Wide-adaptive novel automatic driller

A new type of automatic drill feeding technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of unsatisfactory application of automatic drill feeding system, inability to obtain the system mathematical model, and inability to guarantee parameter configuration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The parameters of the I link, P link and D link of the PID module in this embodiment are all input by the touch screen as the man-machine interface.

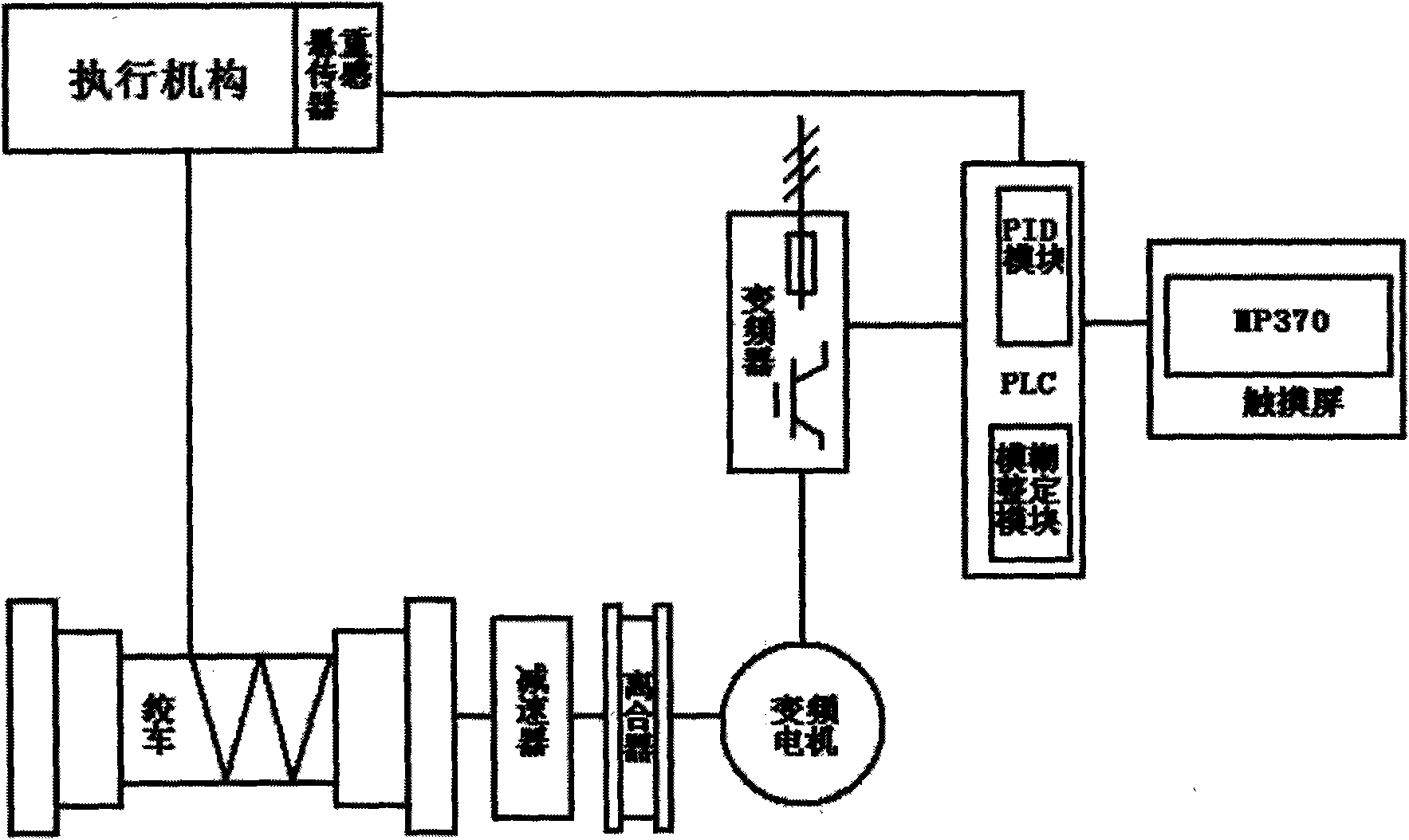

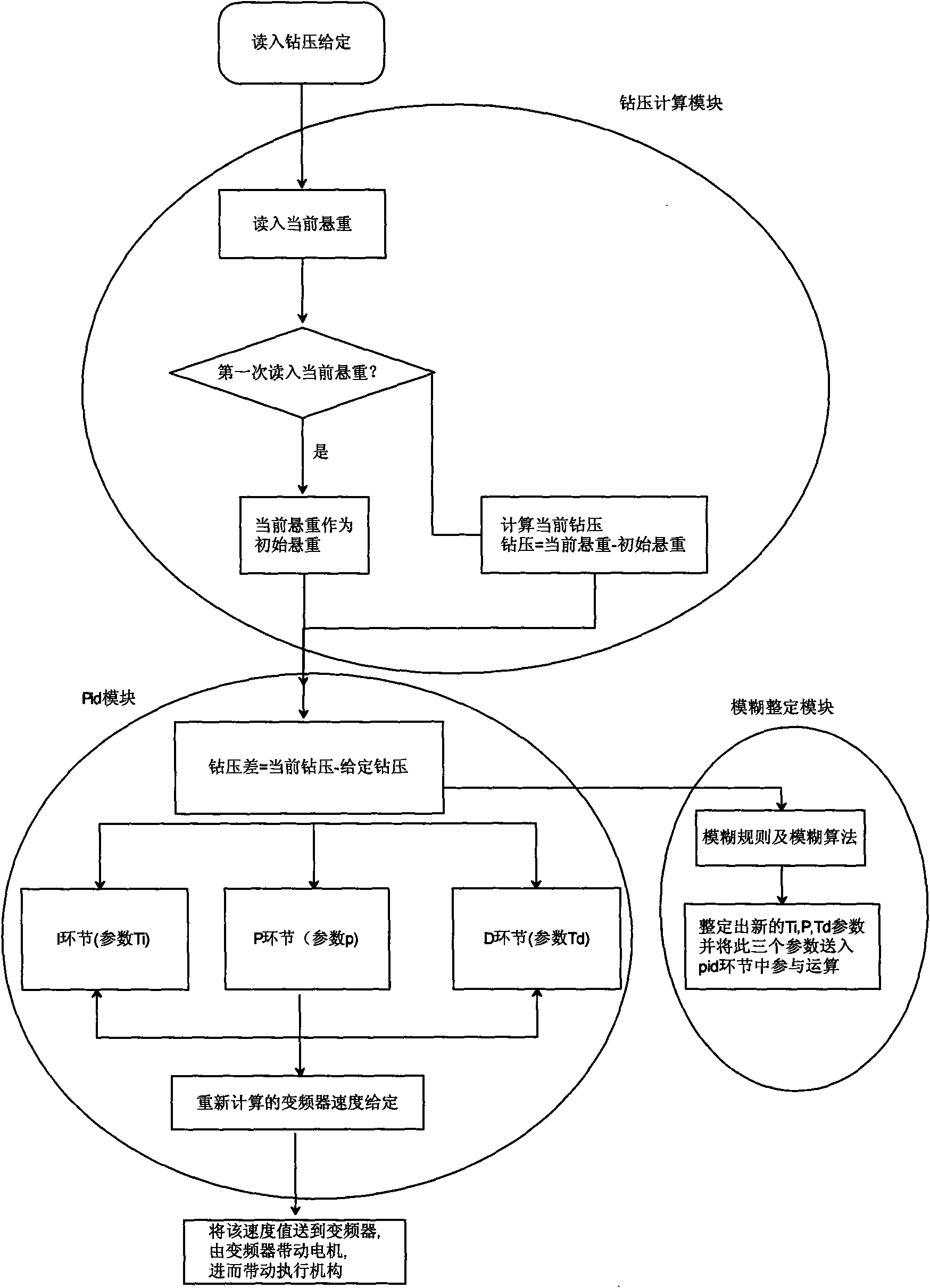

[0064] The wide-adapted novel automatic drilling device in this embodiment includes an actuator, a variable frequency motor and a frequency converter. To the frequency conversion motor, the three-phase power supply is connected to the frequency converter. The above-mentioned actuator is provided with a suspension load sensor, which inputs the measured data to the programmable controller PLC, and the programmable controller PLC is connected to the frequency converter and a touch screen as a man-machine interface, and the programmable control The weight-on-bit calculation module and the PID module are included in the PLC, and the programmable logic controller PLC performs the following steps:

[0065] ① Input the given WOB through the touch screen as the man-machine interface, read the current suspension weight through the...

Embodiment 2

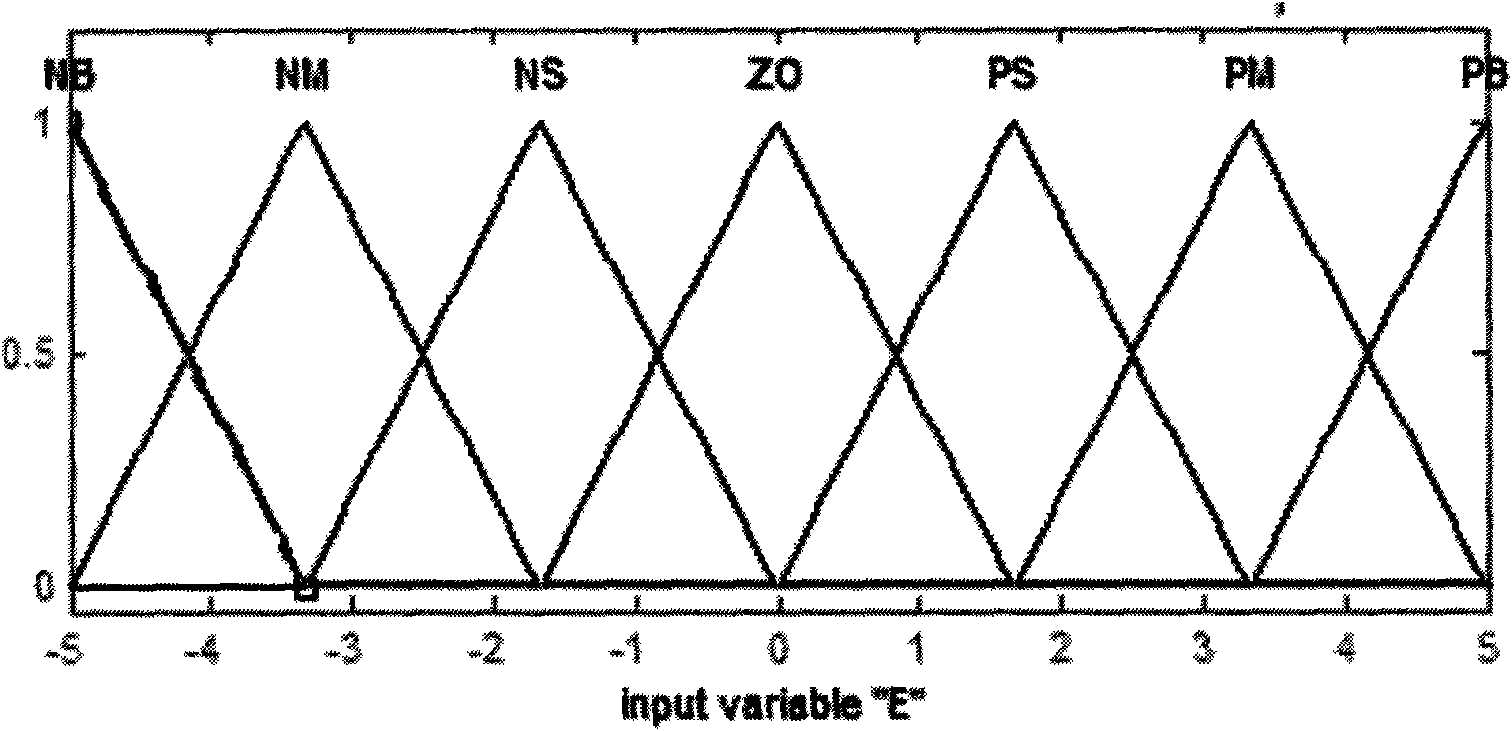

[0087] Among the parameters of the I link, P link and D link of the PID module in this embodiment, the I link and the D link parameters are input by the touch screen as the man-machine interface. The PID control module in the PLC program uses the PID block that comes with Siemens s7-300. In order to increase the stability of the system and prevent shocks, the fixed i parameter is used here, and the fuzzy tuning module only modifies the value of the p parameter.

[0088] The wide-adapted novel automatic drilling device of the present invention includes an actuator, a variable frequency motor and a frequency converter. Frequency conversion motor, the three-phase power supply is connected to the frequency converter. The above-mentioned actuator is provided with a suspension load sensor, which inputs the measured data to the programmable controller PLC, and the programmable controller PLC is connected to the frequency converter and a touch screen as a man-machine interface, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com