Double-needle plate roller hybrid type stretch breaking spinning device

A hybrid and roller-type technology, which is applied in the field of double-needle plate roller hybrid stretch-cut spinning equipment, can solve the problems of affecting the subsequent processing, not getting stretch-cut, and the existence of too many parallel threads, so as to reduce the cost of parallel threads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Dry hemp→soft hemp process→drawing and cutting process→pre-merging process (1-2 steps)→combing process→pinning process (3-4 steps)→roving process→spinning process.

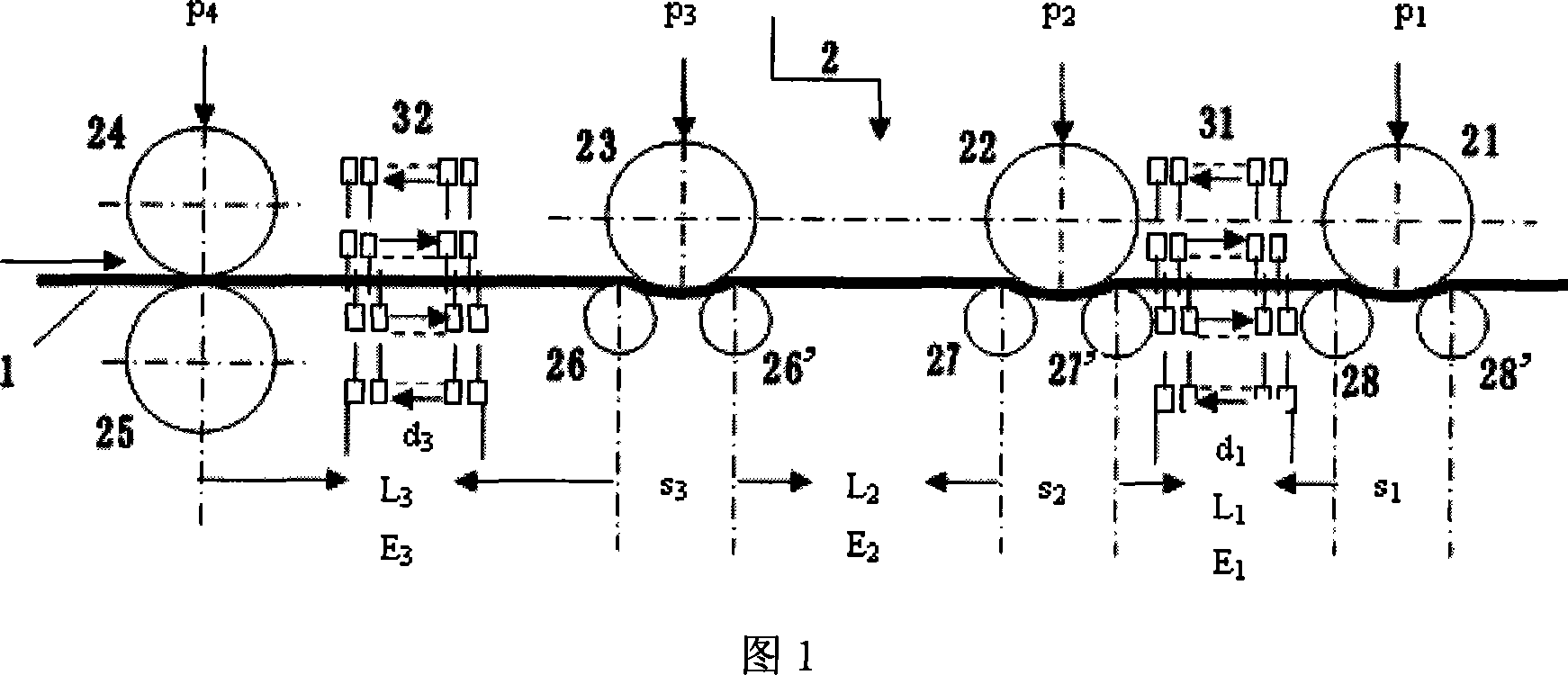

[0016] As shown in Fig. 1, the double-needle plate roller hybrid stretch-cutting spinning equipment used in the stretch-cutting process of the present invention is provided with three stretch-cut zones. The sliver A after softening enters the third stretching zone, the second stretching zone and the first stretching zone successively, and is stretched respectively in these stretching zones to make the fibers straight and parallel, and the long fibers follow With the gradual reduction of the distance in the stretch-cutting area, it is gradually broken into the required length, which ensures the elimination of ultra-long fibers. At the same time, due to the function of the needle plate, it can greatly reduce the mutual binding (bonding) of fibers , that is to reduce the doubling, and the curved fiber bundles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com