Patents

Literature

85results about How to "Less intervention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

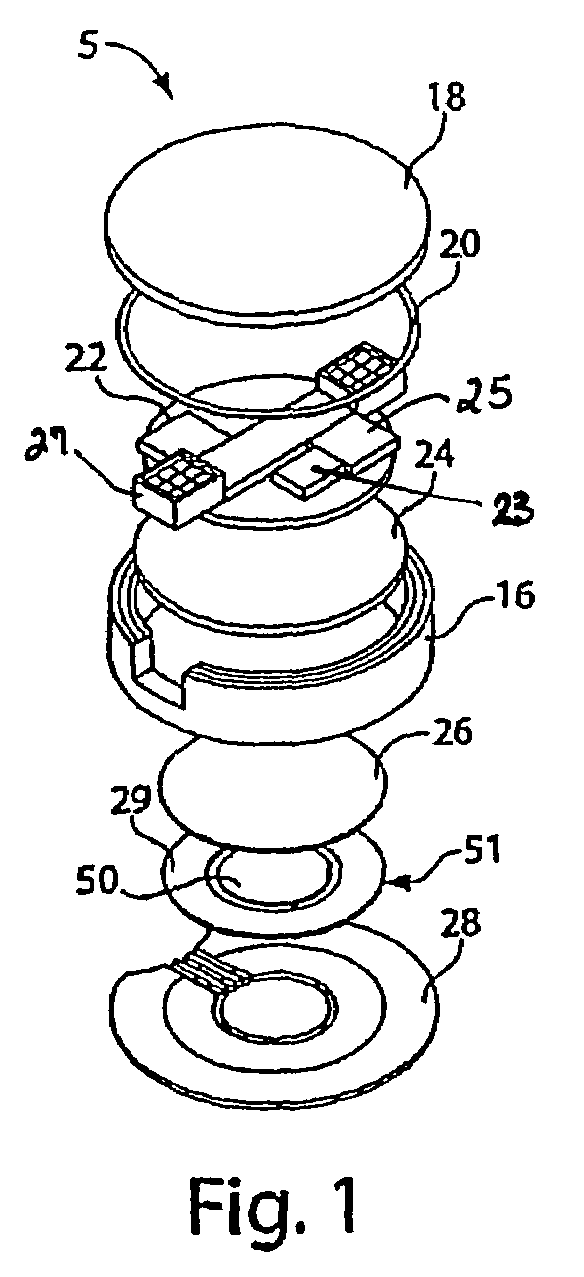

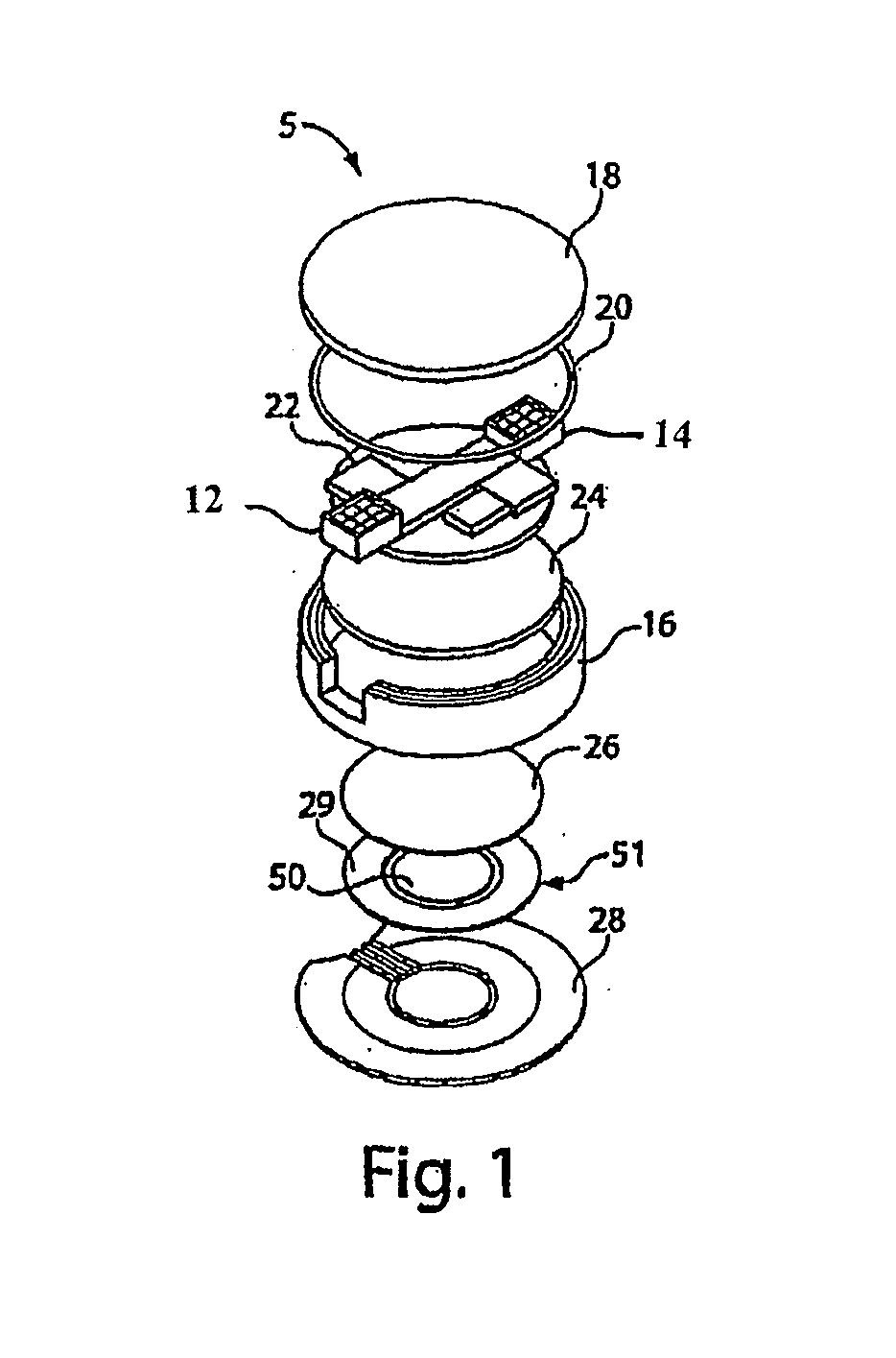

Piezoelectric damage detection device

ActiveUS7469595B2Low costEliminate the problemVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesIn planeElectricity

Owner:METIS DESIGN CORP

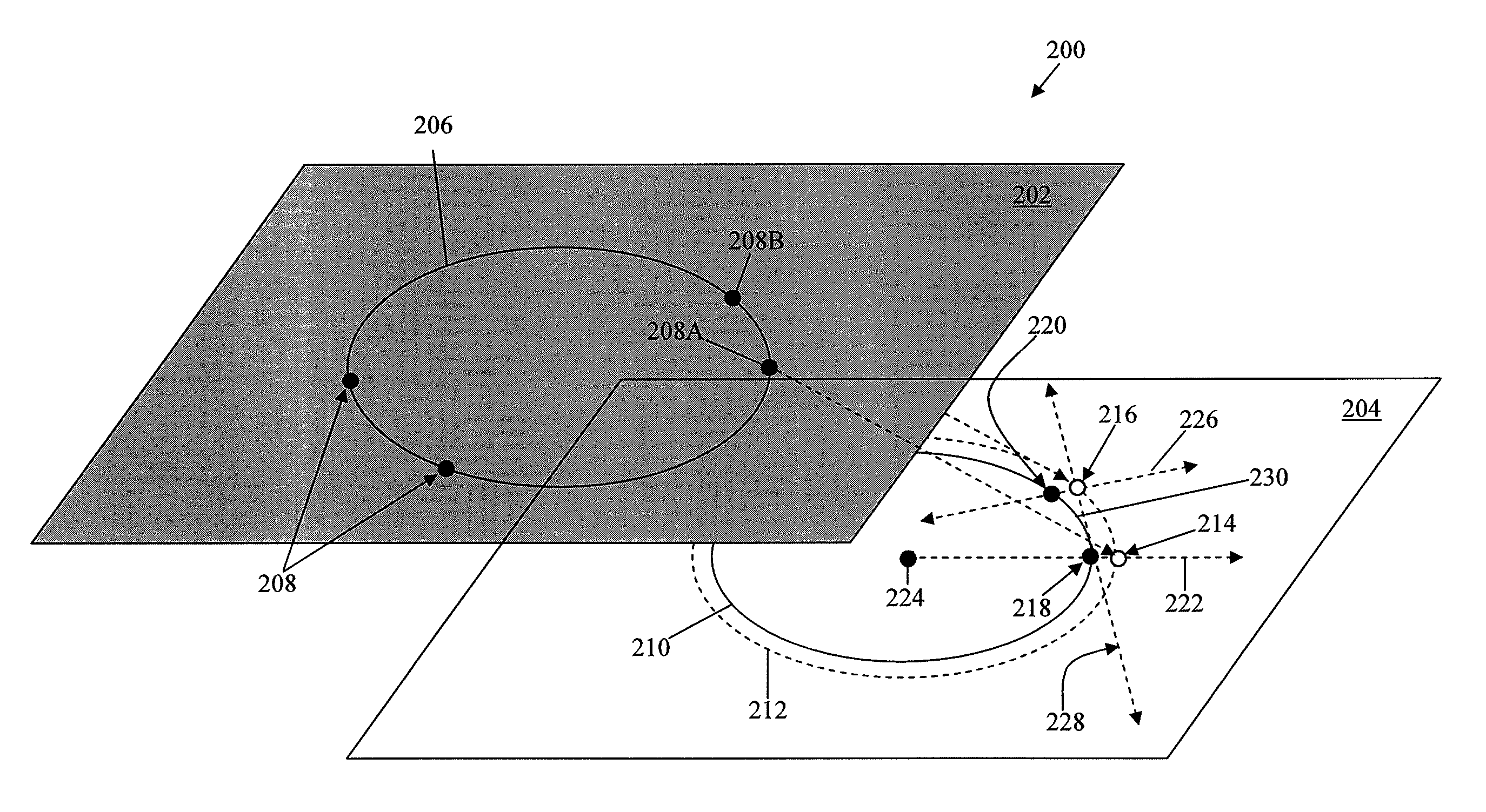

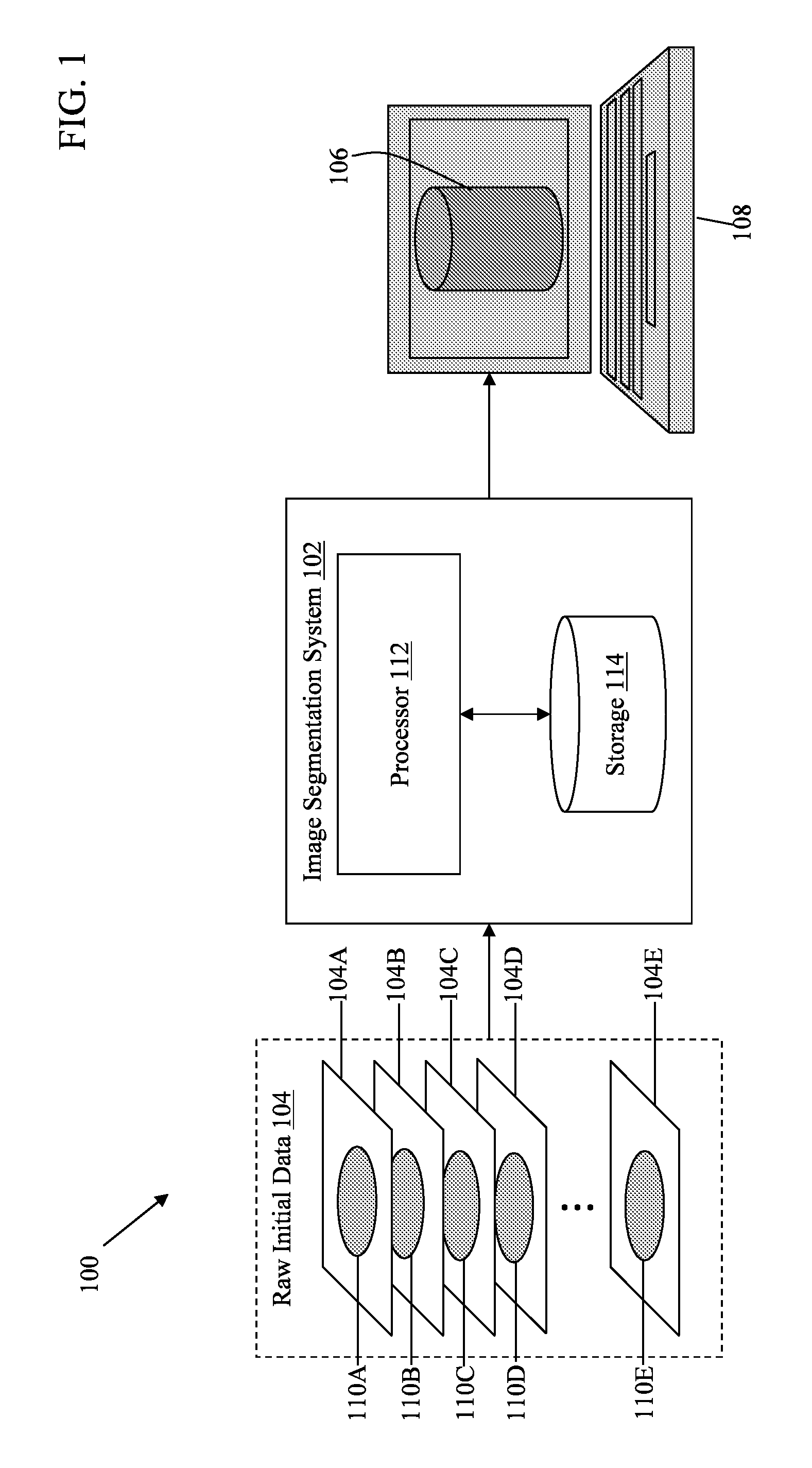

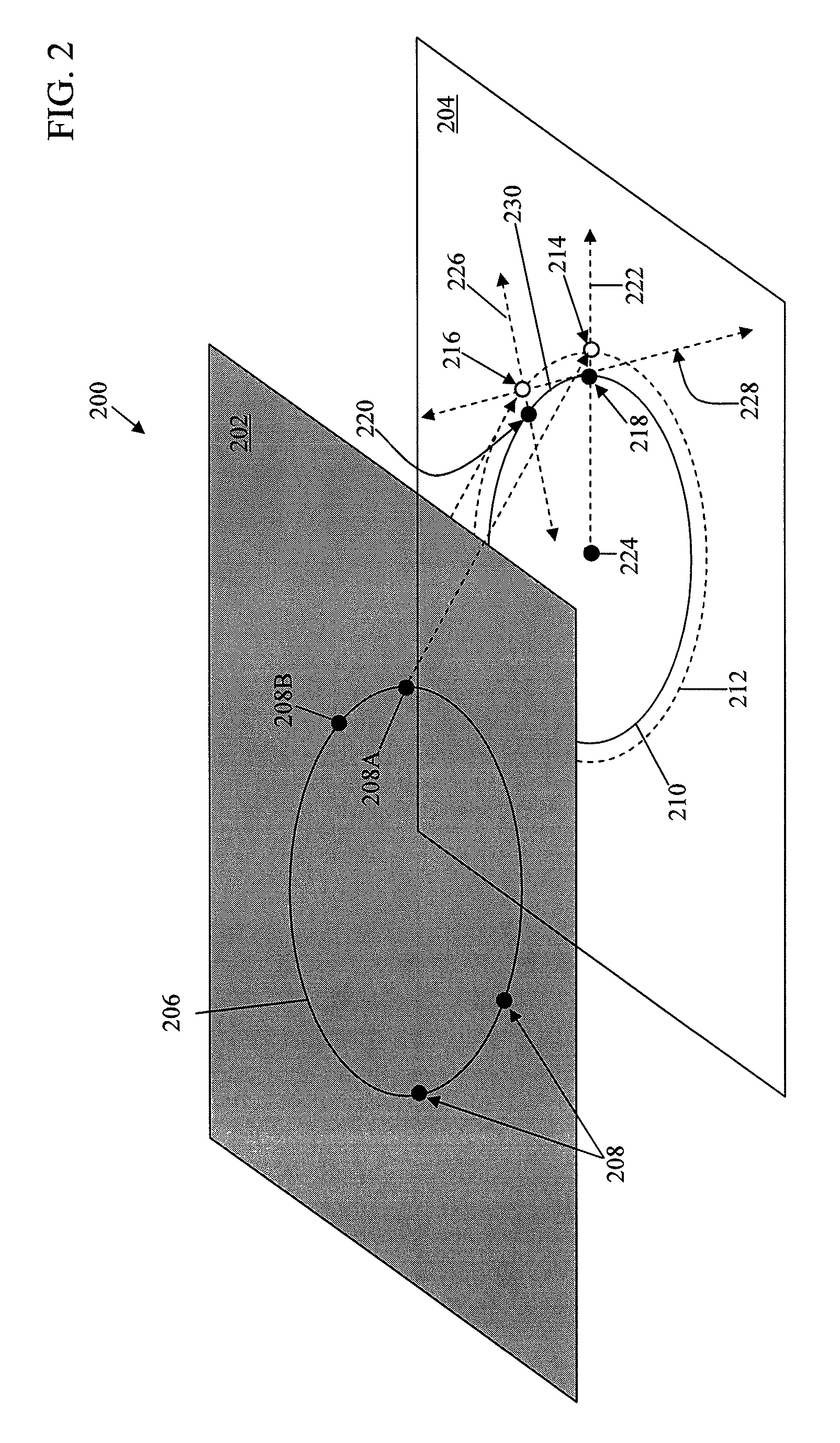

Automatic image segmentation using contour propagation

ActiveUS8249345B2Easy accessAutomatically propagating the contours over parallel imagesImage enhancementImage analysisPattern recognitionComputer graphics (images)

Described are computer-based methods and apparatuses, including computer program products, for automatic image segmentation using contour propagation. A path metric of a candidate piece of a contour in a cross-sectional image is calculated to generate a three dimensional model using a plurality of cross-sectional images of an object. Data indicative of the cross-sectional image is stored. A cost of each of a plurality of pixels associated with the candidate piece is calculated using the data, wherein the cost is representative of a likelihood the pixel is on the contour and the cost is based on one or more templates. An orientation change value is calculated for each of the plurality of pixels associated with the candidate piece based on an initial pixel of the candidate piece and the pixel. A ratio of pixels is calculated. The path metric of the candidate piece of the contour is stored, the value of the stored path metric being based on the calculated cost, the calculated orientation change value, and the calculated ratio.

Owner:MAKO SURGICAL CORP

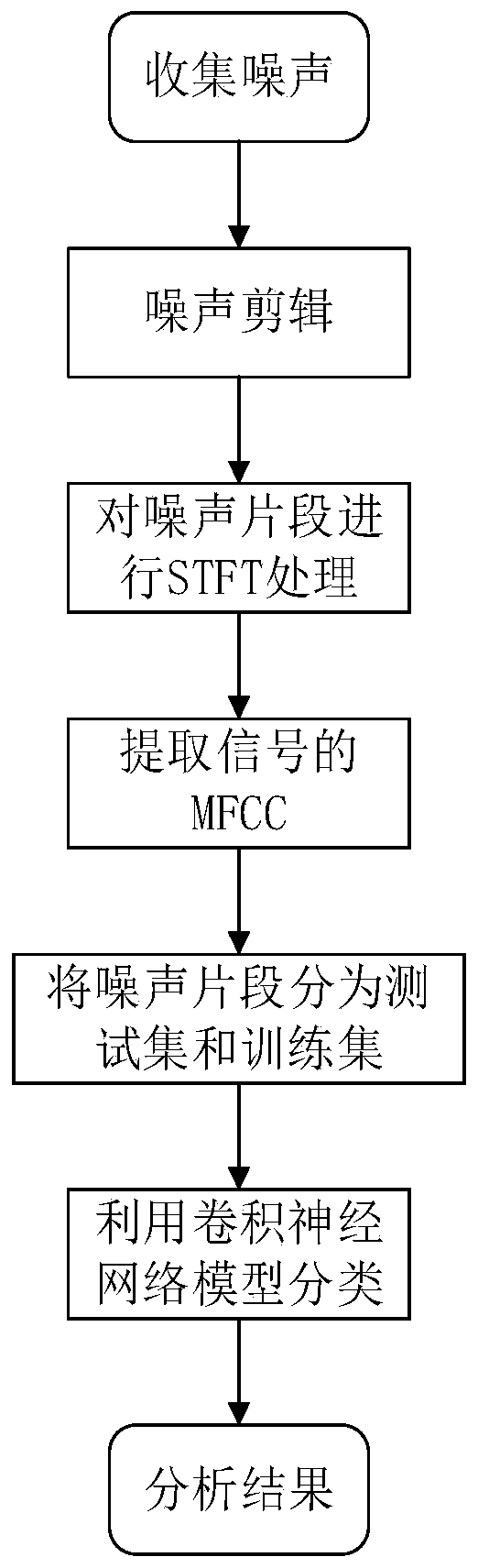

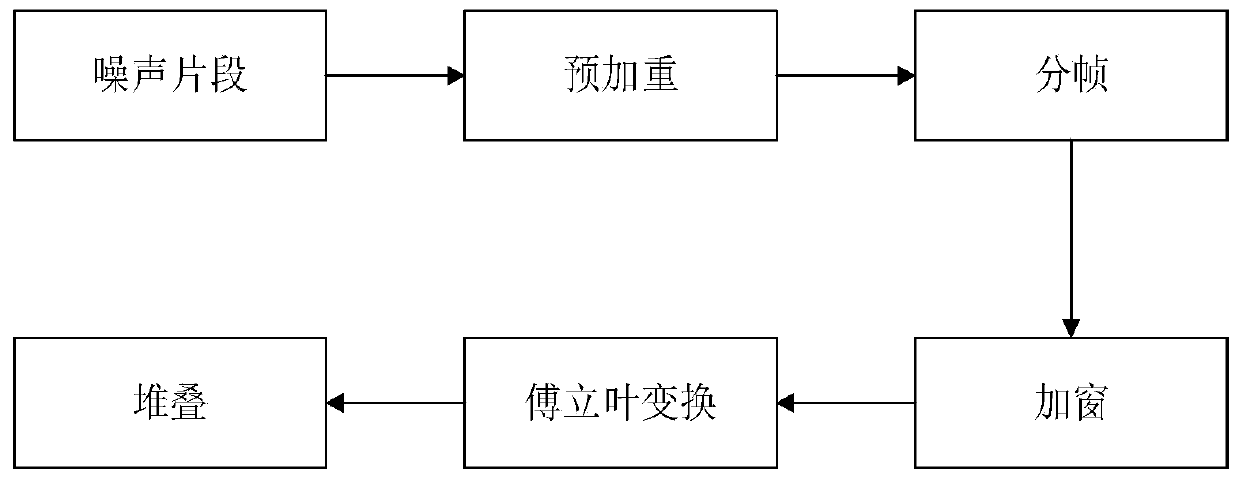

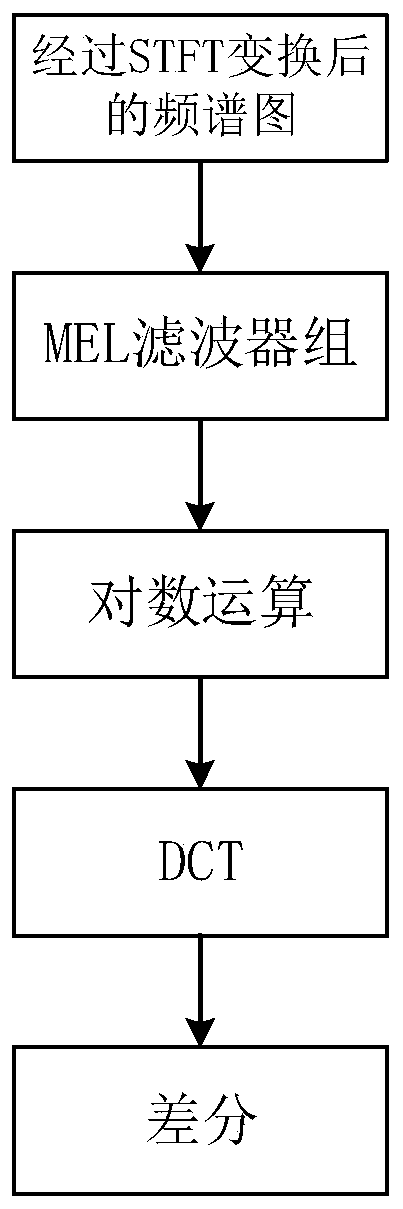

Environment noise identification classification method based on convolutional neural network

InactiveCN109767785AUniversalSolve problems that are easy to fall into the optimal solutionSpeech analysisMel-frequency cepstrumEnvironmental noise

The invention relates to an environment noise identification classification method based on a convolutional neural network. The method comprises the following steps of: S1, extracting natural environment noise, and editing the natural environment noise into noise segments with duration of 300ms to 30s and a converted frequency of 44.1kHz; S2, carrying out short time Fourier transformation on the noise segments, and converting a one-dimensional time-domain signal into a two-dimensional time-domain signal to obtain a sonagraph; S3, extracting a MFCC (Mel Frequency Cepstrum Coefficient) of the signal; S4, forming a training set with 80% of all the noise segments and forming a testing set with the residual 20% of all the noise segments; S5, carrying out noise classification by a convolutionalneural network model; and S6, training a classification model by the training set, and verifying accuracy of the model by the testing set so as to complete environment noise identification classification based on the convolutional neural network. According to the invention, the sound segments are input, sound feature information is extracted, an output is a classification result, and automatic extraction on the sound feature information can be implemented.

Owner:HEBEI UNIV OF TECH

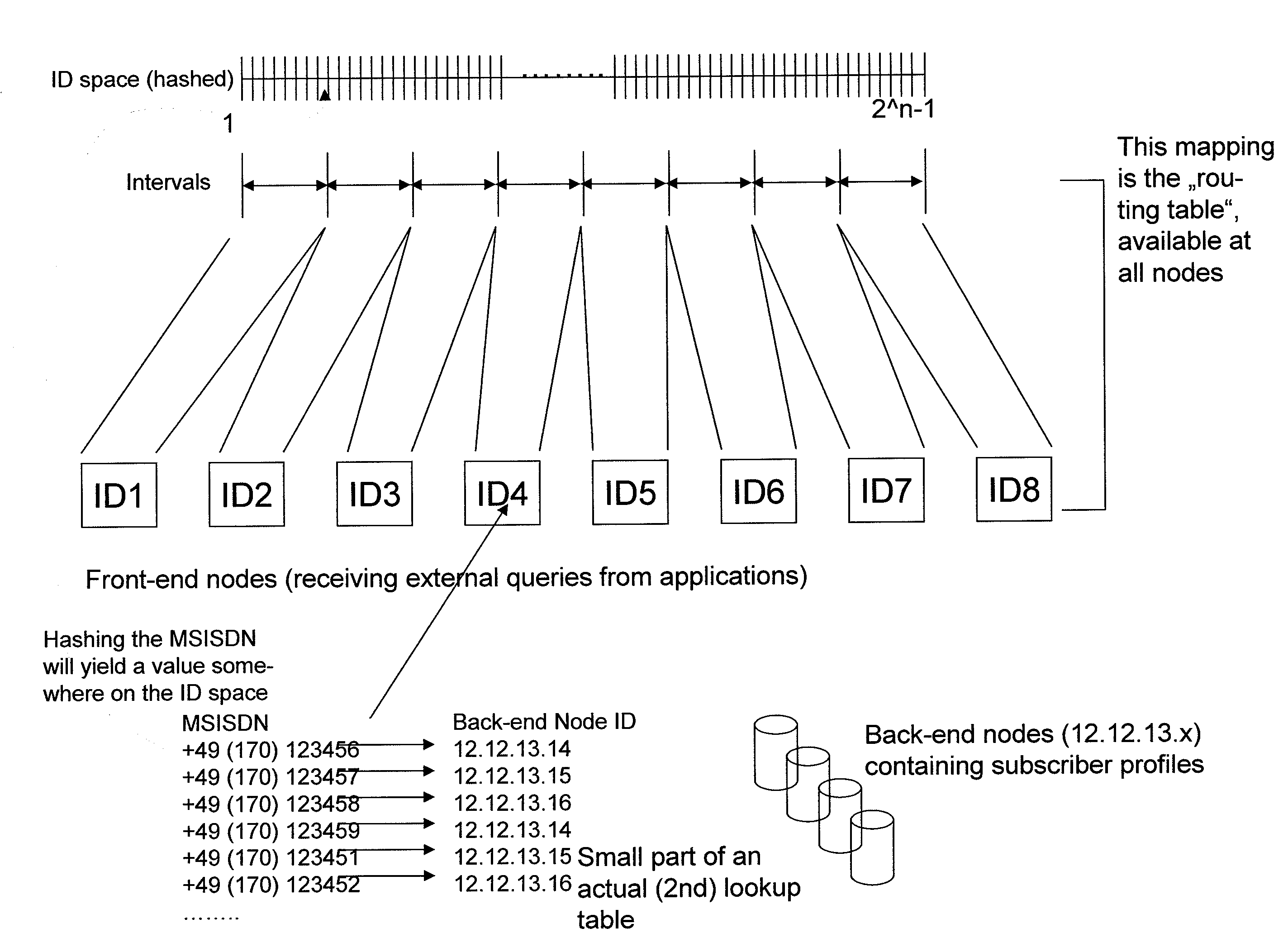

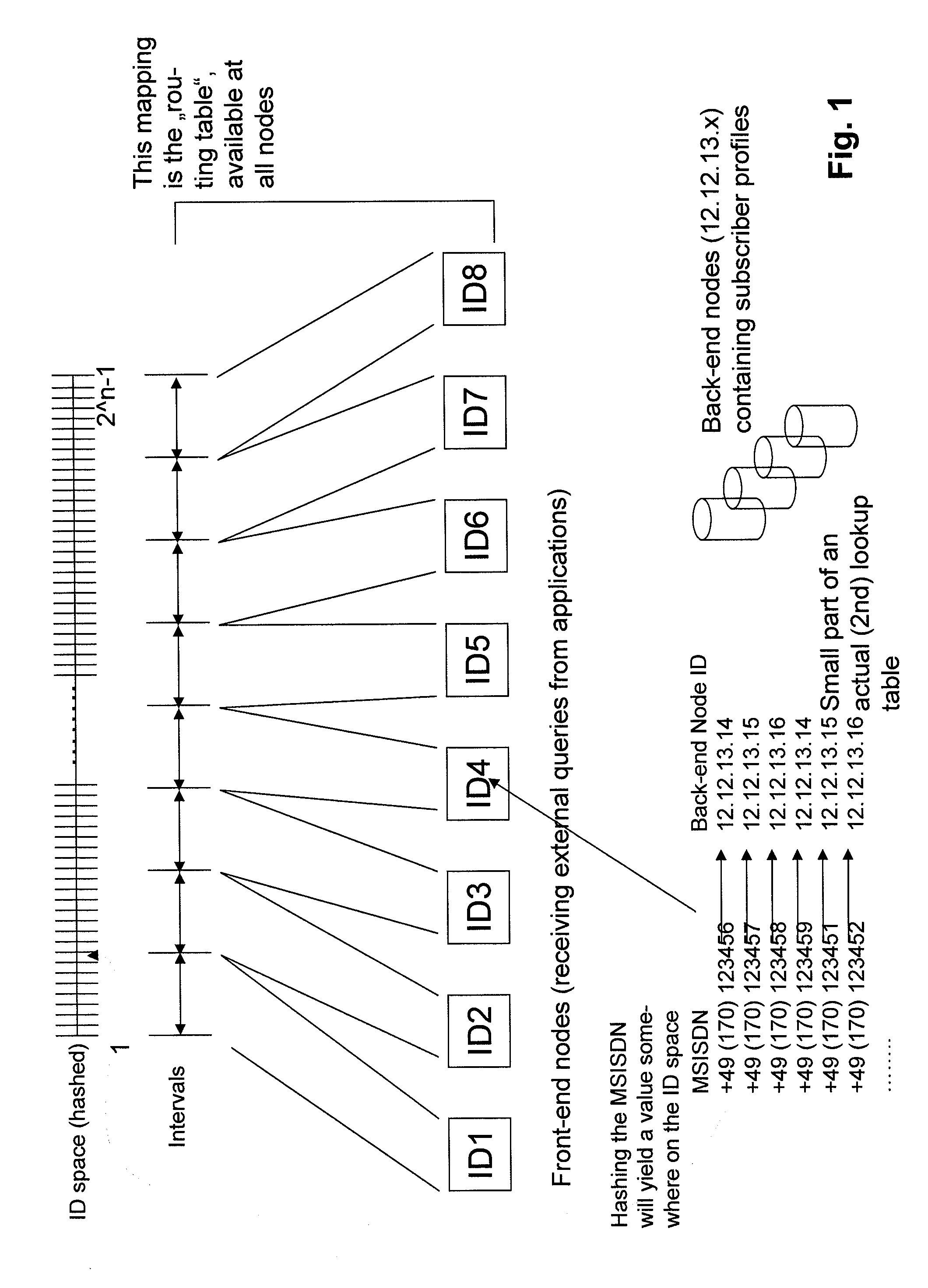

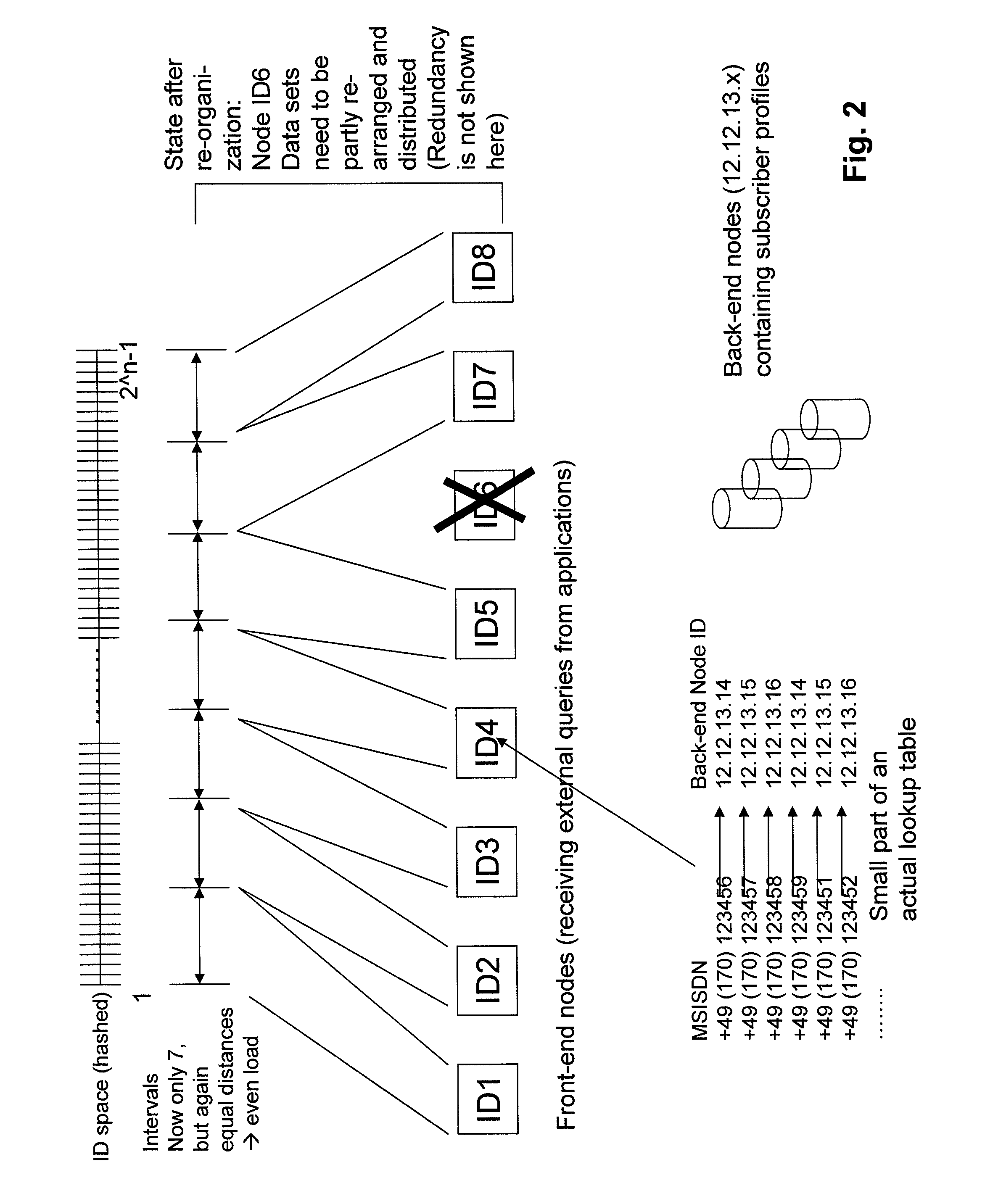

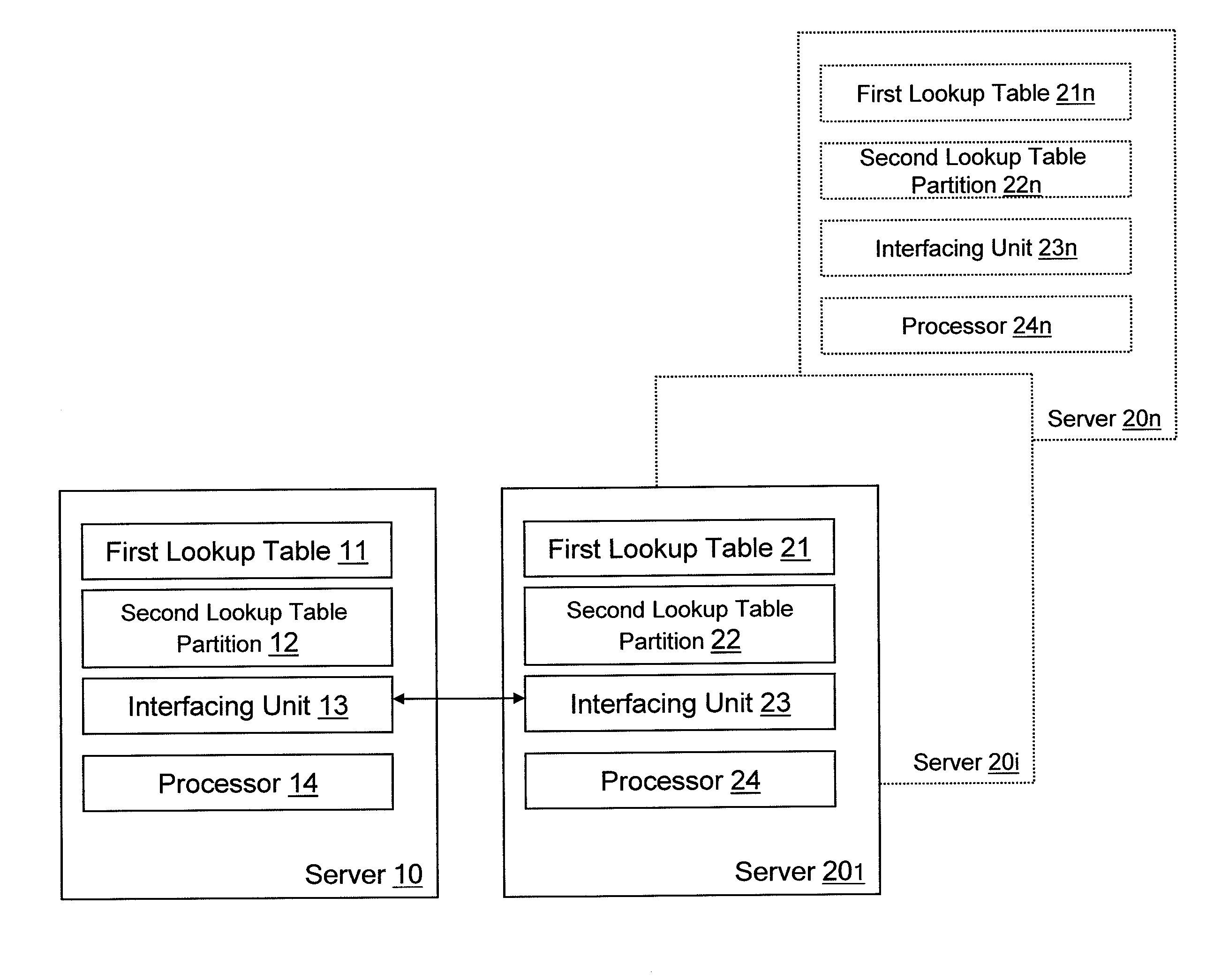

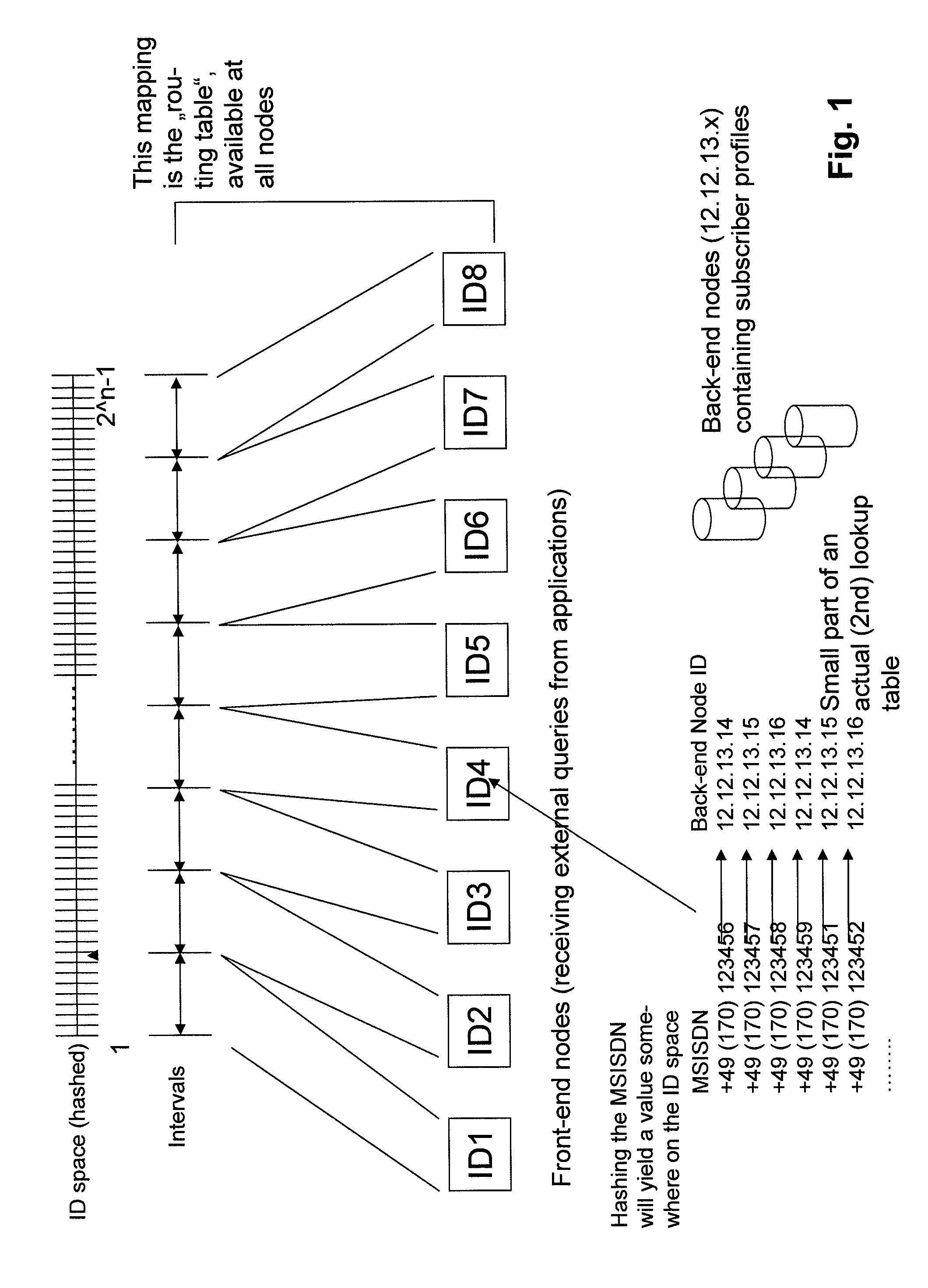

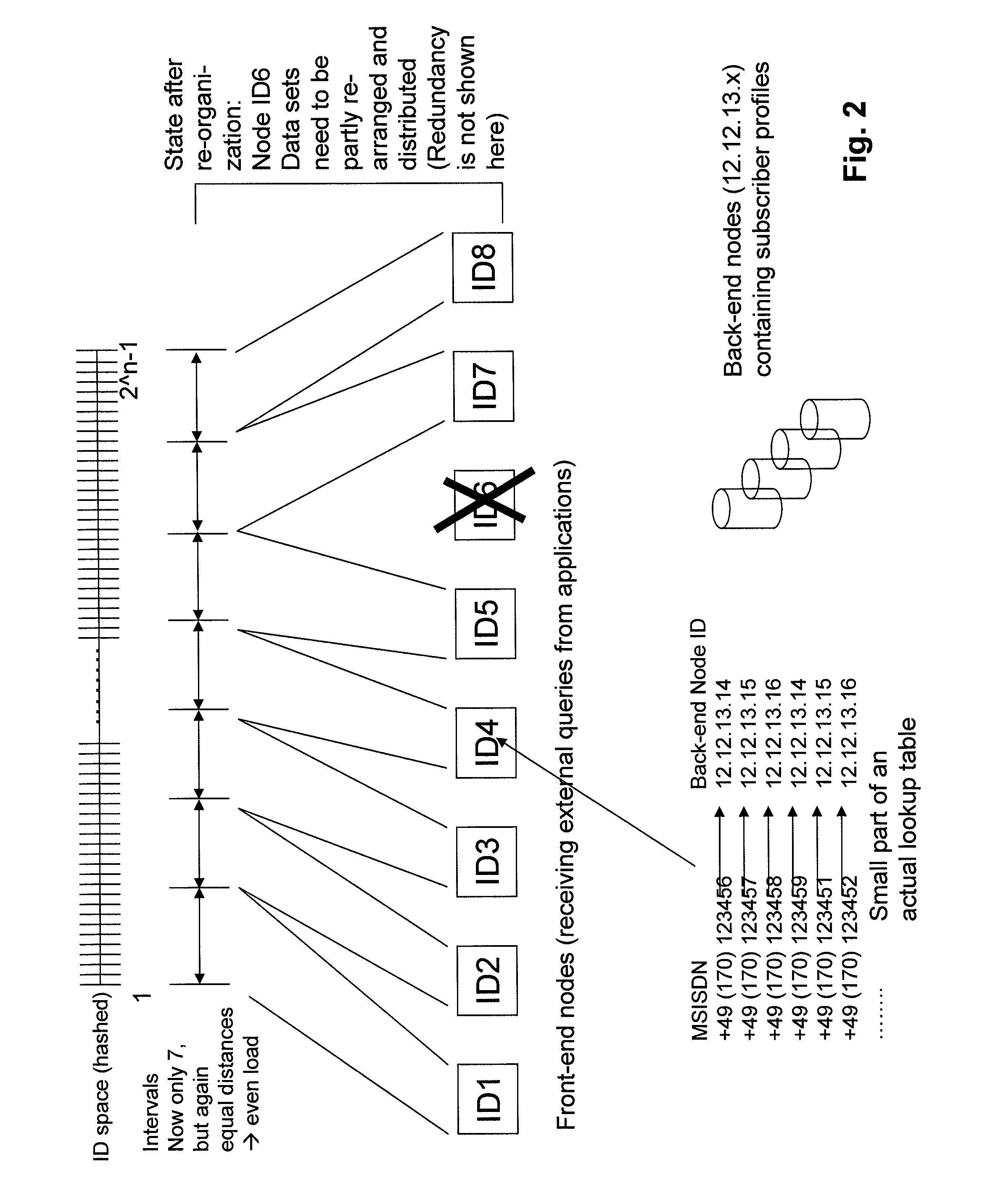

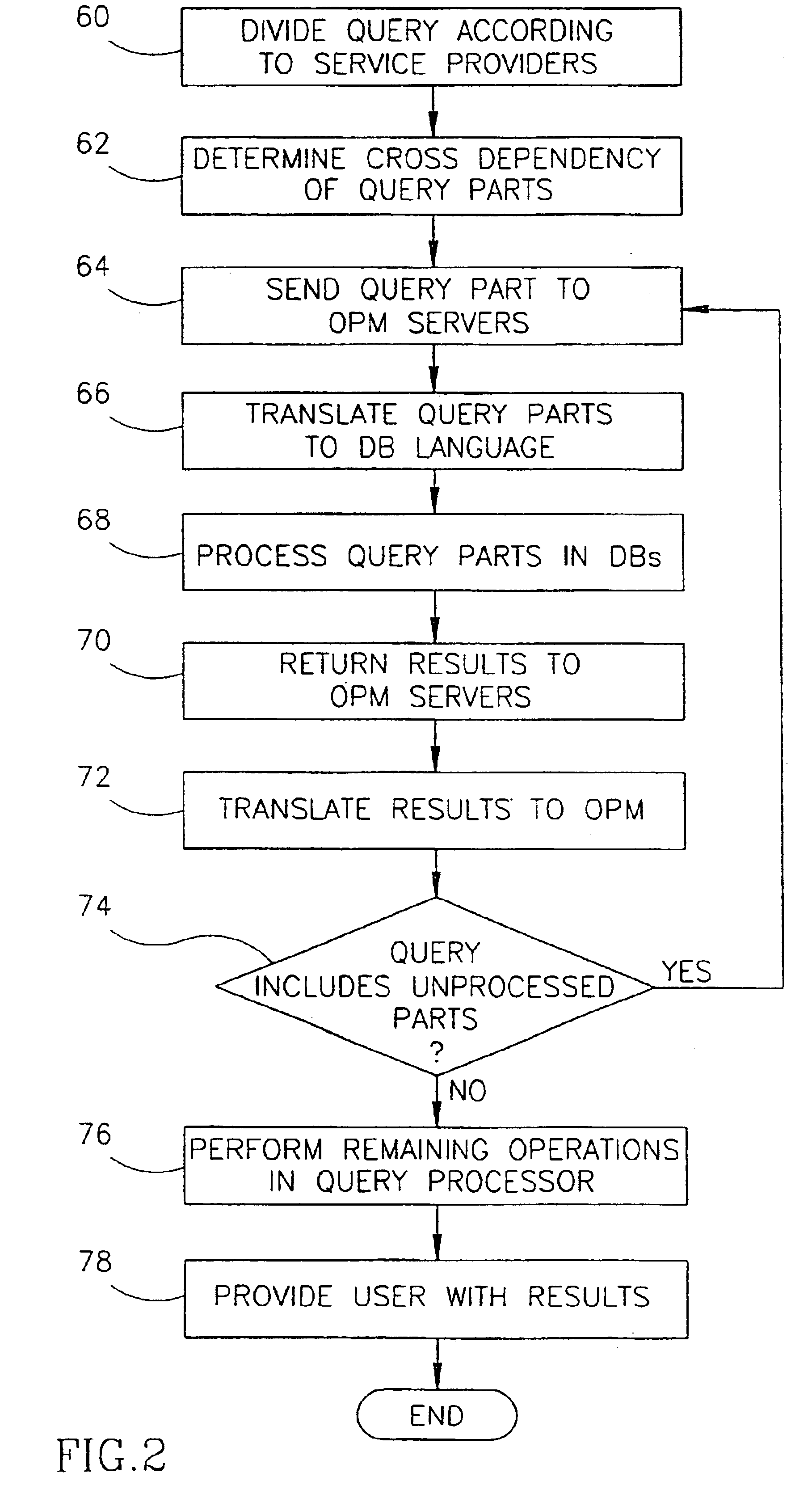

Load distribution in distributed database system

ActiveUS20090157684A1Evenly loadedShorten the time spanProgram controlData switching networksLookup tableLoad distribution

A state change in a network comprising a master server among a plurality of servers is determined, at the master server, a first lookup table is calculated, said first lookup table indicating respective partitions of a second lookup table distributed among active servers of said plurality of servers, the calculated first lookup table is distributed to each active server, and based on the first lookup table, at the master server, a modified partition of the second lookup table is generated.

Owner:NOKIA SOLUTIONS & NETWORKS OY

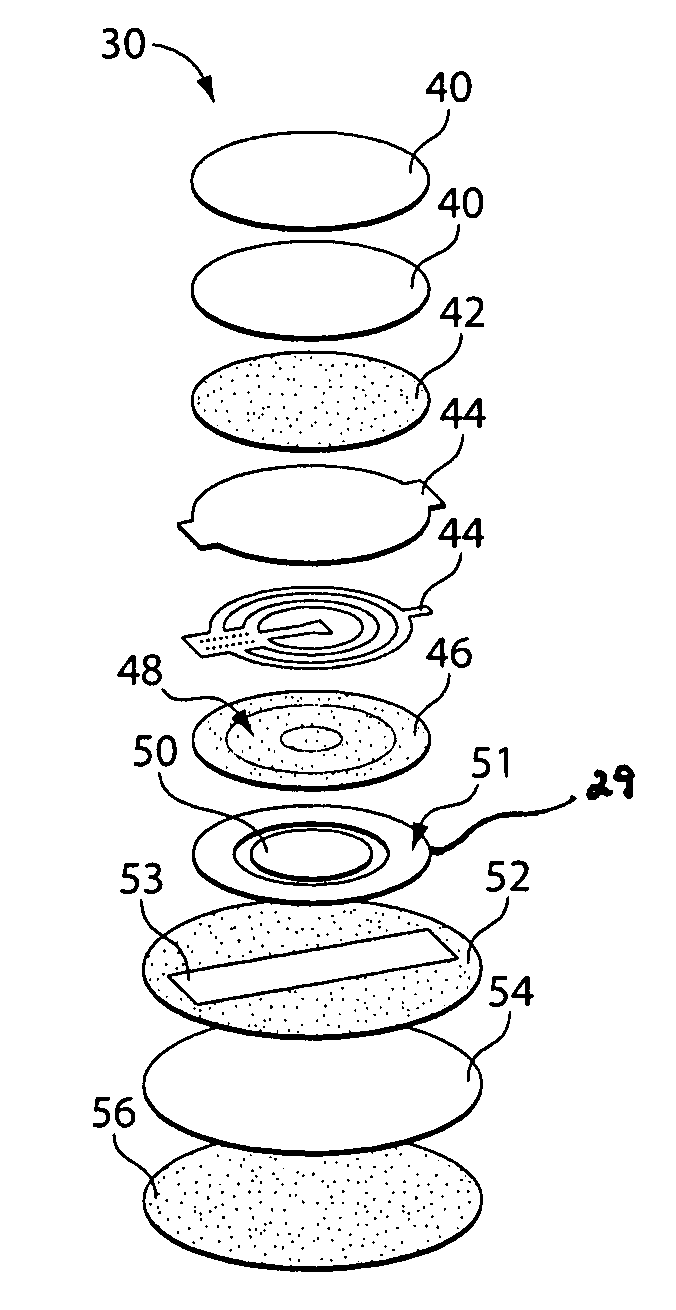

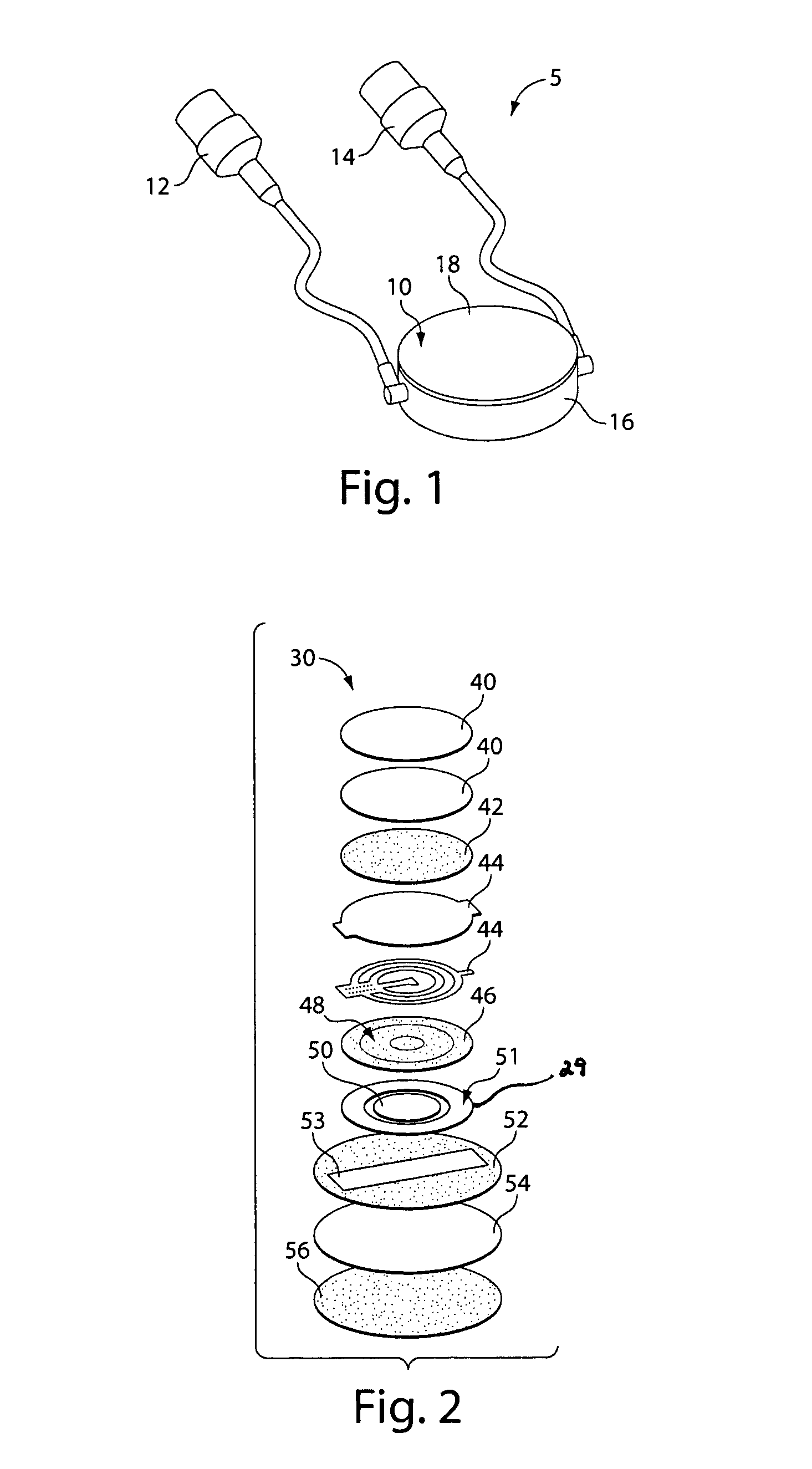

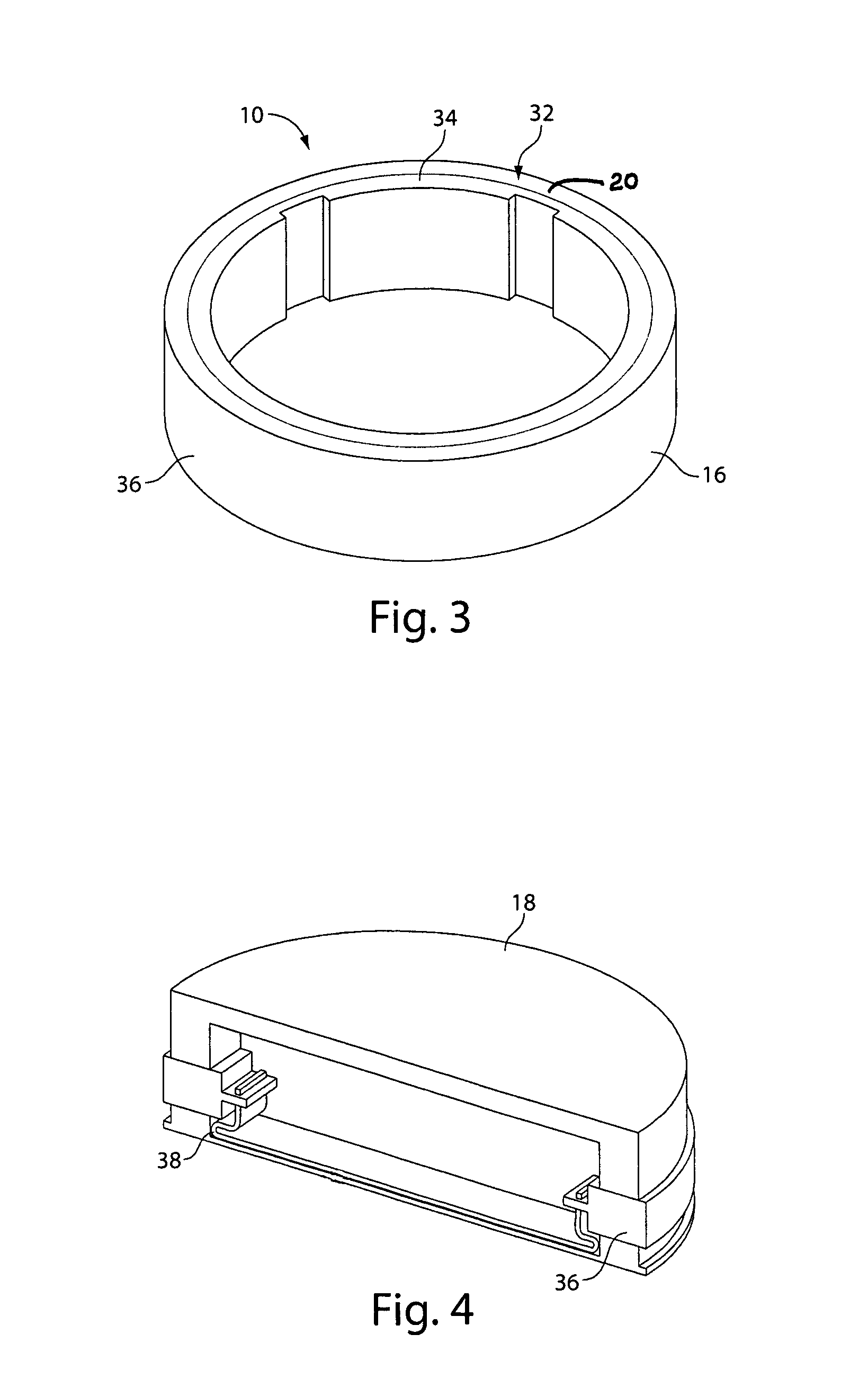

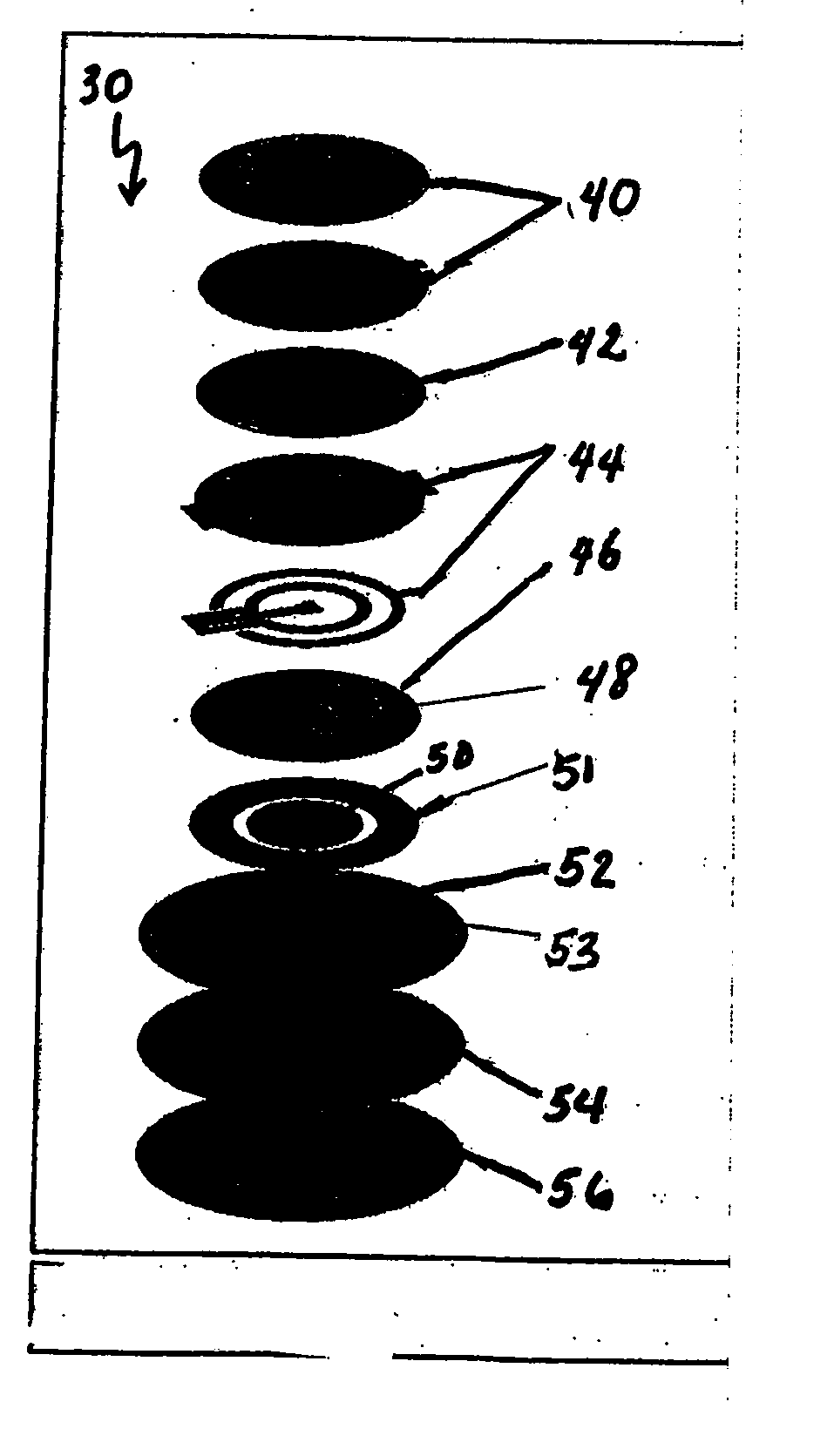

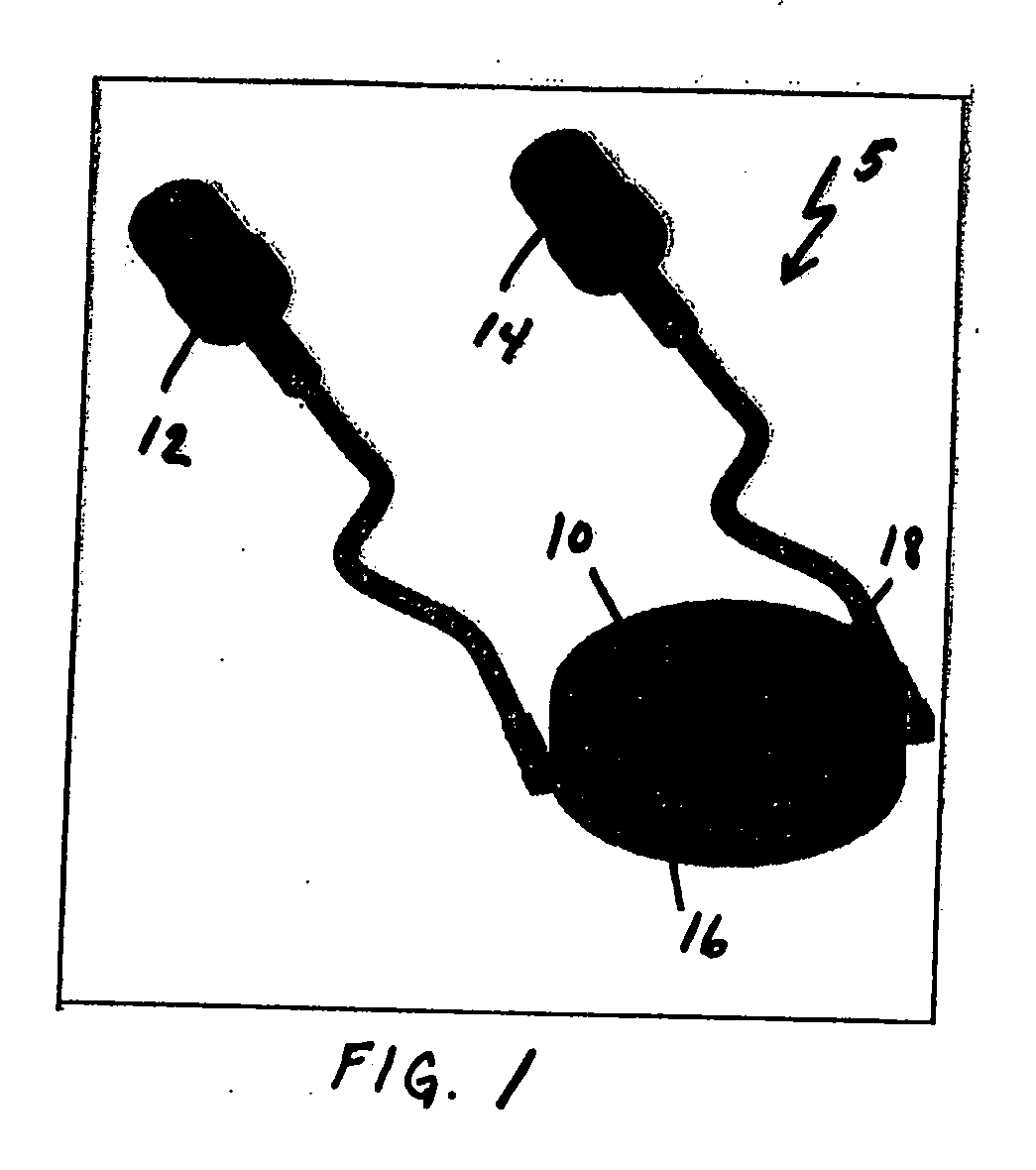

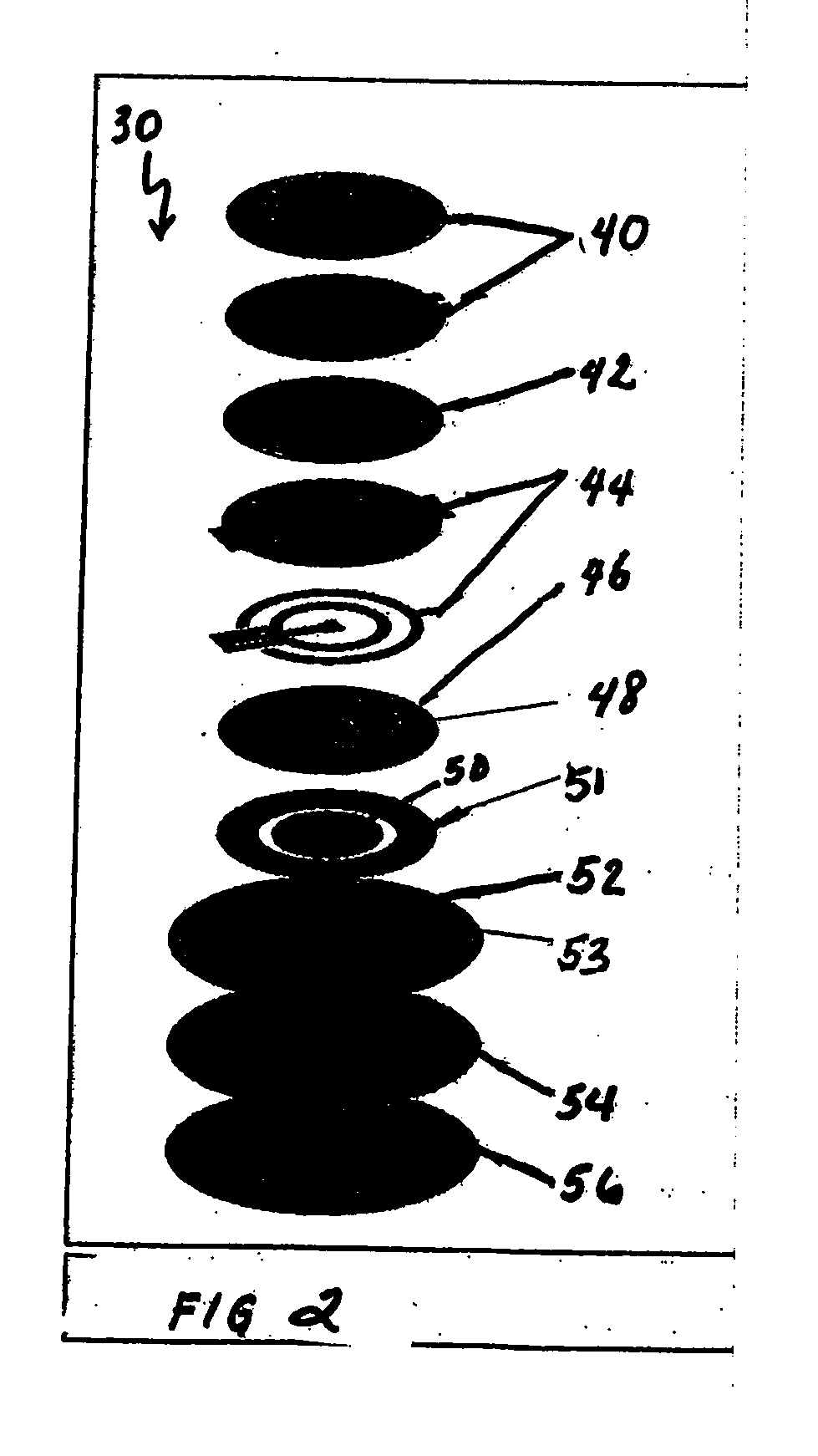

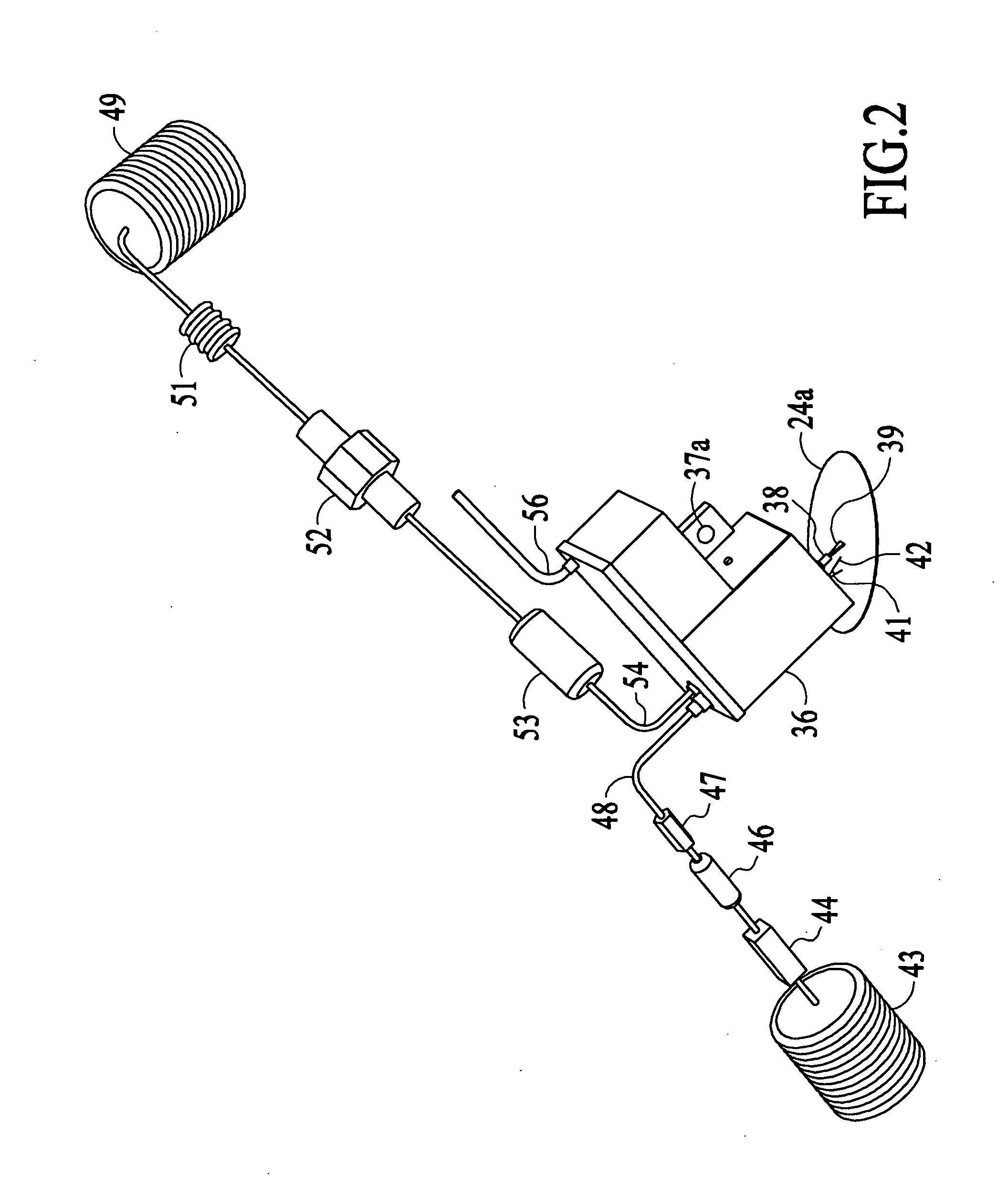

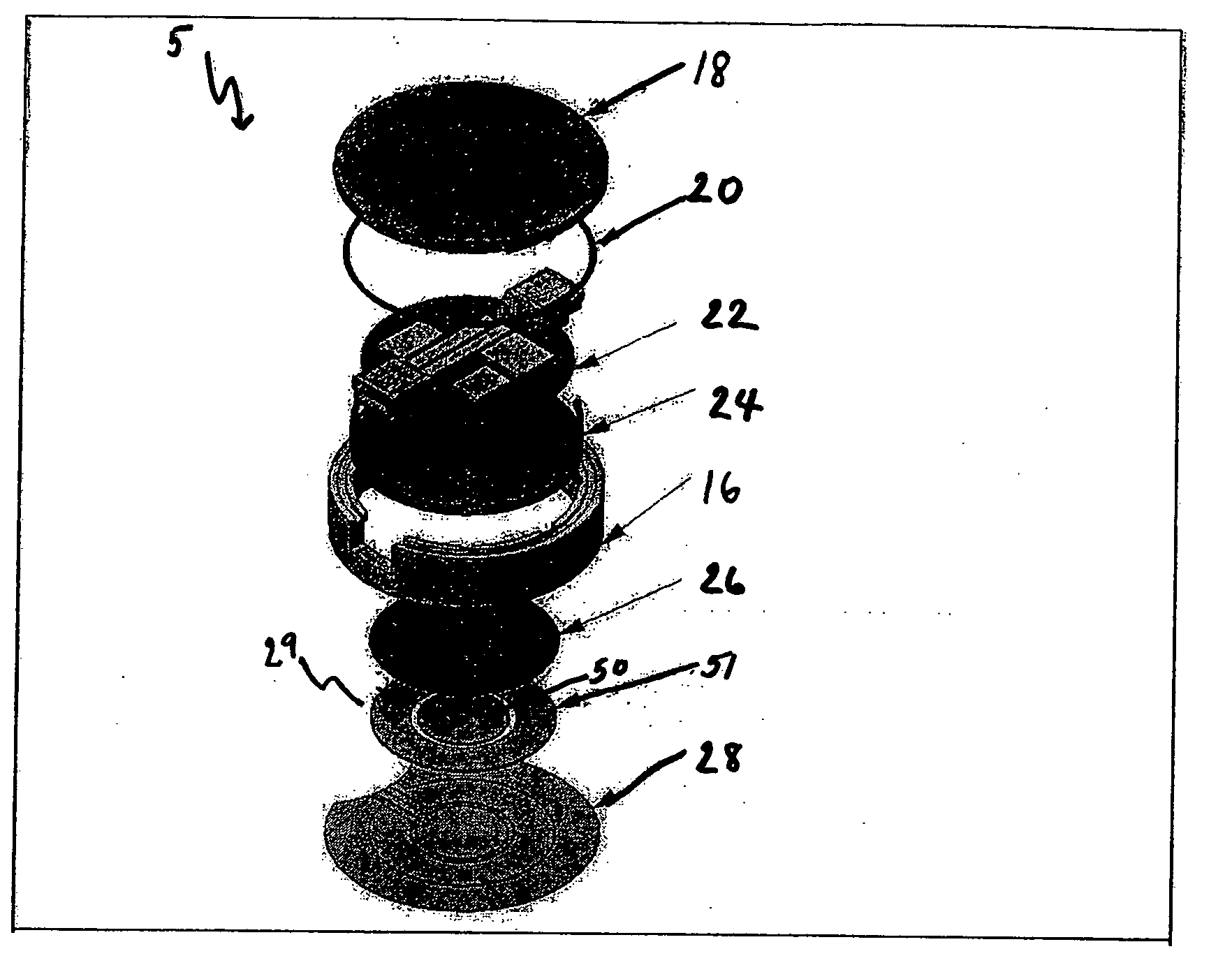

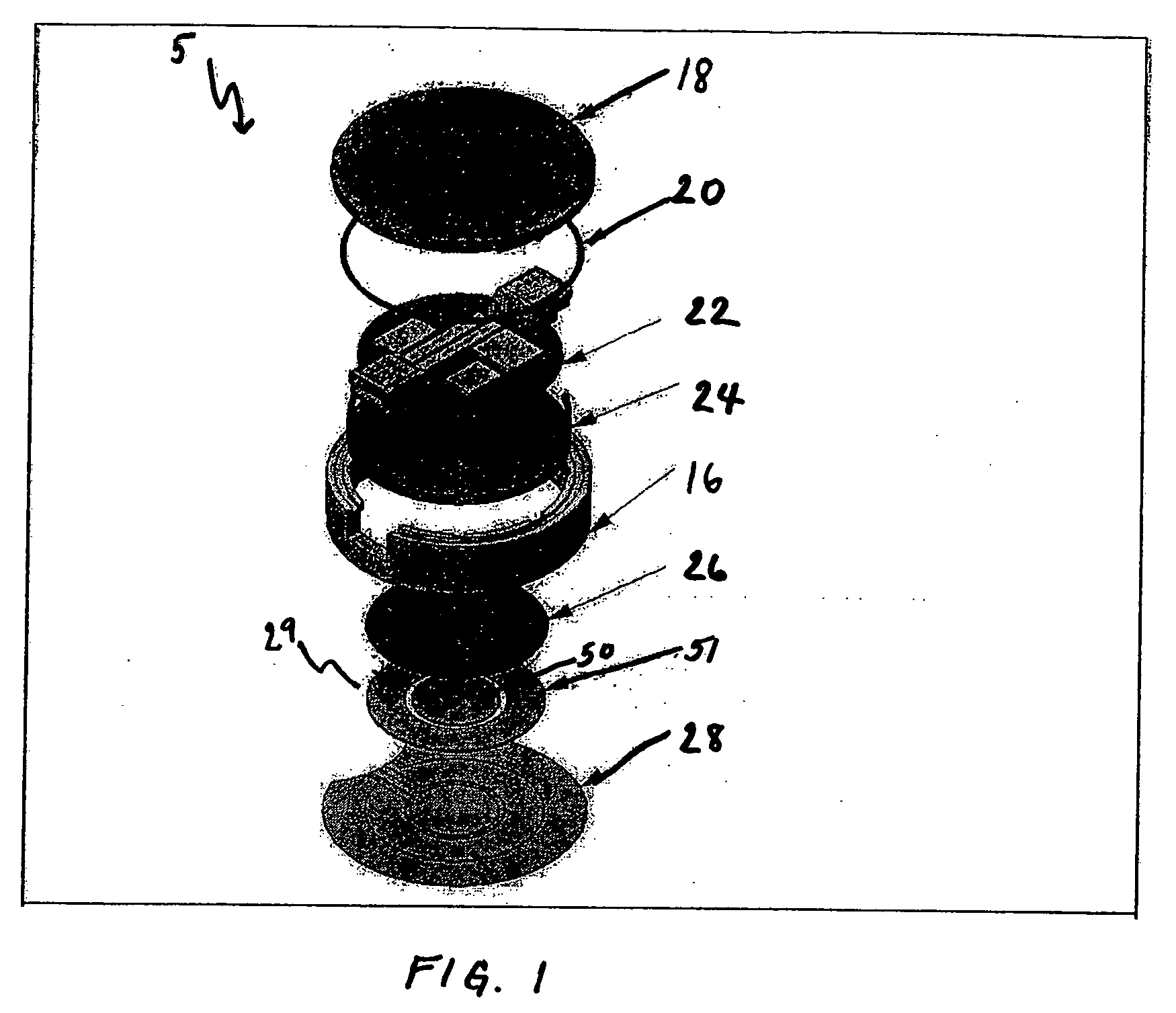

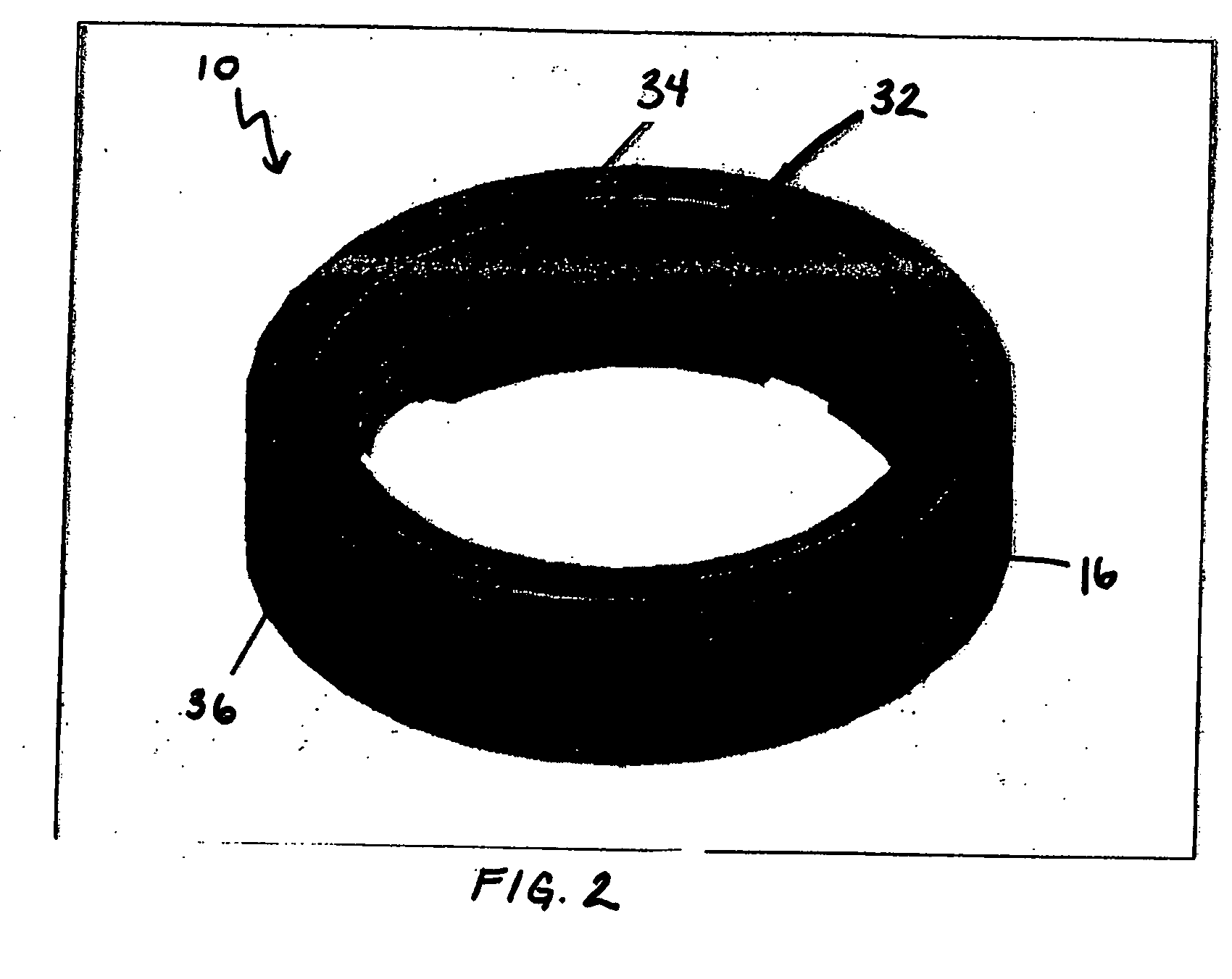

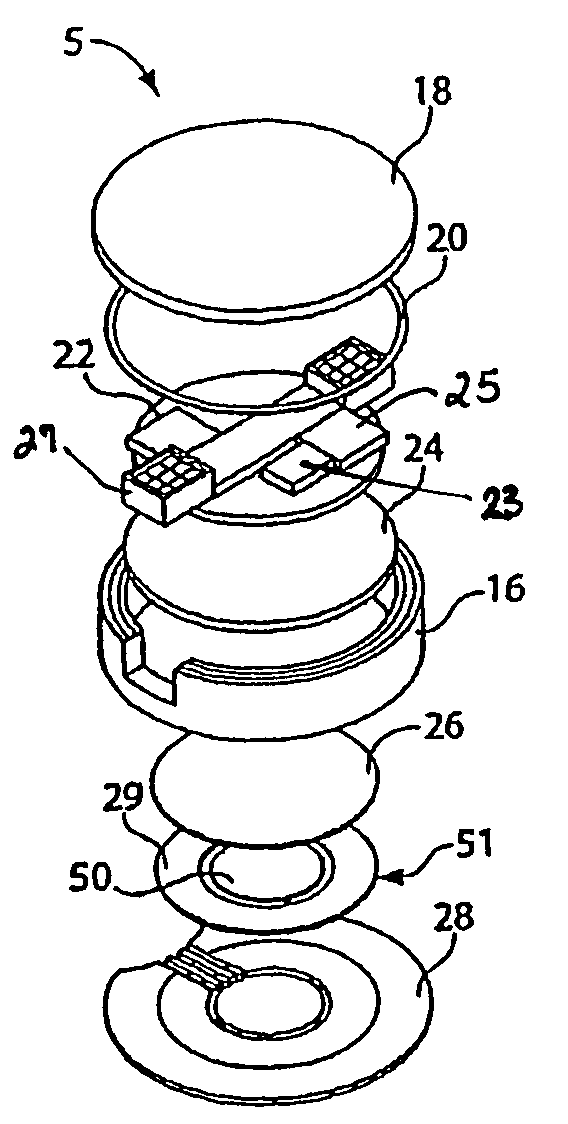

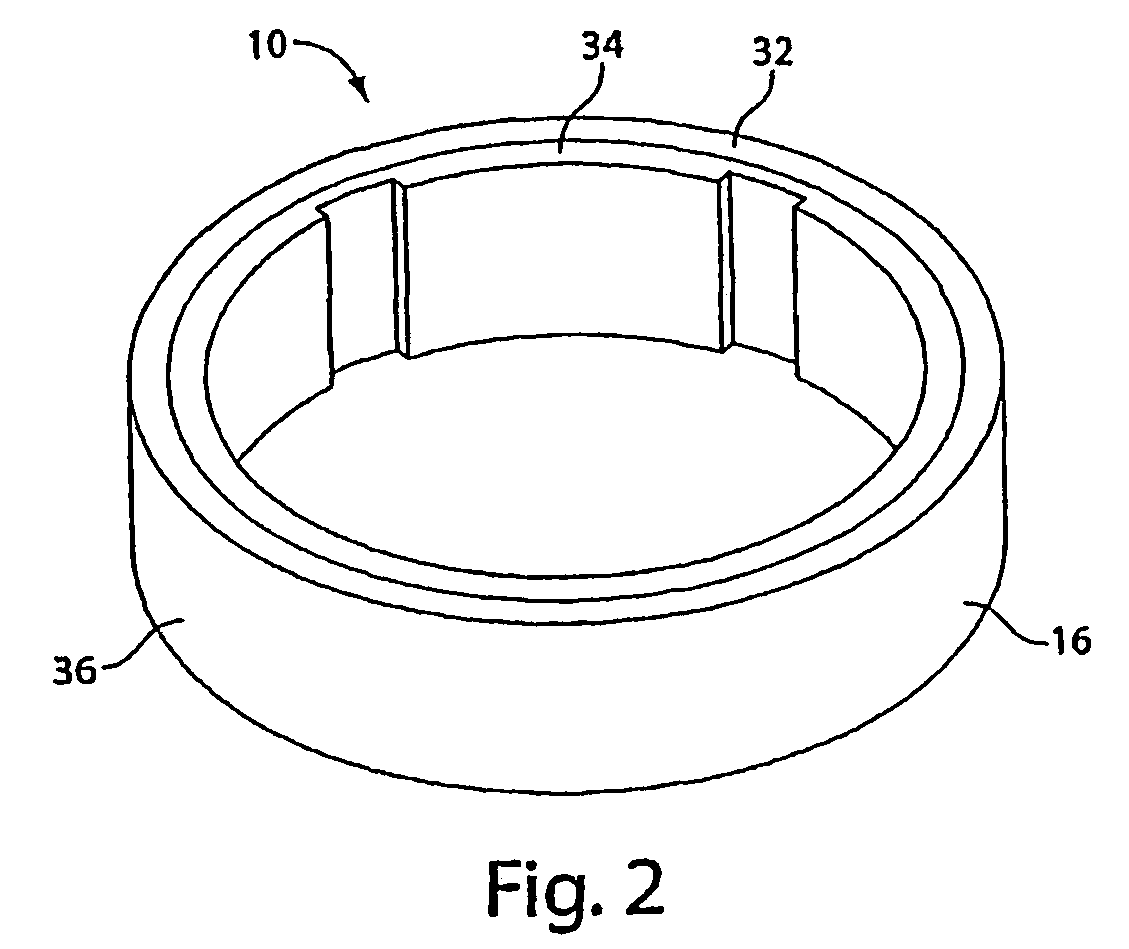

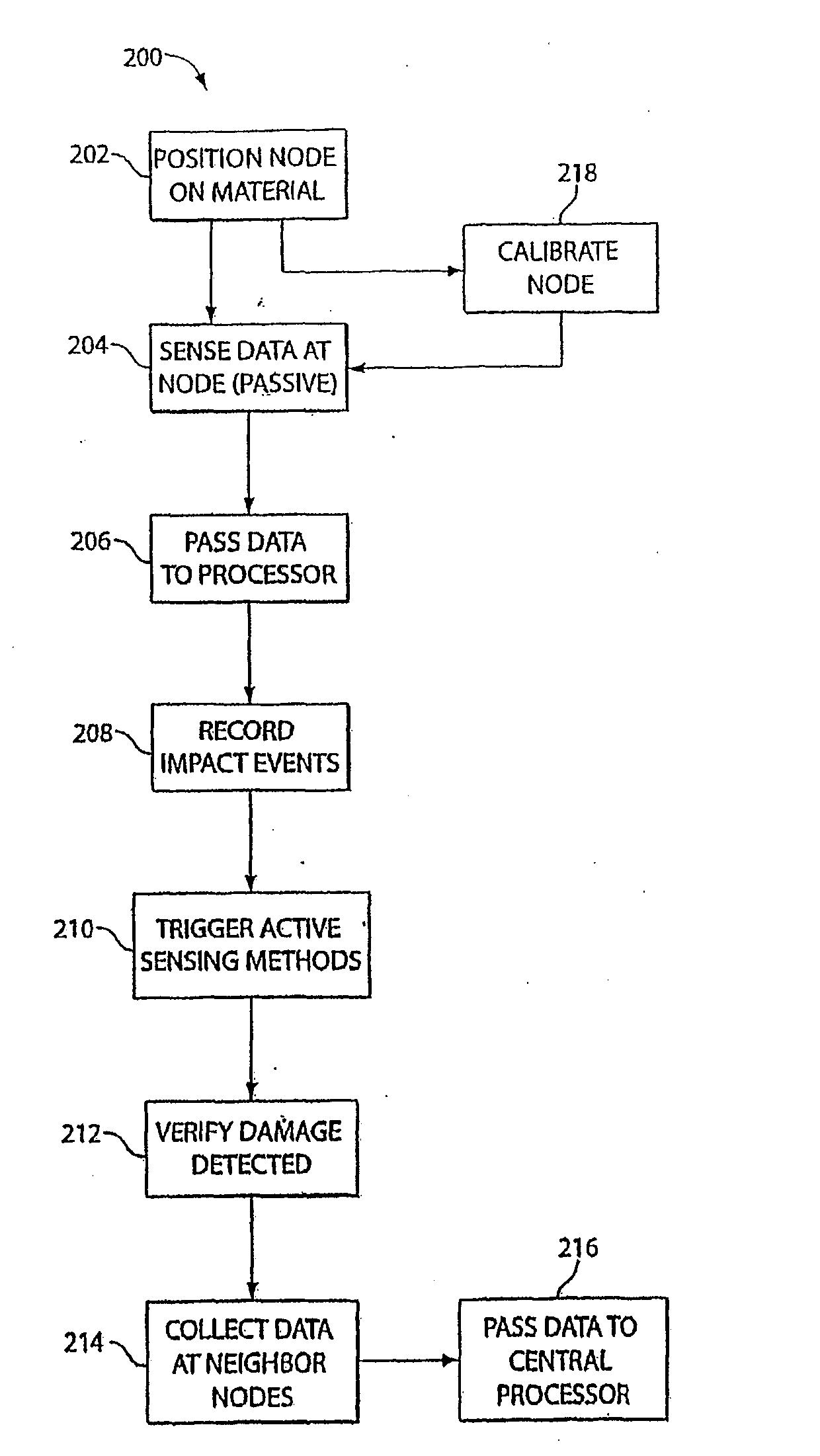

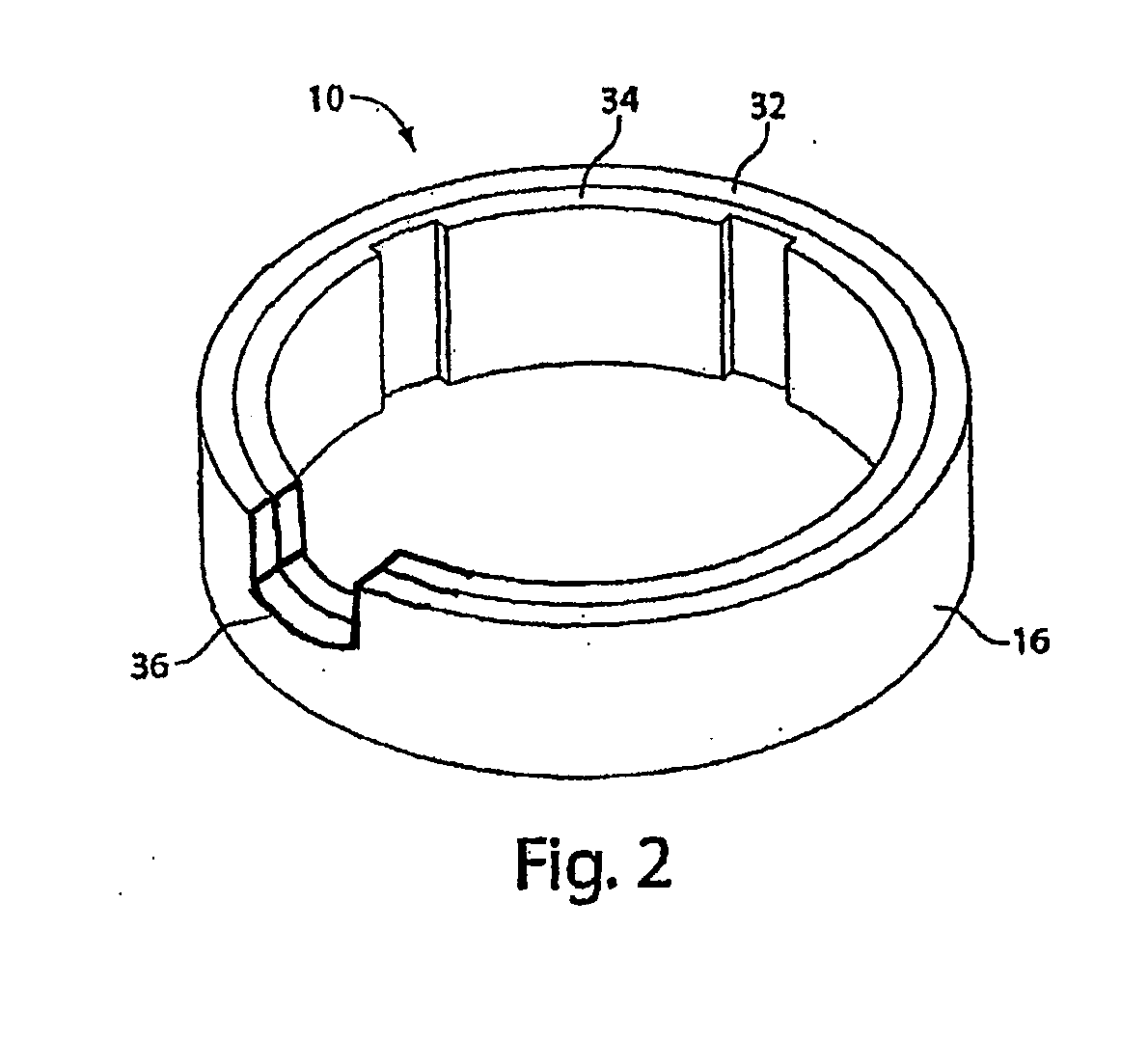

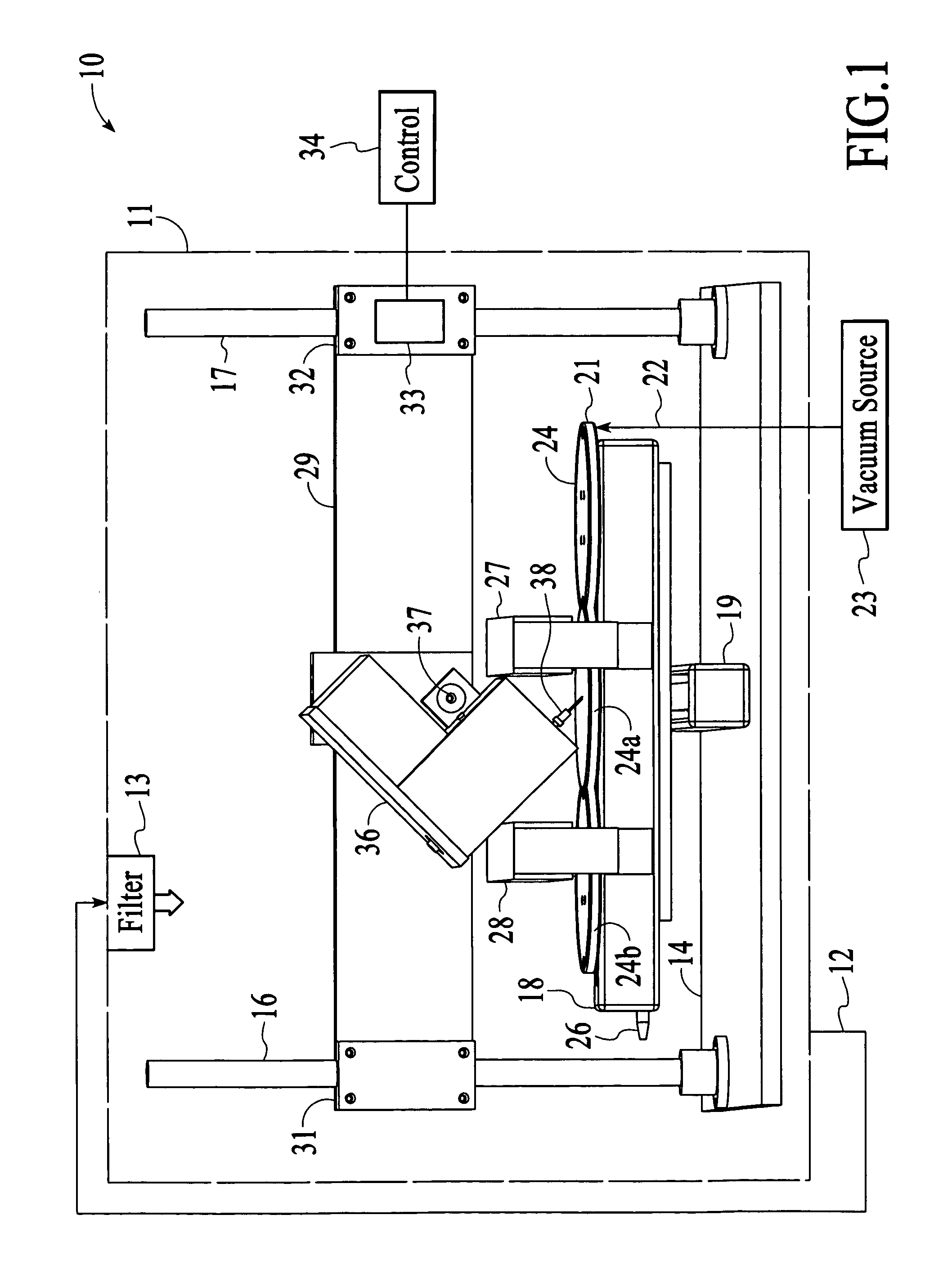

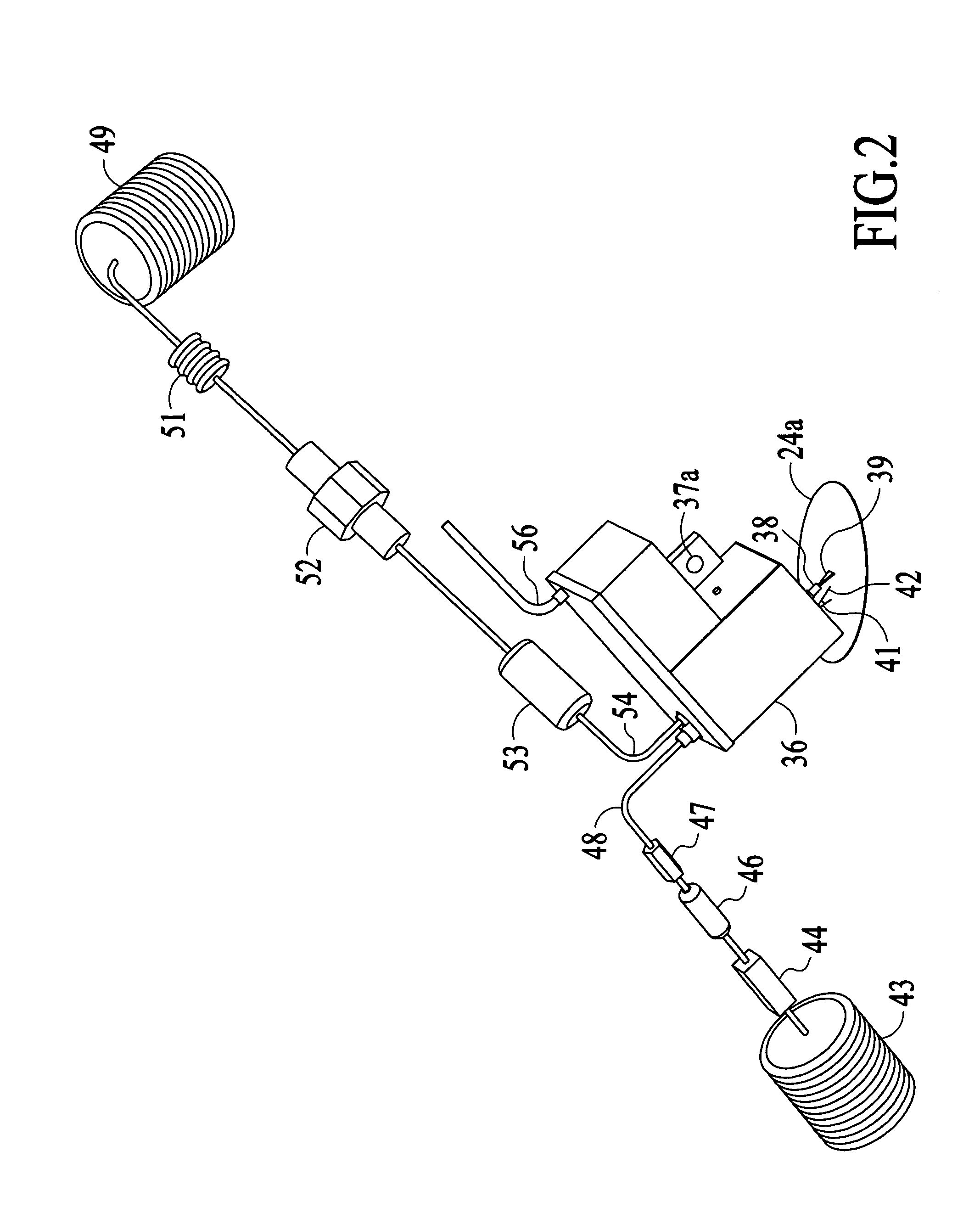

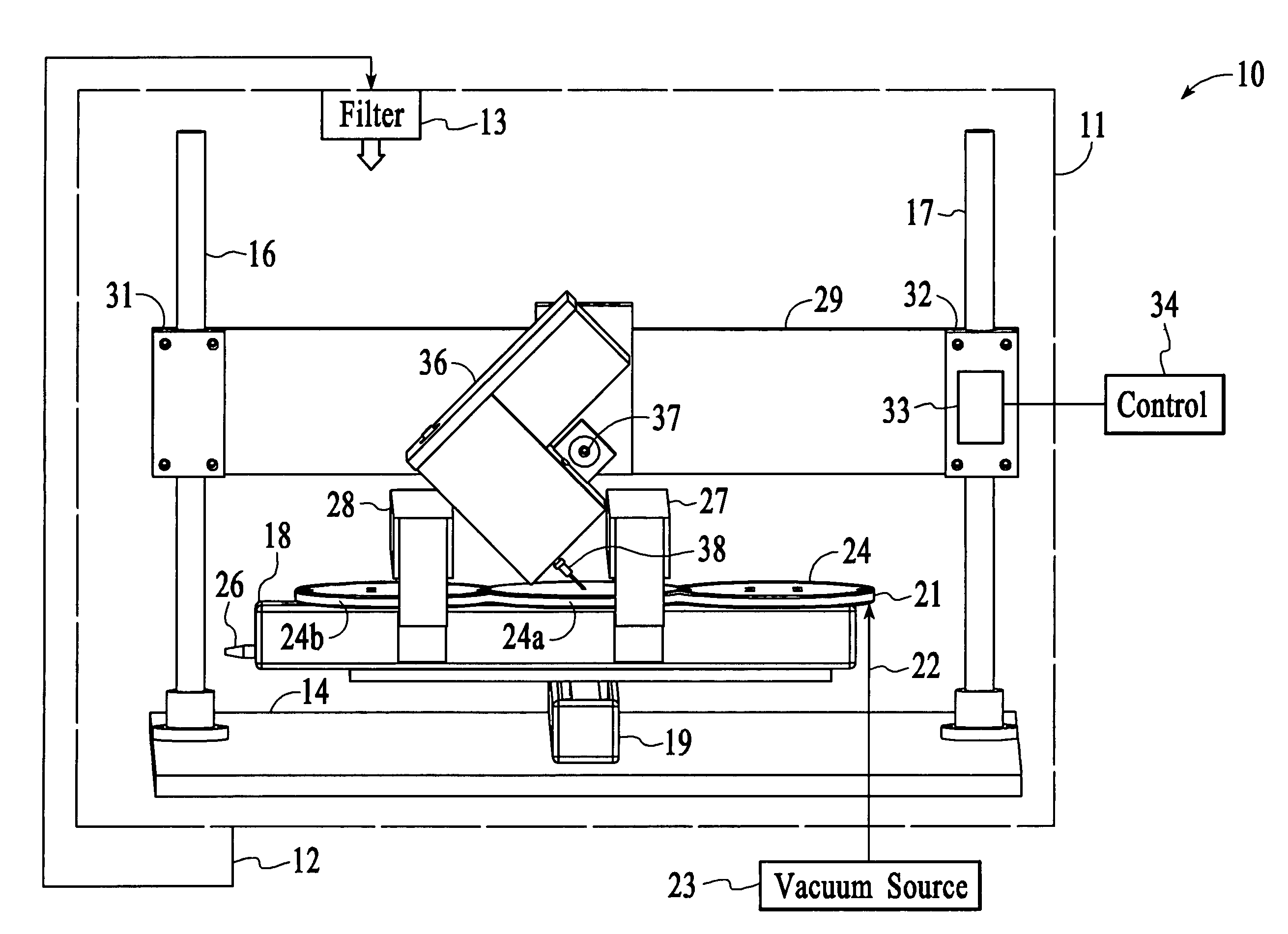

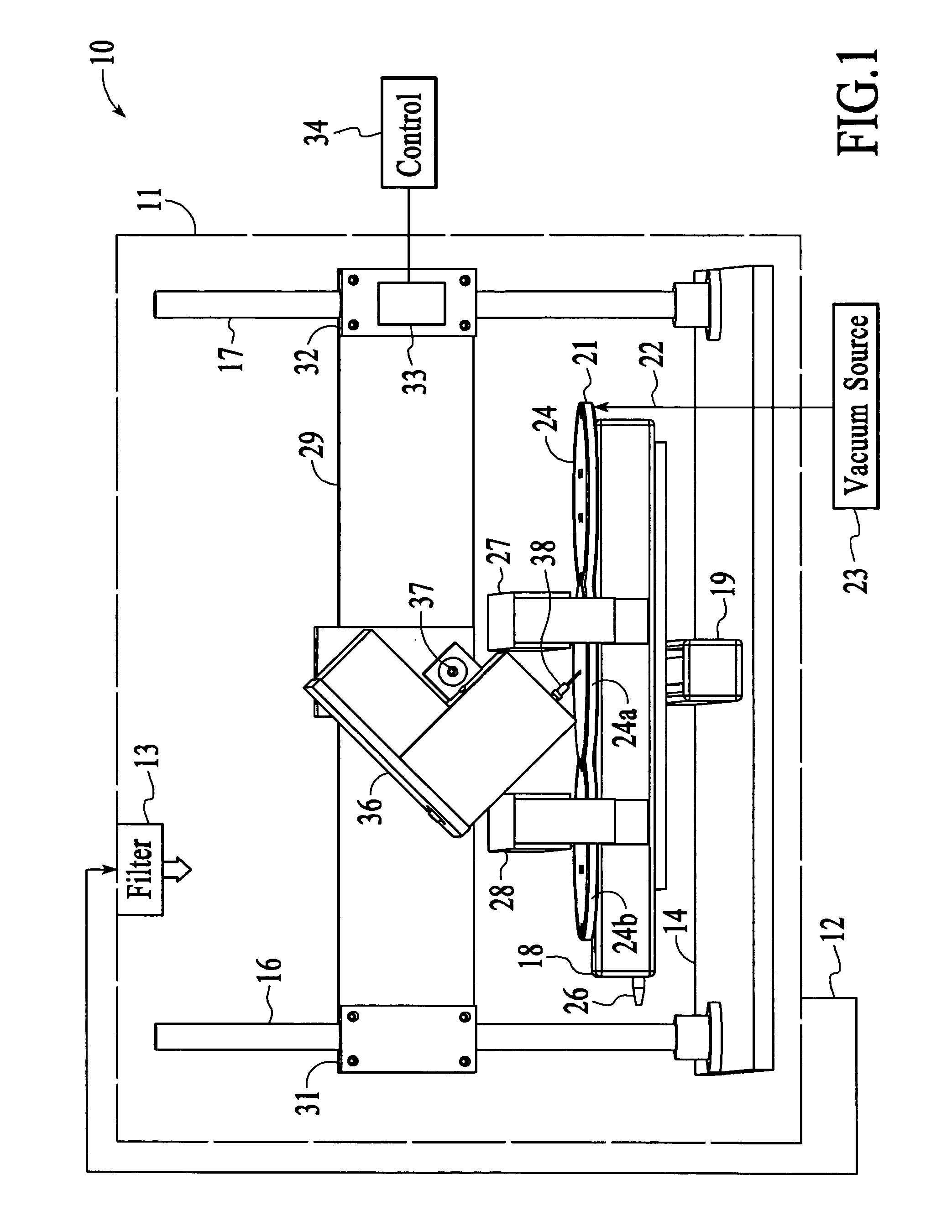

Damage detection device

ActiveUS20060081071A1Elimination of scheduled inspectionImprove reliabilityForce measurement using piezo-electric devicesElectrical/magnetic solid deformation measurementIn planeProviding material

A device for use in detecting structural damage comprises at least one piezoelectric wafer including a sensor, and an actuator in-plane with the sensor. At least one of the sensor and the actuator at least partially surrounds the other of the sensor and the actuator such that the piezoelectric wafer provides radial detection of structural occurrences in a material.

Owner:METIS DESIGN CORP

Distributed database system using master server to generate lookup tables for load distribution

ActiveUS7984183B2Shorten the time spanAvoid excessive controlDigital computer detailsProgram controlLookup tableLoad distribution

A state change in a network comprising a master server among a plurality of servers is determined, at the master server, a first lookup table is calculated, said first lookup table indicating respective partitions of a second lookup table distributed among active servers of said plurality of servers, the calculated first lookup table is distributed to each active server, and based on the first lookup table, at the master server, a modified partition of the second lookup table is generated.

Owner:NOKIA SOLUTIONS & NETWORKS OY

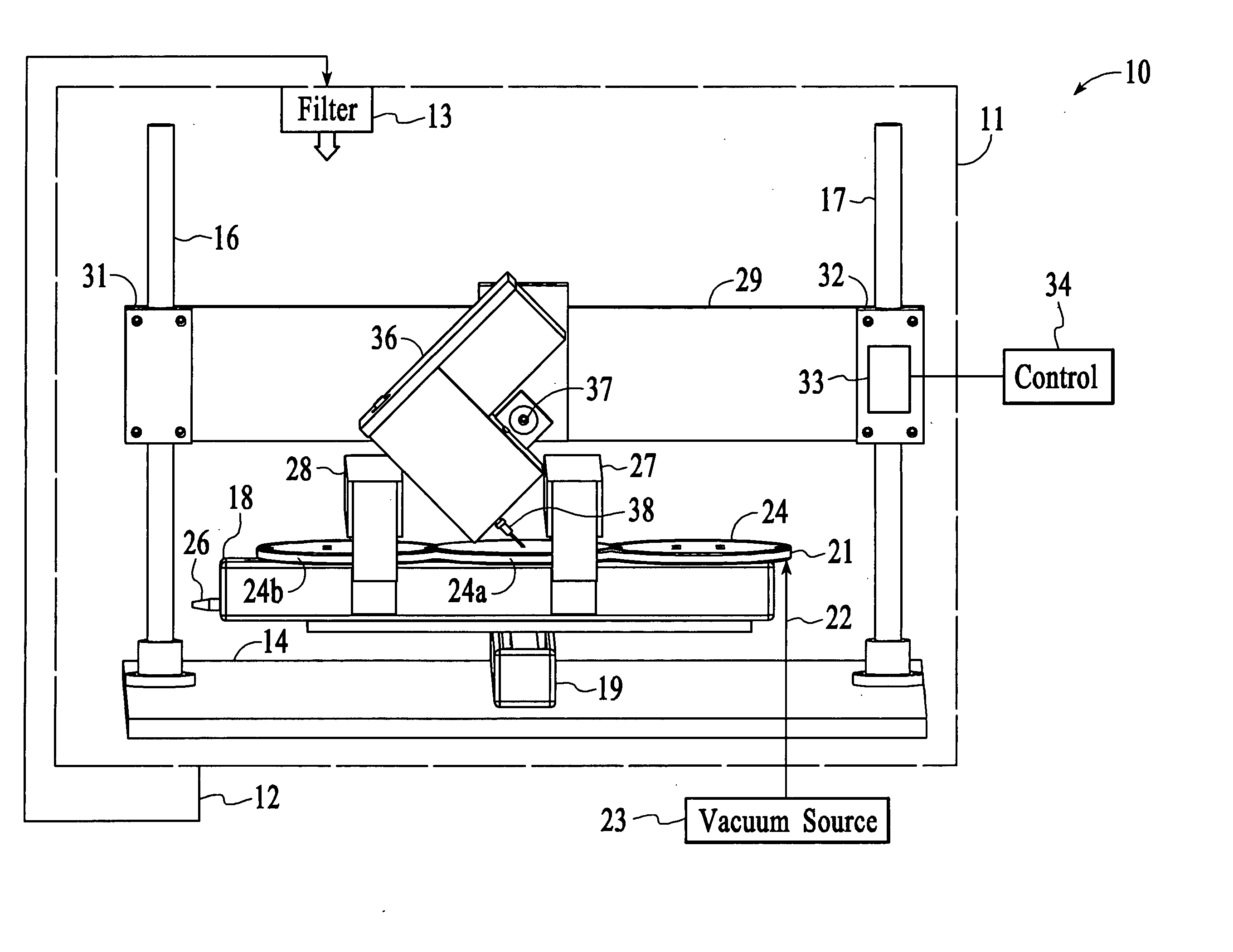

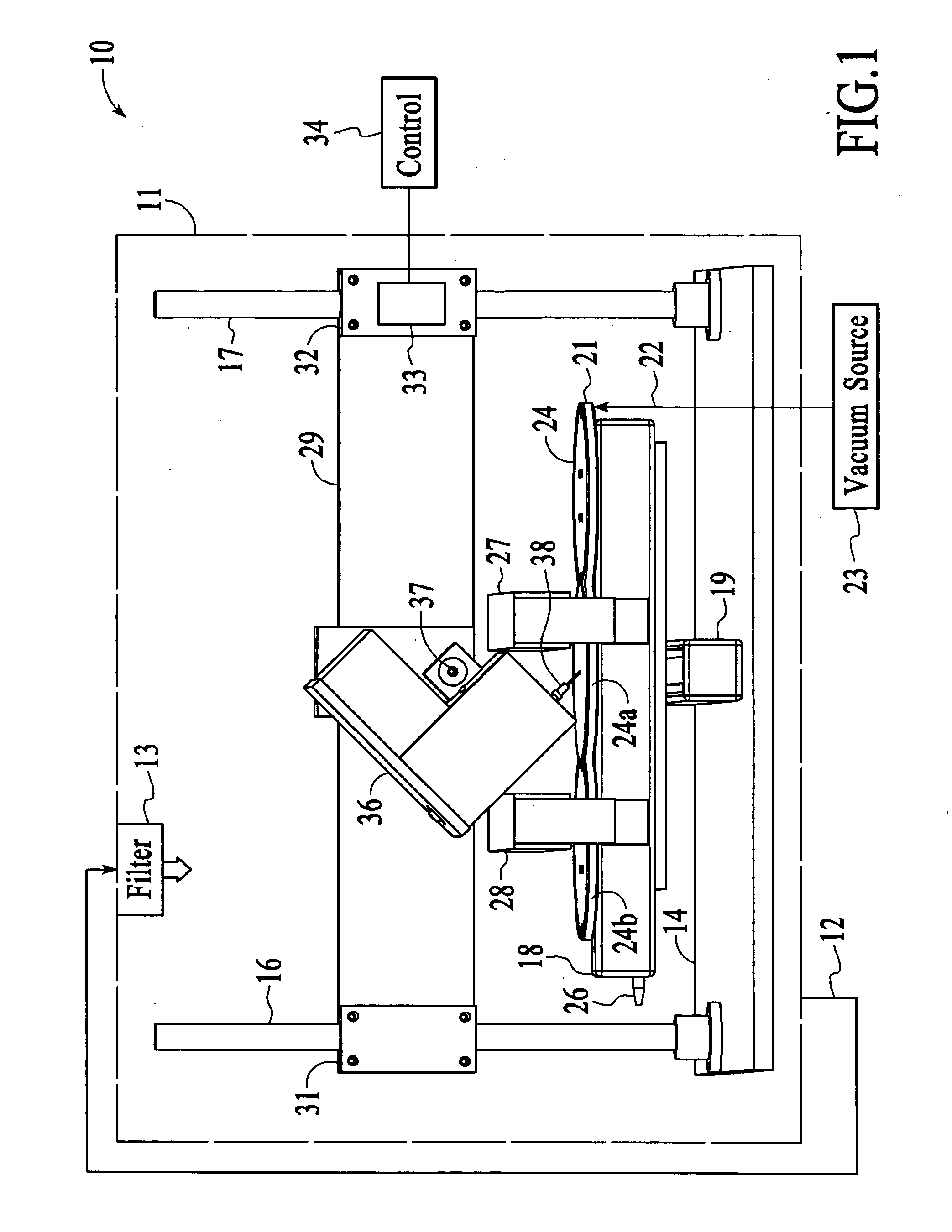

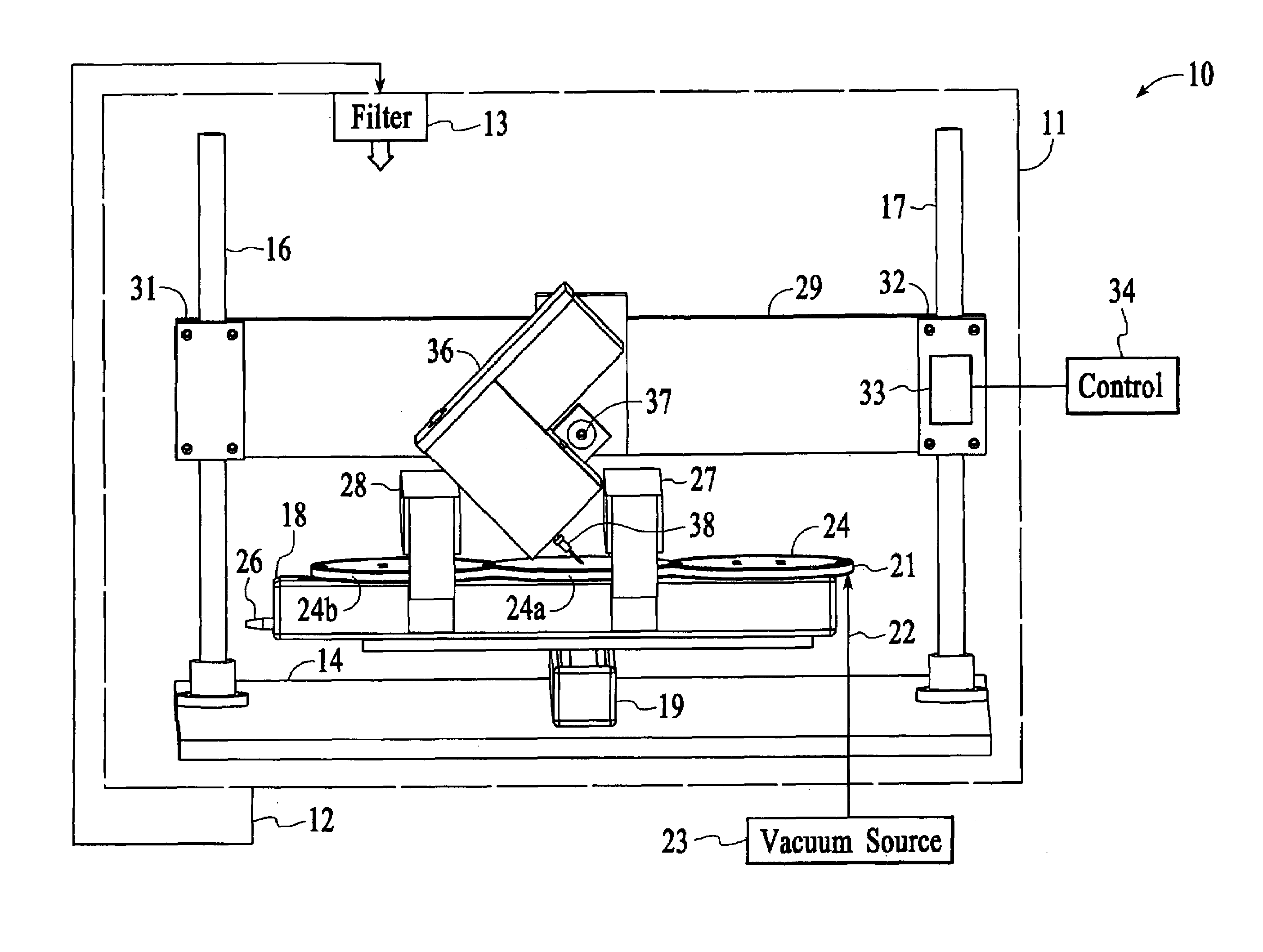

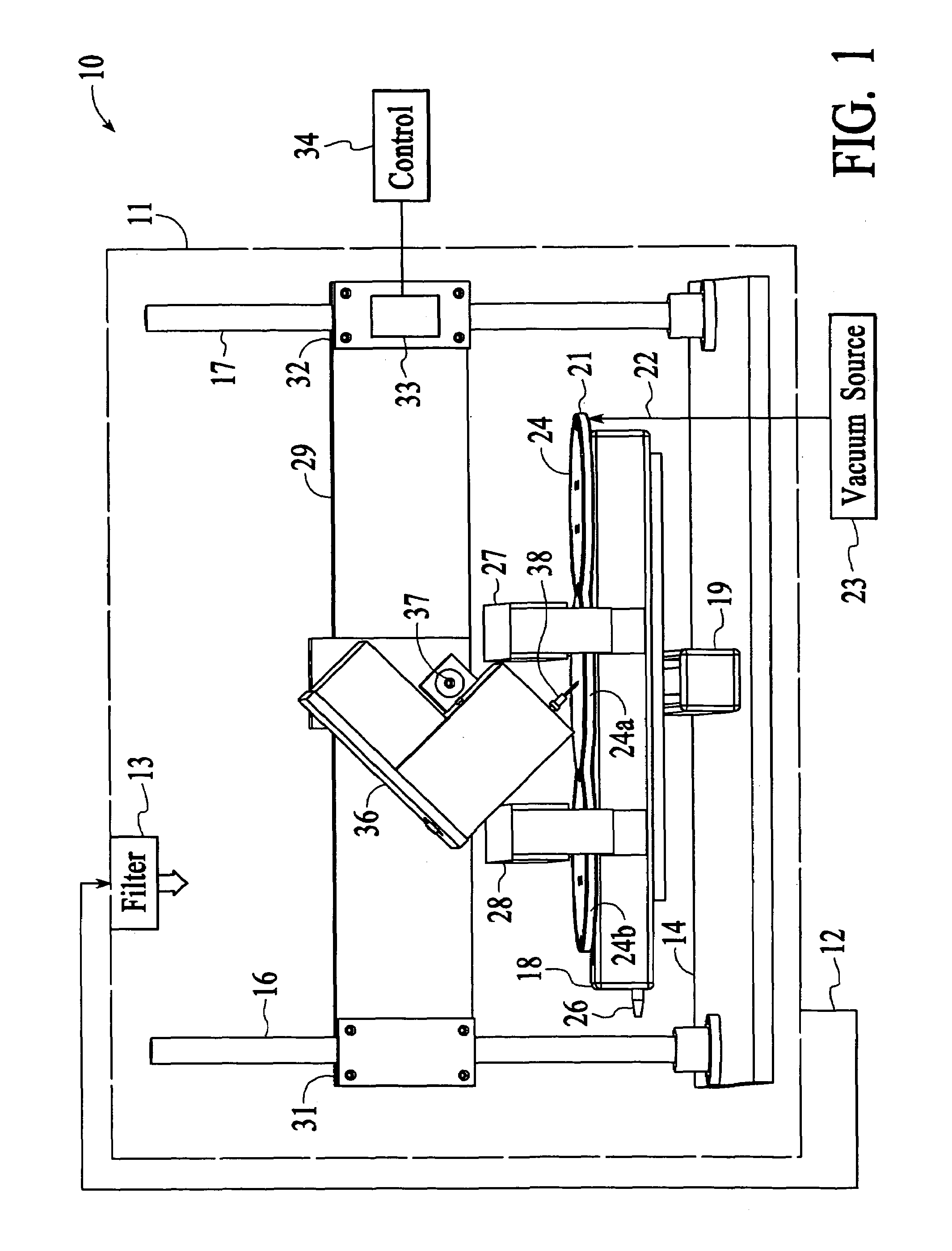

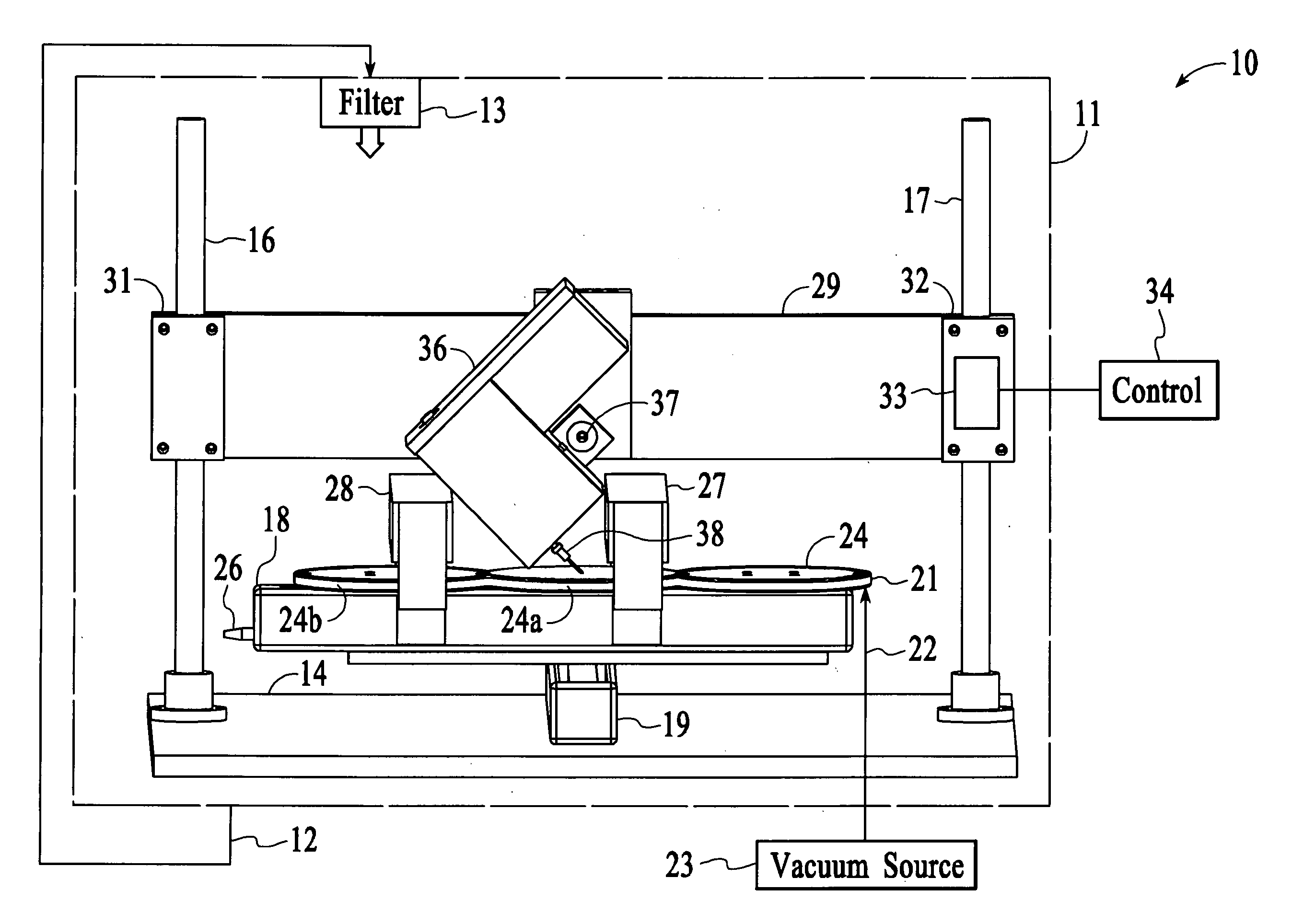

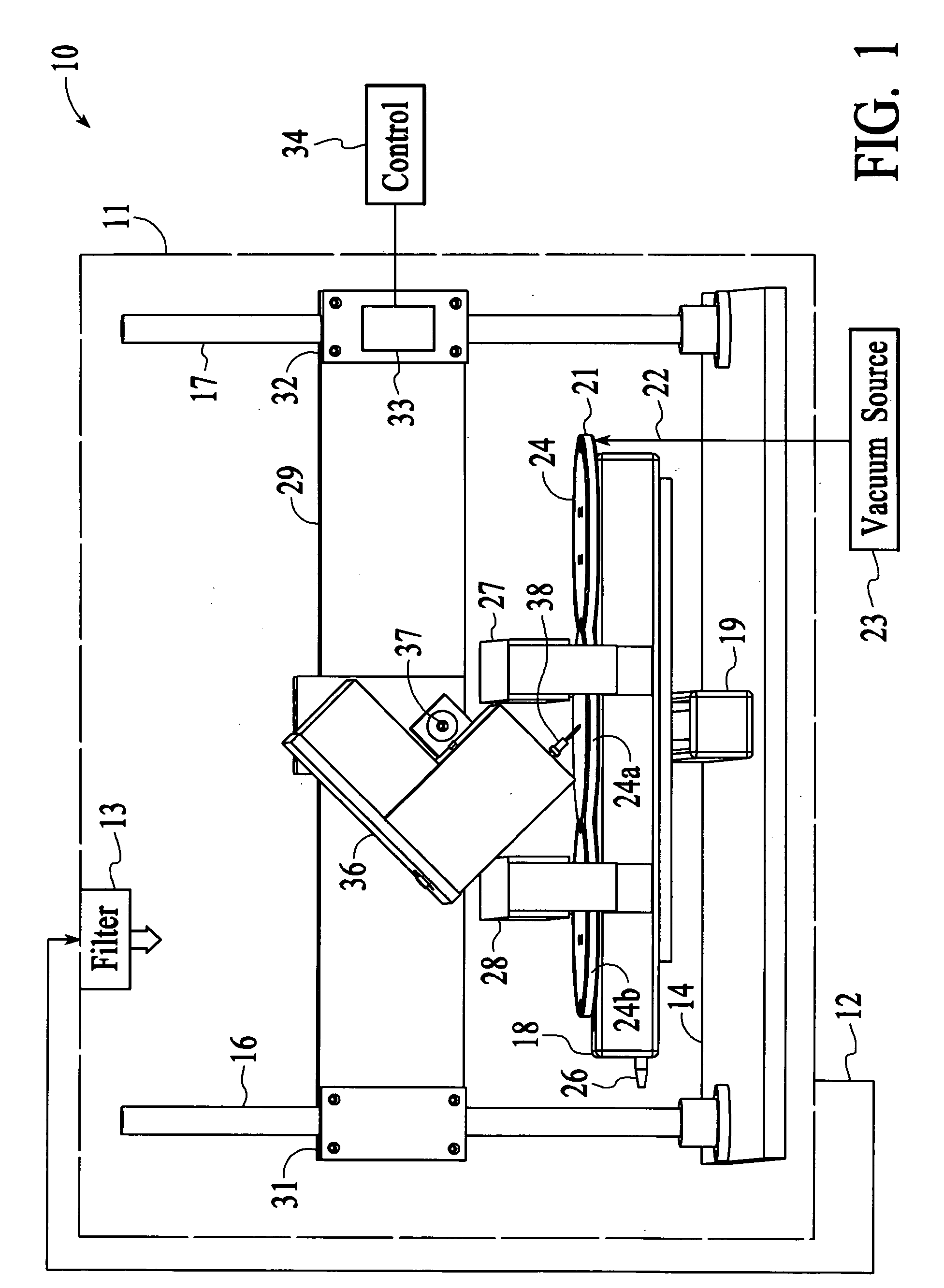

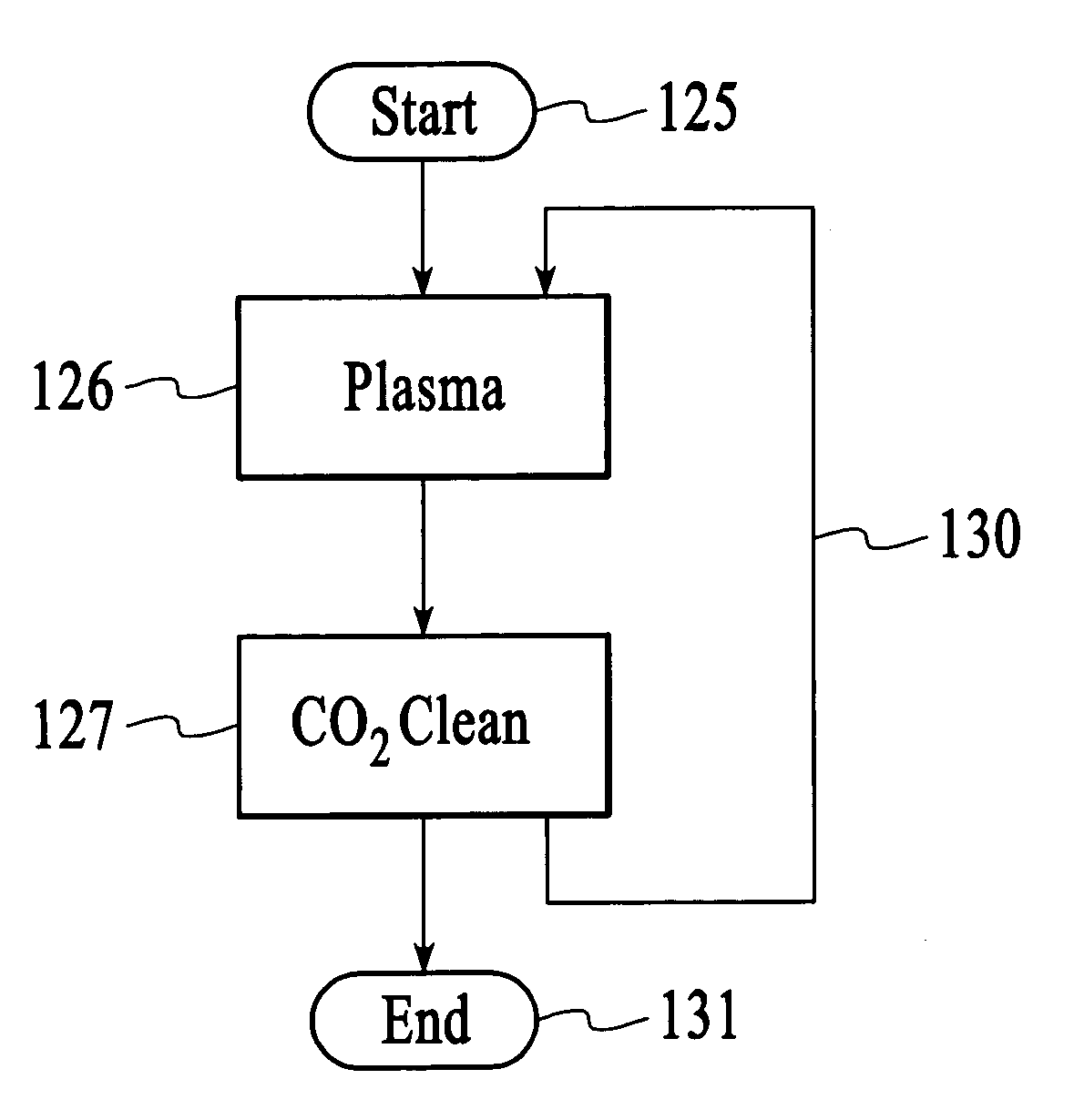

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

A method for manufacturing an article where the article has polymeric residue that is to be removed during the manufacture of the article. The article is introduced into a controlled environment of a processing tool that has at least first and second processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least the first processing chamber where they react with the polymeric residue. A cryogenic cleaning medium is supplied into the second processing chamber where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium The first and second processing chambers may be dedicated to plasma processing or cryogenic processing or each may provide both plasma processing and cryogenic processing.

Owner:NANOCLEAN TECH

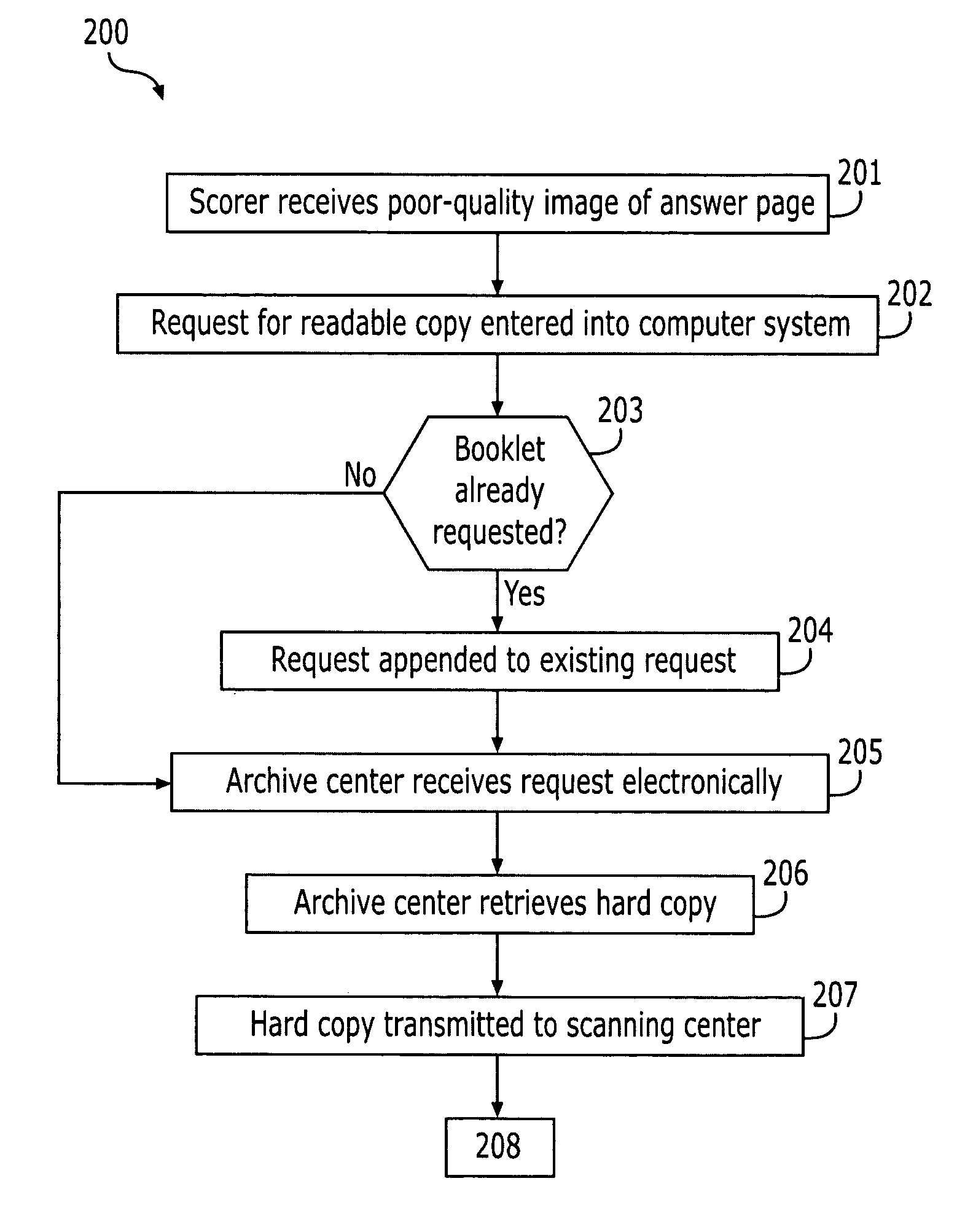

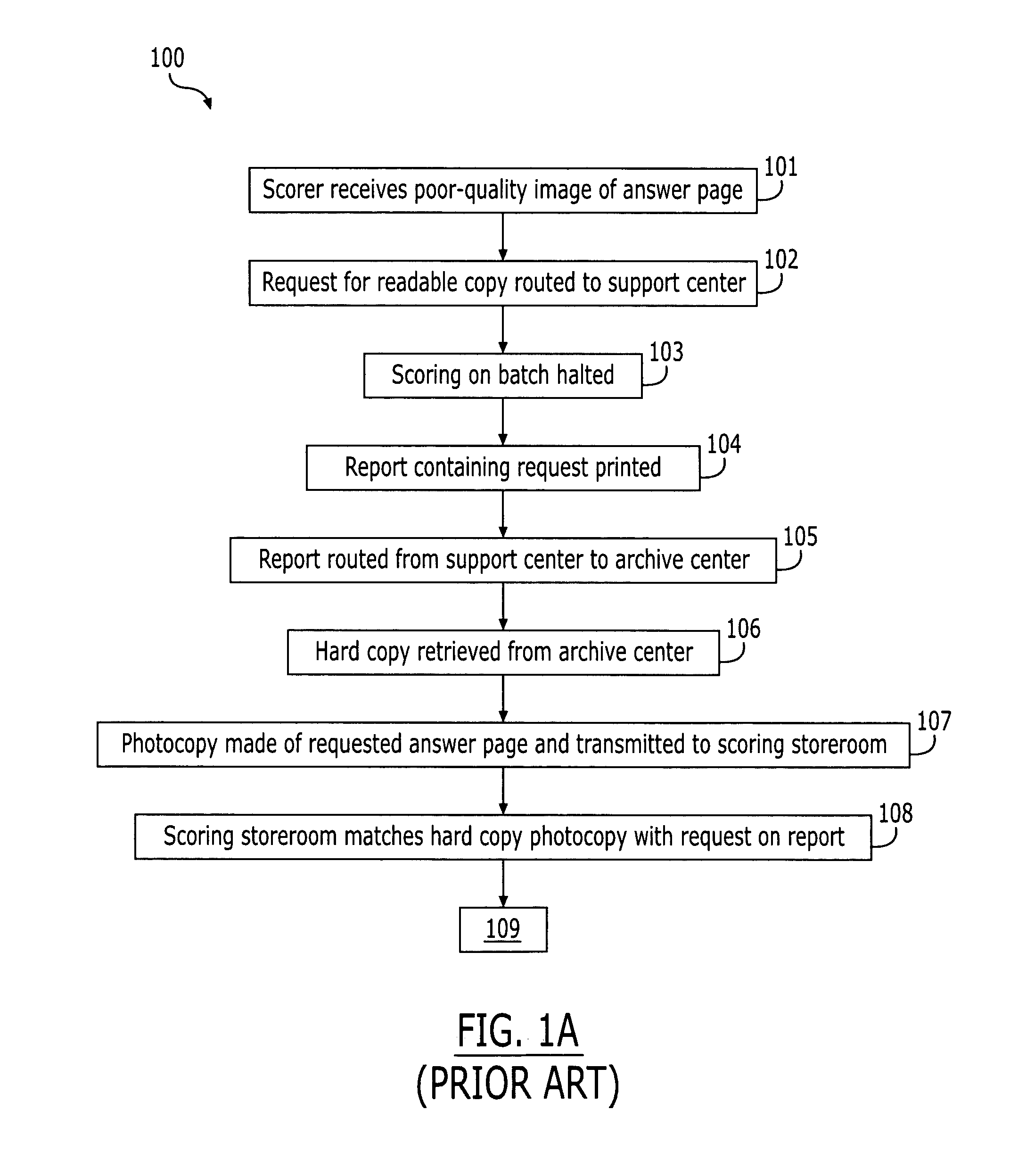

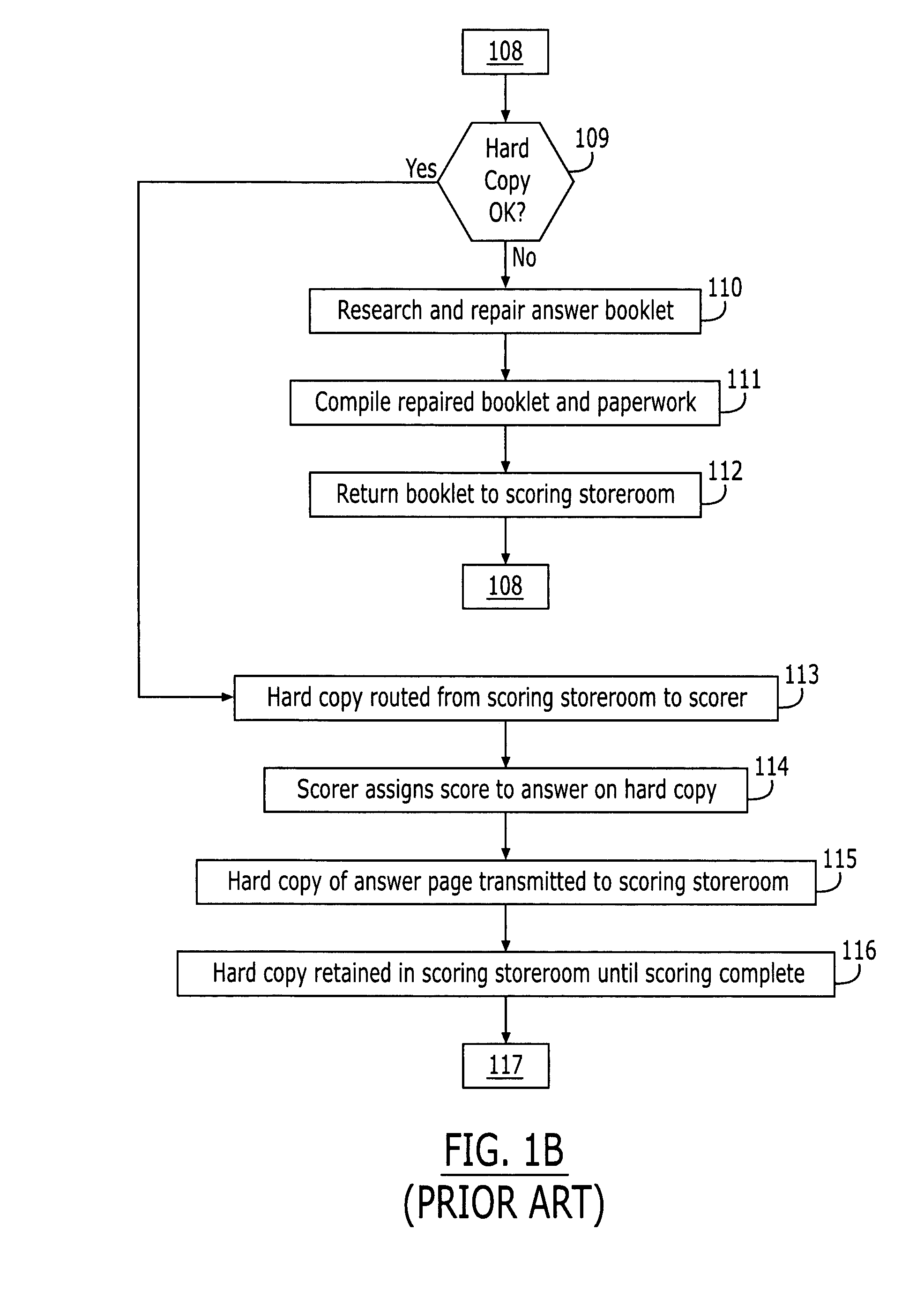

Electronic test answer record image quality improvement system and method

ActiveUS7020435B2Less timeLess human interventionElectrical appliancesMechanical appliancesInput deviceSoftware

A method for improving a scoring process includes displaying an original scanned image of a hard copy page of an answer to a scorer. If the scorer determines that the image is of insufficient quality to read, an electronic request for an improved image is received from the scorer and routed electronically to an archive containing the hard copy page, from which the page is retrieved. The retrieved page is rescanned to form a new image, which is then electronically transmitted to the scorer for scoring. A system includes hardware and software elements, including a processor and a database accessible by the processor containing original scanned images of answer pages. A scorer display and an input device are located at a scoring site, and an archive display and a scanner at an archive site. Software as described above is resident on the processor for implementing the method steps.

Owner:PSYCHOLOGICAL CORPORATION

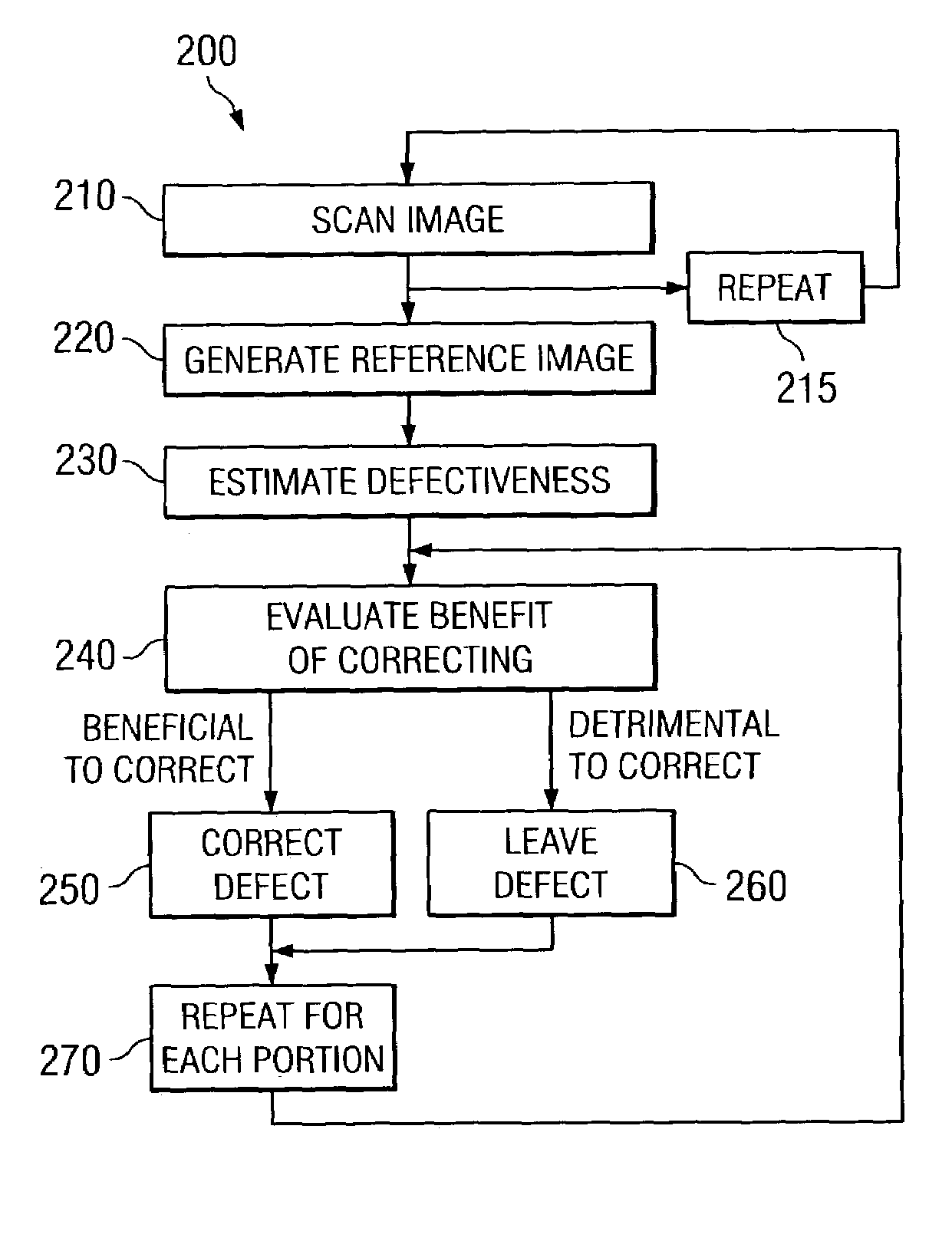

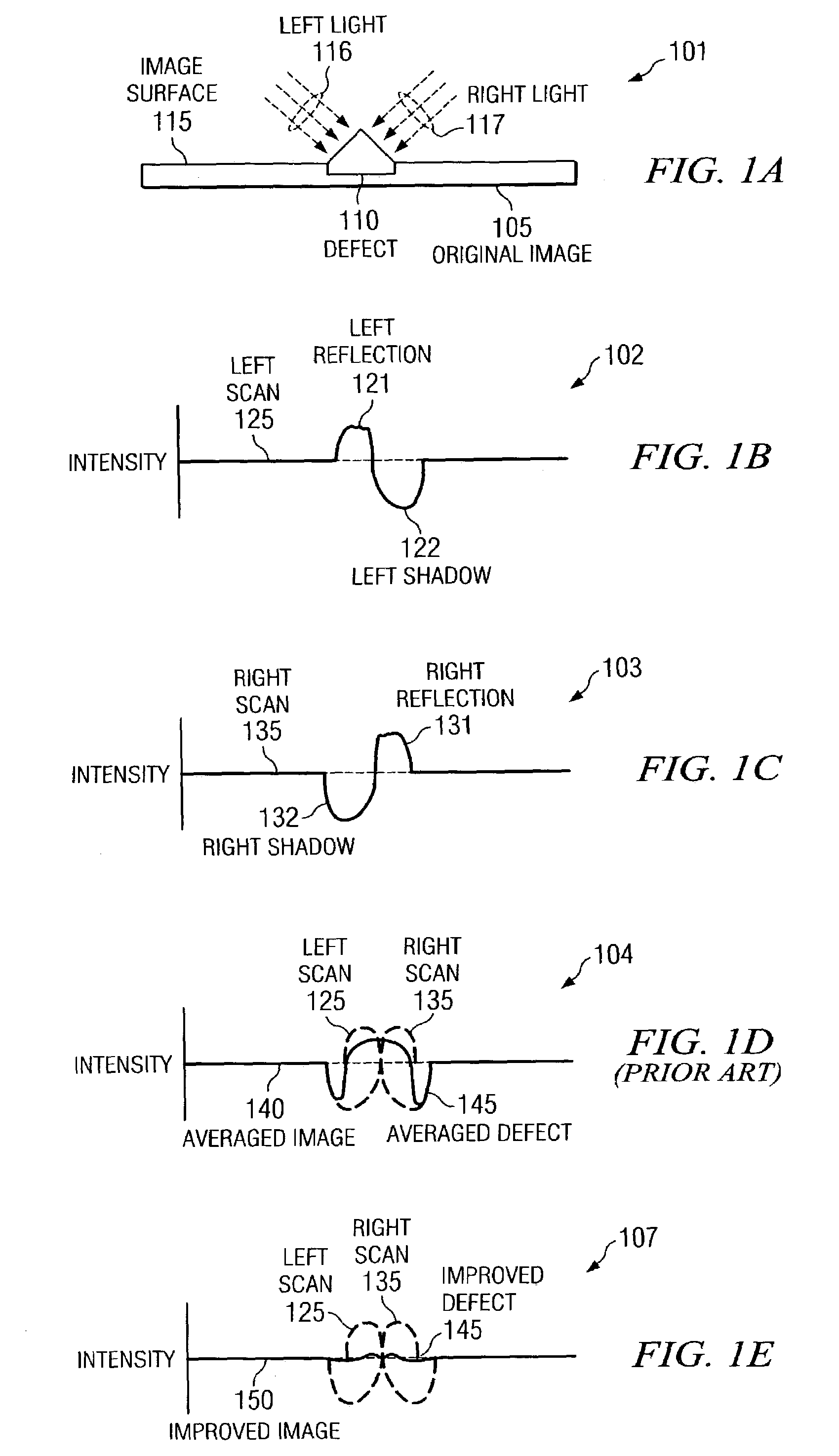

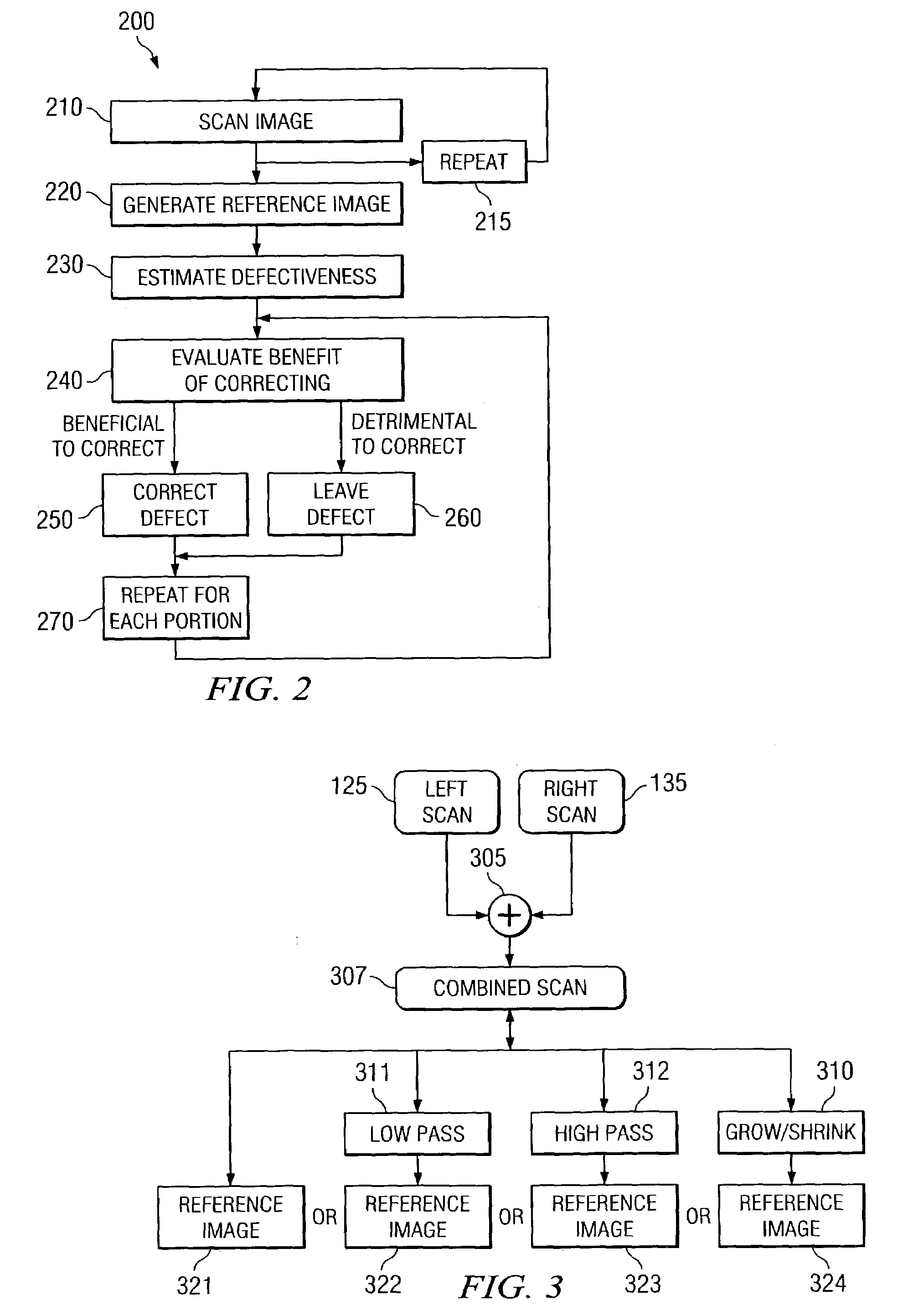

Method, system and software for correcting image defects

ActiveUS6987892B2Quality improvementAvoid damageImage enhancementTelevision system detailsReference imageImage generation

A method, system and software are disclosed for correcting defects formed in a physical medium of an original image. Multiple scans of the original image are recorded, where the multiple scans have different properties. For example, the angle of the light incident to the physical medium or the properties of the light may be changed between scans of original image. The multiple scans can be used to generate a reference image from which defect corrections are made. Alternatively, a reference image can be generated directly from the original image. The multiple scans can also be used to determine the degree of defectiveness and / or an estimate of the signal strength of each portion of the original image. A decision is made on whether or not an image portion having one or more defects should be corrected, where the decision can be based on an evaluation of the potential benefit compared to the potential damage caused by correction of an image portion. In one embodiment, the potential benefit is proportional to the degree of defectiveness, while the potential damage is proportional to the image information that may be removed by correction. If the decision is made to correct an image portion, a variety of methods may be implemented to correct the image portion, such as cloning information from non-defective image portions surrounding the defective image portion. The present invention finds particular use in image capturing systems, such as flatbed scanners, photocopiers, facsimile machines, and the like.

Owner:KODAK ALARIS INC

Sensor infrastructure

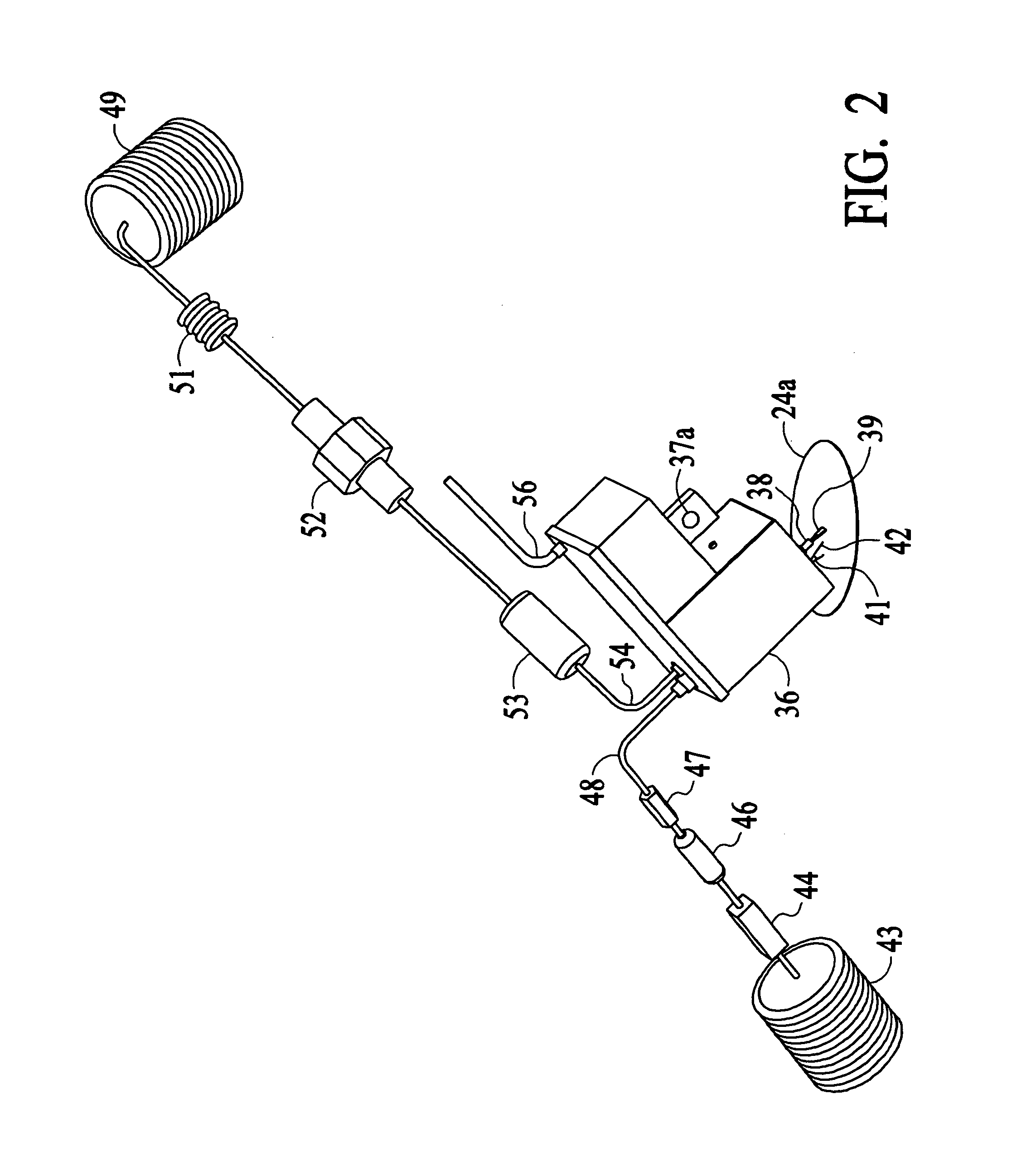

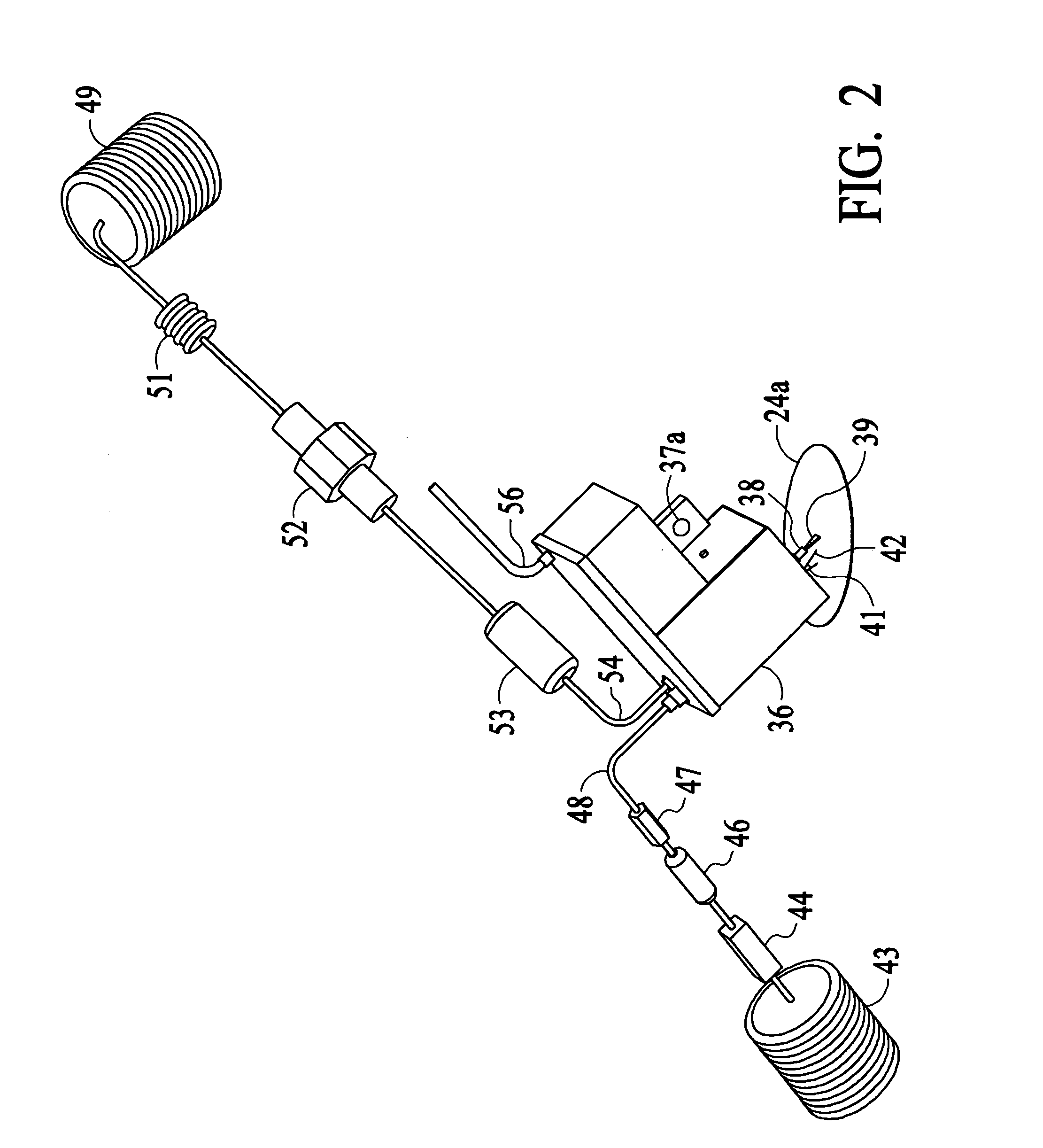

ActiveUS20060080048A1Economic benefitIncrease signal strengthAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurement using piezo-electric devicesPrinted circuit boardIn plane

A device for use in detecting an event in a structure comprises a sensor encapsulation, the encapsulation containing a sensor, an actuator positioned substantially in-plane to the sensor within the housing and a printed circuit board in communication with at least one of the sensor and the actuator. the printed circuit board includes a microprocessor constructed and arranged to collect data from at least one of the sensor and the actuator, a signal generator constructed and arranged to provide excitation to at least one of the sensor and the actuator, and an amplifier to condition the excitation.

Owner:METIS DESIGN CORP

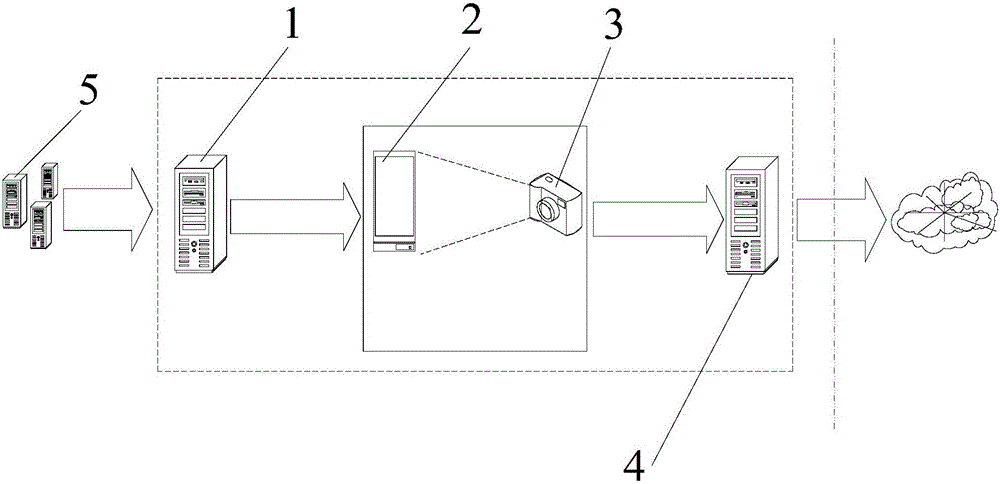

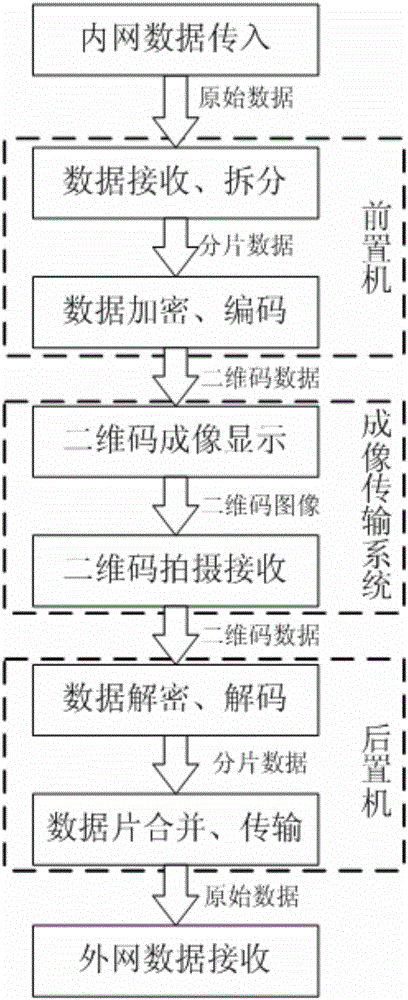

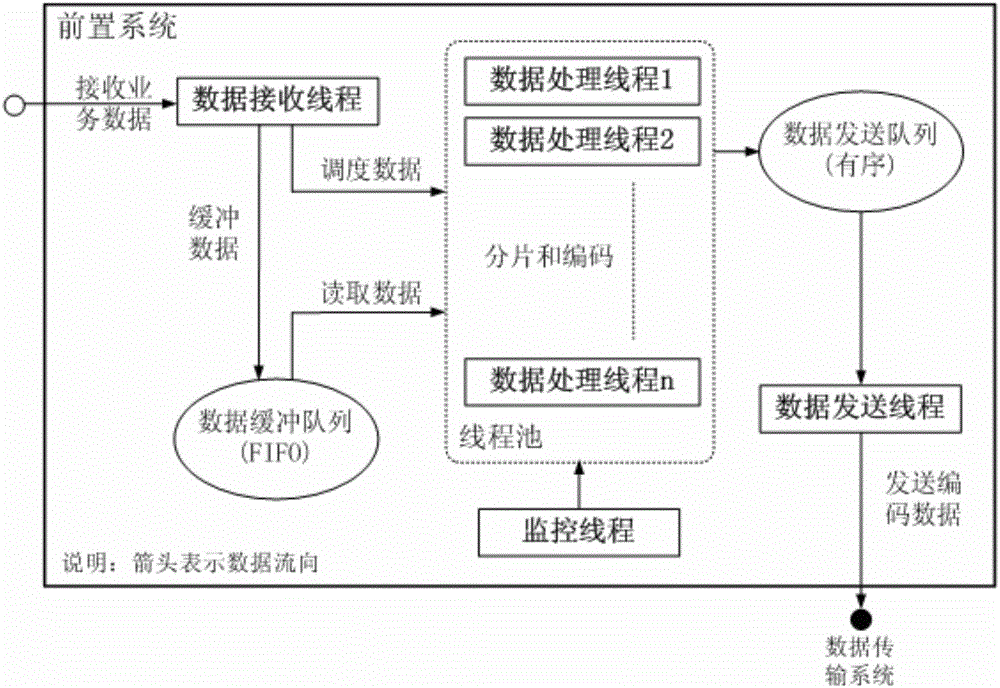

Data transmission method and data transmission system for physical isolation network

PendingCN105847290AImprove transmission efficiencyImprove reliabilityData switching networksData streamNetworked system

The invention provides a data transmission system. The system comprises a front-end subsystem, an imaging device, a photographing device and a post subsystem. The front-end subsystem is used for receiving original service data to be sent by an intranet customer service system through a data interface, splitting the service data into multiple data streams, encrypting the split data streams, and converting the data streams pattern information which can be displayed. The imaging device is used for displaying the pattern information. The photographing device is used for photographing a pattern on the imaging device. The post subsystem is used for receiving the pattern sent by the photographing device, decoding and converting the pattern into data streams, decrypting, merging and reorganizing the data streams to form the original service data, and sending the data to an extranet service network system through the data interface. Through the data transmission system, the data can be safely, efficiently and reliably transmitted between domains of different security levels.

Owner:JIANGSU FEIBO SOFTWARE TECH

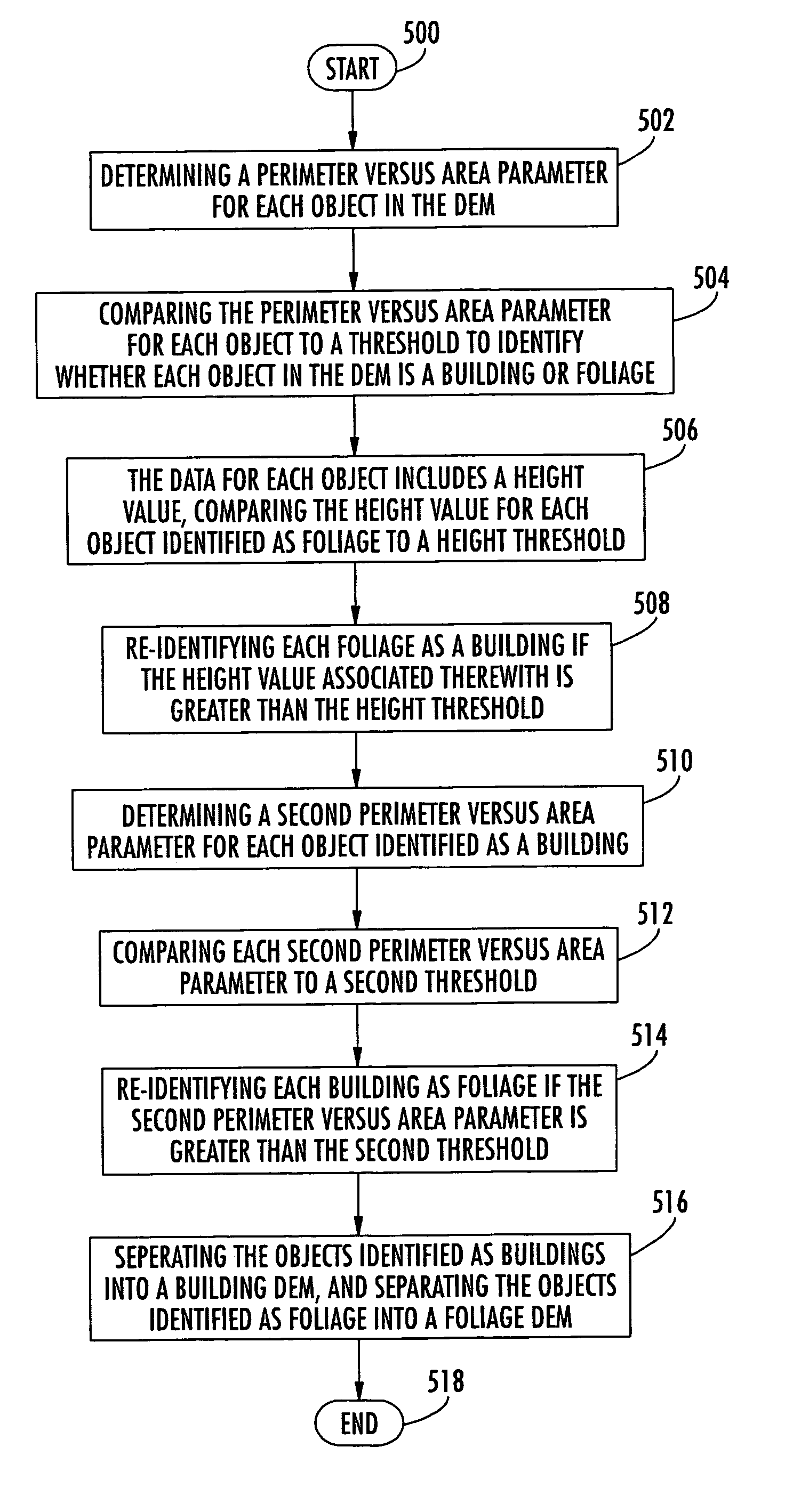

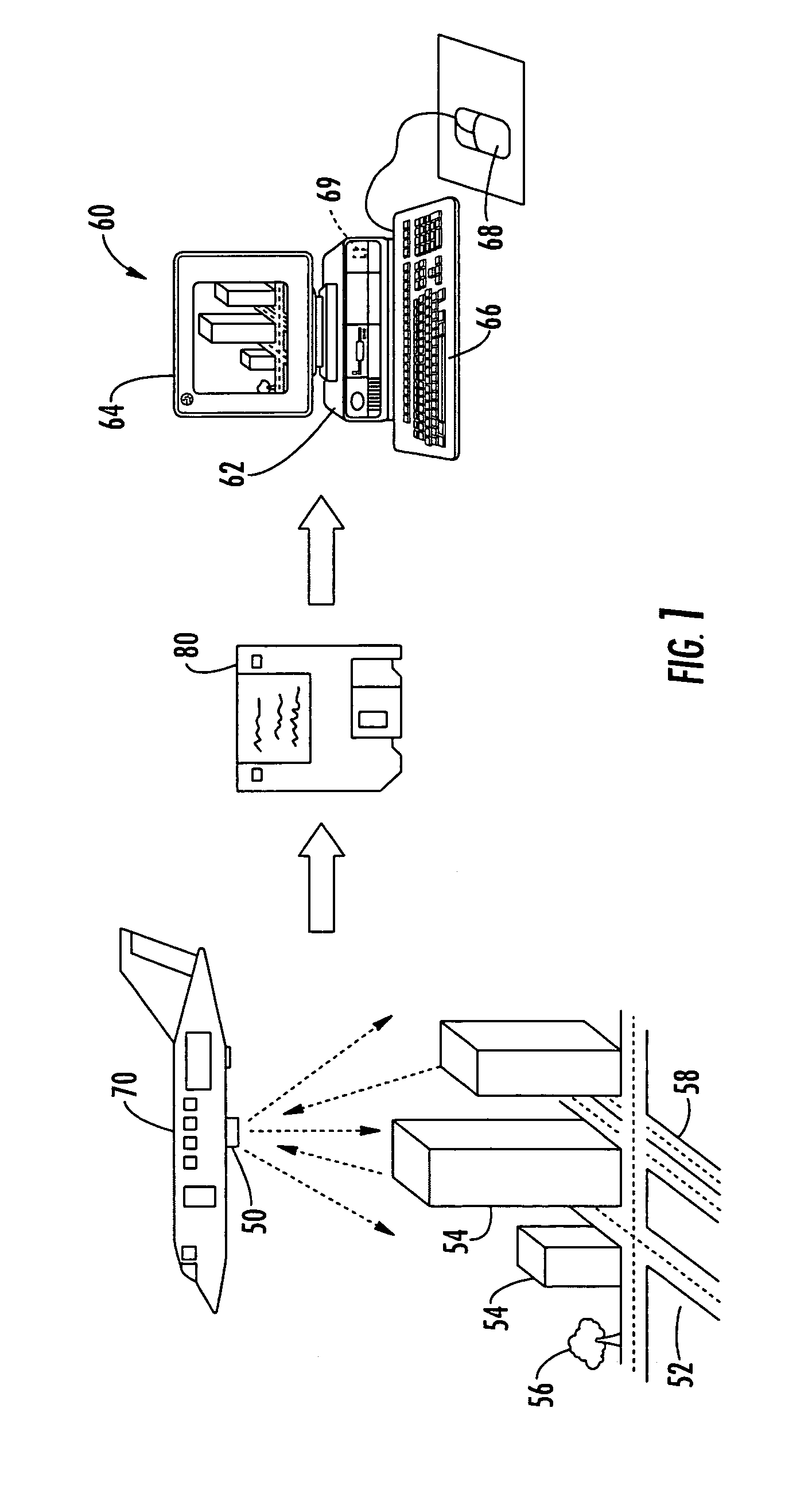

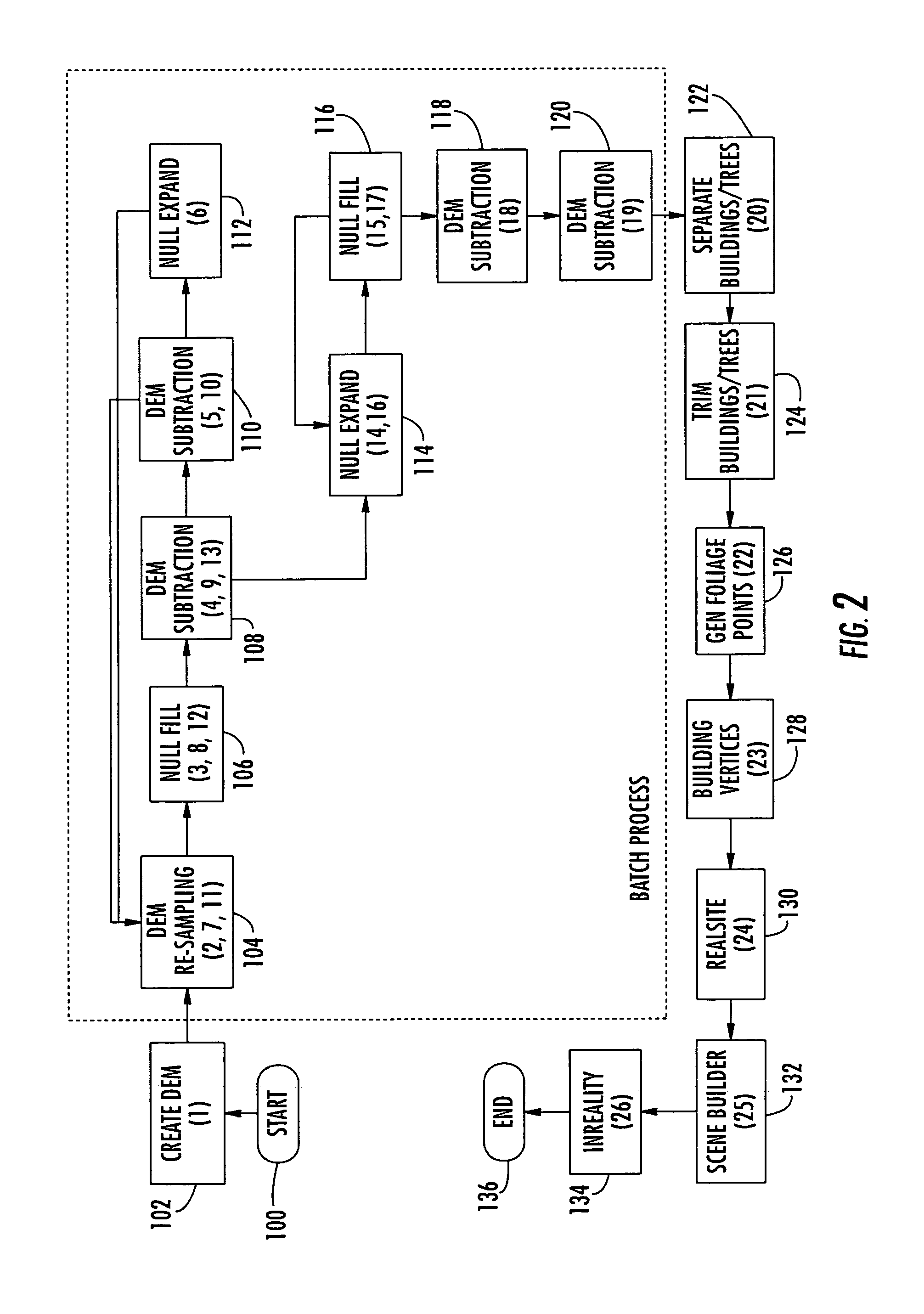

Method and apparatus for distinguishing foliage from buildings for topographical modeling

InactiveUS7191066B1More realistic topographical modelsLess interventionImage enhancementImage analysisLandformComputer science

A computer implemented method is for processing a digital elevation model (DEM) including data for a plurality of objects. The method includes determining a perimeter versus area parameter for each object in the DEM, and comparing the perimeter versus area parameter for each object to a threshold to identify whether each object in the DEM is a building or foliage.

Owner:TECH LICENSING CORP (US)

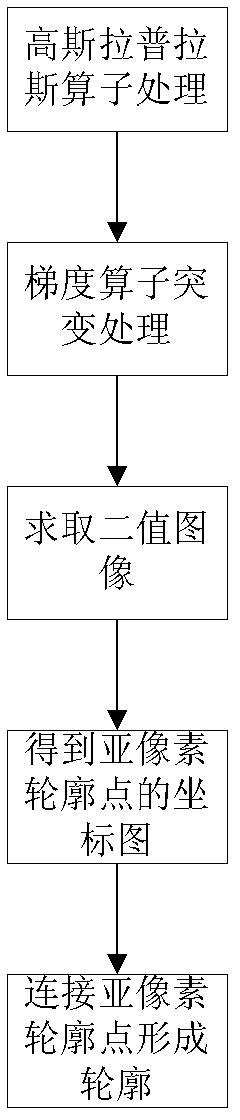

Method for extracting contour of image of printed circuit board (PCB)

ActiveCN102496161ALess interventionImprove stabilityImage analysisPattern recognitionGradient operators

The invention aims to provide a method for extracting a contour of an image of a printed circuit board (PCB). By the method, the defect of inaccuracy in extraction of the contour of the image of the PCB in the conventional contour extraction method is overcome, the accuracy and stability of contour detection are improved, and working efficiency is improved. The method comprises the following steps of: 1) acquisition of an original image of the PCB; 2) Gaussian Laplacian operator processing: processing the original image by using a Gaussian Laplacian operator to obtain a processed Gaussian Laplacian image; 3) gradient operator mutant processing: processing the original image by using a gradient operator to obtain a gradient image which is subjected to mutant processing through the gradientoperator; 4) processing the original image by using high and low threshold values to obtain a binary image; 5) establishing coordinate graphs of sub-pixel contour points, determining the pixel position of the contour according to the boundary of the binary image, and thus obtaining the coordinates of the sub-pixel contour points according to a Gaussian Laplacian value, a pixel value and a gradient value in the corresponding direction of the contour; and 6) connecting the sub-pixel contour points to form the contour, and connecting the sub-pixel contour points into a set in a certain sequence according to the coordinates of the sub-pixel contour points, wherein the coordinates are obtained in the step 5).

Owner:浙江欧威科技有限公司

Sensor infrastructure

ActiveUS7373260B2Increase signal strengthLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurement using piezo-electric devicesIn planeAudio power amplifier

A device for use in detecting an event in a structure includes a sensor encapsulation, the encapsulation containing a sensor, an actuator positioned substantially in-plane to the sensor within the housing and a printed circuit board in communication with at least one of the sensor and the actuator. The printed circuit board includes a microprocessor constructed and arranged to collect data from at least one of the sensor and the actuator, a signal generator constructed and arranged to provide excitation to at least one of the sensor and the actuator, and an amplifier to condition the excitation.

Owner:METIS DESIGN CORP

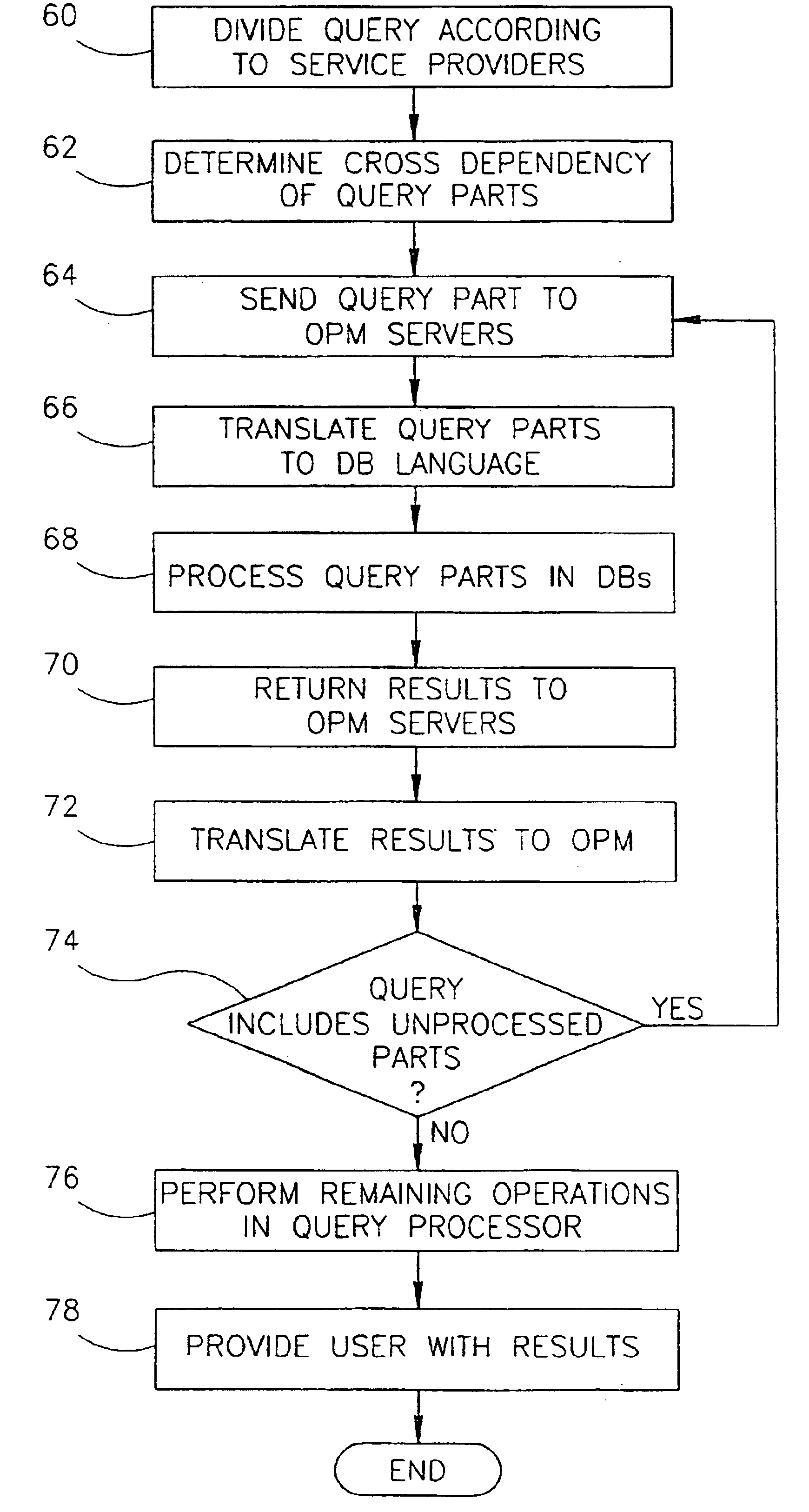

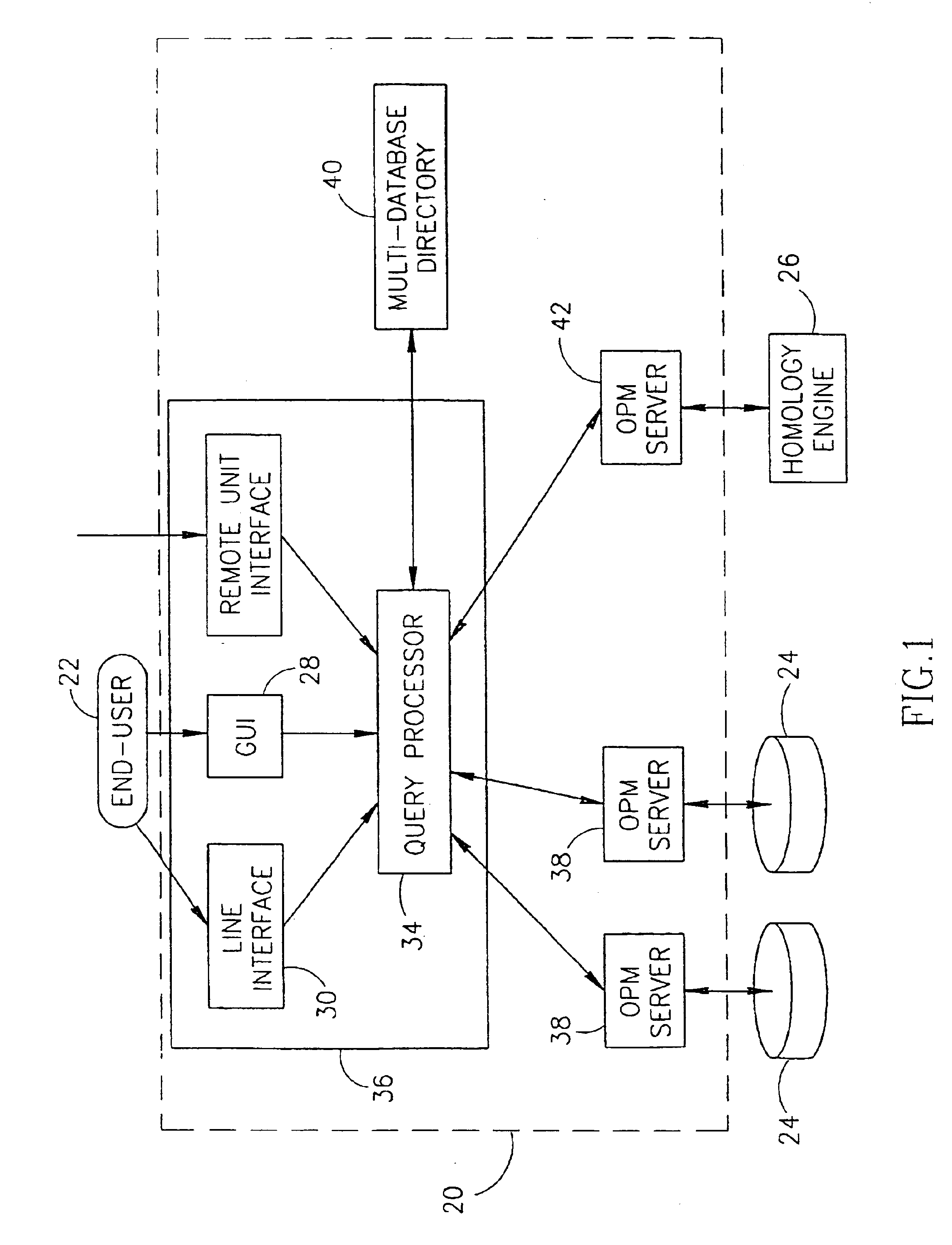

Biological data processing

InactiveUS6931396B1Less user interventionShort response timeDigital data information retrievalData processing applicationsData miningTranslation service

Owner:OCIMUM BIO SOLUTIONS

Sensor Infrastructure

ActiveUS20080312846A1Increase signal strengthLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurement using piezo-electric devicesIn planeAudio power amplifier

A device for use in detecting an event in a structure includes a sensor encapsulation, the encapsulation containing a sensor, an actuator positioned substantially in-plane to the sensor within the housing and a printed circuit board in communication with at least one of the sensor and the actuator. The printed circuit board includes a microprocessor constructed and arranged to collect data from at least one of the sensor and the actuator, a signal generator constructed and arranged to provide excitation to at least one of the sensor and the actuator, and an amplifier to condition the excitation.

Owner:METIS DESIGN CORP

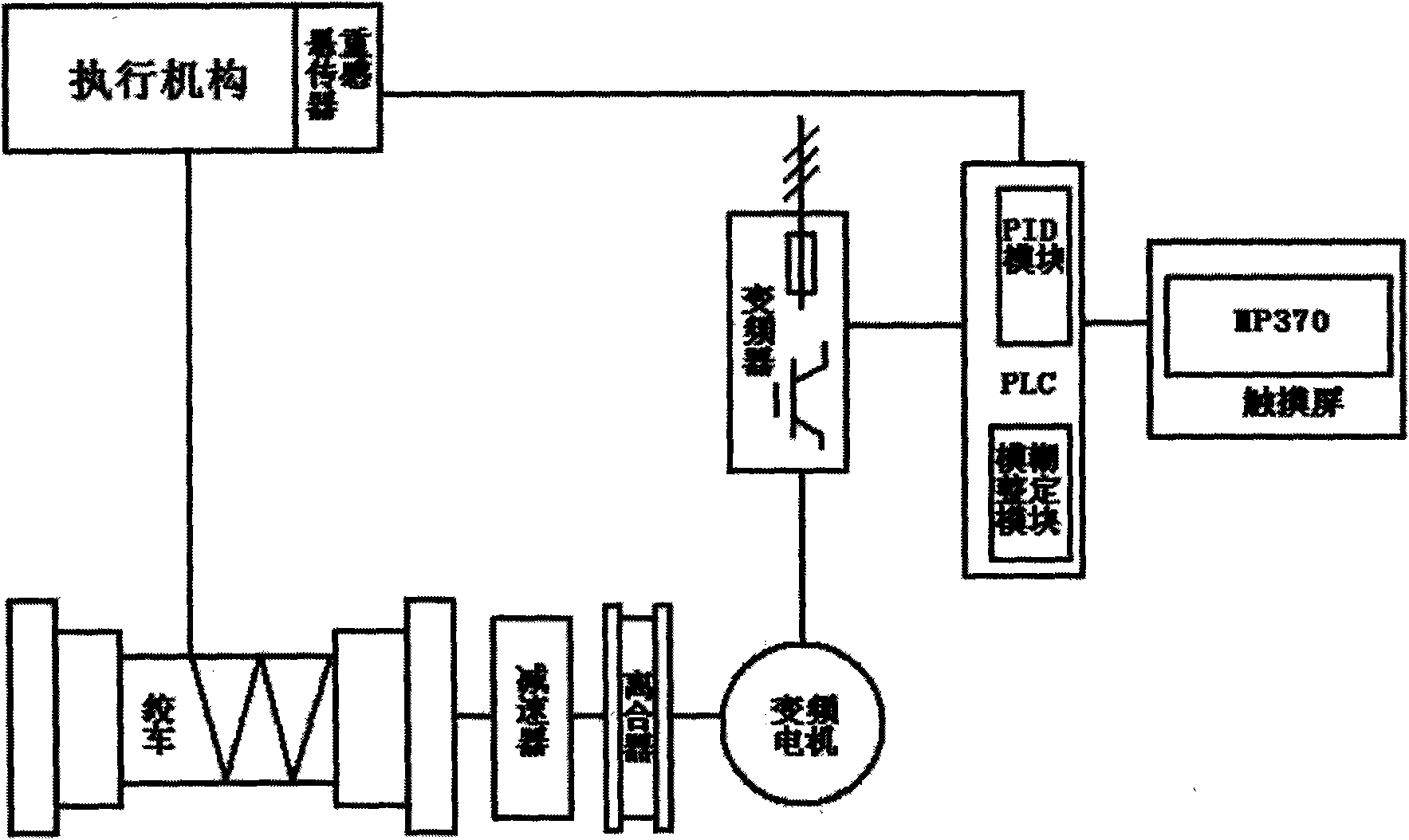

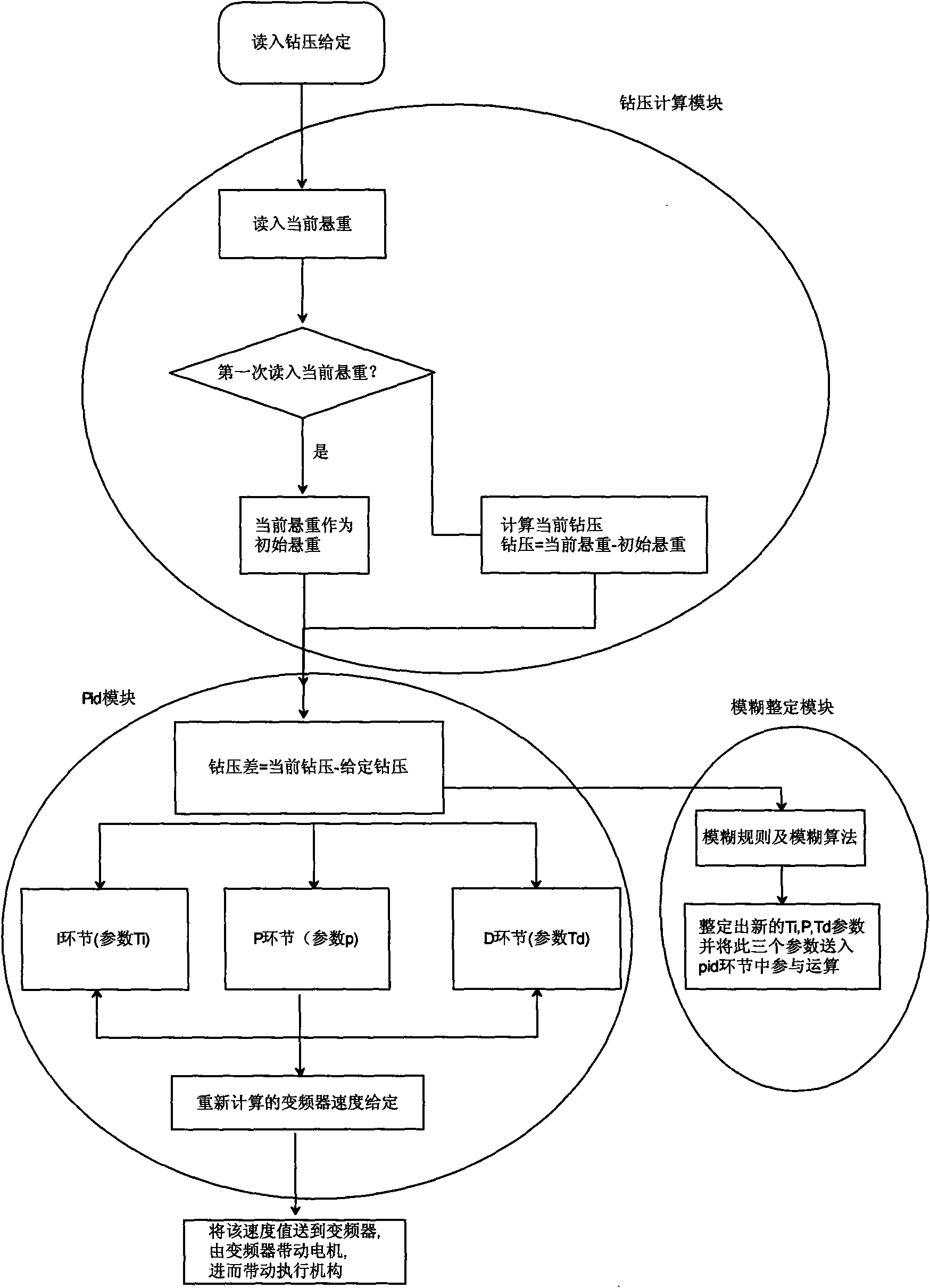

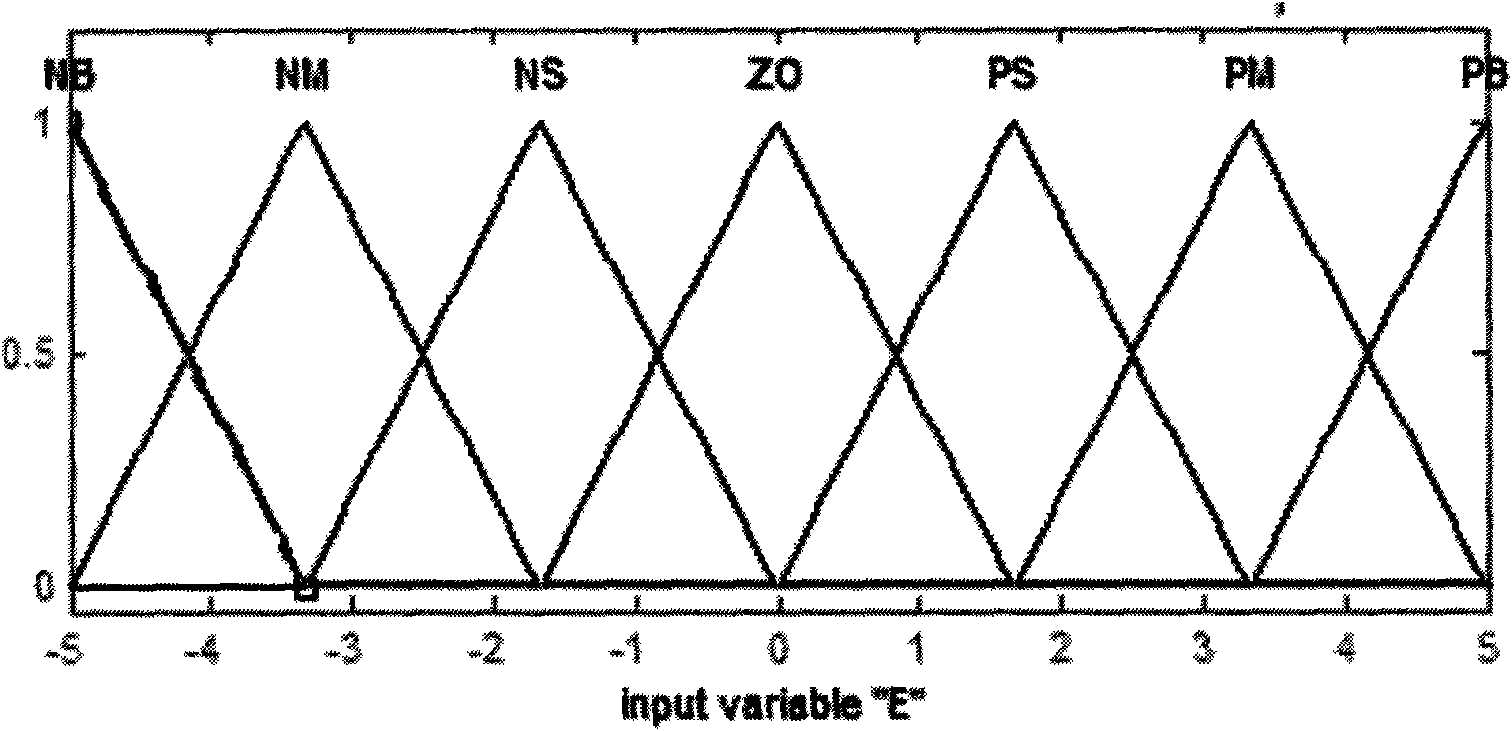

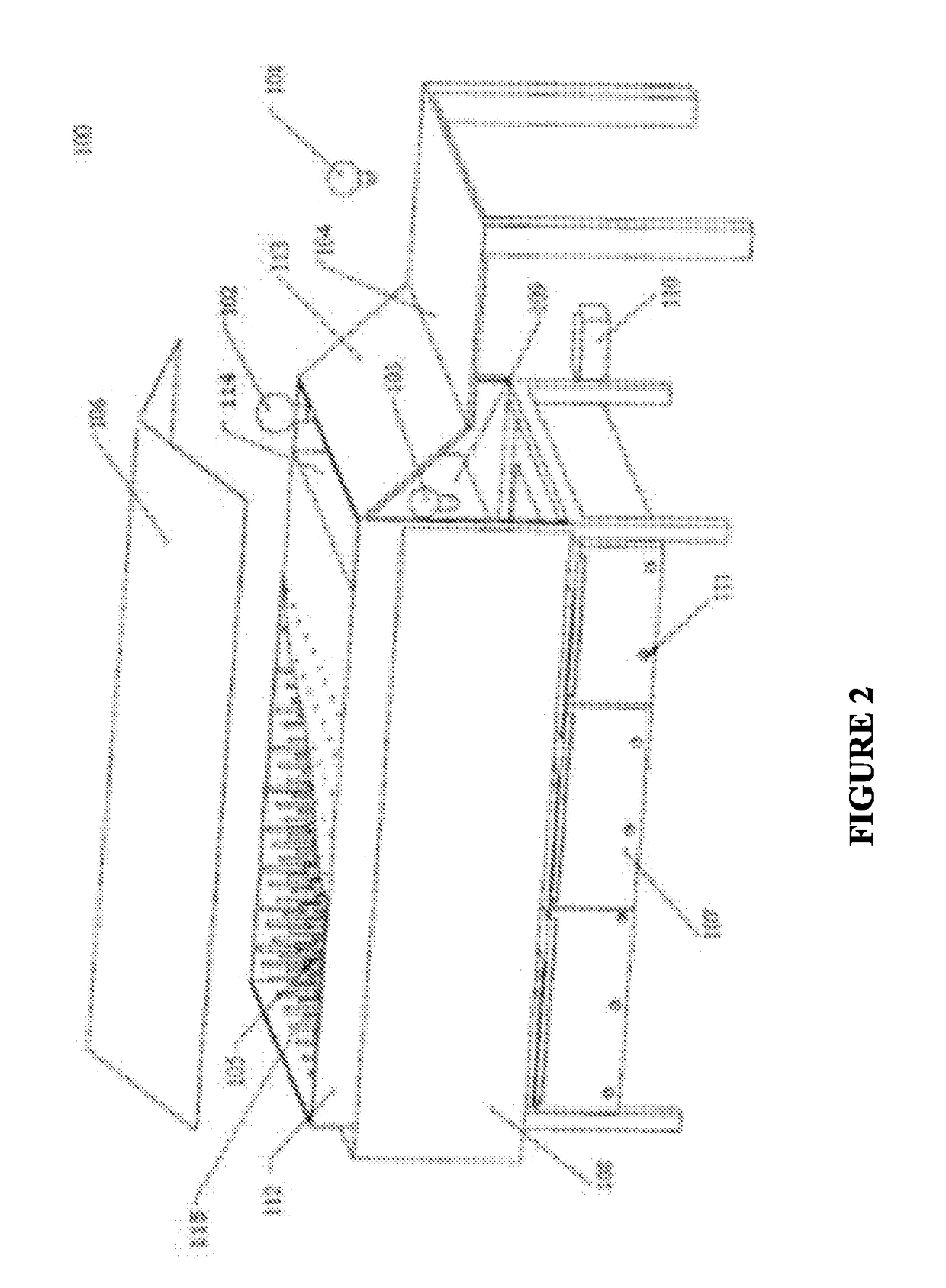

Wide-adaptive novel automatic driller

ActiveCN101566059ALess interventionAchieve optimal configurationProgramme control in sequence/logic controllersAutomatic control for drillingFrequency changerProgrammable logic controller

The invention relates to a wide-adaptive novel automatic driller, which comprises an actuating mechanism, a variable-frequency motor and a frequency convertor. The actuating mechanism is driven by a winch; the winch is connected to the variable-frequency motor through a reduction gearbox and a clutch; the frequency convertor is connected to the variable-frequency motor; a three-phase power is communicated with the frequency convertor; a suspending weight sensor is arranged on the actuating mechanism and inputs the detected data into a programmable logic controller (PLC); and the programmable logic controller (PLC) is communicated with the frequency convertor and a touch screen used as a human-computer interface. The programmable logic controller comprises a drilling pressure calculation module, a PID module and a fuzzy setting module. The wide-adaptive novel automatic driller aims at the characteristics of the control targets of automatic drilling, reduces the interference degree of a driller on a PID control system, introduces a fuzzy control algorithm to set the parameters of the PID system and achieves the purpose of optimal setting of the parameters of the PID control system.

Owner:ZHONGMAN GASOLINEEUM & NATURAL GAS GROUP

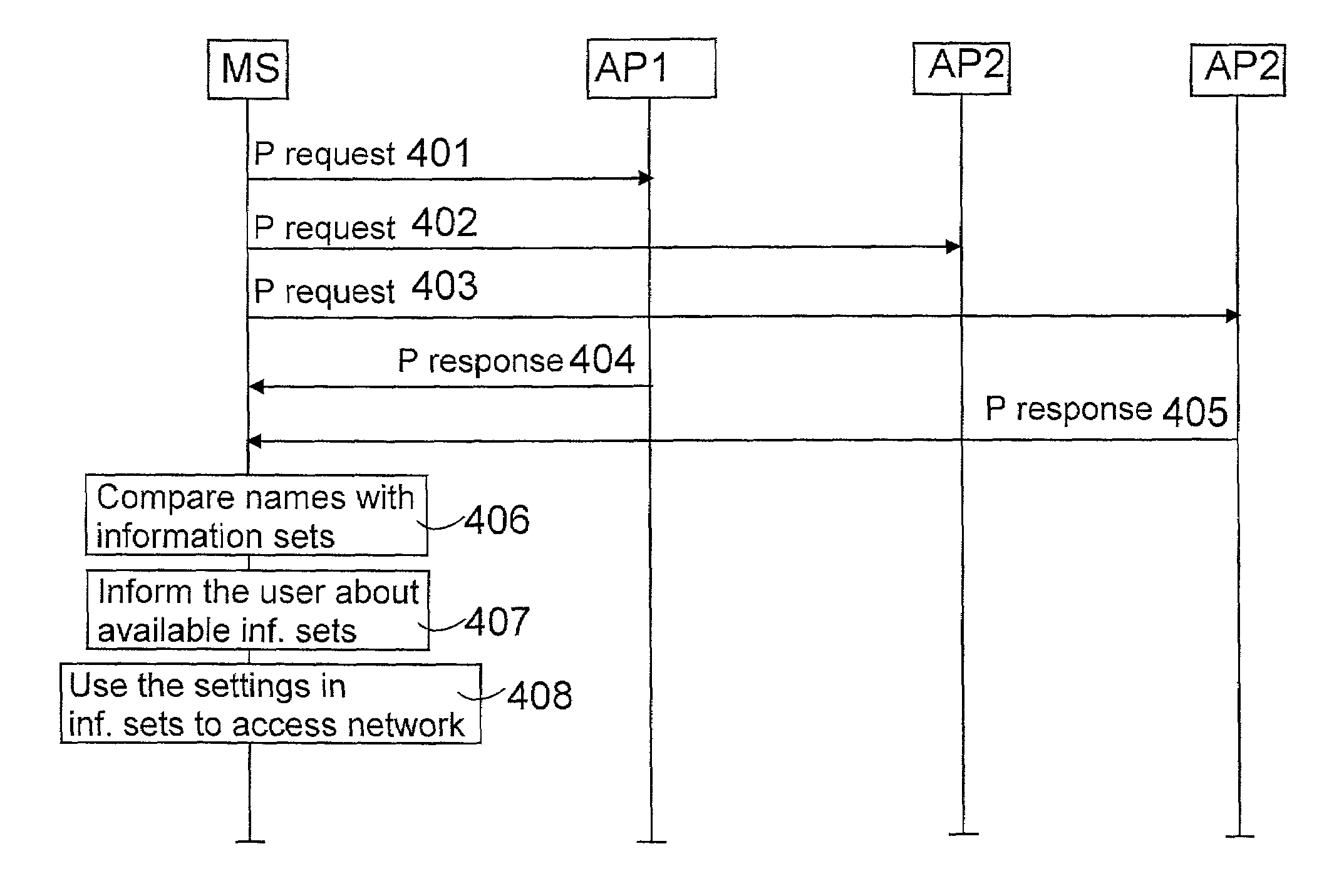

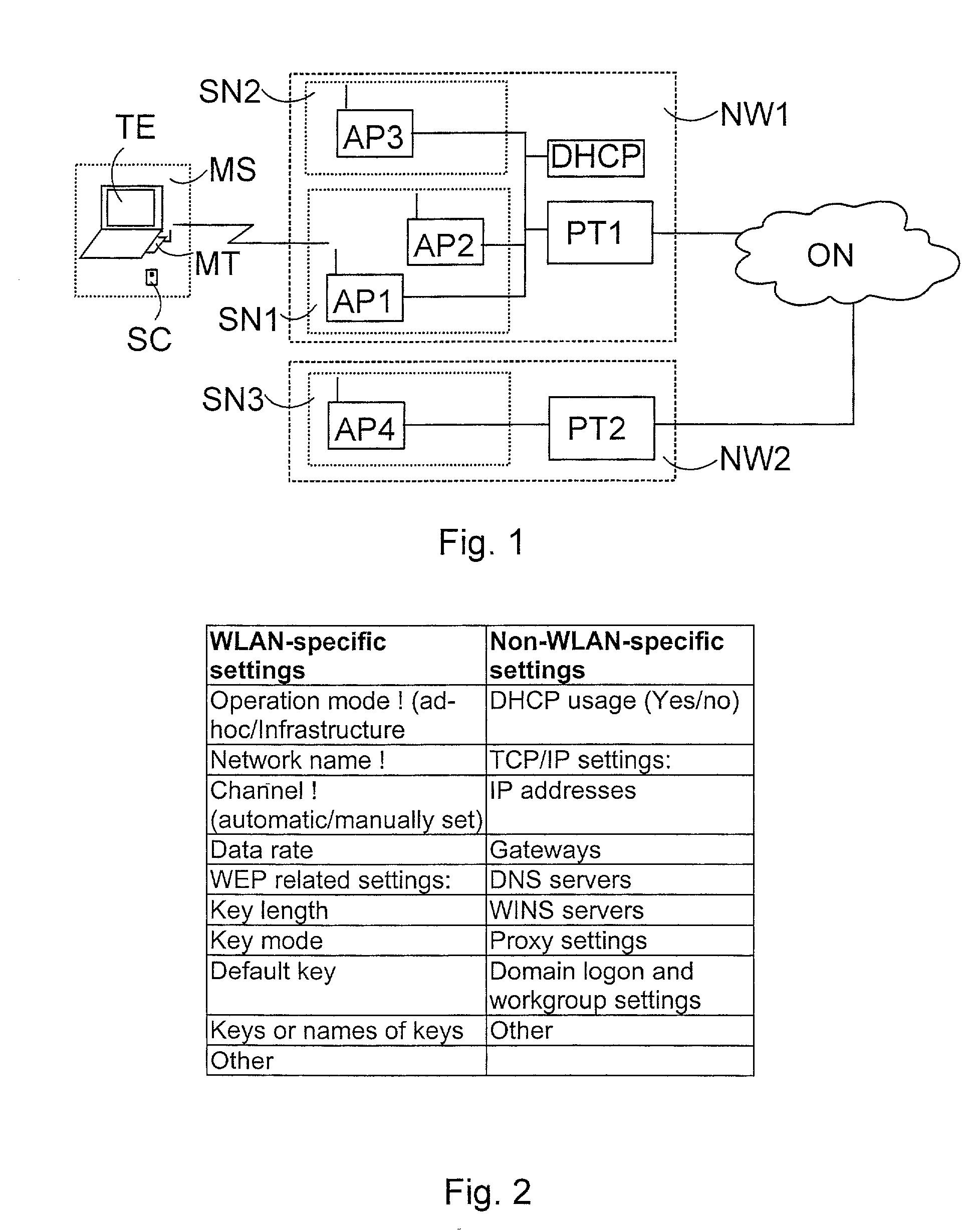

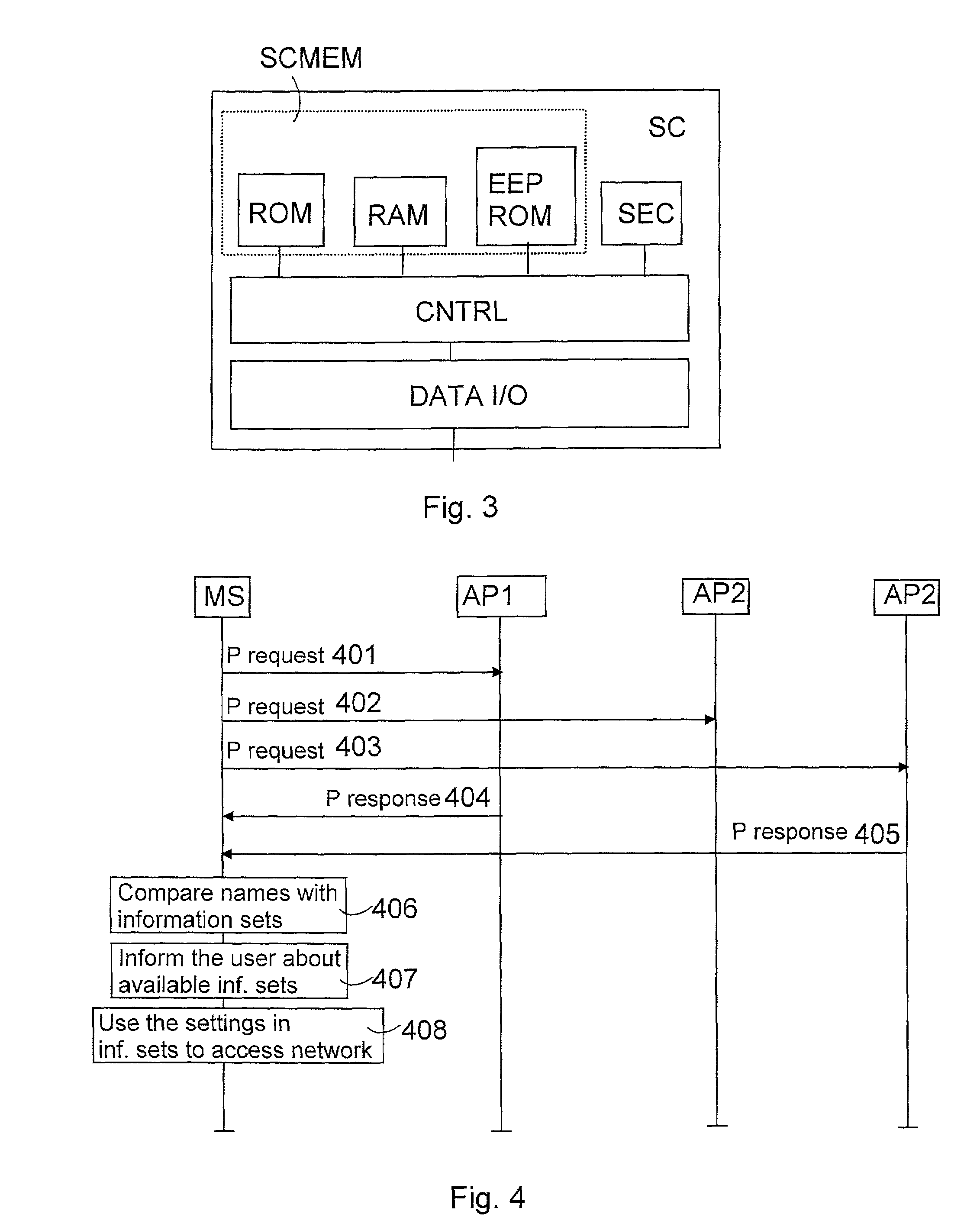

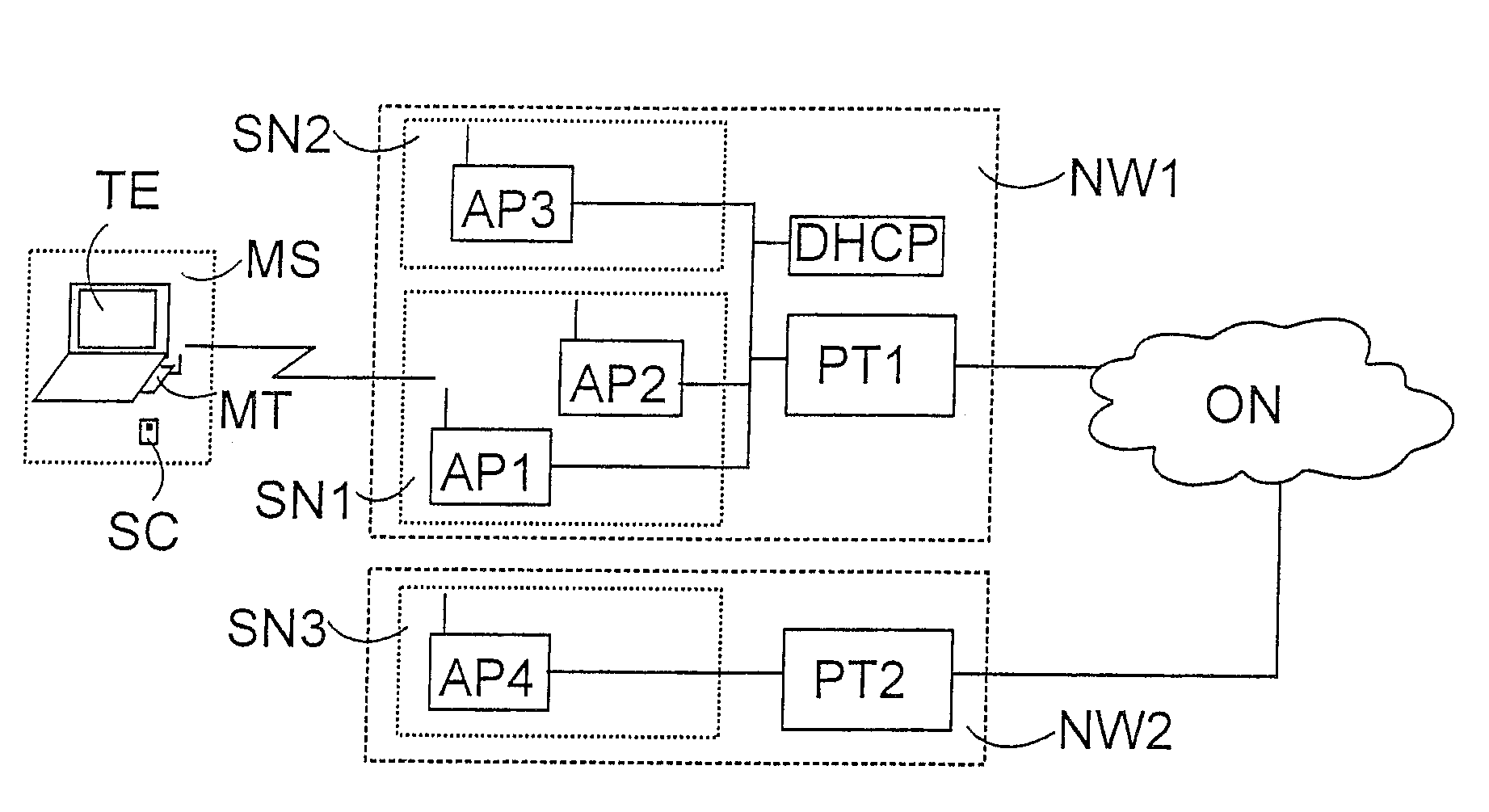

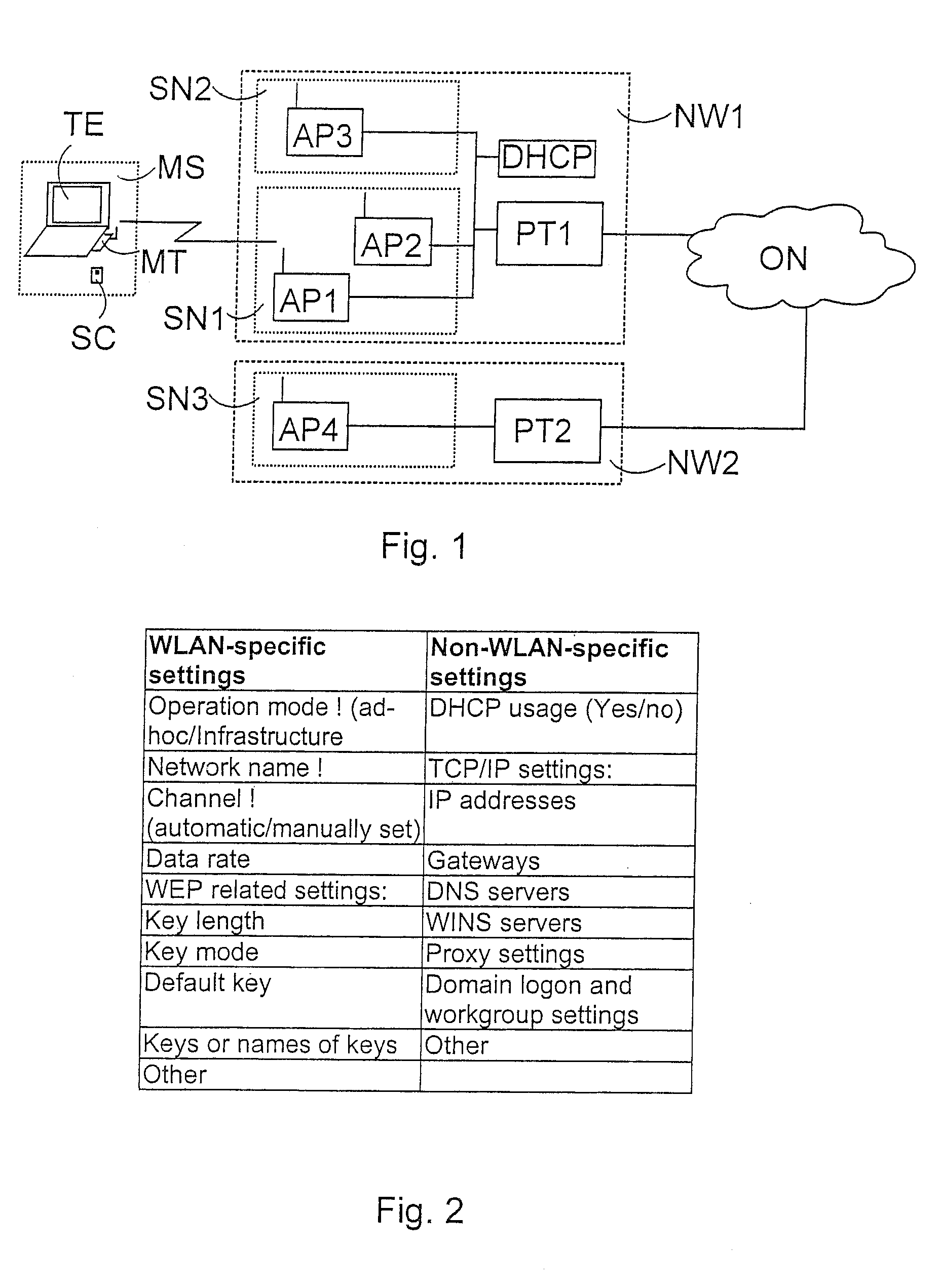

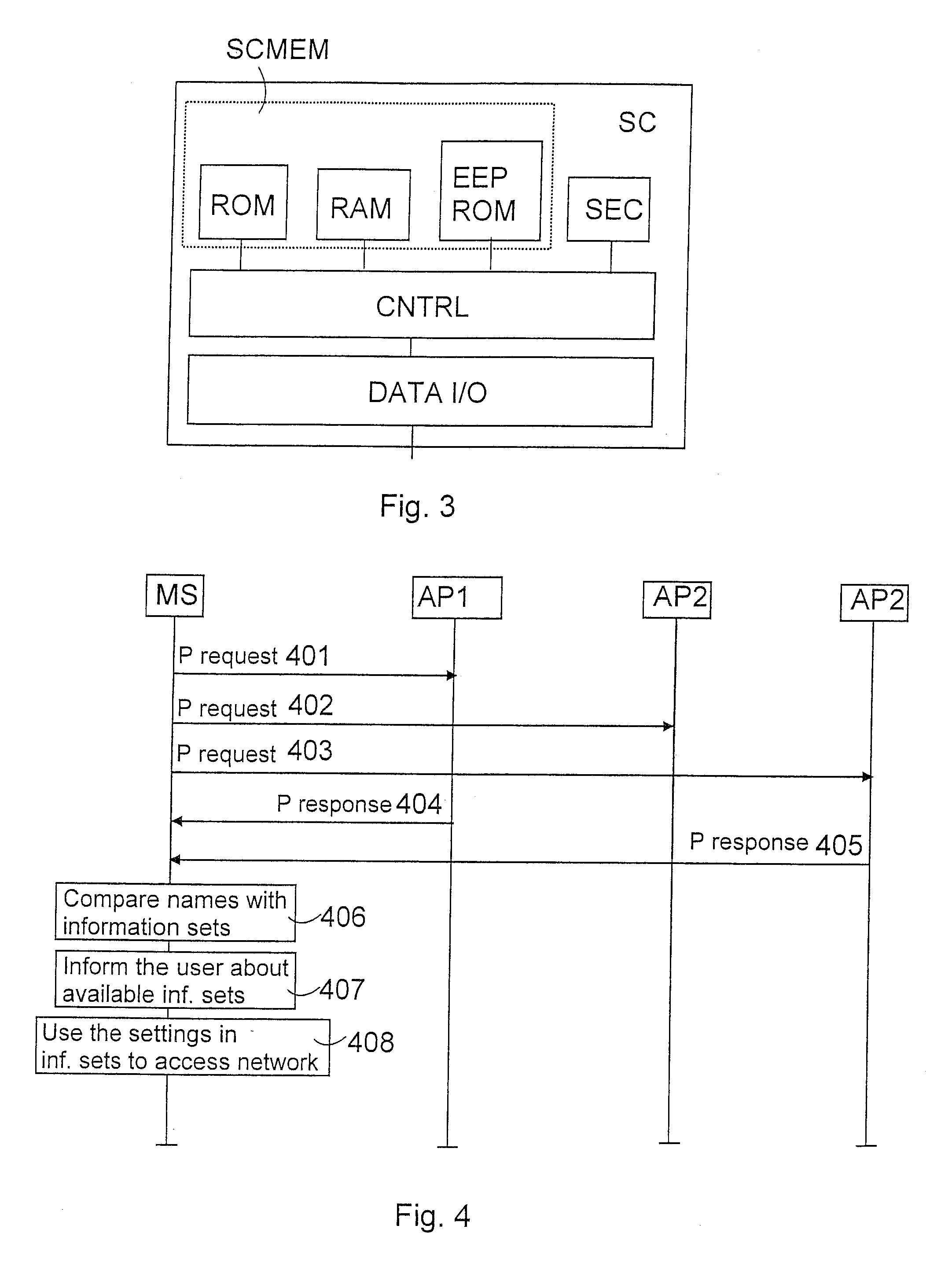

Method and equipment for accessing a telecommunication network

InactiveUS7430604B2Saving expenseShorten the timeAssess restrictionMultiple digital computer combinationsAccess networkTelecommunications network

A method for accessing a network in a telecommunication system which includes at least one terminal and a plurality of networks. Information sets describing settings needed to access networks and their resources are stored in the terminal. The terminal scans for information about available networks. Available information sets are determined by comparing the information about available networks to the stored information sets. At least one network is accessed based on the settings defined in the available information sets.

Owner:NOKIA TECHNOLOGLES OY

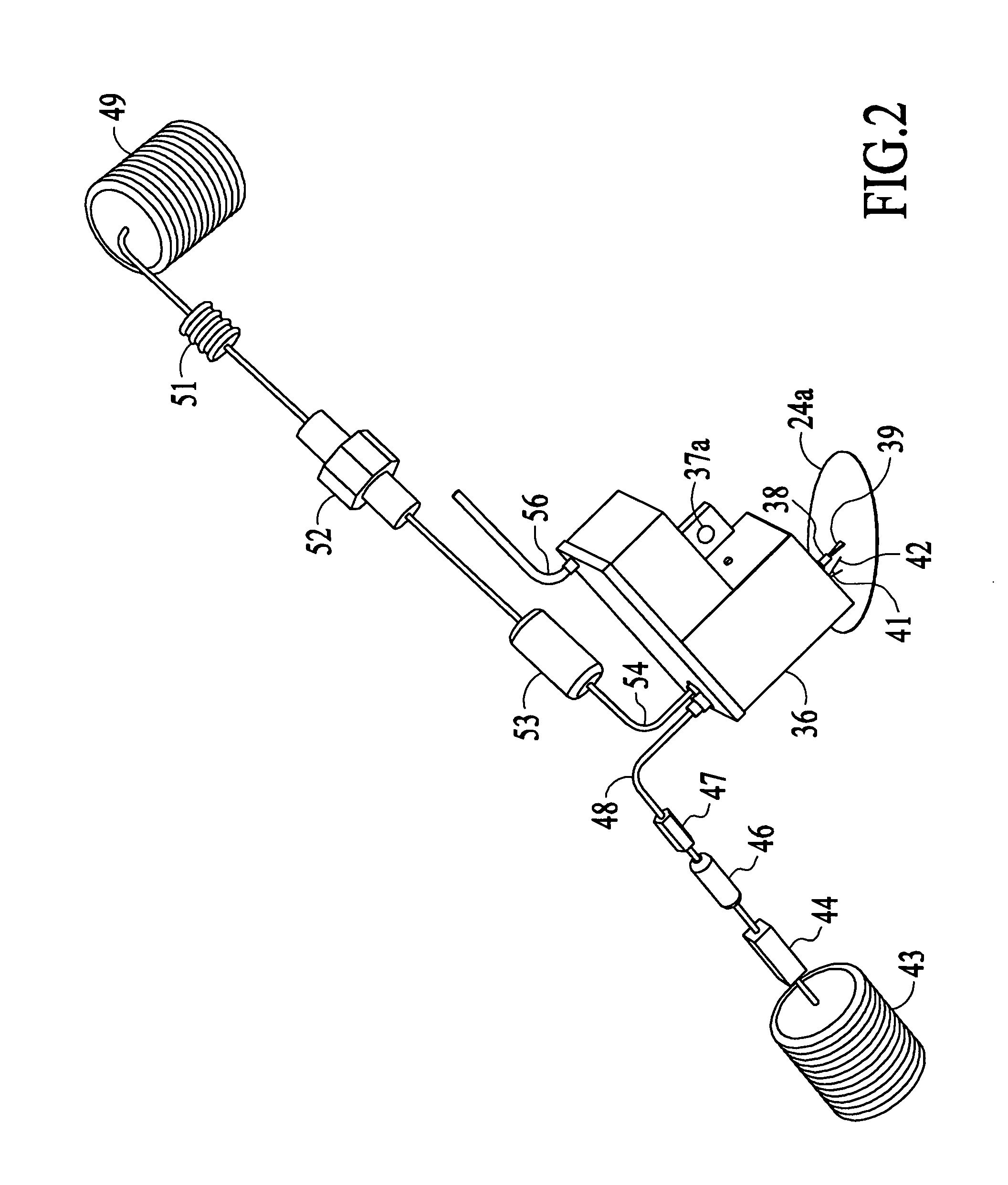

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7297286B2Small footprintEasy to cleanNon-mechanical blast generatorsDecorative surface effectsResistEngineering

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where the cryogenic cleaning medium removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium. The cryogenic cleaning medium is supplied with a pulsating flow via a nozzle implement that sweeps across the article. The pulsating flow may be generated via a piezo device or a rotating shaft with a hole the periodically enables or interrupts flow through a flow channel.

Owner:NANOCLEAN TECH

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS20050127038A1Avoid lostIncrease vacuumDecorative surface effectsSemiconductor/solid-state device manufacturingResistEngineering

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium The cryogenic cleaning medium is supplied via a nozzle implement that sweeps across the article. A slide mechanism and drive motor may be supplied internal or external to the controlled environment.

Owner:MANOCLEAN TECH

Method and equipment for accessing a telecommunication network

InactiveUS20080316989A1Saving expenseShorten the timeAssess restrictionMultiple digital computer combinationsAccess networkTelecommunications network

A method for accessing a network in a telecommunication system which comprises at least one terminal and a plurality of networks in which information sets describing settings needed to access networks and their resources are stored in the terminal. The terminal scans for information about available networks. Available information sets are determined by comparing the information about available networks to the stored information sets. At least one network is accessed based on the settings defined in the available information sets.

Owner:NOKIA TECHNOLOGLES OY

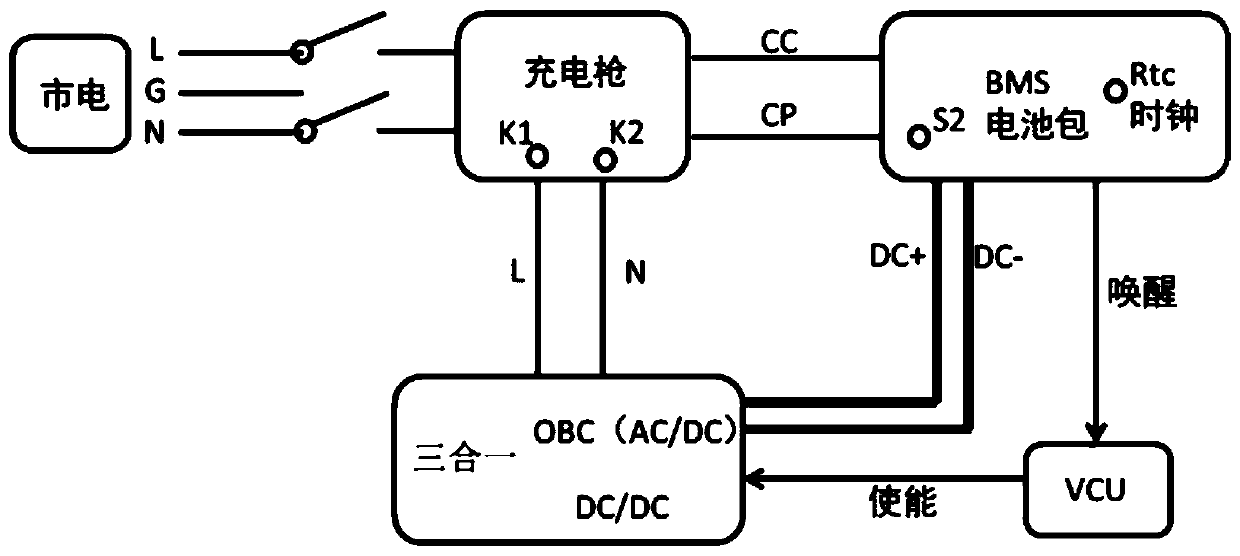

Control method of on-board charger

ActiveCN110065405AGuarantee the safety of useImprove ease of useCharging stationsElectric vehicle charging technologyReal-time clockOn board

The invention discloses a control method of an on-board charger. The control method comprises the following steps that when a charging gun is connected with the charger and no power is supplied, a battery management system (BMS) enters into a dormant state, an internal real-time clock (RTC) is used for awakening the BMS once every first preset time, whether power supply is restored or not is judged by detecting CP signals after self-awakening, when the CP signals are detected, power supply is restored, and otherwise, the BMS enters into the dormant state again until the CP signals are detectedafter the next time of self-awakening and charging is restored. The control method has the technical effects that at the aspects of slow charging use convenience and charging rebooting in the slow charging process, the intervention degree of a user is greatly reduced and the using convenience of the user is improved on the premise that the use safety of the user is ensured.

Owner:湖南猎豹汽车股份有限公司

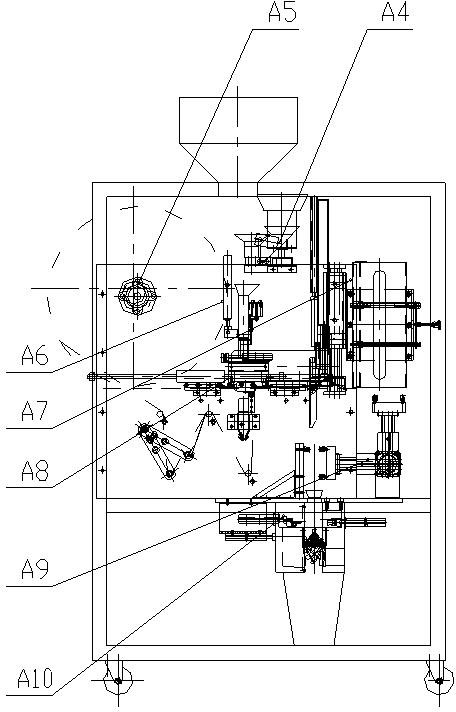

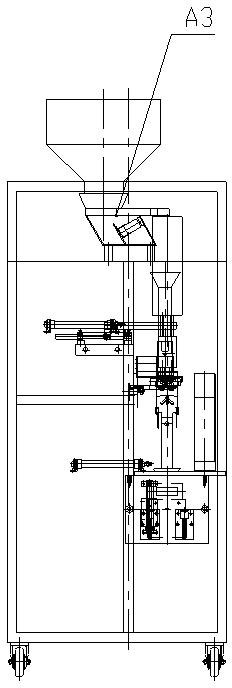

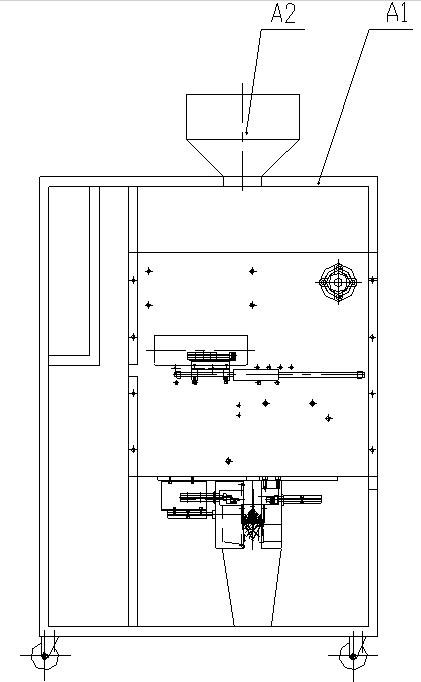

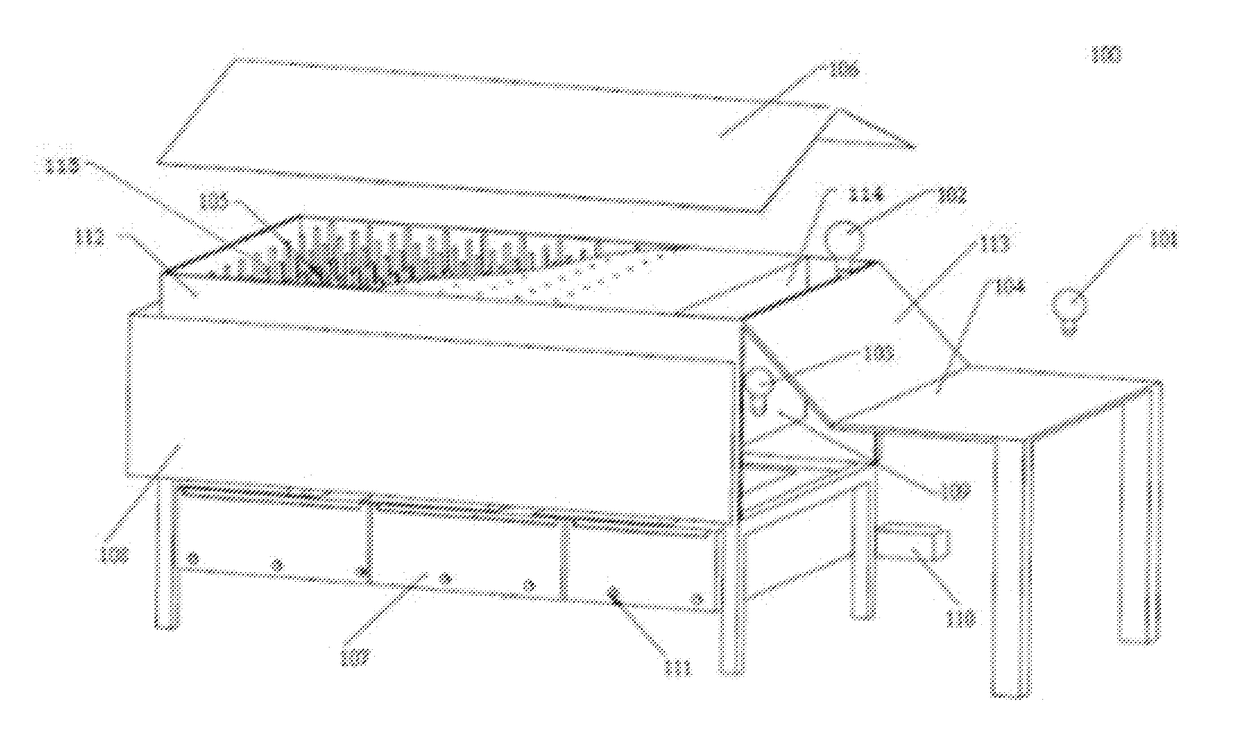

Mechanical, fully-automatic and intelligent vacuum packaging machine for non-particulate materials

InactiveCN102582870ASimple structureLow costWrapper twisting/gatheringPackaging under vacuum/special atmosphereFully automaticVacuum chamber

A mechanical, fully-automatic and intelligent vacuum packaging machine for non-particulate materials comprises a chassis, a feed hopper, a vibration feeding mechanism, a metering mechanism, a bag supplying device, a bag opening device, a bag filling mechanism, a bag sealing and cutting mechanism and a vacuum sealing device. A vacuum packaging device comprises a left cavity and a right cavity, wherein the left cavity and the right cavity are drawn together to form a vacuum chamber; a sealing component used for sealing a packaging bag under the conditions of high temperature and hot pressing isarranged at the upper side of an inner cavity of the vacuum chamber; the middle part of the inner cavity of the vacuum chamber is provided with an anti-sticking positioning device used for positioning and clamping the packaging bag; the anti-sticking positioning device comprises a frame body seat; the two lower side parts of the frame body seat are respectively provided with a positioning shaft in a penetrating way; a pair of supporting plates that can be drawn together in a crossing way so as to support the lower part of the packaging bag are articulated on the two positioning shafts; channels for the crossing of the two supporting plates are arranged on the supporting plates at intervals; the supporting plates are positioned under the frame body seat; and a pair of clamping plates that can be drawn together oppositely so as to clamp the upper part of the packaging bag are articulated on the two positioning shafts in an inner cavity of the frame body seat.

Owner:李康彪 +1

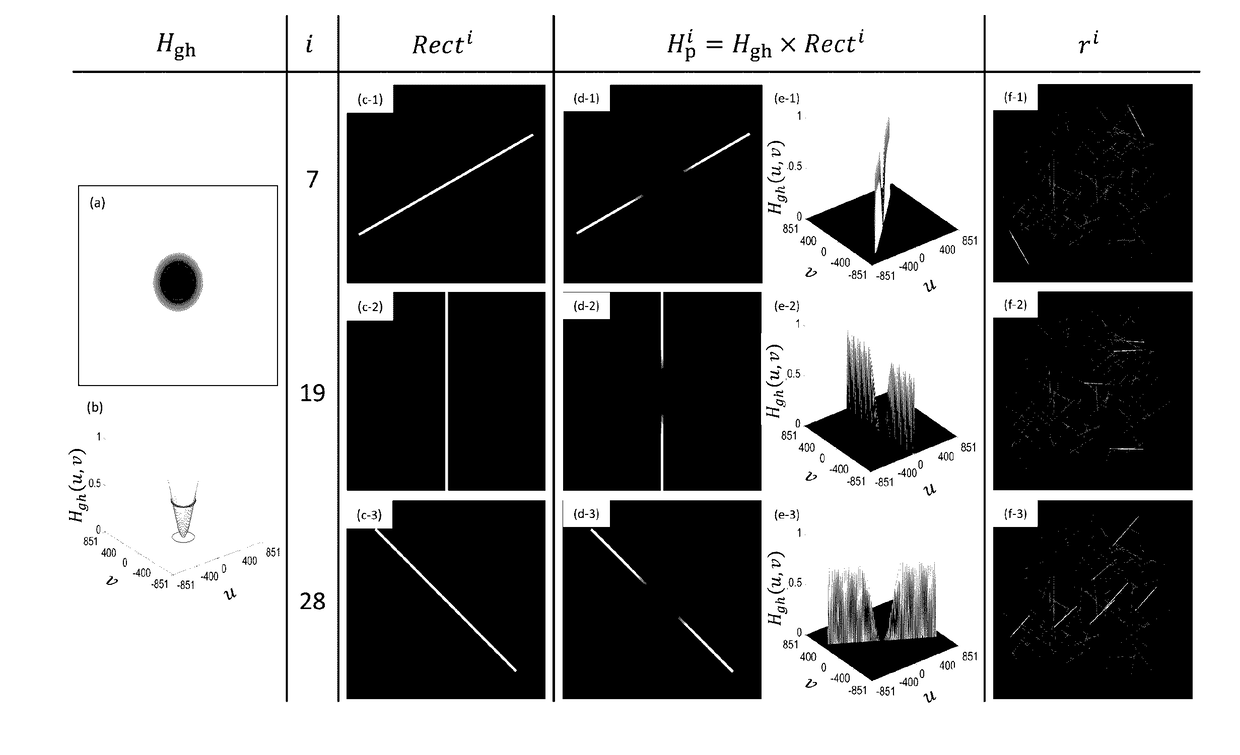

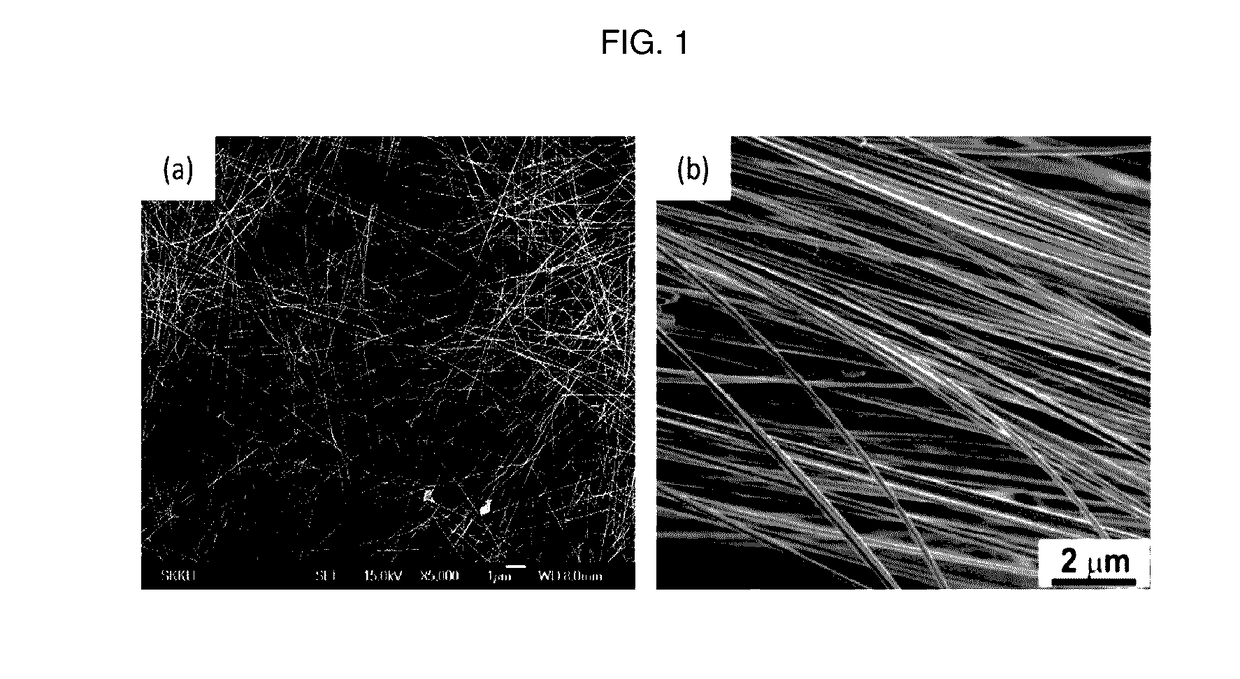

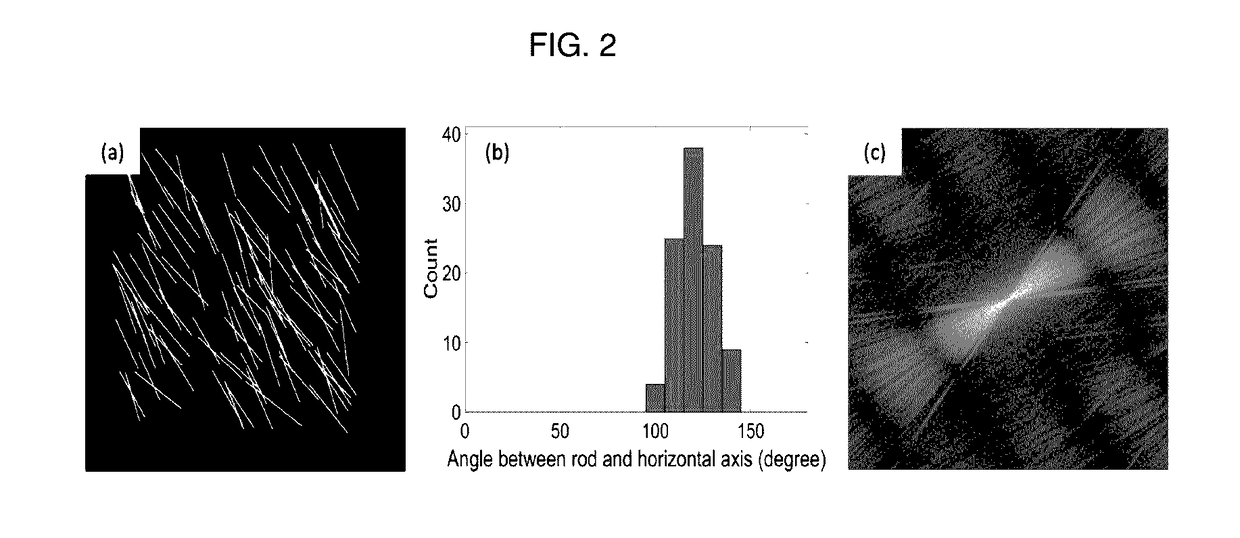

Method of analysing images of rod-like particles

ActiveUS20170140522A1Improve scalabilityLess interventionImage enhancementImage analysisPattern recognitionInverse discrete fourier transform

There is provided a method for analyzing an image of rod-shaped particles, the method comprising: transforming a spatial domain image of rod-shaped particles having random orientations to a frequency domain image thereof using DFT (discrete Fourier transform); extracting connected components from the frequency domain image using a frequency domain filter, wherein the connected components have a predetermined orientation; and back-transforming the frequency domain image having the extracted connected components to a spatial domain image thereof using IDFT (inverse discrete Fourier transform).

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Method and system of cultivating cordyceps

ActiveUS20170273250A1Less manual interventionHigh infection rateFungiLight source combinationsMyceliumTrapping

The present invention relates to a system and method of cultivating Cordyceps, specifically, provided herein is a system of cultivating Cordyceps comprising: a Hepialus moth trapping device; a Hepialus moth eggs screening device, wherein the device is connected with the Hepialus moth trapping device; an ascospores-collecting device; a mycelia-preparing device; a conidia-preparing device; an infection device, wherein the device is connected with the ascospores-collecting device, the mycelia-preparing device and the conidia-preparing device; and a feeding device, wherein the device is connected with the Hepialus moth eggs screening device and the infection device. And also provided is a method of using the system to cultivate Cordyceps.

Owner:NORTH & SOUTH BROTHER PHARMACY INVESTMENT CO LTD

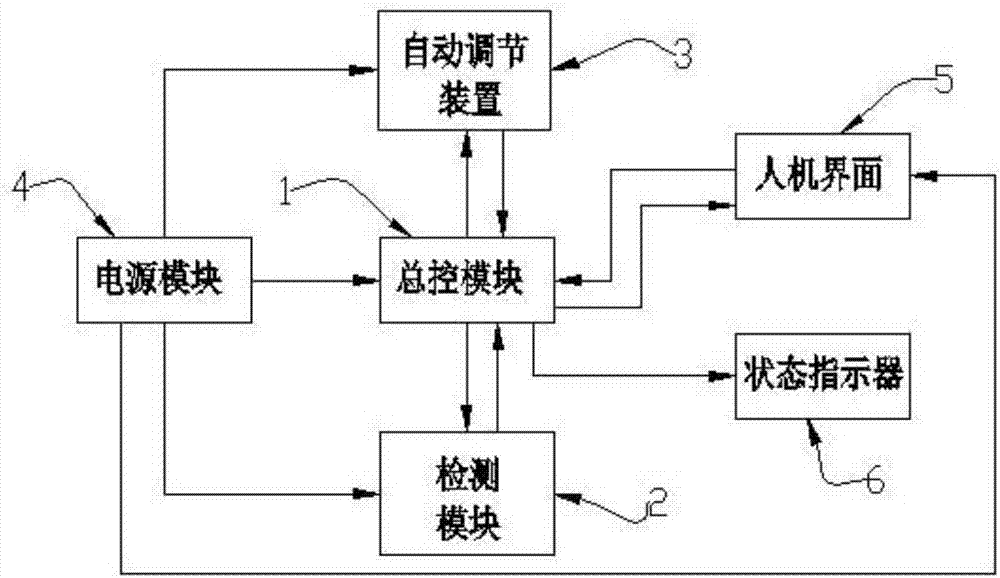

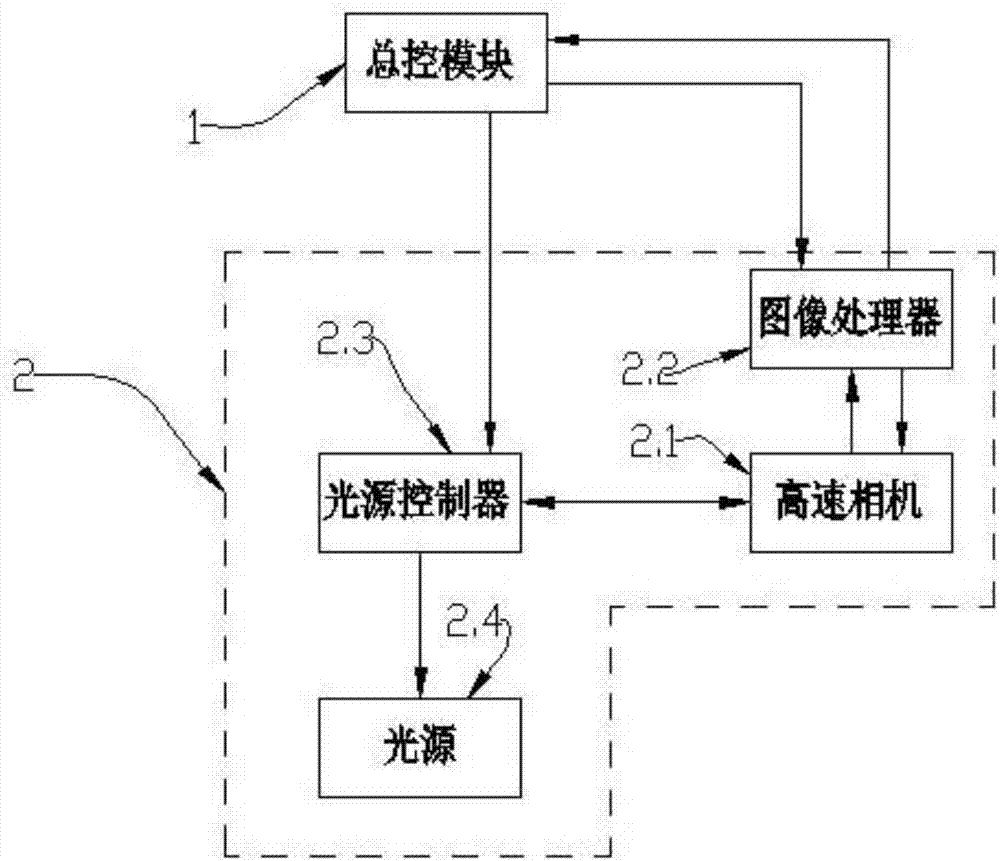

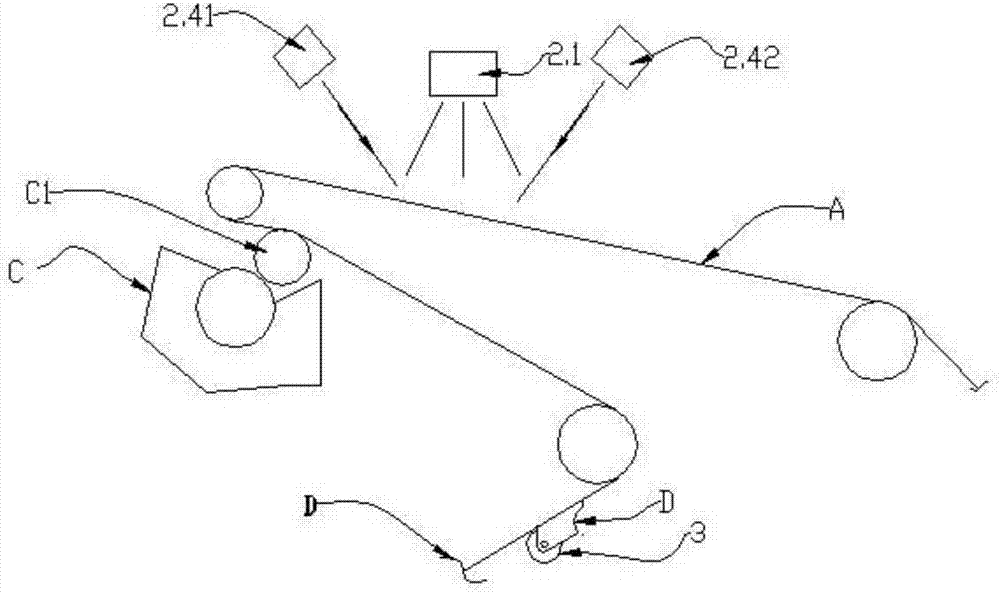

Device and method for automatically detecting and adjusting gluing position of tipping paper of cigarettes

ActiveCN107080284AReduce generationLess interventionCigarette manufactureHuman–machine interfaceMan machine

The invention discloses a device for automatically detecting and adjusting a gluing position of tipping paper of cigarettes. The device comprises a detection module, an automatic adjusting device, a man-machine interface, a state indicator, a power module and a master control module, wherein the master control module controls the automatic adjusting device to adjust the left-right offset of a paper guide block according to glue position offset transmitted by the detection module and controls the gluing device to operate. The method disclosed by the invention comprises the following steps: shooting and sampling by a high-speed camera, and processing images by an image processor so as to obtain the glue position offset; and judging whether the glue position is qualified by the master control module according to the glue position offset, enabling the gluing device to continuously operate when the glue position is qualified, and transmitting an adjusting instruction to the automatic adjusting device and corresponding adjusting the paper guide block when the glue position is unqualified. According to the device and method disclosed by the invention, the offset occurring at the gluing position of the tipping paper can be automatically adjusted and corrected, all the processes are automatically monitored and executed by the master control module, the automation level is improved, the adjusting precision is guaranteed, and wastes are reduced.

Owner:CHINA TOBACCO GUANGXI IND

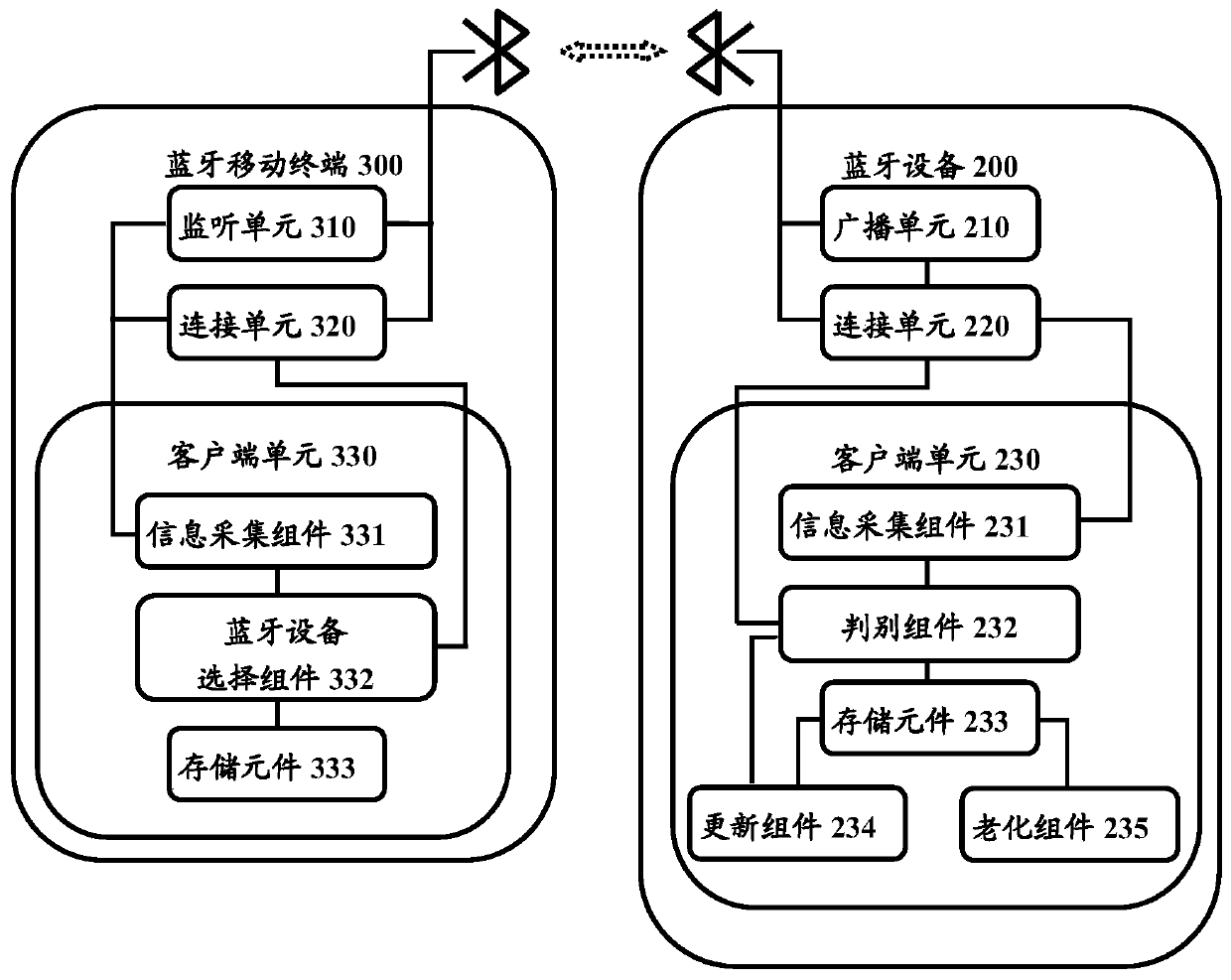

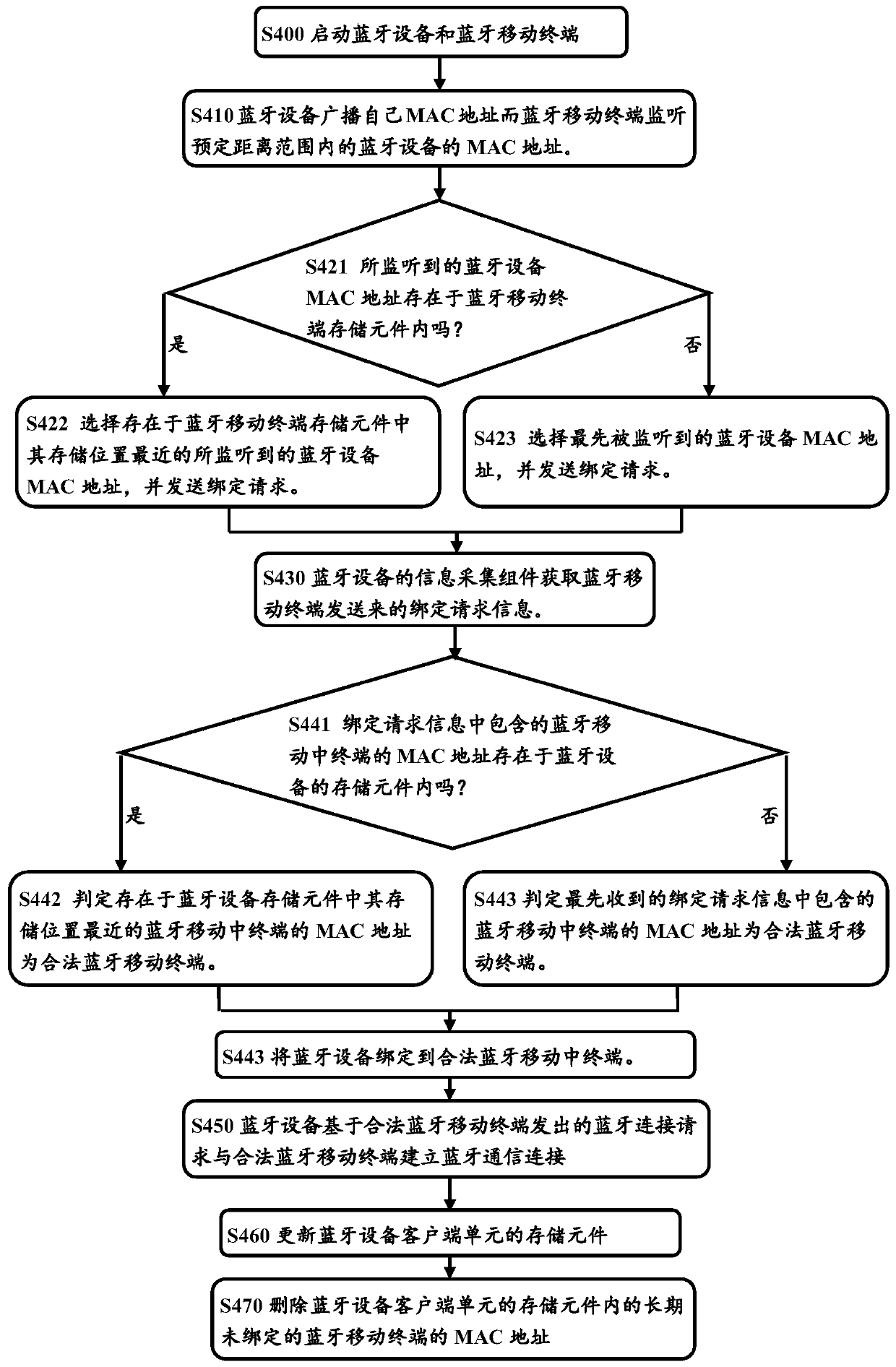

Bluetooth equipment, Bluetooth mobile terminal, Bluetooth quick connection system and method thereof

PendingCN110139261ALess interventionBind connection fast connection and excludeConnection managementSecurity arrangementTelecommunicationsBluetooth

The invention relates to a Bluetooth quick connection system. The Bluetooth quick connection system comprises Bluetooth equipment and a Bluetooth mobile terminal. The Bluetooth mobile terminal selectsone of the monitored Bluetooth equipment to send a binding request to the Bluetooth mobile terminal. Whether the Bluetooth mobile terminal sending the binding request is a legal Bluetooth mobile terminal or not is judged according to the binding request information received by the Bluetooth equipment and the information of the Bluetooth mobile terminal stored in the storage element, and the Bluetooth connection unit of the Bluetooth equipment is indicated to be bound and connected to the legal Bluetooth mobile terminal. The invention also relates to Bluetooth equipment used for the Bluetoothquick connection system, a Bluetooth mobile terminal and a Bluetooth quick connection method.

Owner:SHENZHEN NOVOCARE MEDICAL DEVICES CO INC

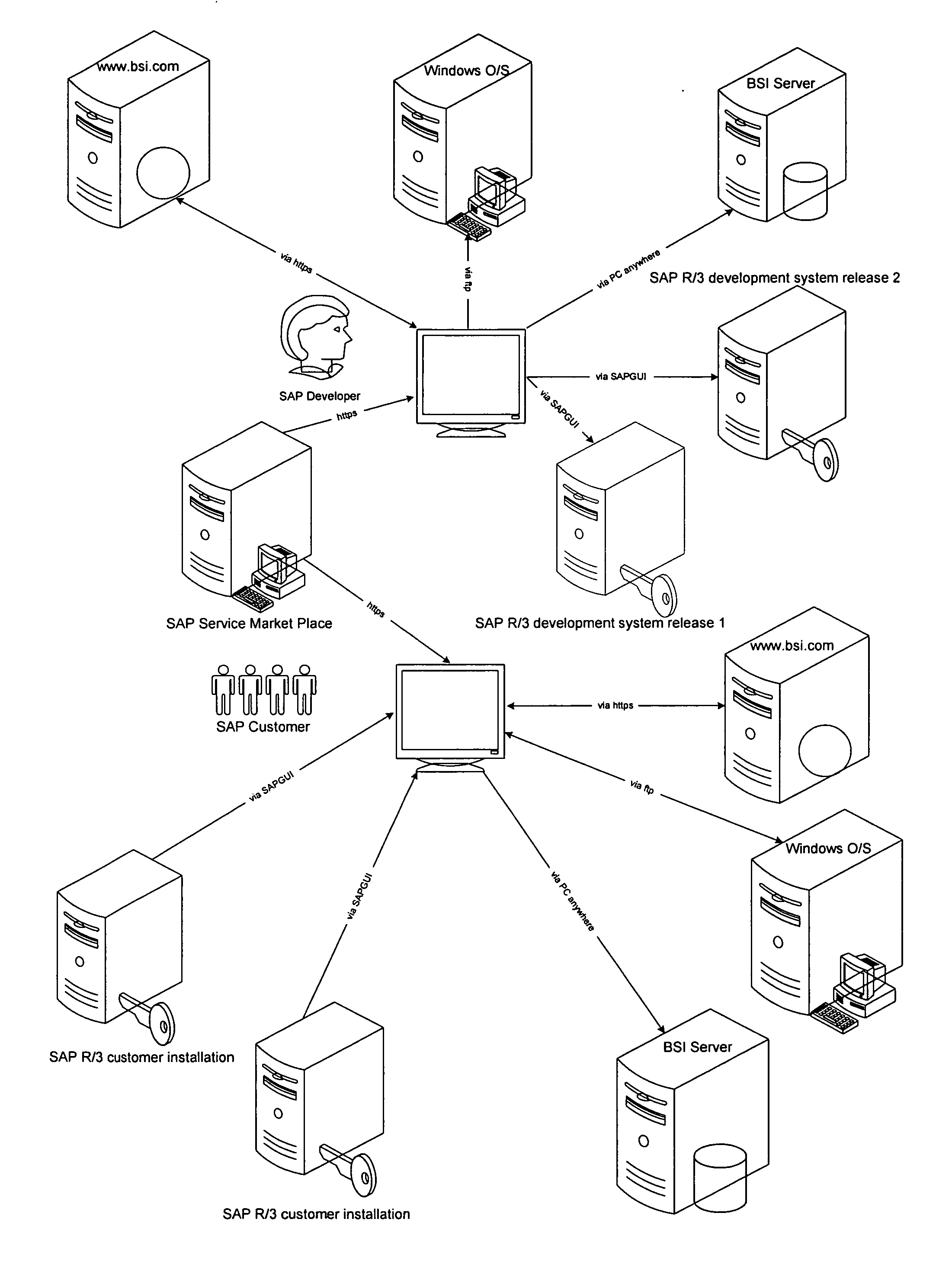

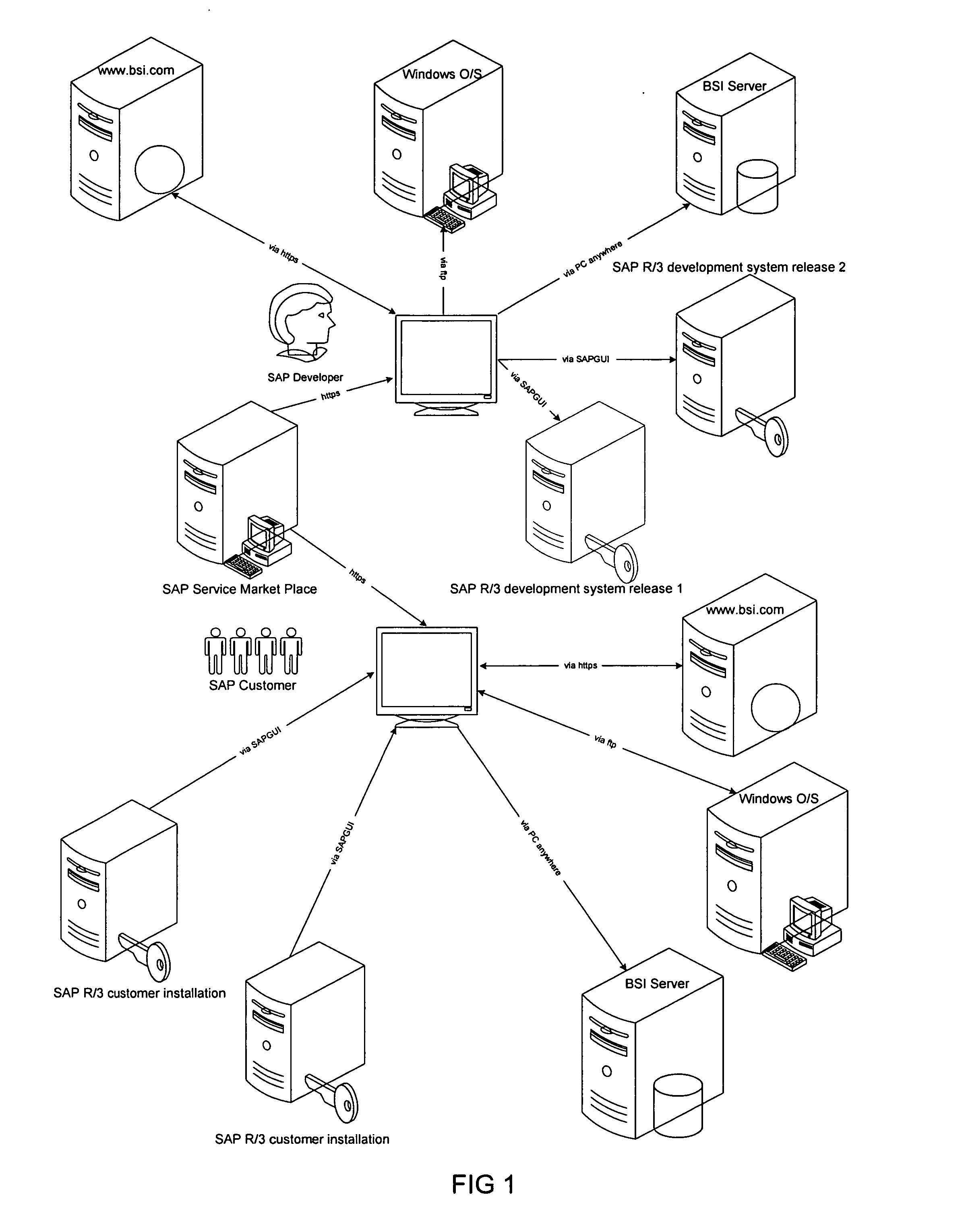

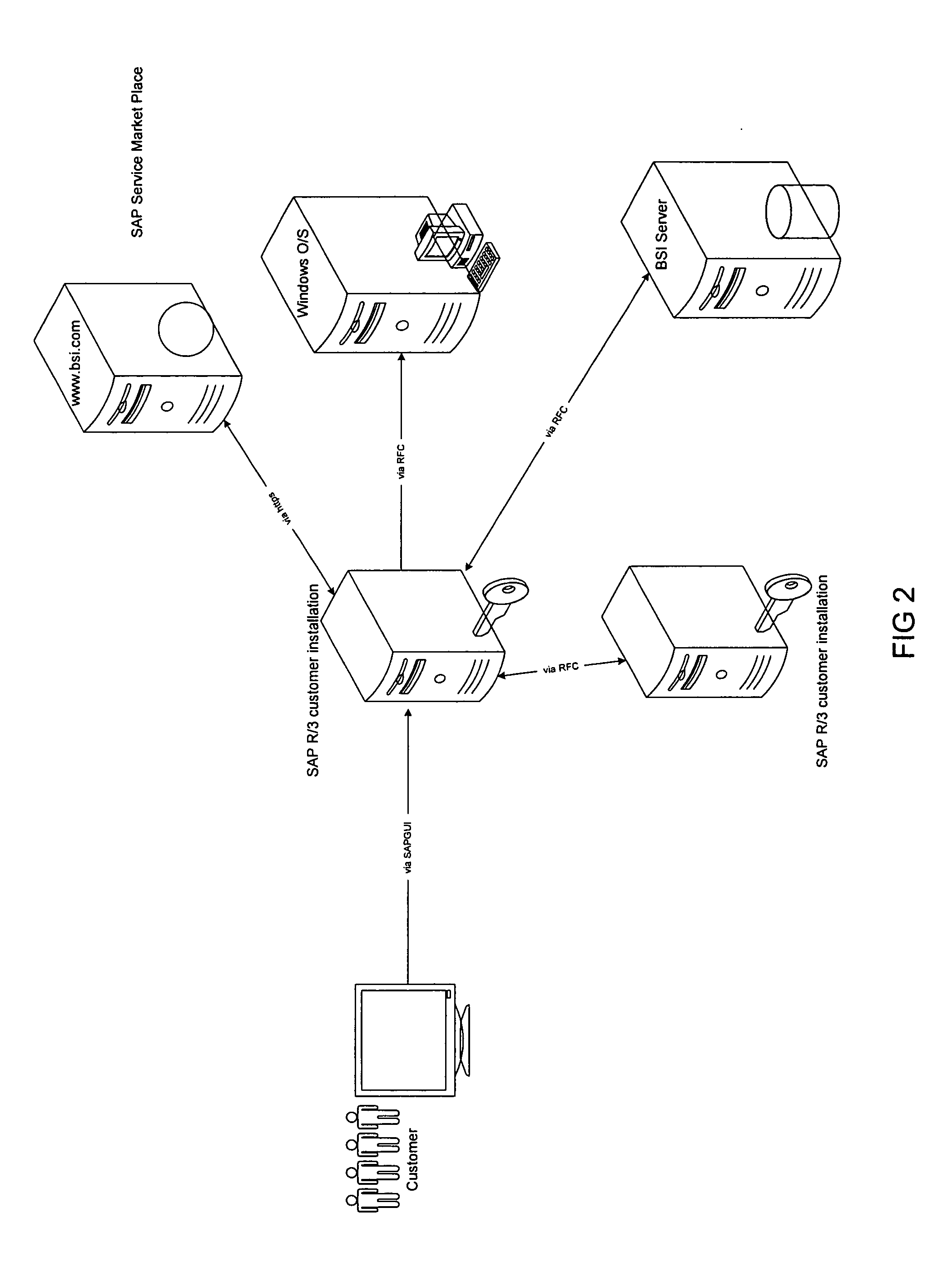

Method and system for assisting in compiling employee tax deduction

InactiveUS20070185792A1Easy to understandEasy to useComplete banking machinesFinanceOperational systemService provision

A method for use by a payroll department for facilitating computing tax deductions of employees in their pay-checks, uses a tax workbench (and UI) which facilitates SAP or other software in carrying out the tax computation process to completion. The method may be incorporated into an existing SAP system known as R / 3 which may be an ERP (enterprise resource planning) system. A user logs on to a single O / S and ensures that a Tax Update Bulletin (TUB) supplied by a service provider and incorporated into the O / S is up to date. Thereafter, the user completes steps in a predetermined sequence selectively either manually or automatically. The method saves user-time in completing the step sequence and eliminates the degree of dependence on the SAP system for importing TUBs, and obviates the need for a high level of user expertise and the need for accessing multiple operating systems.

Owner:SAP AG

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7066789B2Small footprintEasy to cleanSemiconductor/solid-state device manufacturingAbrasive feedersResistDrive motor

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium. The cryogenic cleaning medium is supplied via a nozzle implement that sweeps across the article. A slide mechanism and drive motor may be supplied internal or external to the controlled environment.

Owner:MANOCLEAN TECH

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7101260B2Small footprintEasy to cleanElectrostatic cleaningSemiconductor/solid-state device manufacturingResistPlasma processing

A method for manufacturing an article where the article has polymeric residue that is to be removed during the manufacture of the article. The article is introduced into a controlled environment of a processing tool that has at least first and second processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least the first processing chamber where they react with the polymeric residue. A cryogenic cleaning medium is supplied into the second processing chamber where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium The first and second processing chambers may be dedicated to plasma processing or cryogenic processing or each may provide both plasma processing and cryogenic processing.

Owner:NANOCLEAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com