Multipole composite deep penetration perforation device

A composite perforation and perforation technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., to achieve the effect of maintaining pressure difference balance, preventing flattening, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

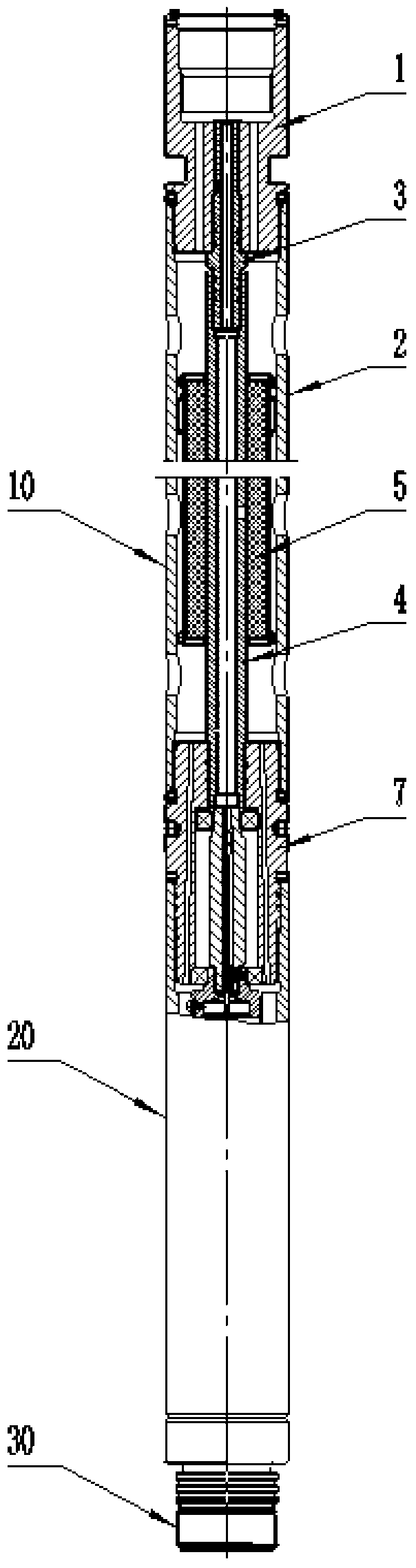

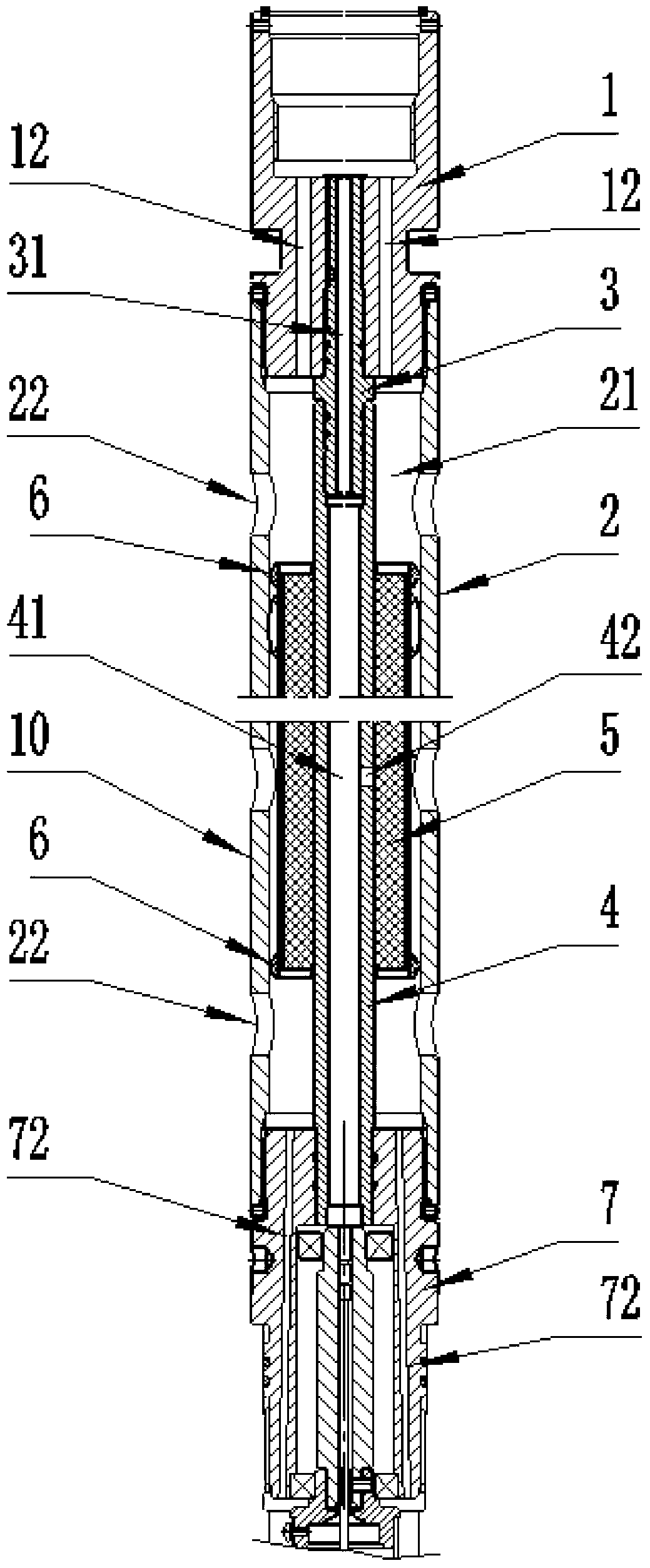

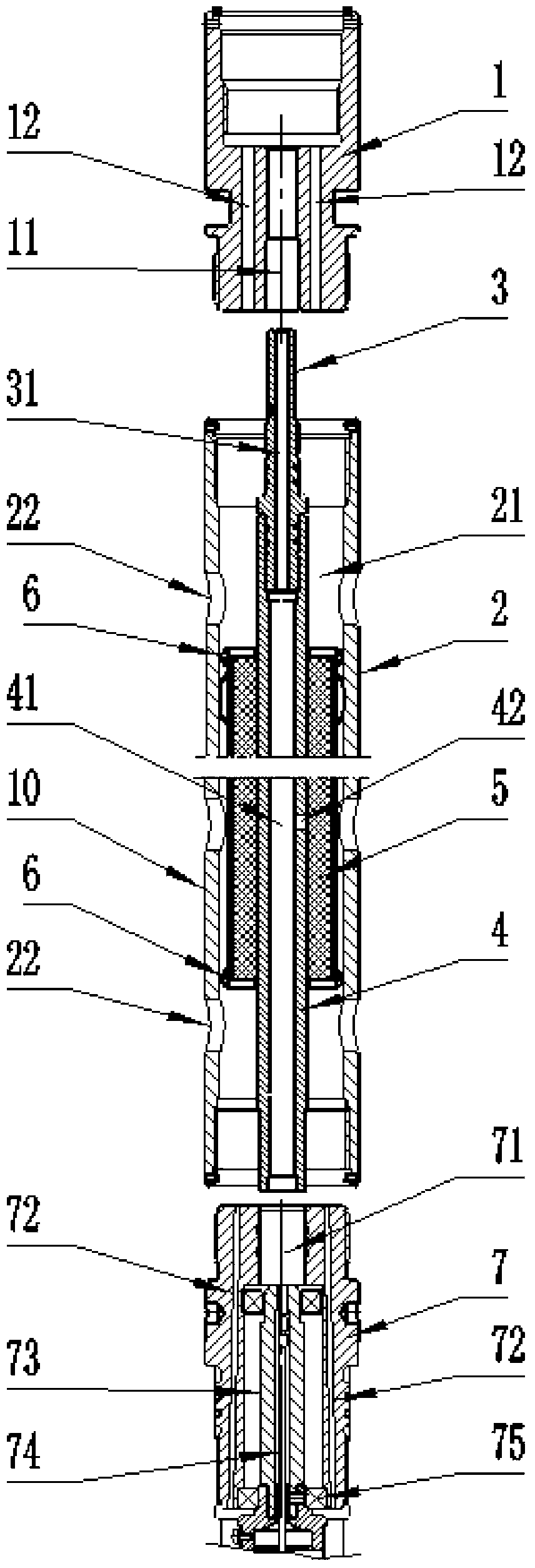

[0023] The multi-stage compound deep penetration perforating device of the present invention will be described in detail below in conjunction with the accompanying drawings. A multi-stage compound deep penetration perforating device includes at least one integral perforating unit, and the upper part of the integral perforating unit It is a fracturing gun assembly 10, and the lower part of the integral perforating unit is a compound perforator 20. The fracturing gun assembly 10 includes a cylindrical upper joint 1 and a cylindrical fracturing gun body fixedly connected sequentially from top to bottom. 2 and a cylindrical intermediate joint 7, the fracturing gun body 2 is sleeved with a central tube 4, and the central tube 4 is provided with a first through hole 41 penetrating in the axial direction, and the upper end of the central tube 4 is fixedly connected with the upper joint 1 And the first through hole 41 communicates with the first detonating cord installation channel 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com