Full-automatic precise ingredient filling equipment and ingredient filling method thereof

A filling equipment and fully automatic technology, applied in the direction of chemical instruments and methods, mixer accessories, mixers, etc., can solve the problems of inconsistent concentration of liquid medicine, heavy smell of liquid medicine, and inability to effectively ensure the uniformity of sewage treatment, etc., to achieve high consistency , increase the dissolution rate, reduce the effect of evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

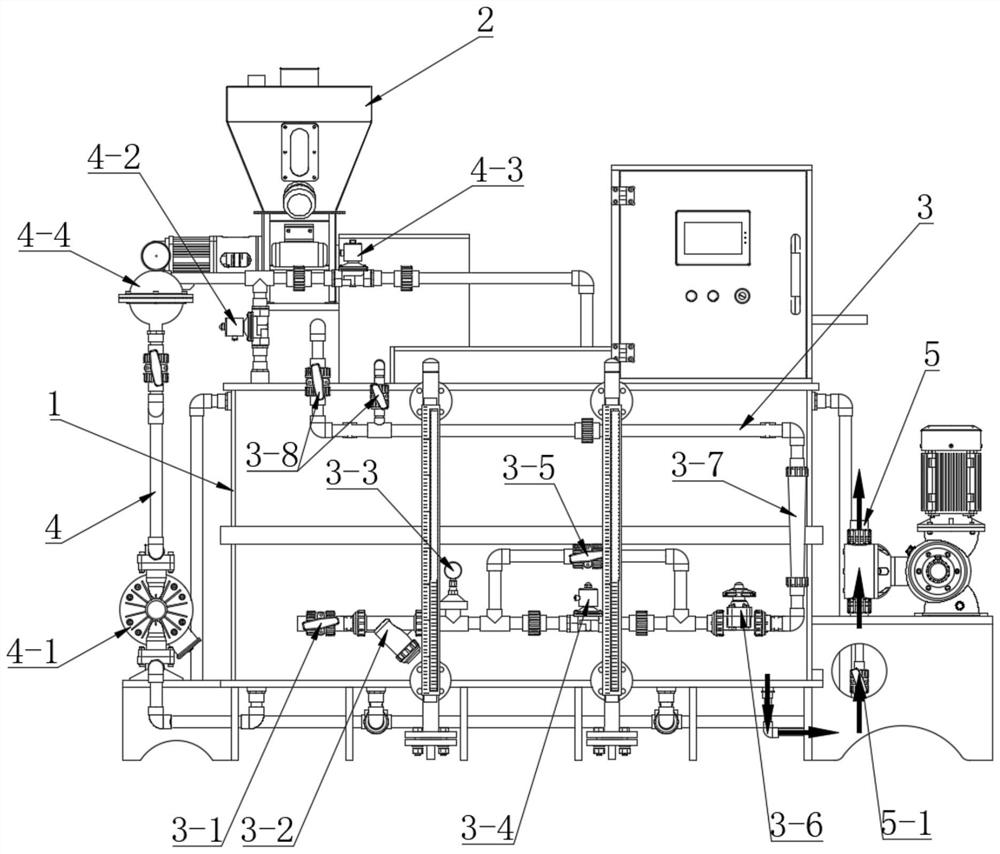

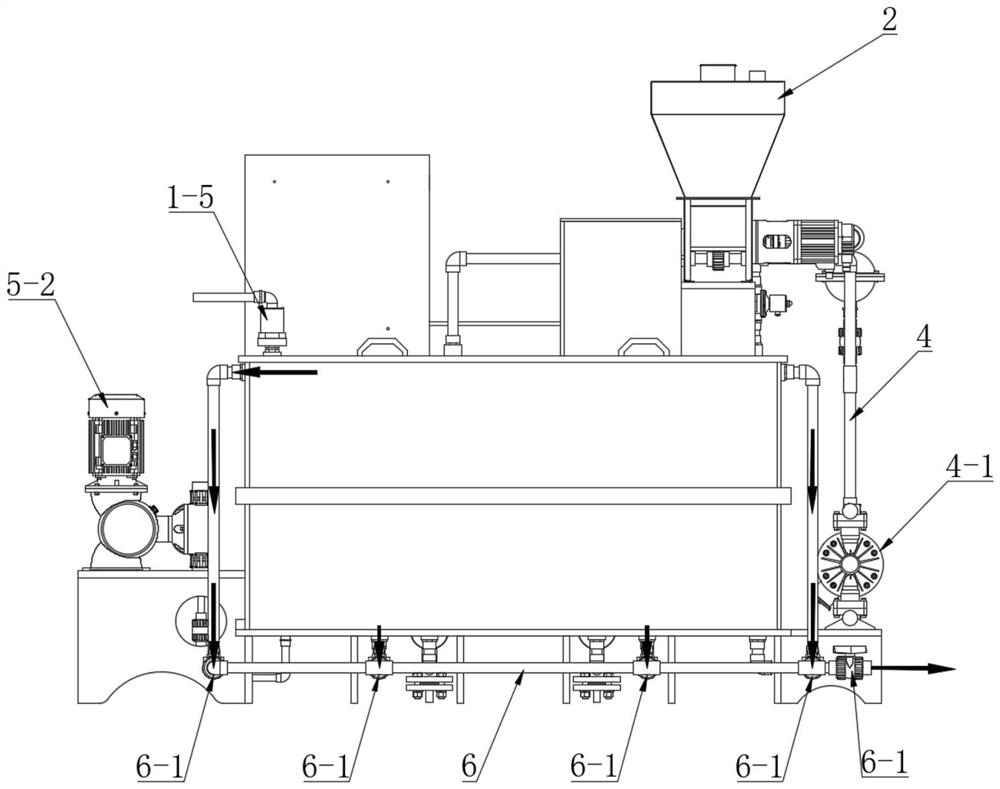

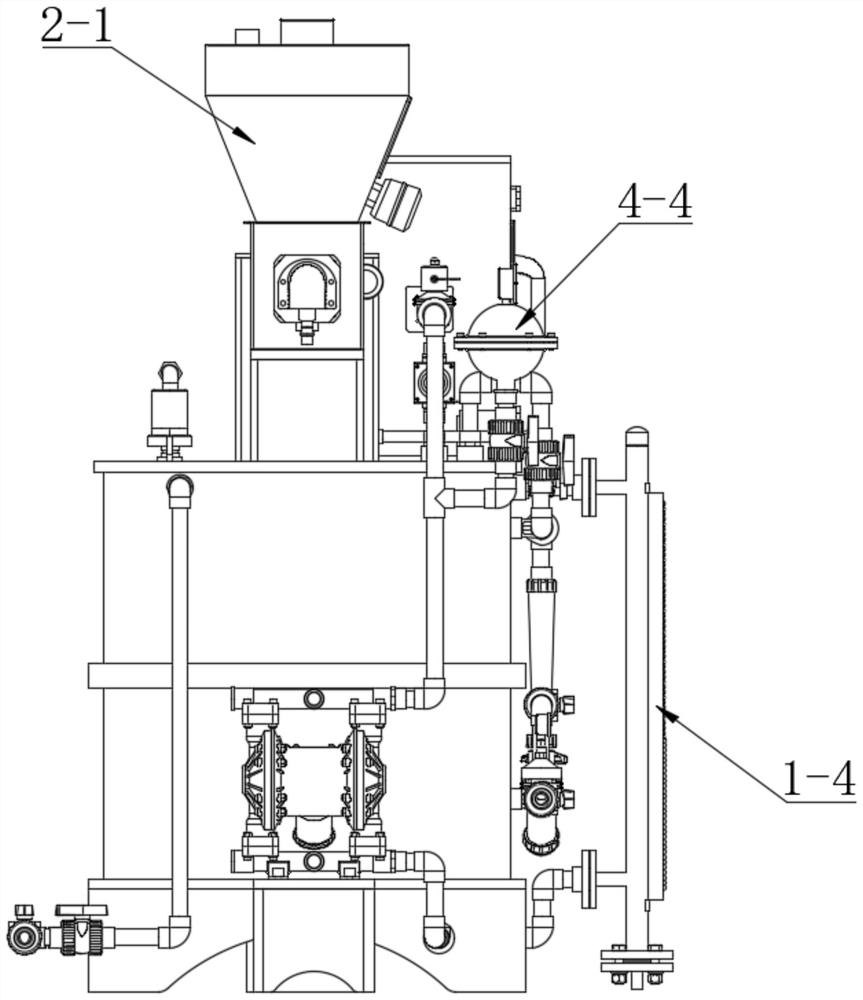

[0071] See Figure 1 to Figure 7 , The fully automatic precision batching and filling equipment of this embodiment includes a main box 1 , a weighing and feeding mechanism 2 , a water supply pipeline 3 , a circulating feeding pipeline 4 , a product liquid output pipeline 5 and a discharge pipe 6 .

[0072] The main box body 1 is provided with a solution cavity 1-1 and a finished product cavity 1-2 which are isolated from each other; the top of the main box body 1 is provided with a blanking spray dissolving hopper 1-3 which communicates with the solution cavity 1-1. Both the solution cavity 1-1 and the finished product cavity 1-2 are connected with a liquid level gauge 1-4, which facilitates real-time observation of the liquid volume in the solution cavity 1-1 and the finished product cavity 1-2. There is a breathing valve 1-5 on the top of the finished cavity 1-2. Since the finished cavity 1-2 is a closed cavity, the breathing valve 1-5 is set to facilitate the ventilation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com