Compartment, push-pedal back-push tipping truck

A push plate and carriage technology, applied in the field of transport vehicles, can solve problems such as accident-prone, poor driving safety, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

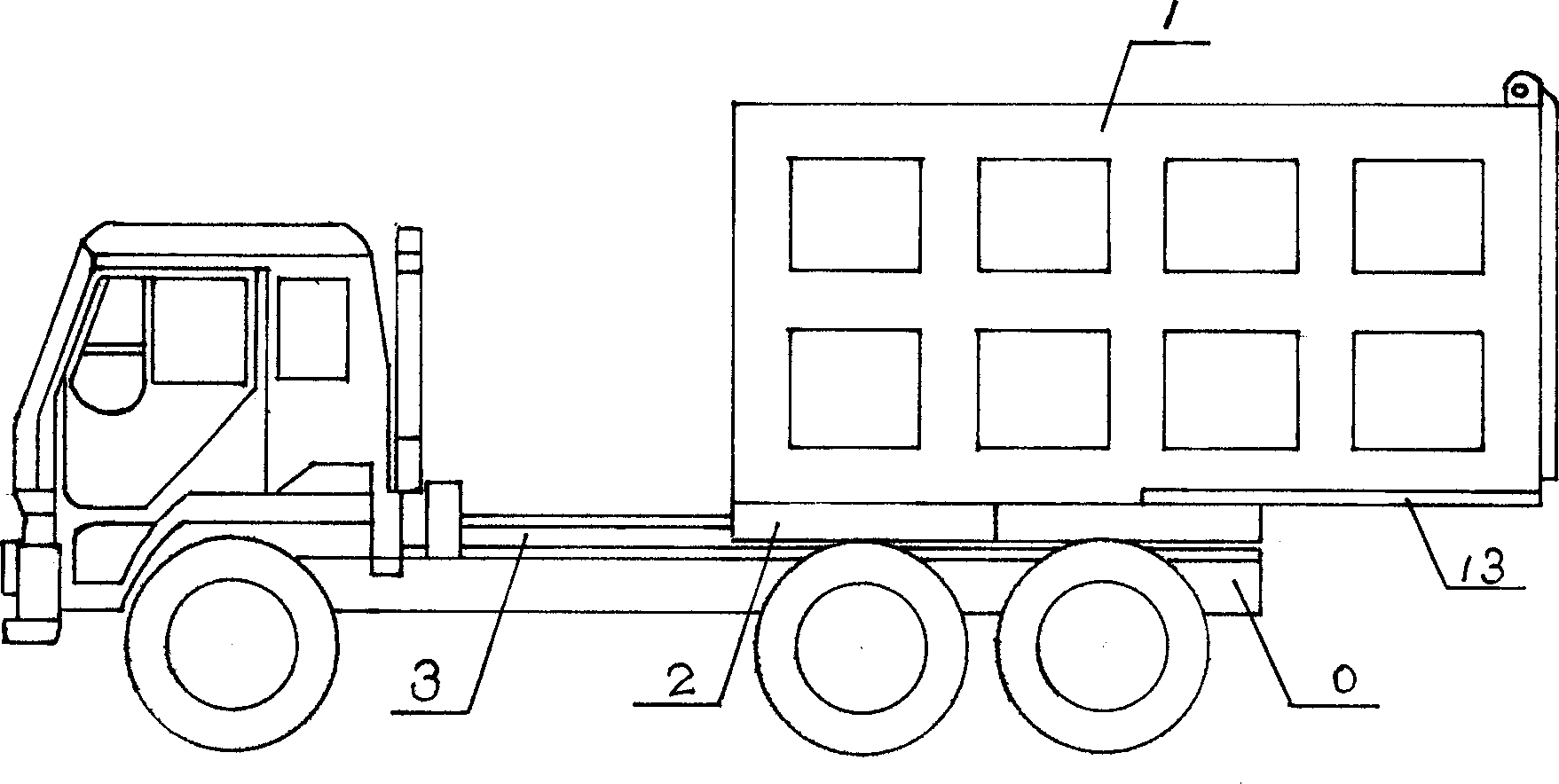

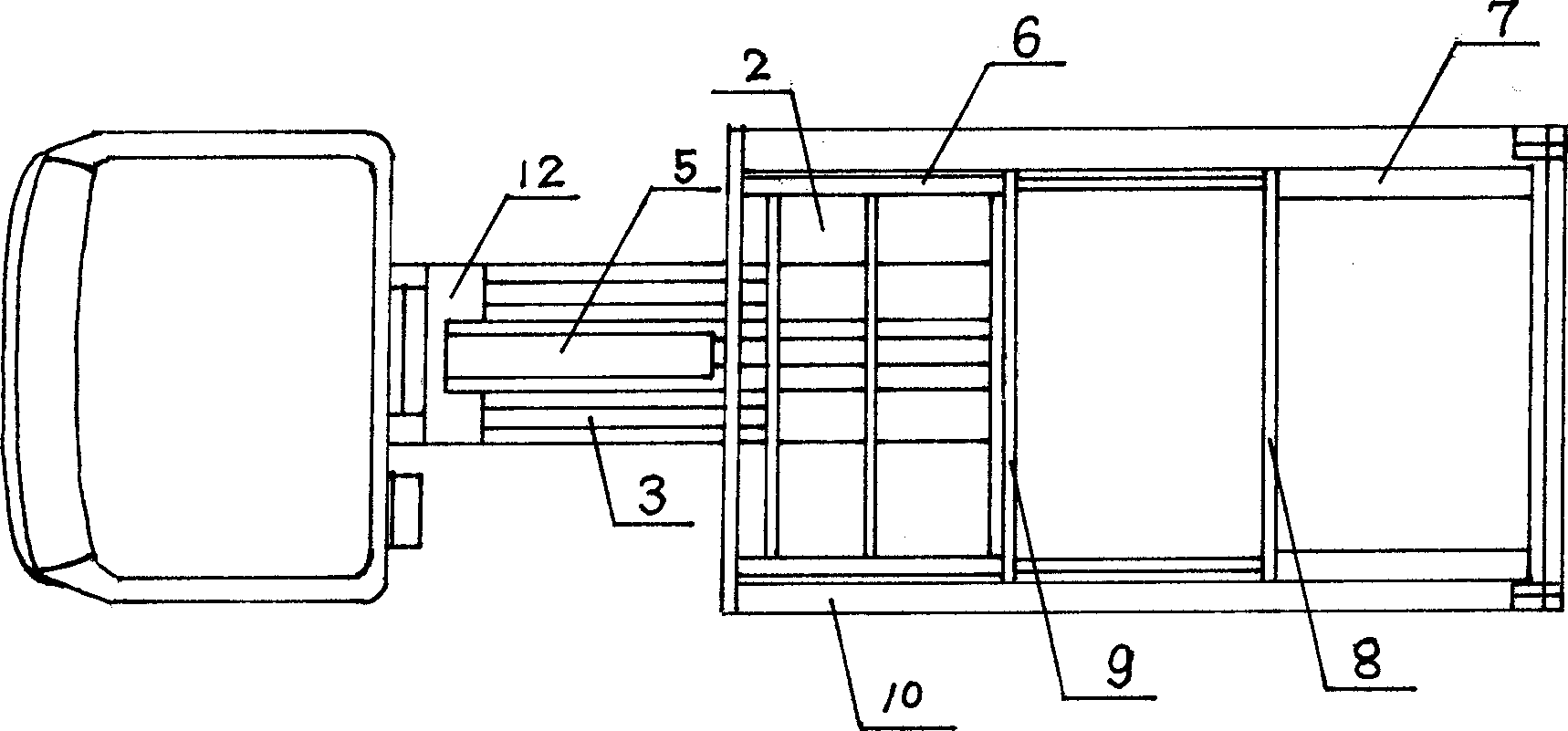

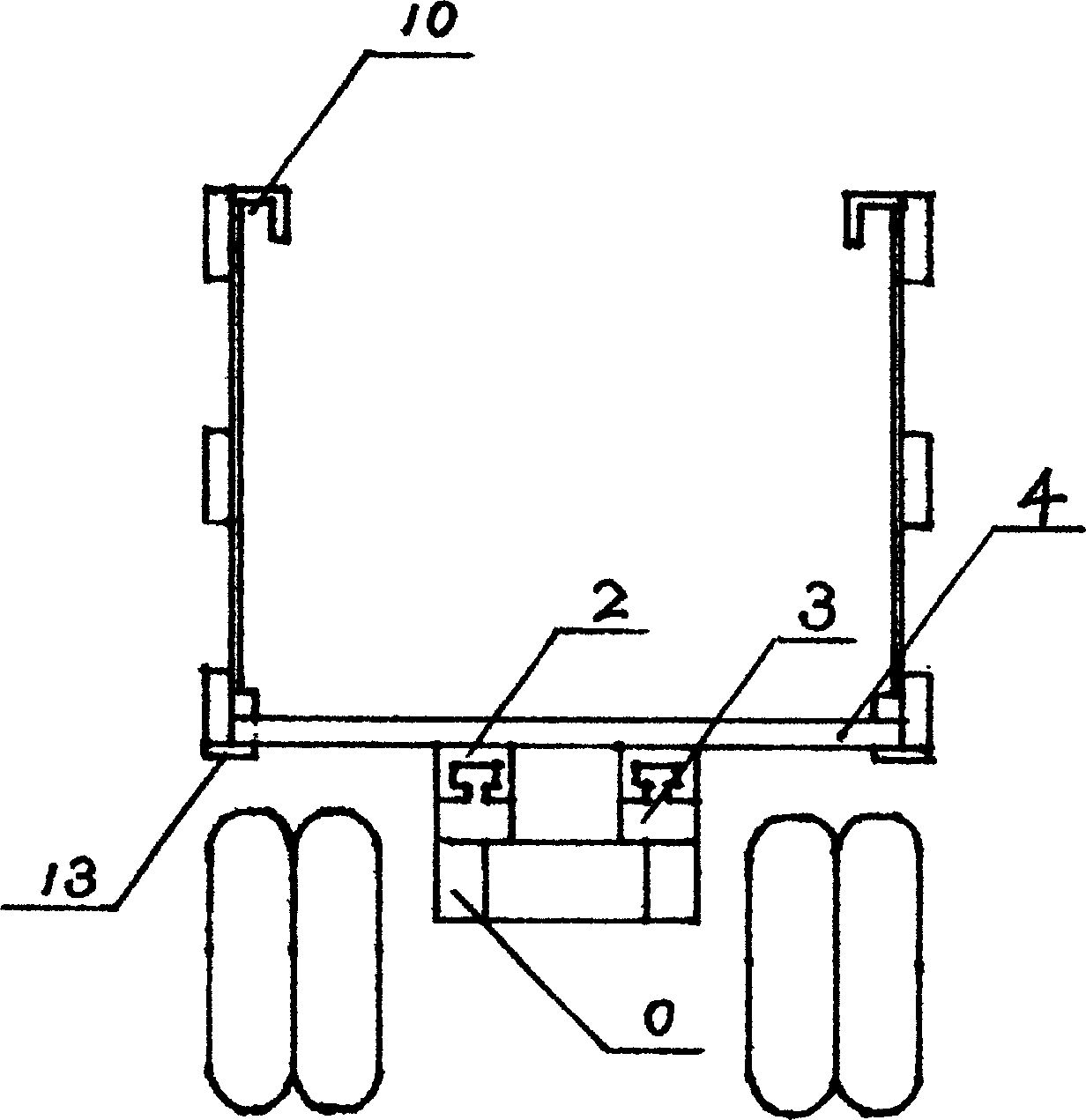

[0009] With reference to the accompanying drawings in the description, the push-back type dump truck of the present invention is described in detail as follows:

[0010] The structure of the compartment and push plate push-back dump truck of the present invention is composed of chassis 0, compartment 1, slideway 2, slide rail 3, fixed vehicle floor 4, compartment horizontal push hydraulic cylinder 5, and double-stage push plate hydraulic cylinder 6. , push plate hydraulic cylinder sleeve 7, push plate (1) 8, push plate (2) 9, push plate chute 10, row 11, front limit 12, box fixed slide plate 13, double-stage push plate hydraulic cylinder The control valve 14 constitutes. Compartment is arranged on row 11, the top of fixed vehicle floor 4. The row 11 is installed on the slide rail 3, the fixed vehicle floor 4 is installed at the rear of the slide rail 3, the fixed sliding plate 13 of the box body is fixed on the rear bottom of the box body 1, and the horizontal pushing hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com