Bin-separation-type truck carriage self-dumping structure

A technology of self-unloading and compartments, which is applied in the direction of freight vehicles, motor vehicles, and vehicles with push plates, etc. It can solve the problems of vehicle rollover, difficult to control the center of gravity, wheel obstruction, etc., to solve the problem of starting difficulties, Effects of avoiding position deviation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

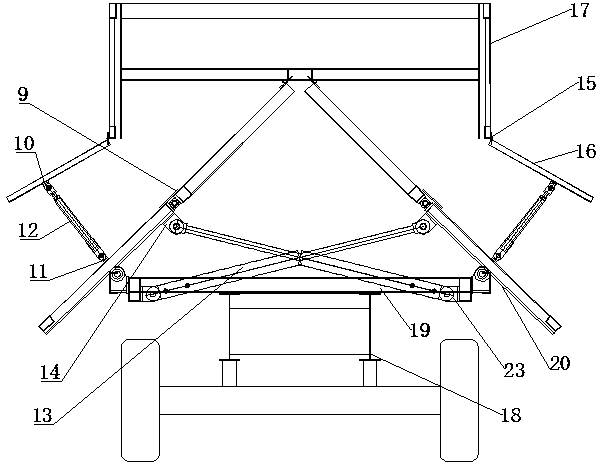

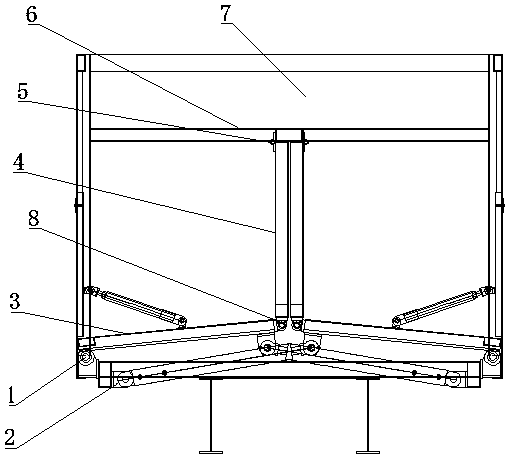

[0034] Such as figure 1 As shown, the self-unloading structure of the sub-compartment truck compartment is provided with a bottom beam 19 on the frame 18, the compartment body 17 is placed on the cross beam 19, and the compartment interior 7 of the compartment body 17 is provided with a self-unloading structure.

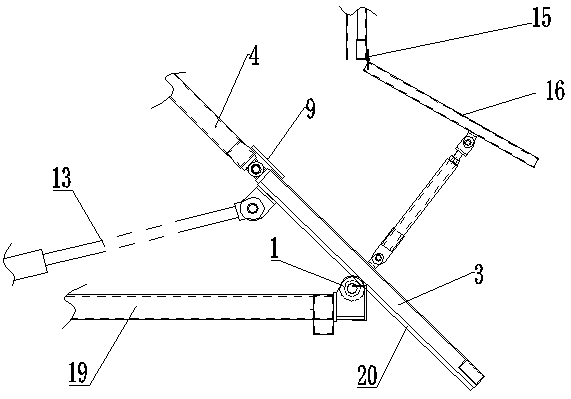

[0035] In the carriage body 17, there are many material compartments 21 arranged along the front-rear direction, and the both sides of the material compartment 21 are hinged with side doors 16 through door hinges 15 (such as image 3 , Figure 4 with Figure 5 shown). Each feed compartment 21 is provided with a self-unloading structure. Preferably, the compartments are separated by partitions 24 to form material compartments 21 .

[0036] The self-unloading str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com