Patents

Literature

168results about "Vehicle with pusher plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

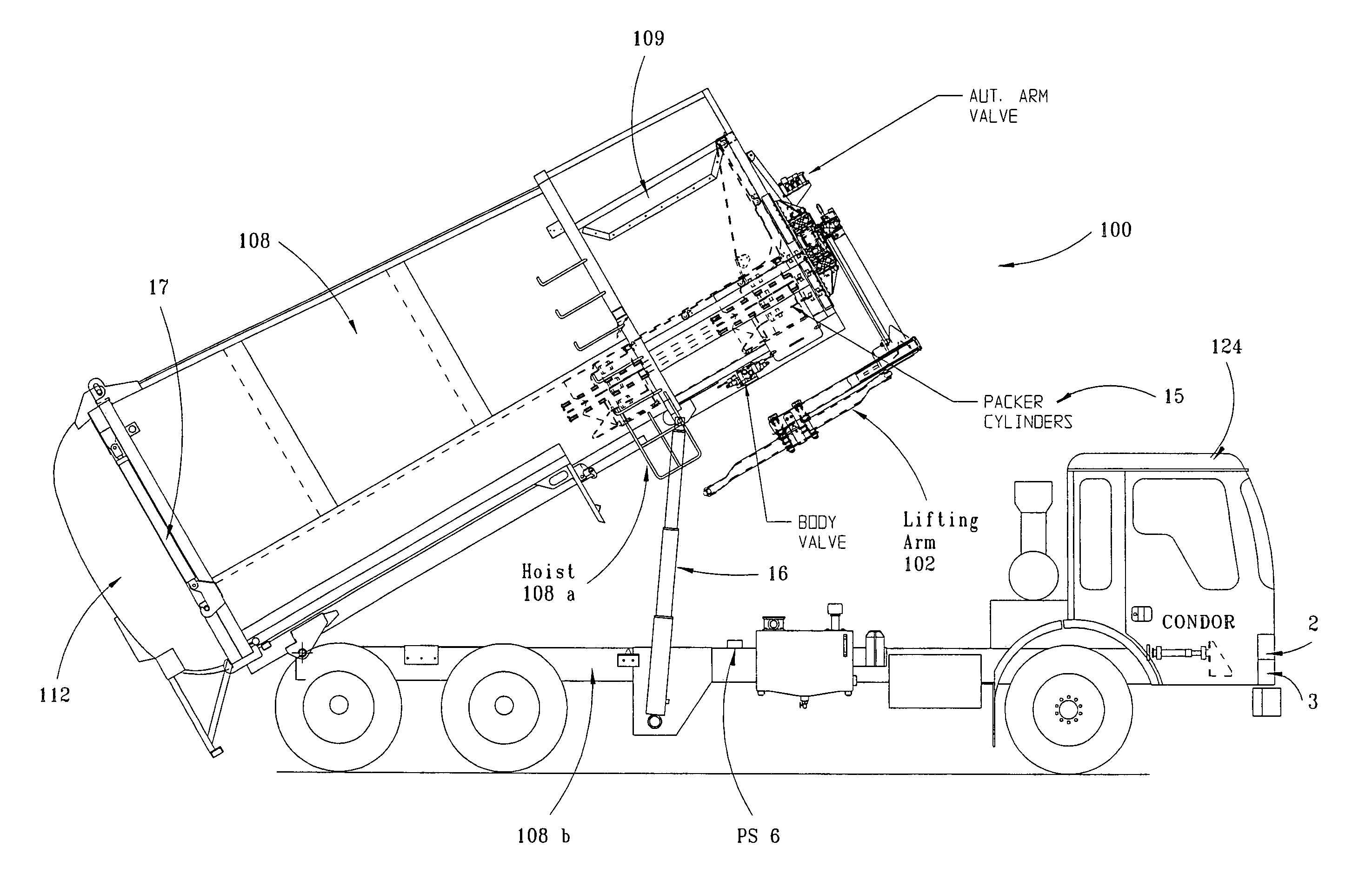

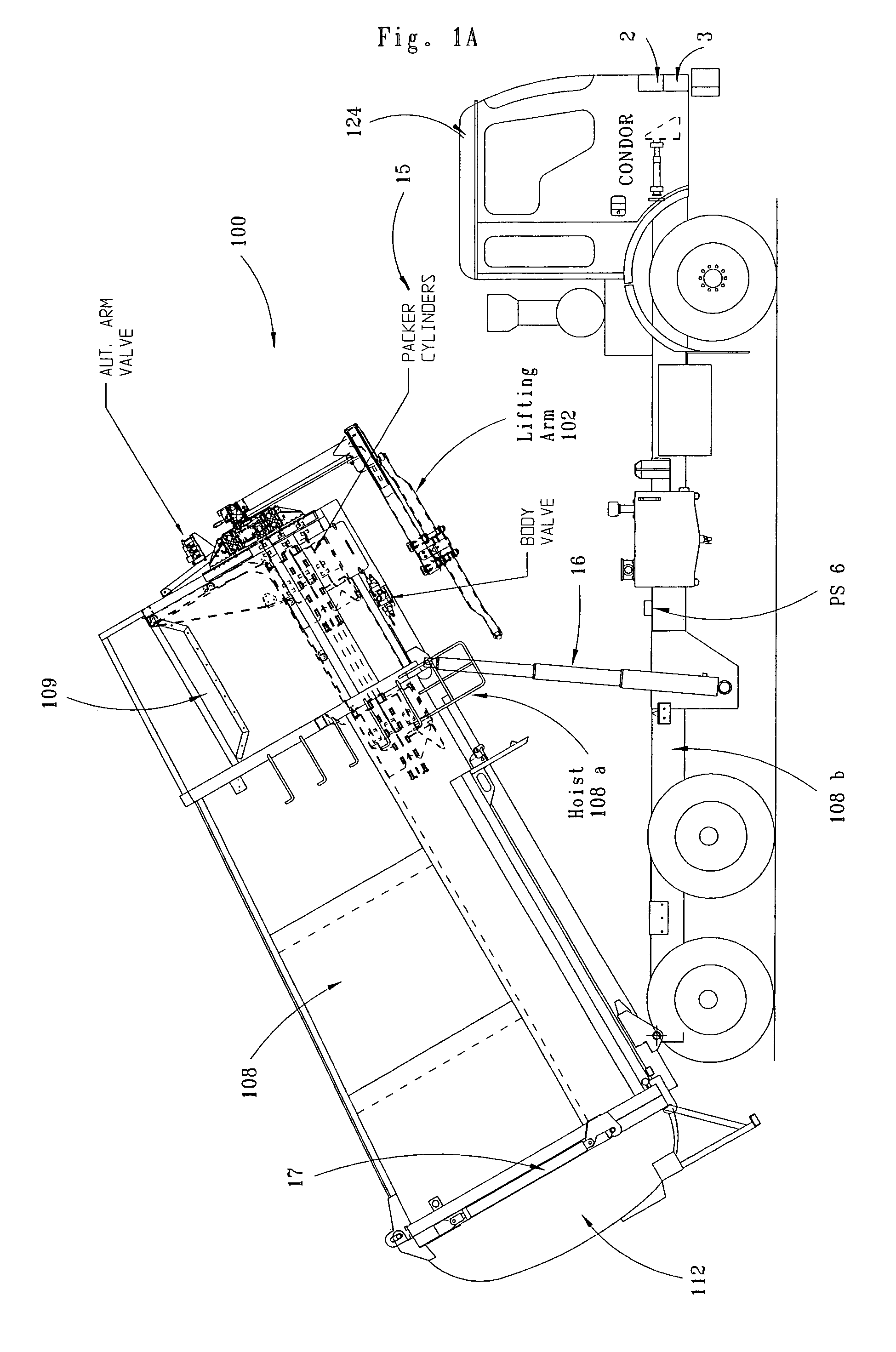

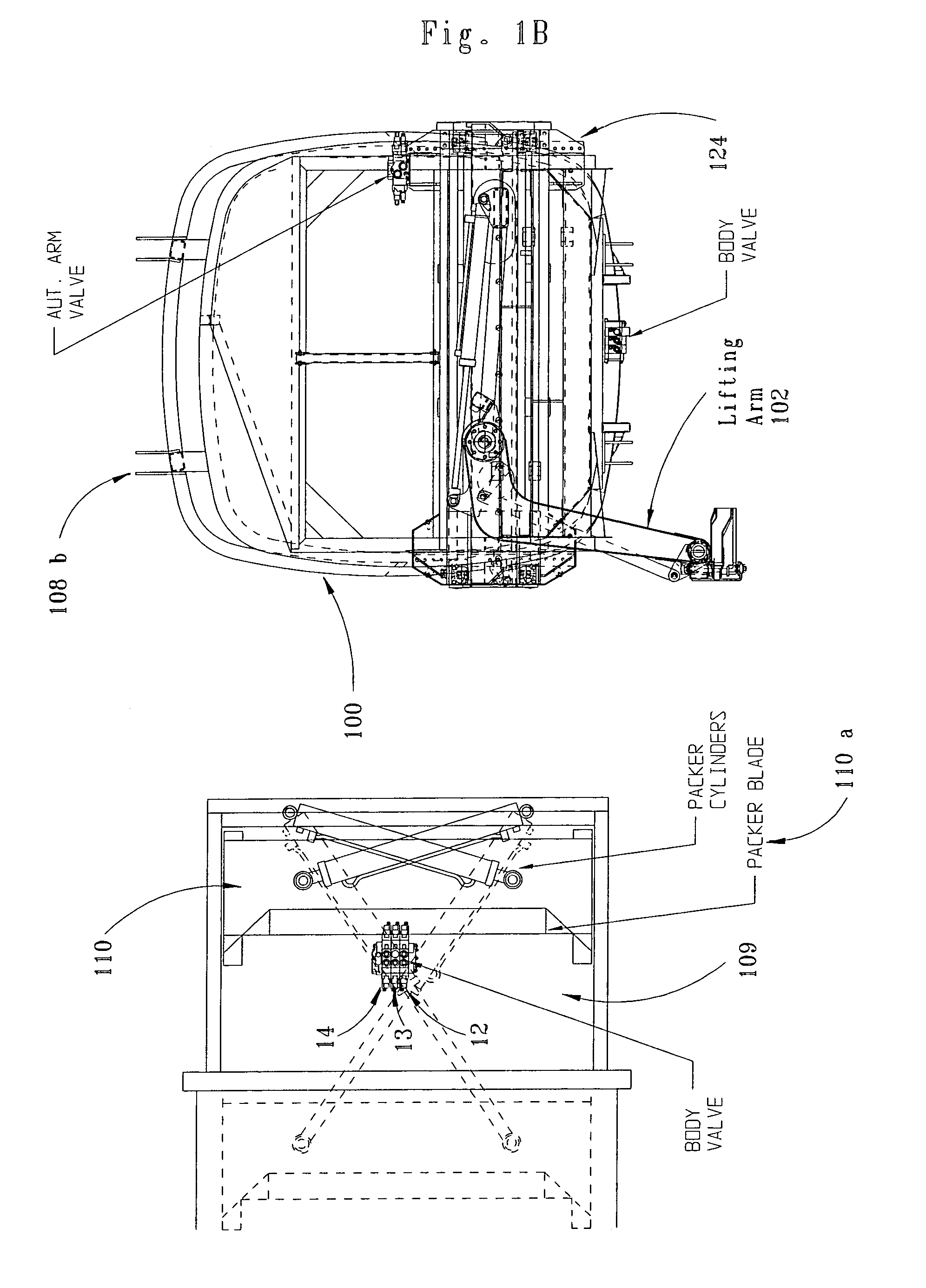

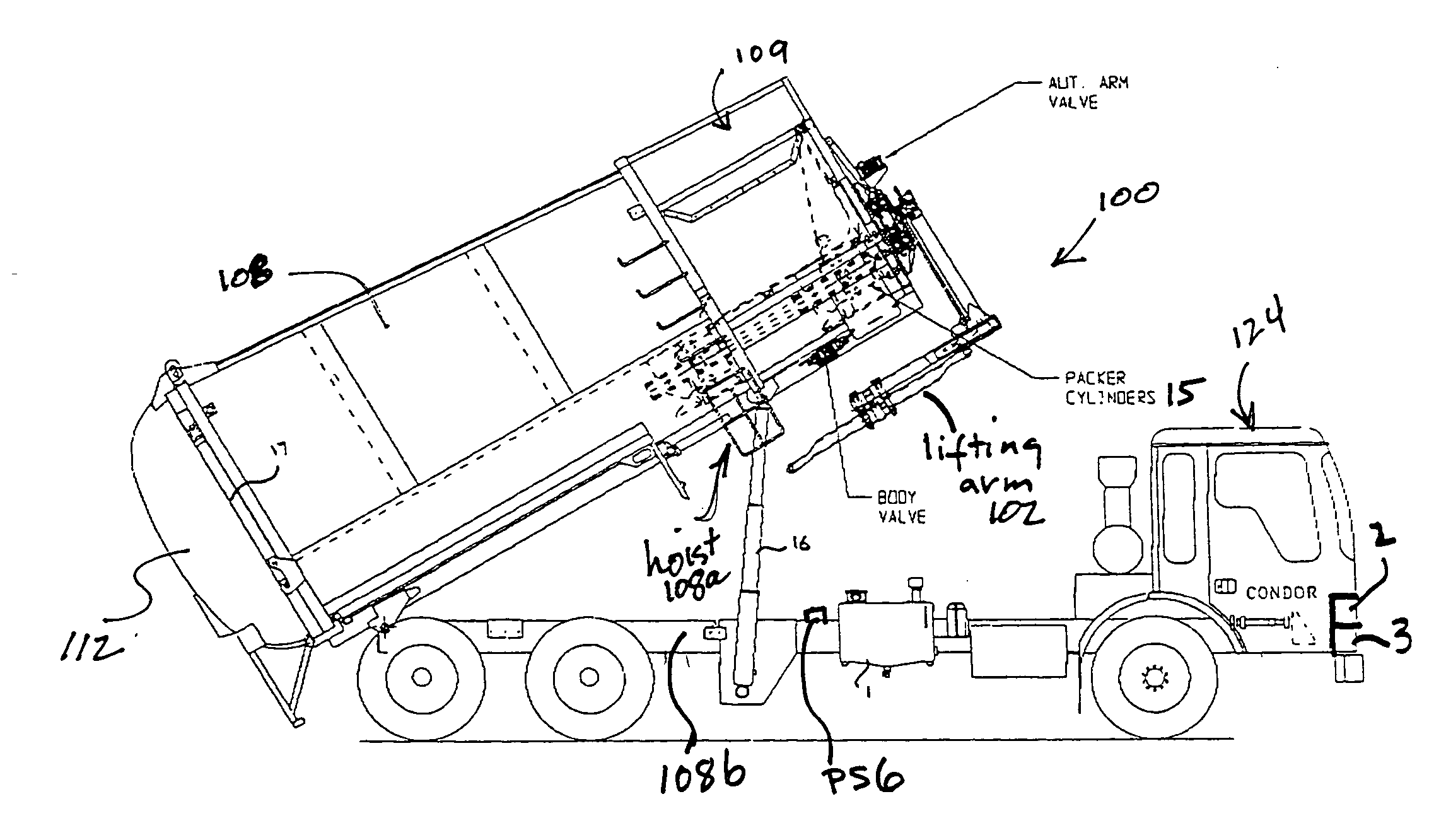

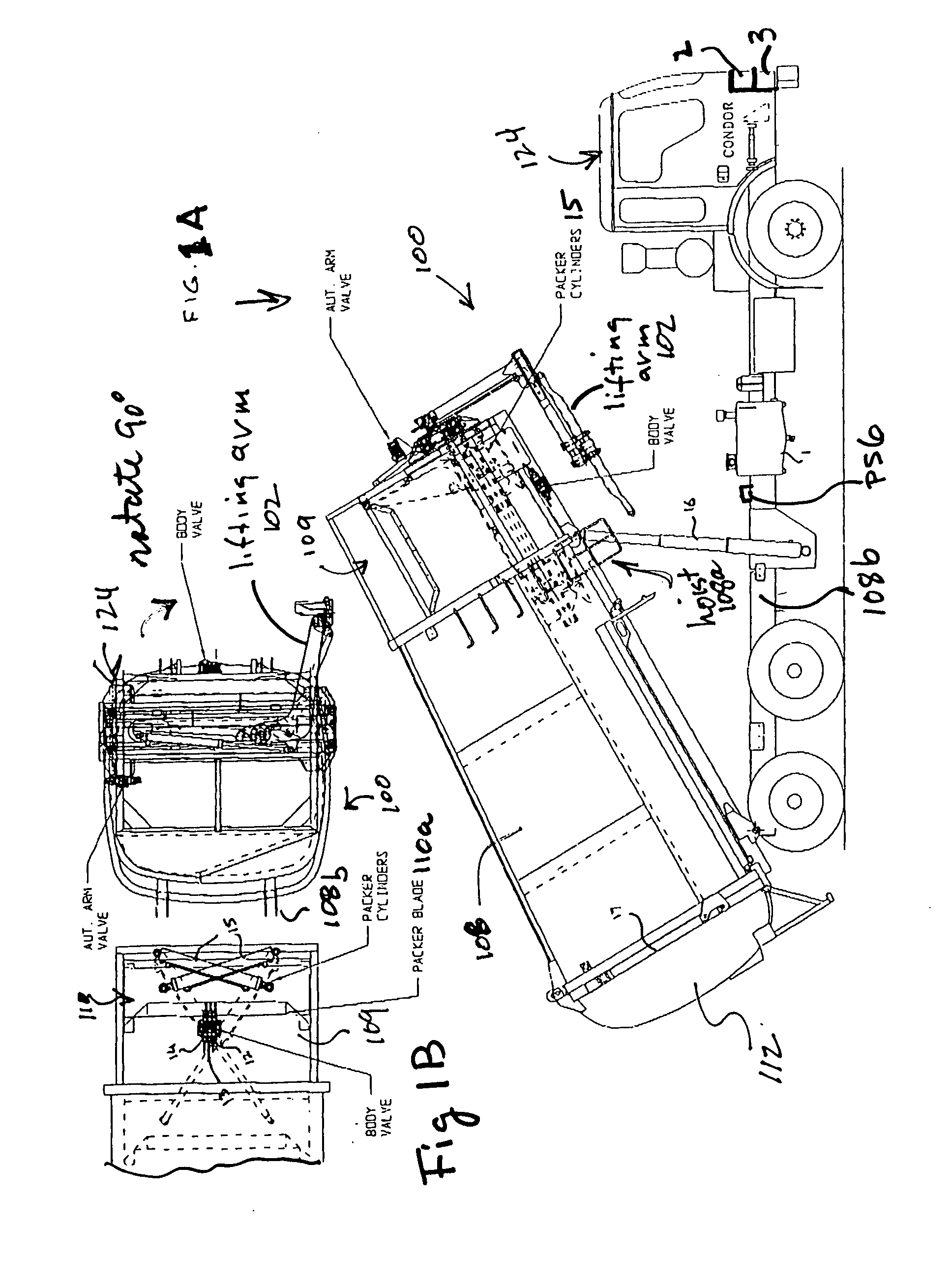

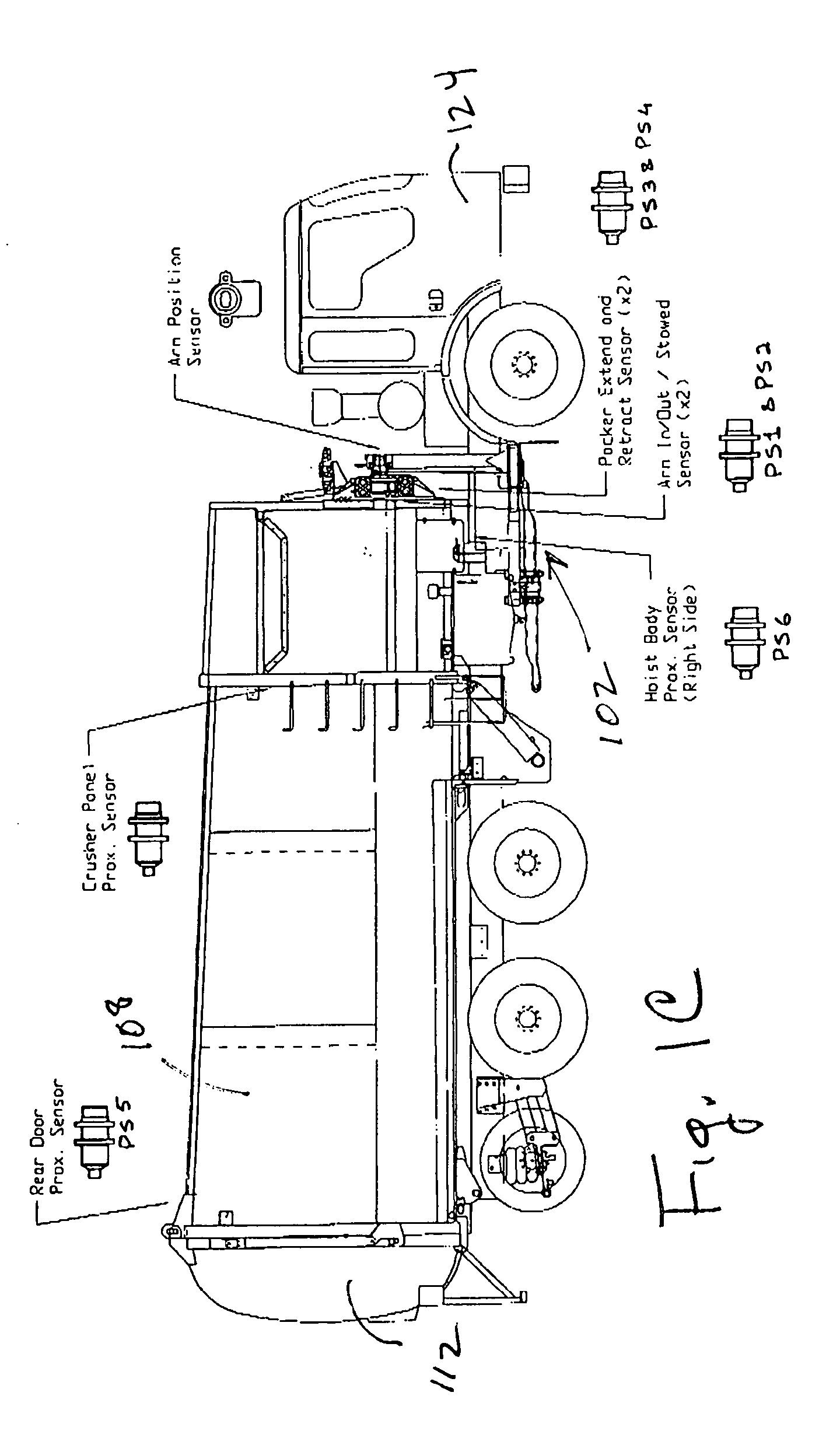

Hydraulic control system for refuse collection vehicle

InactiveUS7070381B2Promote resultsAccurate repeatable controlArticle unpackingRefuse receptaclesRefuse collectionControl system

A front loading refuse vehicle includes at least one positive displacement pump having an associated valve system in fluid communication with drive mechanism that operates a lifting arm, packer, a rear door of the vehicle, and a hoist for a refuse storage body. The valve system includes at least one closed-centered valve with a spool mechanism having a pressure compensator to maintain a constant flow rate of fluid through the valve regardless of differential in pressure across the valve for any given position of the spool mechanism. Two pumps with two separate hydraulic control systems are used with a side loading refuse vehicle. An electrical / electronic control system including a microprocessor operates the valve systems for each vehicle.

Owner:SMART TRUCK SYST

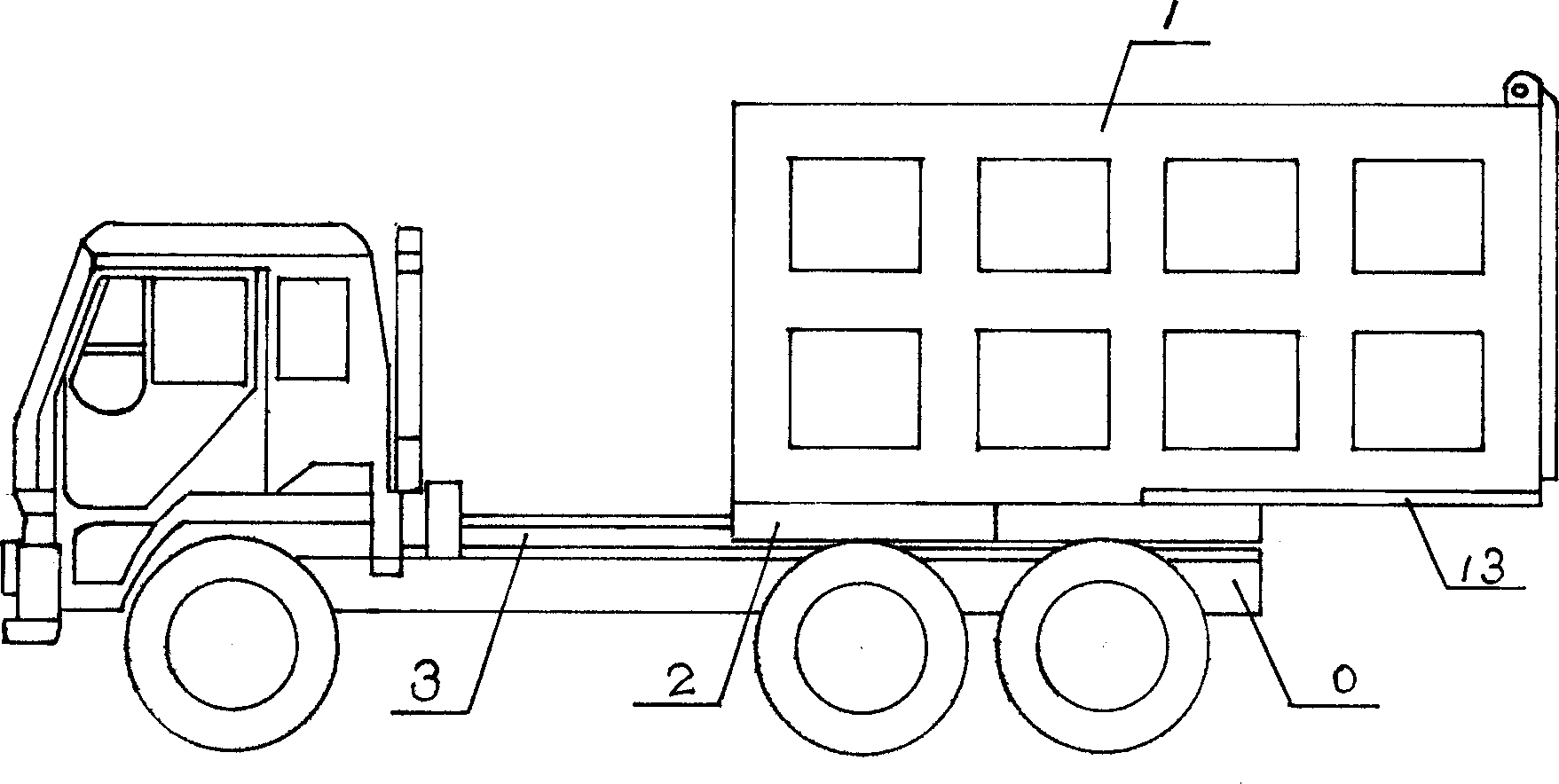

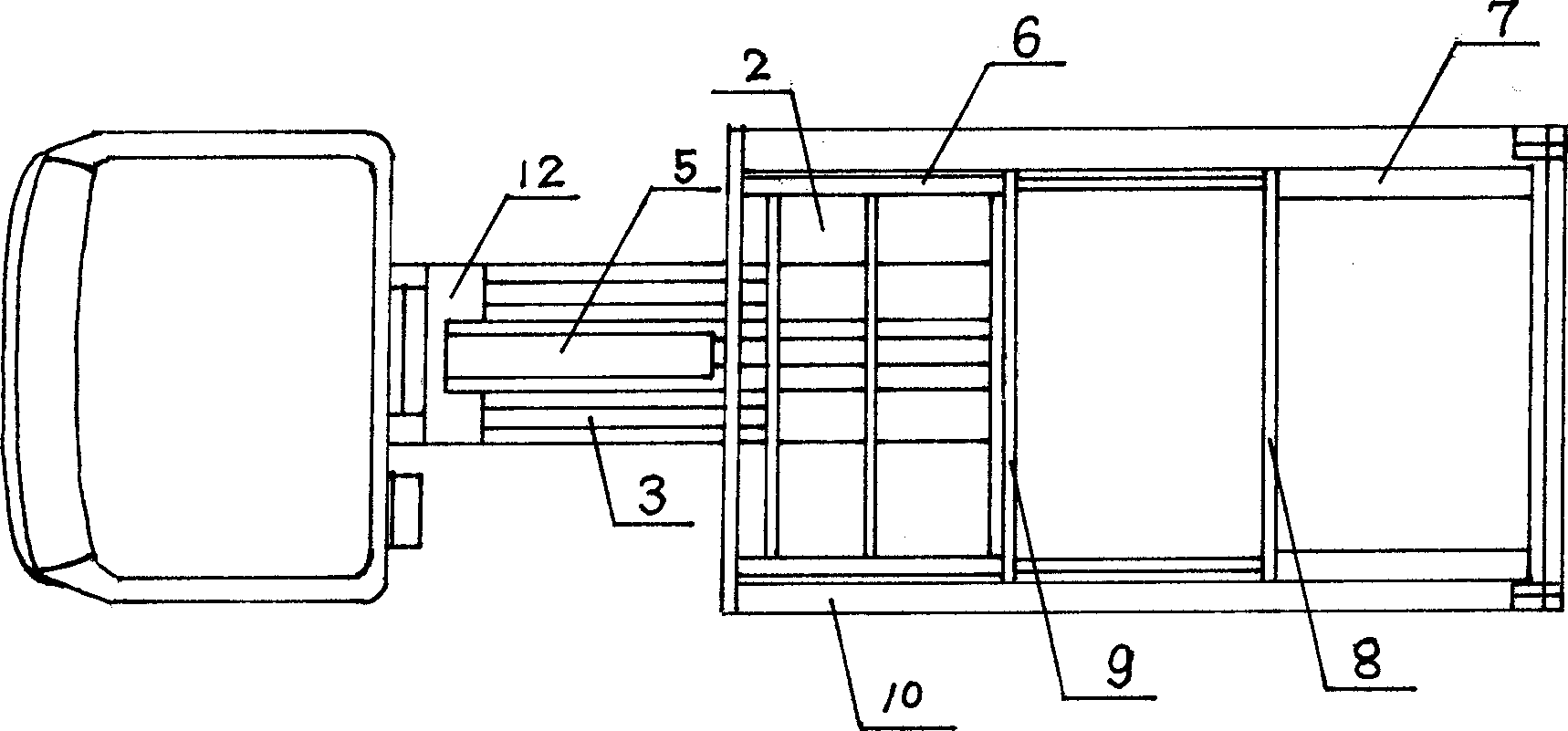

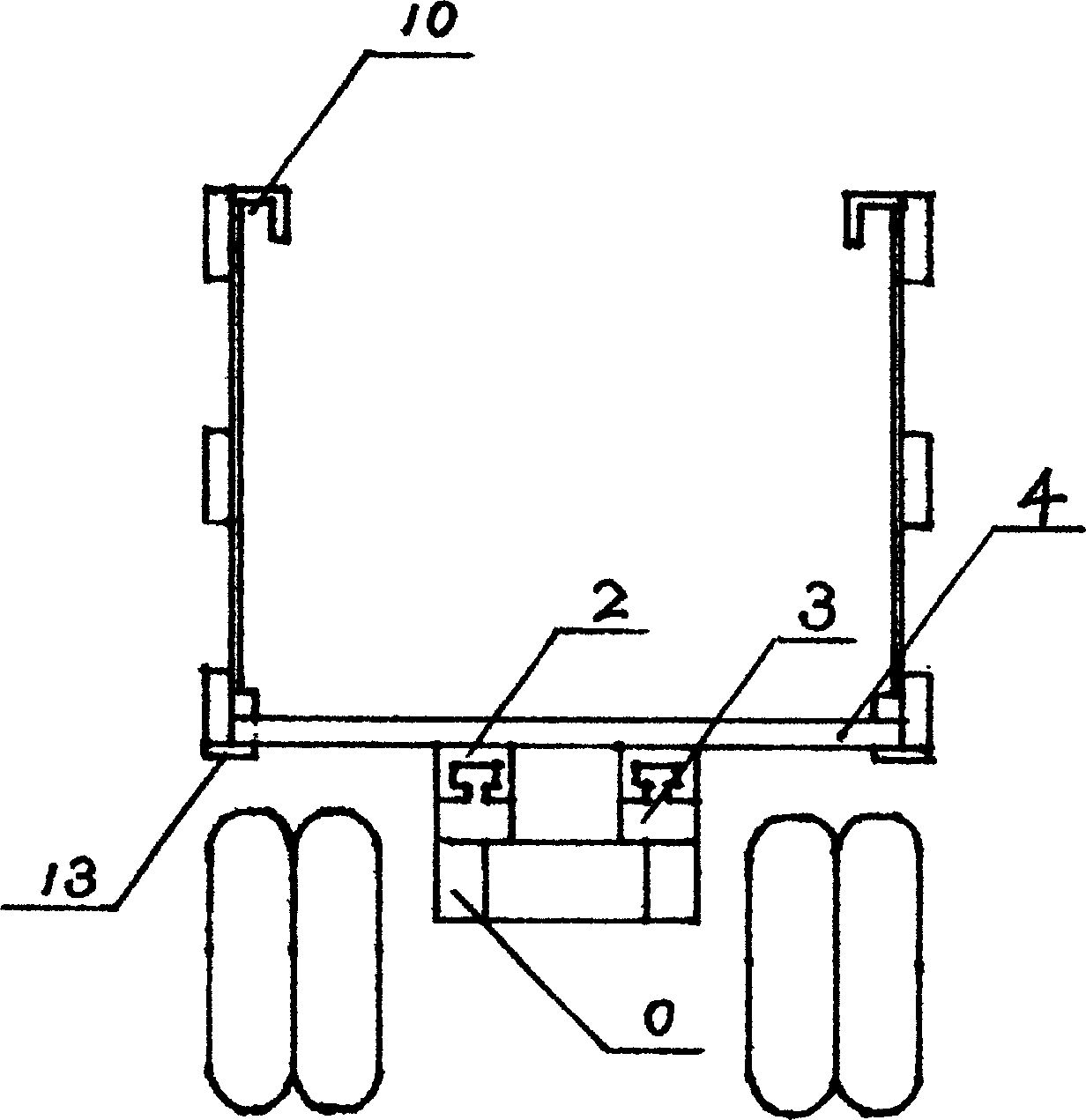

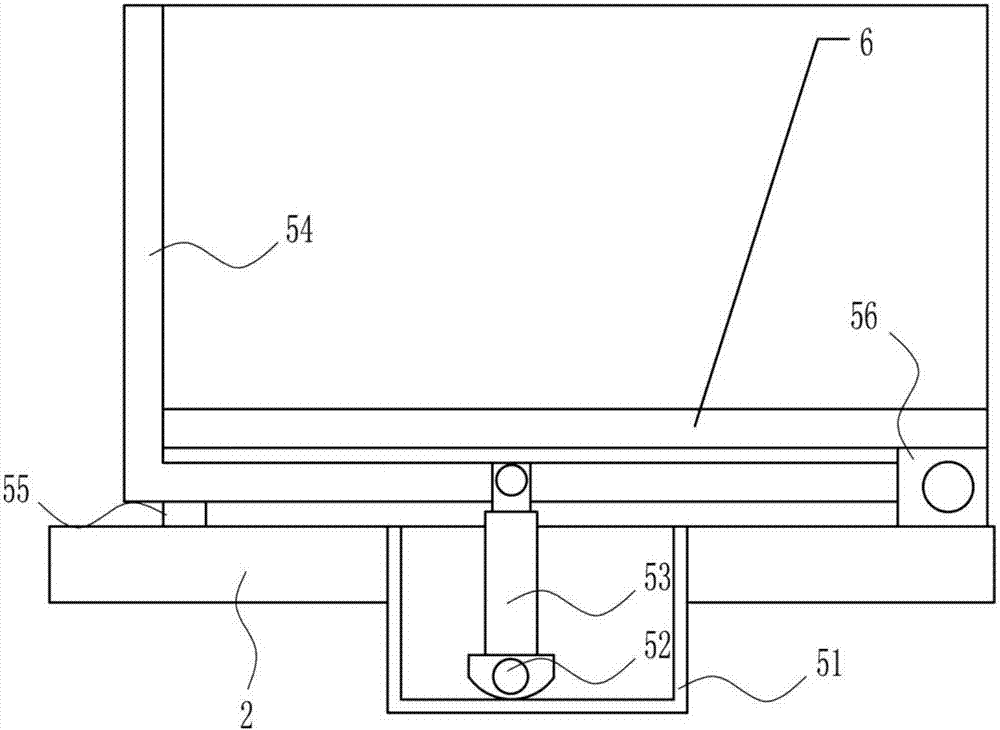

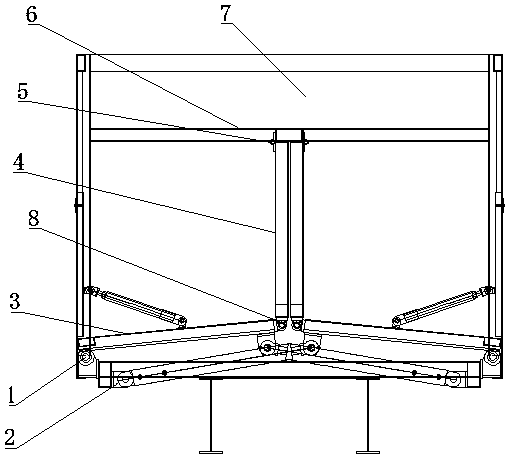

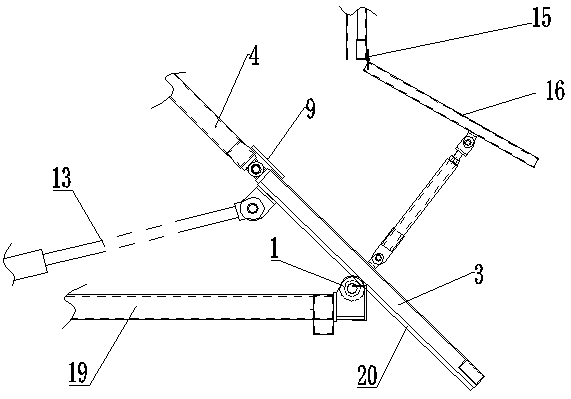

Compartment, push-pedal back-push tipping truck

InactiveCN1422766AVehicle with pusher plateVehicle with tipping movementHydraulic cylinderVehicle frame

The present invention provides a platform and push-plate back-pushed dump truck. The platform formed from two group of push-plates inlaid in the push-plate slideways in the platform can be substituted for sliding track and slipway of auxiliary vehicle frame, fixed vehicle bottom plate and grillage mounted on the slipway and sliding track and hydraulic system formed platform translation hydraulic cylinder and bipolar push-plate hydraulic cylinder for pushing push-plates. The sliding track can be mounted on the chassis, the grillage fixing slipway is locked on the sliding track and can be operated, a fixed vehicle bottom plate is mounted on the rear portion of the sliding track. Said platform is mounted on the grillage and fixed vehicle bottom plate. It can effectively raise its safety or discharging material.

Owner:程颖 +1

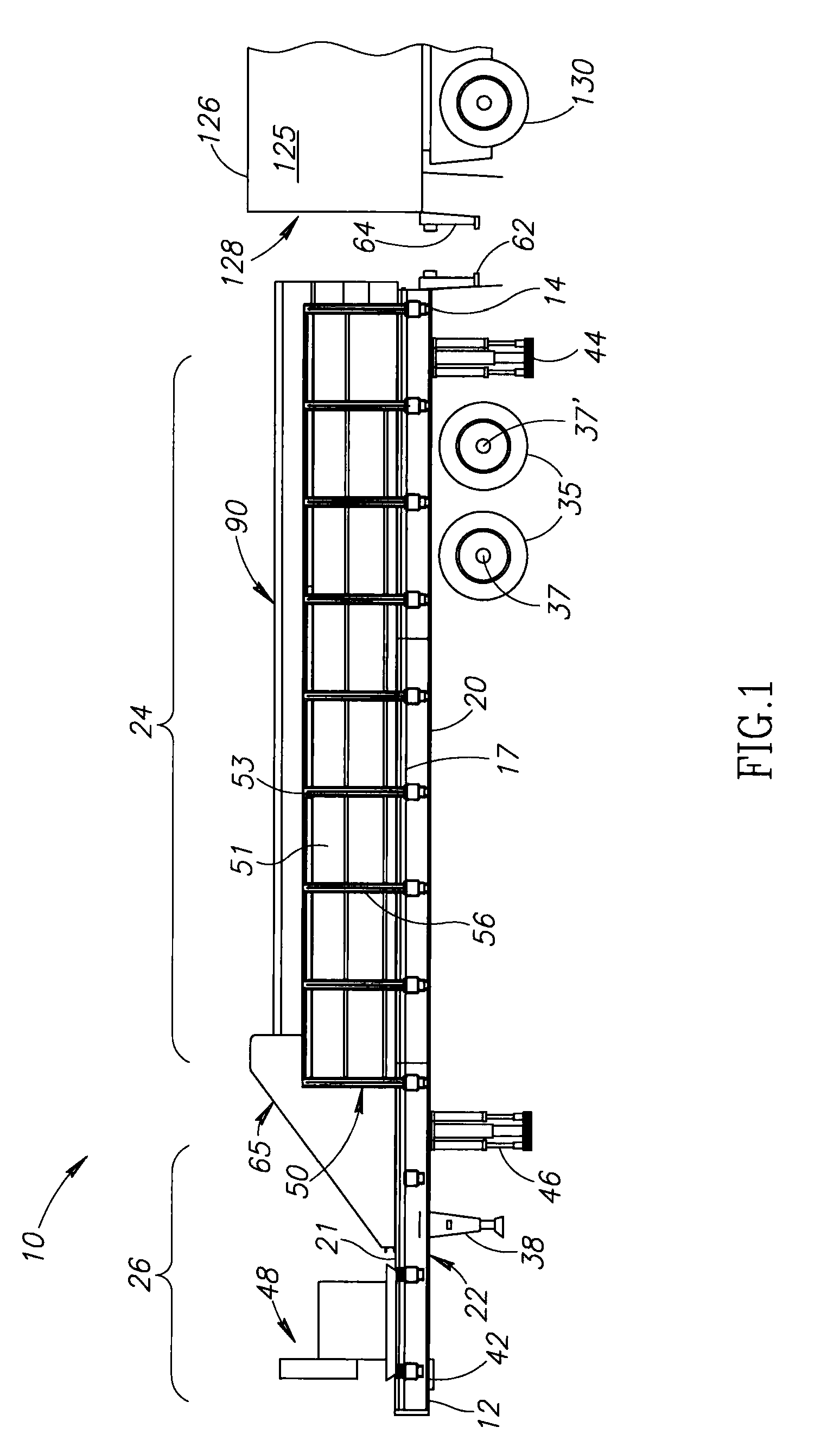

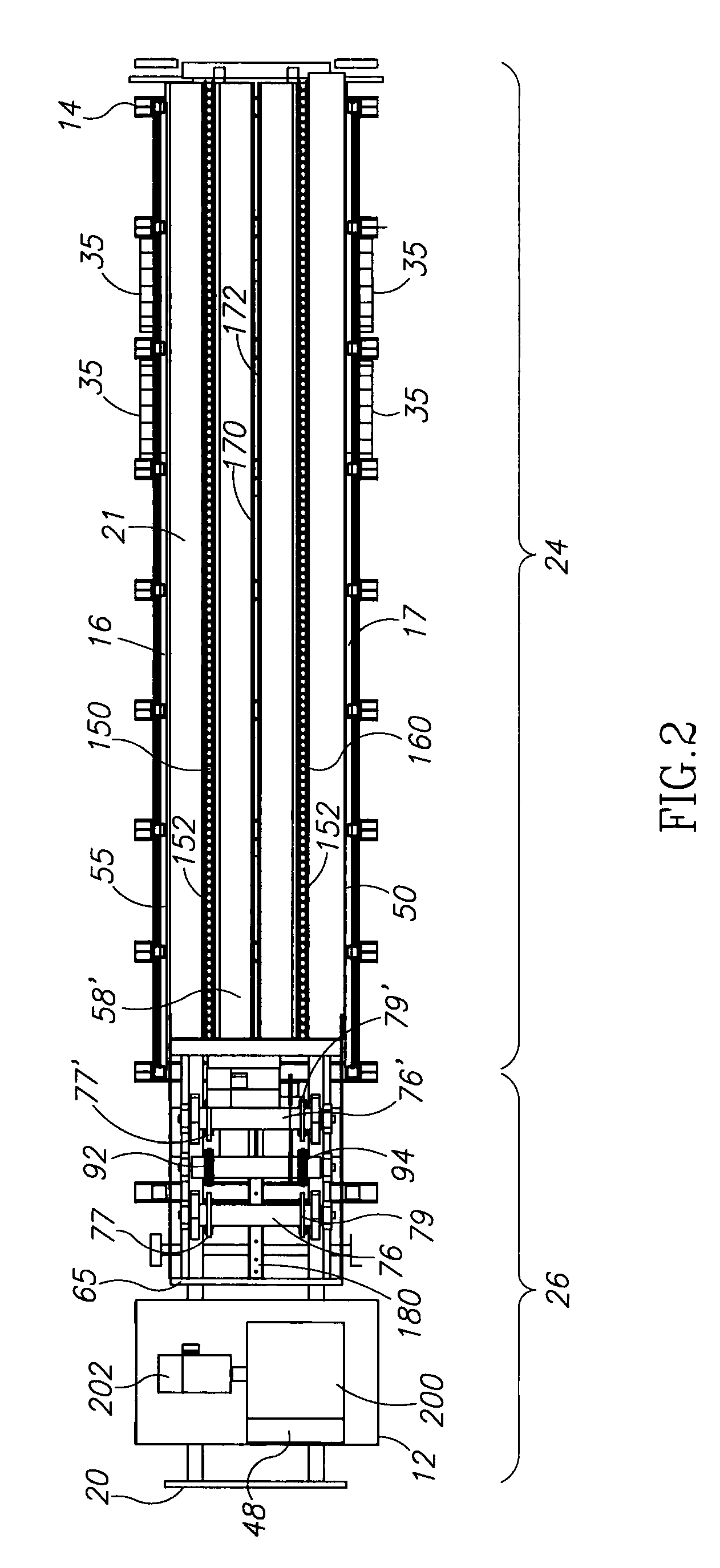

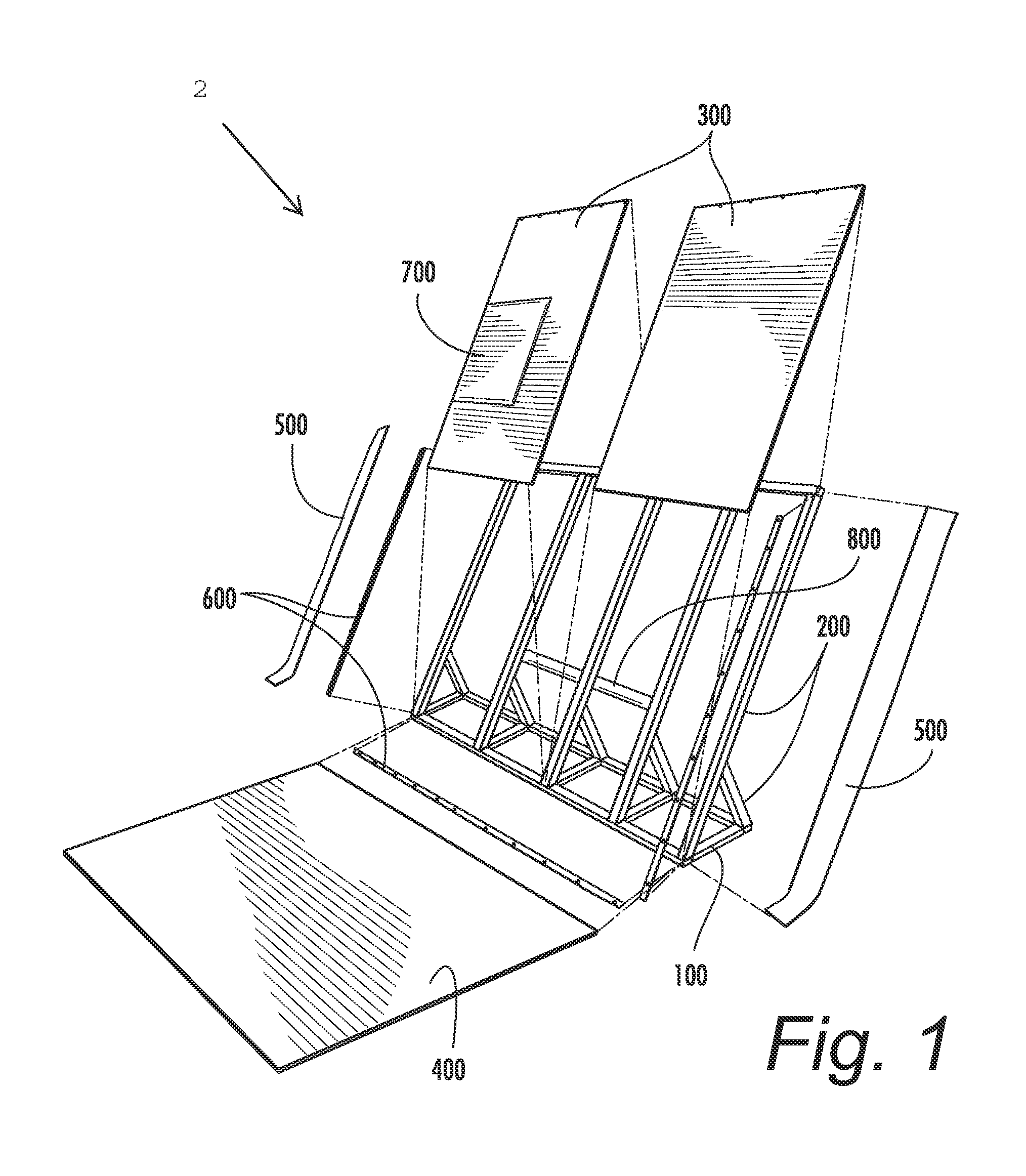

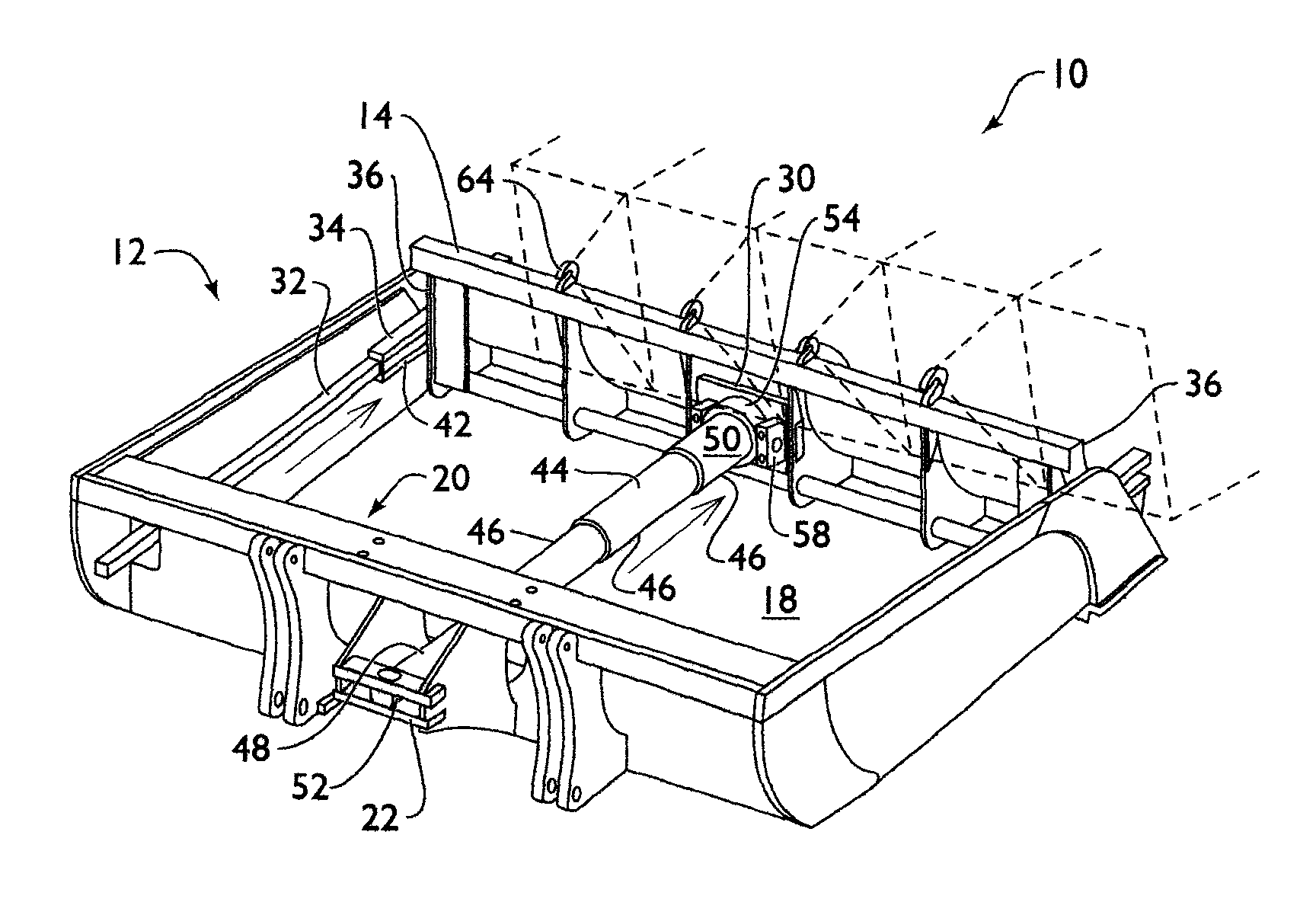

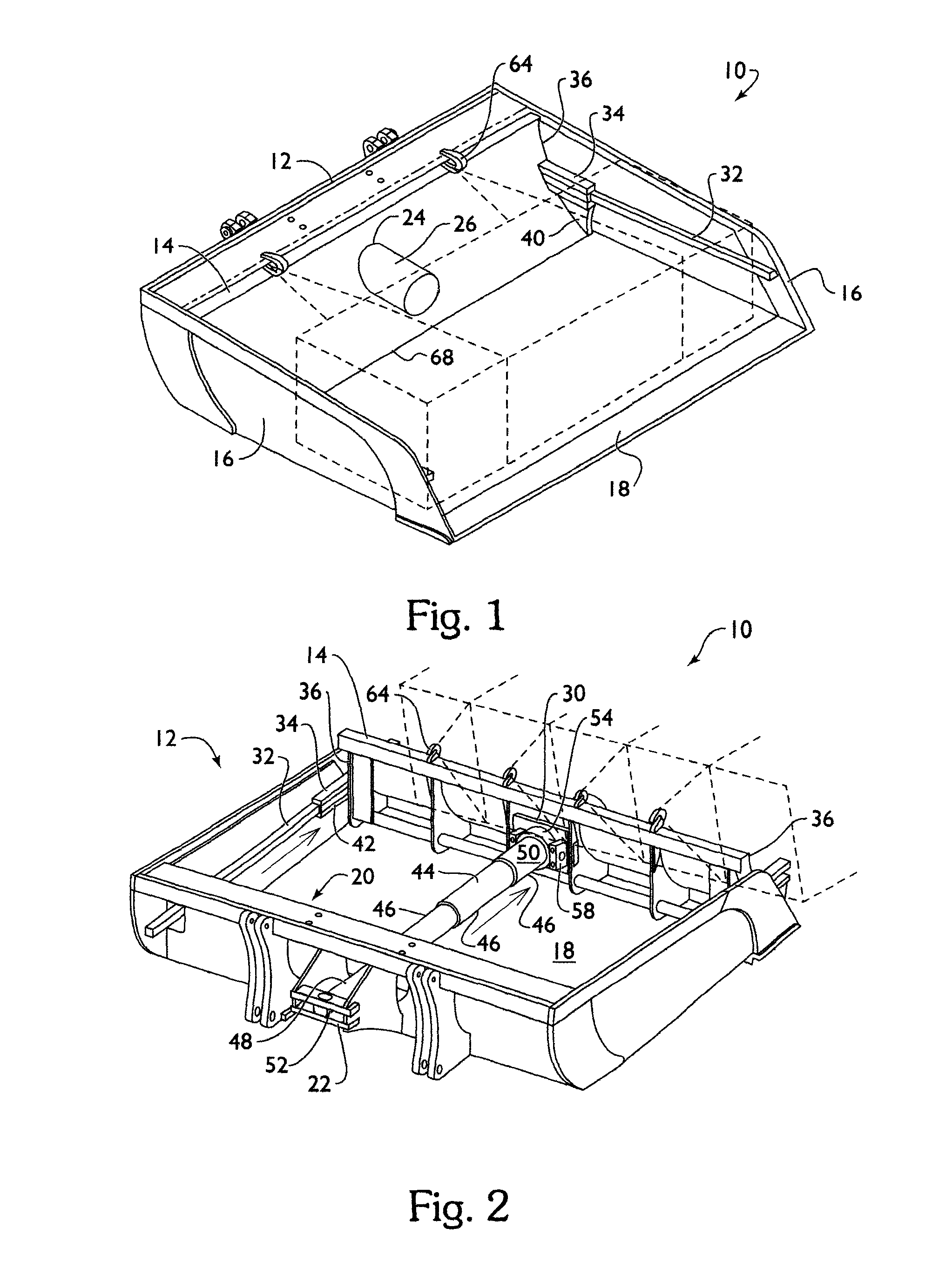

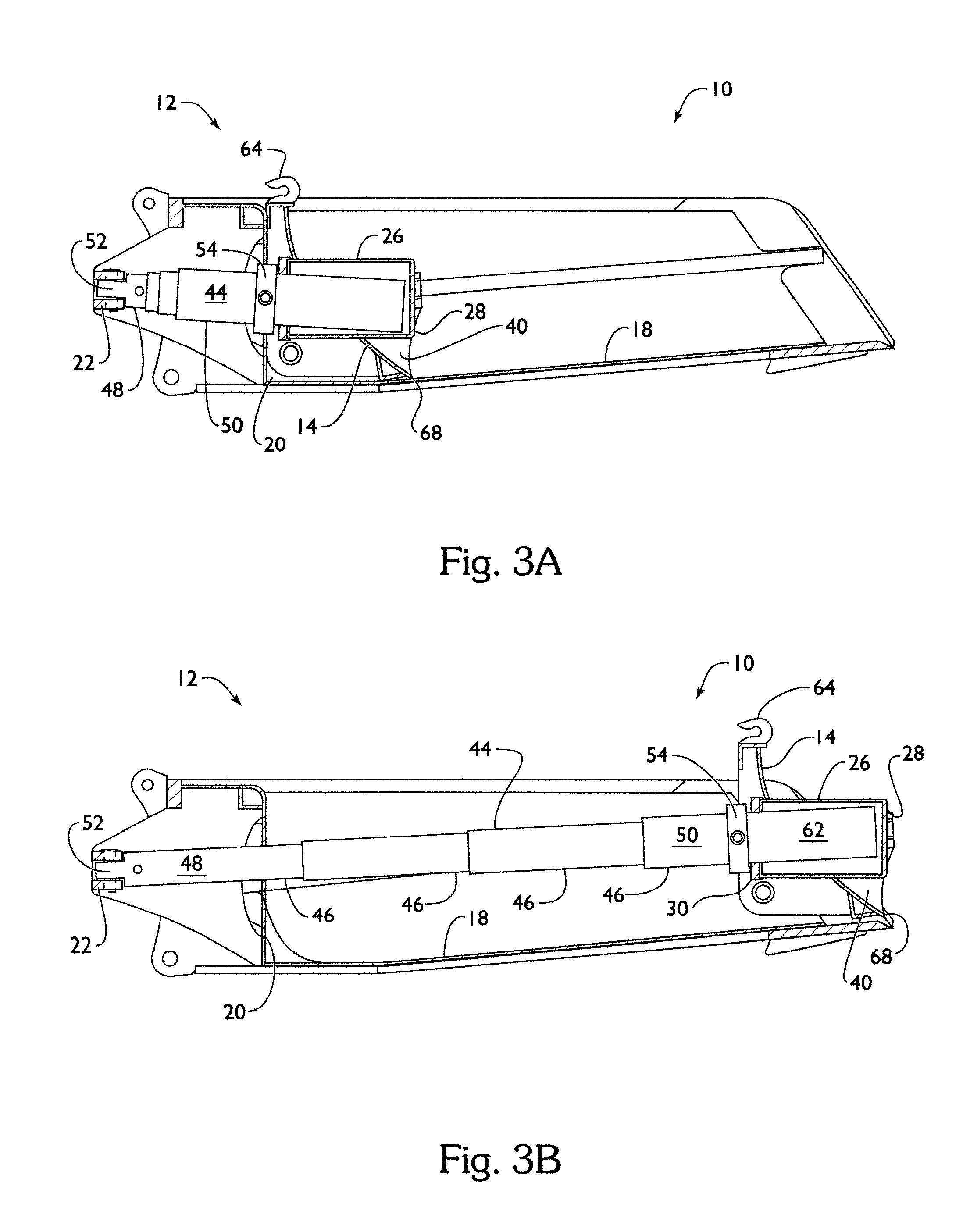

Cargo loader

A cargo loader operable to load cargo into an opening of an enclosed trailer. The loader has an elongated bed with a front portion and a rear open portion. The opening of the trailer is positioned adjacent to the rear open portion of the bed. A pair of sidewalls flank the rear open portion and define an interior cargo receiving area. A carriage is moveably mounted to the bed and coupled to a drive assembly operable to move the carriage between the front portion and the rear open portion. The carriage is positioned on the front portion to allow cargo to be loaded into the cargo receiving area. The carriage is configured to push a ram longitudinally along the bed to push the cargo inside the cargo receiving area into the opening of the enclosed trailer.

Owner:CONTAINER STUFFERS

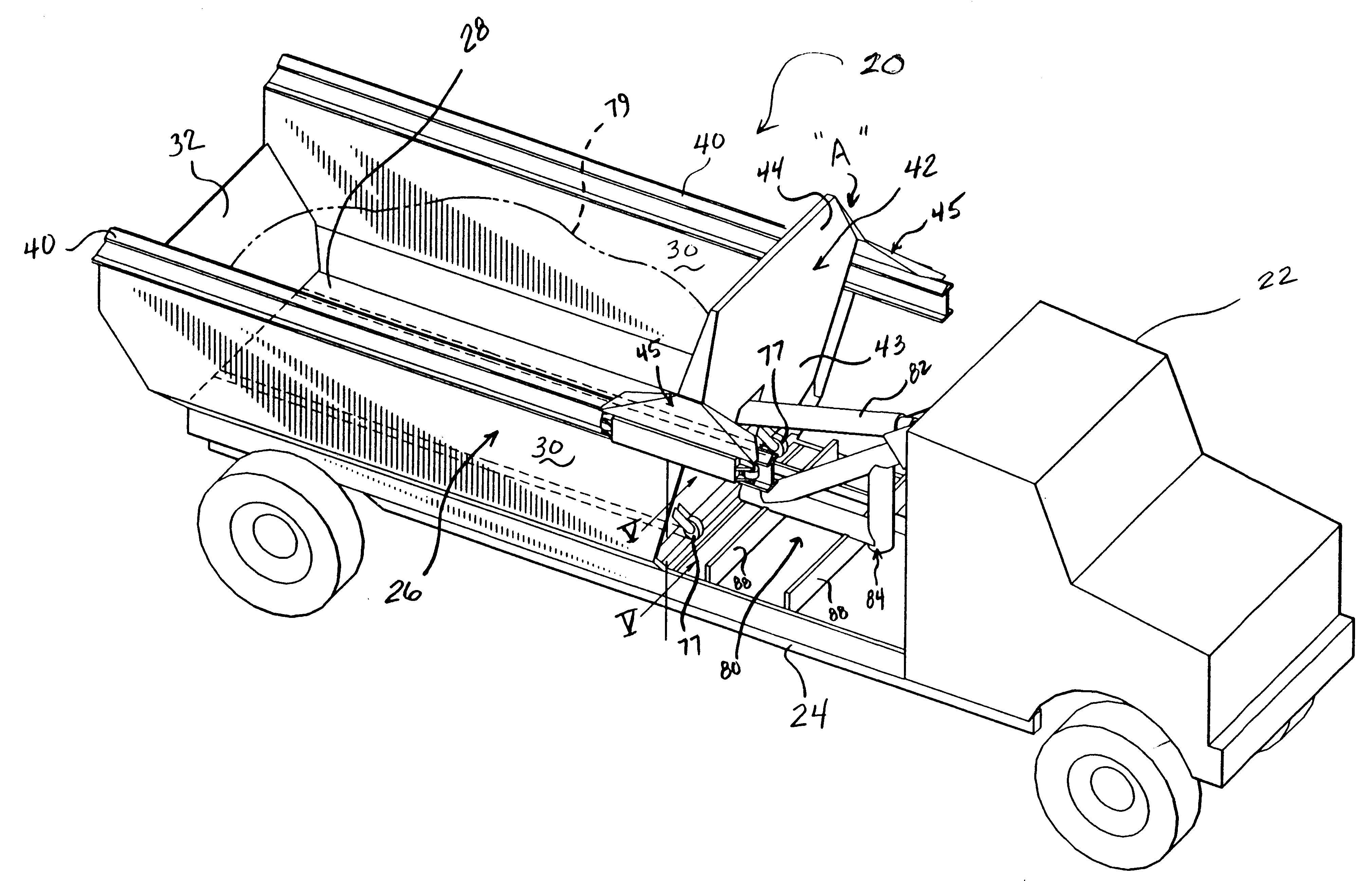

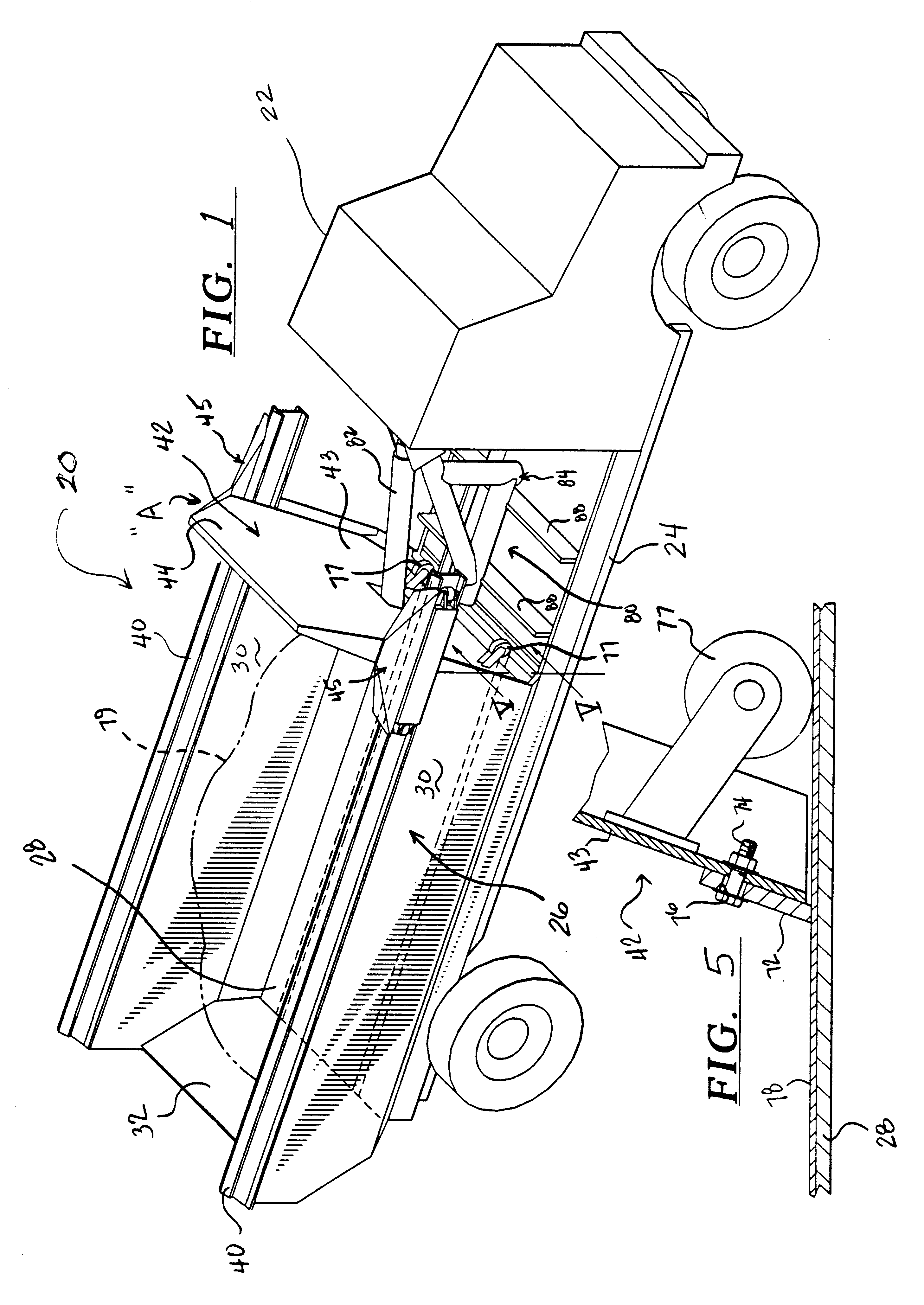

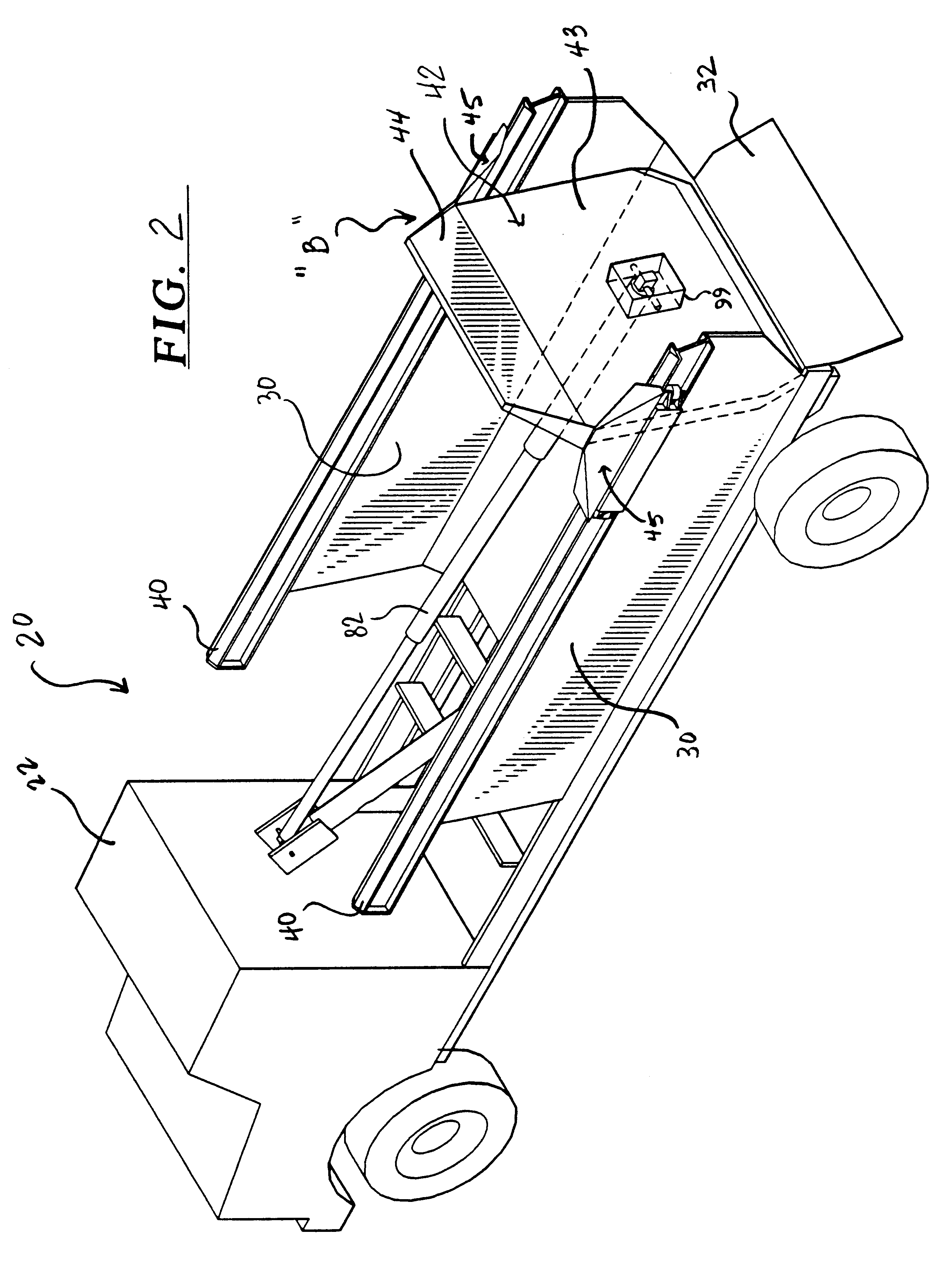

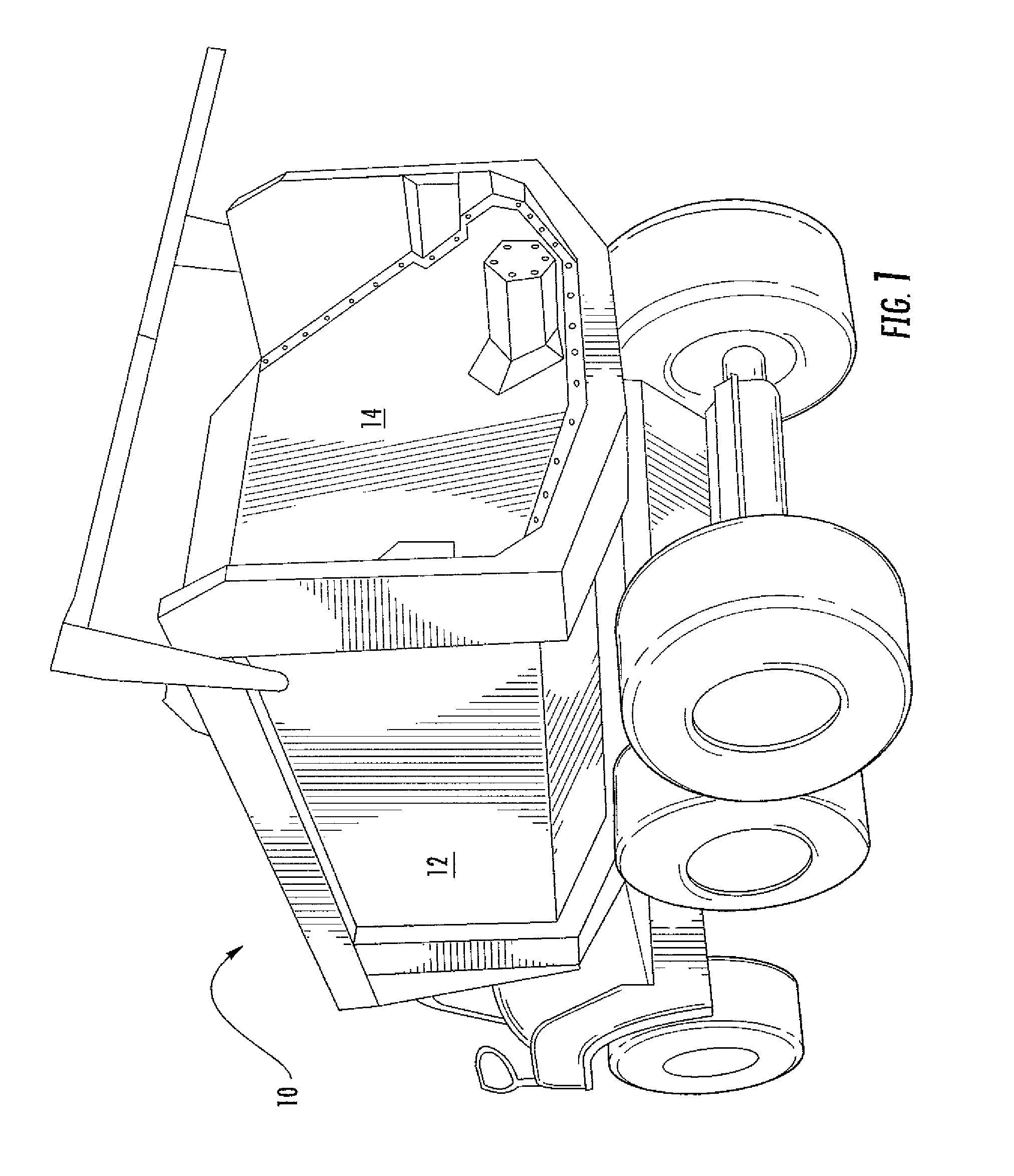

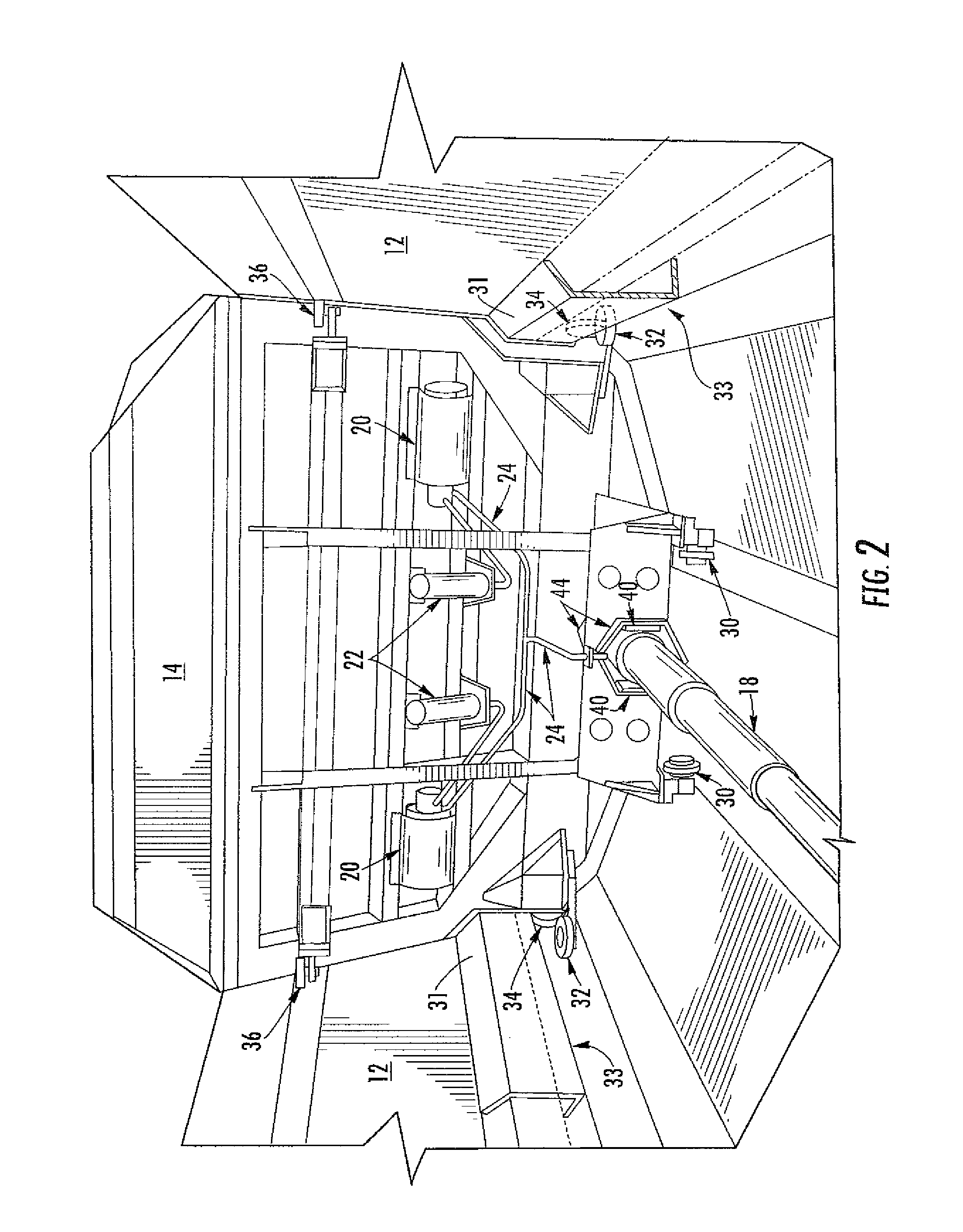

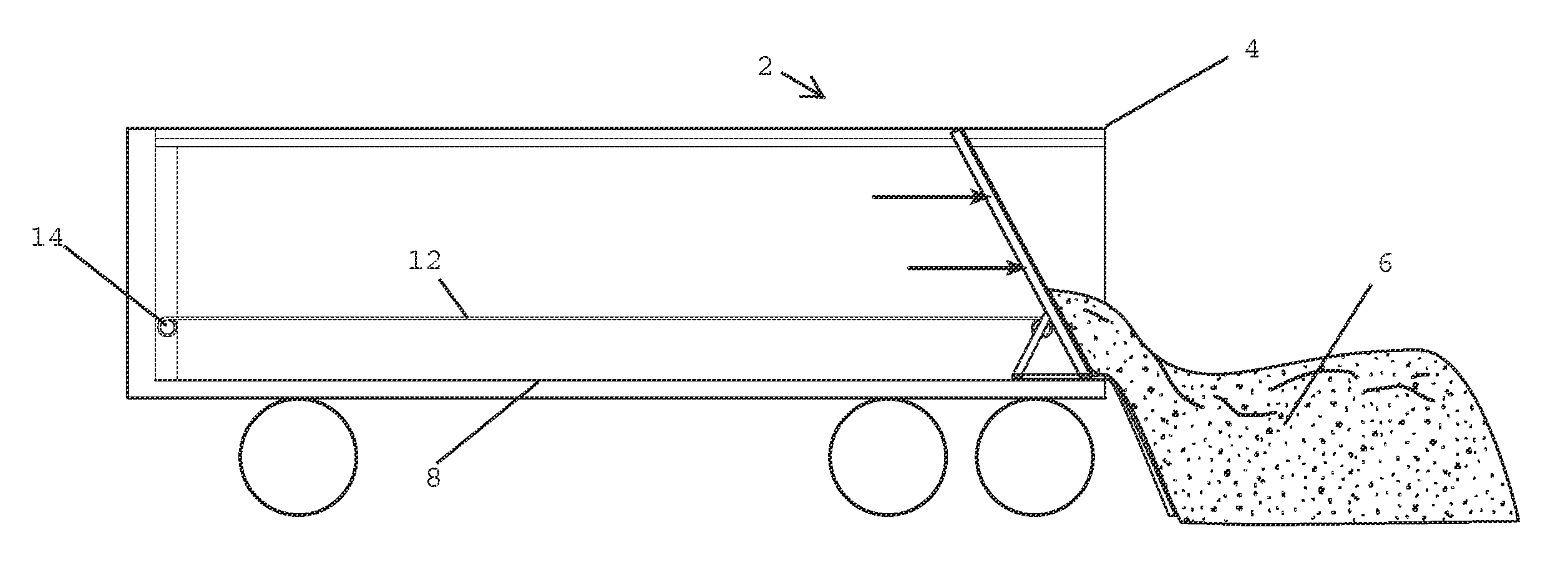

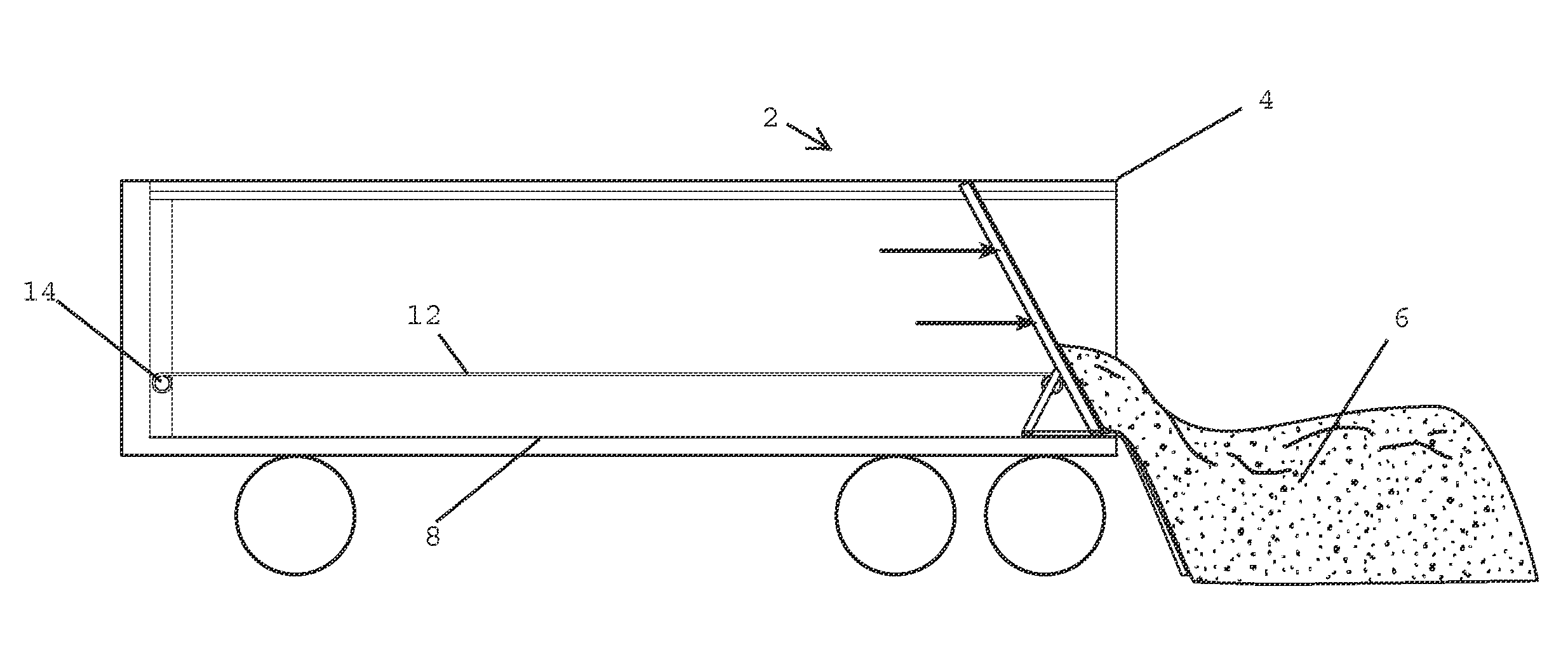

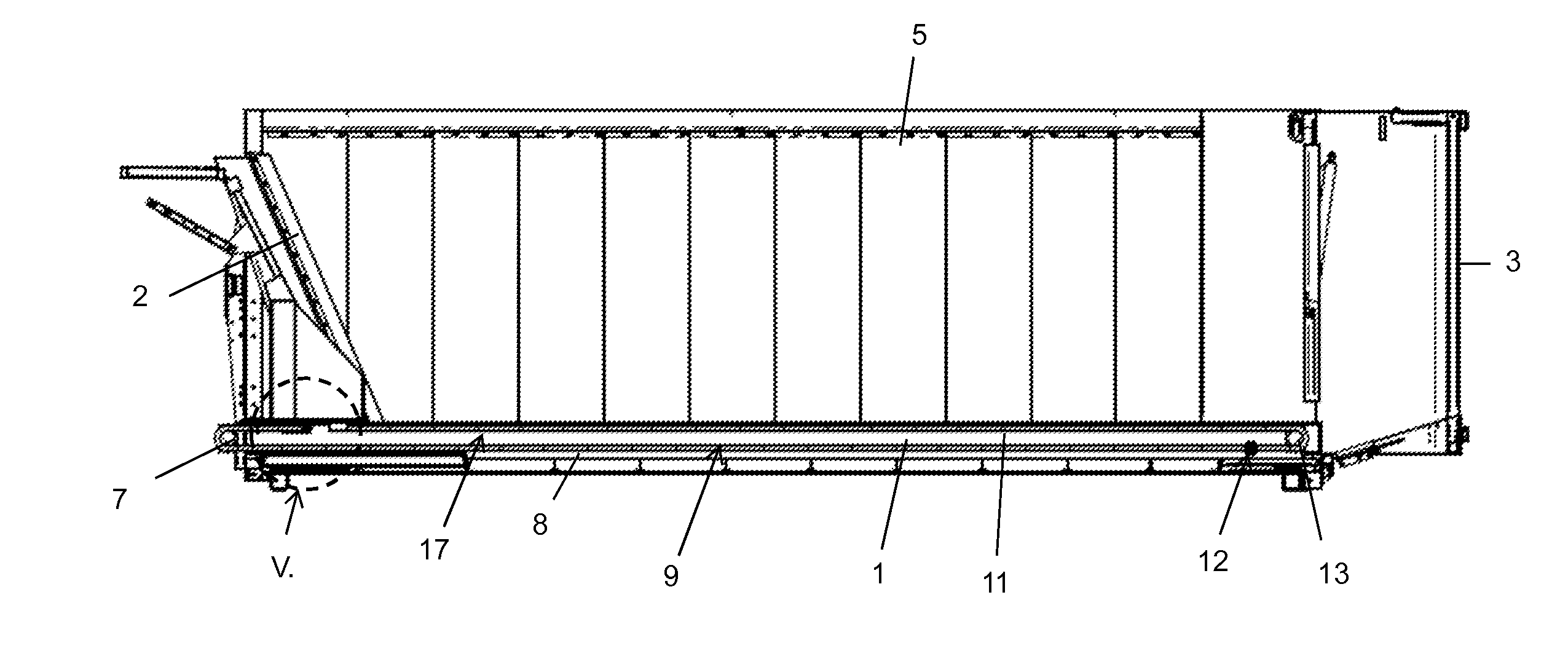

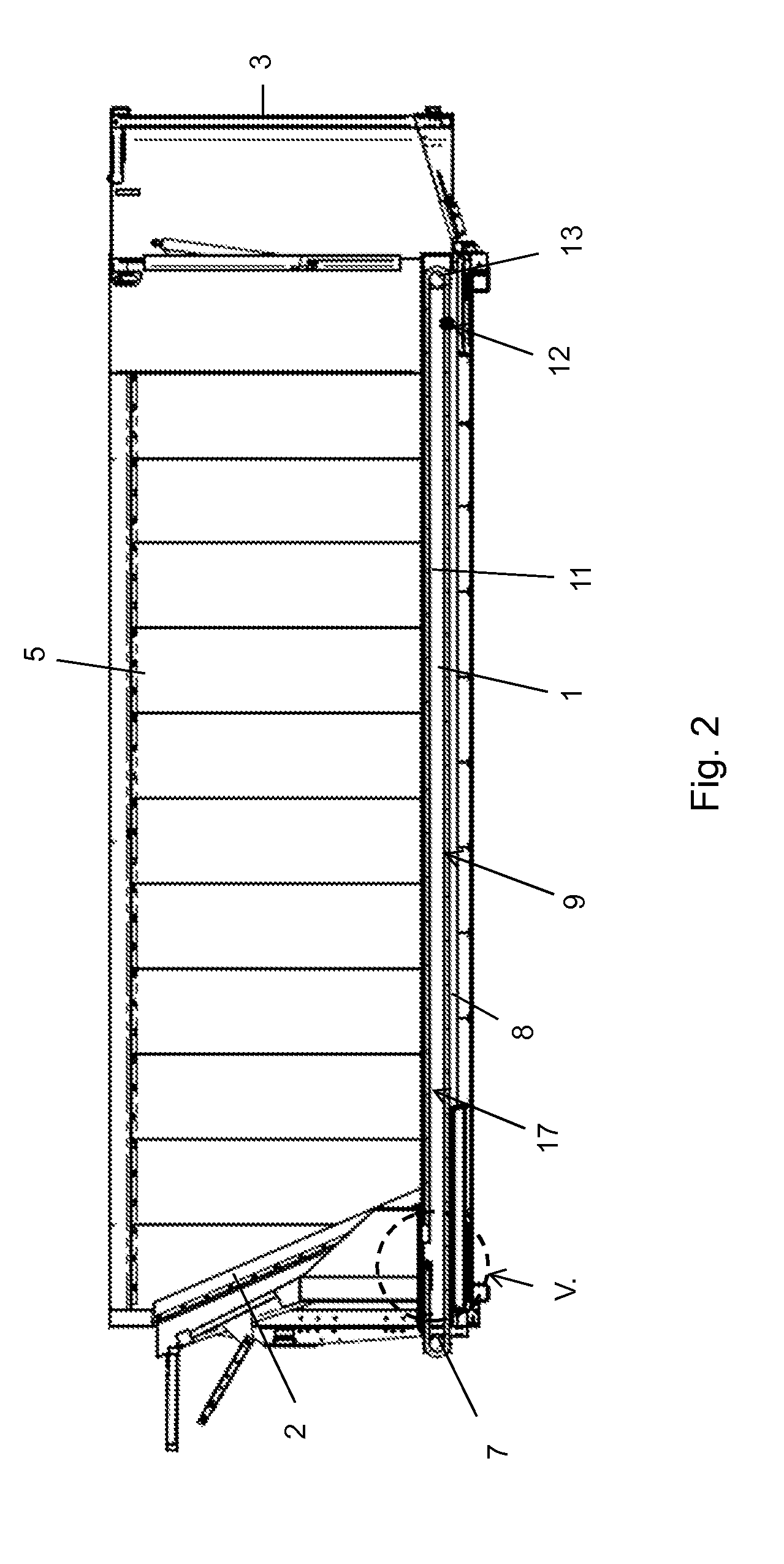

Ejector body and method using a tiltable ejector

An ejecting device for a dump truck has a truck bed with a bed surface, a pair of side walls, and a pivotally moveable tailgate. The ejecting device has a pair of guide rails, one each mounted to a top edge of the side walls of the bed. A generally vertically oriented ejector plate is disposed between the side walls extending transversely there across and has a roller member assembly attached to each side edge. The roller assemblies are carried one in each of the guide rails. The ejector plate is moveable between a fully retracted position at a first end of the truck bed to a fully extended position at a second end of the truck bed adjacent the tailgate. An extendable cylinder is carried on the truck frame and attached to the ejector plate for moving the plate between the fully retracted position and the fully extended position to eject material from the bed.

Owner:CATERPILLAR COMML GENF CH +1

Hydraulic control system for refuse collection vehicle

InactiveUS20050110330A1Promote resultsAccurate repeatable controlArticle unpackingRefuse receptaclesRefuse collectionDifferential pressure

A front loading refuse vehicle includes at least one positive displacement pump having an associated valve system in fluid communication with drive mechanism that operates a lifting arm, packer, a rear door of the vehicle, and a hoist for a refuse storage body. The valve system includes at least one closed-centered valve with a spool mechanism having a pressure compensator to maintain a constant flow rate of fluid through the valve regardless of differential in pressure across the valve for any given position of the spool mechanism. Two pumps with two separate hydraulic control systems are used with a side loading refuse vehicle. An electrical / electronic control system including a microprocessor operates the valve systems for each vehicle.

Owner:SMART TRUCK SYST

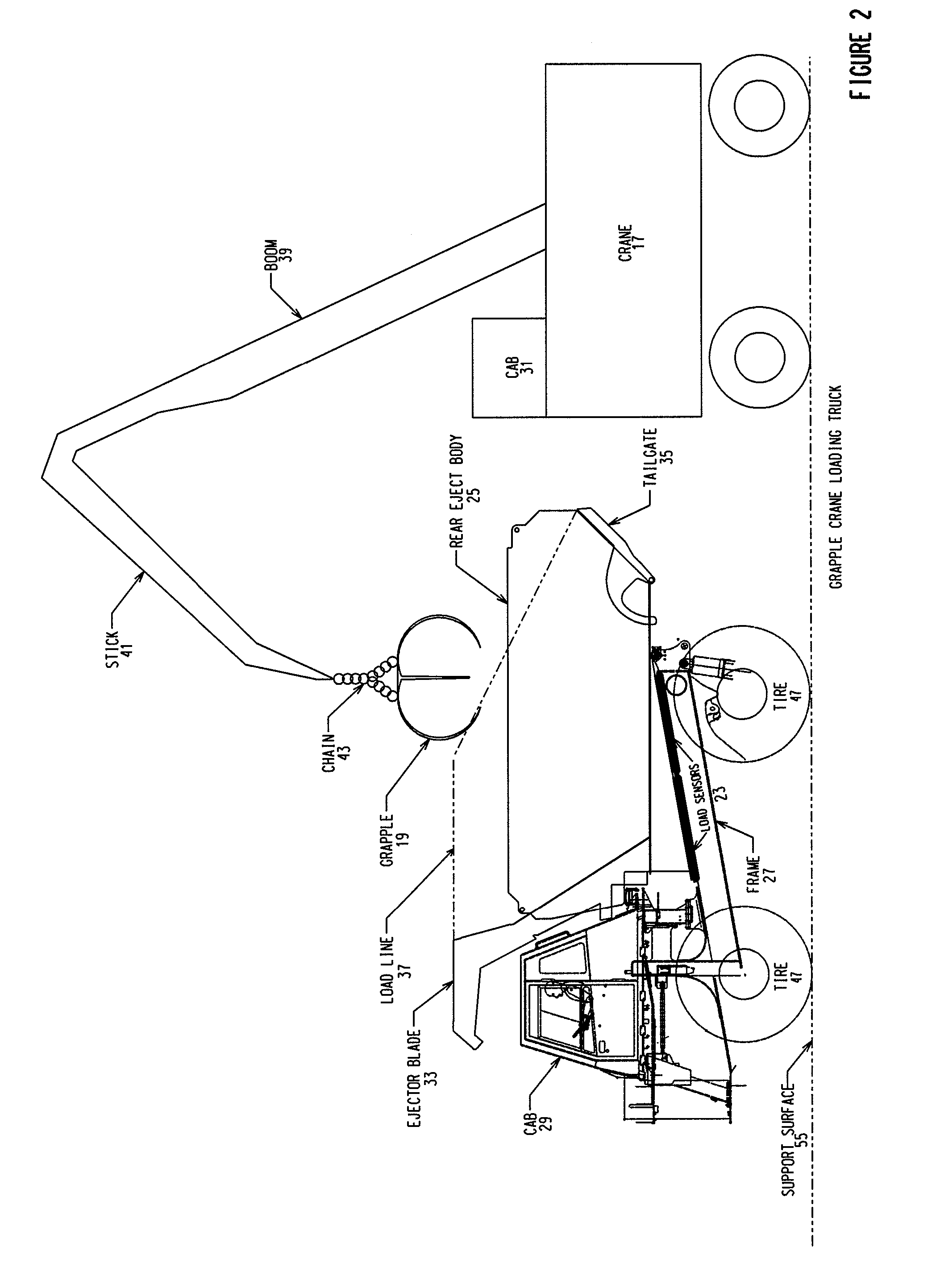

Material ejection system for a vehicle

InactiveUS7147423B2Little strengthIncrease ejection speedRefuse receptaclesVehicle with pusher plateHydraulic cylinderMechanical engineering

Owner:GOLDEN RANDY

Unloading method and dump wagon for potted plants

A dump wagon for transporting potted plants from one location to another and for unloading the potted plants. The dump wagon includes a wagon bed that tilts between a horizontal transport position and a tilted or inclined unloading position. A pusher at one end of the wagon bed is movable towards the other end of the wagon bed to push potted plants off the wagon as the wagon is slowly moved forwardly. The pusher is chain driven and automatically disengages the chains when the pusher reaches the other end of the wagon bed and the unloading operation is complete. Side rails prevent the potted plants from falling off the sides of the wagon, the side rails being movable out of the way for the purpose of loading the dump wagon.

Owner:BAILEY NURSERIES

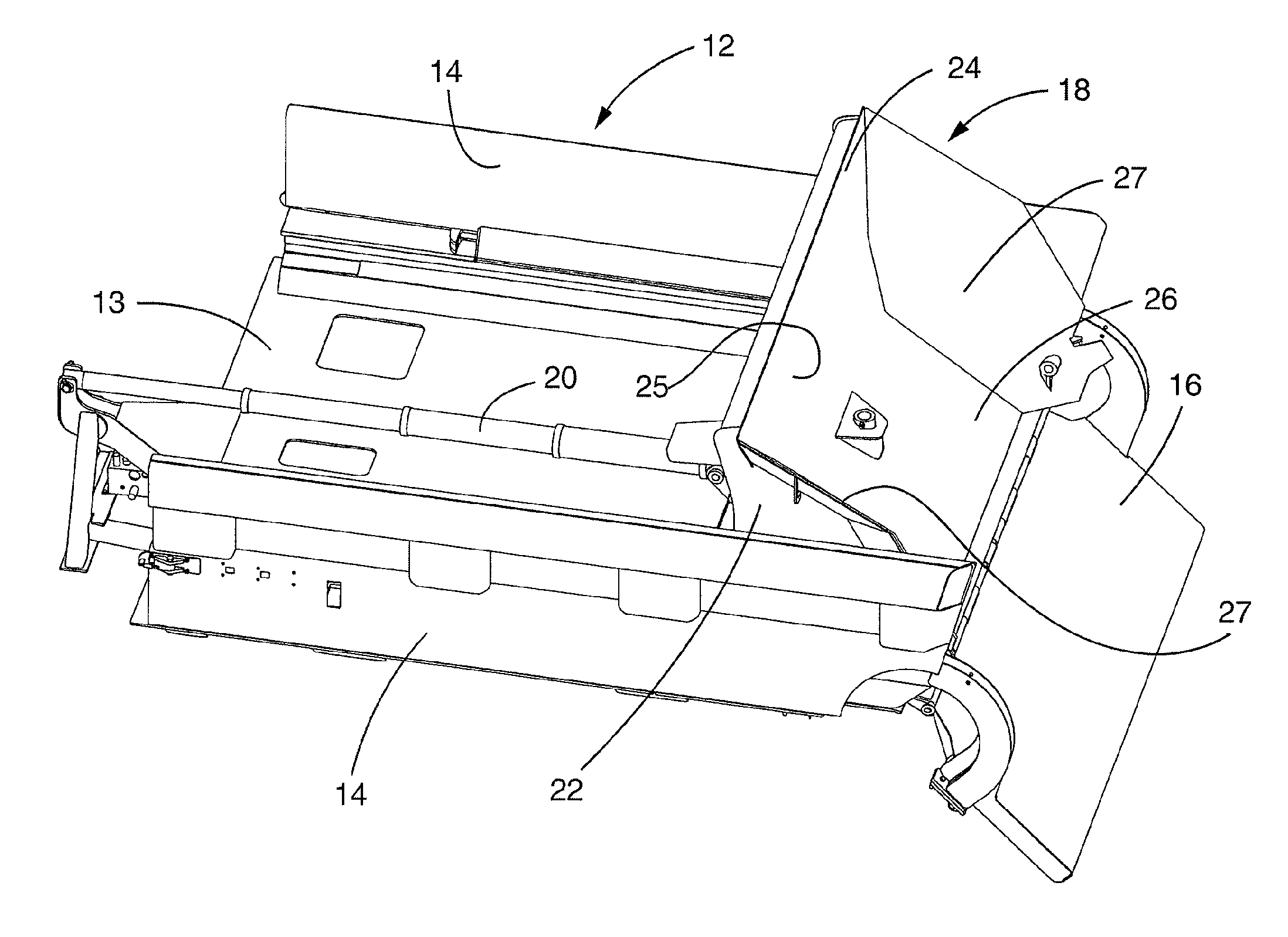

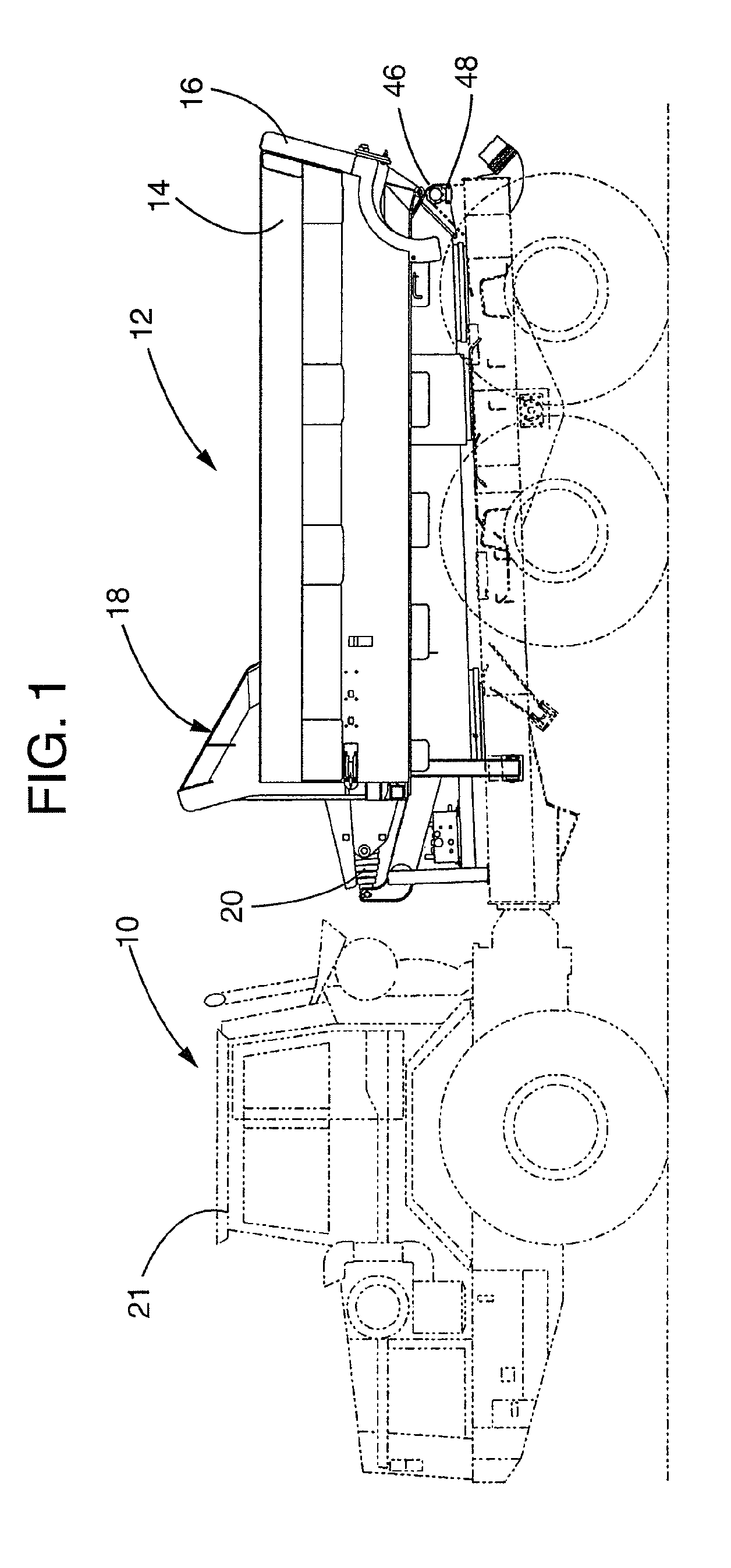

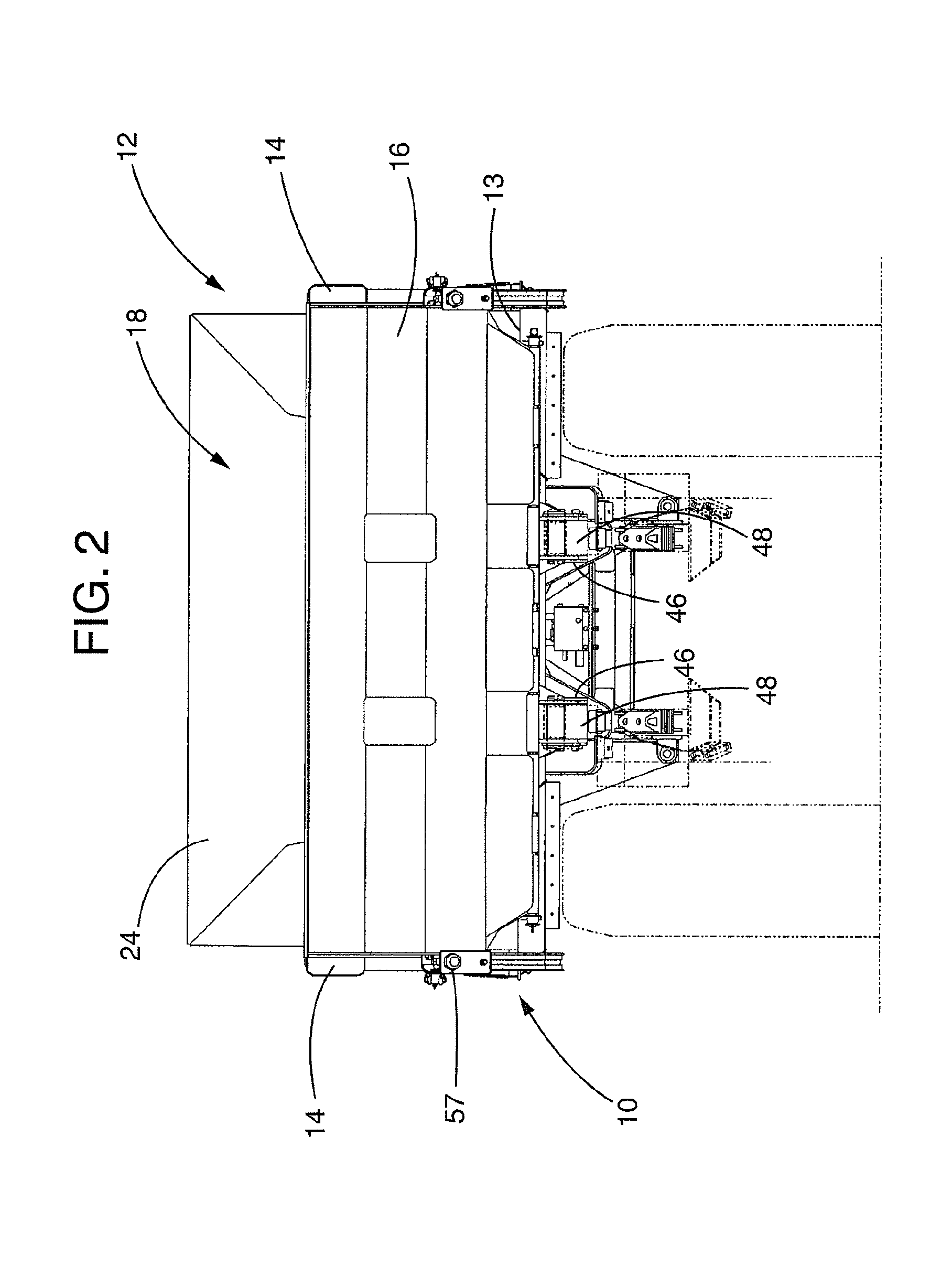

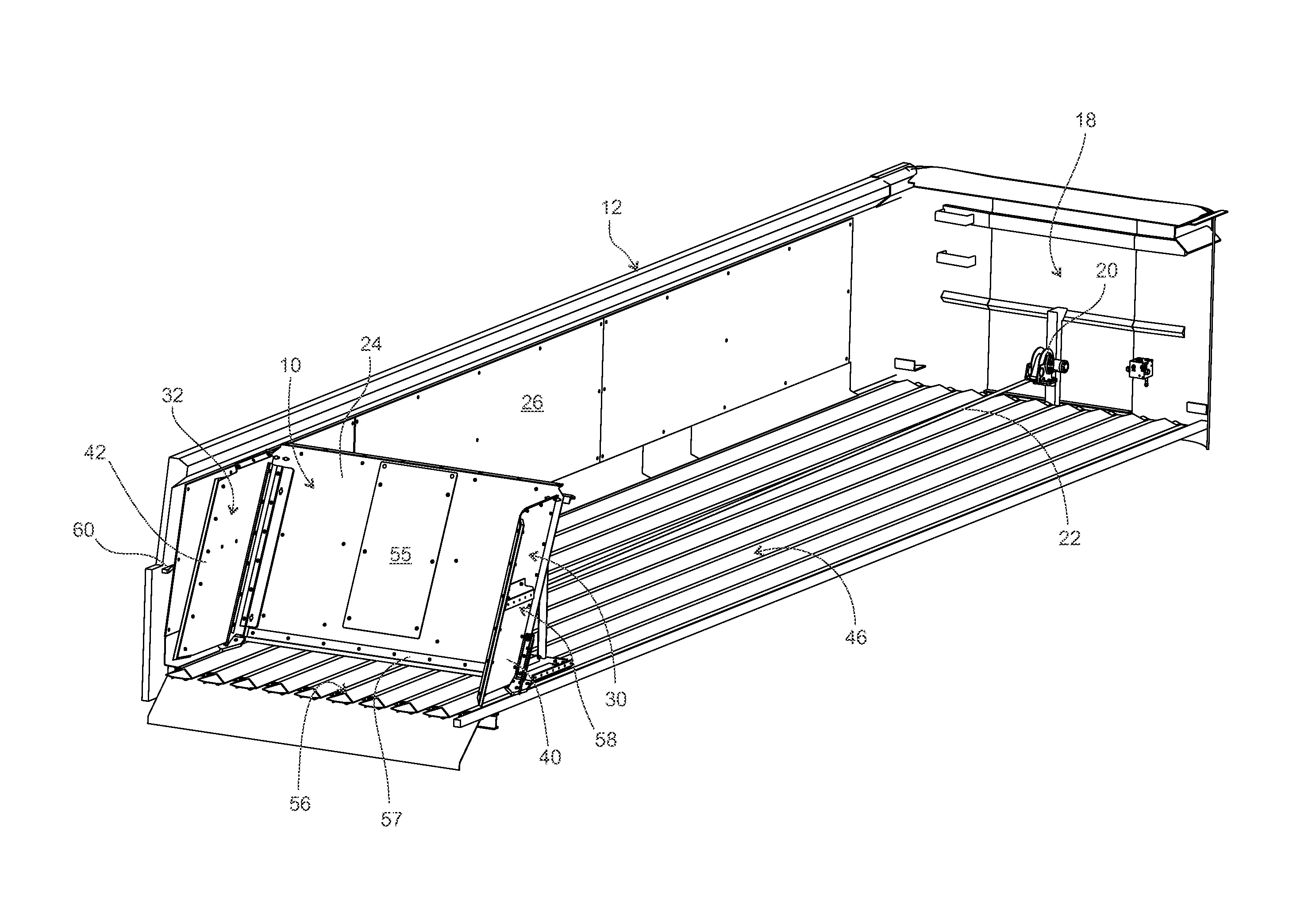

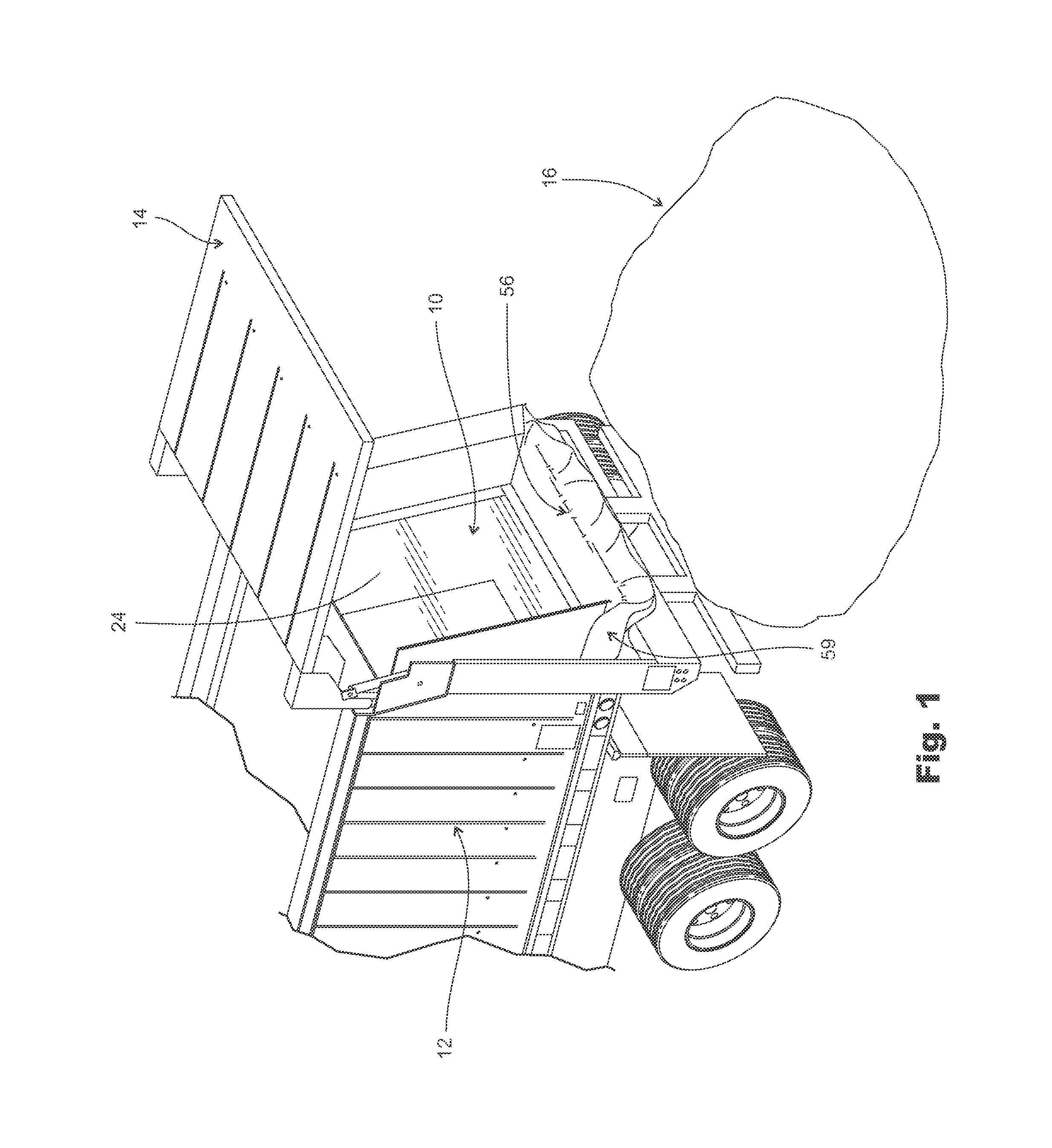

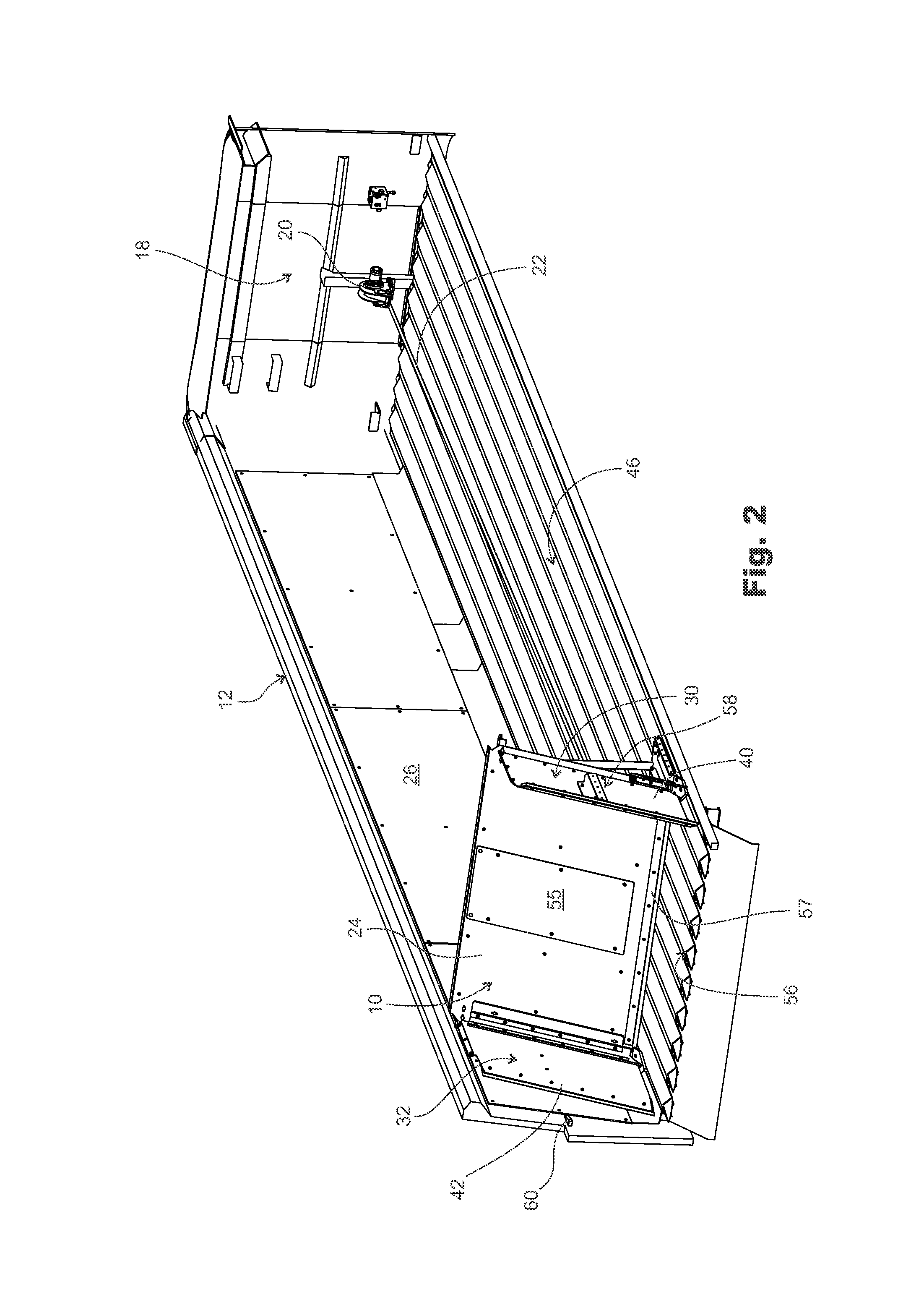

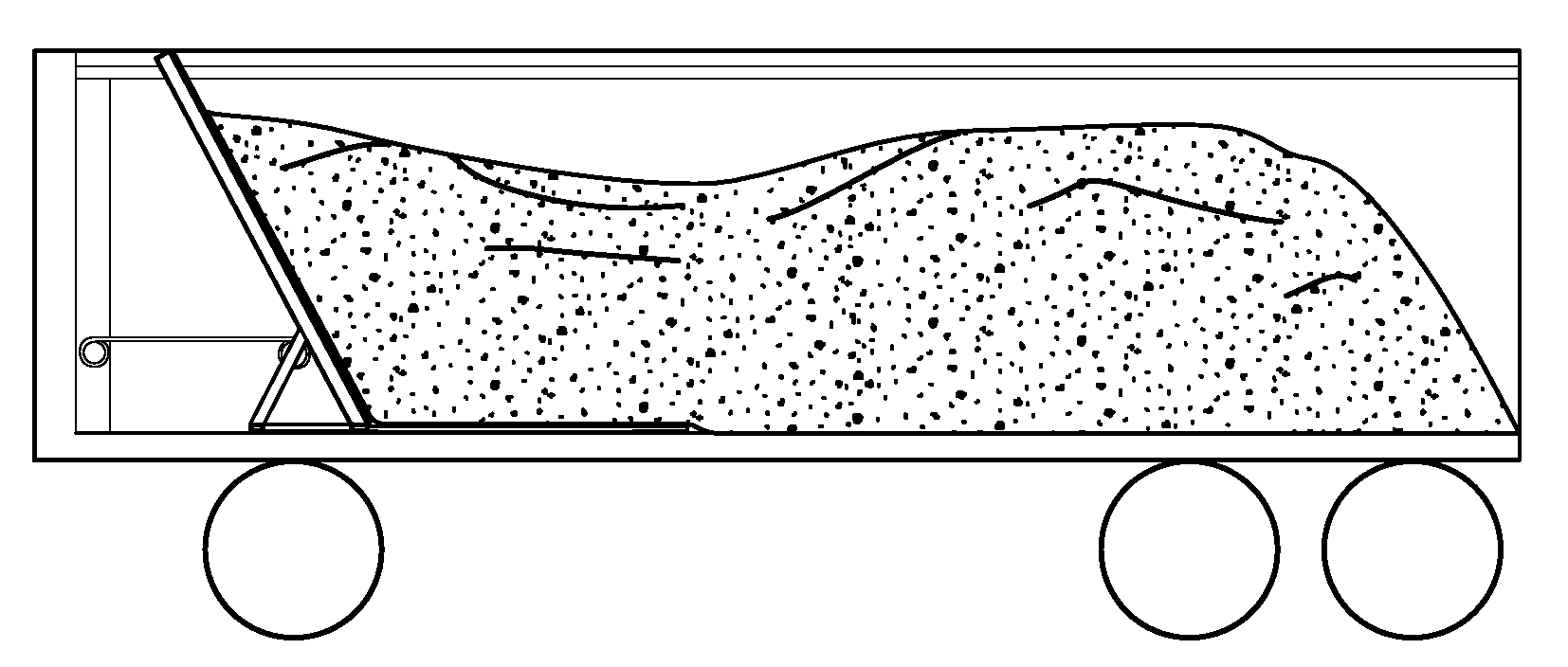

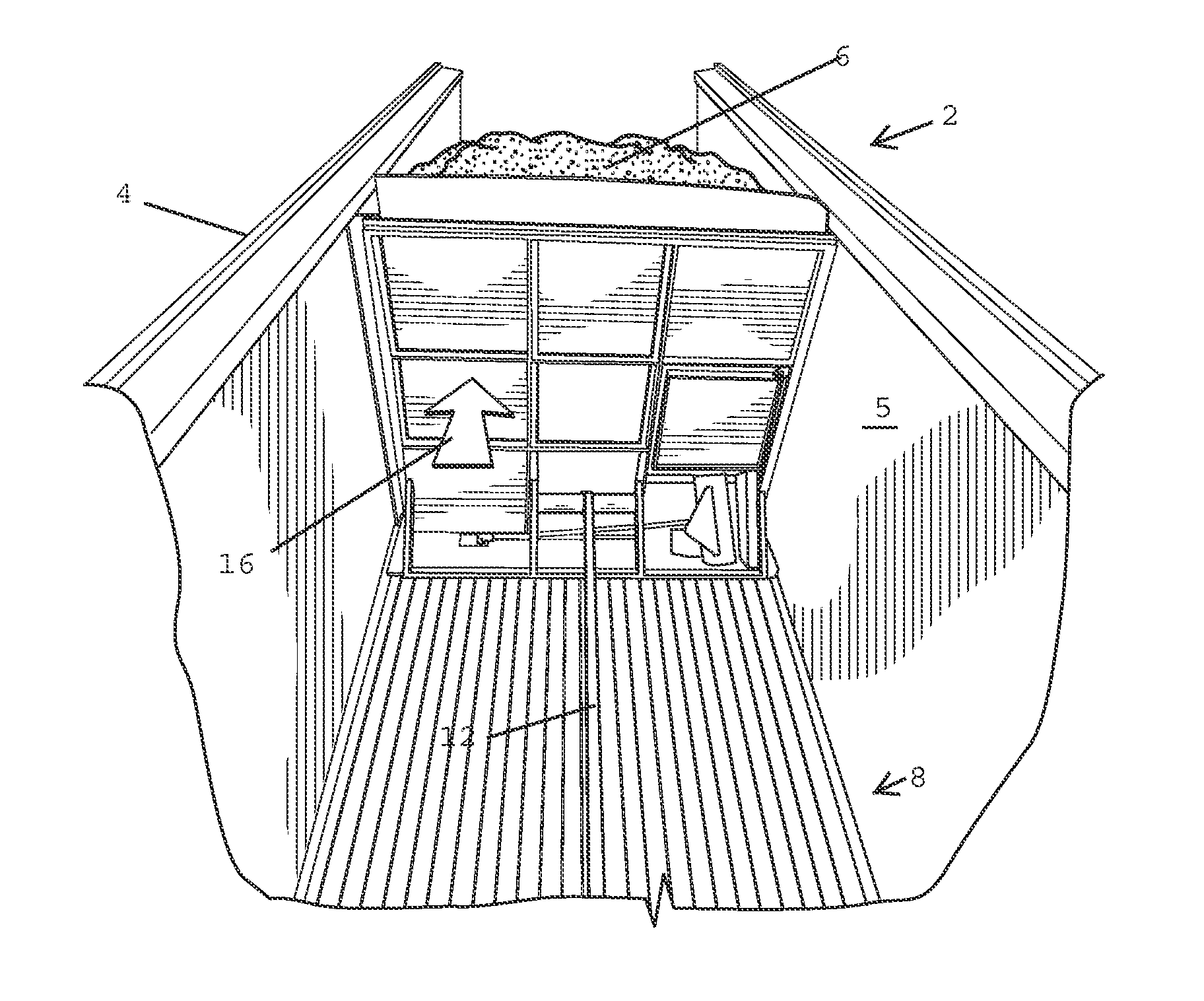

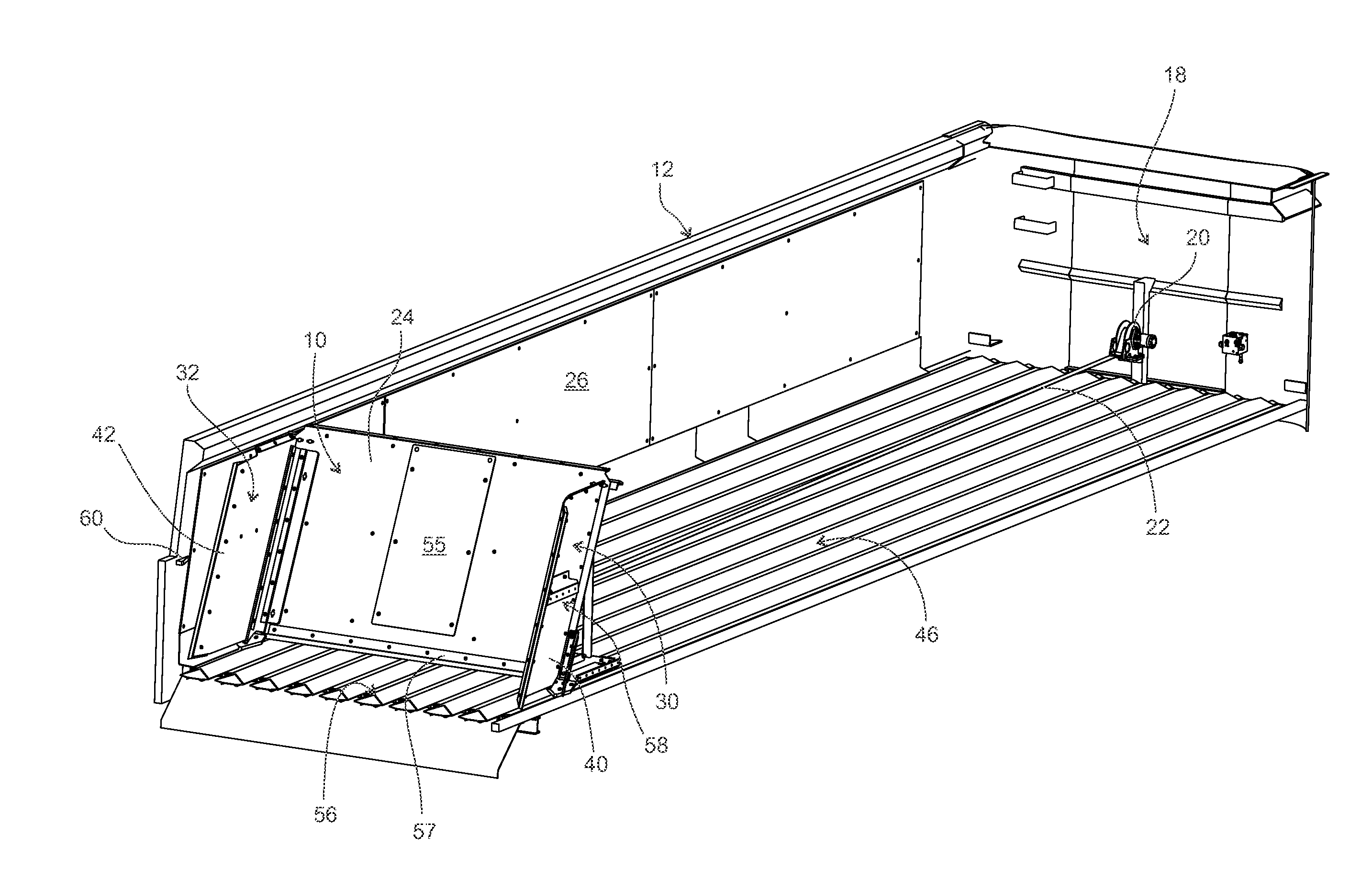

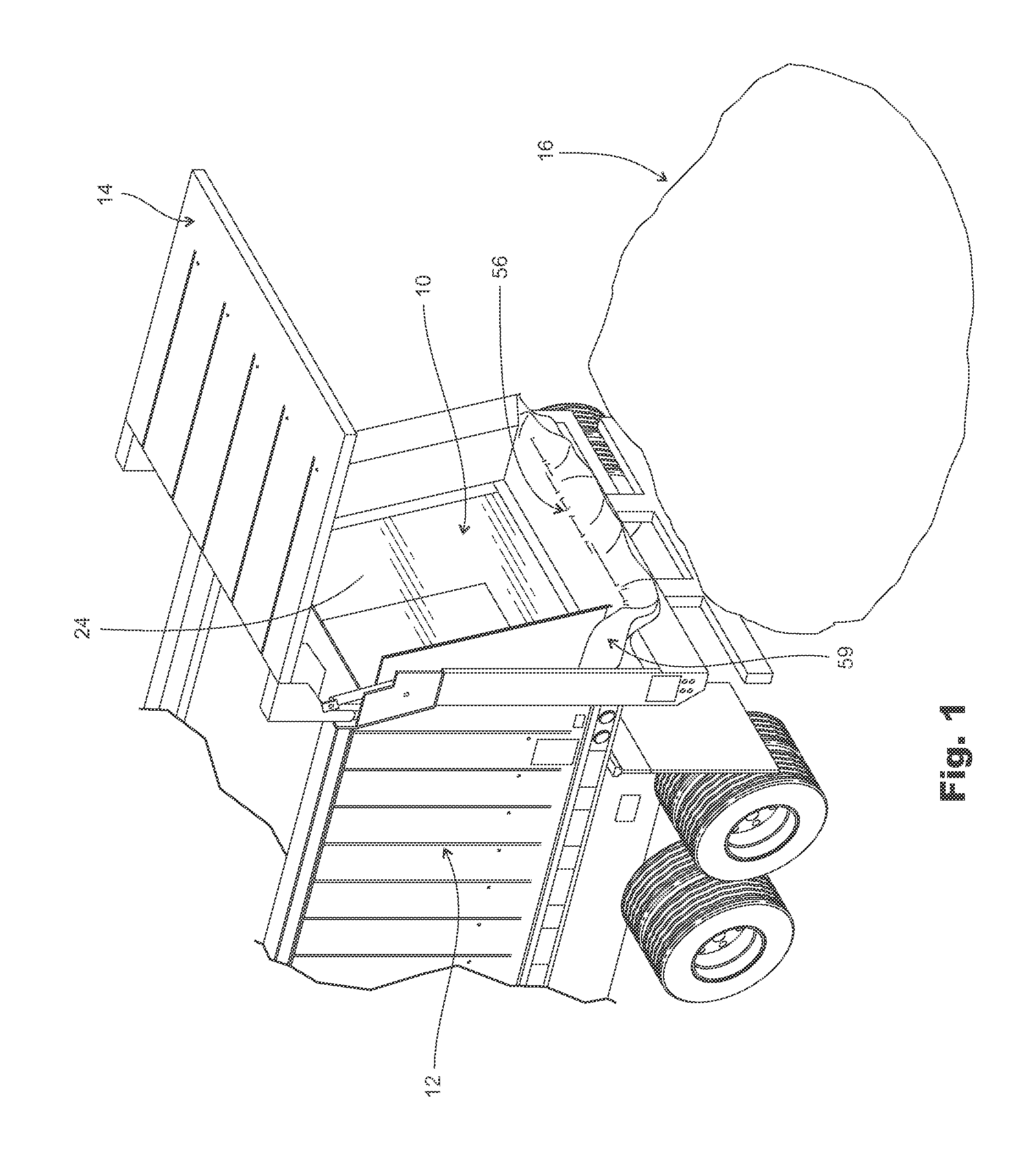

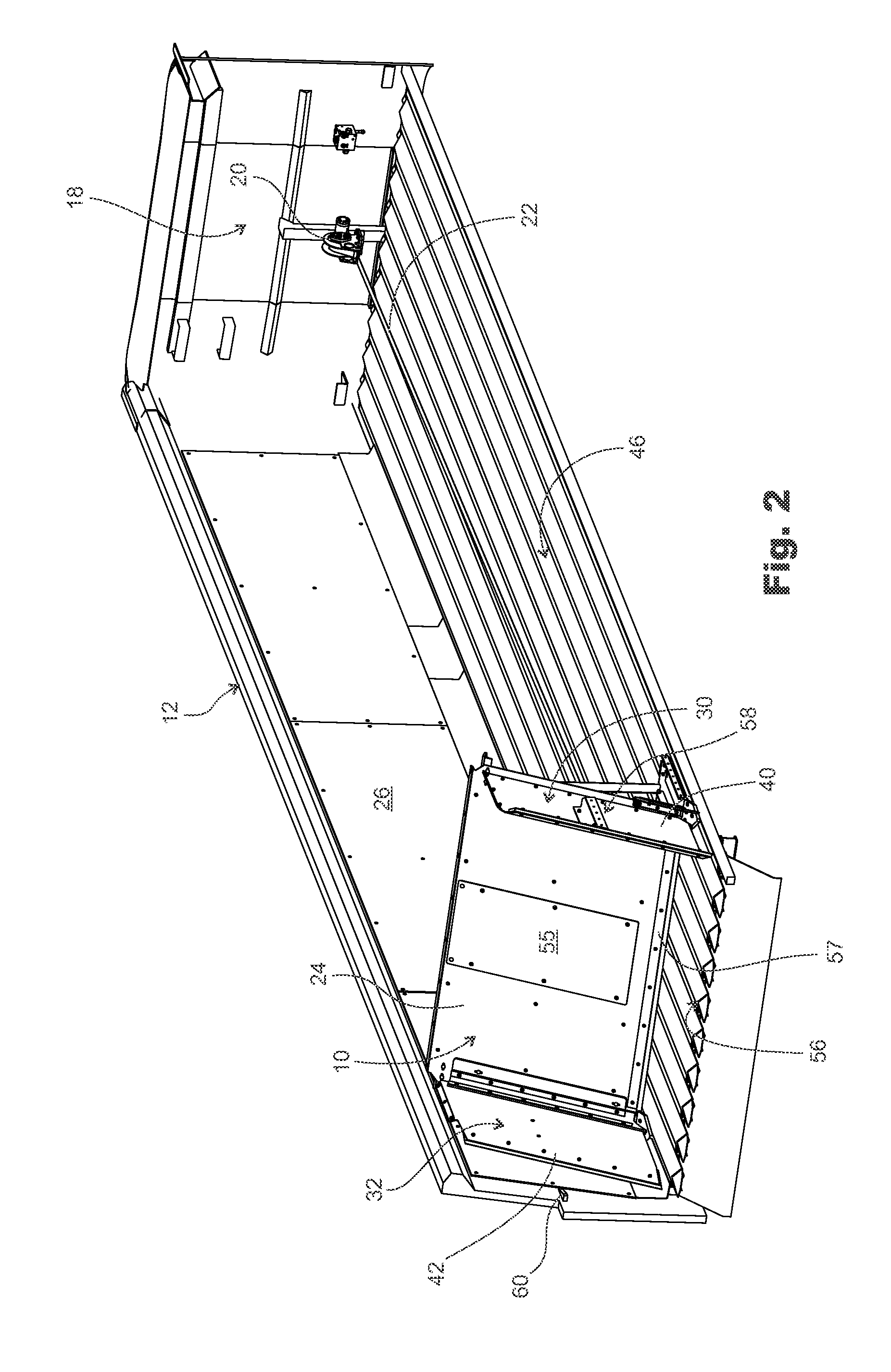

Rear eject body for off-highway haulage units

A rear eject body for a truck is provided. The body includes a floor and a pair of opposing sidewalls. A tailgate extends between the opposing sidewalls at a rear end of the rear eject body. The tailgate is pivotally supported for movement between an open position and a closed position. An ejector is supported in the rear eject body for movement between a retracted position at a forward end of the body and an extended position at the rear end of the body. A tailgate actuation assembly moves the tailgate between the open and closed positions in response to movement of the ejector between the retracted and extended positions. An ejector guide assembly includes sleds that slide in guide tracks to thereby guide the ejector as the ejector moves between the retracted and extended positions.

Owner:HAGENBUCH LEROY G

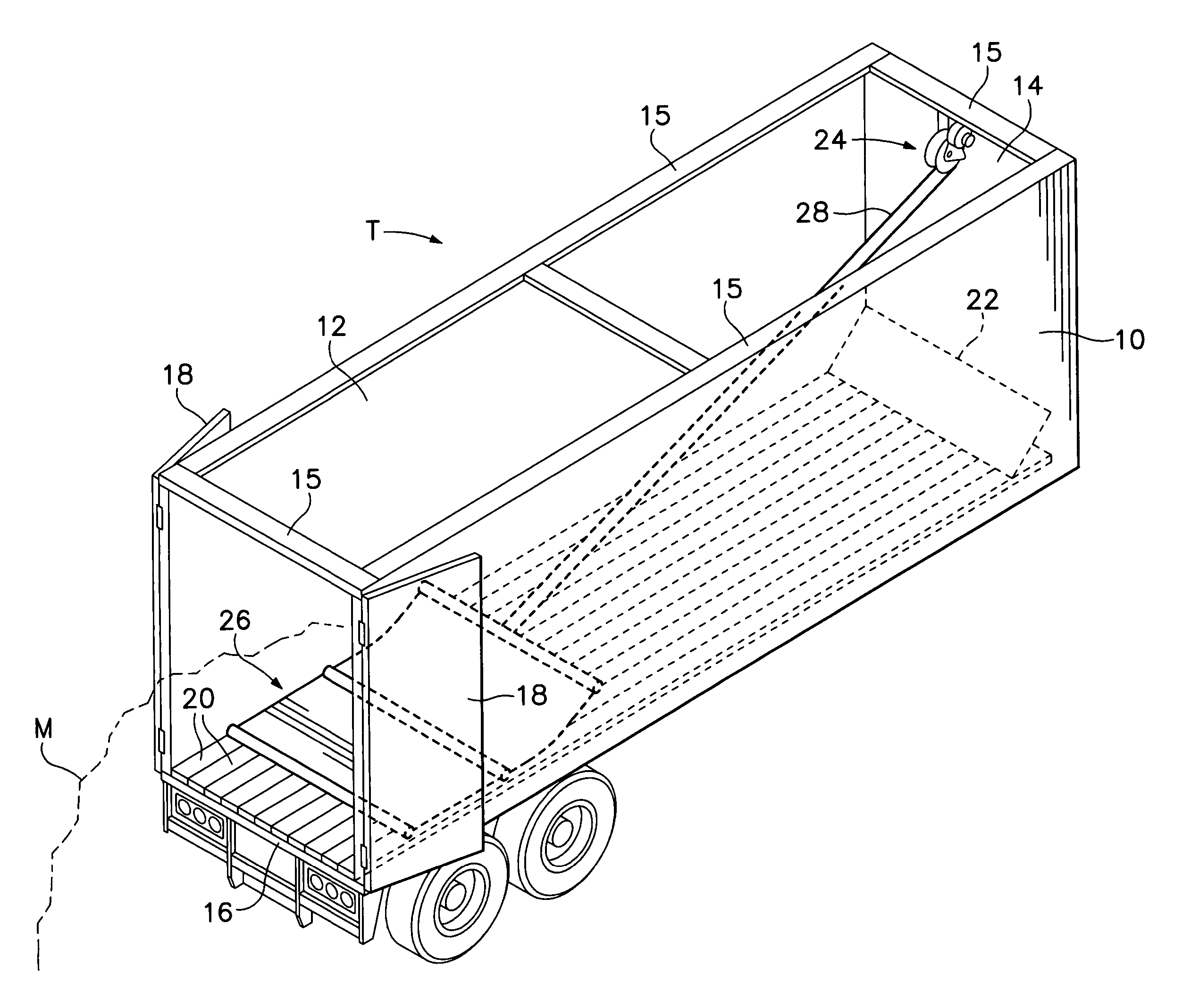

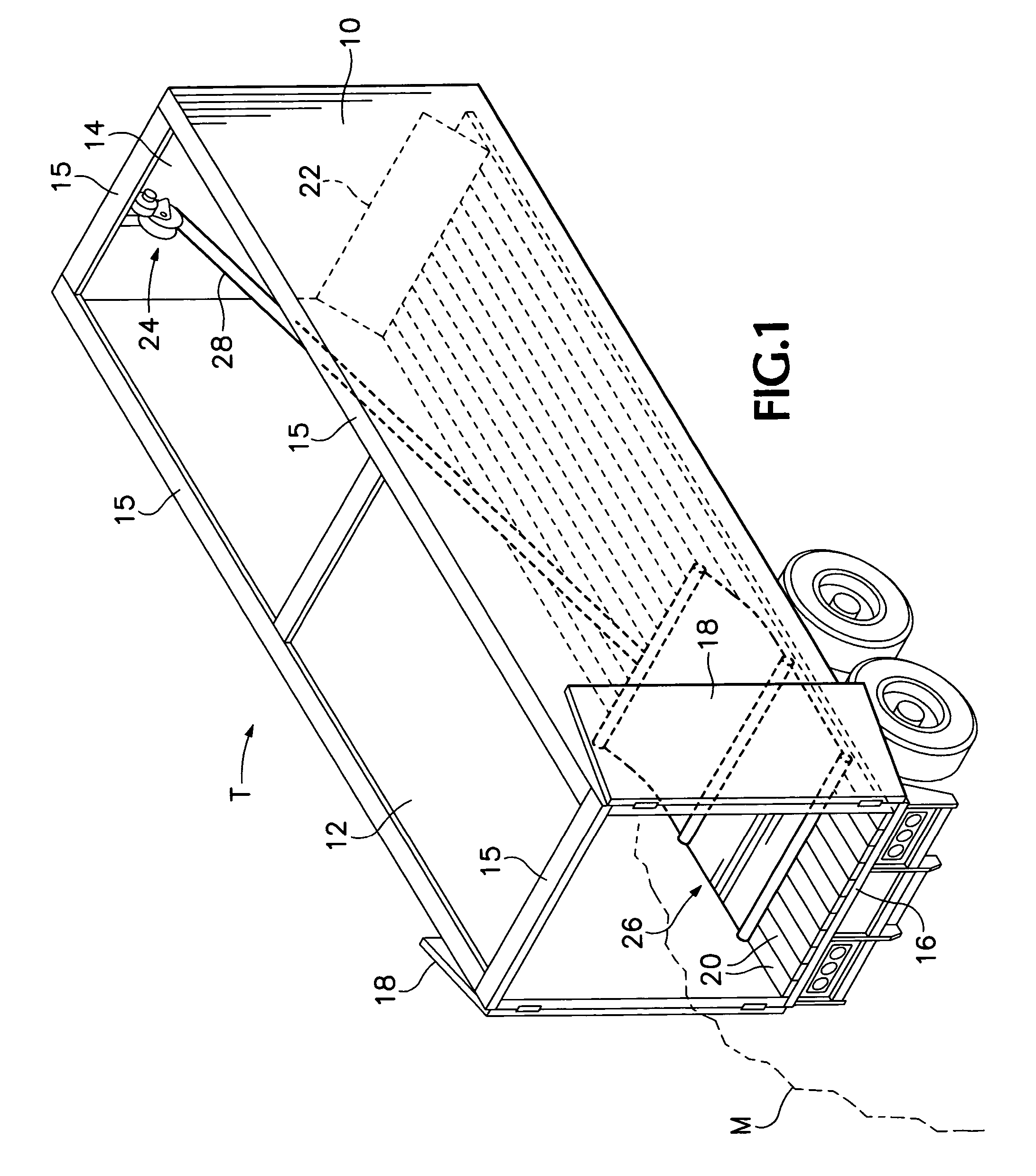

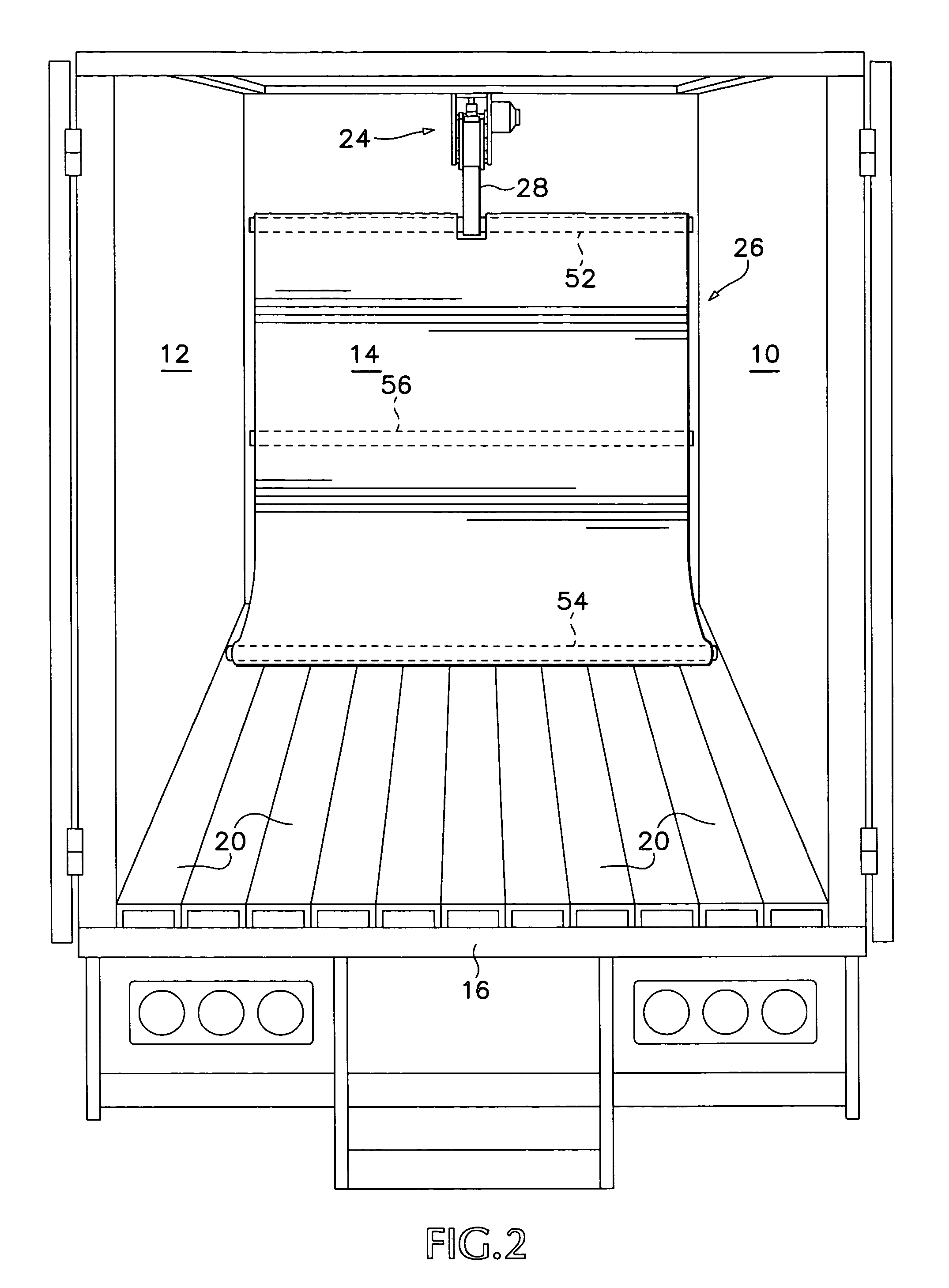

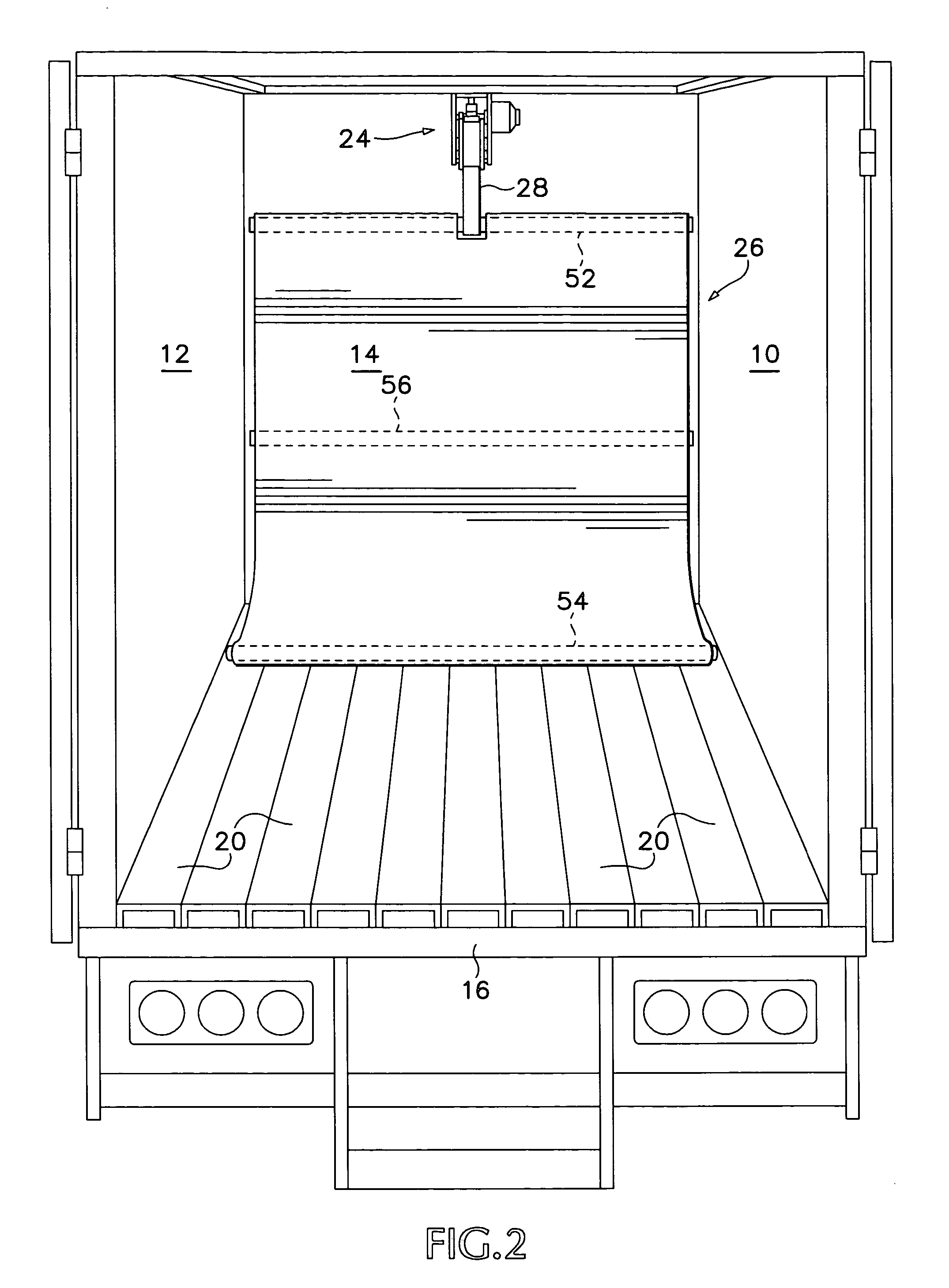

Cleanout cover system for unloading particulate material from reciprocating floor assemblies

ActiveUS6974296B2Simplified cleanout cover systemEasy to installConveyorsLarge containersPull forceCovering system

The cleanout cover system of this invention is operable with a container having a reciprocating slat-type conveyor for supporting and moving particulate material rearwardly at an unloading site. The container has laterally spaced side walls and a front connecting wall, the rear end being operable for unloading. The cleanout system includes a flexible cover sheet spanning the distance between the side walls and an elongated strap connected at one end to the center point of the front end of the cover and at its opposite end to a strap wind-up reel powered by a pneumatic motor. The reel and motor assembly is mounted on the container adjacent the upper end of the front wall of the container centrally between the side walls. A brake system associated with the reel serves to prevent unwinding of the strap when the pneumatic motor is deactivated after the strap is wound fully onto the reel with the cover suspending therefrom and permit unwinding of the strap when pulling tension is applied by the cover during unloading operation of the reciprocating slat-type conveyor of the container.

Owner:SIMRIN KIRK A

Ejector blade system

An ejector blade adapted to be combined with an ejector truck or trailer body. In one embodiment, the blade comprises fluidly actuated vibrators for loosening material that has become adhered to the ejector blade. In another embodiment, the blade is heated to help prevent material from being frozen to the blade. In yet another embodiment, the blade comprises a plurality of low friction guides to aid the blade in moving through the receptacle body.

Owner:HOLMES JAMES +1

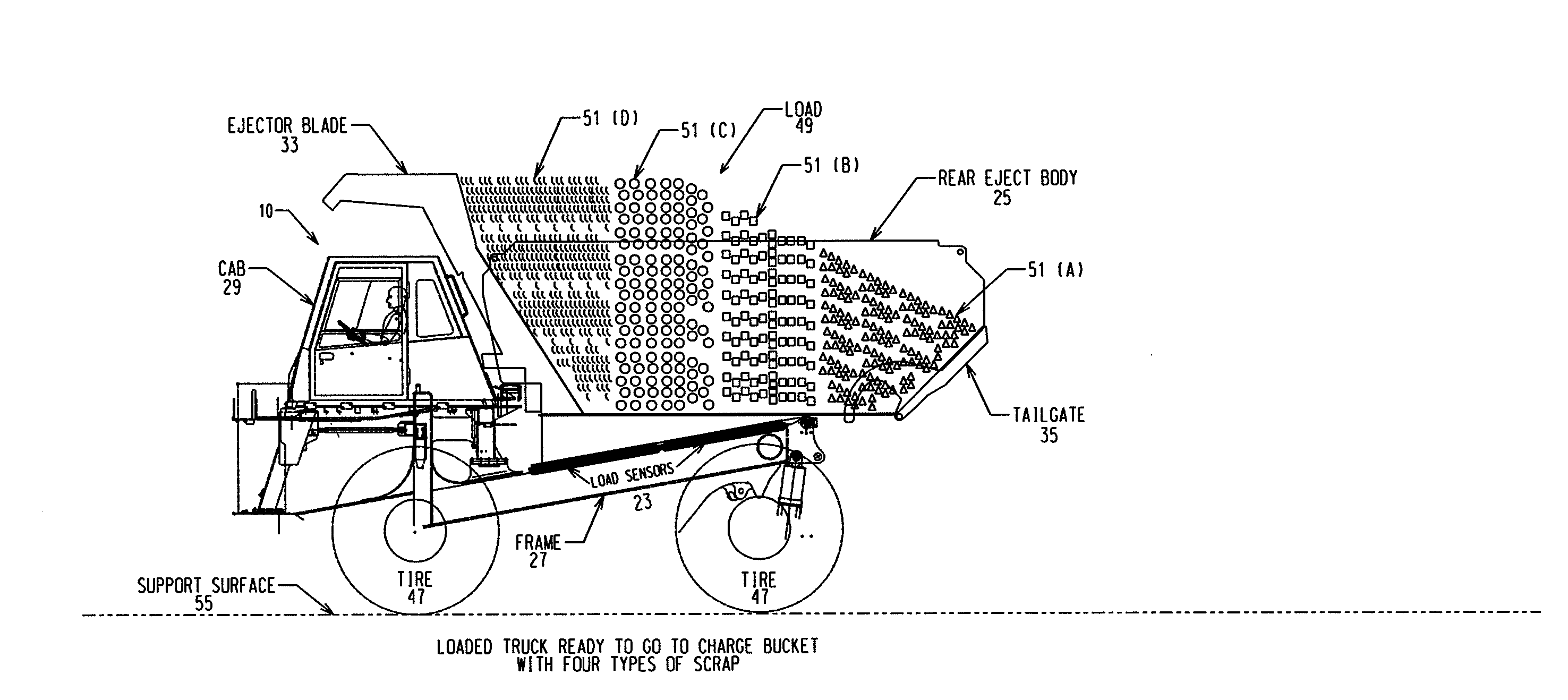

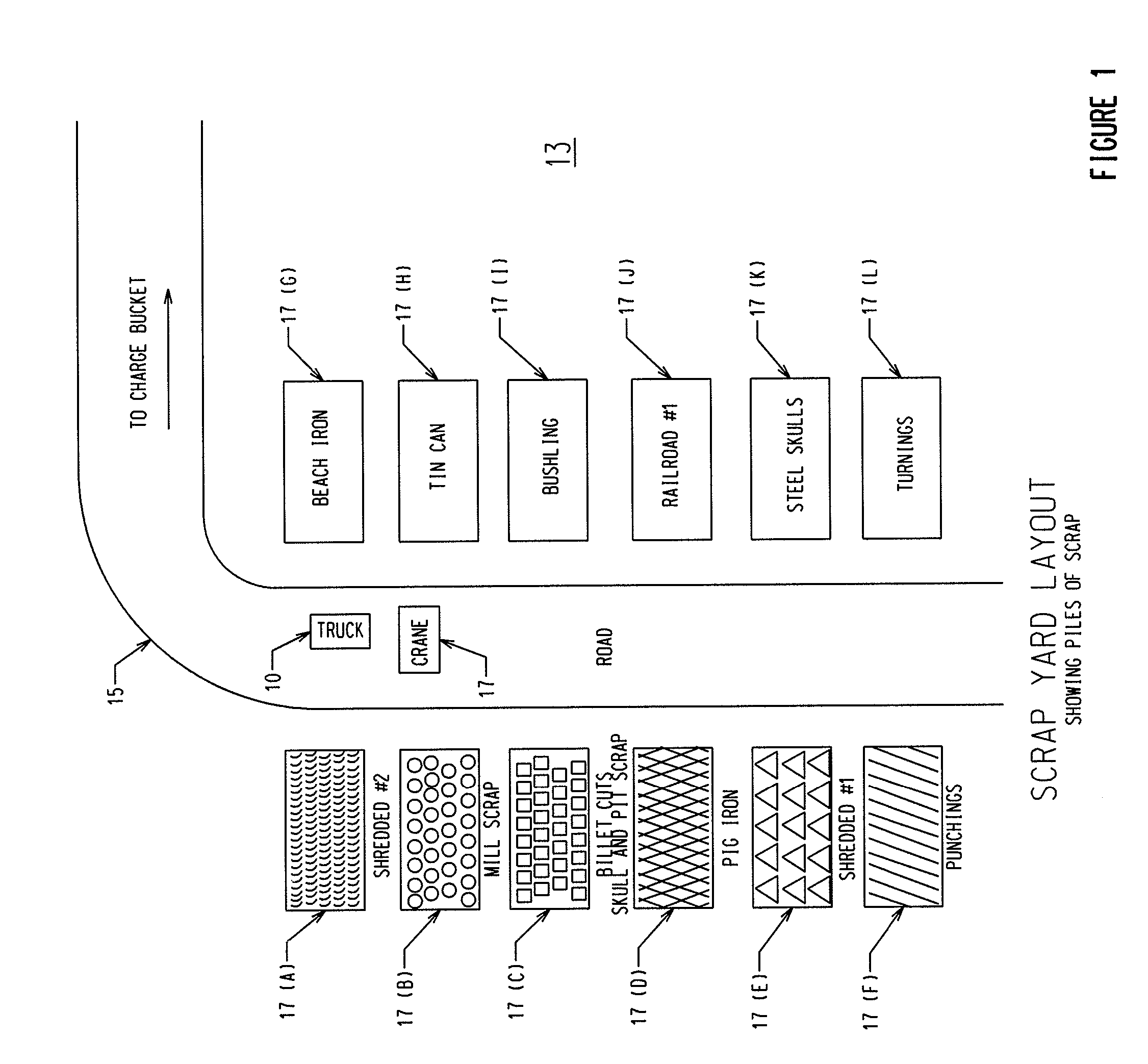

Charge Bucket Loading for Electric ARC Furnace Production

InactiveUS20080298941A1Minimize mixingLittle mixingRefuse receptaclesVehicle with pusher plateElectric arc furnaceTruck

Loads carried by a haulage vehicle are transferred from the vehicle to a container in a manner that maintains an ordered segmentation of materials comprising each of the loads, where each segment comprises a different type of material. The container receives the load such that each segment forms a layer in the container, which in the case of a charge bucket for feeding an electric arc furnace creates a layering of the different types of material according to a desired recipe for melting scrap metal processed by the mill incorporating the furnace. The transferring of the load is implemented by a haulage truck having a rear eject body whose ejector blade pushes the segmented load out and into the container.

Owner:HAGENBUCH LEROY G +1

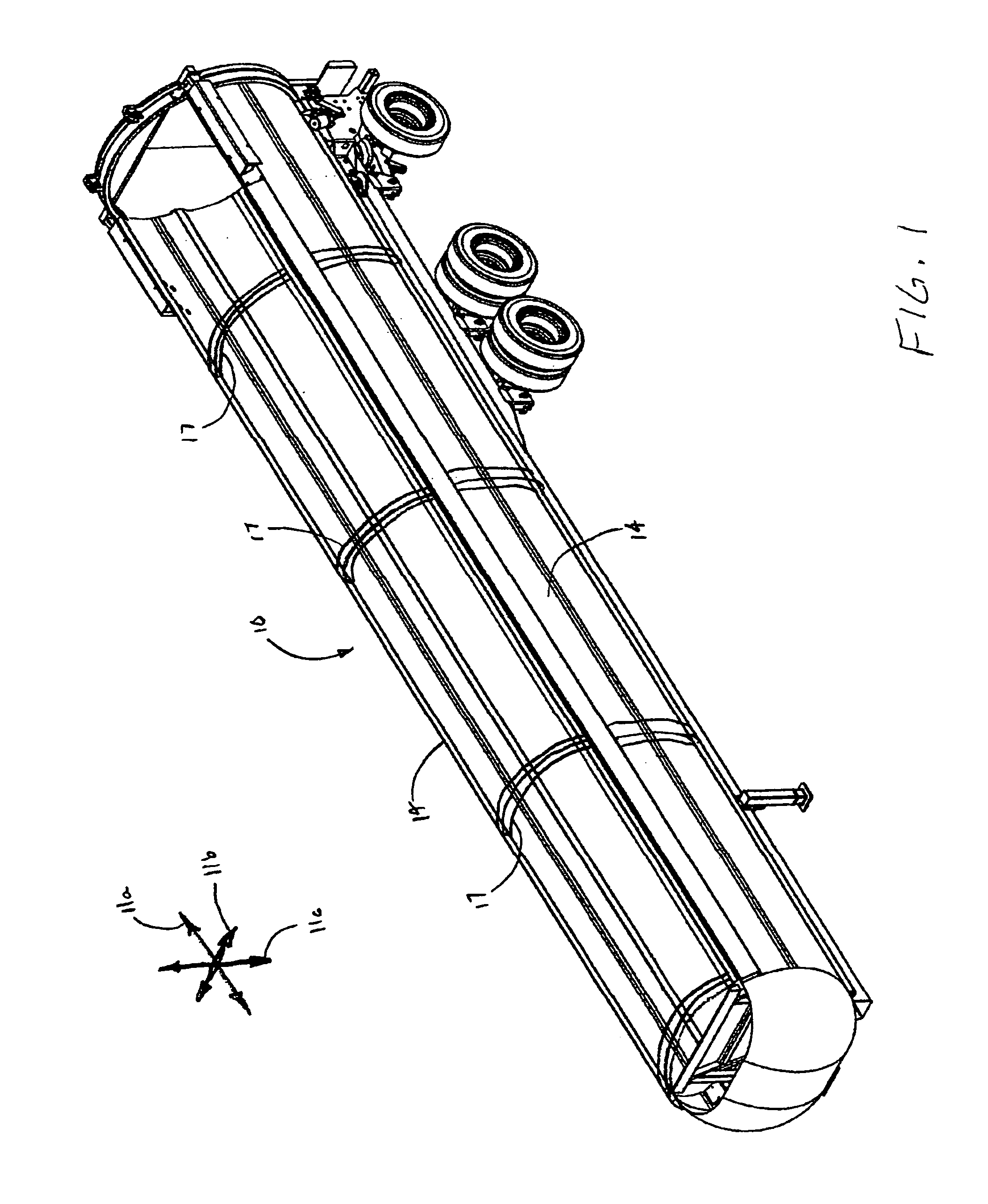

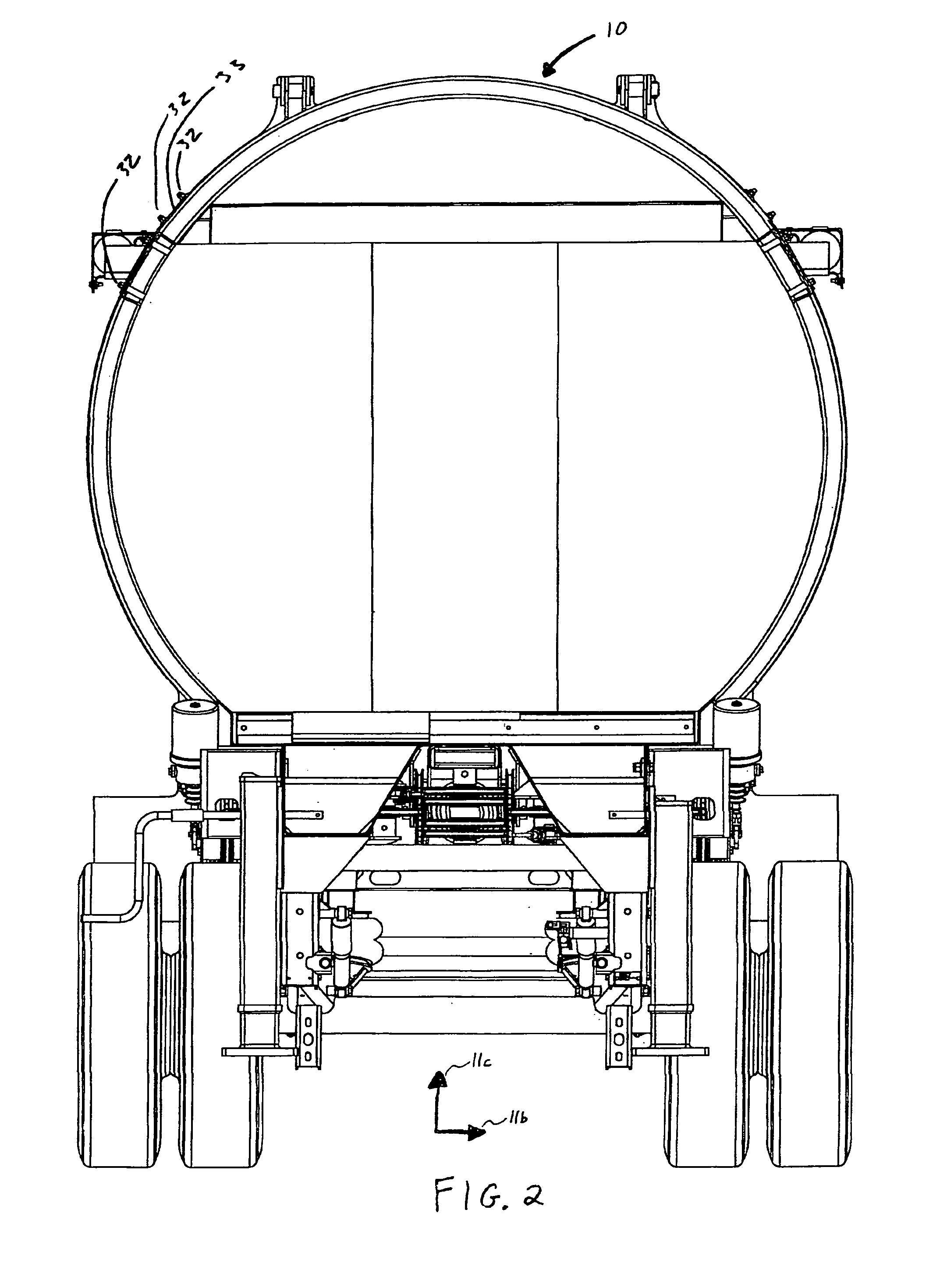

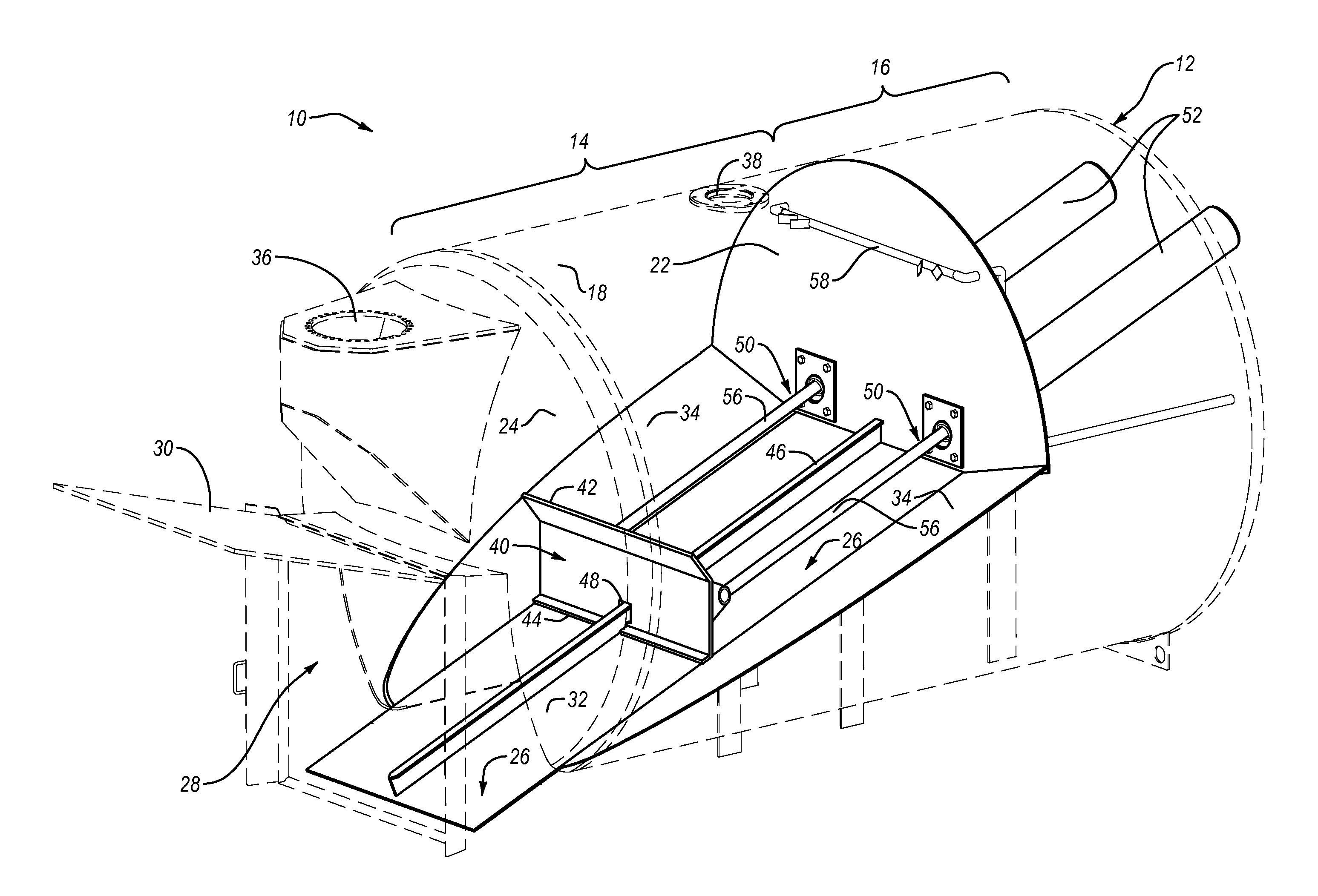

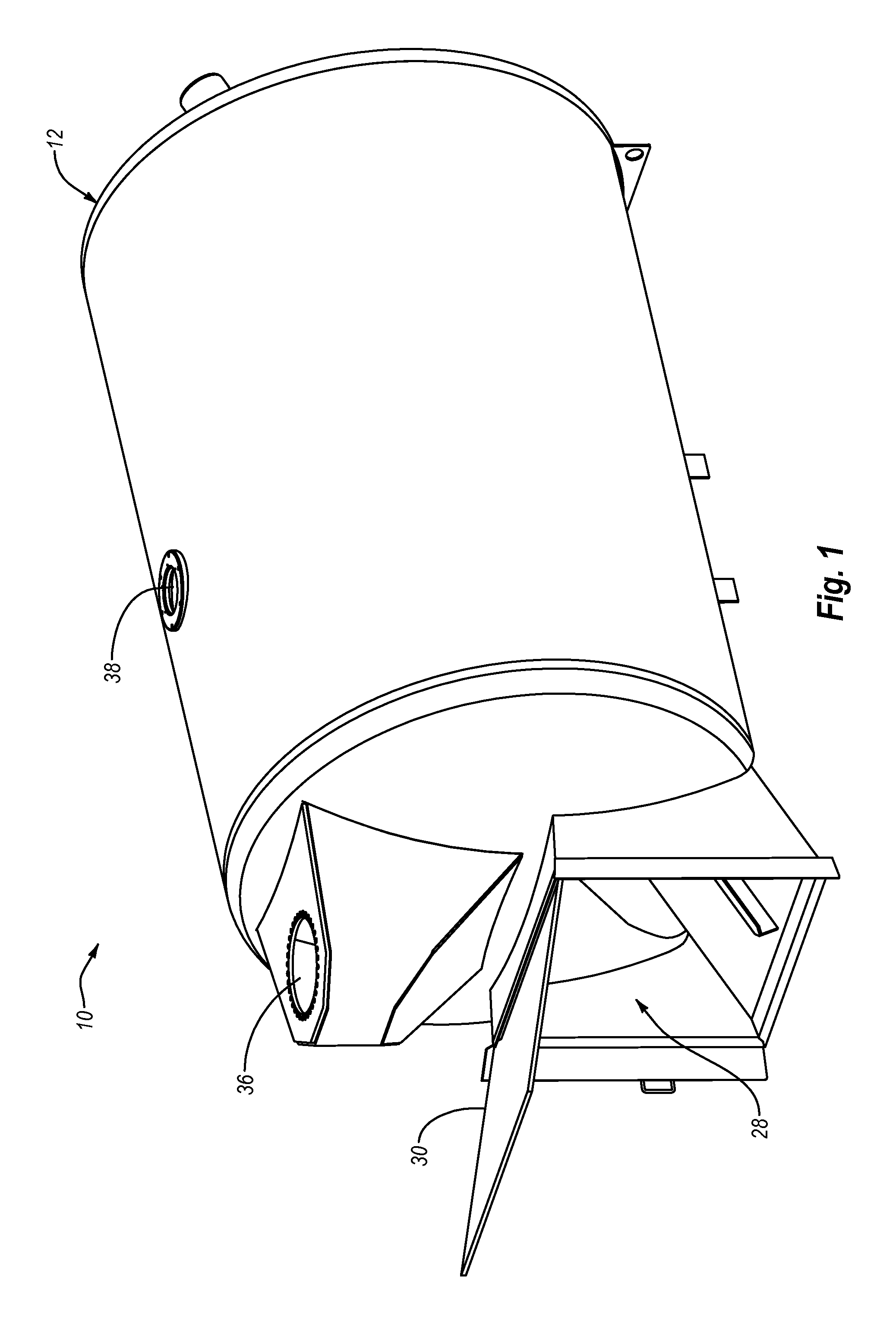

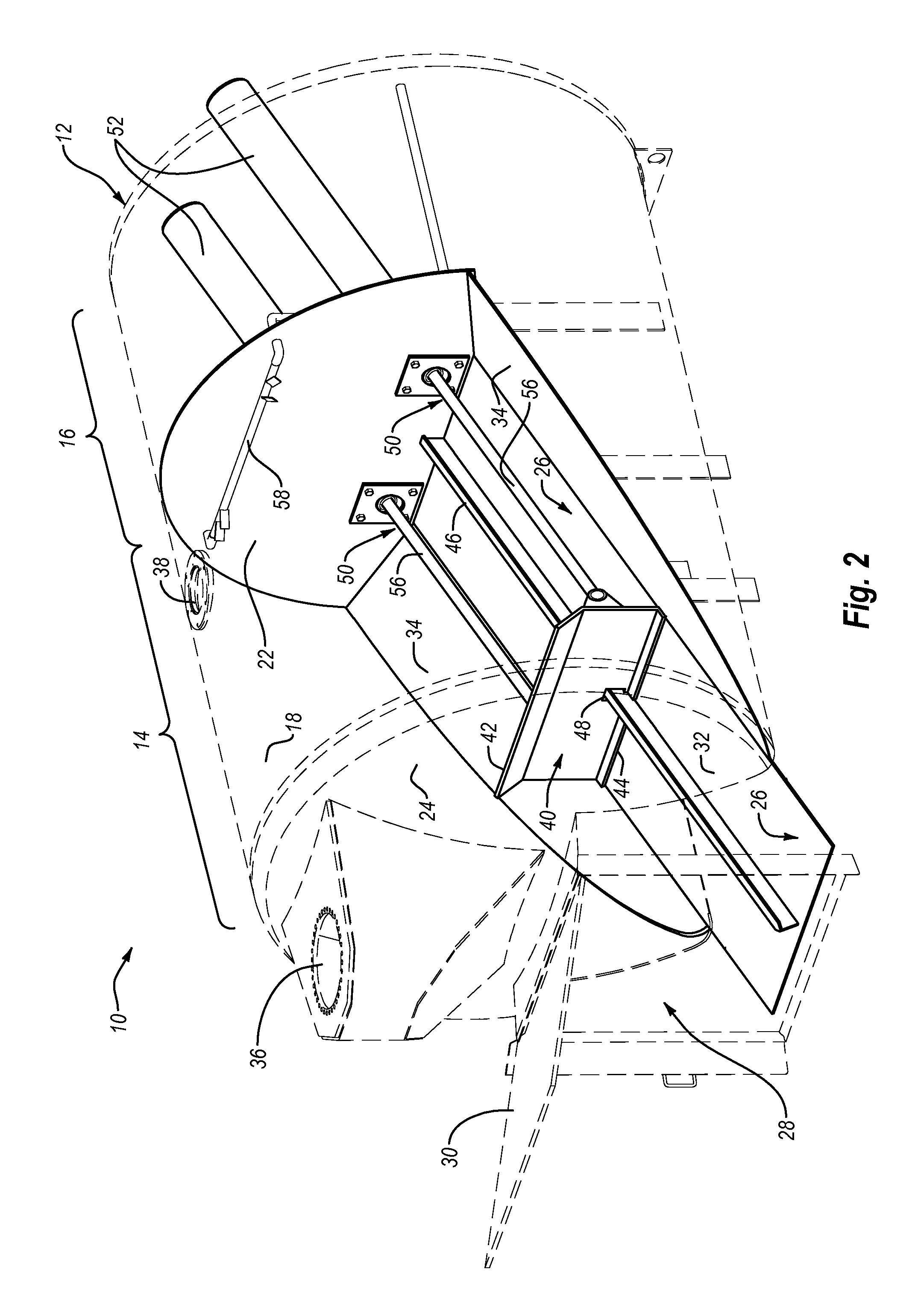

Systems and devices for removing materials from vacuum truck tanks

Systems and devices for removing materials from vacuum truck tanks are disclosed herein. An exemplary system for removing materials from a vacuum truck may include a tank having one or more walls enclosing the tank and an opening in the one or more walls to facilitate removal of materials from the tank; a blade positioned within the tank and configured to push materials towards the opening to remove or discharge collected materials from the tank; and a drive mechanism configured to selectively move the blade towards the opening in the tank. Additional systems and devices for removing materials from vacuum truck tanks are also disclosed herein.

Owner:PRO TECH ENTERPRISES +1

Rear eject body for off-highway haulage units

A rear eject body for a truck is provided. The body includes a floor and a pair of opposing sidewalls. A tailgate extends between the opposing sidewalls at a rear end of the rear eject body. The tailgate is pivotally supported for movement between an open position and a closed position. An ejector is supported in the rear eject body for movement between a retracted position at a forward end of the body and an extended position at the rear end of the body. A tailgate actuation assembly moves the tailgate between the open and closed positions in response to movement of the ejector between the retracted and extended positions. An ejector guide assembly includes sleds that slide in guide tracks to thereby guide the ejector as the ejector moves between the retracted and extended positions.

Owner:HAGENBUCH LEROY G

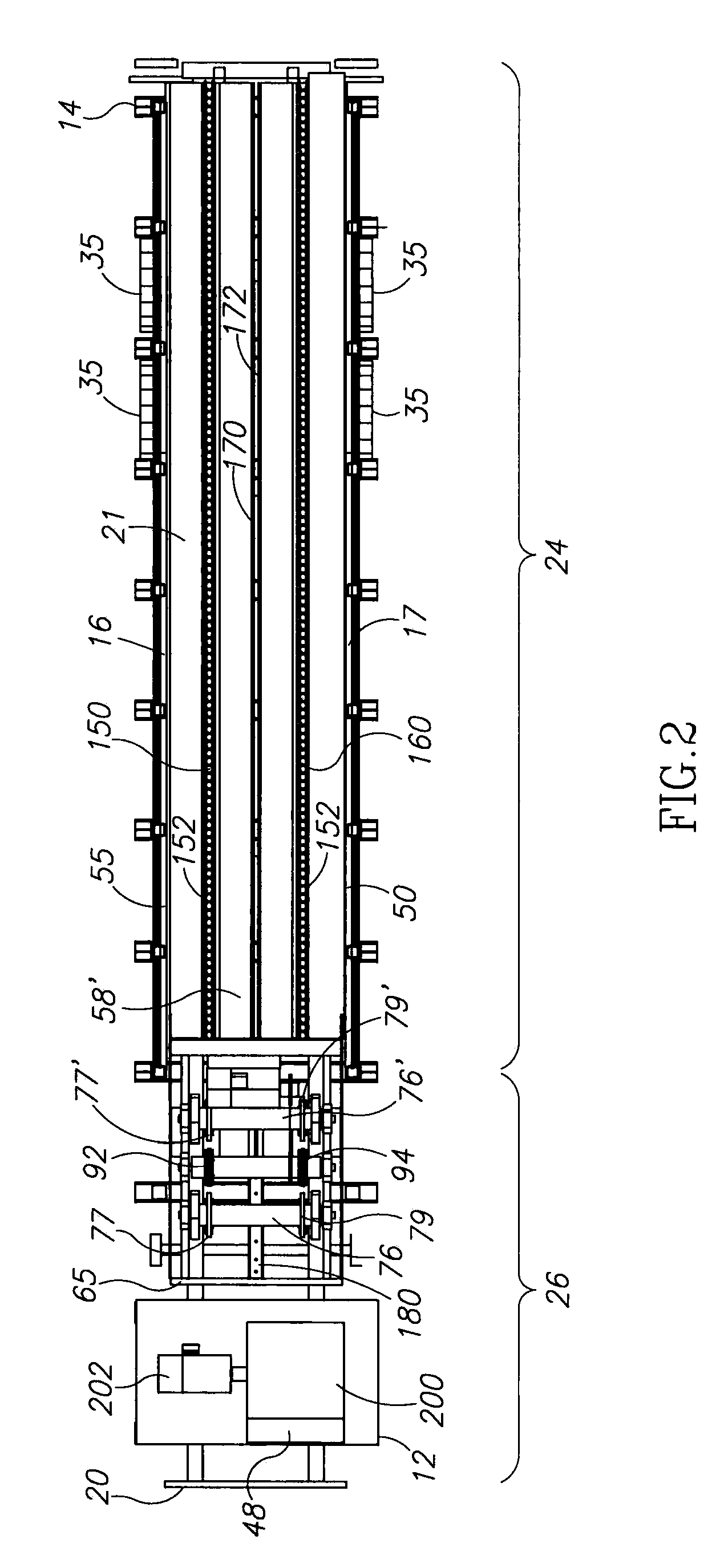

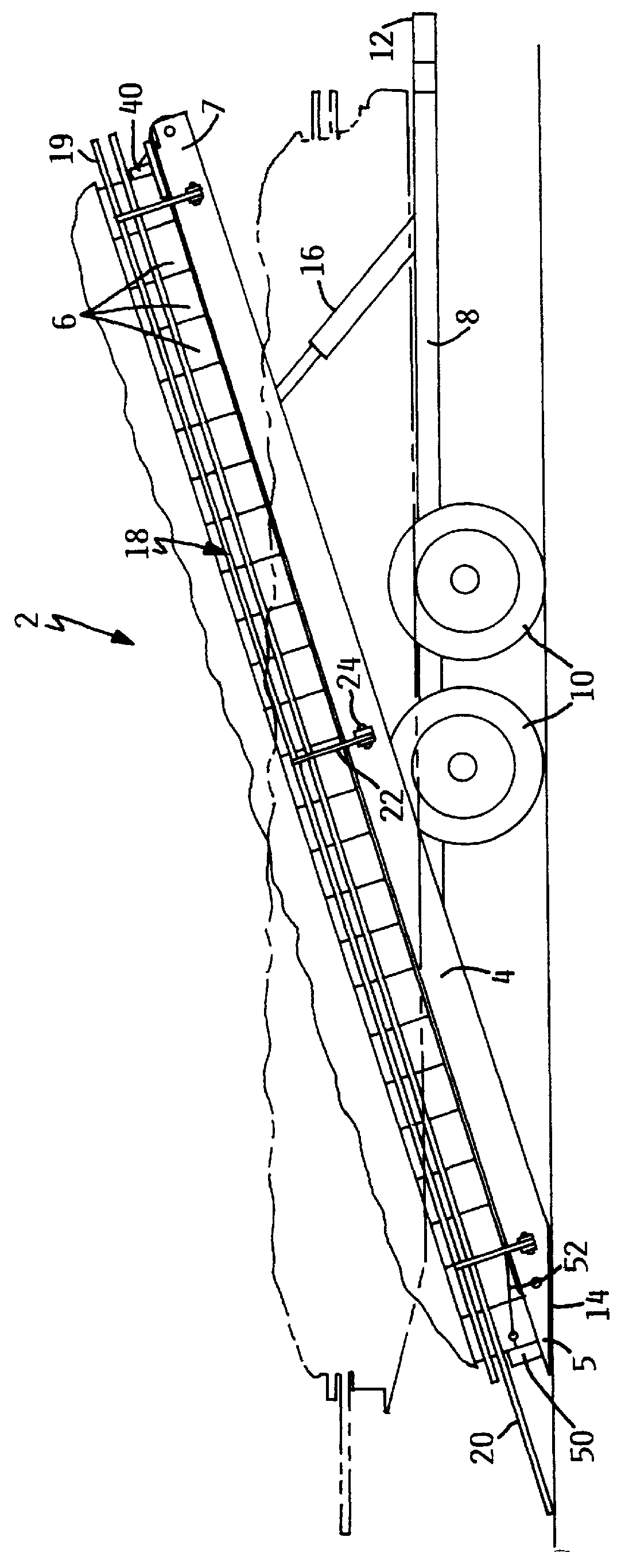

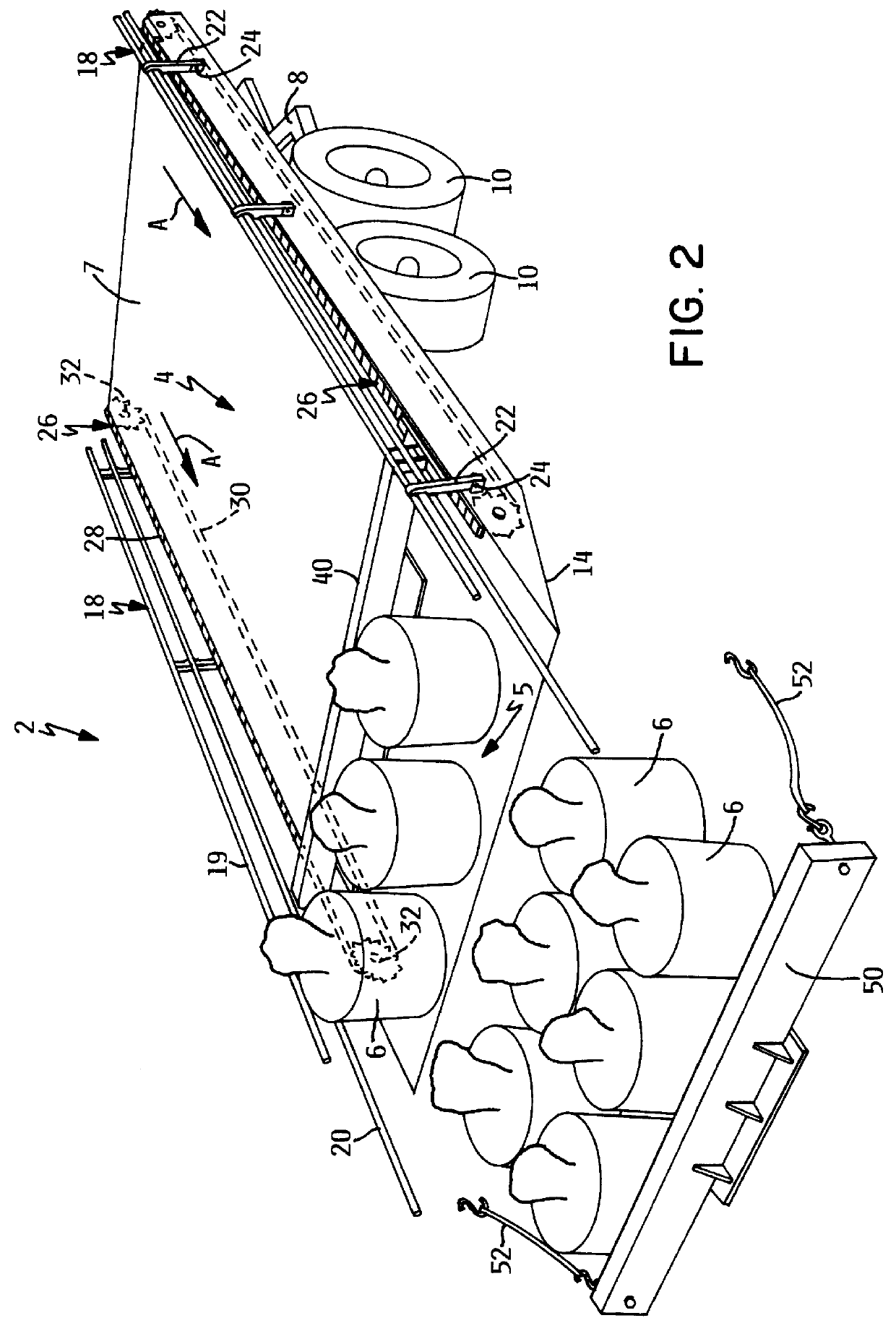

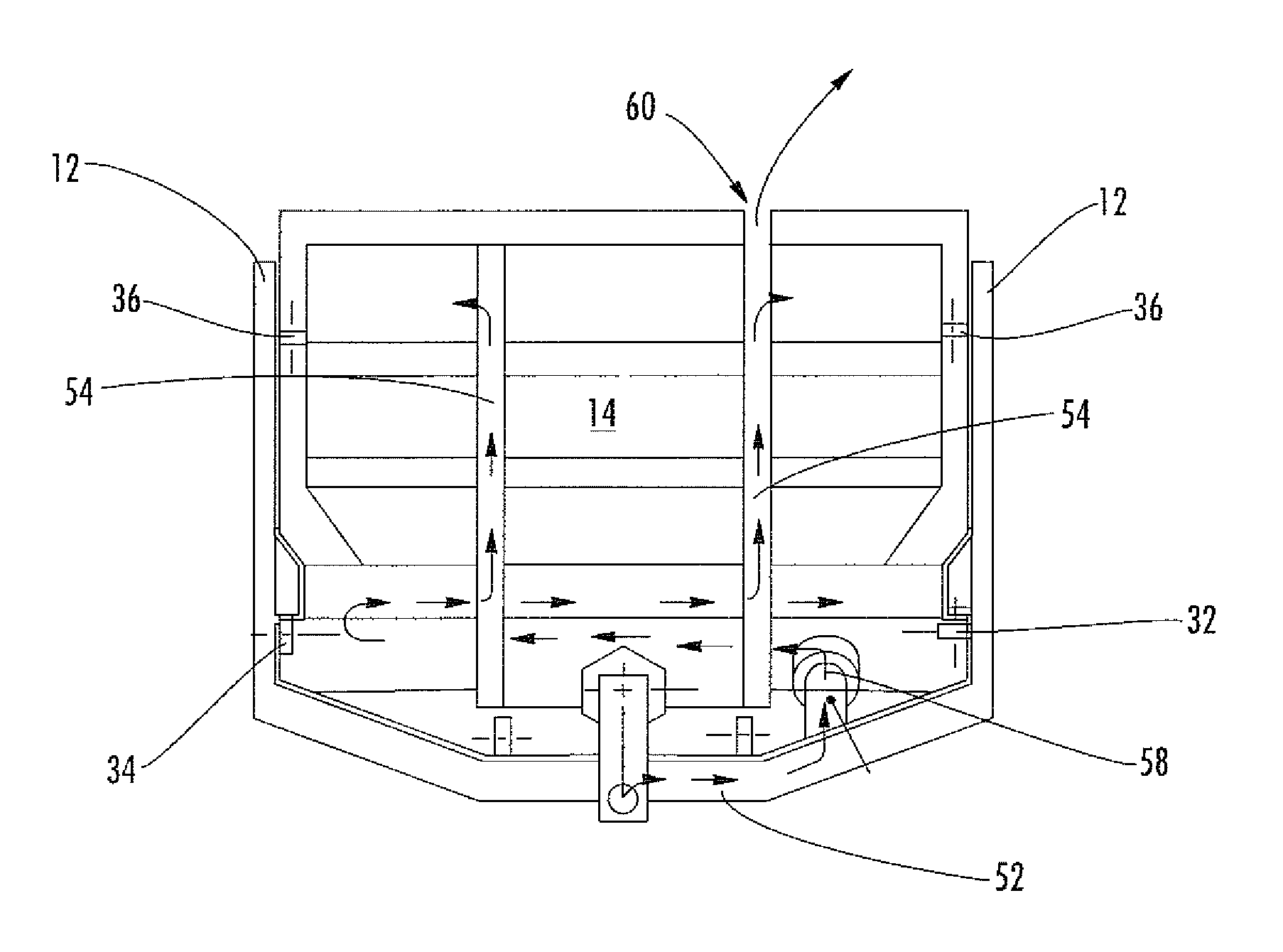

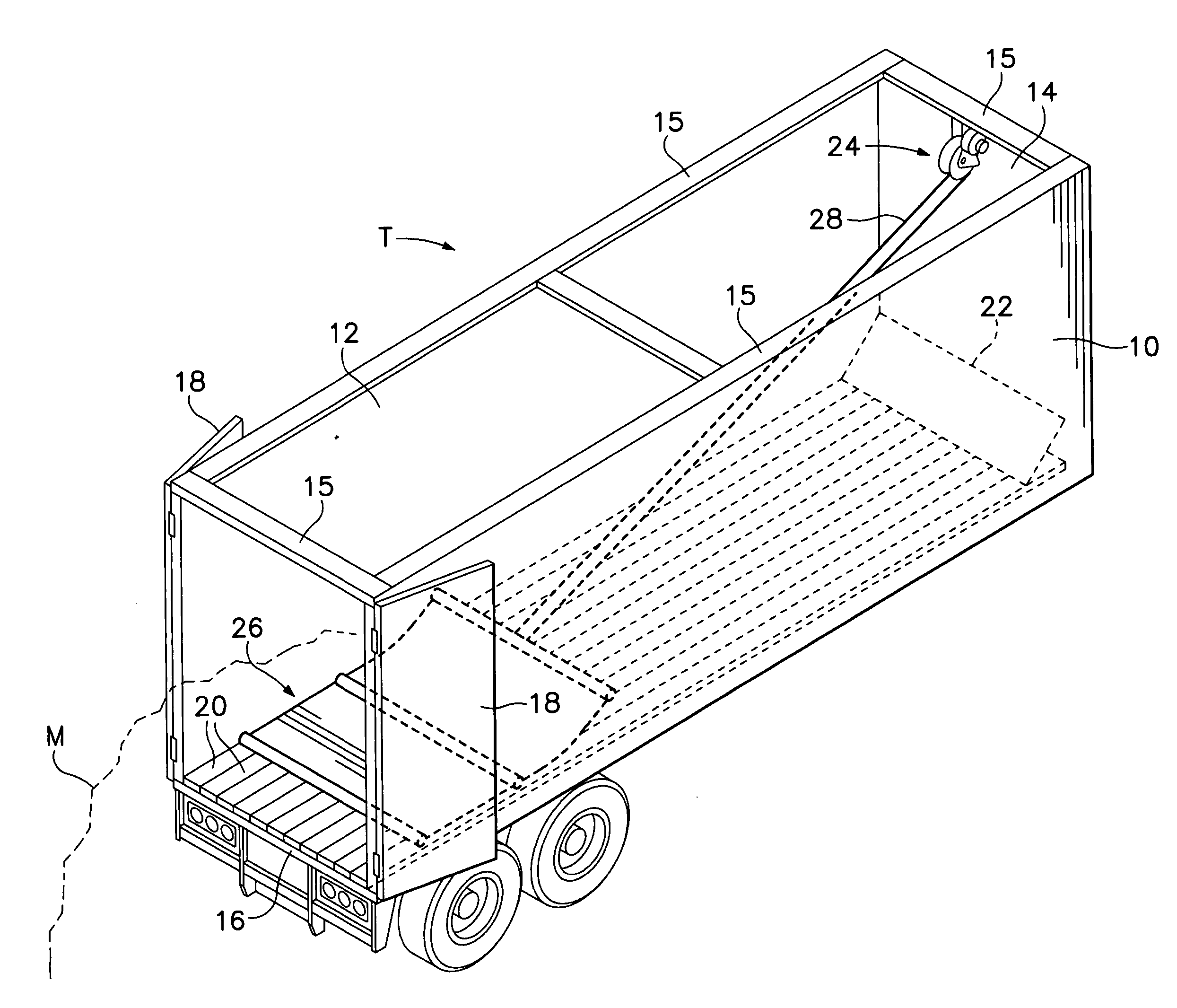

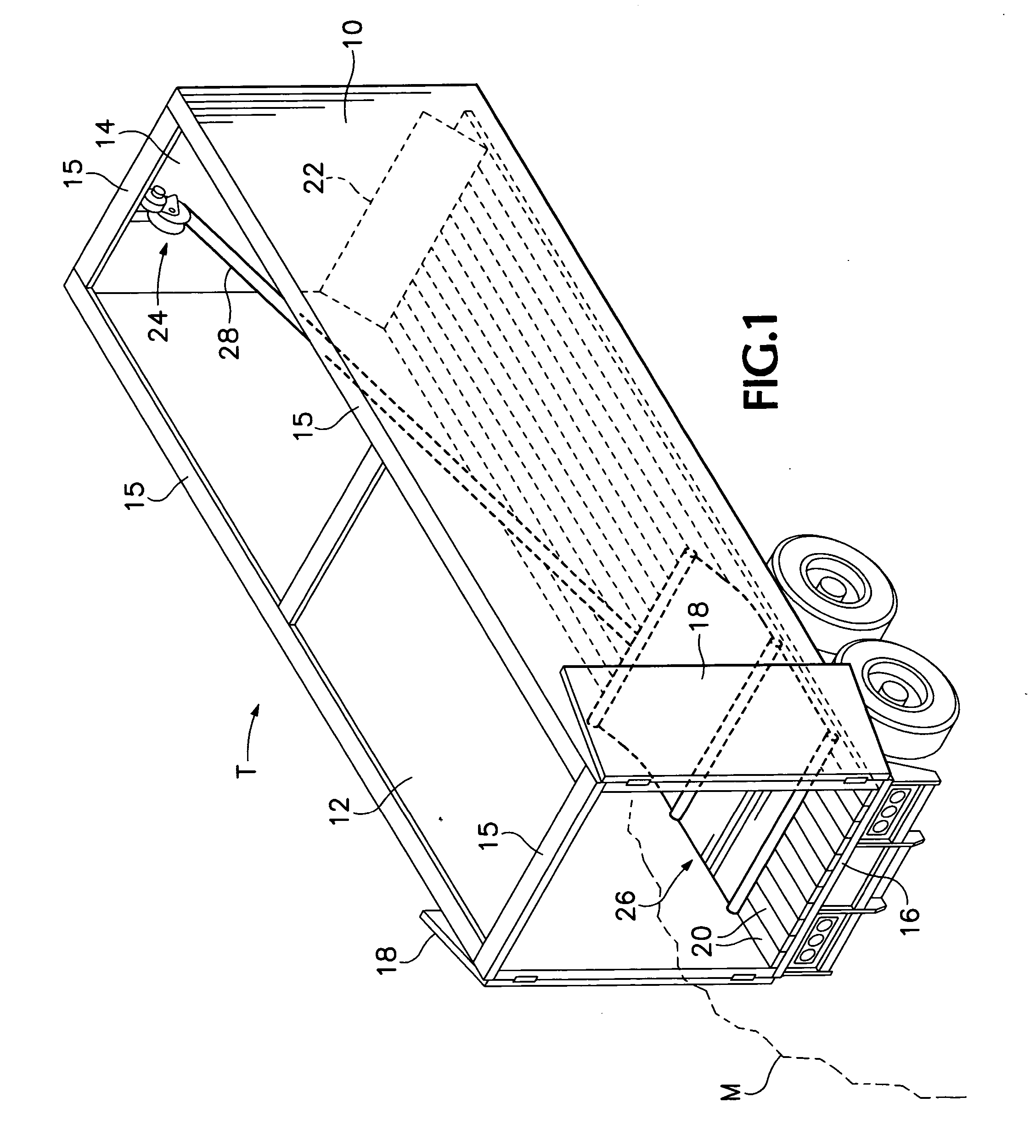

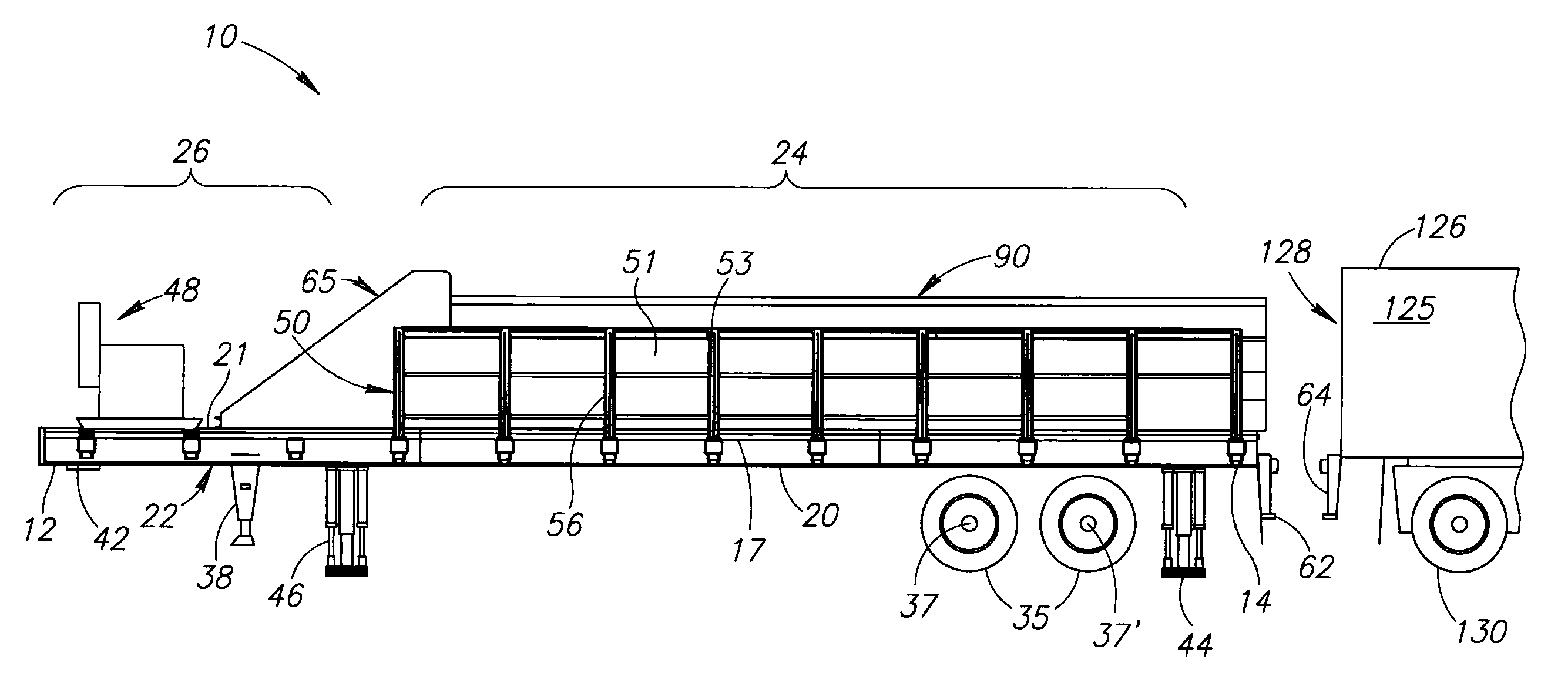

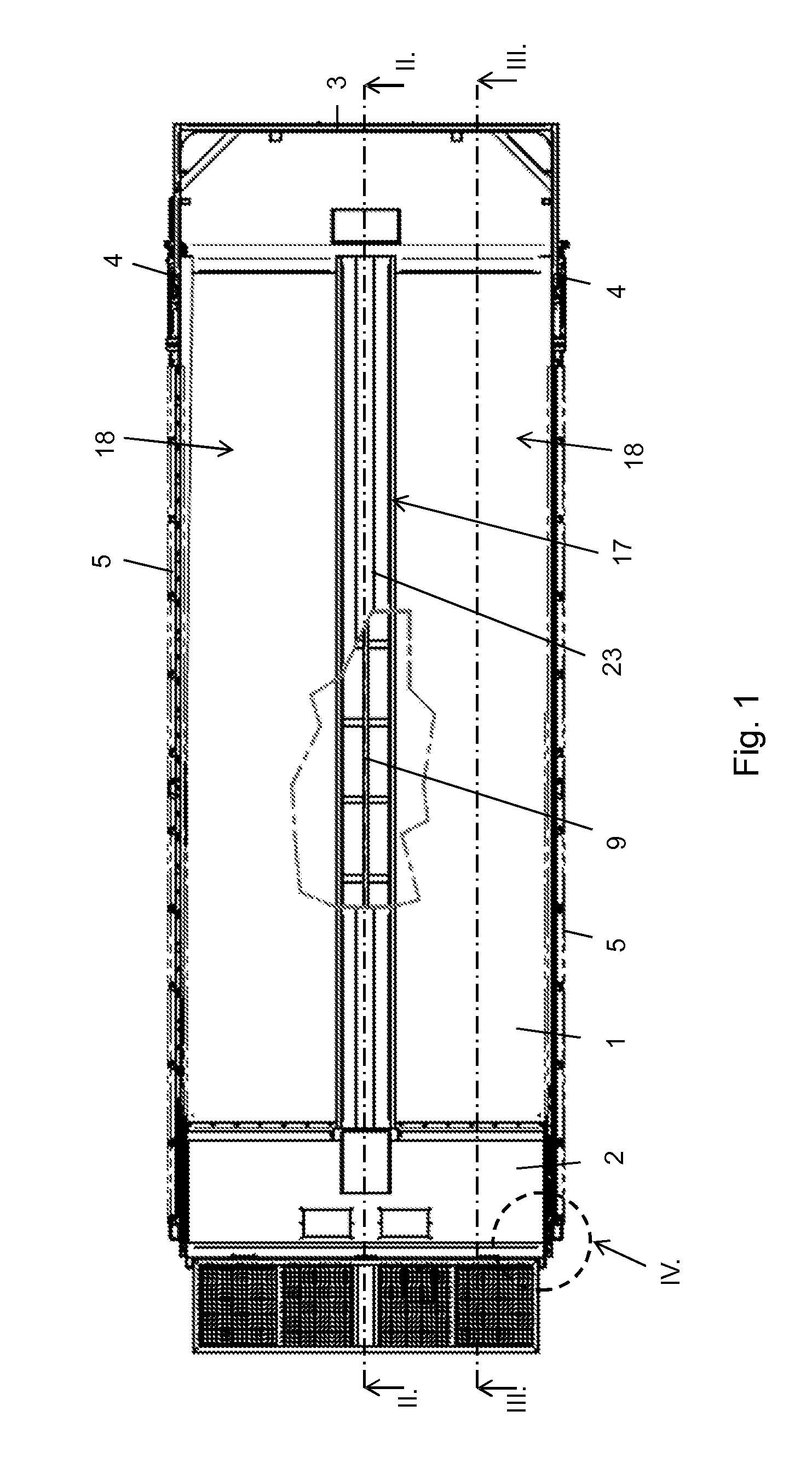

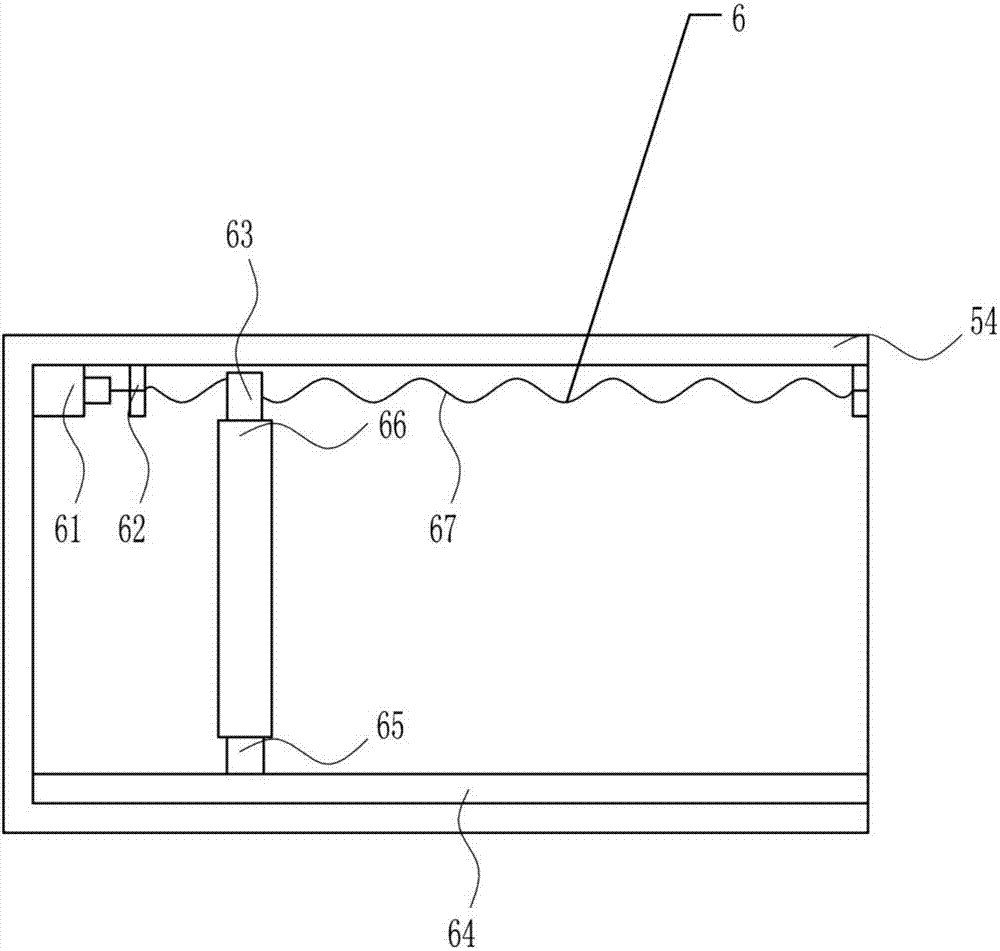

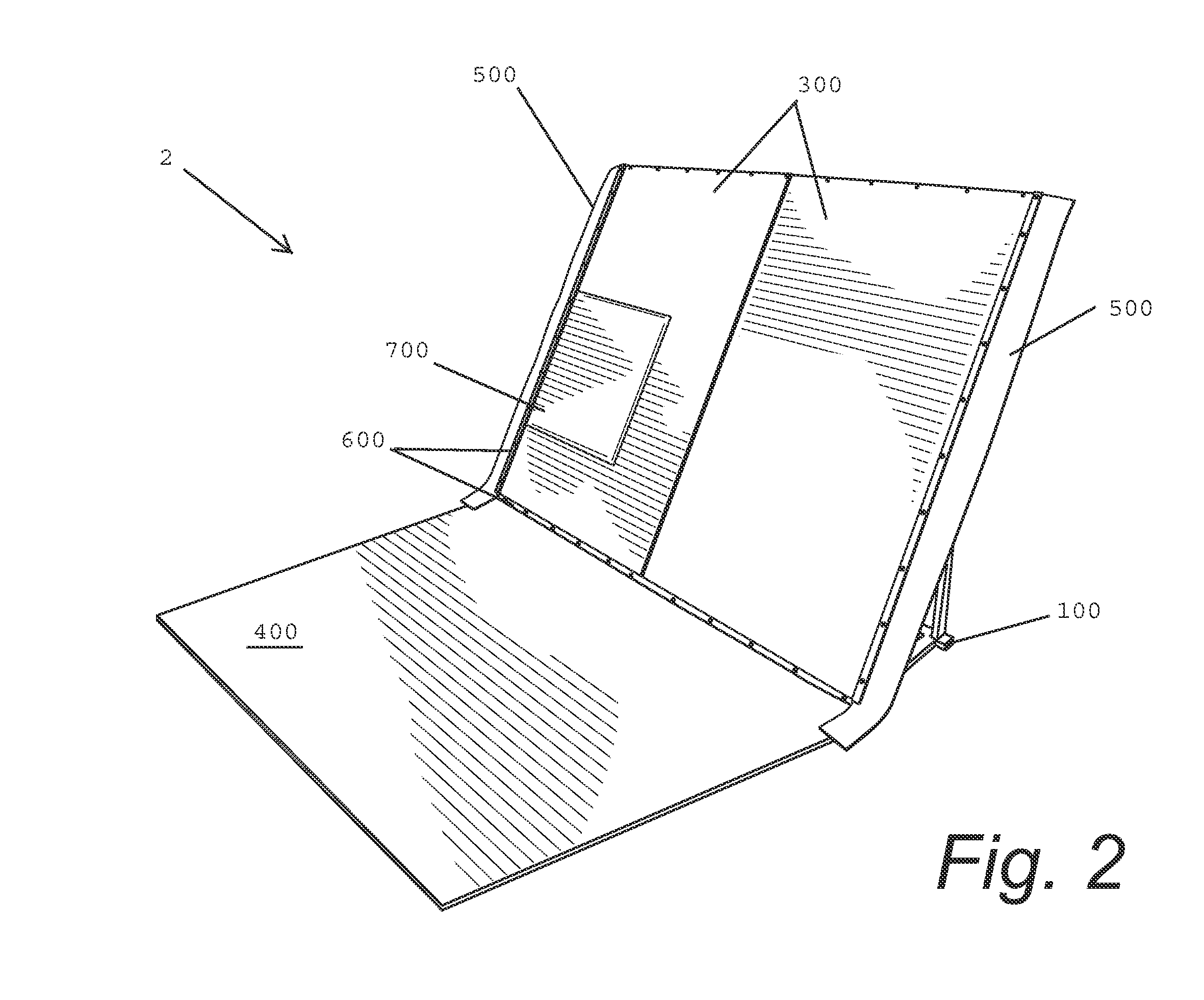

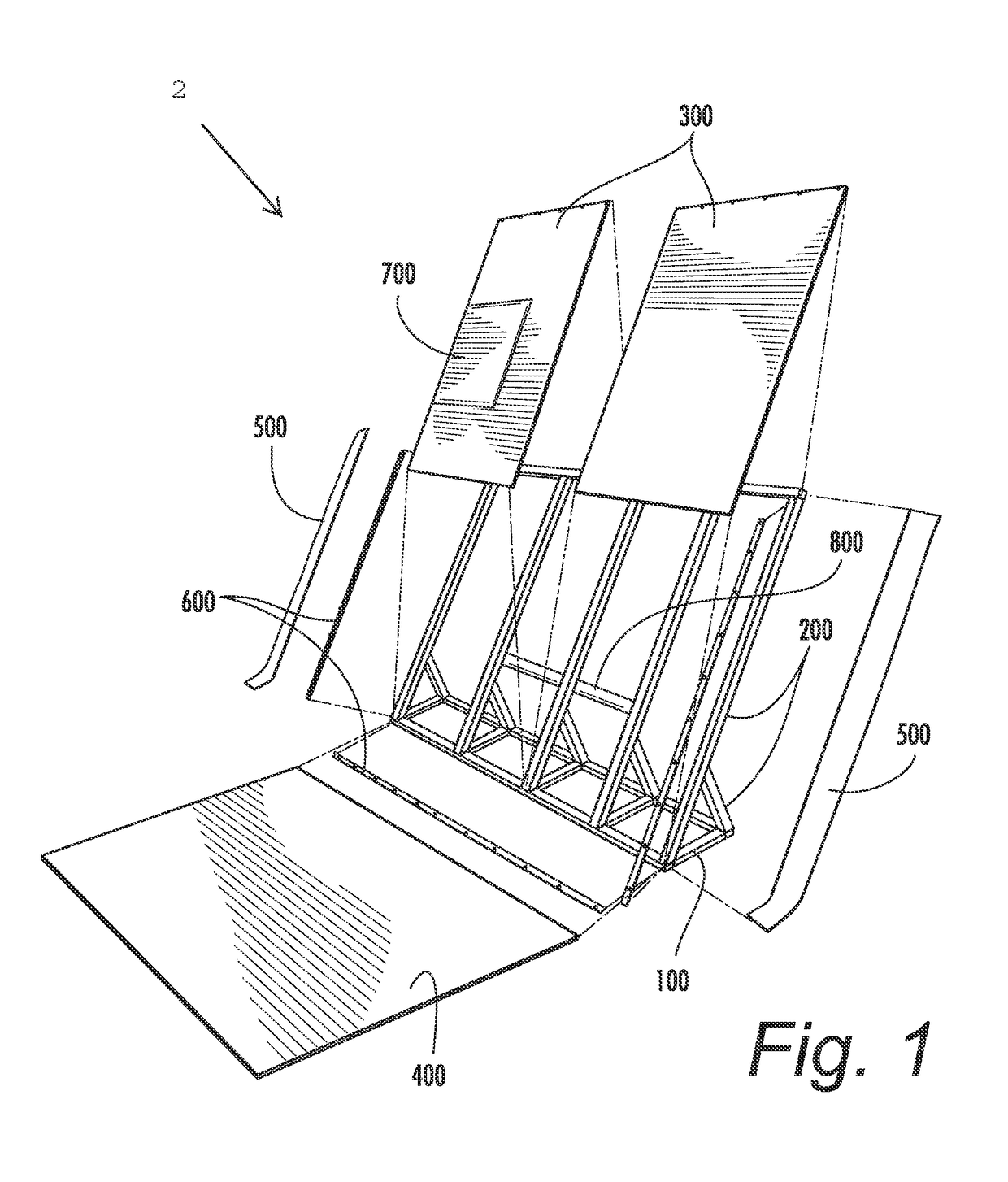

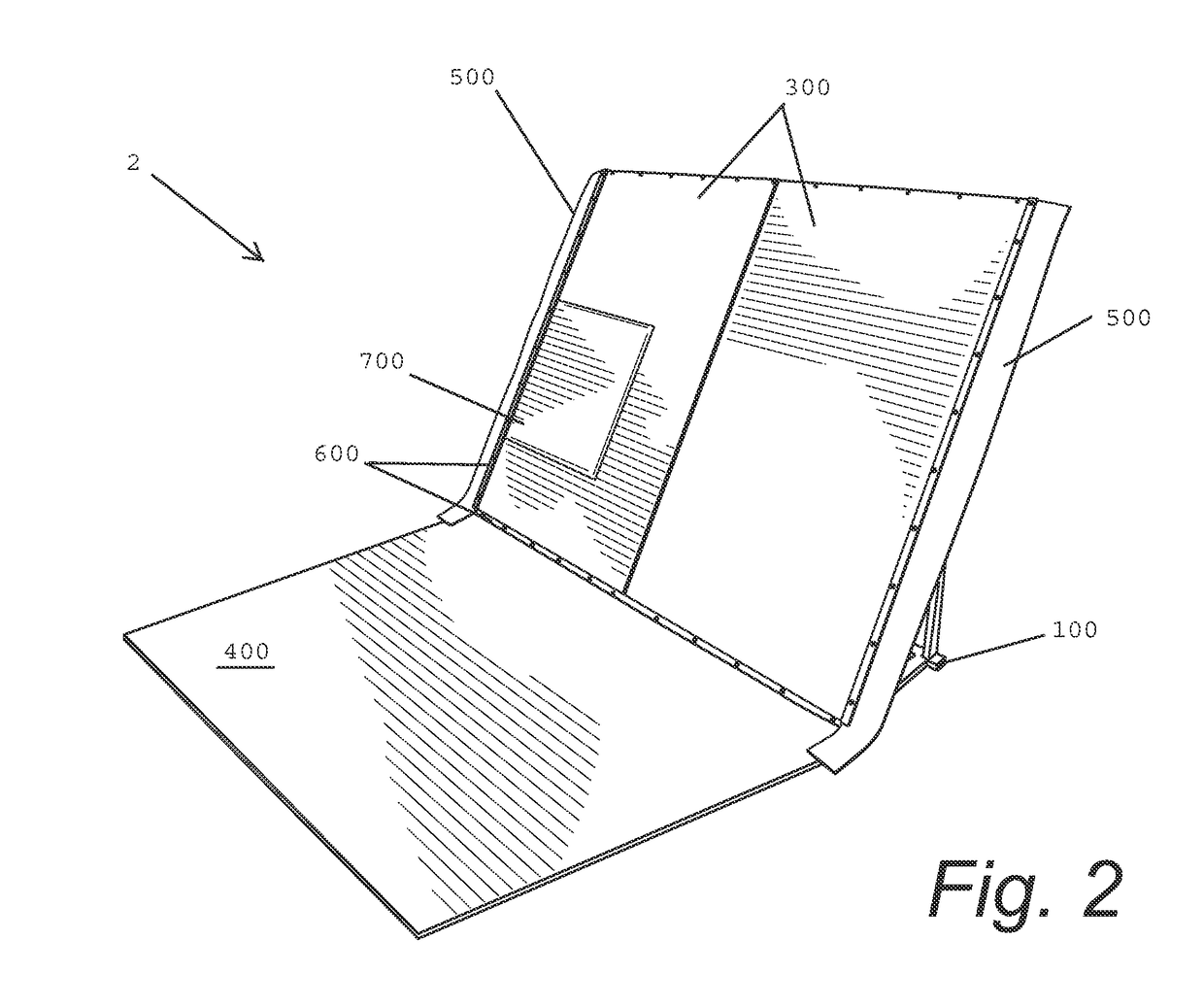

Moving cleanout for reciprocating conveyor system

ActiveUS9090193B2Easy to adjustAvoid flaringVehicle with pusher plateVehicle with tipping movementConveyor systemEngineering

The invention disclosed here is a moving headboard for use in connection with a reciprocating floor slat system. It is particularly well-suited for use in connection with load-hauling trailers that have built-in reciprocating floor slat conveyors for unloading the trailer. Trailers of this kind are used in lieu of hydraulic lifts and involve inching the load off the trailer. The moving headboard sweeps the trailer floor clean during the unloading process.

Owner:KEITH MFG

Cleanout cover system for unloading particulate material from reciprocating floor assemblies

ActiveUS20050042067A1Free spinsSimplified cleanout cover systemConveyorsLarge containersPull forceCovering system

The cleanout cover system of this invention is operable with a container having a reciprocating slat-type conveyor for supporting and moving particulate material rearwardly at an unloading site. The container has laterally spaced side walls and a front connecting wall, the rear end being operable for unloading. The cleanout system includes a flexible cover sheet spanning the distance between the side walls and an elongated strap connected at one end to the center point of the front end of the cover and at its opposite end to a strap wind-up reel powered by a pneumatic motor. The reel and motor assembly is mounted on the container adjacent the upper end of the front wall of the container centrally between the side walls. A brake system associated with the reel serves to prevent unwinding of the strap when the pneumatic motor is deactivated after the strap is wound fully onto the reel with the cover suspending therefrom and permit unwinding of the strap when pulling tension is applied by the cover during unloading operation of the reciprocating slat-type conveyor of the container.

Owner:SIMRIN KIRK A

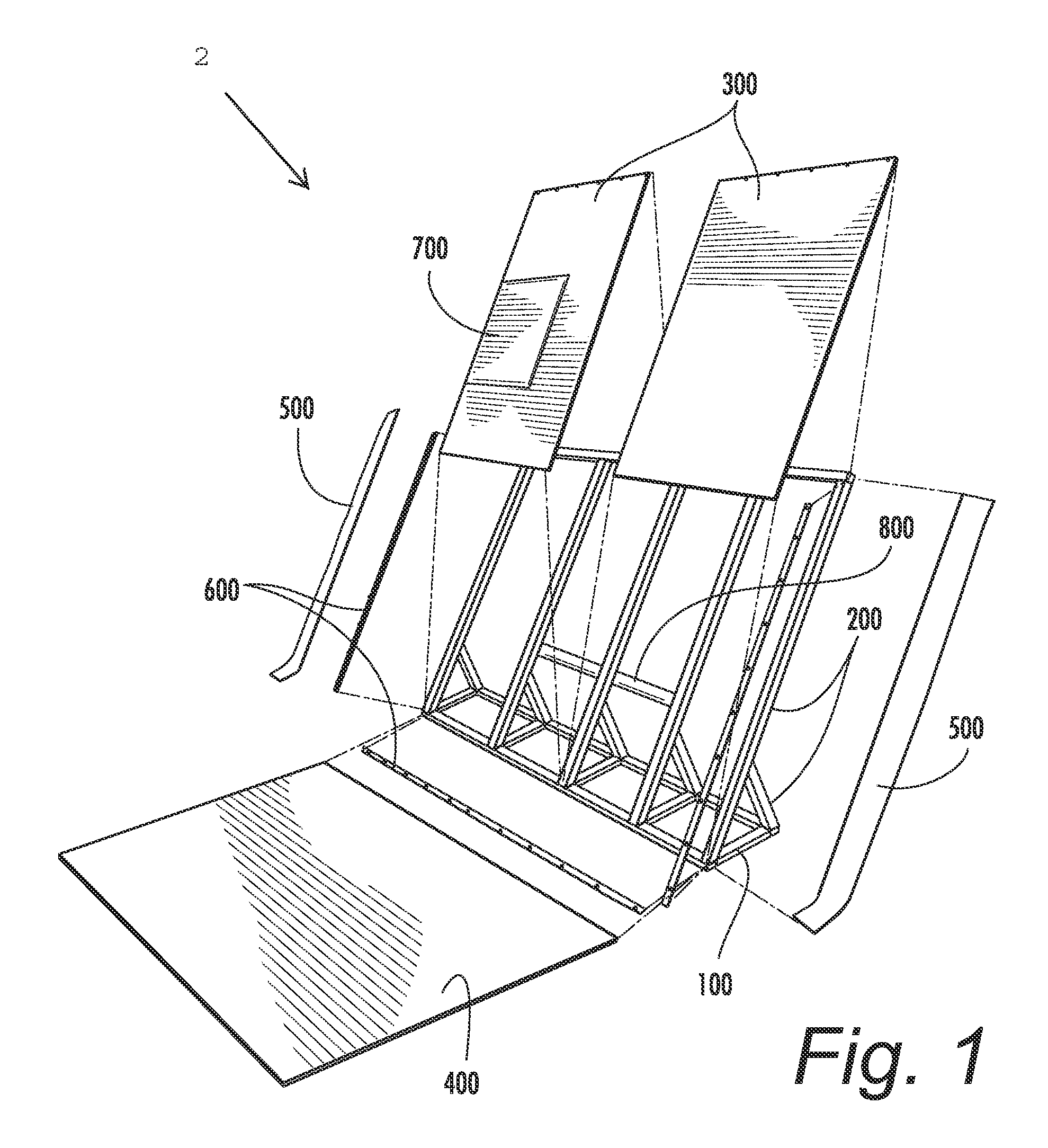

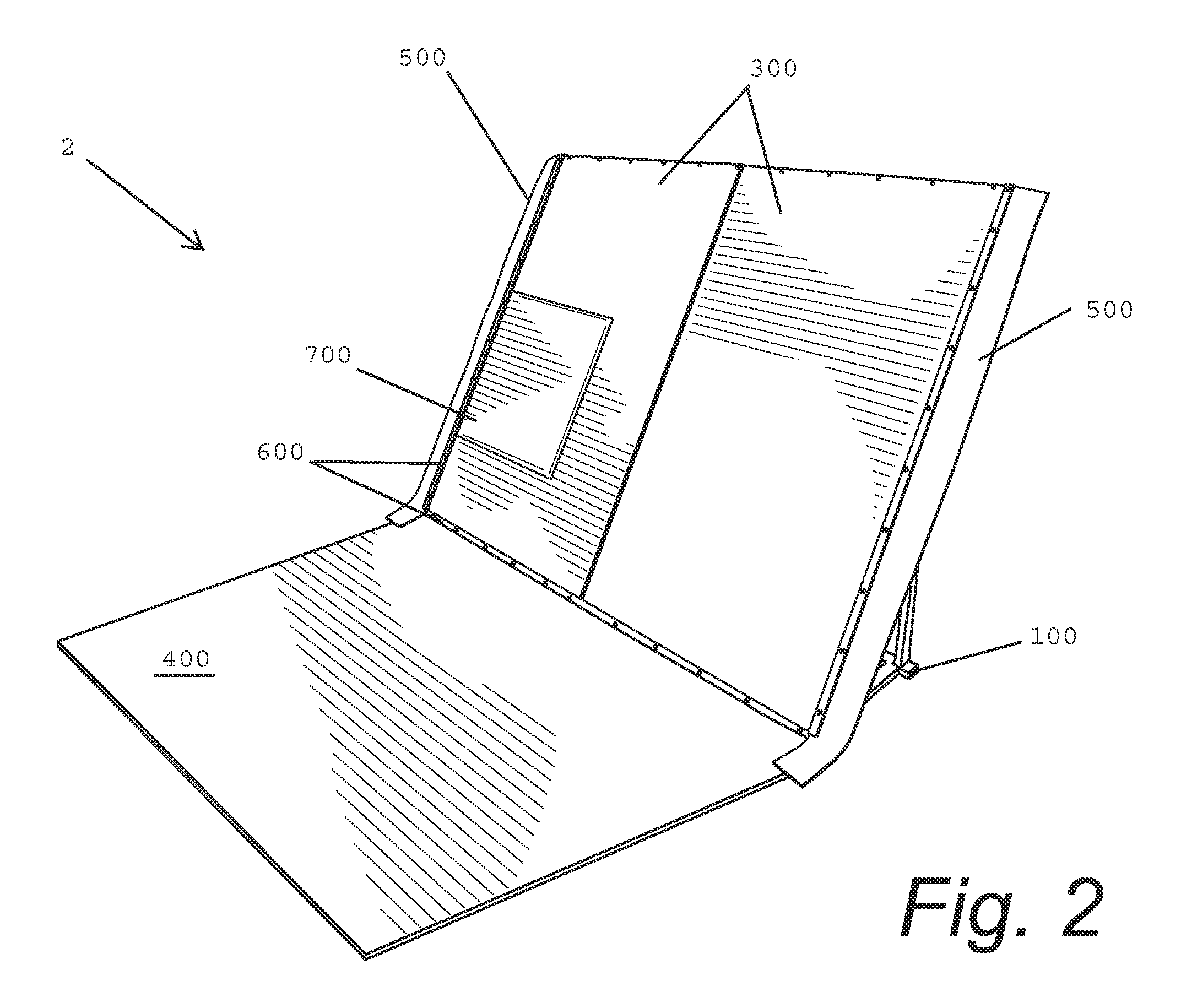

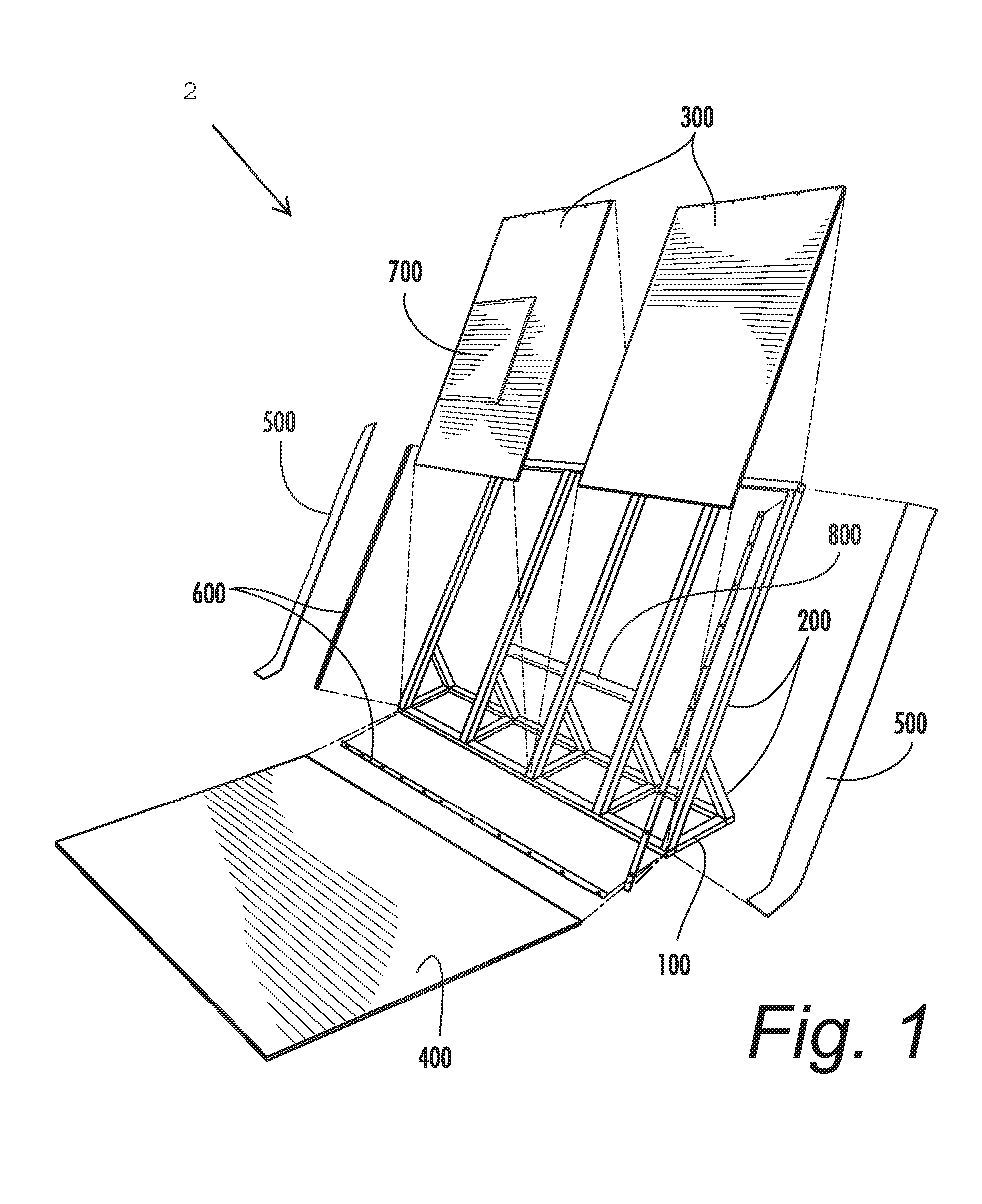

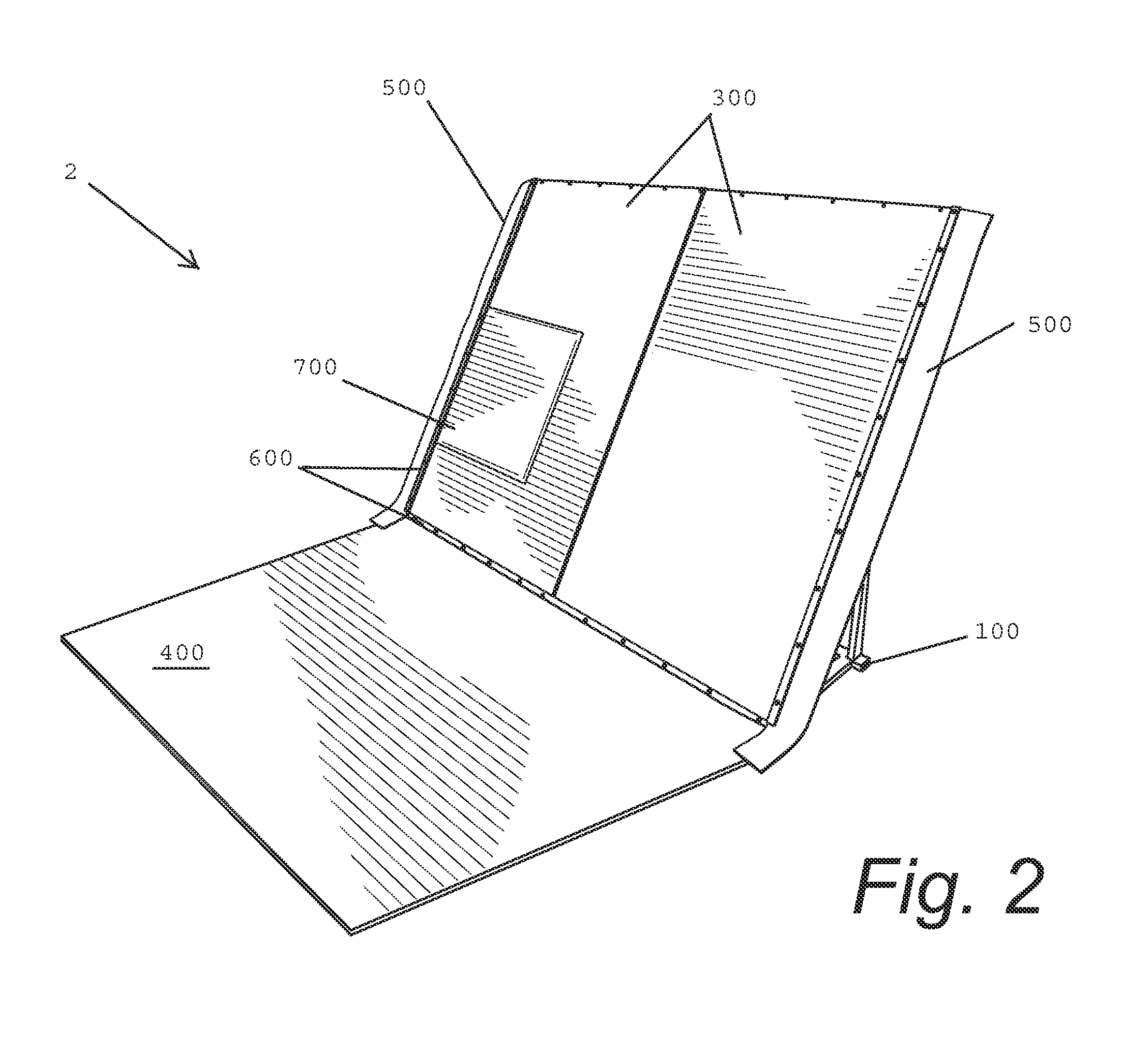

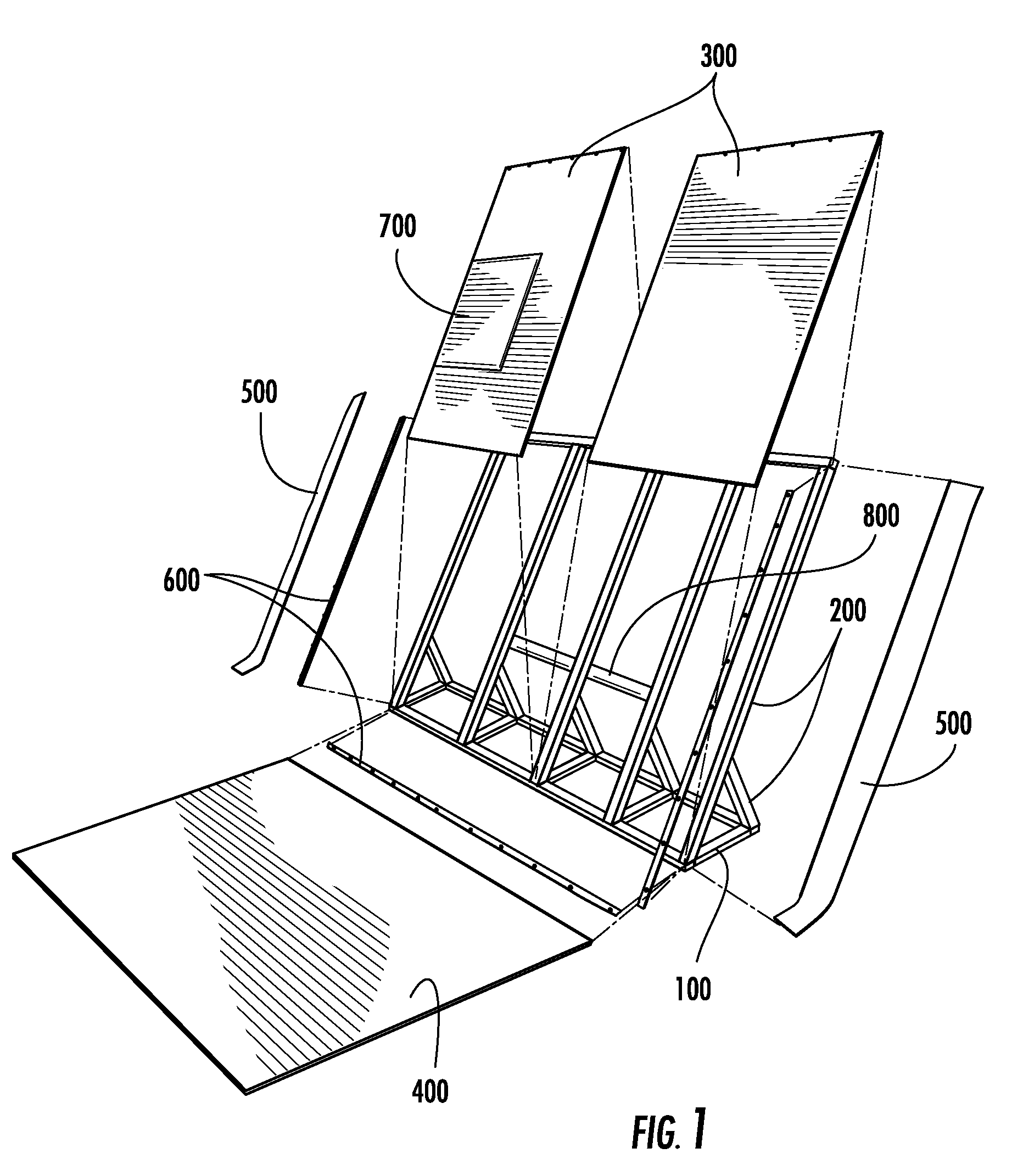

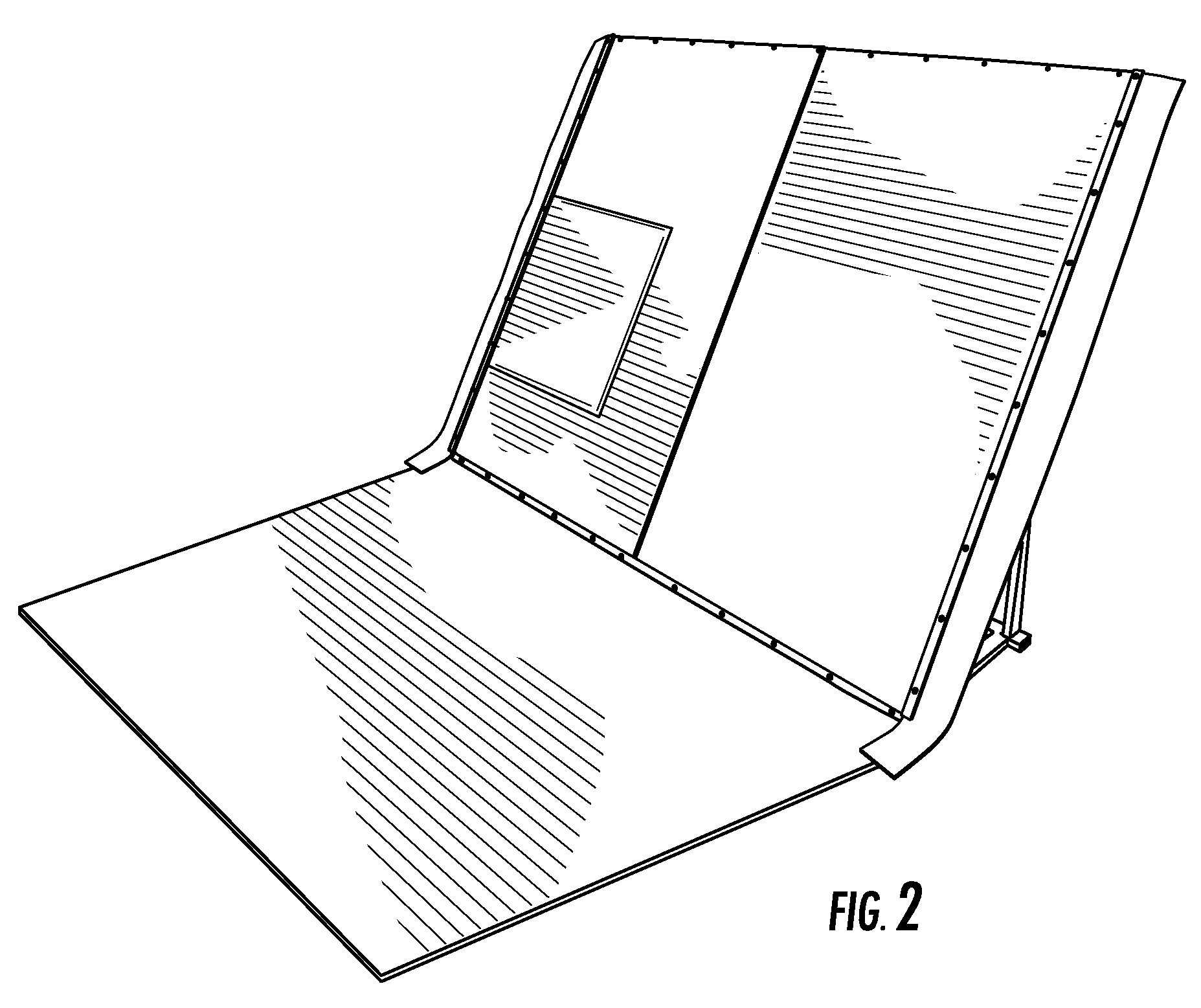

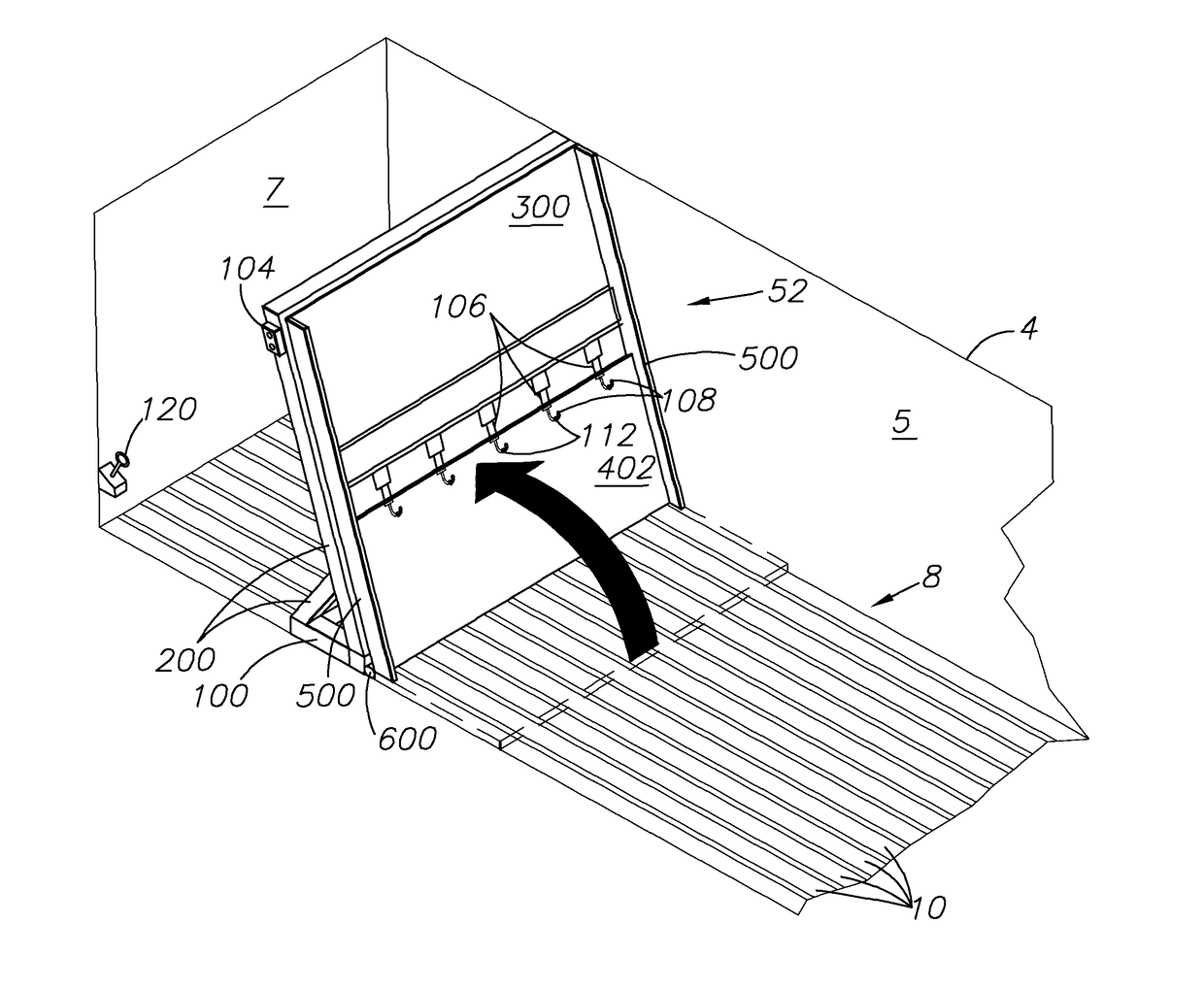

Moving headboard trailer ejector and floor cleaning

The present invention relates to a detachably attachable moving headboard trailer ejector and floor cleaning apparatus for use with a self-unloading trailer having a front end, a rear end, side walls, and either a reciprocating slat conveyor floor or a conveyor belt floor. The invention comprises, in one embodiment, a base, a panel sweeper, one or more panel sweeper support members, a means for traversing the panel sweeper, a tether bar, side flanges, and a base flange. In use, the invention is placed in the front end of a self-unloading trailer and the trailer is loaded with material; when material is ejected from the trailer, the invention transverses or “travels” along the top of the moving floor and pushes the material out of the trailer's back end. The rubber flanges ensure a snug fit within the trailer and keep post ejection residual material at a minimum.

Owner:BUTTERFIELD LARRY D

Moving headboard trailer ejector and floor cleaning apparatus

The present invention relates to a detachably attachable moving headboard trailer ejector and floor cleaning apparatus for use with a self-unloading trailer having a front end, a rear end, side walls, and either a reciprocating slat conveyor floor or a conveyor belt floor. The invention comprises, in one embodiment, a base, a panel sweeper, one or more panel sweeper support members, a means for traversing the panel sweeper, a tether bar, side flanges, and a base flange. In use, the invention is placed in the front end of a self-unloading trailer and the trailer is loaded with material; when material is ejected from the trailer, the invention transverses or “travels” along the top of the moving floor and pushes the material out of the trailer's back end. The rubber flanges ensure a snug fit within the trailer and keep post ejection residual material at a minimum.

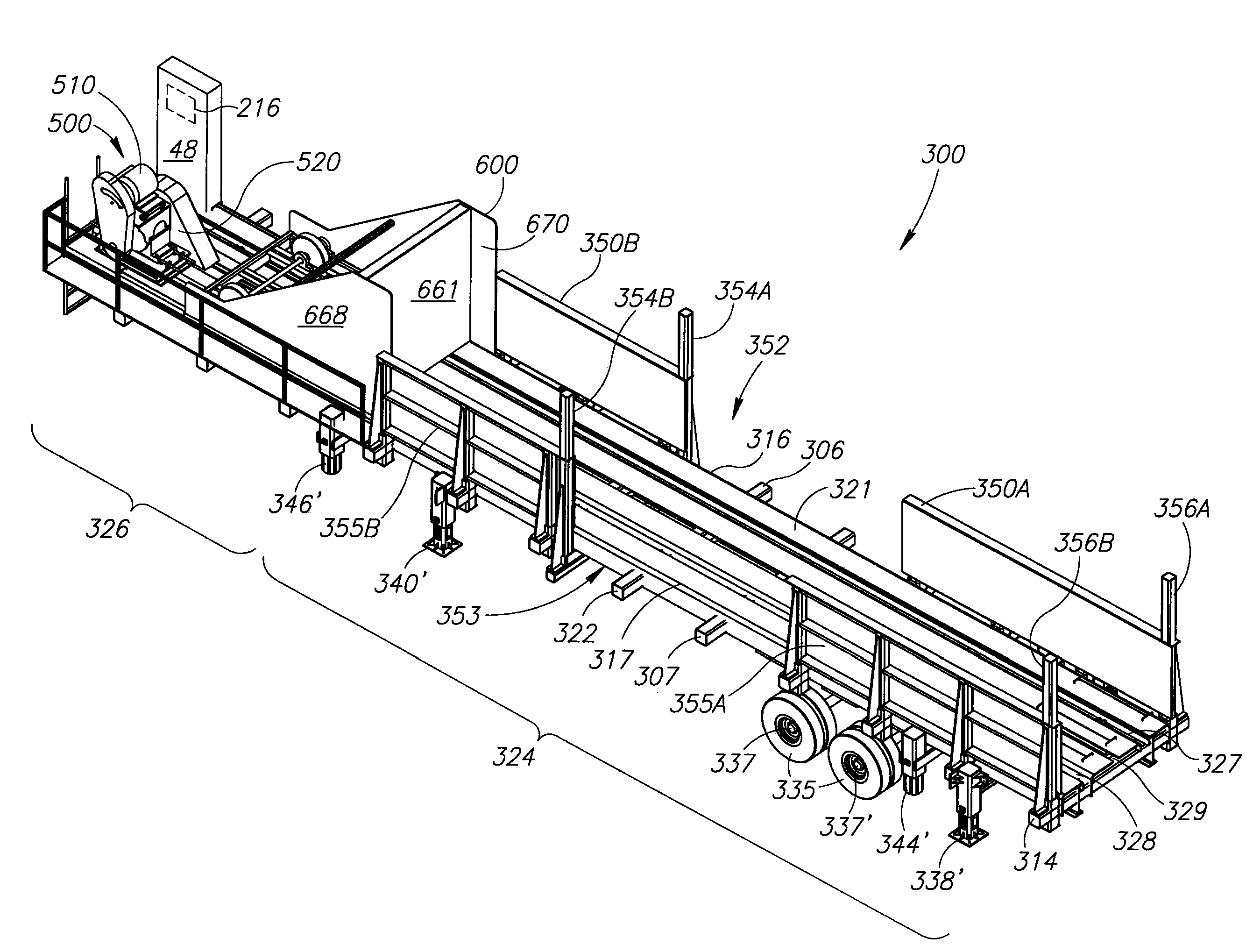

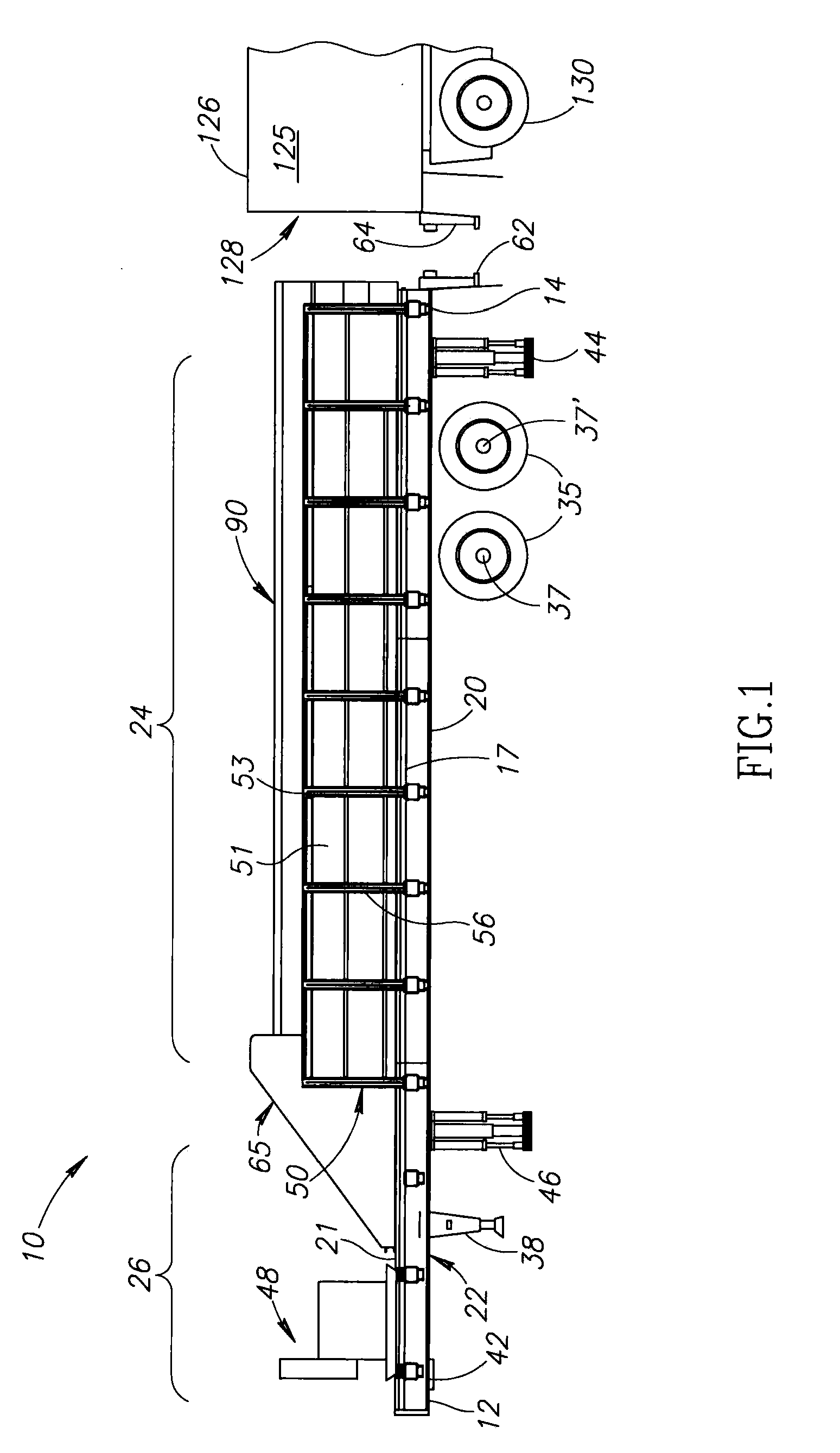

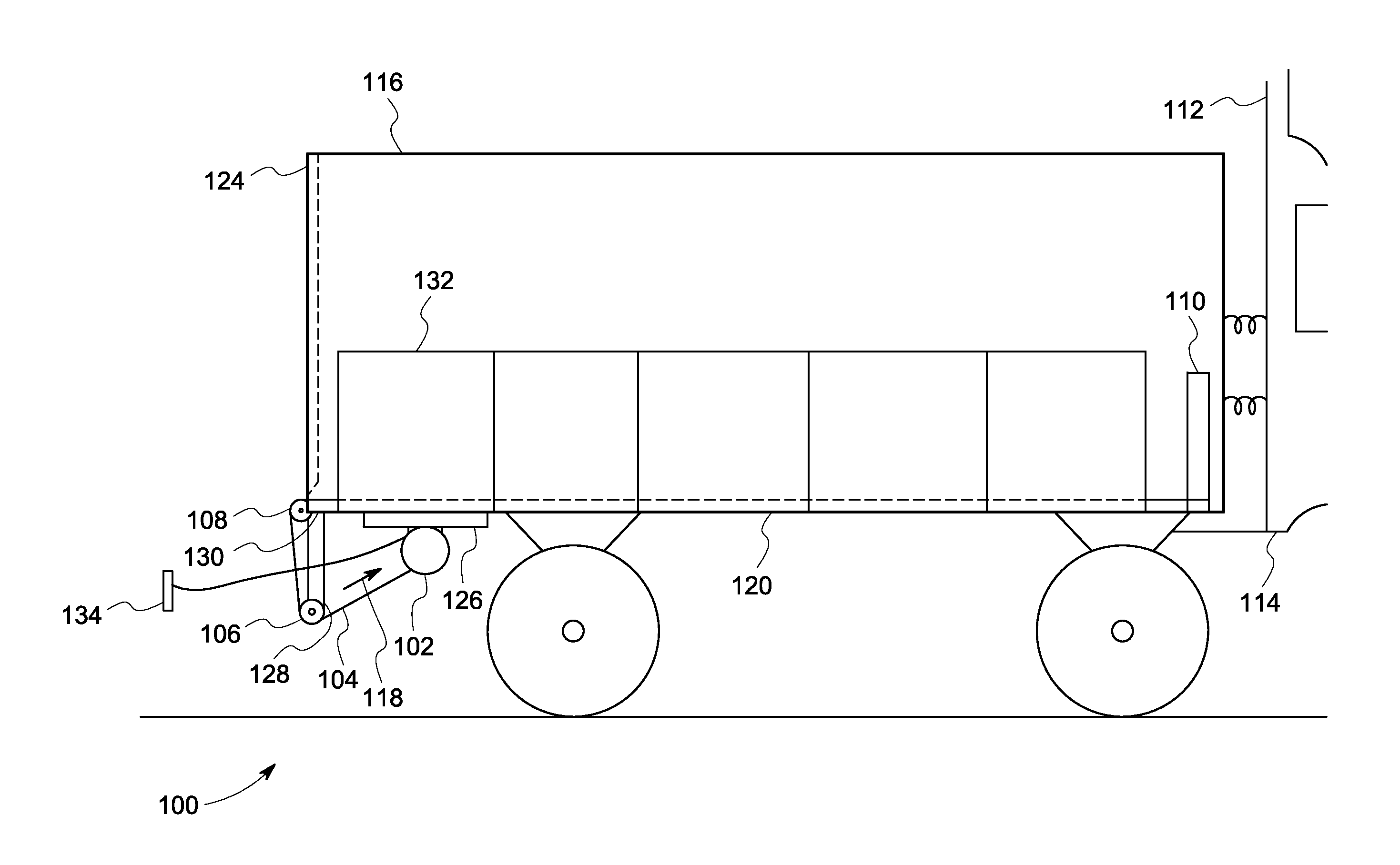

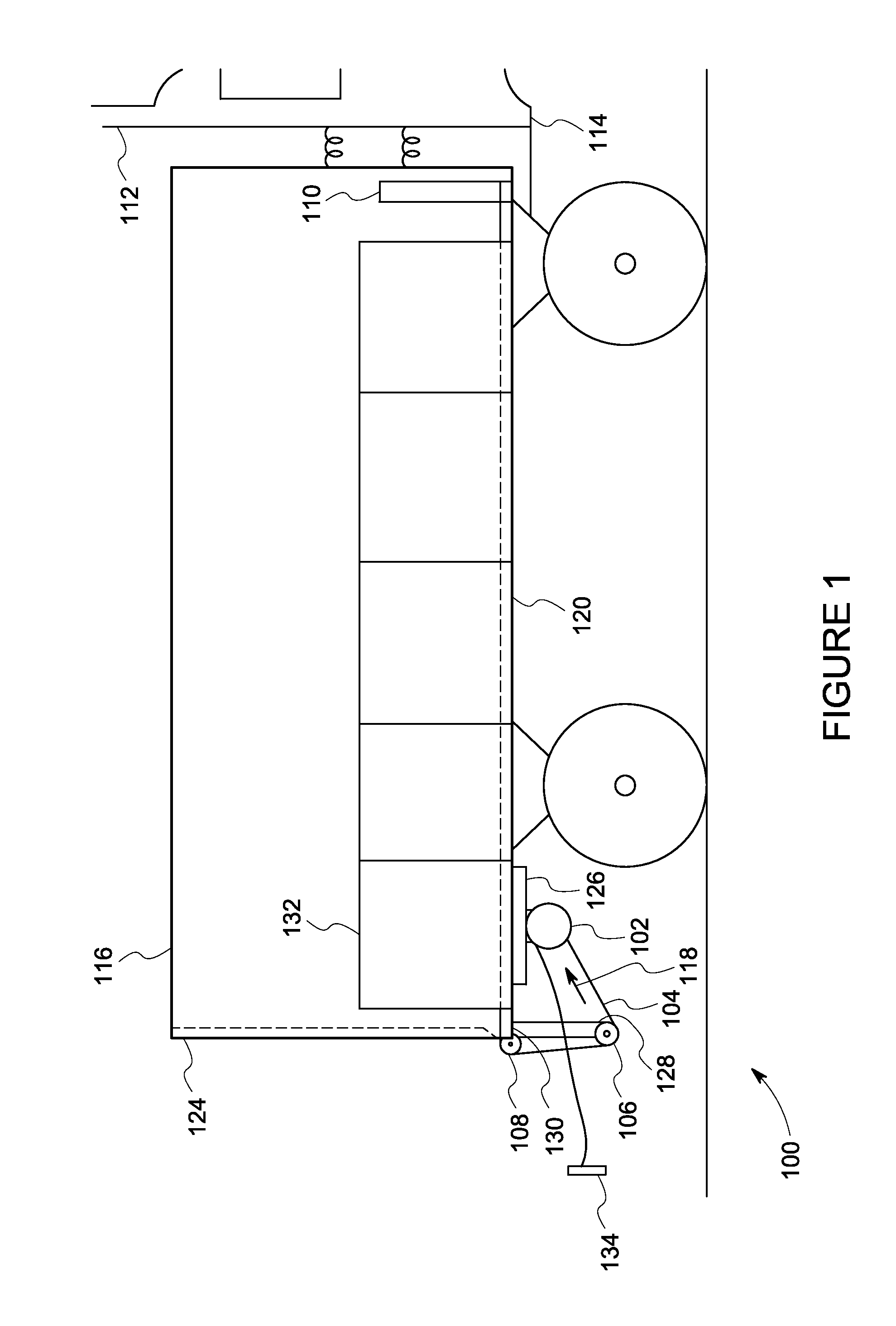

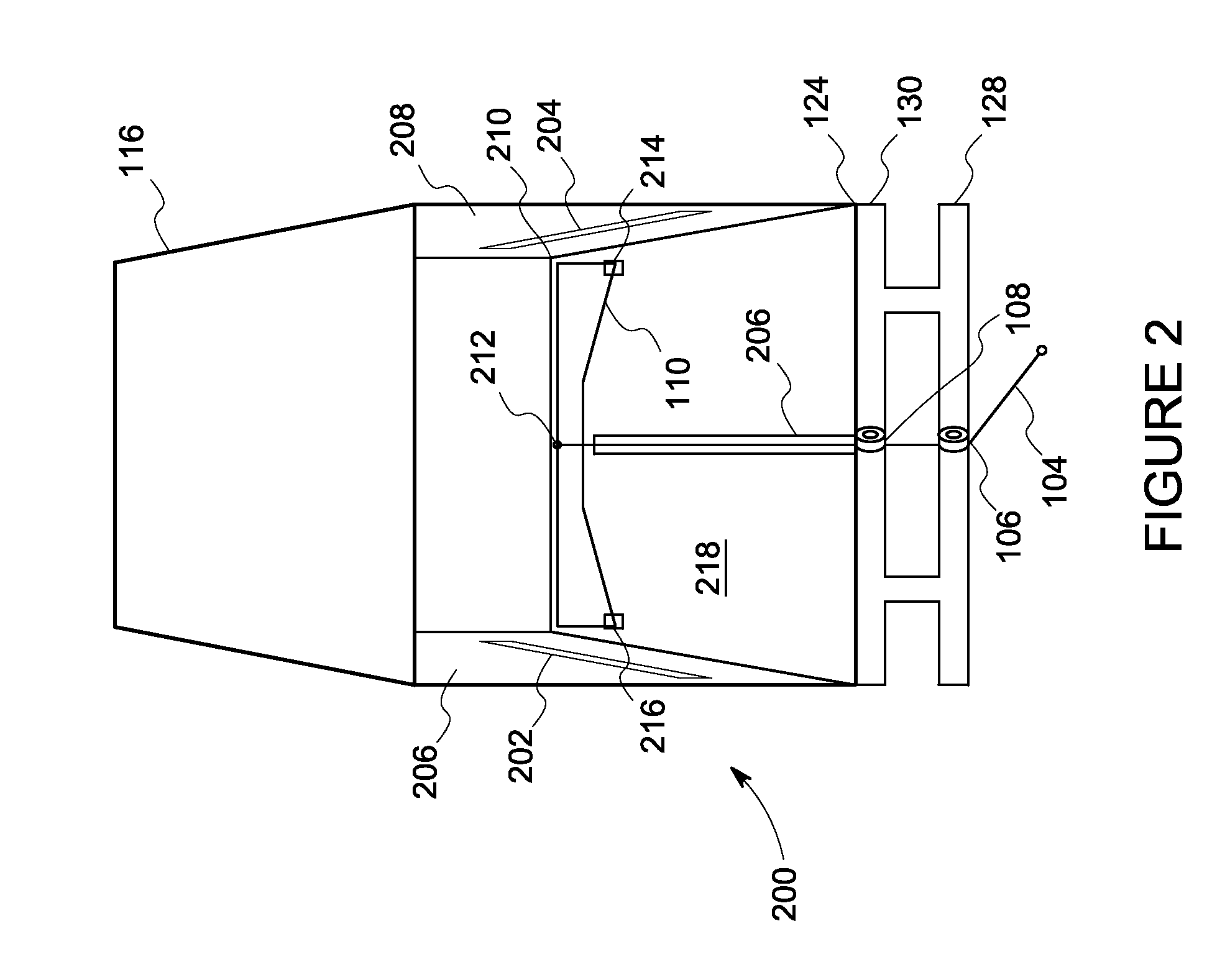

Cargo loader

ActiveUS8257007B2Vehicle to carry long loadsRefuse receptaclesMechanical engineeringMarine engineering

A cargo loader operable to load cargo into an opening of an enclosed trailer. The loader has an elongated bed with a front portion and a rear open portion. The opening of the trailer is positioned adjacent to the rear open portion of the bed. A pair of sidewalls flank the rear open portion and define an interior cargo receiving area. A carriage is moveably mounted to the bed and coupled to a drive assembly operable to move the carriage between the front portion and the rear open portion. The carriage is positioned on the front portion to allow cargo to be loaded into the cargo receiving area. The carriage is configured to push a ram longitudinally along the bed to push the cargo inside the cargo receiving area into the opening of the enclosed trailer.

Owner:CONTAINER STUFFERS

Cargo bay construction with a slideable wall and vehicle with such a cargo bay construction

ActiveUS20150329159A1Improve developmentMassVehicle with living accommodationItem transportation vehiclesEngineeringMechanical engineering

Owner:FLIEGL SR JOSEF

Moving headboard trailer ejector and floor cleaning apparatus

The present invention relates to a detachably attachable moving headboard trailer ejector and floor cleaning apparatus for use with a self-unloading trailer having a front end, a rear end, side walls, and either a reciprocating slat conveyor floor or a conveyor belt floor. The invention comprises, in one embodiment, a base, a panel sweeper, one or more panel sweeper support members, a means for traversing the panel sweeper, a tether bar, side flanges, and a base flange. In use, the invention is placed in the front end of a self-unloading trailer and the trailer is loaded with material; when material is ejected from the trailer, the invention “rides” along the moving floor and pushes the material out of the trailer's back end. The rubber flanges ensure a snug fit within the trailer and keep post ejection residual material at a minimum.

Owner:BUTTERFIELD LARRY

Apparatus and Method for Transferring Freight

The present disclosure provides an apparatus to assist in unloading freight from a transport vessel using a movable winch drum positioned operably proximate an underside of the floor of the transport vessel, a least one roller connectable to a transom of the transport vessel, the at least one roller being dimensioned to receive a cable, the cable being connected to the winch drum at a first end, and a shaped bulkhead connected to the cable at a second, the bulkhead being positioned at a bow of the bed, behind the freight, wherein when the movable winch drum is actuated, the shaped bulkhead is configured to pull freight towards an aft of the bed for unloading. A method for the same is also provided.

Owner:BRAUN GREGORY LEE +1

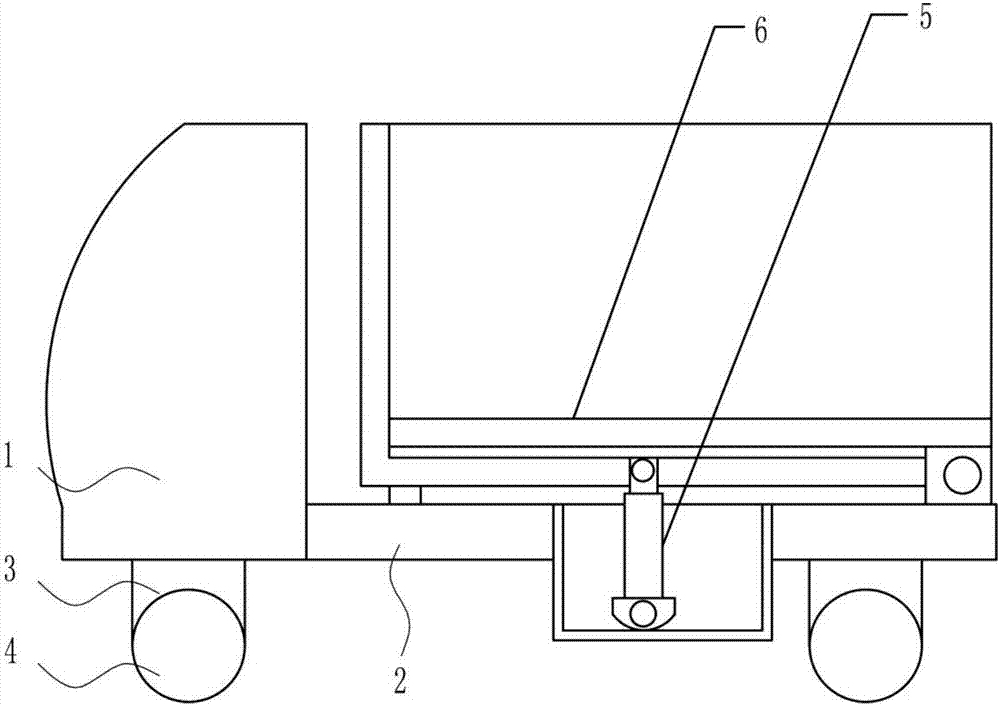

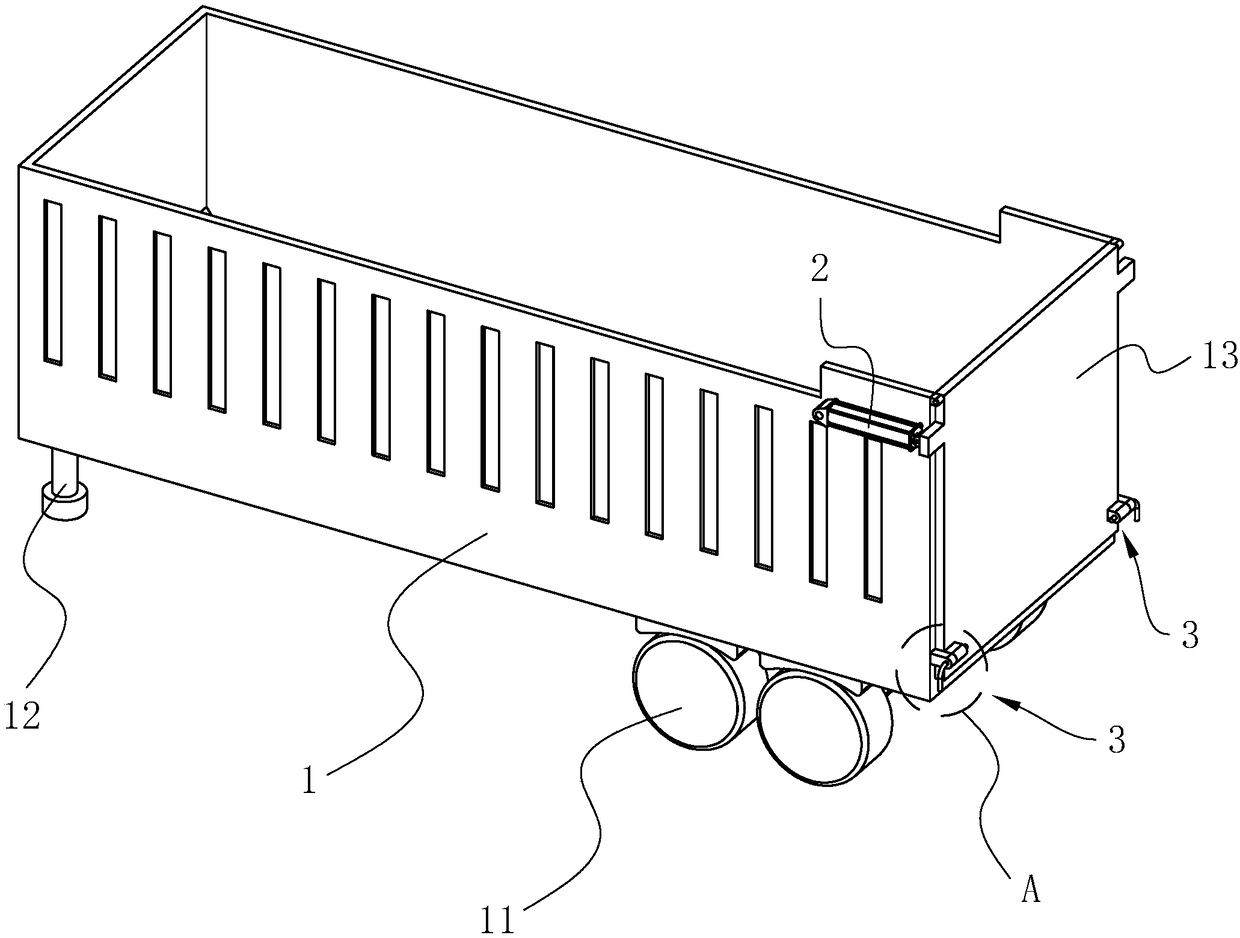

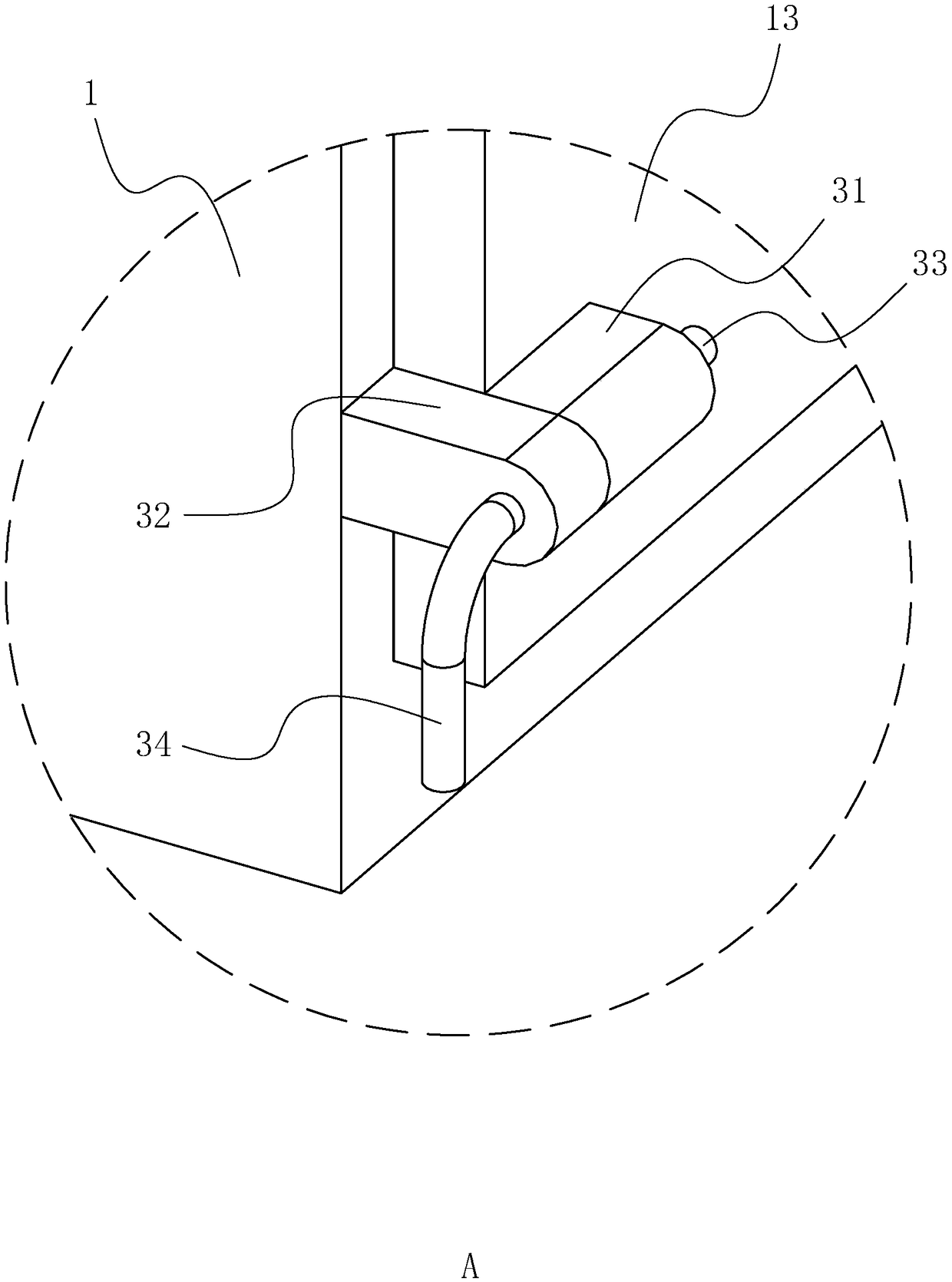

Unloading assistance device for dumper

ActiveCN107499215AFast fallImprove work efficiencyVehicle cleaningVehicle with pusher plateWaste managementMultiple function

Owner:安徽升力机械制造有限公司

Moving headboard trailer ejector and floor cleaning apparatus

The present invention relates to a detachably attachable moving headboard trailer ejector and floor cleaning apparatus for use with a self-unloading trailer having a front end, a rear end, side walls, and either a reciprocating slat conveyor floor or a conveyor belt floor. The invention comprises, in one embodiment, a base, a panel sweeper, one or more panel sweeper support members, a means for traversing the panel sweeper, a tether bar, side flanges, and a base flange. In use, the invention is placed in the front end of a self-unloading trailer and the trailer is loaded with material; when material is ejected from the trailer, the invention transverses or “travels” along the top of the moving floor and pushes the material out of the trailer's back end. The rubber flanges ensure a snug fit within the trailer and keep post ejection residual material at a minimum.

Owner:BUTTERFIELD LARRY D

Moving Cleanout For Reciprocating Conveyor System

ActiveUS20140294545A1Function increaseAvoid flaringVehicle with pusher plateLoading/unloadingEngineeringConveyor system

The invention disclosed here is a moving headboard for use in connection with a reciprocating floor slat system. It is particularly well-suited for use in connection with load-hauling trailers that have built-in reciprocating floor slat conveyors for unloading the trailer. Trailers of this kind are used in lieu of hydraulic lifts and involve inching the load off the trailer. The moving headboard sweeps the trailer floor clean during the unloading process.

Owner:KEITH MFG

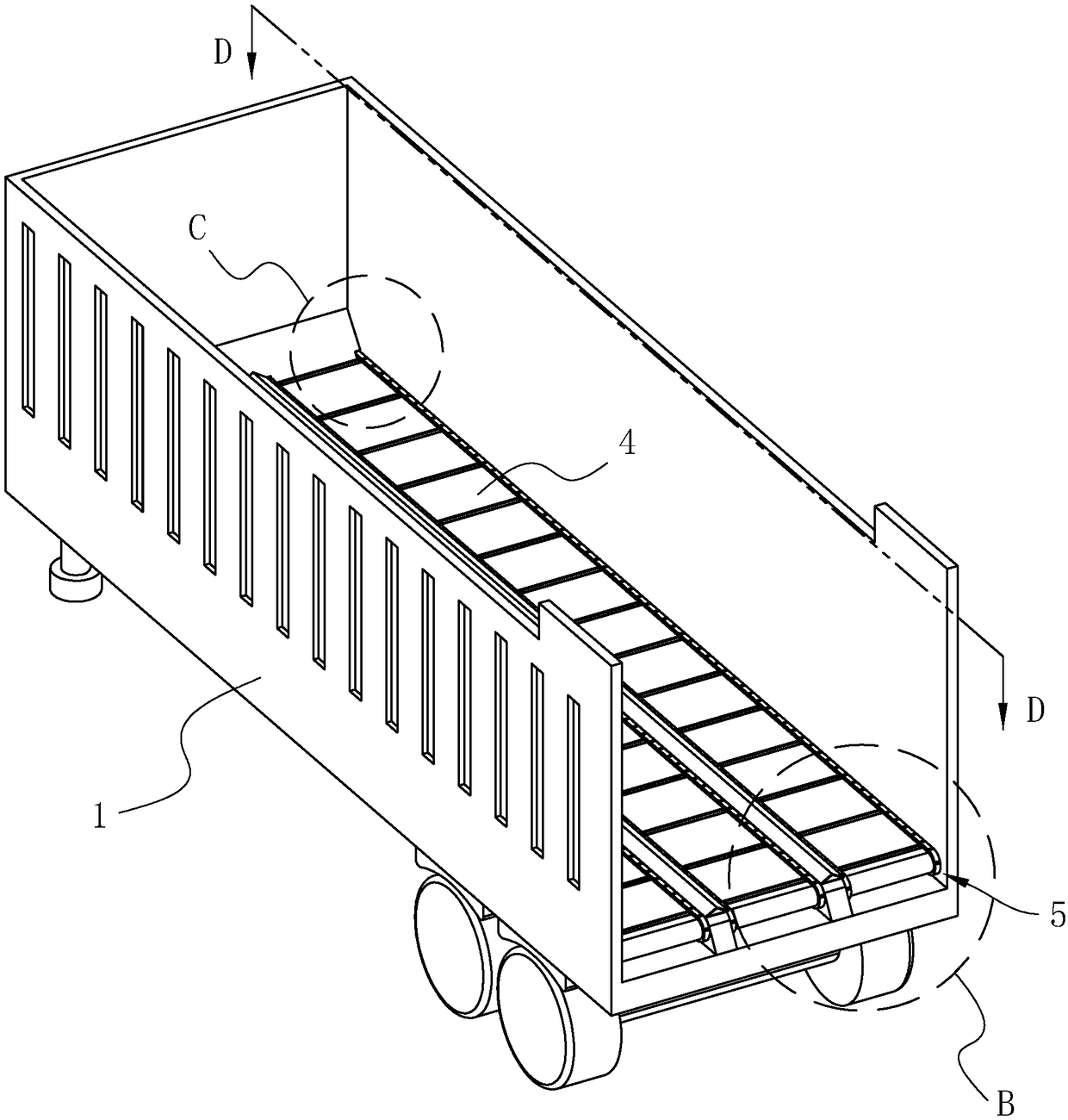

Logistics distribution special truck

ActiveCN109572518AEasy to operateEasy to useVehicles with cranesLoad securingLogistics managementTruck

The invention relates to a logistics distribution special truck which comprises a truck body. A container is arranged on the truck body. A carrying device is arranged at the bottom of the container and comprises multiple roll shafts and a belt installed on the multiple roll shafts. Pressing devices are arranged on the front inner wall and the rear inner wall of the container. Each pressing devicecomprises a pressing board, multiple swing rods, a long rod and an air cylinder. A push board device is arranged on the left inner wall of the container and comprises a push board, motors, gears and long racks. A gripping device is arranged at the top of the right end of the container and comprises a driven rod, a drive rod, a telescopic air cylinder, sliding blocks, a strip board and a lifting clamping jaw. The operation that a worker frequently enters and exits out of the container to stack or take cargo is omitted, the cargo in the truck can be automatically pushed out and mechanically grabbed, labor intensity is greatly reduced, work efficiency is improved, and logistics preparation duration is effectively shortened.

Owner:WUHU OCEANIC LOGISTIC CO LTD

Bin-separation-type truck carriage self-dumping structure

PendingCN110539680AGuaranteed large spaceAvoid position shiftVehicle with pusher plateTransportation itemsInterior spaceEngineering

The invention relates to a bin-separation-type truck carriage self-dumping structure. The bin-separation-type truck carriage self-dumping structure comprises bending pushing plate mechanisms and sealing soft belts; the bending pushing plate mechanisms are symmetrically arranged in the cavity of a carriage; each symmetrical side comprises a bottom pushing plate and a side pushing plate which are hinged to each other; during contraction, the side pushing plates cling to each other, and the bottom pushing plates cling to the bottom surface of the carriage to form a large space; during extension,the bottom pushing plates extend out of the carriage from the side directions so that materials are prevented from being accumulated at wheels; and the sealing soft belts are arranged at clearances atthe hinge parts of the bending pushing plate mechanisms, so that the materials are prevented from being leaked. The bin-separation-type truck carriage self-dumping structure has the beneficial effects that the inner space is large; dumped materials are not accumulated at the wheels; fine materials are not leaked; motion is simple; and safety is high.

Owner:成都创奇汽车制造有限公司

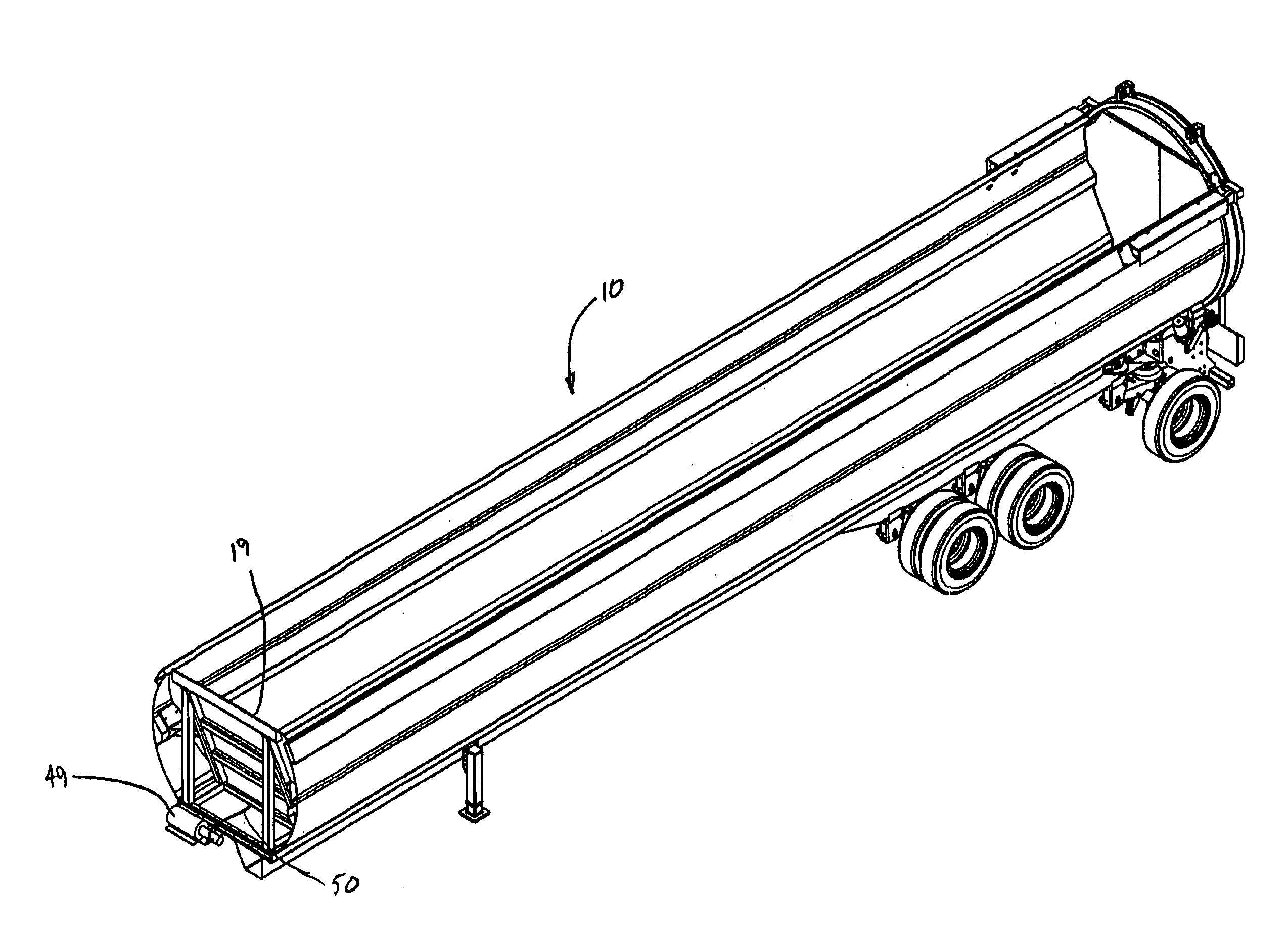

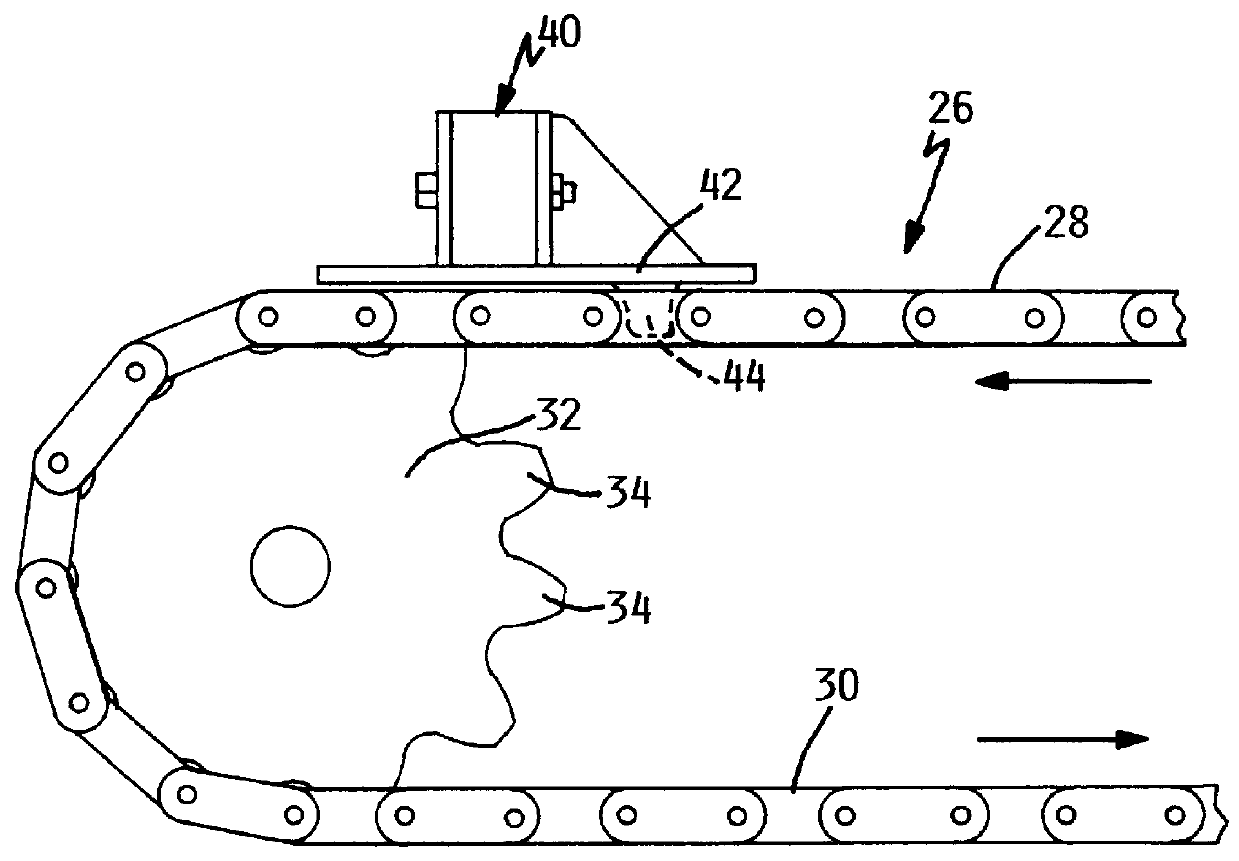

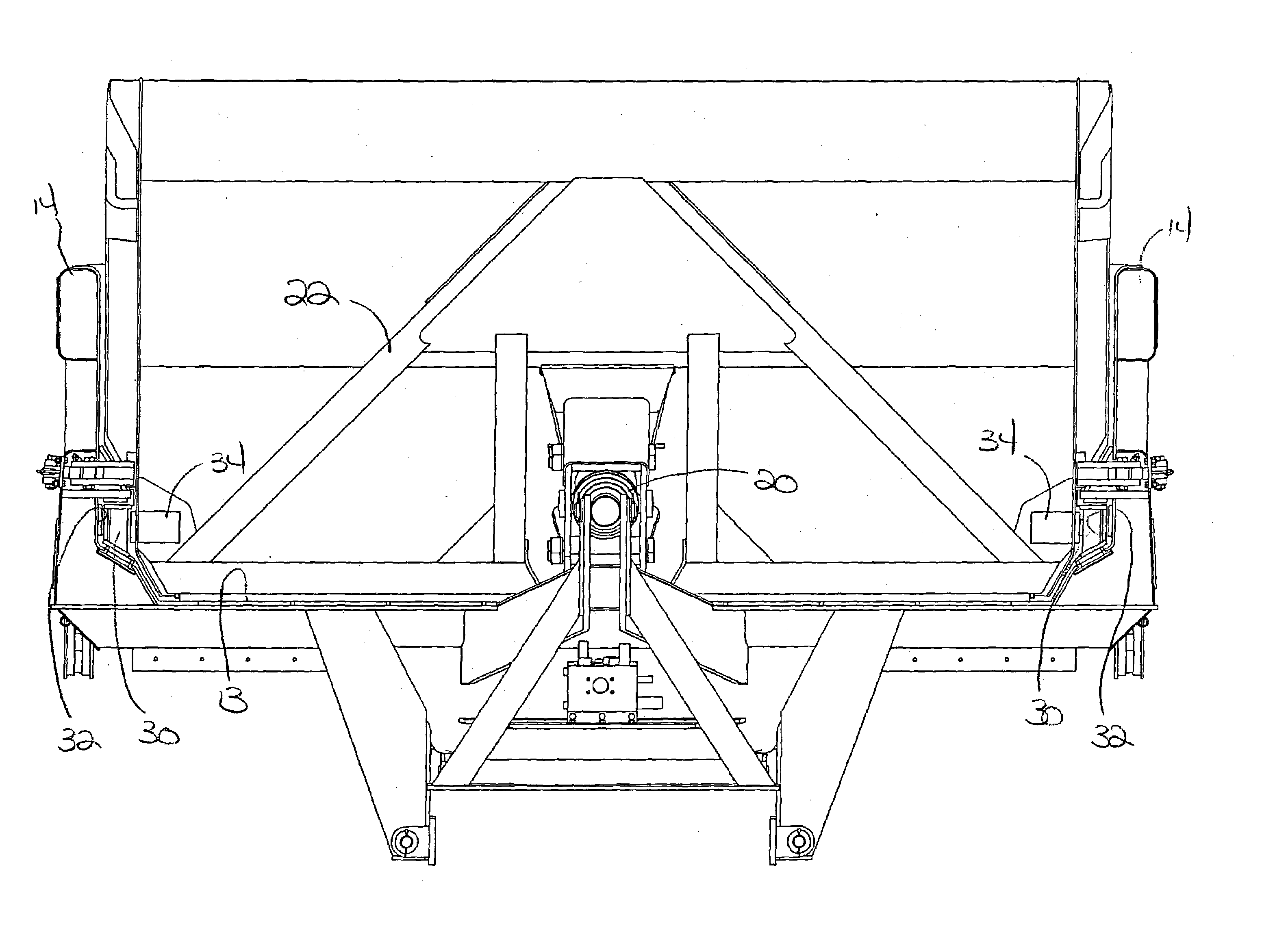

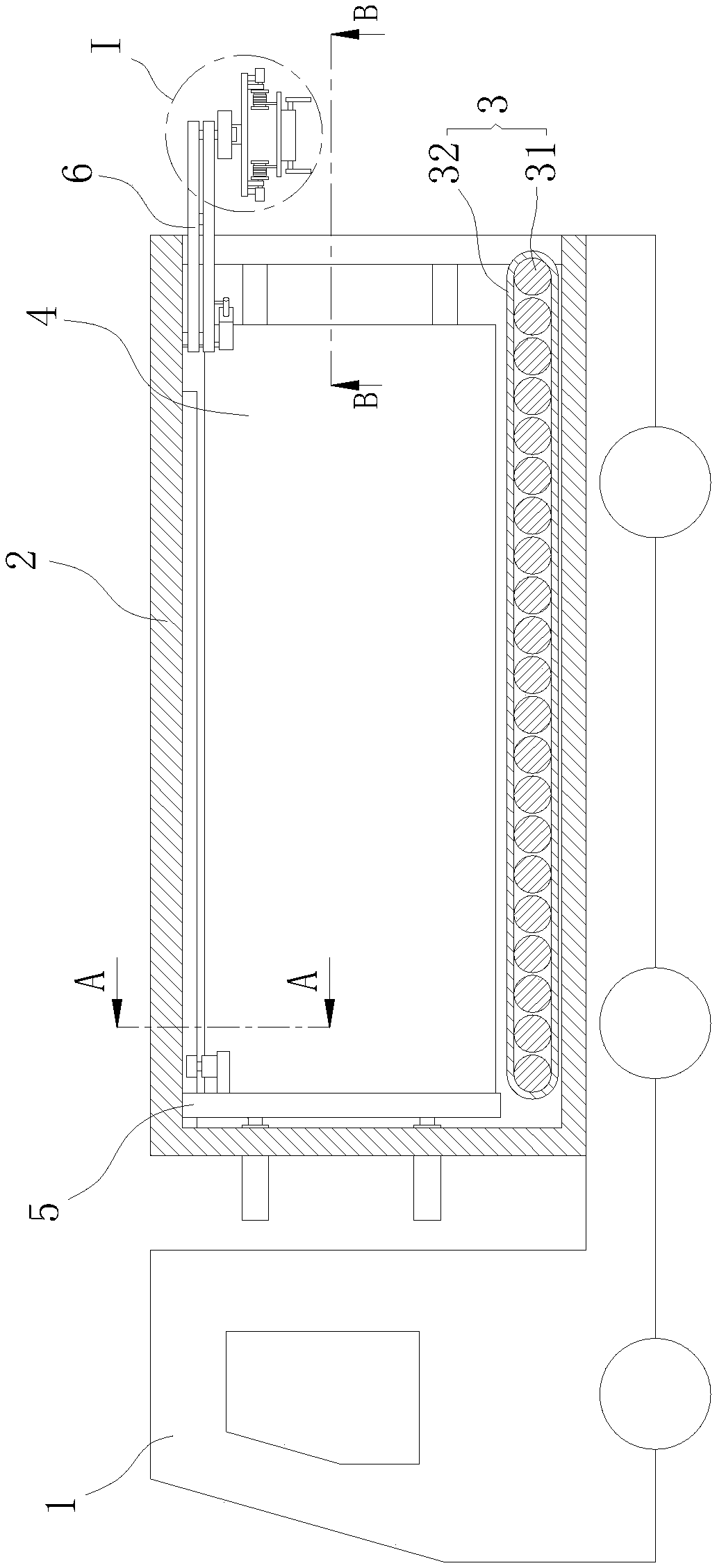

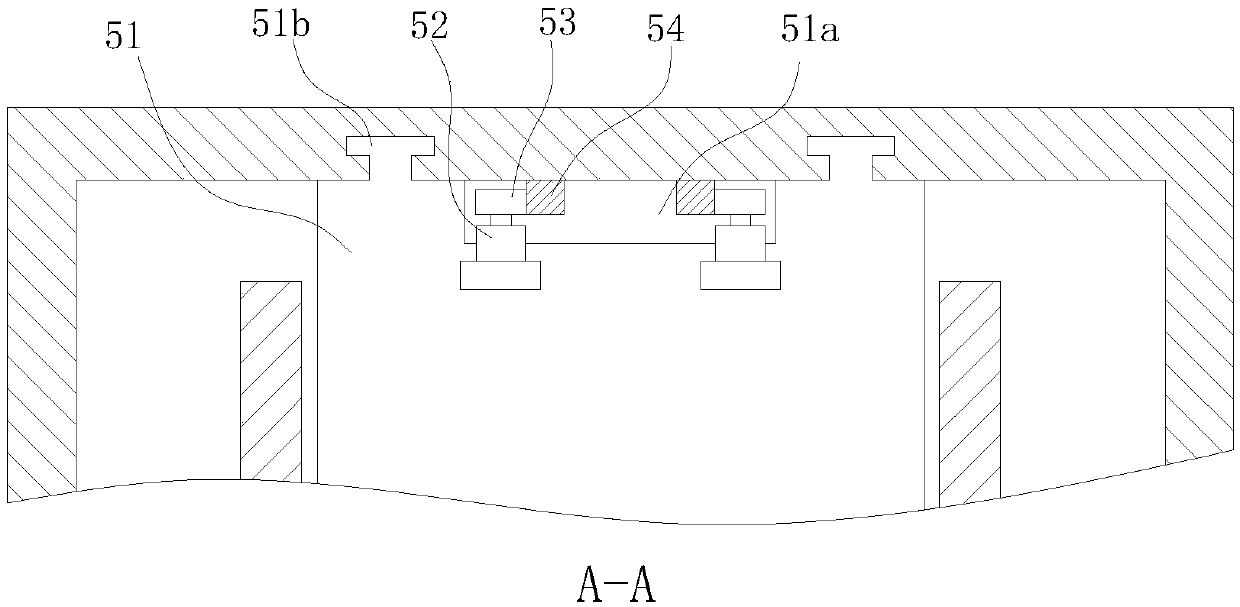

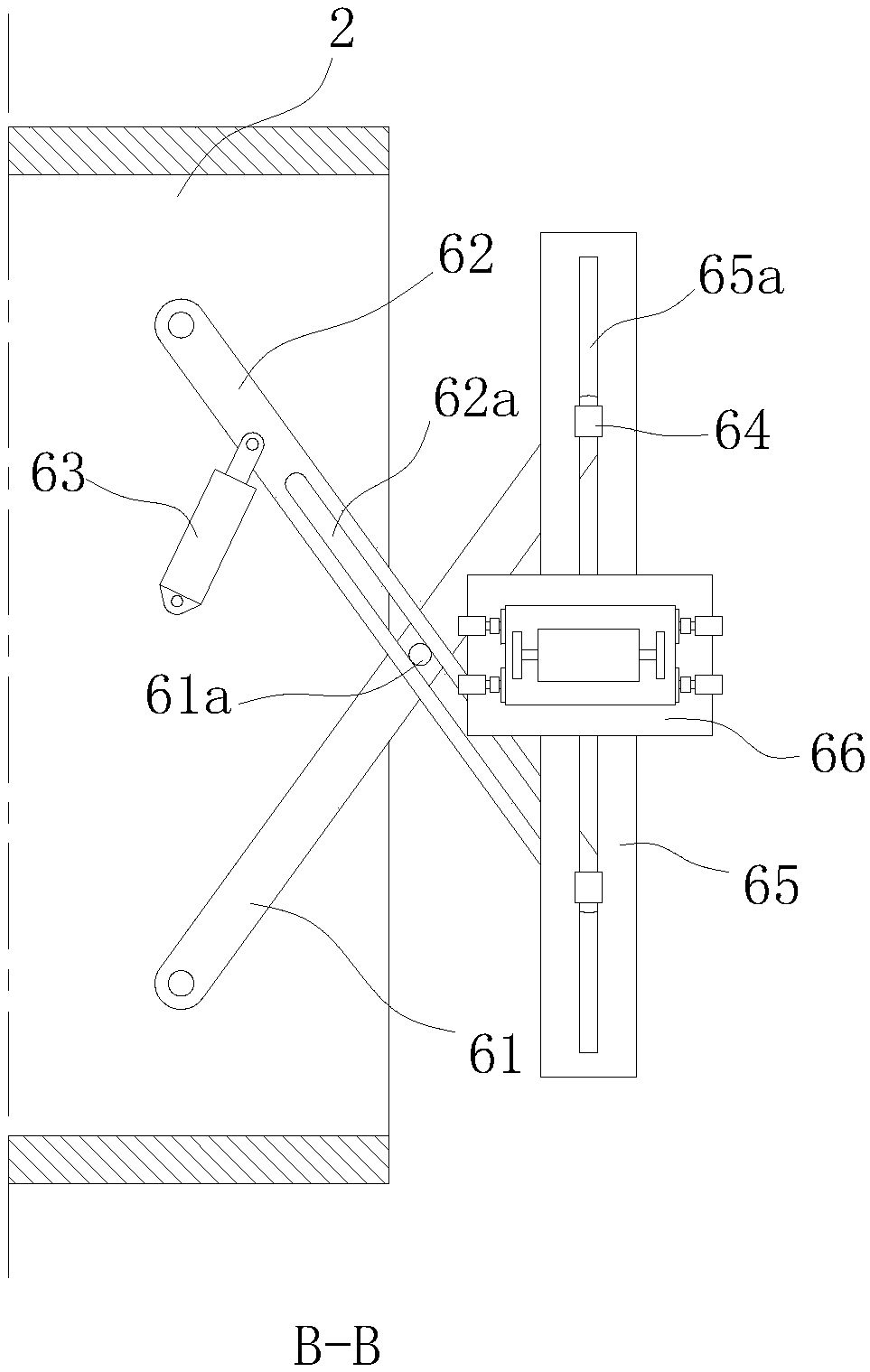

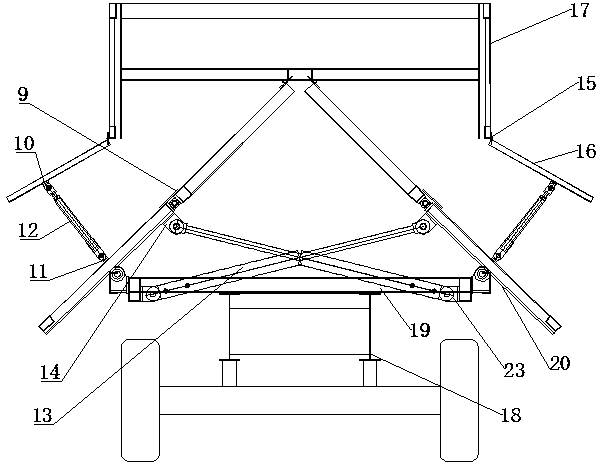

Flat push type self-dumping semi-trailer

ActiveCN109177847AImprove practicalityRealize automatic unloadingVehicle with pusher plateTransportation itemsRolloverSemi-trailer

The invention relates to a flat push type self-dumping semi-trailer, belonging to the technical field of semi-trailers, solving the technical problem that in the prior art the dump semi-trailer is limited by high-altitude space constraints when the dump semi-trailer overturns or rollovers for unloading goods. The flat push type self-dumping semi-trailer includes a carriage, wherein an opening is arranged at the tail end of the carriage; a baffle is arranged at the opening of the carriage, a fixing plate is arranged in the carriage, a push mechanism is arranged on the fixing plate, a drive mechanism is arranged on the carriage, the pushing mechanism comprises a driving roller and a driven roller penetrating the fixing plate, two driving gears fixed to the driving roller, two driven gears fixed to the driven roller, two transmission chains arranged between the driving gear and the driven gear, and a plurality of flat pushrods spaced apart between the two transmission chains, the transmission chains being sleeved on the outer peripheral surfaces of the driving gear and the driven gear. The horizontal push semi-trailer realizes automatic unloading of raw materials by driving the horizontal push rod through the transmission chain, and is not limited by the height space, thus improving its practicability.

Owner:石家庄金多利专用汽车有限公司

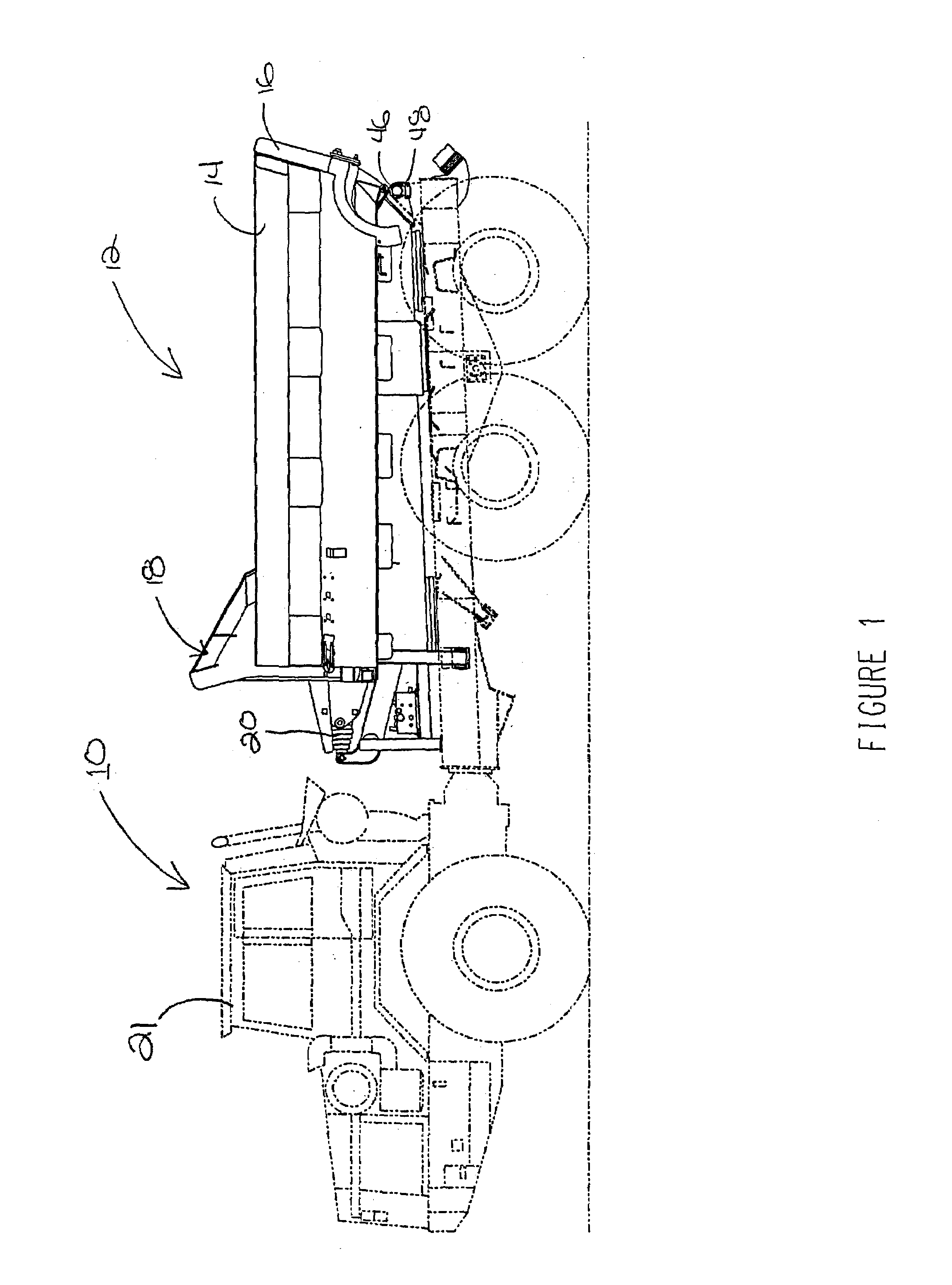

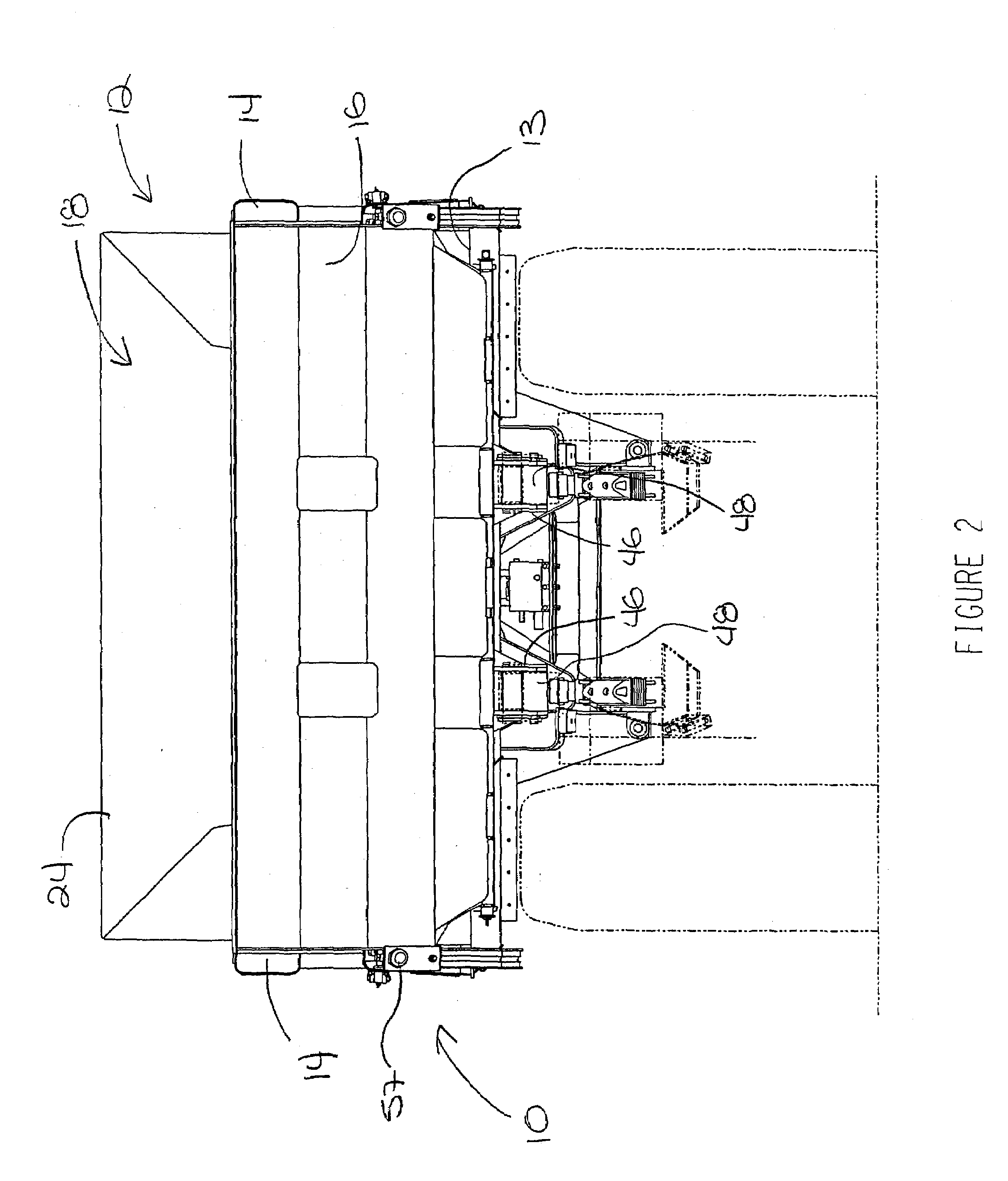

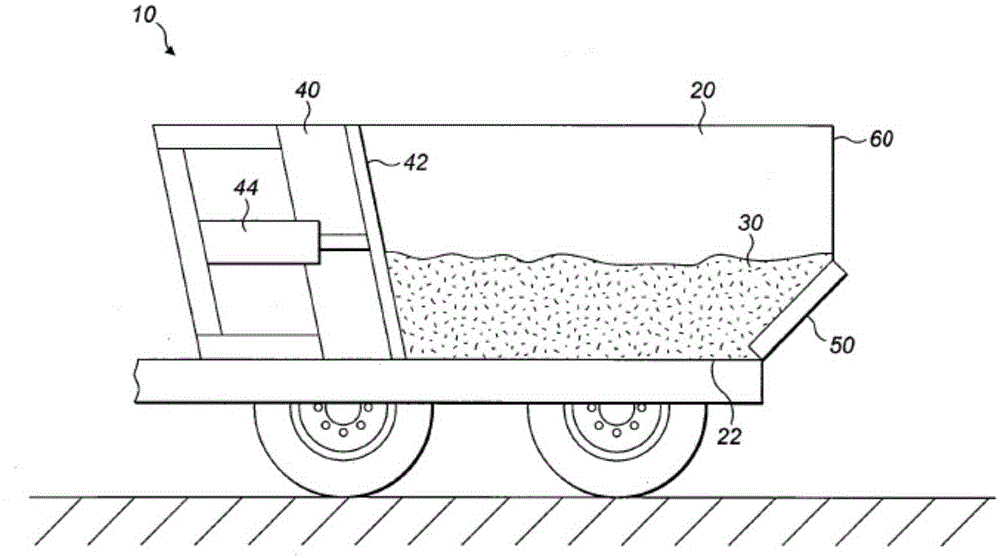

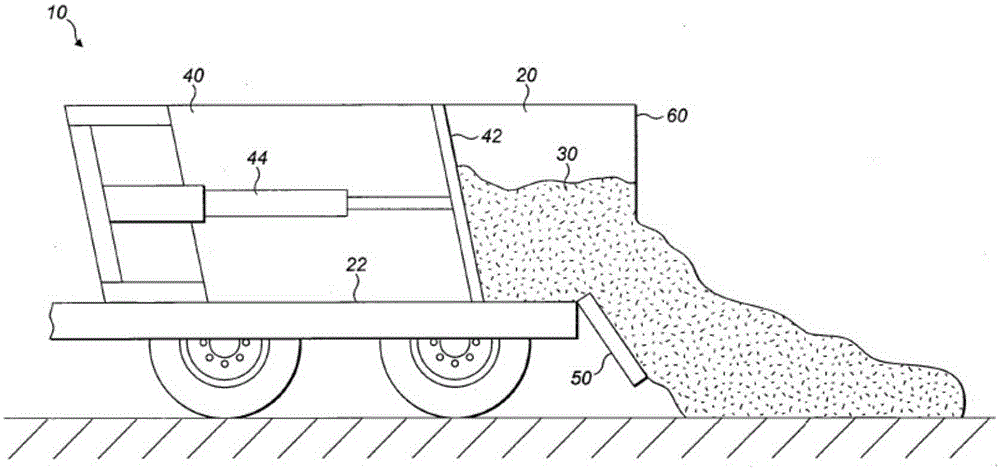

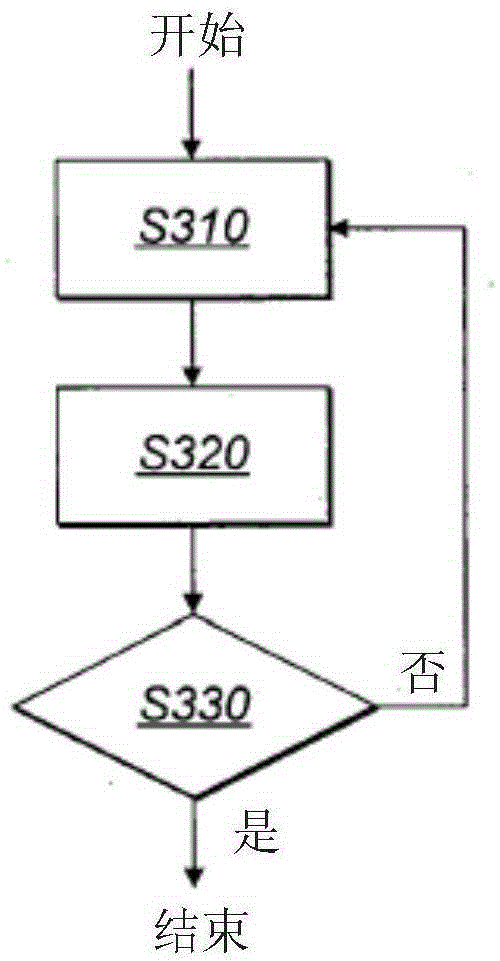

Method and apparatus for controlling a material ejector system

The present disclosure relates to the spreading of a material (30) by pushing the material (30) from the back of a vehicle (10) using a material ejector system (40) whilst the vehicle (10) is moving. The depth of the spread material and how evenly it is spread is dependent on a number of factors that can be difficult and complicated for an operator of the vehicle (10) to control. In the present disclosure the speed at which the material is ejected from the vehicle (10) is set on the basis of a measured speed of the vehicle (10).

Owner:CATEPILLAR SARL

Mining scoop material ejection retrieval system

A bucket and blade assembly has a bucket with opposing side walls, a bottom floor, and a back wall with a centrally located cylinder rod mount. Concentric cylinders ranging from smallest to largest form a telescoping hydraulic cylinder in which the smallest has a cylinder rod mount coupling disposed at one end for engaging the cylinder rod mount. The largest cylinder is engaged in a floating trunnion mount cylinder. The blade is slidably disposed within the bucket with a capped cylinder disposed thereon having an opening into the capped cylinder for accommodating the largest cylinder opposite the rod mount coupling.

Owner:SIMMONS JACK

Moving headboard trailer ejector and floor cleaning apparatus

The present invention relates to a detachably attachable moving headboard trailer ejector and floor cleaning apparatus for use with a self-unloading trailer having a front end, a rear end, side walls, and either a reciprocating slat conveyor floor or a conveyor belt floor. The invention comprises, in one embodiment, a base, a panel sweeper, one or more panel sweeper support members, a means for traversing the panel sweeper, a tether bar, side flanges, and a base flange. In use, the invention is placed in the front end of a self-unloading trailer and the trailer is loaded with material; when material is ejected from the trailer, the invention transverses or “travels” along the top of the moving floor and pushes the material out of the trailer's back end. The rubber flanges ensure a snug fit within the trailer and keep post ejection residual material at a minimum.

Owner:BUTTERFIELD LARRY D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com