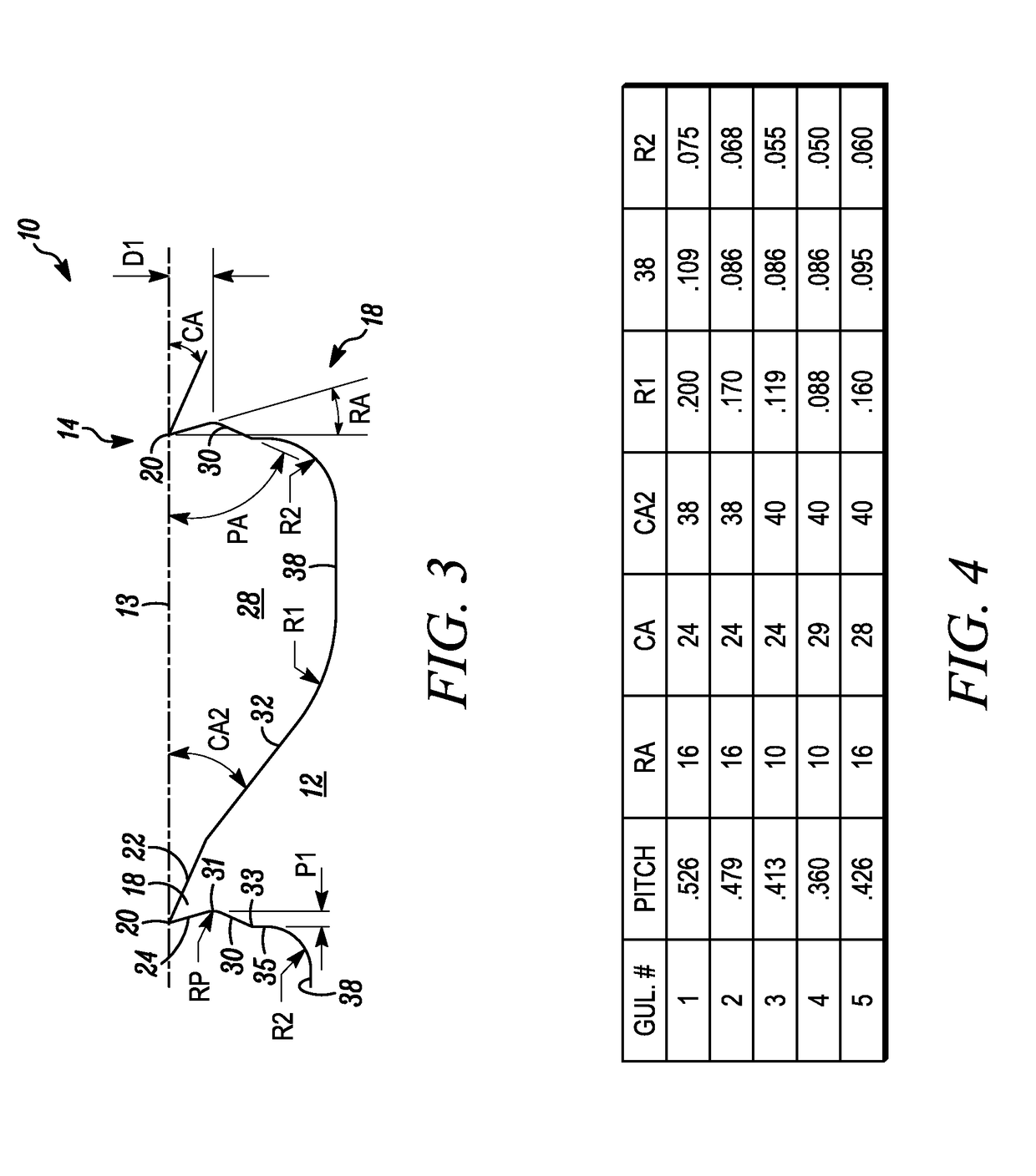

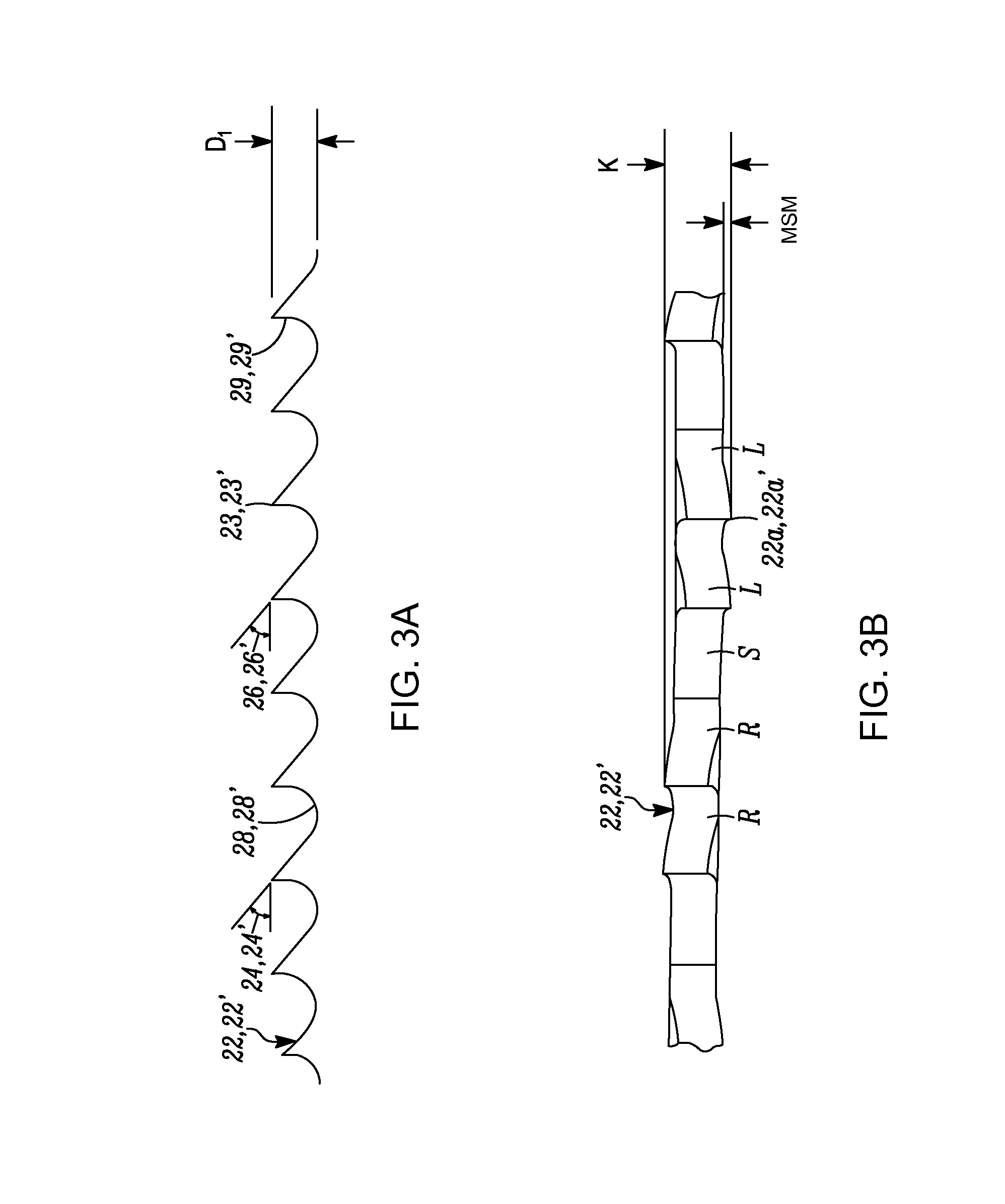

Multi-chip facet cutting saw blade and related method

ActiveUS20050056135A1Extend blade lifeHigh band speedMetal sawing devicesMetal sawing toolsAcute angleEngineering

A metal cutting band saw blade has a plurality of cutting teeth defining a cutting direction, and a repeating tooth pattern of between 3 and 7 teeth. Each tooth defines a laterally-extending upper surface having a width and a height with respect to the back edge of the blade, and side surfaces extending laterally and downwardly on opposite sides of the upper surface relative to each other at acute angles relative to the upper surface. The teeth located rearwardly of the first tooth with respect to the cutting direction of the saw blade define progressively lower heights and progressively smaller acute angles of the side surfaces, and the widths of the upper surfaces of these teeth are greater than the width of the upper surface of the respective first tooth.

Owner:BLACK & DECKER INC

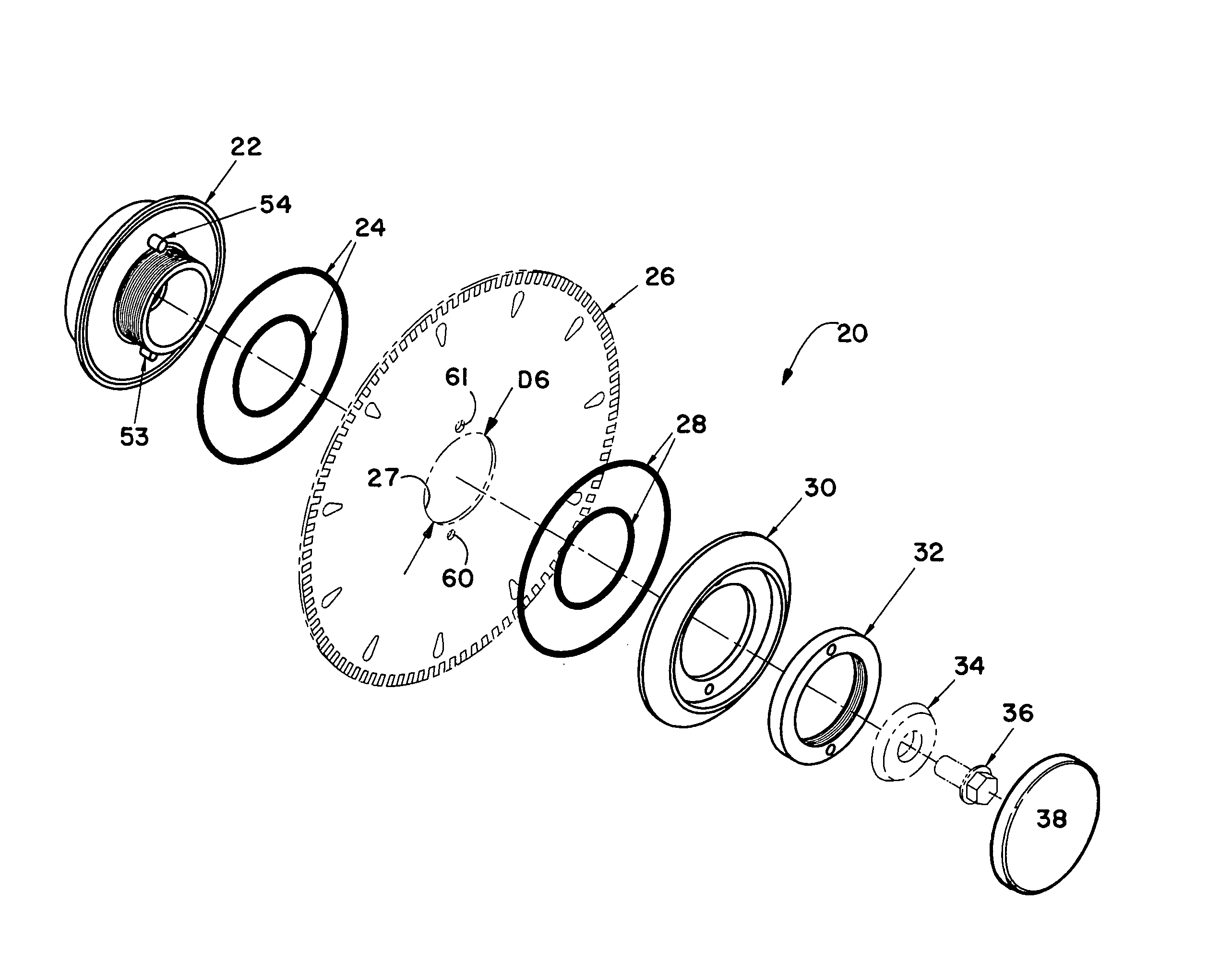

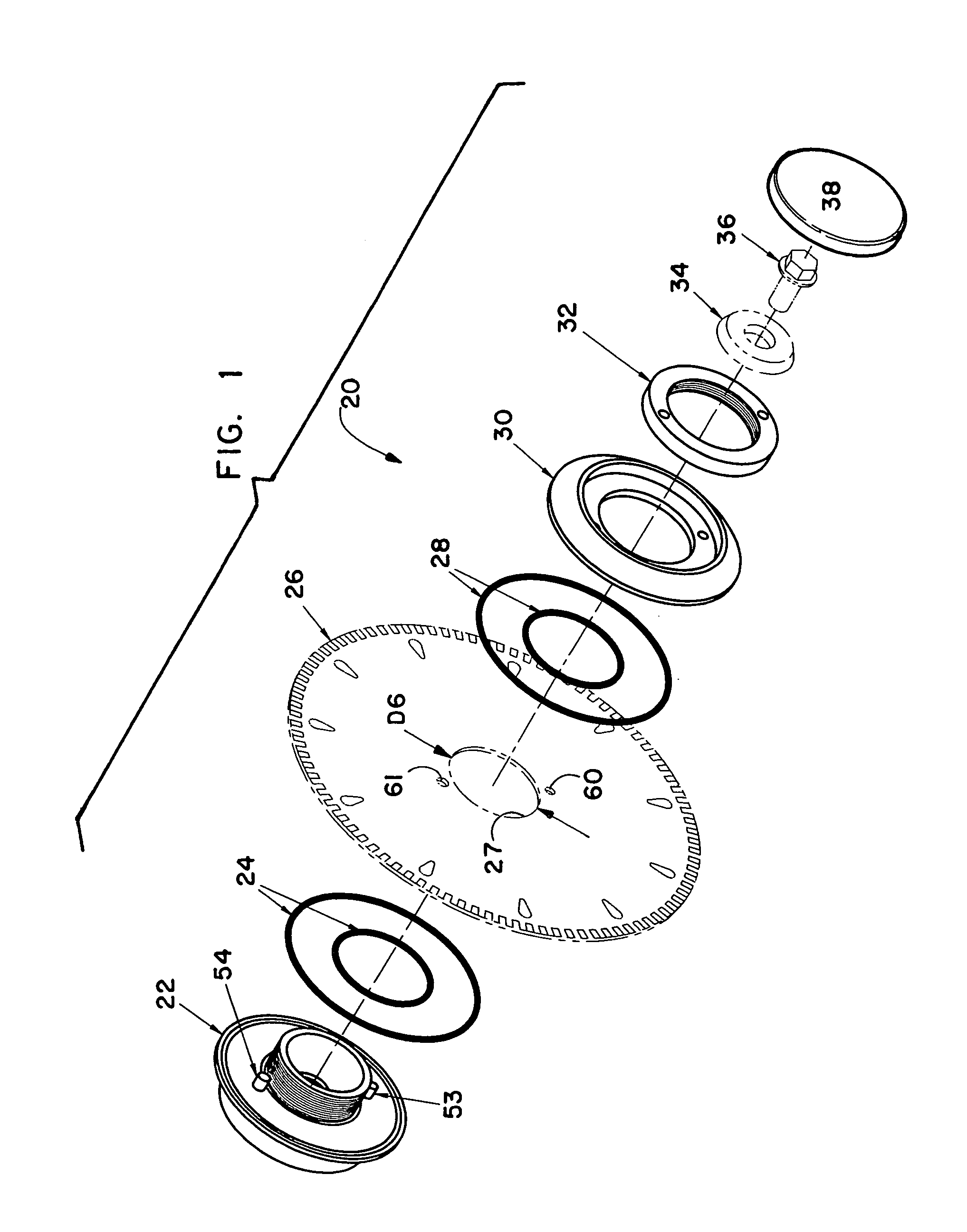

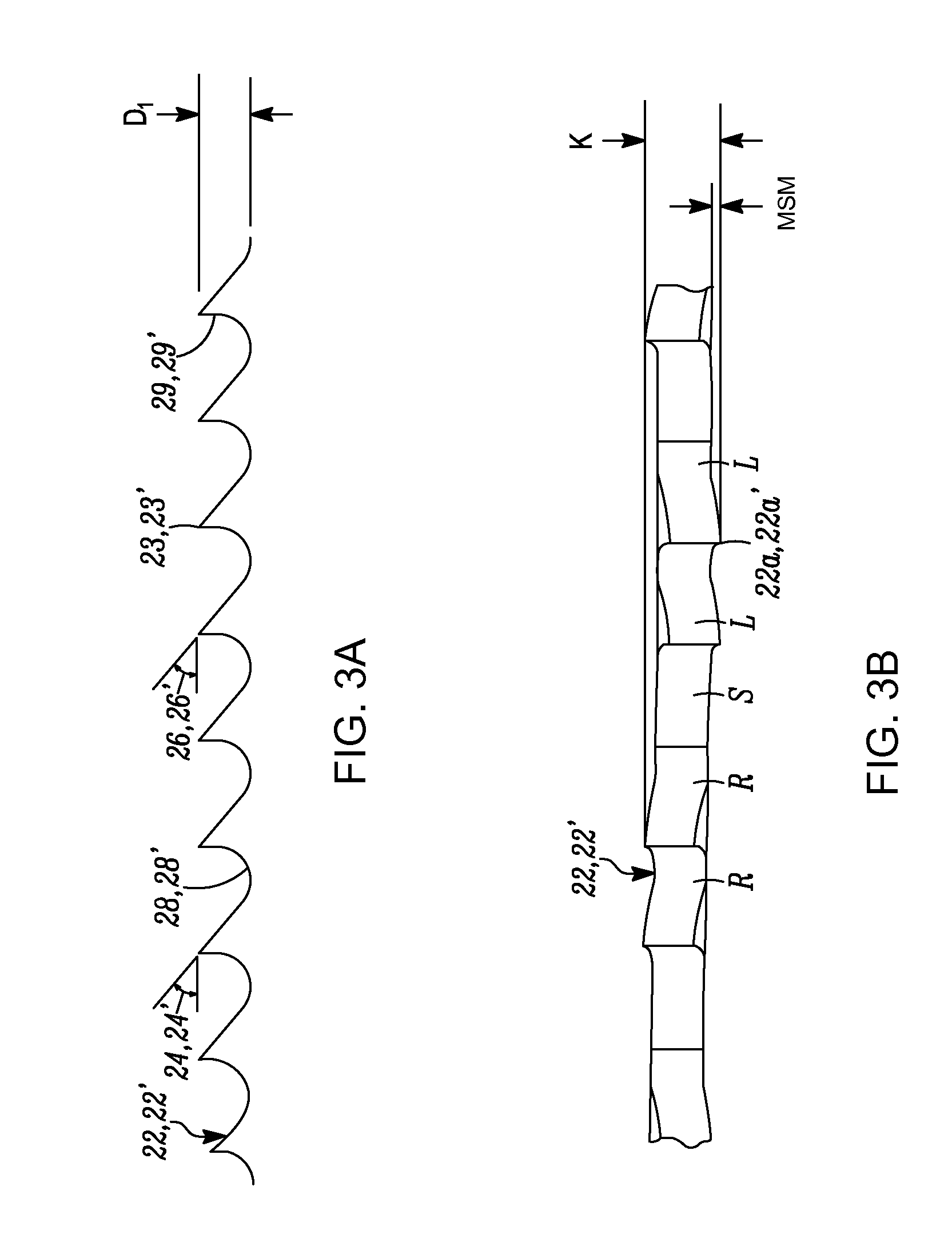

Noise dampener hub assembly for a circular saw

ActiveUS7866242B1Reduction in shop noise fatigueImprove performanceMetal sawing devicesCircular sawsDrive shaftCircular saw

A noise dampener hub assembly for mounting a circular blade on the drive shaft of a circular saw including a spindle hub assembly having an inside noise dampener disc member, a separate outside noise dampener disc member and a spanner hub. The tubular hub member is externally threaded and the spanner hub is internally threaded so that they can be screwed together. The respective inner surfaces of the inside noise dampener disc member and the outside noise dampener disc member have radially spaced annular grooves that removably receive respective O-rings which dampen the noise produced during operation of the circular saw. A pair of pins extend outwardly from the inside noise dampener disc and pass through aligned apertures in the circular saw blade. These pins have different diameters for telescoping into the respective different sized alignment apertures. Also the respective pins and apertures are oriented 170° from each other so that the circular saw blade will always be installed at the same position.

Owner:HARRIS GRACE ELIZABETH

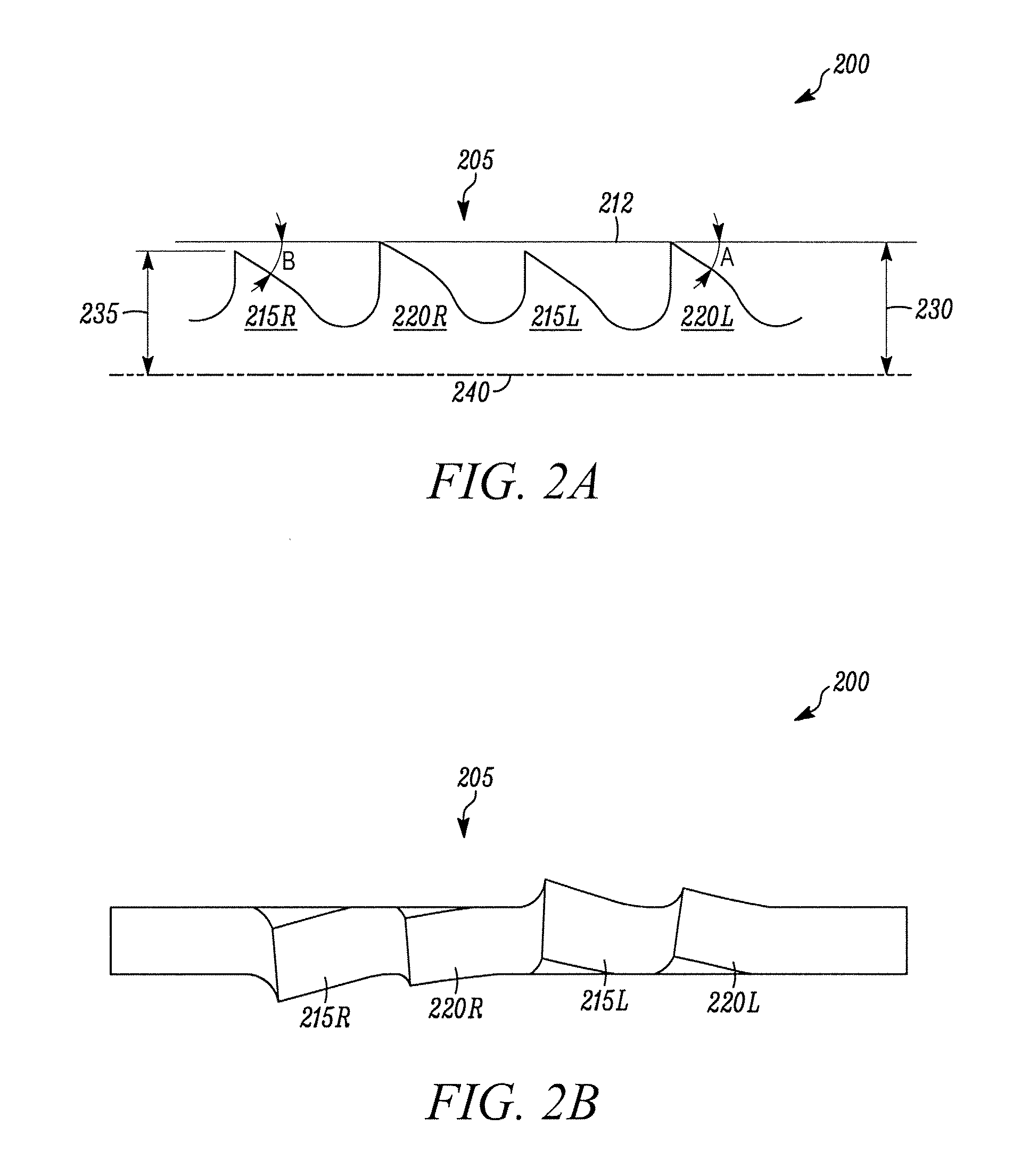

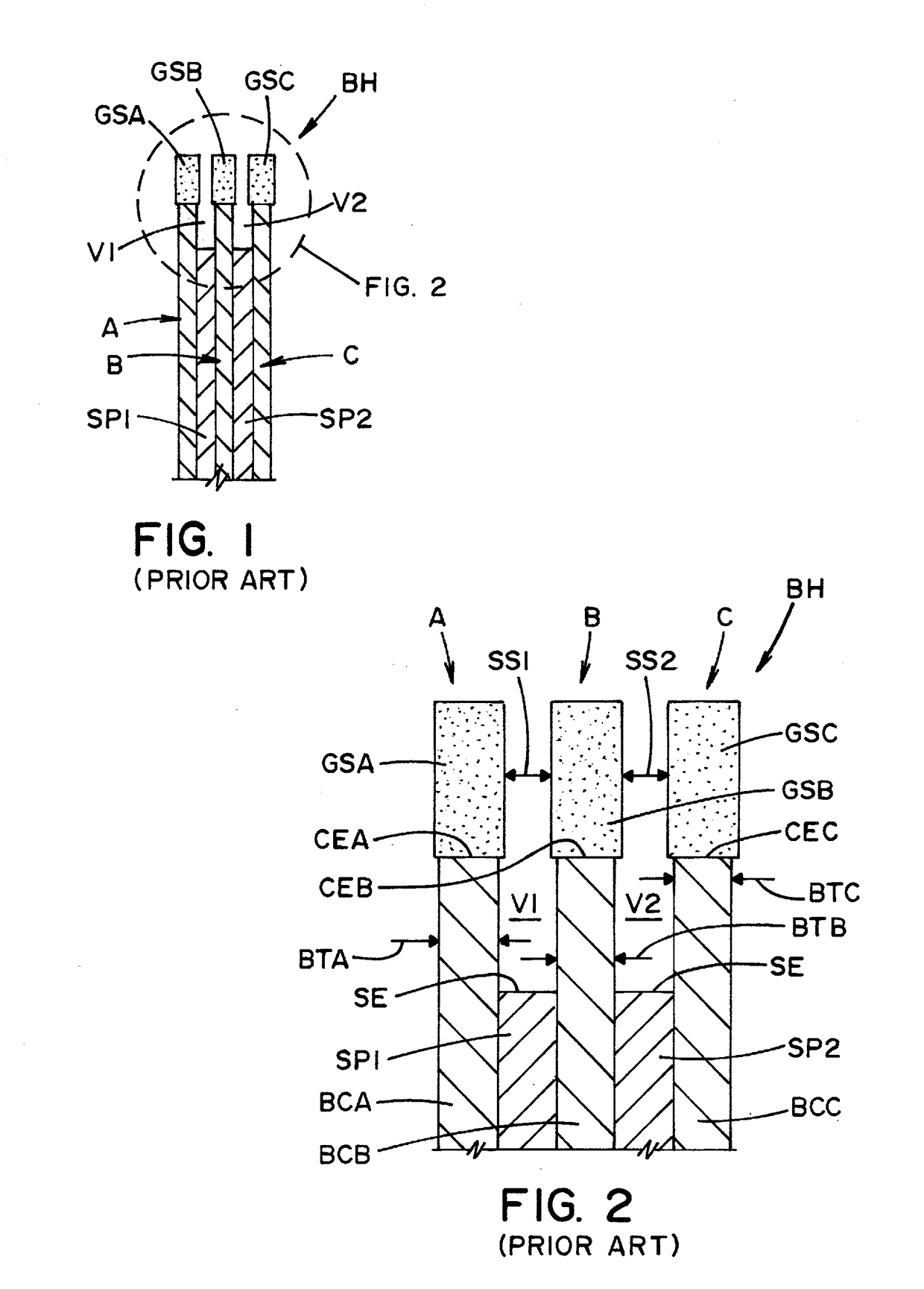

Double sided hand hack saw blade and method of manufacture

ActiveUS20140000117A1Improve cutting efficiencyImprove cut qualityMetal sawing tool makingMetal sawing toolsEngineeringMechanical engineering

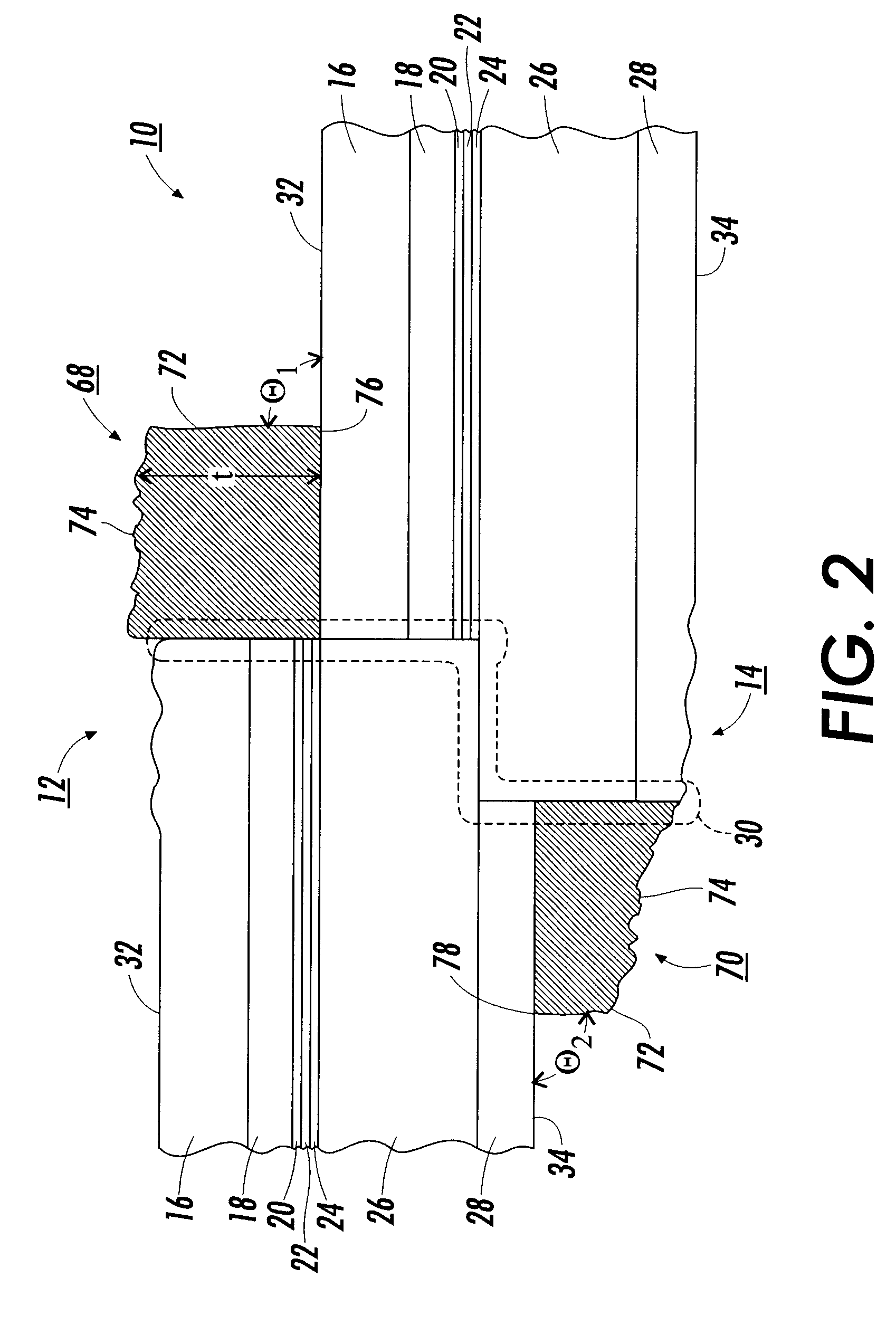

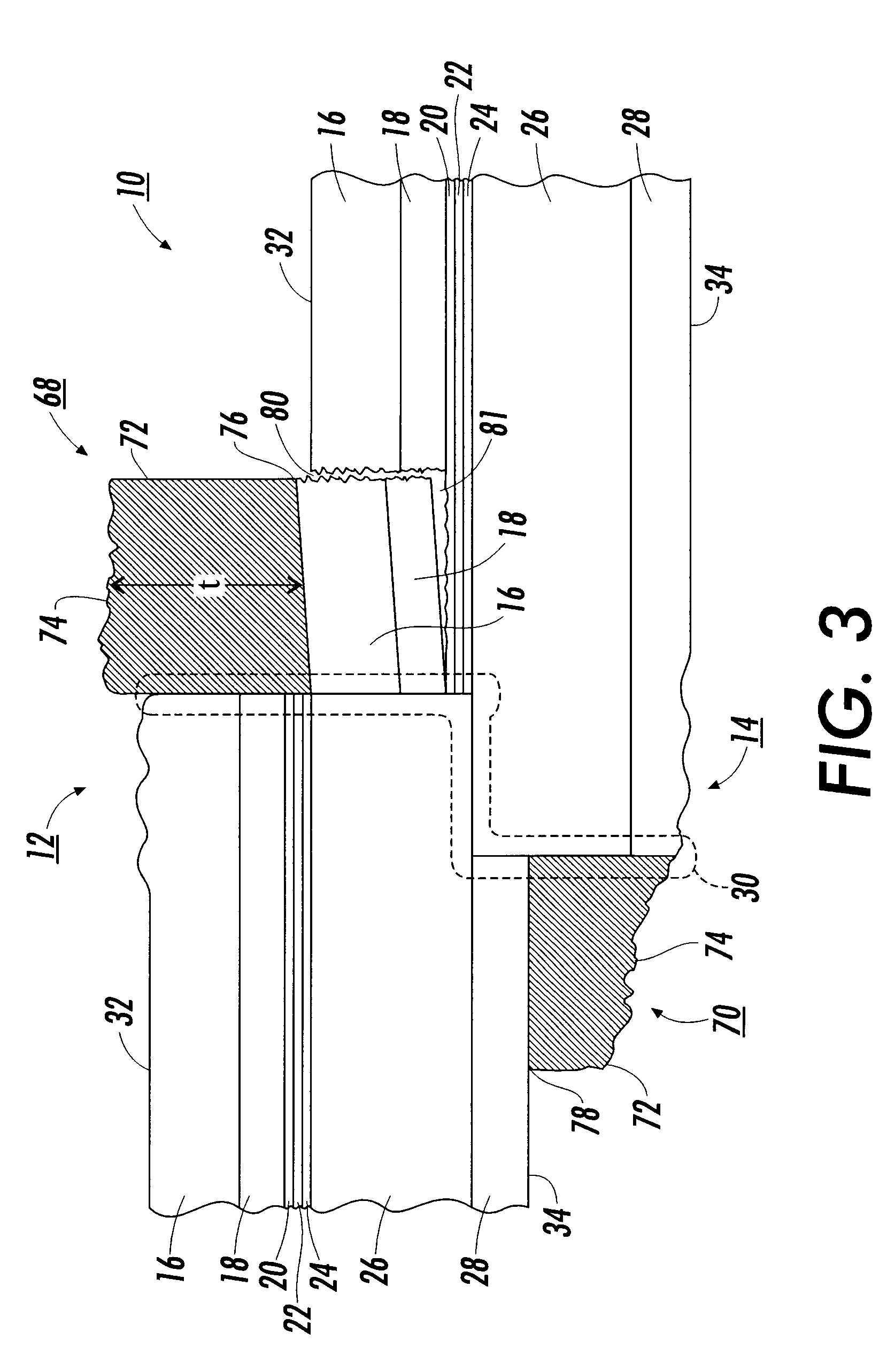

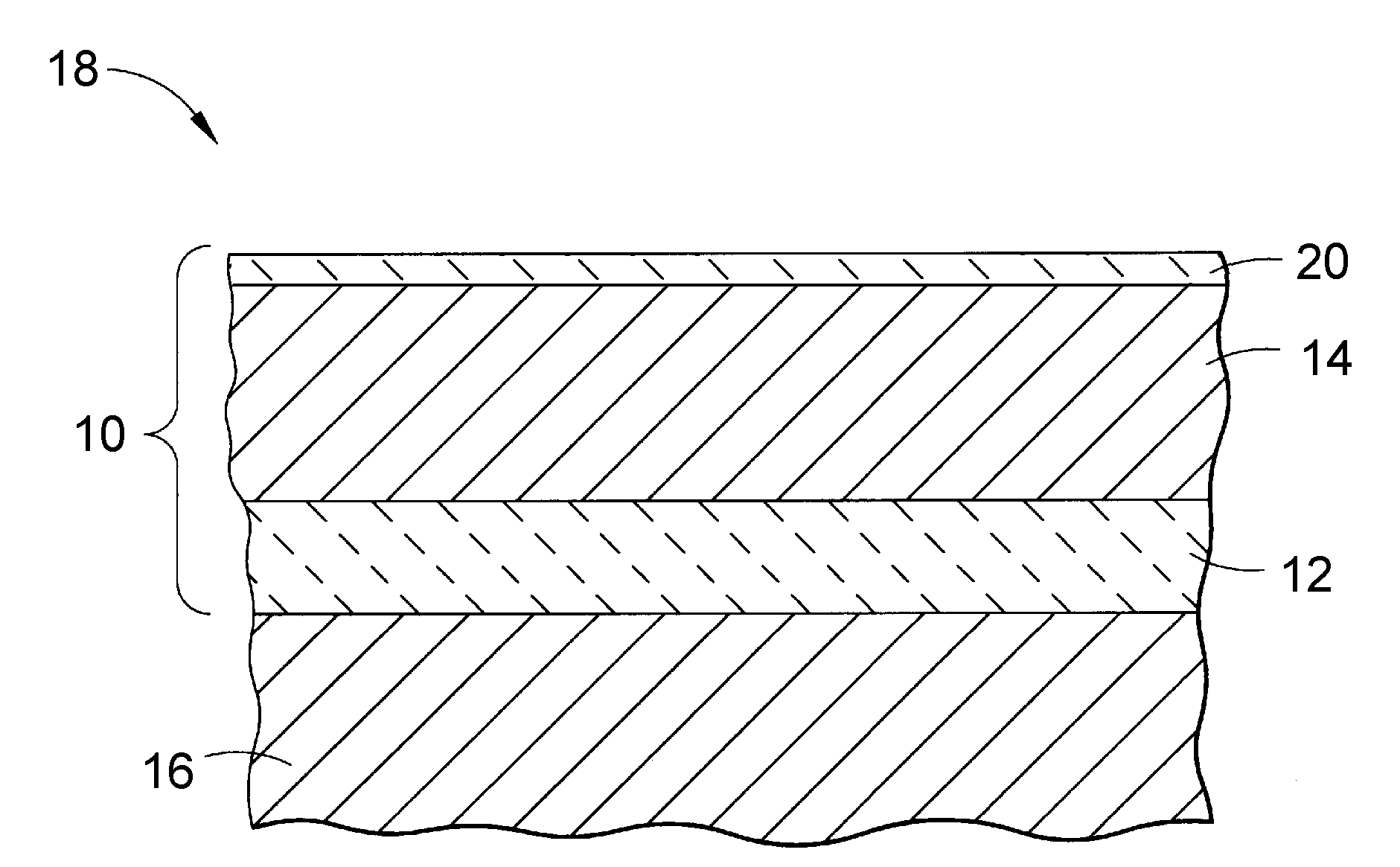

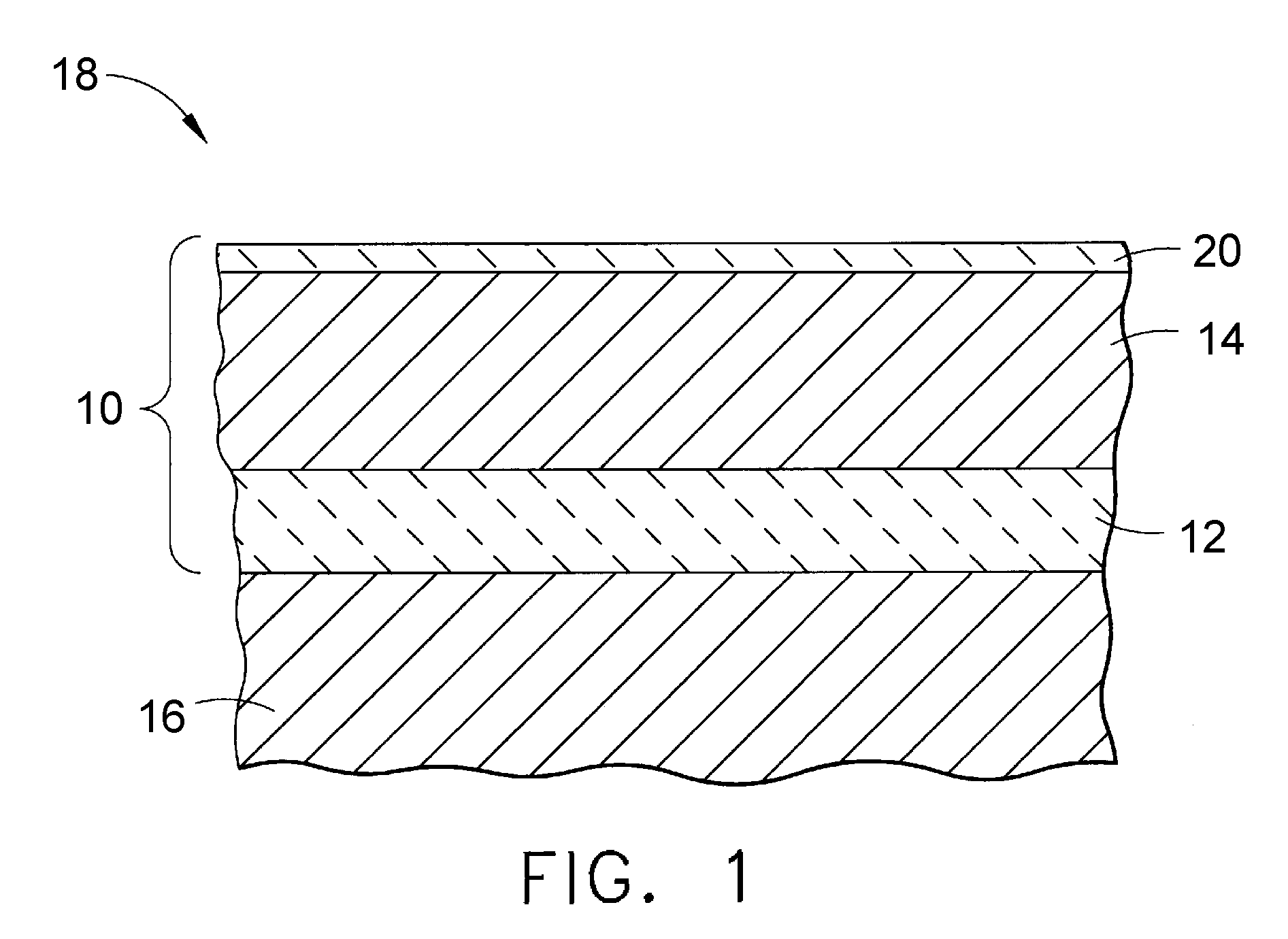

A double-sided saw blade, such as a hack saw blade, comprising a blade body defining a first end and a second end; a first cutting edge located on one side of the blade body defining a first cutting tooth set pattern and a second cutting edge located on an opposite side of the blade body defining a second cutting tooth set pattern; wherein the first set pattern and the second set pattern are (i) timed with respect to one another or (ii) 180 degrees out of phase with respect to one another. A first tooth of the first set pattern may be indexed relative to a designated reference point along the blade body and a first tooth of the second set pattern may be equally indexed relative to the same designated reference point along the blade body.

Owner:BLACK & DECKER INC

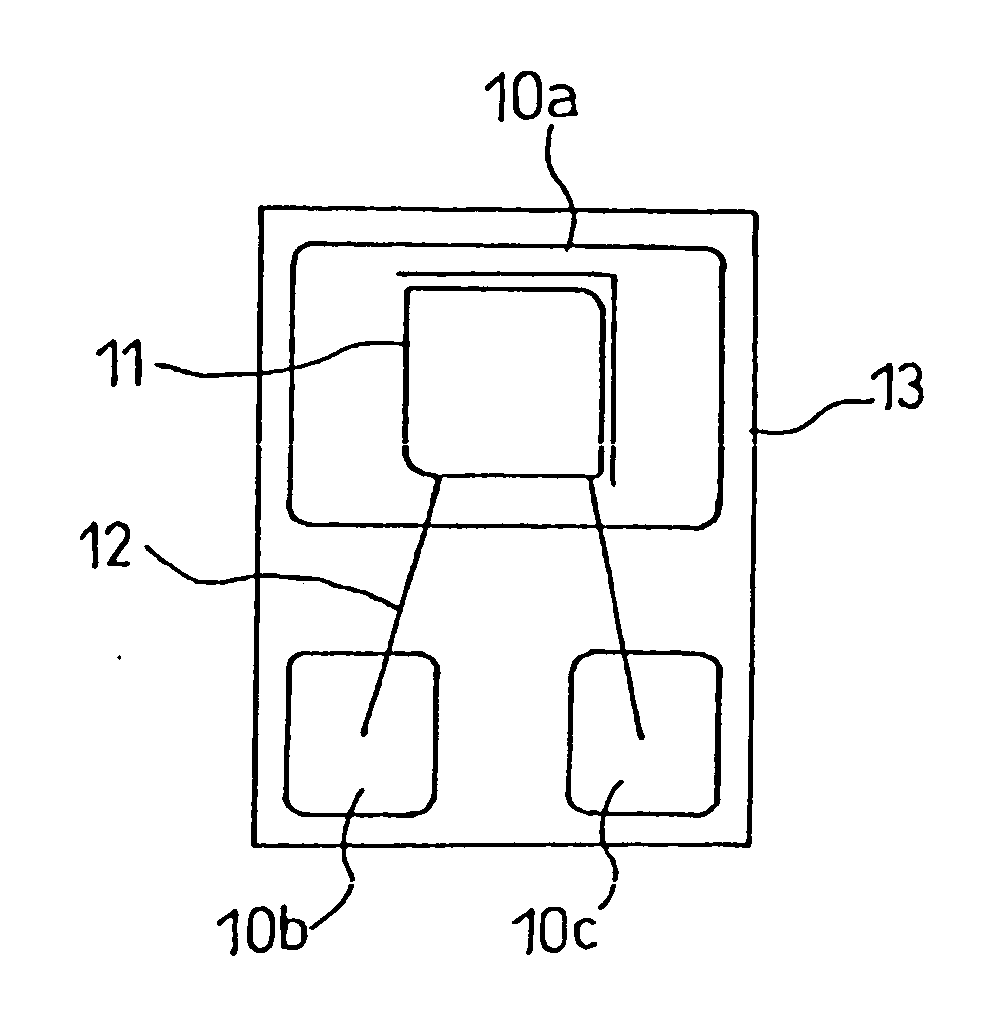

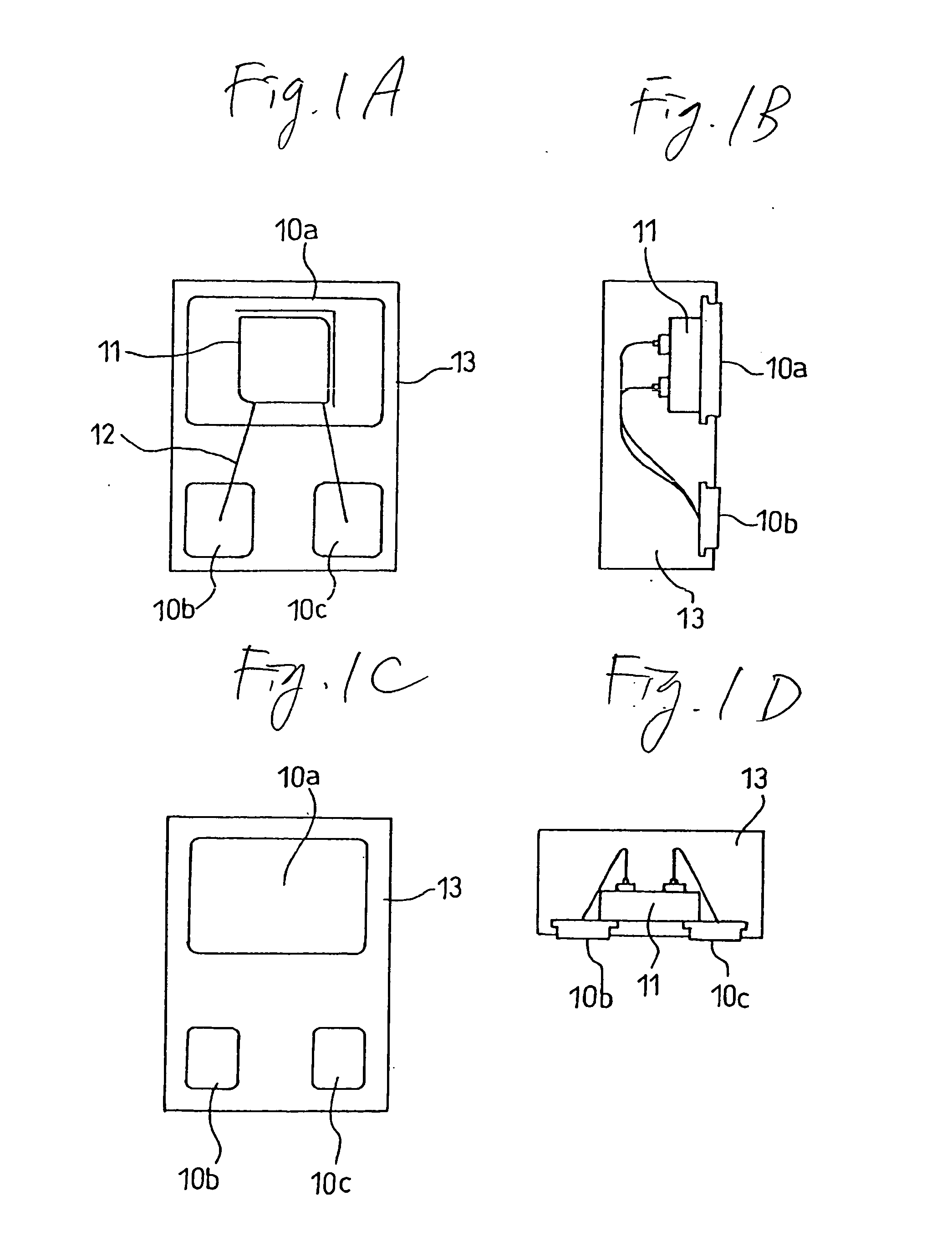

Lead frame, method of manufacturing the same, semiconductor device using lead frame and method of manufacturing semiconductor device

InactiveUS20050224918A1Improve reliabilityNo deformationSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

There is provided a lead frame which comprises: a lead frame body comprising a sheet-shaped body made of metal; a groove portion for forming a lead which is formed by a predetermined depth in a lead forming region on a surface of the lead frame body; and a lead portion formed so that the lead portion can protrude from the groove portion onto the surface of the lead frame body, the lead portion being made of material different from material of the lead frame body. A thin type semiconductor device is provided in which the above lead frame is used and after a chip is mounted, the lead frame body is removed by means of etching.

Owner:COLLABO INNOVATIONS INC

Saw blade with tooth form projection

ActiveUS9731365B2Easy to usePromote formationMetal sawing devicesTransportation and packagingAcute angleEngineering

A saw blade, such as a metal-cutting band saw blade, has a cutting edge including a plurality of teeth. A plurality of the teeth include a tip, a clearance surface located on one side of the tip, a rake face located on an opposite side of the tip relative to the clearance surface, a gullet, and a substantially flat, linear, or non-curvilinear projection formed between the rake face and the gullet and projecting outwardly relative to the rake face. The projection is inclined at an acute angle relative to a plane extending between the tips of consecutive unset teeth. The projection defines an inner end adjacent to the rake face and an outer end adjacent to the gullet. The inner end is located at a depth below the tip of at least about 25 / 1000 inch, and the distance between the inner end and the outer end of the projection in a direction substantially parallel to the plane extending between the tips of at least two teeth is less than about 65 / 1000 inch.

Owner:BLACK & DECKER INC

Hot cut aluminum billet saw

ActiveUS7047784B2Reduce the temperatureReduce frictionMetal sawing devicesMetal sawing accessoriesCross cutCircular saw

A process and apparatus for extruding aluminum into products, wherein aluminum logs are first heated to a predetermined temperature in a furnace, then are cut into billets of predetermined lengths, and then the billets, while still hot, are extruded into predetermined products in an extruder. In the process, the logs are cut into billets with a cross cut circular saw immediately after the logs are heated and before the logs are permitted to cool to a temperature below a suitable extruding temperature. The circular saw is cooled and lubricated during the cutting to as to restrain the saw from sticking in the heated aluminum and so as to maintain the temperature of the log at the cut within a predetermined range wherein the aluminum is relatively easy to cut and waste is minimized.

Owner:BELCO INDS

Cutting Blade

InactiveUS20160113202A1High surface hardnessExtend blade lifeMowersCuttersChromium carbideEngineering

A straw chopper to be mounted at the rear discharge of a combine harvester includes a housing with a feed opening and a discharge opening with a rotor mounted in the housing for chopping and accelerating the crop materials. The rotor has a hub and a plurality of flail blade members where at least some of the blades are formed of a plate having a mounting hole through the plate for mounting on a bushing or pin of the rotor where a bearing surface of the mounting hole of the plate and not the plate surface is coated with material such as tungsten carbide or chromium carbide of a thickness less than 0.020 inches which is harder than a parent material of the plate.

Owner:MAYERLE DEAN

Double sided hand hack saw blade and method of manufacture

ActiveUS9199321B2Improve cut qualityImprove efficiencyMetal sawing tool makingMetal sawing toolsEngineeringMechanical engineering

A double-sided saw blade, such as a hack saw blade, comprising a blade body defining a first end and a second end; a first cutting edge located on one side of the blade body defining a first cutting tooth set pattern and a second cutting edge located on an opposite side of the blade body defining a second cutting tooth set pattern; wherein the first set pattern and the second set pattern are (i) timed with respect to one another or (ii) 180 degrees out of phase with respect to one another. A first tooth of the first set pattern may be indexed relative to a designated reference point along the blade body and a first tooth of the second set pattern may be equally indexed relative to the same designated reference point along the blade body.

Owner:BLACK & DECKER INC

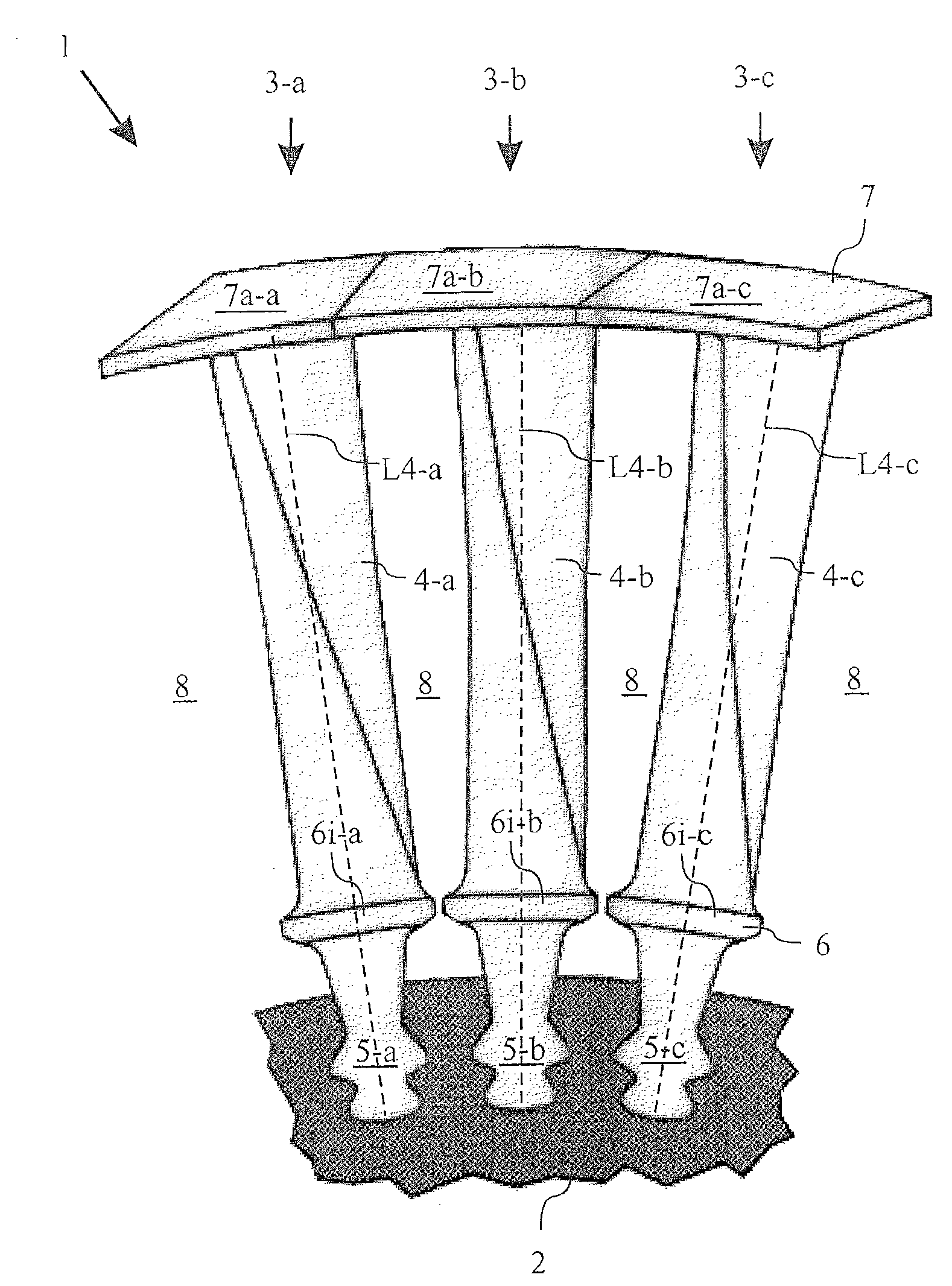

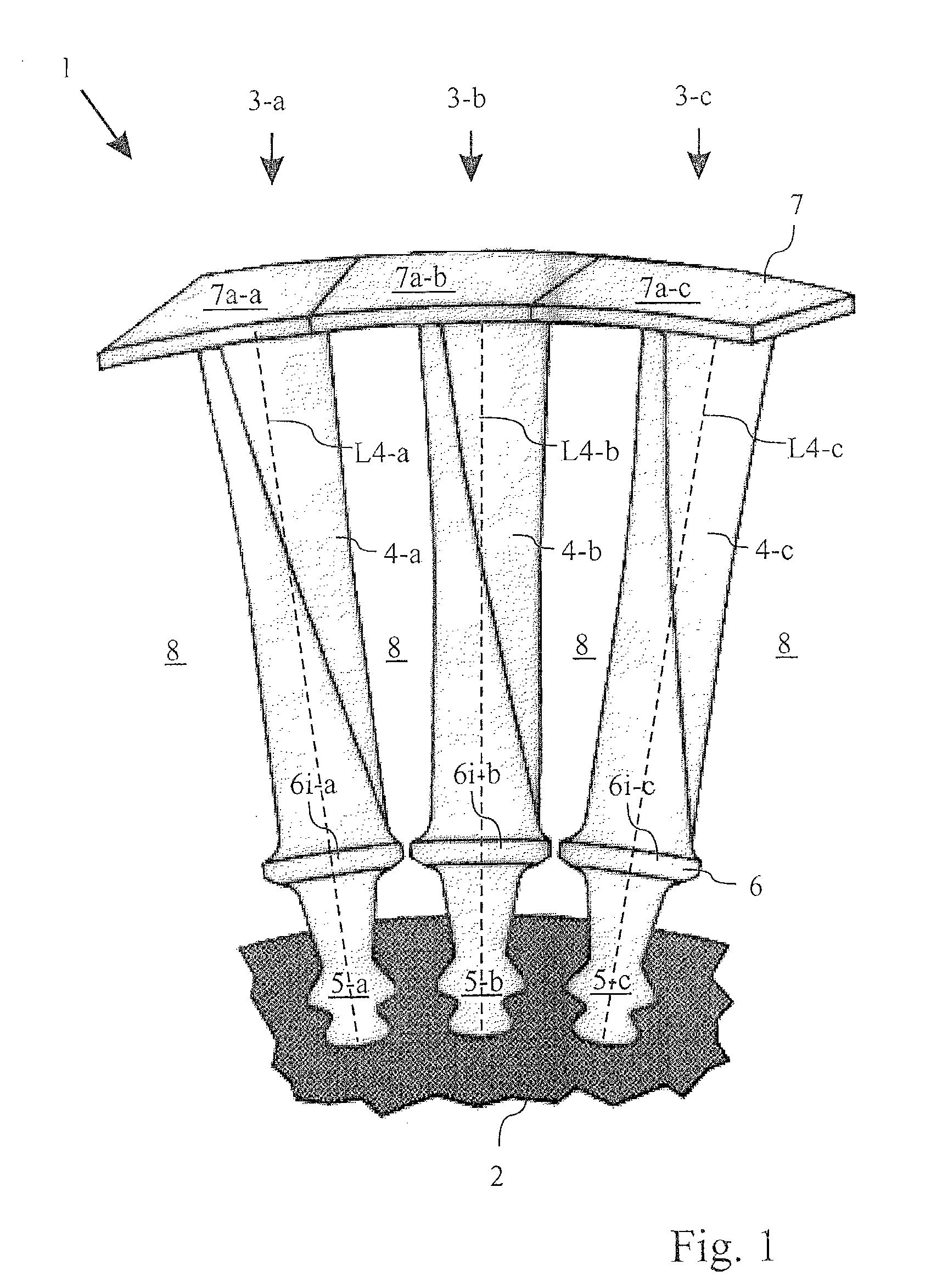

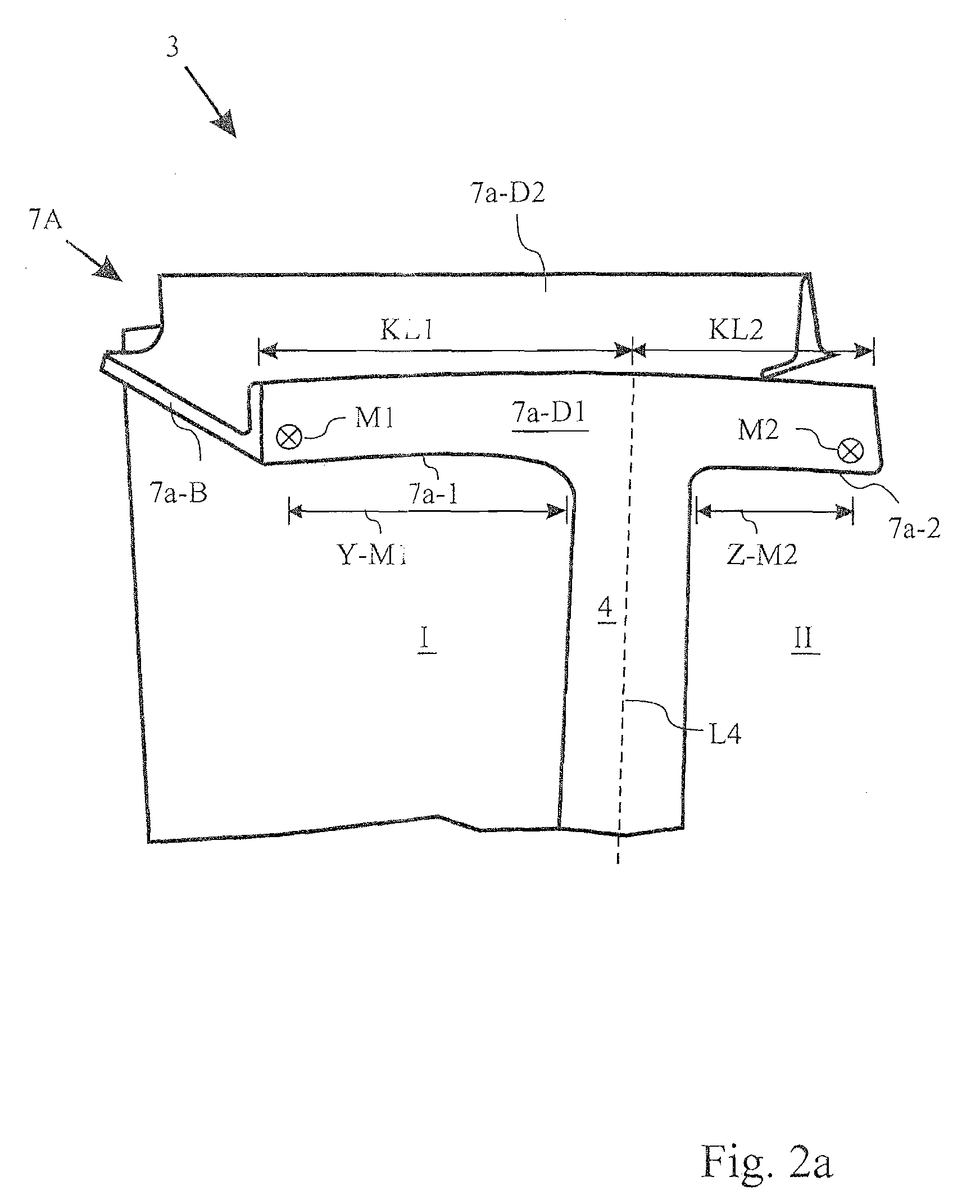

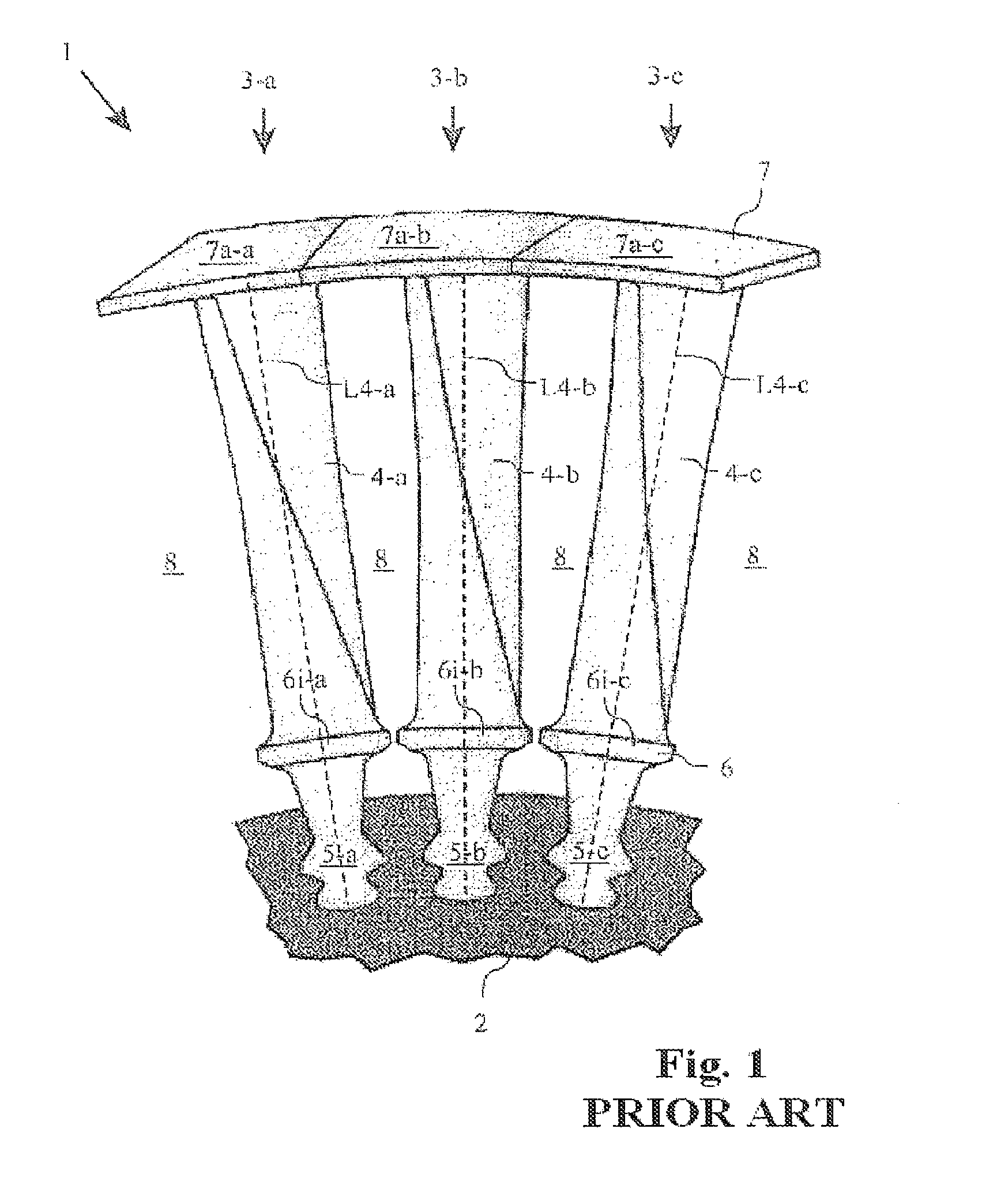

Blade with shroud

ActiveUS20070231143A1Disadvantage is reduced and avoidedExtend blade lifePropellersRotary propellersEngineeringKnife blades

A blade for a turbo machine has a blade section and a shroud element terminating the blade section in the blade section longitudinal direction. The blade section has a suction face and a pressure face. The shroud element extends essentially at right angles to the blade section longitudinal direction and has a first platform section projecting beyond the blade section and a second platform section projecting beyond the blade section. The platform sections are asymmetric with respect to one another. At least the first platform section of the shroud element is arranged at an additional inclination angle with respect to a normal alignment of the first platform section, with the additional inclination angle being in the opposite direction to the bending torque which acts on the first platform section during operation.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Blade with shroud

ActiveUS7654797B2Disadvantage is reduced and avoidedExtend blade lifePropellersRotary propellersKnife bladesEngineering

A blade for a turbo machine has a blade section and a shroud element terminating the blade section in the blade section longitudinal direction. The blade section has a suction face and a pressure face. The shroud element extends essentially at right angles to the blade section longitudinal direction and has a first platform section projecting beyond the blade section and a second platform section projecting beyond the blade section. The platform sections are asymmetric with respect to one another. At least the first platform section of the shroud element is arranged at an additional inclination angle with respect to a normal alignment of the first platform section, with the additional inclination angle being in the opposite direction to the bending torque which acts on the first platform section during operation.

Owner:ANSALDO ENERGIA SWITZERLAND AG

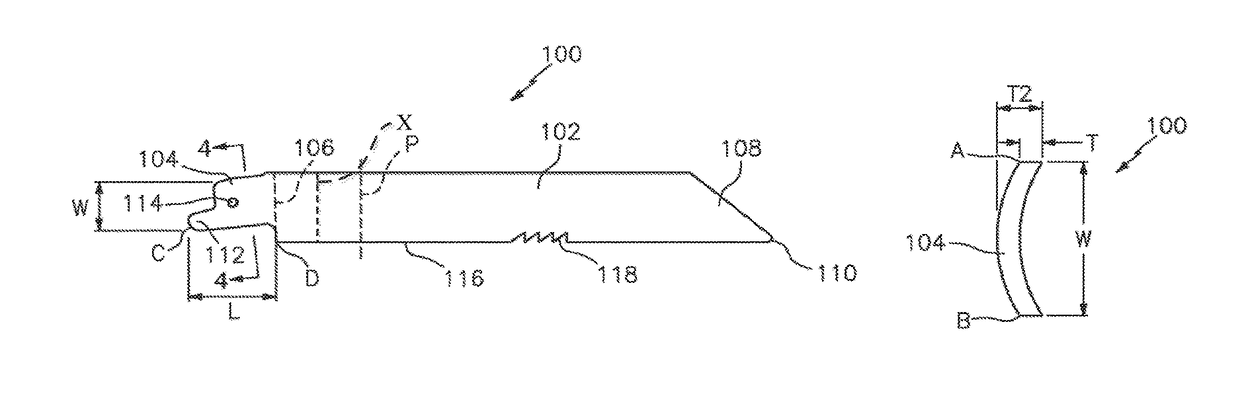

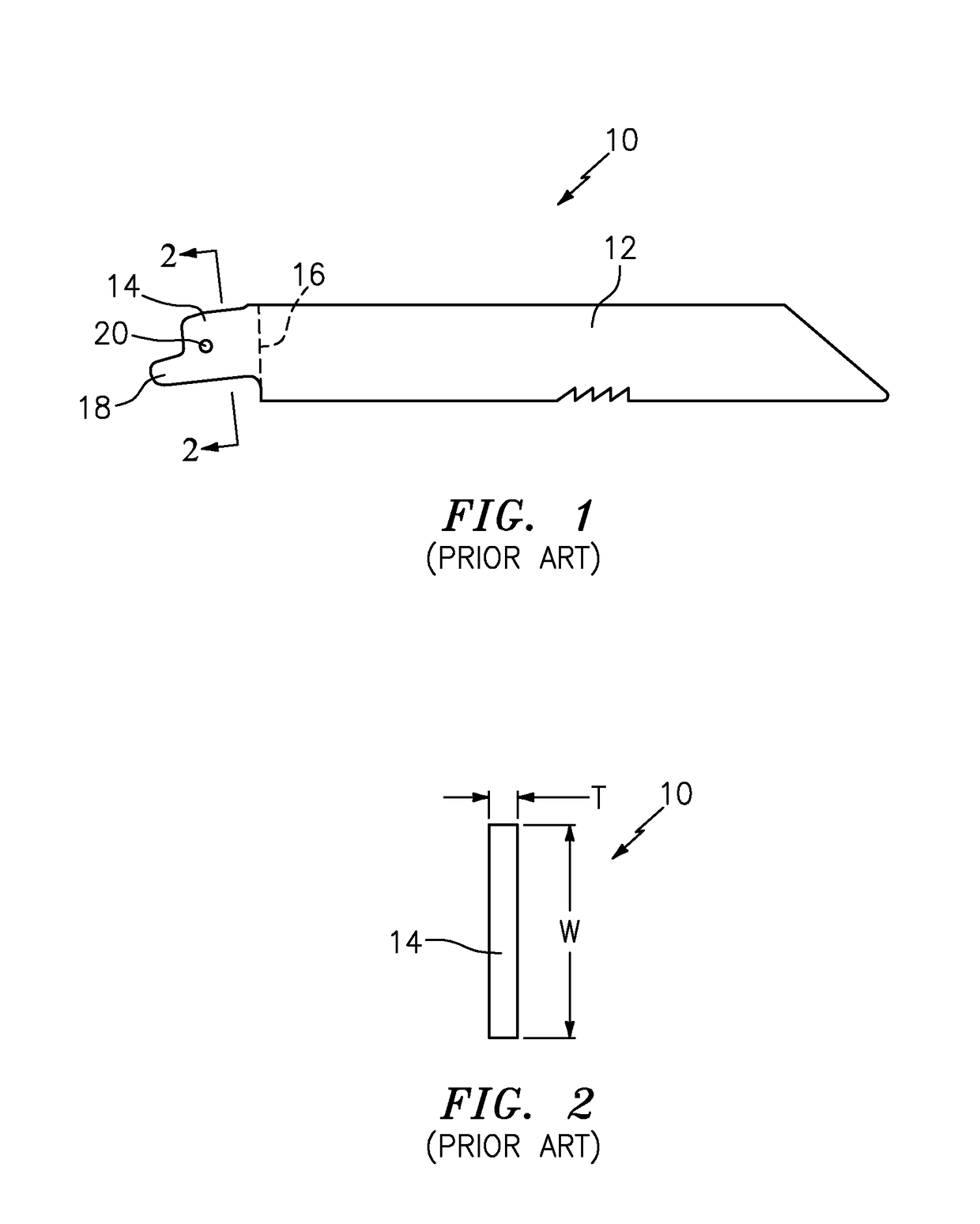

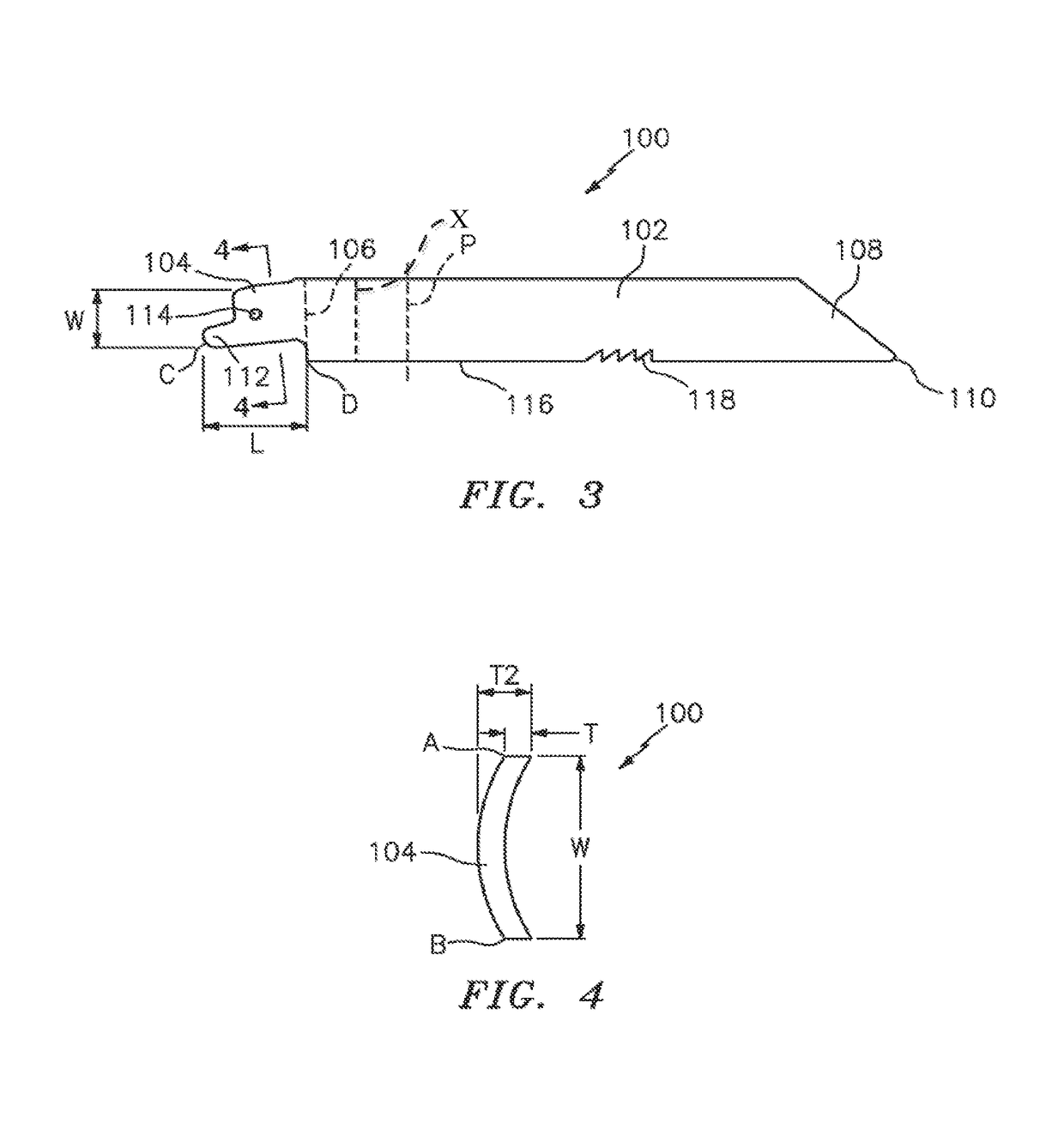

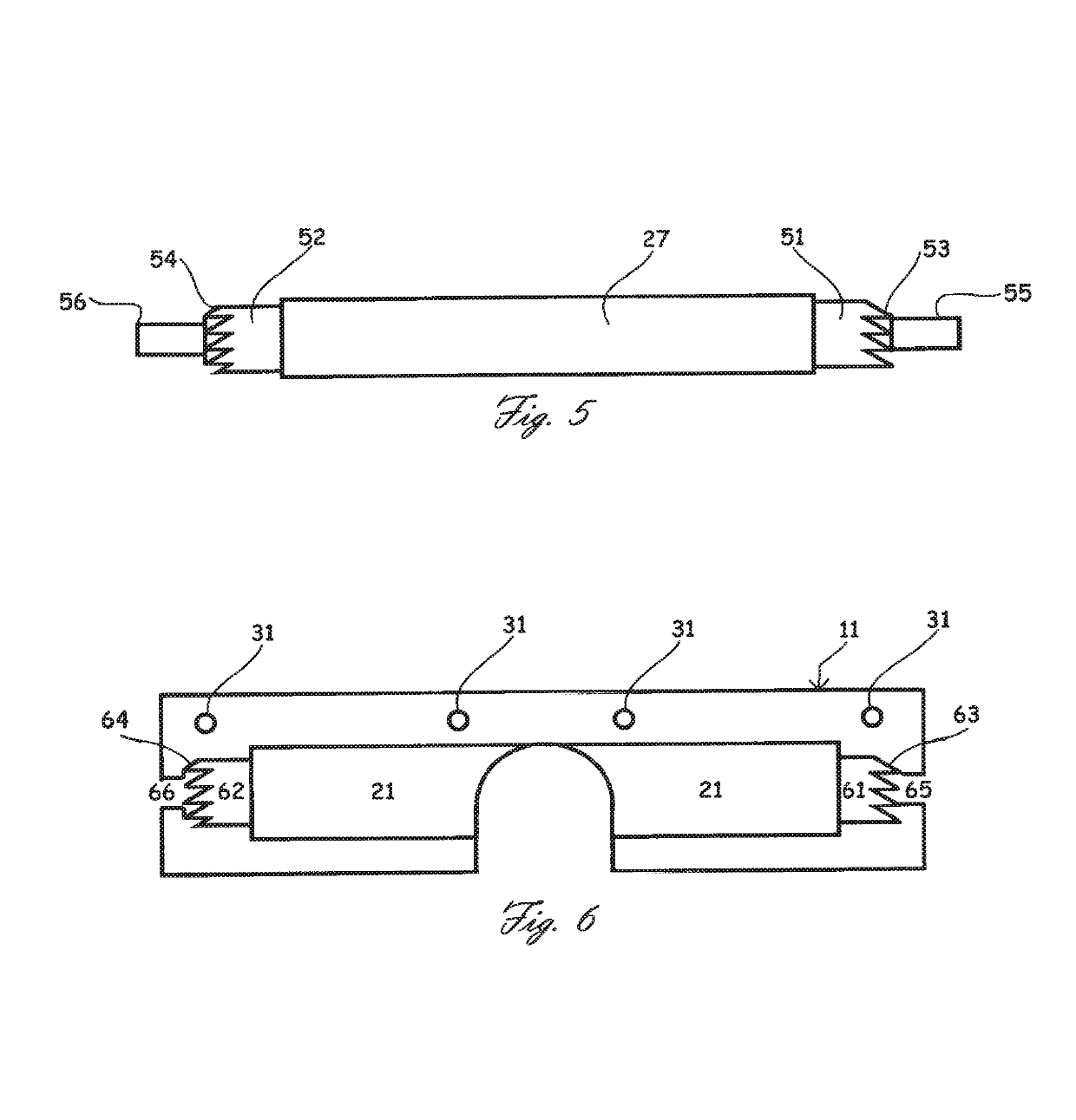

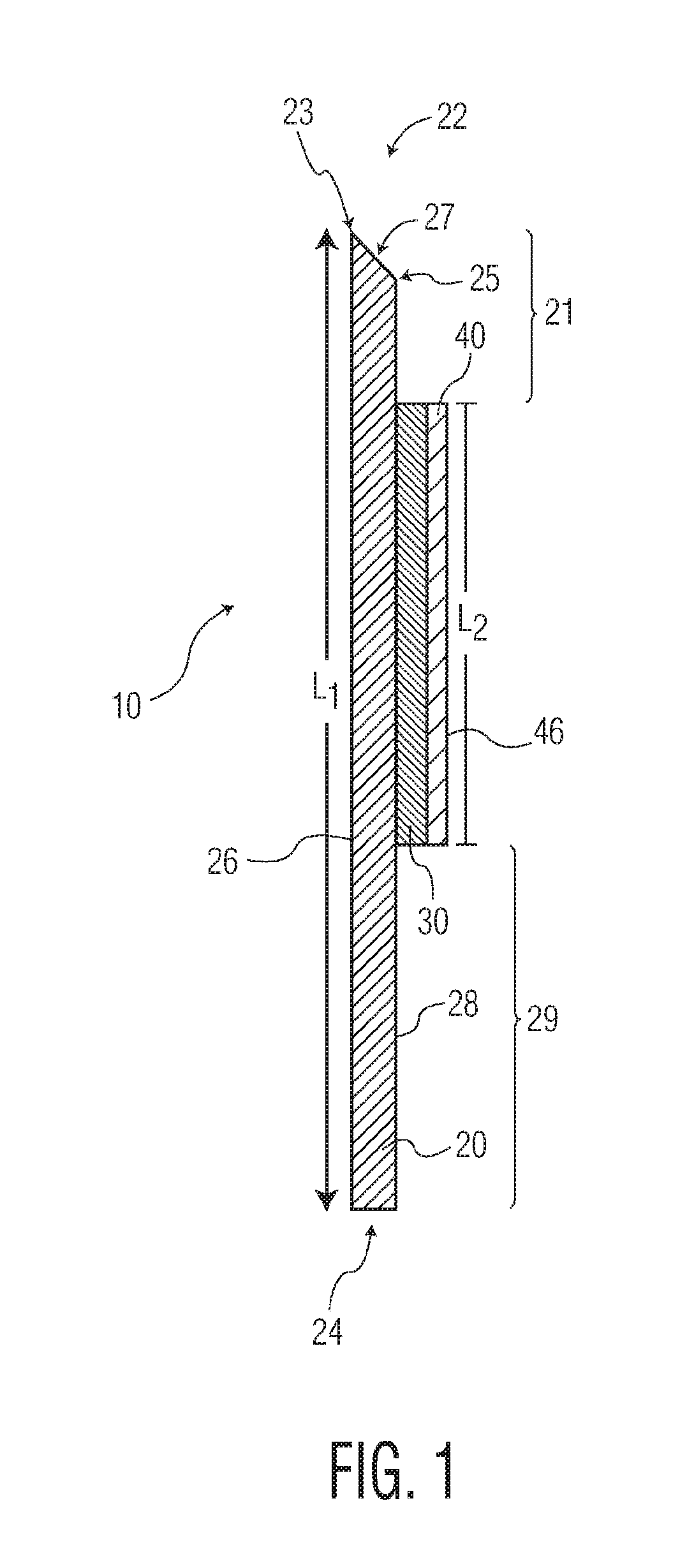

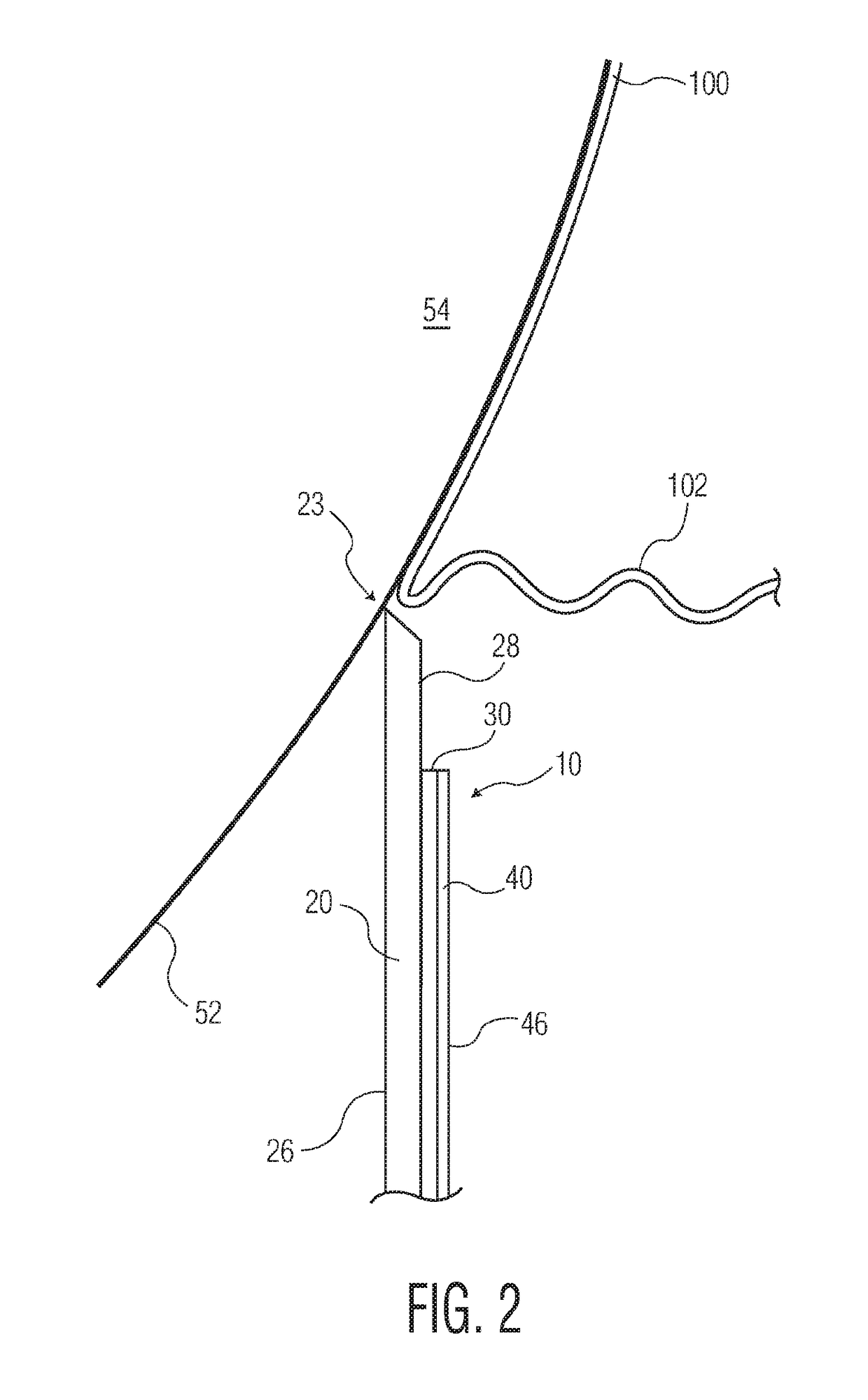

Recip blade

ActiveUS9833851B2Increasing the thicknessReduce oscillationMetal sawing devicesMetal sawing toolsEngineeringMechanical engineering

A recip blade has a blade body including a cutting edge and a tang located at one end of the blade body. The tang defines an arcuate cross-sectional shape or is laminated to increase the overall thickness of the tang and, in turn, enhance the rigidity of the blade and / or reduce oscillation or whipping of the blade during cutting.

Owner:BLACK & DECKER INC

Skate blade sharpener with indexing stone

ActiveUS10384329B2Less interventionUniform wearGrinding/polishing hand toolsGear teeth manufacturing toolsKnife sharpenerReciprocating motion

A handheld skate blade sharpening tool that has an automatically indexing, rotating sharpening stone that matches the concaved profile of the skate blade retained within a two-piece body member. Screws hold the two-piece body member together to keep the round sharpening stone sized to match the desired concave profile. The sharpening stone will remove metal to match the shape of the stone each time the sharpener is moved back and forth along the blade. The sharpening stone has gears on each end of the stone that match the gears inside the two-piece body. As the tool is moved along the skate blade, the sharpening stone will incrementally rotate within the body when the direction is changed in the reciprocating motion by the user's back and forth movement.

Owner:MAINTAIN YOUR EDGE LLC

Dampened creping blade

InactiveUS20170361564A1Reduce vibrationEffective constrained-layer dampingMechanical working/deformationPaper/cardboard articlesEngineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

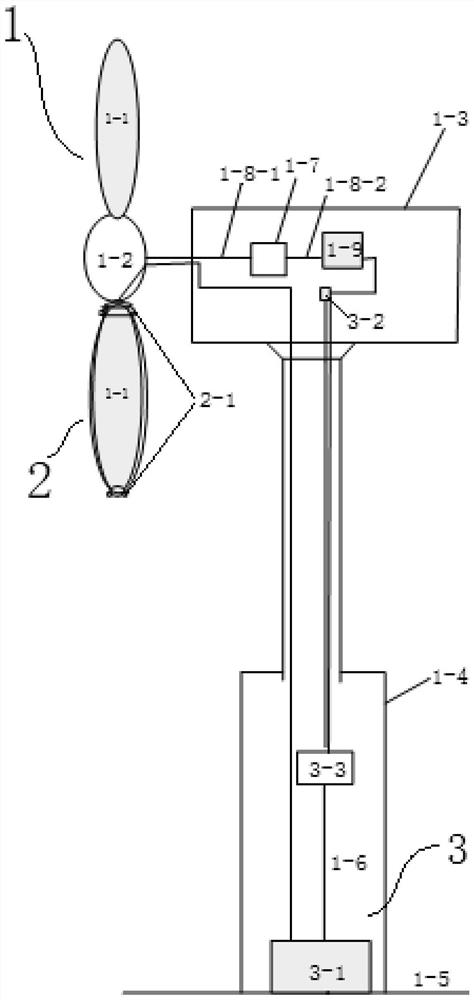

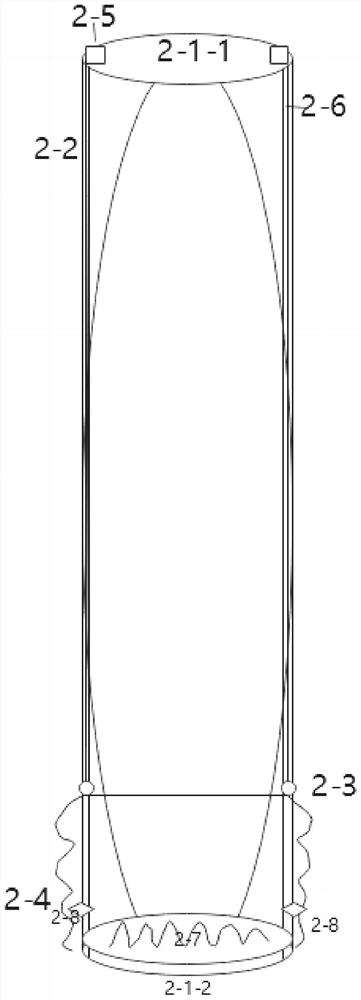

Wind driven generator blade anti-freezing device and method

PendingCN113294302AExtend blade lifeIncrease power generationWind energy with electric storageEnergy storagePhysicsDC - Direct current

The invention discloses a wind driven generator blade anti-freezing device and method. The wind driven generator blade anti-freezing device comprises a wind power generation system and a lifting shielding system. The wind power generation system is used for converting wind energy into electric energy. The lifting shielding system is arranged on blades of the wind power generation system and used for shielding rain and snow. The lifting shielding system comprises an upper and lower fixing ring, a slideway groove, rollers, shielding cloth, a direct-current motor and a lifting rope. The upper and lower fixing ring comprises an upper fixing ring and a lower fixing ring, The upper fixing ring and the lower fixing ring are respectively arranged at upper and lower ends of the blade. The slideway groove is formed between the upper fixing ring and the lower fixing ring, the rollers are arranged in the slideway groove, and the rollers are in sliding connection with the sliding way groove. The rollers are connected with the shielding cloth. The shielding cloth is laminated at the upper end of the lower fixing ring in an initial state. The direct-current motor is arranged on the upper fixing ring, an output shaft of the motor is connected with a lifting rope, and the lifting rope is connected with the rollers in a penetrating and buckling mode. It is guaranteed that a fan generator set is not affected by severe weather, and the service life of blades is prolonged.

Owner:HUANENG CLEAN ENERGY RES INST

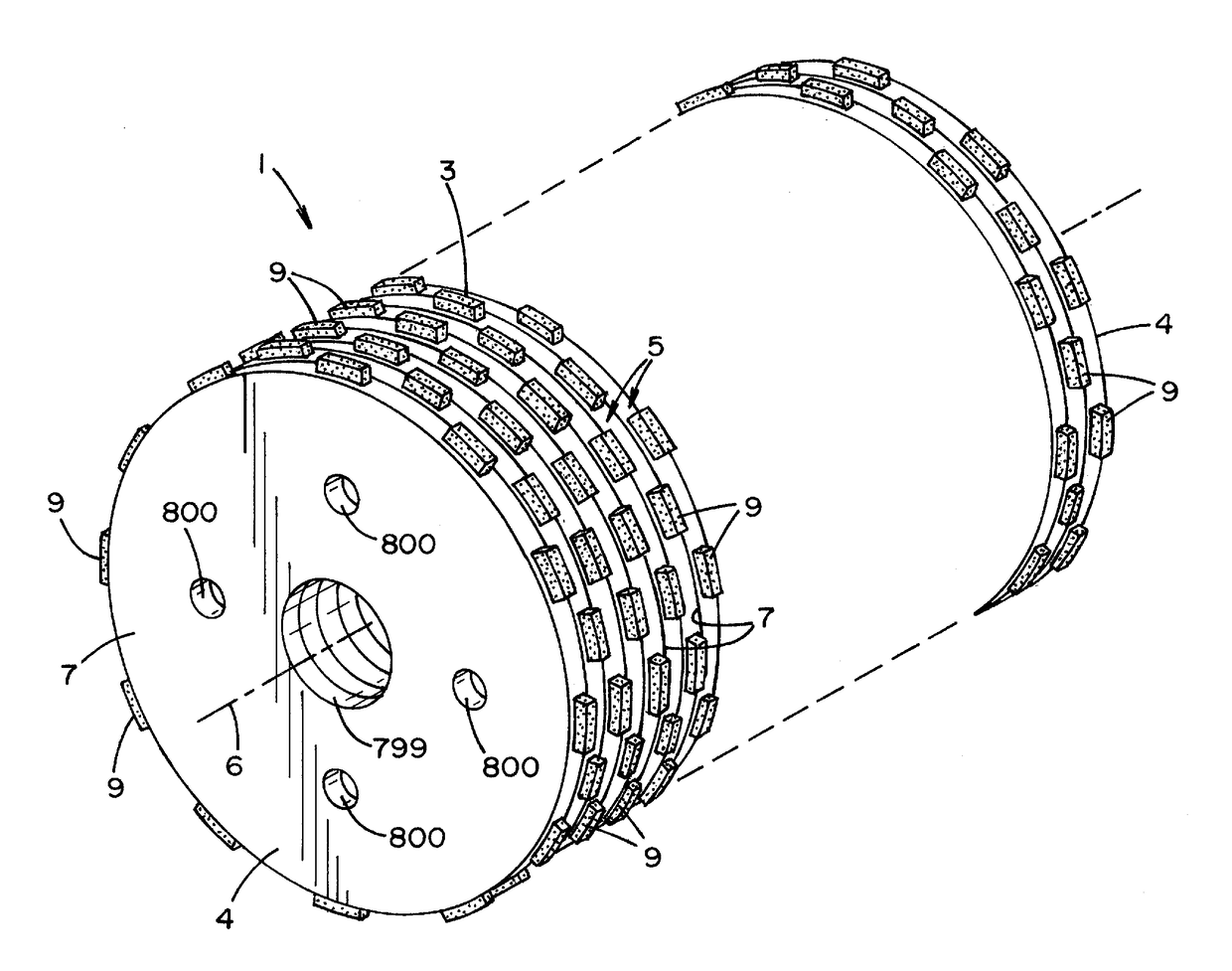

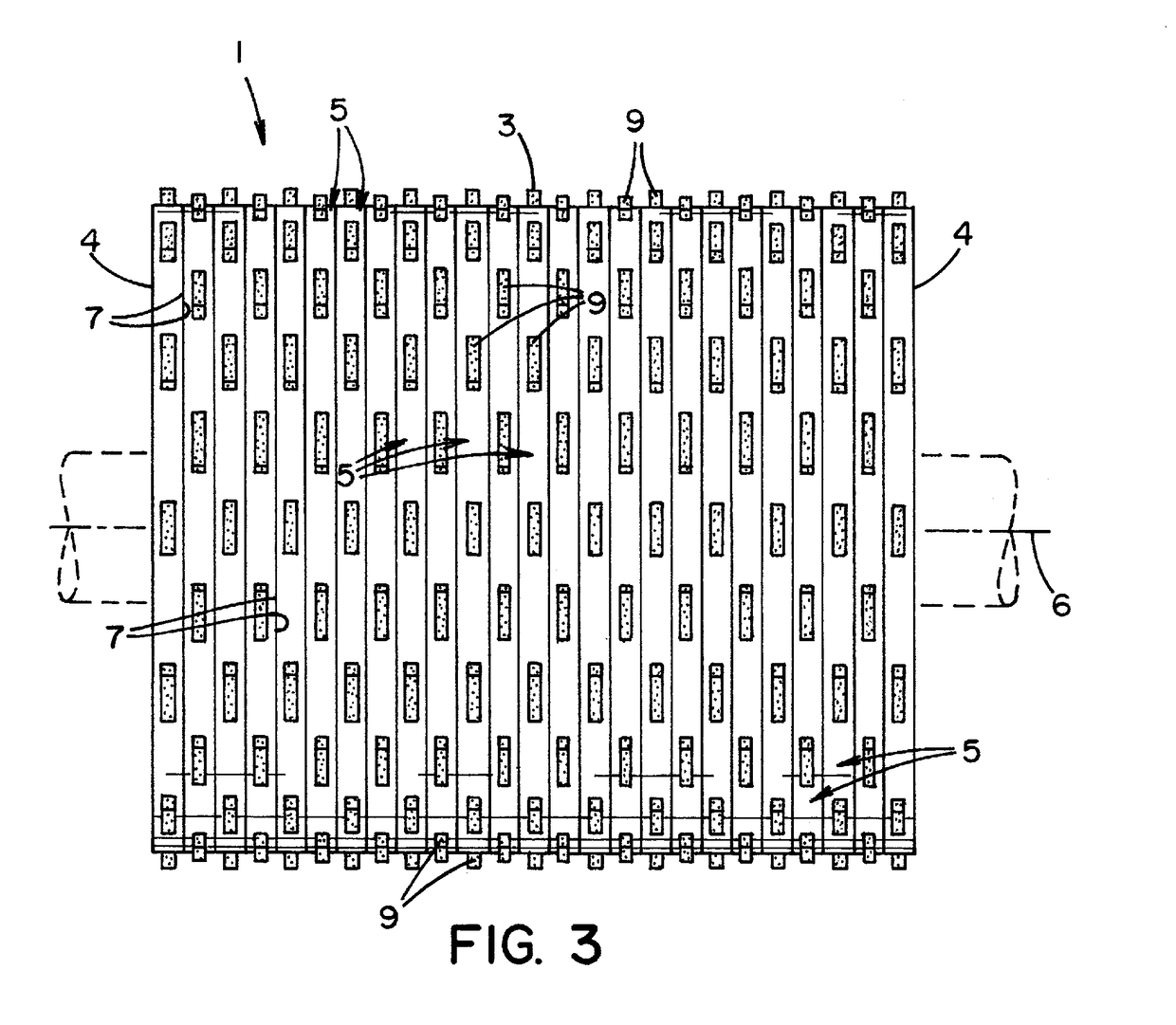

Blade head, blade and method for eliminating spacers in multiple blade stacks

InactiveUS20180147745A1Increase stiffnessShorten assembly timeStone-like material working toolsEngineeringKnife blades

A product and method to eliminate blade spacers in blade heads or stacks that are formed by multiple blades fixed relative to one another including a plurality of spacerless blades wherein the spacerless blades include a blade core with a blade core thickness that is greater than a segment thickness of grinding and / or cutting segments fixed to the blade core to allow core-to-core contact between adjacent blades in the plurality of spacerless circular blades while also producing segments spacings in the plurality of segments between the adjacent blades without the need for blade spacers.

Owner:DIAMOND PROD

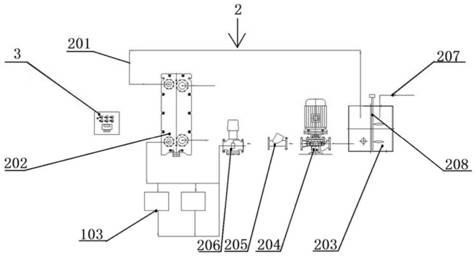

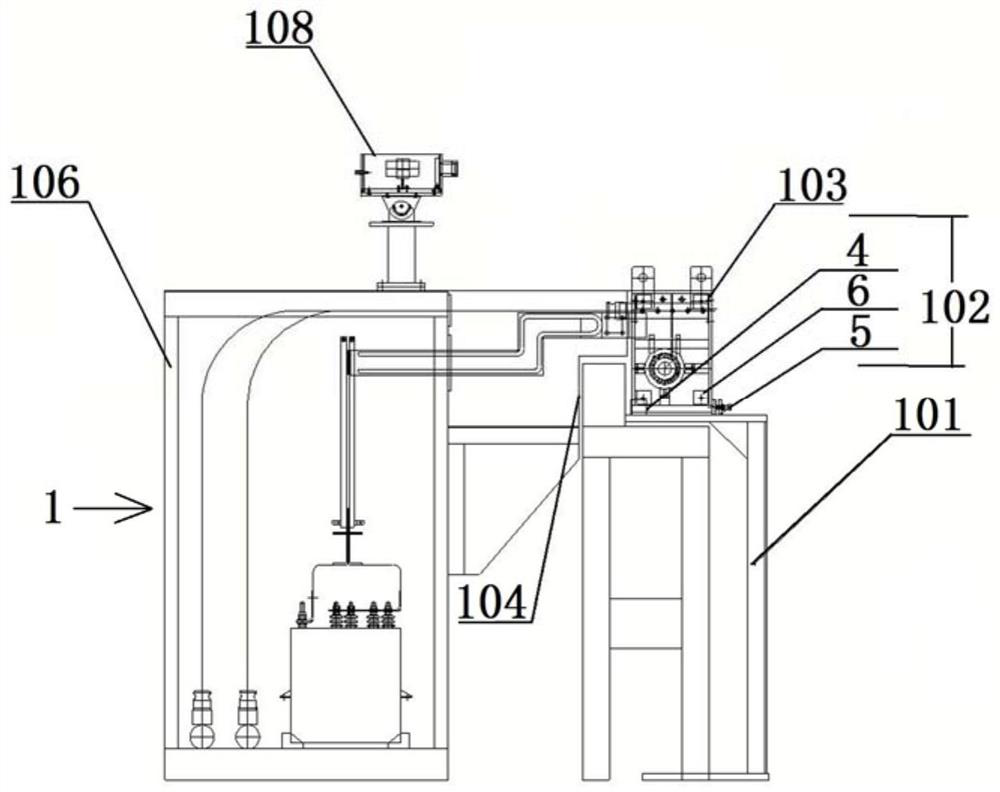

Bar stock shear warm cutting system for forging automobile engine connecting rod

InactiveCN112157441AReduced shear resistancePremium Shear SectionMetal working apparatusTemperature controlPlate heat exchanger

The invention relates to a bar stock shear warm cutting system for forging an automobile engine connecting rod. The system comprises a bar stock shear mechanism for shearing an engine connecting rod bar stock, a high-speed heating device arranged near the bar stock shear mechanism for heating the engine connecting rod bar stock, a cooling device for cooling the high-speed heating device, and an electric cabinet used for controlling the high-speed heating device and the cooling device; the high-speed heating device is high-speed heating pass-type temperature control equipment, and the high-speed heating pass-type temperature control equipment is arranged on a channel in front of a bar stock shear of the bar stock shear mechanism; and the cooling device comprises a circulating pipeline, a plate heat exchanger, a water tank, a stainless steel water pump, a Y-shaped filter, an electric control valve, a water adding one-way electromagnetic valve and a liquid level controller. The system hasthe advantages that the shearing resistance of the heated engine connecting rod bar stock is reduced, a high-quality shearing section can be obtained after the bar stock is sheared by the bar stock shear, residual stress is eliminated, and cracks of the shearing section are avoided.

Owner:BAICHENG ZHONGYI PRECISION FORGING

Recip blade

InactiveUS20140366388A1Reduced quality per unit areaReduce the oscillating or whipping of the distal portionMetal sawing devicesMetal sawing toolsDistal portionEngineering

A recip blade has a blade body and a tang located at one end of the blade body. The blade body has a distal portion located on an opposite end of the blade body relative to the tang. The distal portion defines a tip and at least one aperture extending through the blade body. A cutting edge extends along the blade body between the tang and the tip.

Owner:BLACK & DECKER INC

Scrap chopper device of tension leveling machine

InactiveCN104476591ANot easy to wearGuarantee the need for continuous productionMetal working apparatusAluminum foilSpiral line

The invention discloses a scrap chopper device of a tension leveling machine. The scrap chopper device comprises a movable cutter mounting seat mounted on a base and a roller cutter mounted on the movable cutter mounting seat. A static blade horizontally disposed on the base is disposed on one side of the roller cutter. A pair of movable blades which are in 180-degree symmetrical distribution is fixedly mounted on the roller cutter. The two movable blades can synchronously rotate along with the roller cutter and perform cutting motions. The two movable blades are arranged along a spiral direction, so that the cutting edges of the two movable blades are spiral lines. The two movable blades can move along the trajectory of the spiral lines to contact with the static blade so as to perform aluminum foil cutting. By the structure, the scrap chopper has the advantages that shearing force is reduced, shearing power is correspondingly reduced as compared with an original single-roller scrap chopper, the scrap chopper is low in noise, the cutting edges of the scrap chopper are less prone to abrasion, and the service life of the cutting edges is prolonged; when the scrap chopper is used for cutting strip materials of different thicknesses, edge gaps can be adjusted conveniently by adjusting the static blade, and the long-term continuous production requirements of the tension leveling machine can be satisfied.

Owner:镇江市宏业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com