Patents

Literature

109results about How to "Avoid flattening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

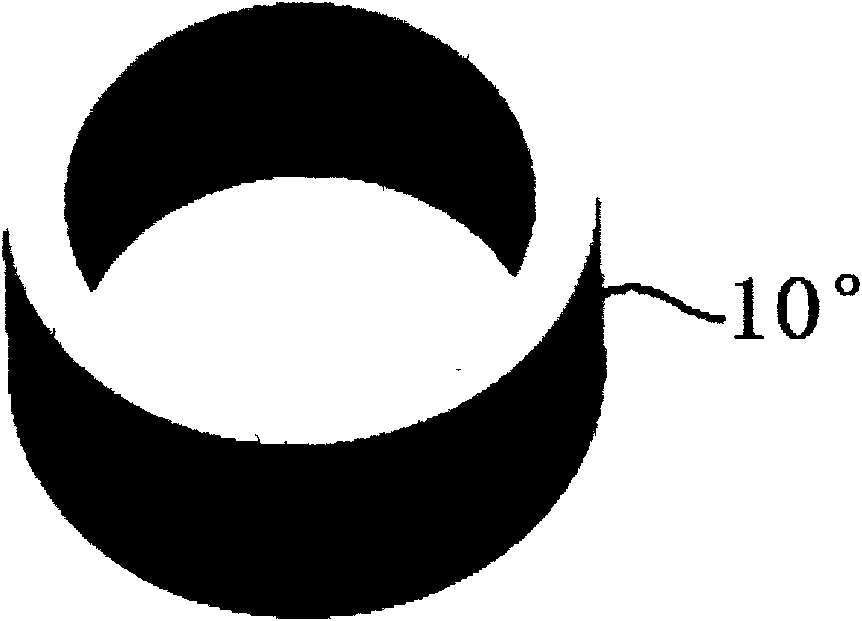

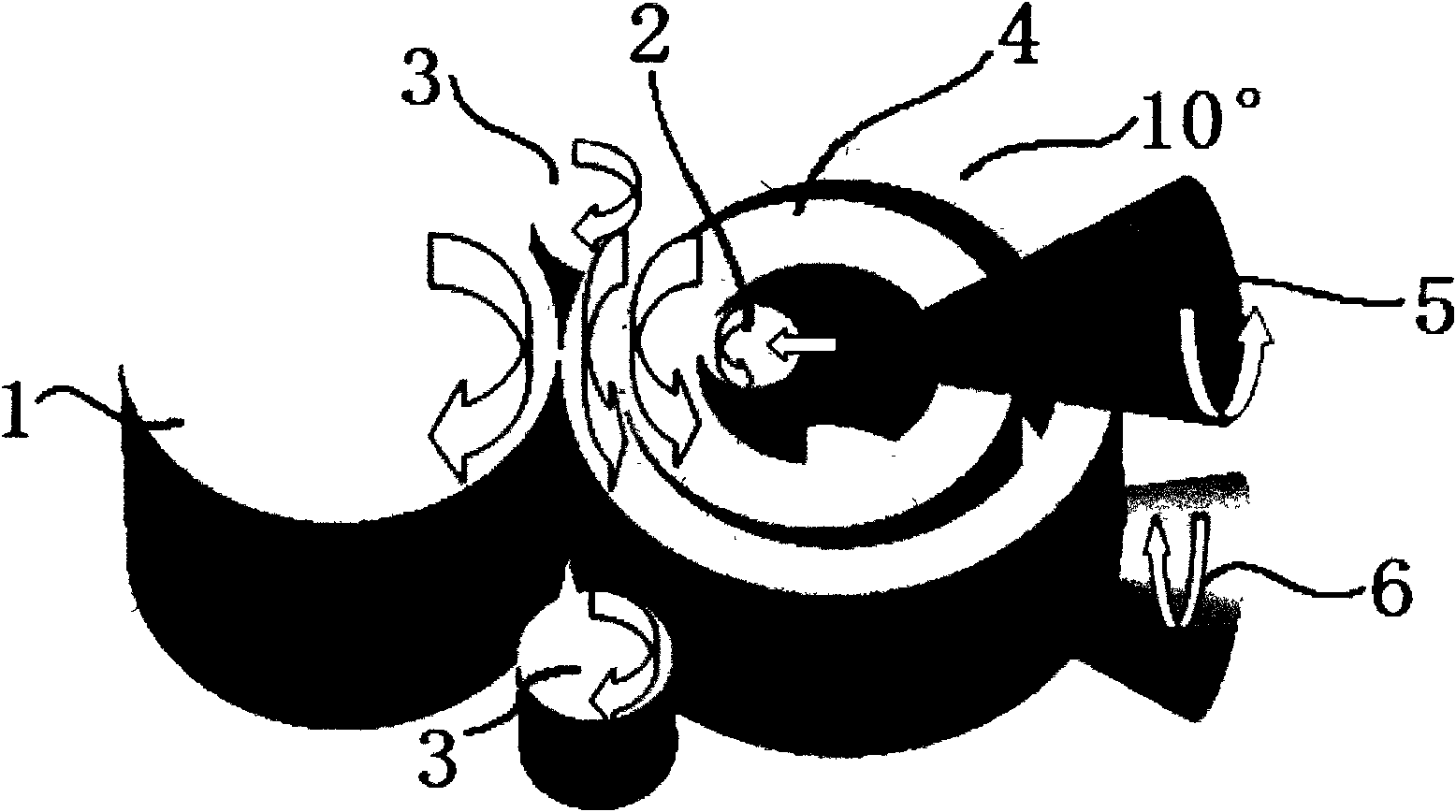

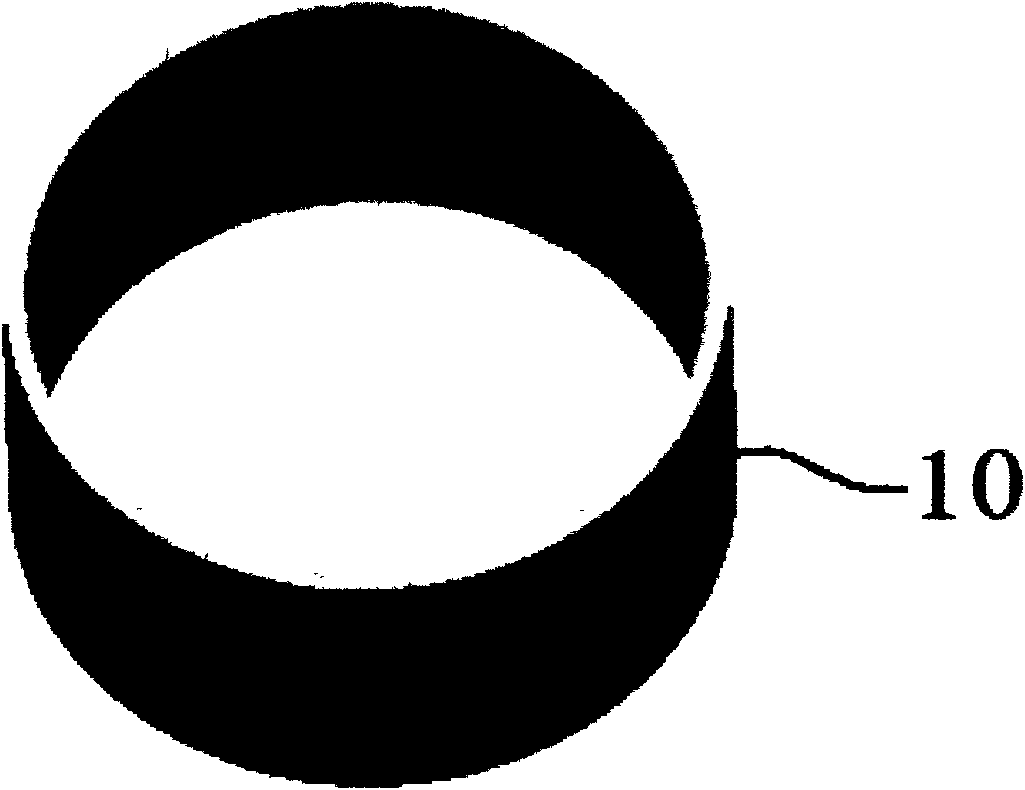

Roll forming method of TC25 titanium alloy thin-walled ring forging

The invention discloses a roll forming method of a TC25 titanium alloy thin-walled ring forging. In order to roll-form a thin-walled ring forging with high dimensional precision and excellent tissue and performance, the technical scheme comprises the steps of: firstly, sleeving a preheated follower die sleeve and a titanium alloy pre-rolled blank heated to a deformation temperature in a ring rolling mill, sleeving the follower die sleeve in the pre-rolled blank, and positioning the two workpieces by using a main roll, a core roll, clutching rolls, an upper cone roll and a lower cone roll of the ring rolling mill; and starting the ring rolling mill, making a feeding motion by the core roll towards the direction of the main roll along the radial direction and rolling the pre-rolled blank at a rolling force of 200-4000KN under the support of the follower die sleeve by the core roll together with the main roll to ensure that the pre-rolled blank expands radially at a speed of 5-10mm / s, wherein the wall thickness is gradually reduced, and the pre-rolled blank is rolled into the thin-walled ring forging when the deformation reaches 25-45 percent. The minimum value of the wall thickness of the titanium alloy thin-walled ring forging roll-formed by adopting the method is 25mm, the maximum value of the height-thickness ratio is 25mm, and the ring forging is mainly used for gyrorotor parts, such as a cylindrical shell and the like used in the fields, such as aerospace and the like.

Owner:GUIZHOU AVIATION TECHN DEV

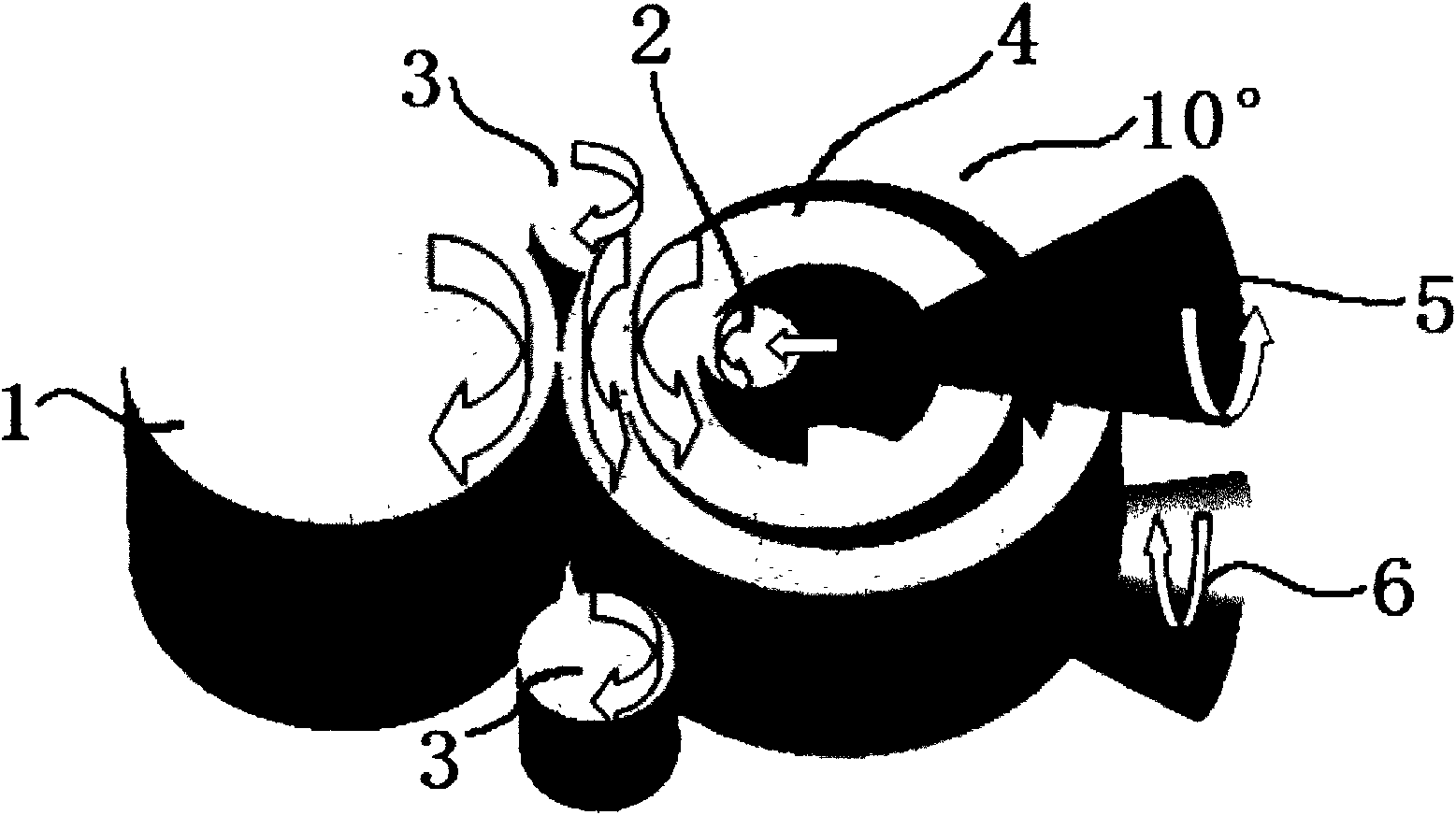

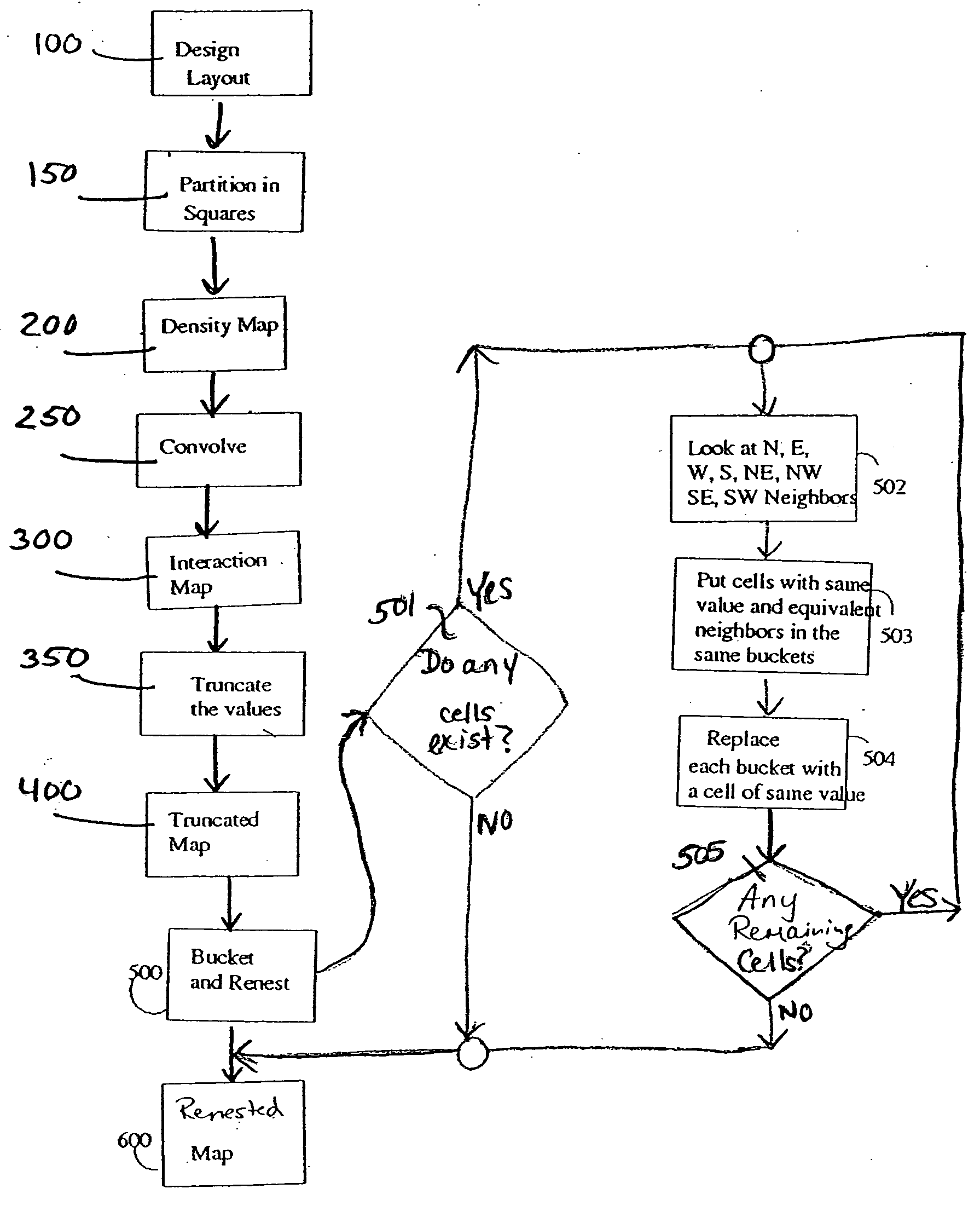

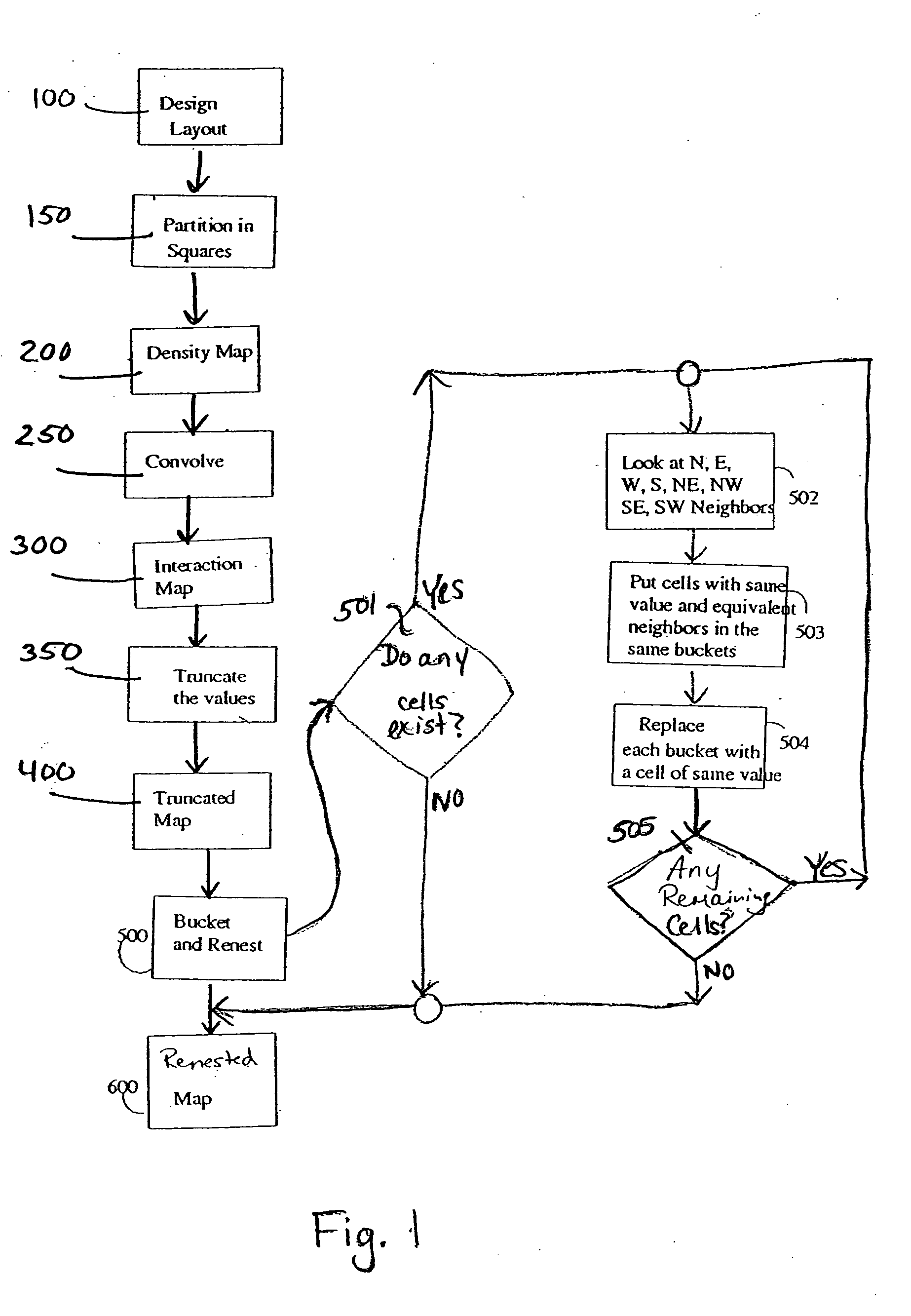

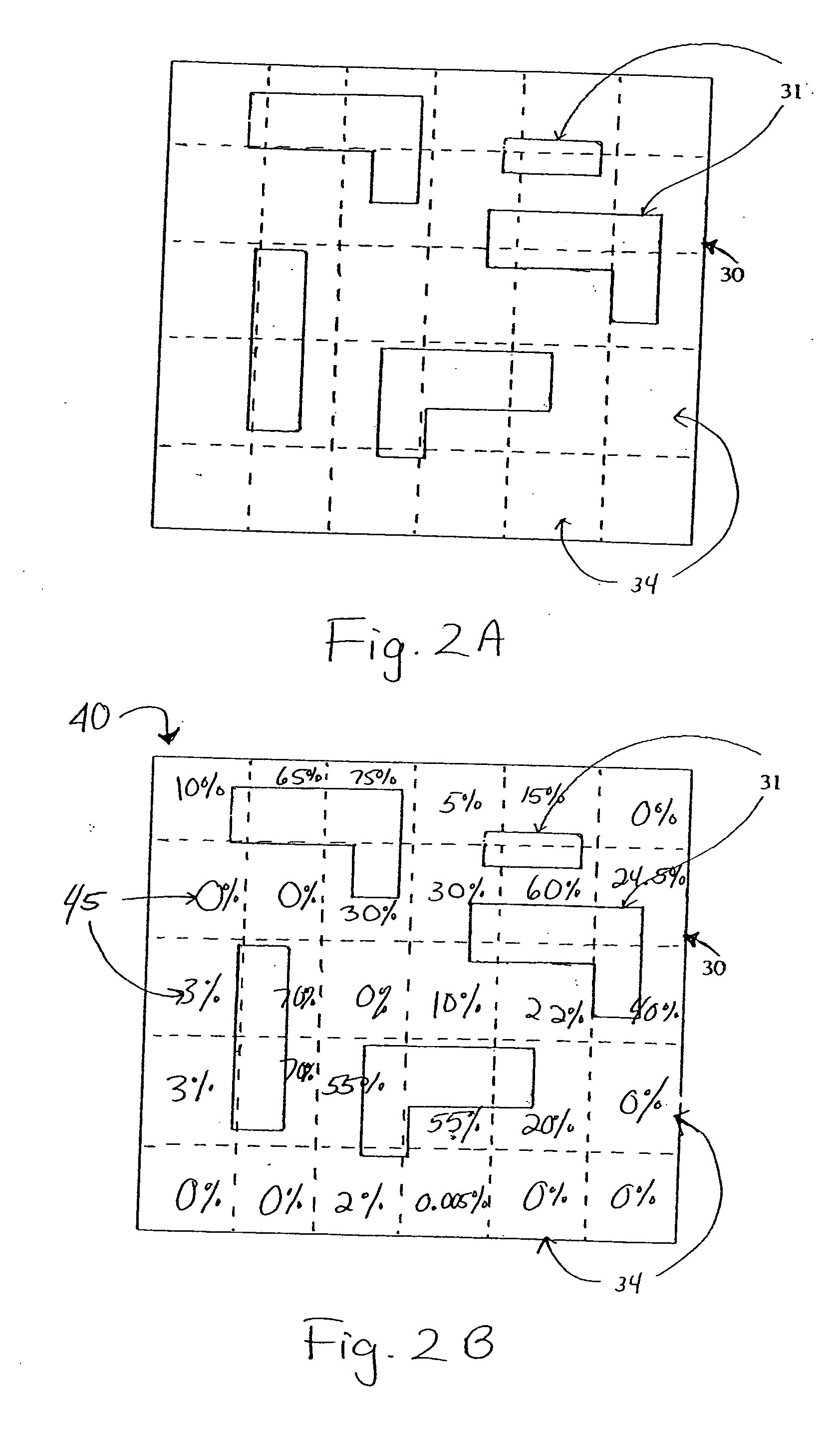

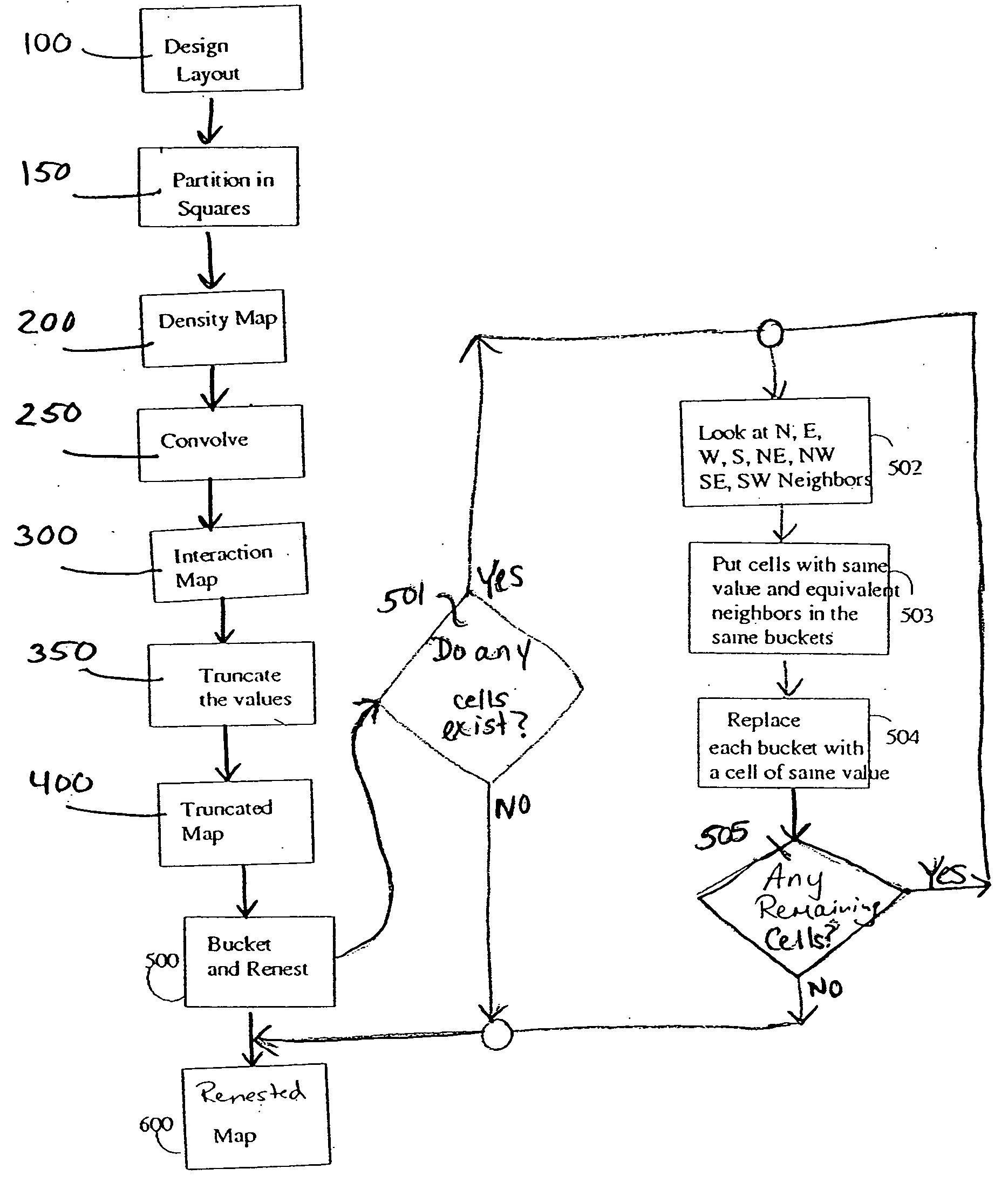

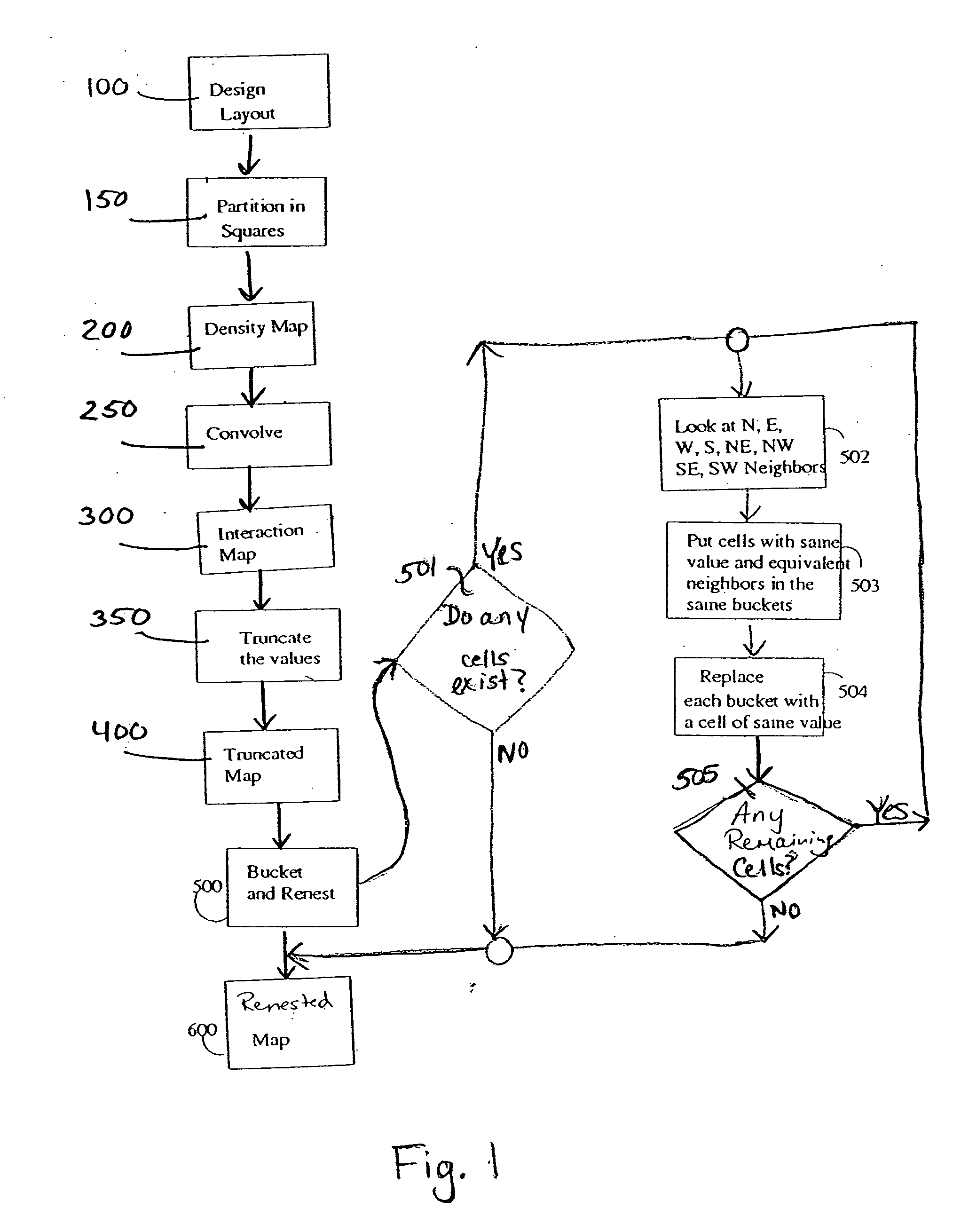

Renesting interaction map into design for efficient long range calculations

InactiveUS20050091634A1Save timeEfficiently and easily and costSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusConvolutionTheoretical computer science

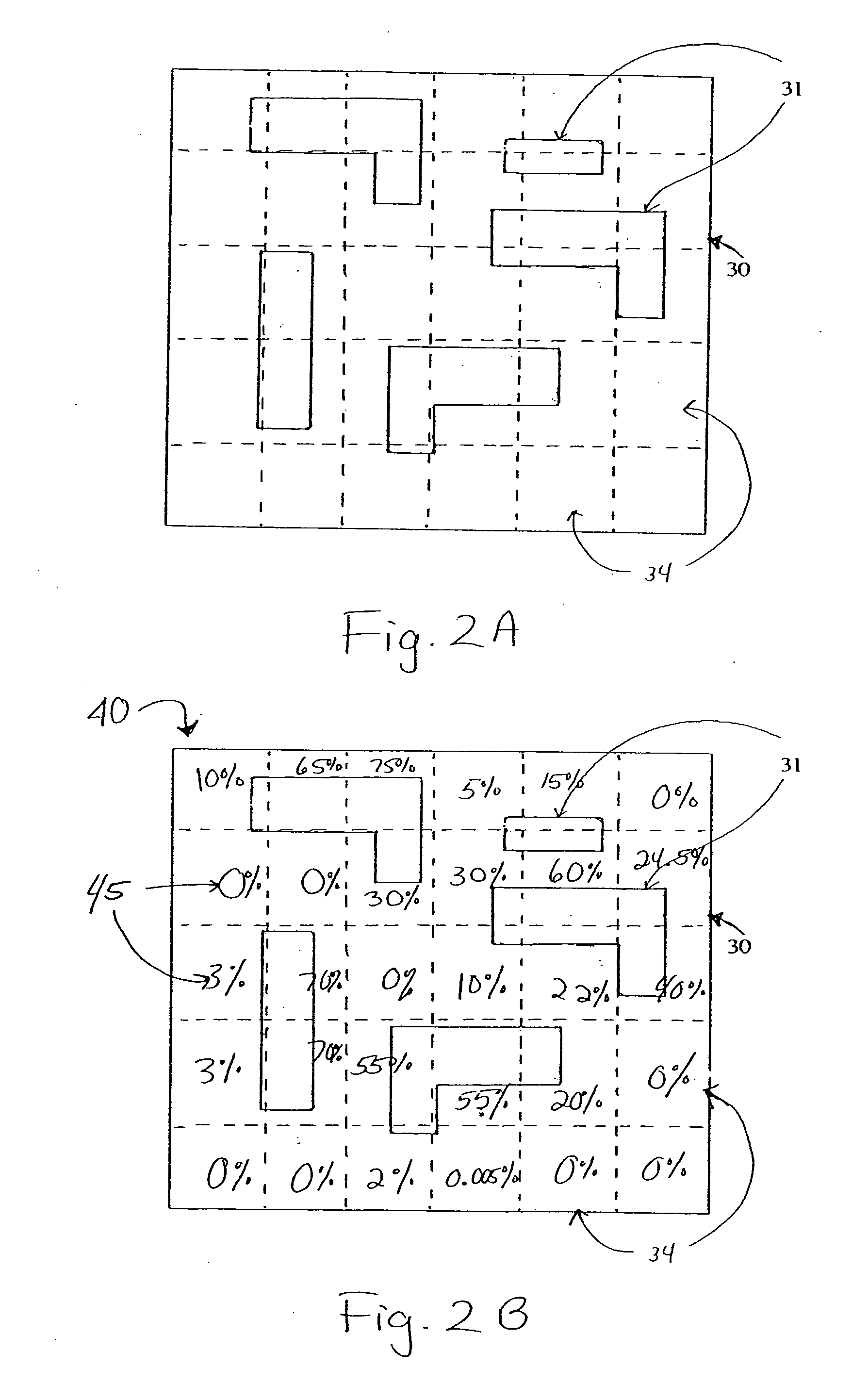

Methods, and program storage devices, for performing model-based optical lithography corrections by partitioning a cell array layout, having a plurality of polygons thereon, into a plurality of cells covering the layout. This layout is representative of a desired design data hierarchy. A density map is then generated corresponding to interactions between the polygons and plurality of cells, and then the densities within each cell are convolved. An interaction map is formed using the convolved densities, followed by truncating the interaction map to form a map of truncated cells. Substantially identical groupings of the truncated cells are then segregated respectively into differing ones of a plurality of buckets, whereby each of these buckets comprise a single set of identical groupings of truncated cells. A hierarchal arrangement is generated using these buckets, and the desired design data hierarchy enforced using the hierarchal arrangement to ultimately correct for optical lithography.

Owner:GLOBALFOUNDRIES INC

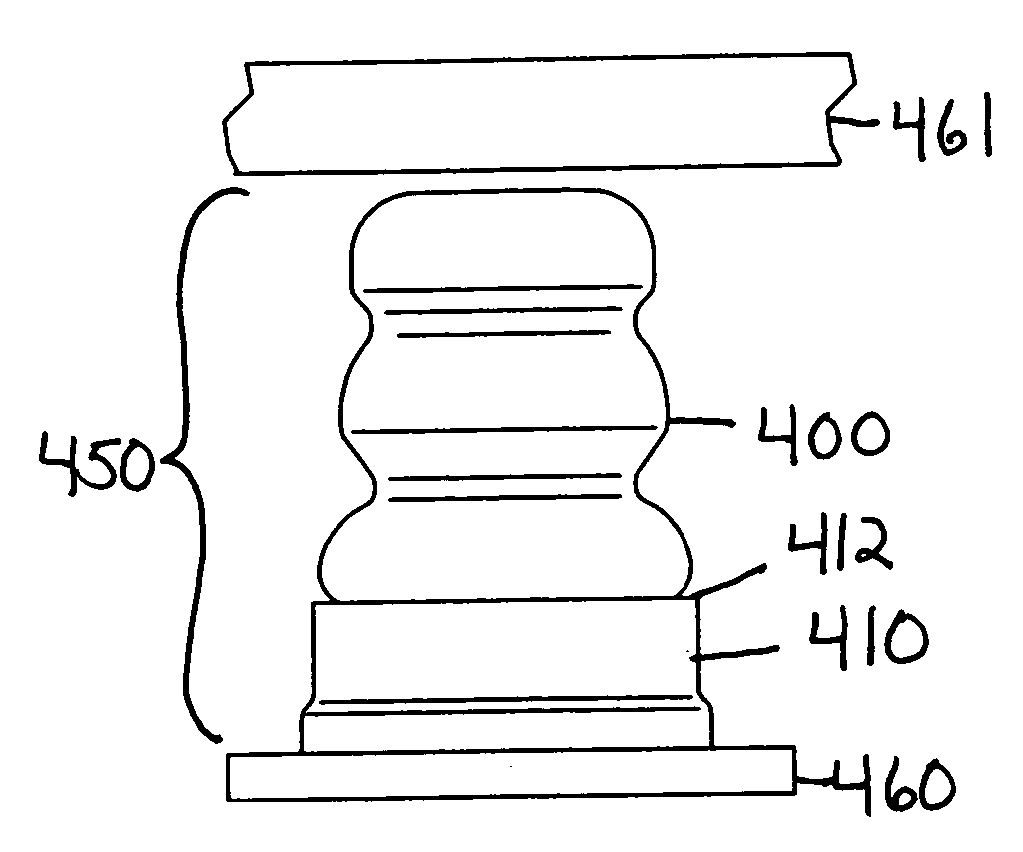

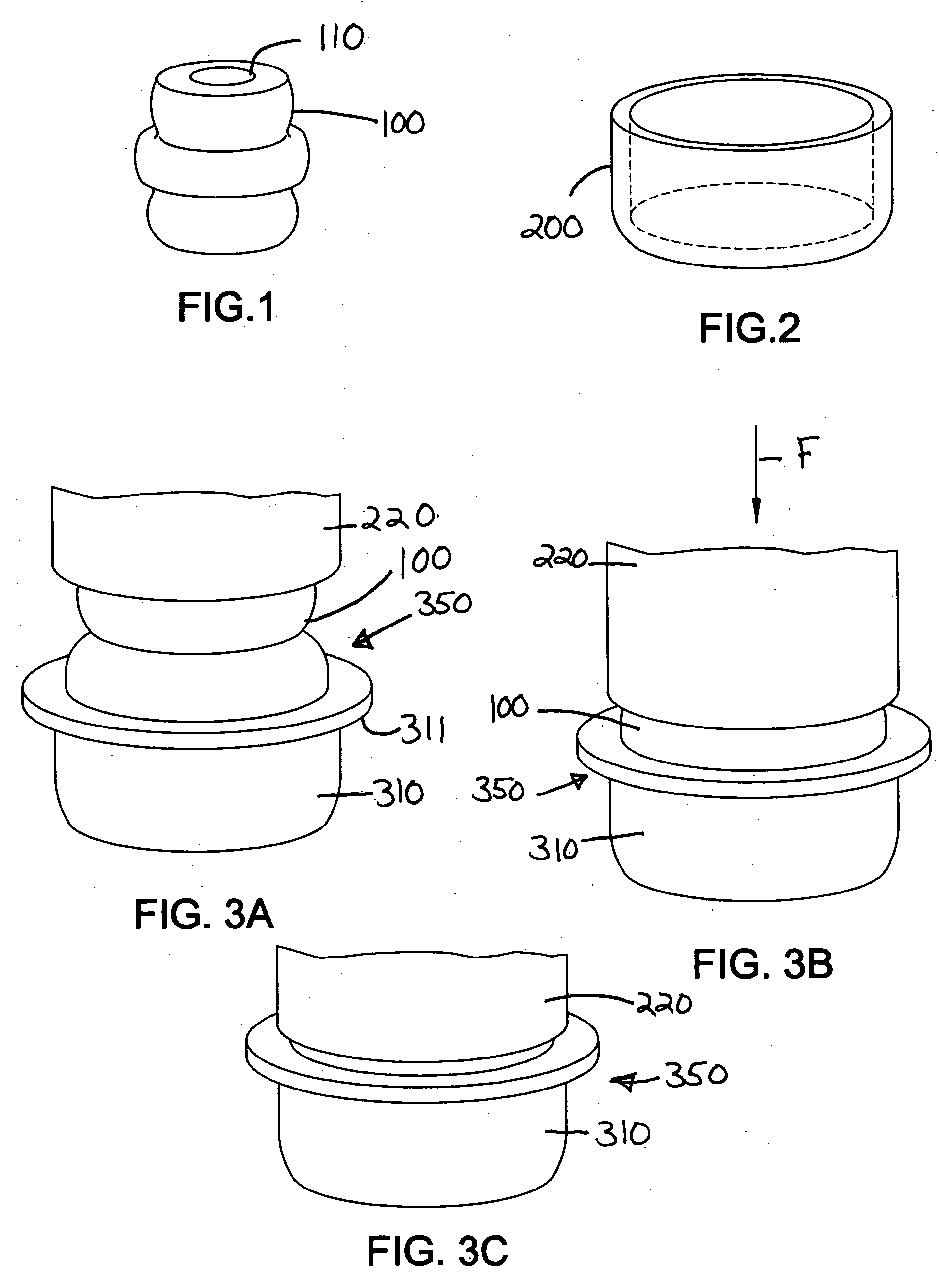

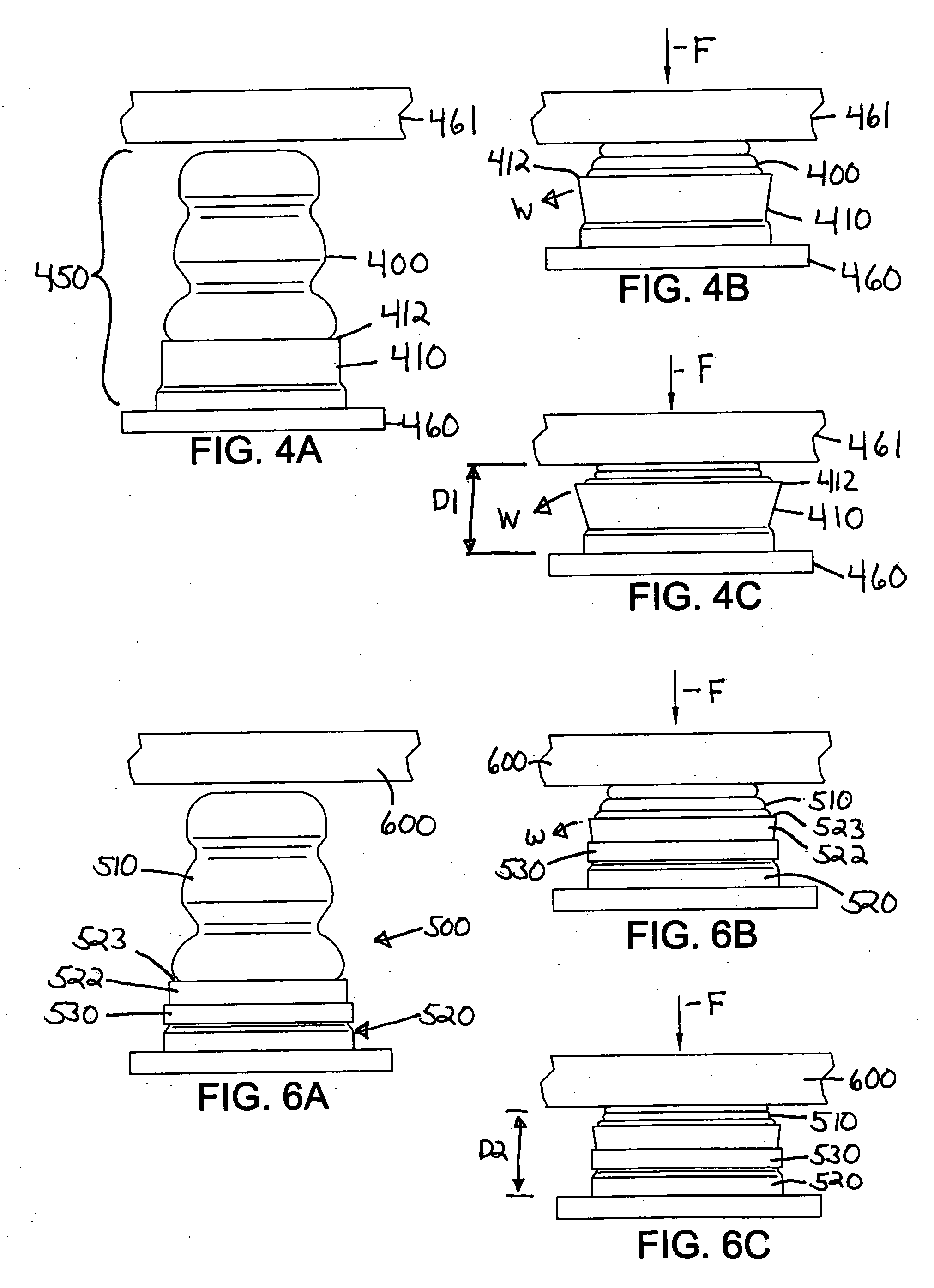

Jounce bumper

InactiveUS20050230891A1More travelOvercome effectMultiple spring combinationsResilient suspensionsEnergy absorptionEngineering

An energy absorption device for providing a softer stop arrangement between a pair of components. A compressible bumper is placed into a flexible cup. A ring is place around the flexible cup. Upon application of force between the components, the compressible bumper collapses into the flexible cup and the cup begins to expand radially. The ring prevents the cup from expanding to the point of flattening and provides the device with a definite rigid stop. The device is usable between any two components to prevent collisions between the components up to a certain force between them and is also usable between a strut assembly and a vehicle suspension frame.

Owner:EDWARDS INDS

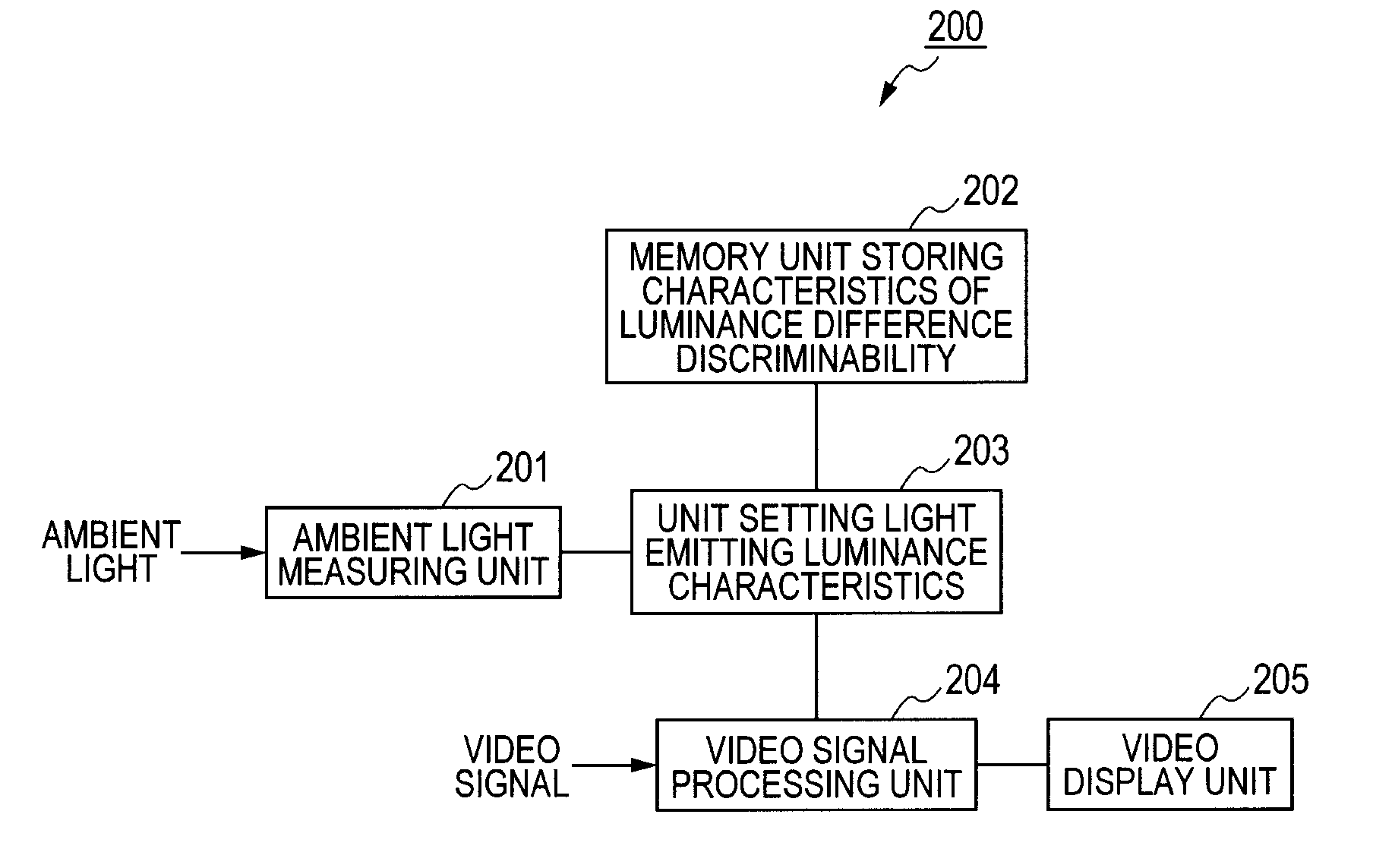

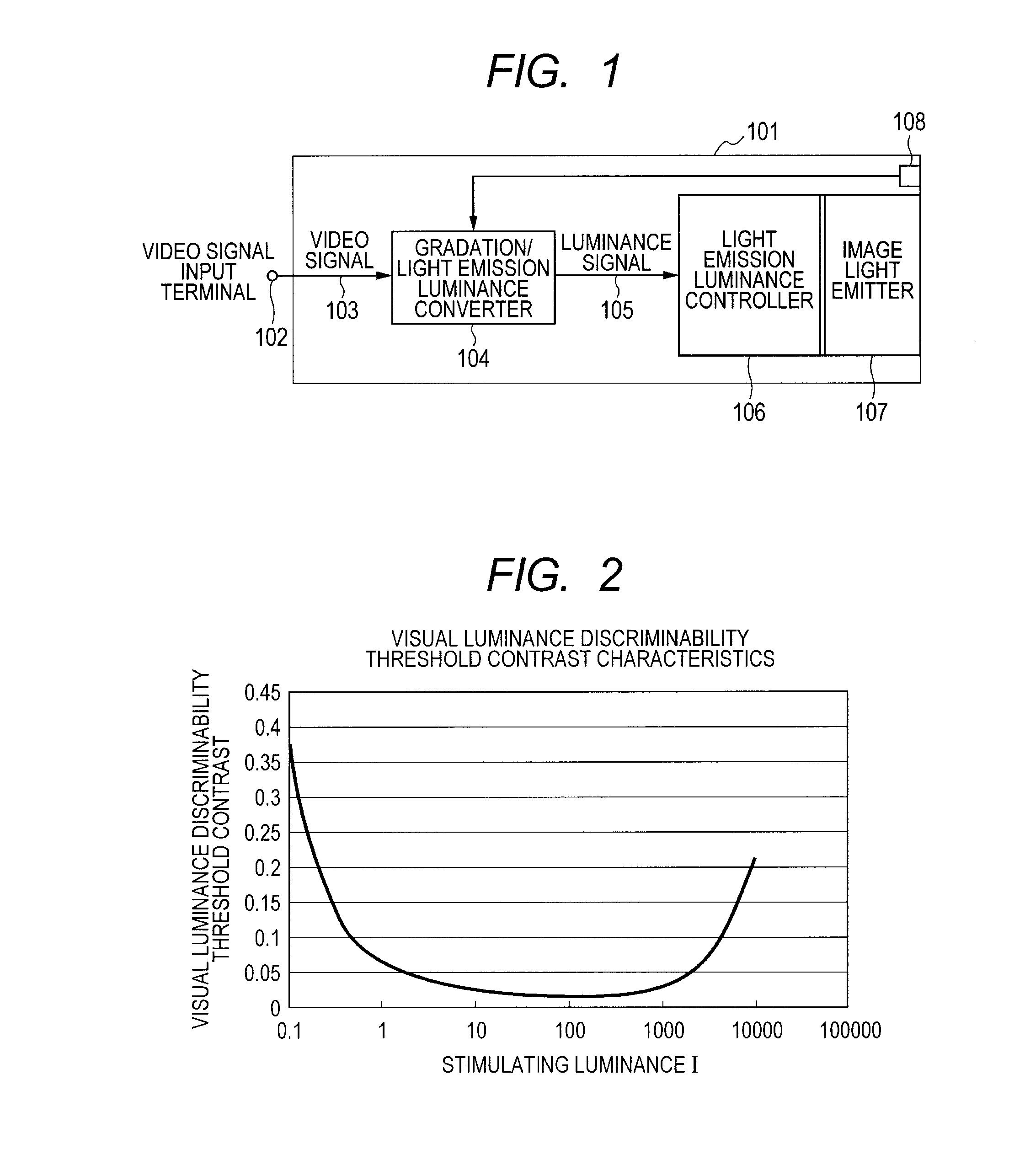

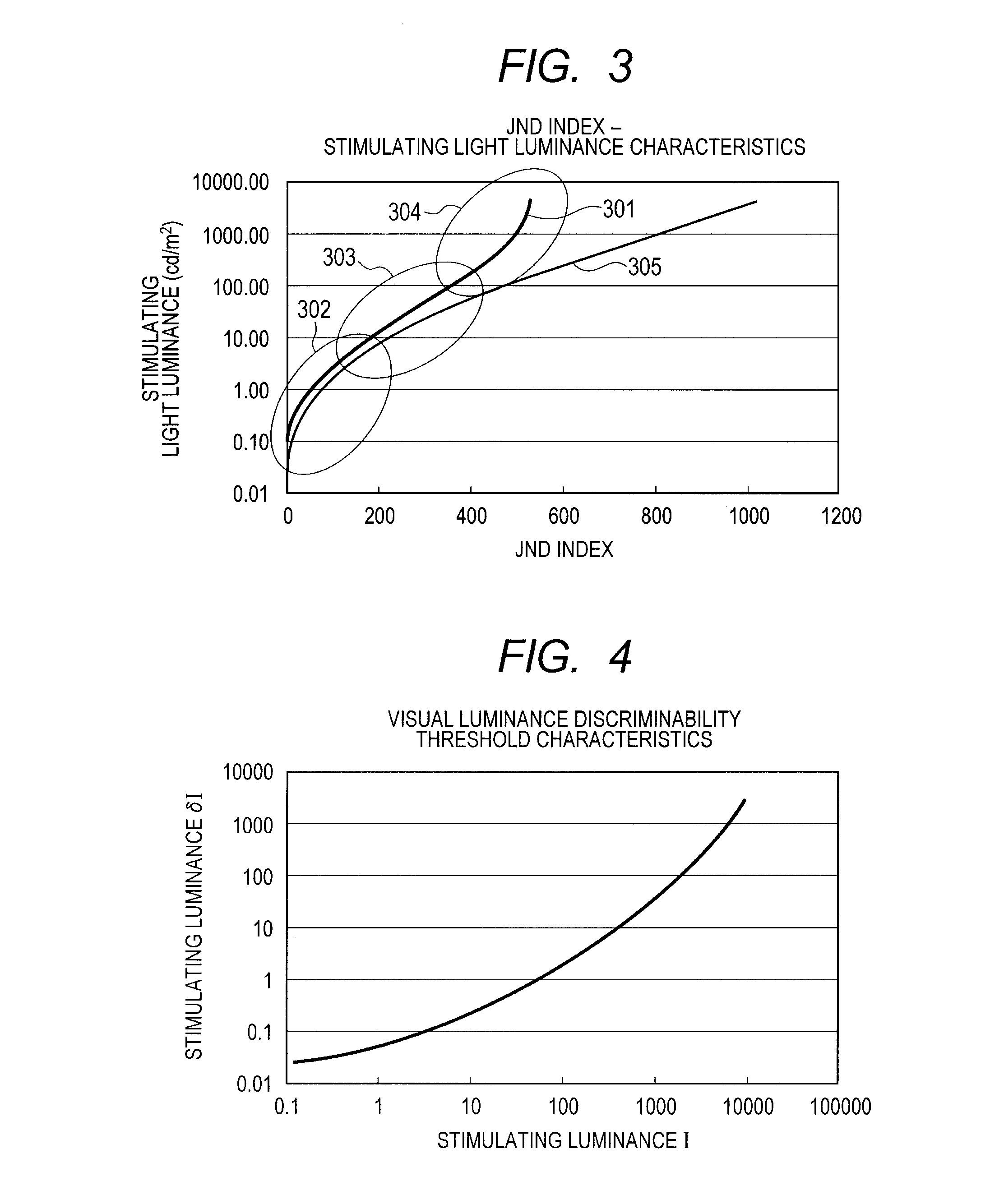

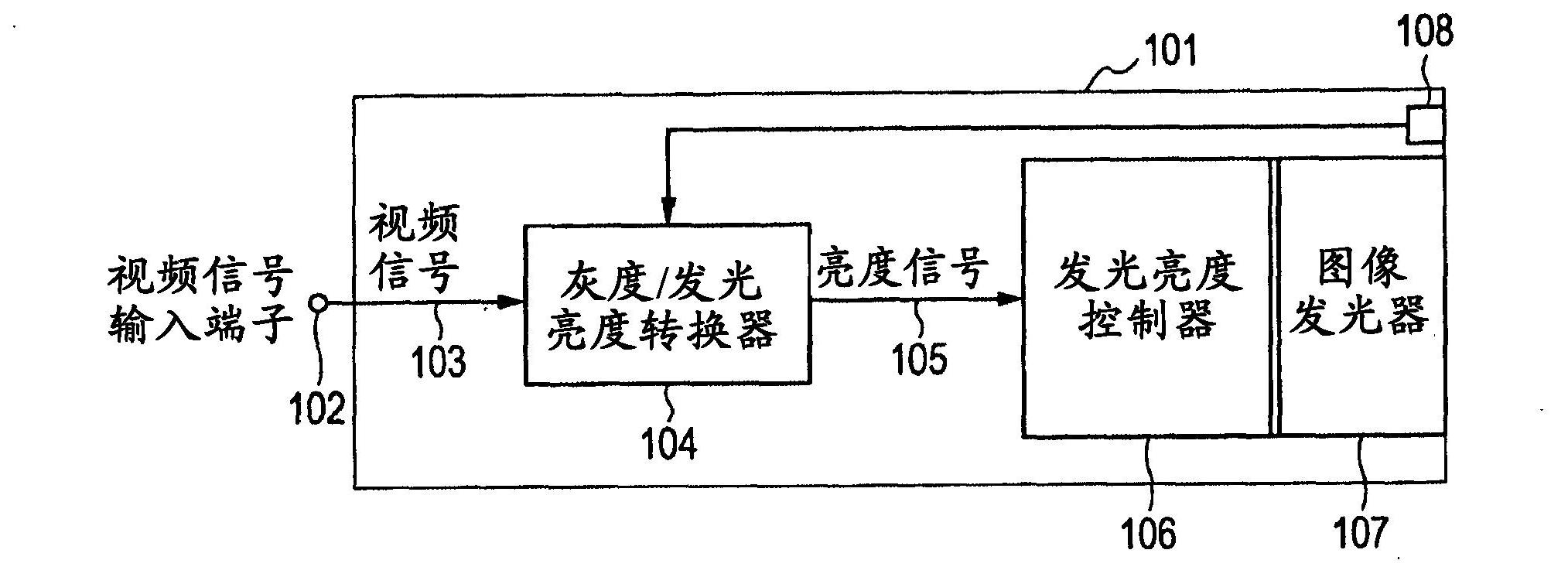

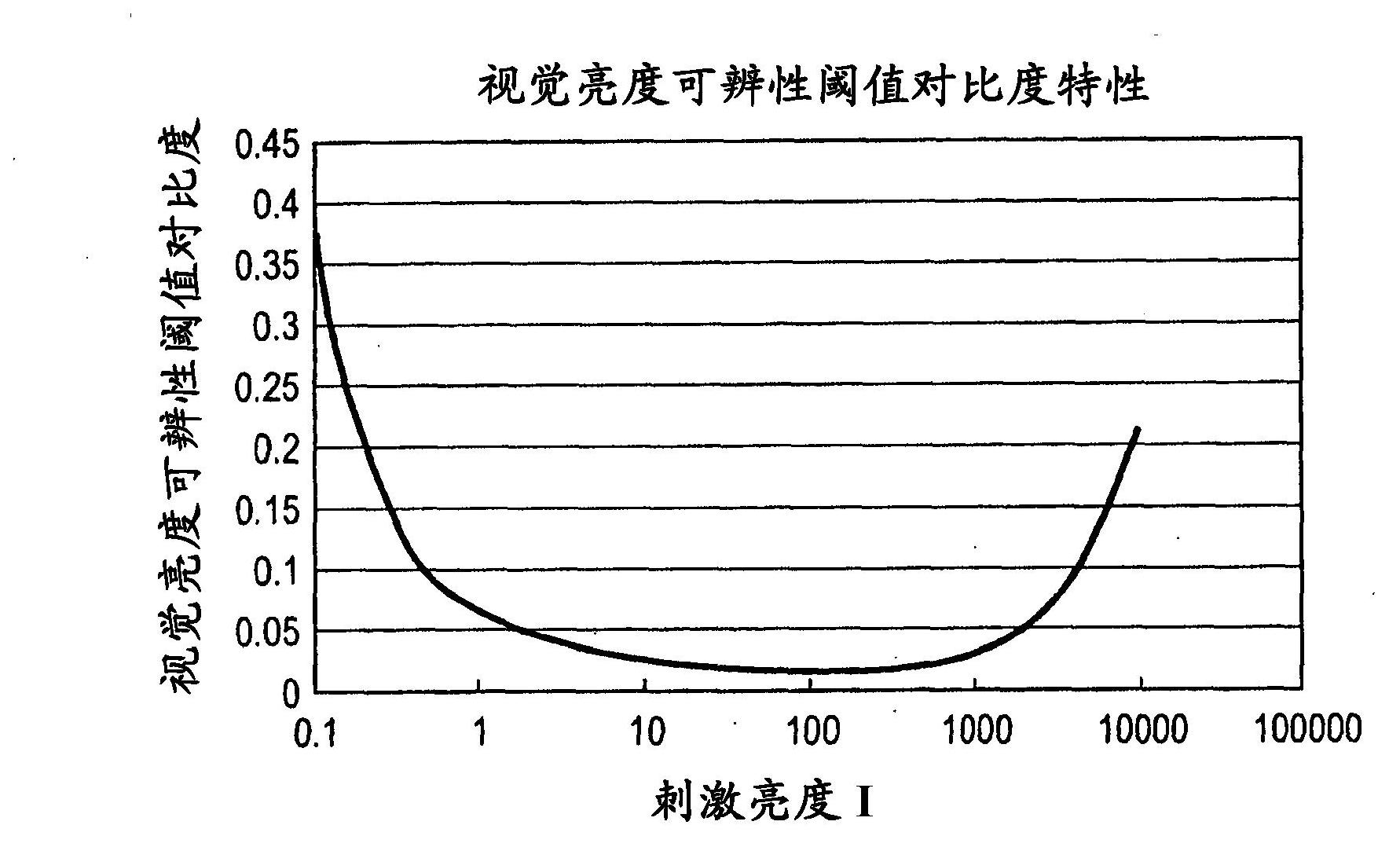

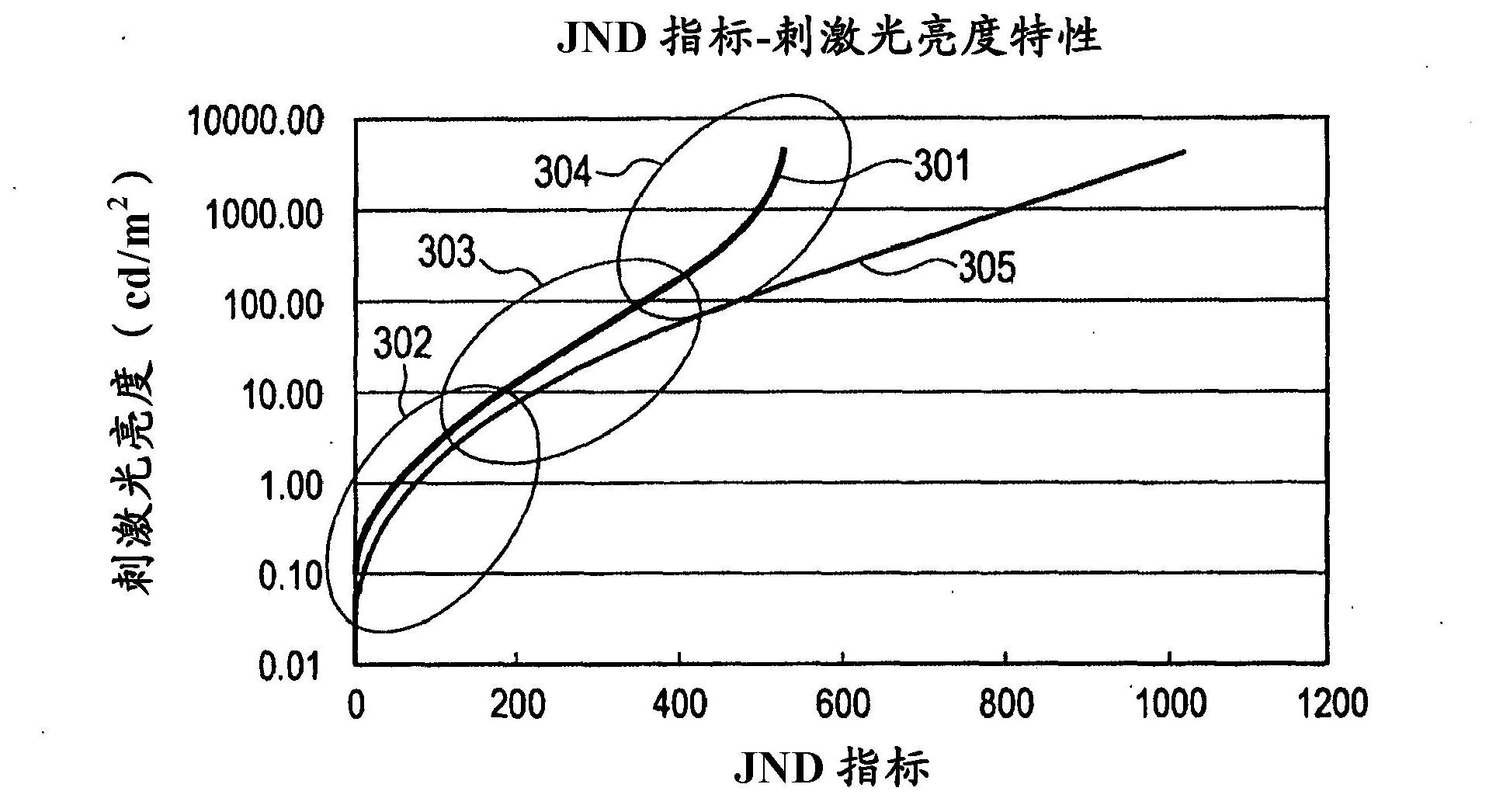

Image display apparatus

InactiveUS20120154355A1High luminance and gradation rangeAvoid flatteningTelevision system detailsCathode-ray tube indicatorsHigh luminanceCommon logarithm

An image display apparatus is provided that avoids discontinuity in a high luminance and gradation range and is capable of displaying gradations where differences in sense of luminance change at equal intervals from an intermediate gradation range to the maximum value of the gradations. A gradation / light emission luminance converter 104 converts the gradation of an input image into data corresponding to a luminance to be displayed by a video light emitter 107 using predetermined conversion characteristics. In an intermediate gradation range, the common logarithms of the luminances to be displayed by the video light emitter 107 have a proportional relation to the gradations. In the high luminance and gradation range, the relation gradually deviates from the proportional relation; the nearer the gradation approaches the maximum value thereof, the larger the variation quantity of the common logarithm of the luminance to be assigned to an increment of the gradations becomes.

Owner:CANON KK

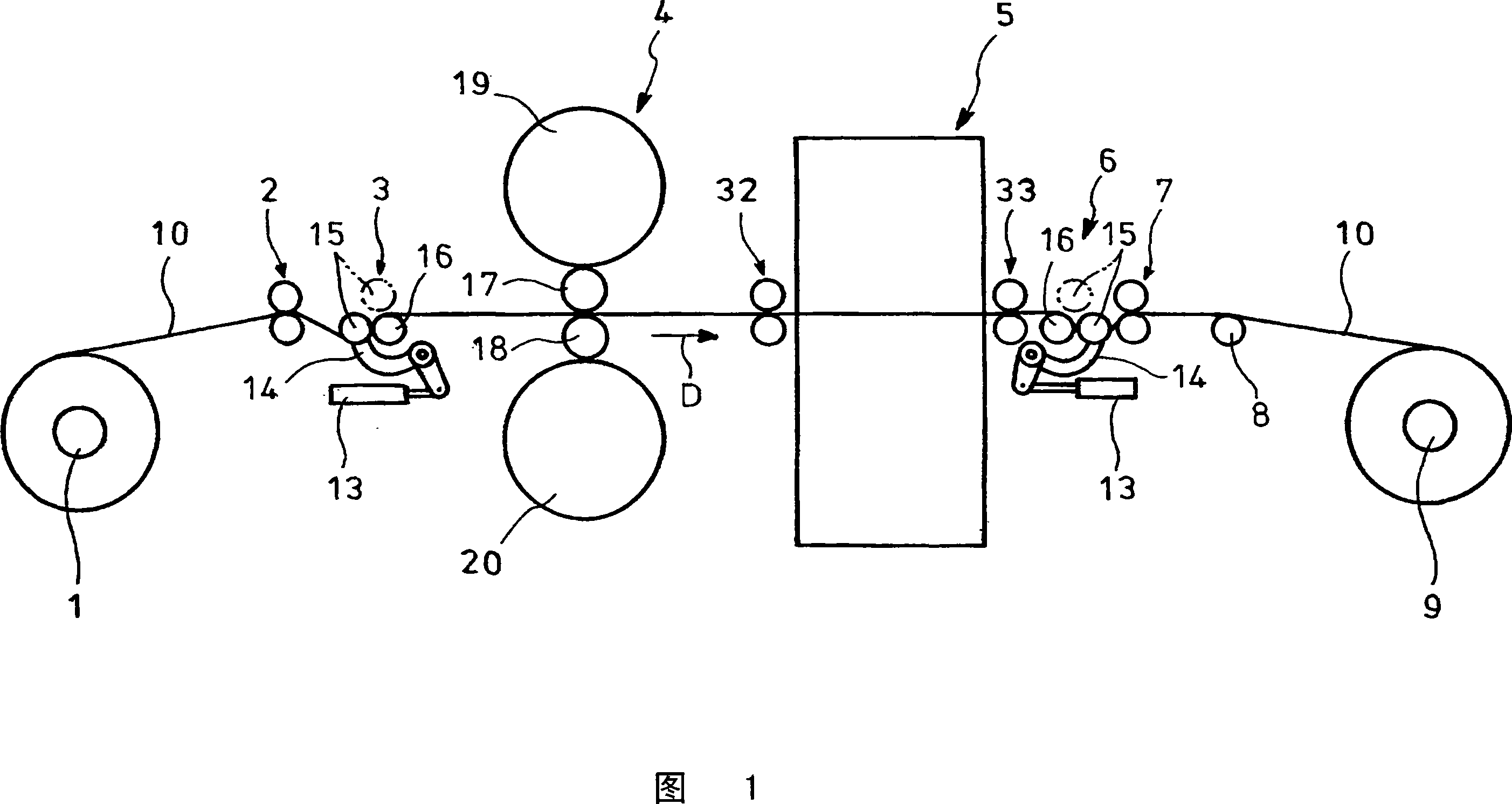

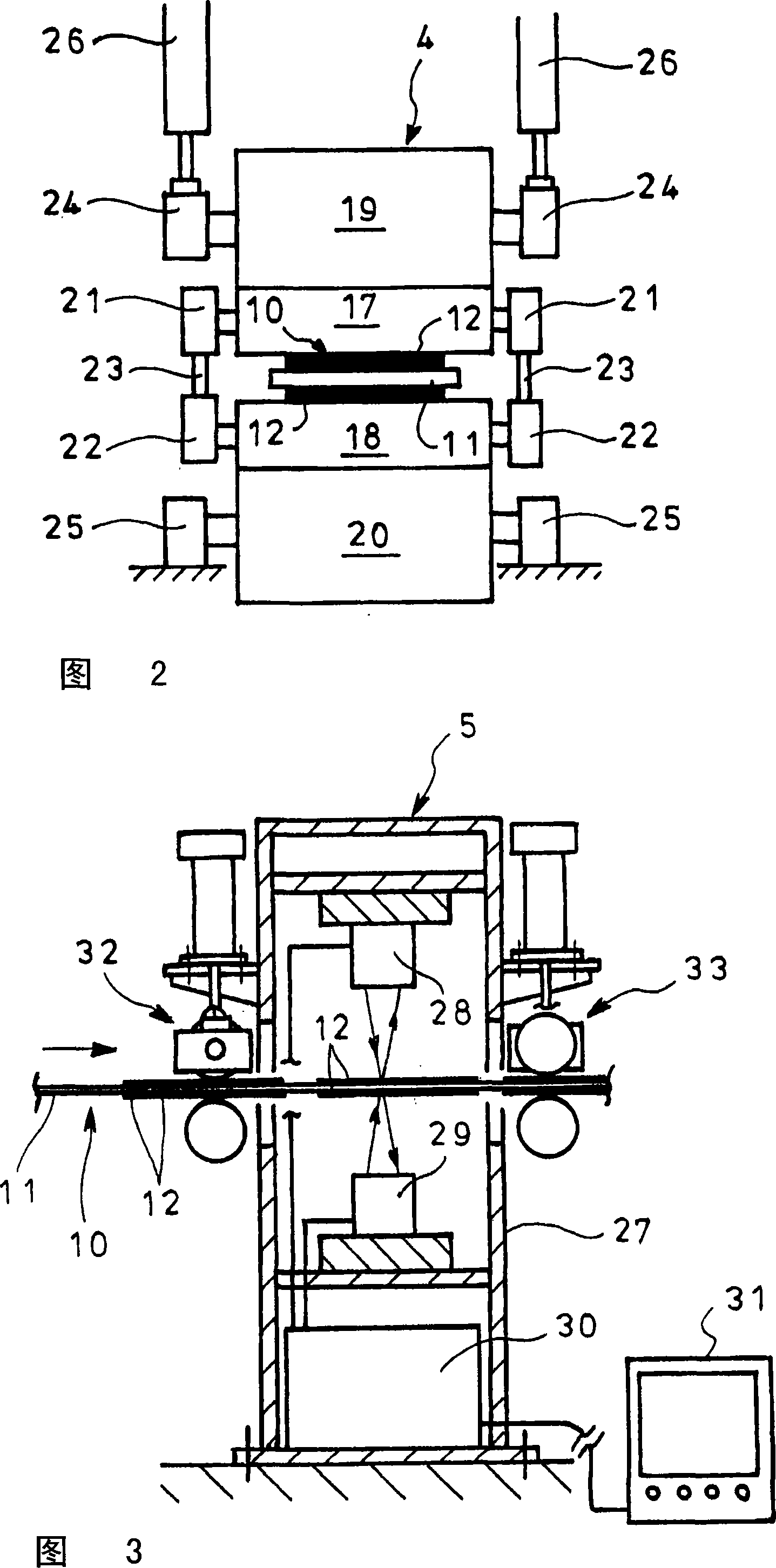

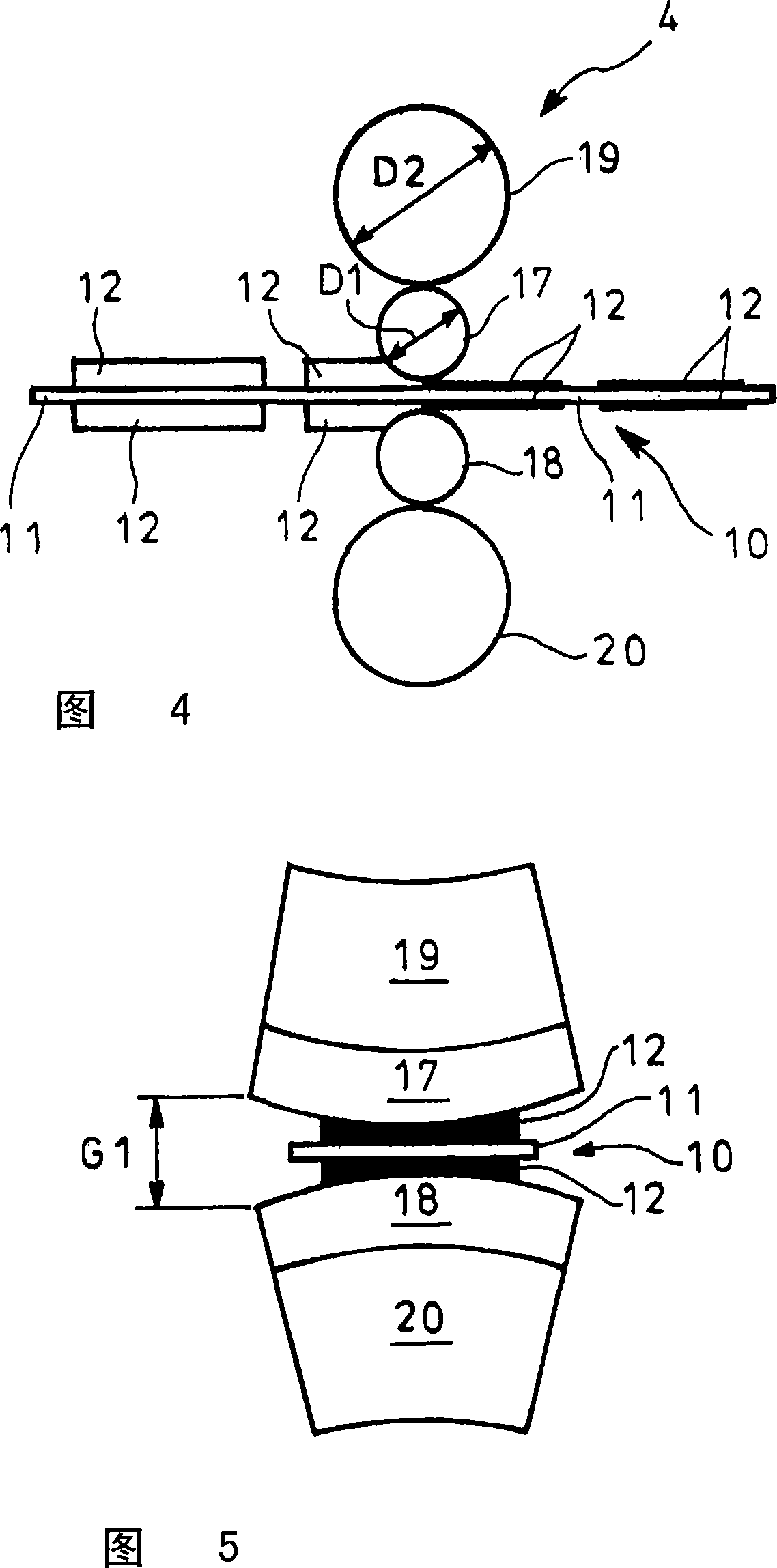

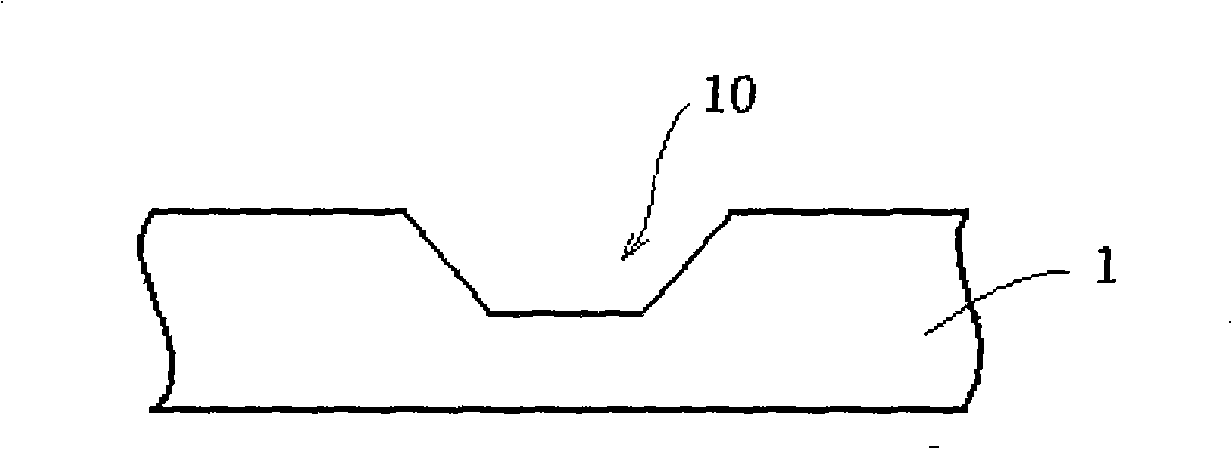

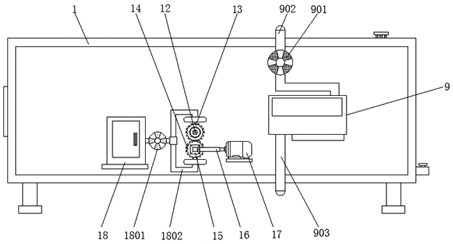

Facility for forming battery electrode plate

InactiveCN101095252AReduce forming loadAvoid bendingElectrode manufacturing processesProduction rateCoated electrodes

A battery electrode board figuration device, in the running direction (D) of the battery electrode board (10) which core is coated electrode active material, setting a decoiling machine (1), a tension endowing device (3), a four-high roller device (4), a thickness detecting device (5), a tension endowing device (6) and a winder (9) from upstream to downstream. Thus, under the state of pressing figuration to the battery electrode board with wide extent so as to improve the volume density of the electrode active material, to produce battery electrode board with high quality reliably and stably.

Owner:IHI CORP

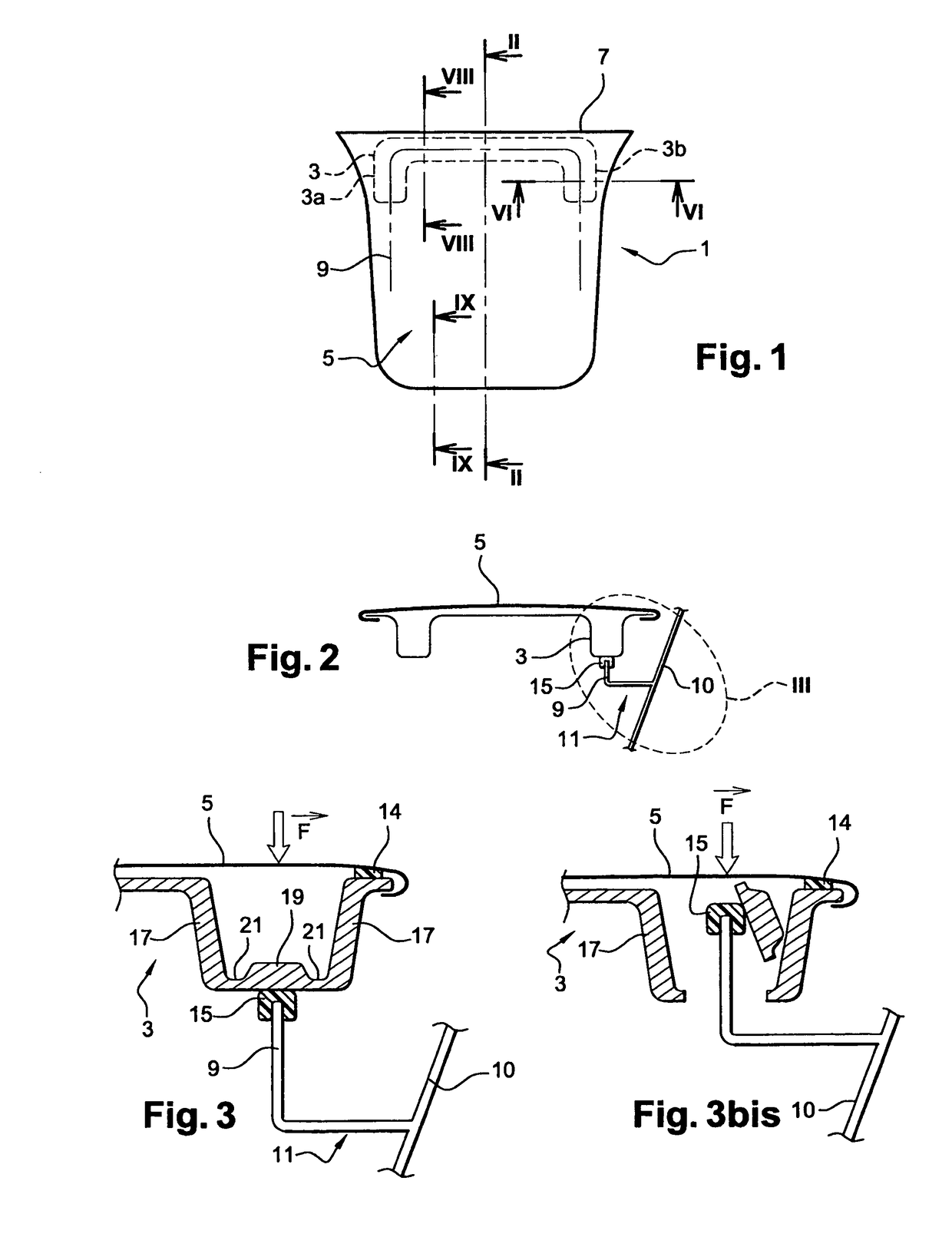

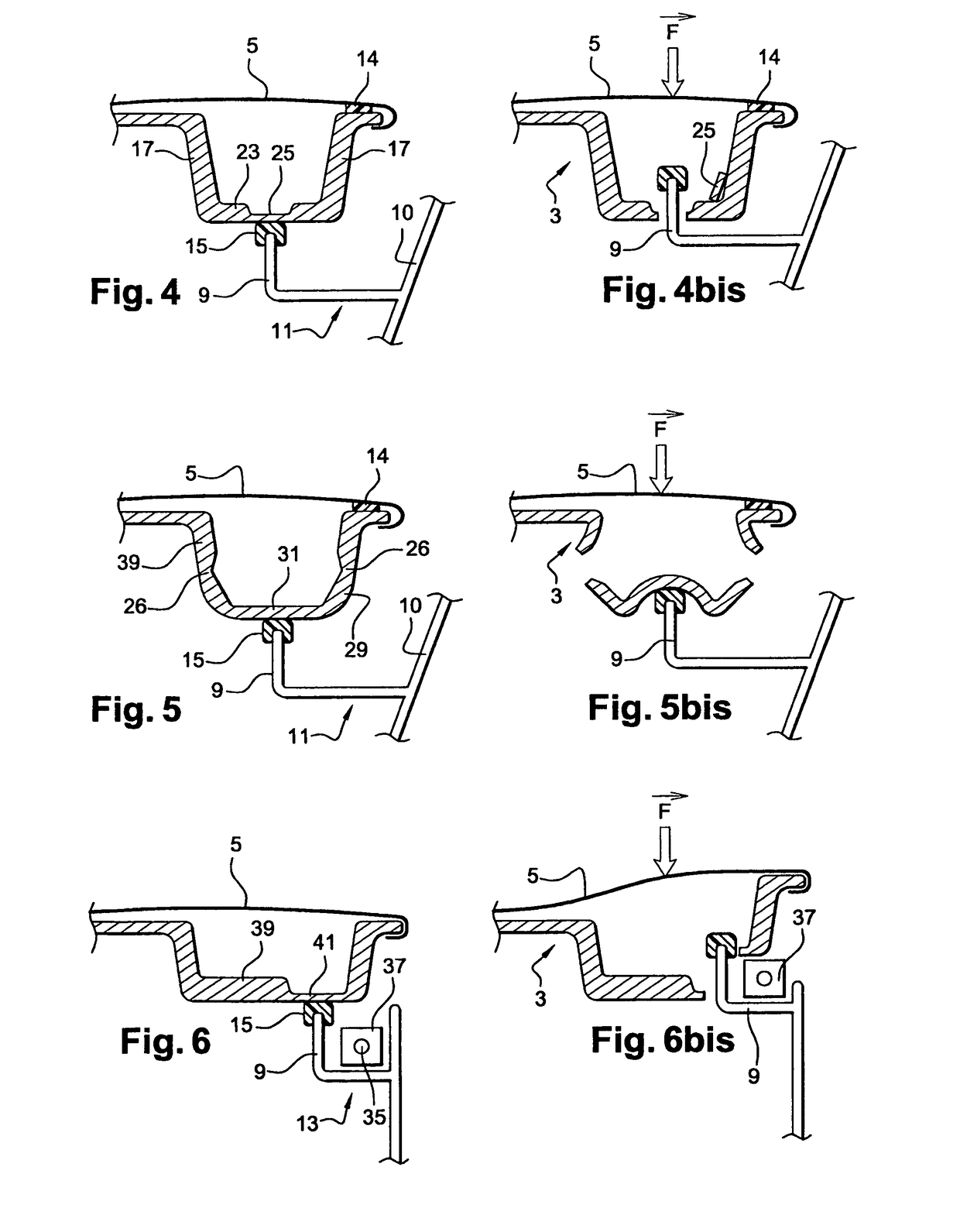

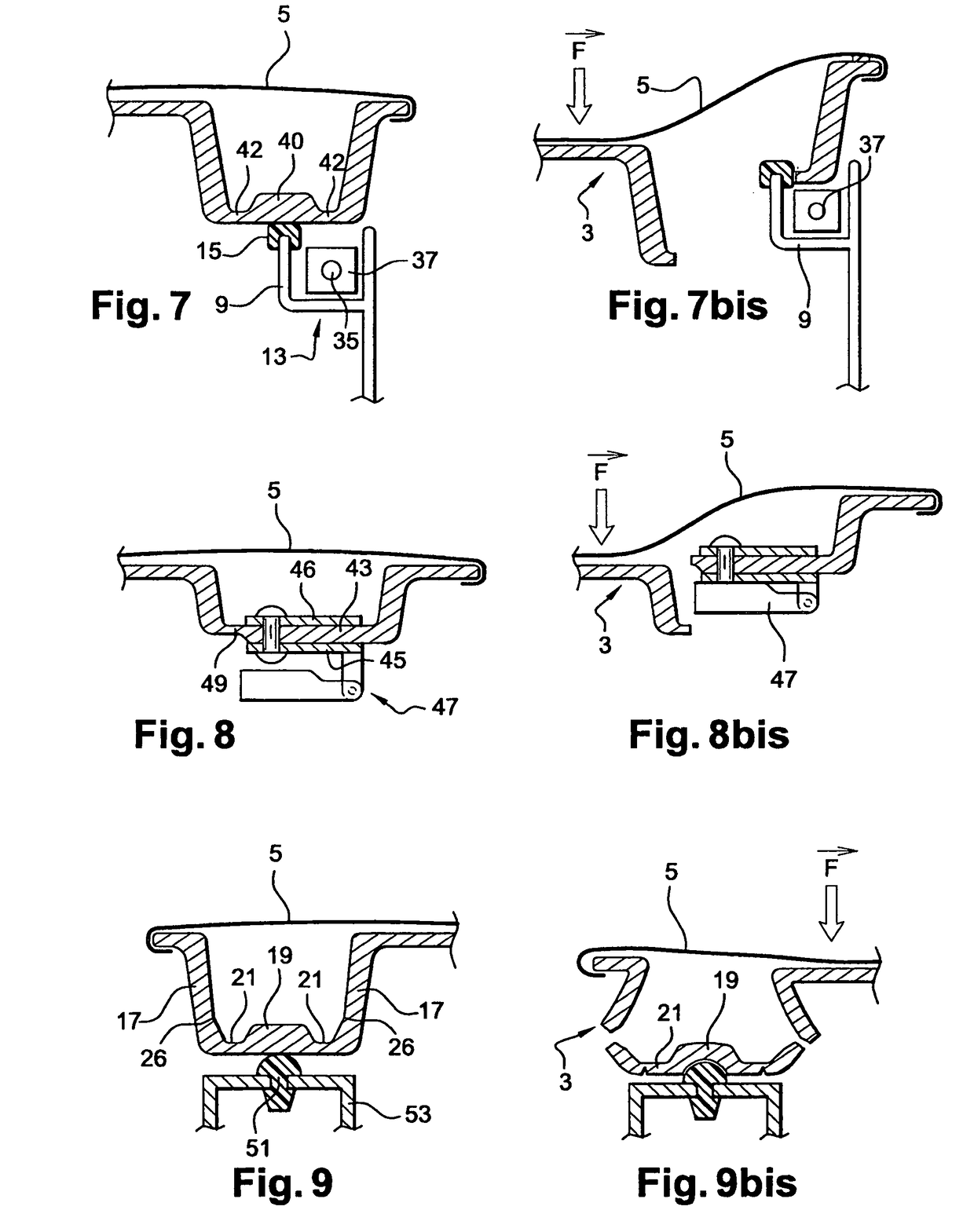

Lining for the hood of an automotive vehicle and combinations thereof with certain parts of the vehicle

InactiveUS8118352B2Handling a pedestrian impact effectivelyEasy to handleVehicle seatsPedestrian/occupant safety arrangementEngineeringWeakness

A motor vehicle hood lining for stiffening the hood in the vicinity of its periphery and co-operating therewith to form a hollow body over at least a fraction of its periphery, the lining being generally of channel section with a bottom and side walls. Said bottom or at least one of said side walls presents, at least locally, a zone of weakness that is dimensioned in such a manner that in the event of the hood impacting the head of a pedestrian, once the bottom of the hollow body has come to bear against a high hard point placed in the engine compartment, the zone of weakness breaks. The invention also relates to a combination of such a lining with various hard points in an engine compartment.

Owner:CO PLASTIC OMNIUM

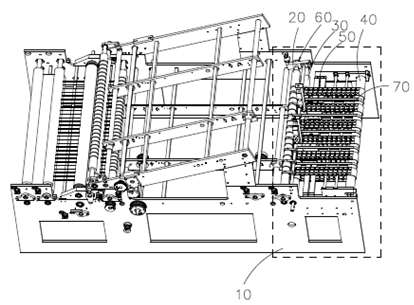

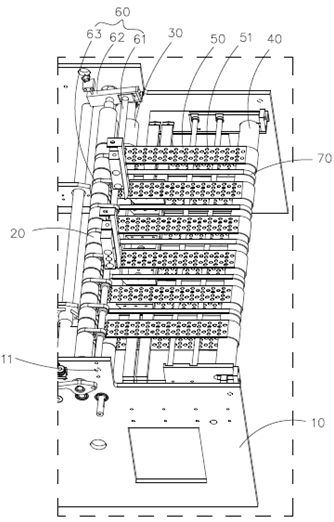

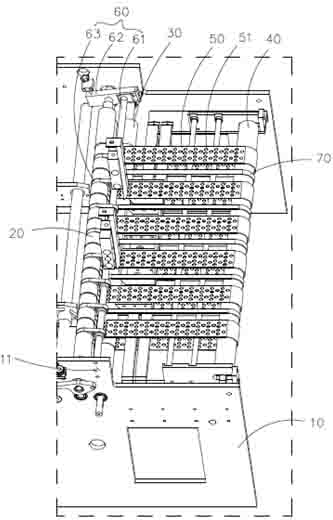

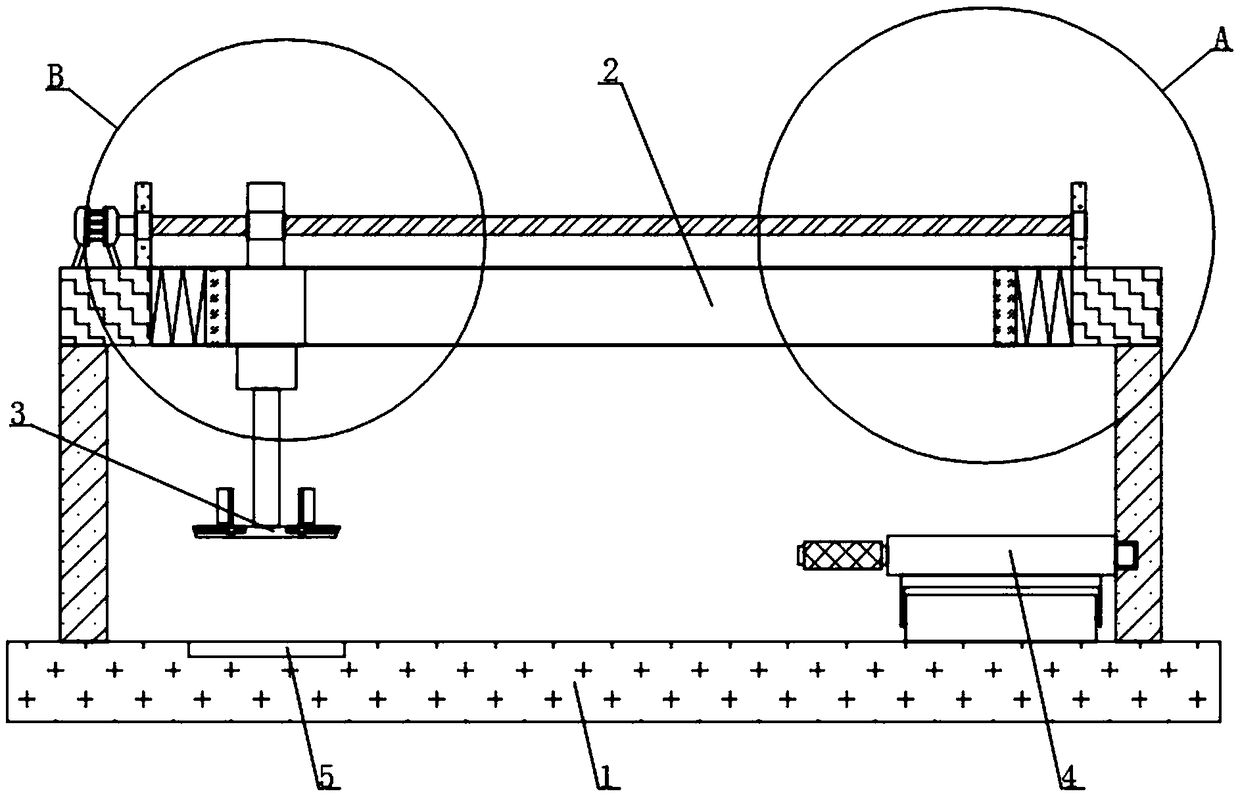

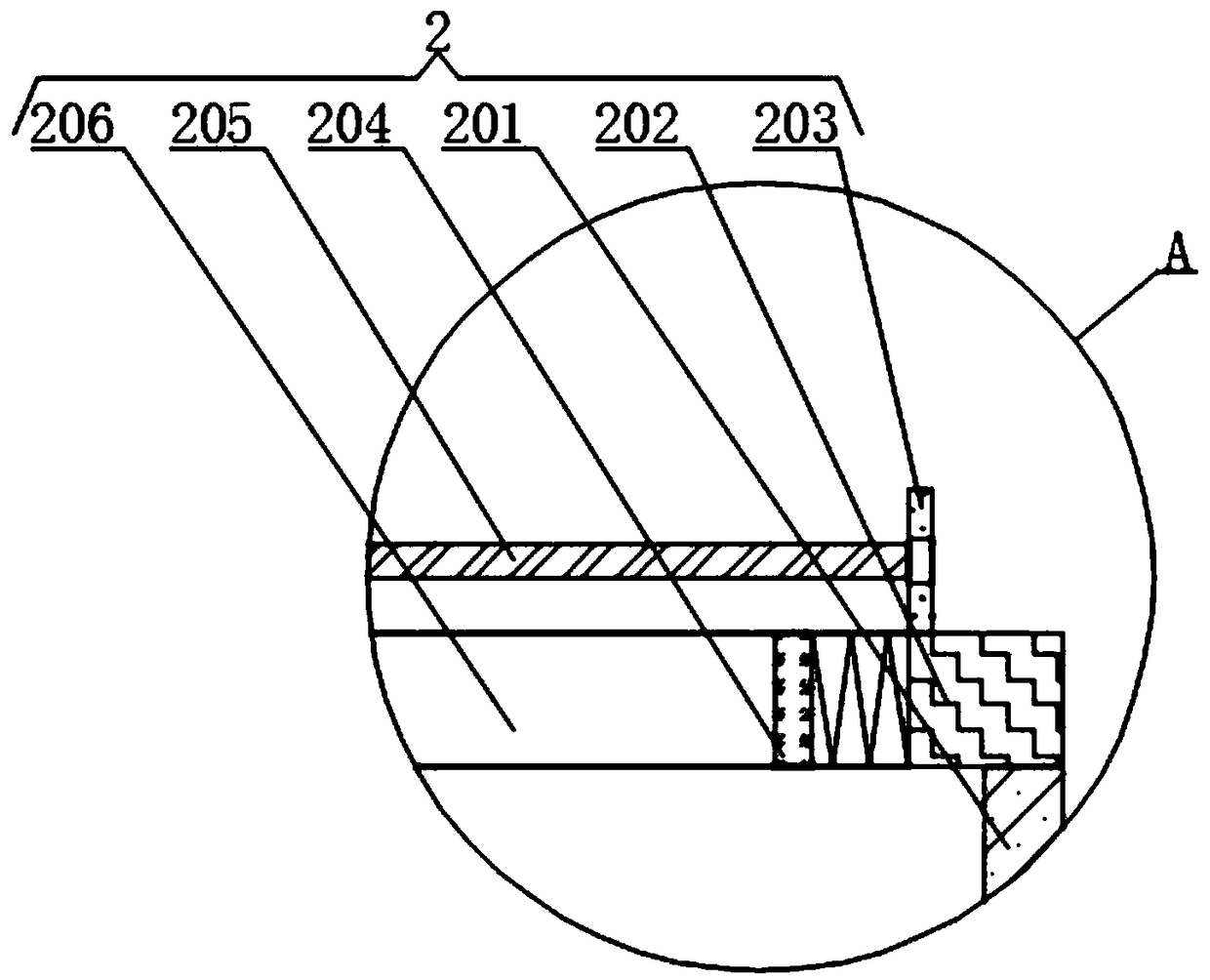

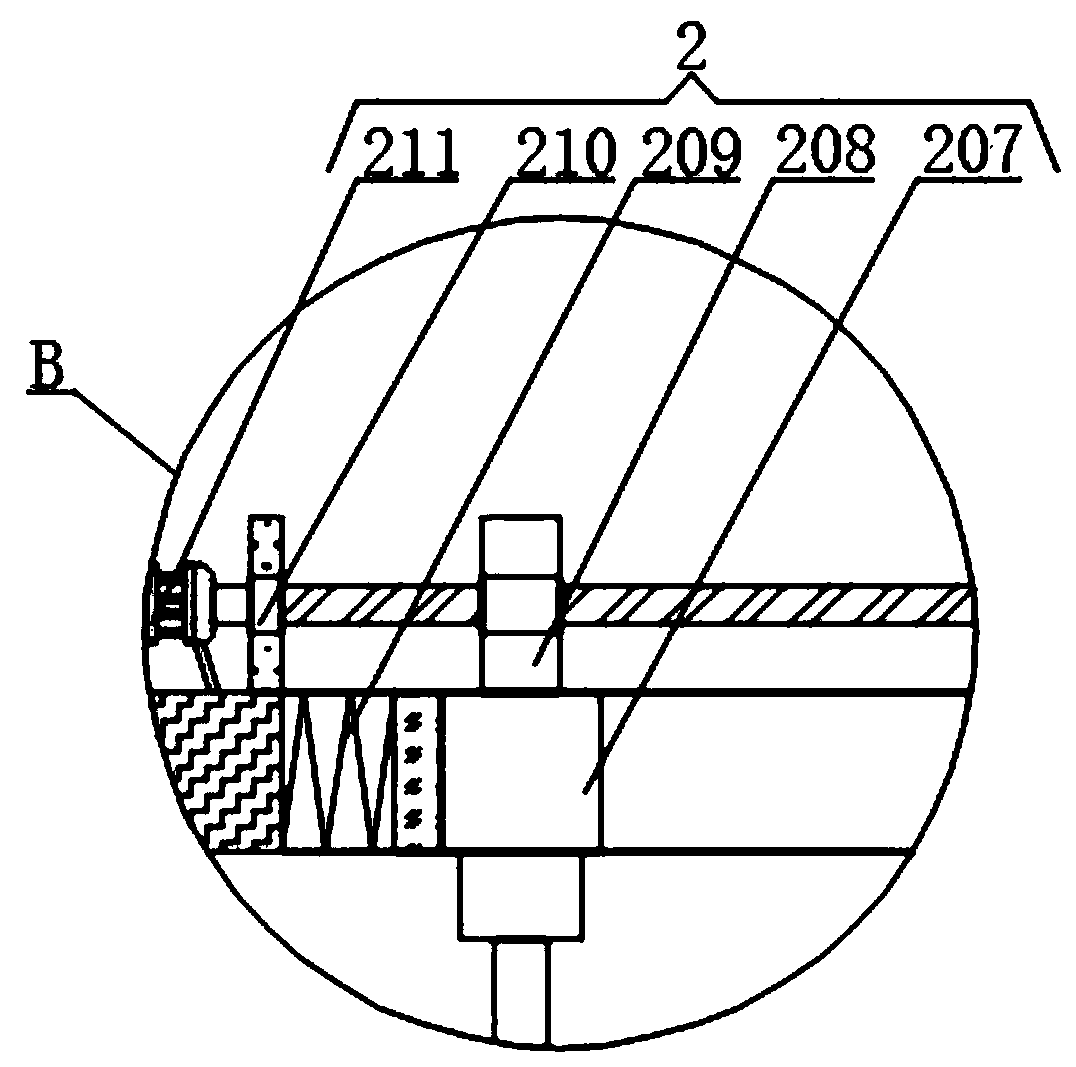

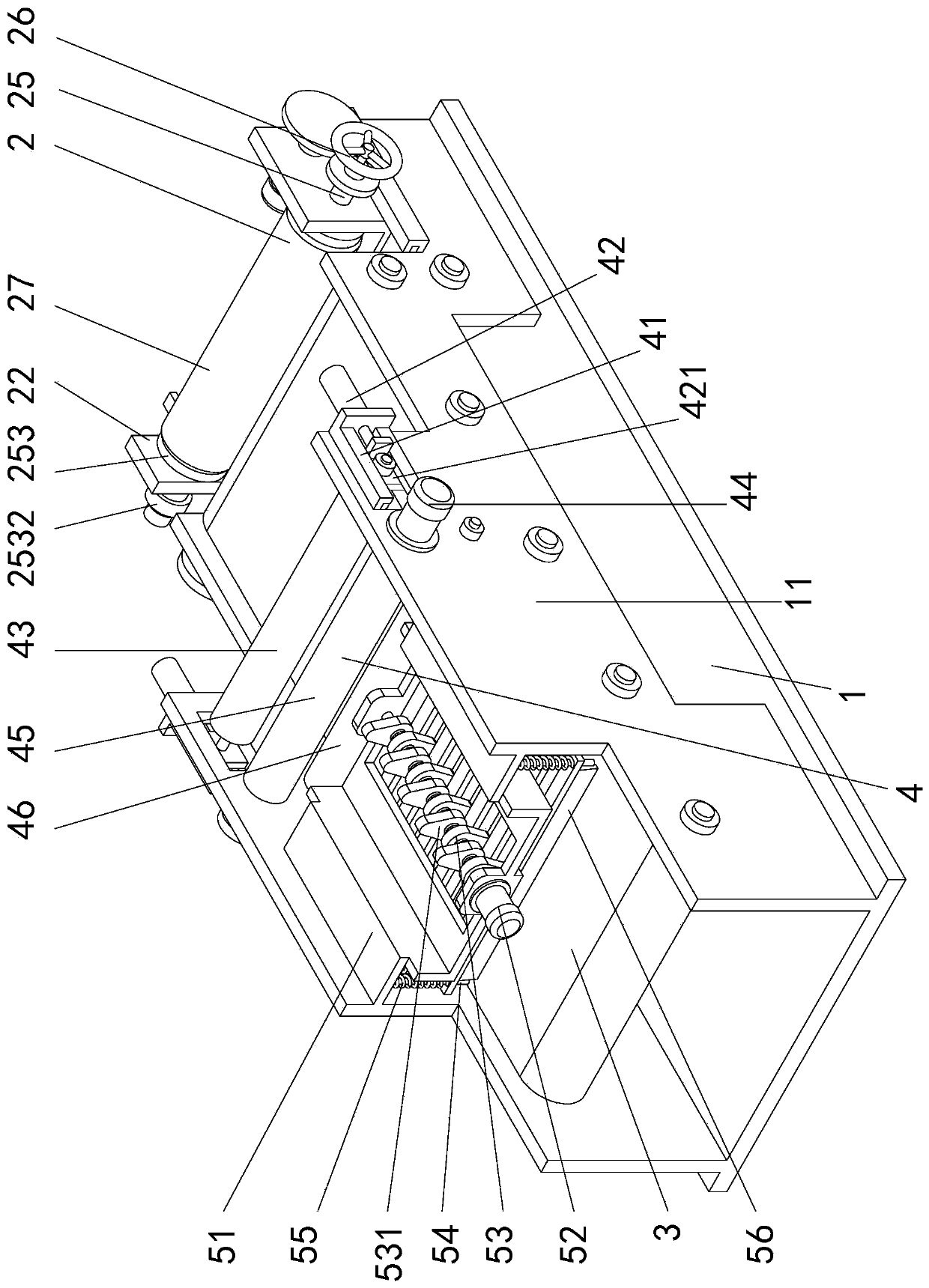

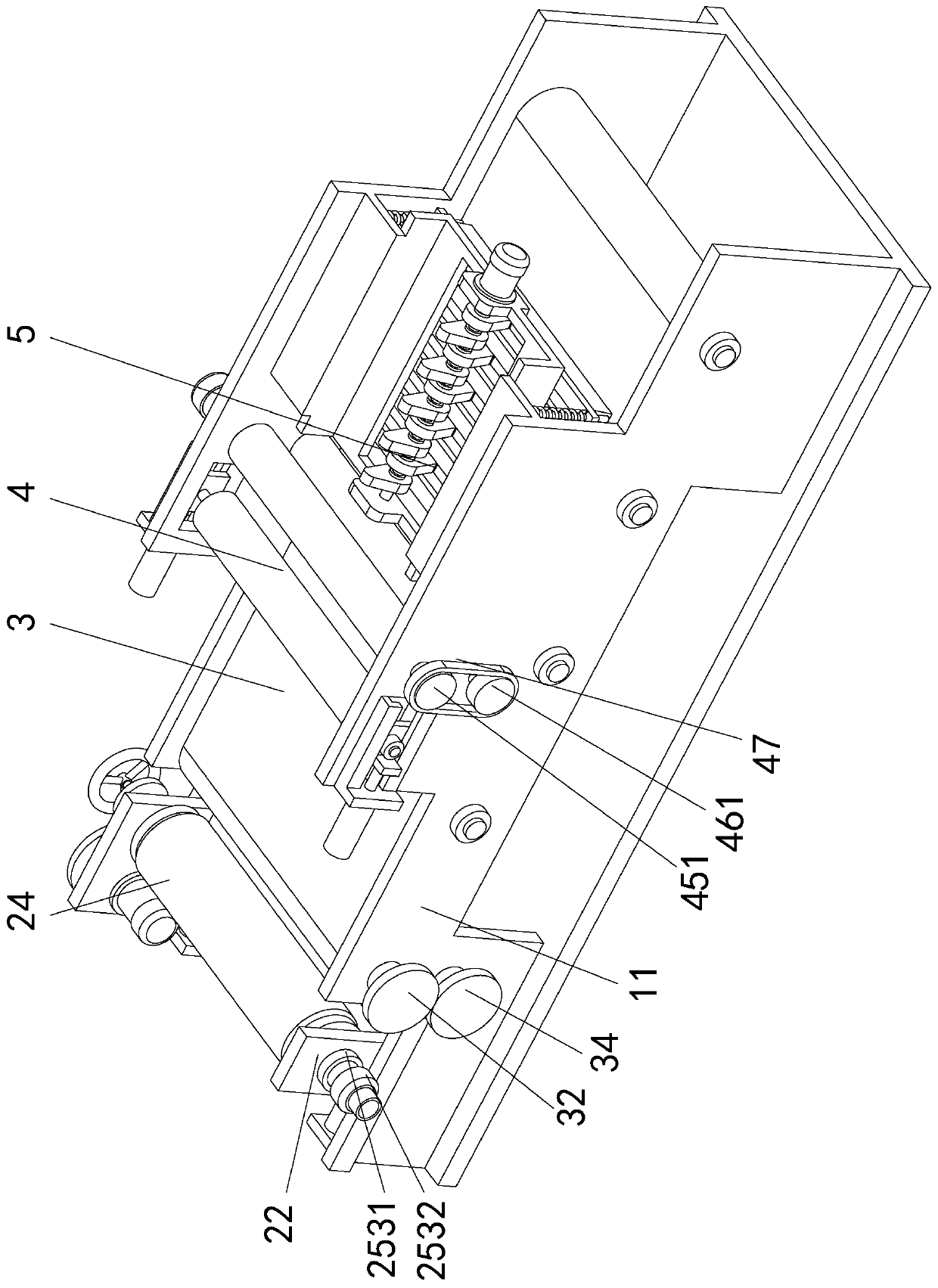

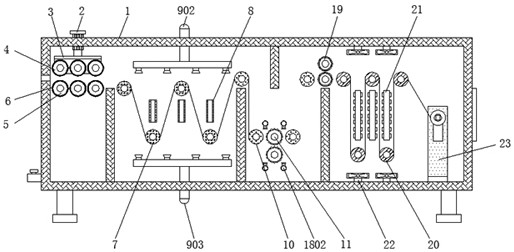

Backing paper feeding mechanism of paper pasting machine

The invention discloses a backing paper feeding mechanism of a paper pasting machine, which comprises a rack, wherein a paper feeding roller, a driving roller, a driven roller, an annular paper conveying belt and a paper pressing adjustment mechanism are arranged on the rack, the driving roller and the driven roller are arranged in parallel, the annular paper conveying belt is sleeved on the driving roller and the driven roller, the paper pressing adjustment mechanism is arranged above the annular paper conveying belt, the paper pressing adjustment mechanism comprises a paper pressing shaft, an adjusting hand wheel and a conveying belt, the paper pressing shaft is fixedly connected with the adjusting hand wheel, the adjusting hand wheel is used for adjusting a gap between the paper pressing shaft and the annular paper conveying belt, and the conveying belt is sleeved on the paper pressing shaft and the paper feeding roller. According to the invention, the paper pressing adjustment mechanism is arranged above the annular paper conveying belt, backing paper is positioned by the paper pressing shaft, and the backing paper is guided by the conveying belt to be conveyed below the paper feeding roller, so that the phenomenon of the paper blockage caused by the deformation of the backing paper is prevented, and a manual paper leveling operation on the deformed paper is avoided, therefore, the labor intensity is reduced, the production efficiency is improved, and the product quality is guaranteed.

Owner:段玉芳

Image display apparatus

InactiveCN102667899AAvoid flatteningTelevision system detailsCathode-ray tube indicatorsCommon logarithmComputer graphics (images)

Owner:CANON KK

Waste carton recycling flattening equipment based on ecological environmental protection

The invention discloses waste carton recycling flattening equipment based on ecological environmental protection, and belongs to the technical field of environmental protection. The waste carton recycling flattening equipment comprises a base, the upper surface of the base is fixedly connected with a moving mechanism, the lower part of the moving mechanism is fixedly connected with a propping-openmechanism, a flattening mechanism is arranged on the right side of the upper surface of the base, the moving mechanism comprises a vertical plate, a horizontal plate, a supporting plate, a limiting block, a screw rod, a first sliding groove, a first sliding block, a screw ring, a first spring, a bearing and a forward and reverse rotation motor. According to the waste carton recycling flattening equipment based on ecological environmental protection, by arranging the forward and reverse rotation motor, under the action of the screw rod, the screw ring, the first sliding groove and the first sliding block, the propping-open device can carry a carton to move to the right, and the carton is fully and automatically transferred and ready to be propped-open and flattened; by arranging blades, the carton can be cracked; and by arranging a roller, the cracked carton can be flattened.

Owner:惠州市恒顺昌科技有限公司

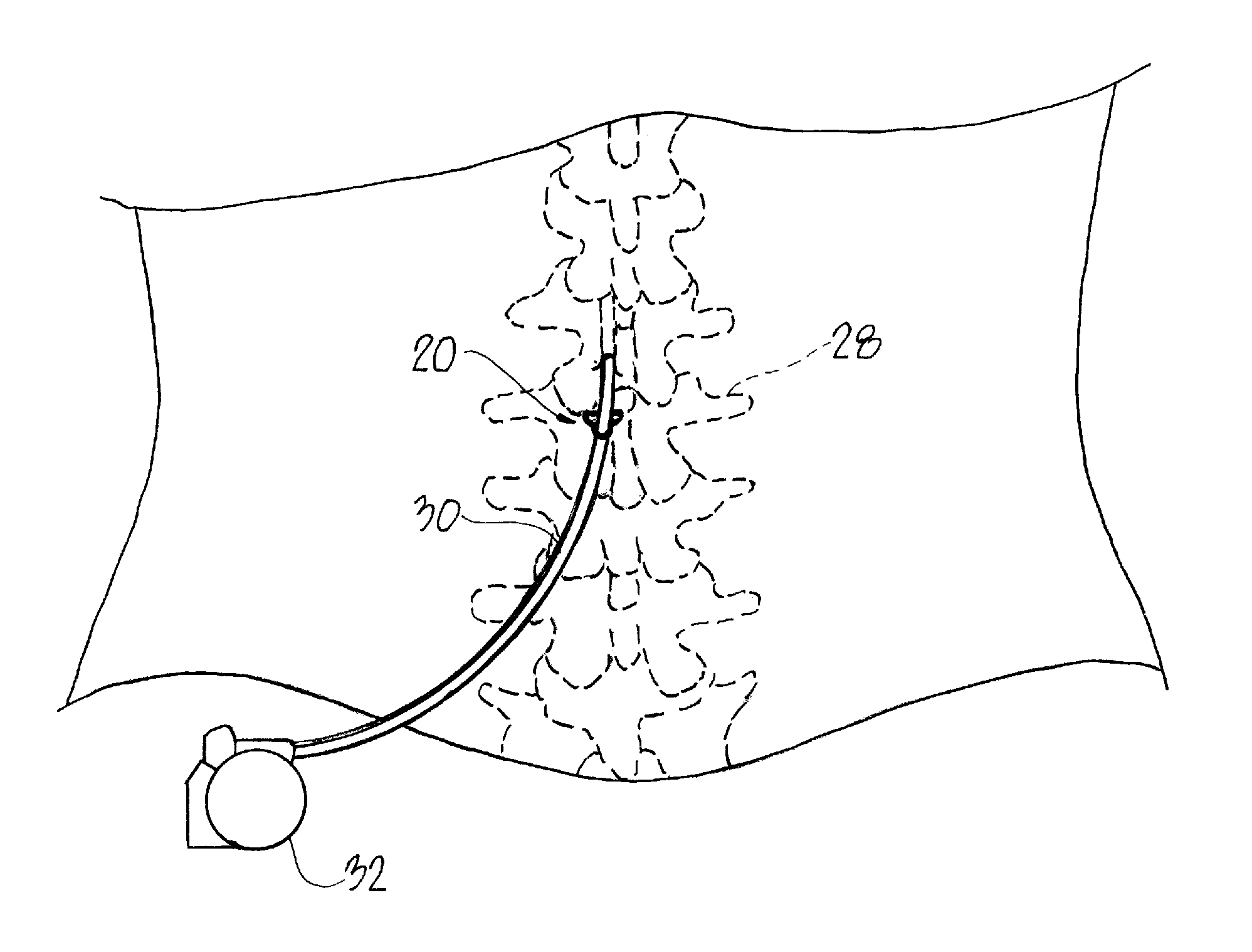

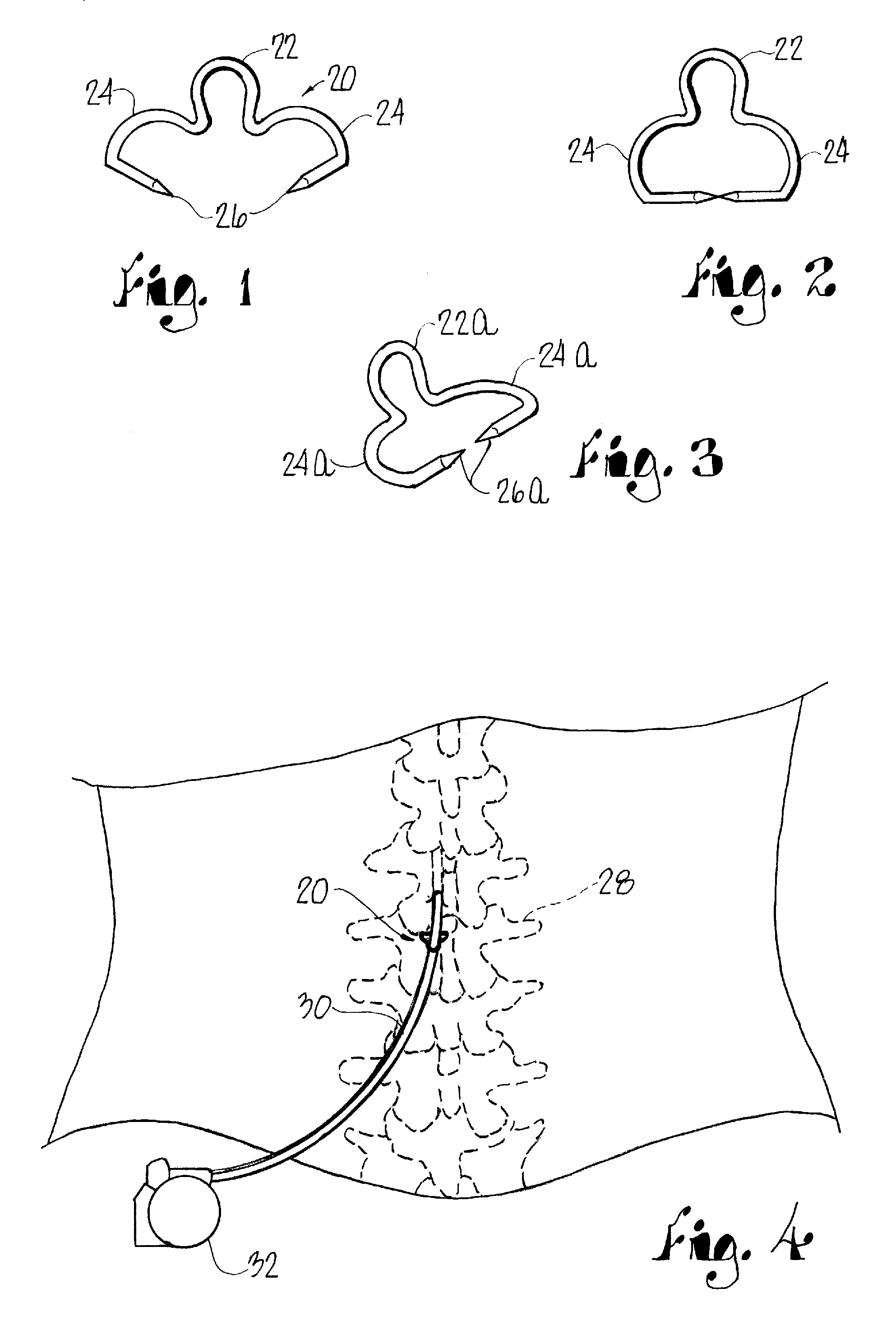

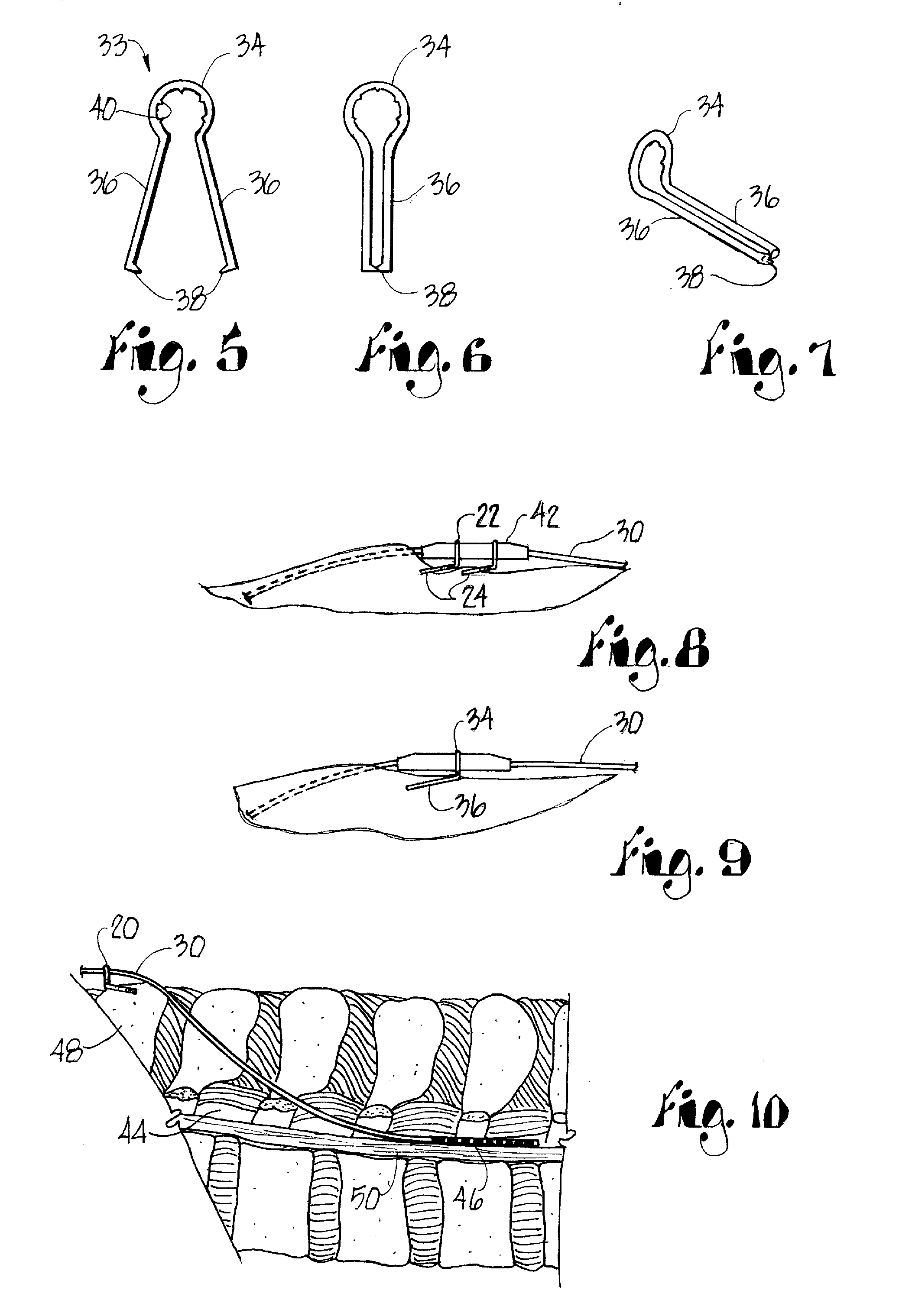

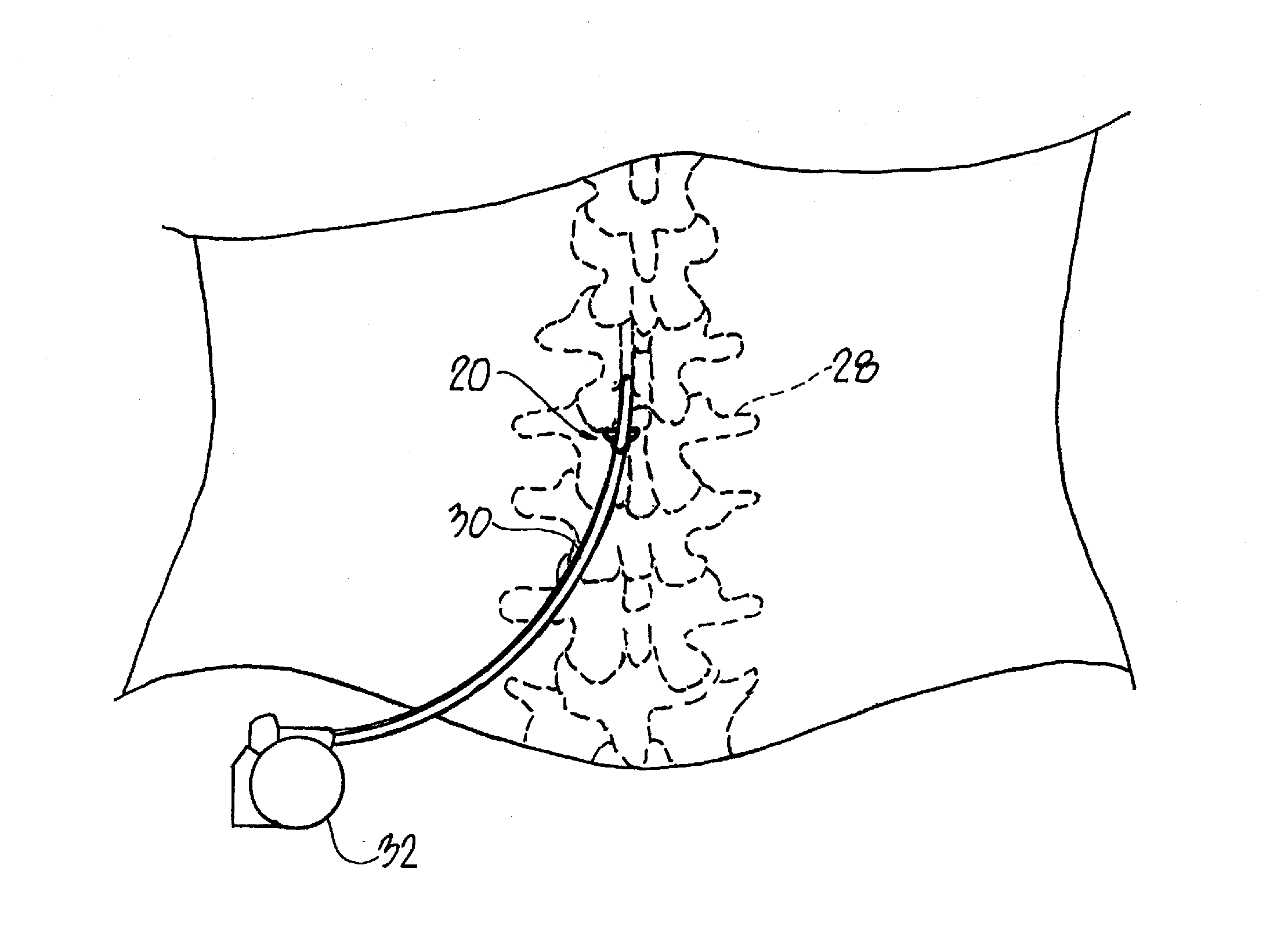

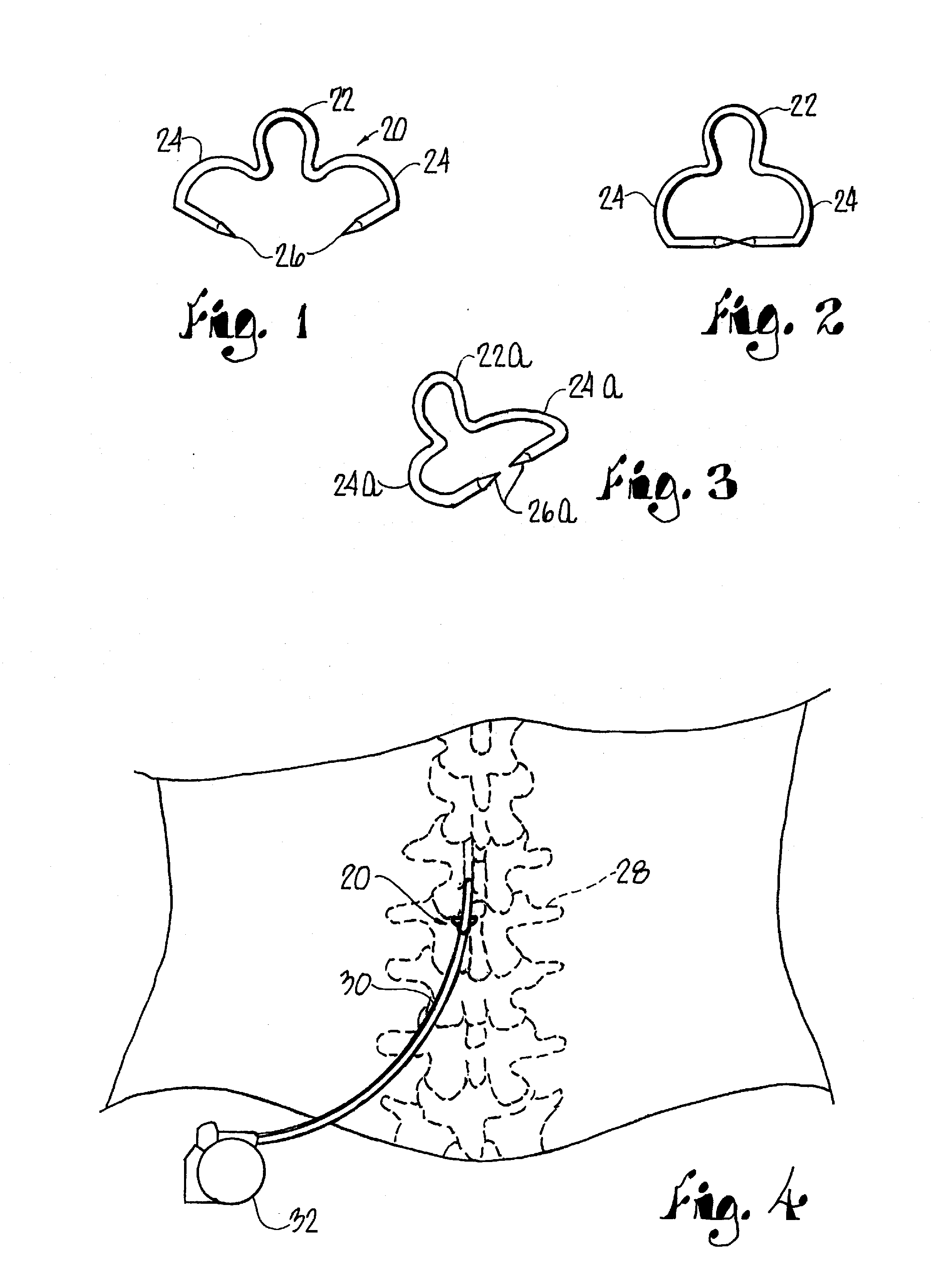

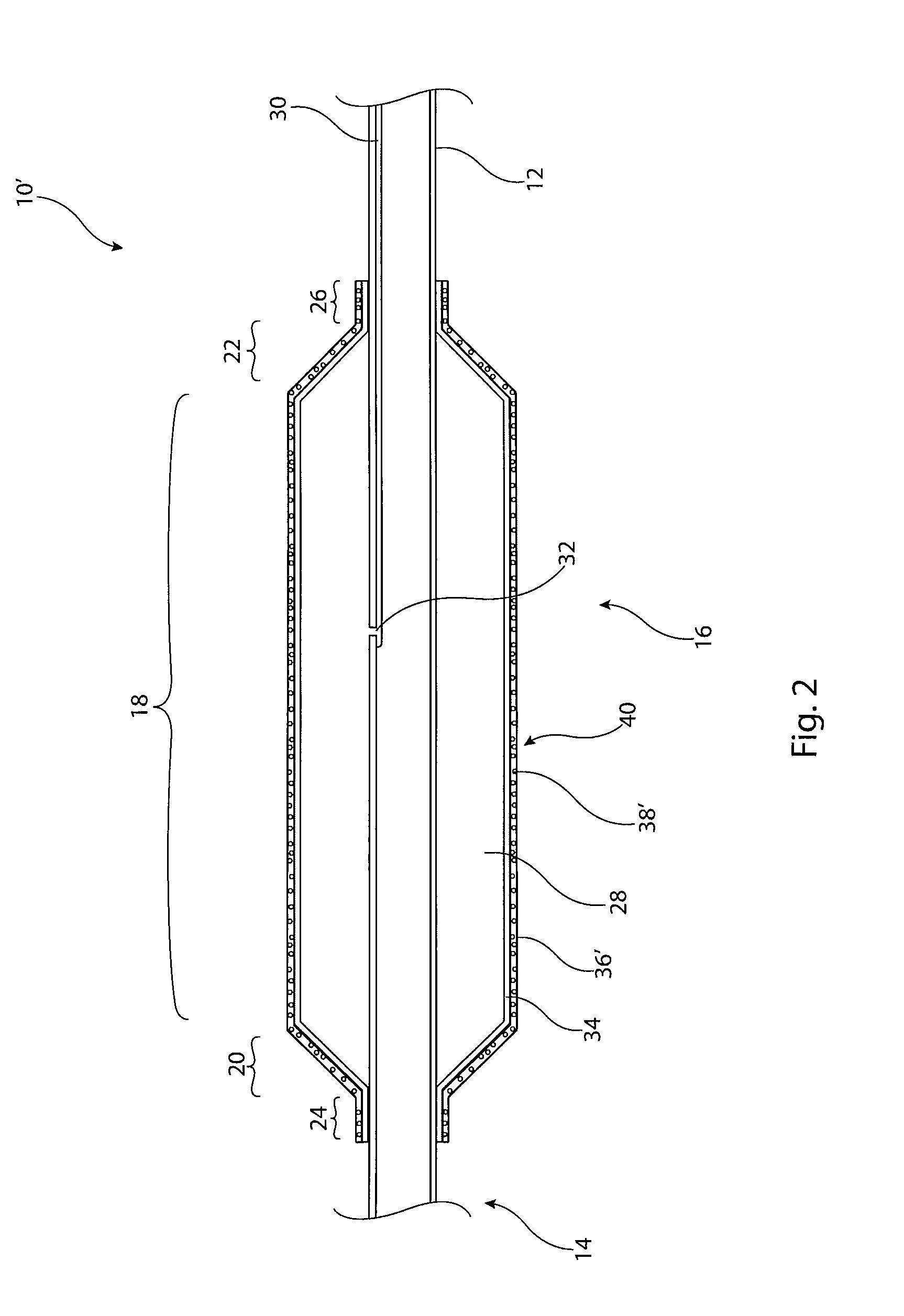

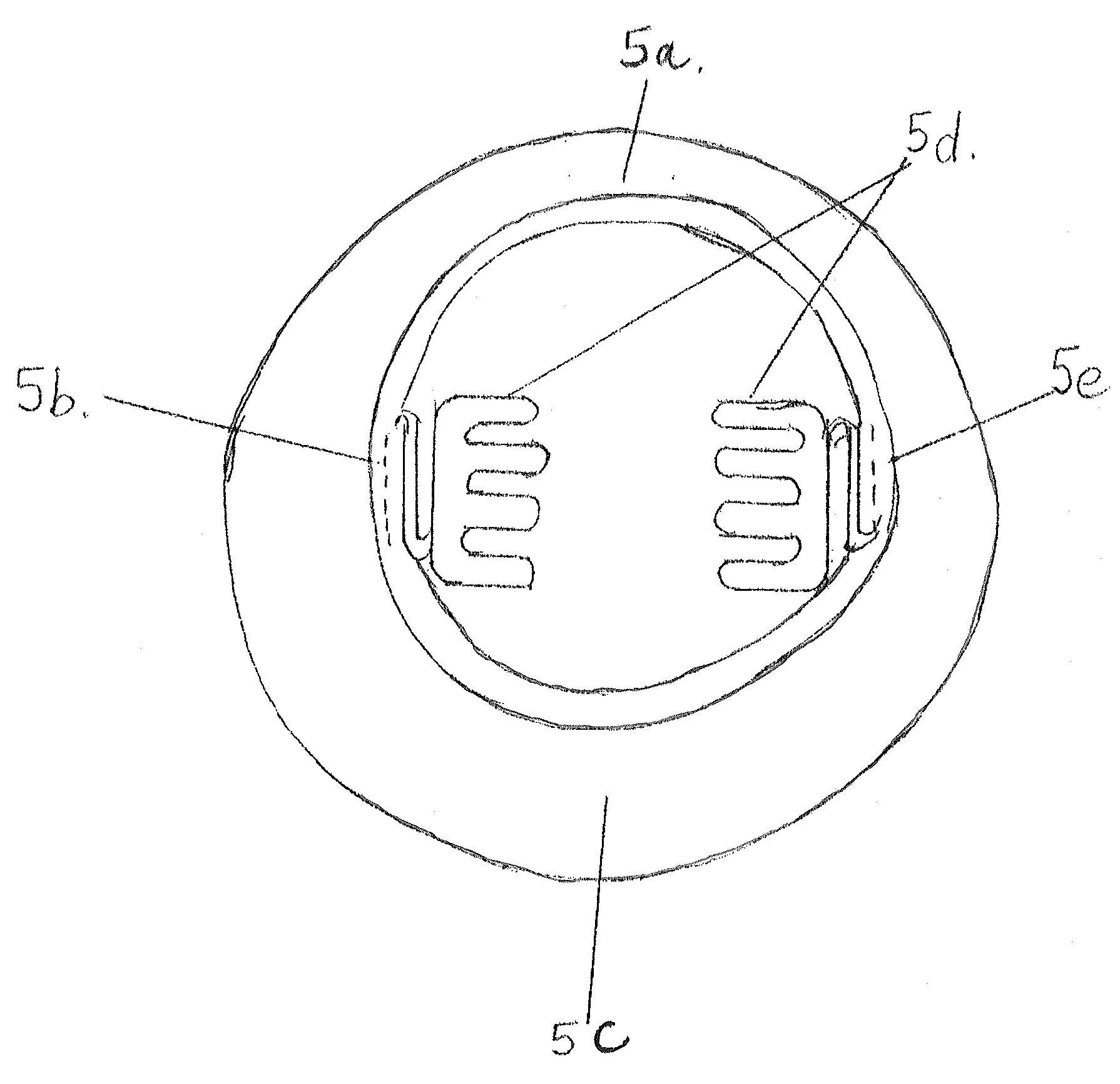

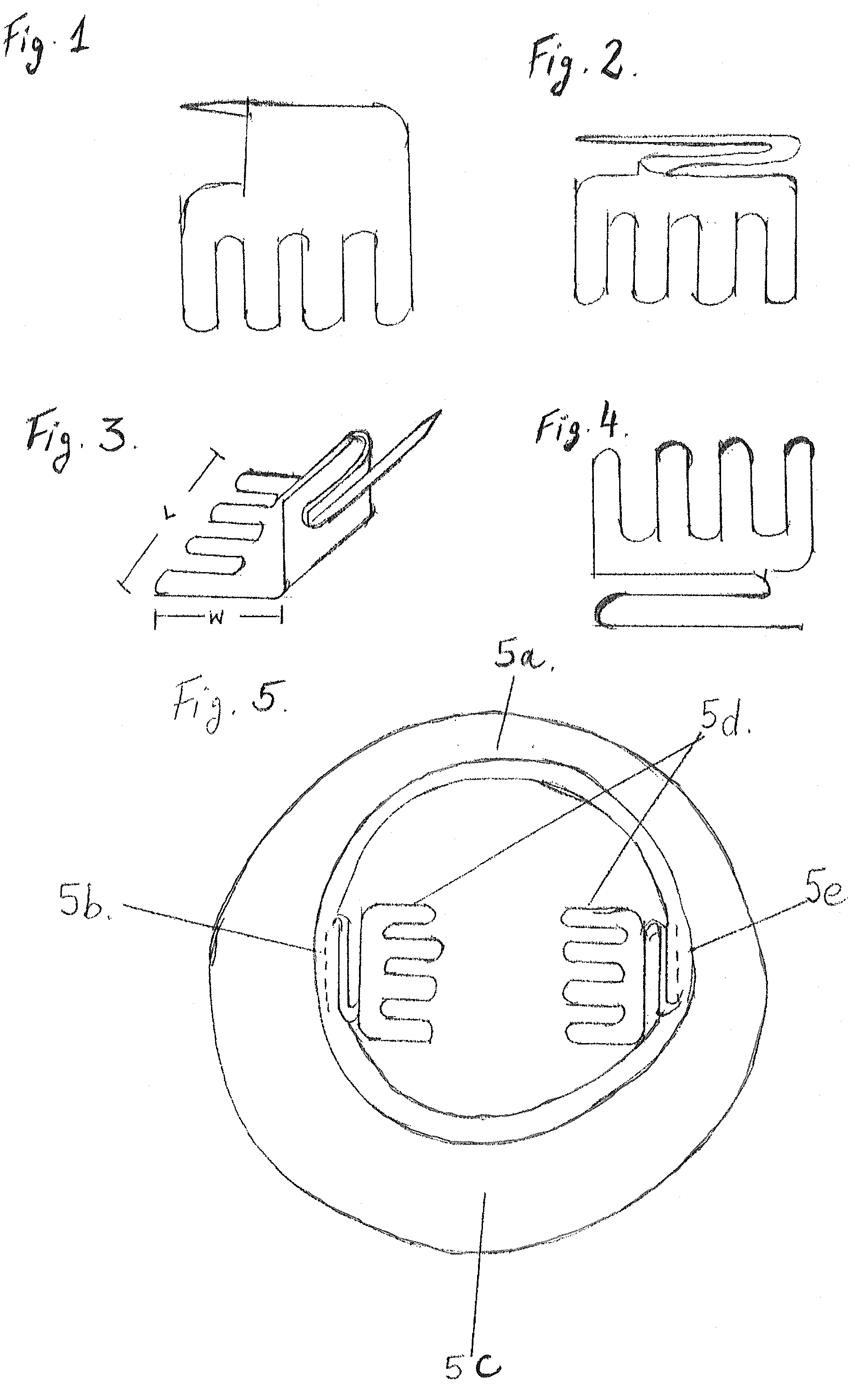

Spinal cord stimulator lead anchor

InactiveUS20110264180A1Minimize migrationAvoid flatteningSpinal electrodesExternal electrodesEngineeringLigament

The lead of a spinal cord stimulator implanted along the spinal cord of a recipient is secured by an anchor staple at a selected location. The anchor staple comprises a loop that receives and holds the lead at the selected location along the spine. A pair of spaced legs extend from the loop and present an initially open configuration for receiving an anchor point presented by bone, ligament, fascia or skin. The legs are closed to engage the anchor point and thereby positively secure the lead to prevent migration of the implanted lead. Several staples may be applied in a row to assure optimal positioning of the lead.

Owner:HAMILTON DENNISON R

Renesting interaction map into design for efficient long range calculations

ActiveUS20060041851A1Efficiently and easily and costEfficiently and easily and cost-effectively rebuildsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusTheoretical computer scienceRe engineering

Methods, and program storage devices, for performing model-based optical lithography corrections by partitioning a cell array layout, having a plurality of polygons thereon, into a plurality of cells covering the layout. This layout is representative of a desired design data hierarchy. A density map is then generated corresponding to interactions between the polygons and plurality of cells, and then the densities within each cell are convolved. An interaction map is formed using the convolved densities, followed by truncating the interaction map to form a map of truncated cells. Substantially identical groupings of the truncated cells are then segregated respectively into differing ones of a plurality of buckets, whereby each of these buckets comprise a single set of identical groupings of truncated cells. A hierarchal arrangement is generated using these buckets, and the desired design data hierarchy enforced using the hierarchal arrangement to ultimately correct for optical lithography.

Owner:GLOBALFOUNDRIES US INC

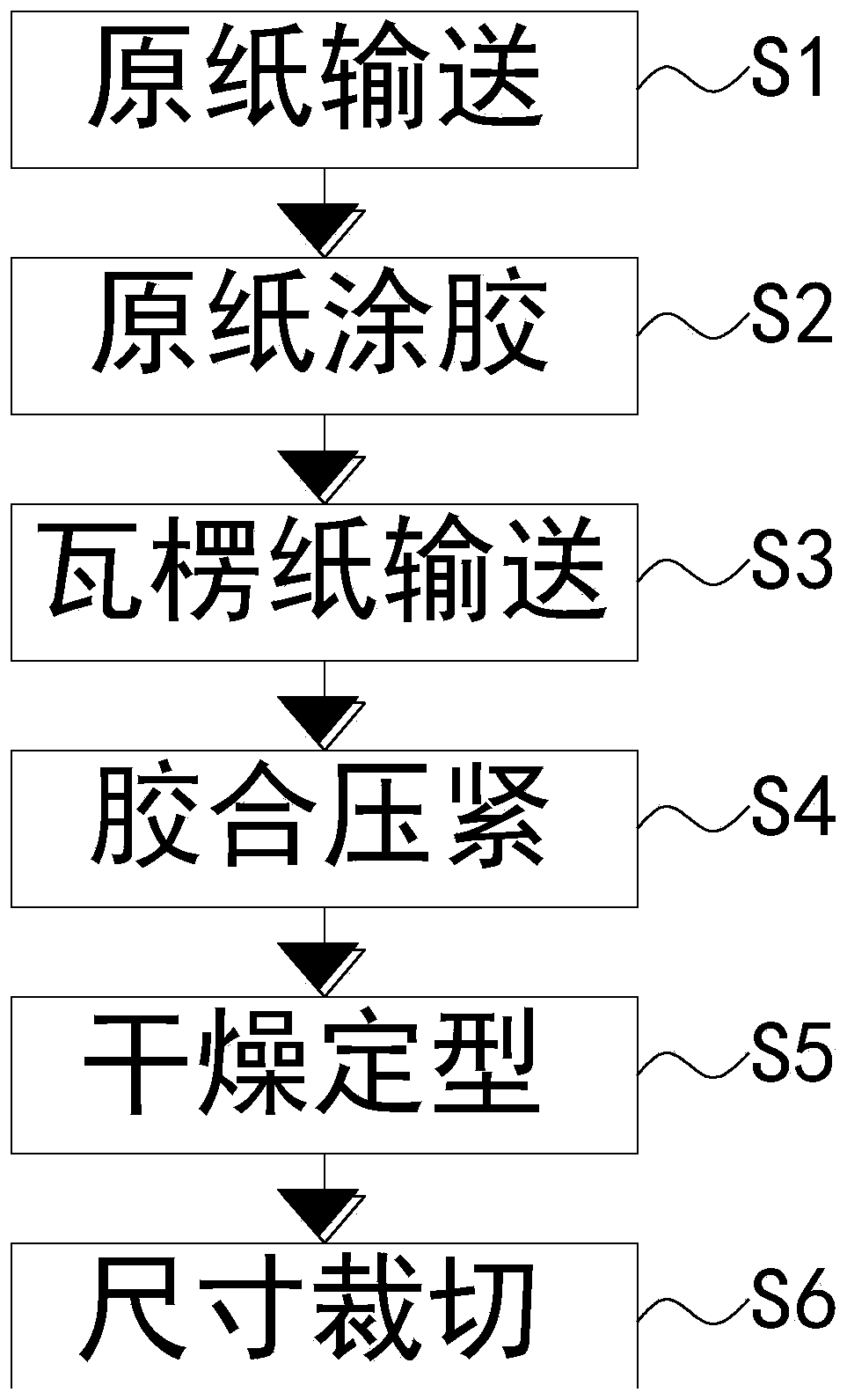

Corrugated board manufacturing and processing technology

ActiveCN111421900AAvoid flatteningGlued effectivelyLiquid surface applicatorsMechanical working/deformationIndustrial engineeringProduction quality

The invention relates to a corrugated board manufacturing and processing technology, in particular to a corrugated board manufacturing and processing machine. The machine comprises a rack, an automatic gluing mechanism, a raw paper conveying mechanism, a corrugated paper conveying mechanism and a gluing and pressing mechanism, wherein two sides plates are arranged on the rack in parallel; the automatic gluing mechanism, the raw paper conveying mechanism, the corrugated paper conveying mechanism and the gluing and pressing mechanism are all arranged on the two side plates; the automatic gluingmechanism is located on the side of the raw paper conveying mechanism; the corrugated paper conveying mechanism and the gluing and pressing mechanism are both located above the raw paper conveying mechanism; and the corrugated paper conveying mechanism is close to the automatic gluing mechanism. The machine involved in the process provided by the invention can ensure that corrugated paper and rawpaper are glued more effectively, so that the corrugated paper is prevented from being flattened and thinned, in addition, the gluing uniformity of gluing can be ensured, and the production quality ofcorrugated boards is improved.

Owner:泰州市源鑫包装有限公司

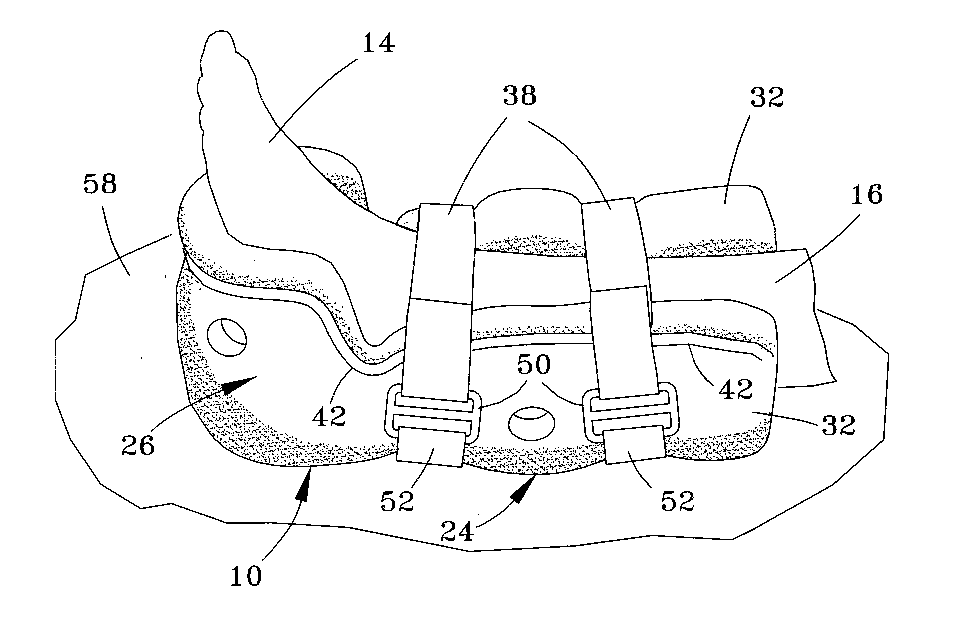

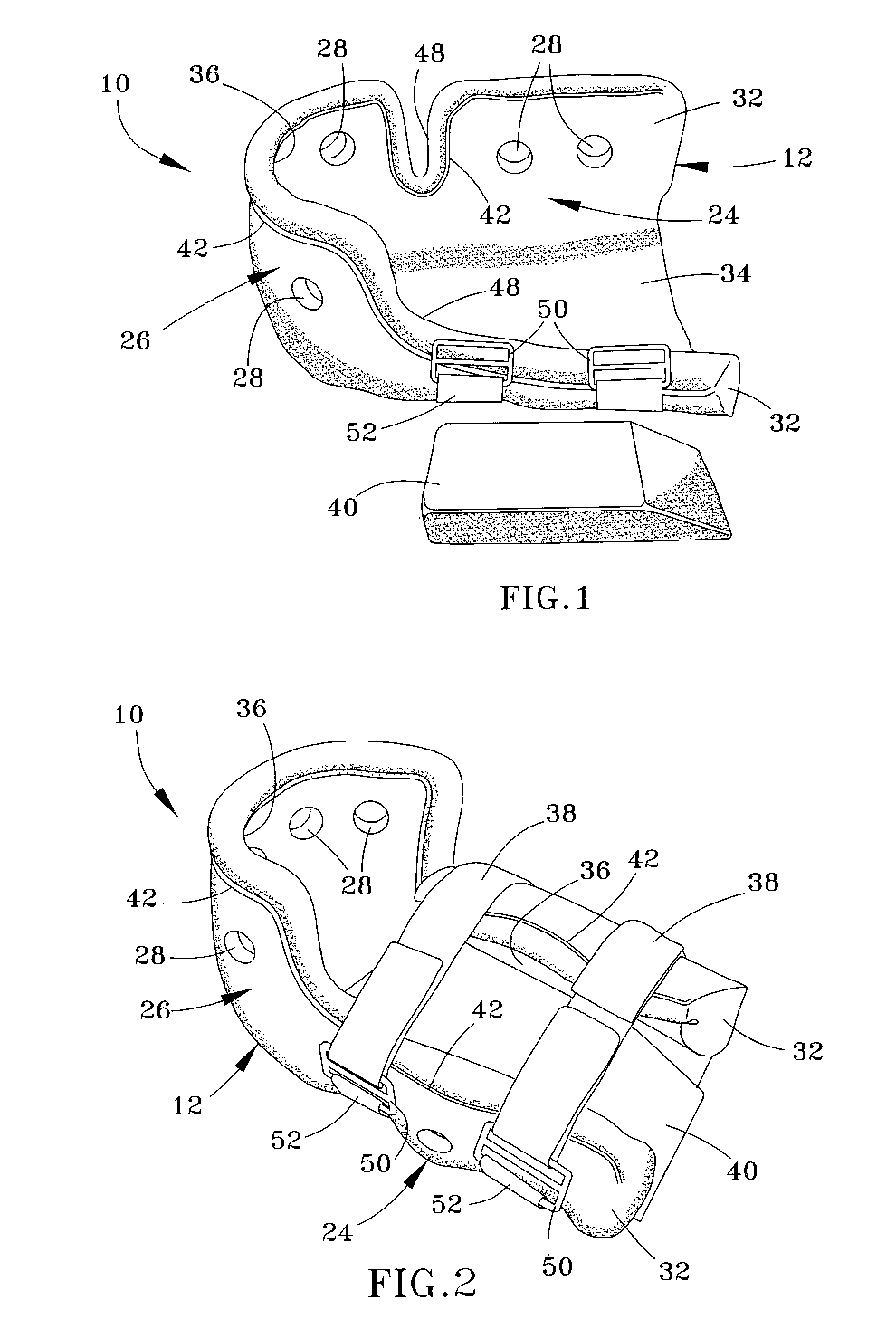

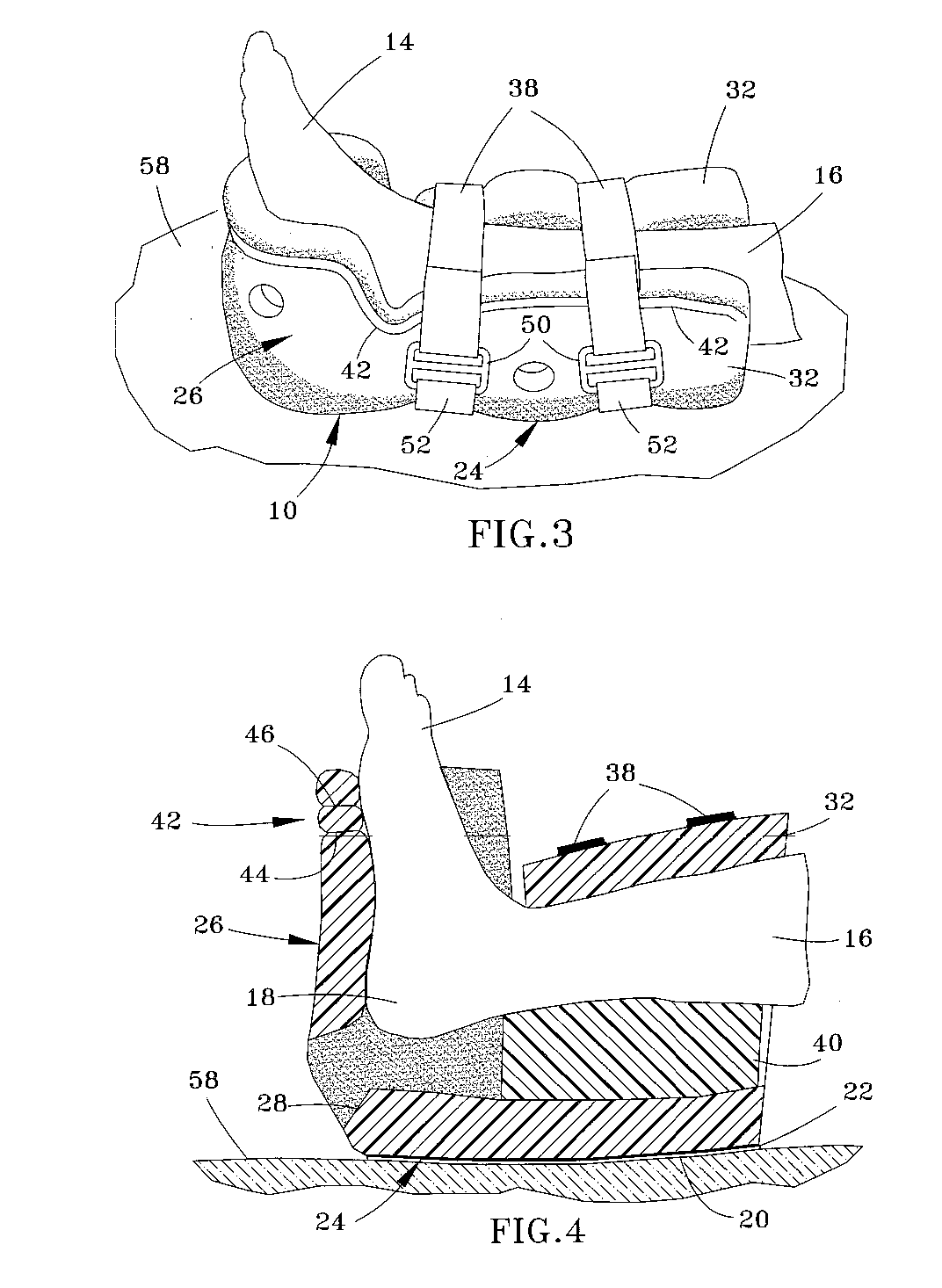

Heel-supporting protective boot

ActiveUS20070073208A1Avoid flaringAvoid flatteningRestraining devicesFeet bandagesLateral regionHeel

A heel-supporting boot capable of supporting a leg of a person in a supine reclining position, such as a bedridden patient, to reduce the risk of bed sores, foot drop, etc. The boot includes a flexible and compressible body having leg and forefoot portions, a continuous cavity within the leg and forefoot portions, an anterior opening to permit a patient's foot and leg to pass therethrough into the cavity, oppositely-disposed lateral regions defined by the leg portion and separated by the anterior opening, and an adjustable closing feature for closing the anterior opening with the lateral regions. A stitch pattern is disposed along at least the forefoot rim, and preferably also the lateral rims, bounding the anterior opening. The stitch pattern is sufficiently close to the forefoot rim and optionally the lateral rims to structurally reinforce the forefoot rim and inhibit elastic and plastic deformation of the forefoot portion.

Owner:WALGREEN HEALTH SOLUTIONS LLC

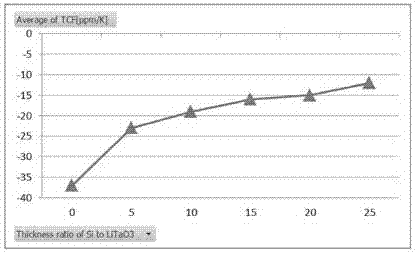

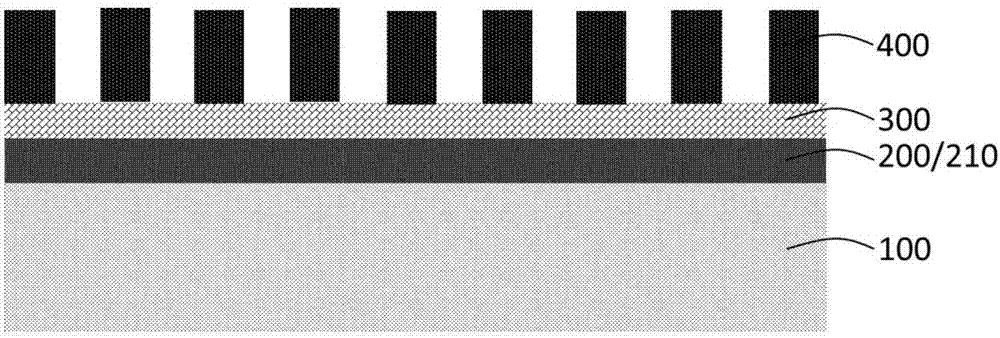

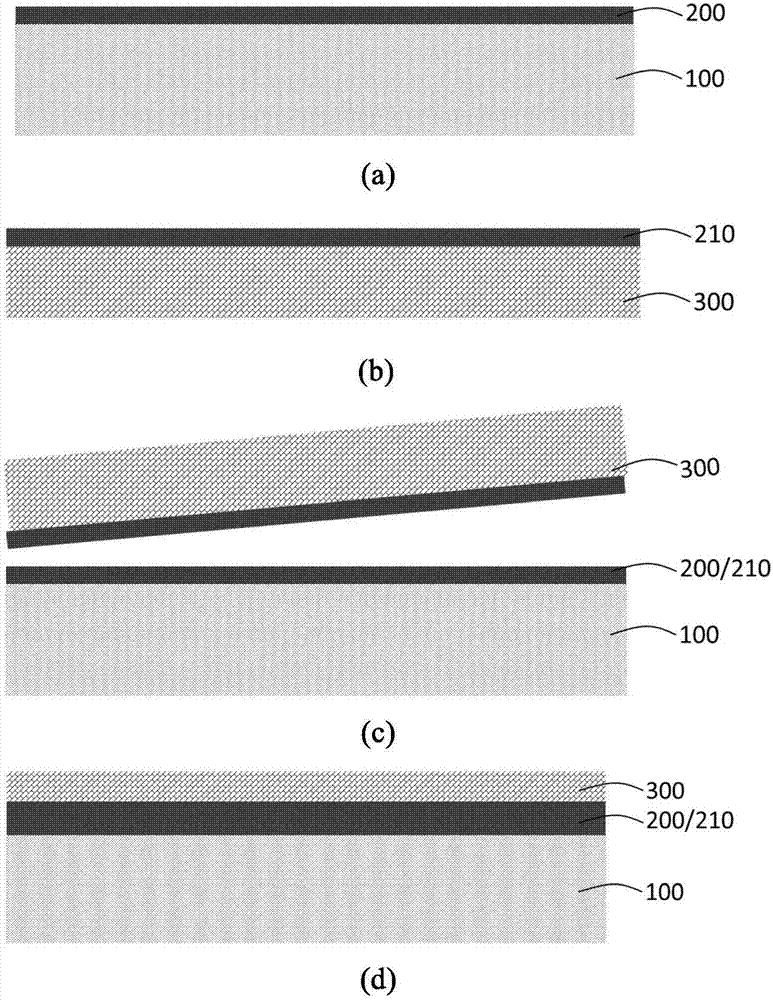

Temperature compensation surface acoustic wave resonator and preparation method thereof

PendingCN107493086AAvoid depositionAvoid flatteningImpedence networksHigh level techniquesSi substrateMaterials science

The invention provides a temperature compensation surface acoustic wave resonator. The temperature compensation surface acoustic wave resonator comprises a substrate, a piezoelectric material base plate located on the substrate and an interdigital structure formed on the piezoelectric material base plate, wherein a bonding layer is arranged between the substrate and the piezoelectric material base plate to form a composite base plate. The temperature compensation surface acoustic wave resonator has the advantages that the process difficulty can be effectively reduced, the process stability and reliability are improved, the product yield is increased, the frequency temperature coefficient is decreased, and the performance of the device is improved.

Owner:HANGZHOU SAPPLAND MICROELECTRONICS TECH CO LTD

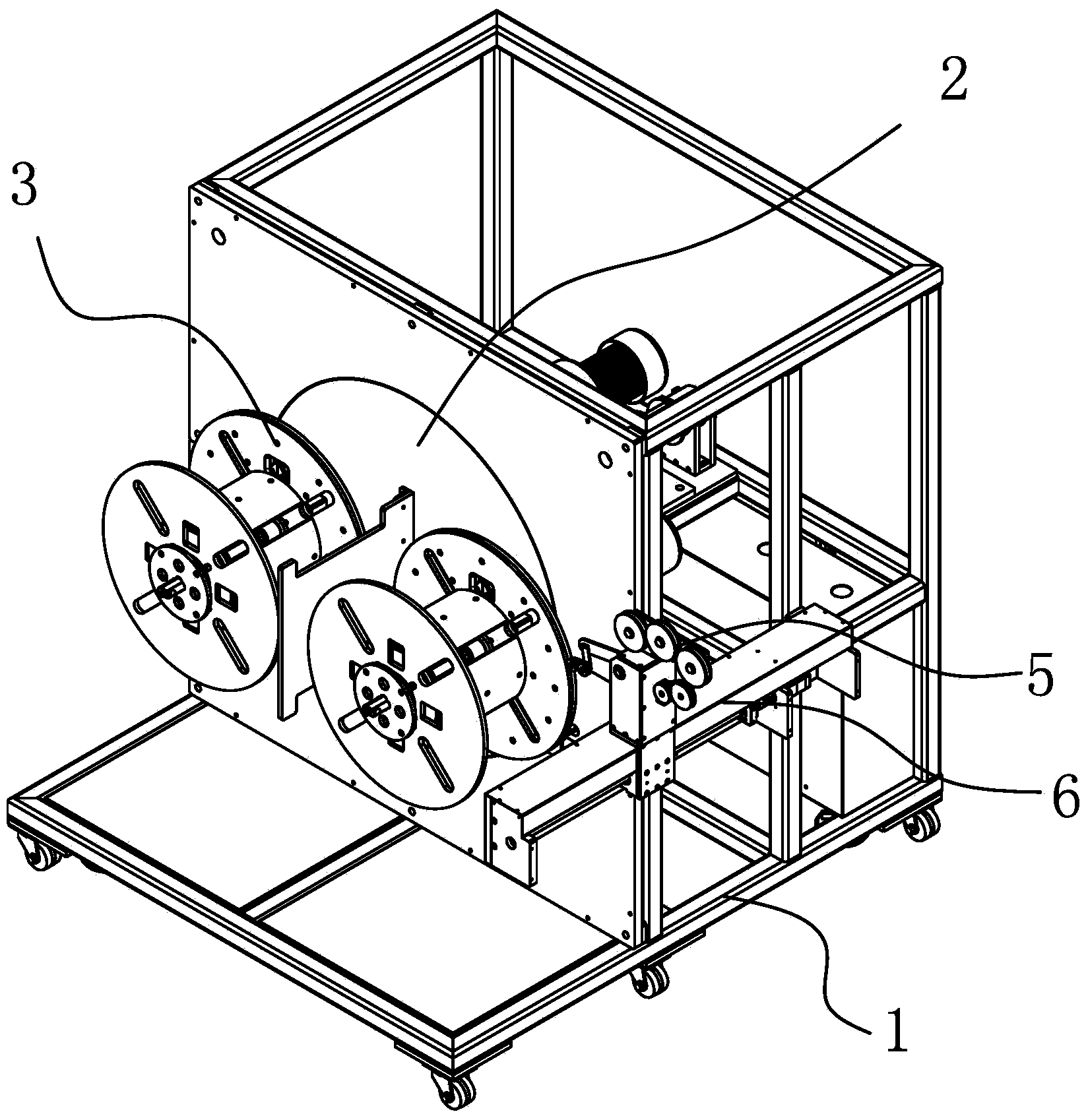

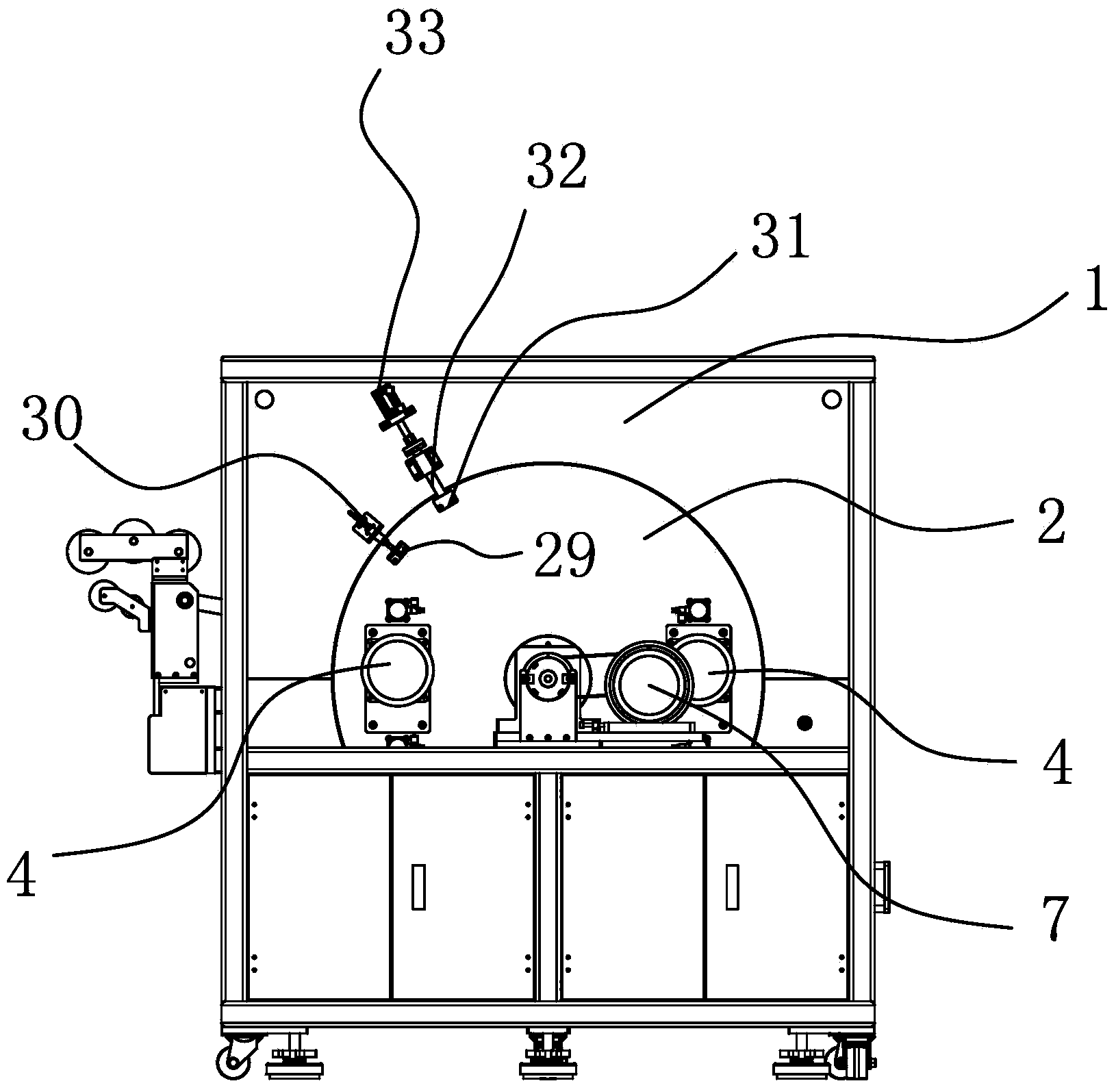

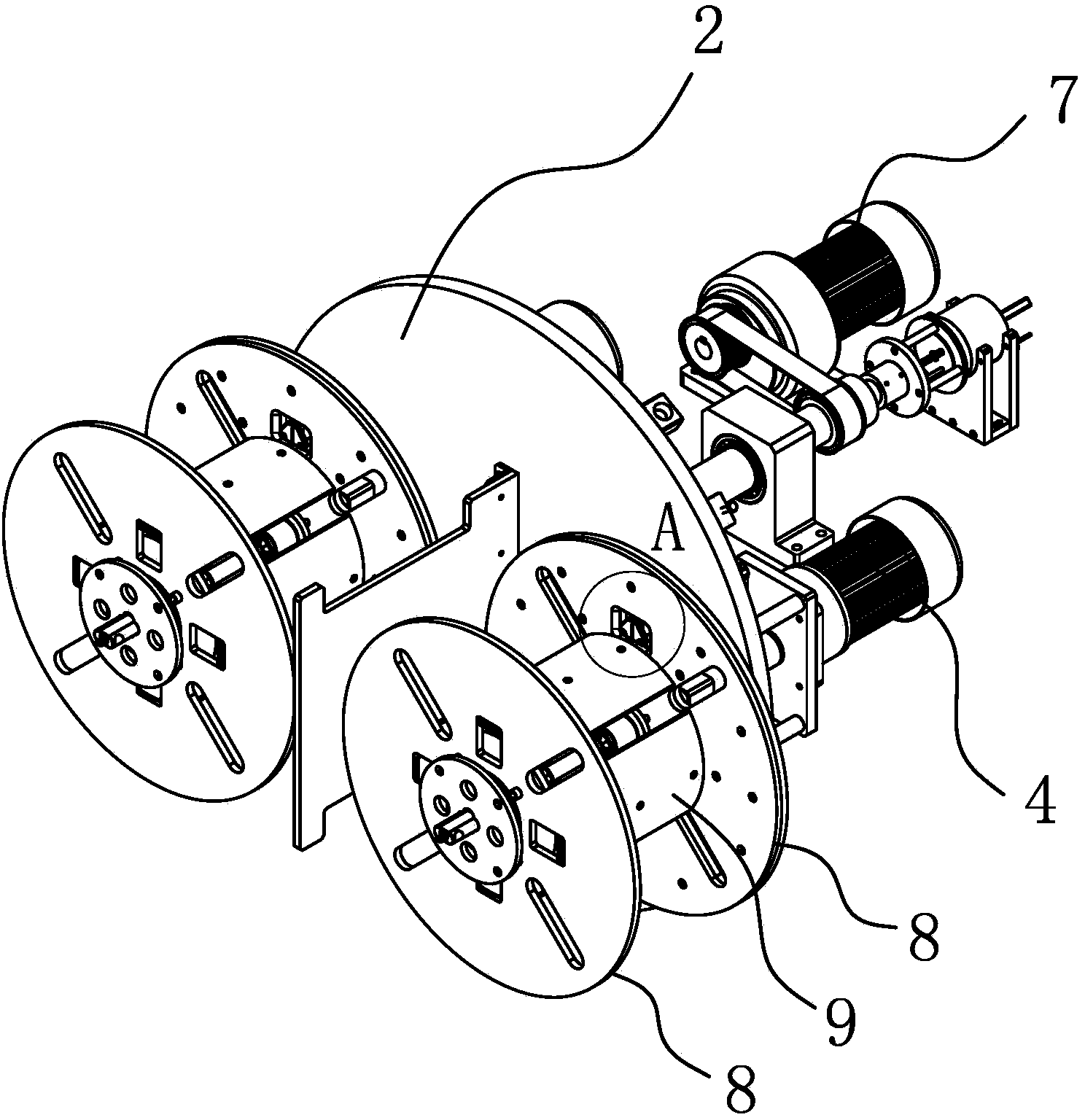

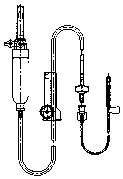

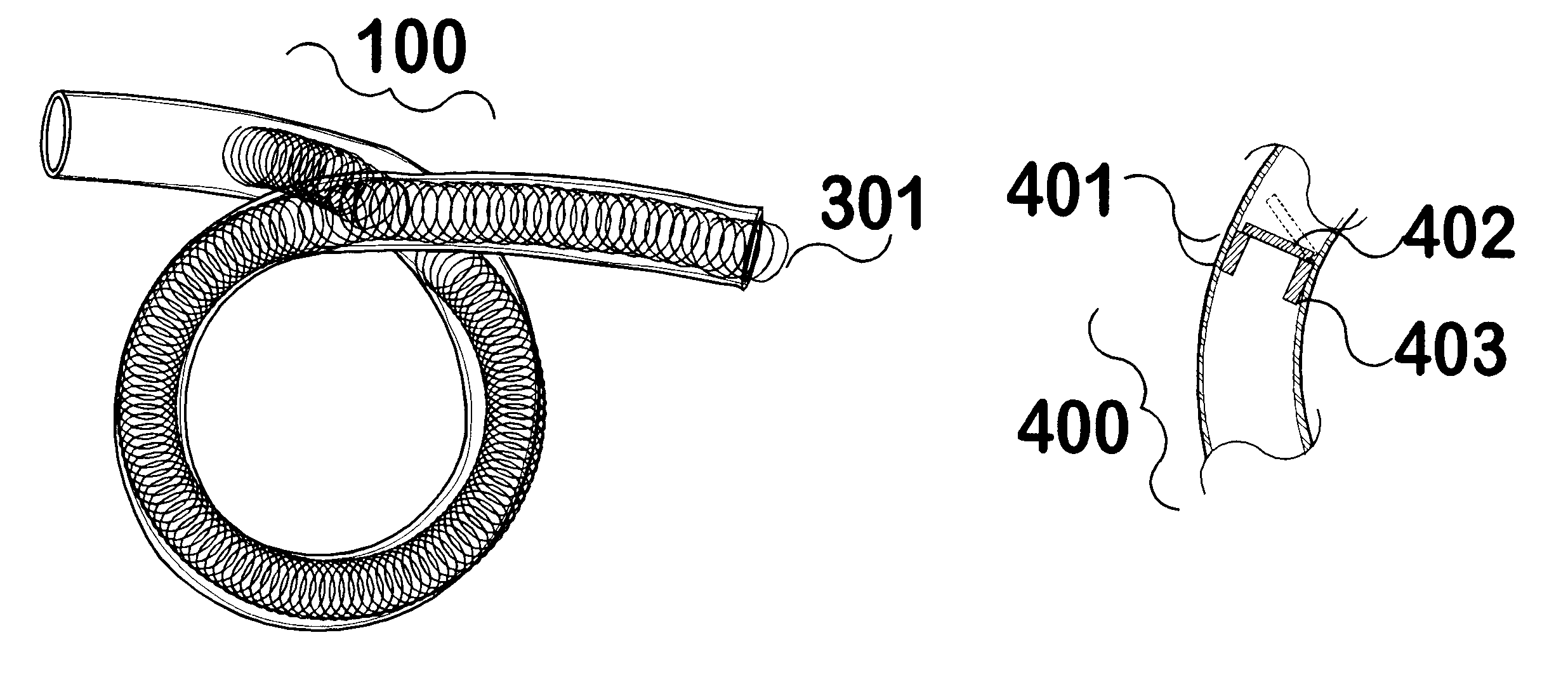

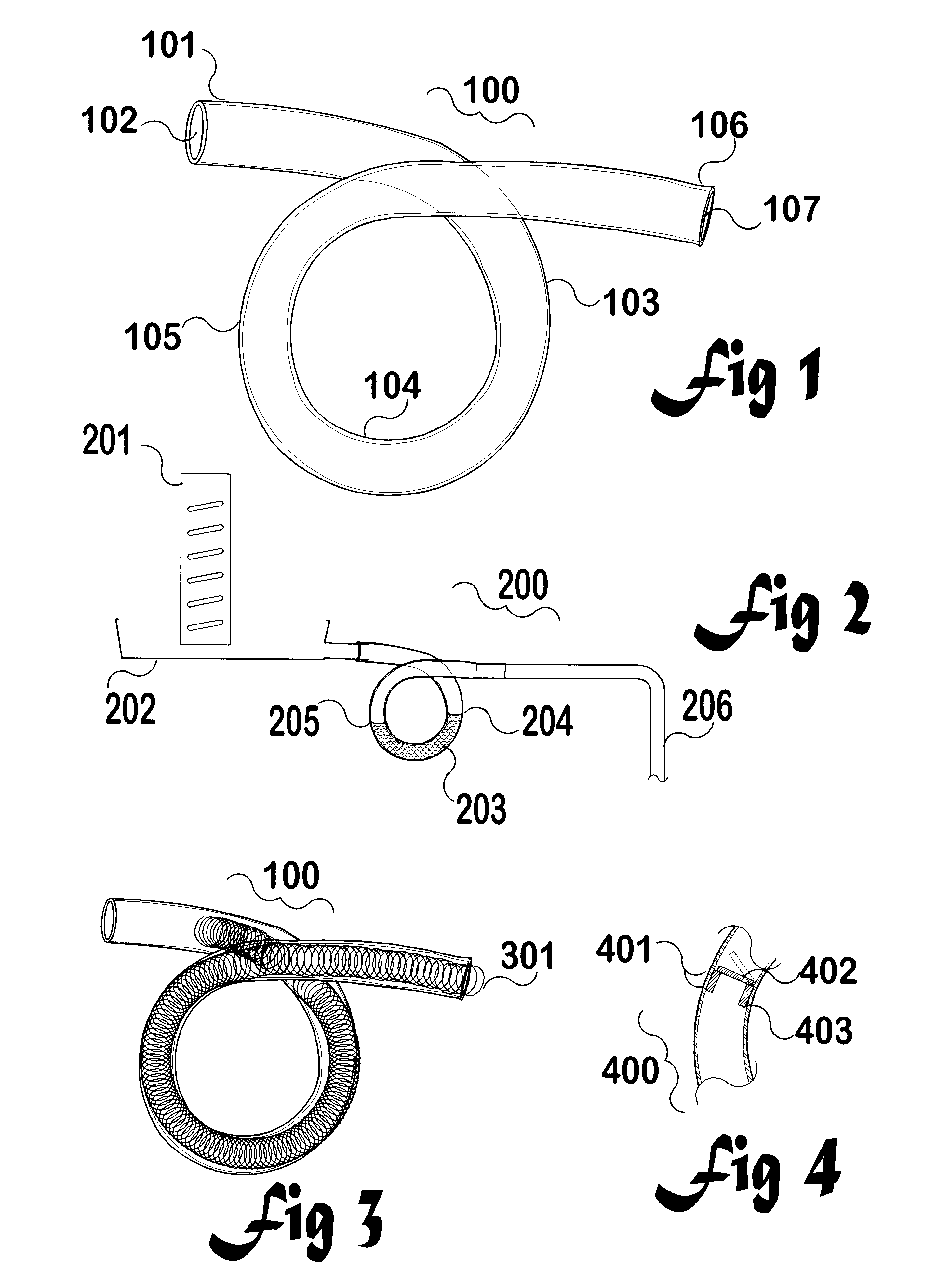

Pipe coiling machine

The invention provides a pipe coiling machine, and belongs to the technical field of pipe coiling equipment. The pipe coiling machine solves the technical problems that in the prior art, the tensioning force intensity during the guide pipe coiling cannot be controlled in an effective mode, and the like. The pipe coiling machine comprises a machine frame, wherein a turntable is arranged on the machine frame, a material coiling disc used for coiling a target guide pipe is arranged on the turntable, the material coiling disc and the turntable are positioned in the radial direction of the material coiling disc, and can relatively rotate in the peripheral direction of the material coiling disc, a first power source capable of enabling the material coiling disc to rotate in the peripheral direction is arranged between the turntable and the material coiling disc, a tensioning wheel group used for tensioning the target guide pipe is also arranged on the machine frame, and a first driving mechanism capable of enabling the tensioning wheel group to flatly moving in the axial line direction of the material coiling disc is arranged between the machine frame and the tensioning wheel group. The pipe coiling machine has the advantages that the combination of the material coiling disc and the tensioning wheel group is adopted, so that the tensioning force of the target guide pipe maintains the constant state, and phenomena of looseness knotting due to too small tensioning force and flat pressing of the guide pipe due to excessive tensioning force are avoided.

Owner:MAIDER MEDICAL IND EQUIP

Spinal Cord Stimulator Lead Anchor

InactiveUS20110264181A1Minimize migrationAvoid flatteningSpinal electrodesExternal electrodesCardiologySpinal cord stimulators

The lead of a spinal cord stimulator implanted along the spinal cord of a recipient is secured by an anchor staple at a selected location. The anchor staple comprises a loop that receives and holds the lead at the selected location along the spine. A pair of spaced legs extend from the loop and present an initially open configuration for receiving an anchor point presented by bone, ligament, fascia or skin. The legs are closed to engage the anchor point and thereby positively secure the lead to prevent migration of the implanted lead. Several staples may be applied in a row to assure optimal positioning of the lead.

Owner:HAMILTON DENNISON R

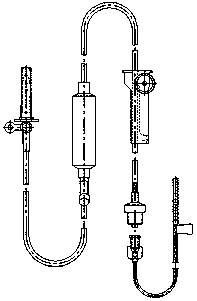

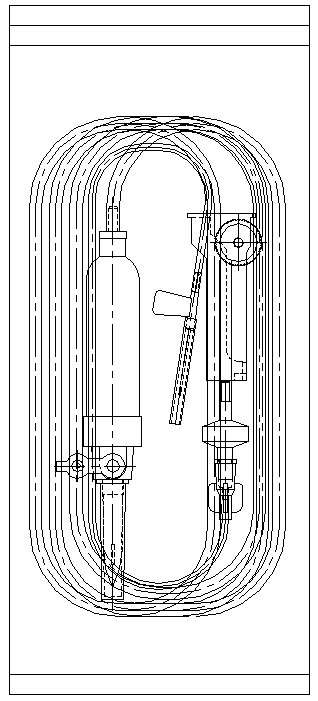

Automatic winding and bagging machine for infusion set and working method thereof

The invention discloses an automatic winding and bagging machine for an infusion set and a working method thereof. An infusion set hanging and conveying device comprises a rotary conveying mechanism and a suspended rear lower automatic alignment positioning mechanism arranged on one side of the rotary conveying mechanism; the output end of the rotary conveying mechanism is connected to the transferring and connecting mechanism; after the infusion set on the rotary conveying mechanism is positioned by the suspended rear lower automatic alignment positioning mechanism, the upper end of the infusion set is fixed in a positioning clamping seat of the infusion set winding device through the transferring and connecting mechanism, a winding rod is installed at the edge of the positioning clampingseat, the lower part of the infusion set is fixed in a clamping air claw of the infusion set winding device, and the positioning clamping seat and the pipe winding rod are close to the clamping air claw when the infusion set is coiled; an infusion set bagging and sealing device comprises a material taking mechanism, a movable bagging bucket and a bagging and sealing component; and the infusion set wound by the infusion set winding device is taken down by the material taking mechanism, then is placed in the movable bagging bucket, and is connected to the bagging and sealing assembly. Accordingto the automatic winding and bagging machine, automatic winding and bagging sealing of the infusion set is realized.

Owner:HANGZHOU ZHONGYI AUTOMATION EQUIP

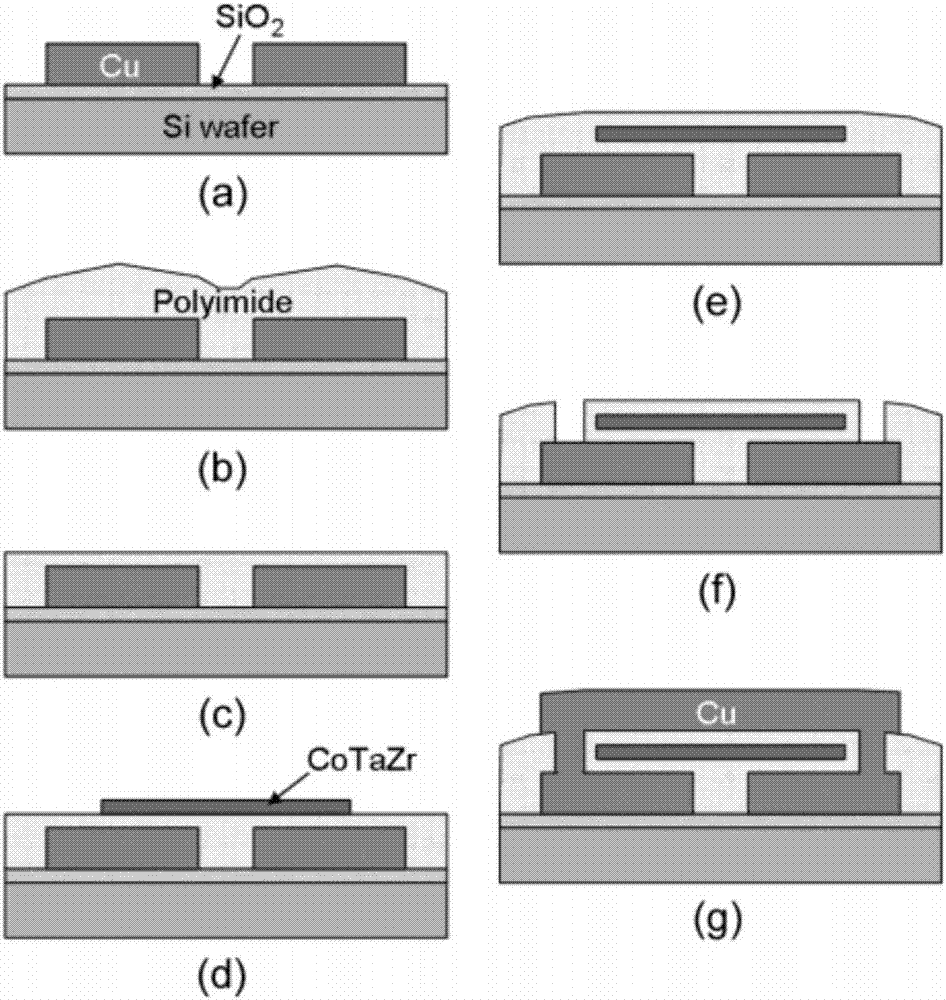

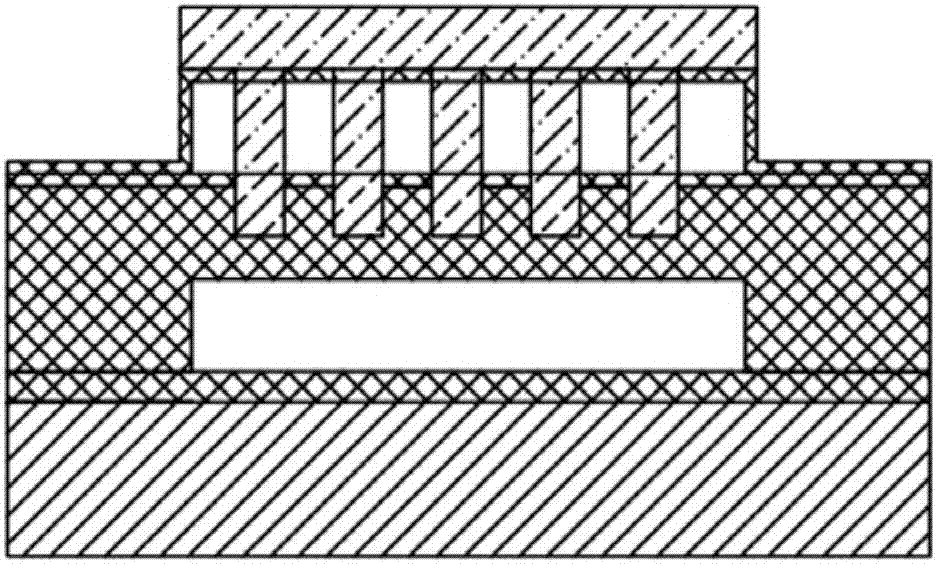

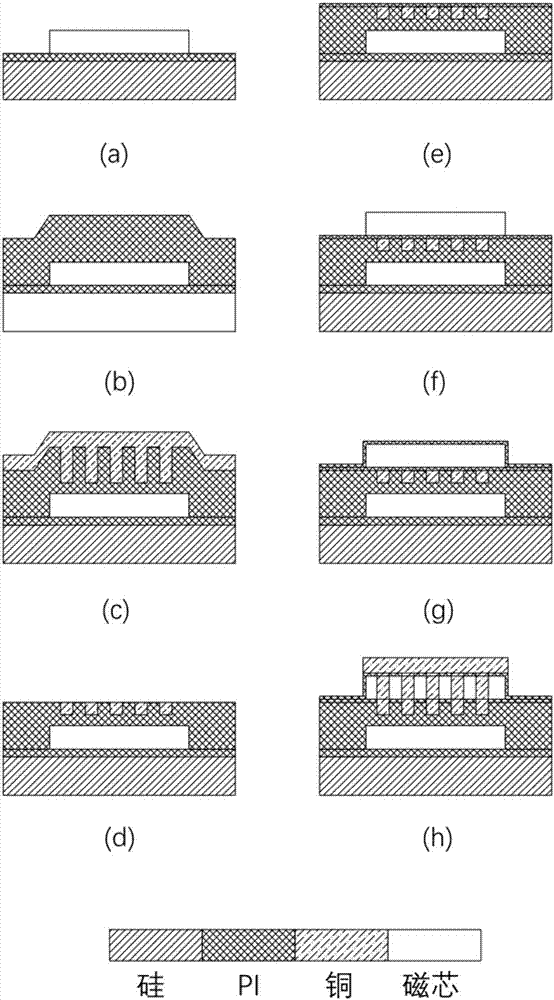

Integration solenoid double-layer magnetic film inductor and preparation method thereof

ActiveCN107039395AIncrease inductance densityAvoid planarization problemsSemiconductor/solid-state device detailsSolid-state devicesFilm structureInductor

The present invention belongs to the integration circuit technology field, and provides an integration solenoid double-layer magnetic film inductor and a preparation method thereof. The objective of the invention is to further improve inductor inductance value density and reduce substrate loss. The present invention comprises a silicon substrate, a lower layer of magnetic core film, a deeply buried layer, a lower layer of coils, an insulation layer, an upper layer of magnetic core film, an insulation layer and an upper layer of coils; the lower layer of magnetic core film is arranged on the silicon substrate, the silicon substrate is covered with the deeply buried layer, the deeply buried layer is configured to deeply bury the lower layer of magnetic core film, the upper surface of the deeply buried layer is provided with a groove of the lower layer of coils, the lower layer of coils is correspondingly arranged in the groove of the lower layer of coils; and the upper layer of magnetic core film is located on the deeply buried layer, the upper layer of coils is located on the upper layer of magnetic core film, the installation layers are respectively arranged between the lower layer of coils and the upper layer of magnetic core film and between the upper layer of coils and the upper layer of magnetic core film for isolation, and the upper layer of coils and the lower layer of coils are conducted through a through hole. The integration solenoid double-layer magnetic film inductor and the preparation method thereof employ a double-layer magnetic core film structure so as to improve the inductance value density of the inductor and reduce loss of parasitic capacitors between coils, and the preparation technology is simple, the preparation cost is low so as to facilitate industrialization production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

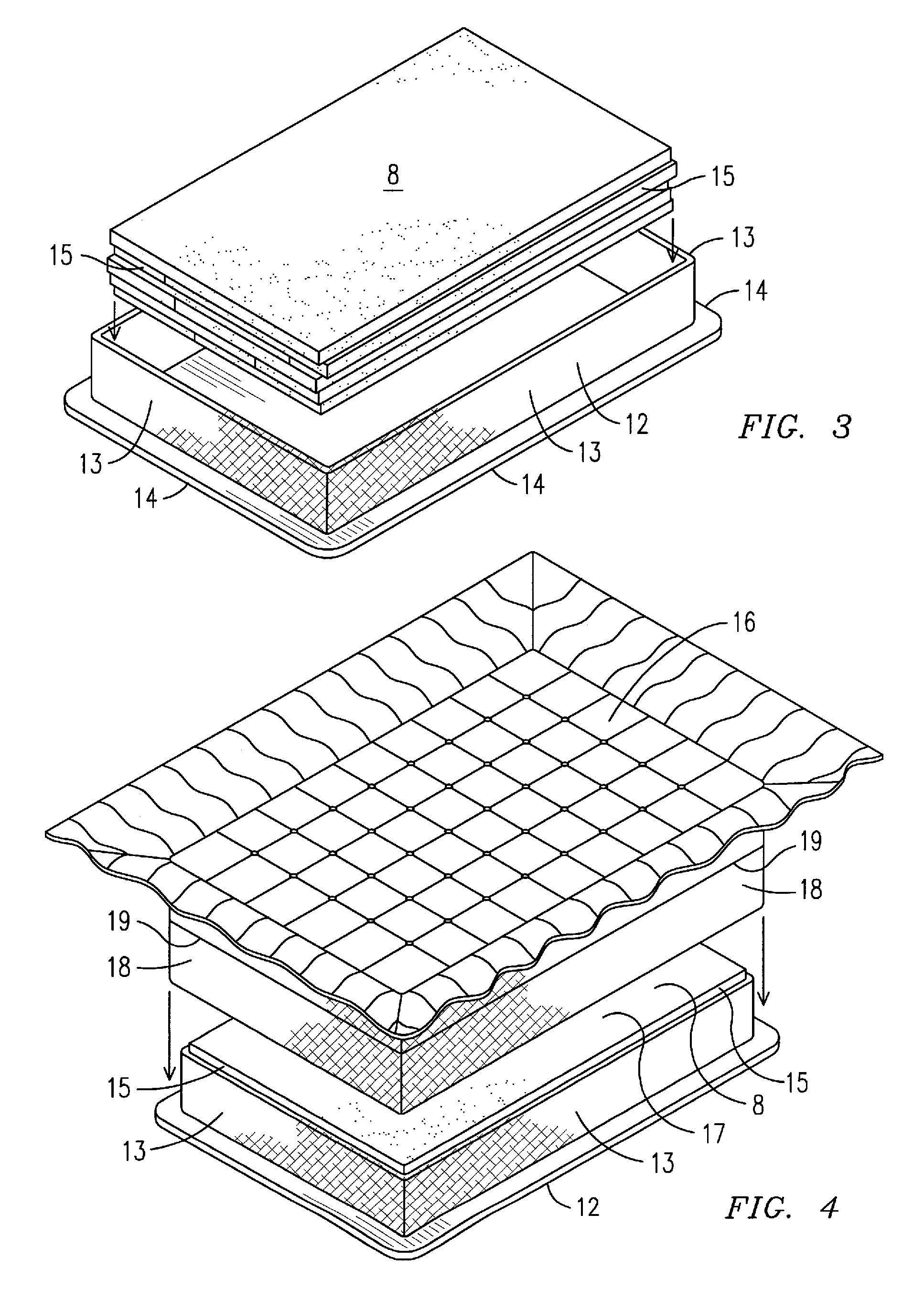

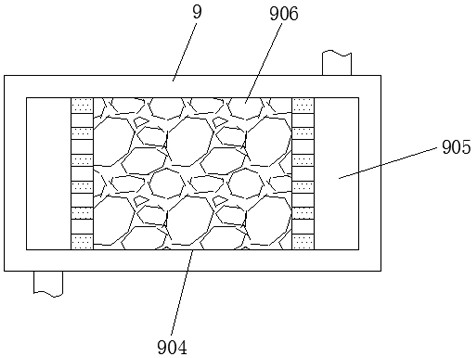

Medical balloon with particles therein

ActiveUS9409001B2Function increaseAvoid flatteningBalloon catheterSurgeryBalloon catheterSurface roughening

A balloon catheter includes a balloon having a plurality of layers. The inner layer acts as a support layer to the outer layer. Embedded within the outer layer is a plurality of particles or pellets which in one embodiment provide roughening of the outer surface of the balloon. The particles or pellets, particularly in conjunction with an inner support layer, ensure maintenance of the roughened outer surface of the balloon during inflation of the balloon. In another embodiment, the particles or pellets may be radiopaque and / or echogenic with or without creating surface roughening of the balloon.

Owner:COOK MEDICAL TECH LLC

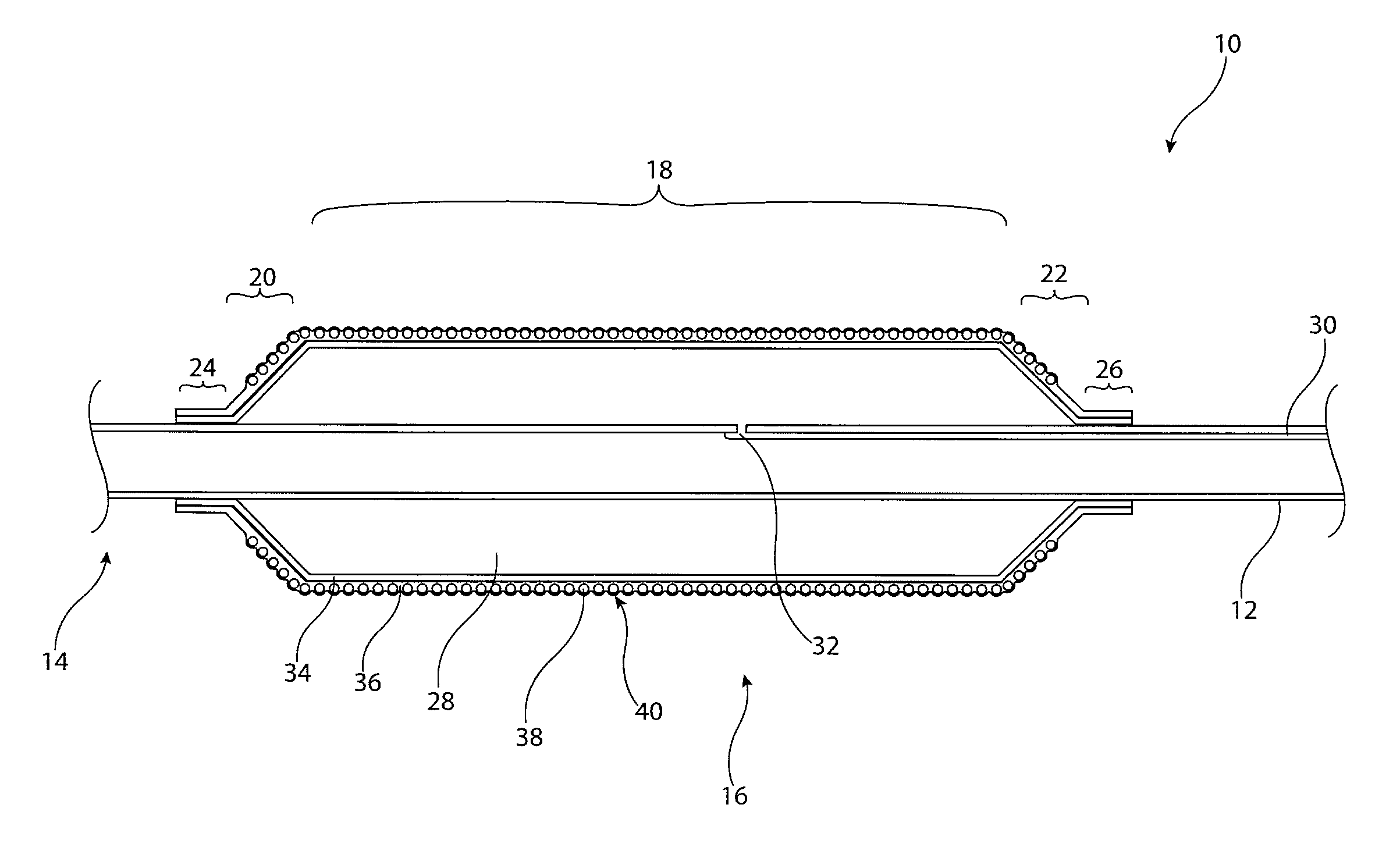

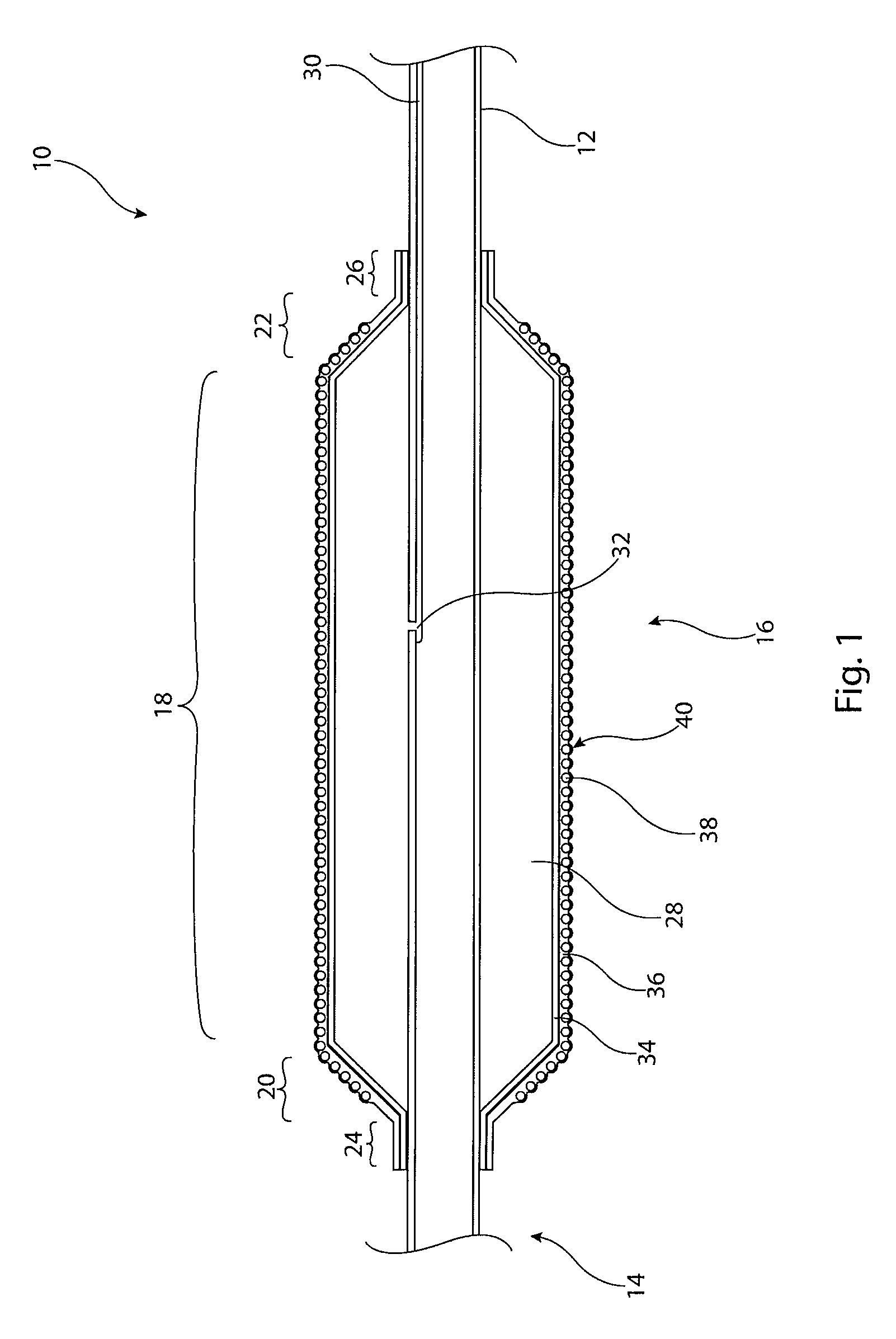

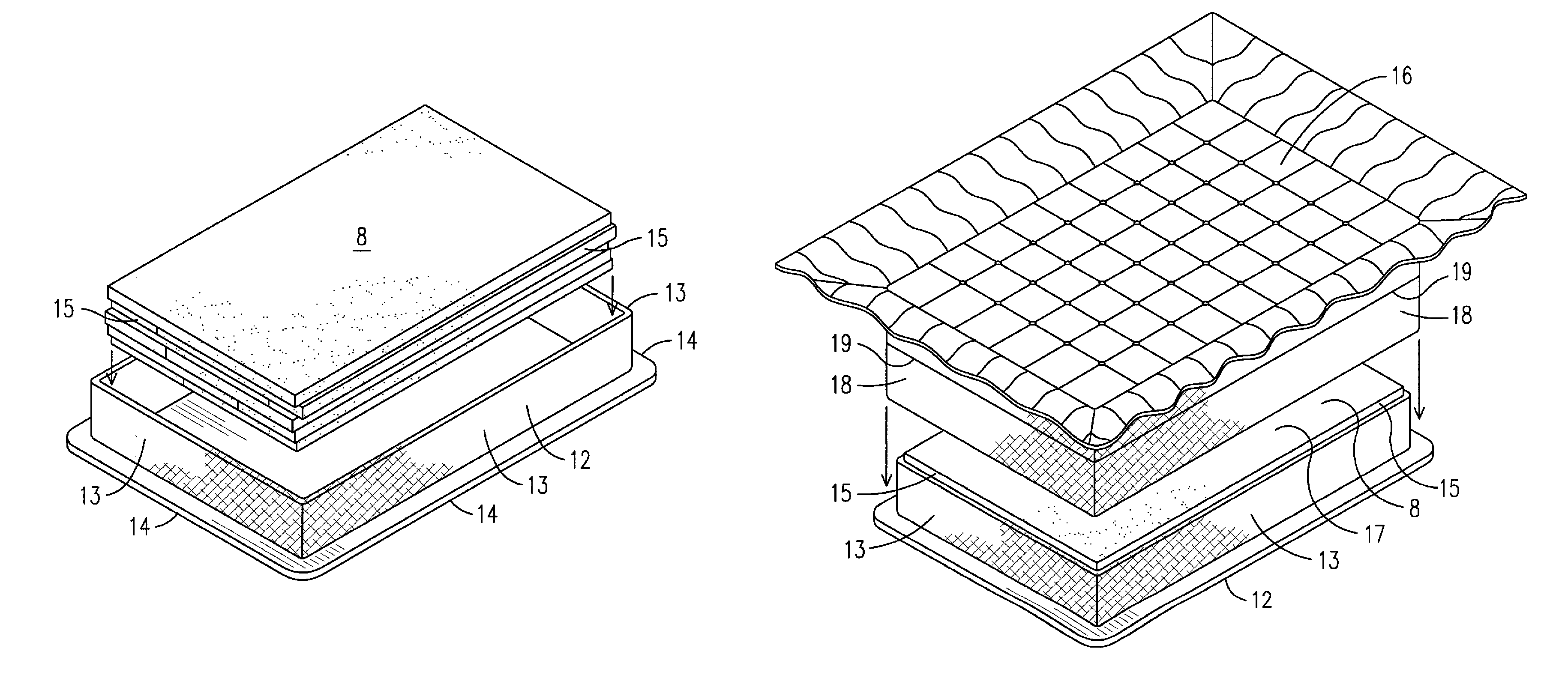

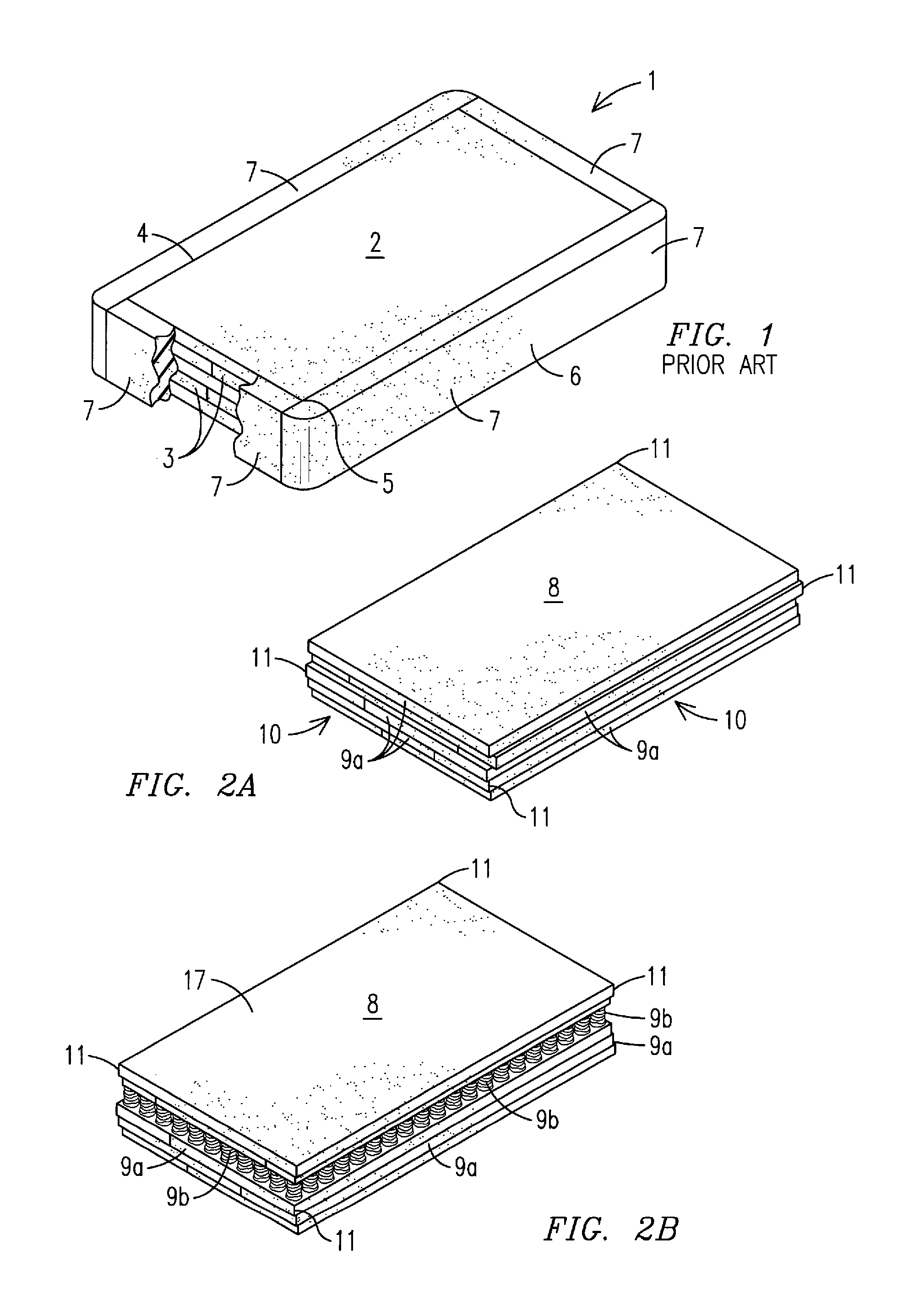

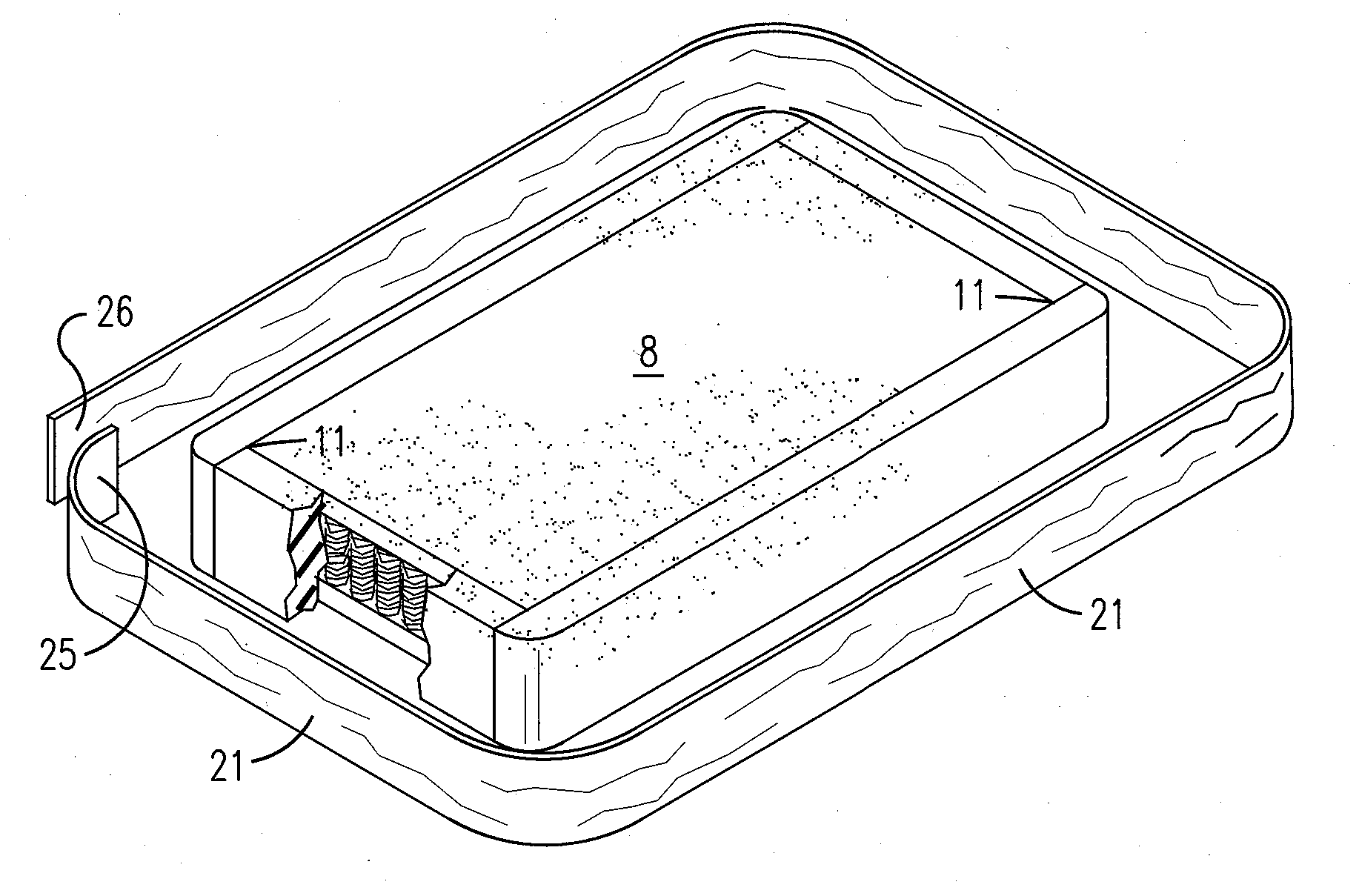

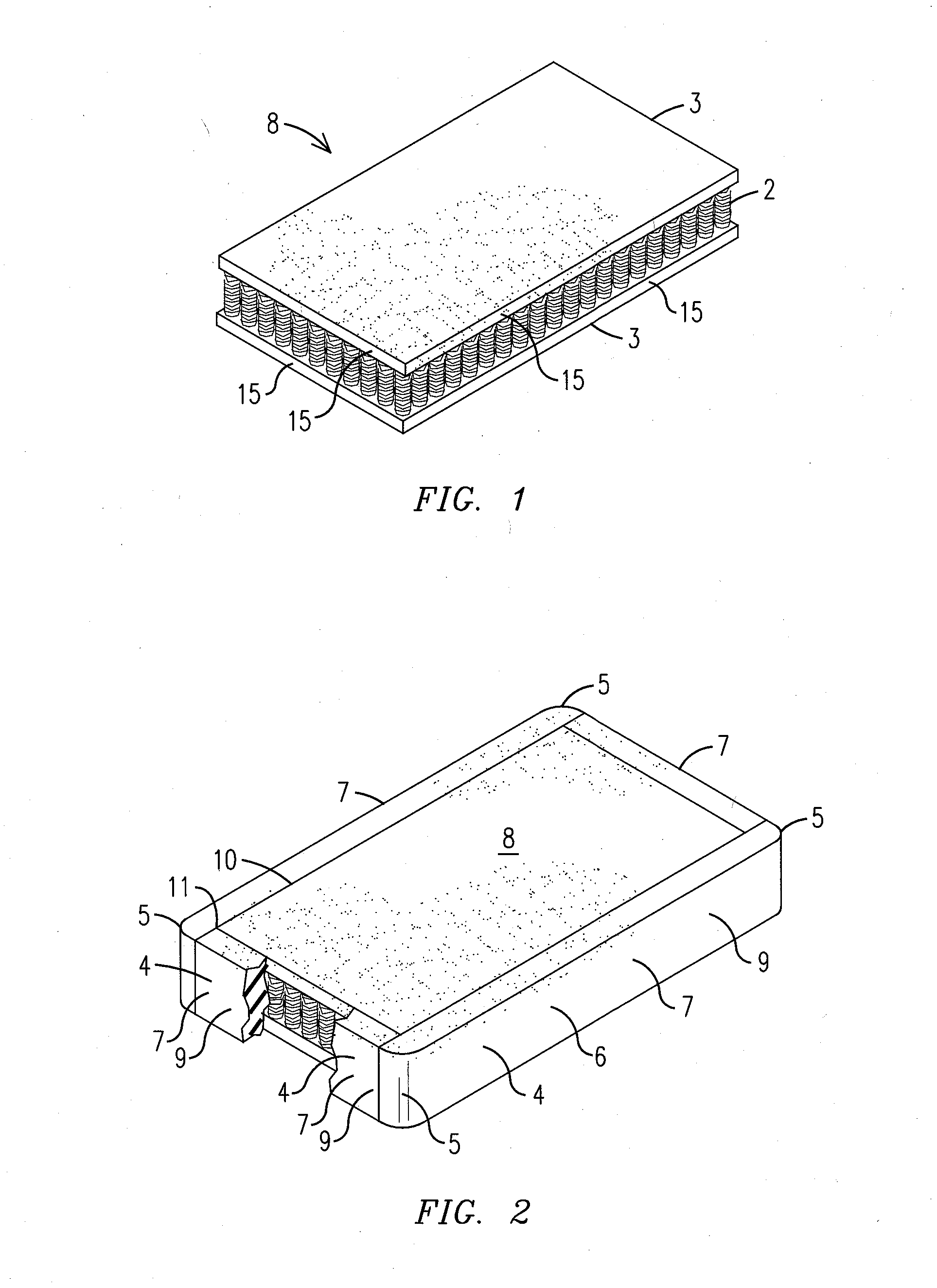

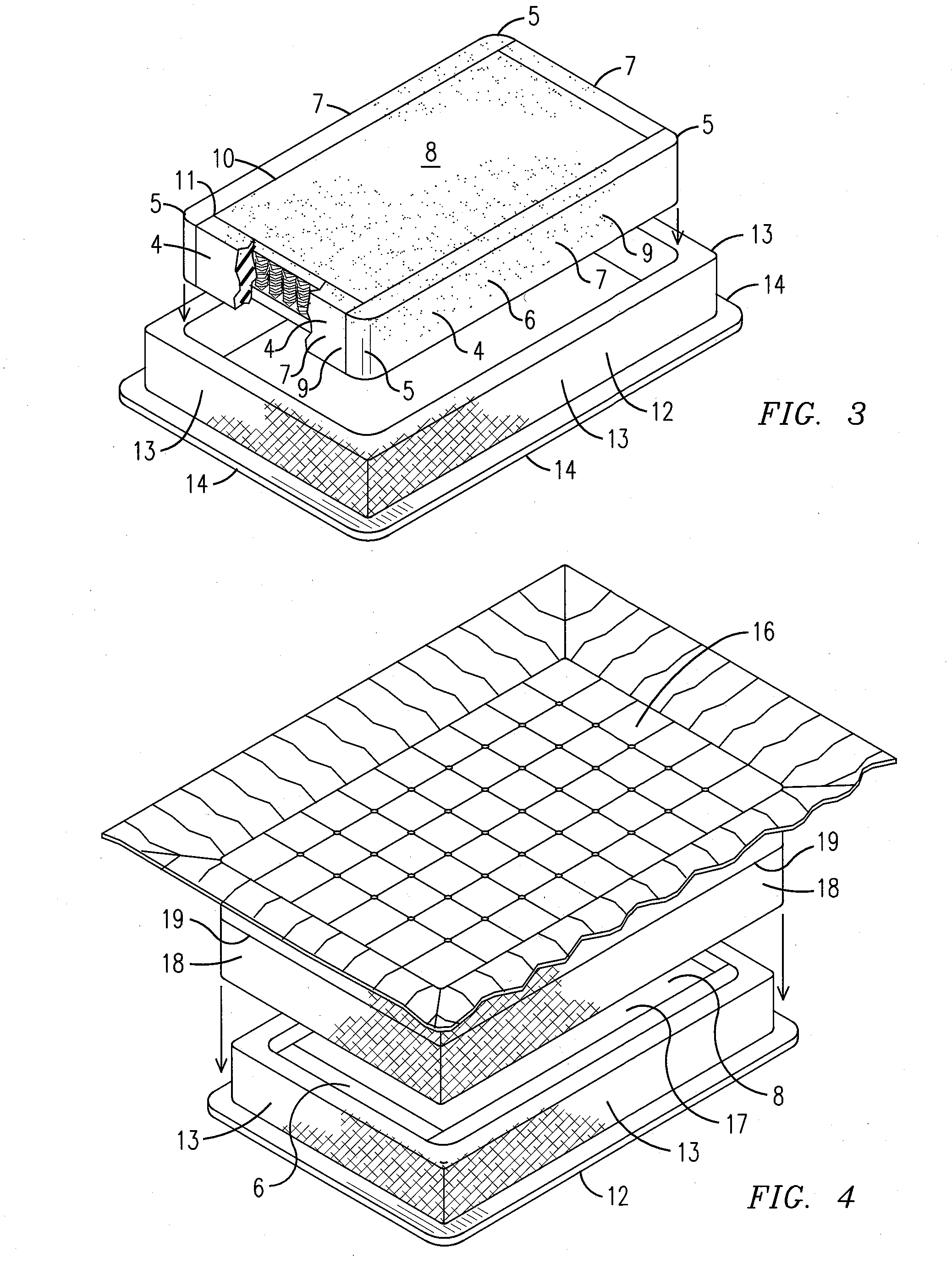

Perimeter-wrapped mattress and method of manufacture

ActiveUS8955182B1Eliminate needAccurate shapeUpholstery manufactureStuffed mattressesMicro coilEngineering

A mattress (22) having a foam core (8) completely extends to the perimeter edges of the mattress wherein side walls (15) of the foam core are compressed inward and held in place using a preferably non-woven strip of fabric (21) or similar non-elastic or non-stretchable material that is wrapped around the side walls of the foam core. A method of wrapping the foam core allows corners (5) of the foam core to be formed under the inward pressure of the non-woven fabric, thereby creating a strong perimeter for the mattress that prevents outward pressure against the sidewalls created by the downward pressure of an individual lying on the mattress from flattening of the mattress by providing more upward pushback against the individual. An optional layer of micro-coil springs (2a) may be located within the foam core to provide more buoyancy and springiness in the mattress.

Owner:PRANASLEEP

Flexible trap for drains

InactiveUS6543470B2Preventing loss of patencyAvoid flatteningValve arrangementsCondensate preventionPolyvinyl chlorideRelative motion

Owner:MANS DANIEL RUDOLF

Modified type polishing pad regulating apparatus technique

The invention provides an improved process for polishing pad regulator, which relates to a chemical mechanical polishing process. By adopting the existing process for polishing pad regulator, the crystals of polishing slurry on the surface of the polishing pad can be effectively removed and the service life of the polishing pad is shorter. In the improved process for polishing pad regulator of the invention, the surface of the polishing pad is first washed and dressed adopting high-pressure water or the polishing slurry so as to remove the crystals of the polishing slurry, and then a main polishing procedure is carried out on the condition of low pressure. In the steps of high-pressure washing and dressing, the distance from the initial position of the polishing pad regulator to the center of the polishing pad ranges from 1.4 to 1.6 inches. By adopting the process for polishing pad regulator of the invention, polishing slurry residues left in the grooves of the polishing pad can be reduced, tiny abrasion on the circular surface of the crystal caused in the process of process can be avoided, and moreover the service life of the polishing pad can be greatly prolonged.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Perimeter-wrapped mattress and method of manufacture

ActiveUS20150096127A1Avoid flatteningRetain its shapeStuffed mattressesSpring mattressesEngineeringMechanical engineering

Owner:PRANASLEEP

Production equipment for drying treatment of textiles

PendingCN111764078AAvoid flatteningAvoid wrinklesMechanical cleaningPressure cleaningEngineeringIndustrial engineering

The invention discloses production equipment for drying treatment of textiles. The production equipment comprises an equipment body, a clearing roll and an ironing roll. A hydraulic telescopic rod isarranged on the equipment body, and the lower end of the hydraulic telescopic rod penetrates through the upper surface of the equipment body to be connected with a supporting frame. The inner side wall of the supporting frame is rotationally connected with first pressing rolls, and protection bushes are arranged on the outer side faces of the first pressing rolls and the outer side faces of secondpressing rolls. Meanwhile, the second pressing rolls are rotationally connected to the inner side wall of the equipment body, the inner side wall of the equipment body is rotationally connected withfirst guide rolls, and the first guide rolls are arranged on the right sides of the second pressing rolls. Heating elements are arranged in the equipment body, and the heating elements are arranged between the first guide rolls. According to the production equipment for drying treatment of the textiles, placed cloth is flattened through the first pressing rolls and the second pressing rolls, and the phenomenon that when subsequent textile cloth is dried, wrinkles are generated is avoided; and meanwhile too much water in the textile cloth can be extruded out under the action of the first pressing rolls and the second pressing rolls, and subsequent drying is benefited.

Owner:湖州市千金金耀制丝有限公司

Hat Hair Comb Pin

InactiveUS20100180906A1Preserve hair styleAvoid flatteningSewing needlesScarvesBiomedical engineering

A hat hair comb pin is provided. The hat hair comb pin is a one piece L shaped metal casted device. The lower part of the L is designed with flat prongs spaced evenly that penetrate the hair and provide a comfortable structure that rests on the head while supporting the hat. The upper part of the L shape creates distance between the inside of the hat and the hair. There is a curved appendage on the tipper part of the backside of the L shape. The extreme end of the appendage is designed to penetrate the inside brim of the hat thus securely attaching the hat hair comb pin to the hat.

Owner:MAROZSAN MARTHA +1

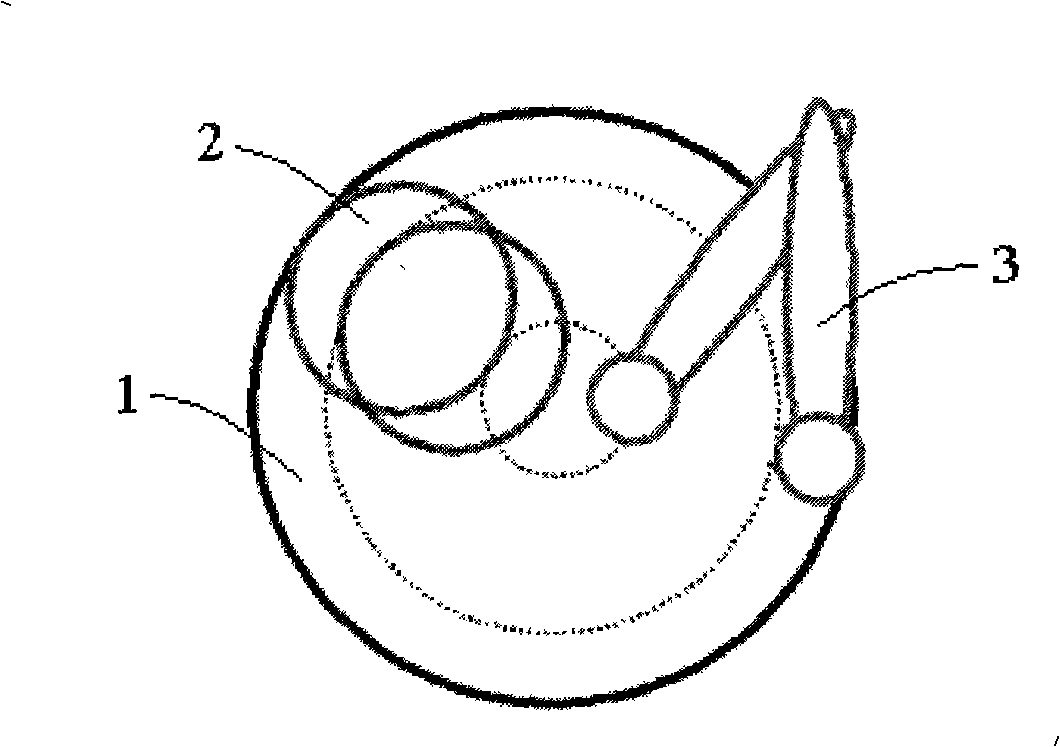

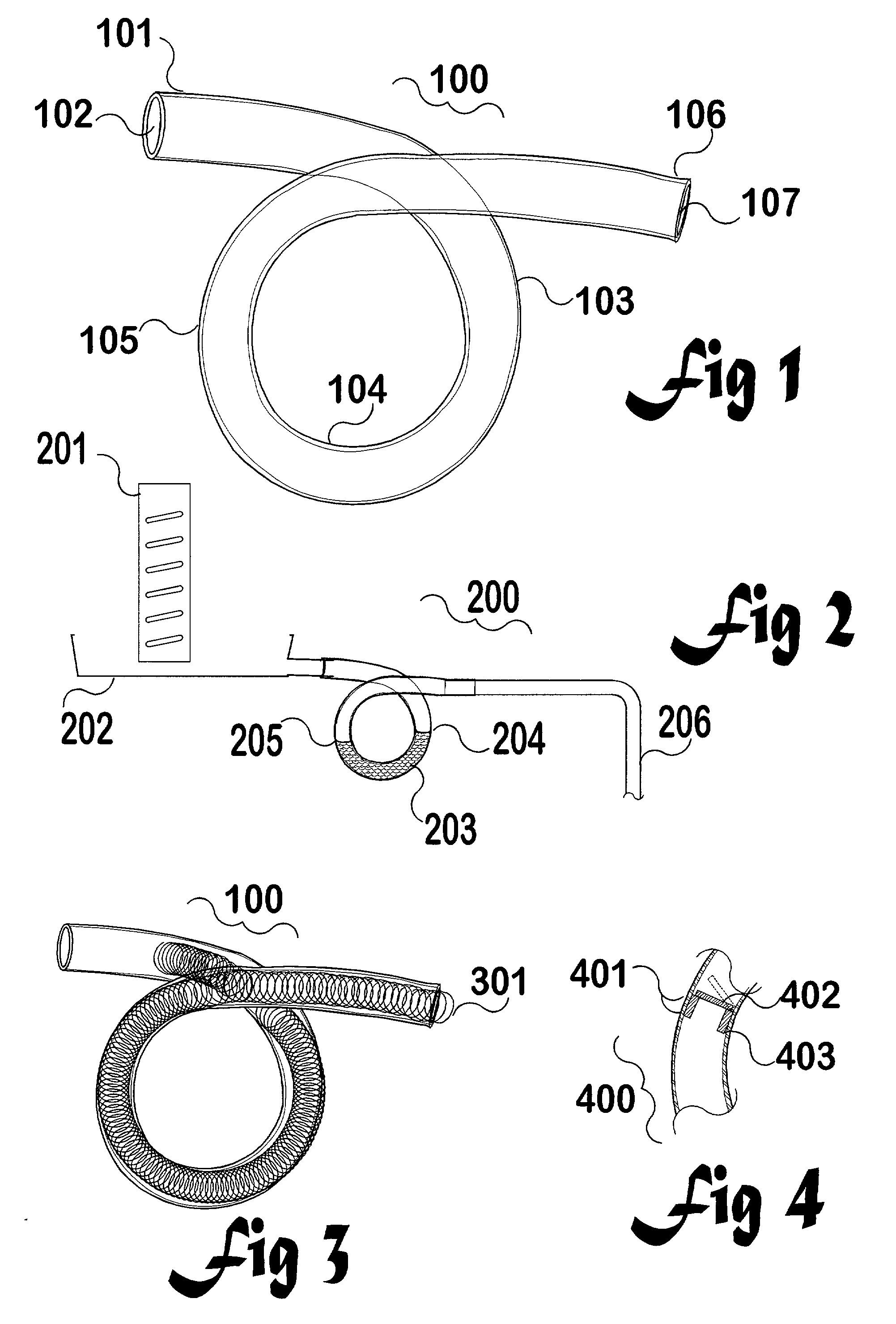

Flexible trap for drains

InactiveUS20010047823A1Preventing loss of patencyAvoid flatteningValve arrangementsCondensate preventionPolyvinyl chlorideRelative motion

Traps particularly intended for carrying condensate from air conditioner drip trays towards a drainage system are constructed from a single turn of a flexible thermoplastic pipe; each unit being preformed when in a heat-softened state into a shape of a one-turn coil resembling the twist in a pig's tail, or the Greek "alpha" (alpha) symbol. Traps are made of a transparent flexible durable thermoplastics material, such as polyvinyl chloride, and internal contents may be inspected through the trap wall. Being flexible, the traps can reliably connect mis-aligned conduits. Being flexible, the traps can serve as reliable connectors between conduits where relative movement is a problem such as where vibration or earthquakes occur.

Owner:MANS DANIEL RUDOLF

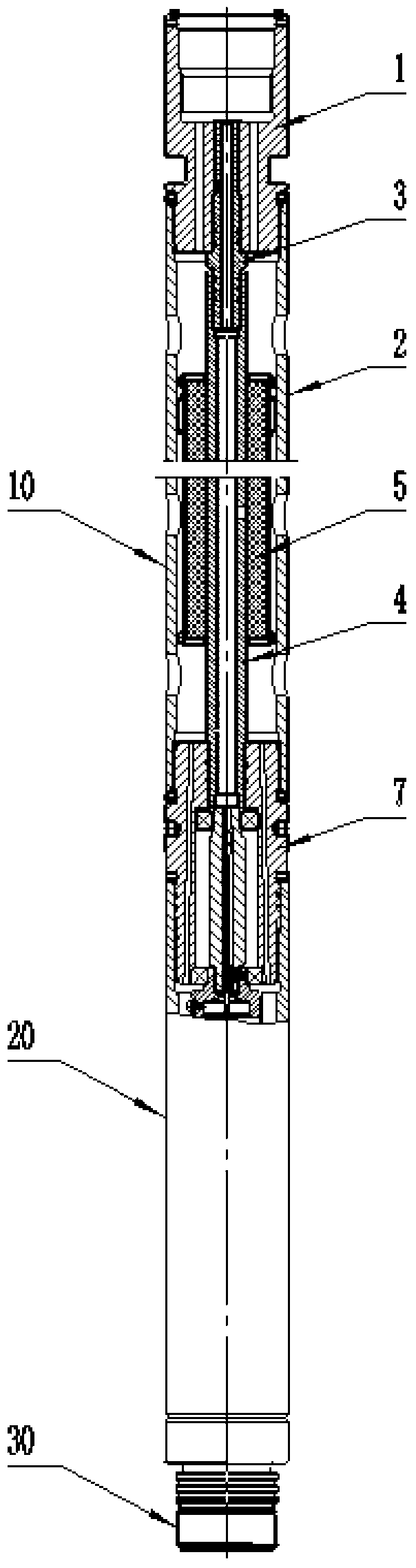

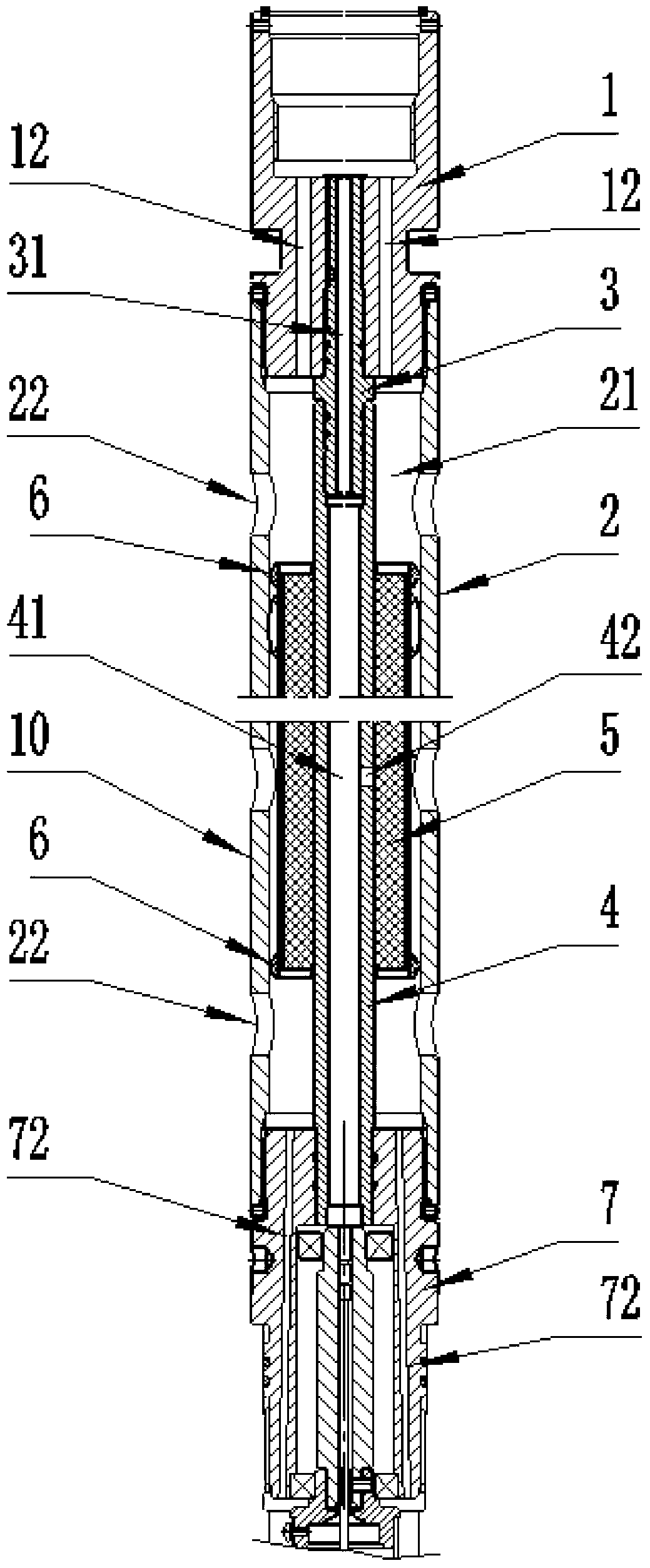

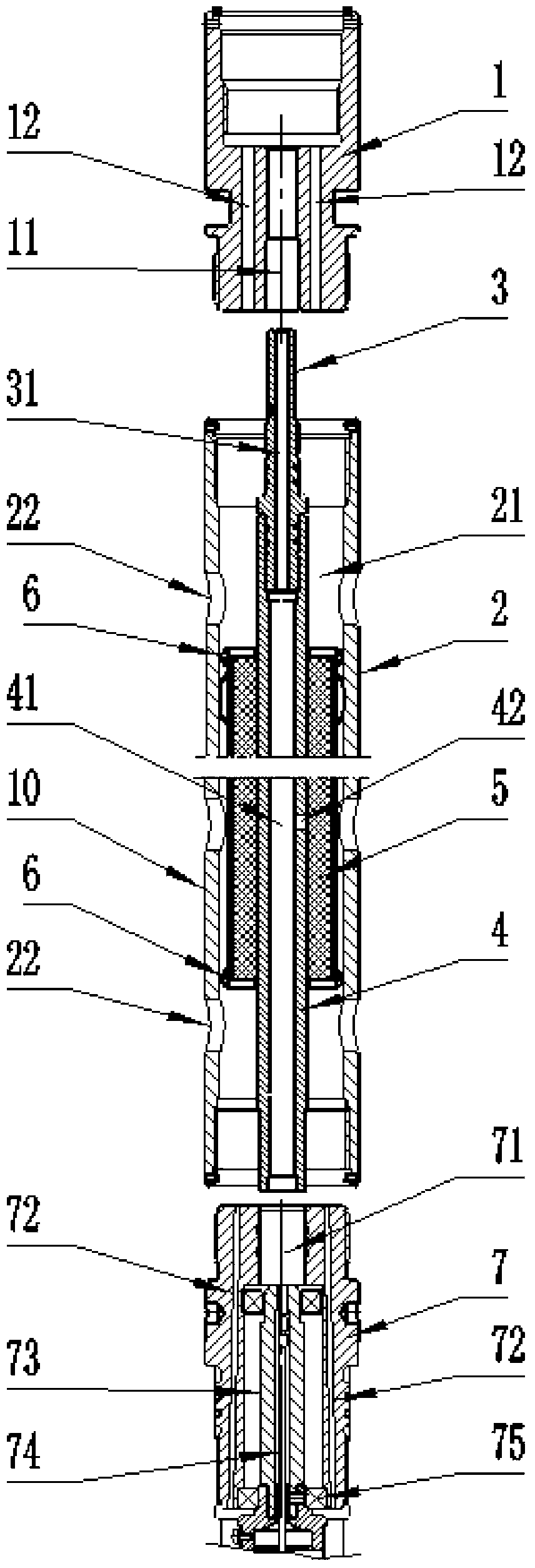

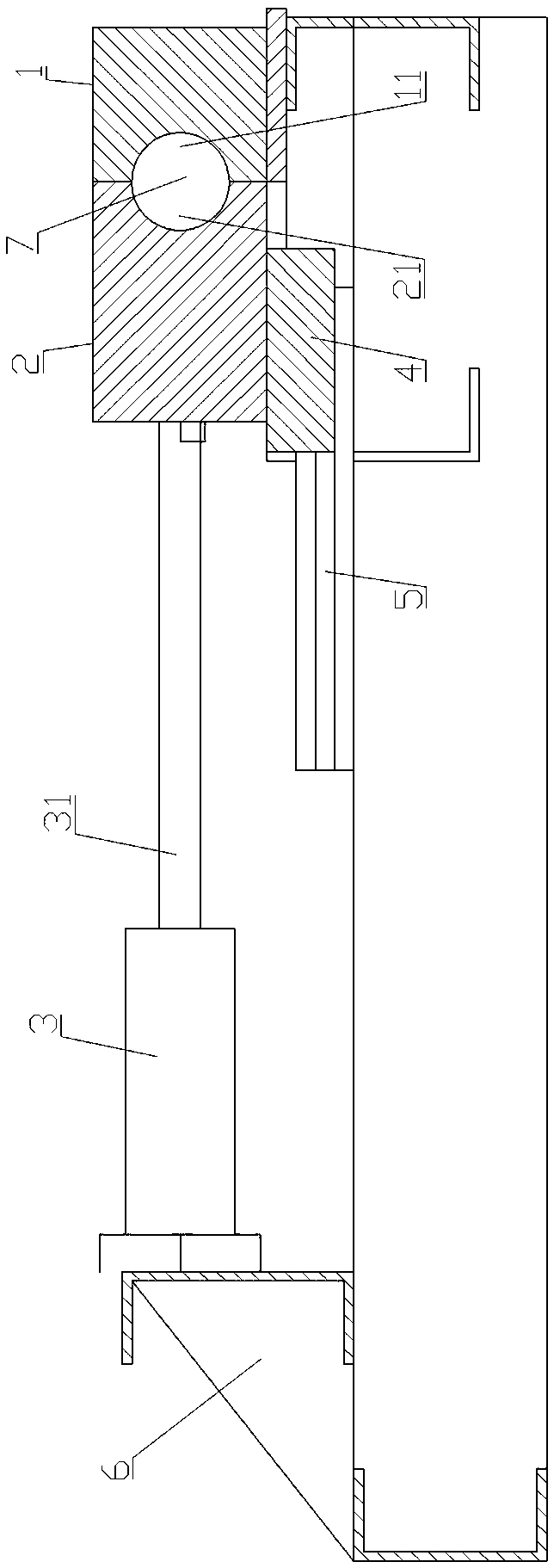

Multipole composite deep penetration perforation device

The invention discloses a multipole composite deep penetration perforation device which comprises at least one integral perforation unit, wherein the integral perforation unit includes a fracturing gun component (10) and a composite perforator (20), the fracturing gun component (10) comprises a barrel-shaped upper joint (1), a barrel-shaped fracturing gun body (2) and a barrel-shaped middle joint (7) which are fixedly connected from the top down; the fracturing gun body (2) is provided with a fracturing charge pillar (5); and a plurality of pressure-relief holes (22) are formed in the side wall of the fracturing gun body (2). When a hole channel is formed through perforating of perforating bullets in the composite perforator, explosive in two poles are excitated and burned step by step, and then high-temperature and high-pressure gas can be generated in a well casing and then enters the perforation hole channel directly. After repeated acting, pressure action time can be greatly prolonged, so that a relatively thin and unconventional hydrocarbon reservoir can be gas-fractured effectively, then hole and sew combined deep penetration can be formed, and the flow conductivity of the area adjacent to the well casing can be improved.

Owner:PETROCHINA CO LTD

Rolling and forming method for 0Cr25Ni20Mo2 stainless steel thin-wall ring

The invention discloses a rolling and forming method for a 0Cr25Ni20Mo2 stainless steel thin-wall ring, aiming to roll and form the thin-wall ring with high forming size precision and good tissue and performance. The invention has the technical scheme that the method comprises the following steps of: firstly, sheathing a 0Cr25Ni20Mo2 stainless steel pre-rolled blank which is heated to deformation temperature and a preheated follow-up die sleeve into a ring rolling machine, sheathing the follow-up die sleeve into the pre-rolled blank, and positioning the two workpieces by using a home roll, a core roll, a snubber roll and upper and lower cone rolls of the ring rolling machine; then starting the ring rolling machine, and enabling core roll to make the feed movement along the radial direction towards the direction of the home roll and roll the pre-rolled blank together with the home roll by a rolling force of 150KN-2,900KN under the support of the follow-up die sleeve to make the pre-rolled blank broadened along the radial direction at the speed of 7mm / s-13mm / s so that the wall thickness of the pre-rolled blank is gradually reduced; and rolling the pre-rolled blank into the thin-wall ring after the deformation of the pre-rolled blank reaches 40-60 percent. The minimum wall thickness value of the 0Cr25Ni20Mo2 stainless steel thin-wall ring rolled and formed by the method is 25mm, and the maximum value of height-thickness ratio is 25mm. The ring is mainly used for a revolving body part used in oil gas field and the like.

Owner:GUIZHOU AVIATION TECHN DEV

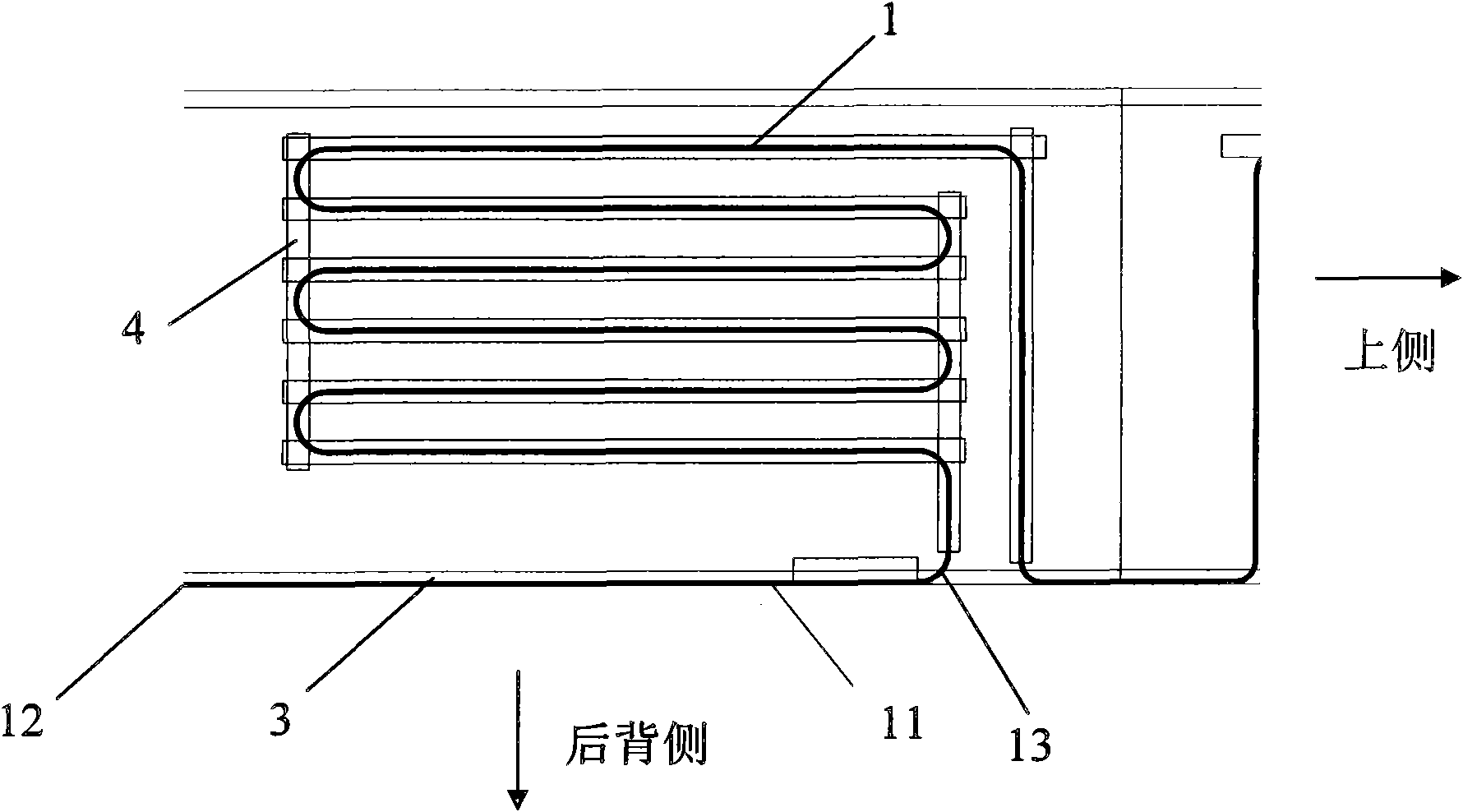

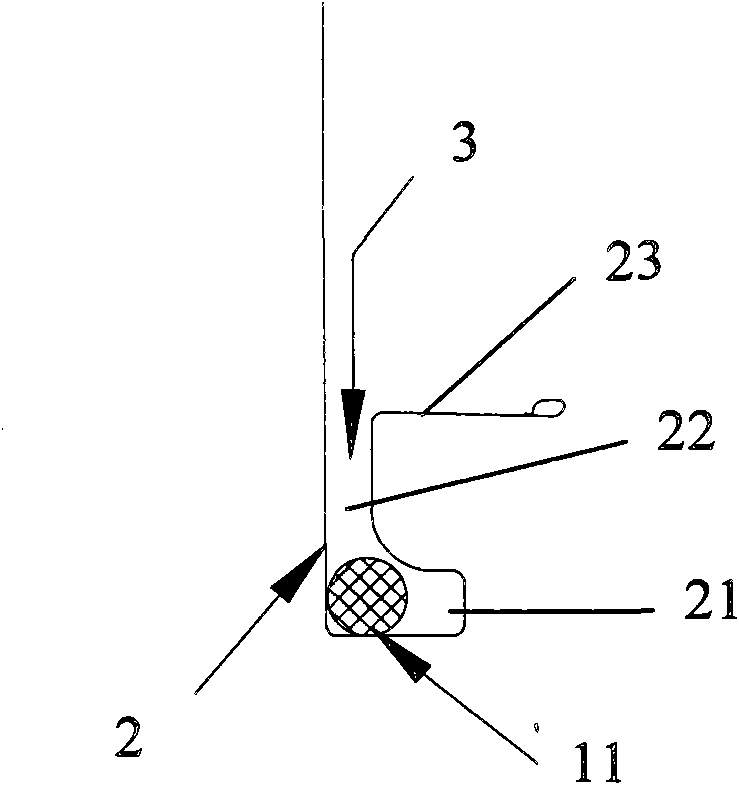

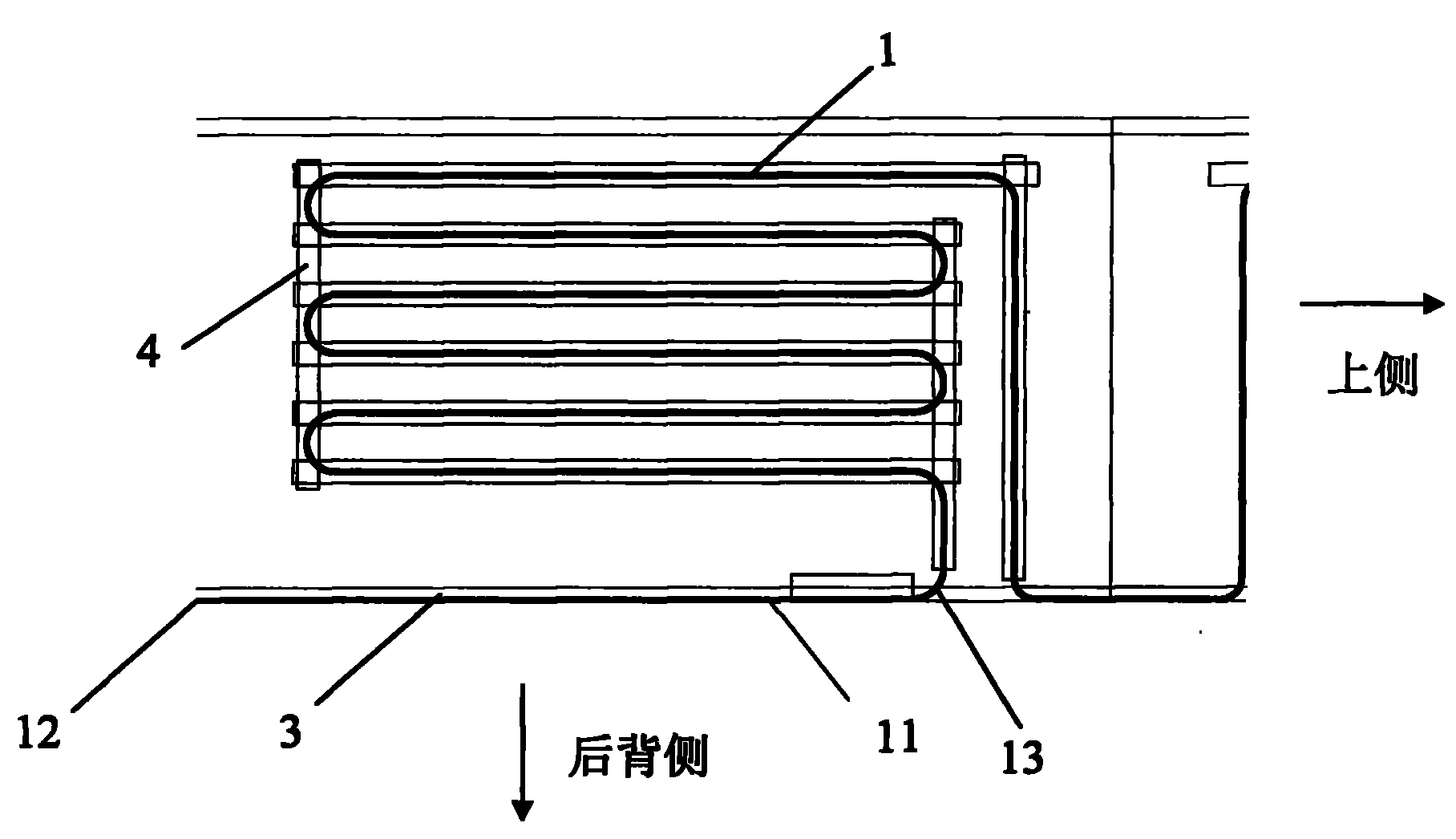

Refrigerator condensator installation structure

InactiveCN102128535AReduce heat dissipationHeat dissipation, so the size of the side plate condenser is reducedEvaporators/condensersRefrigeration devicesEngineeringRefrigerated temperature

The invention provides a refrigerator condensator installation structure, which comprises a refrigerator housing (2) and a condensator (1) tightly attached to the inner side of the refrigerator housing, wherein a back clamping groove (3) is formed at the inner side of the refrigerator housing (2); and a pipeline (11) at the initial segment of the condensator (1) is inserted into the back clamping groove (3). Because the pipeline at the initial segment of the condensator (1) is directly in contact with three surfaces of the refrigerator housing basically, the heat transfer area of the pipeline at the initial segment for transferring heat to outside directly through the refrigerator housing is greatly increased; moreover, because both the pipeline at the initial segment and the refrigerator housing have higher coefficient of heat conductivity, the coefficient of heat conductivity of the pipeline at the initial segment to the outside is higher; and compared with a traditional lateral plate condensator, the heat dissipating capacity of the condensator to the outside is greatly increased.

Owner:HAIER GRP CORP +1

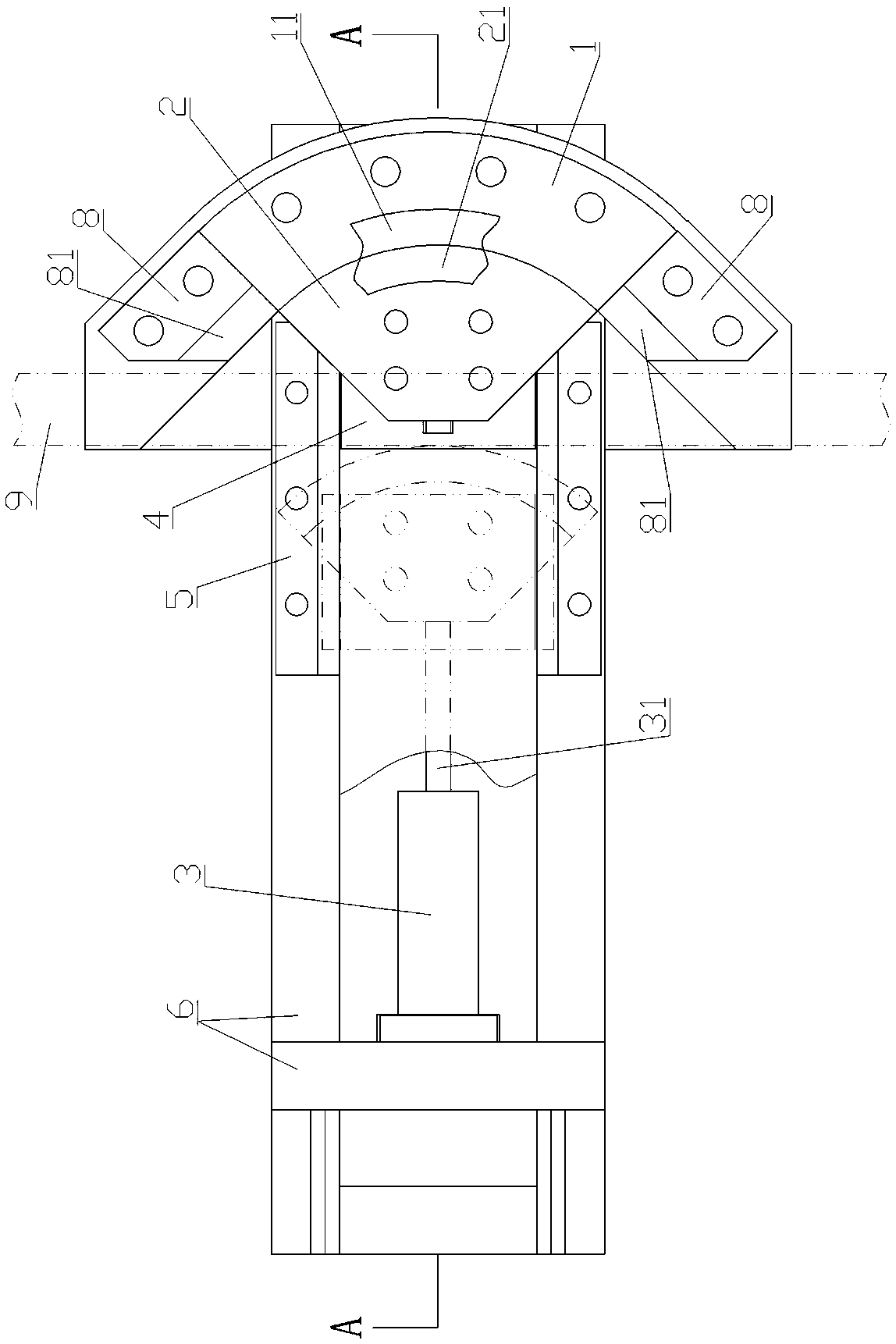

Pipe punching bending device

A pipe punching bending device comprises a circular arc external mold, a circular arc internal mold, a jack, a sliding block, a sliding rail and a support base; the circular arc external mold is in sectorial cylinder shape, and the lower end face of the circular arc external mold is fixedly connected to the support base; the circular arc internal mold is in the sectorial cylinder shape, and the lower end face of the circular arc internal mold is fixedly connected to the sliding block; the jack is fixedly connected to the support base, and a piston rod of the jack extends out horizontally, andis connected to the connection surface of a piston rod in the circular arc external mold; the sliding block is movably installed on the sliding rail; the sliding rail is fixedly installed on the support base; and when the circular arc internal mold moves and comes into contact with the circular arc external mold, an arc-shaped groove A of the circular arc internal mold and an arc-shaped groove B of the circular arc external mold are spliced and combined to form a steel tube setting cavity. The pipe punching bending device provided by the invention has the advantages that the jack is started tomake the circular arc external mold and the circular arc internal mold combined, so that the bending of a straight steel tube can be achieved, and the operation is easy. In the press bending process,the arc-shaped groove A of the circular arc internal mold and the arc-shaped groove B of the circular arc external mold come into full contact with the outer wall of the straight steel tube, and thephenomenon that the bending part is flattened locally due to uneven stress is prevented effectively.

Owner:湖南长宏南雁锅炉修理安装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com