A cutting mechanism with adjustable cutter angle and its adjustment method

A cutting knife and angle technology, applied in metal processing and other directions, can solve the problem of incomplete cutting of paper, and achieve the effects of improving incomplete cutting, reducing energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

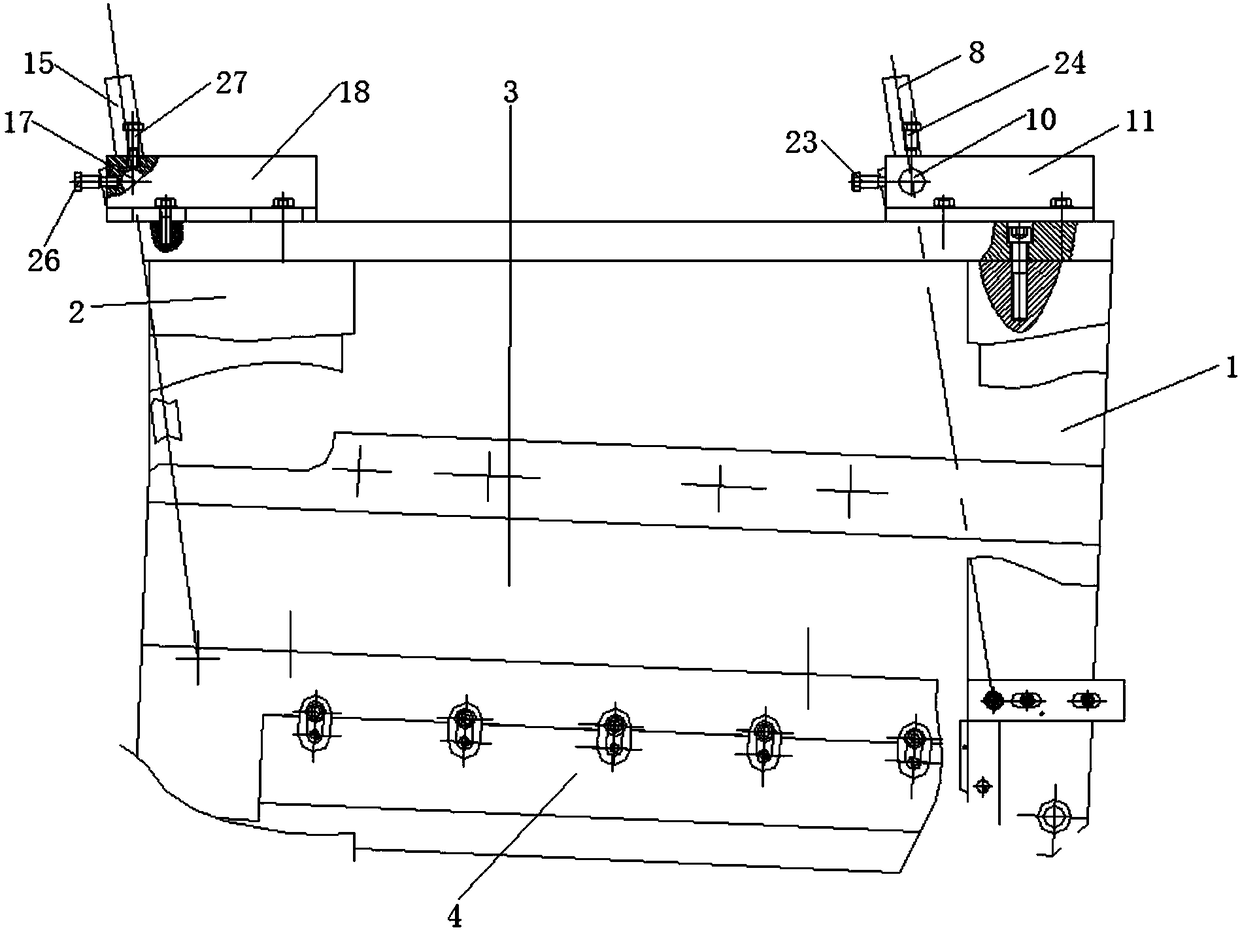

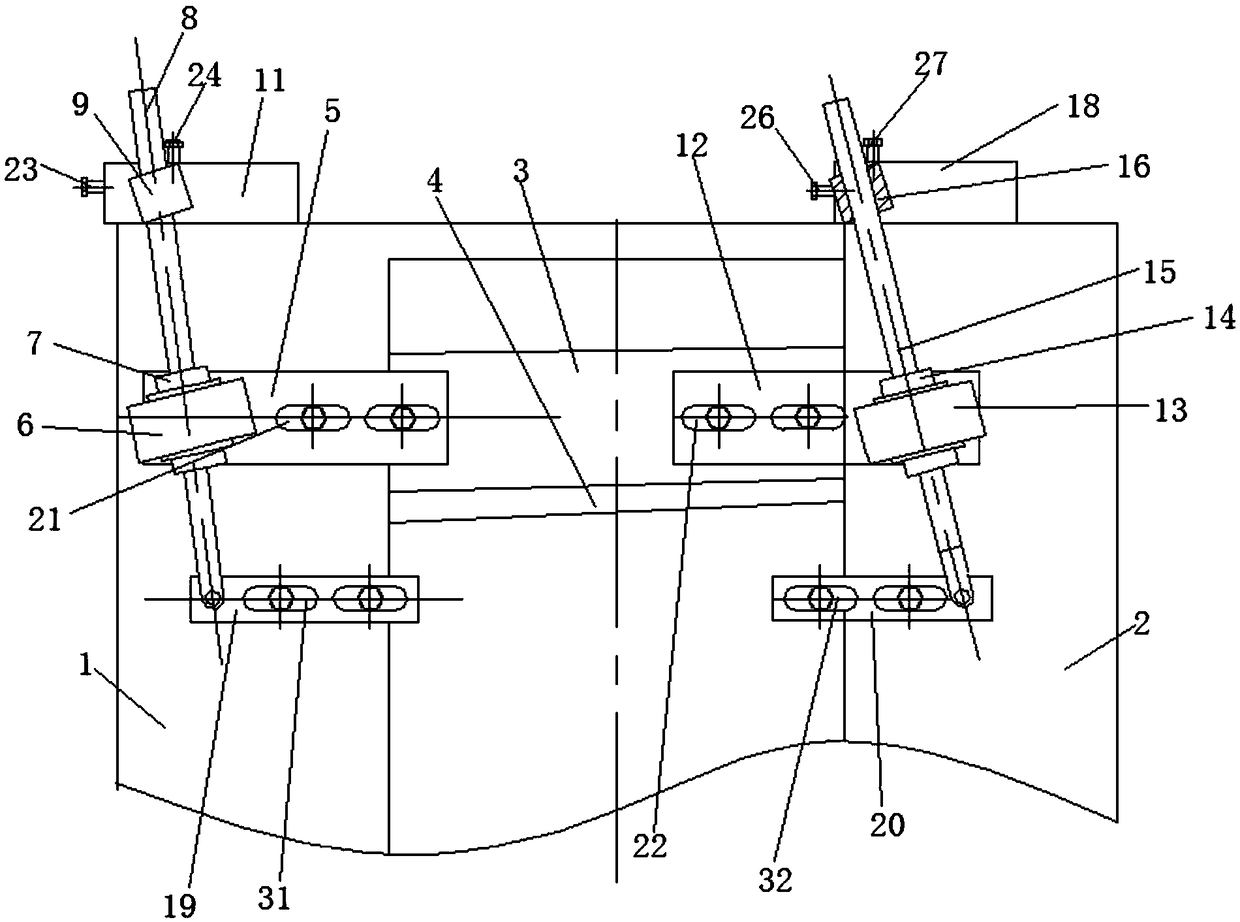

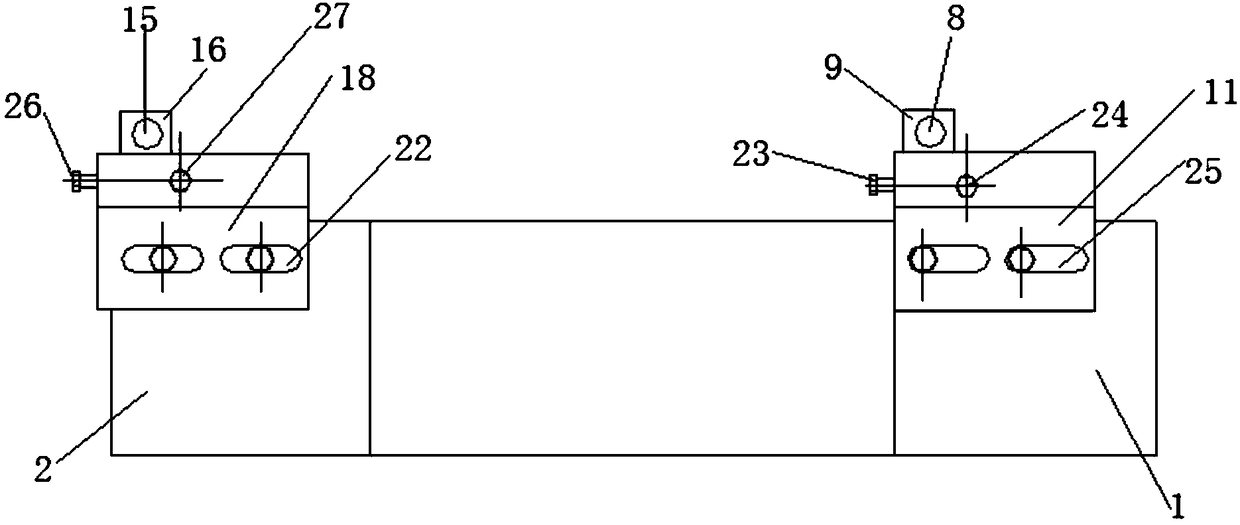

[0030] The present invention is a cutting mechanism with adjustable cutter angle, the structure is as follows: figure 1 , 2 As shown, including wallboard A1 and wallboard B2, a knife bed 3 is provided between the wallboard A1 and wallboard B2, a cutting knife 4 is arranged on the knife bed 3, and one end of the support plate A5 is connected to the back of the knife bed 3 (back One side of the console is the back side), the other end of the support plate A5 is connected to the hollow guide block A6, the guide block A6 is provided with a linear bearing A7, and the linear bearing A7 is sleeved with an obliquely arranged guide rod A8, The upper end of the guide rod A8 is sleeved with a hollow guide block B9, one side of the guide block B9 is fixedly connected with the positioning shaft A10, and the positioning shaft A10 is connected with the upper end surface of the wall panel A1 through the locking block A11; the lower end of the guide rod A8 is hinged There is a support plate C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com