Logistics distribution special truck

A technology for logistics distribution and trucks, which is applied to vehicles, motor vehicles, and transport objects used for freight transportation, and can solve the problems of prolonging logistics preparation time, unfavorable logistics transportation, and low work efficiency, and achieve shortening logistics preparation time and automation. High and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

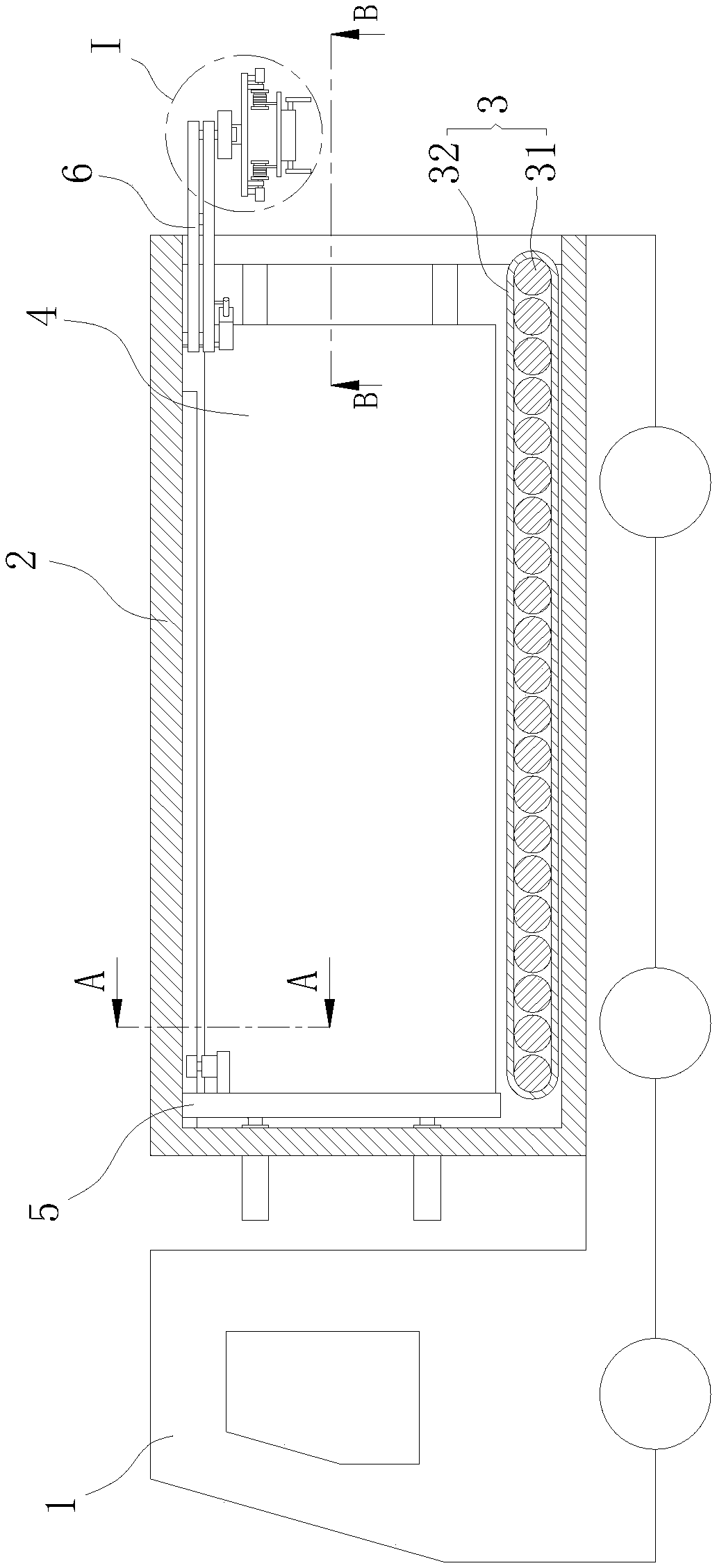

[0023] Such as Figure 1 to Figure 5 As shown, a special truck for logistics and distribution includes a body 1 on which a cargo box 2 is arranged, and a loading device 3 is arranged on the bottom of the cargo box 2, and the cargo device 3 includes a cargo box 2. A number of rollers 31 evenly arranged in the length direction and a belt 32 installed on the number of rollers 31. Through the densely distributed rollers 31, the belt 32 can achieve good support for the goods, and the goods can pass through the belt 32. Move counterclockwise on the roller shaft 31 to enter the cargo box 2 for easy loading;

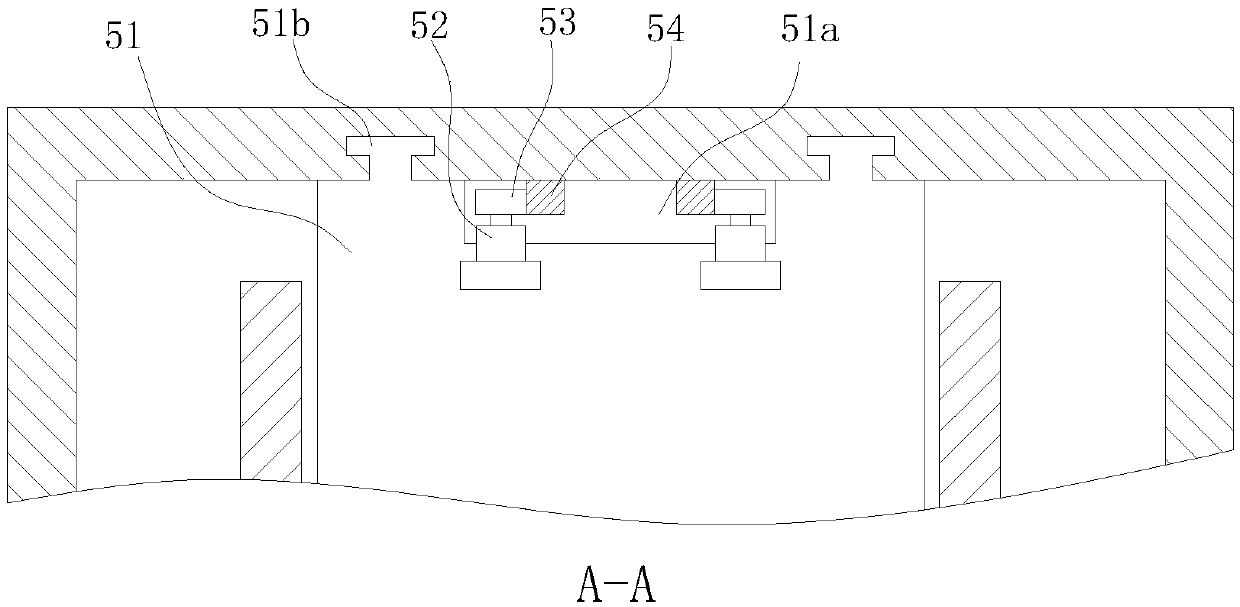

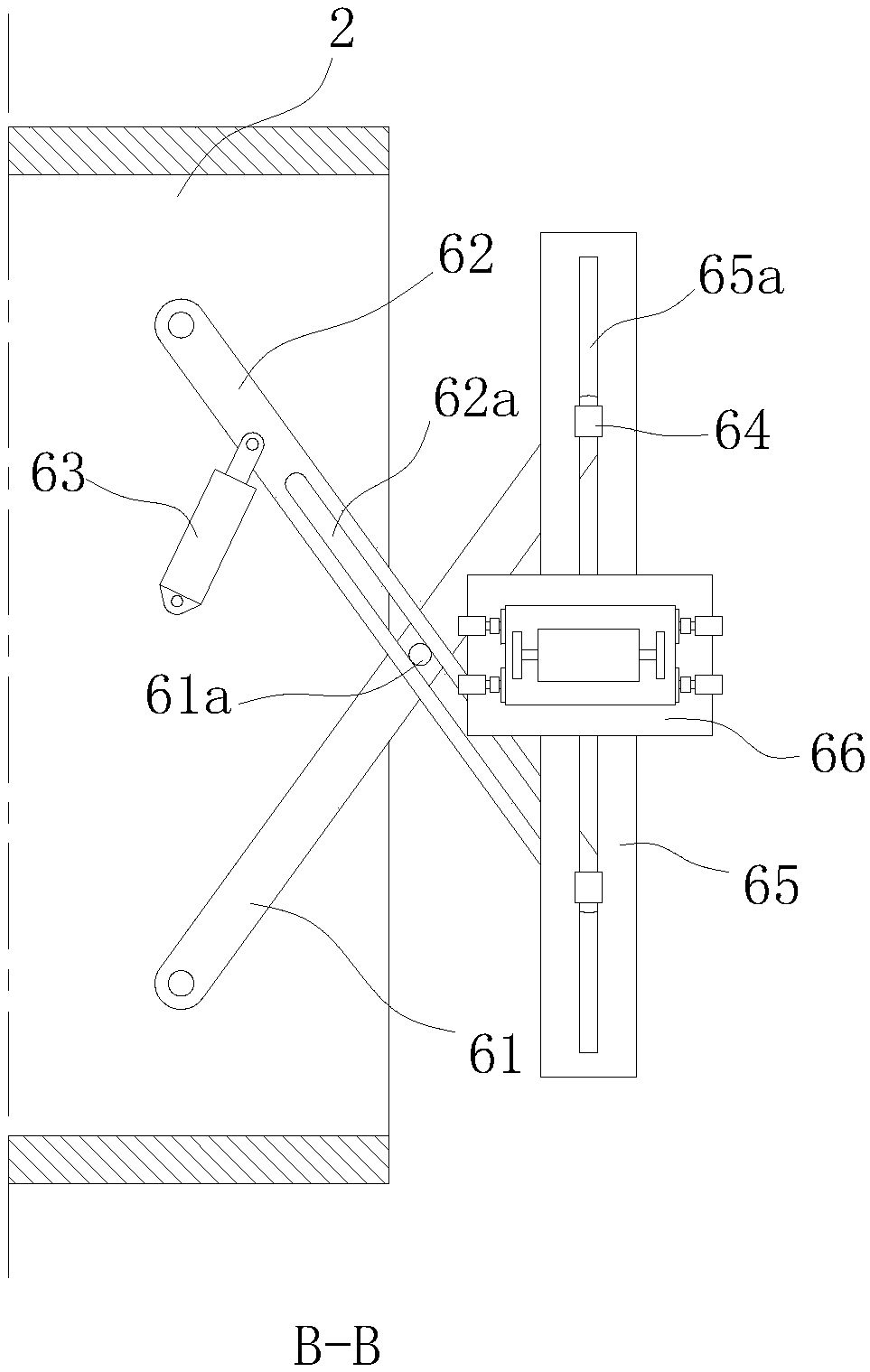

[0024] Both the front inner wall and the rear inner wall of the cargo box 2 are provided with a pressing device 4, the pressing device 4 includes a pressing plate 41, a plurality of swing rods 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com