Rotary cutting type cut-to-length device for plate of moderate thickness

A fixed-length shearing and rolling cutting technology, which is applied to the shearing device, the accessory device of the shearing machine, the knives used in the shearing machine, etc., can solve the mutual shearing accident of the upper and lower shearing blades, and the upper and lower knife rests The gap value becomes negative, the stability of the shearing machine equipment is affected, etc., and the overall deformation is small, the lubrication effect is obvious, and the effect of improving the shearing quality is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

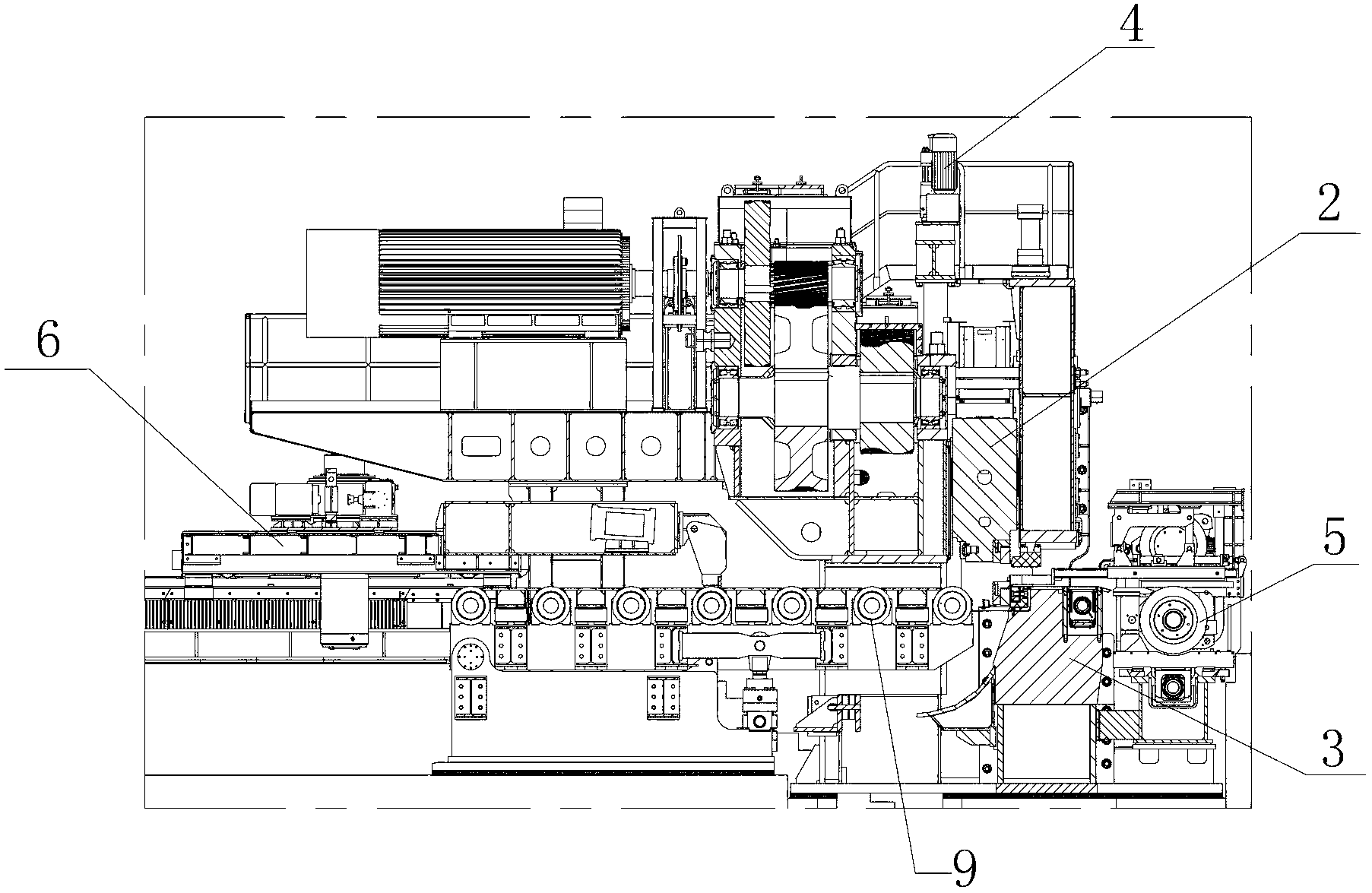

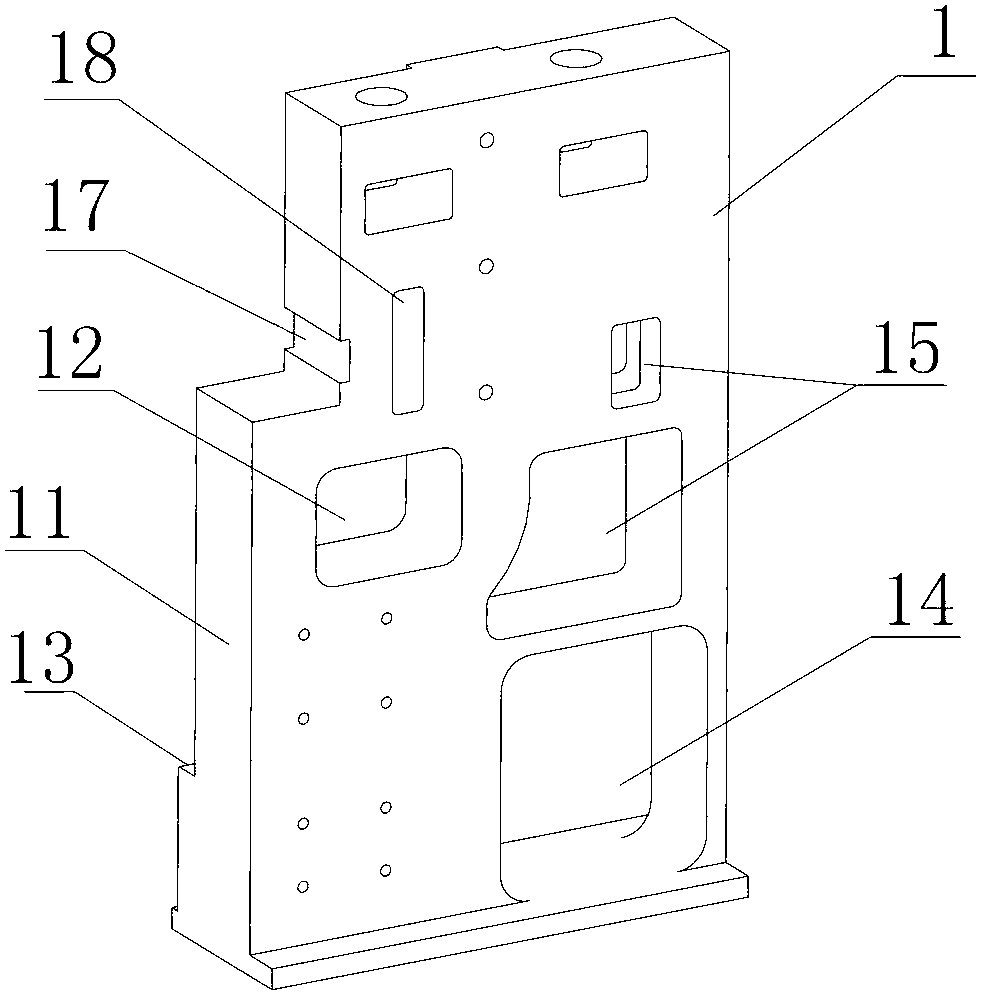

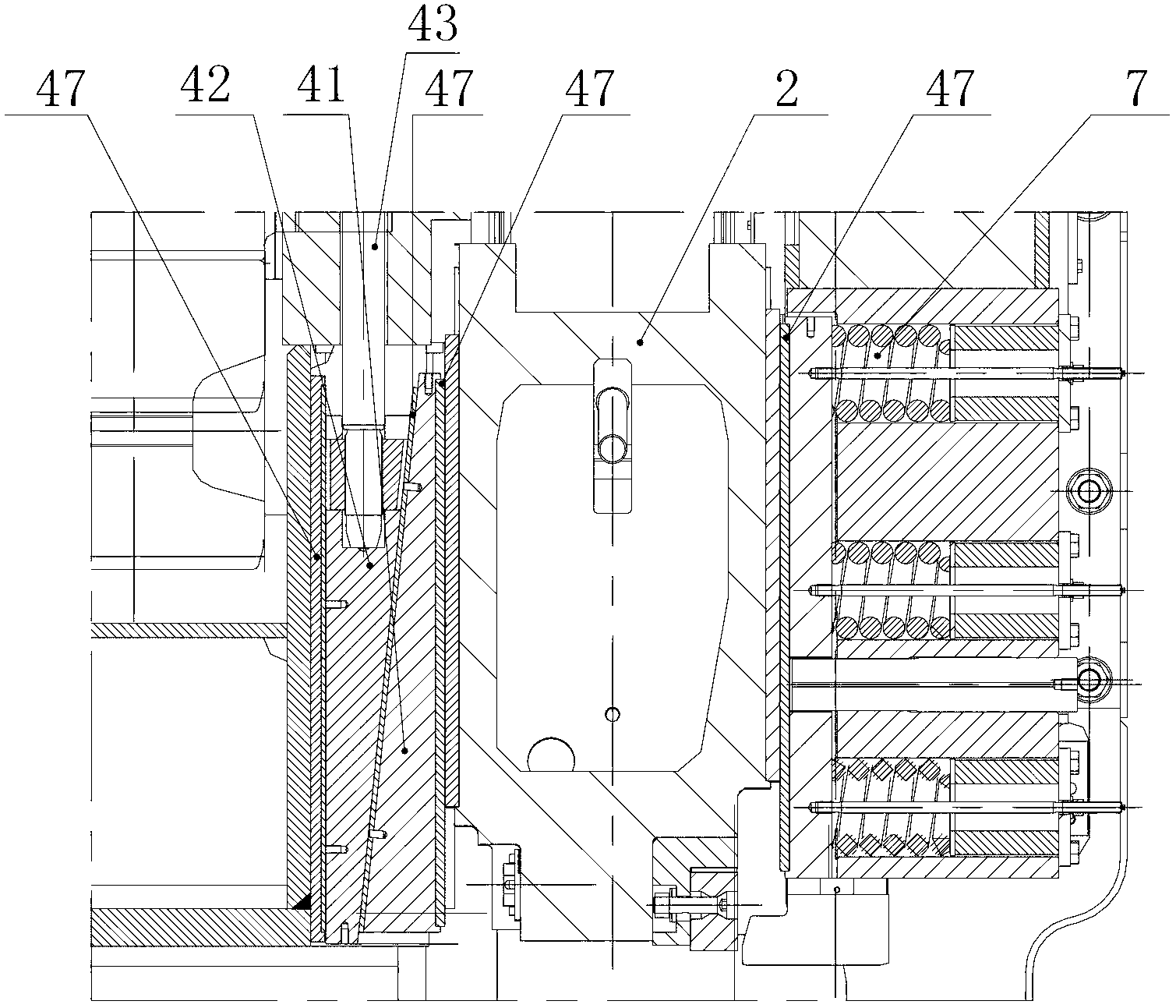

[0038] Please refer to figure 1 , figure 2 , are respectively the structural schematic diagram of the medium-thick plate rolling cutting type cut-to-length shear device and the three-dimensional structural schematic diagram of the frame of the present invention. As shown in the figure, the medium-thick plate rolling cut-to-length shearing device proposed by the present invention at least includes a frame 1, a panel, an upper knife rest 2, a lower knife rest 3, a cutting edge gap adjustment mechanism 4, a pinch roller 5, The over-balanced swinging roller mechanism 9 and the sizing machine 6, the upper knife rest 2 and the lower knife rest 3 are relatively arranged at the front of the sizing shear device, and the medium and thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com