Bar stock shear warm cutting system for forging automobile engine connecting rod

A technology for automobile engines and engine connecting rods, applied in metal processing and other directions, can solve problems such as material cracks, reduce equipment wear, reduce equipment maintenance costs, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

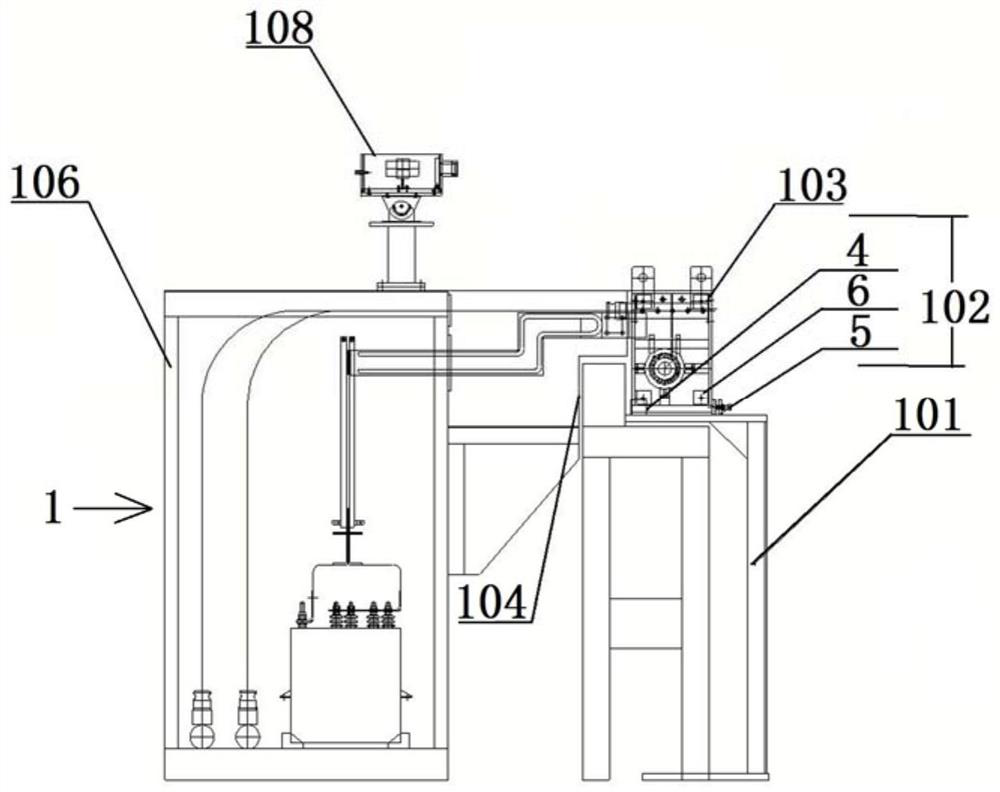

[0023] Figure 1-3 A schematic diagram of the overall structure according to an embodiment of the present invention is shown.

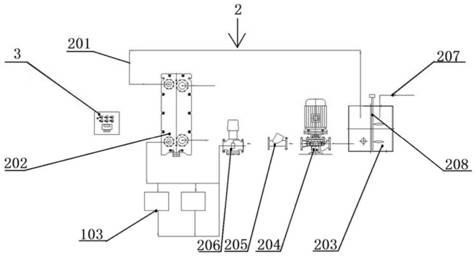

[0024] Such as Figure 1-3 As shown, the automobile engine connecting rod bar stock high-speed heating pass-through temperature control system provided by the embodiment of the present invention includes: a bar stock shearing mechanism for shearing the engine connecting rod bar stock, and a bar stock shear mechanism is provided near the bar stock shear mechanism. High-speed heating device 1 for heating engine connecting rod bar material, cooling device 2 for cooling high-speed heating device 1, and electric control box 3 for controlling high-speed heating device and cooling device;

[0025] Wherein, the high-speed heating device 1 is a high-speed heating through-type temperature control equipment, and the high-speed heating through-type temperature control equipment is arranged on the channel in front of the bar shears of the bar shear mechanism, and...

Embodiment 2

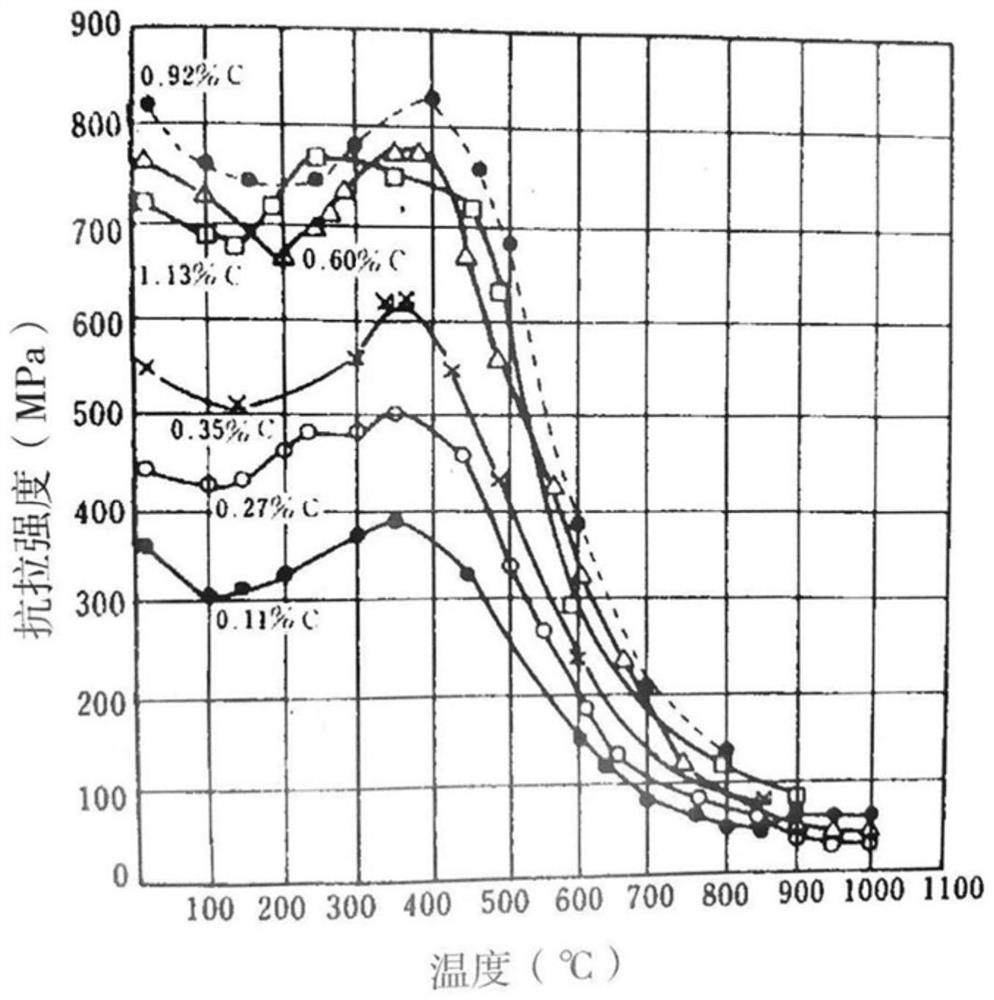

[0029] After the heater 103 of the high-speed heating device 1 carries out high-temperature heat treatment to the engine connecting rod bar, the bar tensile strength test is as follows:

[0030] Such as Figure 4 As can be seen, the tensile strength of materials with different carbon contents decreases significantly at 100°C, and begins to rise at around 300°C and begins to drop sharply at 400°C.

[0031] Such as Figure 5 As shown, the elongation of materials with different carbon contents decreased significantly at 100°C, and began to increase at 500°C. Therefore, it is advisable to control the temperature range at 100-500°C.

[0032] Comparison table of cutting temperature of different materials

[0033] serial number material diameter Material grade carbon content type Shear temperature (℃) 1 Φ42±0.4 36MnVS4 0.36 Low-alloy steel 150-180 2 Ф40±0.4 36MnVS4 0.36 Low-alloy steel 150-180 3 Φ36±0.4 36MnVS4 0.36 Low-alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com