Calcium-tellurium synergistic gear steel and preparation method and application thereof

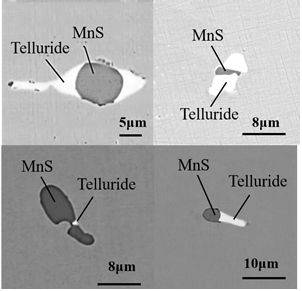

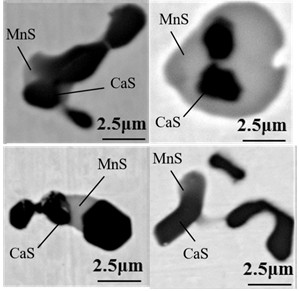

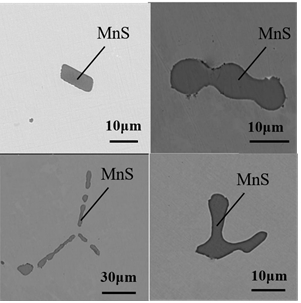

A technology for gear steel and molten steel, applied in the field of alloys, can solve problems such as difficulty in the form of MnS, and achieve the effects of alleviating the problem of uneven processing, facilitating uniform distribution, and improving the probability of layered precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The application also provides a method for preparing the described calcium-tellurium synergistic gear steel, comprising:

[0047] The raw materials are subjected to converter smelting, LF refining, RH refining and continuous casting to obtain the calcium-tellurium synergistic gear steel.

[0048] The function of converter smelting: adjust the temperature of molten steel, decarburize and dephosphorize, and control the C and P of the end point within the target value range.

[0049] The function of LF furnace refining: adjust the oxygen content in the molten steel, adjust the composition of the molten steel, and control the content of sulfur and tellurium in the molten steel within the target value range.

[0050] The function of RH furnace refining: adjust the composition of molten steel and control the content of calcium in the molten steel within the target value range.

[0051] The role of continuous casting: the production process of continuously casting the refined...

Embodiment 1

[0074] This embodiment provides a calcium-tellurium synergistically treated gear steel, the composition (wt%) of which is: C: 0.41%, Si: 0.25%, Mn: 0.78%, S: 0.02%, P: 0.018%, Cr: 1.08%, Mo: 0.20%, Ca: 0.002%, Te: 0.01%, and the rest are Fe and inevitable impurity elements. where [Ca] / ω[S]: 0.1, ω[Te] / ω[S]: 0.5.

[0075] The gear steel adopts the process flow of converter smelting → LF refining → RH refining → continuous casting, as follows:

[0076] Converter smelting: the content of Si in the molten iron is 0.60%, the content of P is 0.11%, and the amount of slag is 0.48%. Pay attention to the residual elements of molten iron and molten steel before and during production to ensure that the standard requirements are met. High tension blowing is adopted to control the composition of tapping: C: 0.08%, P: 0.008%. When tapping, add manganese silicon to the ladle: 7.5kg / t, high carbon ferrochromium Cr54C7.2: 14.5kg / t, and ferromolybdenum: 3.1kg / t; the amount of alloy is adjust...

Embodiment 2

[0082] This embodiment provides a calcium-tellurium synergistically treated gear steel, the composition (wt%) of which is: C: 0.41%, Si: 0.25%, Mn: 0.78%, S: 0.02%, P: 0.018%, Cr: 1.08%, Mo: 0.20%, Ca: 0.003%, Te: 0.02%, and the rest are Fe and inevitable impurity elements. where [Ca] / ω[S]: 0.15, ω[Te] / ω[S]: 1.

[0083] The gear steel adopts the process flow of converter smelting → LF refining → RH refining → continuous casting, as follows:

[0084] Converter smelting: the content of Si in the molten iron is 0.60%, the content of P is 0.11%, and the amount of slag is 0.48%. Pay attention to the residual elements of molten iron and molten steel before and during production to ensure that the standard requirements are met. High tension blowing is adopted to control the composition of tapping: C: 0.08%, P: 0.008%. When tapping, add manganese silicon to the ladle: 7.5kg / t, high carbon ferrochromium Cr54C7.2: 14.5kg / t, and ferromolybdenum: 3.1kg / t; the amount of alloy is adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com