Ultra-high pressure sewage sludge deep dewatering device

A technology of sewage sludge and deep dewatering, which is applied in the fields of dewatering/drying/concentrating sludge treatment, sludge treatment, water/sludge/sewage treatment, etc. High hydraulic power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0018] The present invention covers any alternatives, modifications, equivalent methods and solutions made on the essence and scope of the present invention. In order for the public to have a thorough understanding of the present invention, specific details are described in the following preferred embodiments of the present invention, and those skilled in the art can fully understand the present invention without the description of these details. In addition, for the sake of illustration, the drawings of the present invention are not drawn exactly according to the actual scale, and are described here.

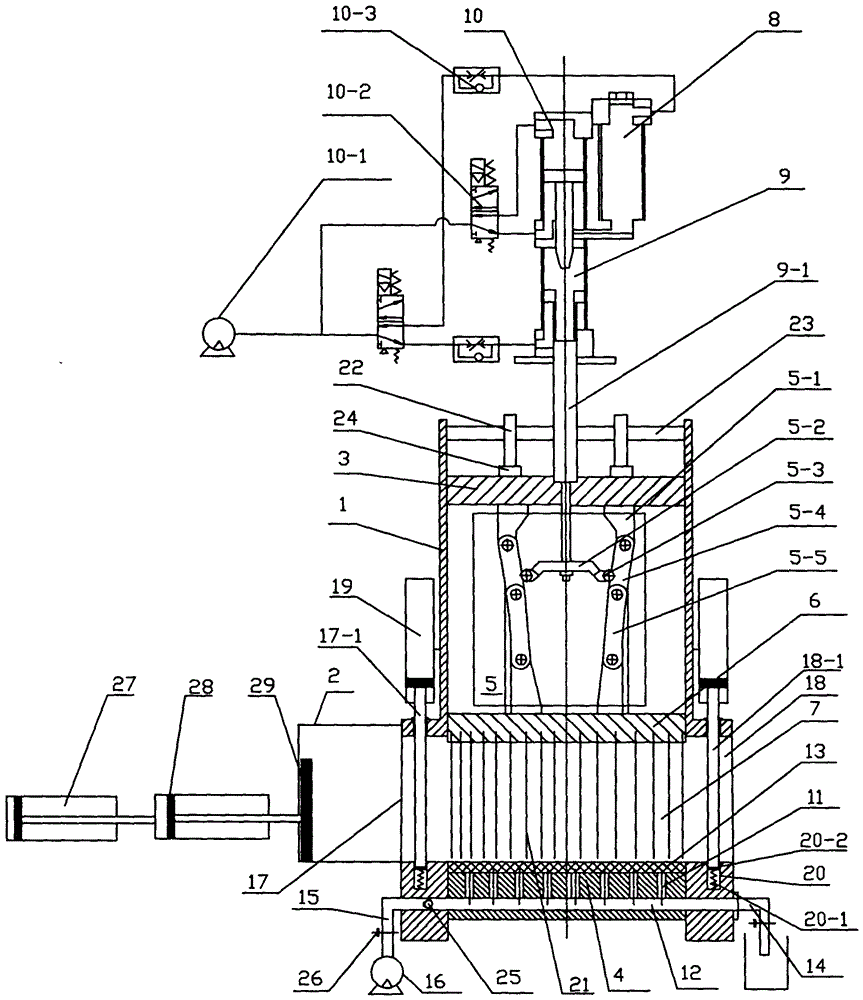

[0019] Such as figure 1 As shown, an ultra-high pressure sewage sludge deep dehydration device of the present invention includes a cylinder body 1, a storage bin 2, an upper fixing plate 3 arranged on the upper part of the cylinder body 1, and a lower fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com