Patents

Literature

207results about How to "Added fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

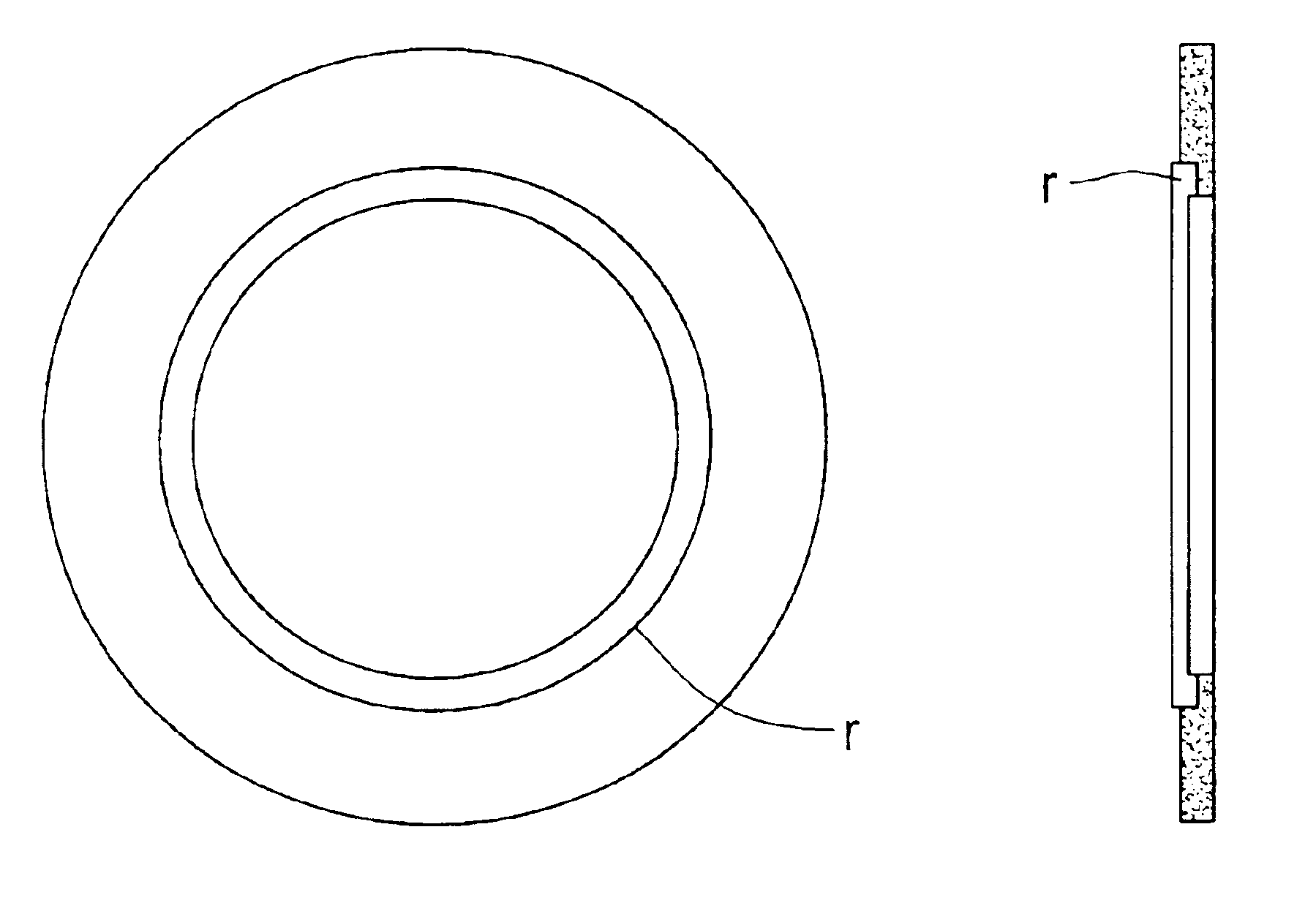

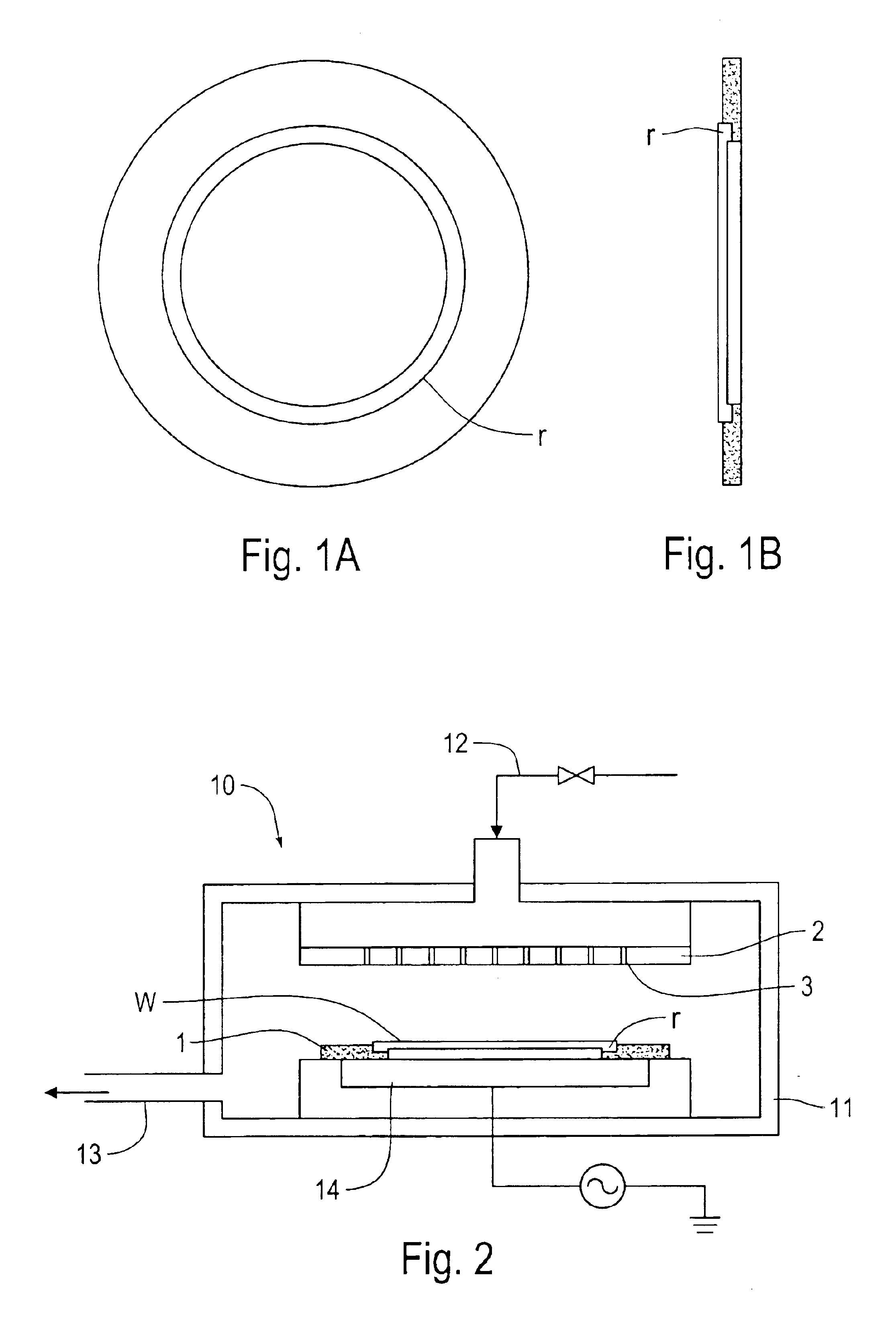

Silicon focus ring and method for producing the same

InactiveUS6815352B1Reduce Particle GenerationAvoid roughnessPolycrystalline material growthElectric discharge tubesCzochralski methodSingle crystal

There is disclosed a silicon focus ring consisting of silicon single crystal used as a silicon focus ring in a plasma apparatus, wherein concentration of interstitial oxygen contained in the silicon focus ring is not less than 5x10<17 >atoms / cm<3 >and not more than 1.5x10<18 >atoms / cm<3>, and a producing method for a silicon focus ring used for a plasma apparatus, wherein a single crystal silicon wherein concentration of interstitial oxygen contained in the silicon focus ring is not less than 5x10<17 >atoms / cm<3 >and not more than 1.5x10<18 >atoms / cm<3 >is grown by a Czochralski method, the single crystal silicon is processed in a circle, and a silicon focus ring is produced. There can be provided a silicon focus ring, which can prevent disadvantage due to impurities such as heavy metal.

Owner:SHIN ETSU CHEM IND CO LTD

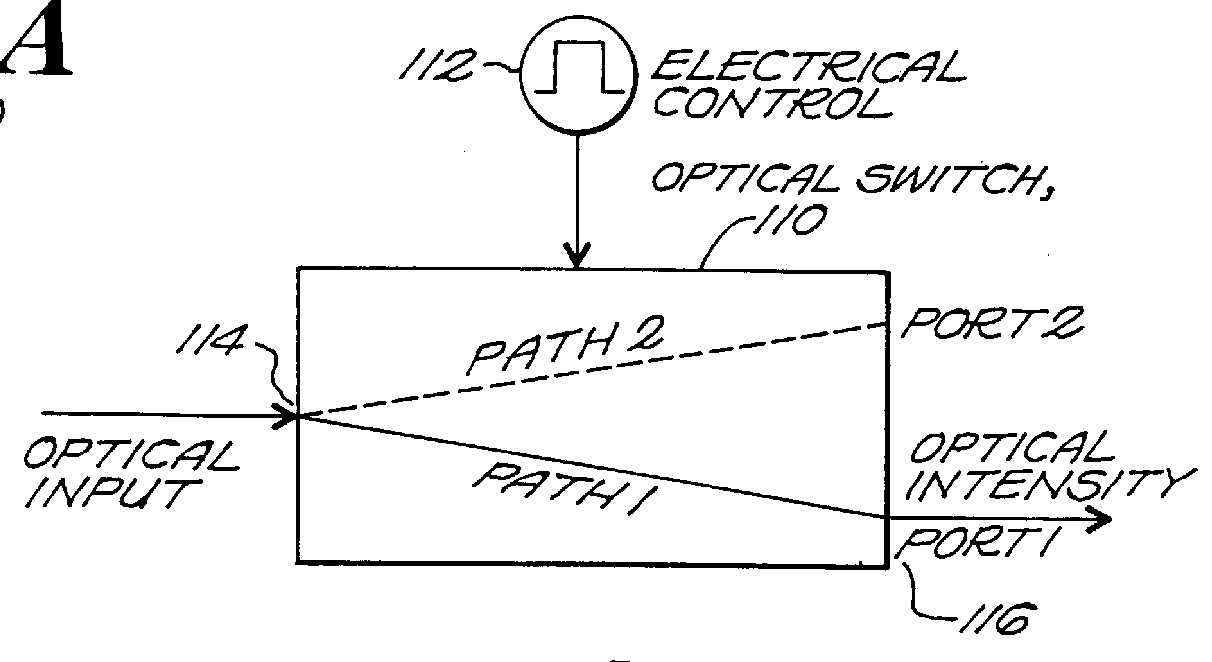

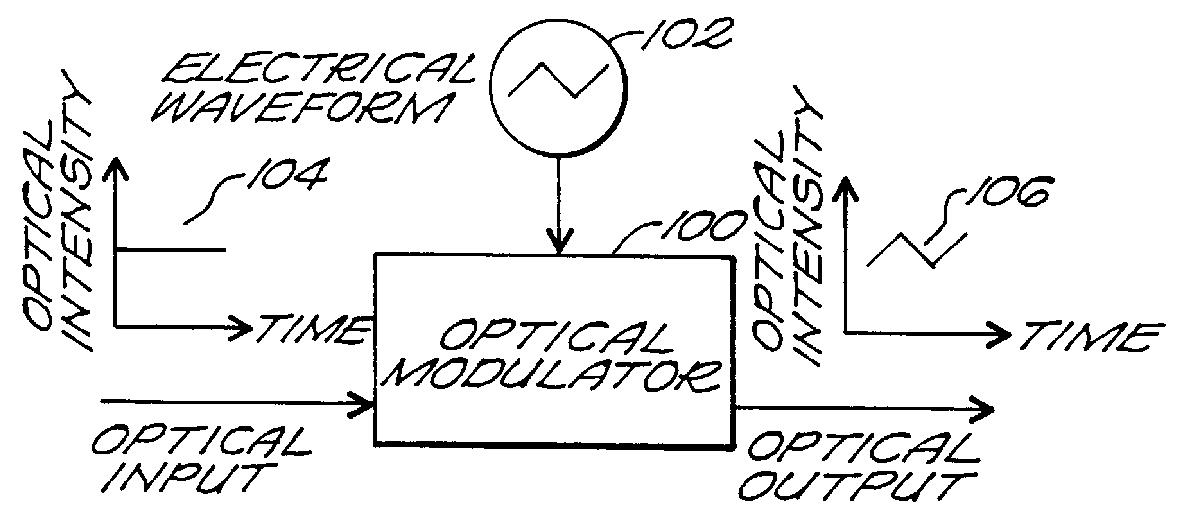

Resonator modulators and wavelength routing switches

InactiveUS6052495ASmall sizeImprove responseCoupling light guidesNon-linear opticsClosed loopRefractive index

The invention provides an optical switch and modulator which uses a closed loop optical resonator. The optical resonator is a dielectric cavity whose primary function is to store optical power. Various structures are possible, and a particularly advantageous one is a ring shaped cavity. The wavelength response at the output port of a ring resonator side coupled to two waveguides is determined by the details of the resonator, and the coupling between the resonator and the waveguides. By coupling to adjacent resonators, the modulator response can be improved over that of a single resonator. One such improvement is in modulator efficiency, which is defined as the ratio of the change in optical intensity at the output, to a change in absorption in the ring waveguides. Absorption is used for switching and modulation without incurring significant optical attenuation. Another improvement involves making the resonance insensitive to small deviations in wavelength or index change. The latter improves fabrication tolerances and compensates for possible drift of the signal wavelength. Collectively, the behavior of multiple coupled resonators yields higher order responses.

Owner:MASSACHUSETTS INST OF TECH

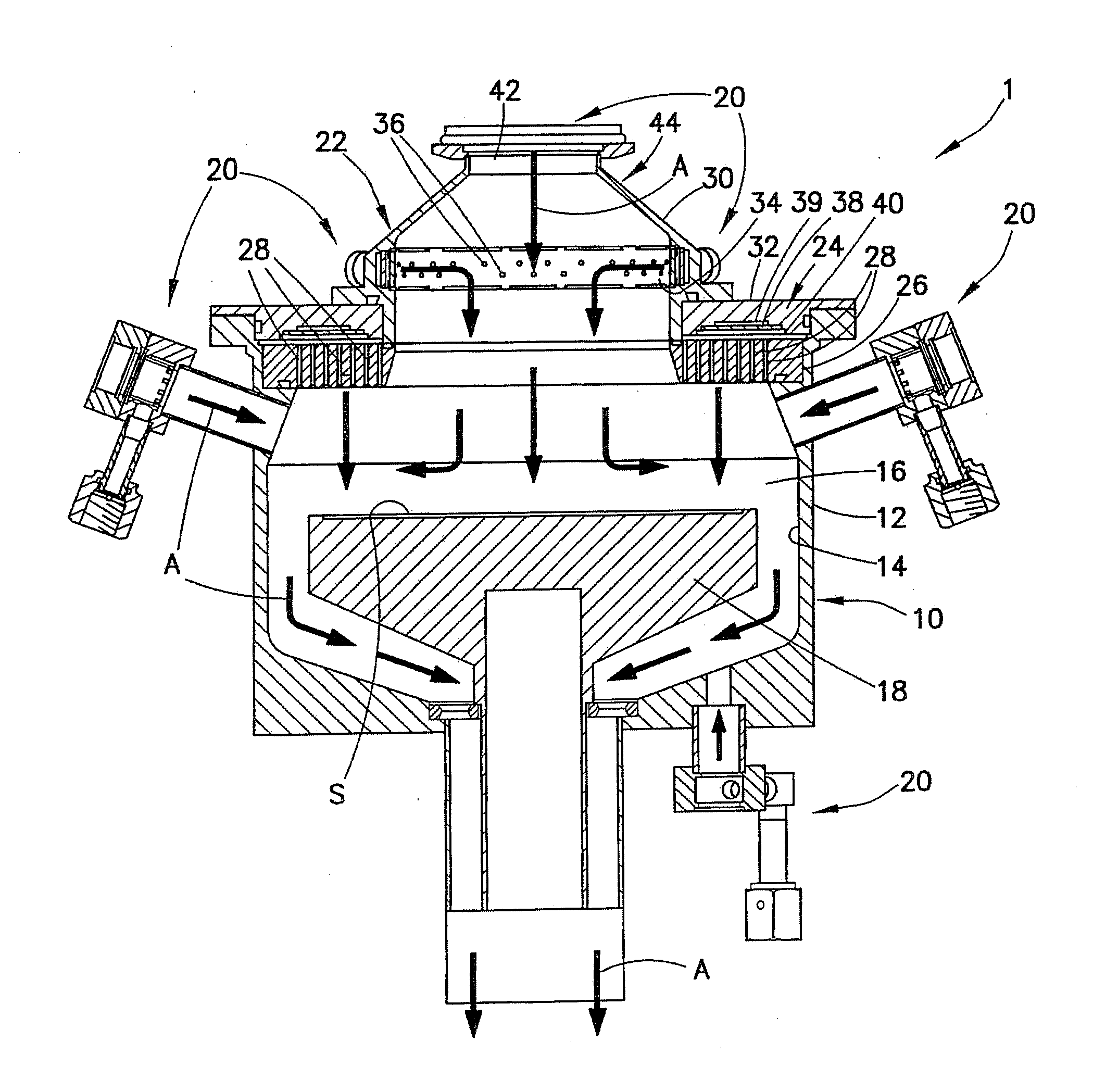

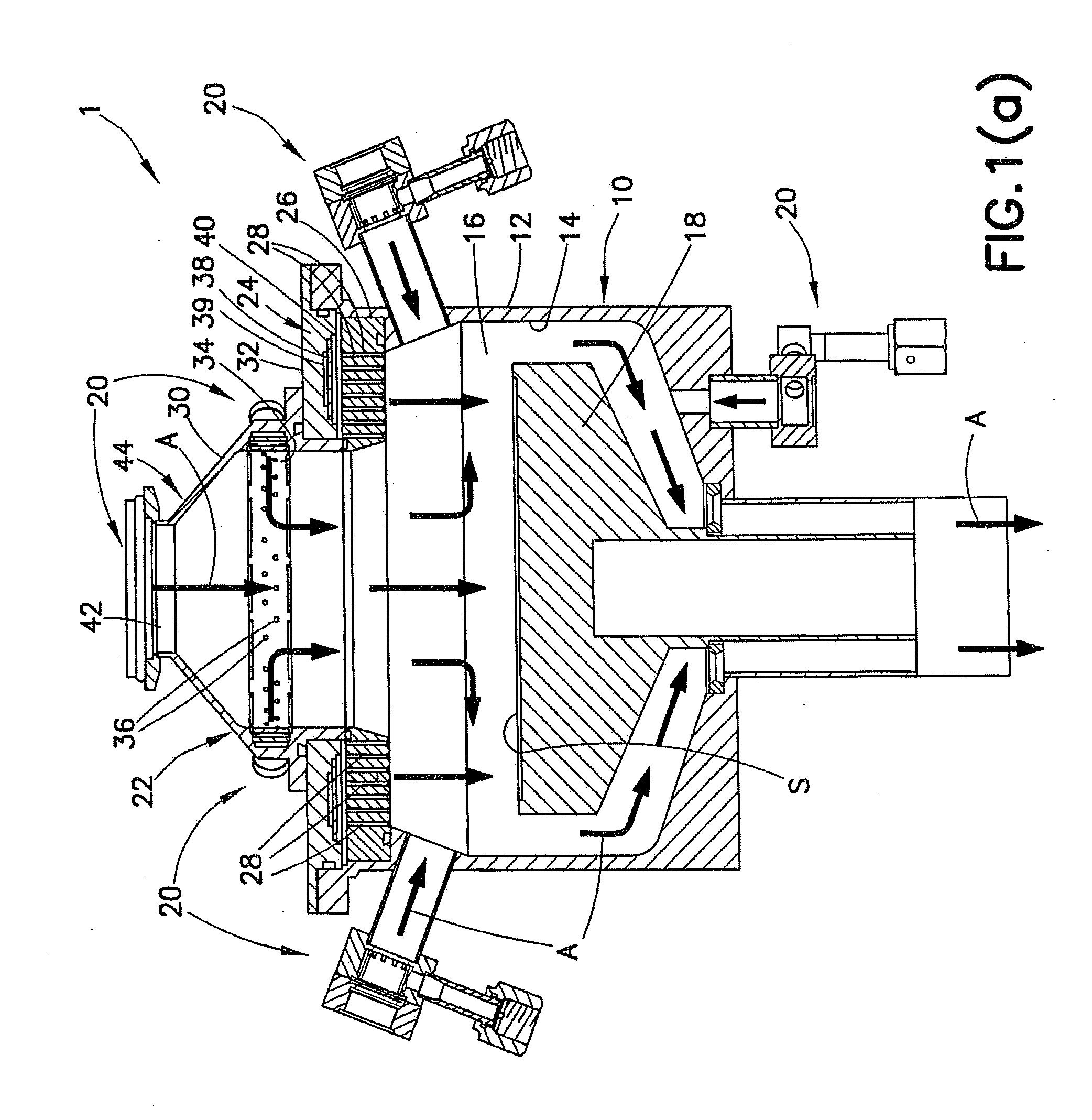

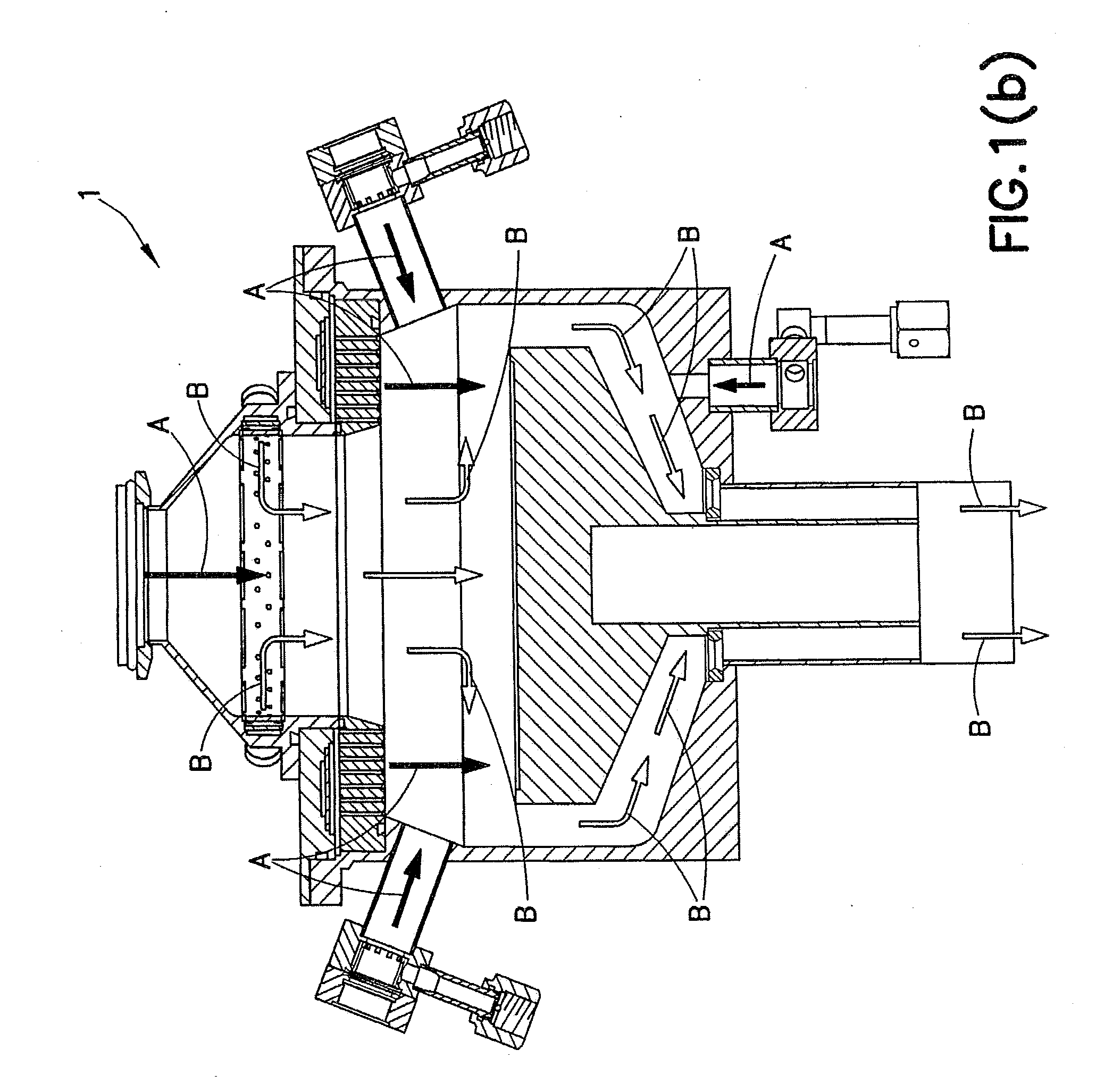

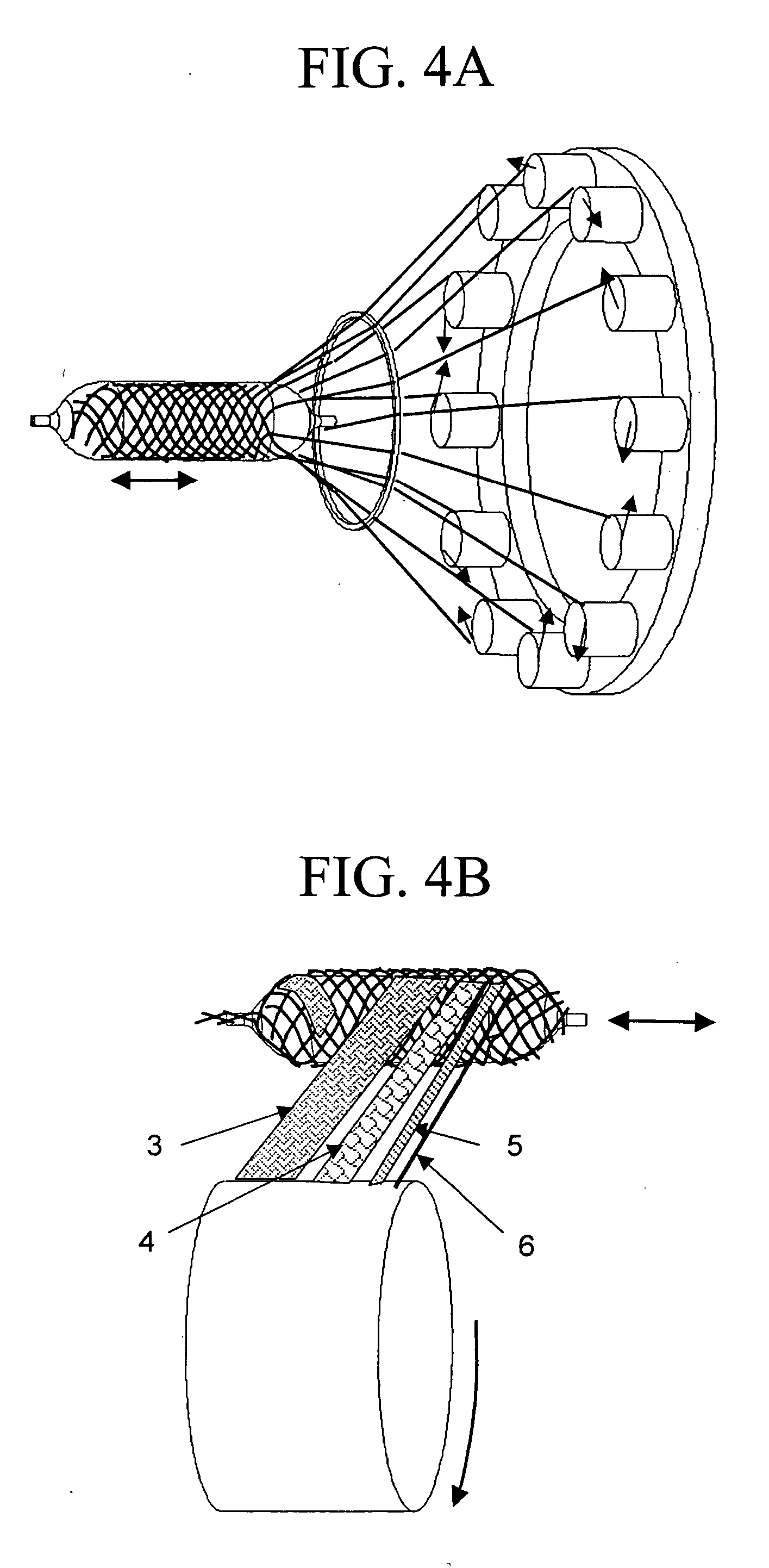

Atomic Layer Deposition Apparatus and Process

ActiveUS20120269968A1Improve characteristicFacilitate growthLiquid surface applicatorsElectric discharge tubesGas dispersionEngineering

An atomic layer deposition apparatus, including: a chamber with an internal volume; a fixture assembly to hold a substrate within the internal volume of the chamber; a plurality of gas injection ports to facilitate the introduction of gas; at least one precursor gas arrangement to introduce precursor gas into the internal volume; and at least one inactive gas dispersion arrangement to introduce inactive gas into the internal volume. The inactive gas dispersion arrangement is in the form of a primary dispersion member configured to concentrically focus the precursor gas towards a surface of the substrate. A modeling system for an atomic layer deposition apparatus is also disclosed.

Owner:KURT J LESKER

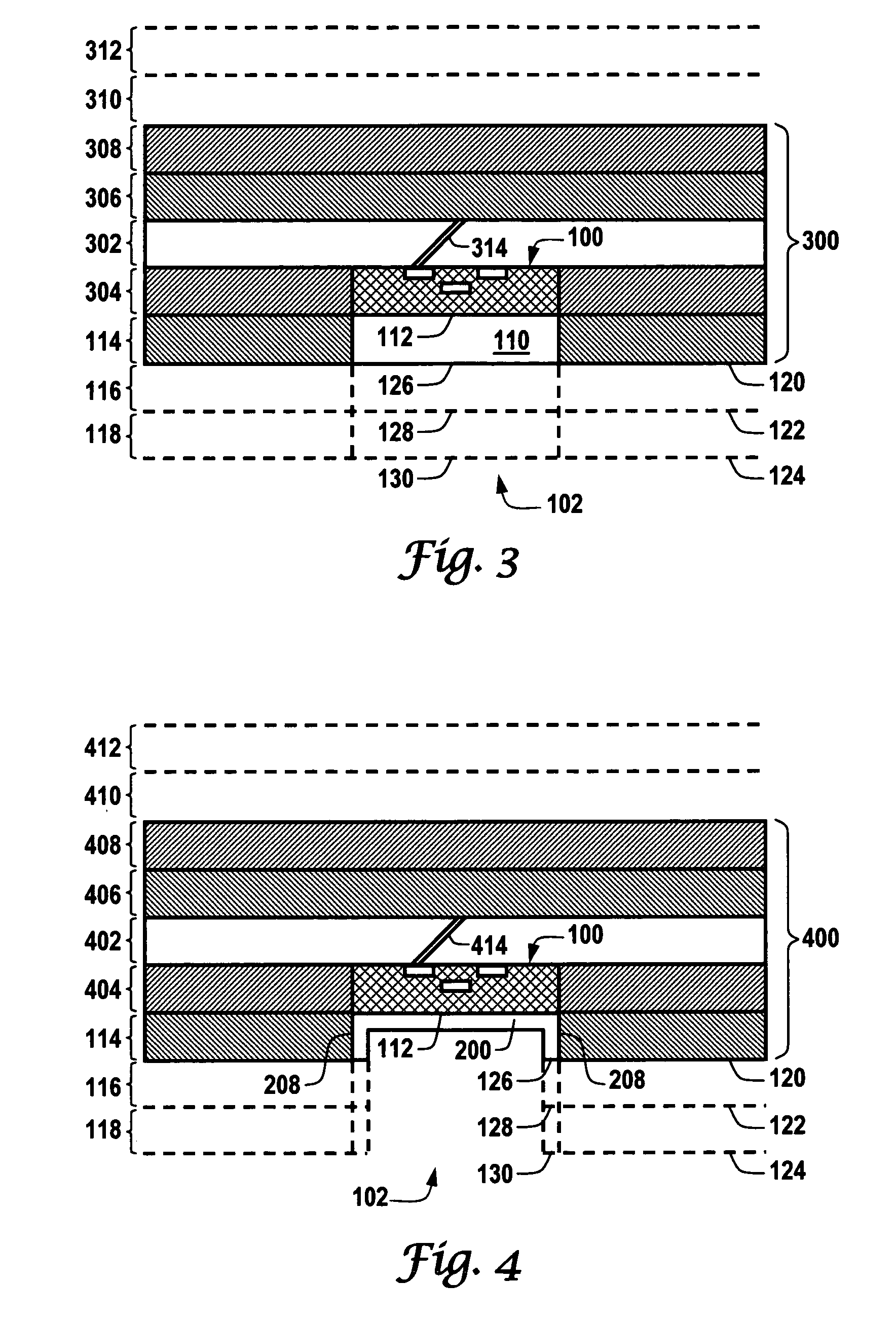

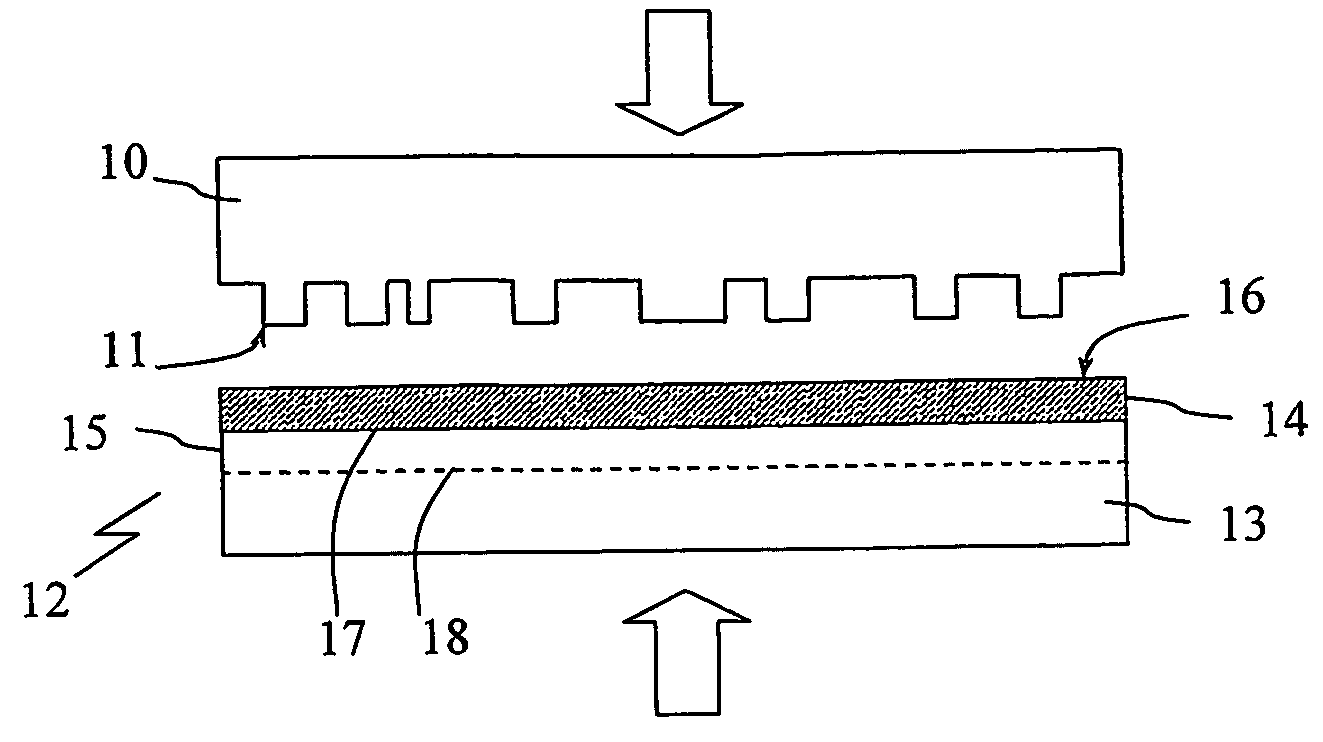

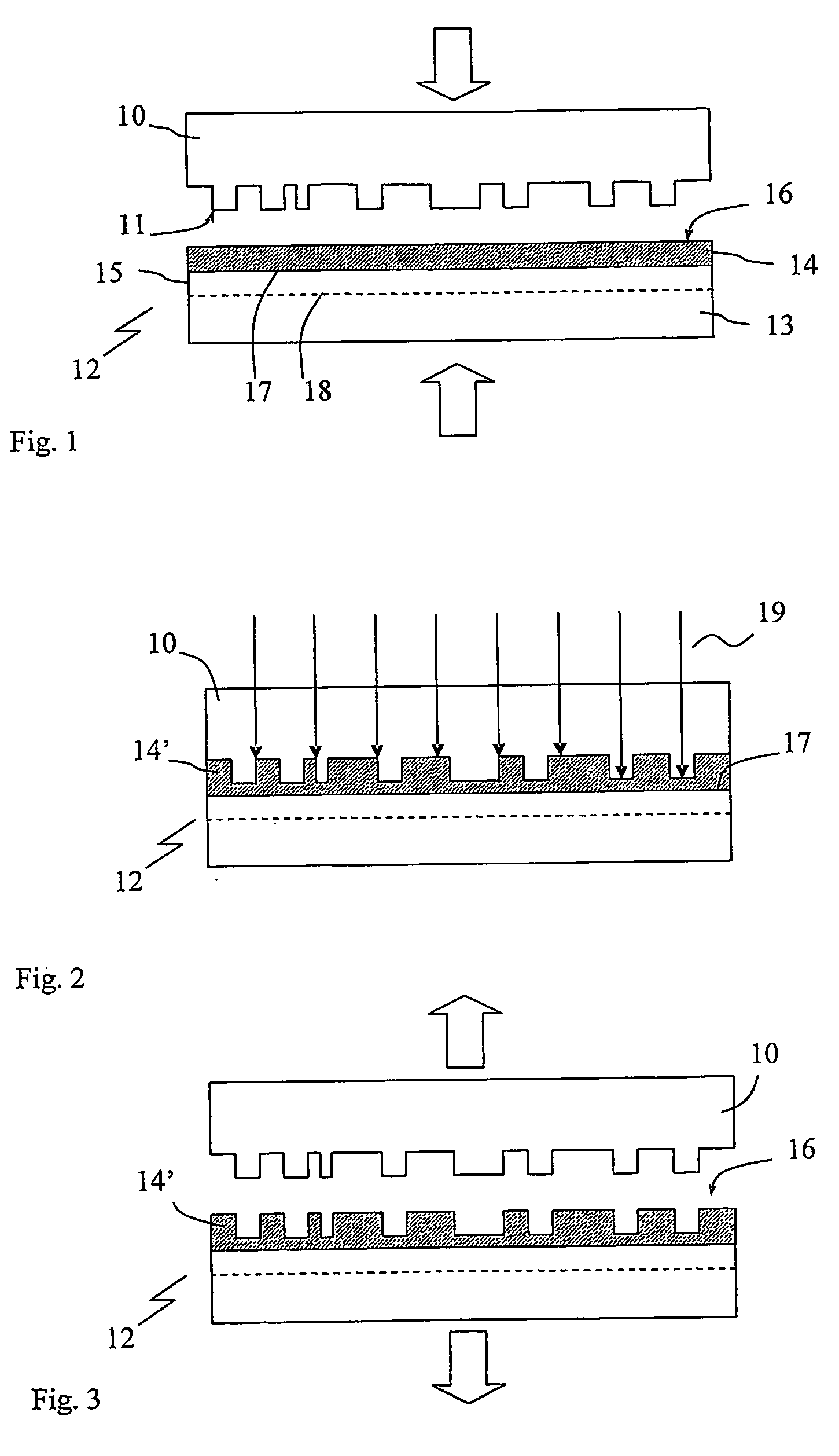

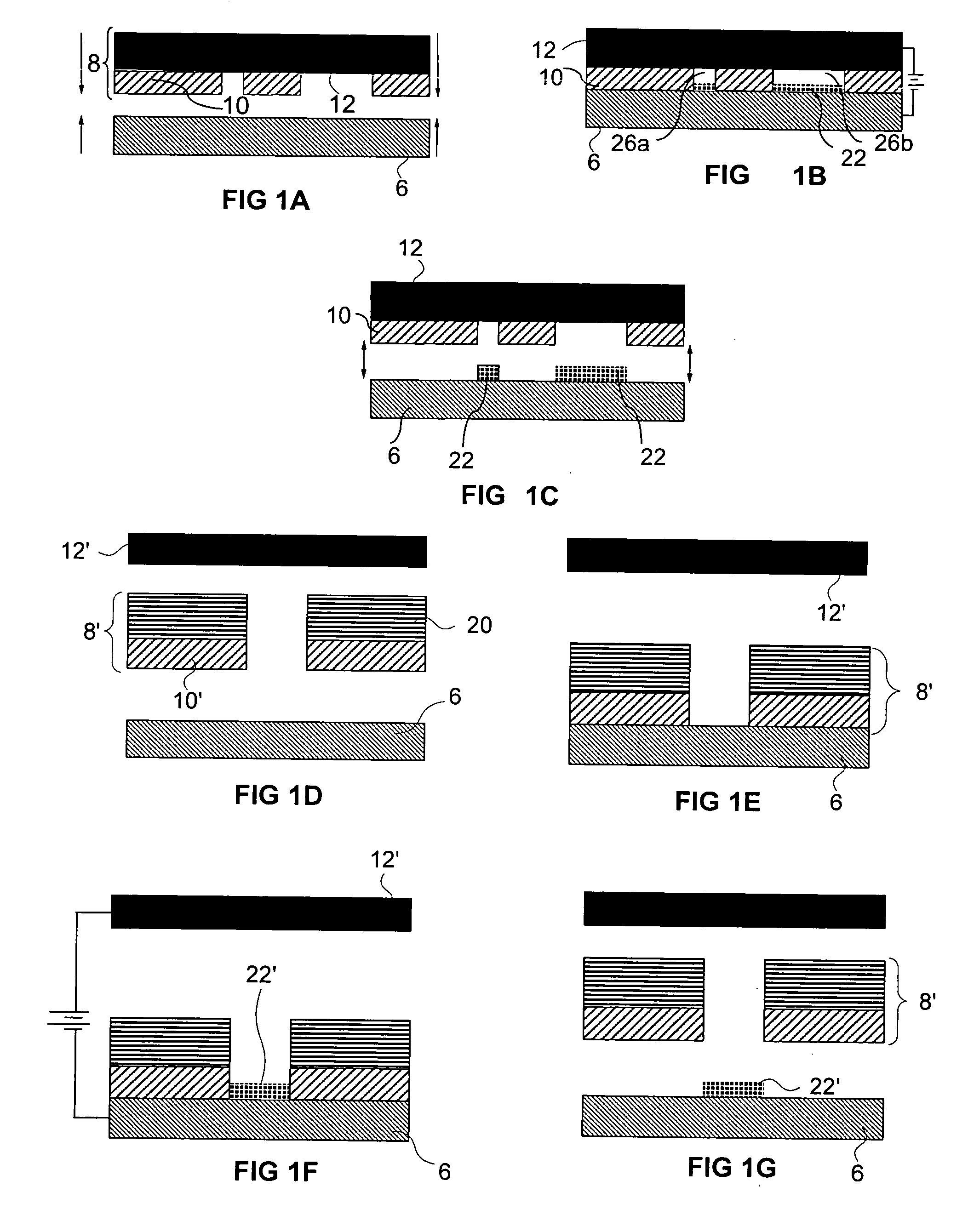

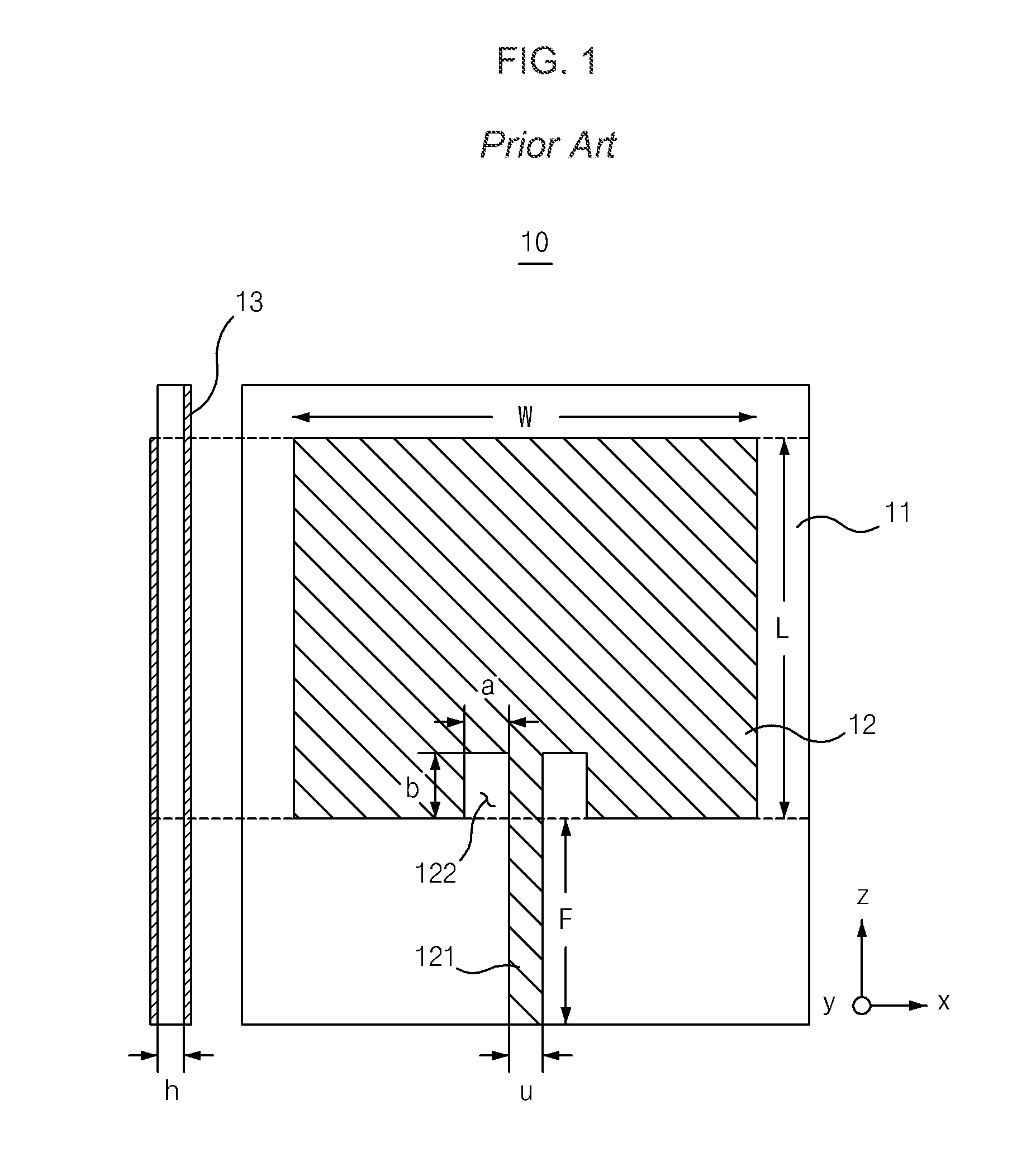

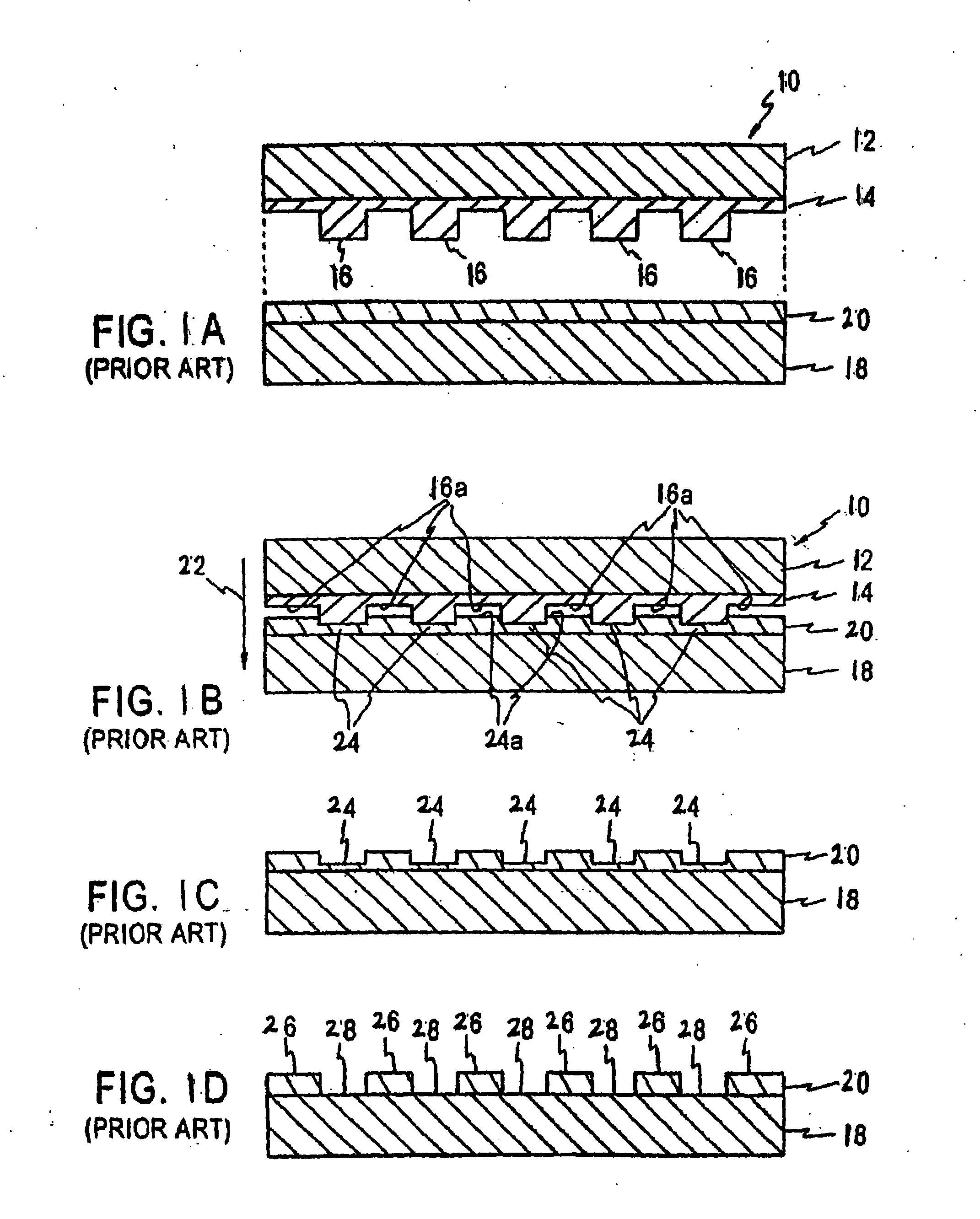

Device and method for lithography

InactiveUS20050274693A1Cost-effective and more versatileAdded fabricationDecorative surface effectsNanoinformaticsSurface layerFluid layer

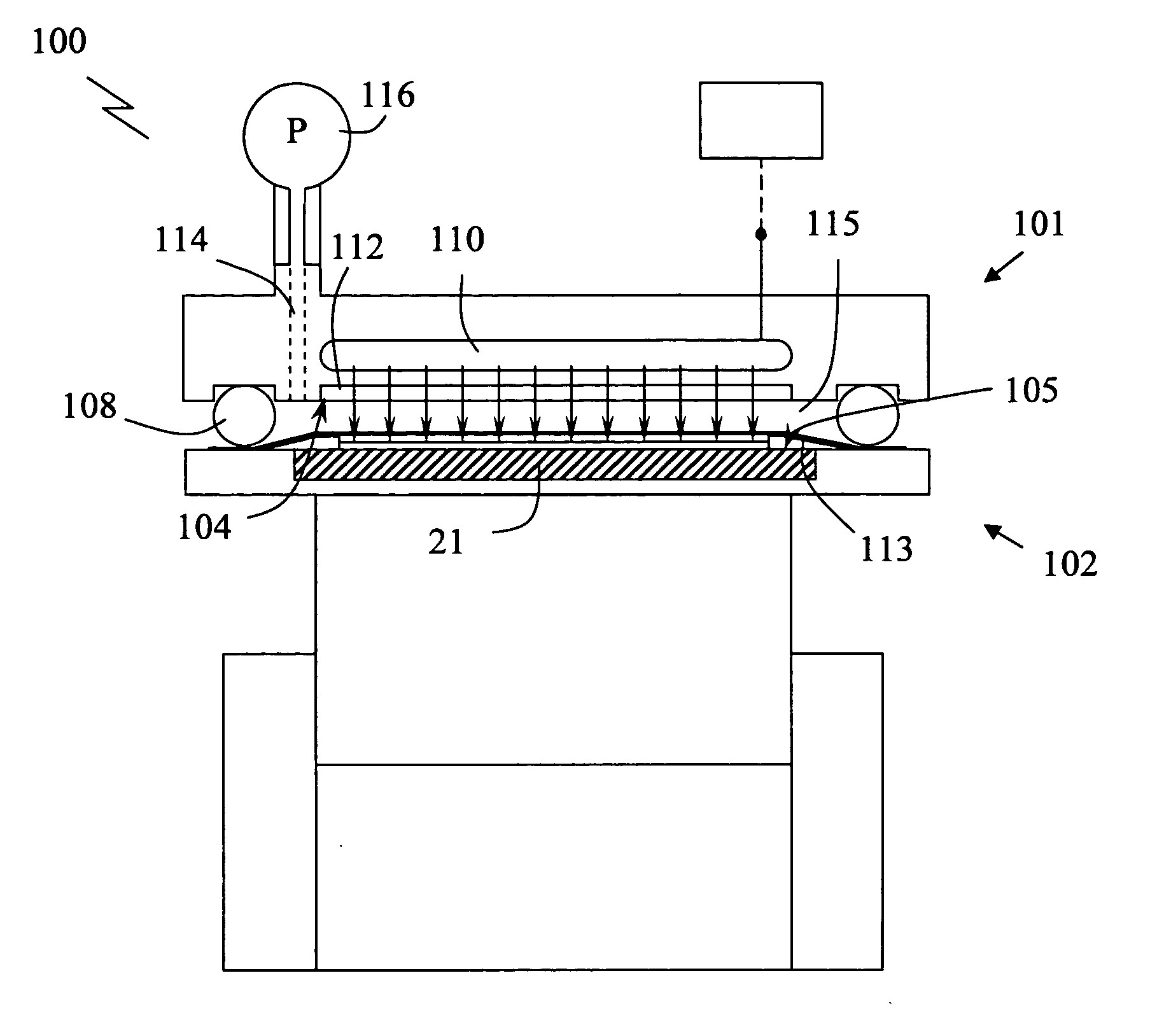

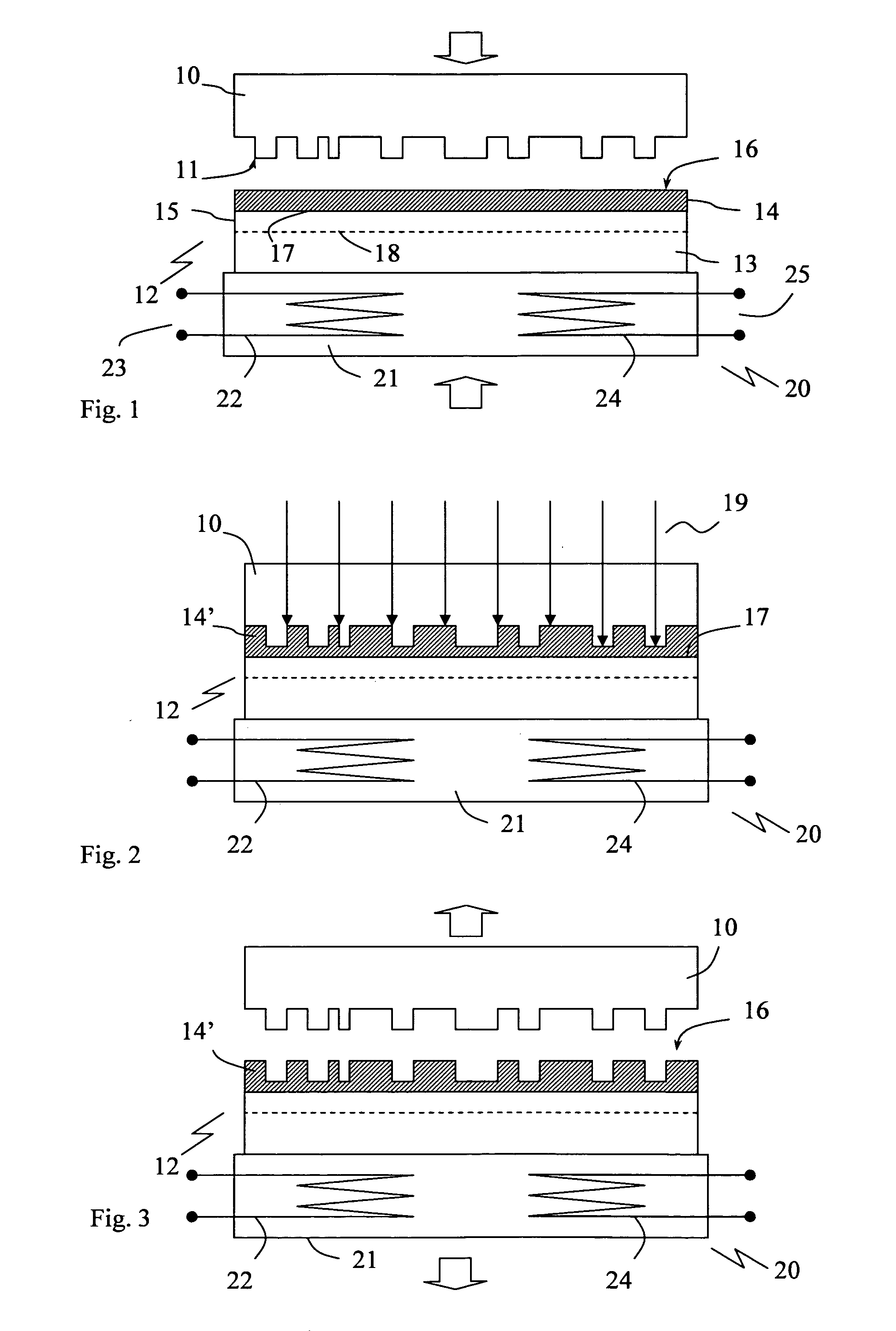

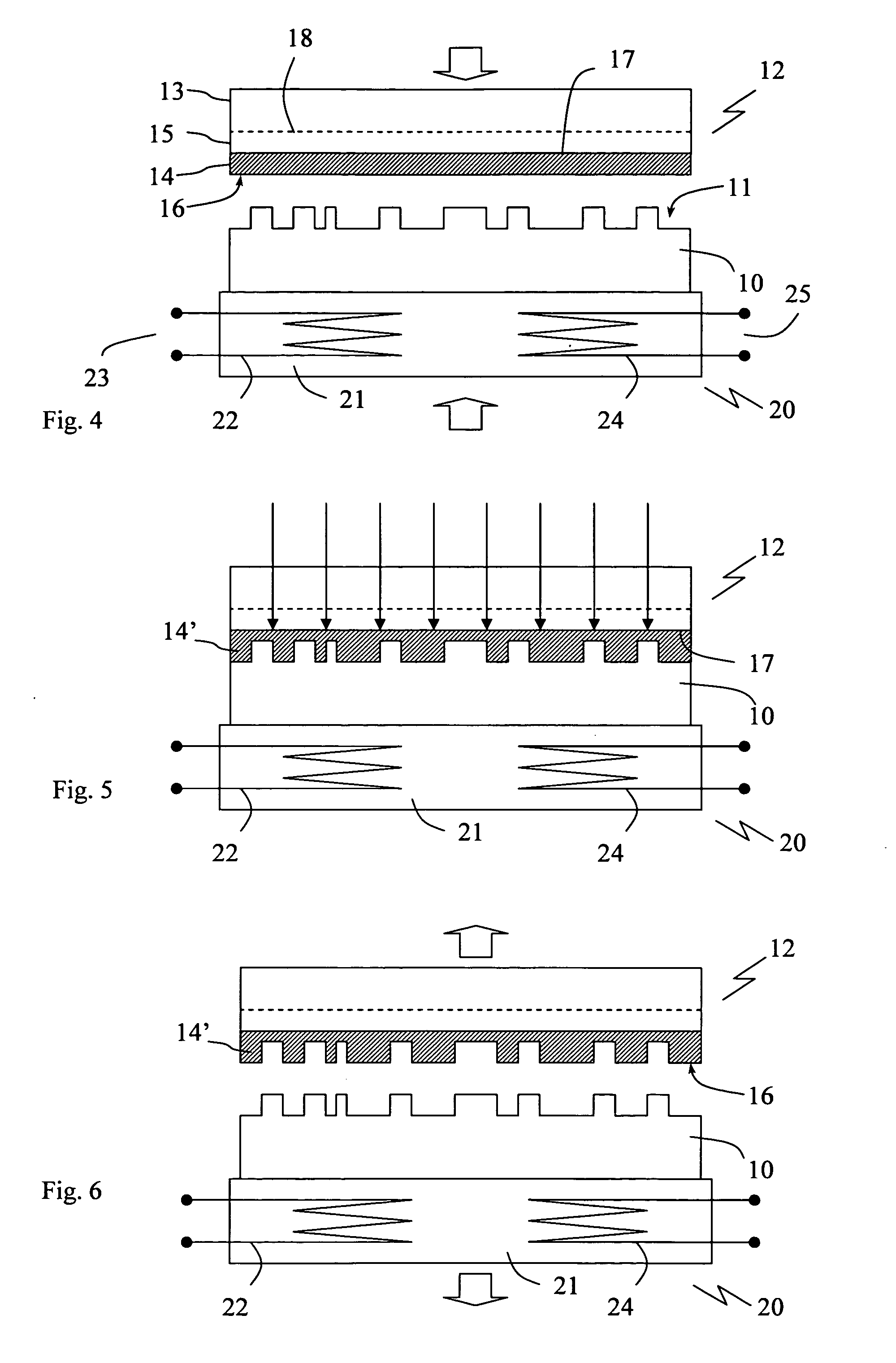

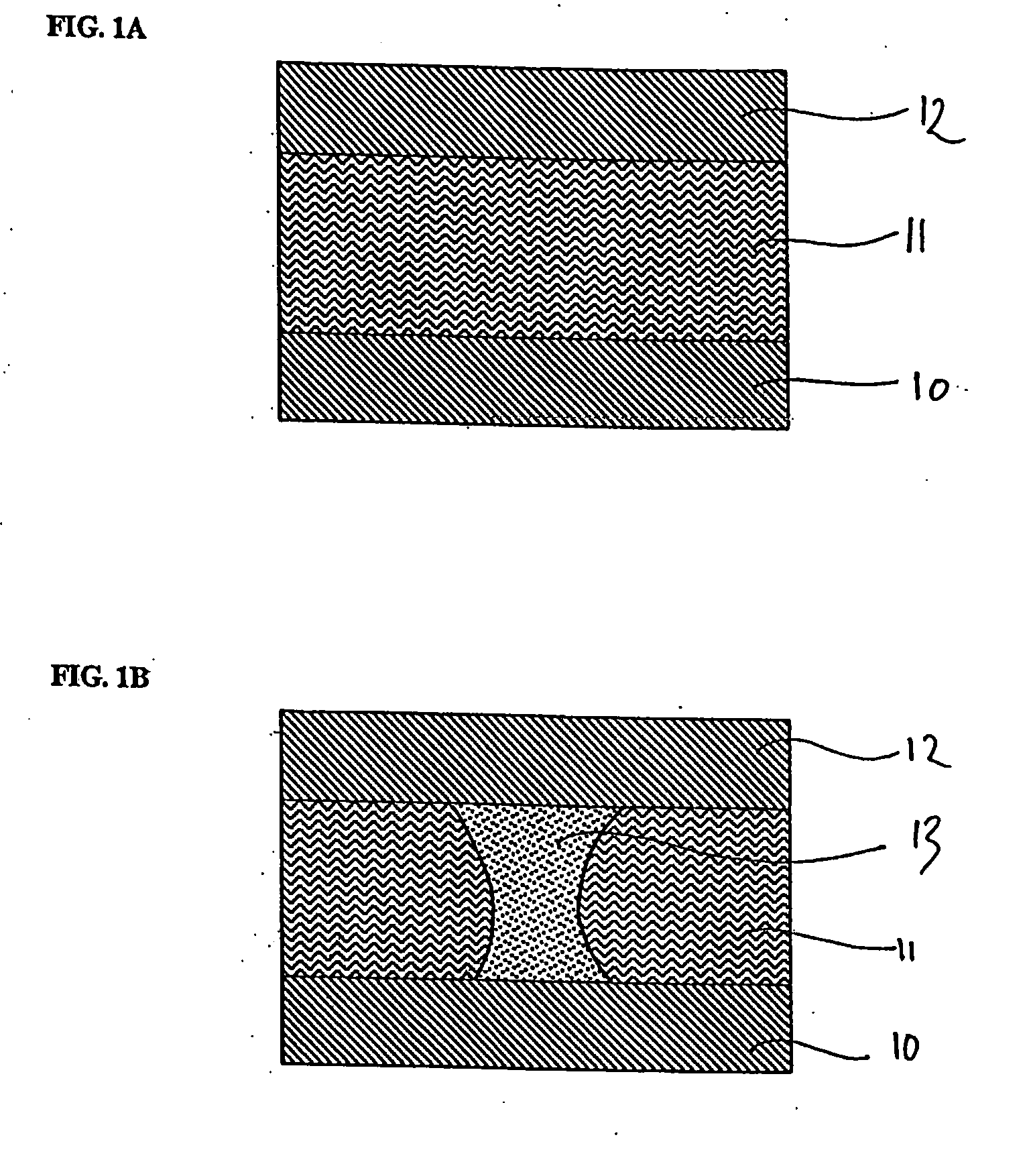

Apparatus and method for transferring a pattern from a template (10) having a structured surface to a substrate (12) carrying a surface layer of a radiation polymerisable fluid (14). The apparatus comprises a first main part (101) and a second main part (102) having opposing surfaces (104;105), means for adjusting a spacing (115) between said main parts, support means (106) for supporting said template and substrate in mutual parallel engagement in said spacing with said structured surface facing said surface layer, a radiation source (110) devised to emit radiation into said spacing. A cavity (115) has a first wall comprising a flexible membrane (113) devised to engage said template or substrate, and means (114;116) are provided for applying an adjustable overpressure to a medium present in said cavity, whereby an even distribution of force is obtained over the whole of the contact surface between the substrate and the template. The apparatus further includes a heater device having a surface facing said spacing, for heating either fluid layer (14).

Owner:OBDUCAT AB SE

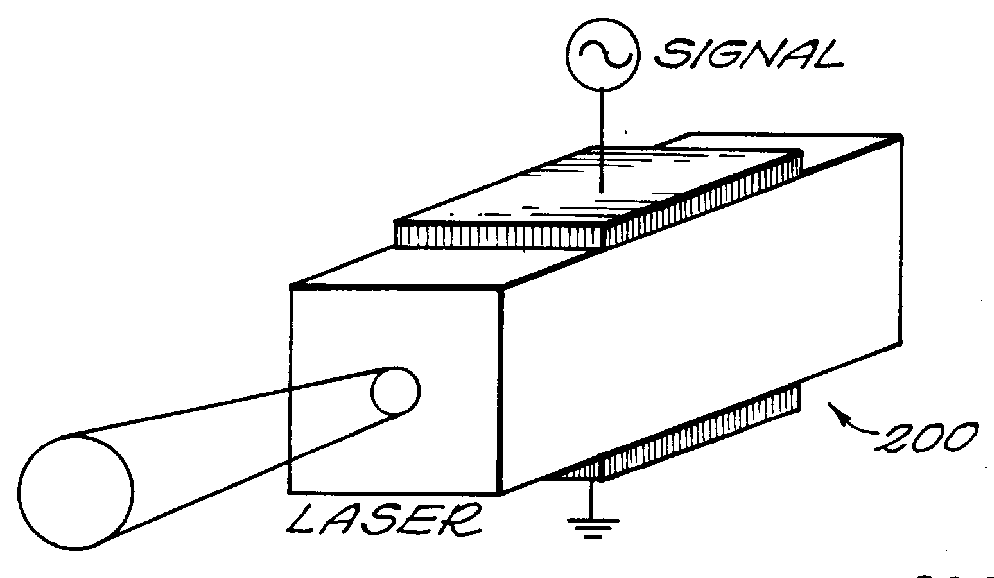

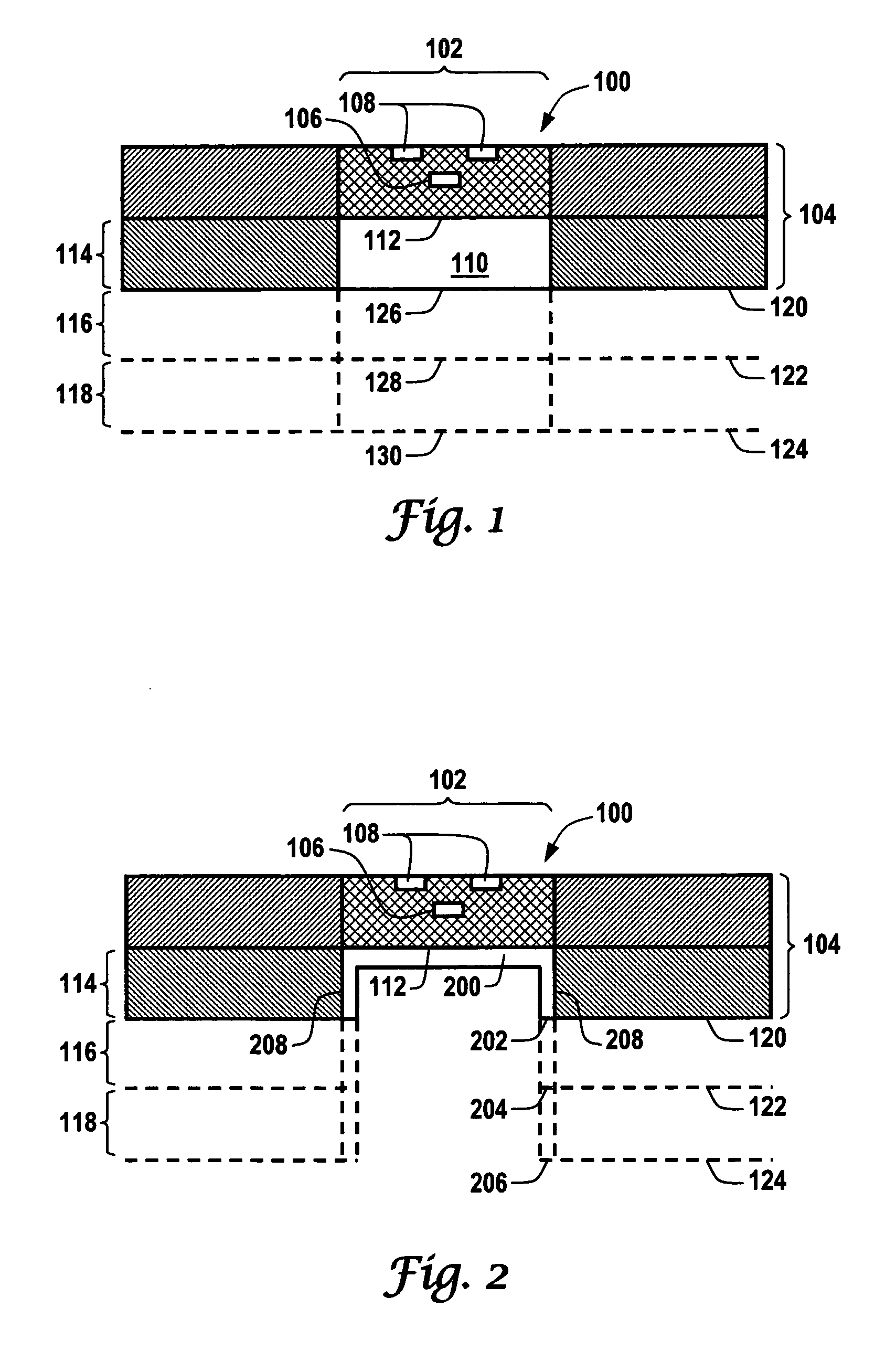

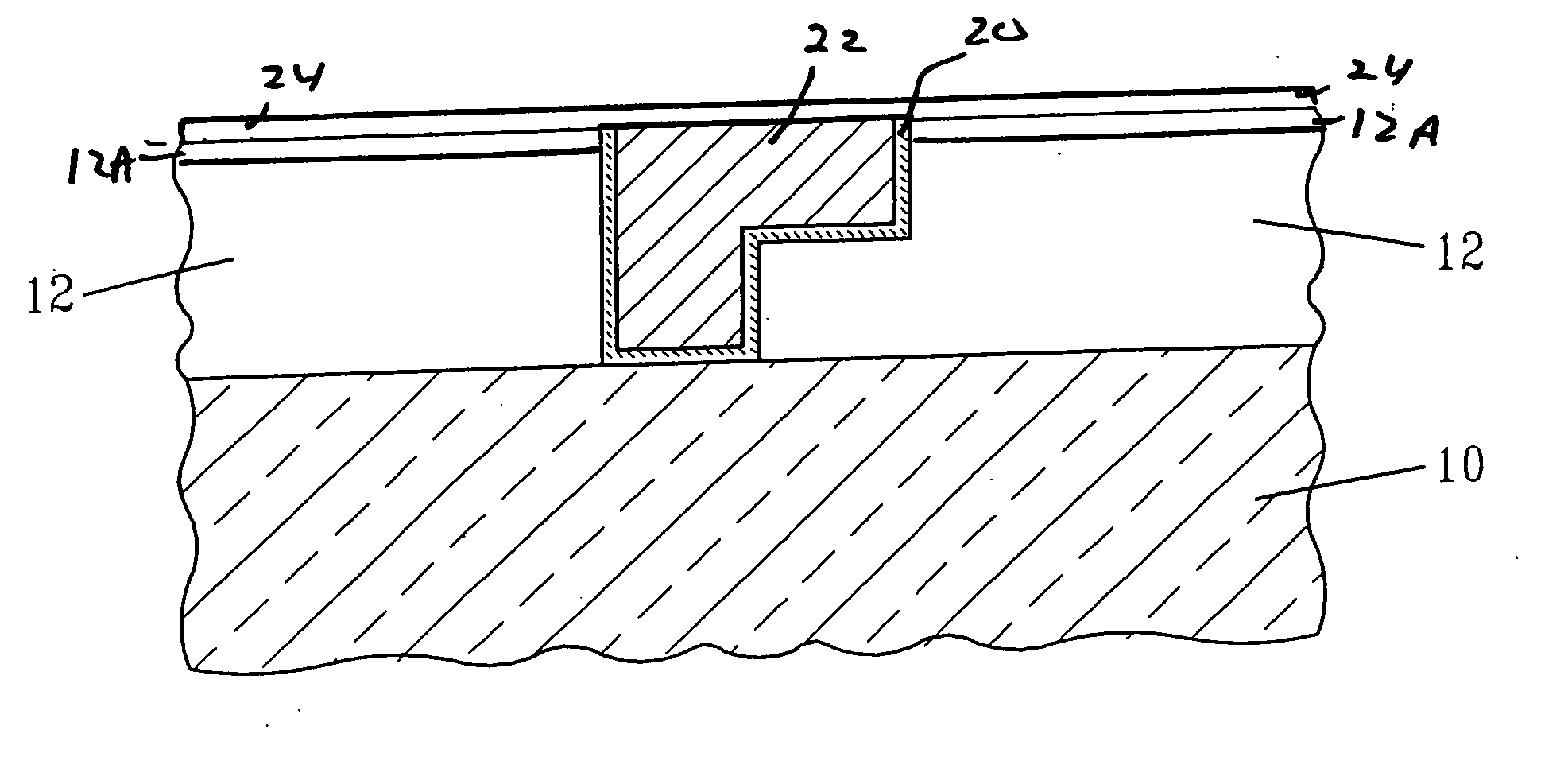

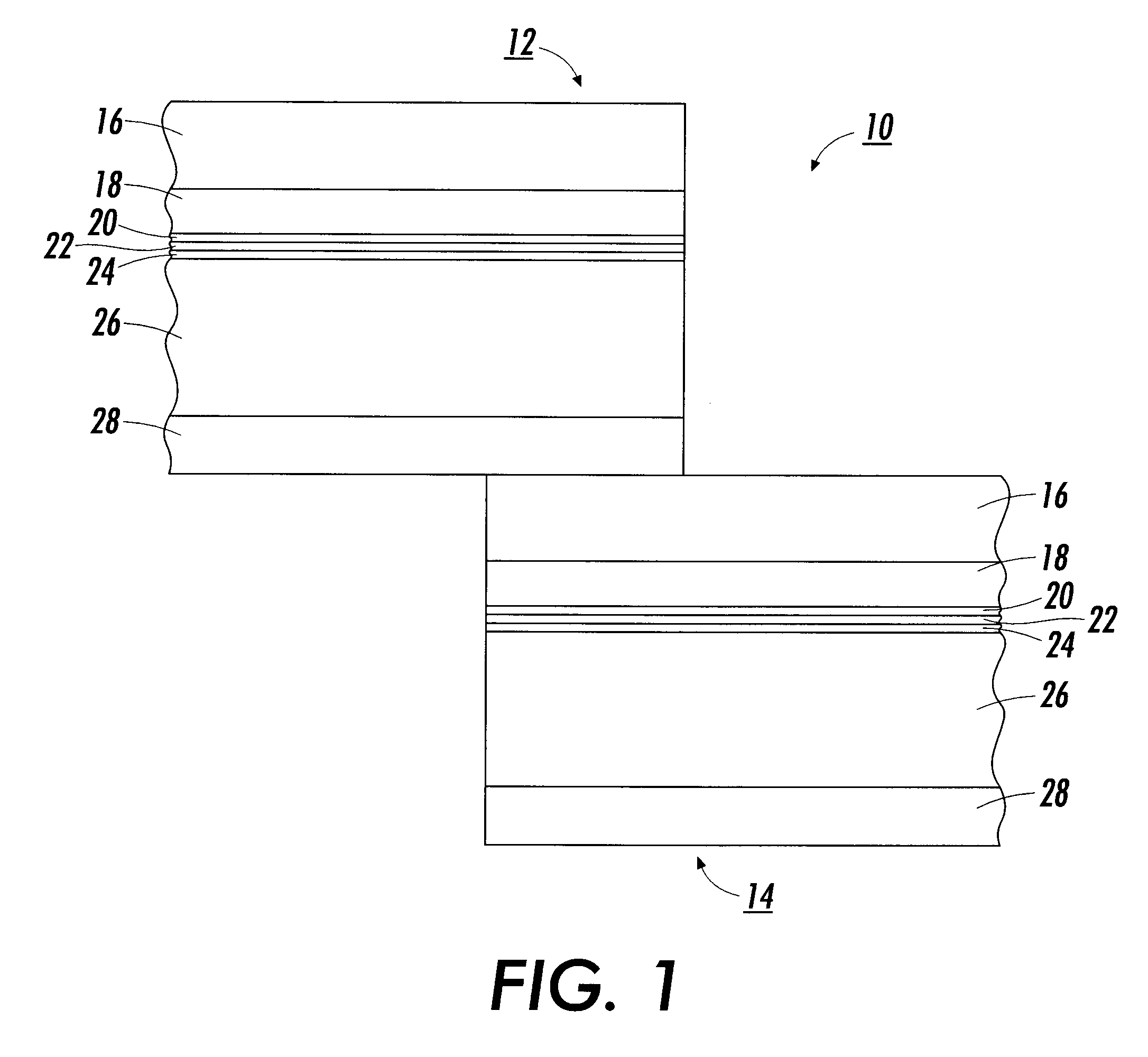

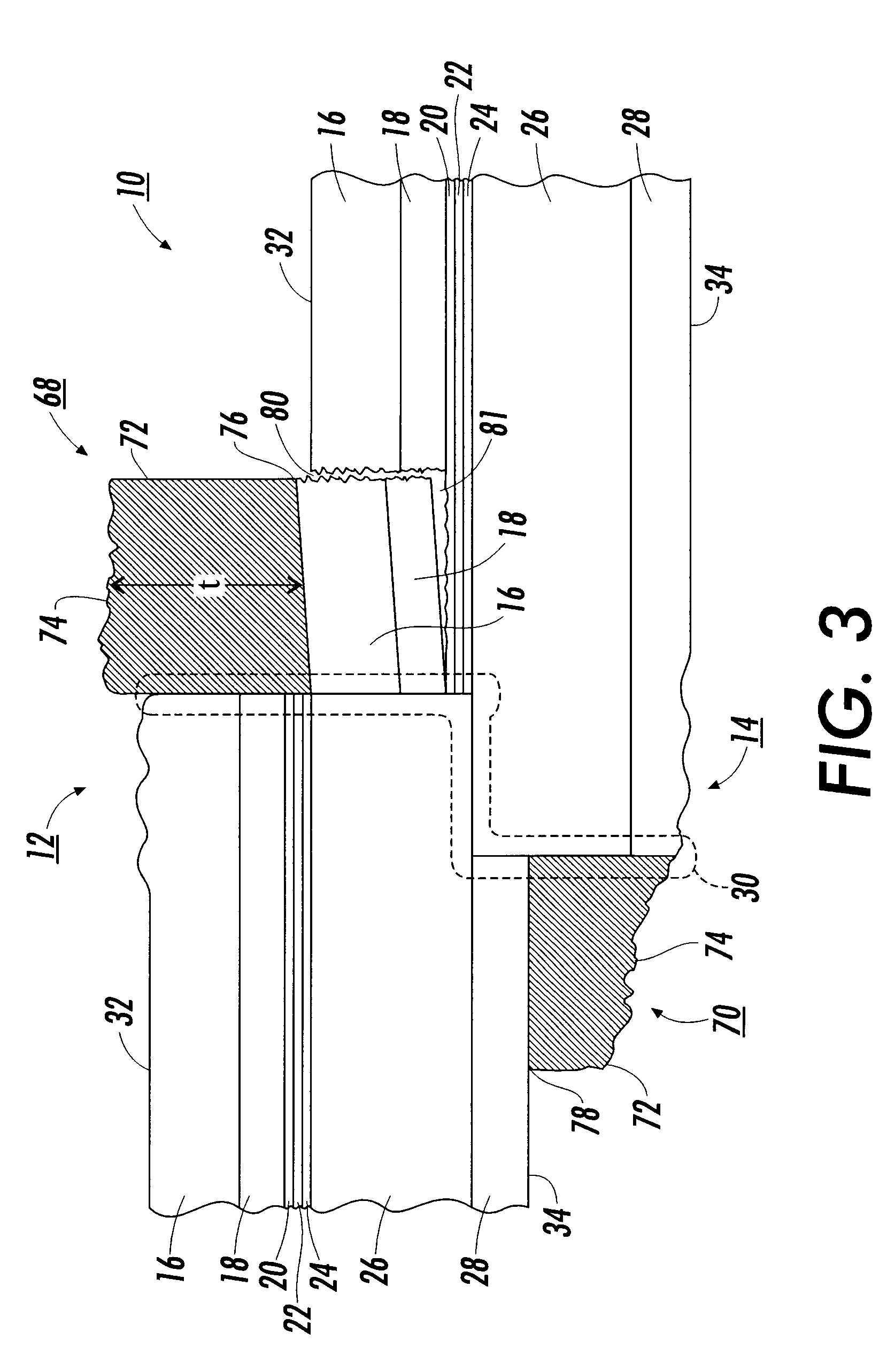

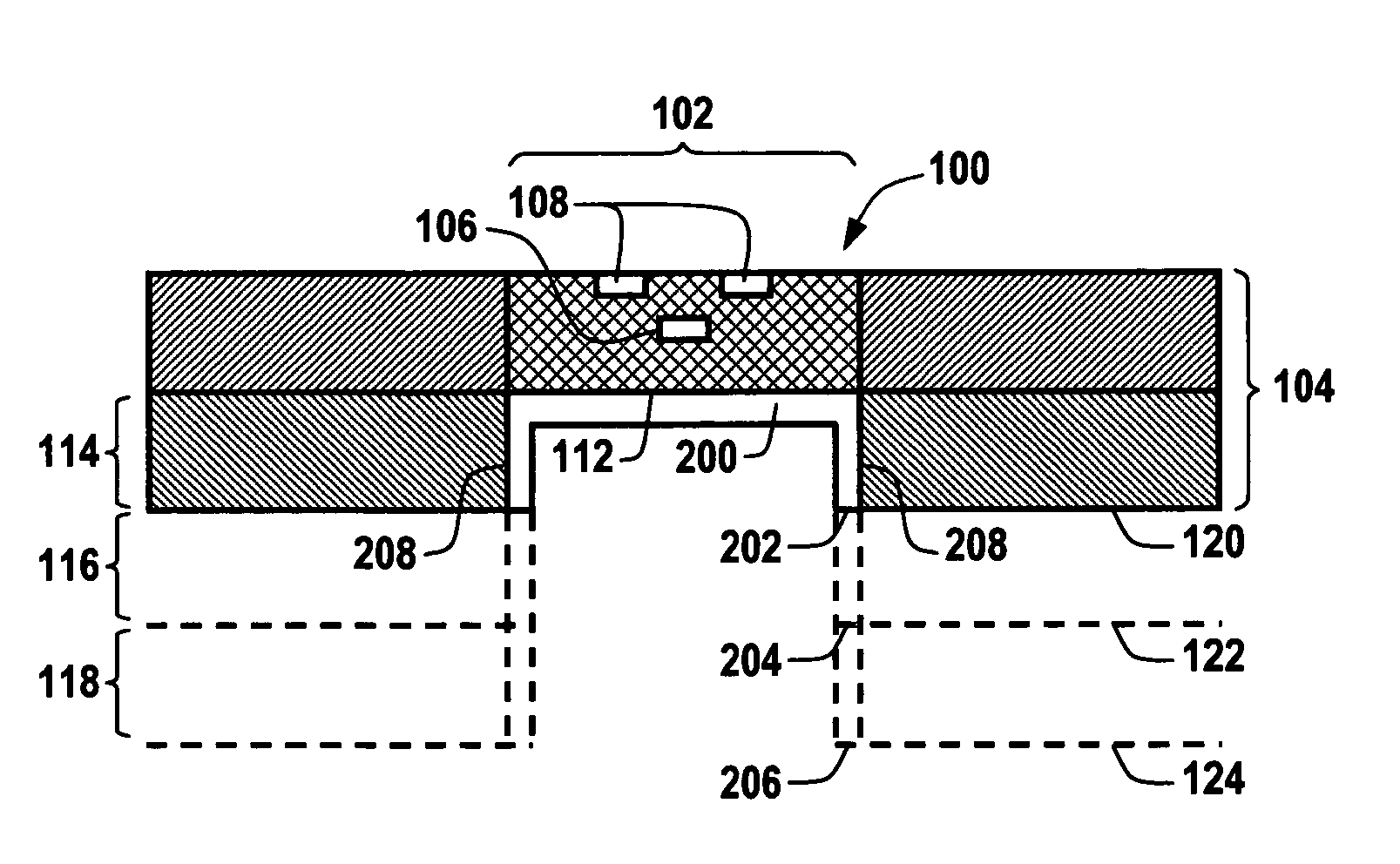

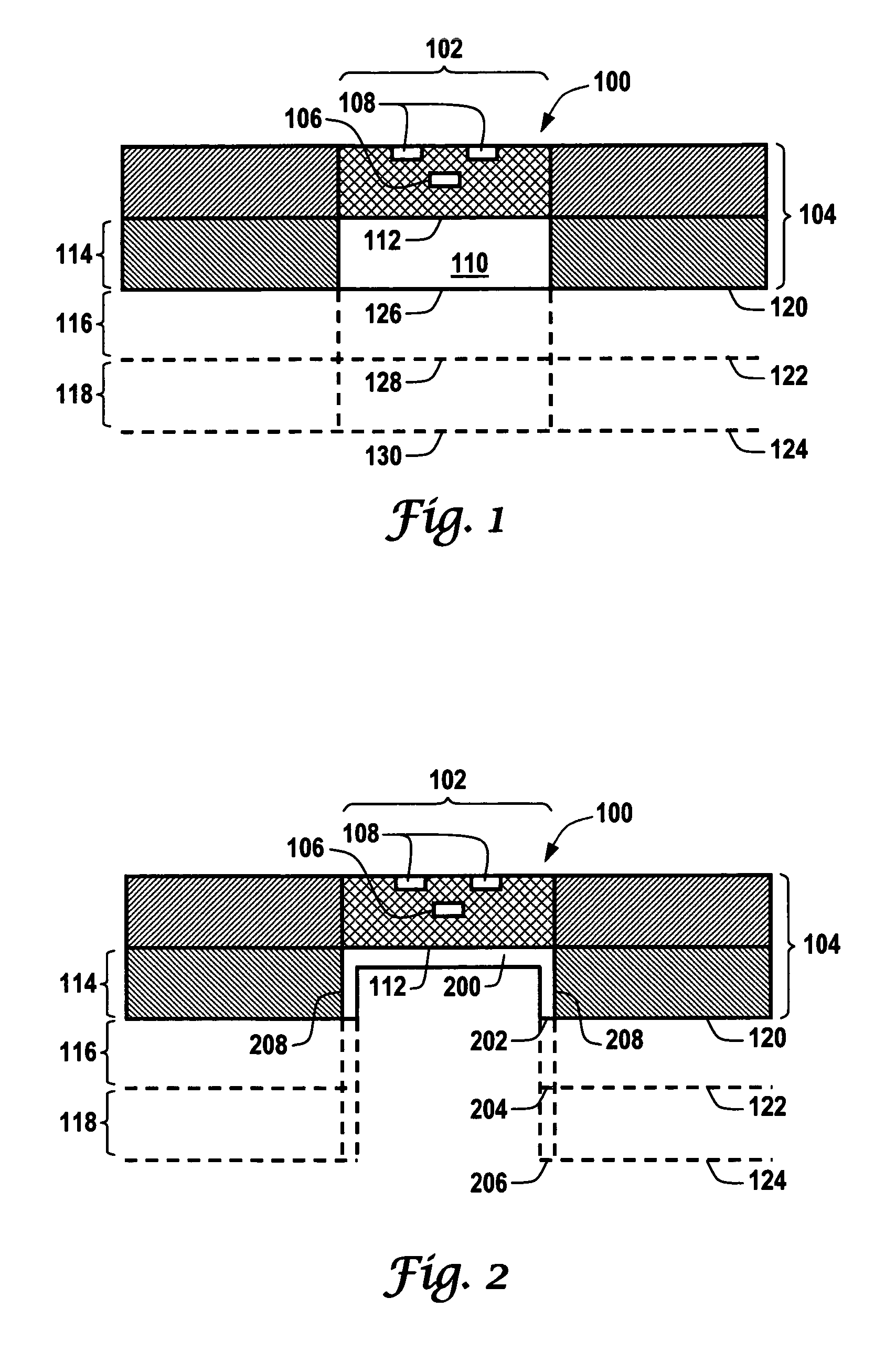

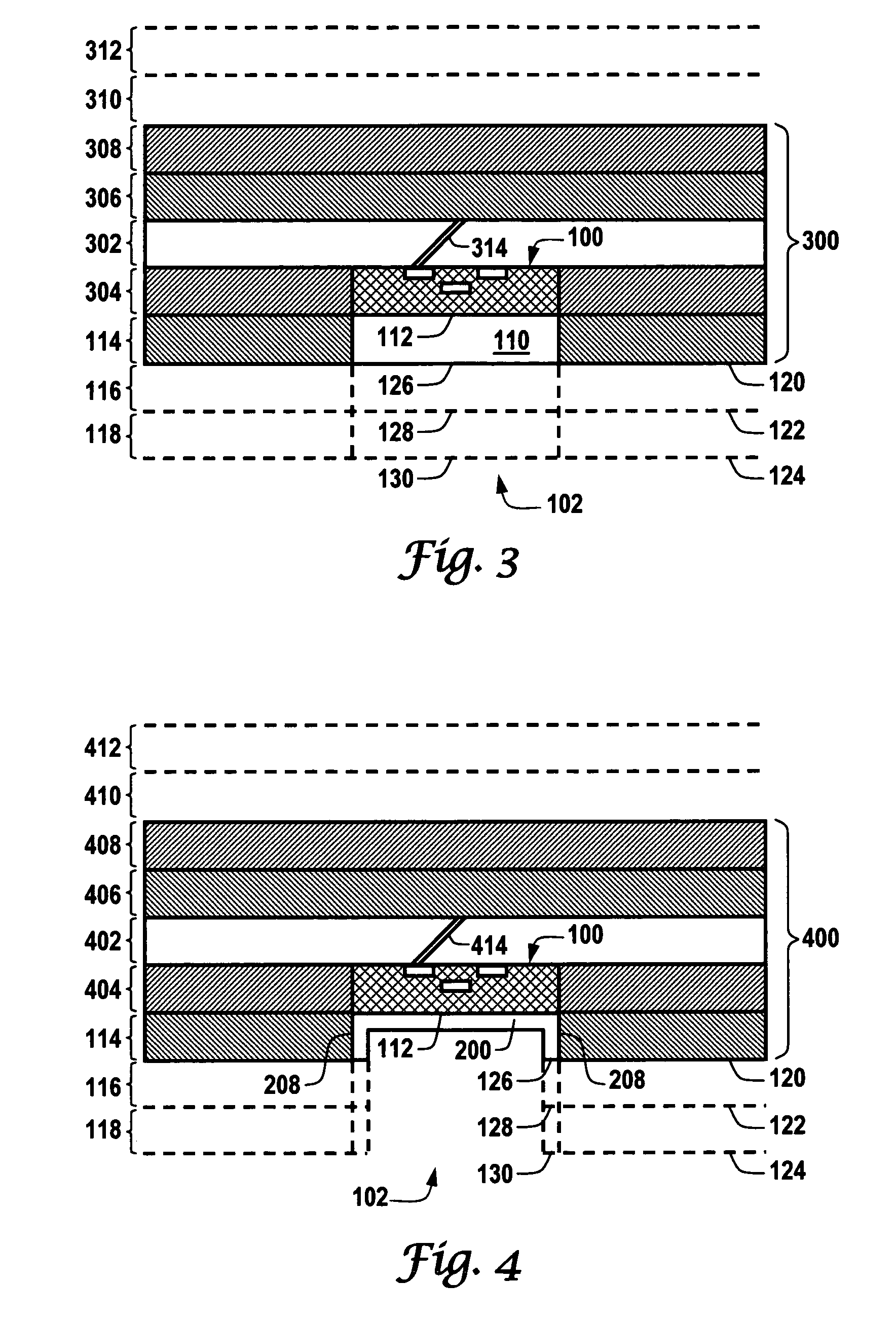

System, method and apparatus for improved electrical-to-optical transmitters disposed within printed circuit boards

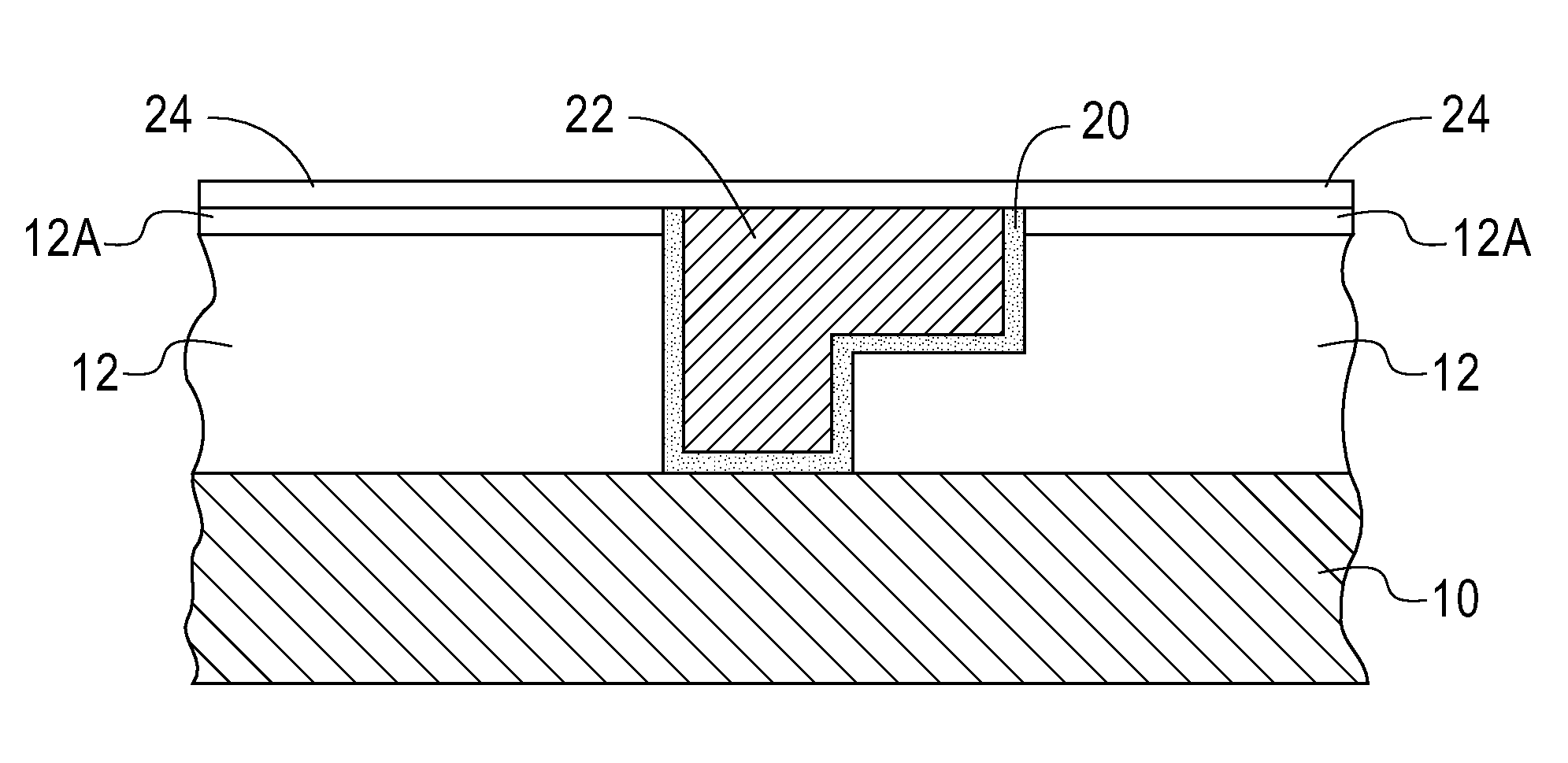

InactiveUS20050046011A1Simple and reliable processAdded fabricationCircuit optical detailsSemiconductor/solid-state device detailsCommunications systemConductive materials

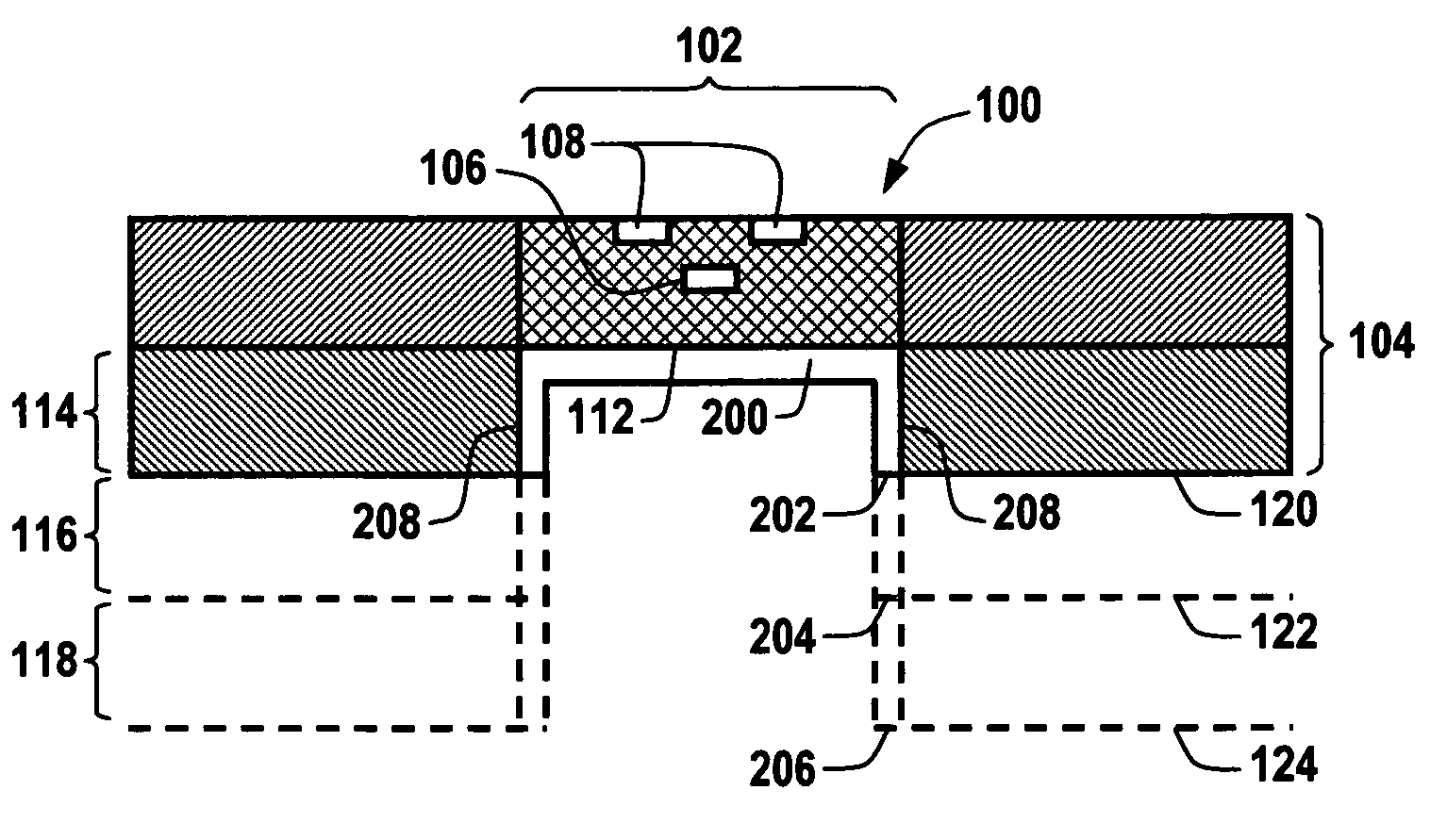

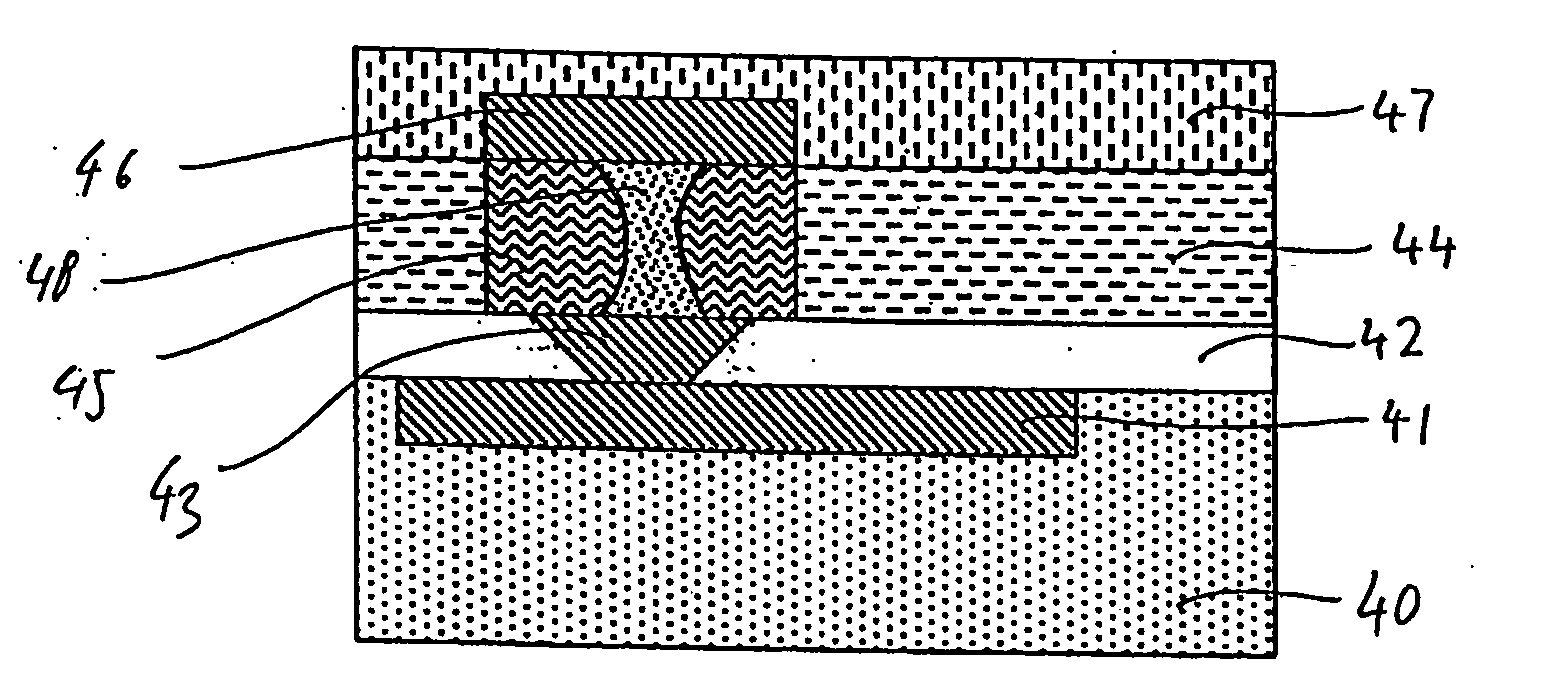

The present invention provides a system, method and apparatus for improved electrical-to-optical transmitters (100) disposed within printed circuit boards (104). The heat sink (110, 200) is a thermal conductive material disposed within a cavity (102) of the printed circuit board (104) and is thermally coupled to a bottom surface (112) of the electrical-to-optical transmitter (100). A portion of the thermal conductive material extends approximately to an outer surface (120, 122 or 124) of a layer (114, 116 or 118) of the printed circuit board (104). The printed circuit board may comprise a planarized signal communications system or an optoelectronic signal communications system. In addition, the present invention provides a method for fabricating the heat sink wherein the electrical-to-optical transmitter disposed within a cavity of the printed circuit board is fabricated. New methods for flexible waveguides and micro-mirror couplers are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

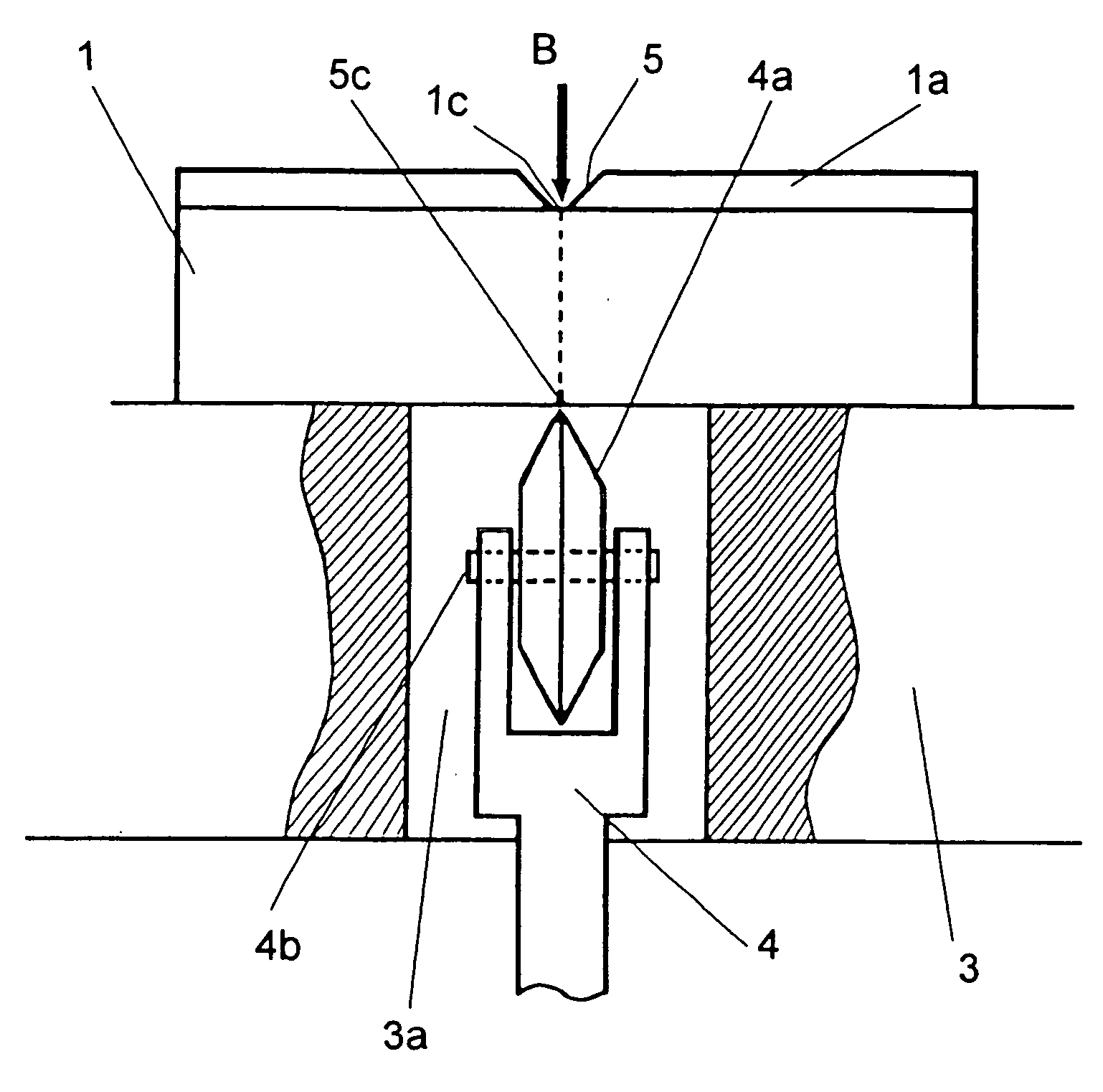

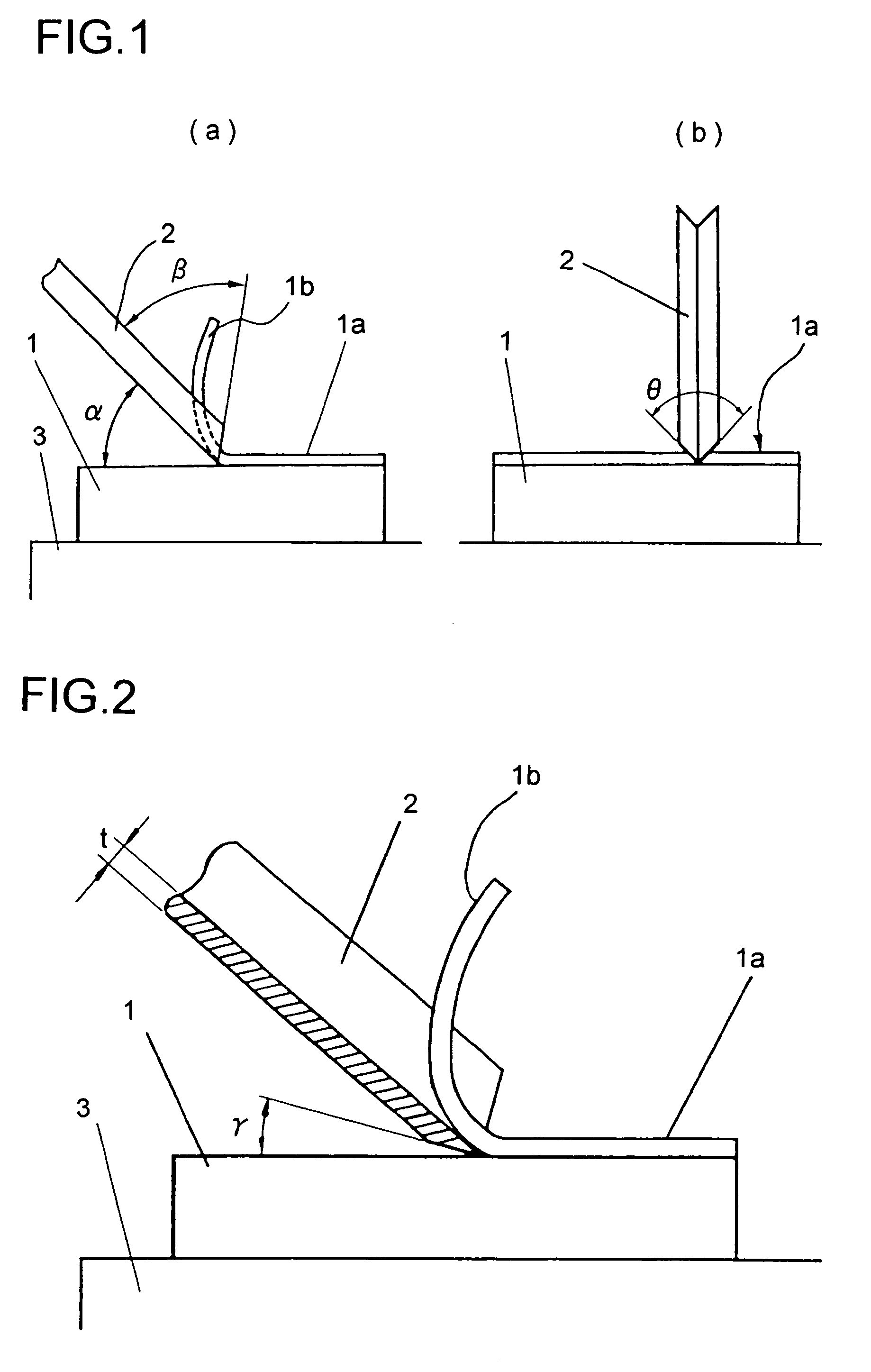

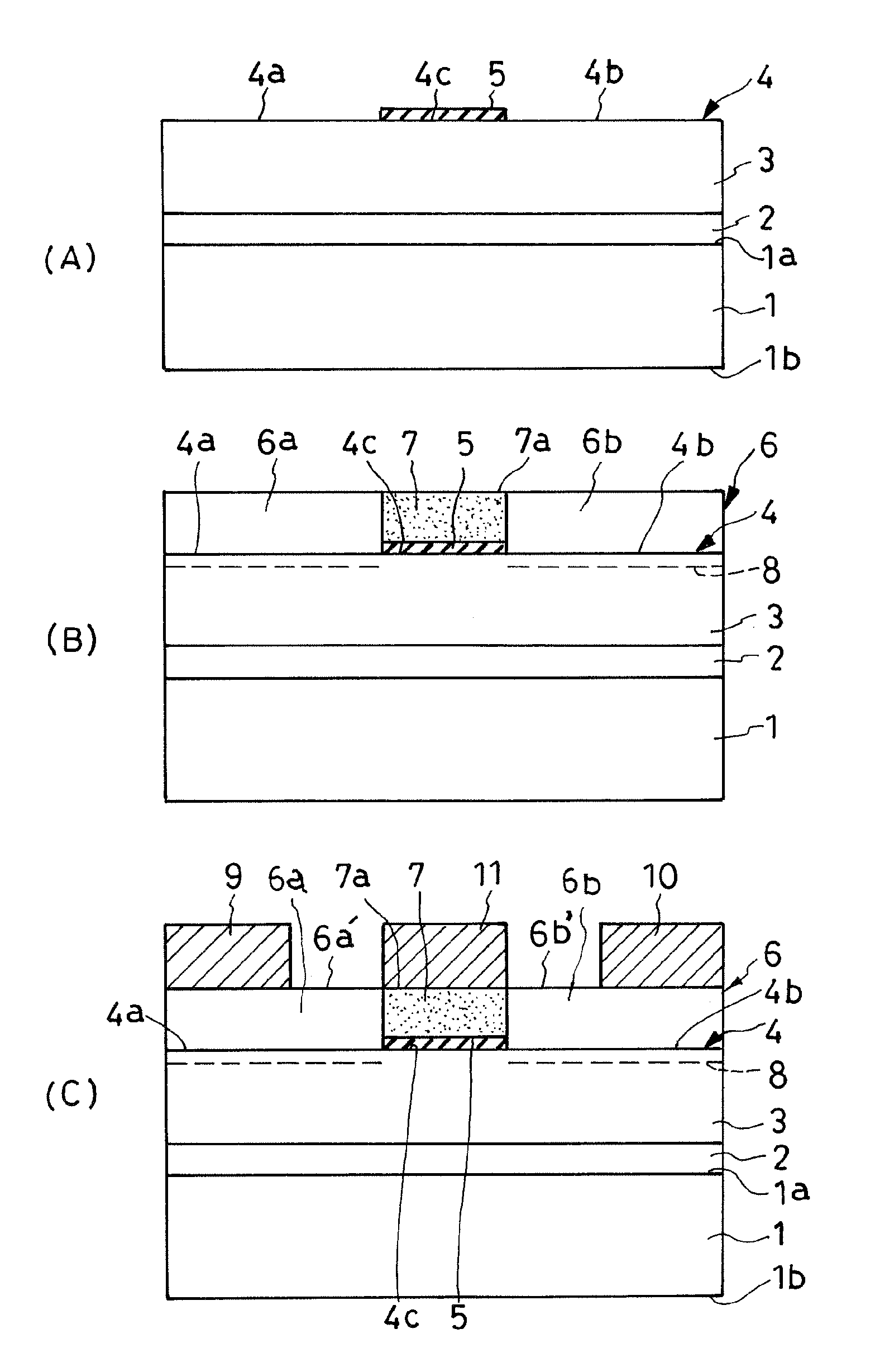

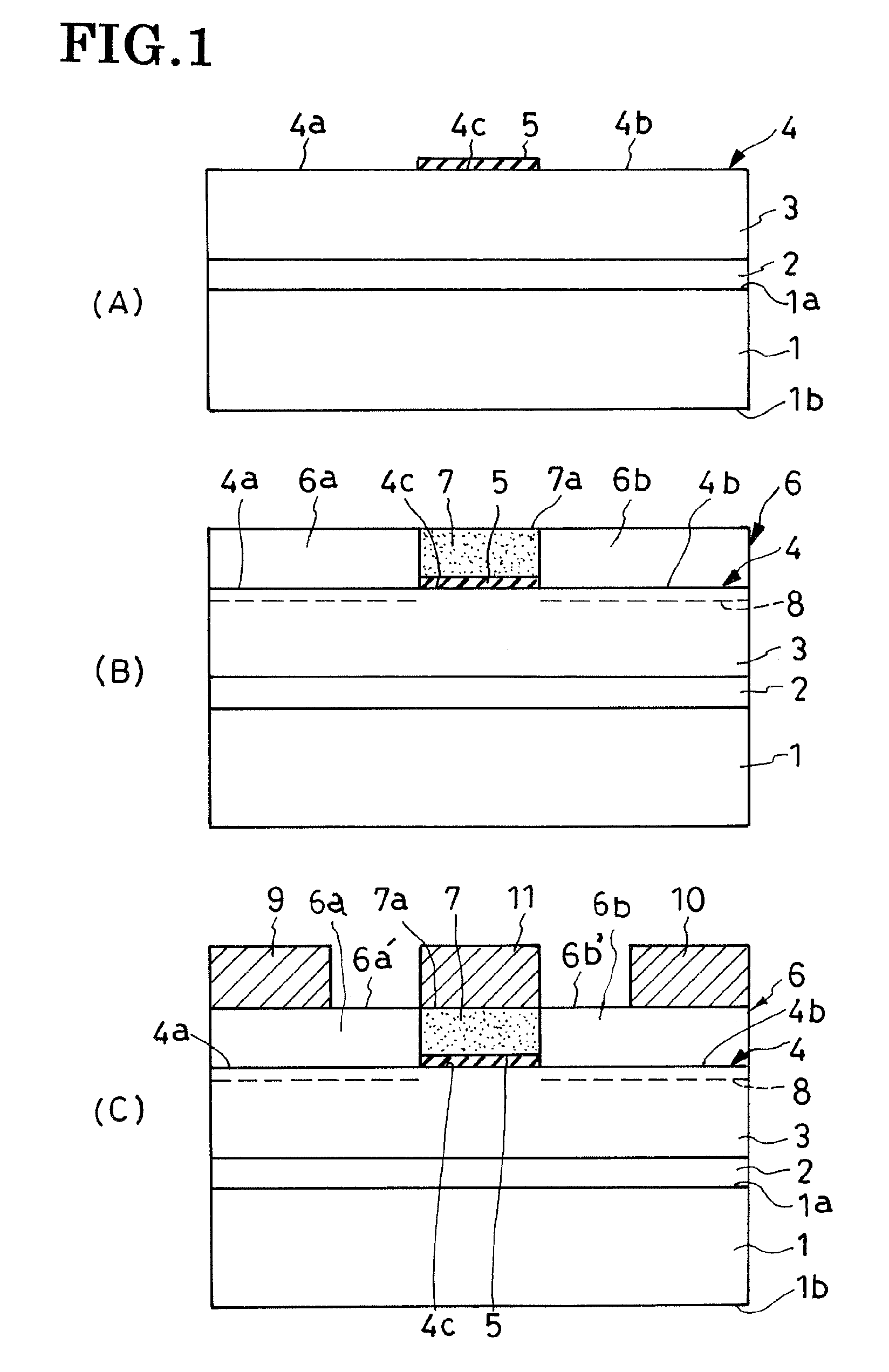

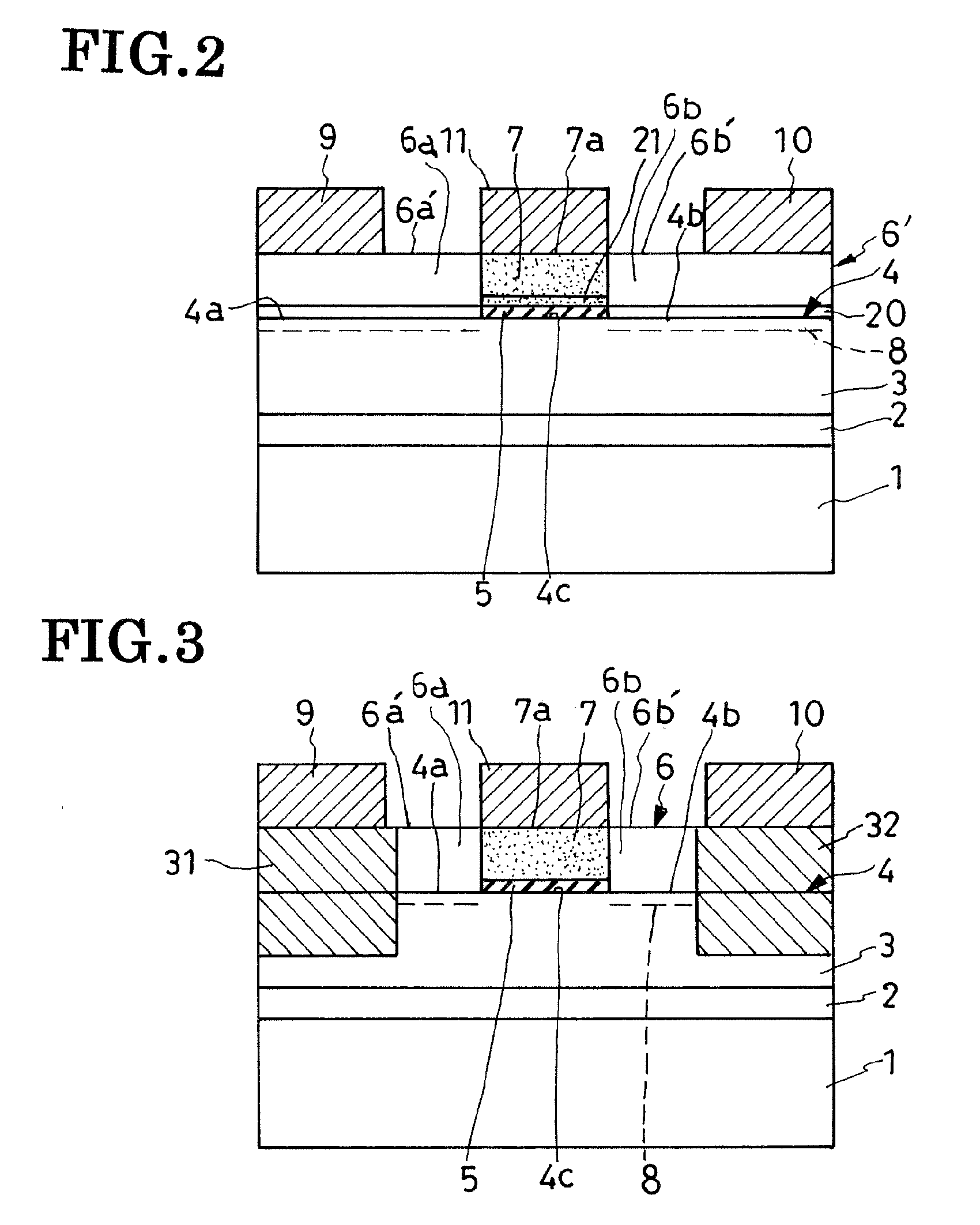

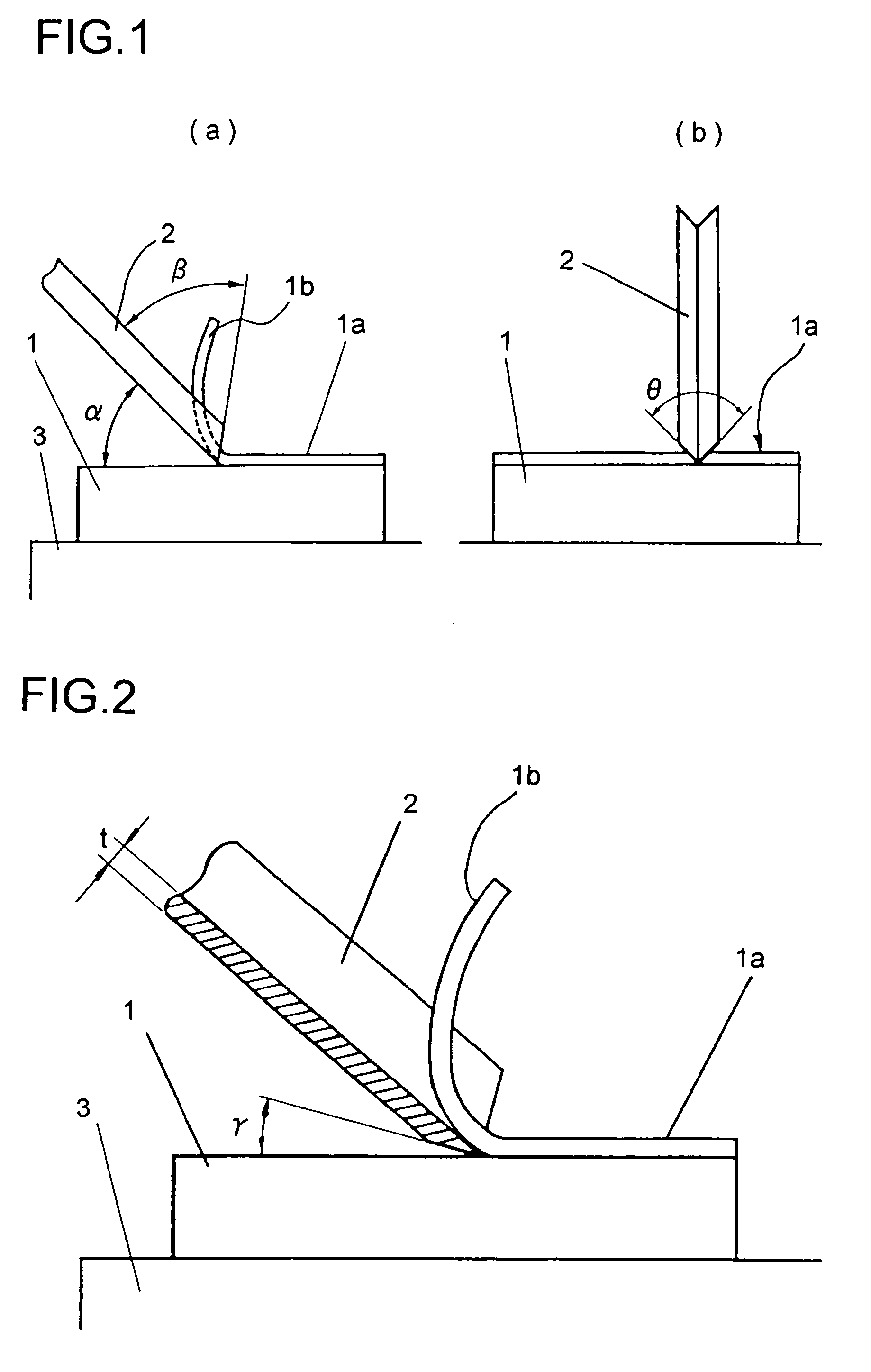

Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device

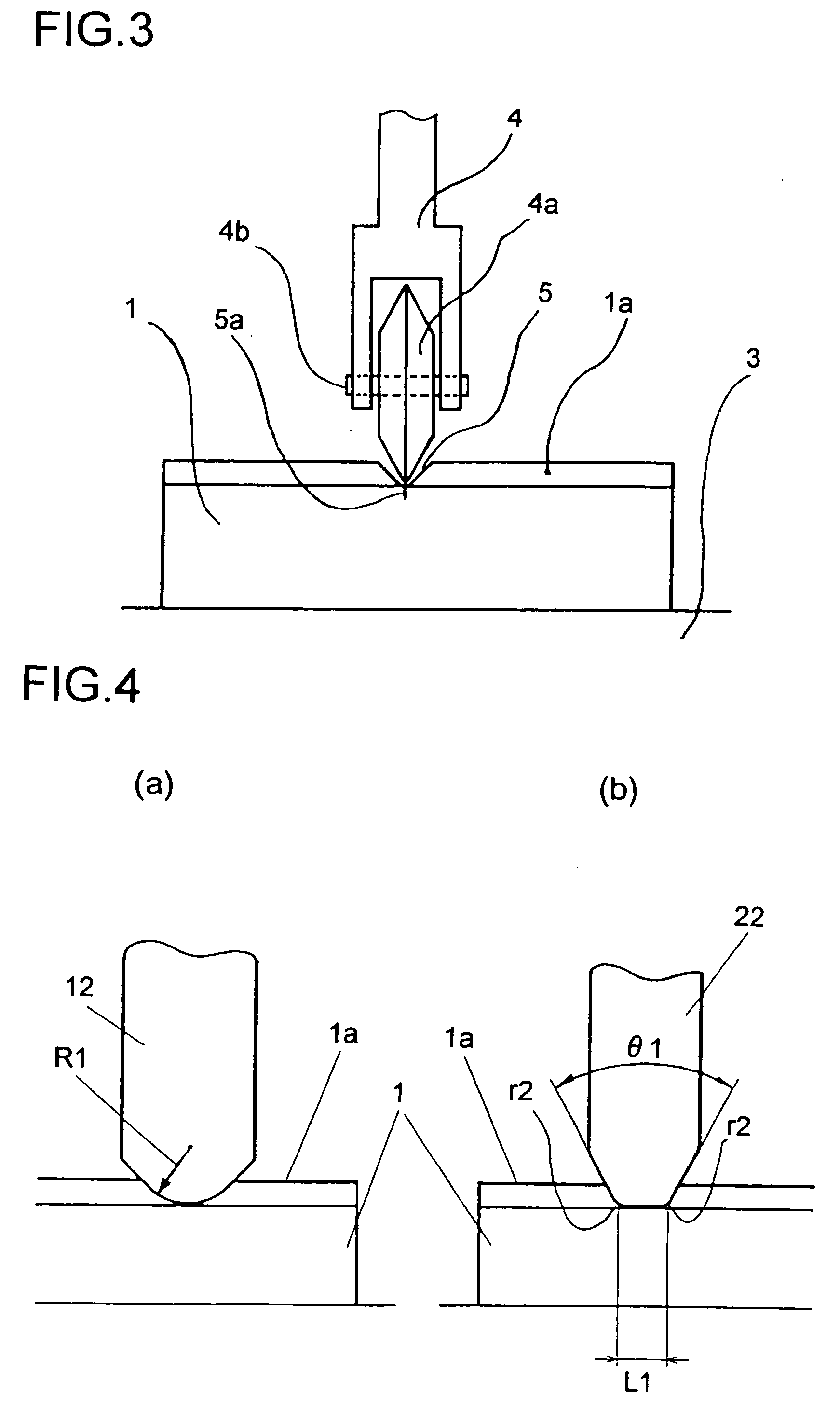

InactiveUS20050056127A1High mechanical strengthPrevent peelingLiquid crystal compositionsBox making operationsLiquid-crystal displayCutting glass

A method for cutting apart a glass substrate is provided whereby scribing of the glass substrate is possible without being affected by the presence or thickness of a deposited film formed thereon and without scratching the deposited film. To treat a glass substrate (1) having a deposited film (1a), such as a thin film or resin film, formed on one surface thereof, there are provided a shaving means (202), which is a blade that removes strip-shaped portions of the deposited film (1a) to expose strip-shaped regions on the glass substrate (1), and a wheel cutter (14a) that forms scribed lines along the strip-shaped regions exposed on the glass substrate (1). The glass substrate (1) is cut apart along the scribed lines.

Owner:SHARP KK +1

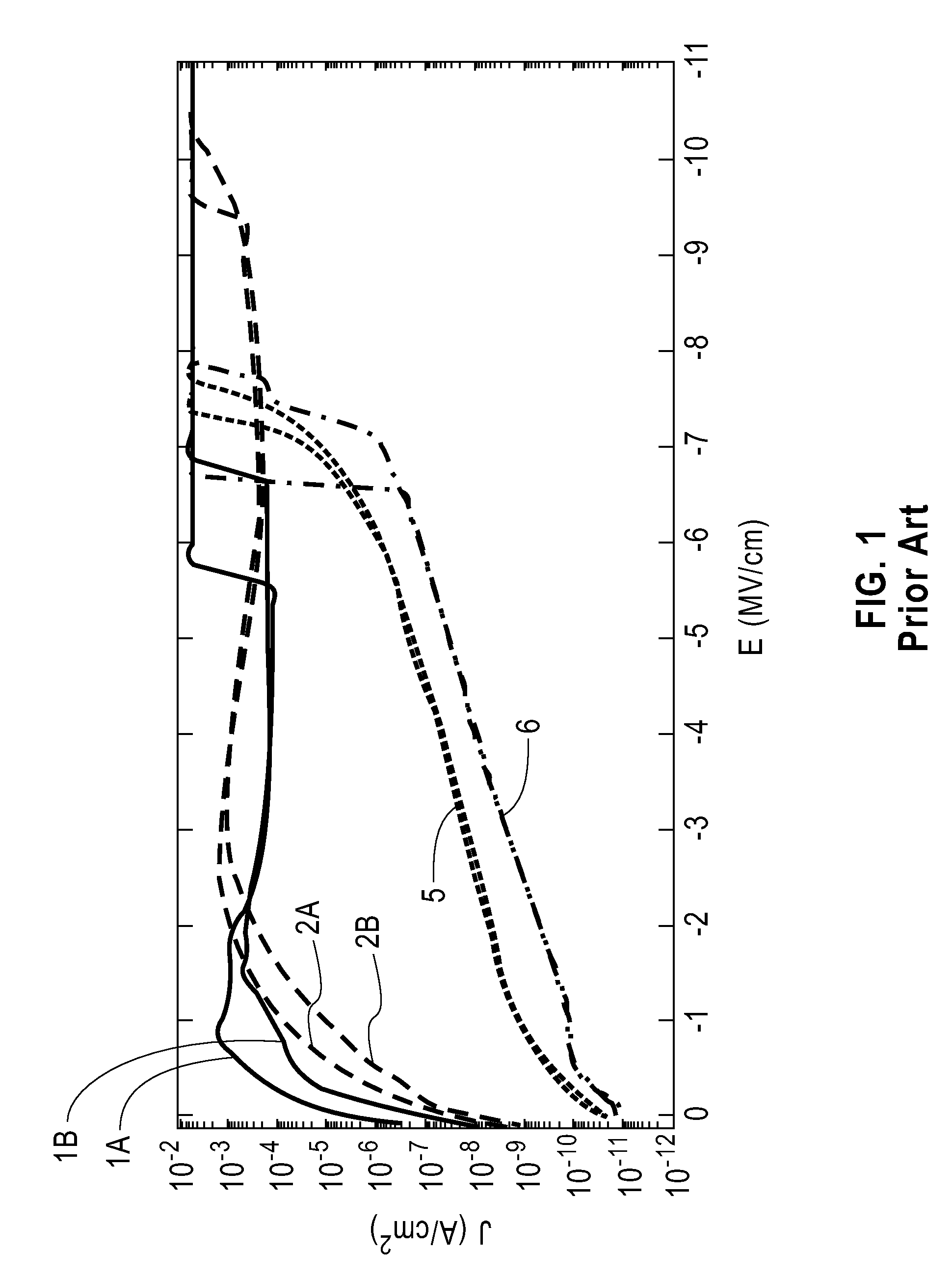

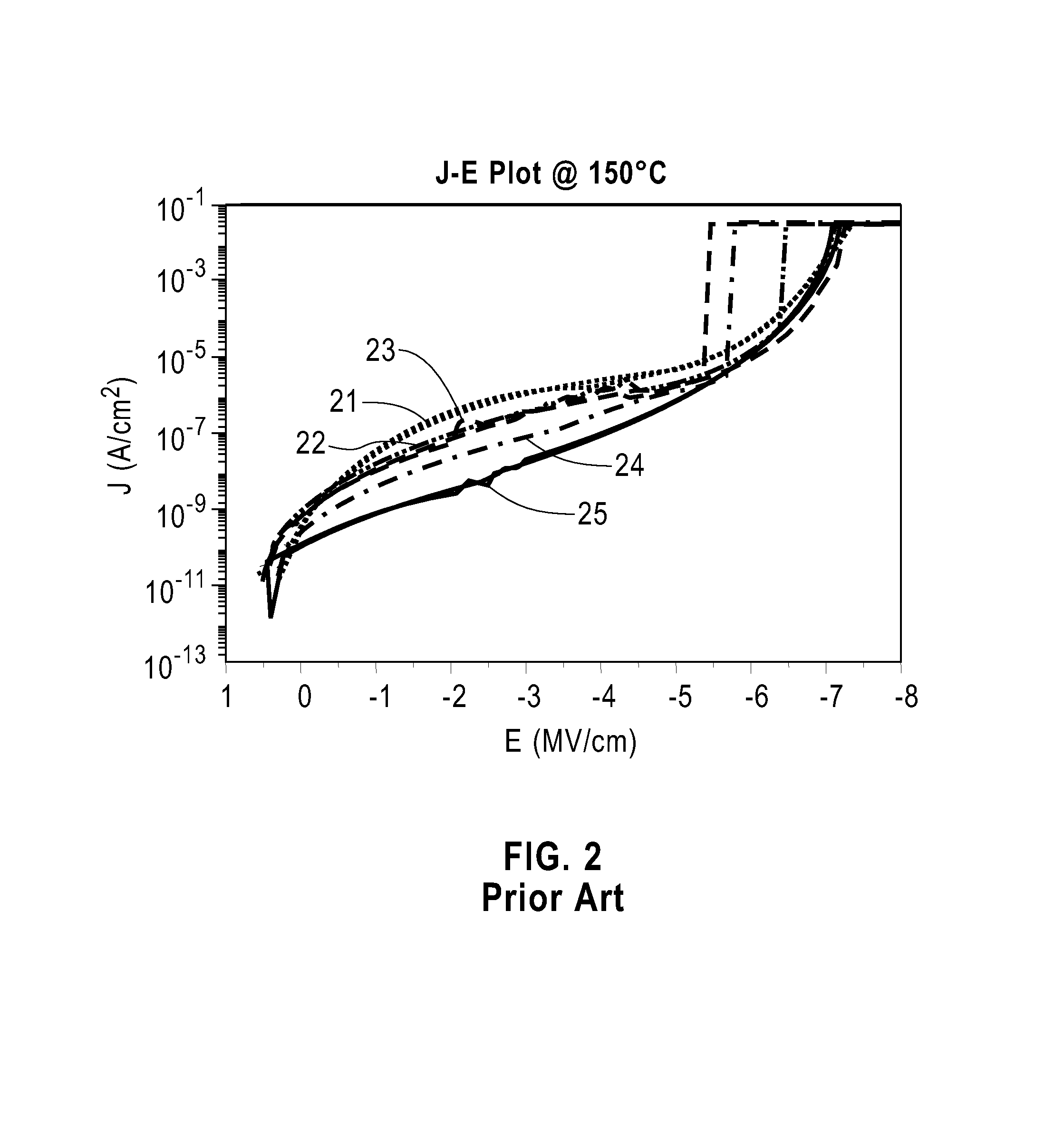

Reliable BEOL integration process with direct CMP of porous SiCOH dielectric

InactiveUS20060189133A1Added fabricationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSurface layerCompound (substance)

The present invention relates to methods of improving the fabrication of interconnect structures of the single or dual damascene type, in which there is no problem of hard mask retention or of conductivity between the metal lines after fabrication. The methods of the present invention include at least steps of chemical mechanical polishing and UV exposure or chemical repair treatment which steps improve the reliability of the interconnect structure formed. The present invention also relates to an interconnect structure which include a porous ultra low k dielectric of the SiCOH type in which the surface layer thereof has been modified so as to form a gradient layer that has both a density gradient and a C content gradient.

Owner:GLOBALFOUNDRIES INC

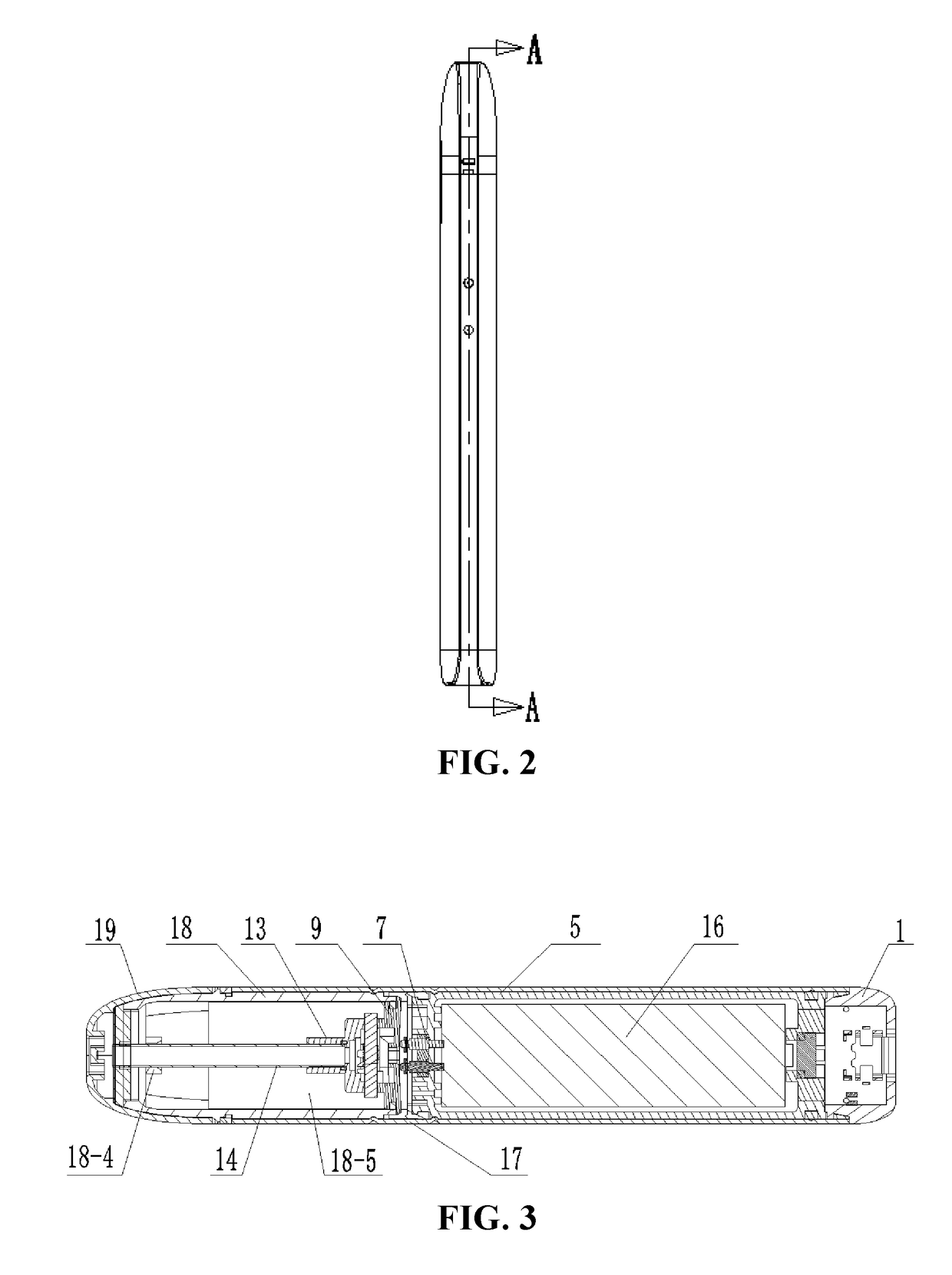

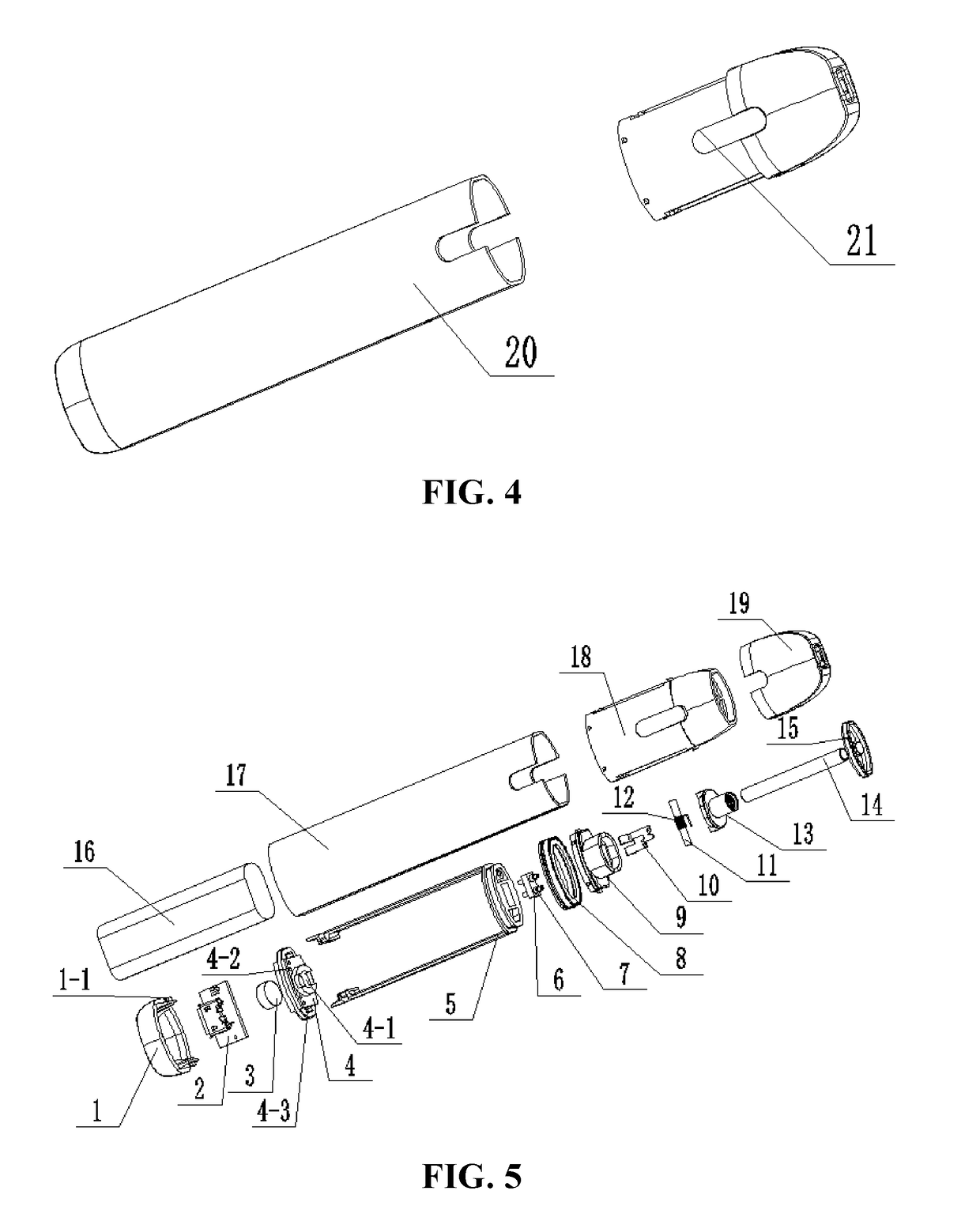

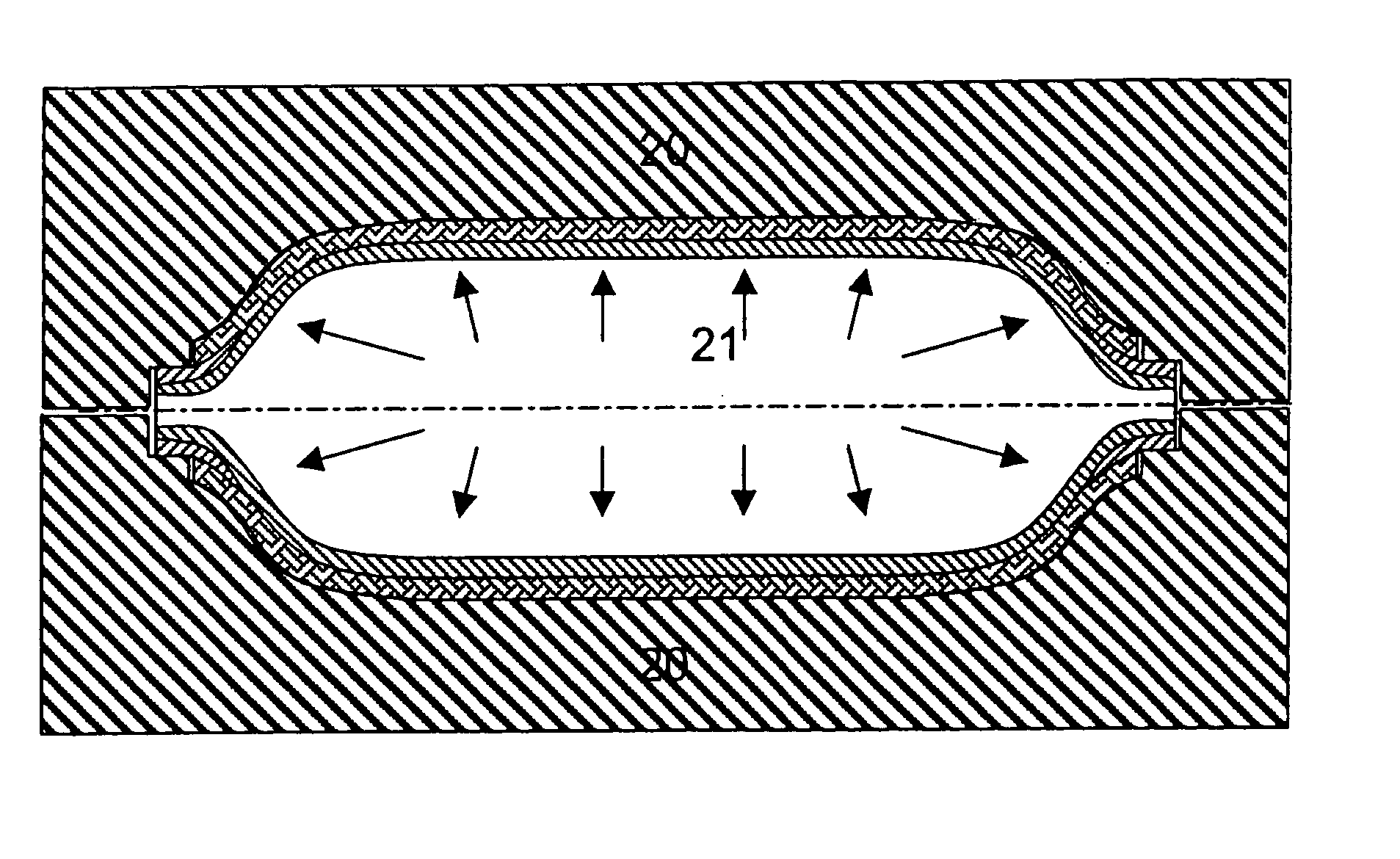

Cigarette cartridge and electronic cigarette using the same

ActiveUS20190037926A1Simplified assembly stepsAdded fabricationTobacco treatmentTobacco devicesVaporizationEngineering

A cigarette cartridge (21) has a liquid-storage assembly and a vaporization assembly. The vaporization assembly is disposed in the liquid-storage assembly. The liquid-storage assembly has an upper cover (19) having a smog outlet (19-2), and a housing (18). The vaporization assembly has a heat-generating mechanism (111) a atomizing base (9), and a ventilation pipe (14). The heat-generating mechanism (111) is disposed on the atomizing base (9); the atomizing base (9) is sealingly arranged on one end of the housing (18), and the upper cover (19) is arranged on the other end of the housing (18) opposite to the atomizing base (9); the ventilation pipe (14) is in communication with the heat-generating mechanism (111) and the smog outlet (19-2). The space between the ventilation pipe (14), the housing (18), the atomizing base (9), and the upper cover (19) is a liquid-storage chamber (18-5).

Owner:CHANGZHOU JUWEI INTELLIGENT TECH CO LTD

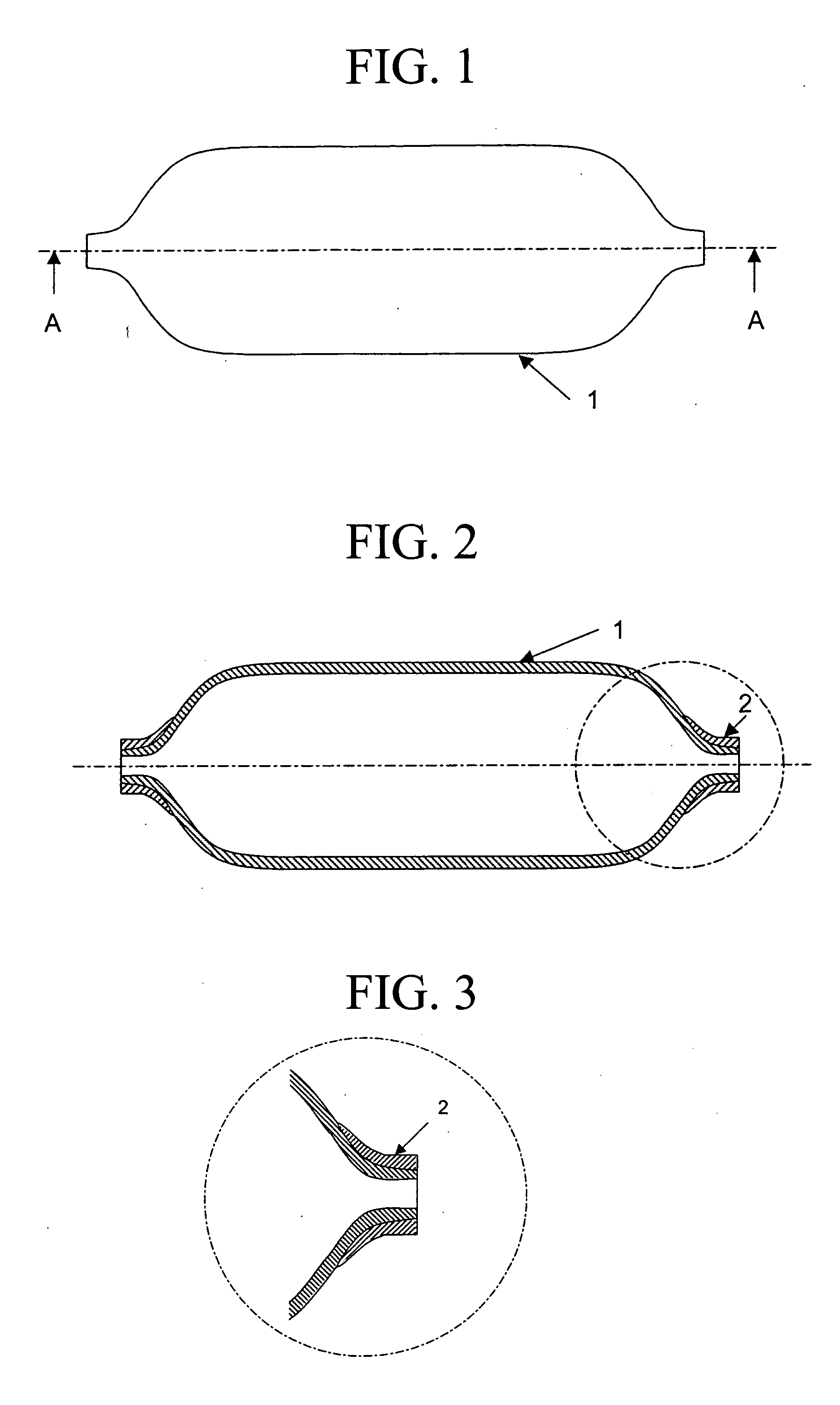

Non-isothermal method for fabricating hollow composite parts

InactiveUS20050258575A1Added fabricationShorten cycle timeLaminationLamination apparatusCross-linked polyethylenePolypropylene

A process for making hollow composite structures or vessels which includes the steps of: A) heating a mixture of thermoplastic matrix and reinforcing fibres wrapped over a rigid or semi-rigid thermoplastic liner or bladder above the melting point of the thermoplastic composite matrix outside of a moulding tool; B) transferring the heated assembly to a mould that is maintained below the melting temperature of the thermoplastic matrix of the composite; C) closure of the mould and application of internal fluid pressure to the liner or bladder to apply pressure to the thermoplastic matrix and reinforcing fibres; D) optionally the use of a special coupling system for rapid connection of the internal pressure; E) cooling of the liner or bladder and thermoplastic matrix and reinforcing fibre assembly in contact with the cold or warm mould while consolidation of the assembly occurs; F) opening of the mould and removal of the finished assembly. Suitable thermoplastic materials for the liner / bladder and thermoplastic composite matrix material include: polypropylene, polyamide, polyethylene, cross-linked polyethylene, polybutylene terephthalate, polyethylene terephthalate, polyoxymethylene, polyphenylene sulfide and polyetheretherketone.

Owner:KRUSE CHRISTIAN +3

Electrostatographic imaging member

InactiveUS6303254B1Improve thickness uniformityReduces undesirable dirtElectrographic process apparatusMicrometerPolymer chemistry

An electrostatographic imaging member including: a flexible supporting substrate; an imaging layer having an optional adjacent ground strip layer coated on one side of the substrate; and an anti-curl backing layer coated on the other side of the substrate which layer is comprised of a film forming polymer binder, an optional adhesion promoting polymer, and a dispersion of polytetrafluoroethylene particles which dispersion has particles with a narrow diameter particle size distribution of from about 0.19 micrometer to about 0.21 micrometer, and an average diameter particle size of about 0.20 micrometer. The optional ground strip layer can include the same dispersion of polytetrafluoroethylene particles as the anti-curl backing layer.

Owner:XEROX CORP

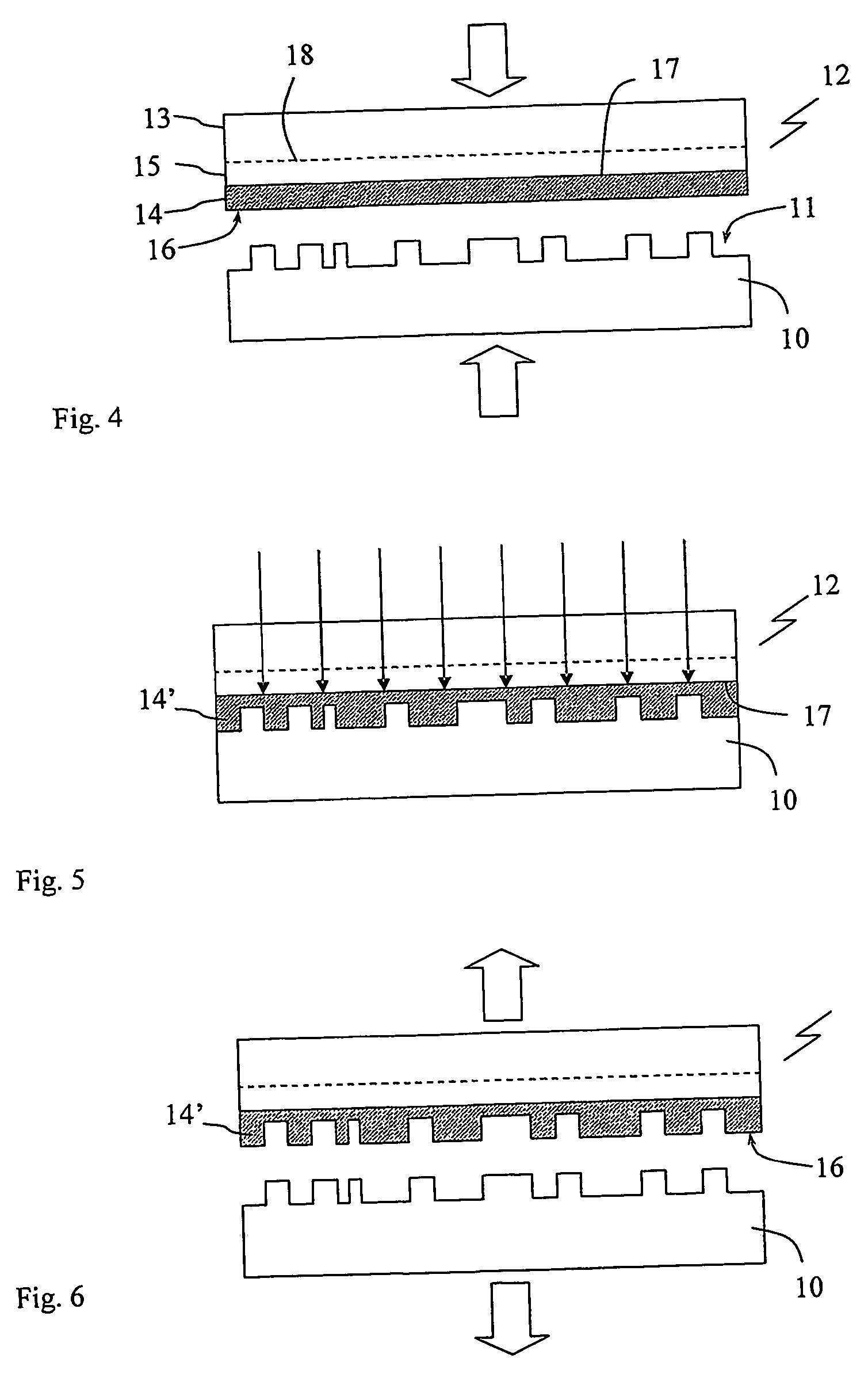

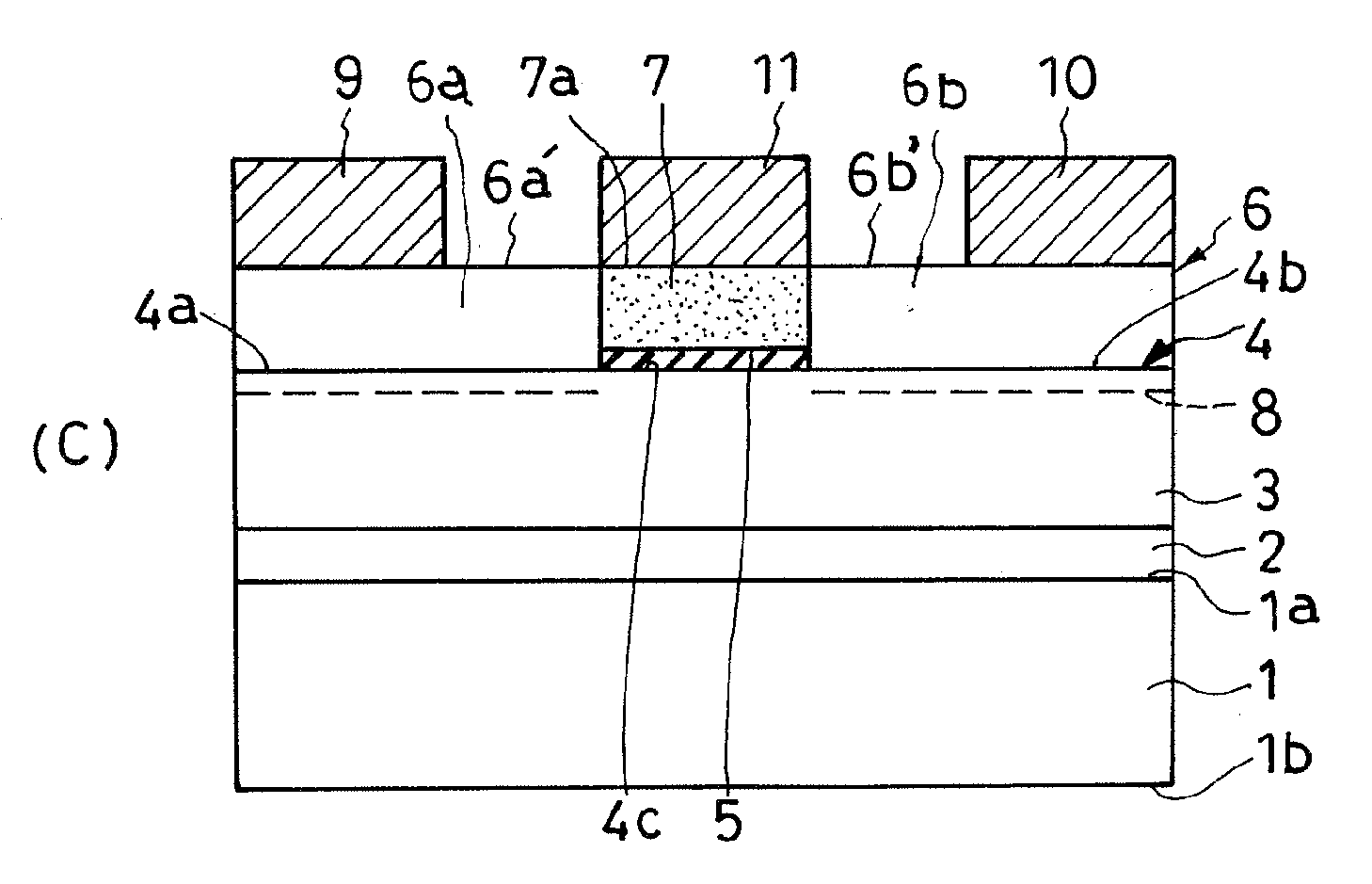

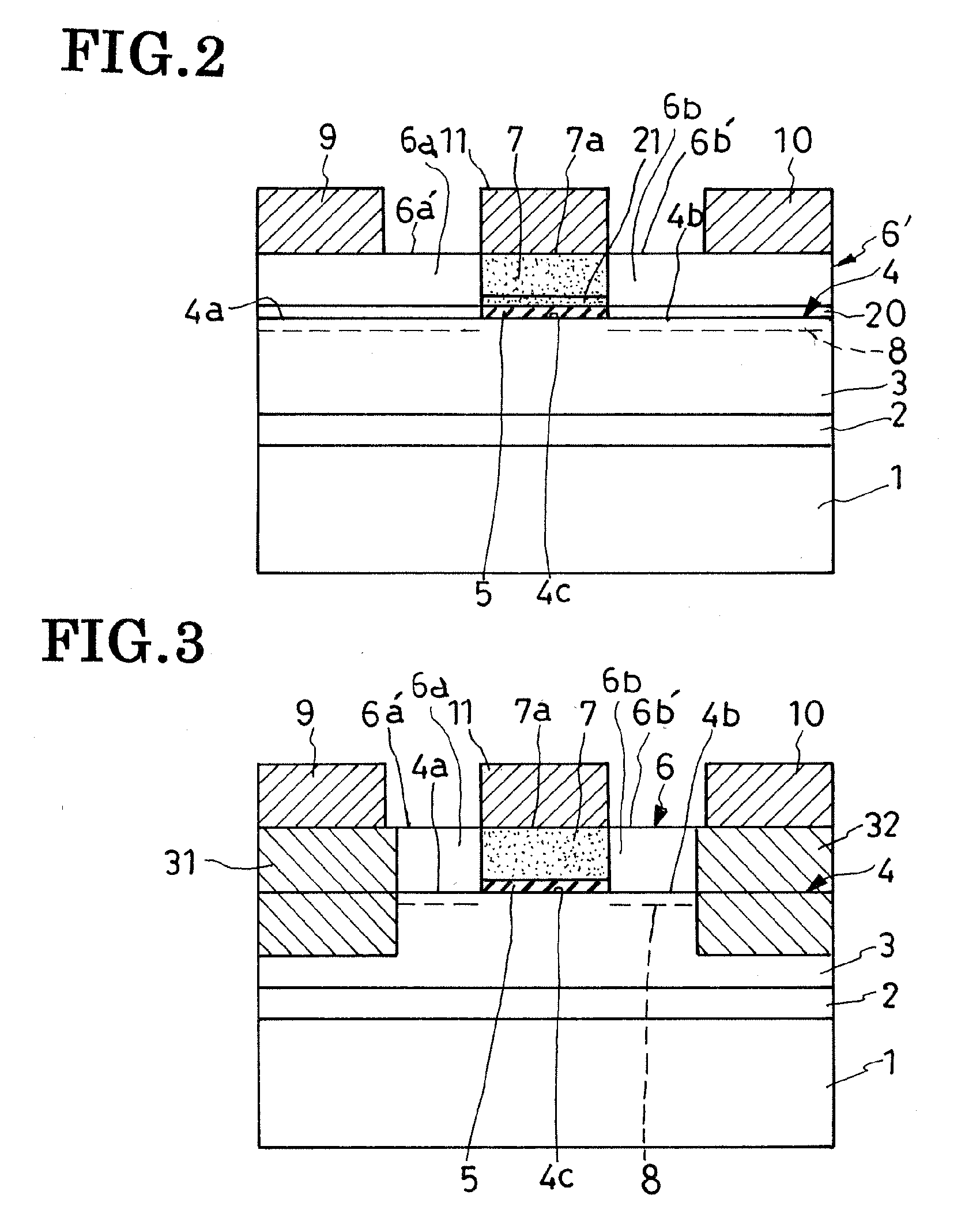

Normally-off field-effect semiconductor device

InactiveUS7777254B2Efficient manufacturingEasy to controlTransistorSemiconductor/solid-state device manufacturingHeterojunctionSemiconductor materials

After creating an electron transit layer on a substrate, a baffle is formed on midpart of the surface of the electron transit layer, the surface having a pair of spaced-apart parts left on both sides of the baffle. A semiconducting material different from that of the electron transit layer is deposited on its surface thereby conjointly fabricating an electron supply layer grown continuously on the pair of spaced-apart parts of the electron transit layer surface, and a discontinuous growth layer on the baffle in the midpart of the electron transit layer surface. When no voltage is being impressed to the gate electrode on the discontinuous growth layer, this layer creates a hiatus in the two-dimensional electron gas layer generated along the heterojunction between the electron supply layer and electron transit layer. The hiatus is closed upon voltage application to the gate electrode.

Owner:SANKEN ELECTRIC CO LTD

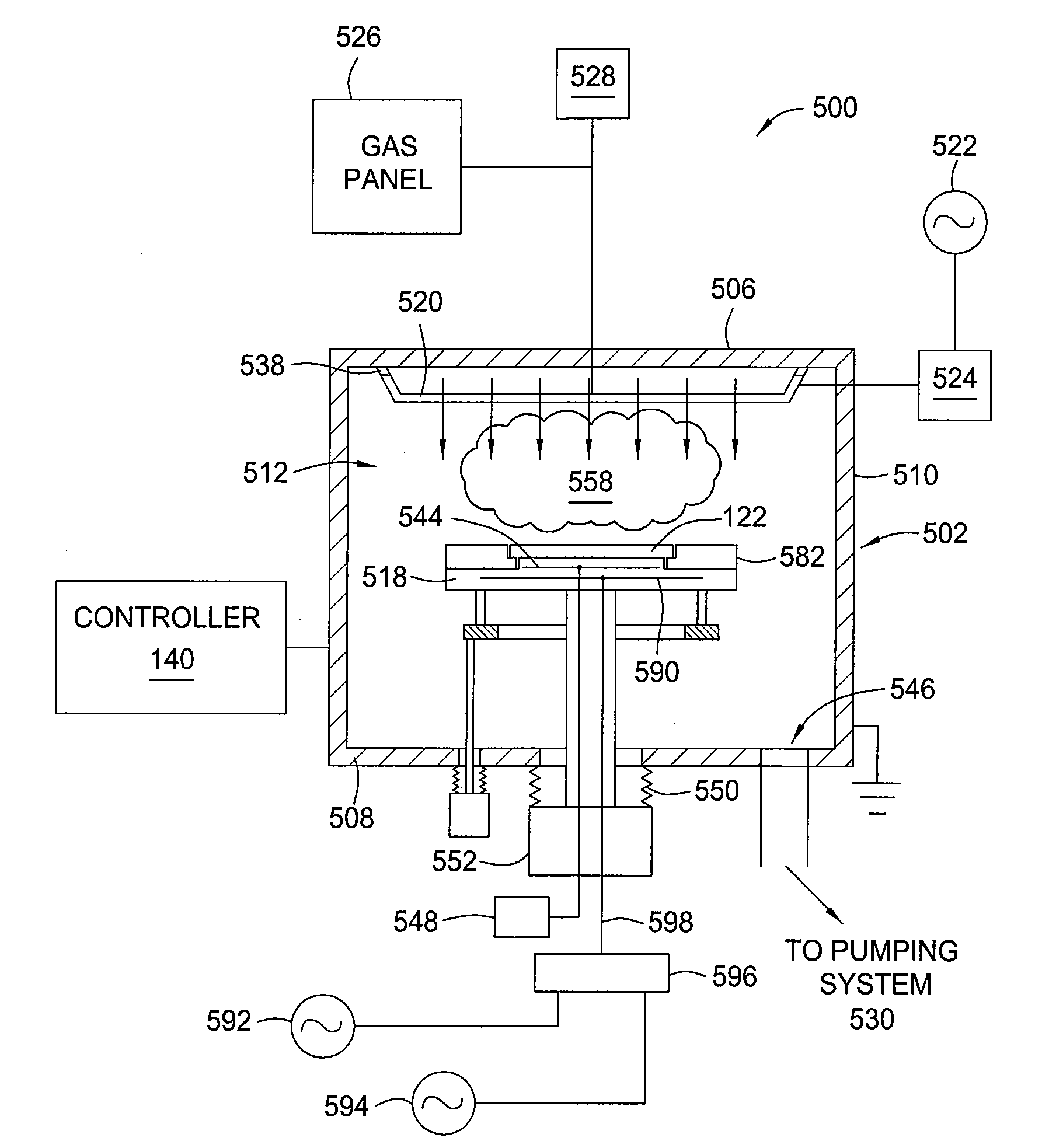

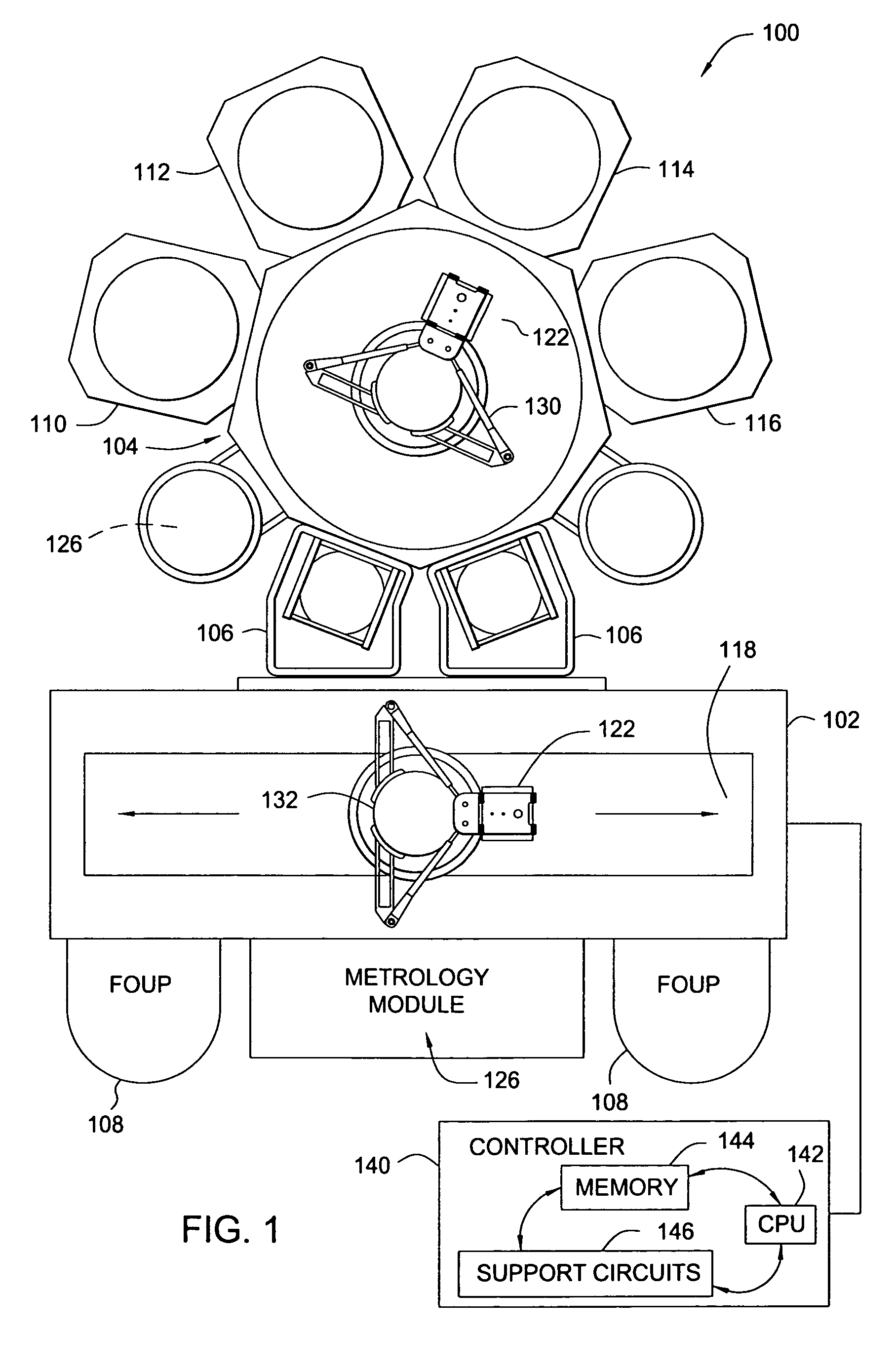

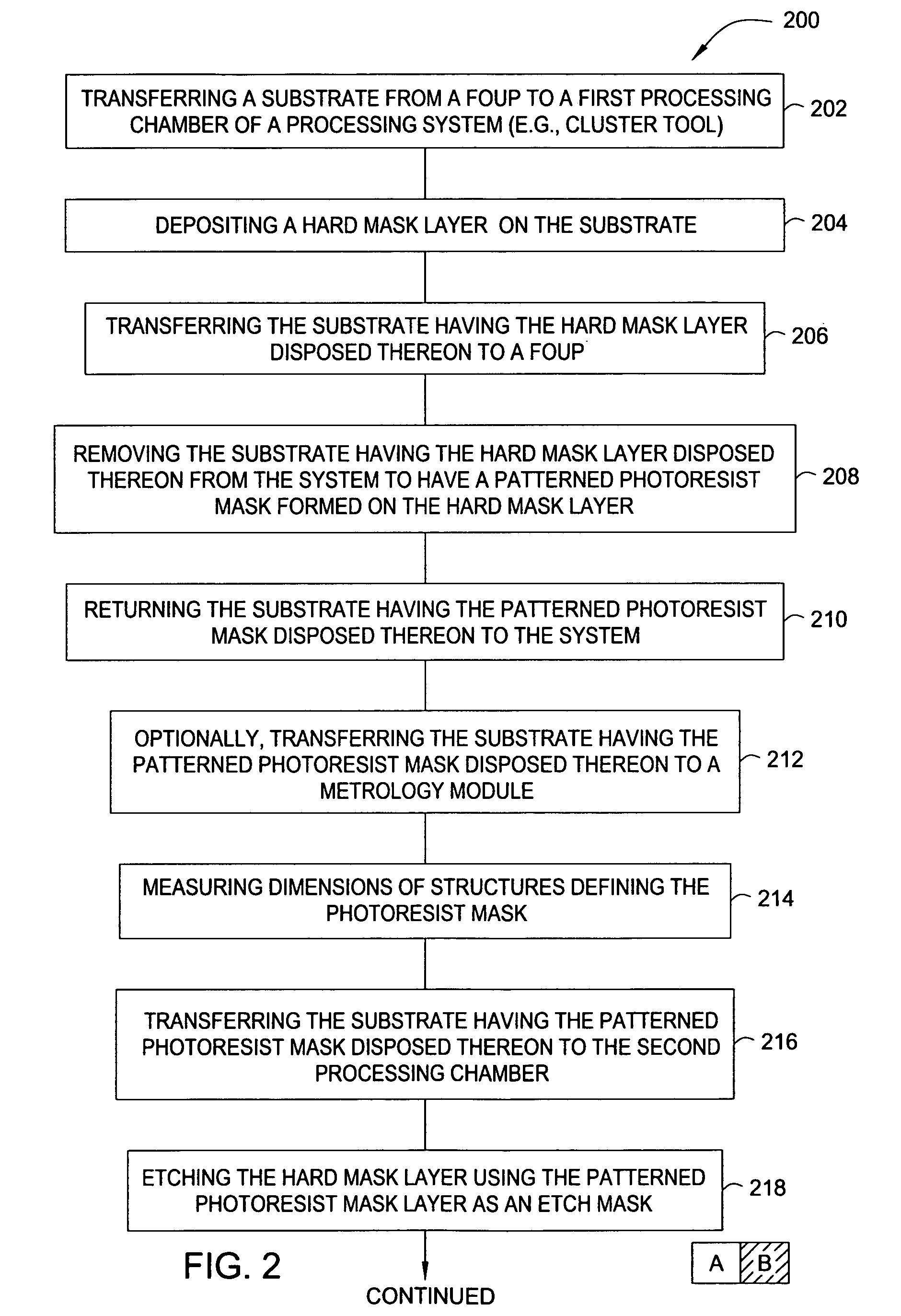

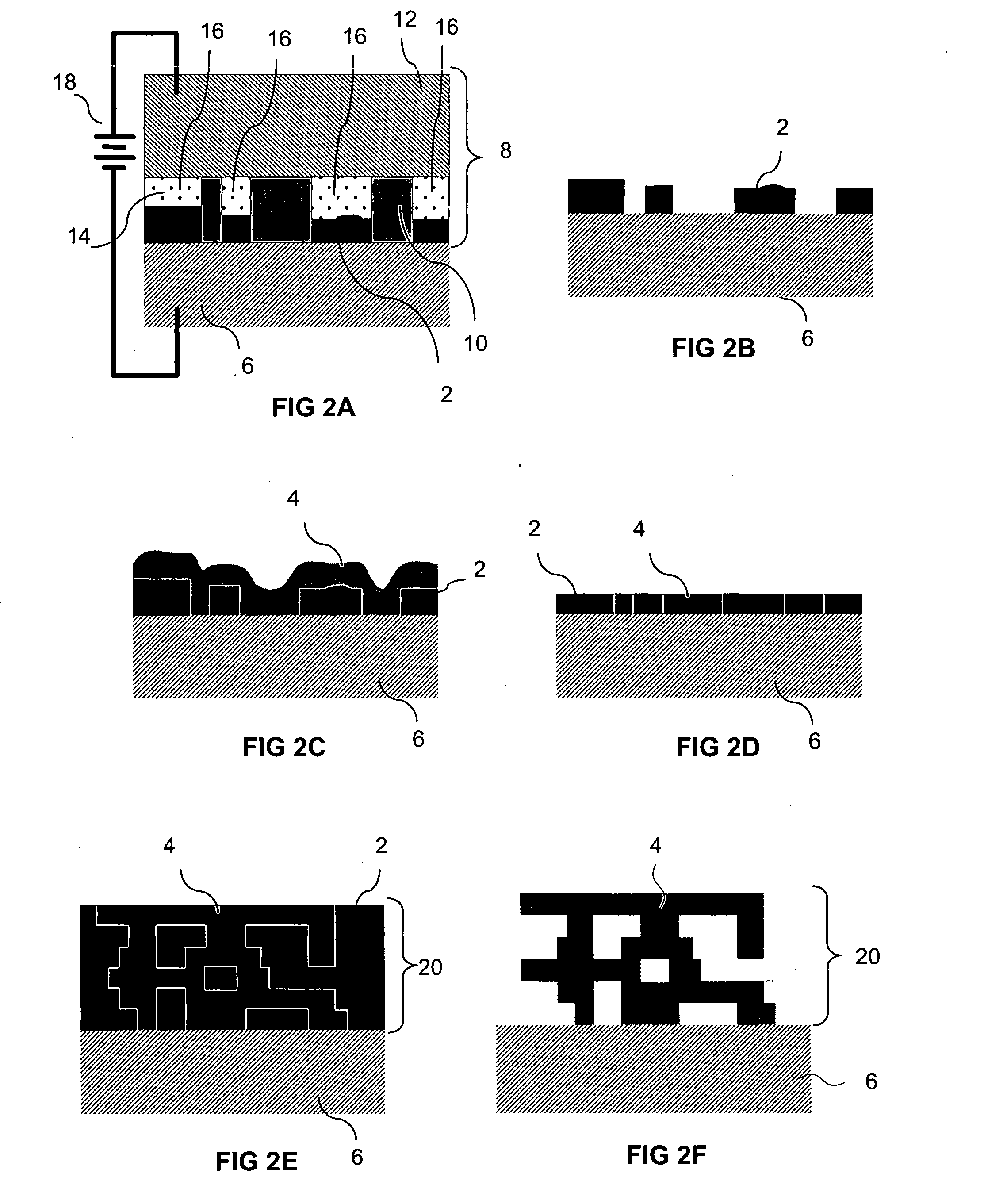

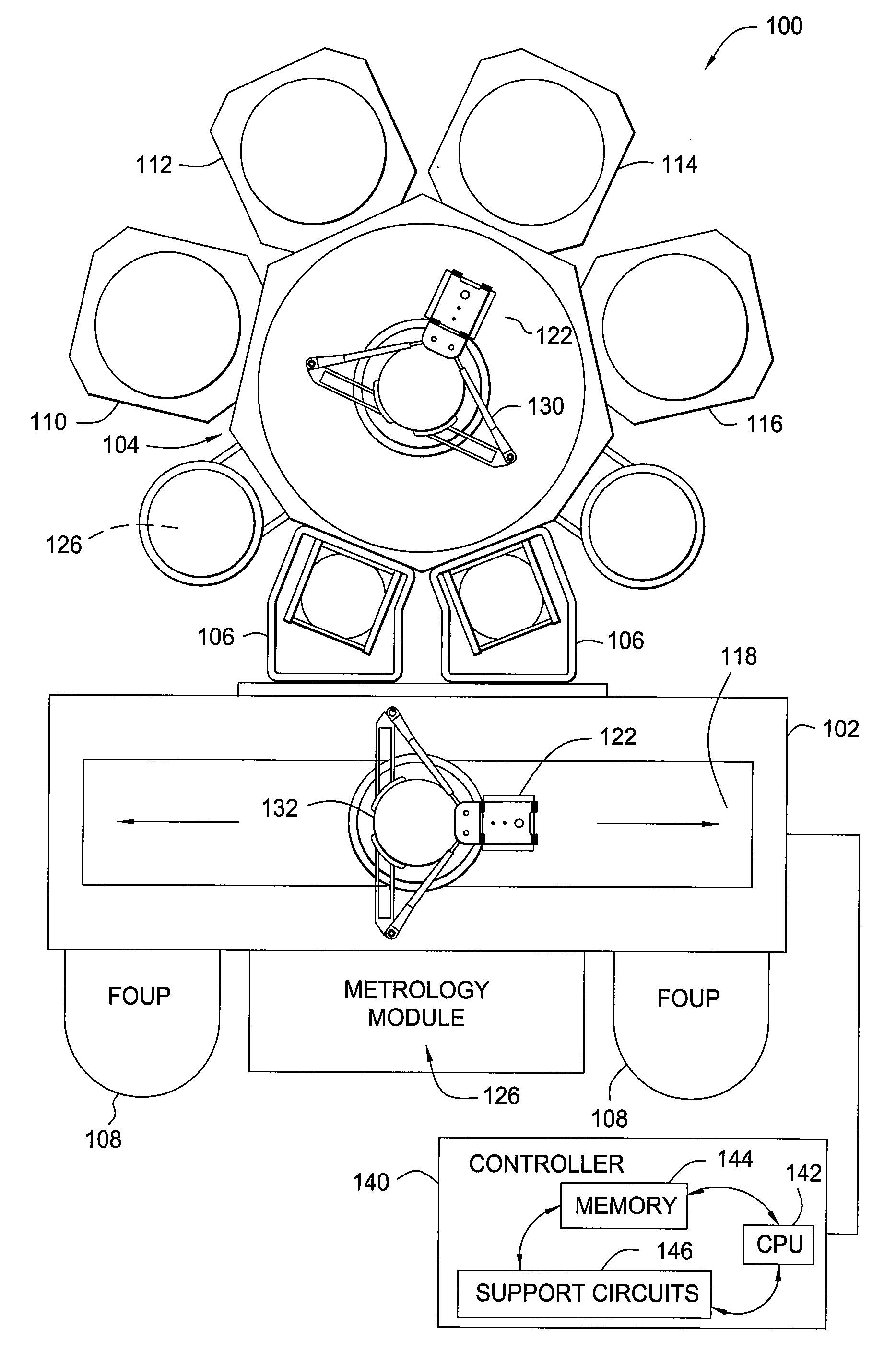

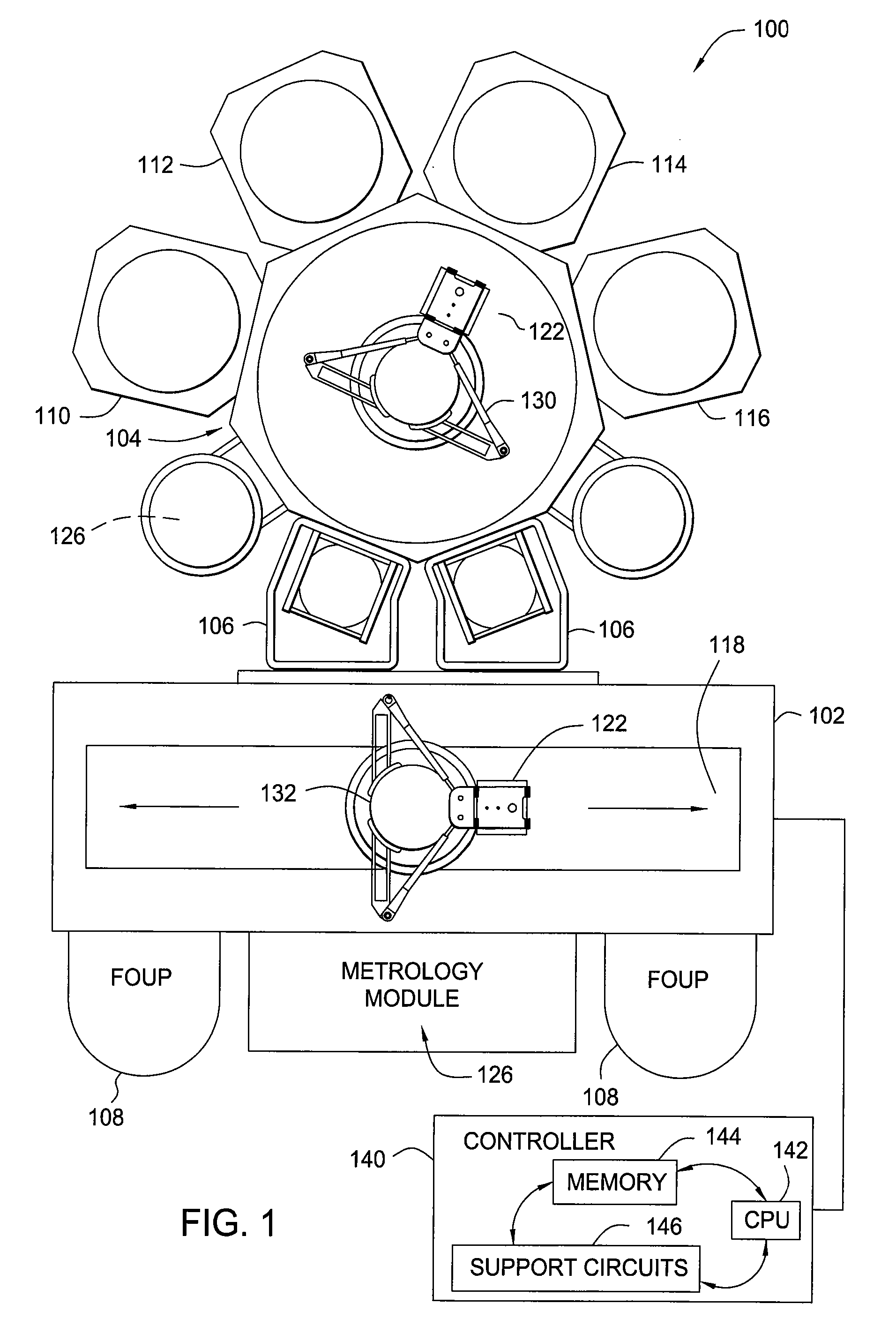

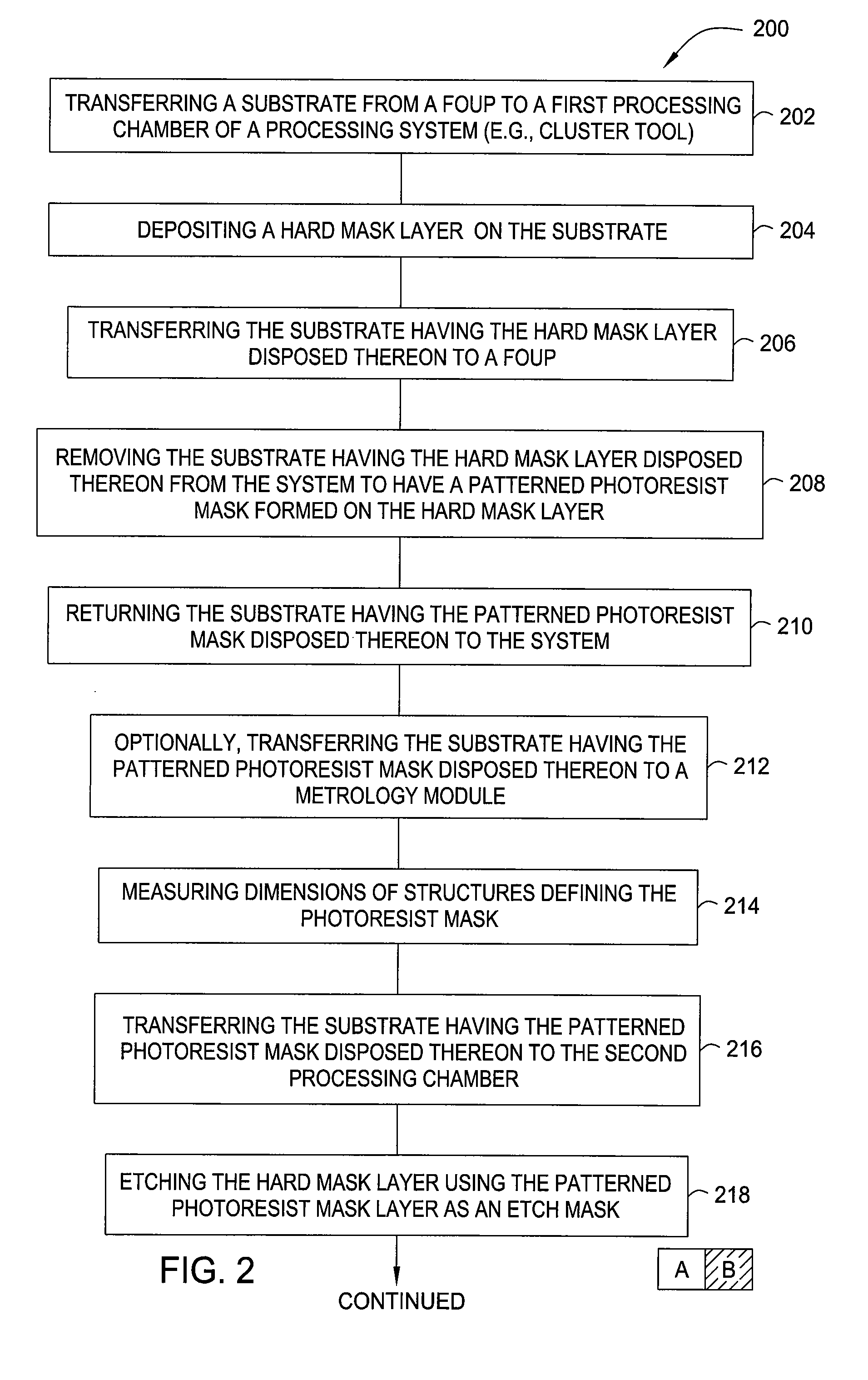

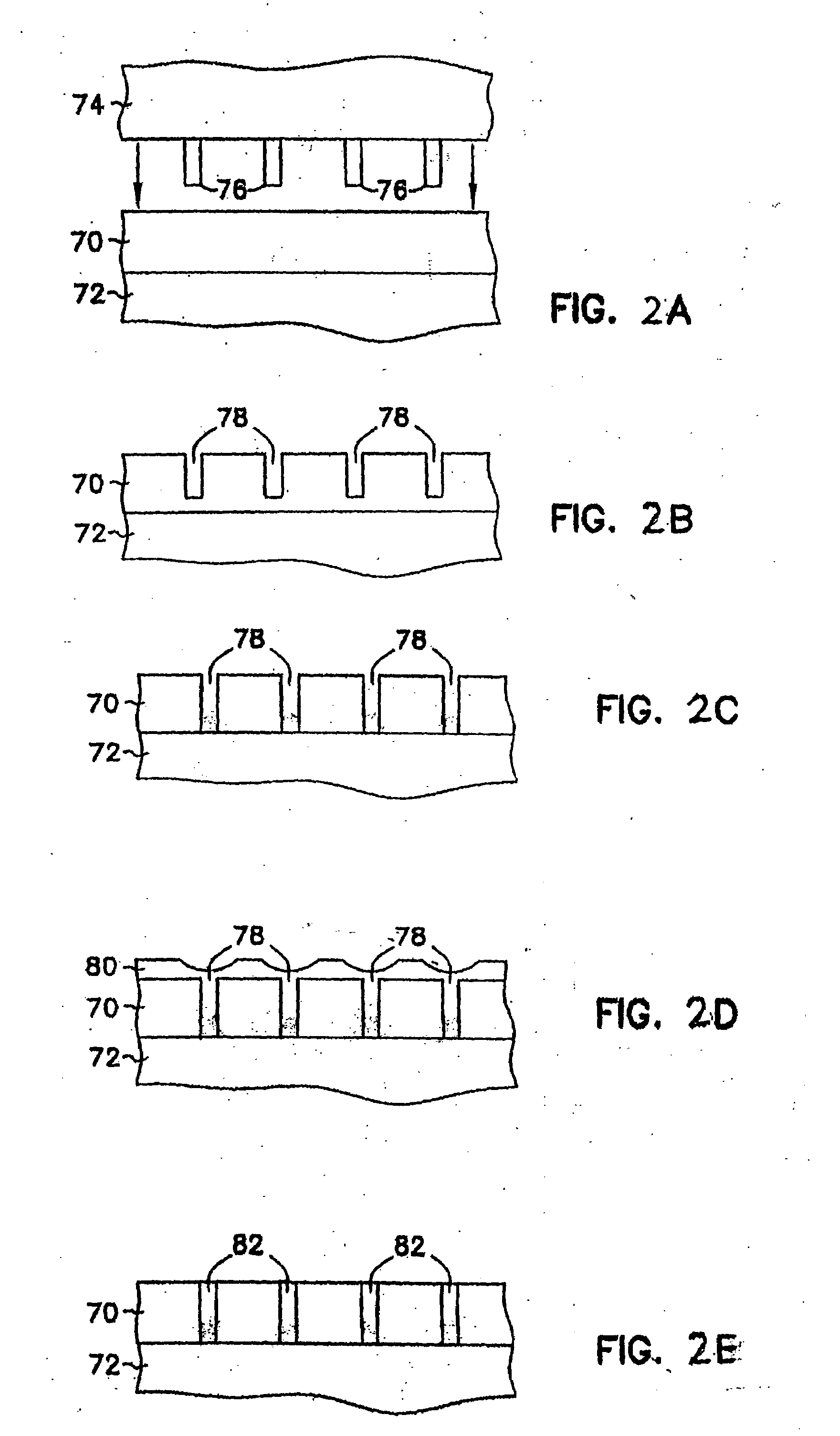

Cluster tool and method for process integration in manufacturing of a photomask

InactiveUS20070026321A1Improve photomask fabricationMinimal financial investmentDecorative surface effectsPhotomechanical apparatusResistProcess integration

A method and apparatus for process integration in manufacture of a photomask are disclosed. In one embodiment, a cluster tool suitable for process integration in manufacture of a photomask including a vacuum transfer chamber having coupled thereto at least one hard mask deposition chamber and at least one plasma chamber configured for etching chromium. In another embodiment, a method for process integration in manufacture of a photomask includes depositing a hard mask on a substrate in a first processing chamber, depositing a resist layer on the substrate, patterning the resist layer, etching the hard mask through apertures formed in the patterned resist layer in a second chamber; and etching a chromium layer through apertures formed in the hard mask in a third chamber.

Owner:APPLIED MATERIALS INC

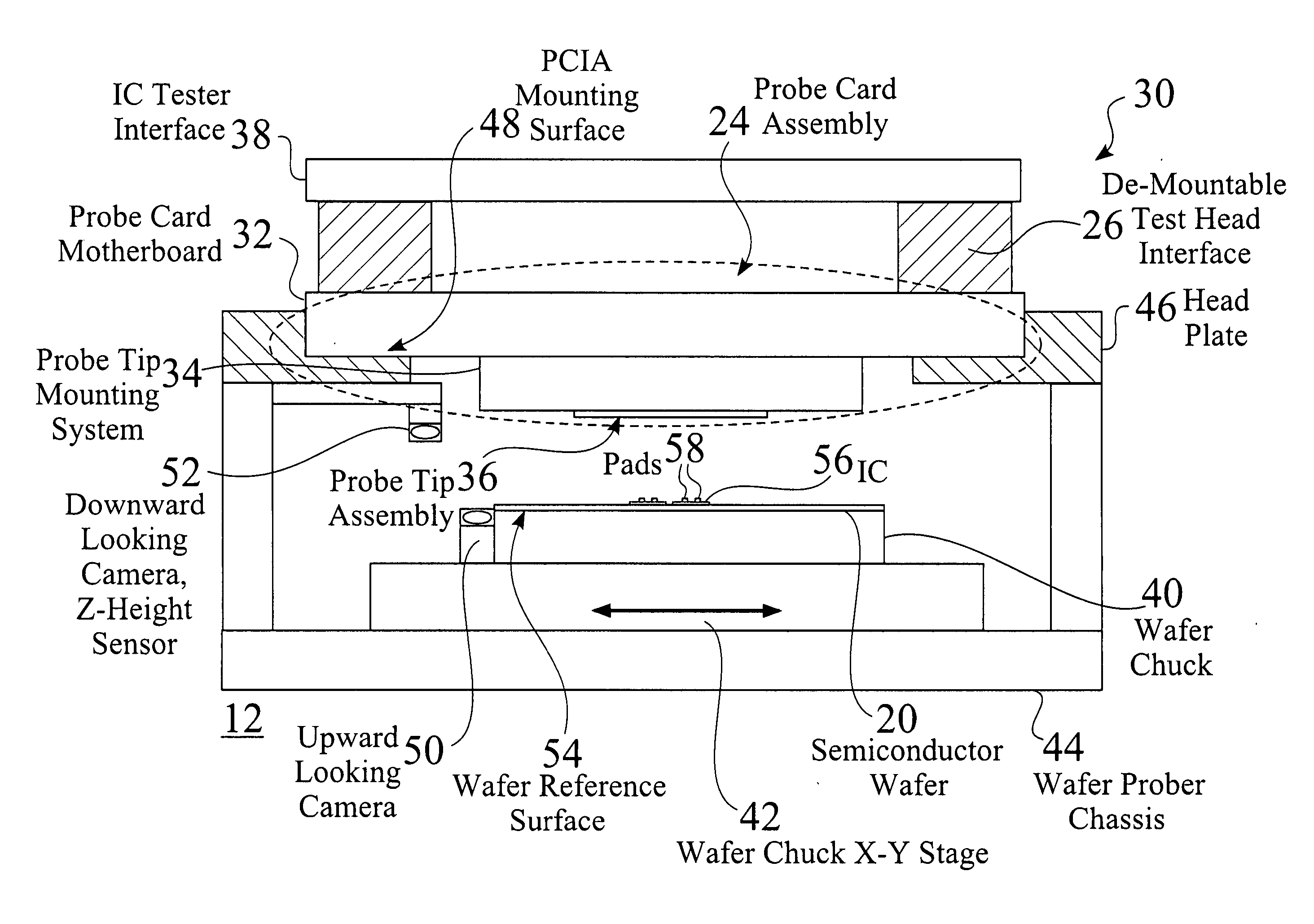

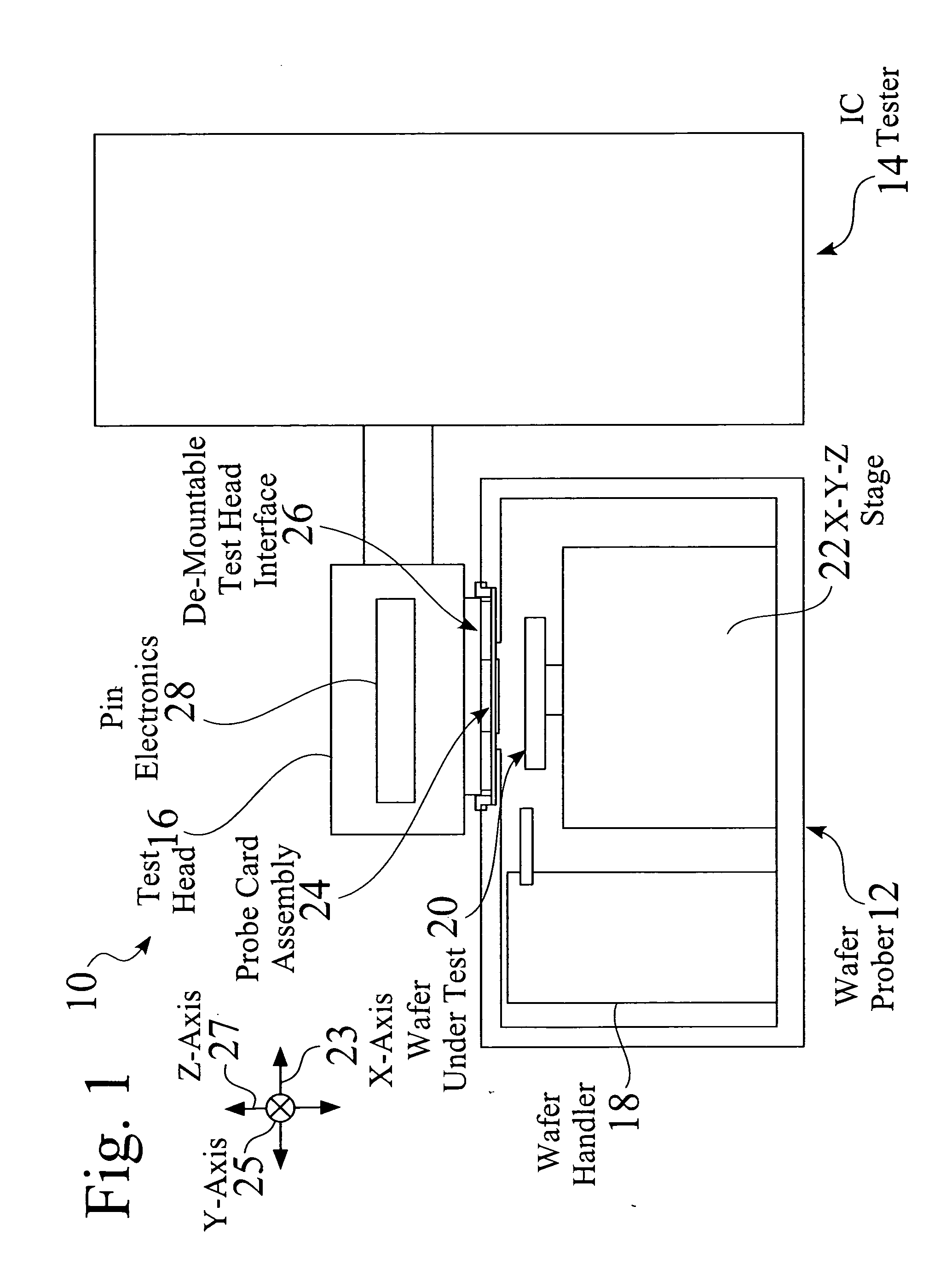

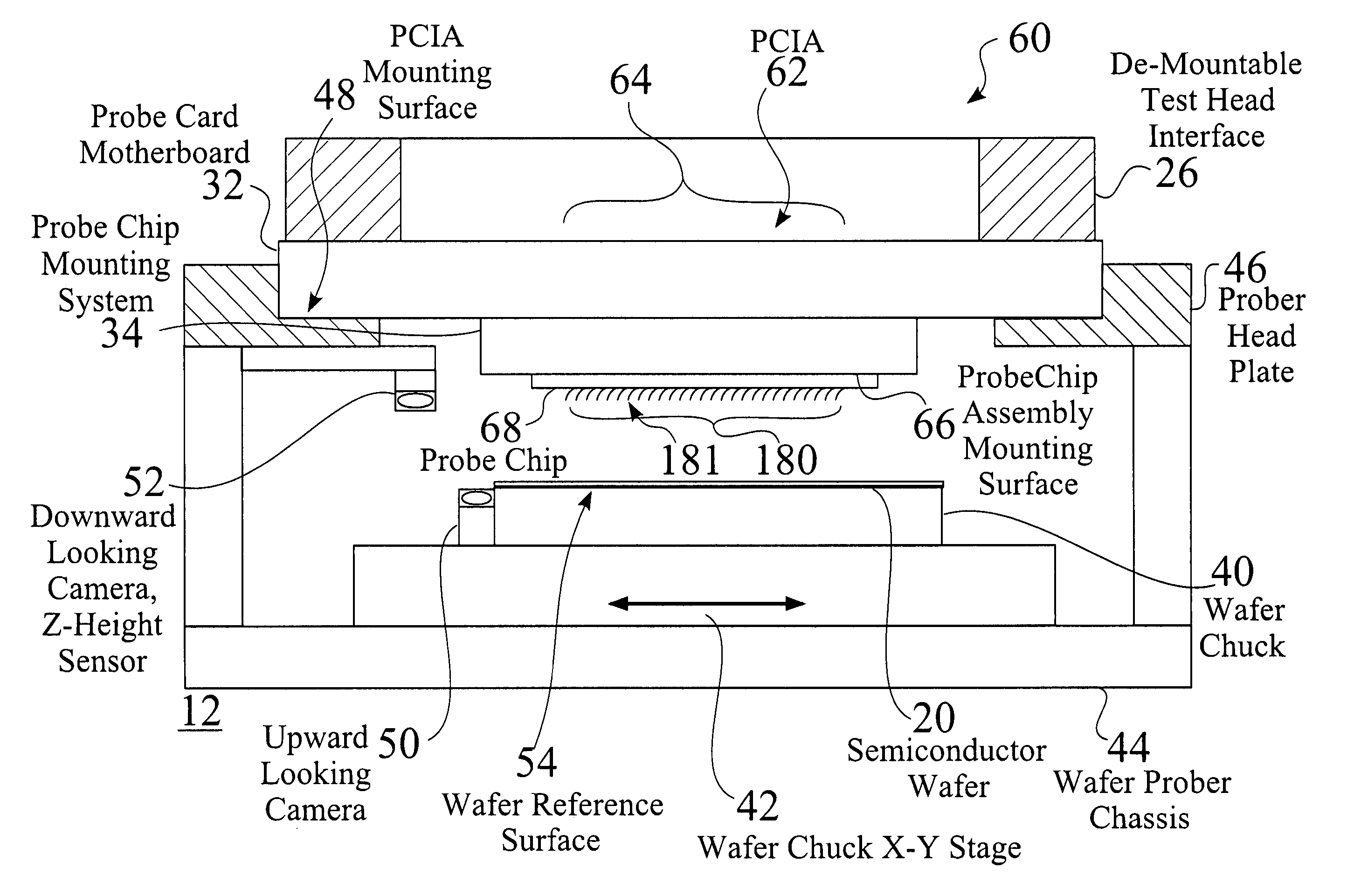

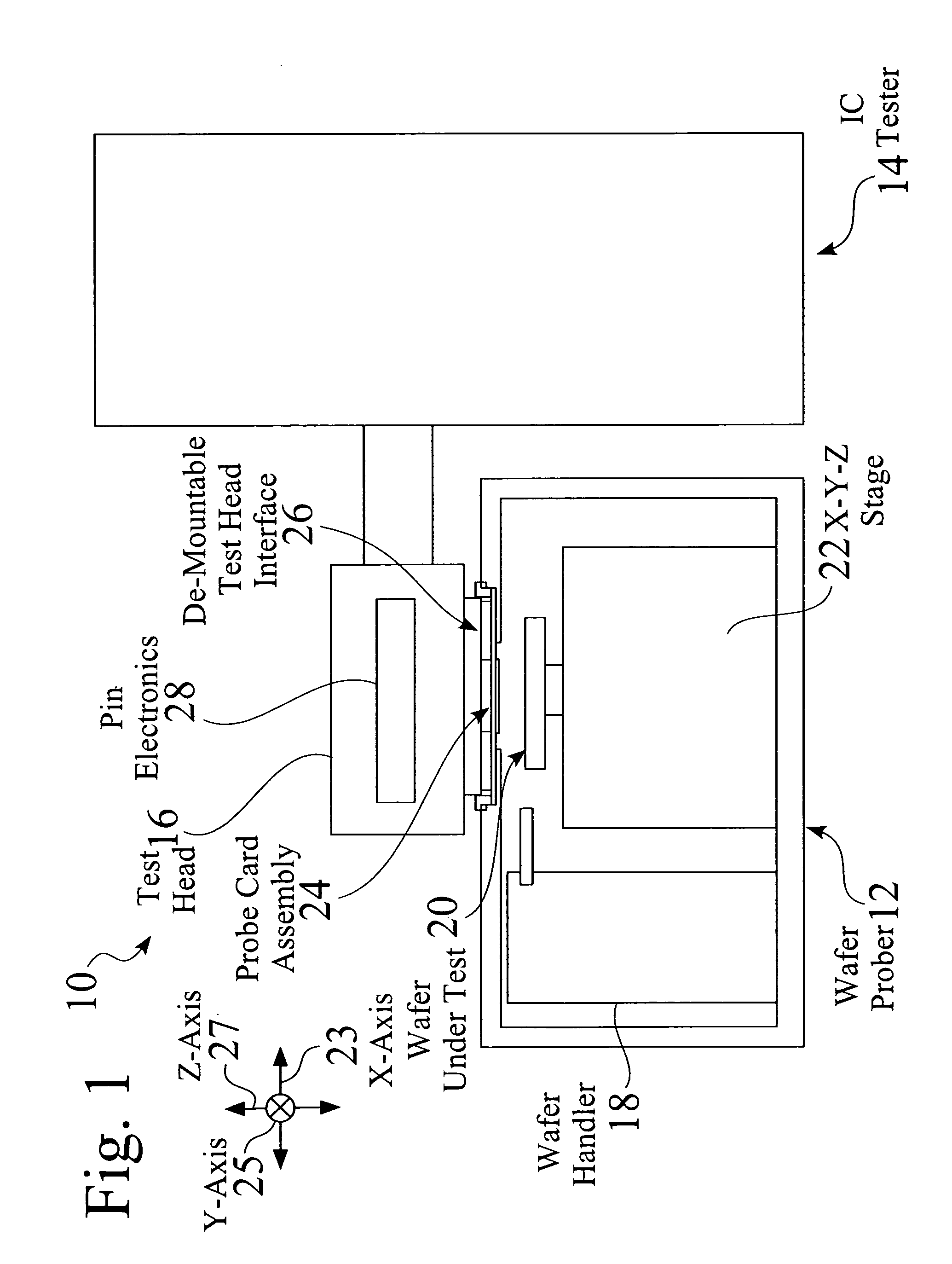

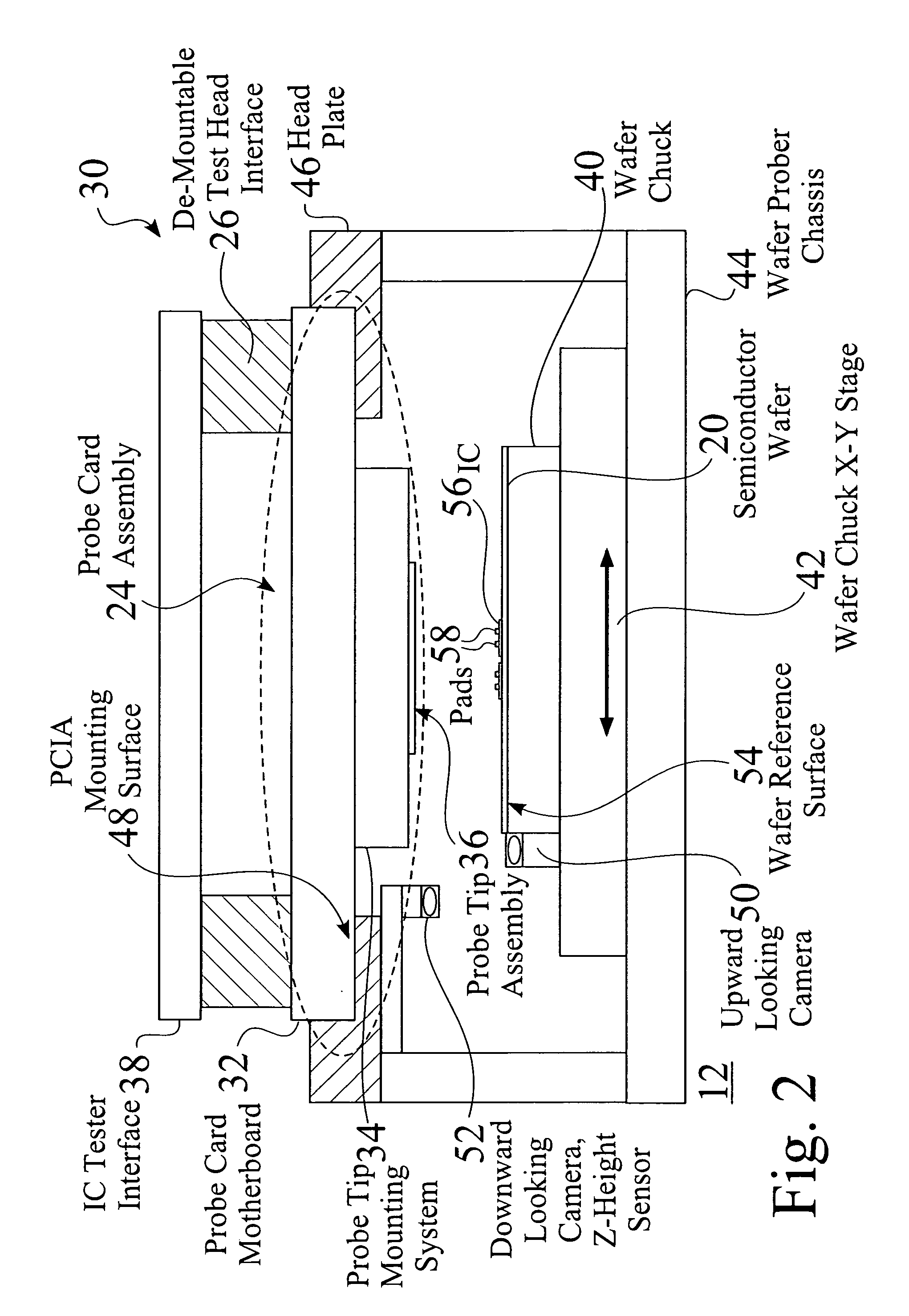

High density interconnect system having rapid fabrication cycle

InactiveUS20050275418A1Added fabricationSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityHigh density

An improved interconnection system and method is described, such as for connectors, socket assemblies and / or probe card systems. An exemplary system comprises a probe card interface assembly (PCIA) for establishing electrical connections to a semiconductor wafer mounted in a prober. The PCIA comprises a motherboard parallel to the semiconductor wafer having an upper surface and an opposing lower planar mounting surface, a reference plane defined by a least three points located between the lower surface of the motherboard and the wafer, at least one component located below the motherboard mounting surface, and a mechanism for adjusting the planarity of the reference plane with respect to the wafer. A probe chip having a plurality of spring probes extending there from is mountable and demountable from the PCIA, without the need for further planarity adjustment. The interconnection structures and methods preferably provide improved fabrication cycles.

Owner:ADVANTEST SINGAPORE PTE LTD

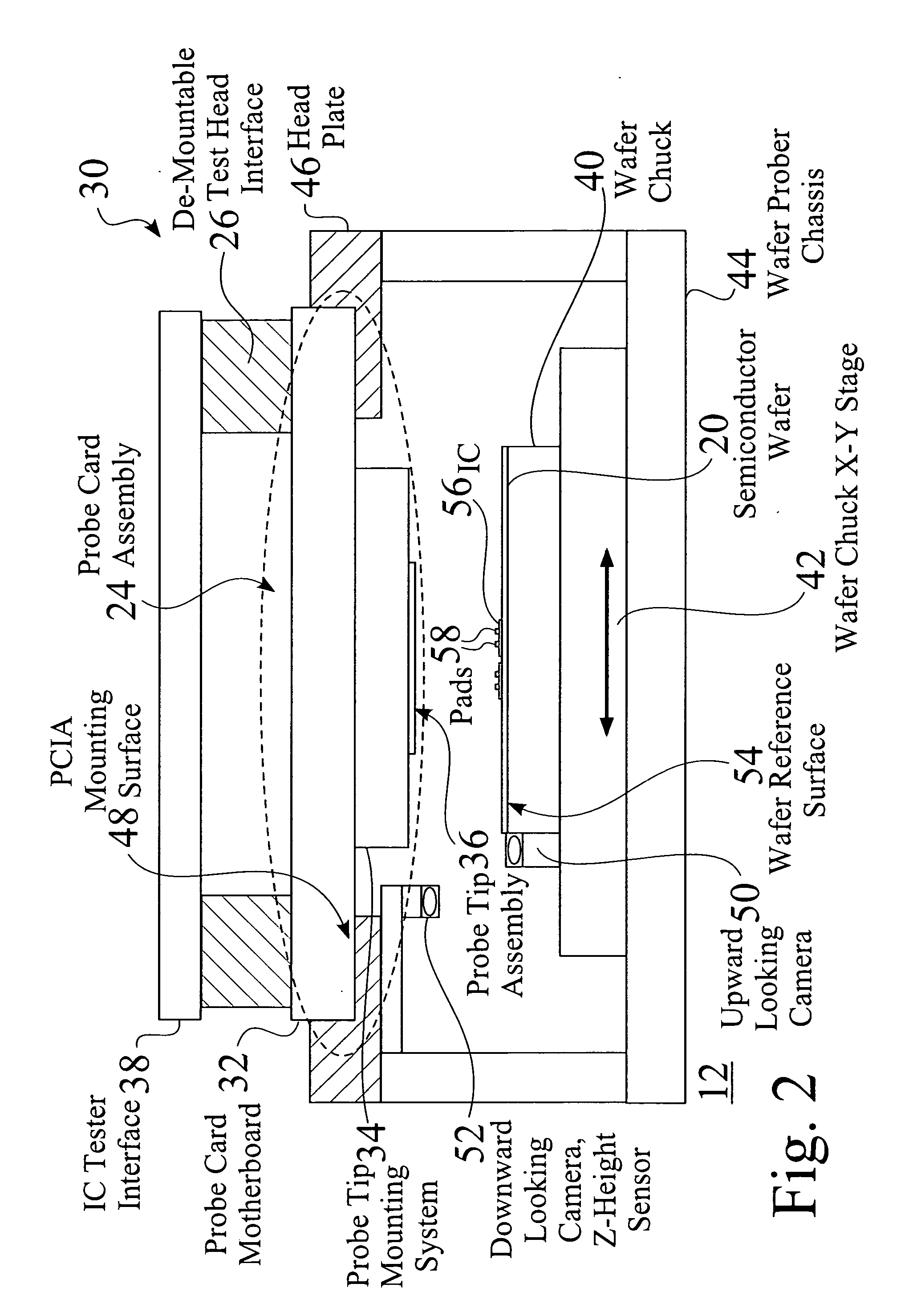

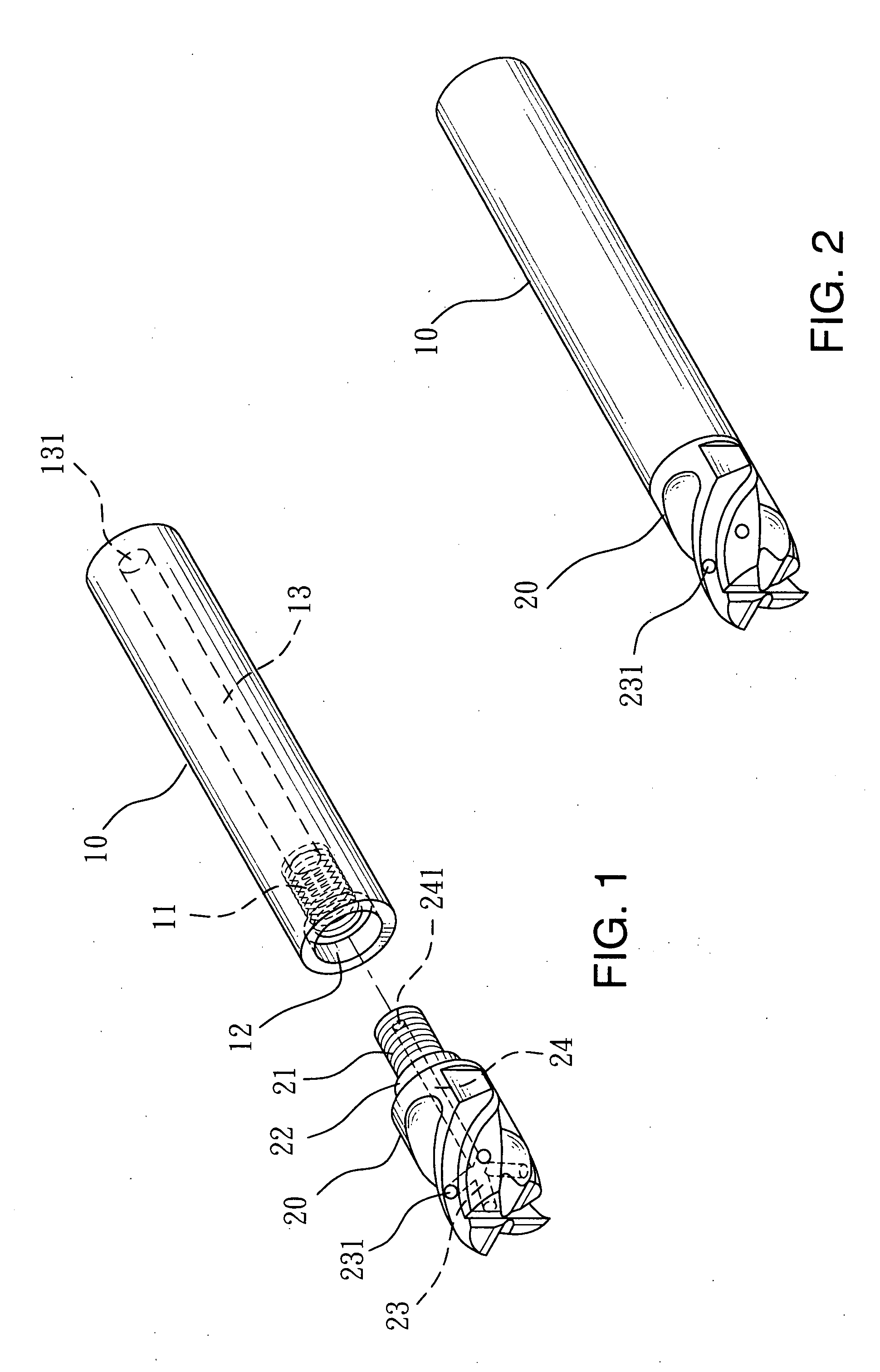

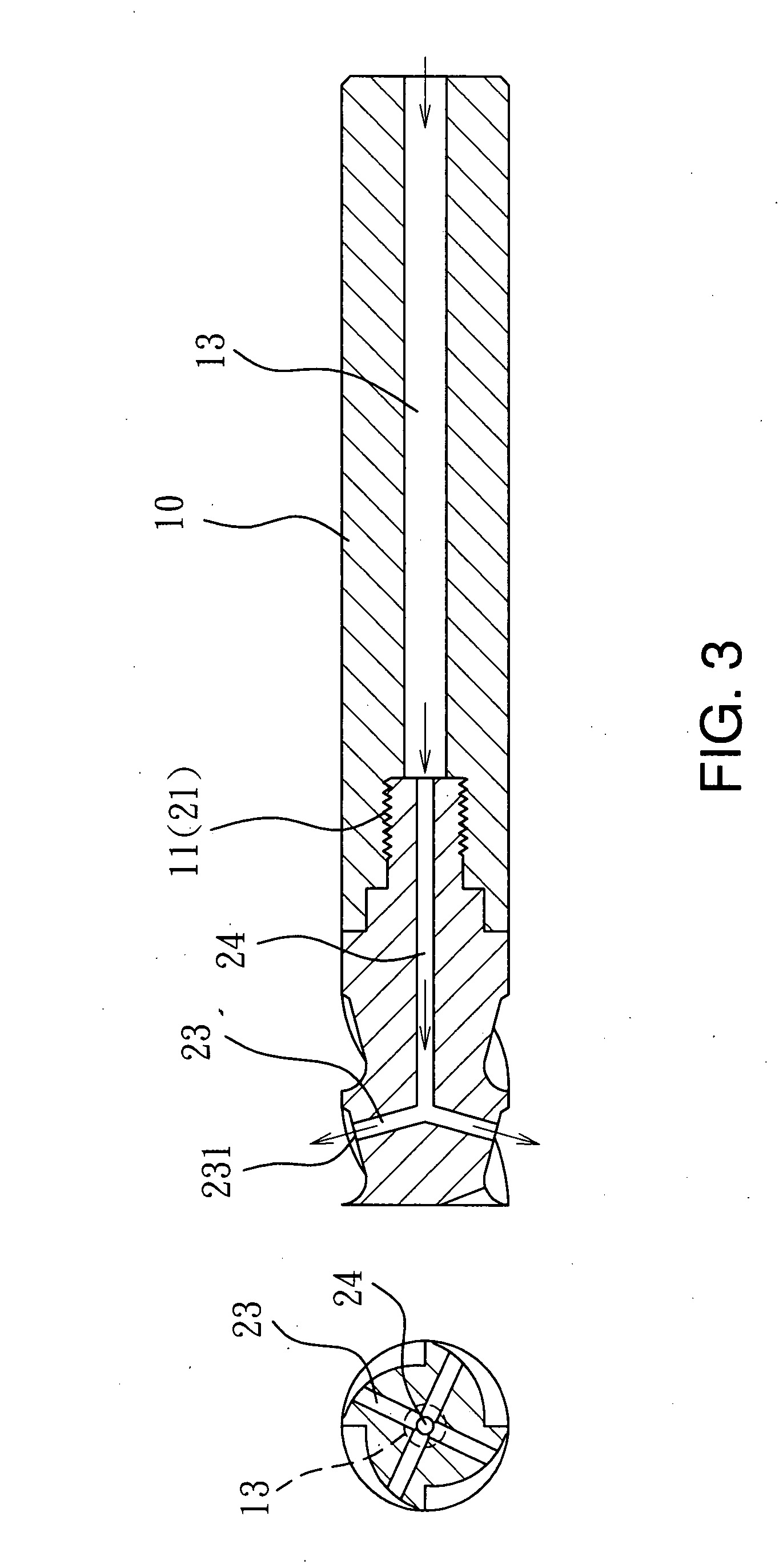

Tungsten steel cutter

InactiveUS20090142150A1Overcomes shortcomingAvoid accumulationWood turning toolsTransportation and packagingWater dischargeCoupling

A tungsten steel cutter which is lower cost to use and can increase fabrication efficiency and improve quality mainly includes a shank and a bit screwing at a front end of the shank. Both are made of tungsten steel and formed in an integrated fashion. The shank has a screw hole at the front end and a coupling trough formed at the front end of the screw hole. The bit has a screw bar extended from the bottom end thereof and a coupling neck at the front section of the screw bar. The coupling trough is formed at a depth same as the height of the coupling neck and the coupling trough and the coupling neck are formed at the same size. The bit and the shank have respectively a water discharge passage and a water drawing passage, and a water intake passage that communicate with each other. The water intake passage is formed at a greater diameter than the water discharge passage and water drawing passage. Thus when the bit and the shank are screwed together, in addition to screw coupling of the screw hole and the screw bar, the coupling trough and the coupling neck also form a tight coupling to minimize gaps that might otherwise happen between them like the conventional ones do. The water discharge passage and water intake passage provide cooling effect for cutting fluid and prevent debris from accumulating on the bit and affecting cutting quality. The invention provides a two-section coupling that can save the cost and improve steadiness and fabrication efficiency of precision tools.

Owner:DHF PRECISION TOOL TRADING

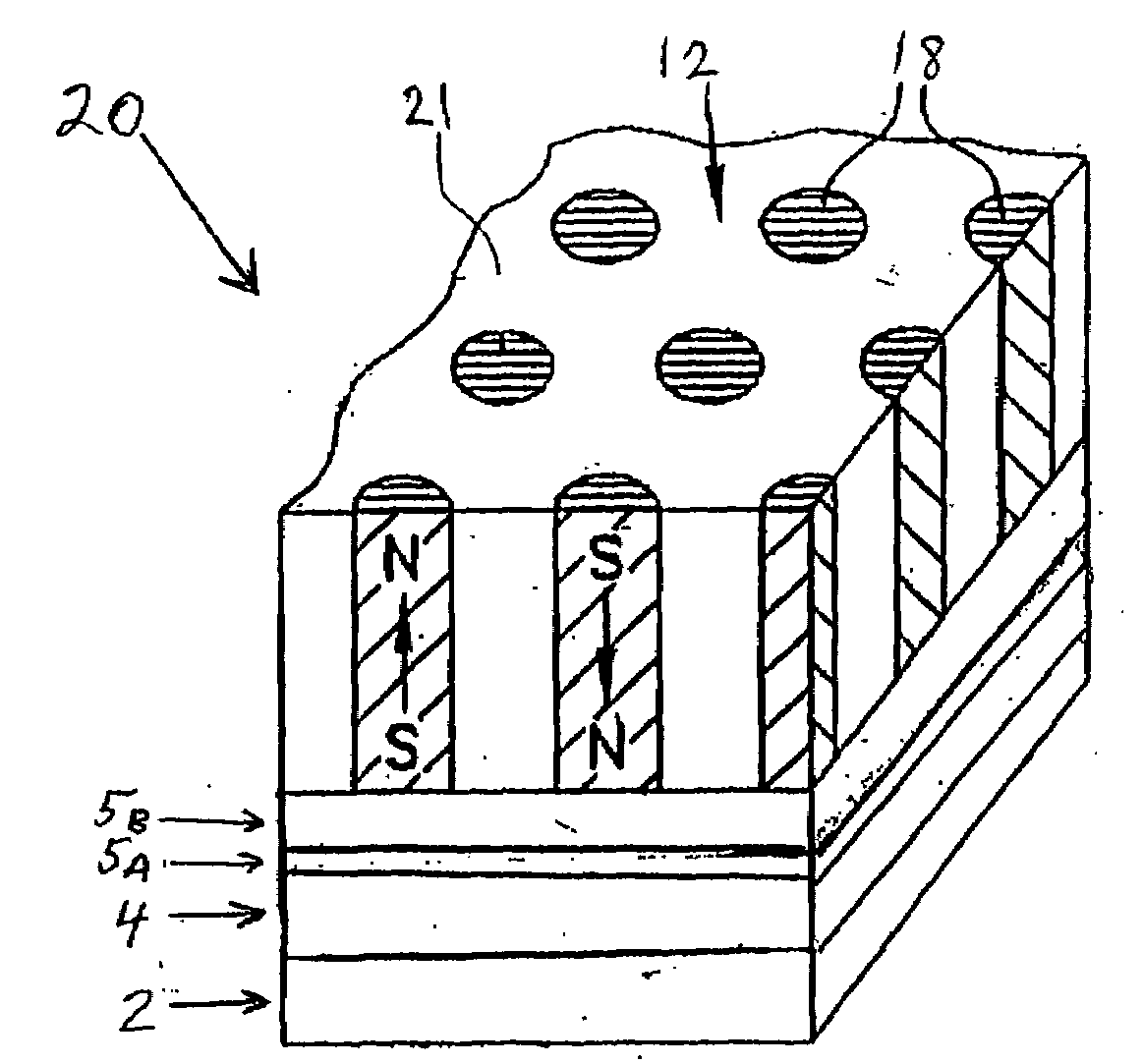

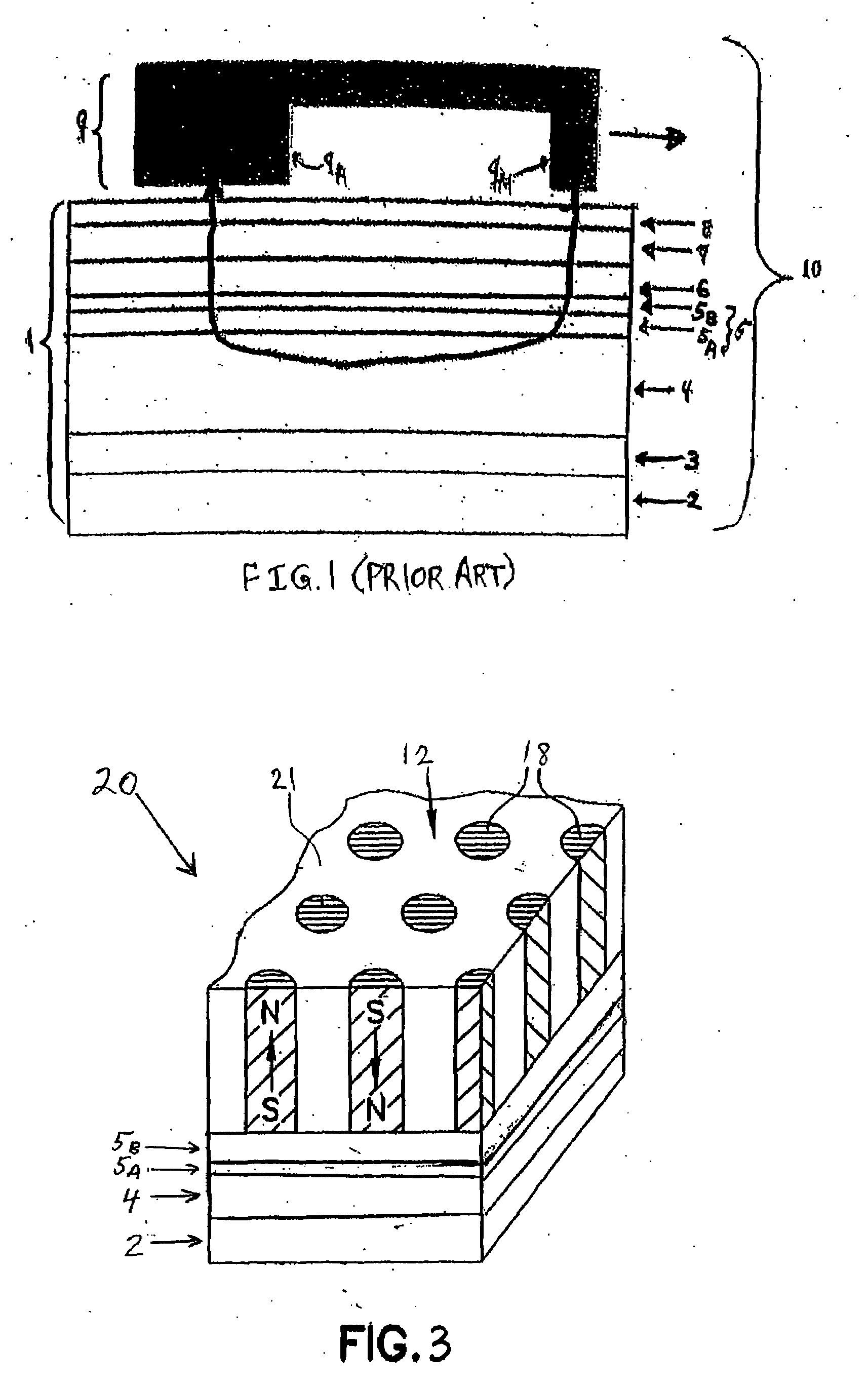

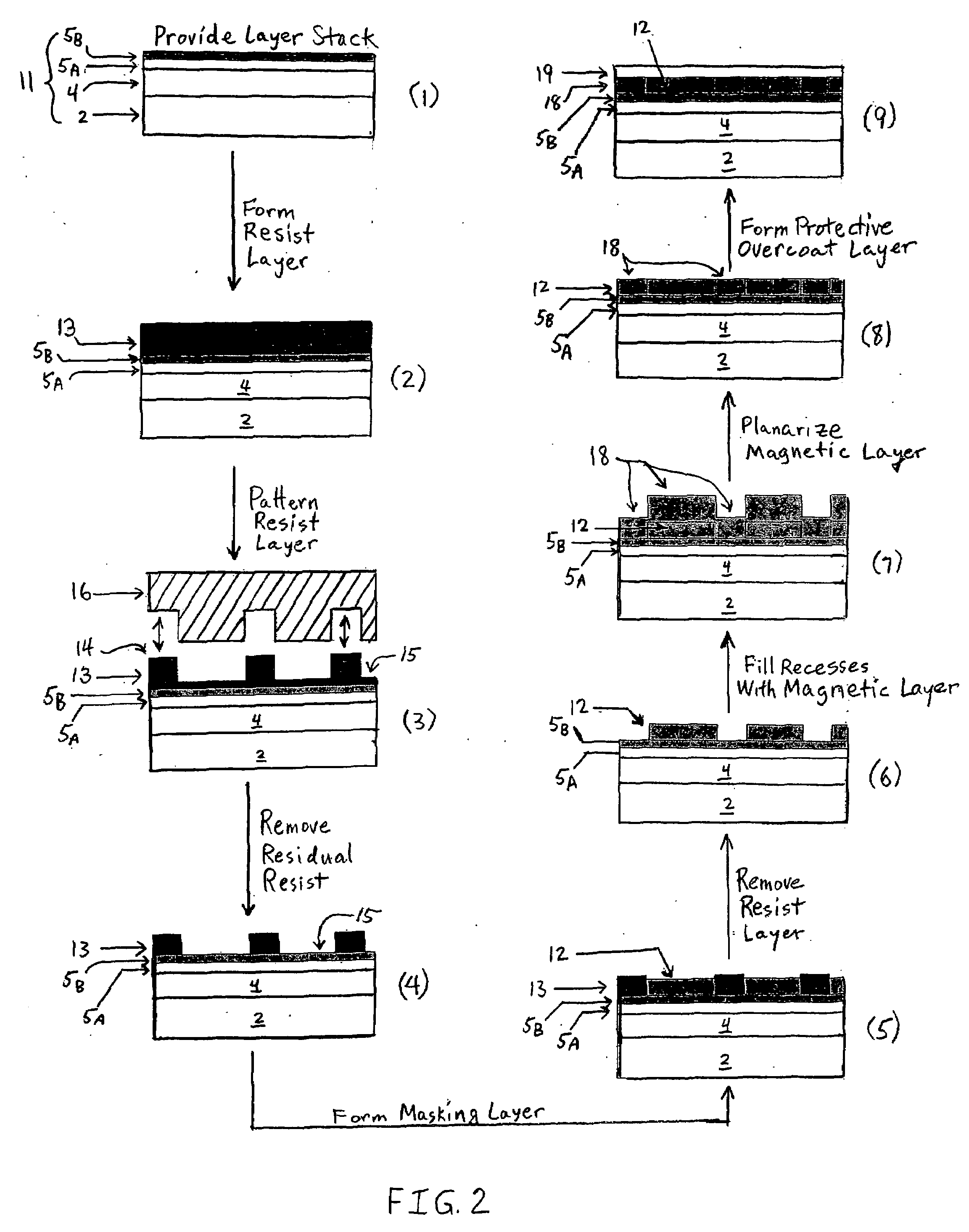

Process for fabricating patterned magnetic recording media

InactiveUS20080093336A1Added fabricationSimple methodDecorative surface effectsRecord information storageResistEngineering

A method of fabricating a patterned magnetic recording medium, comprises steps of: (a) providing a layer stack including an uppermost non-magnetic interlayer; (b) forming a resist layer on the interlayer; (c) forming a first pattern comprising a first group of recesses extending through the resist layer and exposing a first group of spaced apart surface portions of the interlayer; (d) filling the first group of recesses with a layer of a hard mask material; (e) selectively removing the resist layer to form a second pattern comprising a second group of recesses extending through the hard mask layer and exposing a second group of spaced apart surface portions of the interlayer; and (f) filling the second group of recesses with a layer of a magnetically hard material forming a magnetic recording layer.

Owner:SEAGATE TECH LLC

Resistive memory device

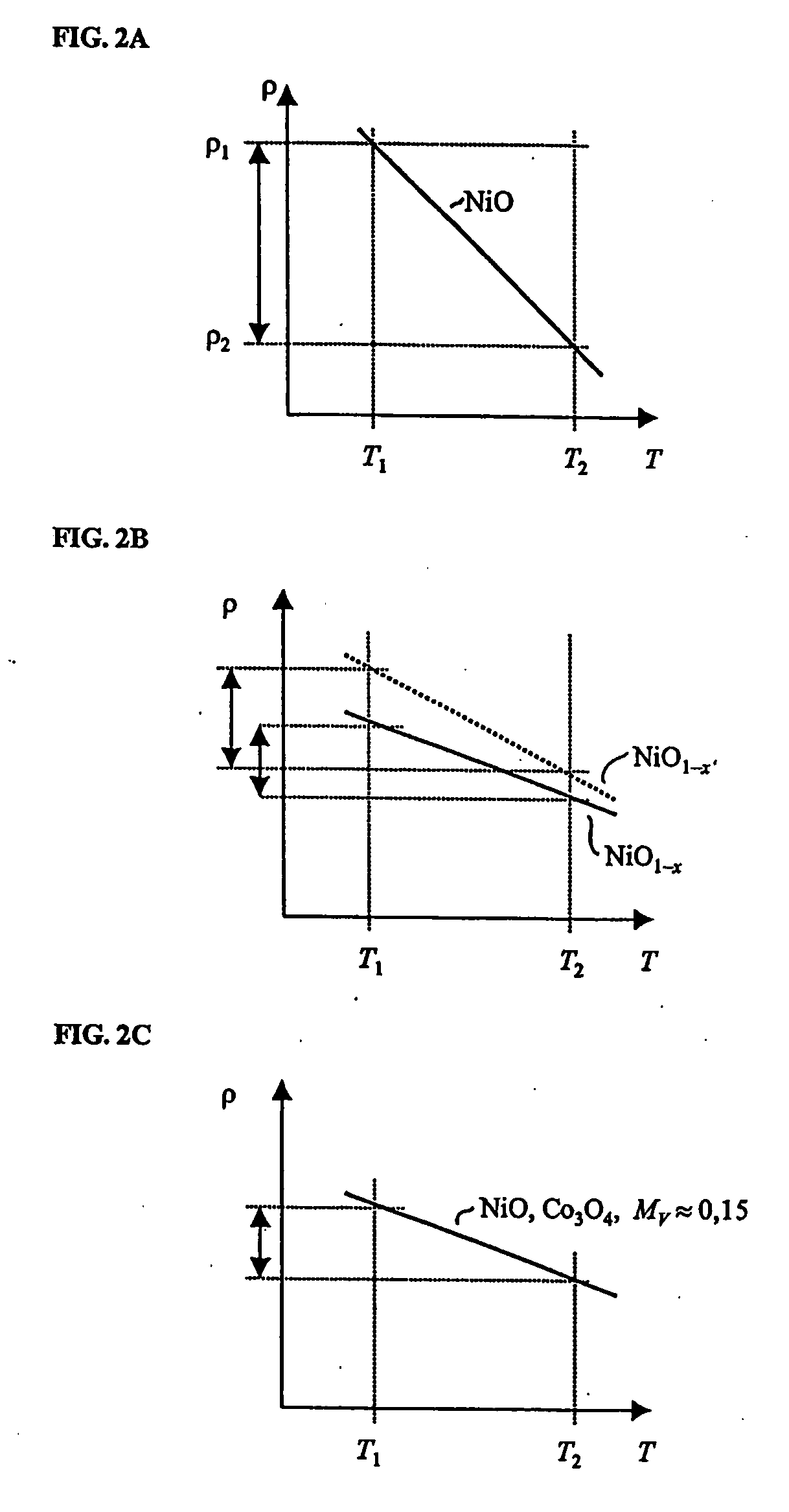

InactiveUS20070267621A1Added fabricationEasy to prepareSolid-state devicesBulk negative resistance effect devicesEngineeringTransition metal

A programmable resistive memory cell comprising a lower electrode, a programmable resistance layer, and an upper electrode, wherein the programmable resistance layer comprises a first transition metal oxide and a second transition metal oxide.

Owner:INFINEON TECH AG

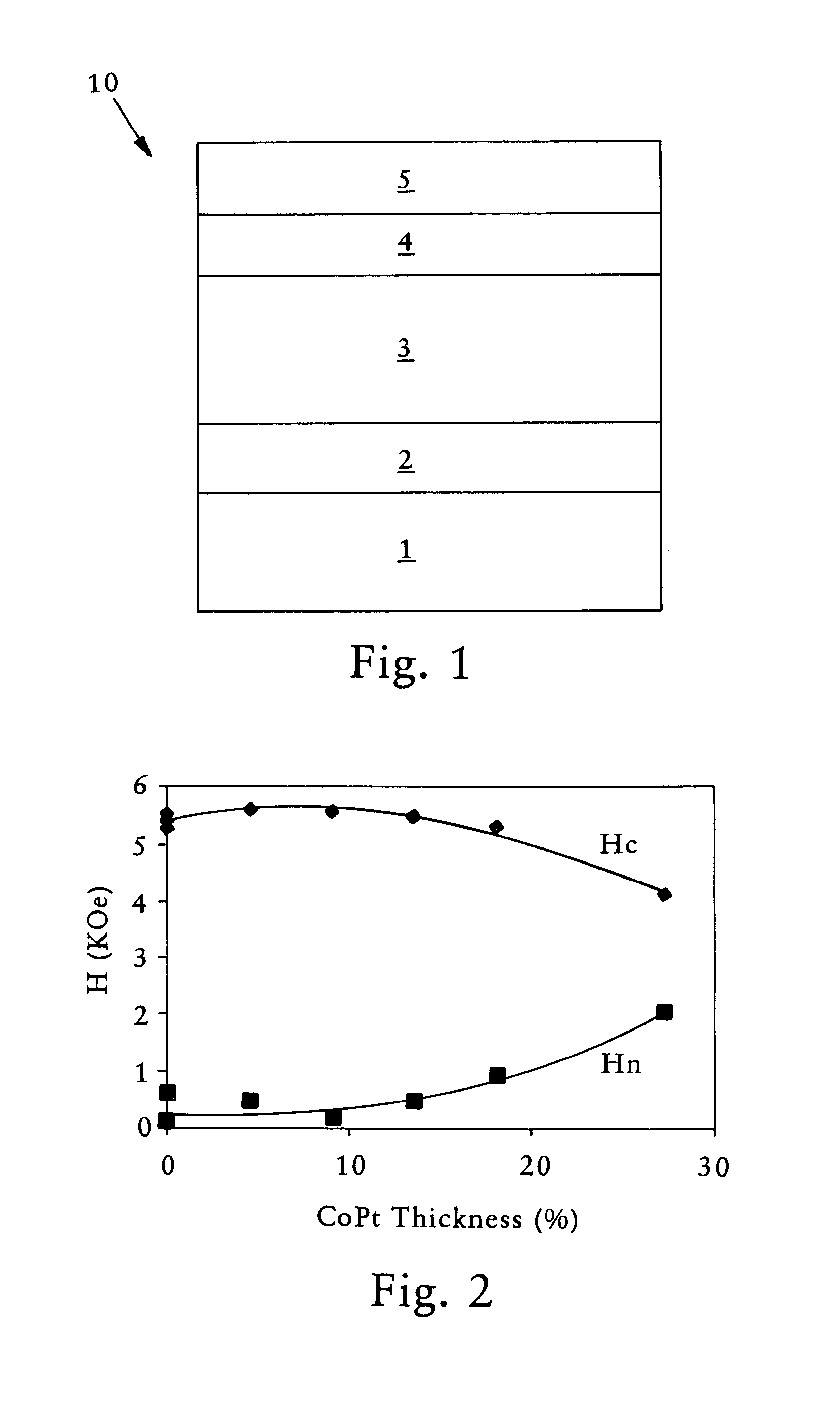

Magnetic recording media with tuned exchange coupling and method for fabricating same

ActiveUS7384699B2Improved perpendicular magnetic recording mediaImproved longitudinal magnetic recording mediaRecord information storageMagnetic recordingCouplingNon magnetic

A magnetic recording medium with tuned exchange coupling comprises:(a) a non-magnetic substrate having a surface; and(b) a stack of thin film layers on the substrate surface, including:(i) a compositionally segregated, exchange decoupled magnetic layer with substantially non-magnetic grain boundaries; and(ii) an exchange coupled magnetic layer adjacent to and in direct contact with the exchange decoupled magnetic layer.

Owner:SEAGATE TECH LLC

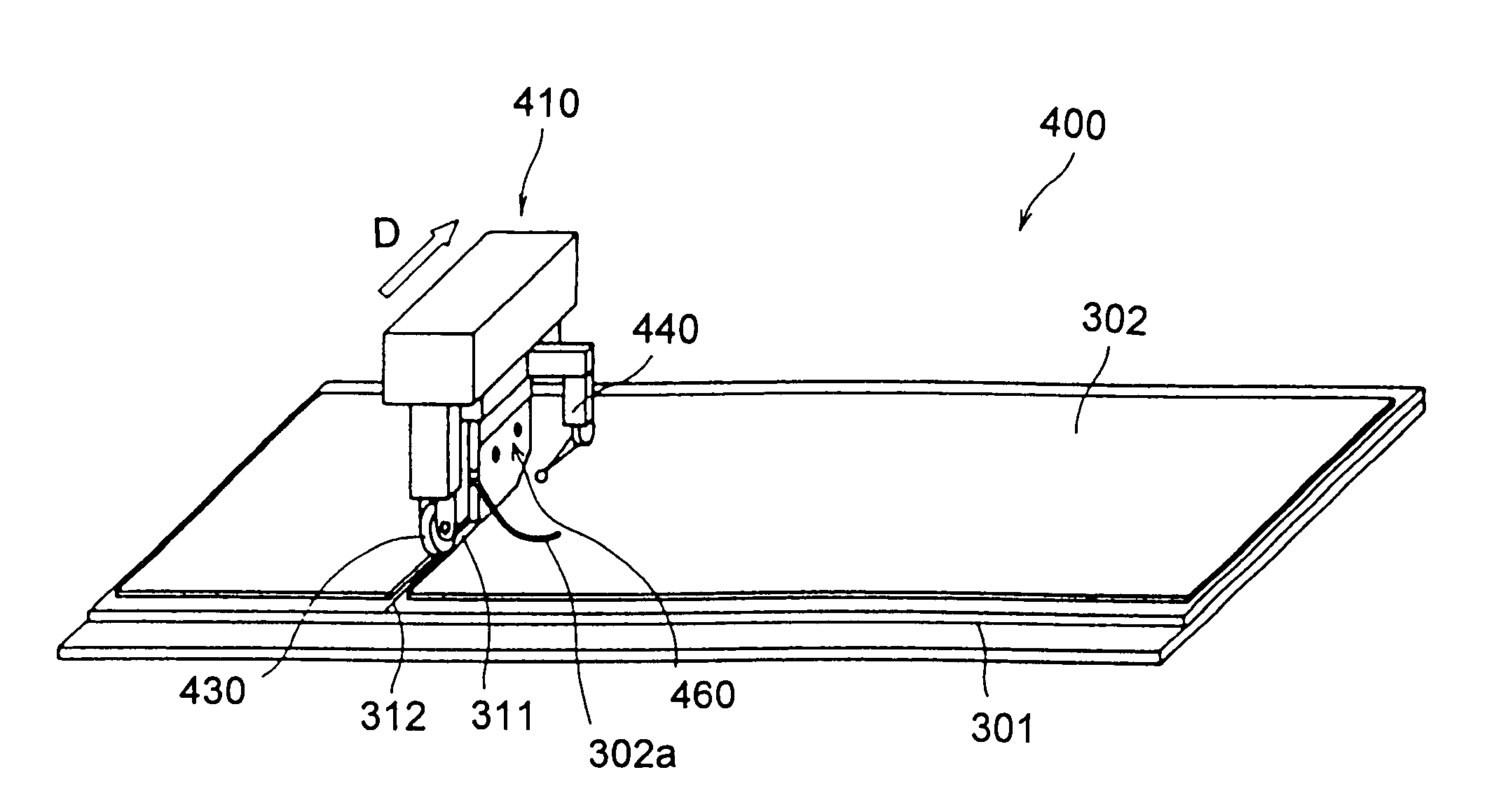

Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device

InactiveUS7553390B2Added fabricationLiquid crystal compositionsPaper-makingCrystallographyCutting glass

A method for cutting apart a glass substrate is provided whereby scribing of the glass substrate is possible without being affected by the presence or thickness of a deposited film formed thereon and without scratching the deposited film. To treat a glass substrate having a deposited film, such as a thin film or resin film, formed on one surface thereof, there are provided a shaving device, which is a blade that removes strip-shaped portions of the deposited film to expose strip-shaped regions on the glass substrate, and a wheel cutter that forms scribed lines along the strip-shaped regions exposed on the glass substrate. The glass substrate is cut apart along the scribed lines.

Owner:SHARP KK +1

System, method and apparatus for improved electrical-to-optical transmitters disposed within printed circuit boards

InactiveUS7112885B2Improve electrical-to-optical transmittersSimple and reliable processCircuit optical detailsSemiconductor/solid-state device detailsCommunications systemConductive materials

The present invention provides a system, method and apparatus for improved electrical-to-optical transmitters (100) disposed within printed circuit boards (104). The heat sink (110, 200) is a thermal conductive material disposed within a cavity (102) of the printed circuit board (104) and is thermally coupled to a bottom surface (112) of the electrical-to-optical transmitter (100). A portion of the thermal conductive material extends approximately to an outer surface (120, 122 or 124) of a layer (114, 116 or 118) of the printed circuit board (104). The printed circuit board may comprise a planarized signal communications system or an optoelectronic signal communications system. In addition, the present invention provides a method for fabricating the heat sink wherein the electrical-to-optical transmitter disposed within a cavity of the printed circuit board is fabricated. New methods for flexible waveguides and micro-mirror couplers are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

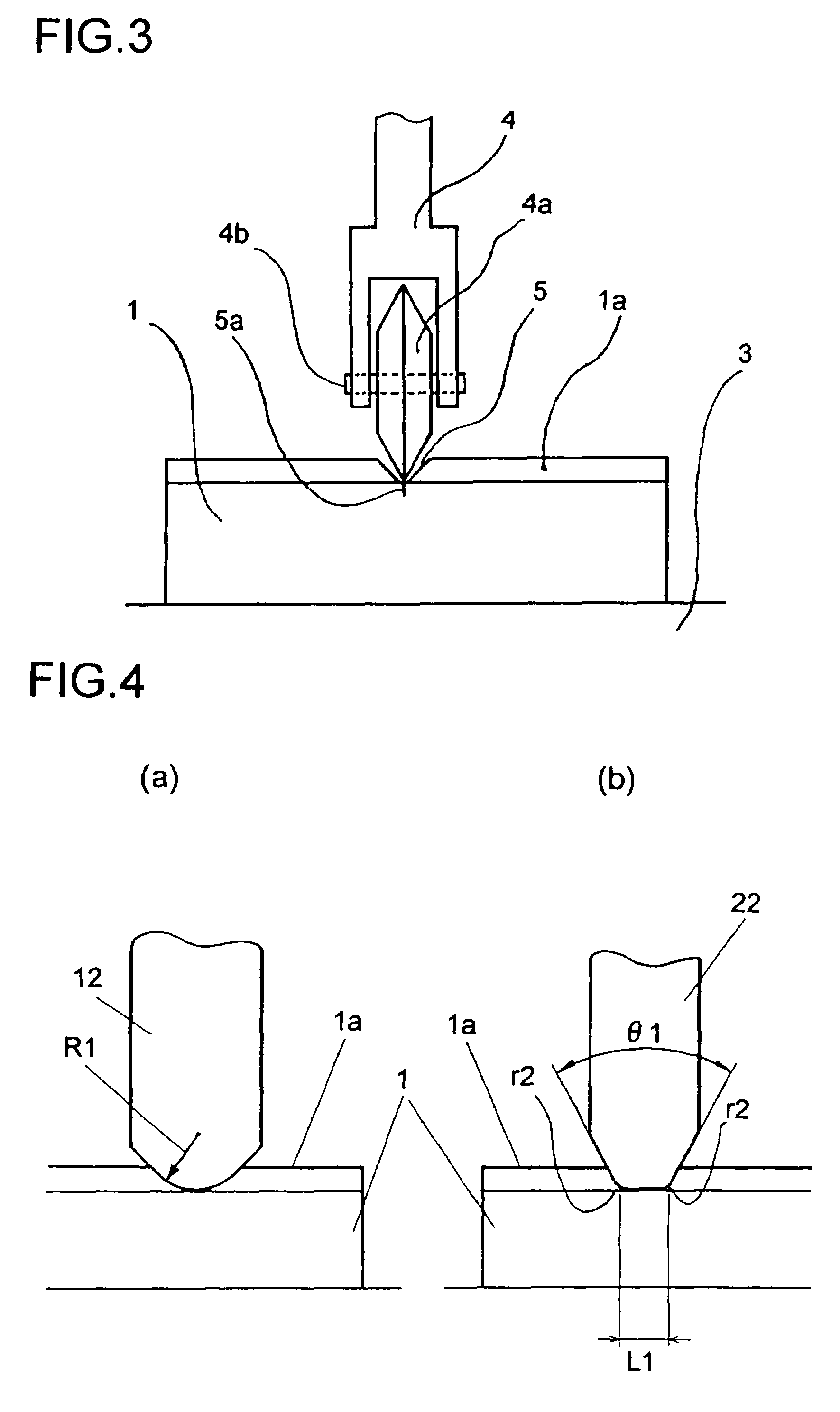

Device and method for large area lithography

ActiveUS20070018362A1Added fabricationEqually distributedNanoinformaticsConfectionerySurface layerBiomedical engineering

Apparatus and method for transferring a pattern from a template (10) having a structured surface to a substrate (12) carrying a surface layer of a radiation polymerisable fluid (14). The apparatus comprises a first main part (101) and a second main part (102) having opposing surfaces (104; 105), means for adjusting a spacing (115) between said main parts, support means (106) for supporting said template and substrate in mutual parallel engagement in said spacing with said structured surface facing said surface layer, a radiation source (110) devised to emit radiation into said spacing. A cavity (115) has a first wall comprising a flexible membrane (113) devised to engage said template or substrate, and means (114; 116) are provided for applying an adjustable overpressure to a medium present in said cavity, whereby an even distribution of force is obtained over the whole of the contact surface between the substrate and the template.

Owner:OBDUCAT AB SE

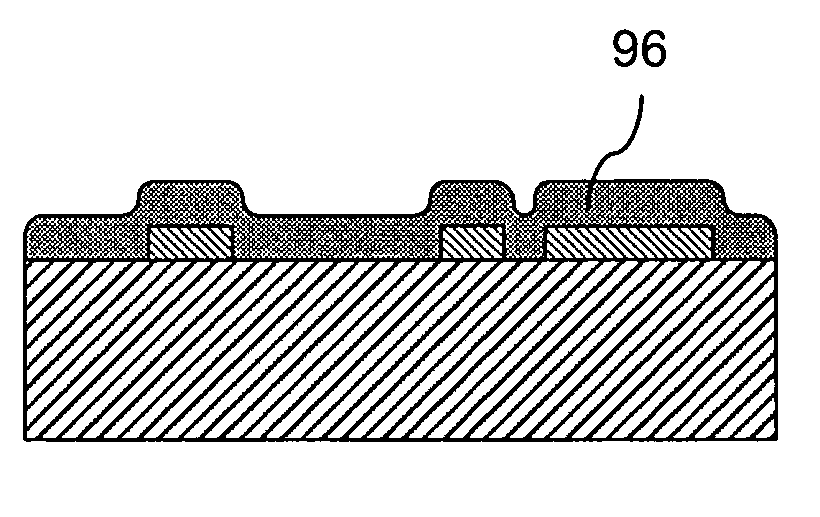

Field-effect semiconductor device and method of fabrication

InactiveUS20080303064A1Efficient manufacturingEasy to controlTransistorSemiconductor/solid-state device manufacturingHeterojunctionSemiconductor materials

After creating an electron transit layer on a substrate, a baffle is formed on midpart of the surface of the electron transit layer, the surface having a pair of spaced-apart parts left on both sides of the baffle. A semiconducting material different from that of the electron transit layer is deposited on its surface thereby conjointly fabricating an electron supply layer grown continuously on the pair of spaced-apart parts of the electron transit layer surface, and a discontinuous growth layer on the baffle in the midpart of the electron transit layer surface. When no voltage is being impressed to the gate electrode on the discontinuous growth layer, this layer creates a hiatus in the two-dimensional electron gas layer generated along the heterojunction between the electron supply layer and electron transit layer. The hiatus is closed upon voltage application to the gate electrode.

Owner:SANKEN ELECTRIC CO LTD

High density interconnect system having rapid fabrication cycle

InactiveUS7382142B2Added fabricationSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityHigh density

An improved interconnection system and method is described, such as for connectors, socket assemblies and / or probe card systems. An exemplary system comprises a probe card interface assembly (PCIA) for establishing electrical connections to a semiconductor wafer mounted in a prober. The PCIA comprises a motherboard parallel to the semiconductor wafer having an upper surface and an opposing lower planar mounting surface, a reference plane defined by a least three points located between the lower surface of the motherboard and the wafer, at least one component located below the motherboard mounting surface, and a mechanism for adjusting the planarity of the reference plane with respect to the wafer. A probe chip having a plurality of spring probes extending there from is mountable and demountable from the PCIA, without the need for further planarity adjustment. The interconnection structures and methods preferably provide improved fabrication cycles.

Owner:ADVANTEST SINGAPORE PTE LTD

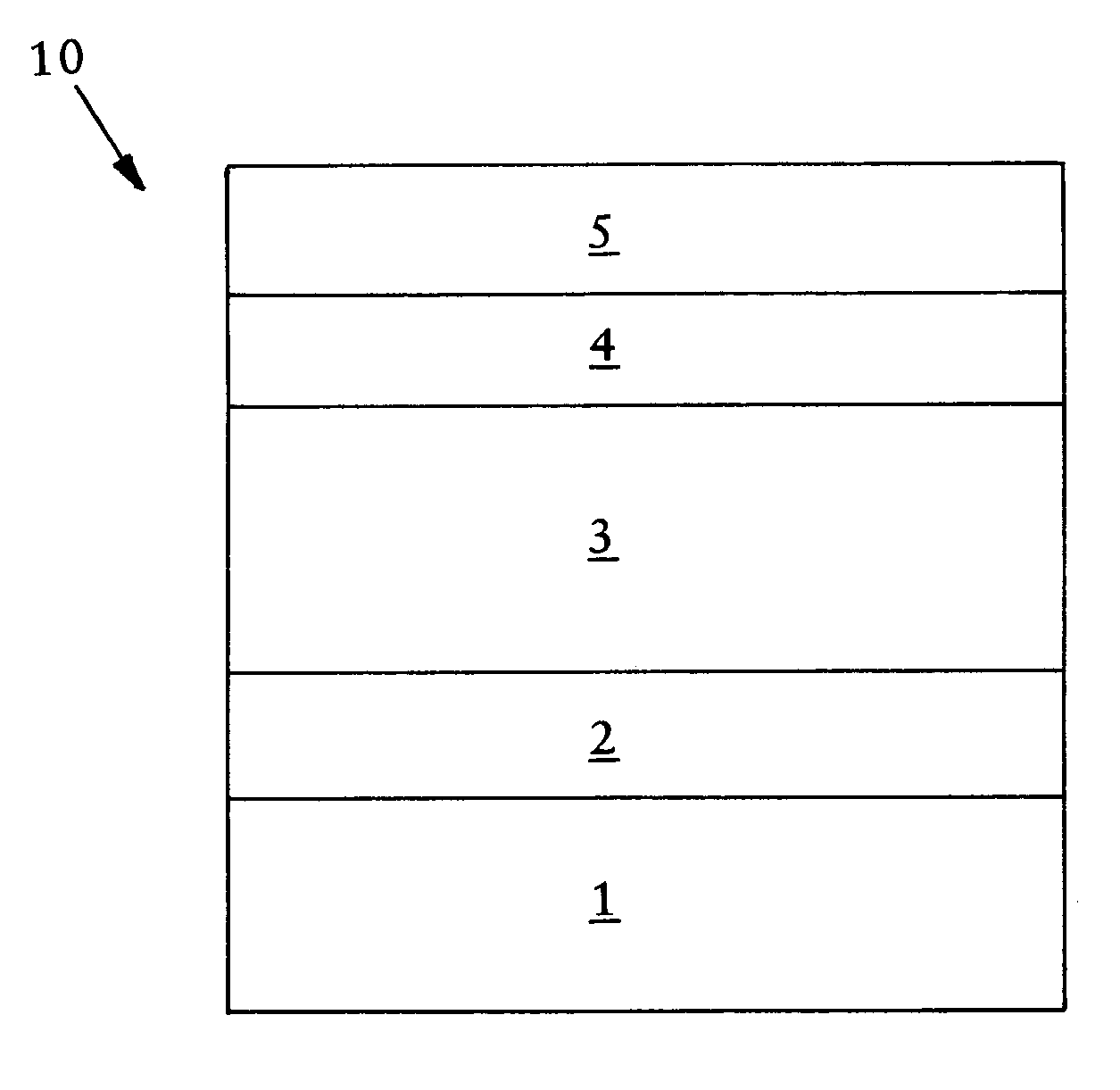

Electrochemical fabrication methods incorporating dielectric materials and/or using dielectric substrates

InactiveUS20050202667A1Enhanced electrochemical fabricationAdded fabricationAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingDielectric substratePhotopolymer

Various embodiments are directed to the electrochemical fabrication of multilayer mesoscale or microscale structures which are formed using at least one conductive structural material, at least one conductive sacrificial material, and at least one dielectric material. In some embodiments the dielectric material is a UV-curable photopolymer. In other embodiments, electrochemically fabricated structures are formed on dielectric substrates.

Owner:UNIV OF SOUTHERN CALIFORNIA

Cluster tool and method for process integration in manufacturing of a photomask

InactiveUS20070023390A1Improve photomask fabricationMinimal financial investmentDecorative surface effectsPhotomechanical apparatusResistChromium

A method and apparatus for process integration in manufacture of a photomask are disclosed. In one embodiment, a cluster tool suitable for process integration in manufacture of a photomask including a vacuum transfer chamber having coupled thereto at least one hard mask deposition chamber and at least one plasma chamber configured for etching chromium. In another embodiment, a method for process integration in manufacture of a photomask includes depositing a hard mask on a substrate in a first processing chamber, depositing a resist layer on the substrate, patterning the resist layer, etching the hard mask through apertures formed in the patterned resist layer in a second chamber; and etching a chromium layer through apertures formed in the hard mask in a third chamber.

Owner:APPLIED MATERIALS INC

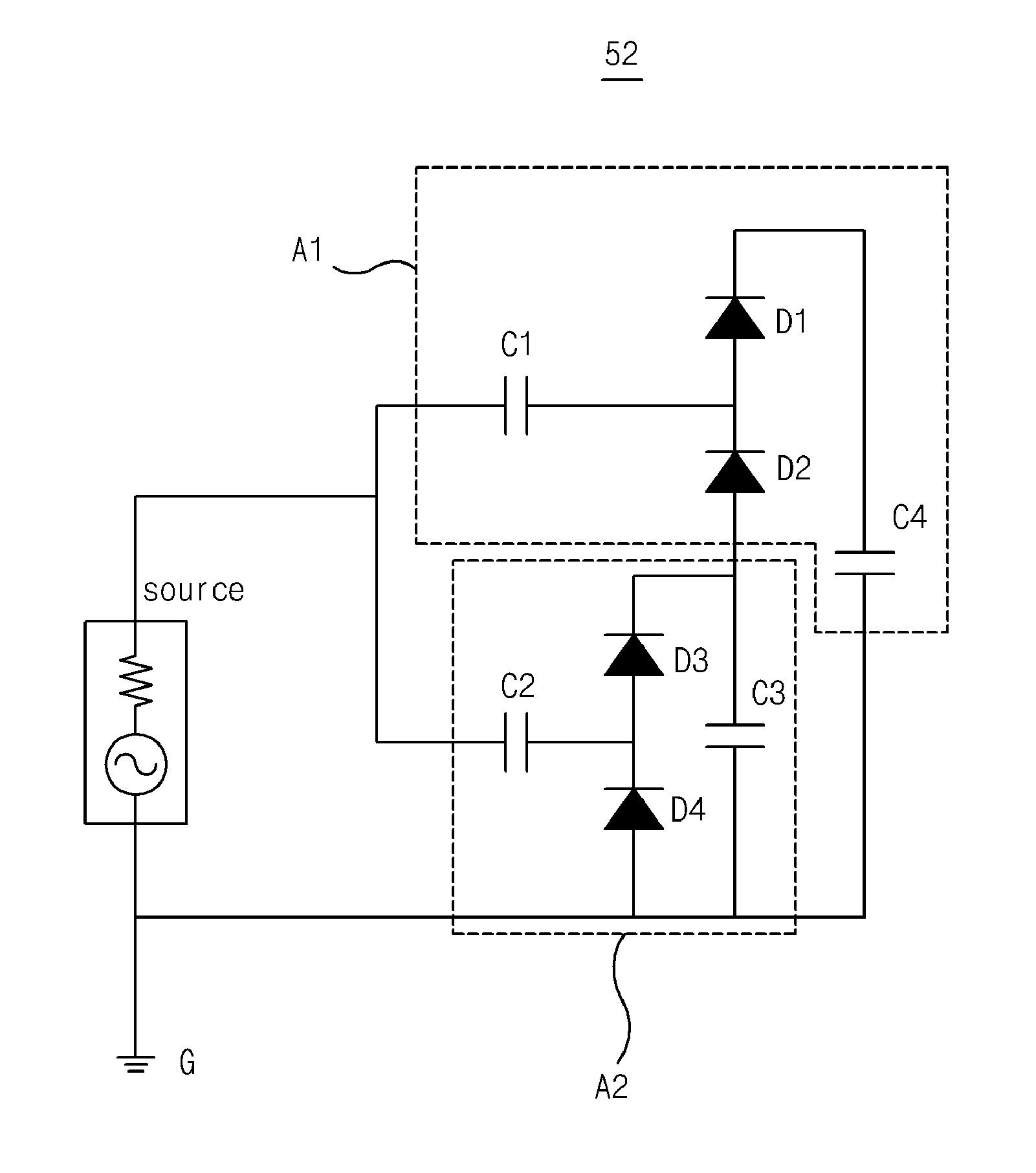

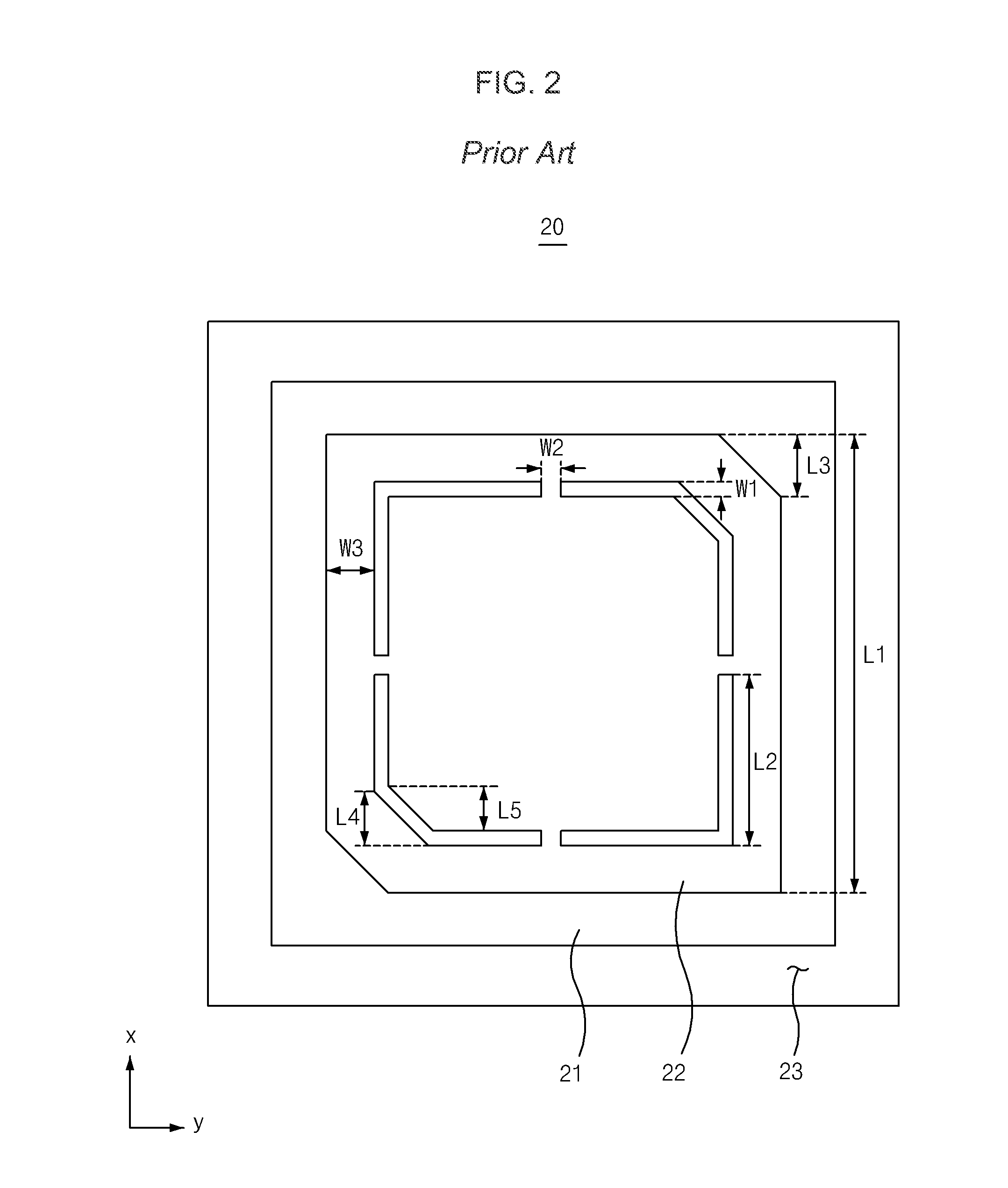

Patch antenna and rectenna using the same

ActiveUS20110242863A1Easy impedance matchingAdded fabricationAc-dc conversion without reversalElectromagnetic wave systemCapacitanceDielectric substrate

A patch antenna for receiving high frequency wireless signal and a rectenna using the same, more particularly, an impedance-matched patch antenna adopting a slot capacitive coupling structure and a rectenna capable of generating electrical energy from the wireless signals having different frequency band. A rectenna for receiving an A.C. wireless signal carrying electrical energy and converting the wireless signal into a D.C. electrical energy, is comprised of: a patch antenna for receiving the wireless signal comprising an dielectric substrate, a patch that is formed at the upper area of the surface of the dielectric substrate and providing the first frequency response characteristics, a ground plane formed on the other surface of the dielectric substrate, and an impedance matching means providing the second frequency response characteristics; and a rectifying unit that converts the wireless signal, received via the patch antenna, into a D.C. electrical energy by rectifying the wireless signal.

Owner:KOOKMIN UNIV IND ACAD COOP FOUND

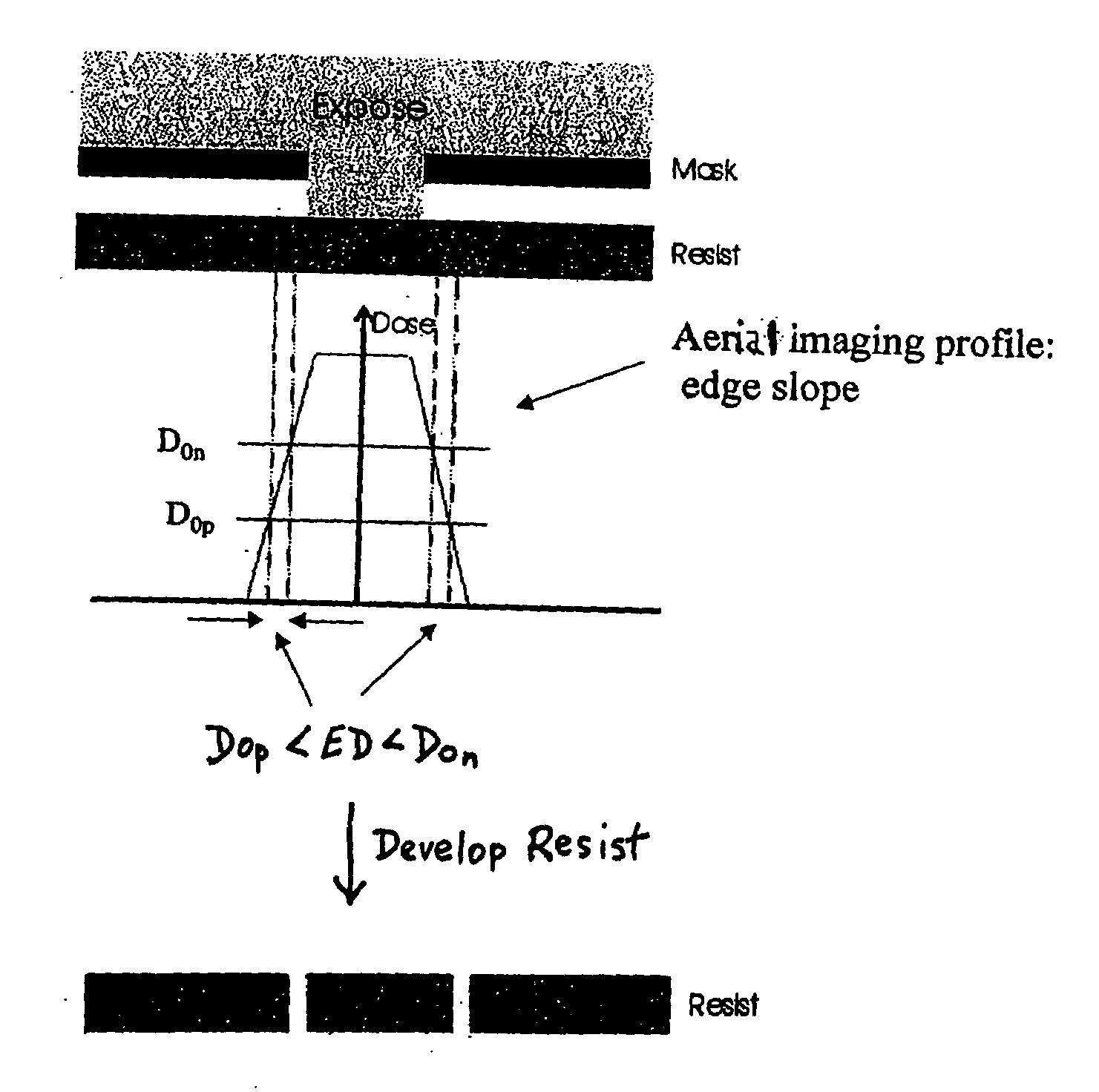

Method for fabricating master stamper/imprinters for patterned recording media utilizing hybrid resist

InactiveUS20080113157A1Added fabricationSimple methodElectric discharge tubesLayered productsResistLatent image

A method of fabricating a master stamper / imprinter for manufacturing a patterned recording medium by nano-imprint lithography comprises steps of: (a) providing a substrate having a surface; (b) forming a layer of a hybrid resist material on the surface, the resist layer having an exposed upper surface; (c) subjecting selected areas of the exposed upper surface of the resist layer to an energy beam to form therein a latent image of a topographical pattern to be formed in the resist layer and having a correspondence to a pattern to be formed in a patterned recording medium; and (d) developing the latent image into the topographical pattern in the resist layer, wherein only those areas of the resist layer which have received an energy beam exposure dose between a positive-tone threshold dose D0p and a negative-tone threshold dose D0n are developed.

Owner:SEAGATE TECH LLC

Reliable BEOL integration process with direct CMP of porous SiCOH dielectric

InactiveUS7253105B2Added fabricationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSurface layerHard mask

The present invention relates to methods of improving the fabrication of interconnect structures of the single or dual damascene type, in which there is no problem of hard mask retention or of conductivity between the metal lines after fabrication. The methods of the present invention include at least steps of chemical mechanical polishing and UV exposure or chemical repair treatment which steps improve the reliability of the interconnect structure formed. The present invention also relates to an interconnect structure which include a porous ultra low k dielectric of the SiCOH type in which the surface layer thereof has been modified so as to form a gradient layer that has both a density gradient and a C content gradient.

Owner:GLOBALFOUNDRIES INC

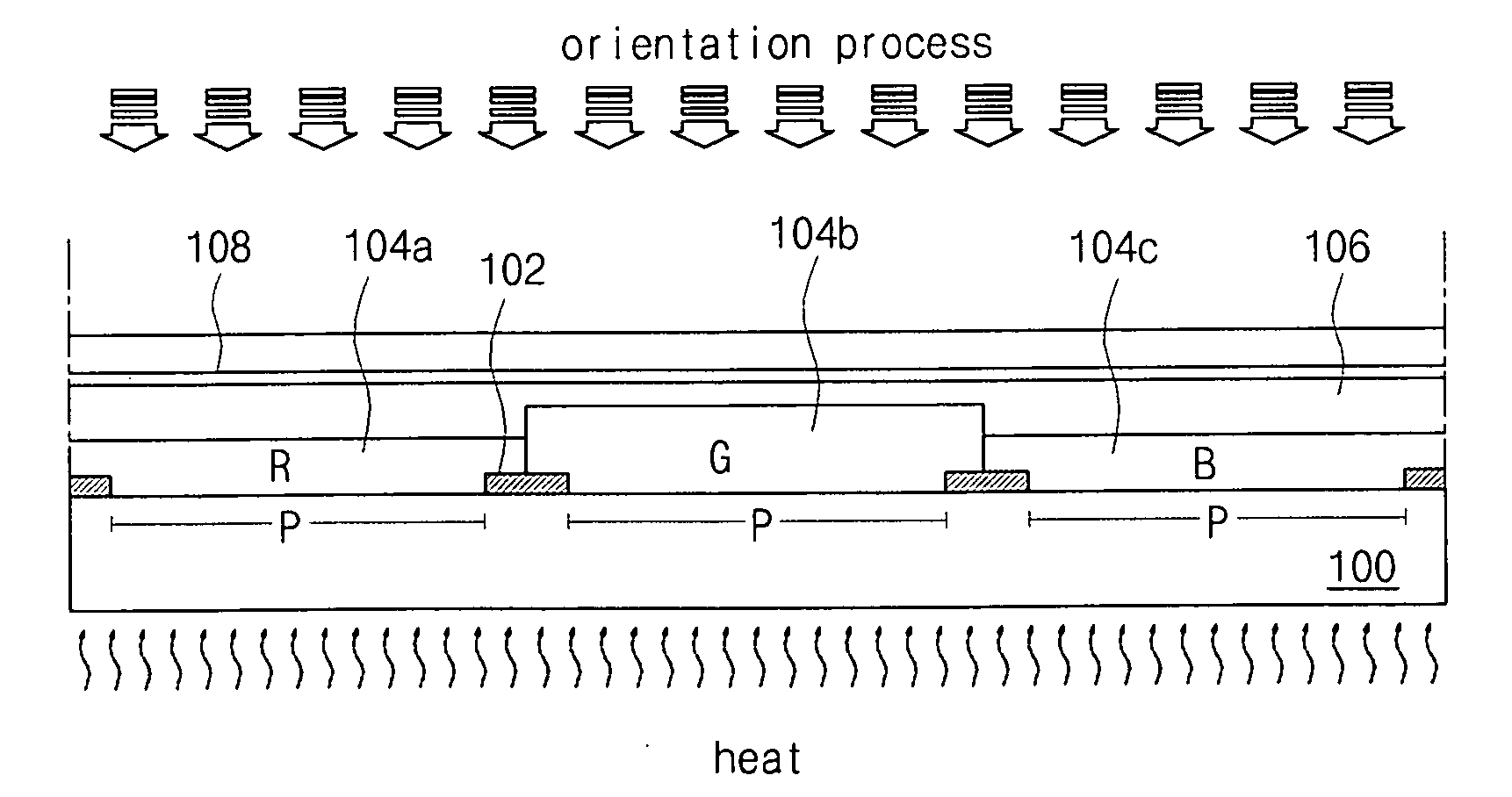

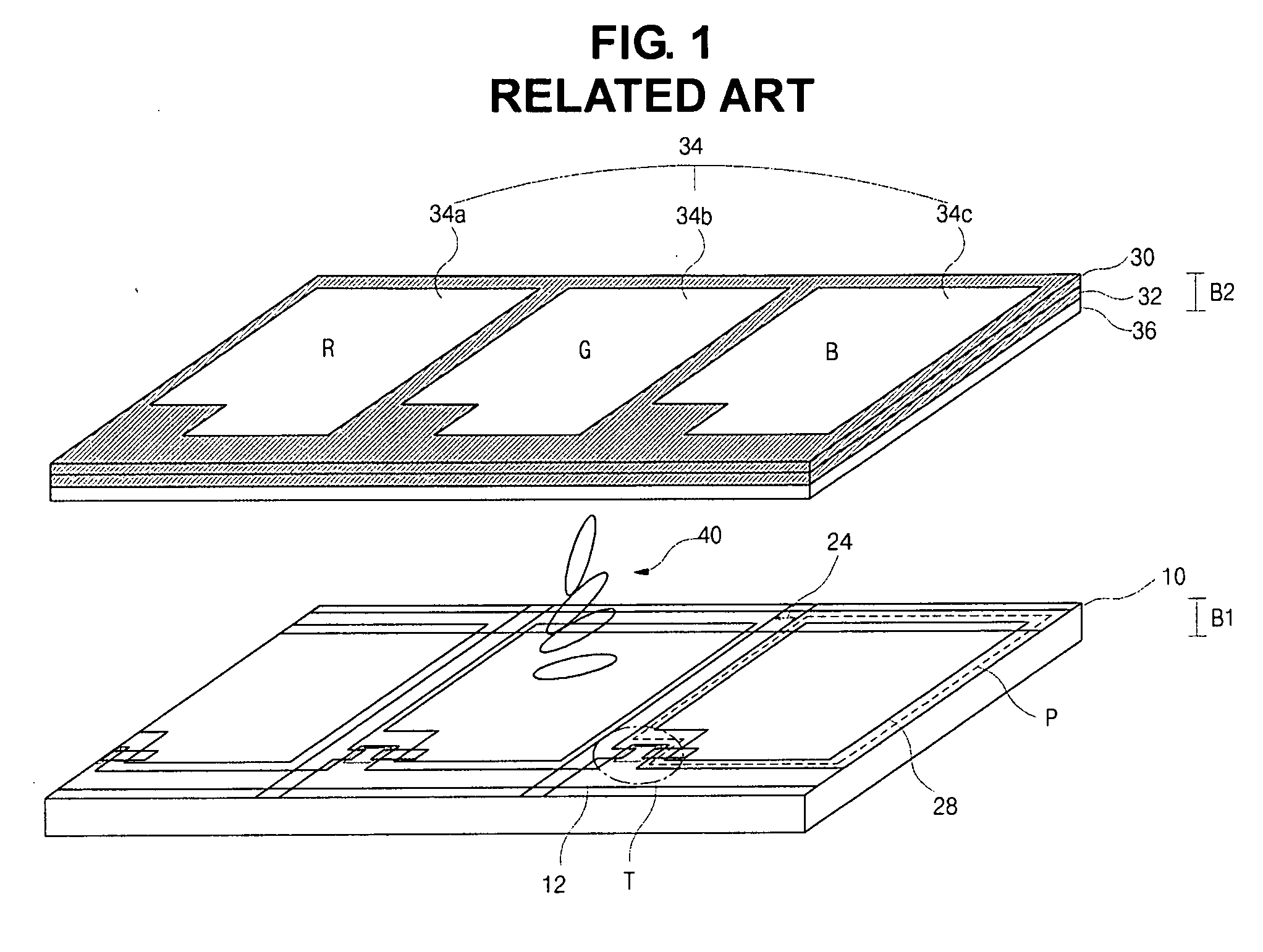

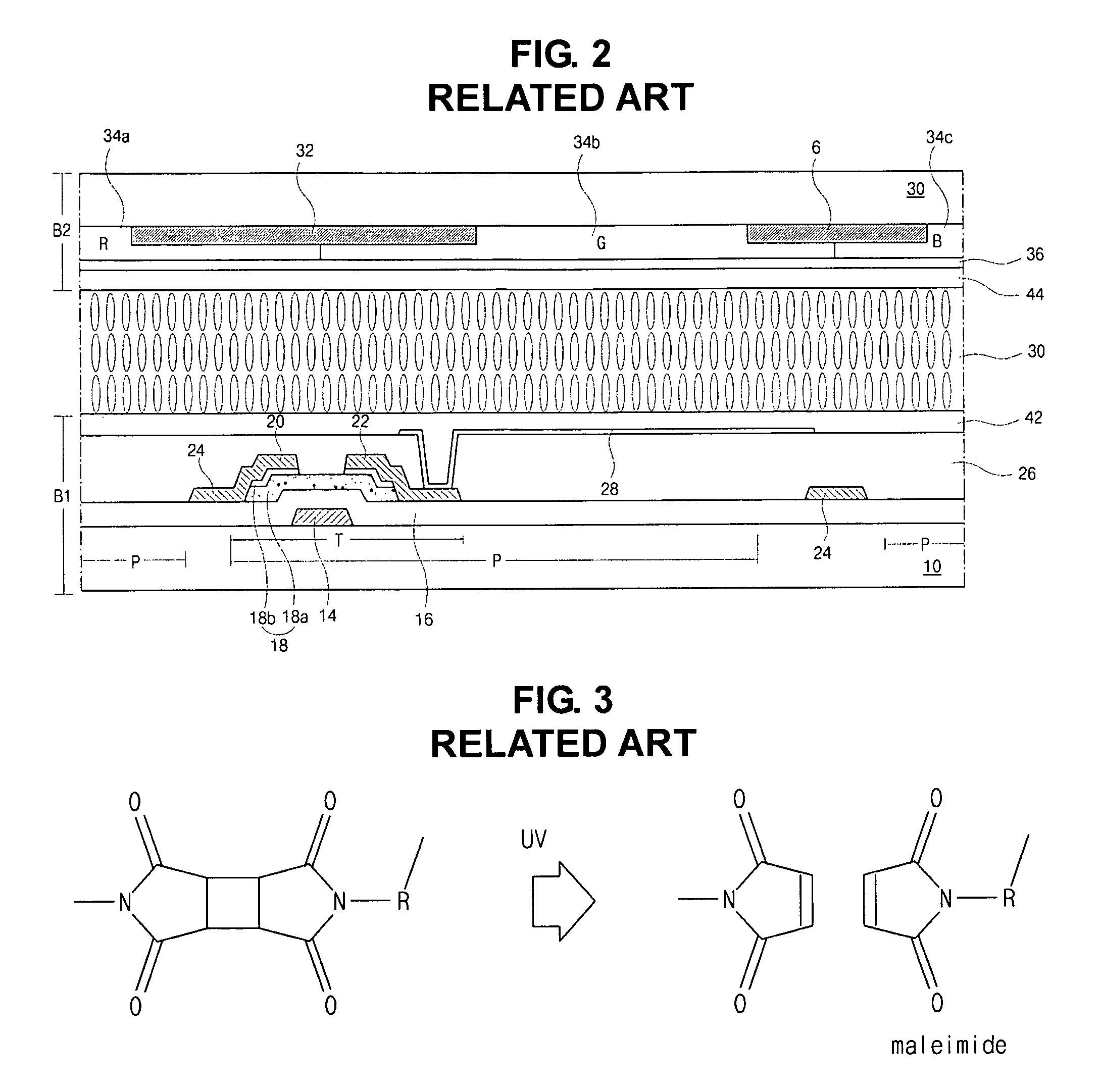

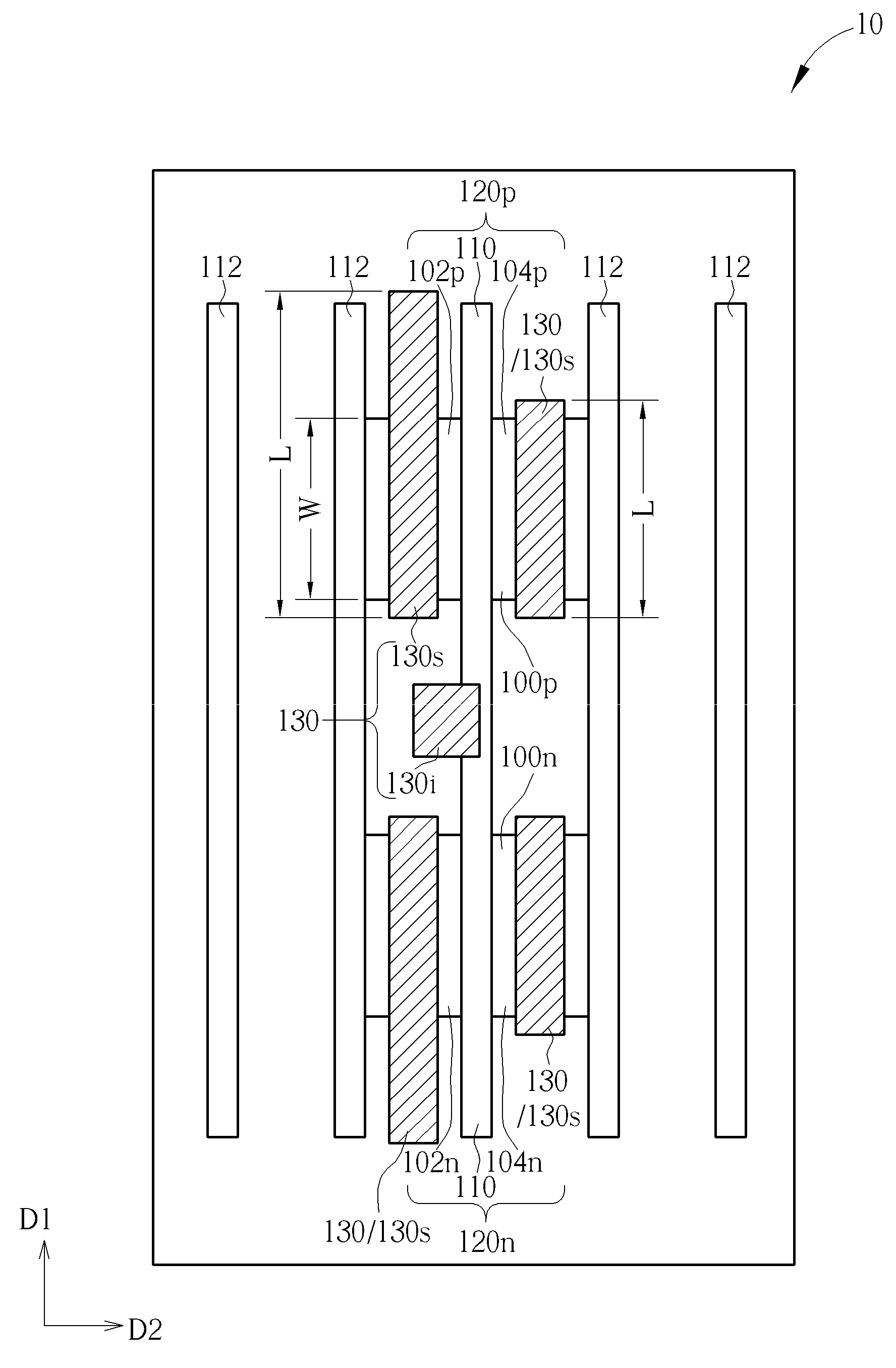

Method of fabricating alignment layer for liquid crystal display device

ActiveUS20080231786A1Improve method of fabricateAdded fabricationDielectric heatingRadiation applicationsLiquid-crystal display

A method of fabricating an alignment layer for a liquid crystal display device includes forming an alignment material layer on a substrate by coating an alignment material, irradiating UV rays onto the alignment material layer and pre-baking the alignment material layer; and post-baking the alignment material layer.

Owner:LG DISPLAY CO LTD

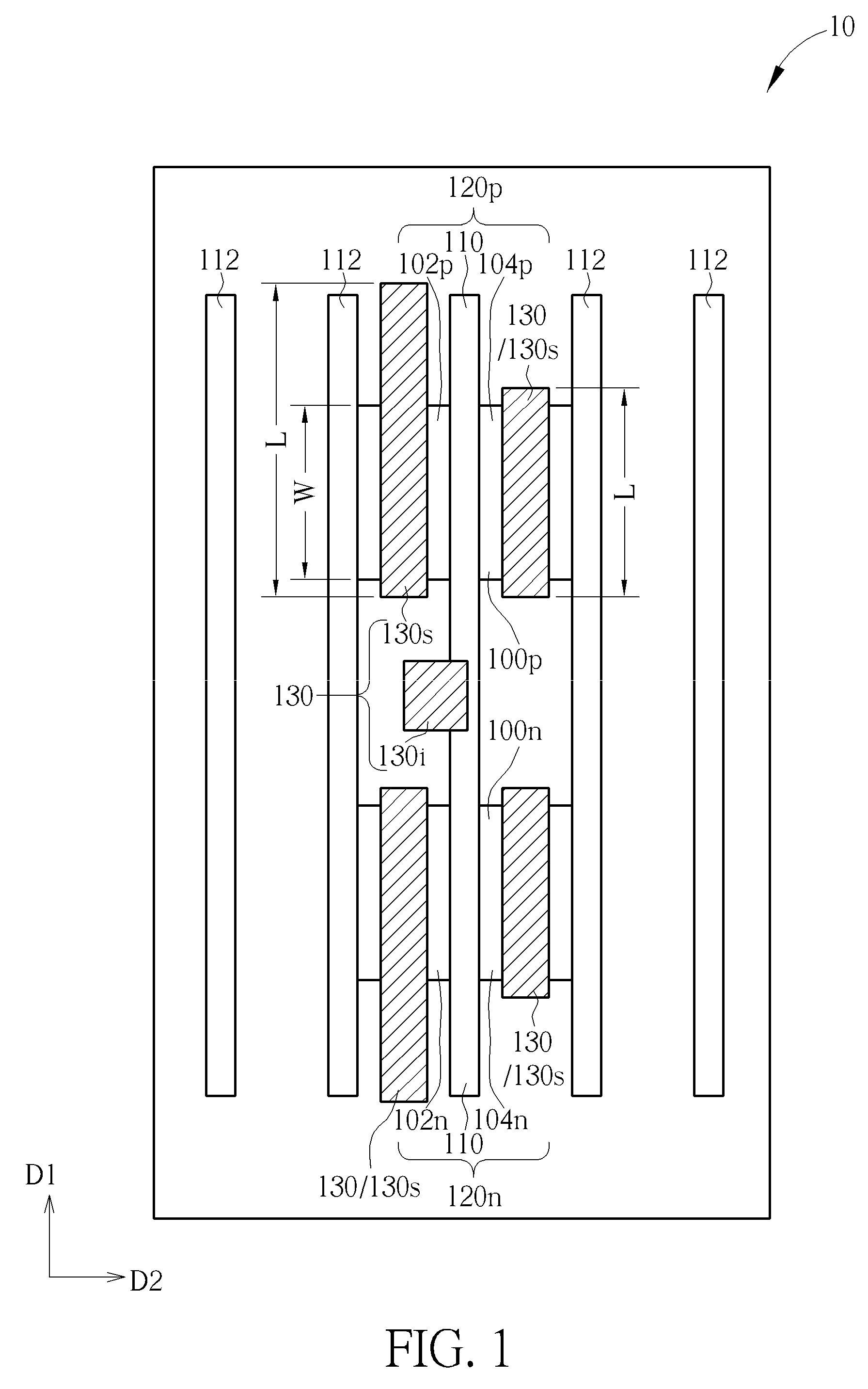

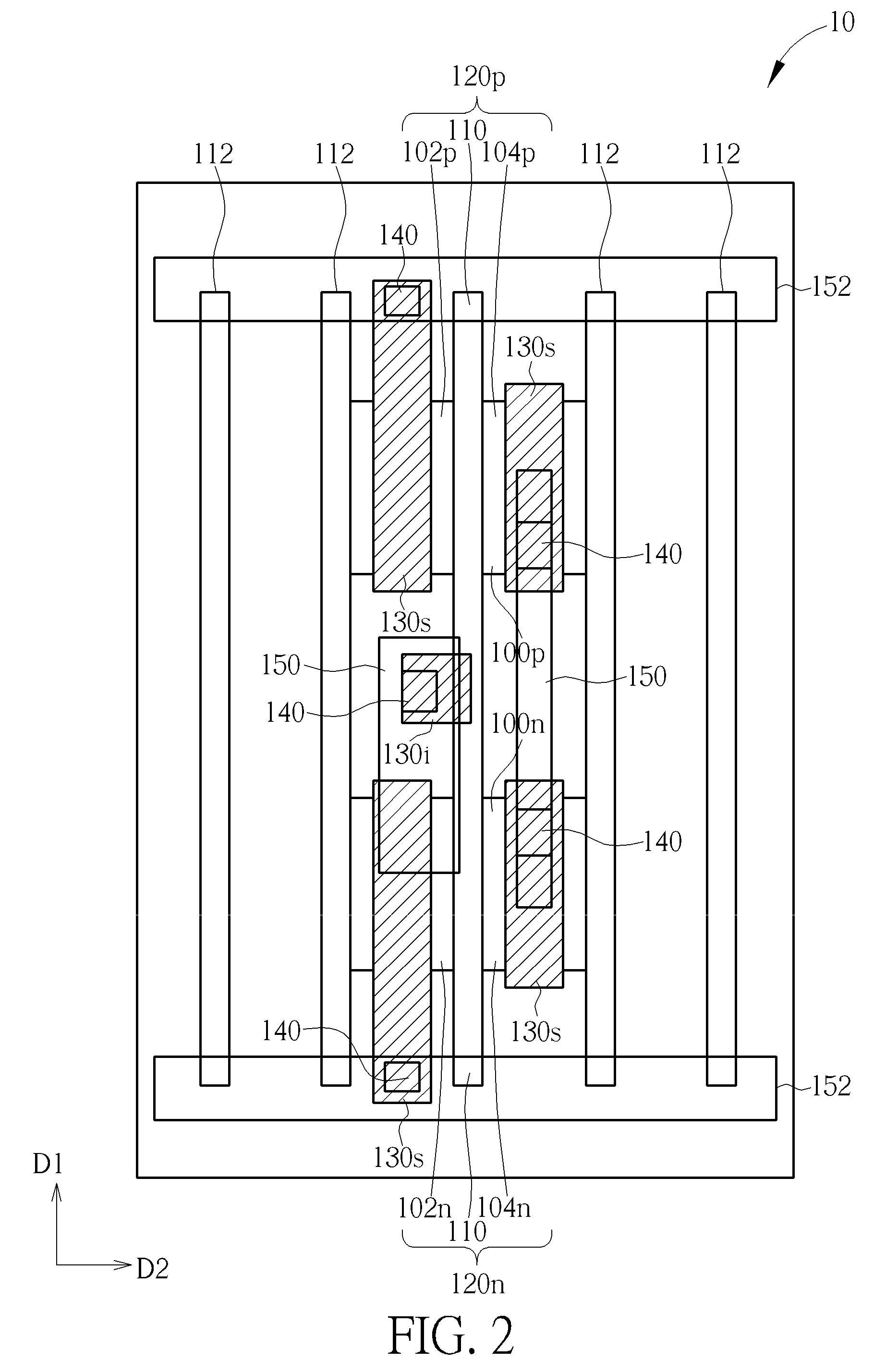

Semiconductor integrated circuit layout structure

ActiveUS20160329276A1Easy layout designAdded fabricationTransistorSemiconductor/solid-state device detailsEngineeringIntegrated circuit layout

A semiconductor integrated circuit layout structure includes a first active region, a second active region isolating from the first active region, a gate structure straddling the first active region and the second active region, and a plurality of conductive structures. The first active region at two opposite sides of the gate structure respectively forms a first source region and a first drain region. The second active region at two opposite sides of the gate structure respectively forms a second source region and a second drain region. The conductive structures include a plurality of slot-type conductive structures and one island-type conductive structure. The slot-type conductive structures are respectively formed on the first source region, the first drain region, the second source region and the second drain region. The island-type conductive structure is formed on the gate structure.

Owner:UNITED MICROELECTRONICS CORP

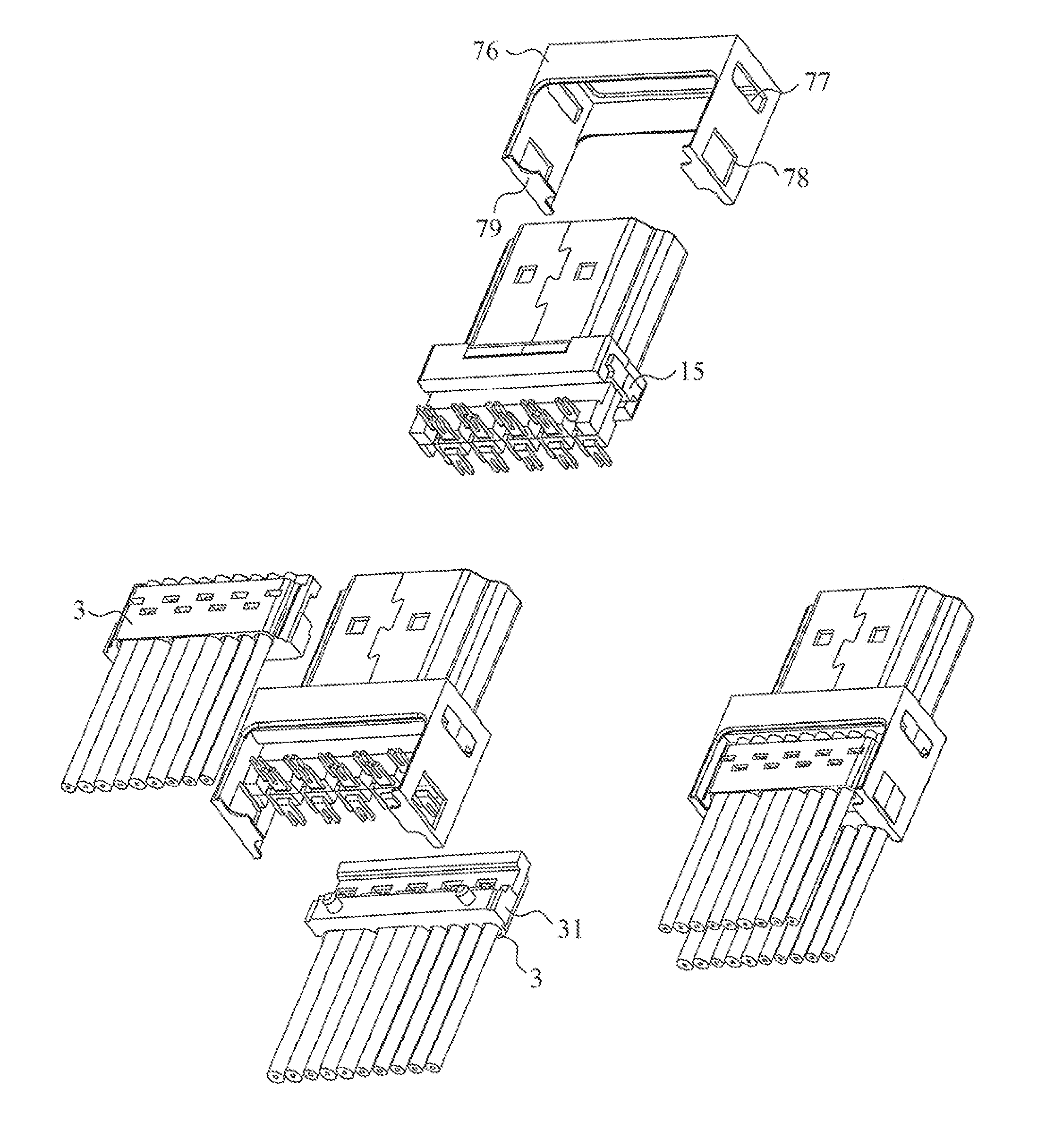

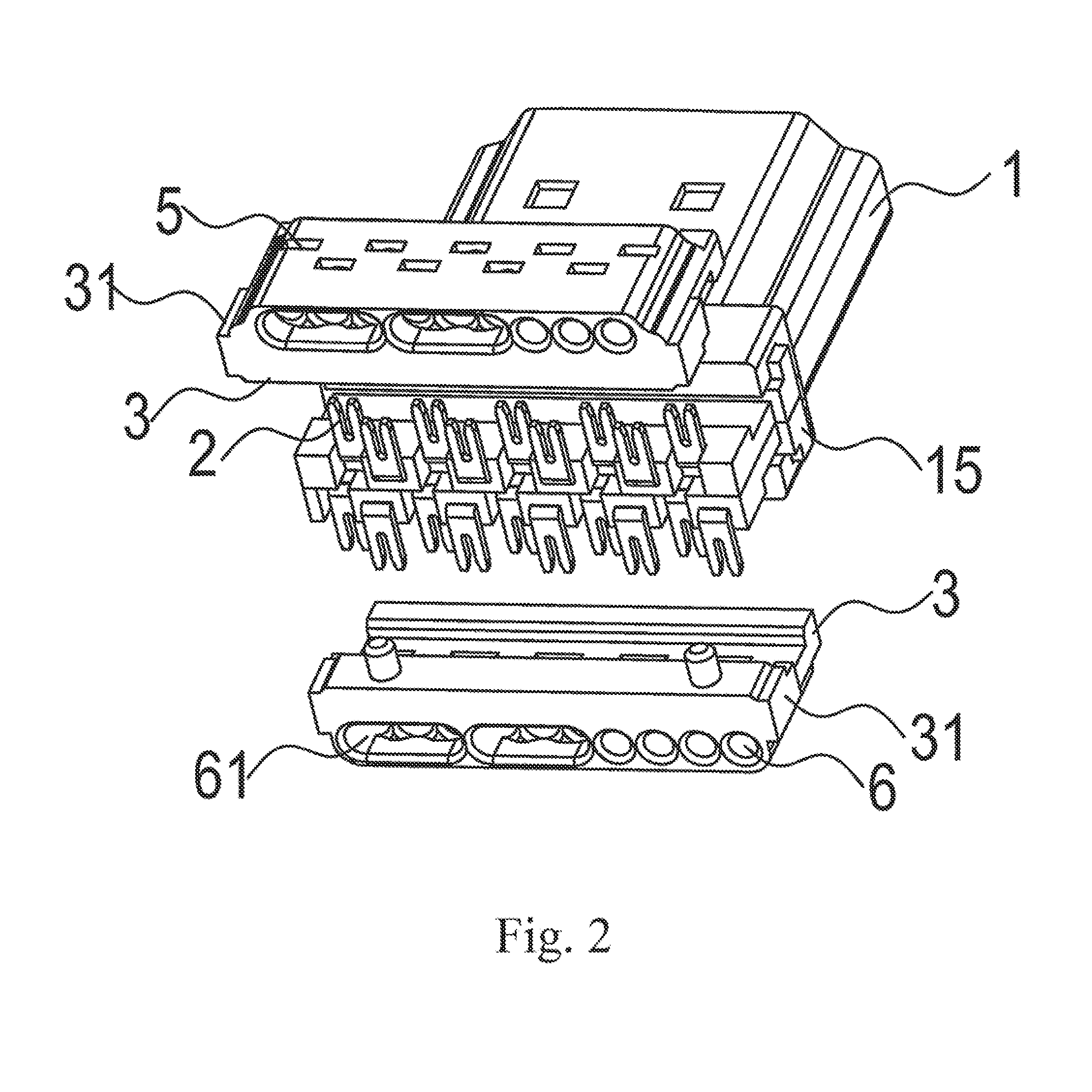

Bayonet type electronic connector

ActiveUS8052461B2Added fabricationGuaranteed smooth progressRelieving strain on wire connectionElectric discharge tubesEngineeringElectrical connector

A bayonet type electronic connector (1) comprises metal contacts arranged on the upper and lower surfaces of the connector (1). Metal contacts all are U-shaped bayonets (2). The U-shaped bayonet's terminal forms a right angle. The adjacent U-shaped bayonets (2) on each surface are staggered fore and aft in two rows. Enough functional space is arranged between the two rows.

Owner:WANG FENGLIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com