Patents

Literature

49results about How to "Avoid flaring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

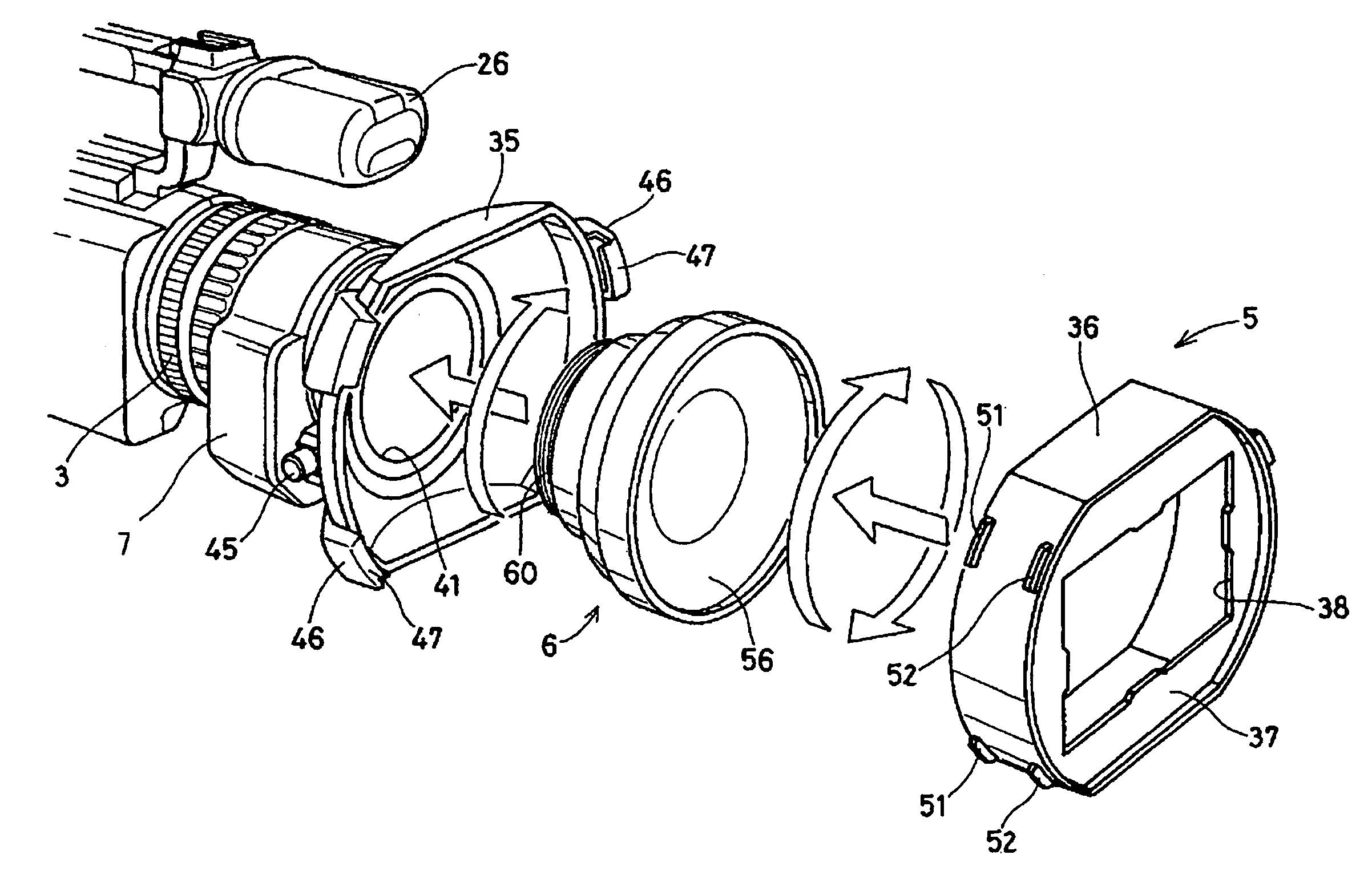

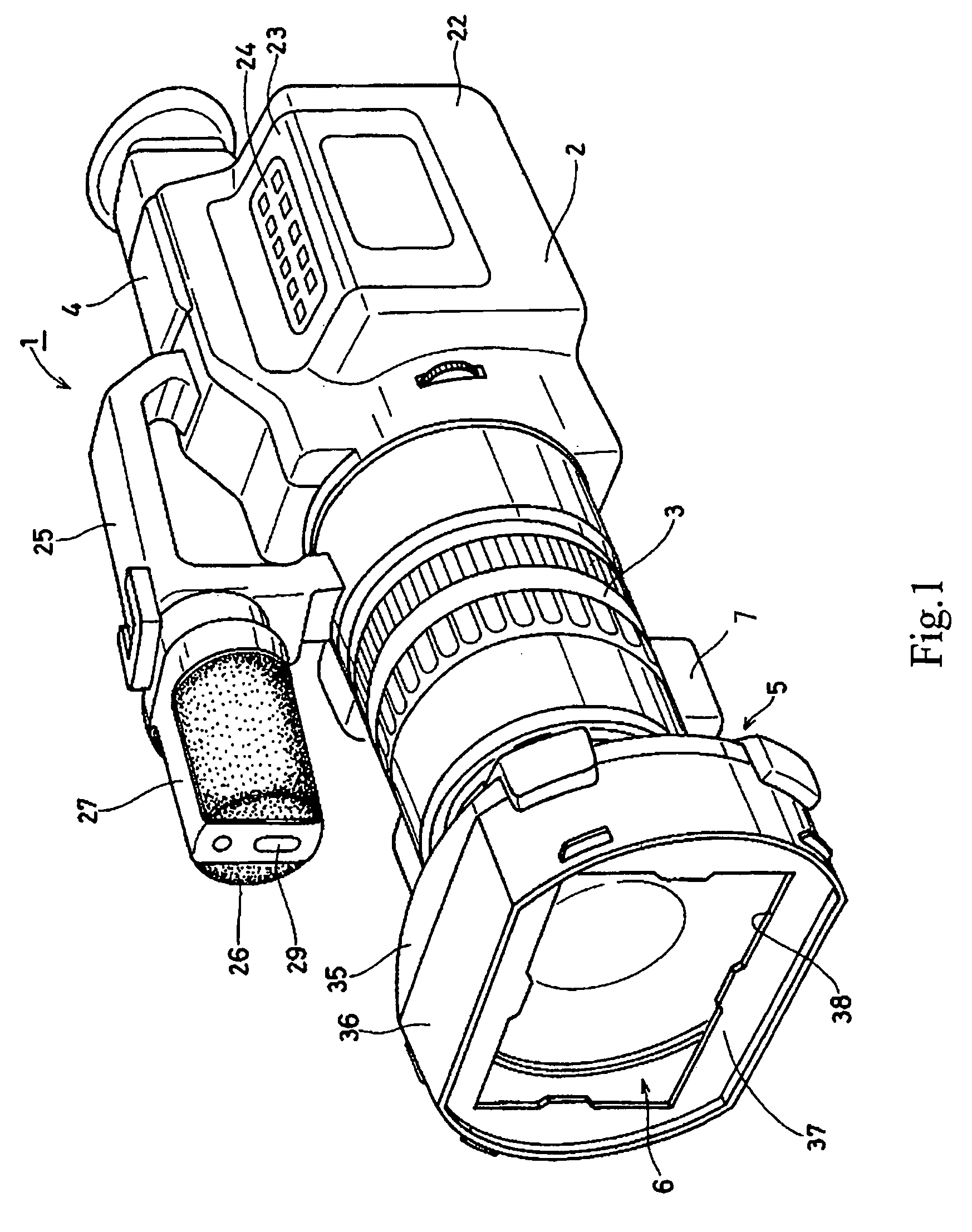

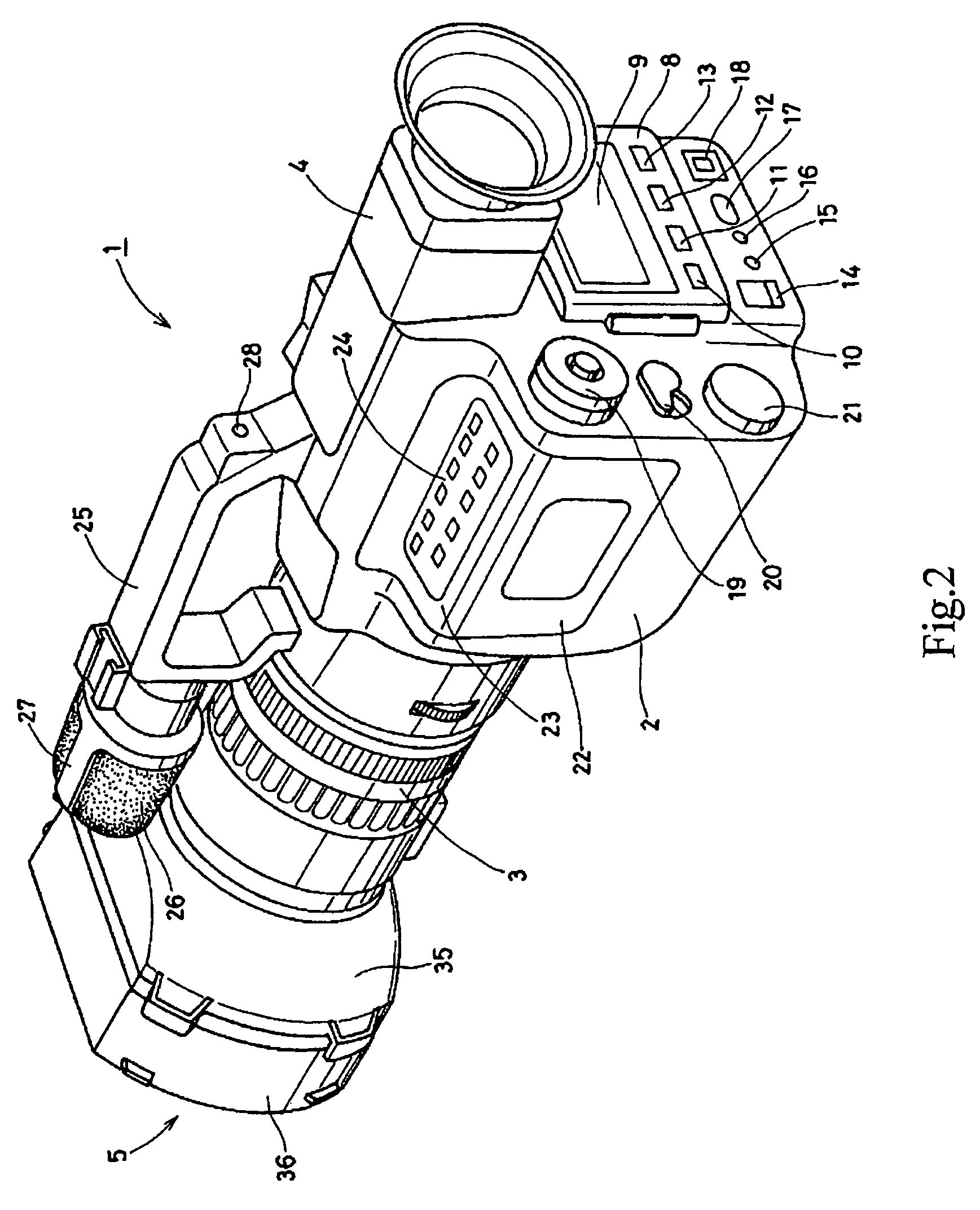

Imaging device

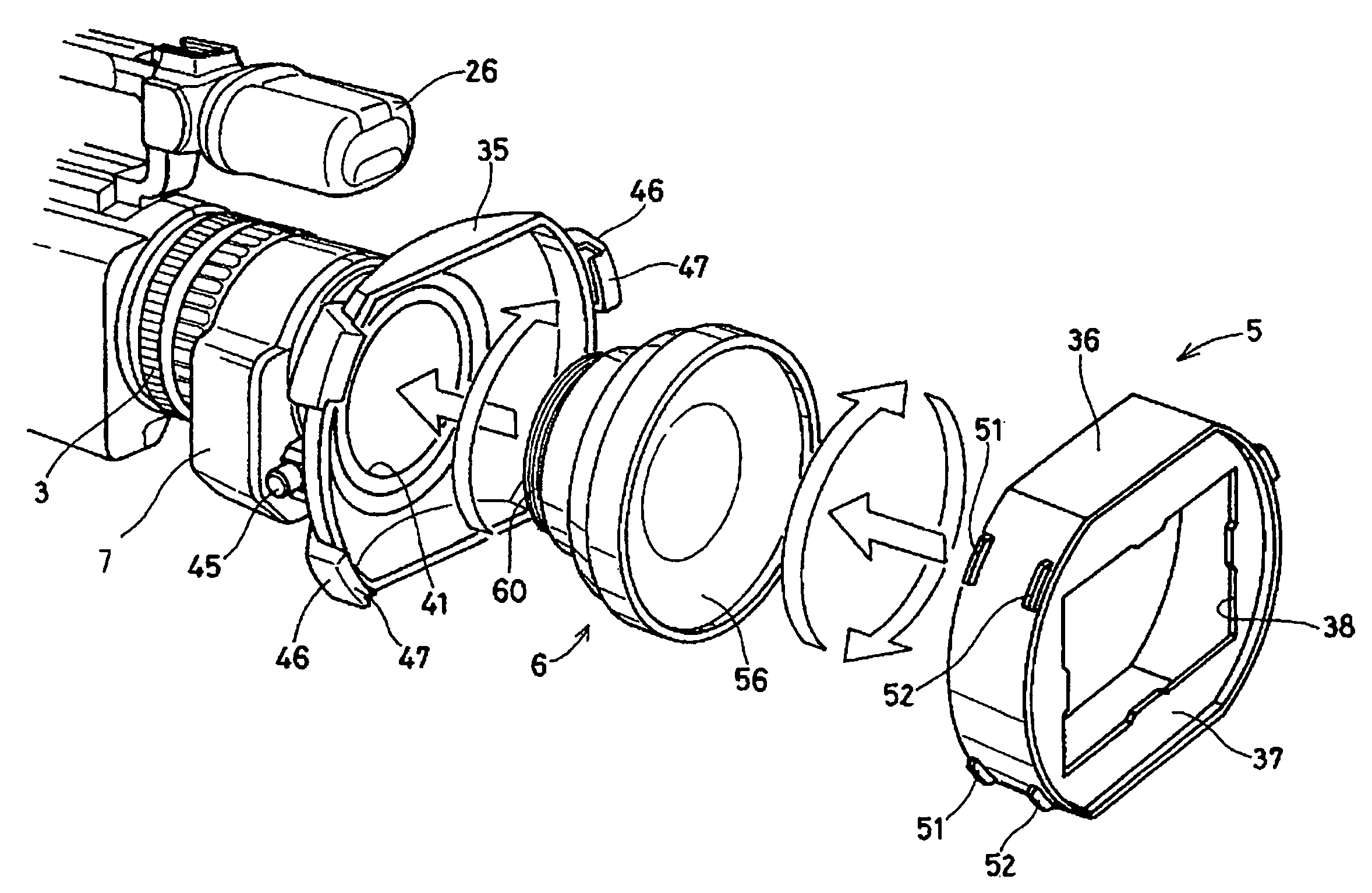

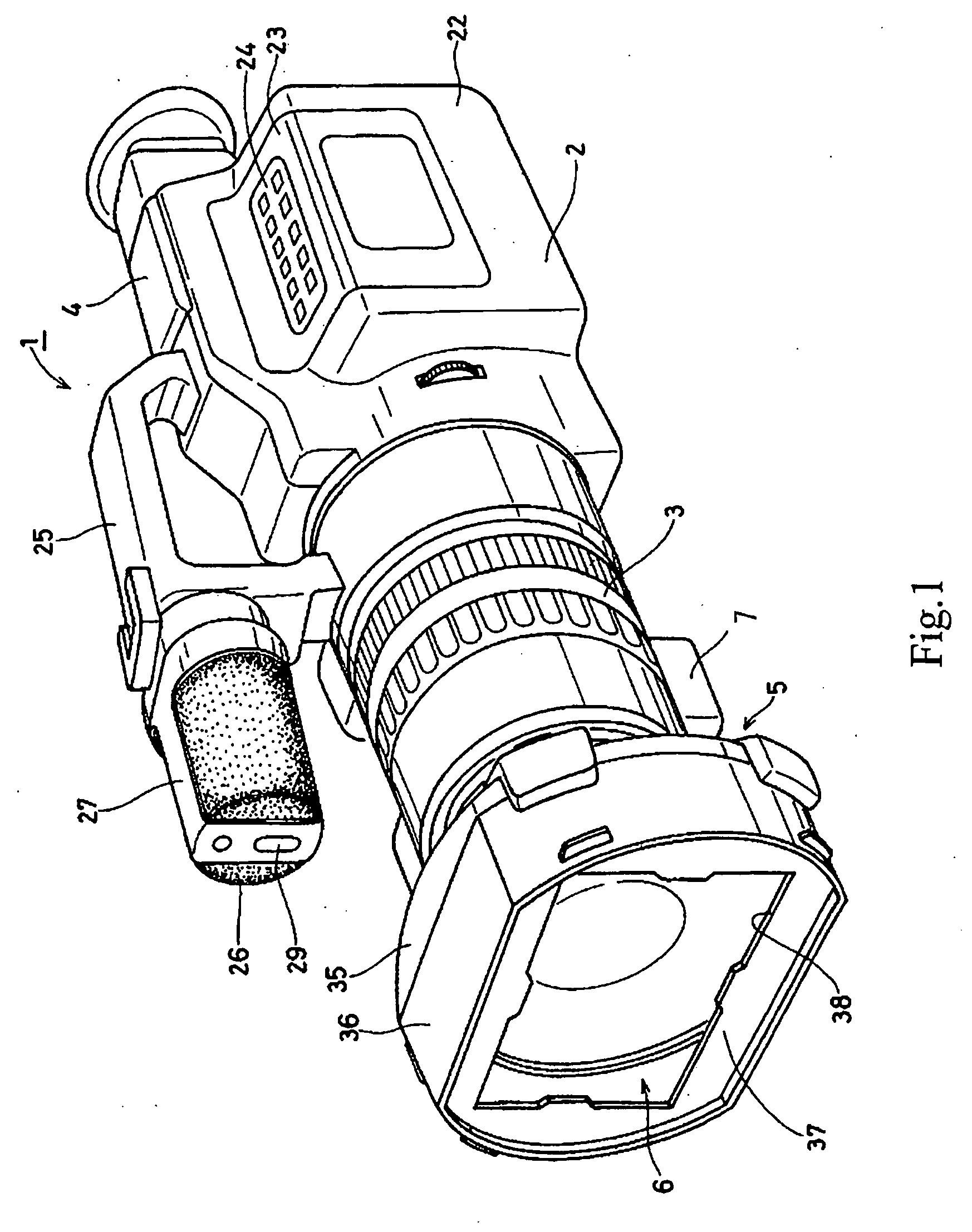

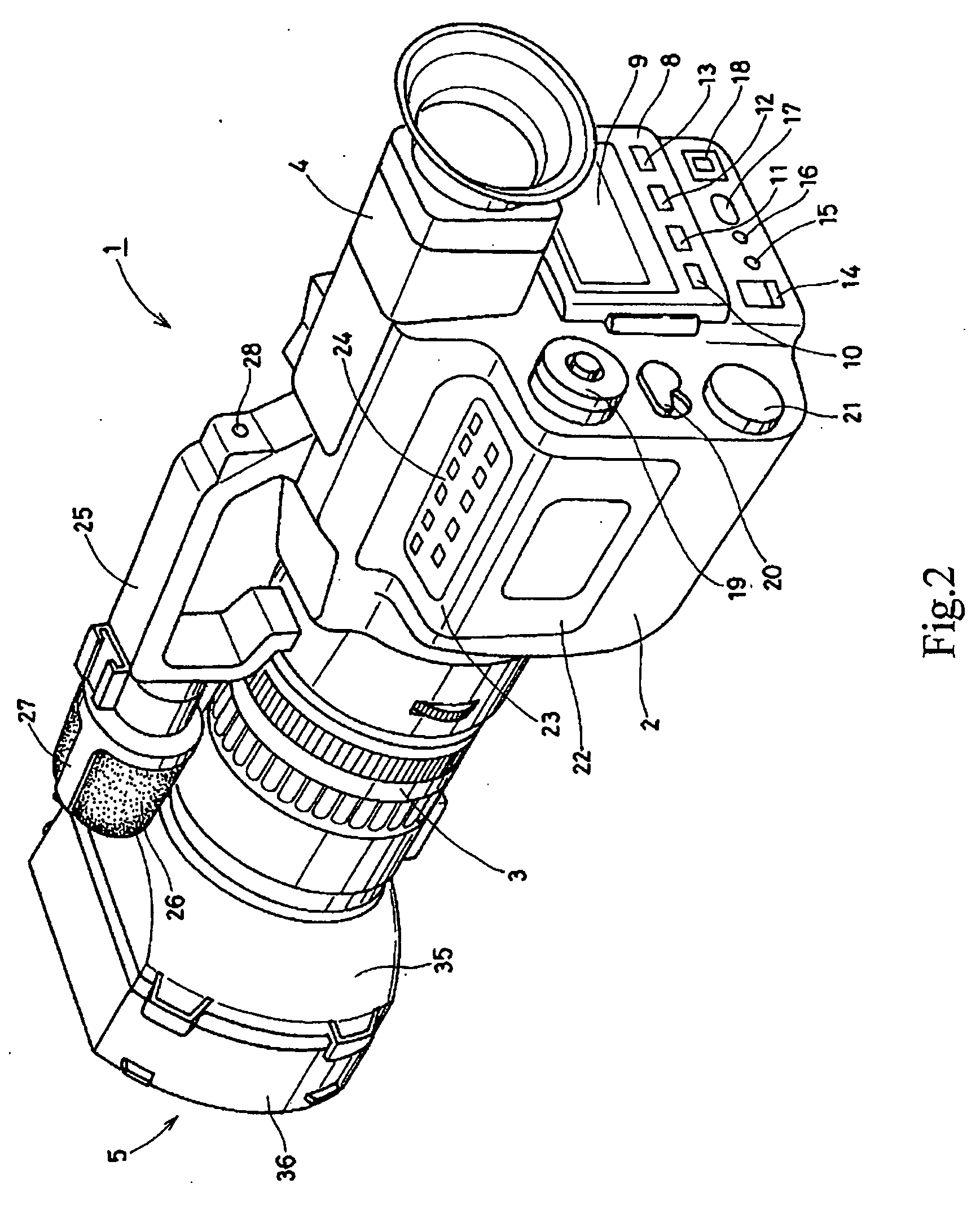

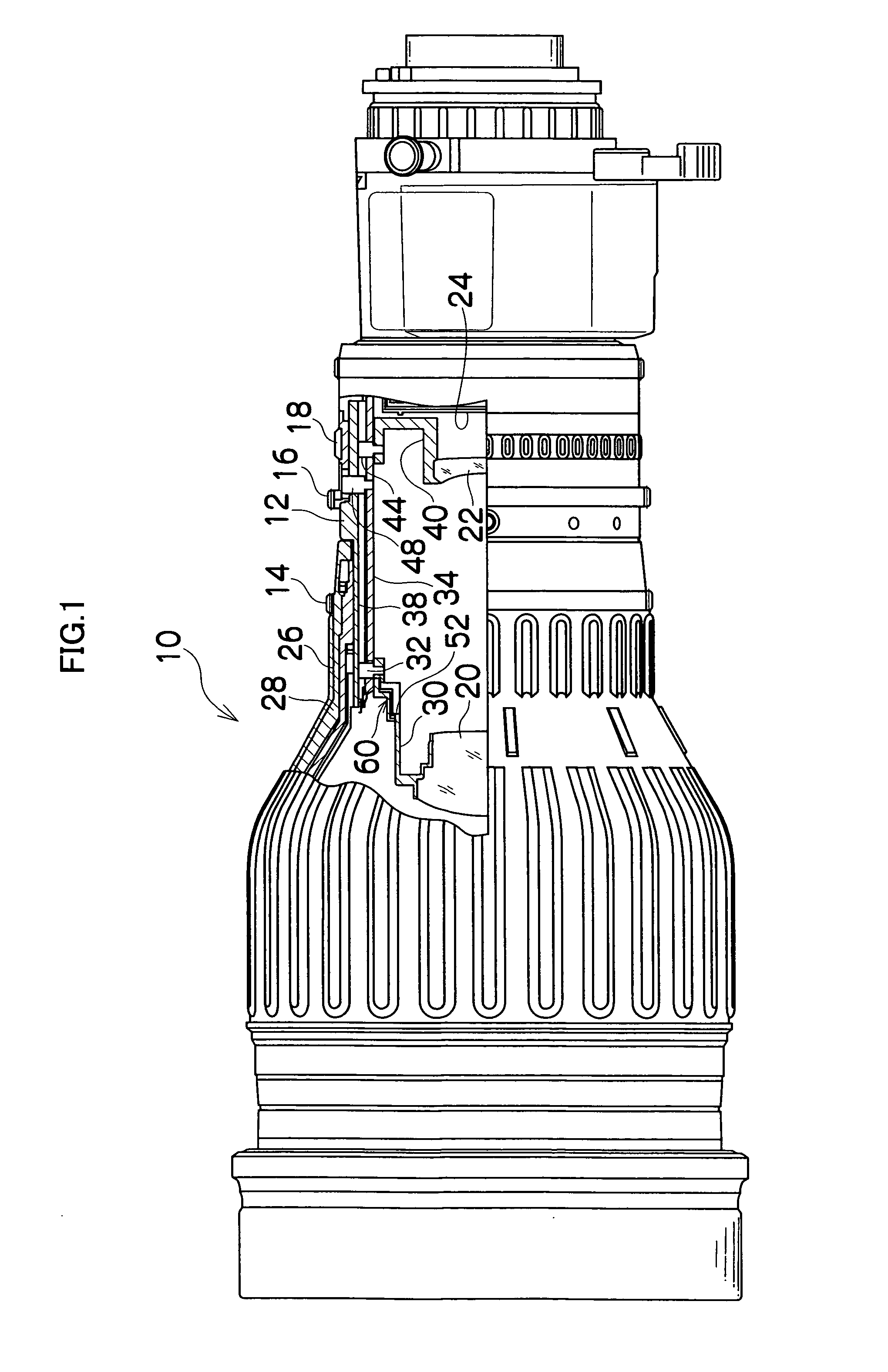

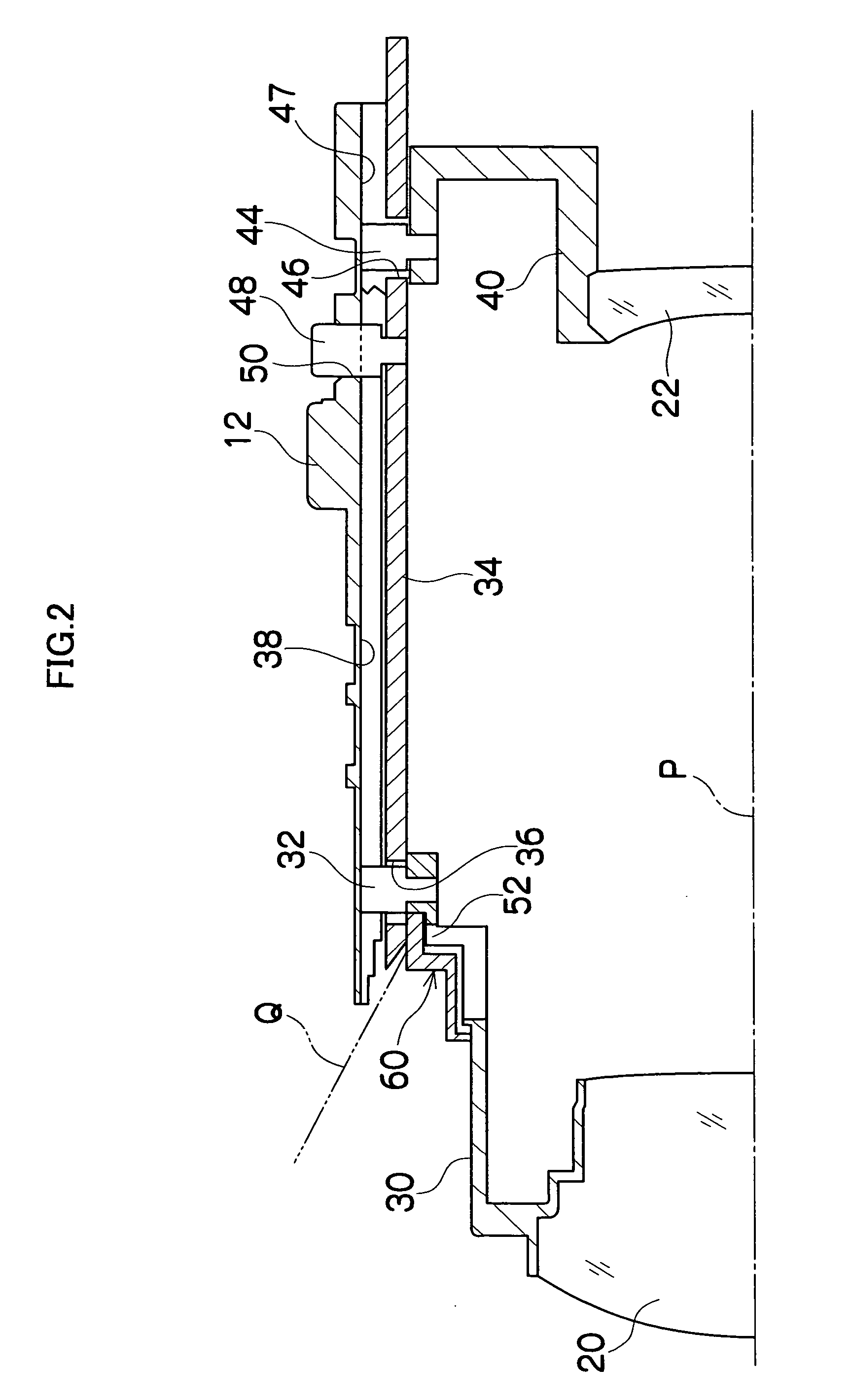

InactiveUS20060007551A1Operation of detaching the lens hood has been laboriousAvoid flaringTelevision system detailsColor television detailsLens hoodEngineering

An image pickup apparatus is provided. The image pickup apparatus permitting a conversion lens to be mounted and dismounted, wherein a lens hood is composed of a base portion on the mounting side and a tubular portion on the front side, the base portion and the tubular portion are detachably coupled to each other, and another lens is contained in the inside of the lens hood when the another lens is mounted on the front side of an optical system, whereby even when the conversion lens is being used, the lens hood can be used as it is, and the incident light contracting function of the lens hood can be maintained.

Owner:SONY CORP

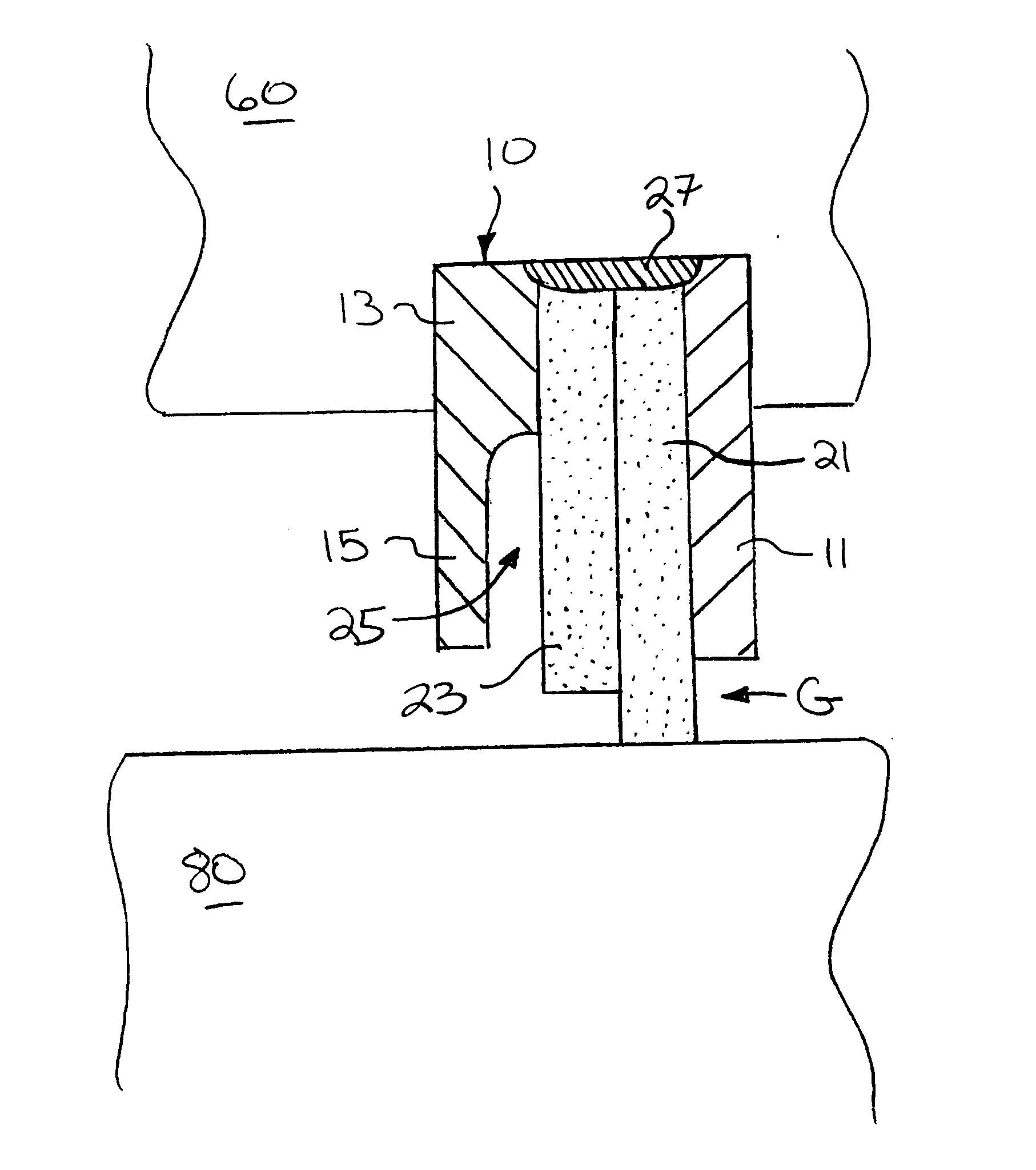

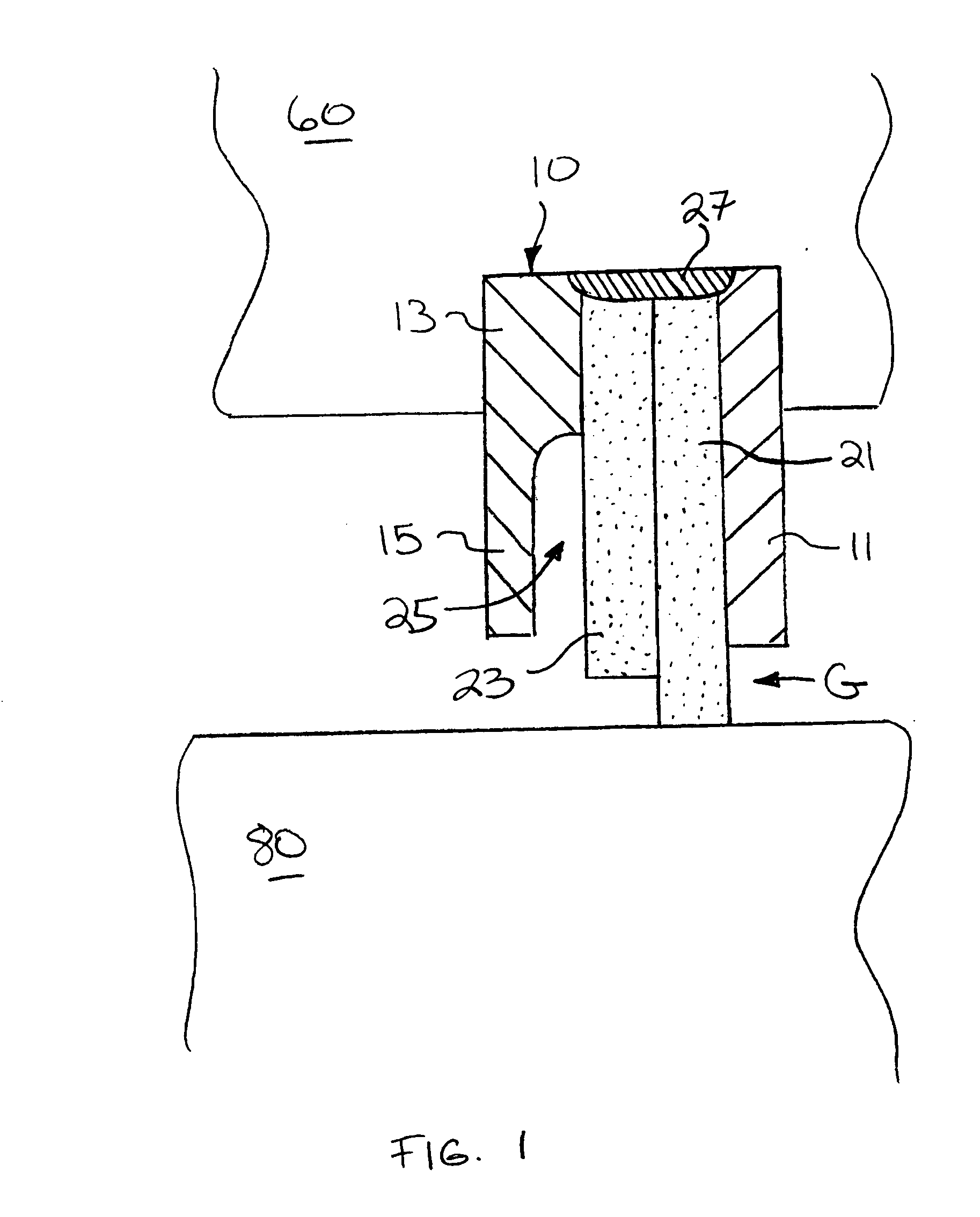

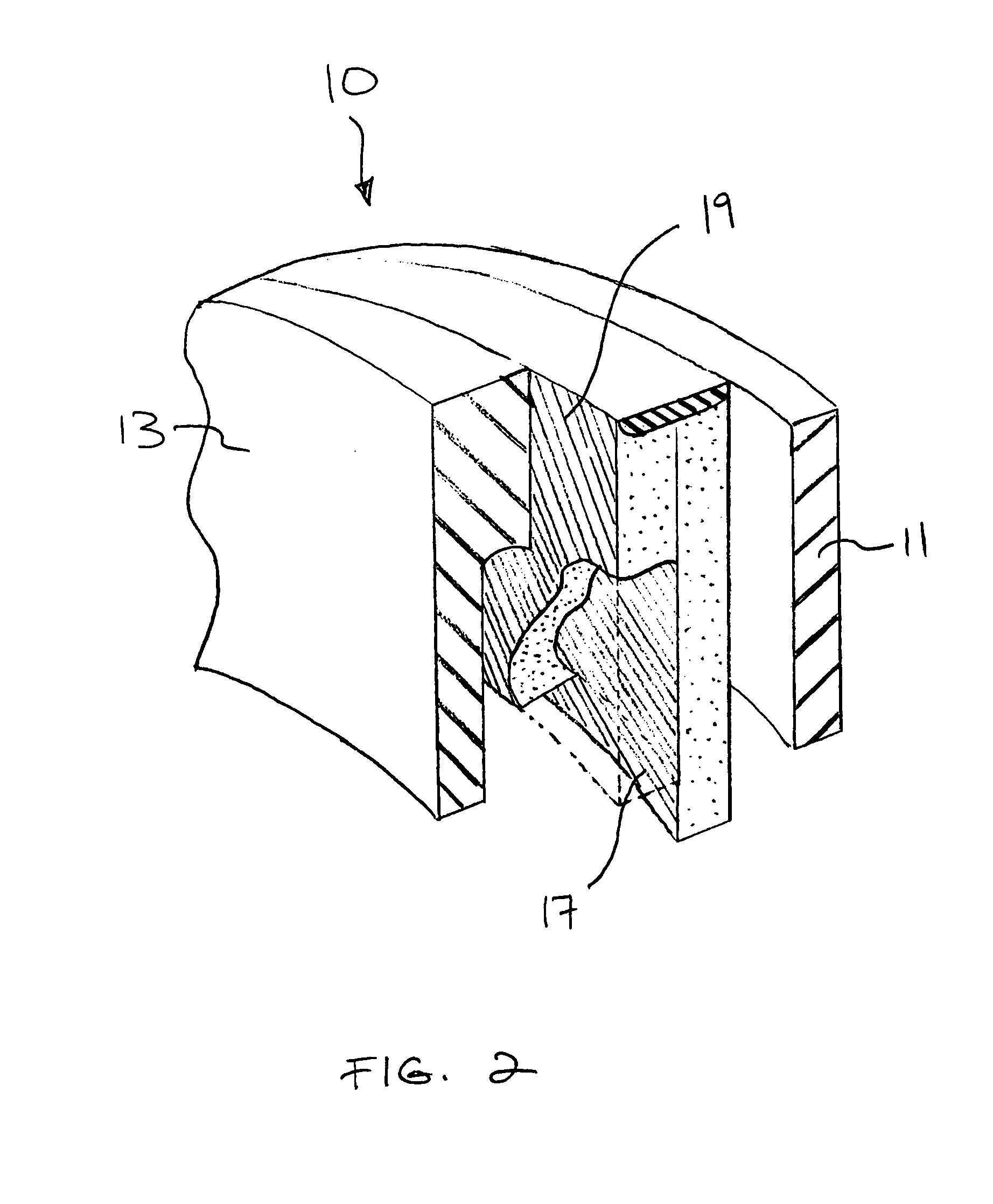

Brush seal with windage control

InactiveUS20050006851A1Avoid flaringEffective sealing lengthEngine sealsLeakage preventionBristleHigh pressure

A brush seal with: a back plate; a side plate; a first set of bristles; and a second set of bristles between the first set of bristles and the side plate, The second set of bristles have a characteristic, different than the first set of bristles, that reduces windage effects on the first set of bristles. A brush seal for sealing a gap between first and second components, having: a back plate; a side plate; a set of contacting bristles that engages the second component; and a set of non-contacting bristles that extends towards, but does not engage, the second component. The non-contacting bristles reside between the contacting bristles and the side plate. In a brush seal having a set of longer bristles adjacent a set of shorter bristles, wherein the improvement comprises the shorter bristles located on a high pressure side of the longer bristles.

Owner:UNITED TECH CORP

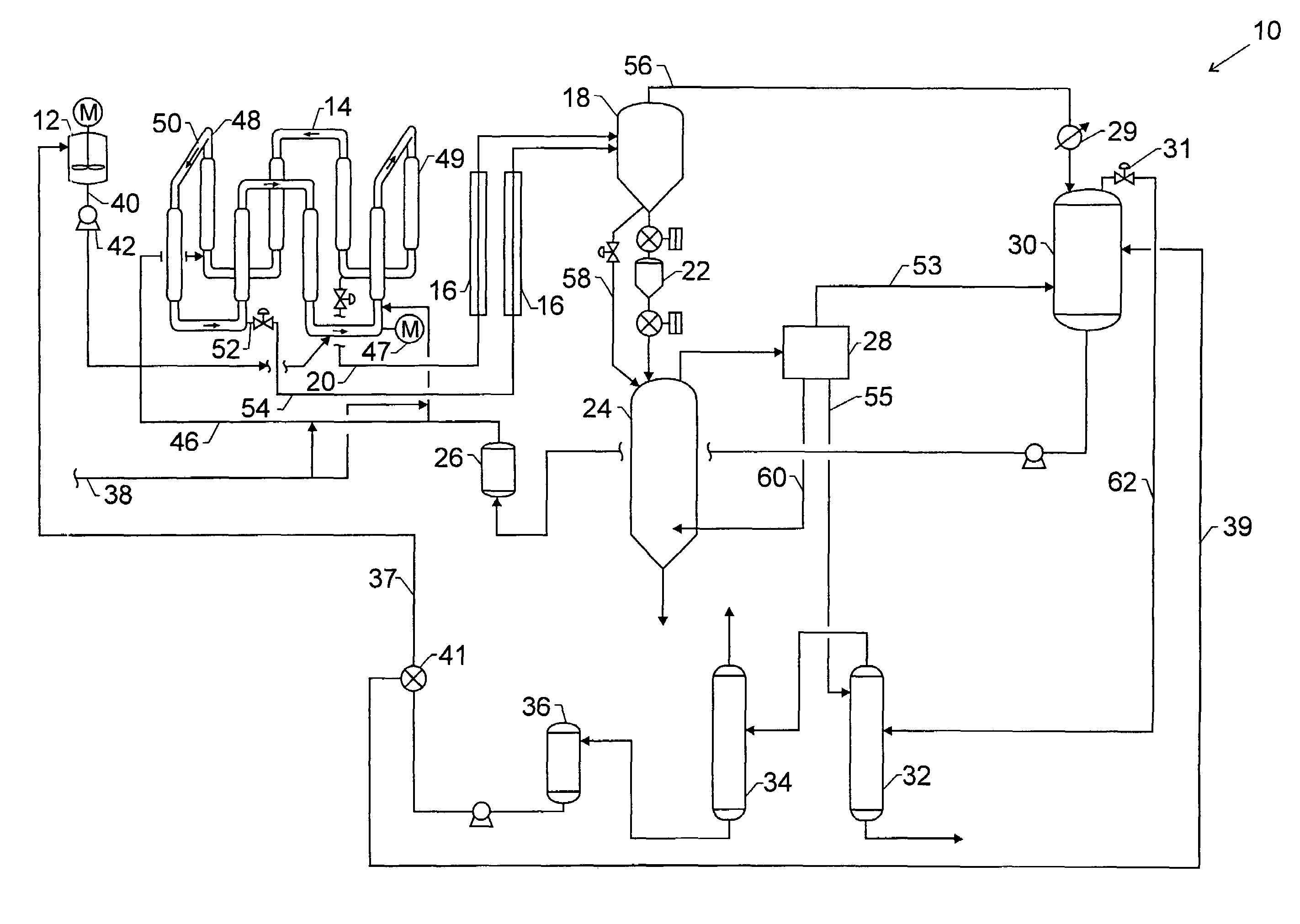

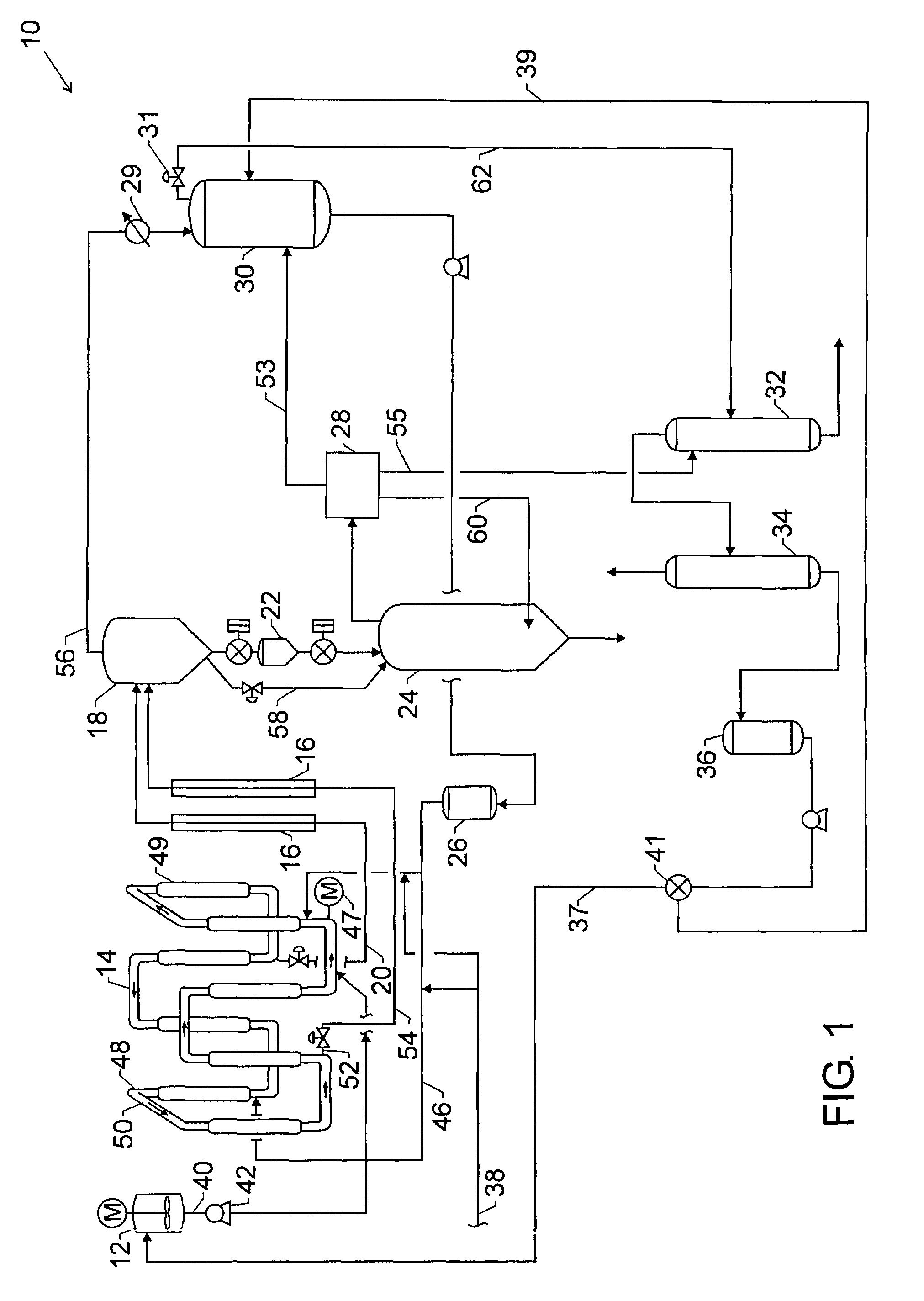

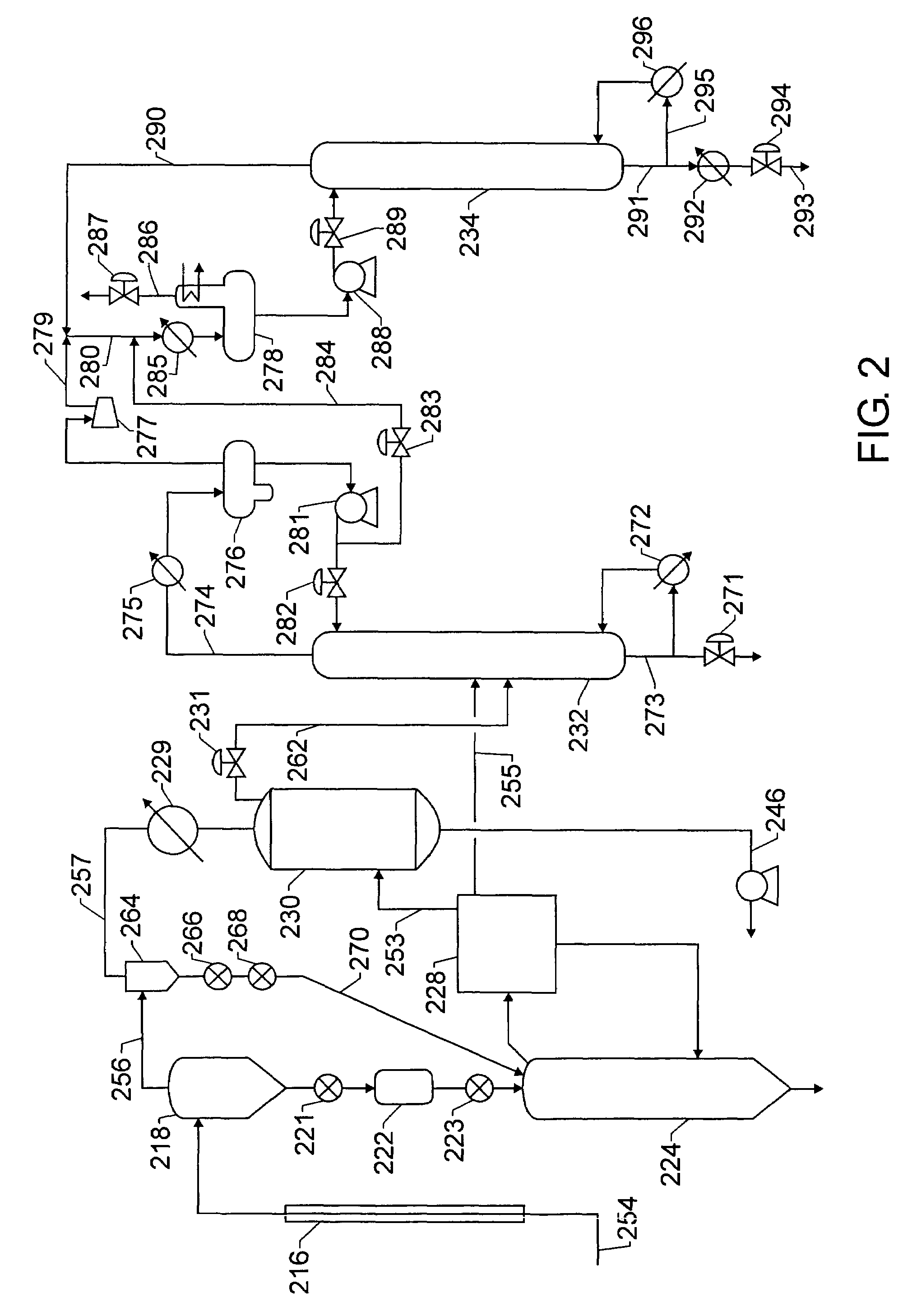

Process and apparatus for separating polymer solids, hydrocarbon fluids, and purge gas

ActiveUS7524904B2Avoid flaringChemical/physical/physico-chemical stationary reactorsFeed devicesFractionationGas passing

A process and apparatus for separating polymer solids, hydrocarbon fluids, and purge gas in an intermediate pressure zone and a purge zone. The purge gas in the purge zone is used to remove hydrocarbon fluids from the polymer solids, and a stream containing the purge gas and hydrocarbons is passed to a hydrocarbon / purge gas recovery zone. High-purity purge gas from the recovery zone is efficiently used by passing a portion back to the purge zone and another portion to an extruder feed zone. Hydrocarbon fluids separated from polymer solids in the intermediate pressure zone and in the hydrocarbon / purge gas recovery zone are liquefied and passed to a recycle zone, and the hydrocarbons (typically liquid diluent and / or unreacted monomer) are recycled to the reactor without fractionation.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

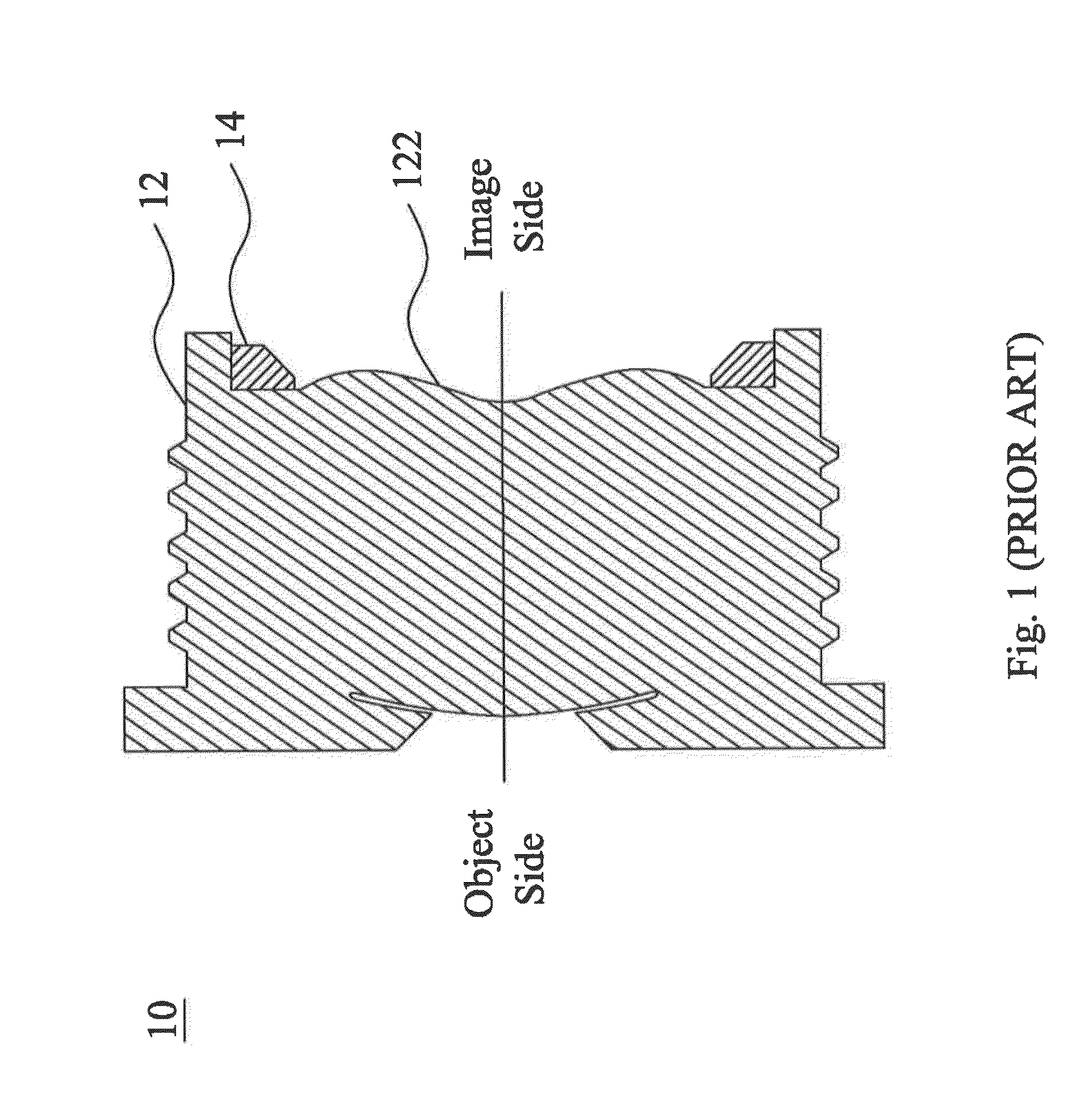

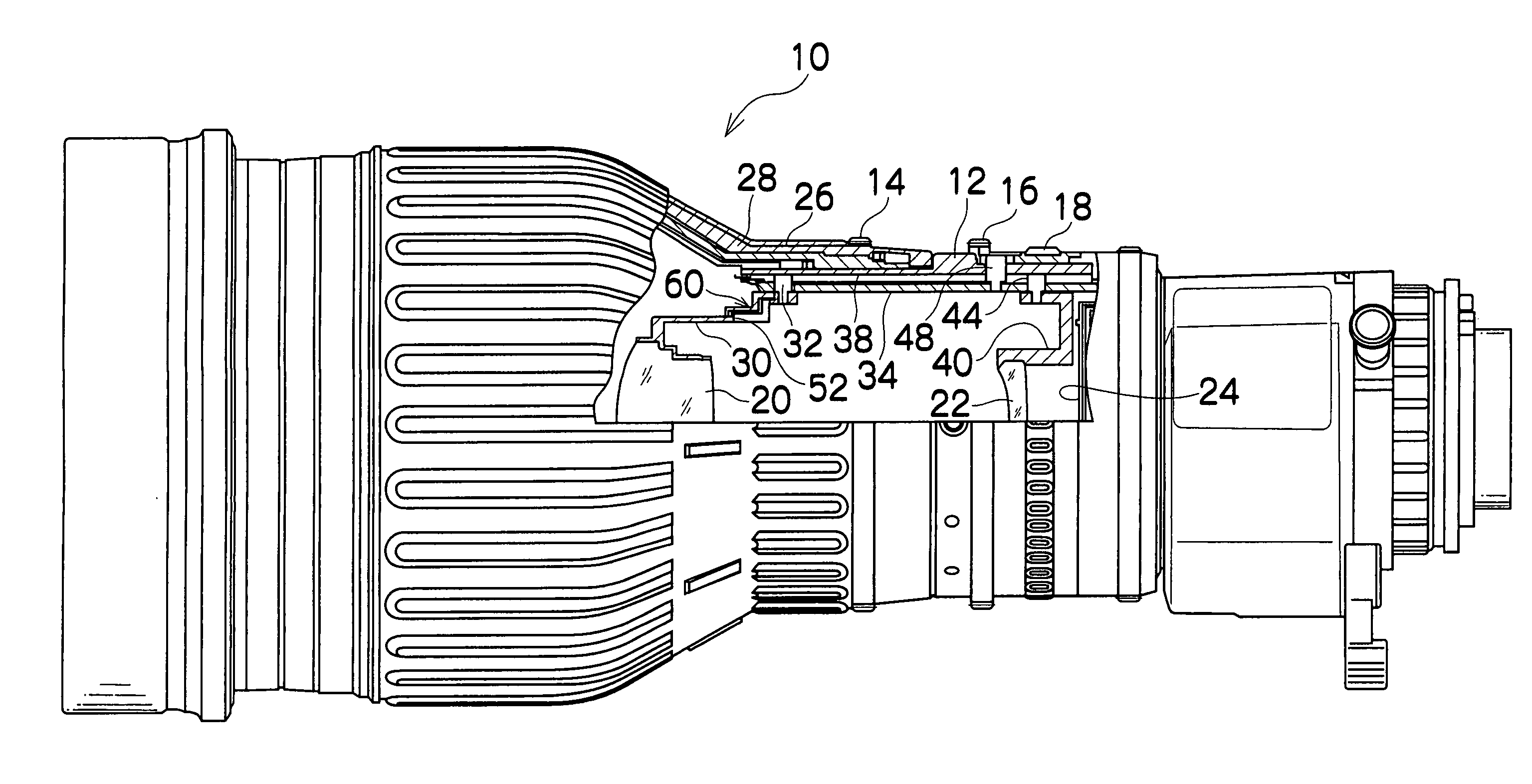

Image pickup apparatus

InactiveUS7161749B2Operation of detaching the lens hood has been laboriousAvoid flaringTelevision system detailsColor television detailsCamera lensLens hood

An image pickup apparatus is provided. The image pickup apparatus permitting a conversion lens to be mounted and dismounted, wherein a lens hood is composed of a base portion on the mounting side and a tubular portion on the front side, the base portion and the tubular portion are detachably coupled to each other, and another lens is contained in the inside of the lens hood when the another lens is mounted on the front side of an optical system, whereby even when the conversion lens is being used, the lens hood can be used as it is, and the incident light contracting function of the lens hood can be maintained.

Owner:SONY CORP

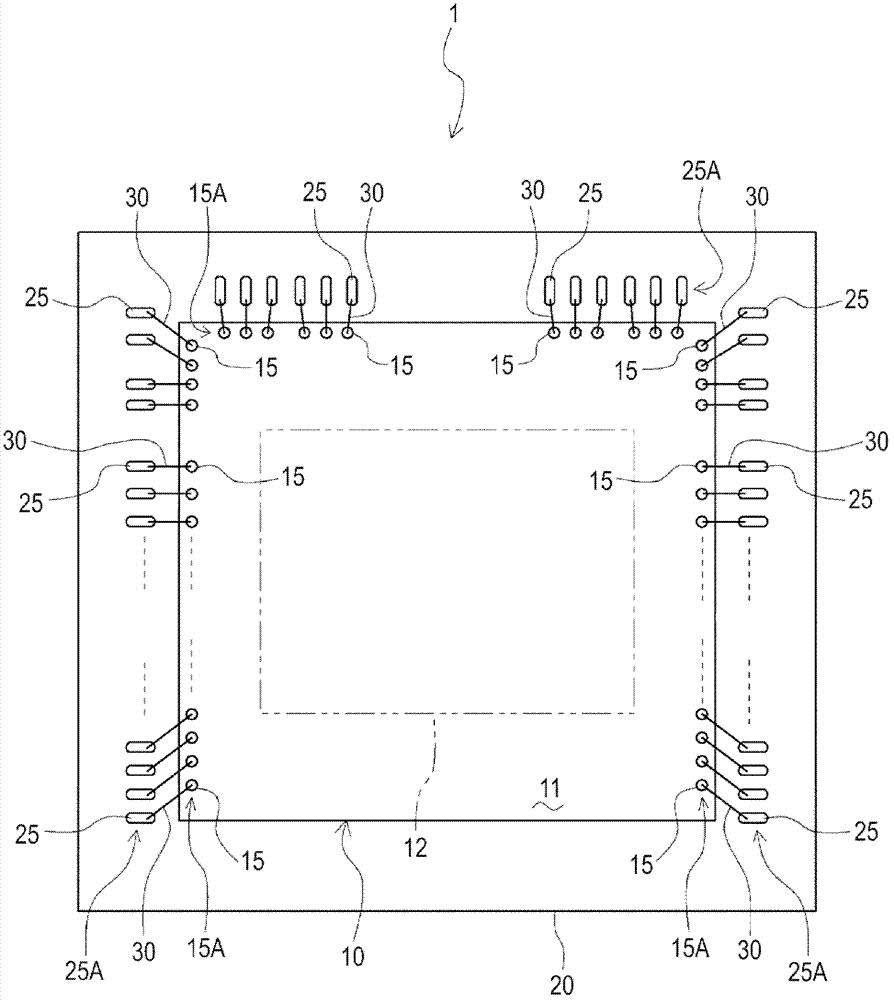

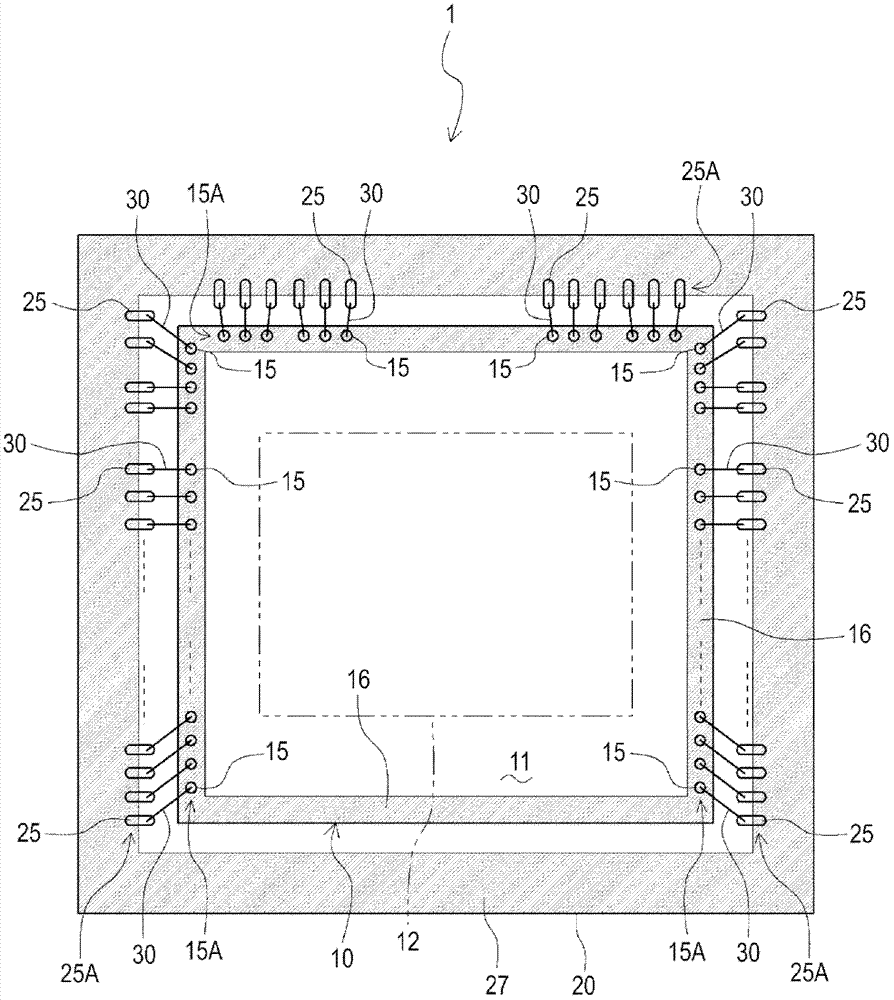

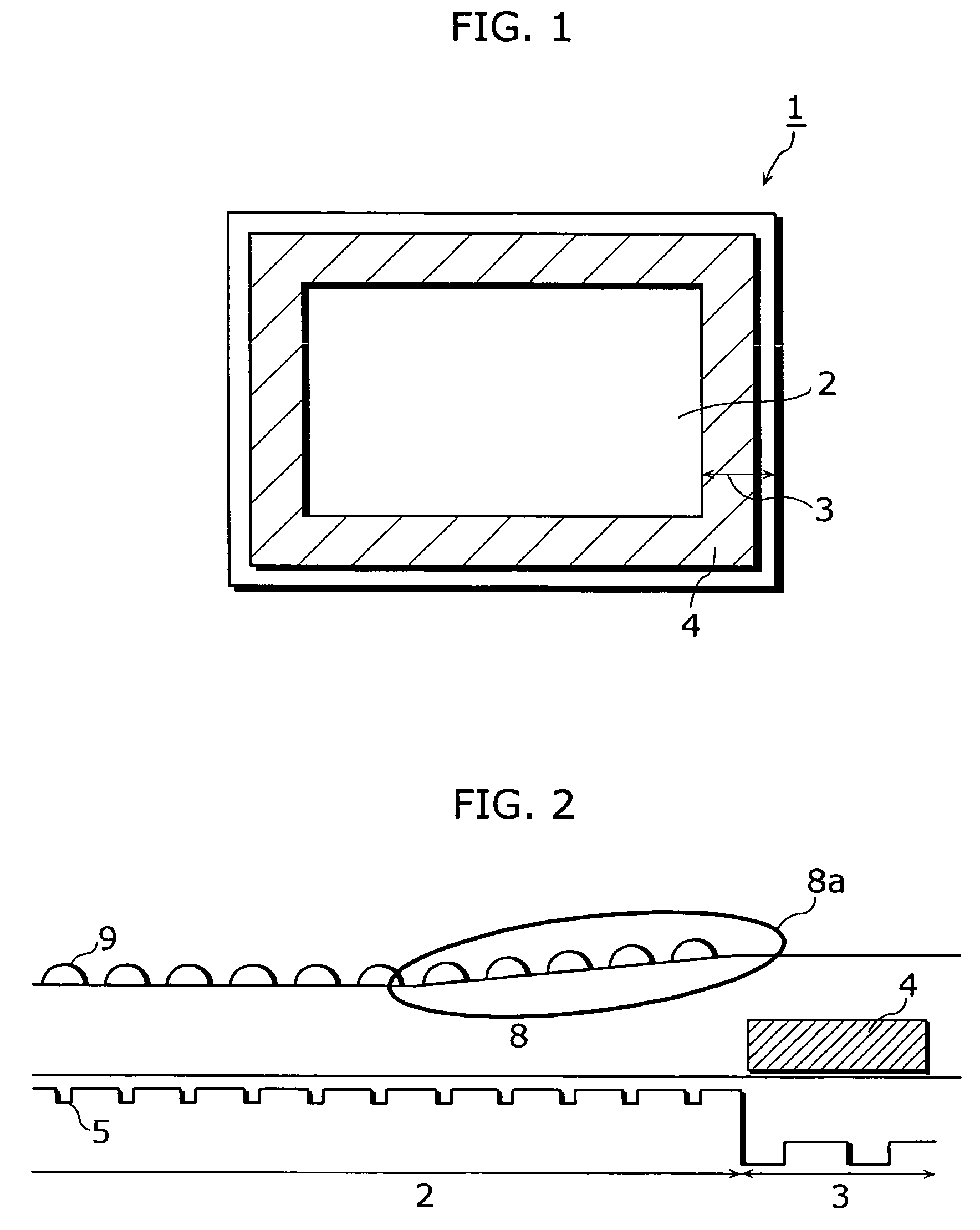

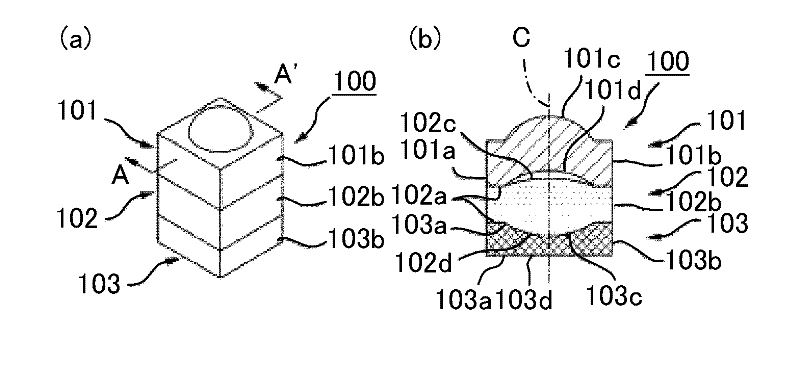

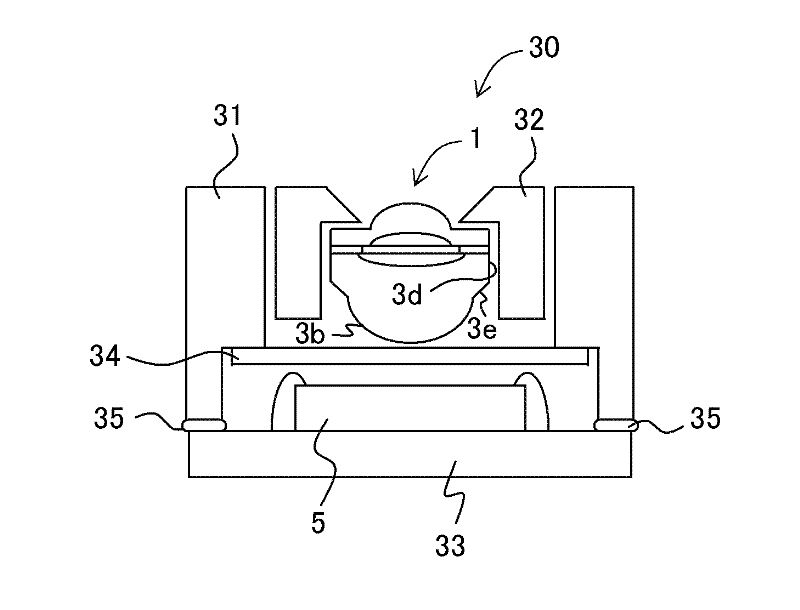

Solid-state imaging apparatus, method for manufacturing same, and electronic system

InactiveCN102738189AFlare suppressionAvoid flaringTelevision system detailsSolid-state devicesElectronic systemsEngineering

The invention relates to a solid-state imaging apparatus, a method for manufacturing the same, and an electronic system. The solid-state imaging apparatus includes: a solid-state imaging device mounted on a substrate; a bonding wire that electrically connects a pad formed on the solid-state imaging device to a lead island formed on the substrate; a frame member that has a frame-like shape and surrounds side portions of the solid-state imaging device; and a light-transmissive optical member so accommodated in the frame member that the optical member faces an imaging surface of the solid-state imaging device, wherein the frame member has a leg portion extending from the side where the optical member is present toward the imaging surface, and the frame member is integrally fixed to the solid-state imaging device with an end of the bonding wire that is connected to the pad covered with the leg portion. The solid-state imaging apparatus restrains solar flare caused by reflected light of the bonding wire and realizes reduction of size.

Owner:SONY CORP

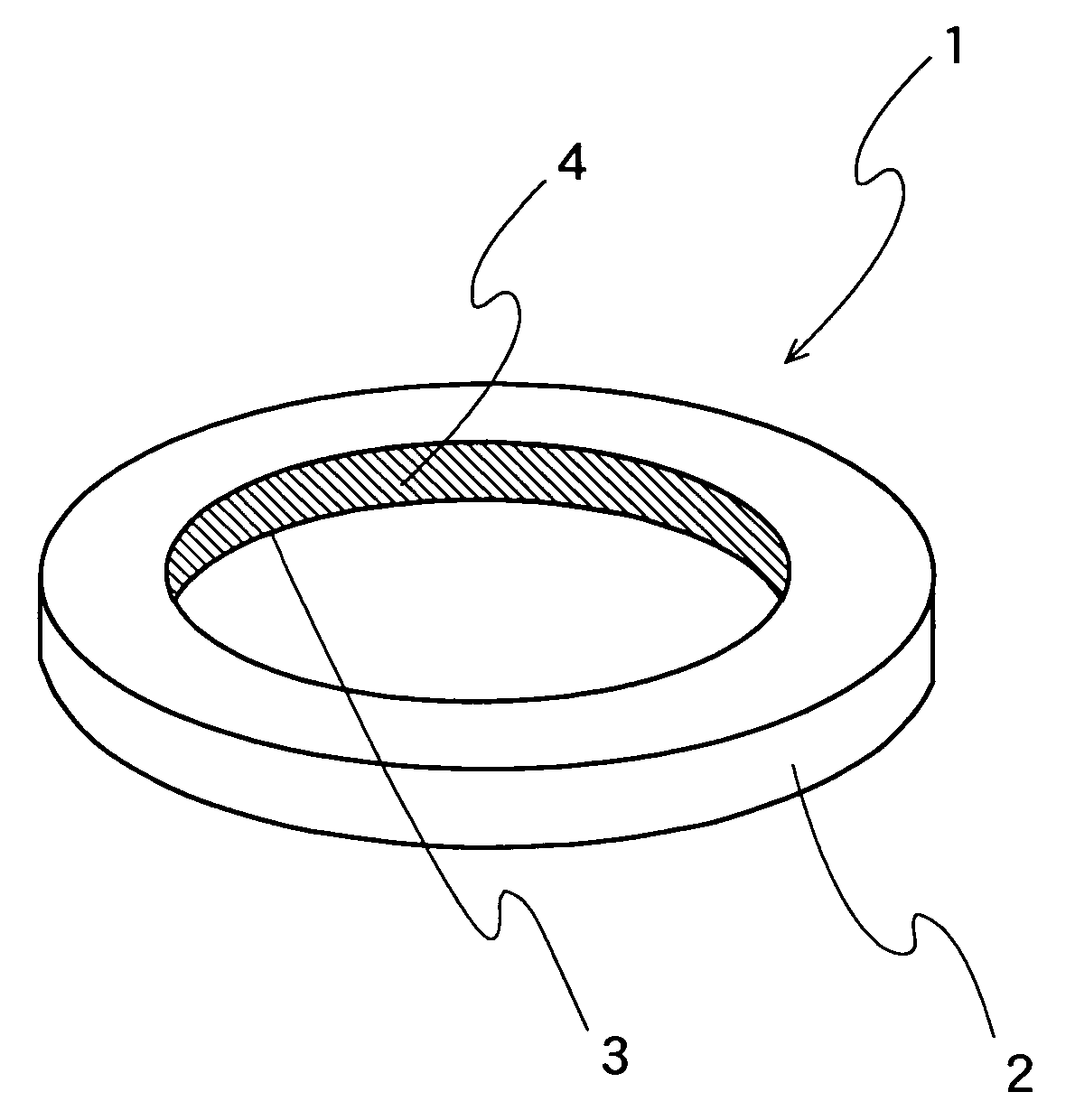

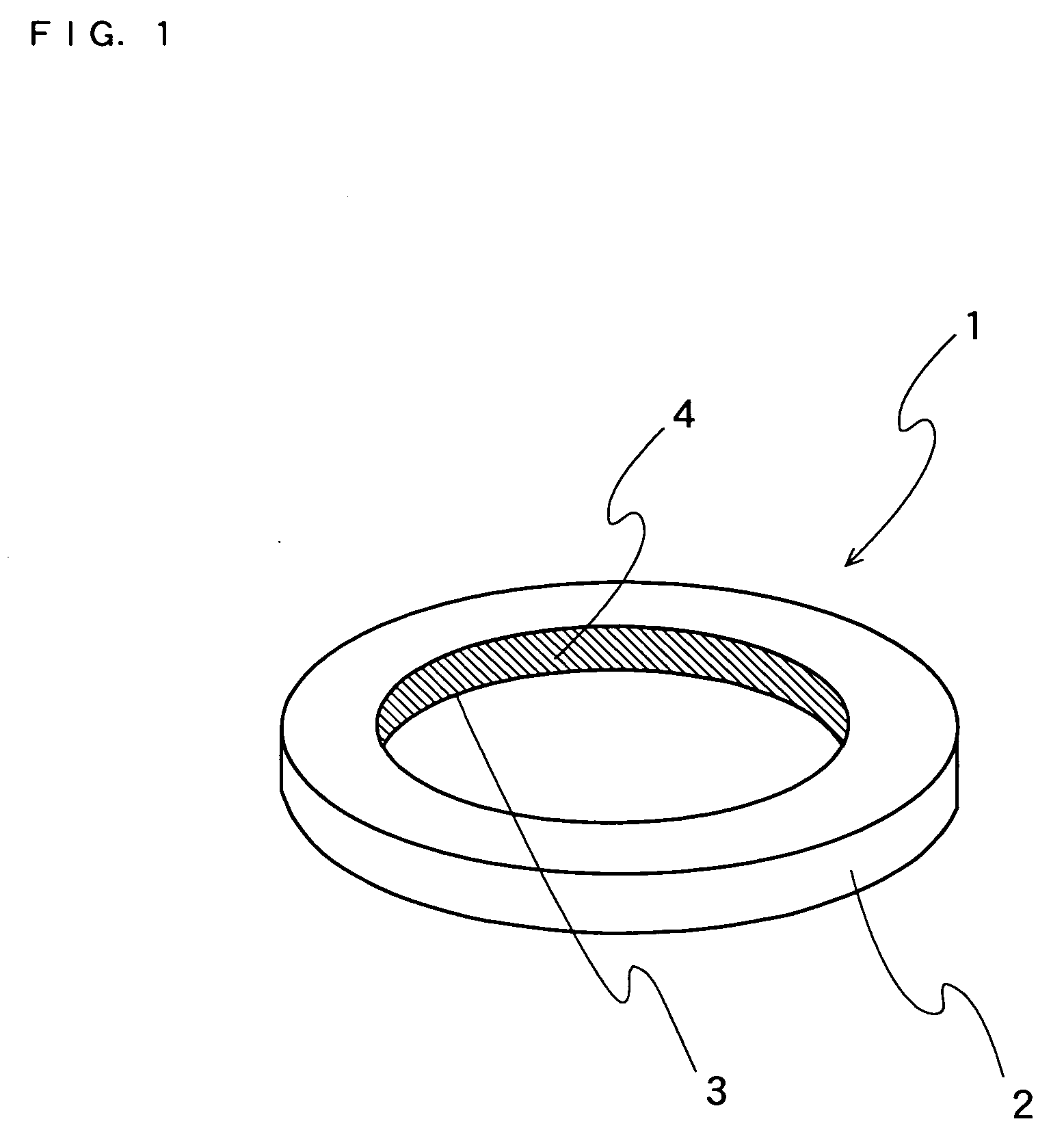

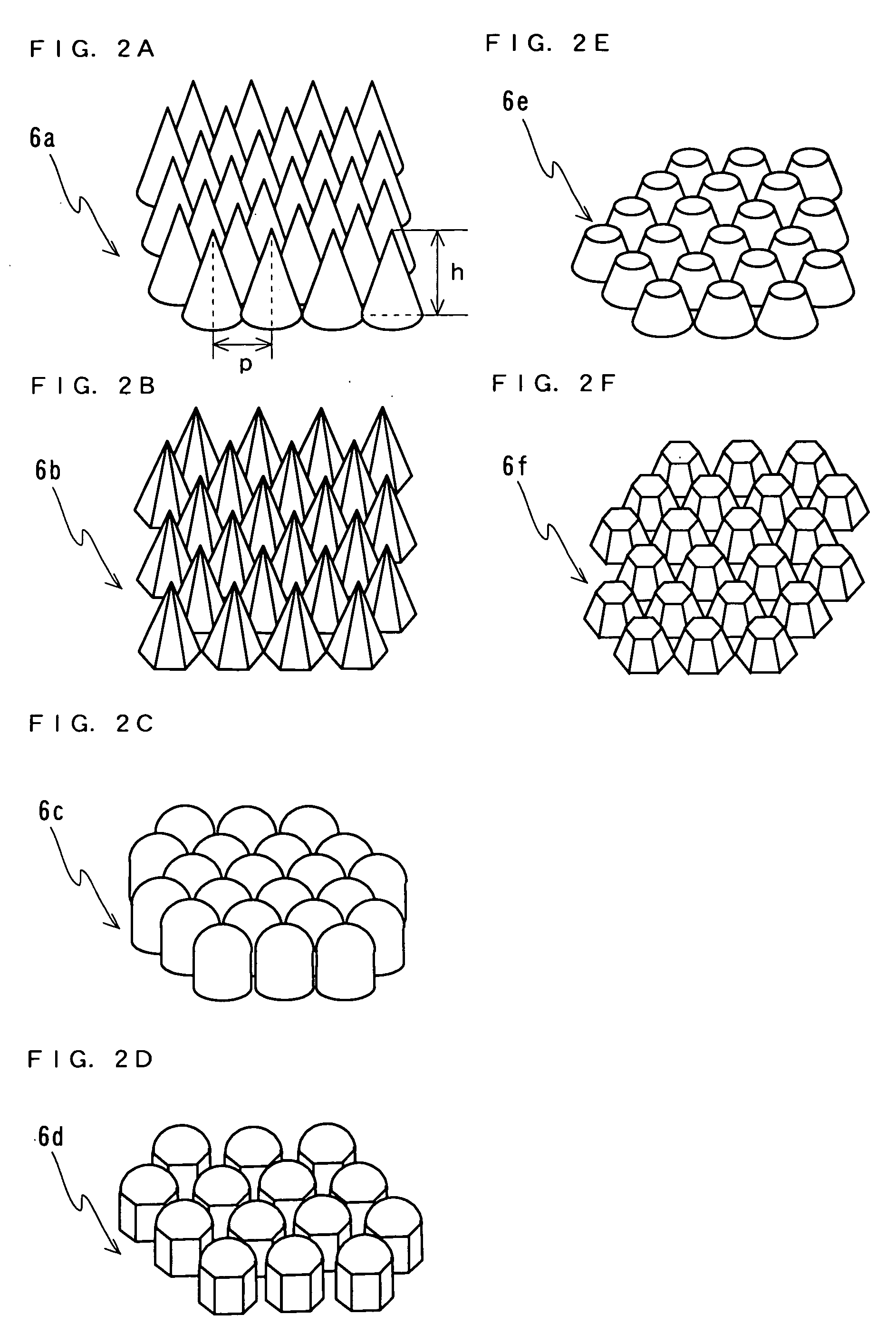

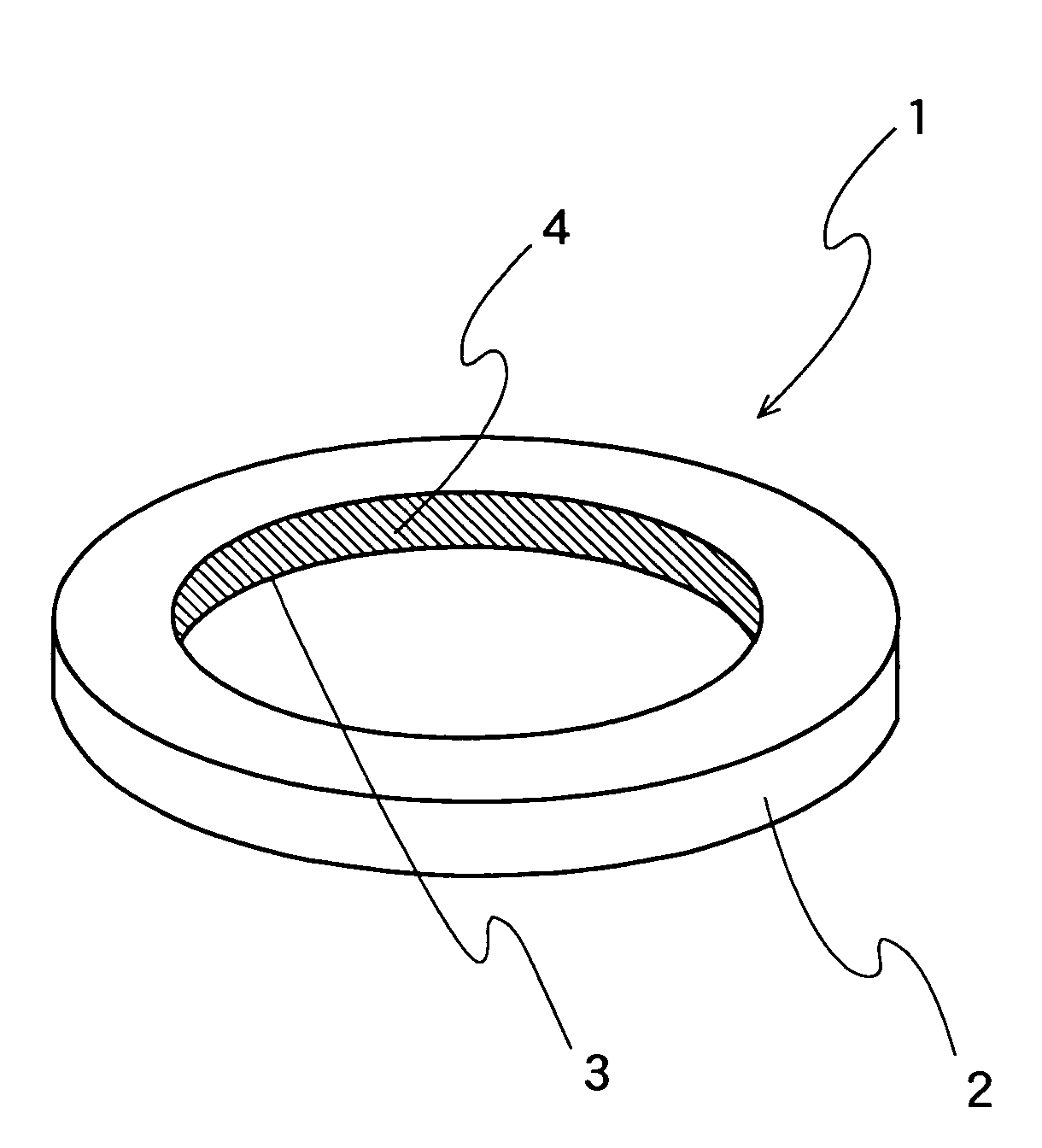

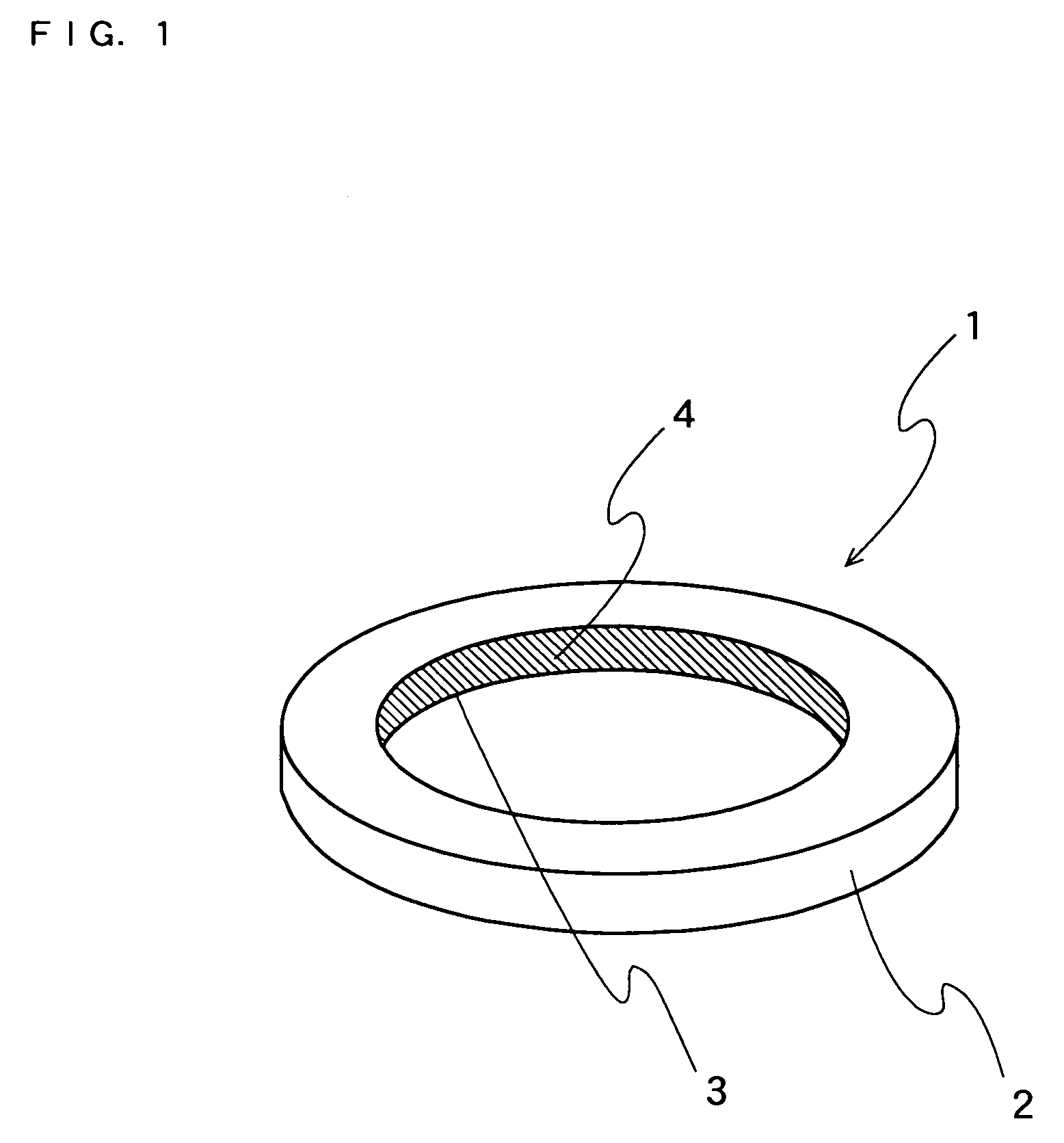

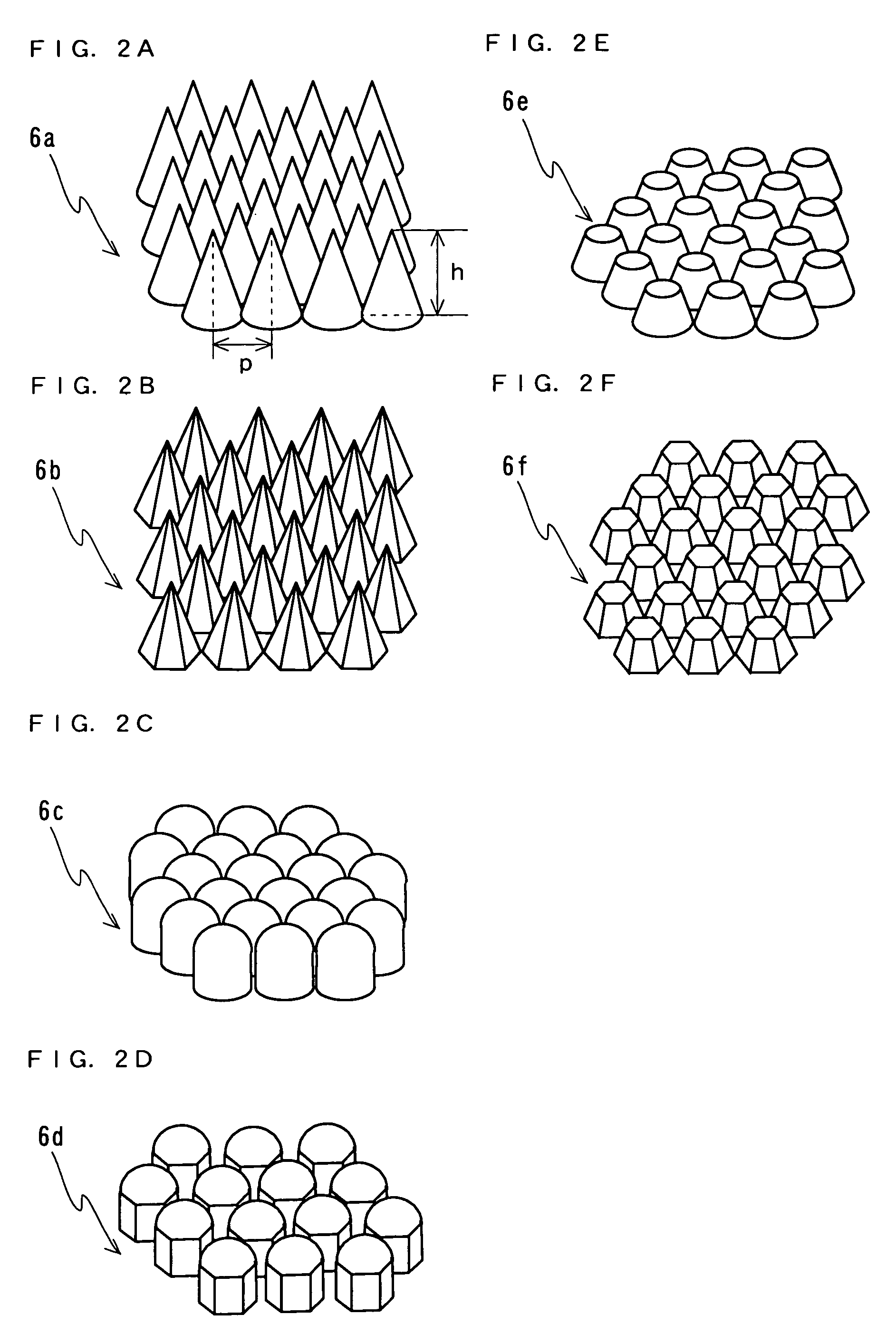

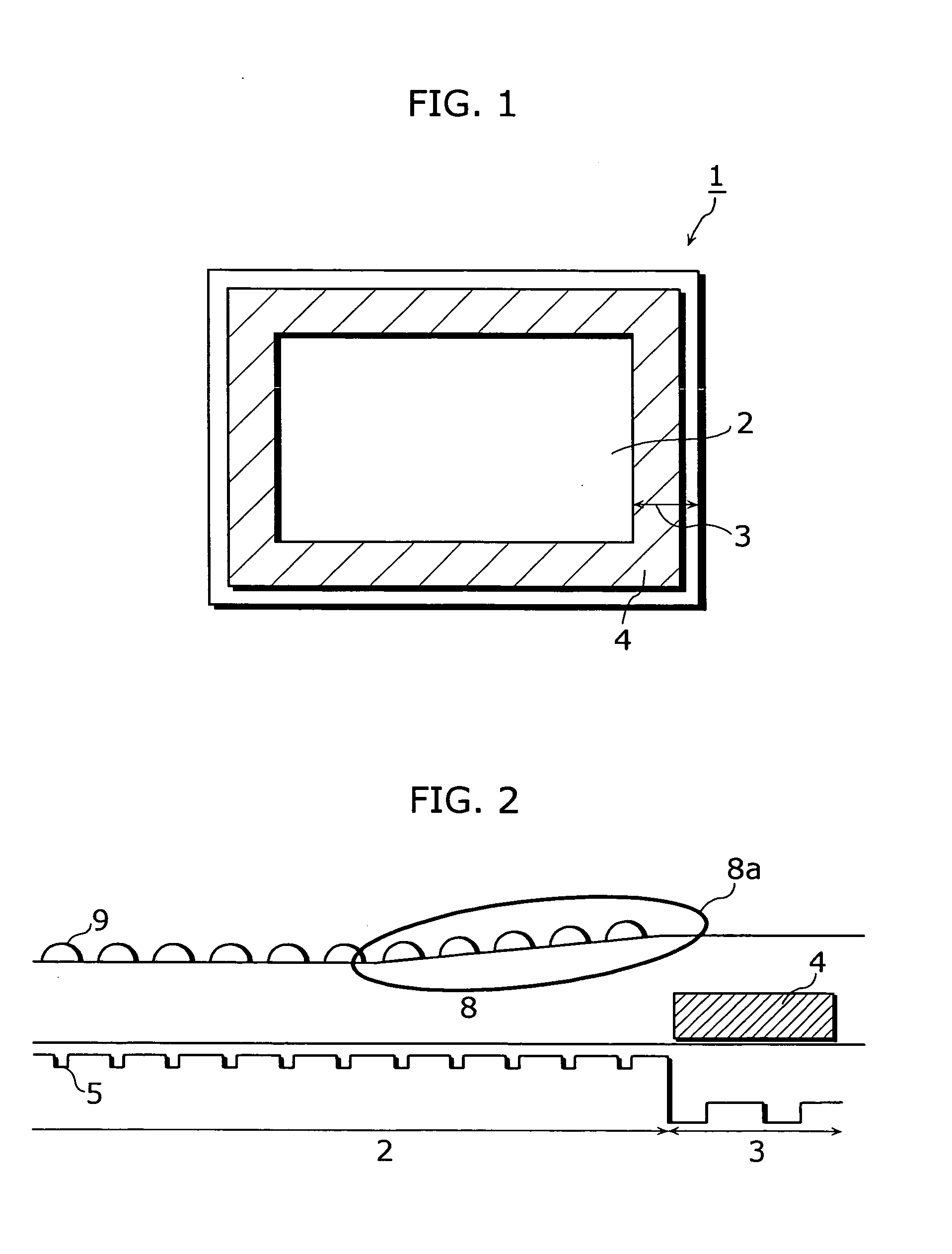

Member having antireflection structure

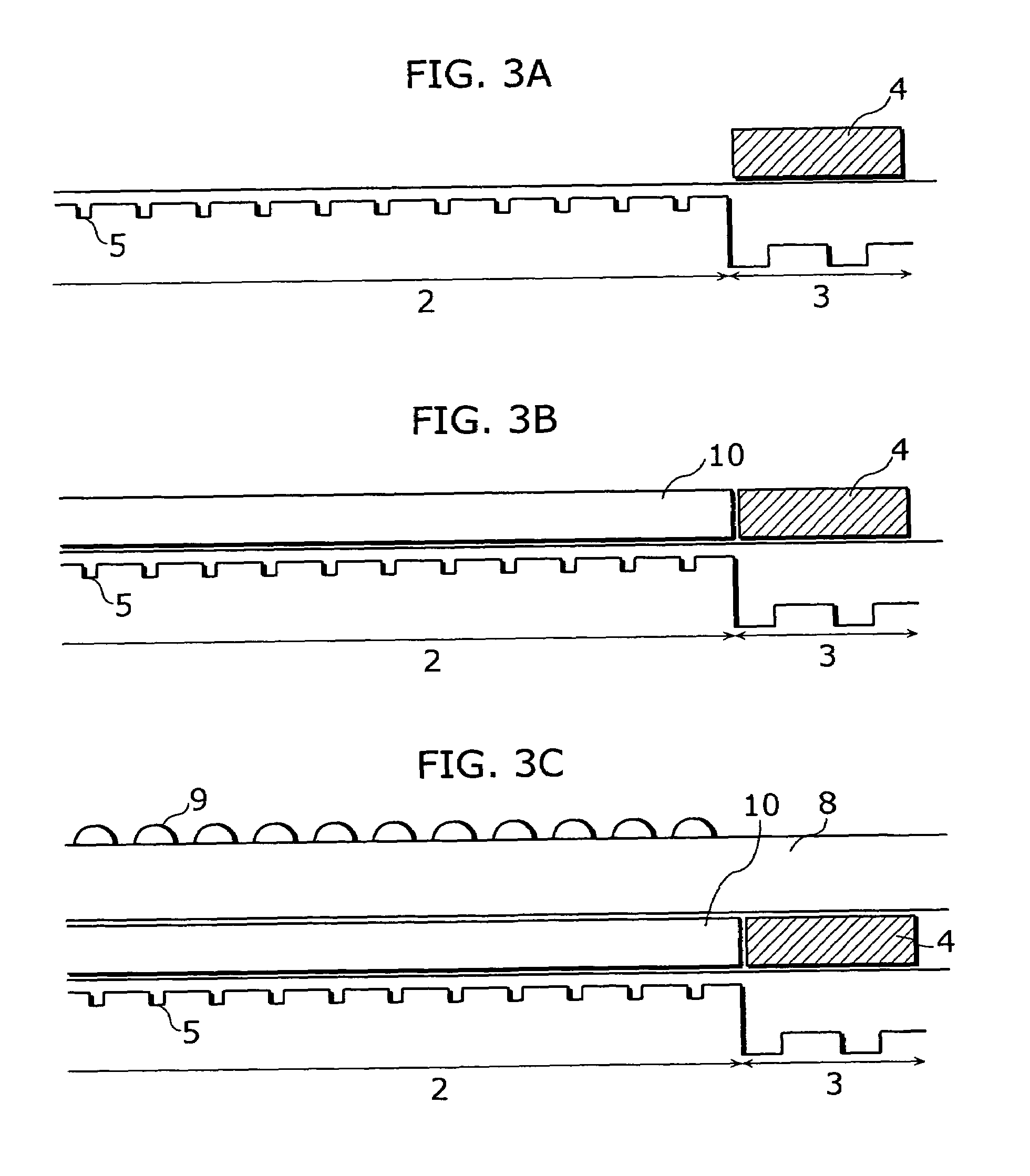

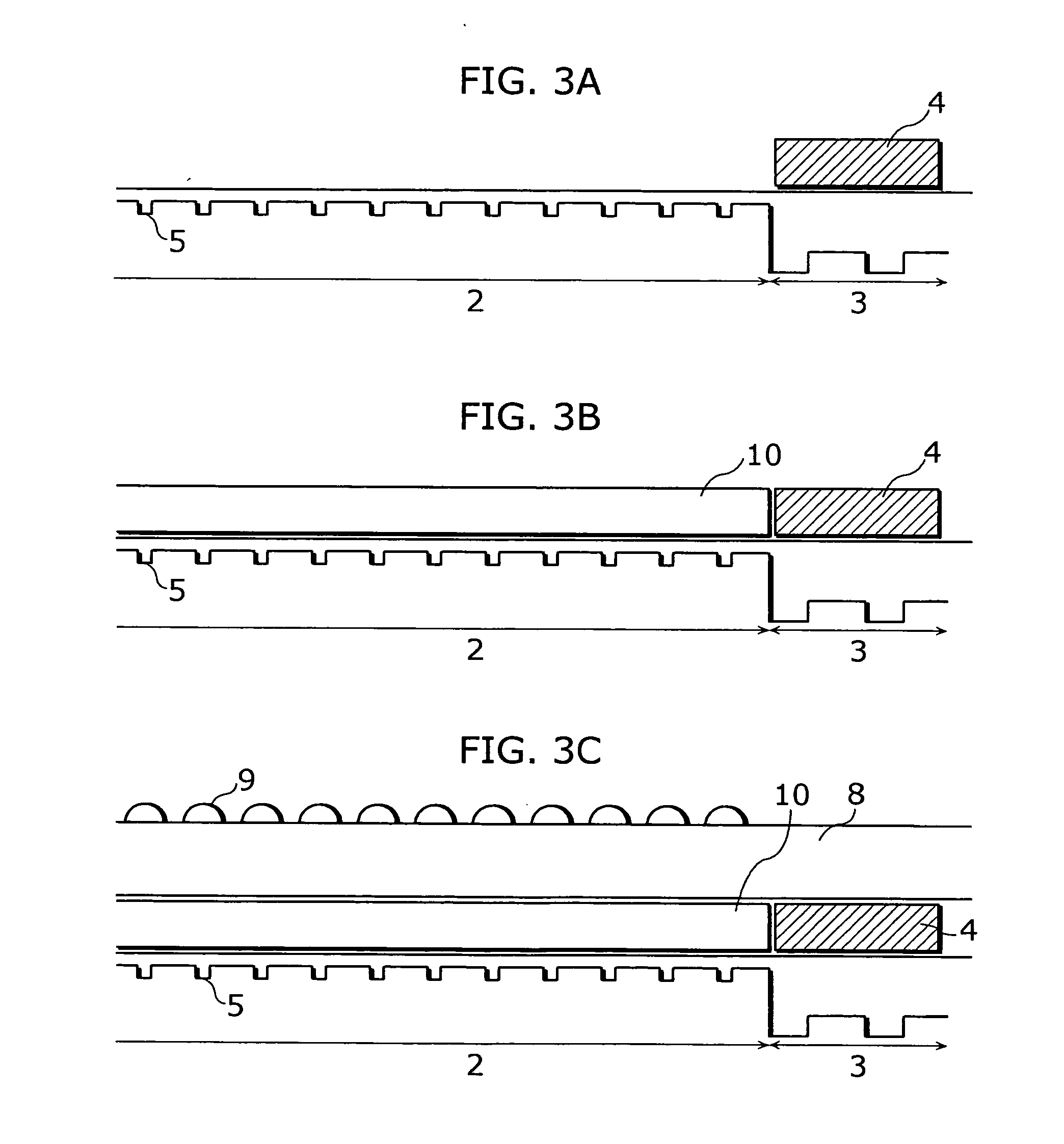

InactiveUS20060227834A1Avoid reflectionsInhibitionLaser detailsDiffraction gratingsLength waveStray light

A reflection of unnecessary light, which should be prevented, can be suppressed, and occurrence of stray light can be reduced using a member having an antireflection structure, comprising a plate-like portion 2, and an aperture portion 3 formed in the plate-like portion 2, wherein the antireflection structure having an aspect ratio of 1 or more and comprising structural elements arranged in an array form at a period smaller than the shortest wavelength of light, the reflection of which should be prevented, is formed on an inner wall 4 of the aperture portion 3.

Owner:PANASONIC CORP

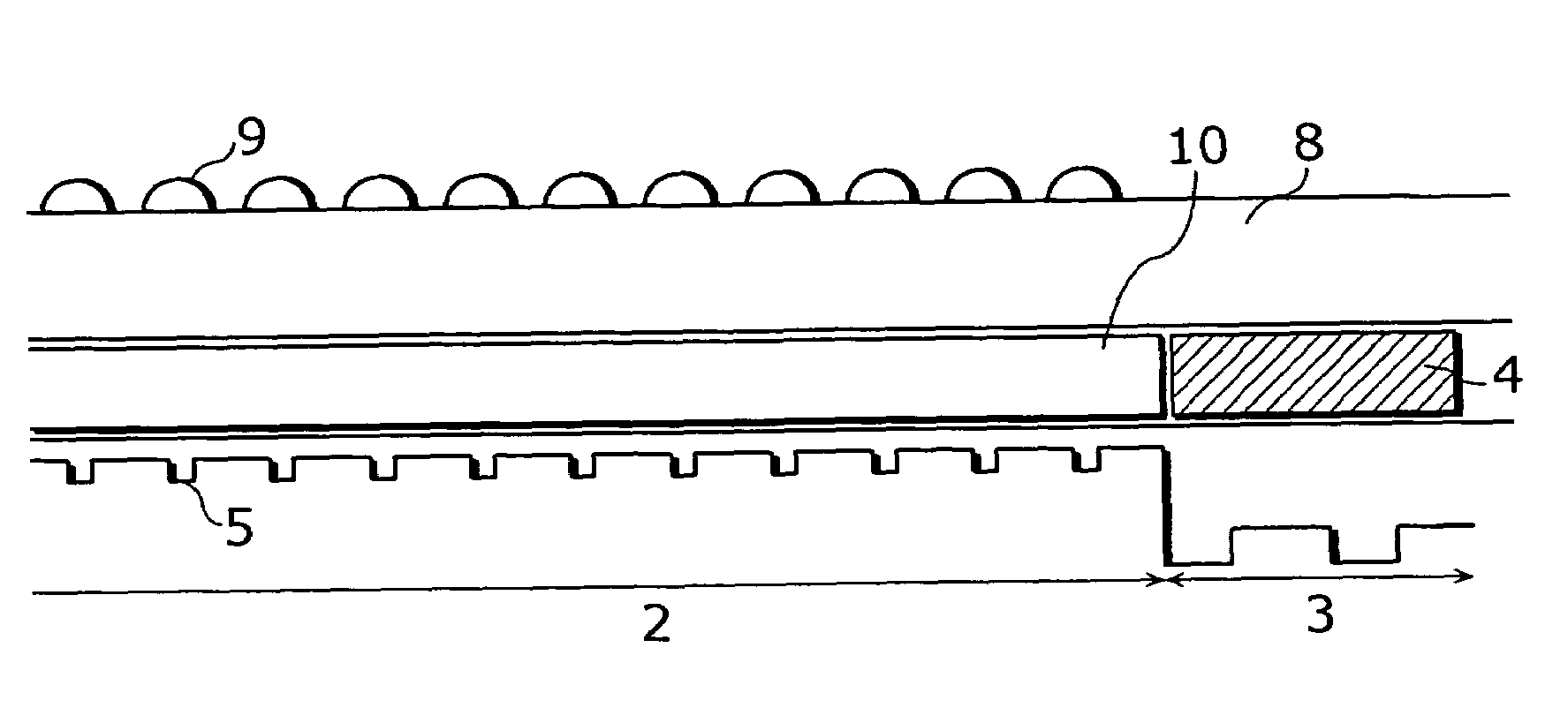

Image sensor and manufacturing method of image sensor

ActiveUS7078258B2Less-uneven sensitivityAvoid flaringTelevision system detailsSolid-state devicesMethod of imagesEngineering

In a manufacturing method of an image sensor, a lightproof film (an antireflective film for avoiding flares) is formed over a wiring area; a transparent film is formed over an imaging area using a material capable of patterning; a transparent film, for forming micro lense on top, is formed on the transparent film, wherein a height of the top surfaces of the transparent film and the lightproof film are evenly formed.

Owner:COLLABO INNOVATIONS INC

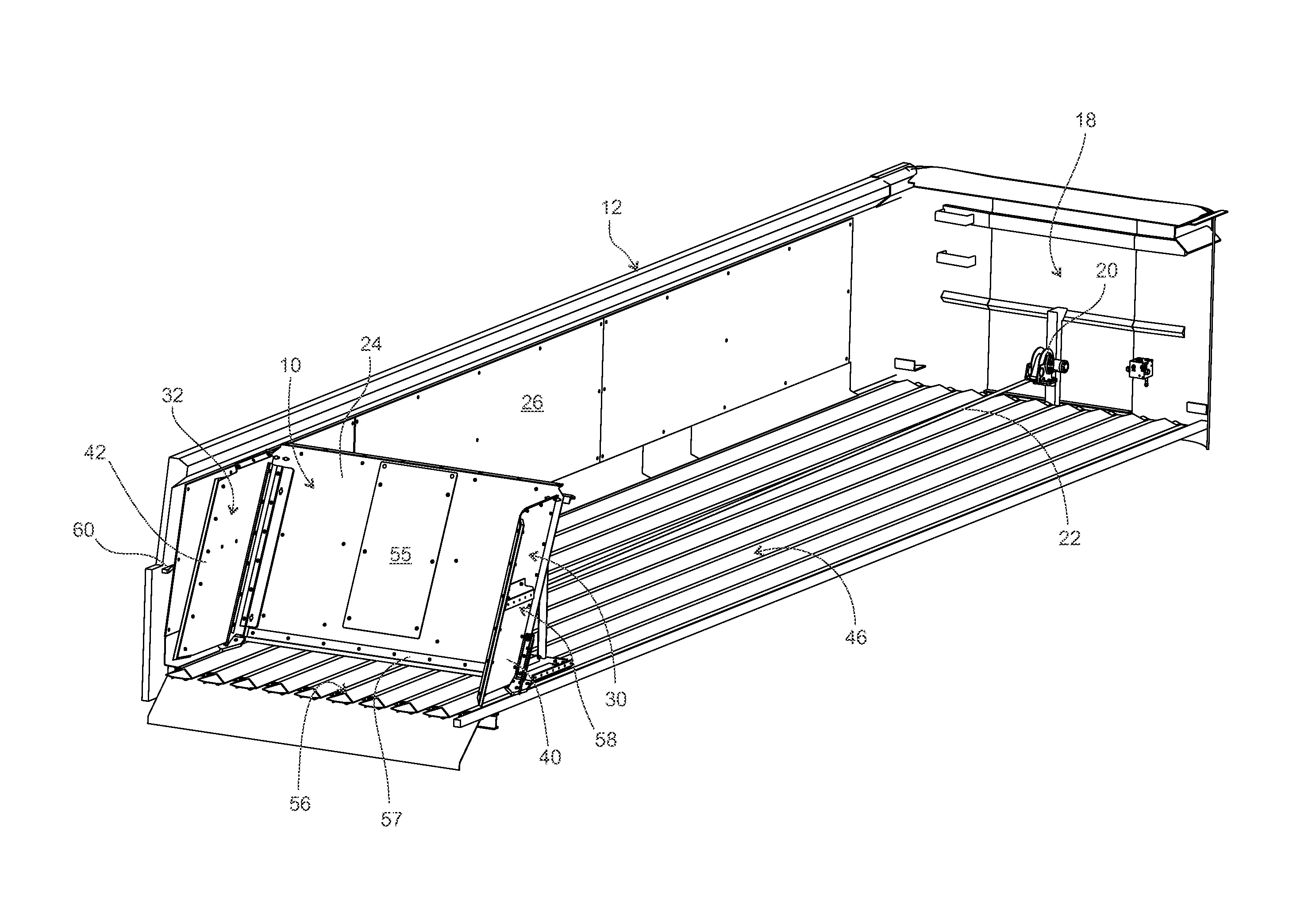

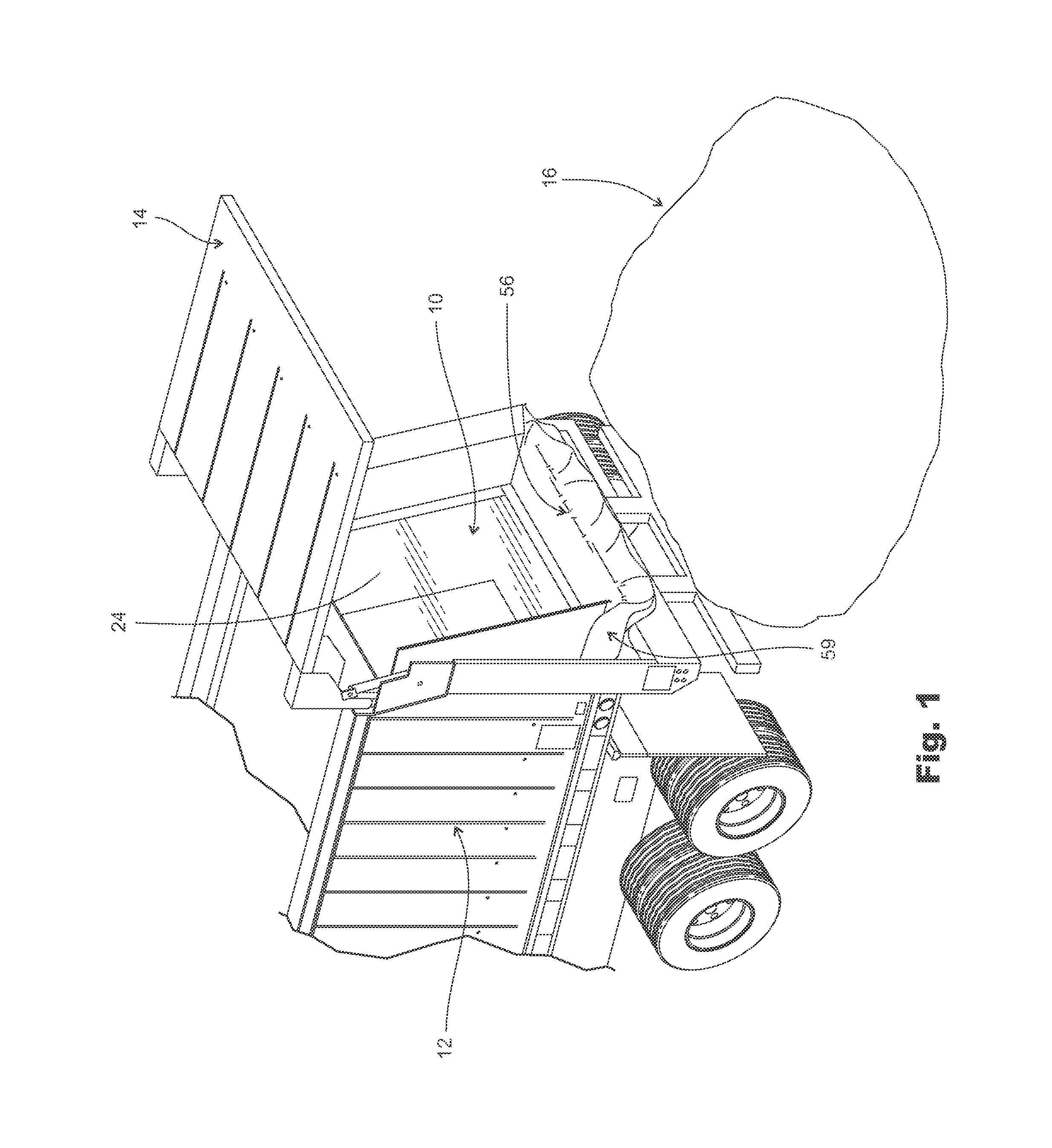

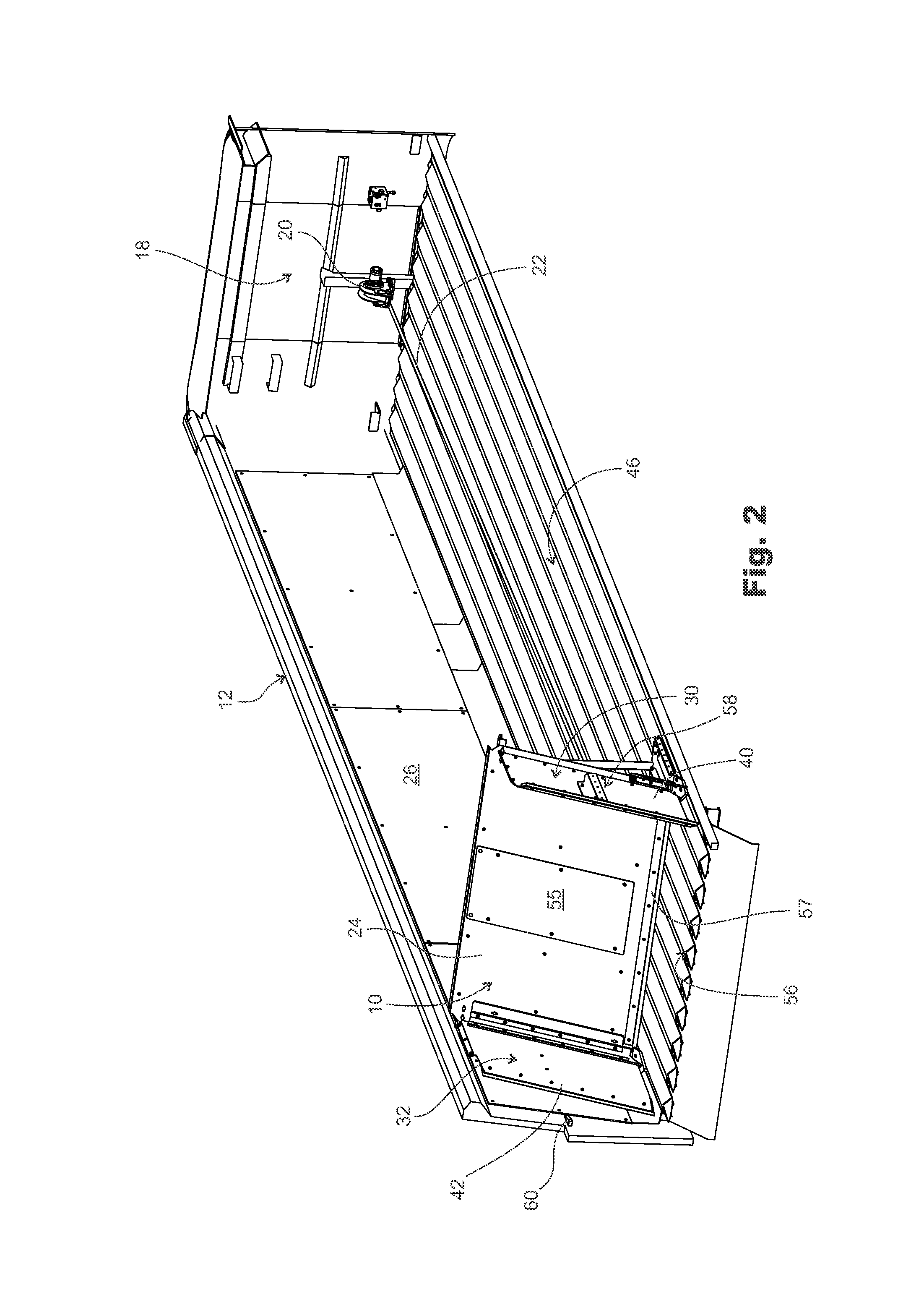

Moving cleanout for reciprocating conveyor system

ActiveUS9090193B2Easy to adjustAvoid flaringVehicle with pusher plateVehicle with tipping movementConveyor systemEngineering

The invention disclosed here is a moving headboard for use in connection with a reciprocating floor slat system. It is particularly well-suited for use in connection with load-hauling trailers that have built-in reciprocating floor slat conveyors for unloading the trailer. Trailers of this kind are used in lieu of hydraulic lifts and involve inching the load off the trailer. The moving headboard sweeps the trailer floor clean during the unloading process.

Owner:KEITH MFG

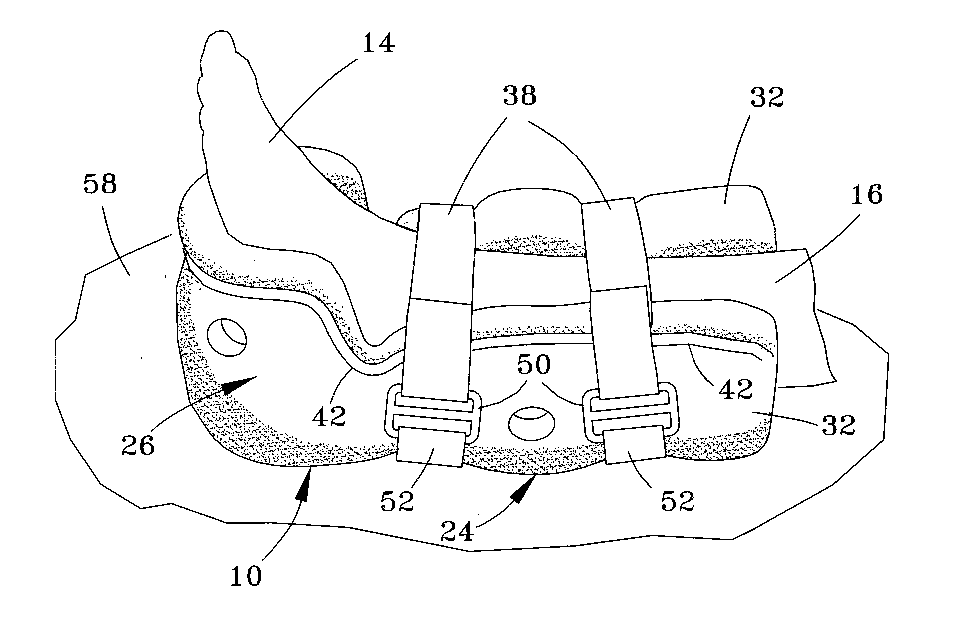

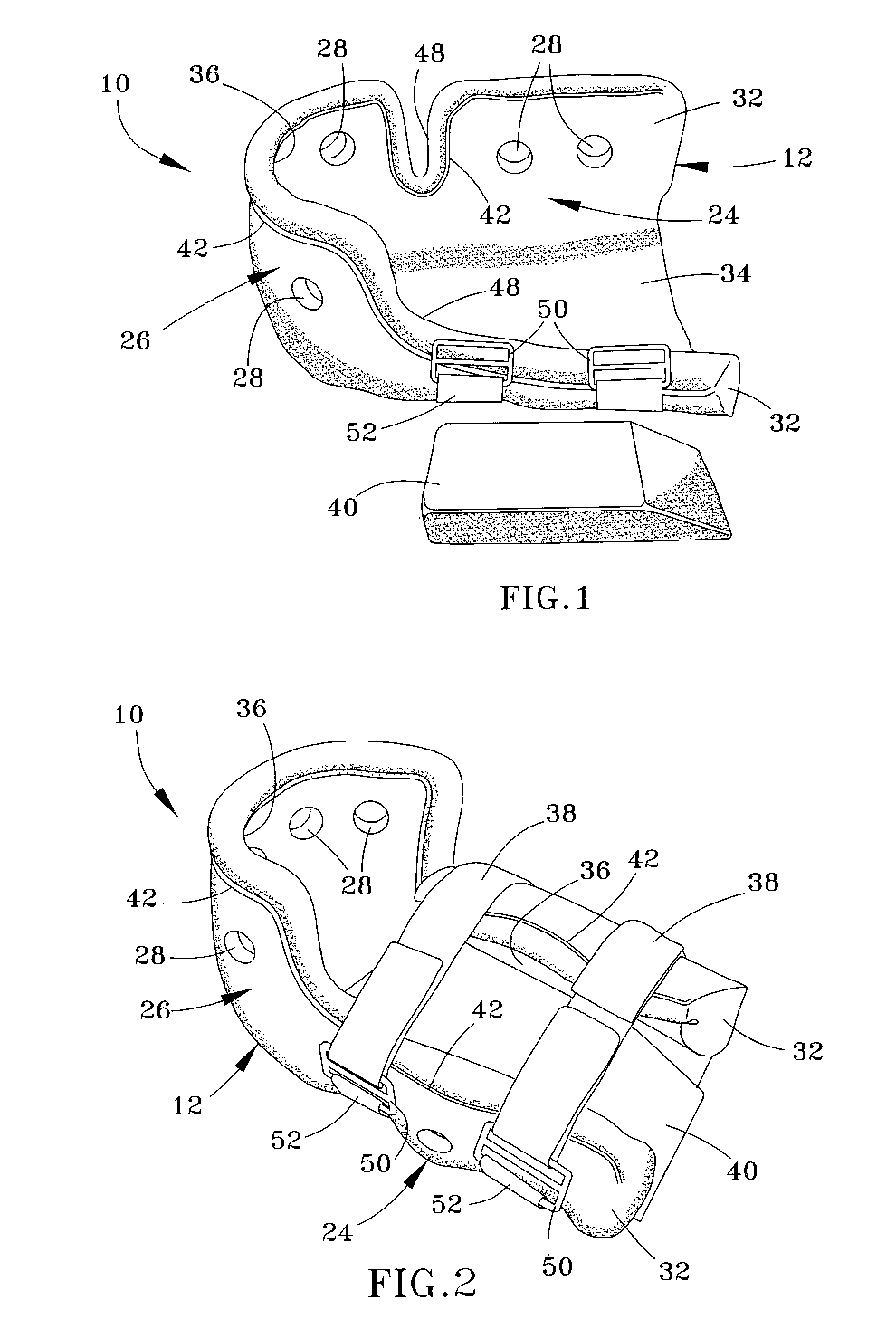

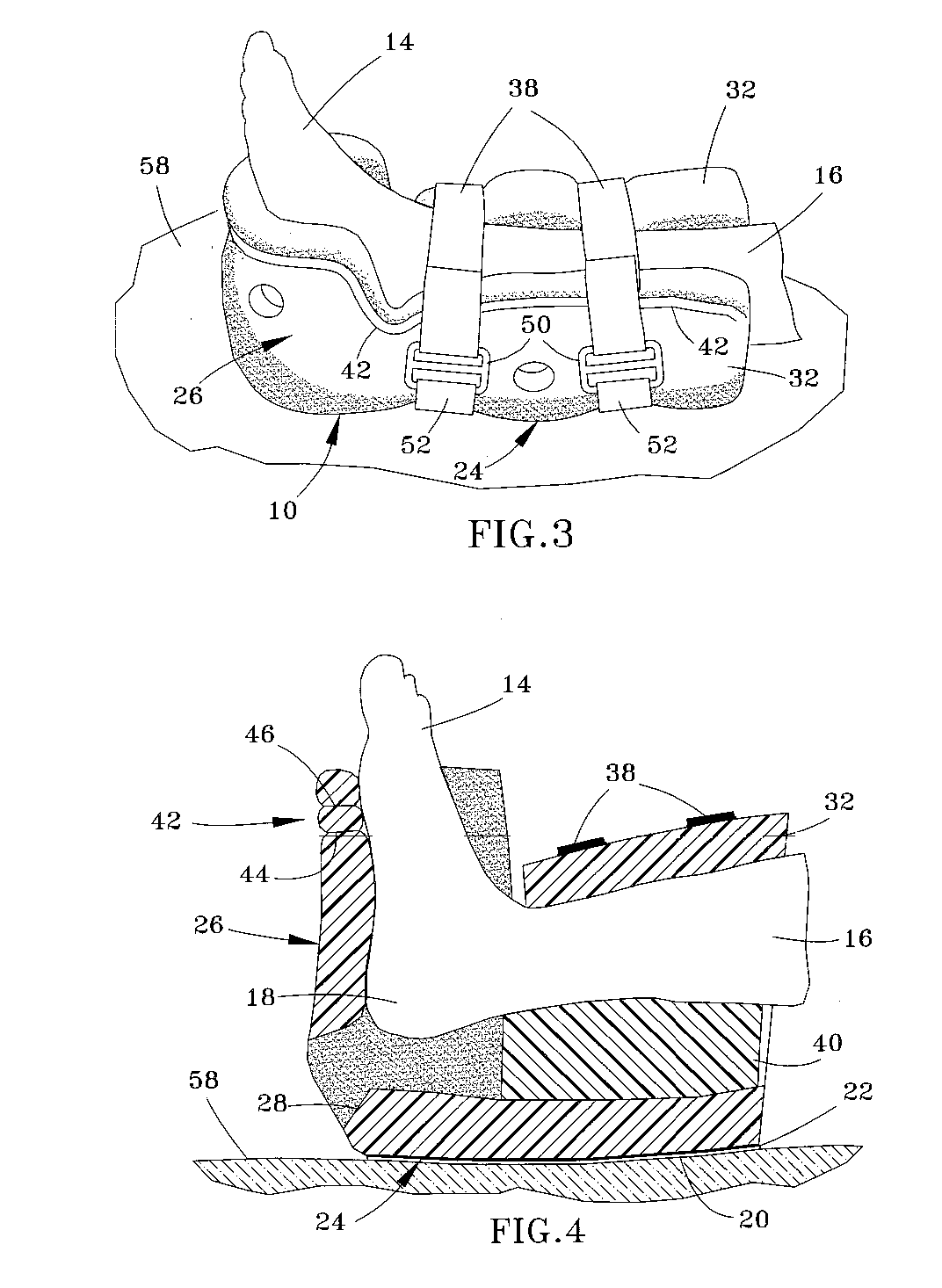

Heel-supporting protective boot

ActiveUS20070073208A1Avoid flaringAvoid flatteningRestraining devicesFeet bandagesLateral regionHeel

A heel-supporting boot capable of supporting a leg of a person in a supine reclining position, such as a bedridden patient, to reduce the risk of bed sores, foot drop, etc. The boot includes a flexible and compressible body having leg and forefoot portions, a continuous cavity within the leg and forefoot portions, an anterior opening to permit a patient's foot and leg to pass therethrough into the cavity, oppositely-disposed lateral regions defined by the leg portion and separated by the anterior opening, and an adjustable closing feature for closing the anterior opening with the lateral regions. A stitch pattern is disposed along at least the forefoot rim, and preferably also the lateral rims, bounding the anterior opening. The stitch pattern is sufficiently close to the forefoot rim and optionally the lateral rims to structurally reinforce the forefoot rim and inhibit elastic and plastic deformation of the forefoot portion.

Owner:WALGREEN HEALTH SOLUTIONS LLC

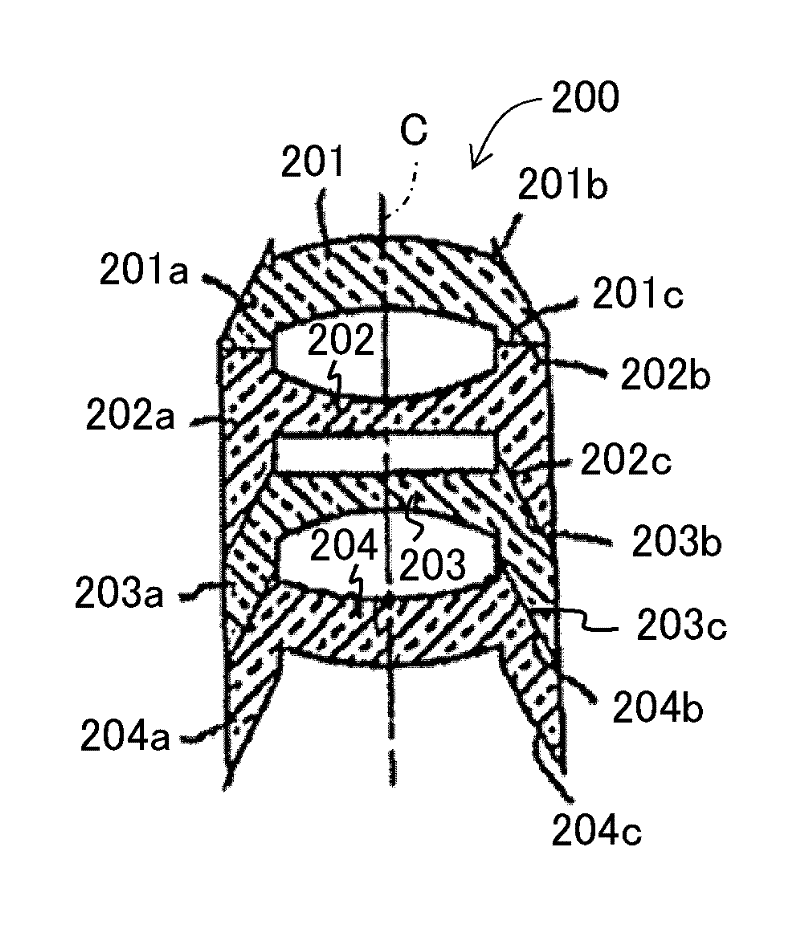

Member having antireflection structure

InactiveUS7787184B2Reflection of unnecessary lightInhibitionDiffraction gratingsMountingsLength waveStray light

A reflection of unnecessary light, which should be prevented, can be suppressed, and occurrence of stray light can be reduced using a member having an antireflection structure, comprising a plate-like portion 2, and an aperture portion 3 formed in the plate-like portion 2, wherein the antireflection structure having an aspect ratio of 1 or more and comprising structural elements arranged in an array form at a period smaller than the shortest wavelength of light, the reflection of which should be prevented, is formed on an inner wall 4 of the aperture portion 3.

Owner:PANASONIC CORP

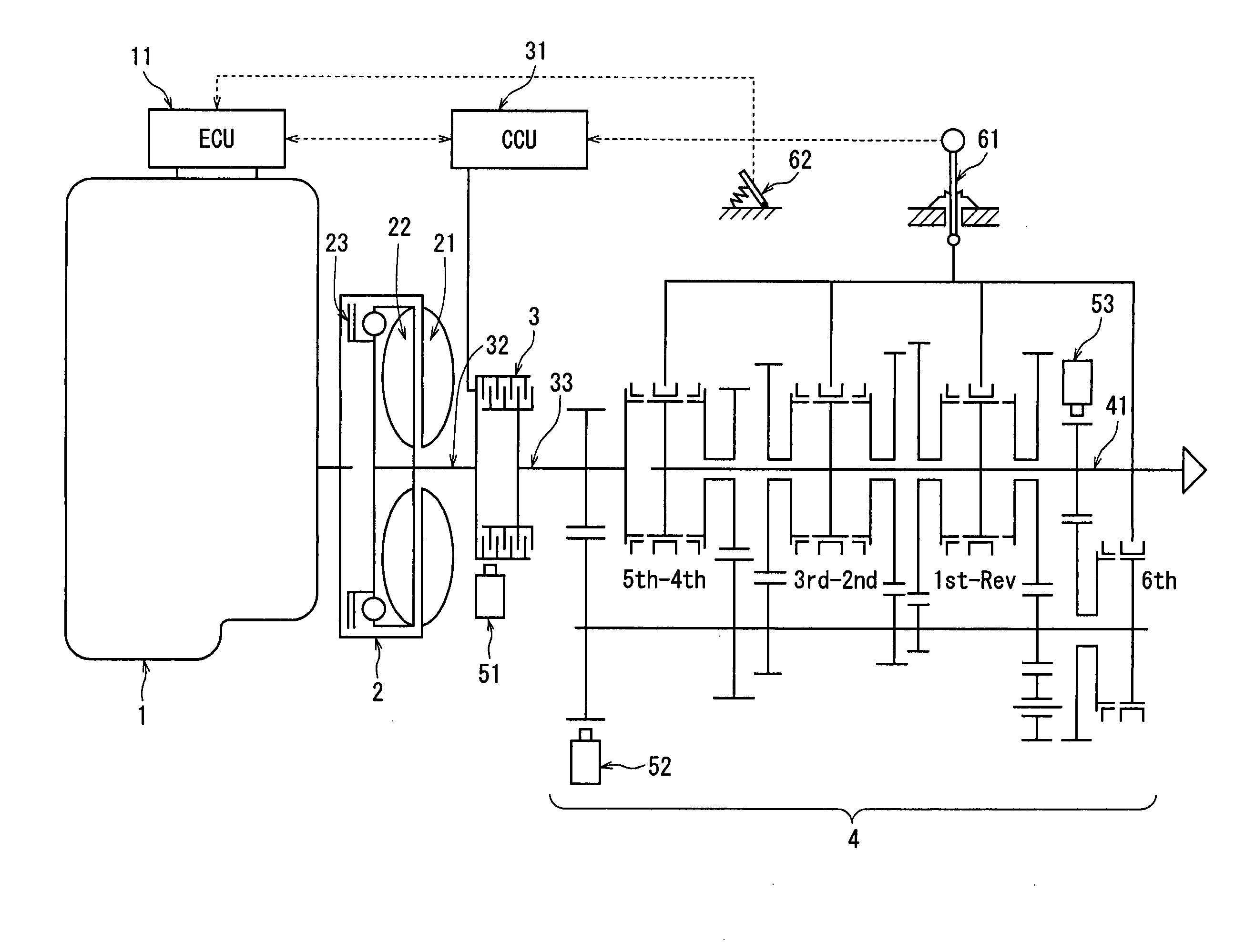

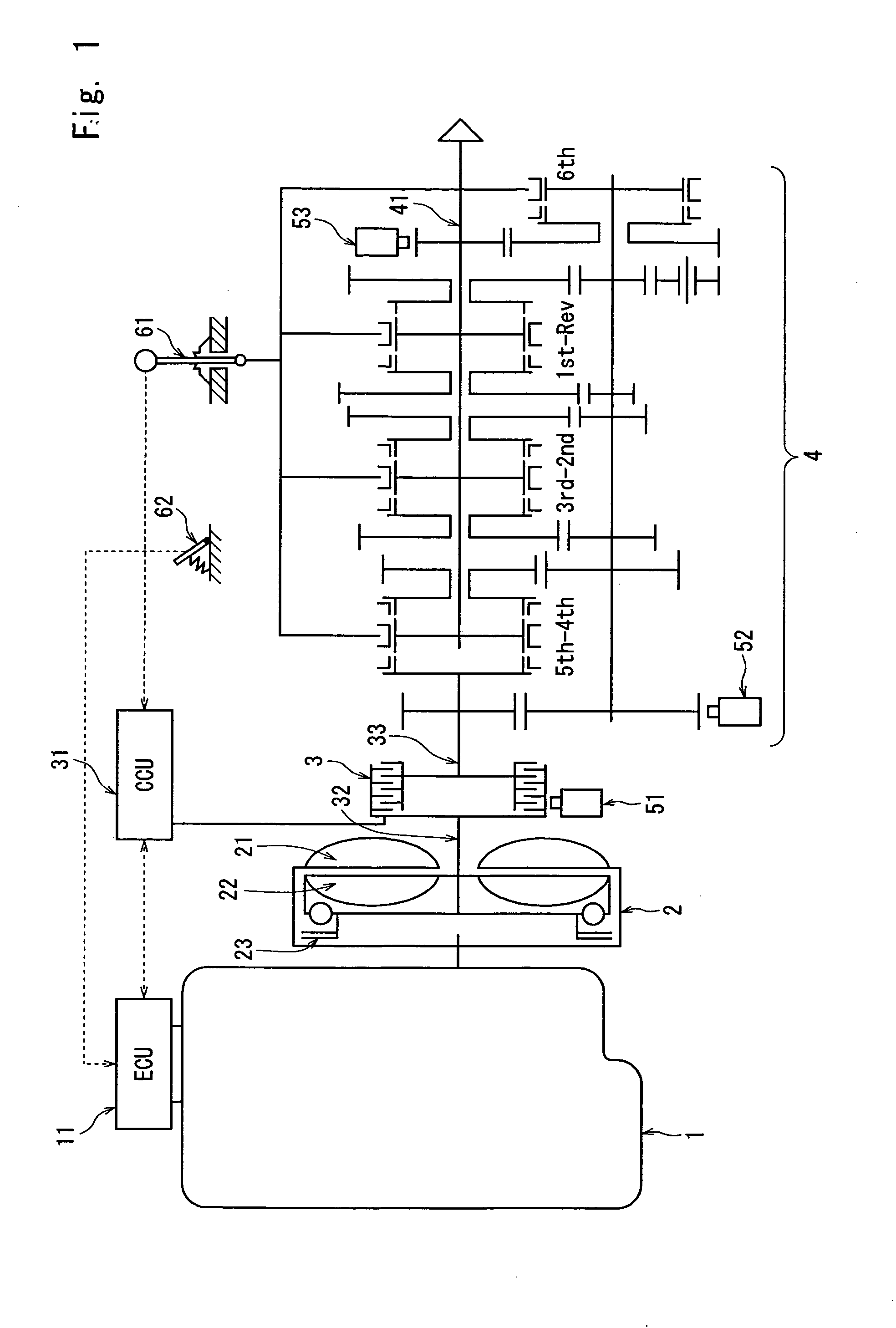

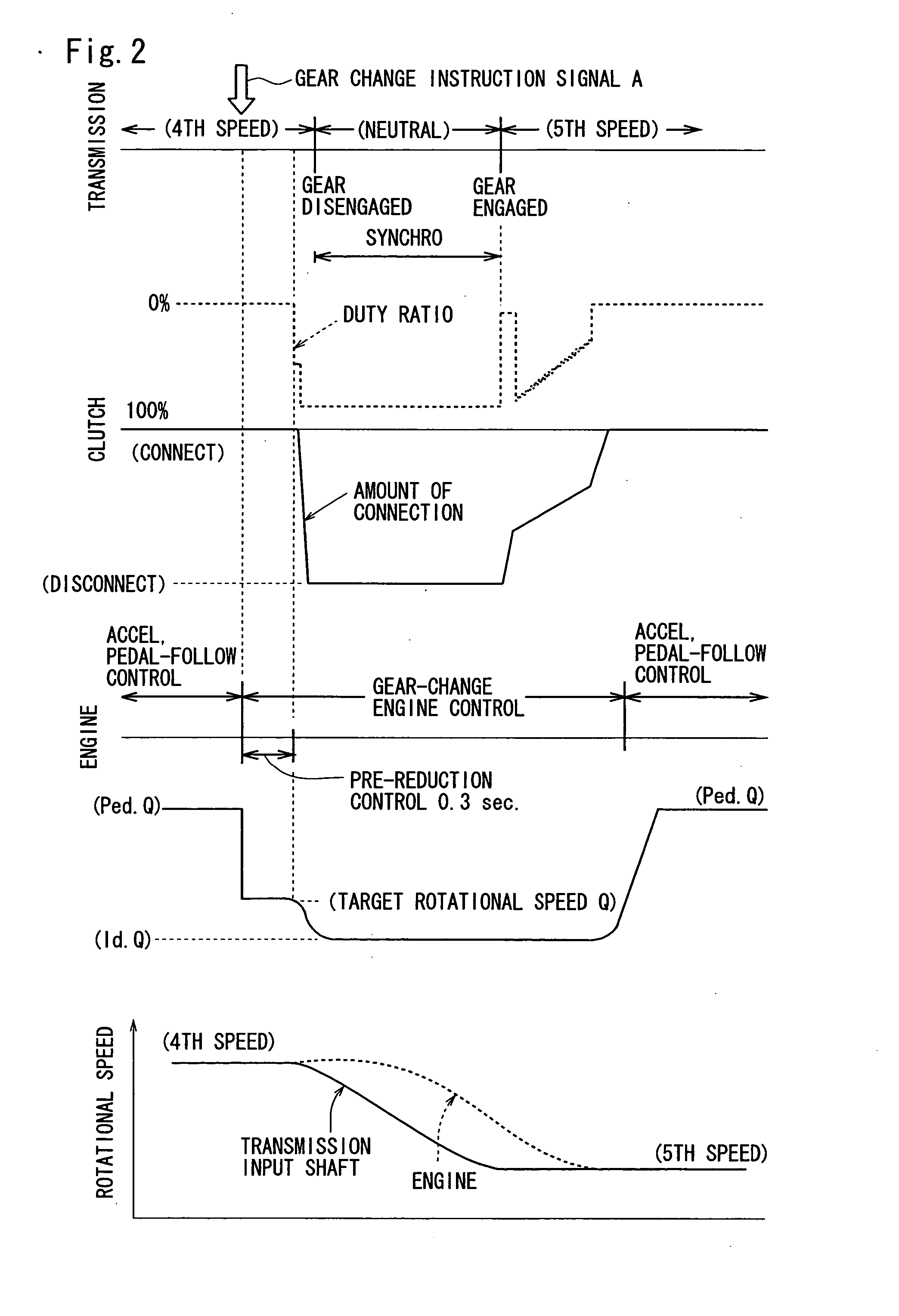

Vehicle controller of a vehicle power transmission device

InactiveUS20070173374A1Relaxing “ acceleration spoiling ”Increase engine speedEngine controllersMachines/enginesAcceleration UnitClutch

In a vehicle power transmission device equipped with an automatic clutch, the gear-change for shifting up is effected suppressing a sudden increase in the engine rotational speed that results when the automatic clutch is disconnected, preventing deterioration in the drive feeling caused by the change of gear such as a shock due to the change of gear. At the time of changing the gear for shifting up, an engine controller (11) executes a pre-reduction control for decreasing the output of the engine 1 for a predetermined period of time prior to disconnecting the clutch (3). Since the engine output has been decreased, the rotational speed of the engine (1) does not suddenly rise despite the vehicle traveling load is removed as a result of disconnecting the clutch 3. A target value for decreasing the engine output is suitably set depending upon the vehicle operating conditions, and a sudden increase in the rotational speed is prevented in all gears while relaxing the shock of gear-change caused by a sharp change in the acceleration.

Owner:ISUZU MOTORS LTD

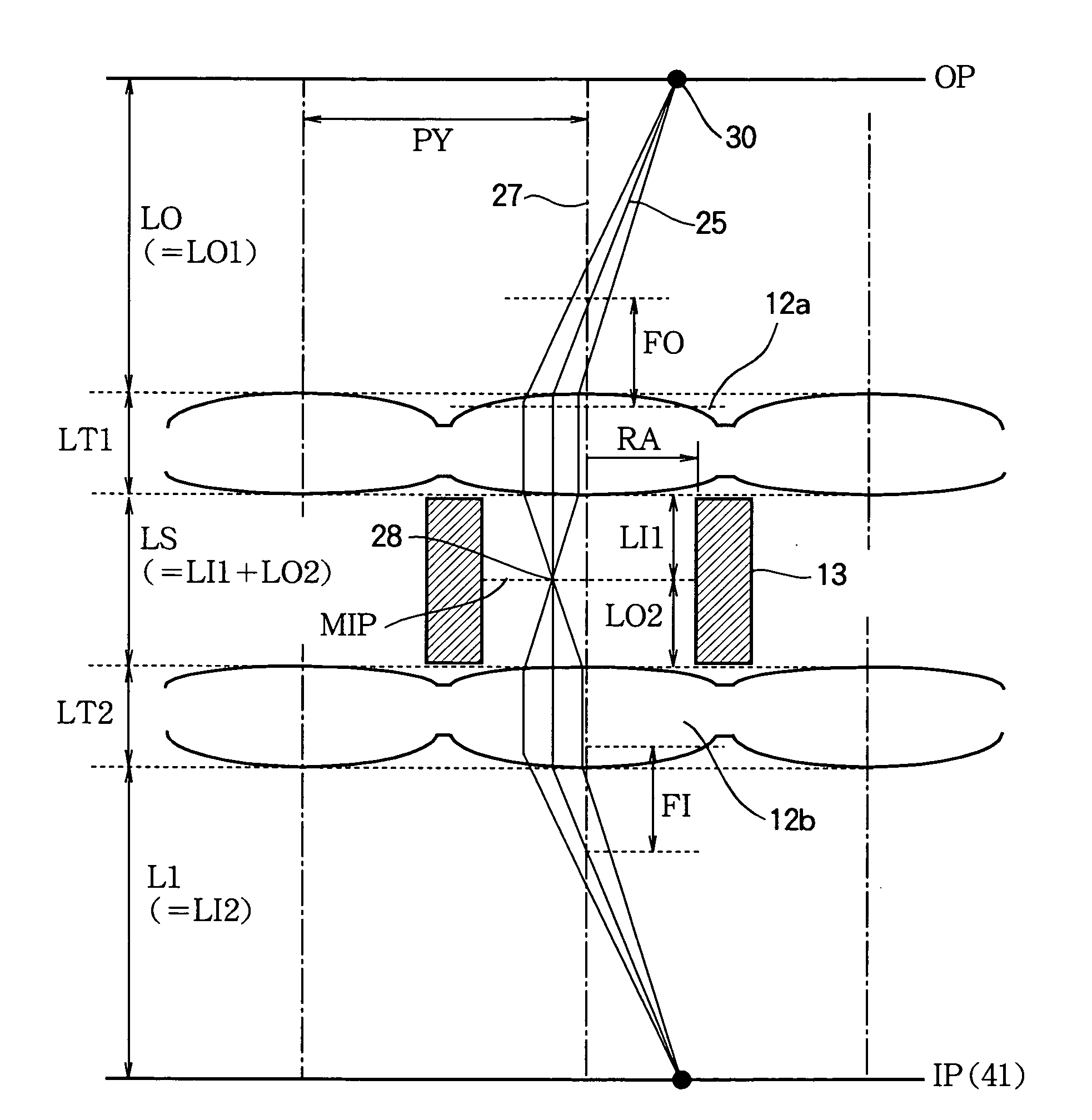

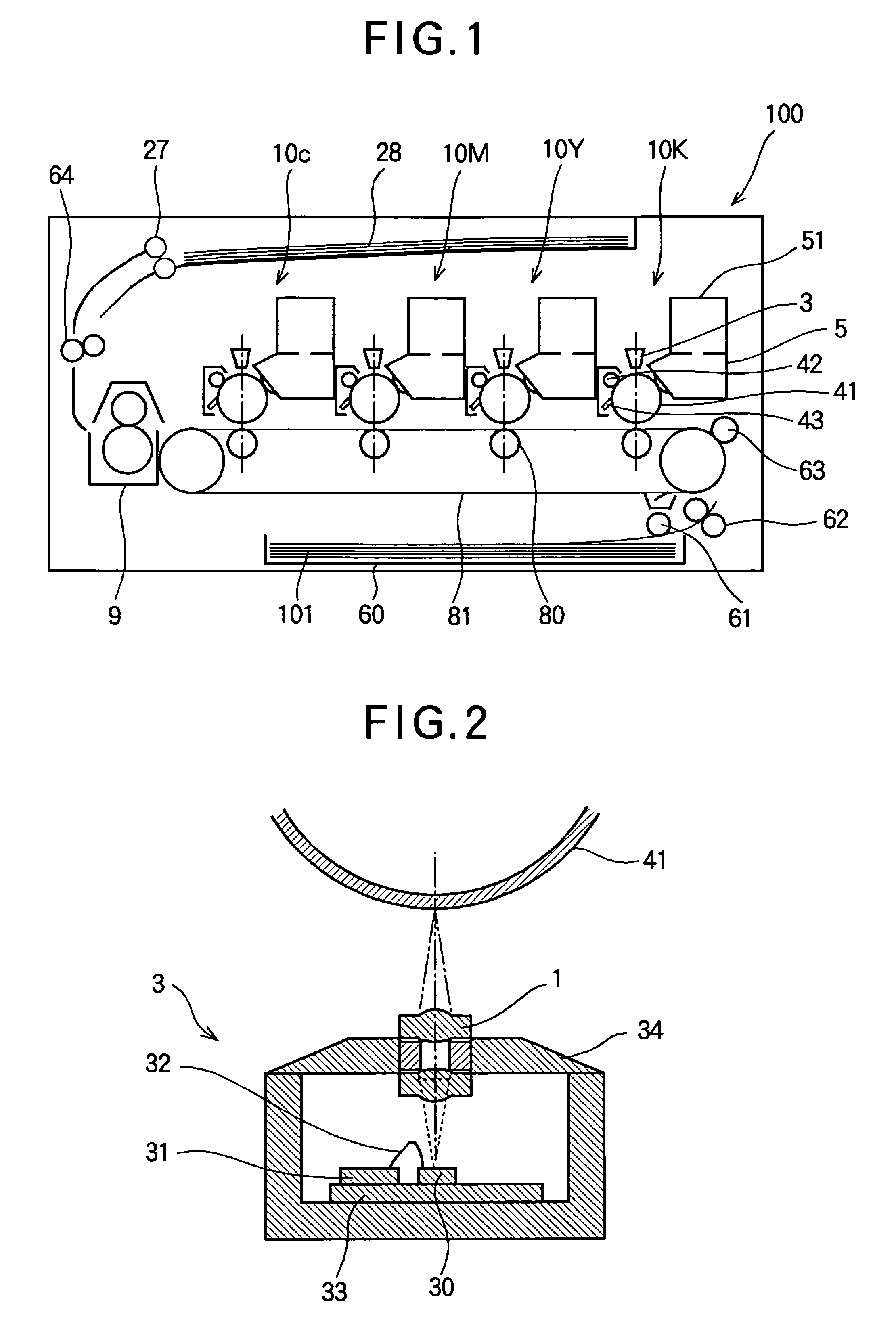

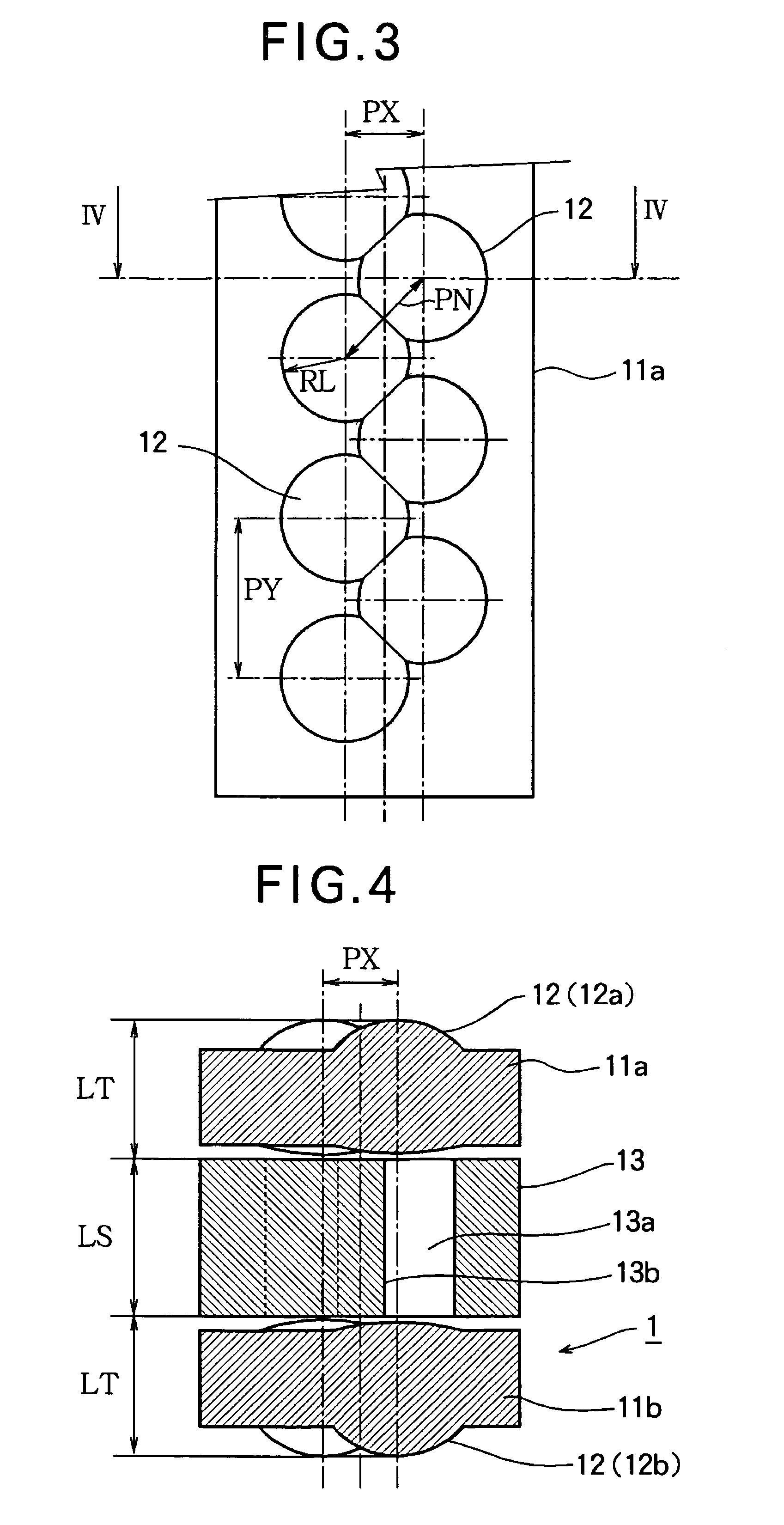

Lens array, LED head, exposure device, image forming apparatus and reading apparatus

A lens array includes a plurality of lens units each of which includes a plurality of microlenses linearly arranged, and a light shielding member having a plurality of openings as apertures. The openings are disposed so as to face the microlenses of respective lens units. Facing microlenses of the lens units have optical axes substantially aligned with each other and passing the openings of the light shielding member. Light absorbing portions are provided in the openings.

Owner:OKI DATA CORP

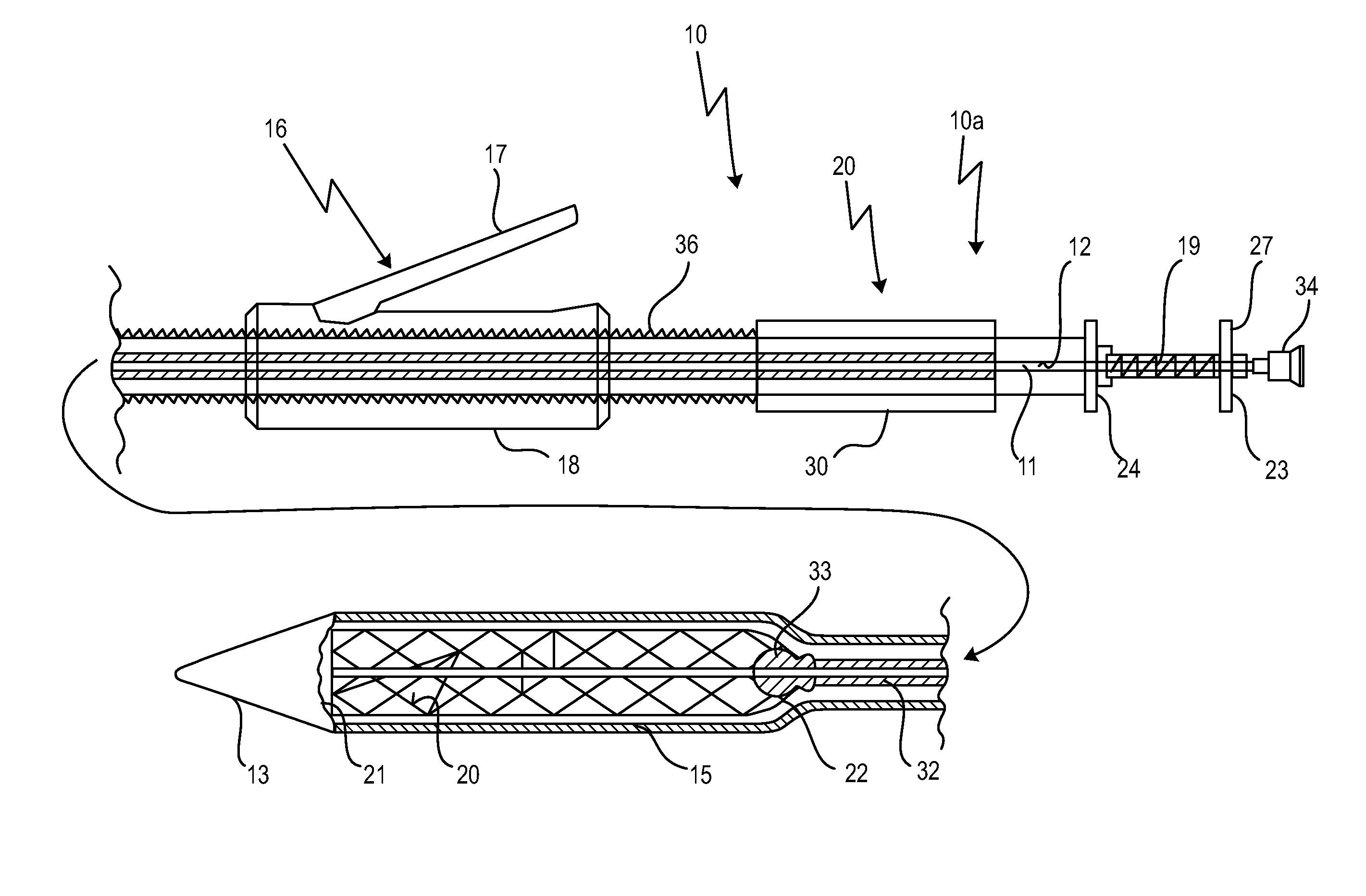

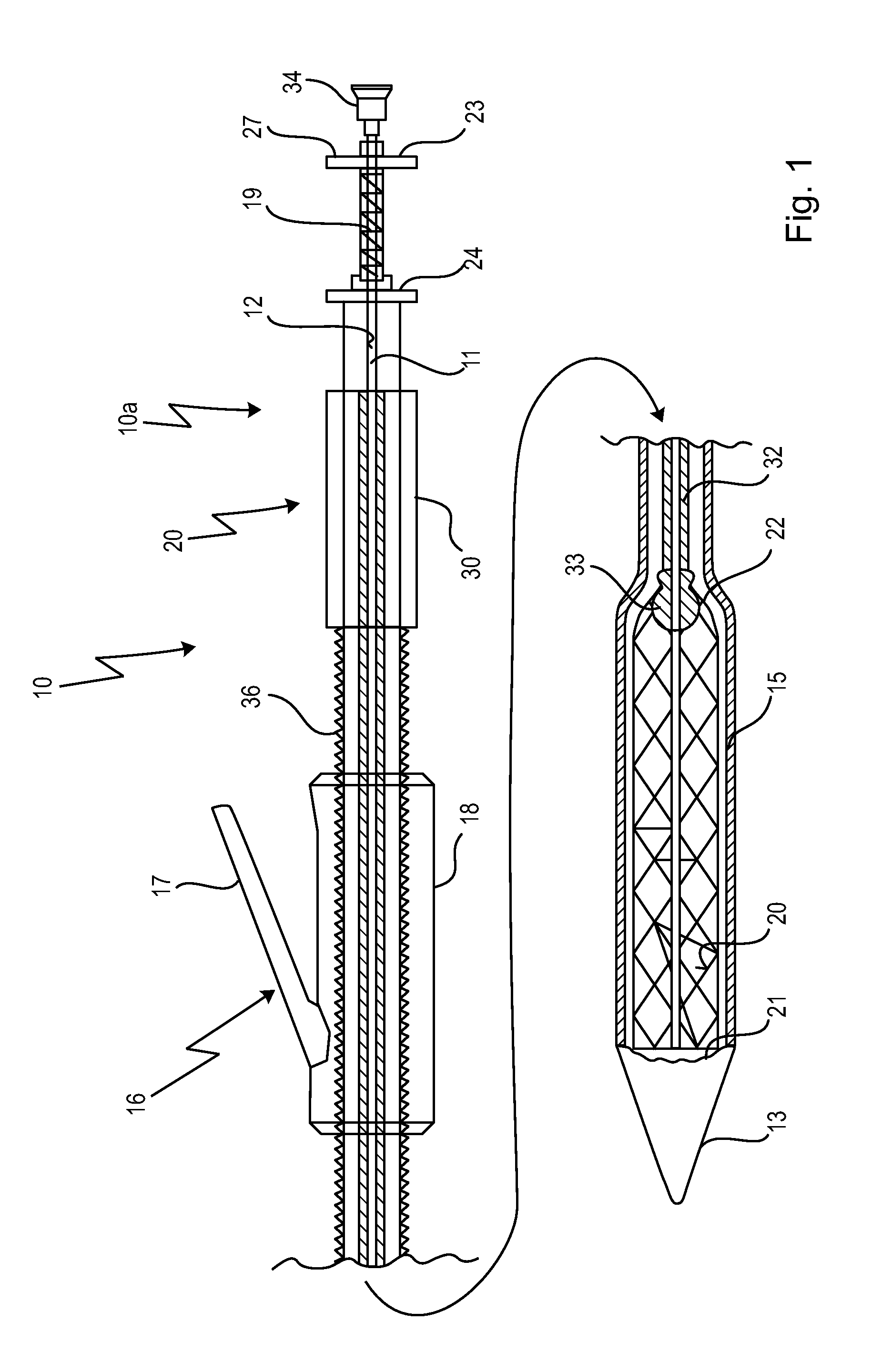

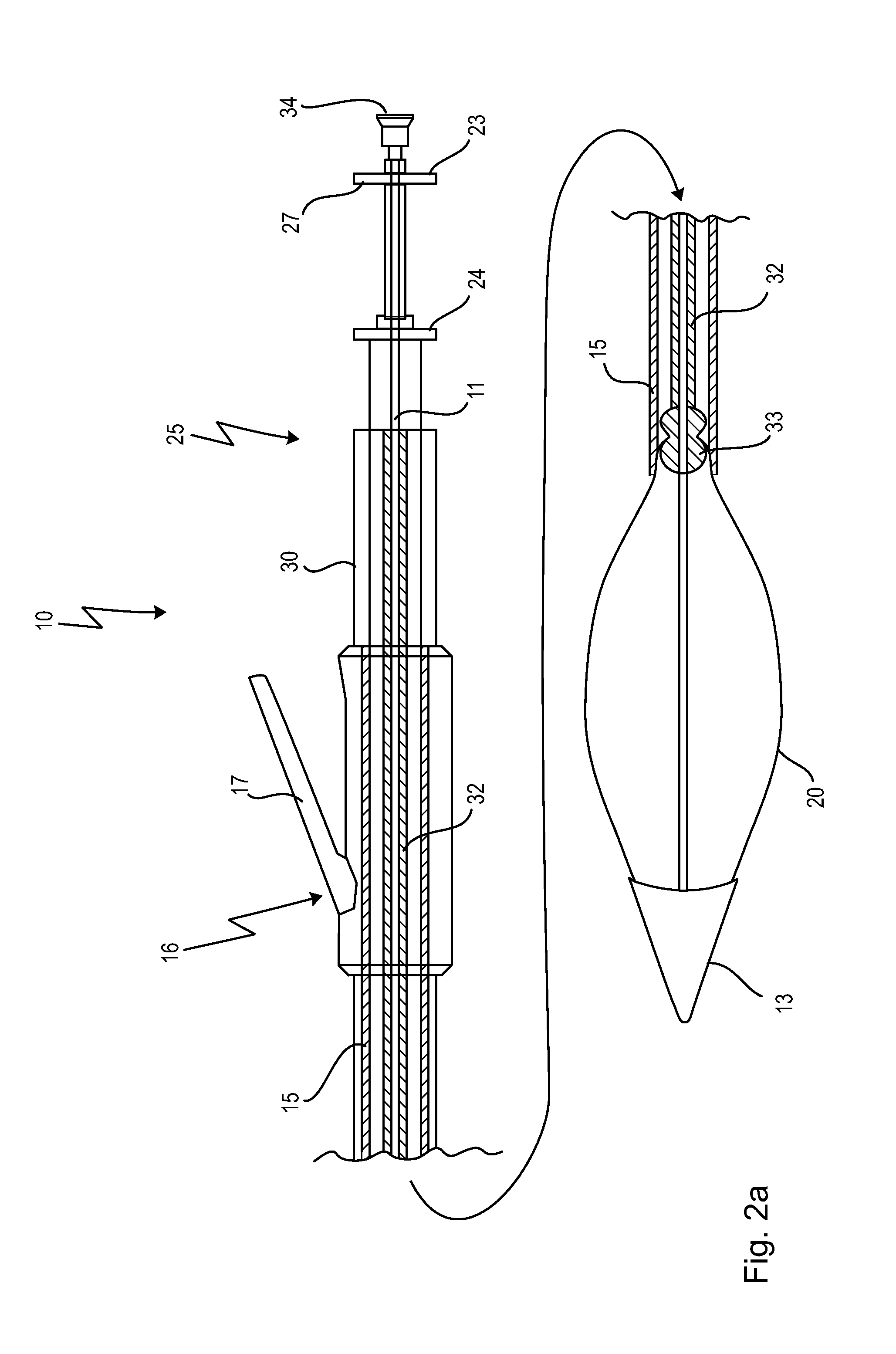

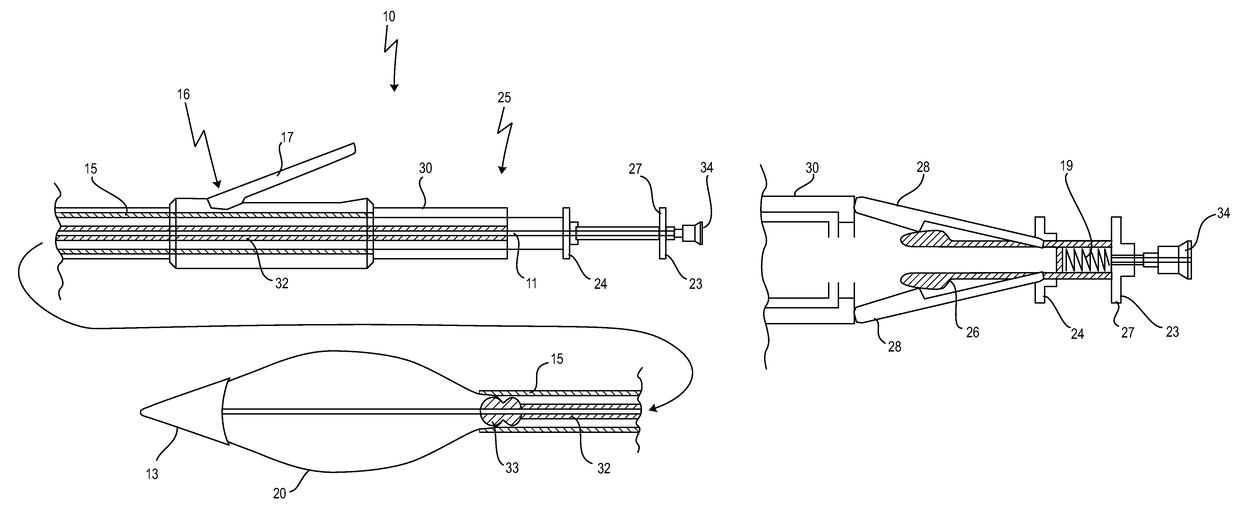

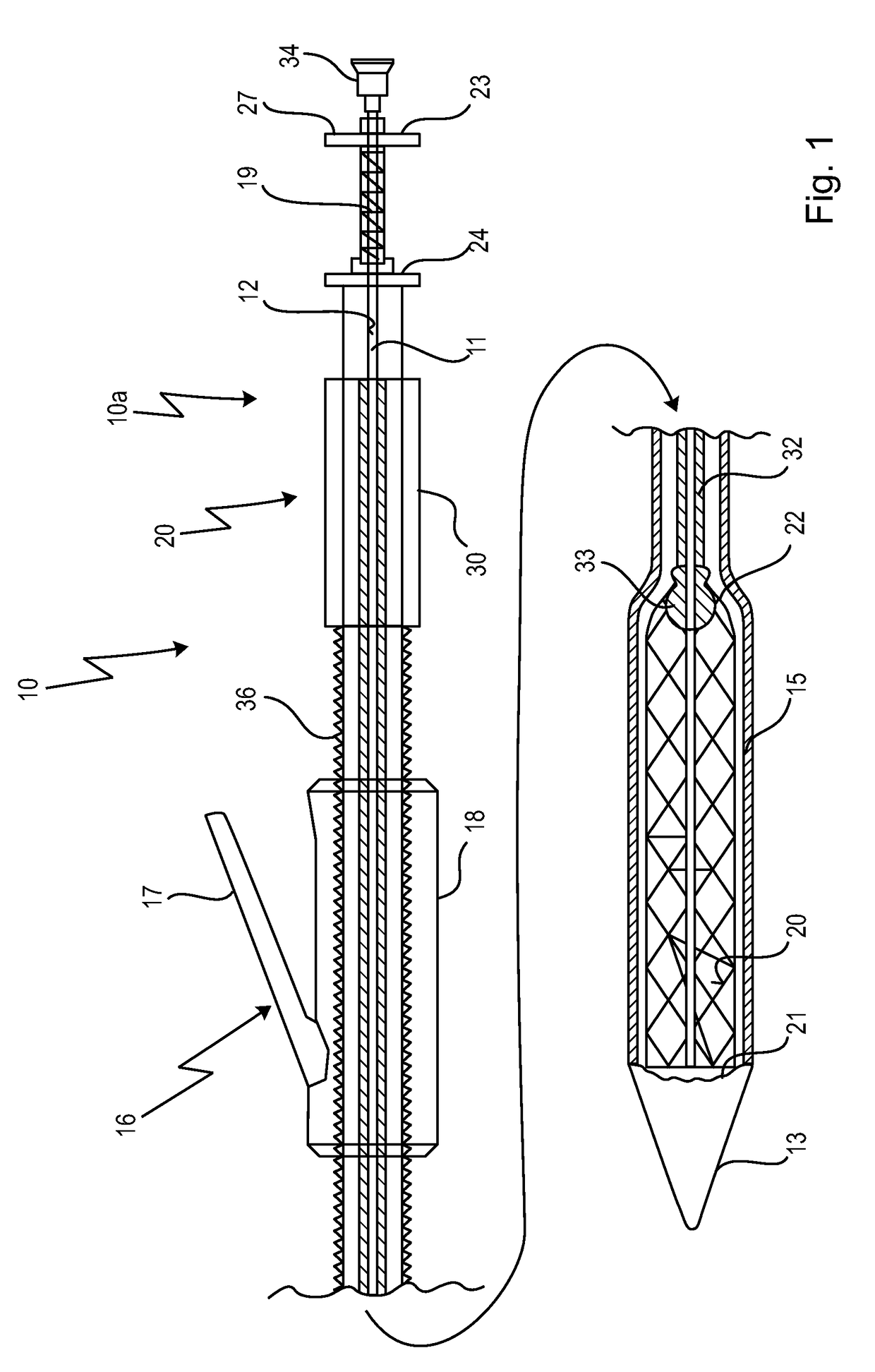

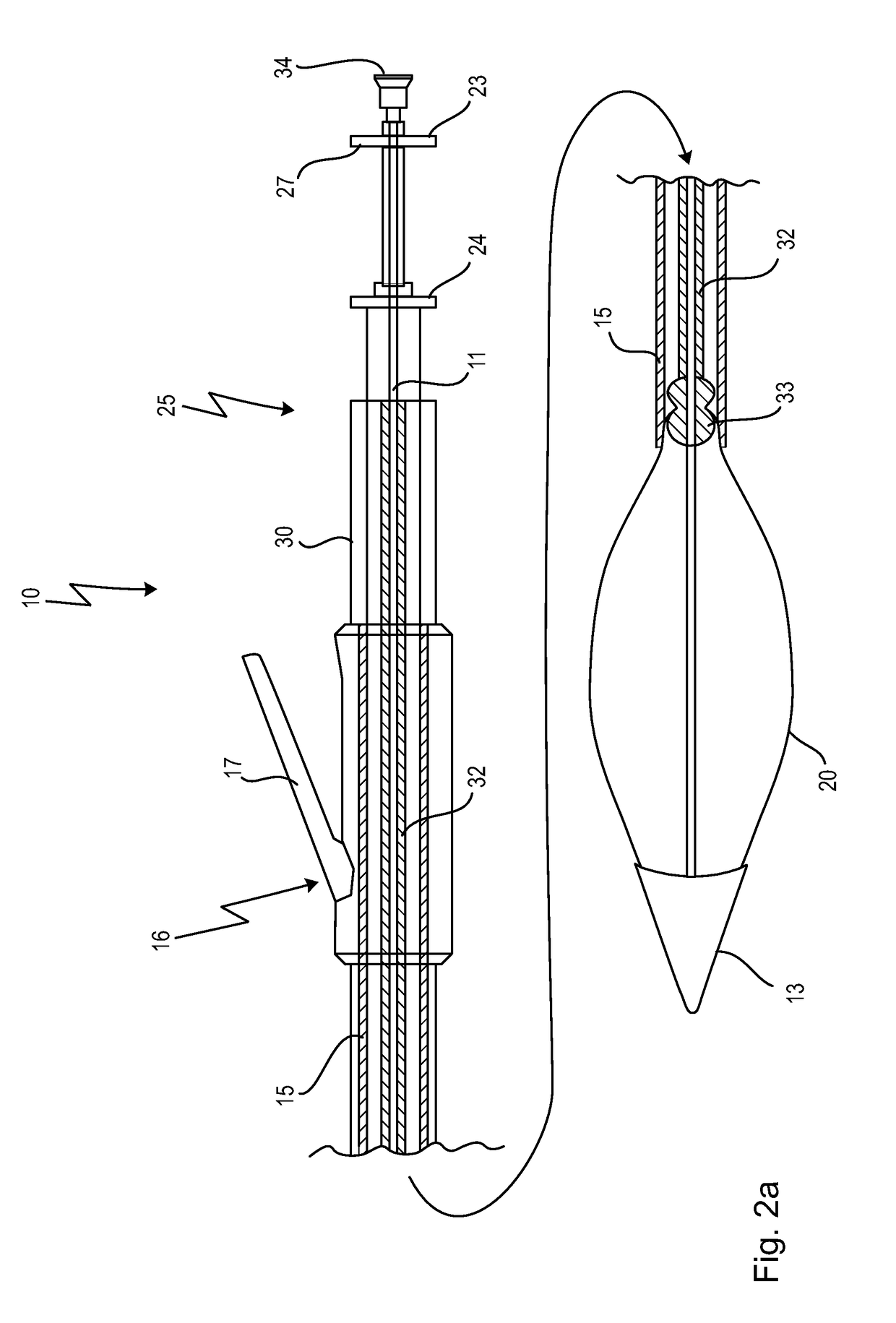

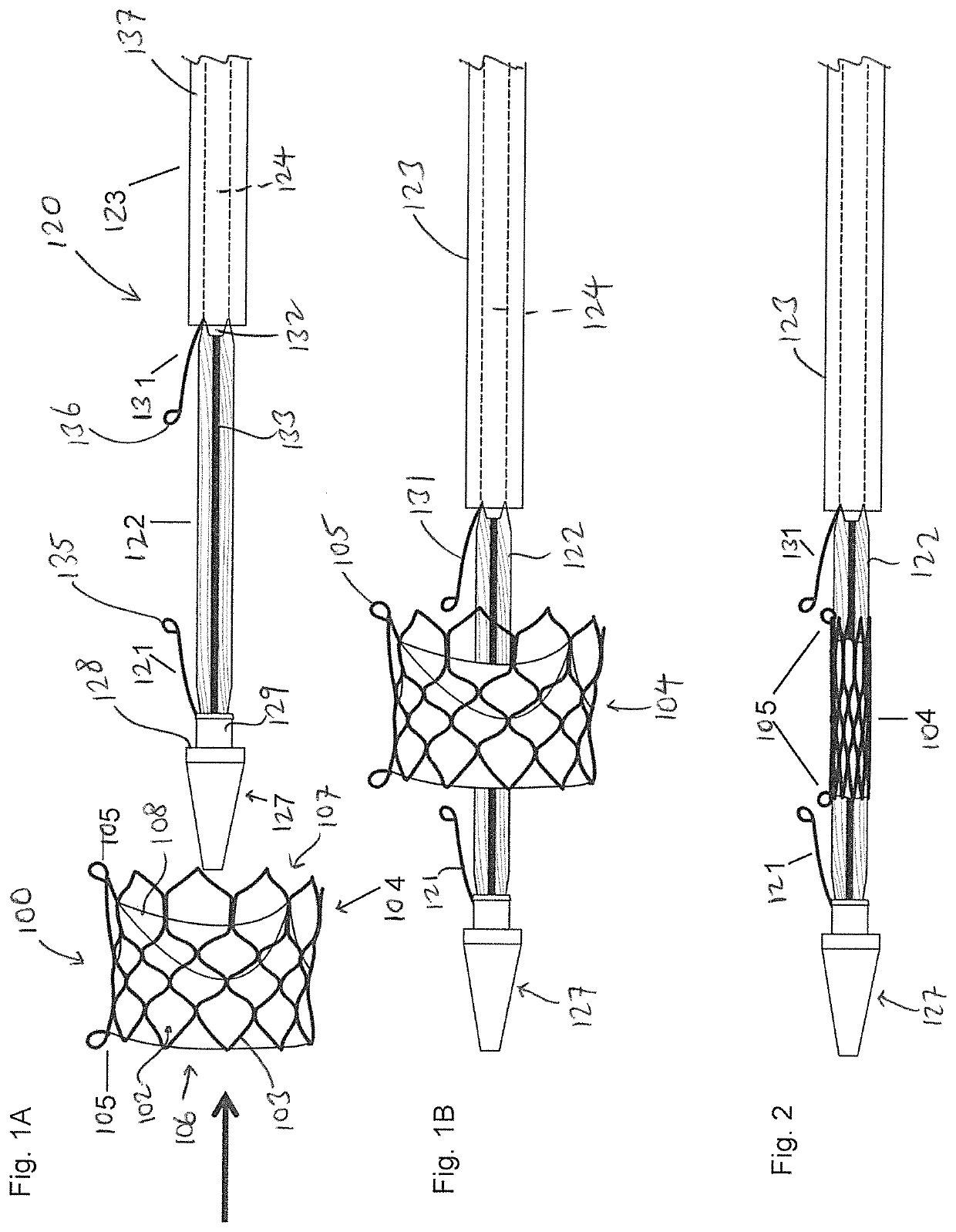

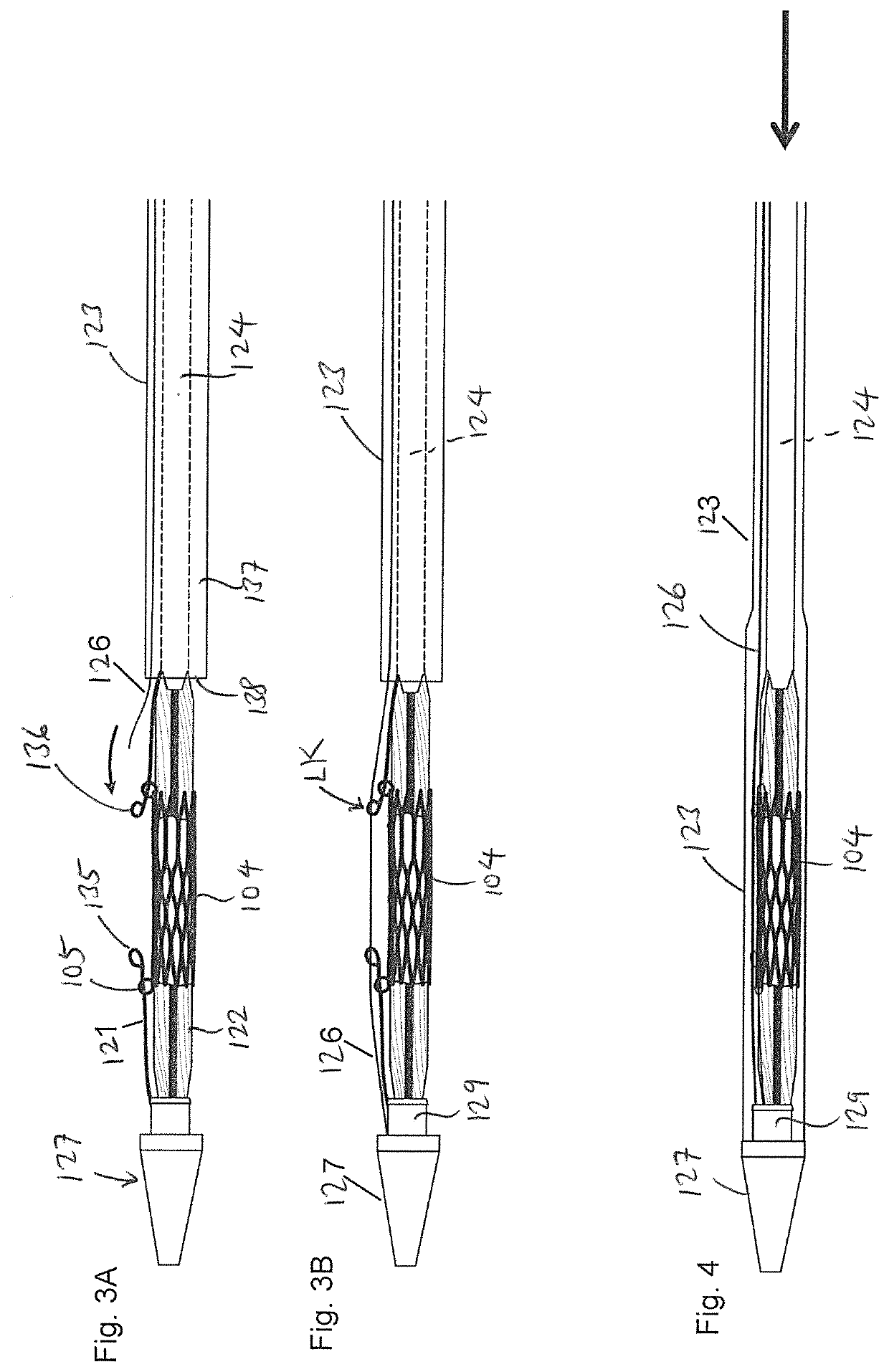

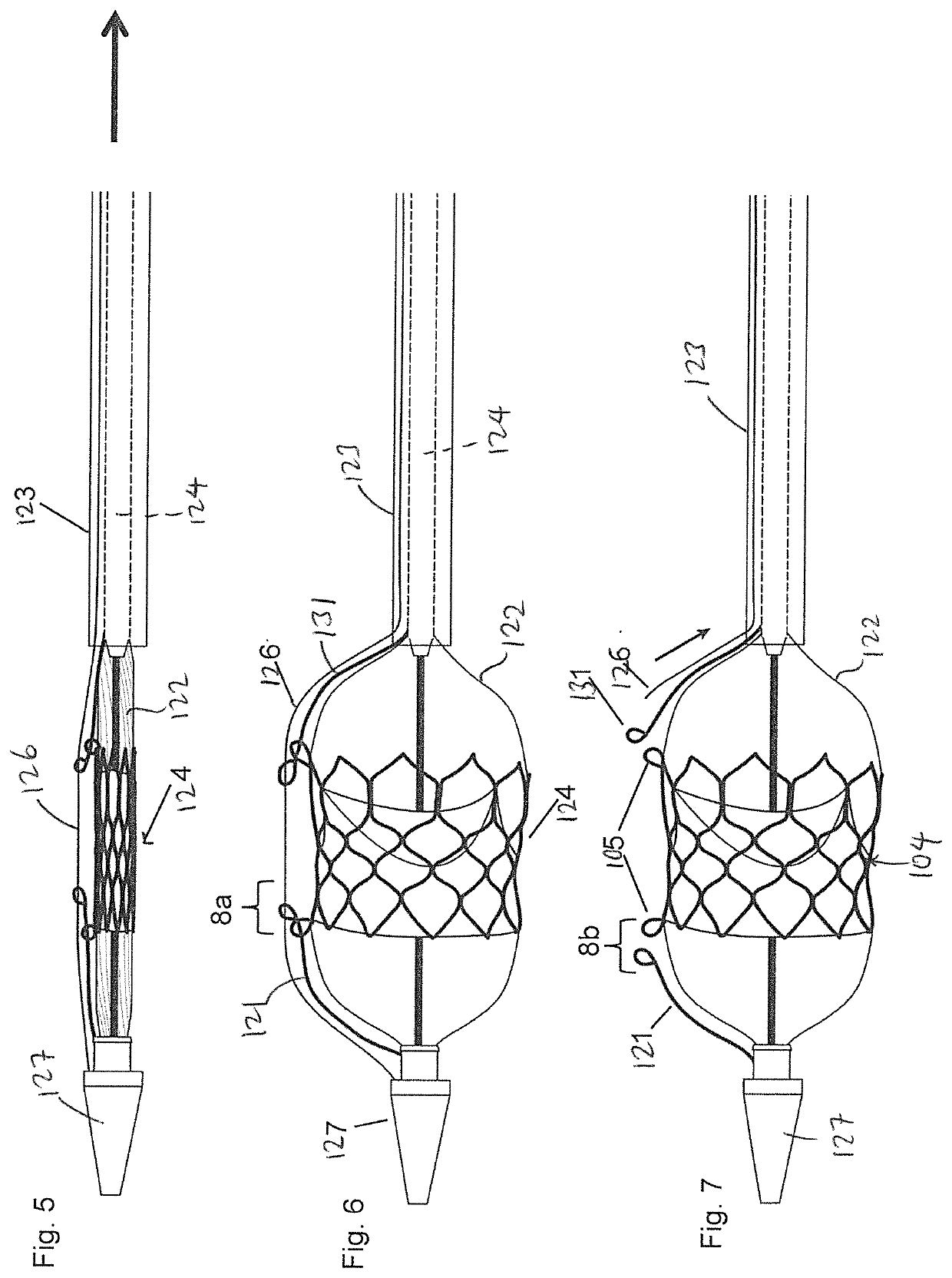

Cardiac valve prosthesis deployment system

ActiveUS20140088686A1Accurate placementNot to obstruct blood flowStentsHeart valvesCardiologyValve prosthesis

The present invention relates to a deployment system (10) for deploying an expandable cardiac valve prosthesis. The deployment system comprises a first tube (11) being designed to carry an expandable cardiac valve prosthesis; further, a tip (13), being firmly connected to the first tube at a distal end of the first tube, wherein the tip is designed such, that it detachably accommodates and holds a proximal end (21) of a cardiac valve prosthesis (20); a sheath (15) designed to be disposed over and holding the prosthesis (20) in a compressed state, and a first actuating mechanism (16) being linked to the sheath (15) and being slidable in a proximal direction for stepwise retracting the sheath (15). The deployment system (10) further comprises a biasing element being linked to the tip (13), and a blocking mechanism (24), wherein the blocking mechanism is being designed such, that a movement of the first actuating mechanism (16) in the proximal direction relative to the tip (13) is limitable to a maximum path of travel by the blocking mechanism (24).

Owner:NVT

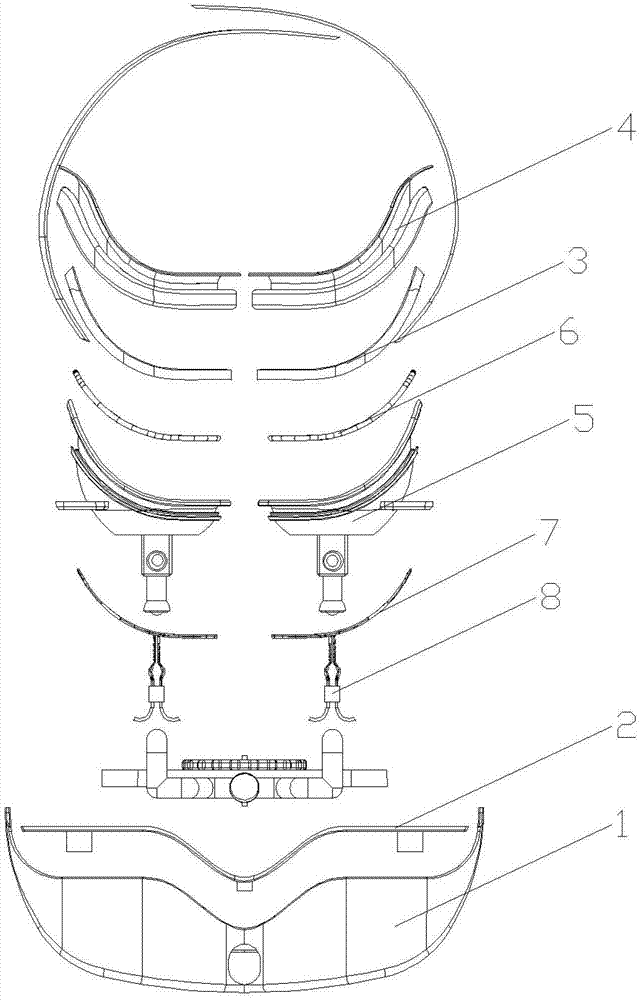

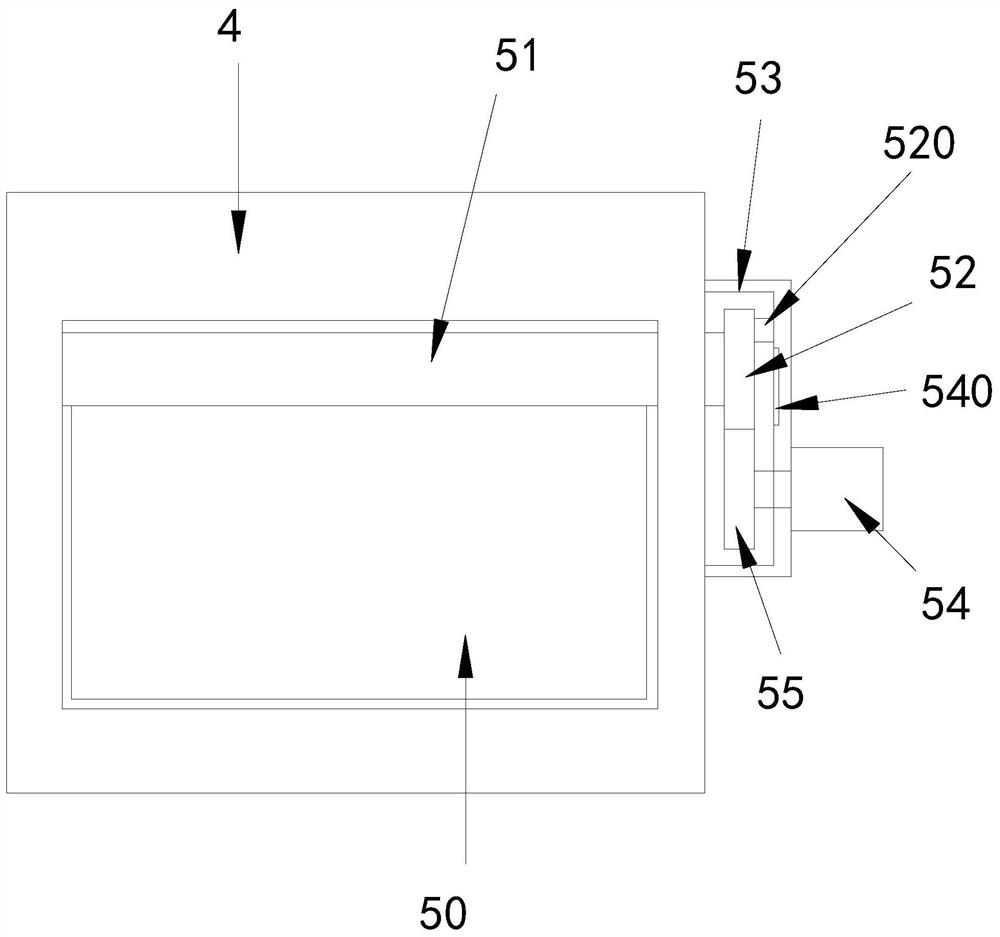

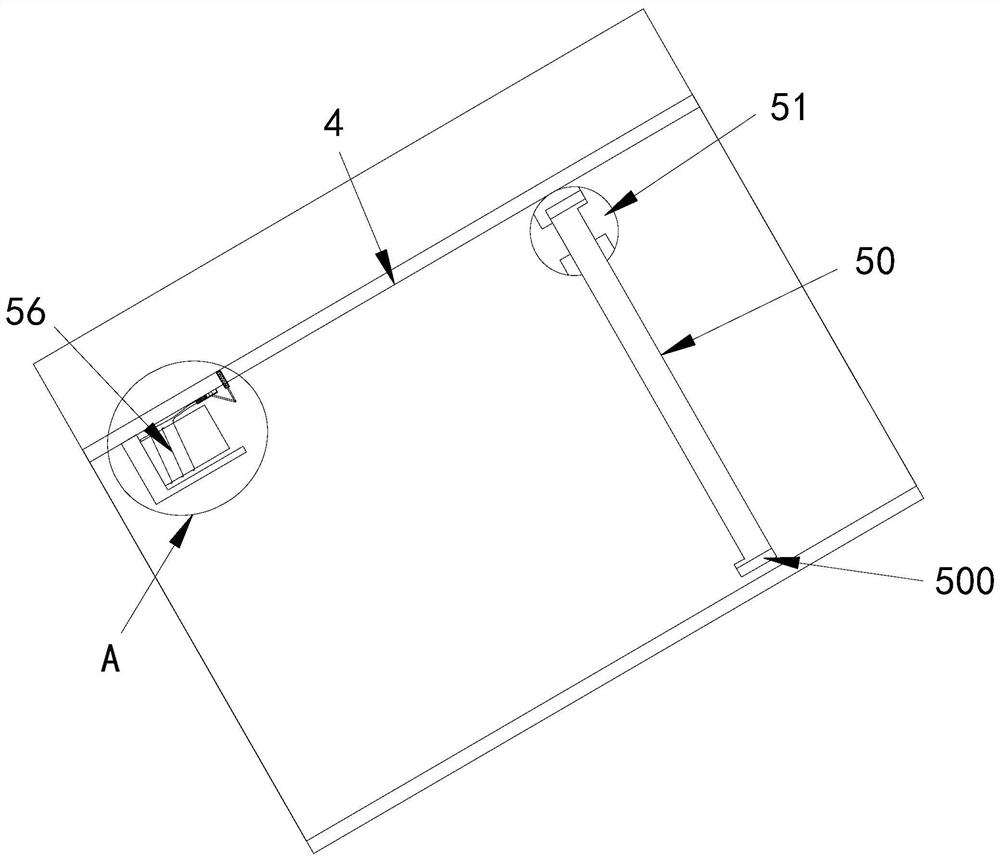

Massager eyeshade

ActiveCN103239325APrevent leakageImprove sealingDevices for heating/cooling reflex pointsDevices for pressing relfex pointsHuman bodyEngineering

The invention discloses a massager eyeshade which comprises an outer shade (1), a rear cover (2), a pair of thin films (3), a pair of orbit rings (4), a pair of eyeshade bodies (5) and a pair of air tubes. The eyeshade bodies (5) can fit with orbits of a human body, and the air tubes are connected onto the corresponding eyeshade bodies (5); the rear cover (2) is fixed to the back of the outer shade (1), and each thin film (3) is fixed onto the corresponding eyeshade body (5) by the aid of the corresponding orbit ring (4); and a first sealing structure is arranged on each eyeshade body (5) and the corresponding thin film (3) and is used for sealing and fixing the eyeshade body (5) and the thin film (3). The massager eyeshade has the advantages that air cannot leak easily from the massager eyeshade, insufficient pressure is prevented, and normal usage of the massager eyeshade is guaranteed.

Owner:NINGBO YOUSHIJIA VISION CARE

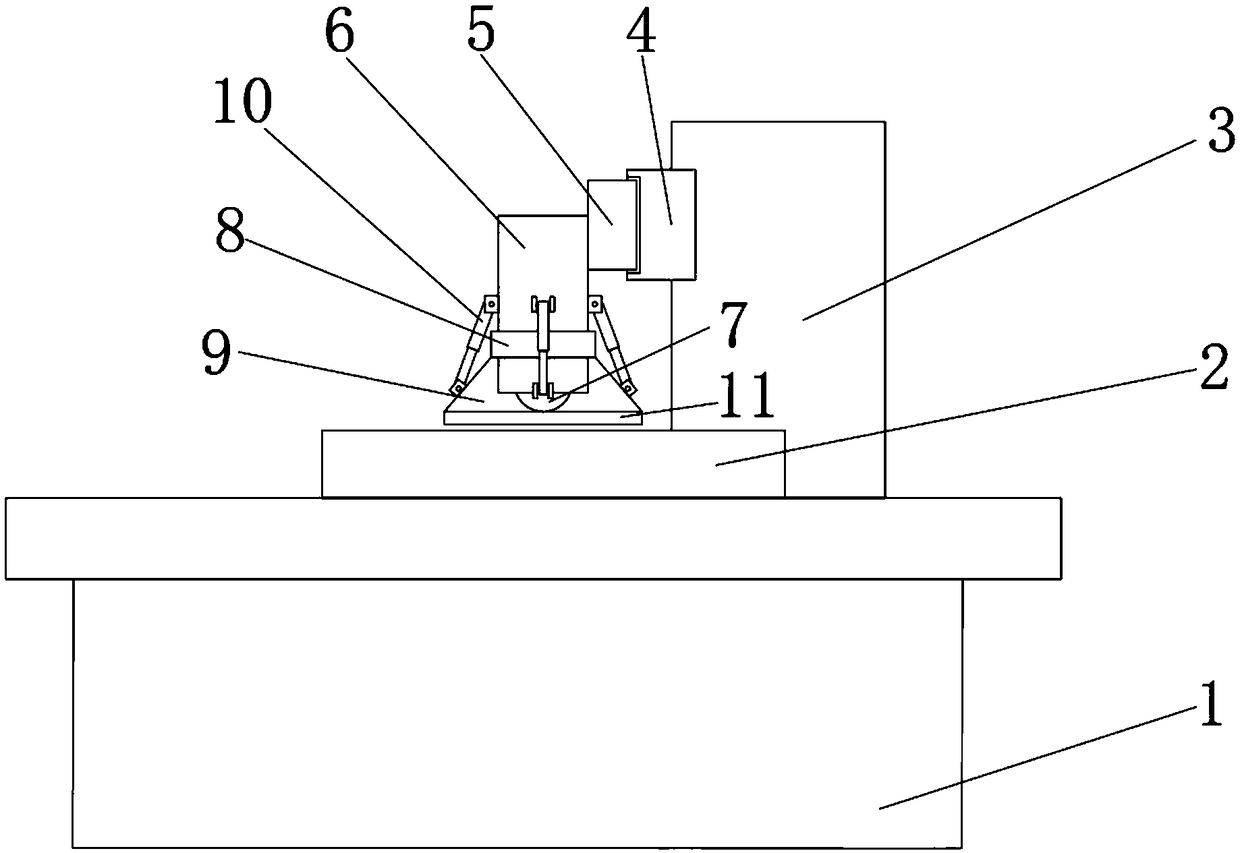

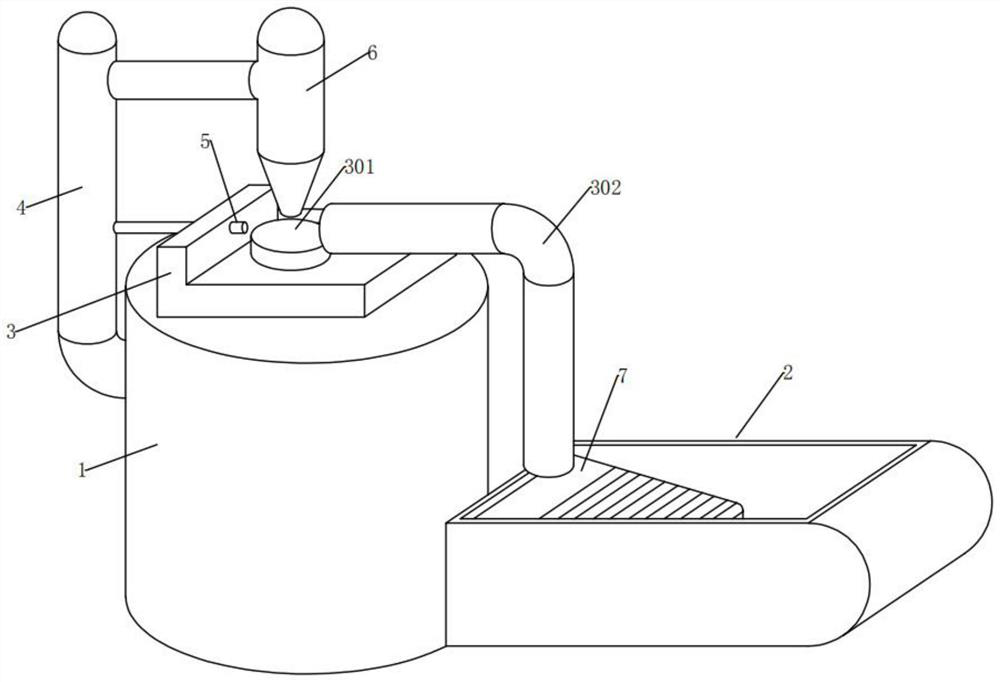

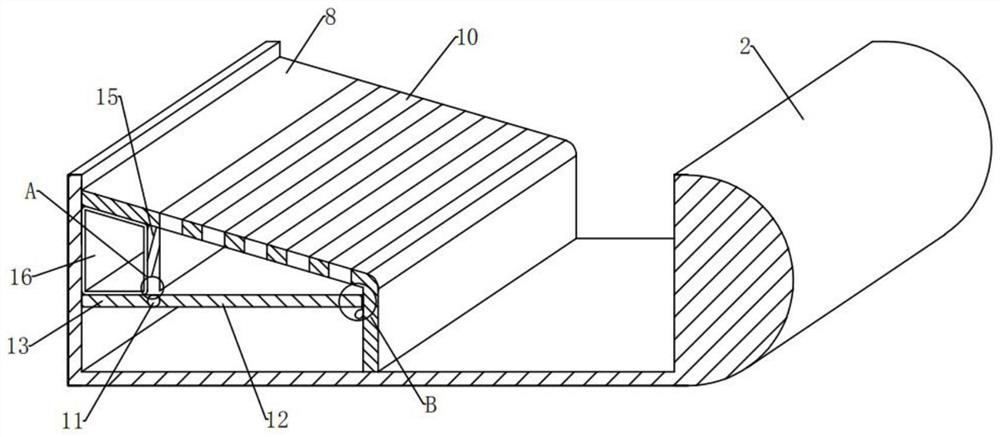

Surface grinding machine with dustproof function

InactiveCN108747649AAvoid residueDoes not affect observationGrinding drivesPlane surface grinding machinesEngineeringSurface grinding

The invention discloses a surface grinding machine with the dustproof function, and belongs to the technical field of surface grinding machines. The surface grinding machine comprises a lathe bed, a worktable is arranged on the top of the lathe bed, a stand column is arranged at the rear end of the lathe bed, a lifting sliding block is arranged on the left end of the stand column, a front and backsliding block is arranged at the left end of the lifting sliding block, a grinding wheel frame is arranged at the left end of the front and back sliding block, a corrugated pipe is arranged on the outer wall of the grinding wheel frame, a dustproof cover is connected to the bottom of the corrugated pipe, the outer wall of the grinding wheel frame is provided with electric telescopic rods througha rotating shaft base, the bottoms of the electric telescopic rods are connected with the outer wall of the dustproof cover through a rotating shaft base, and a brush is arranged on the bottom of thedustproof cover. The transparent dustproof cover is adopted in the device, dust prevention is carried out while the observing machining process is not affected, four sets of electric telescopic rods are matched with the corrugated pipe to lift the dustproof cover at different angles, and the phenomenon that during special-shaped workpiece grinding, the dustproof cover collides, and losses are caused is avoided.

Owner:高邮市金利达机械有限公司

Cardiac valve prosthesis deployment system

ActiveUS10092401B2Ensure normal flowAvoid flaringStentsHeart valvesProsthesisCardiac valve prosthesis

The present invention relates to a deployment system (10) for deploying an expandable cardiac valve prosthesis. The deployment system comprises a first tube (11) being designed to carry an expandable cardiac valve prosthesis; further, a tip (13), being firmly connected to the first tube at a distal end of the first tube, wherein the tip is designed such, that it detachably accommodates and holds a proximal end (21) of a cardiac valve prosthesis (20); a sheath (15) designed to be disposed over and holding the prosthesis (20) in a compressed state, and a first actuating mechanism (16) being linked to the sheath (15) and being slidable in a proximal direction for stepwise retracting the sheath (15). The deployment system (10) further comprises a biasing element being linked to the tip (13), and a blocking mechanism (24), wherein the blocking mechanism is being designed such, that a movement of the first actuating mechanism (16) in the proximal direction relative to the tip (13) is limitable to a maximum path of travel by the blocking mechanism (24).

Owner:NVT

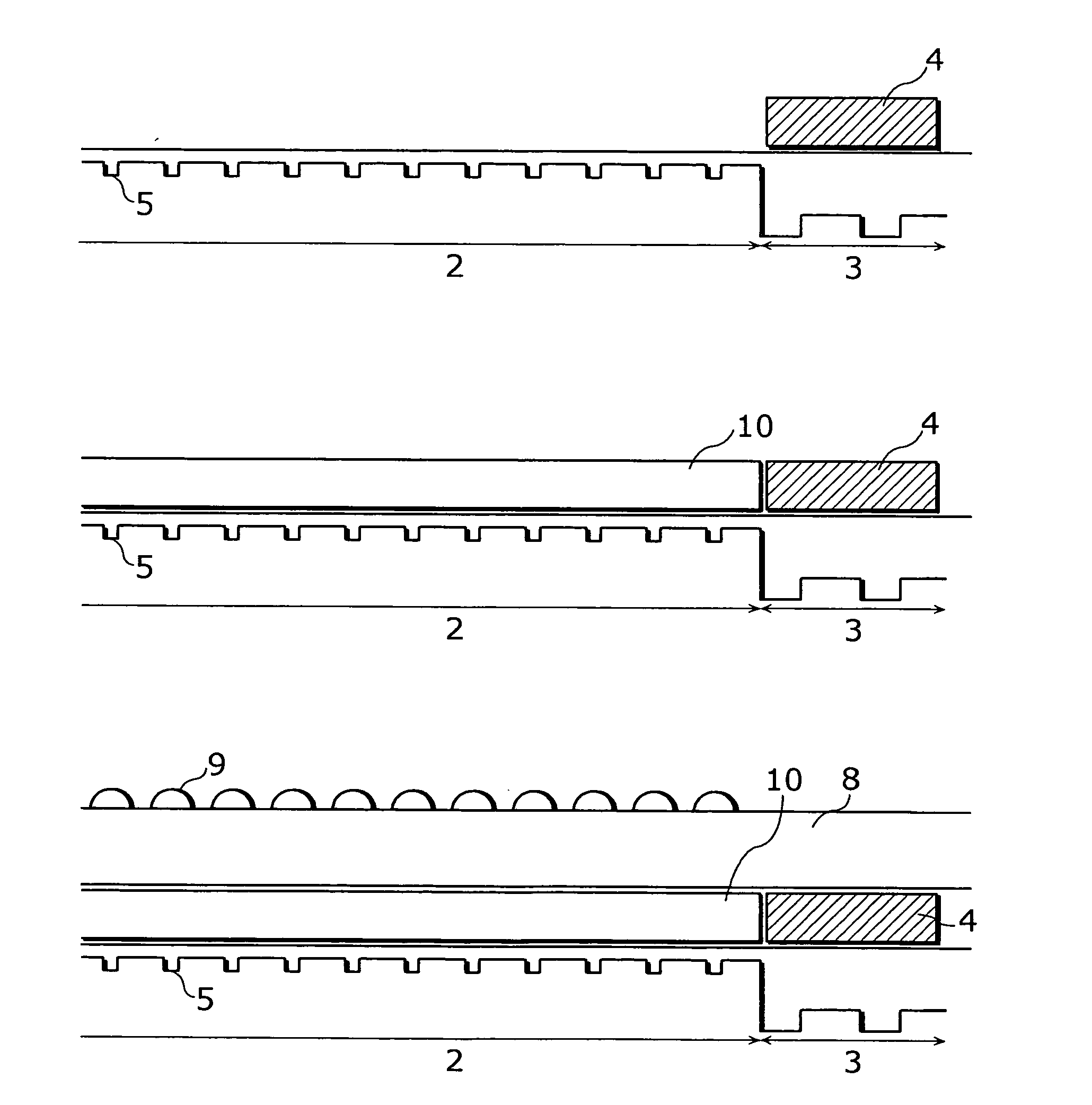

Image sensor and manufacturing method of image sensor

ActiveUS20040241898A1Less-uneven sensitivityAvoid flaringTelevision system detailsSolid-state devicesMethod of imagesOptoelectronics

According to the manufacturing method of the image sensor of the present invention, the lightproof film4 (the antireflective film for avoiding flares) is formed over the wiring area3; the transparent film10 is formed over the imaging area2 using the material capable of patterning; the transparent film8, for forming micro lenses on top, is formed on the transparent film10; and the top surface of the transparent film10 and the lightproof film4 is evenly formed.

Owner:COLLABO INNOVATIONS INC

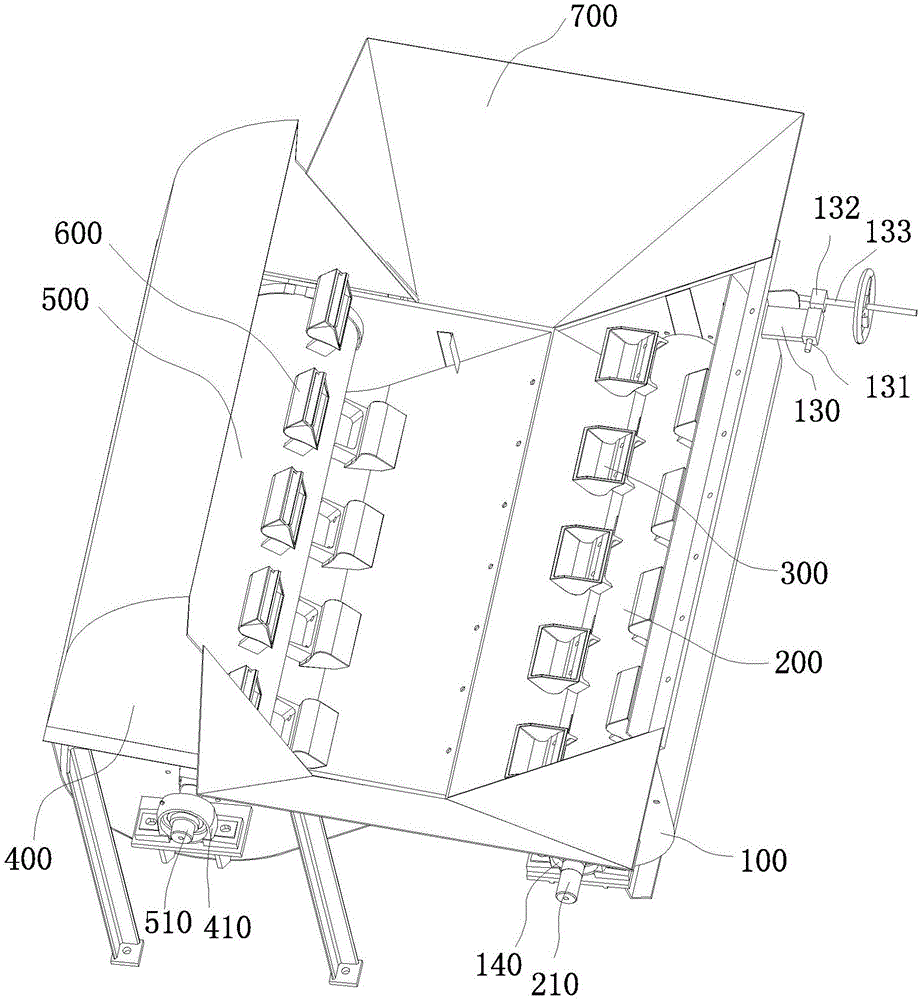

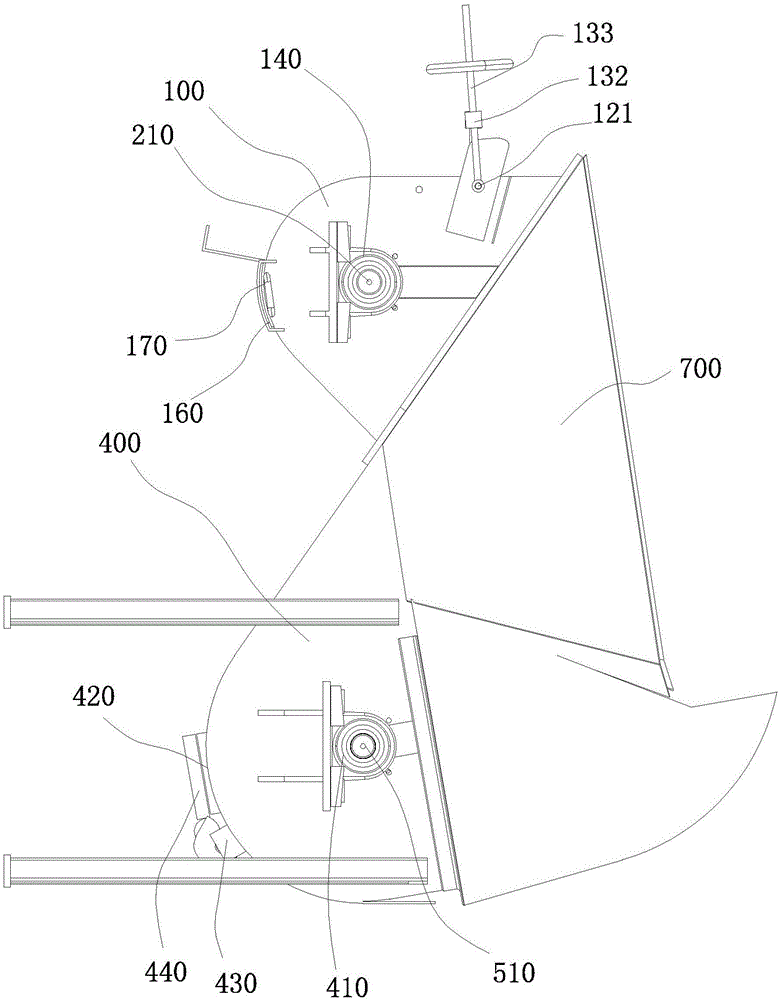

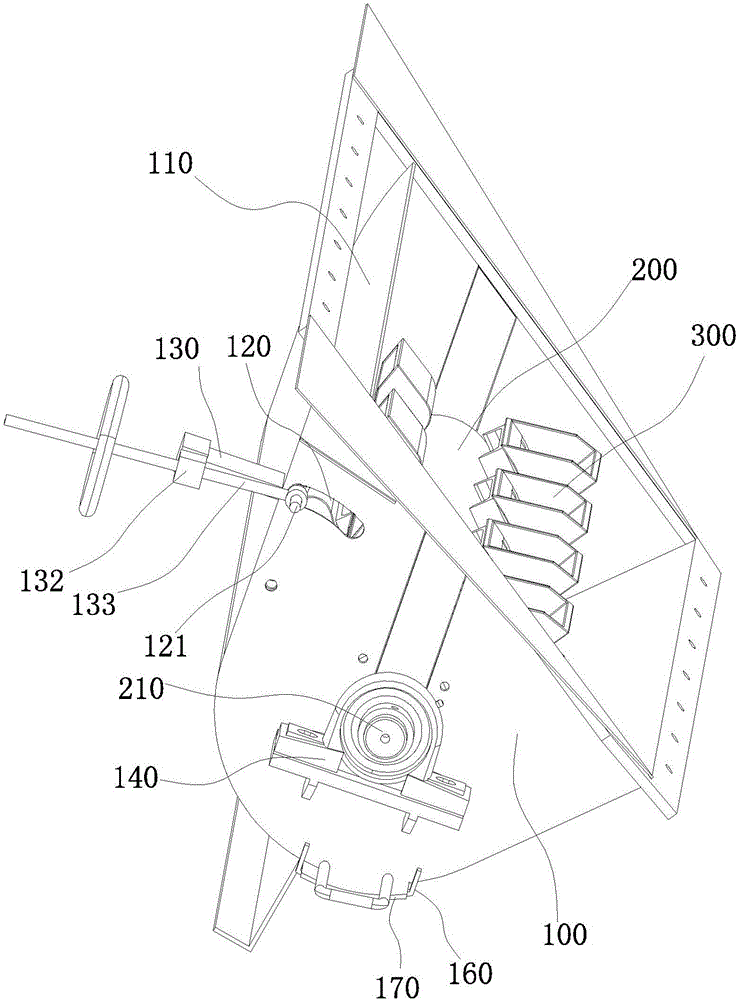

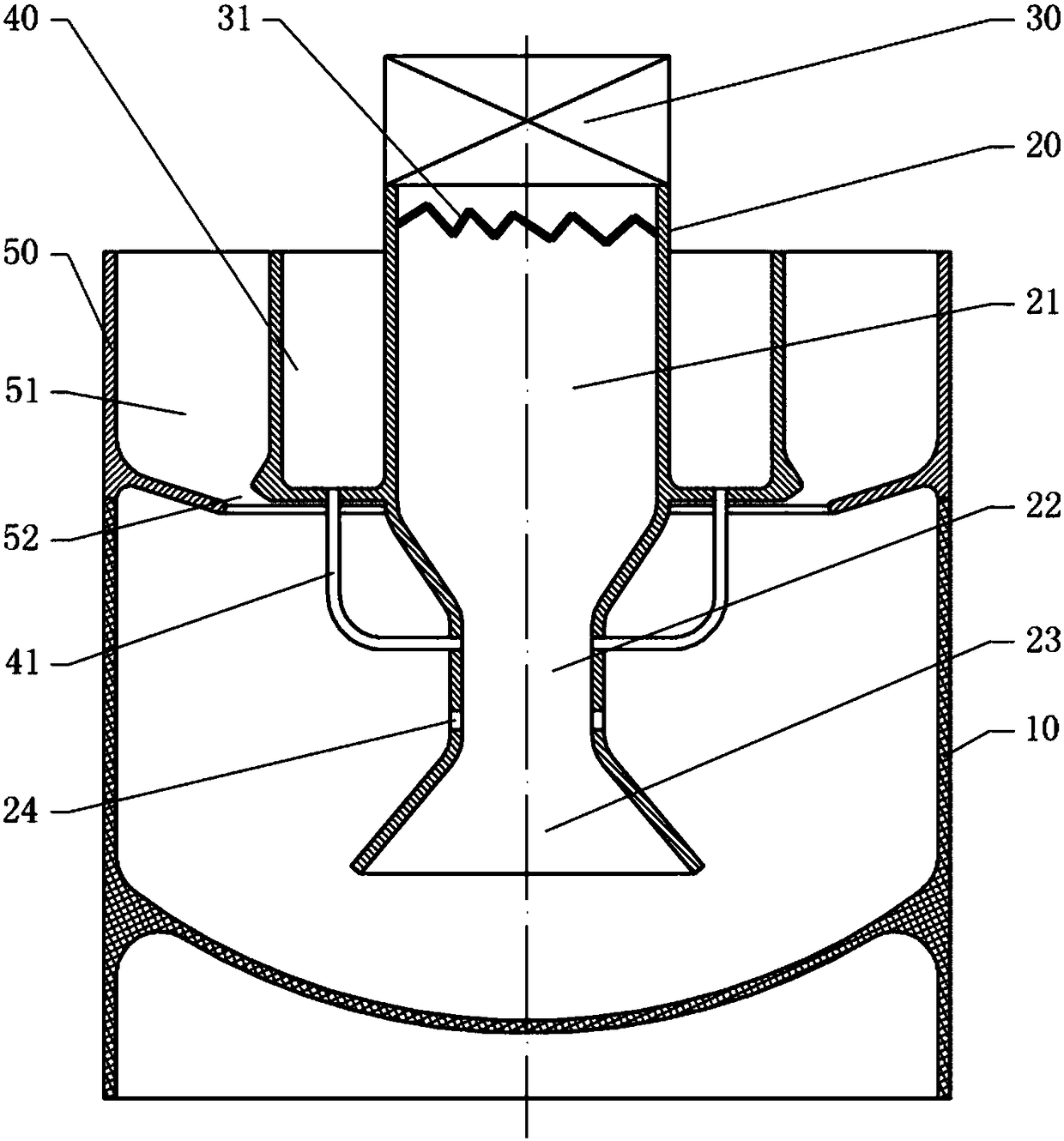

Dual-roller sand turnover box

ActiveCN106424544ABreak up fullySimple structureMould handling/dressing devicesEngineeringFunnel shape

The invention provides a dual-roller sand turnover box. The dual-roller sand turnover box comprises a funnel-shaped first box body and a funnel-shaped second box body. A first roller capable of rotating around the axis of the first roller is arranged in the first box body and provided with a plurality of first sanding bowls, and the two ends of the first roller are arranged on the two sides of the first box body in a penetrating manner. The first box body and the second box body are connected to be used for bearing sand turned out from the first box body, a second roller capable of rotating around the axis of the second roller is arranged in the second box body and provided with a plurality of second sanding bowls, and the two ends of the second roller are arranged on the two sides of the second box body in a penetrating manner. The dual-roller sand turnover box has the beneficial effects that the structure is simple, the actual use effect is obvious, and sand lumps can be scattered thoroughly.

Owner:宁波创二代机械科技有限公司

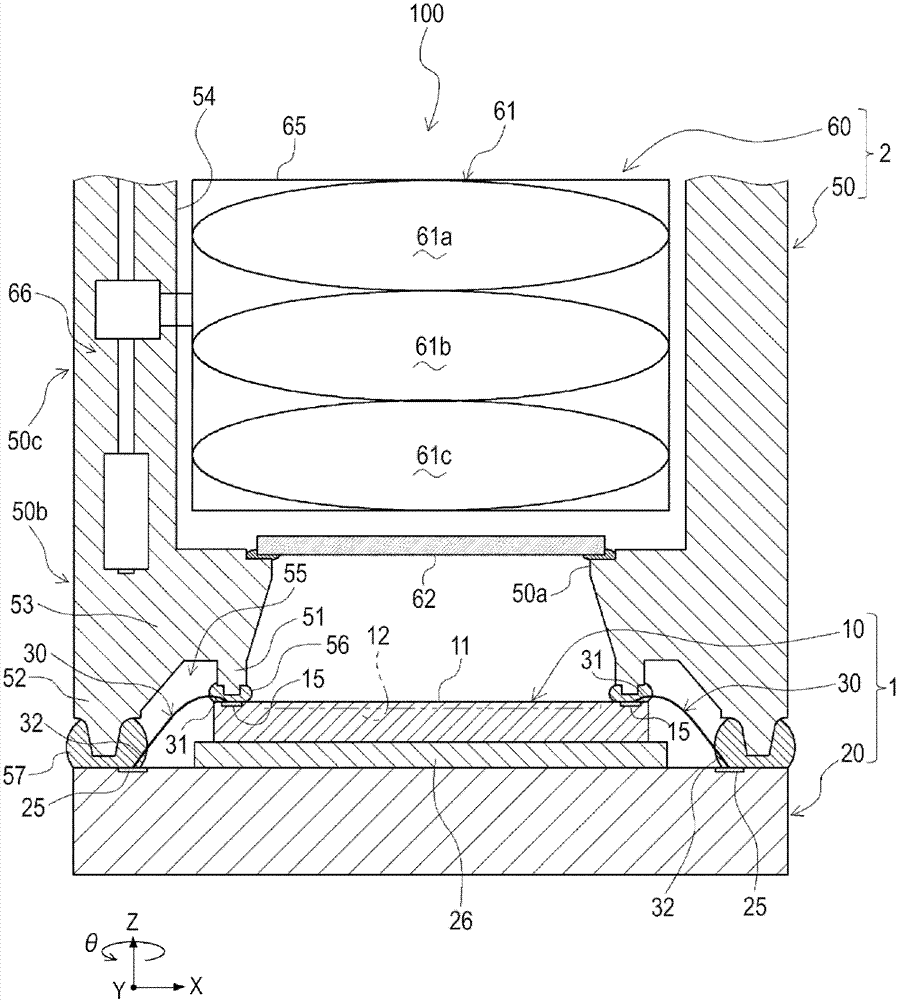

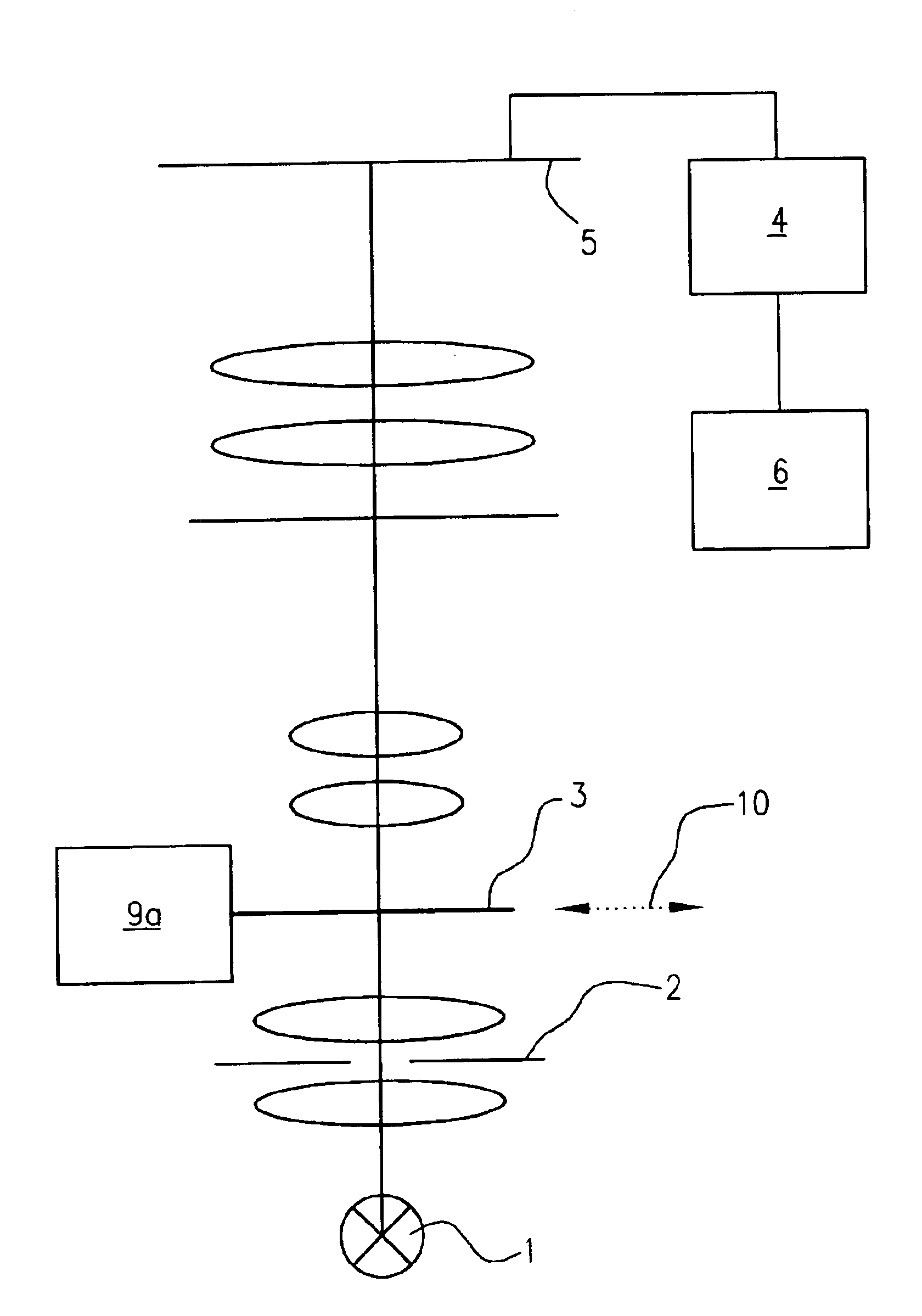

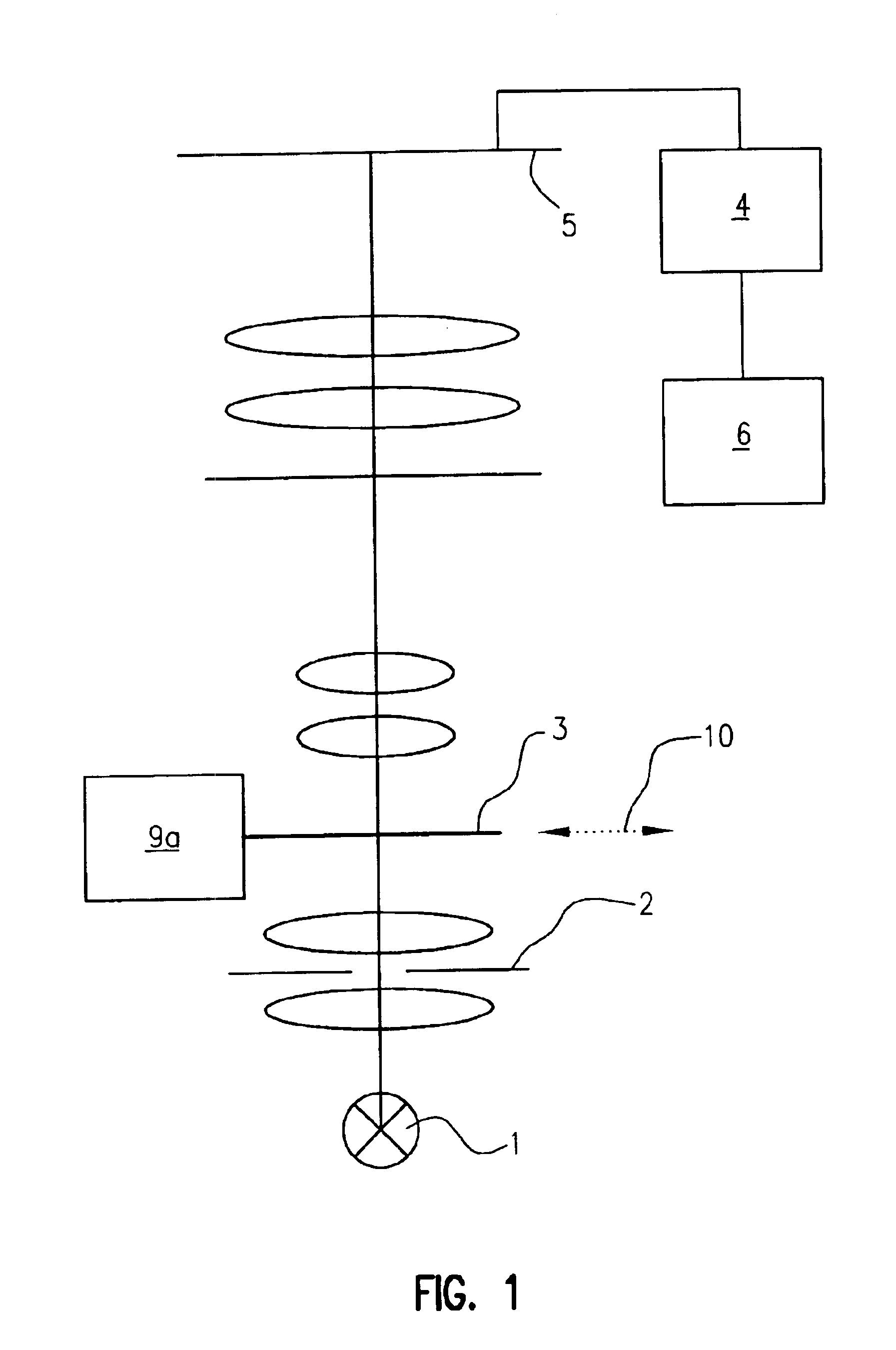

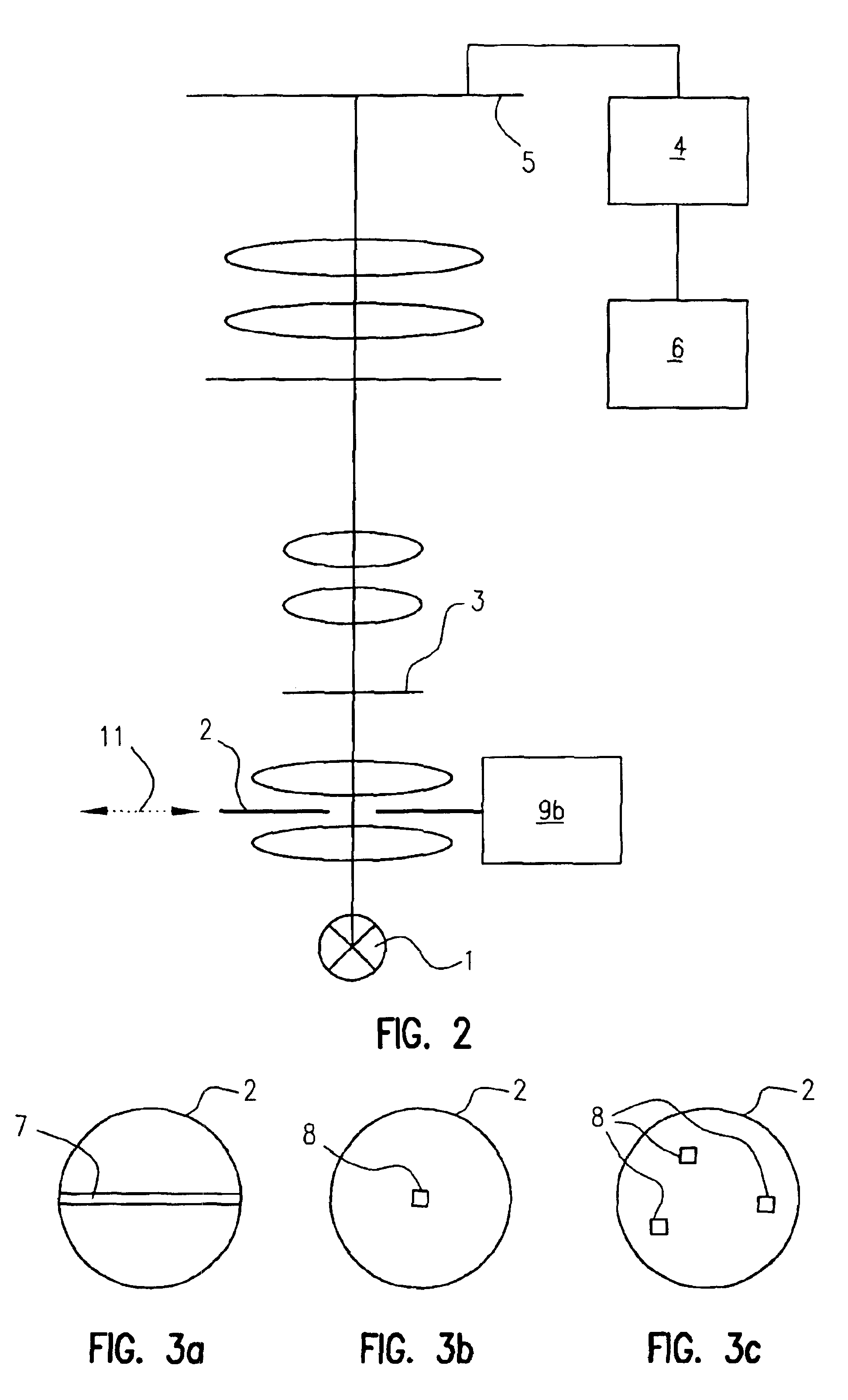

Microscope having a contrast-increasing image a acquisition apparatus

InactiveUS6882470B2Fast imagingSolve the lack of spaceTelevision system detailsColor television detailsAcquisition apparatusLight beam

The invention concerns a microscope having an image sensor (5) for recording the microscope images. The specimen (3) to be examined can be scanned by means of a stop (2) in the beam path of the illumination unit and a positioning unit which moves the specimen (3) or the stop (2). Opening the stop (2) or removing it from the beam path permits the entire image to be scanned with the image sensor (5).

Owner:LEICA MICROSYSTEMS CMS GMBH

Optical element, optical element module, electronic element module, and electronic information device

InactiveCN102681045AAvoid flaringTelevision system detailsColor television detailsComputer moduleDiffuse reflection

The present invention provides an optical element, comprising: a side surface where incident light undergoes diffuse reflection inside the optical element, between the outline of a top optical surface and a bottom optical surface; and an inclined surface for total reflection of diffuse reflection from the side surface, formed at least between the side surface and the bottom optical surface.

Owner:SHARP KK

Method and Assembly for Securing an Implantable Medical Device on a Delivery System

ActiveUS20220104956A1Avoid flaringRisk minimizationStentsBalloon catheterBalloon catheterMedical device

A method and an assembly for securing a crimped medical device over a deflated balloon of a balloon catheter is provided. The medical device is positioned in its expanded state over the deflated balloon of the balloon catheter, and is then crimped over the deflated balloon. First and second eyelets of first and second strings, respectively, are then threaded through first and second rings, respectively, that are provided on the medical device. Next, a locking wire is advanced through a lumen defined between the sheath and the catheter body to exit the distal end of the sheath, and then advanced through the first and second eyelets and into the distal tip of the balloon catheter. The sheath is then advanced over the crimped medical device to the distal tip to completely cover the crimped medical device.

Owner:VENUS MEDTECH (HANGZHOU) INC

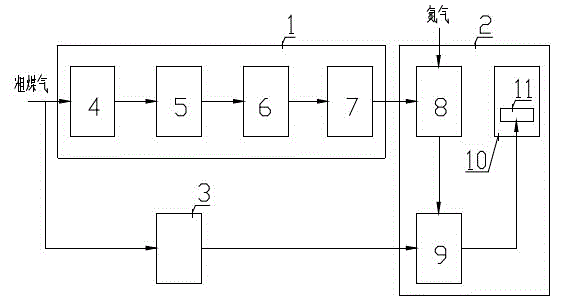

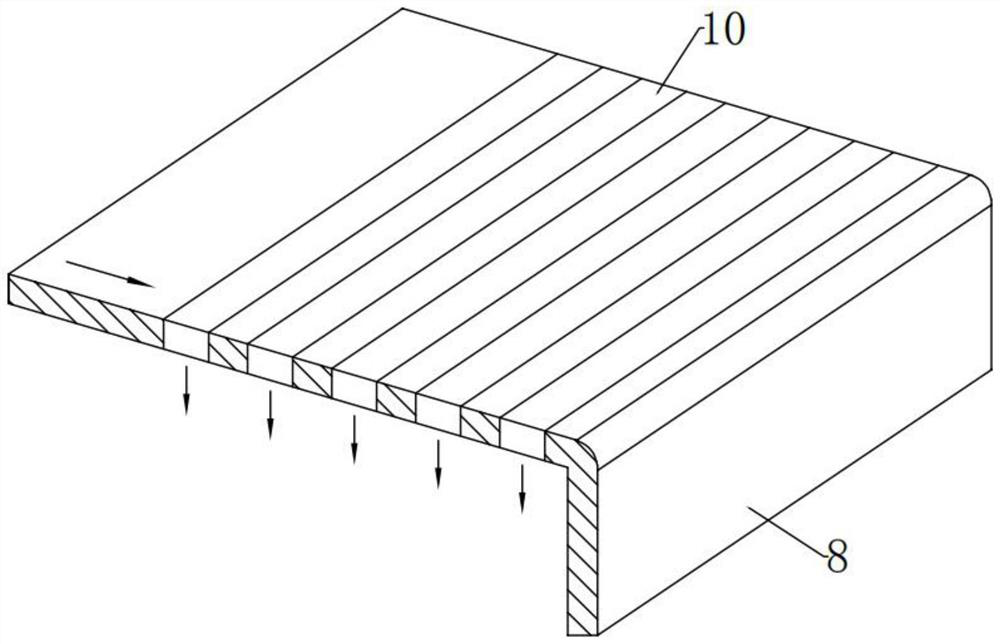

Advanced heating system for ammonia synthesis catalyst and heating method

InactiveCN104556145AReduce driving timeReduce dosageBulk chemical productionAmmonia preparation/separationMolecular sieveChemistry

The invention discloses an advanced heating system for an ammonia synthesis catalyst. The advanced heating system comprises an ammonia synthesis unit (2), wherein the ammonia synthesis unit (2) is connected with a pretreatment unit (1) and a non-shift gas washing tower (3) respectively; the pretreatment unit (1) comprises a CO conversion device (4); the CO conversion device (4) is connected with a molecular sieve (6) through a shift gas washing tower (5); the molecular sieve (6) is connected with a liquid nitrogen washing device (7); the ammonia synthesis unit (2) comprises an ammonia synthesis compressor (8); the ammonia synthesis compressor (8) is connected with an ammonia synthesis device (10) through a start-up heating furnace (9); the ammonia synthesis device (10) is provided with an ammonia synthesis catalyst bed (11). The advanced heating system greatly improves the production efficiency of synthesis ammonia, avoids the waste of process gas, reduces the production cost of synthesis ammonia, and effectively increases the utilization rate of the process gas.

Owner:GUIZHOU TIANFU CHEM

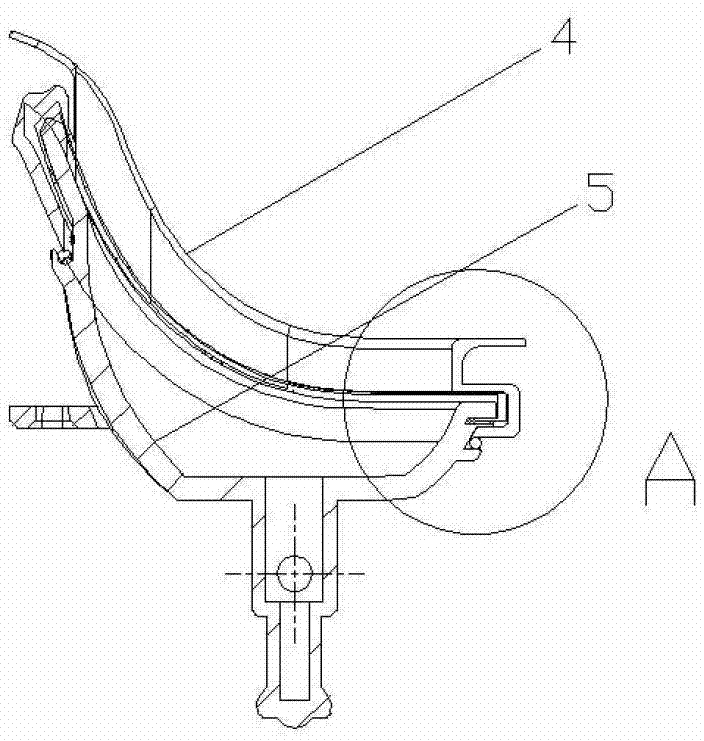

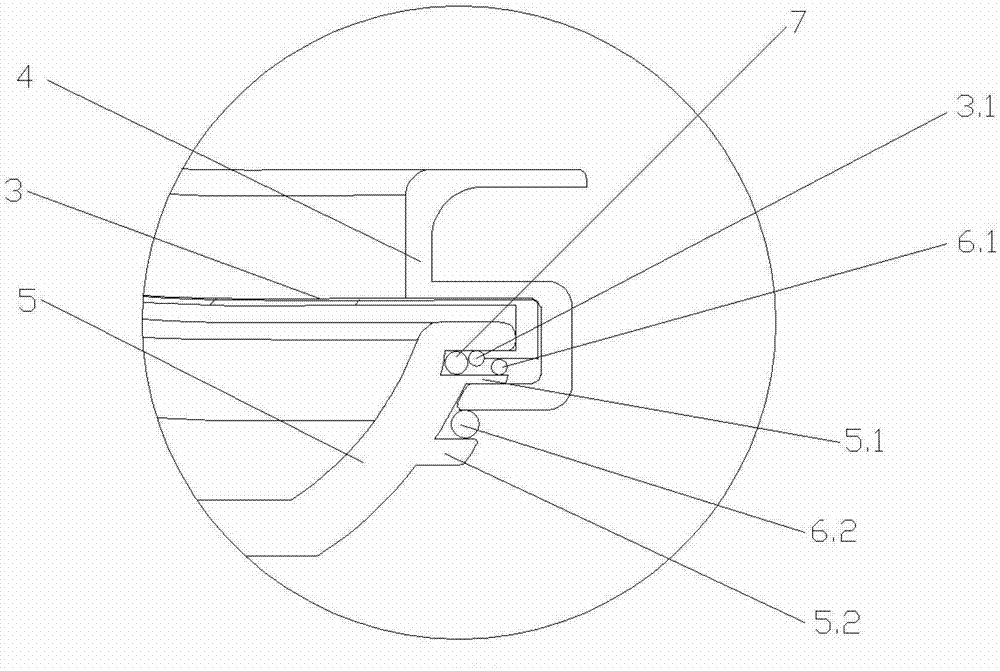

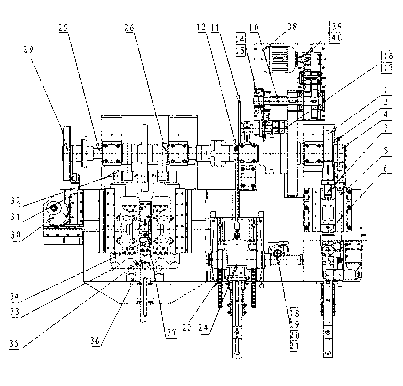

Main leaf spring eye shaping equipment and processing method thereof

InactiveCN103286564ACompact structureEasy to replaceOther manufacturing equipments/toolsGear wheelAgricultural engineering

The invention belongs to the technical field of automobile main leaf spring eye processing, particularly relates to the technical field of automobile main leaf spring eye shaping equipment and processing methods thereof, and discloses main leaf spring eye shaping equipment and a processing method thereof. The main leaf spring eye shaping equipment comprises a head cutting system, a spring eye system and a shaping system which are arranged on a rack, wherein the head cutting system comprises a head cutting blade; the head cutting blade is connected with a rocker arm by a ball head screw; an eccentric wheel is arranged on the rocker arm; a compressing cam is arranged on the eccentric wheel; the spring eye system comprises a transmission spindle; the transmission spindle is connected with a traction wheel by a clutch flywheel; the traction wheel is connected with splines by a traction rod; the splines are connected with a spring eye rotating roller; the spring eye rotating roller is connected with a spring eye mandrel by a pull pin spline; the shaping system comprises a shaping die; the shaping die is connected with a shaping mandrel; and the shaping mandrel is connected with a shaping transmission spindle by a sector gear and a spline.

Owner:ANHUI ANHUANG MACHINERY

Production process for wood-plastic composite park seat

ActiveCN108501168AWell mixedReduce interactionTransportation and packagingMixersMetal particleMaleic anhydride

The invention relates to the technical field of composites, in particular to a production process for a wood-plastic composite park seat. The production process comprises the following steps that (1)raw materials are weighed by weight, including 100 parts of wood flour, 35-55 parts of plastic particles, 3-6 parts of lubricants, 8-14 parts of antioxygens, 5-10 parts of light stabilizers, 9-15 parts of maleic anhydride grafted plastic particles and 2-5 parts of metal particles; (2) the wood flour, the plastic particles, the maleic anhydride grafted plastic particles and the light stabilizers are mixed by an airflow mixer; (3) mixtures are subjected to fusion extrusion through a double-screw extruder and cooled and cut into wood-plastic composite aggregates; (4) the wood-plastic composite aggregates, the metal particles and the lubricants are added into the airflow mixer to be mixed uniformly; (5) the mixtures are added into the extruder for fusion, and extrusion molding is conducted toobtain ageing-resistant wood-plastic composites; and (6) the ageing-resistant wood-plastic composites are formed into the seat. The seat with high ageing-resistant performance can be obtained by uniformly mixing the raw materials.

Owner:XINJIANG HUATING IND & TRADE

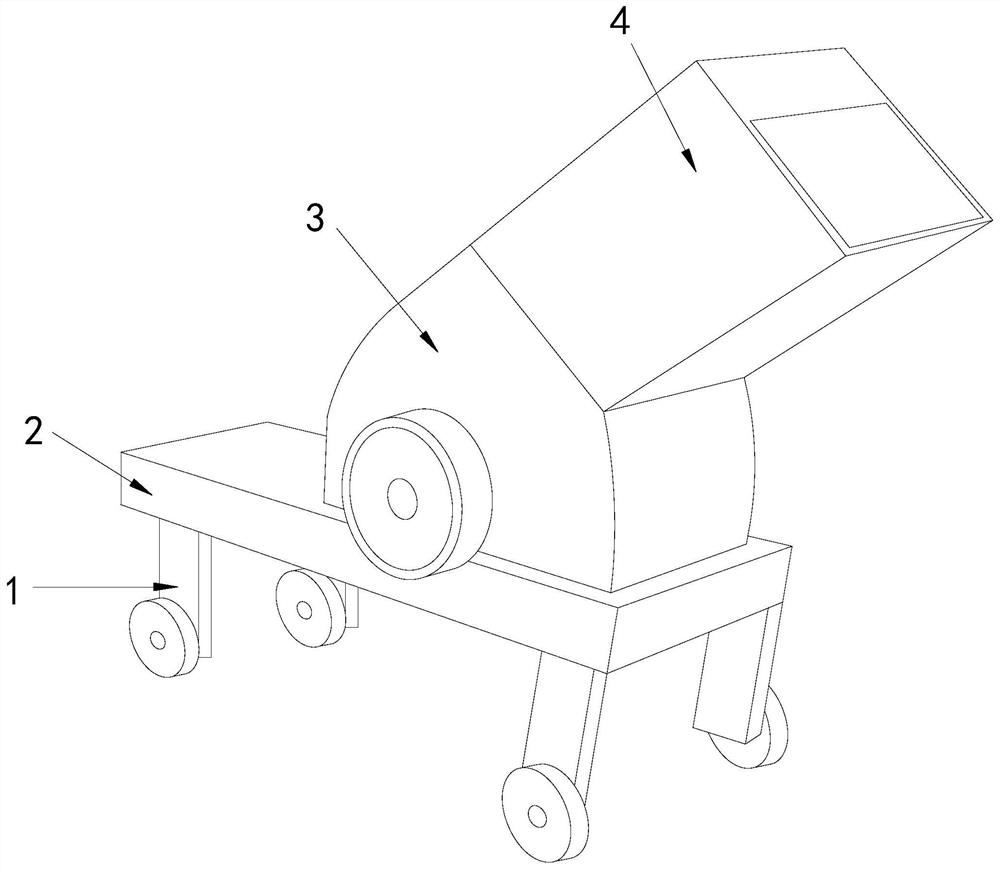

Special construction waste crusher

InactiveCN112791835ASmooth entryAvoid flaringDirt cleaningGrain treatmentsElectric machineGear wheel

The invention discloses a special construction waste crusher. The special construction waste crusher structurally comprises moving wheels, a base, a crusher body, a feeding pipe and a dust suppression device, wherein the moving wheels are connected to the bottom of the base, the crusher body is welded to the top of the base, the feeding pipe is connected to the top of the crusher body, and the dust suppression device is arranged on the feeding pipe, and comprises a dust suppression plate, a rotating shaft, a rotating disc, a protective cover, a motor, a gear and an electromagnetic structure; the rotating shaft is arranged in the feeding pipe; the dust suppression plate is arranged on the rotating shaft; the protective cover is connected to the outer side of the feeding pipe; the gear is arranged in the protective cover and connected with the motor; and the rotating disc is arranged above the gear. The special construction waste crusher has the beneficial effects that the dust suppression device is started by using the power of garbage entering, the dust suppression device can be raised to block a feeding pipe orifice again, garbage can enter smoothly, the dust suppression plate can be automatically reset for shielding, dust generated during crushing is prevented from flying out of the feeding pipe, and the influence on workers is reduced.

Owner:李志强

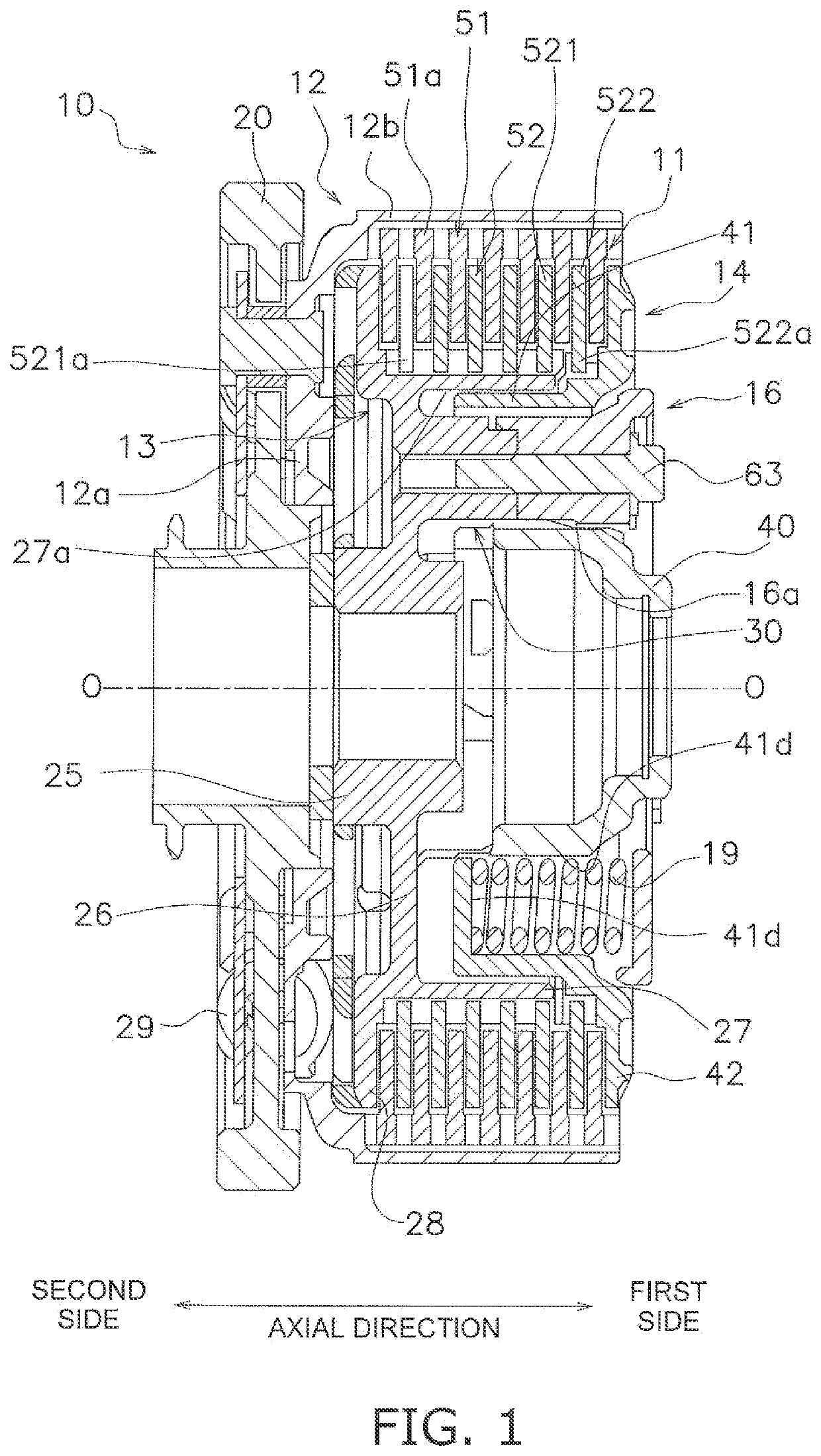

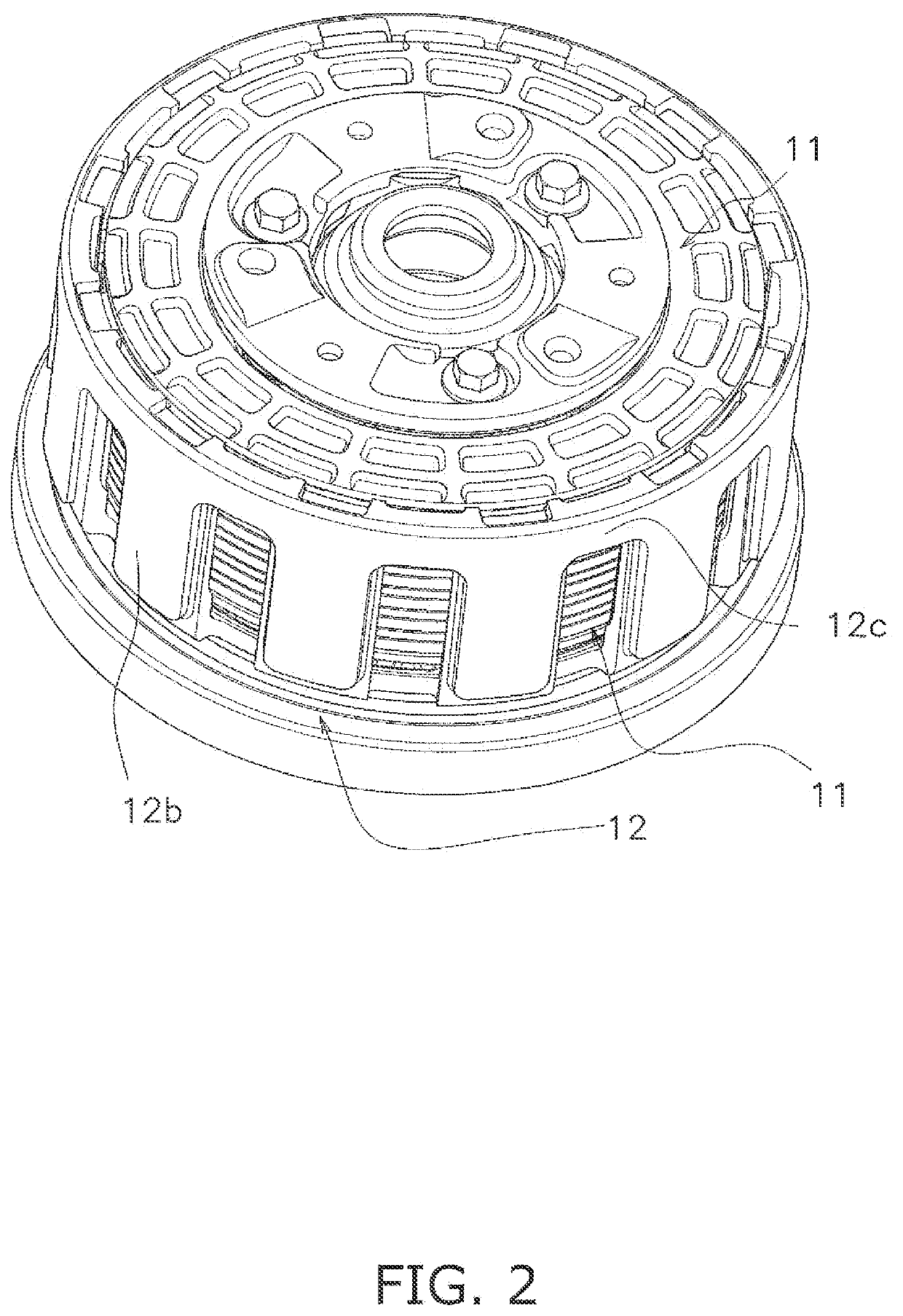

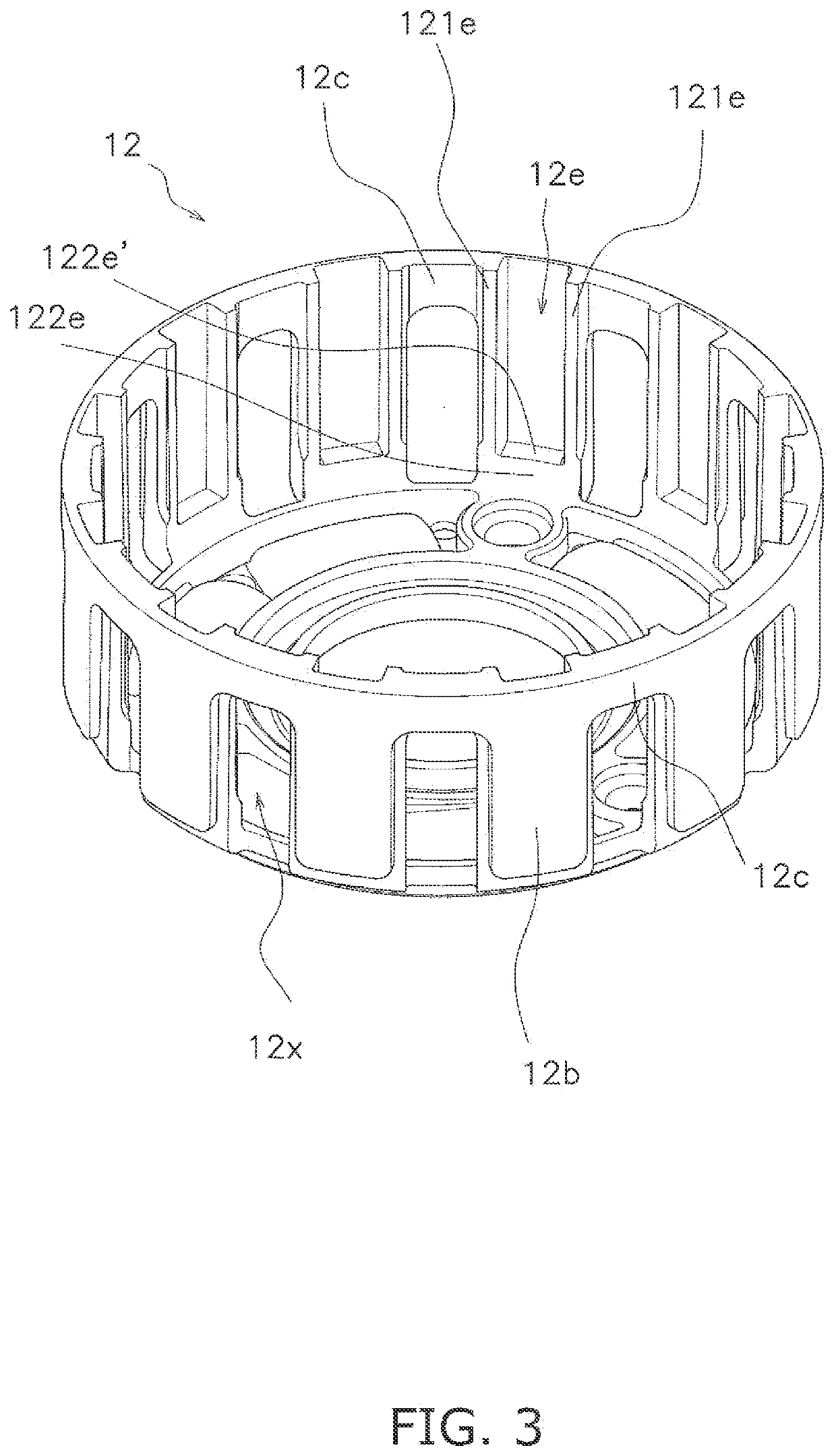

Clutch device

ActiveUS20210310524A1Improve propertiesImprove anti-wear performanceFriction clutchesCouplingsCircular discClutch

A clutch device includes a clutch plate and a clutch outer. The clutch plate includes a plurality of teeth circumferentially disposed apart from each other. The clutch outer includes a bottom portion, a plurality of cover portions, and a plurality of openings. The bottom portion has a disc shape and is greater in diameter than the clutch plate. The cover portions axially extend from an outer peripheral edge of the bottom portion so as to cover the teeth. The cover portions are circumferentially disposed apart from each other. Each opening is disposed between each adjacent pair of the cover portions. Each opening is radially opened.

Owner:EXEDY CORP

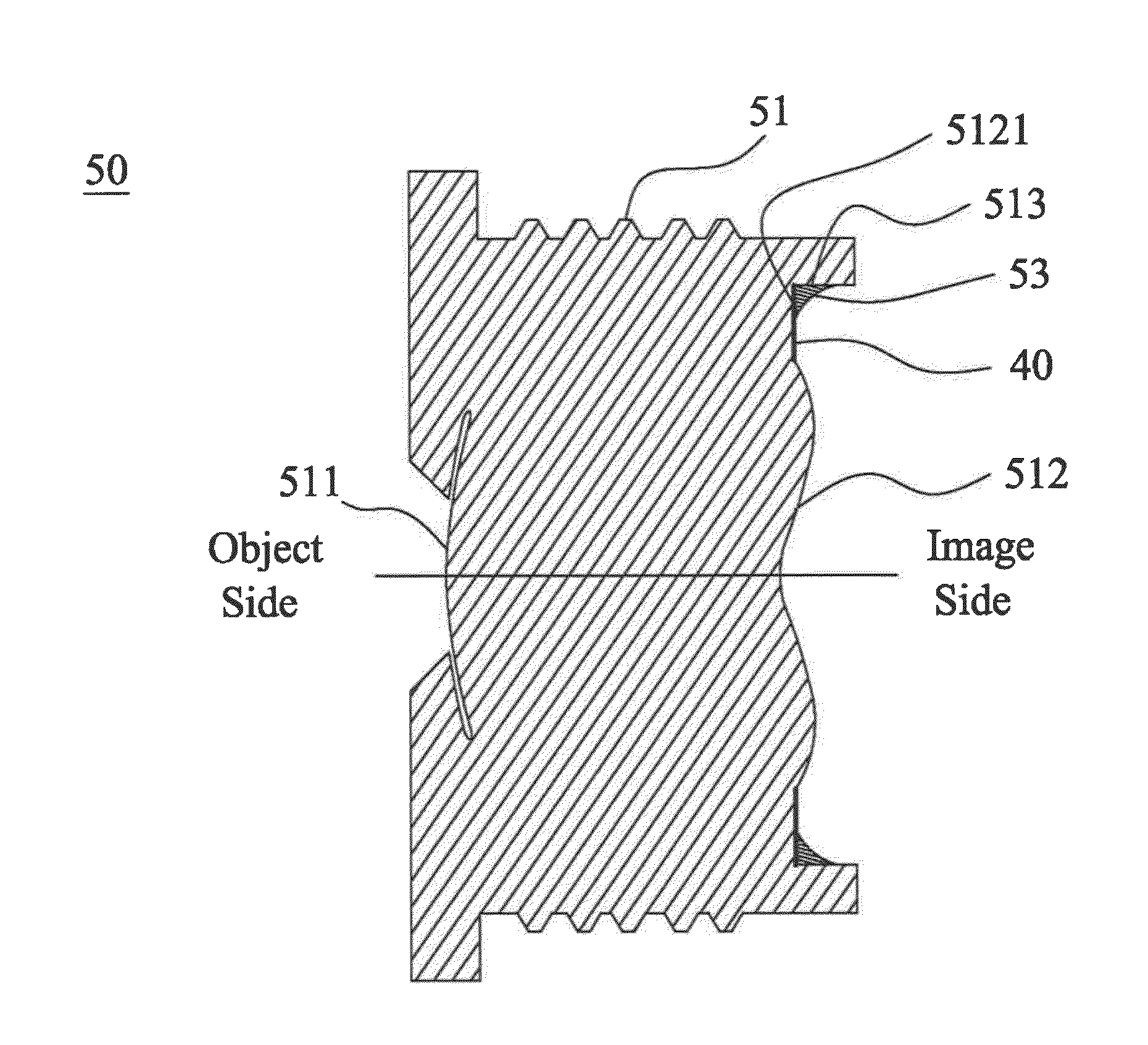

Lens assembly and baffle thereof

A lens assembly and a baffle thereof are provided. The baffle includes an annular body and a plurality of protrusions. The annular body includes an annular main body, an outer ring and an inner ring. The annular main body connects the outer ring and the inner ring. The annular main body is disposed between the outer ring and the inner ring. The protrusions protrude from the outer ring. The lens assembly includes a first lens and a baffle, all of which are arranged in sequence from an object side to an image side along an optical axis. The first lens includes a first surface facing the object side and a second surface facing the image side.

Owner:SINTAI OPTICAL SHENZHEN CO LTD +1

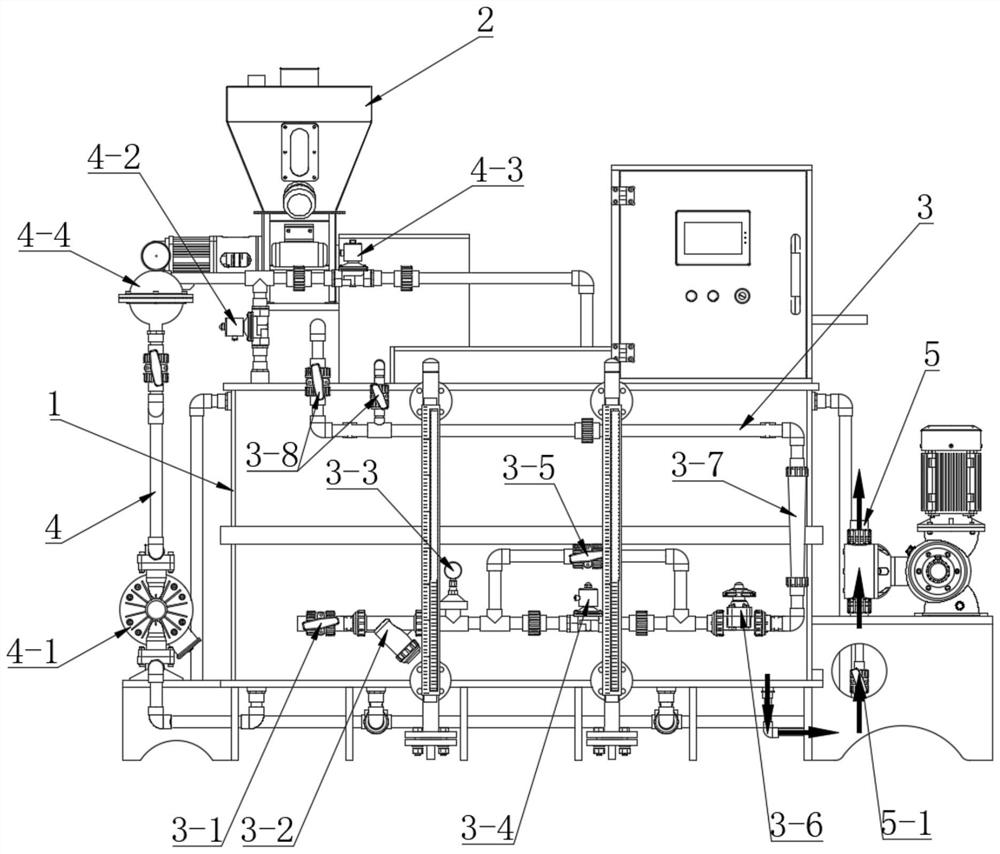

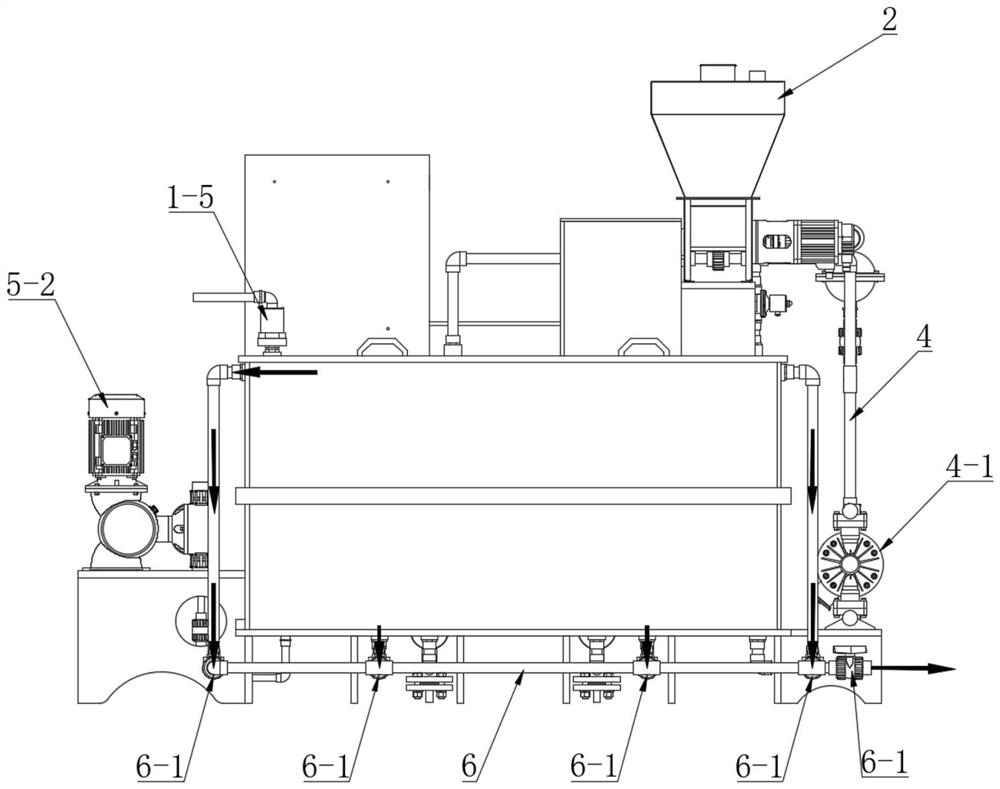

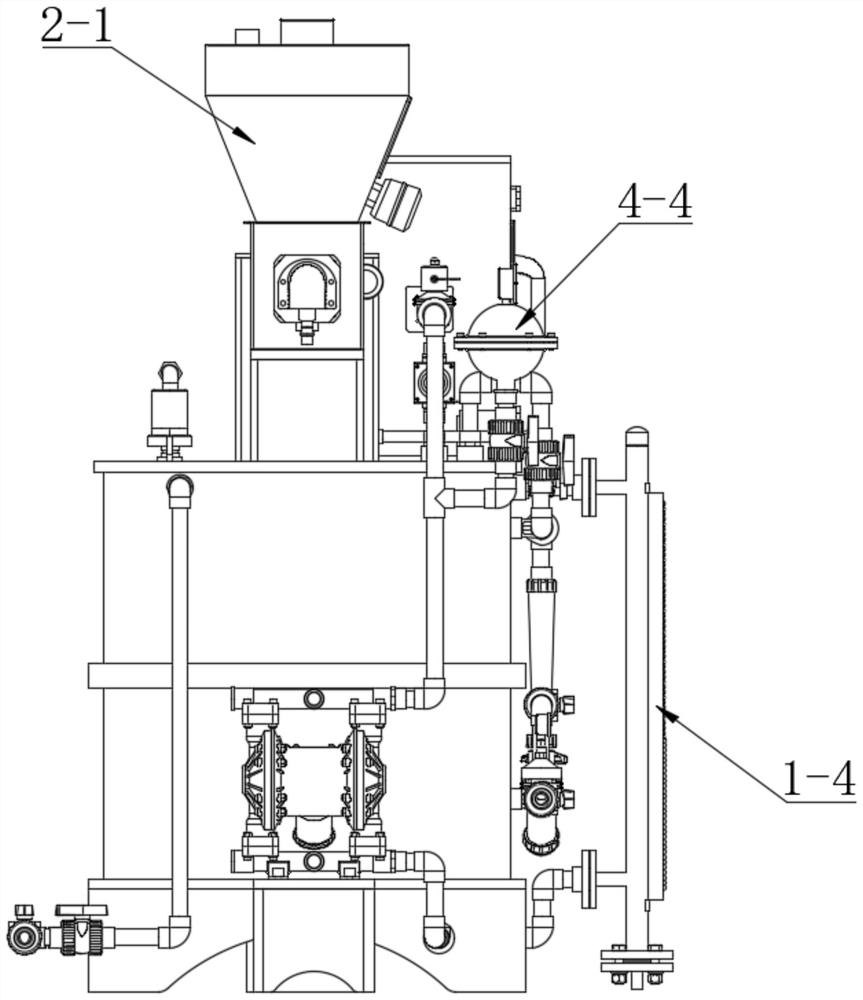

Full-automatic precise ingredient filling equipment and ingredient filling method thereof

PendingCN114713054AImprove solubilityImprove consistencyFlow mixersTransportation and packagingProcess engineeringIndustrial engineering

The invention discloses full-automatic precise ingredient filling equipment and an ingredient filling method thereof. The full-automatic precise ingredient filling equipment comprises a main box body, a weighing and charging mechanism, a water supply pipeline, a circulating feeding pipeline and a finished product liquid output pipeline, a solution cavity and a finished product cavity which are isolated from each other are arranged in the main box body; a blanking, spraying and dissolving hopper communicated with the solution cavity is arranged at the top of the main box body; the weighing and feeding mechanism is used for conveying the medicine powder into the blanking, spraying and dissolving hopper; the water supply pipeline supplies water to the solution cavity and the blanking, spraying and dissolving hopper; an inlet of the circulating feeding pipeline is communicated with the solution cavity from the bottom of the main box body, and an outlet of the circulating feeding pipeline is communicated with the solution cavity and the finished product cavity; an inlet of the finished product liquid output pipeline is communicated with the finished product cavity from the bottom of the main box body. The device is not limited by use occasions, the consistency of the concentration of the output liquid medicine is very high, a stirring device does not need to be configured, the cost is saved, the noise is low, and vibration is little.

Owner:JIANGSU TOM PACKAGING MACHINERY

Lens device

ActiveUS20060176586A1Effective optical path diameterMaximize distanceTelevision system detailsColor television detailsOptical axisEngineering

A lens device in which a first movable lens holding frame and a second movable lens holding frame are moved along an optical axis by rotating a cam cylinder rotatably provided on a lens barrel, an escape channel for escapement of a portion of the second movable lens holding frame being formed in the first movable lens holding frame, the lens device comprising: a light shielding member moved along the optical axis by the rotation of the cam cylinder, the light shielding member being moved to a position at which the light shielding member closes the escape channel of the first movable lens holding frame.

Owner:FUJI PHOTO OPTICAL CO LTD

Automatic defective product removing device for chip detection

PendingCN113964058AAvoid exaggerationAvoid flaringSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringMechanical engineering

The invention provides an automatic defective product removing device for chip detection, which comprises a chip detection table, a bracket is fixedly arranged at the center position of the top end of the chip detection table, the appearance of the bracket is L-shaped on a longitudinal section, and a chip placing table is fixedly arranged at the center position of the outer surface of the top side of the bracket; a collecting box is included and is fixedly mounted at the bottom of the right end of the chip detection table, and the collecting box is hollow inside, open at the upper part, closed at the lower part, straight at the left part and convex at the right part; and a dust collection assembly is also included. According to the automatic defective product removing device for chip detection, the collecting box can have a dust collecting function, when defective products are removed by blowing of a blowing device on the chip placing table, even if external dust impurities and chips are blown into the collecting box together through the collecting pipe, and dust in the collecting box can be collected and treated. And the phenomenon that too much dust and impurities adhere to the surfaces of the collected chips, and consequently the chips are damaged is avoided.

Owner:蓝芯存储技术(赣州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com