Scrap chopper device of tension leveling machine

A technology of straightening machine crushing and side shearing, applied in metal processing and other directions, can solve the problems of inconvenience, easy blunt cutting edge, time-consuming and laborious adjustment of the cutting edge gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

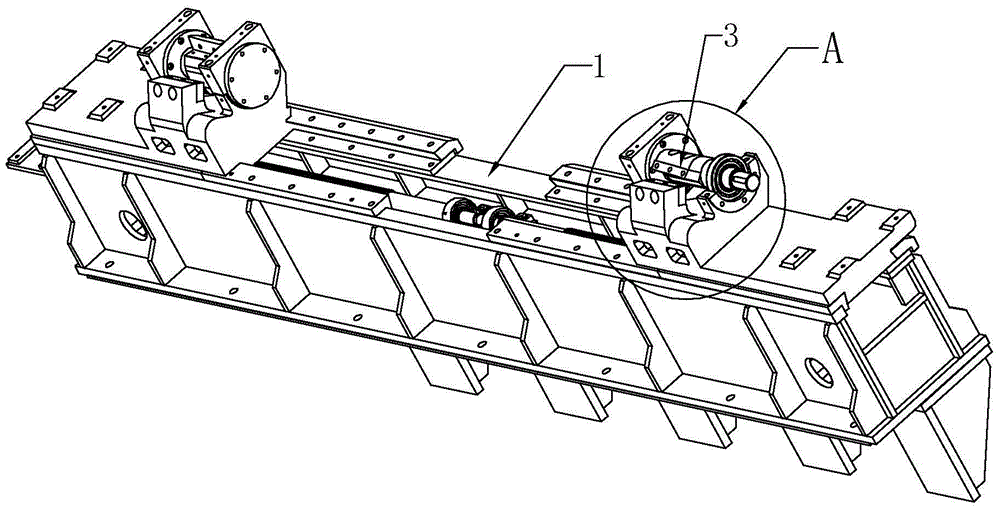

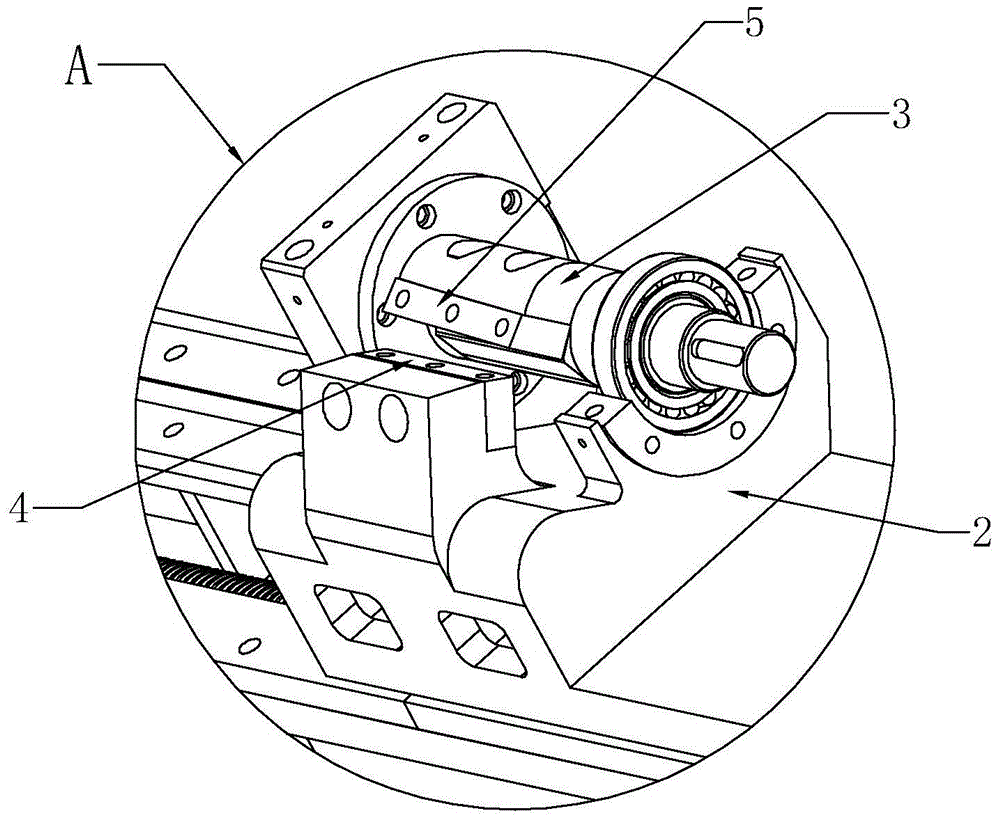

[0010] Below in conjunction with the accompanying drawings and specific embodiments, the scraper device of the tension bending straightener of the present invention will be further described in detail.

[0011] As shown in the figure, the edge scraping and shearing device of the stretch bending straightener of the present invention includes a moving knife mounting seat 2 installed on the machine base 1 and a roller cutter body 3 installed on the moving knife mounting seat 2, and the roller cutter body 3 There is also a static knife mounting seat horizontally arranged on the machine base 1, the static blade 4 is installed on the static knife mounting seat so that the cutting edge of the static blade is in the horizontal direction, and the roller cutter body 3 is provided with 180° symmetrical distribution. There are two spiral knife grooves, and a movable blade 5 is installed in each spiral groove, so that the two movable blades 5 are also symmetrically distributed at 180°, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com