Strong-core cement-soil tubular pile, construction method and tubular rotary drilling tool

A construction method and cement-soil technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of waste of building materials, segregation, exposed tendons, broken piles, limited bearing capacity and pull-out resistance, etc. The effect of construction period and cost, easy ferrule process and strong shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

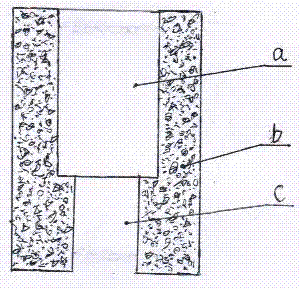

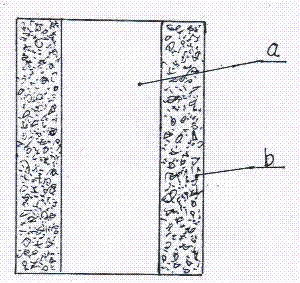

[0018] Embodiment 1 of the construction method of using the above-mentioned tubular rotary drilling tool to form a cement-soil cylinder pile with a strong core: 1. A core pile a with one of the following forms is first made by using various materials and construction methods: prestressed pipe piles, bamboo piles Core piles with features such as section piles, solid square piles, hollow square piles, steel pipe piles, and composite prefabricated piles. The above-mentioned core piles can also be cast-in-situ concrete pouring piles, and the pouring piles are special-shaped pile body pouring piles, composite pouring piles, or composite piles of prefabricated piles and pouring piles. The composite pile has the following forms: the upper part is a prefabricated pile and the lower part is a cast-in-situ pile; the upper part is a cast-in-place pile and the lower part is a prefabricated pile, or the outer part is a cast-in-situ pile and the inner part is a prefabricated pile; 2. Use a ...

Embodiment 2

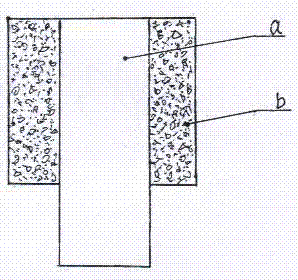

[0019] Embodiment two, 1, put the cylindrical rotary drilling tool 1 whose diameter is greater than the diameter of the core pile, after adjusting the inner and outer rotary functions of the vertical jet and the horizontal spray pipe, align the pile position, level the drilling machine, Adjust the verticality of the cylindrical rotary drilling tool 1; 2. Start the drilling rig to make the cylindrical rotary drilling tool 1 rotate and drill, when the inner spray nozzle 3-2 and the outer spray nozzle 3-2 of the horizontal spray pipe 3 1 After entering the soil, start the spinning function of the grouting pipe on one side, and use vertical high-pressure jetting to spray media such as cement slurry vertically into the formation at high pressure, so that it can cut the soil, emulsify in advance, and cool the drill bit to facilitate drilling. The inner and outer spray nozzles 3-2 and 3-2 of the slurry pipe 3 spray slurry and other materials into the inner and outer soil layers of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com