Mechanical, fully-automatic and intelligent vacuum packaging machine for non-particulate materials

A vacuum packaging machine, fully automatic technology, applied in the field of packaging, can solve the problems that affect the normal production, the packaging bag is easy to stick, and cannot be dropped normally, so as to save equipment, stop maintenance time and frequency, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

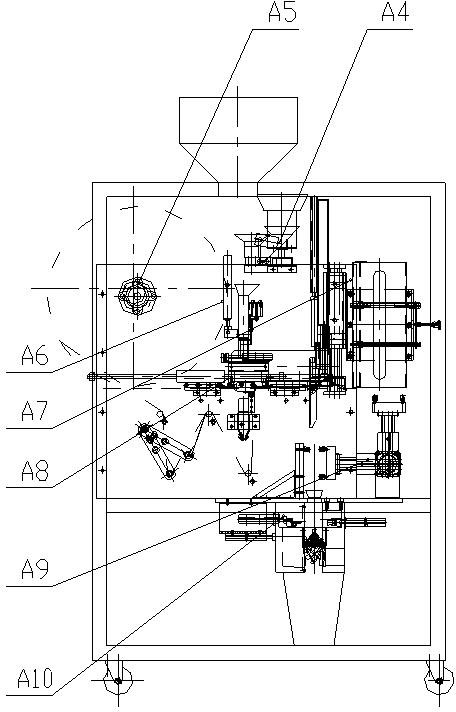

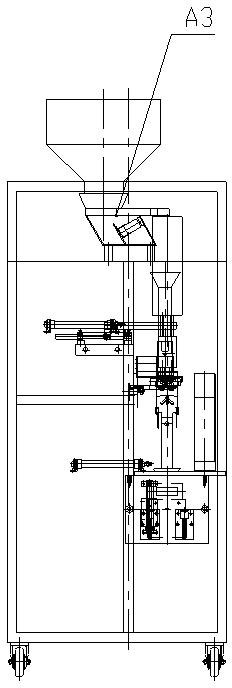

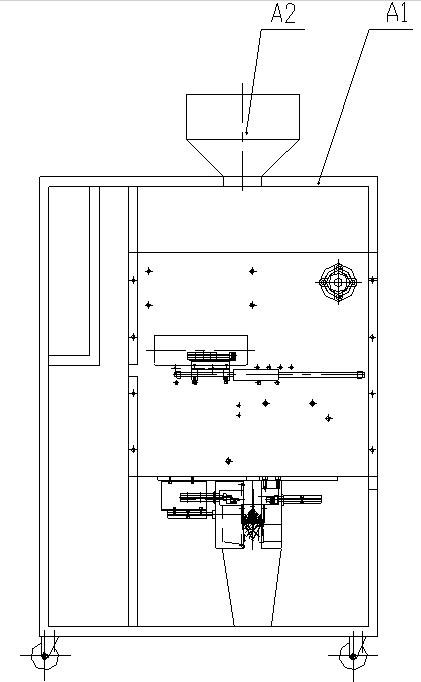

[0036] Please see Figure 1~6, a mechanical fully automatic non-granular intelligent vacuum packaging machine, including a chassis A1, a feeding hopper A2 is arranged on the top plate of the chassis A1, and a vibrating feeding mechanism A3 is arranged on the lower outlet of the feeding hopper in sequence, For the metering mechanism A4 of the hopper, the bag supporting device A6 for pulling the inner bag, the bag filling mechanism A7, the sealing and cutting bag mechanism A8 and the vacuum sealing device A10, the side of the bag supporting device A6 is also provided with a bag supporting device A6 The bag supply device A5 for the inner bag, and the side of the vacuum sealing device A10 is also provided with an outer bag opening and supply device A9 for deliverin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com