Connecting plate for abnormal-shape double-row piles

A technology of connecting plates and double-row piles, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of weakening of shear bearing capacity and flexural bearing capacity, so as to enhance the flexural bearing capacity and solve the problem of flexural bearing capacity. Problems, the effect of enhancing the shear bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

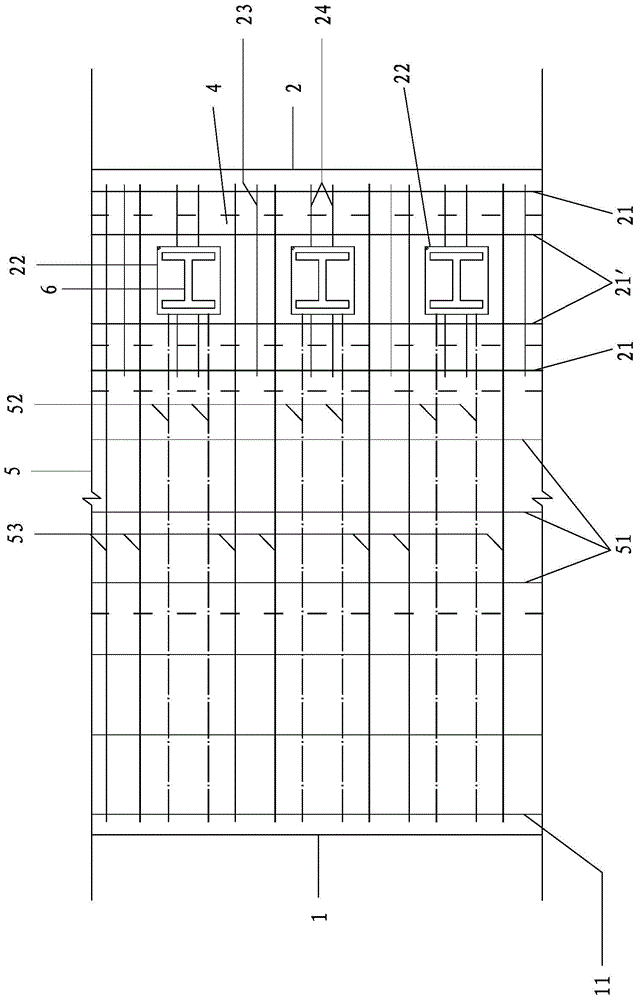

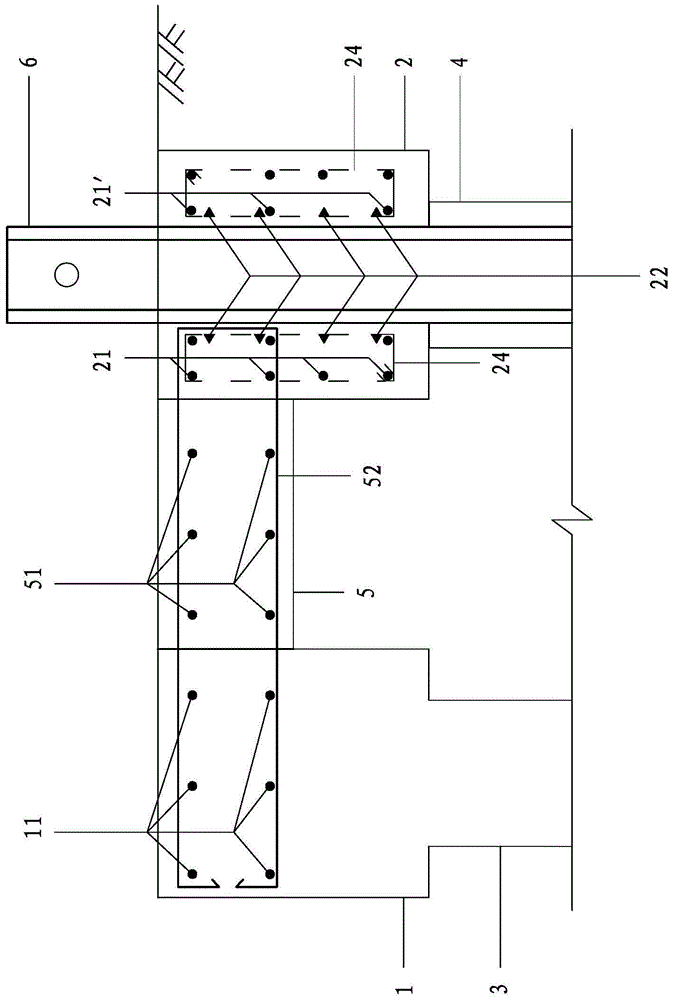

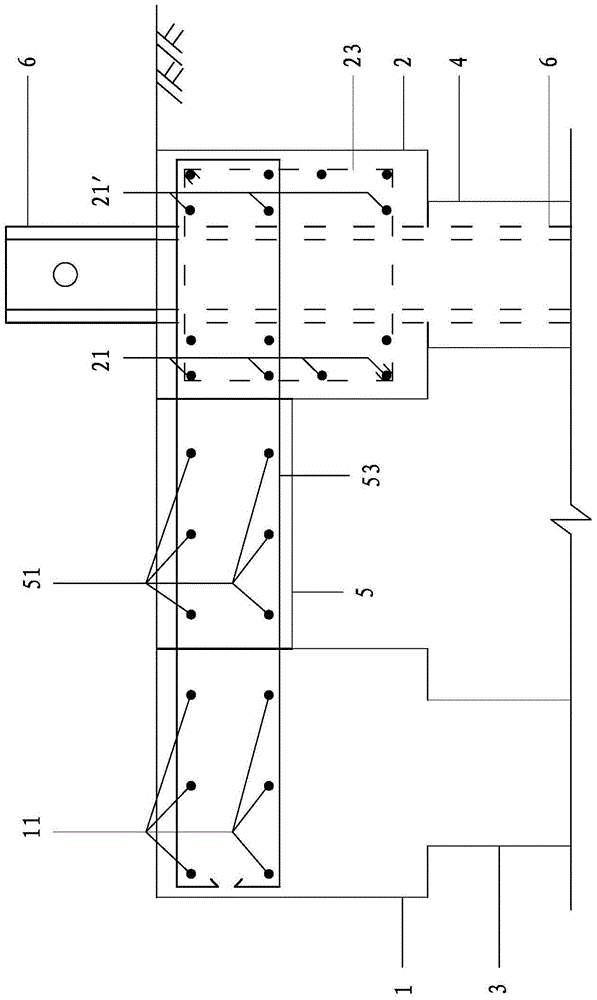

[0028] A connection plate for special-shaped double-row piles, such as Figure 1-Figure 3 , including the front pile crown beam 1, the rear wall crown beam 2 and the connecting plate 5 for connecting the front row piles 3 and the rear wall 4, the front pile crown beam 1 is arranged at the top position of the front row piles 3, and the rear row The row wall crown beam 2 is arranged at the top position of the rear row wall 4, and the connecting plate 5 is connected between the front row pile crown beam 1 and the rear row wall crown beam 2, and the front row piles 3 and the rear row wall 4 are formed by the connecting plate 5 Double row of piles.

[0029] The third longitudinal reinforcement 11 is bound in the front pile crown beam 1, and the rear wall 4 is built with a section steel 6. The height of the section steel 6 is 30-50cm higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com