Edge buster series round blade sharpener and the edge tracker sharpener

a technology of round blades and sharpeners, which is applied in the direction of grinding machines, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to maintain factory edge angles, inability to convert to manual mode, or sharpen blades, and inability to convert to sharpen blade edges of different geometrical profiles. , to achieve the effect of destroying the temper of the blade and prolonging the life of the blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In describing the preferred embodiment of the invention illustrated in the drawings, specific terminology will be resorted to for the sake of clarity. However the invention is not intended to be limited to the specific terms so selected and it is to be understood that each specific term includes all technical equivalents which operate in a similar manner to accomplish a similar purpose.

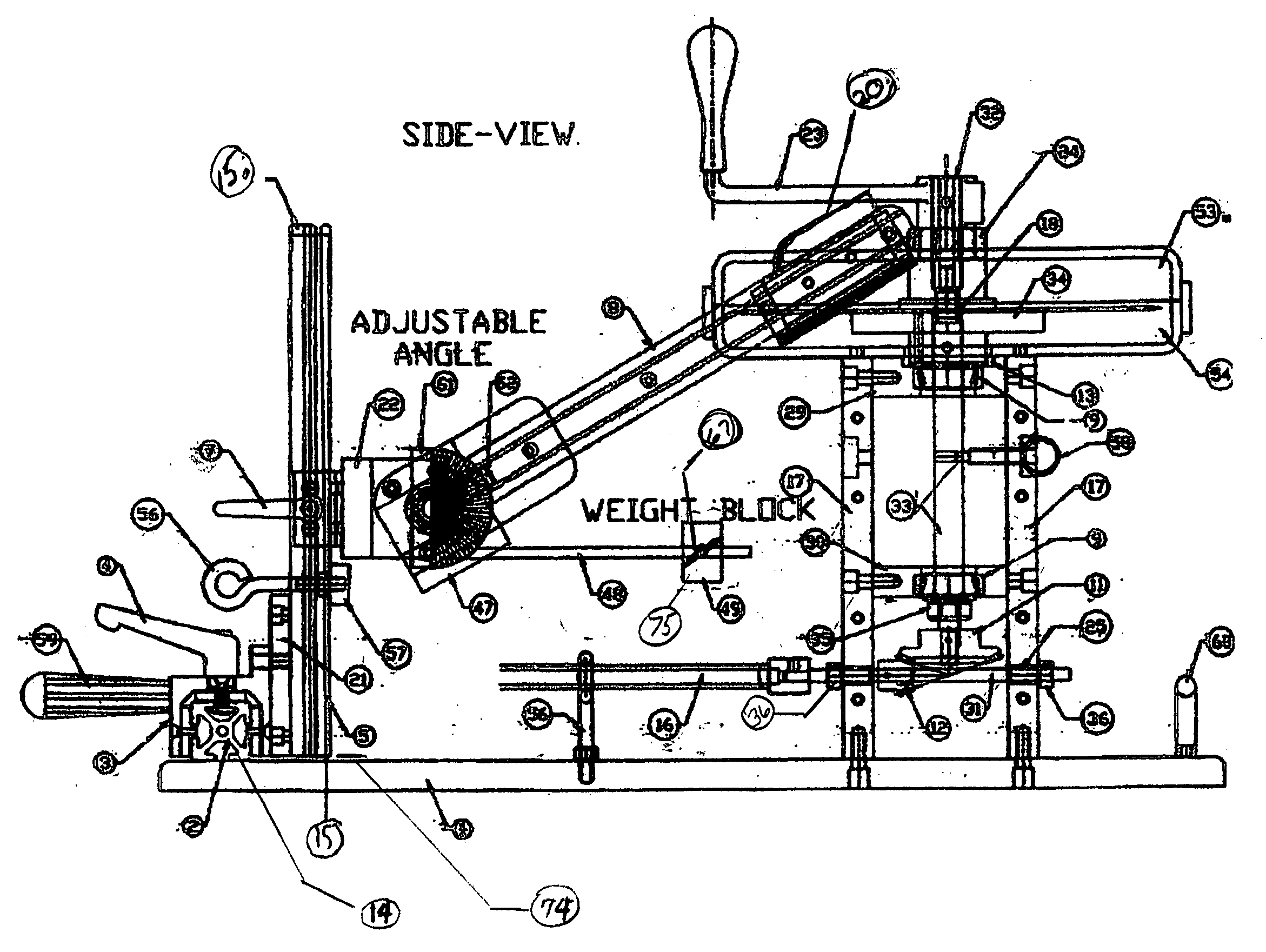

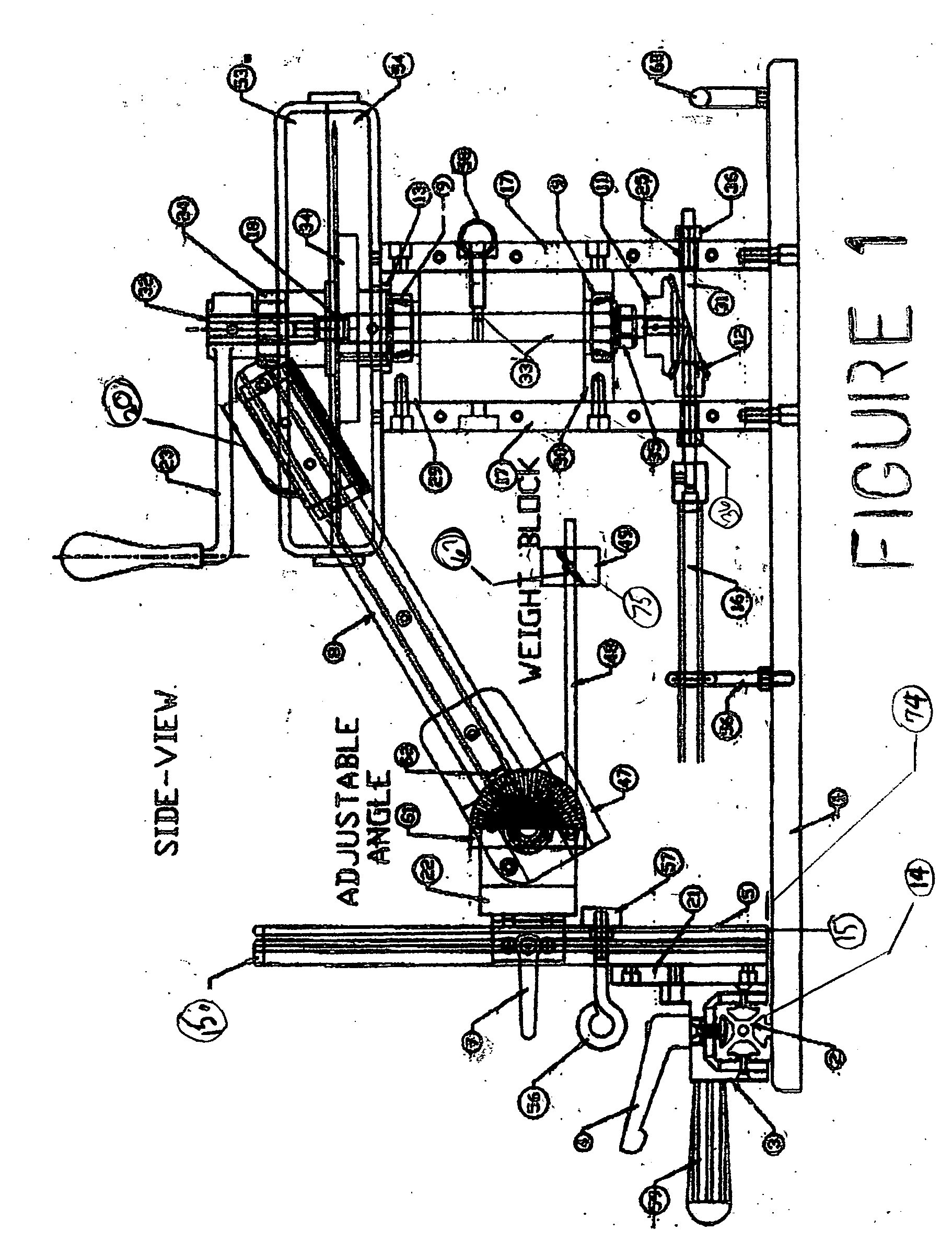

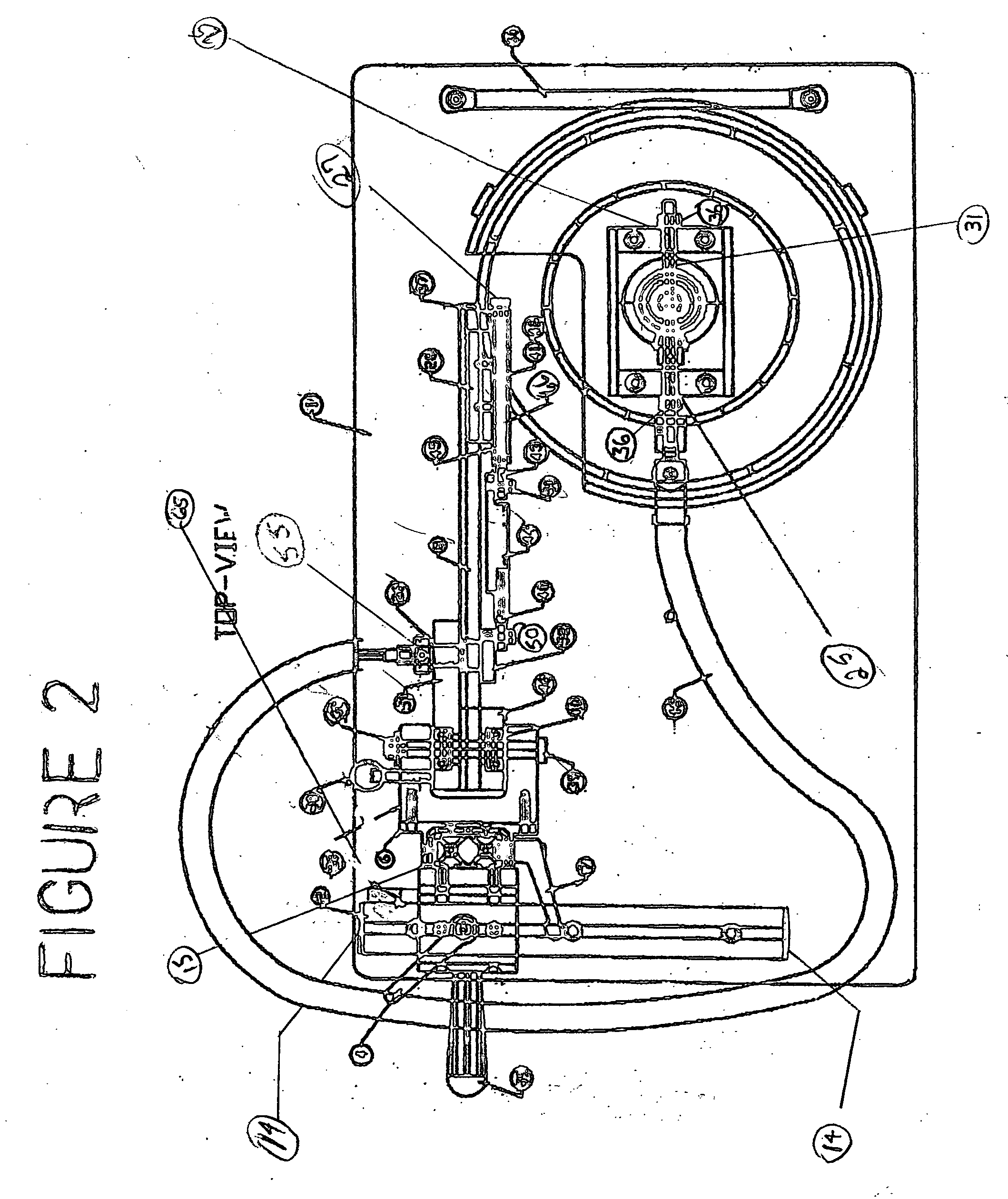

[0045] With reference to the drawings, FIGS. 6-20 and in particular a round blade sharpener embodying the teachings of the subject invention is generally designated as 1 with reference to its orientation in FIGS. 6, 11. The round blade sharpener includes a rectangular aluminum base 2. The base 2 include components which comprise and make up the round blade sharpener 1. The round blade sharpener 1 incorporates 4 each adjustable mounting feet 3 for leveling a crank handle 4 that can be turned in either direction. FIG. 6 The crank handle 4 can be quickly removed and re-mounted female receptacle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| precision angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com