Device and method for automatically detecting and adjusting gluing position of tipping paper of cigarettes

An automatic detection and automatic adjustment technology, applied in the fields of tobacco, cigarette manufacturing, and application, can solve the problems of untimely adjustment, substandard products, and unreliable detection, so as to reduce waste, reduce the degree of intervention, and improve the level of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The automatic glue thickness detection device of the present invention can be applied to the detection of glue thickness on various pieces to be glued. In this embodiment, the piece to be glued is tipping paper as an example for introduction.

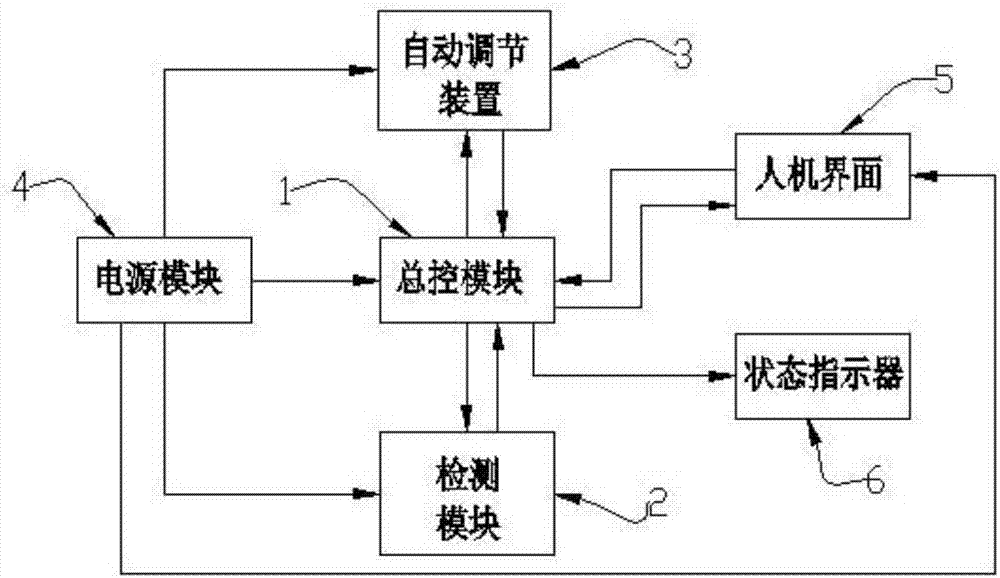

[0045] Such as Figure 1-8 As shown, a device of the present invention for automatically detecting and adjusting the gluing position of cigarette tipping paper, comprising

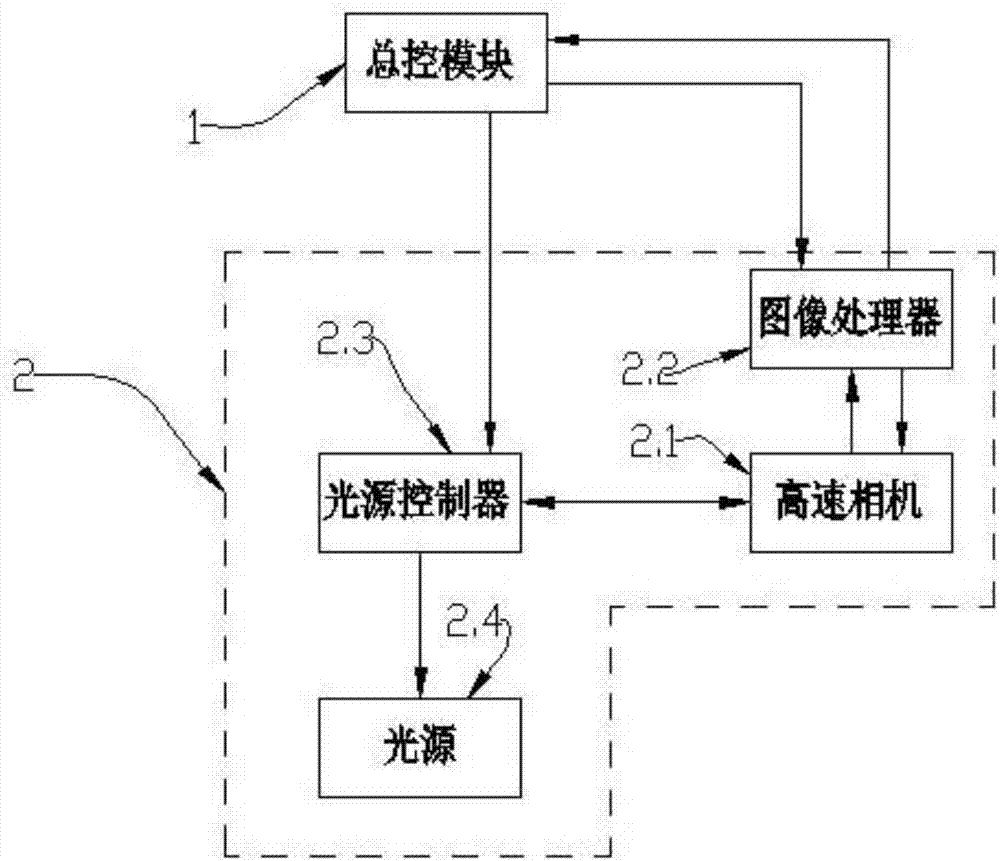

[0046] The detection module 2 is used to detect the glue application position of the tipping paper, process the detected glue application position information, and transmit the glue position bias obtained after processing;

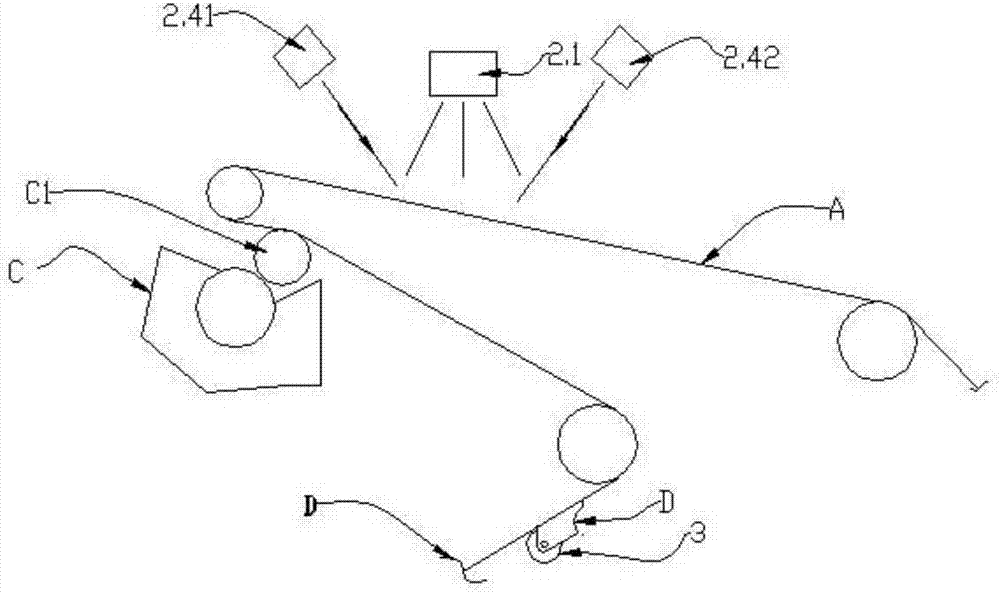

[0047] The automatic adjustment device 3 adjusts the gluing position of the tipping paper by adjusting the paper guide block D to move left and right;

[0048] The master control module 1 is electrically connected with the detection module 2, the automatic adjustment device 3, and the gluing device, and controls the automatic adjustment ...

Embodiment 2

[0063] Such as Figure 8 As shown, a method for automatic detection and adjustment of the gluing position of cigarette tipping paper of the present invention comprises the following steps:

[0064] Detection steps: the high-speed camera 2.1 takes pictures and samples the tipping paper A and the glue-coated road B, the interval time is t, the sampled photos are sent to the image processor 2.2, and the image processor 2.2 processes the photos to obtain the glue position offset , and send out the glue position offset;

[0065] Adjustment steps: The master control module 1 receives the offset of the glue position sent by the image processor 2.2, and judges whether the glue position is qualified. When the glue position is qualified, the gluing device C continues to run. The adjustment device 3 sends an adjustment instruction to adjust the paper guide block D accordingly.

[0066] The adjustment step also includes: when the glue position is unqualified for more than a certain peri...

Embodiment 3

[0069] The difference between Embodiment 3 and Embodiment 2 lies in the manner in which the image processor 2.2 processes the photos in the detection step. In this embodiment 3, the processing of the photo by the image processor 2.2 is as follows: the image processor 2.2 directly obtains the distance from the edge of the corresponding tipping paper A to the edge of the gluing road B through calculation in real time according to the images collected in real time value a1 and the real-time value b1 of the width of the gluing road B, the image processor 2.2 transmits the two values to the master control module 1, and the master control module 1 compares the distance real-time value a1 and the width real-time value b1 with the distance standard value a0 and the width respectively The standard value b0 is compared, if the distance difference a2=a0-a1 exceeds the tolerance range of the distance, and the continuation time t1 is greater than the specified time, then it is determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com