Patents

Literature

97results about How to "Easy to organize production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface chemico-thermal treatment method for mechanical parts and equipment used thereby

ActiveCN102776470AEasy to organize productionPlay equipment efficiencySolid state diffusion coatingFurnace typesCarburizingDiffusion chamber

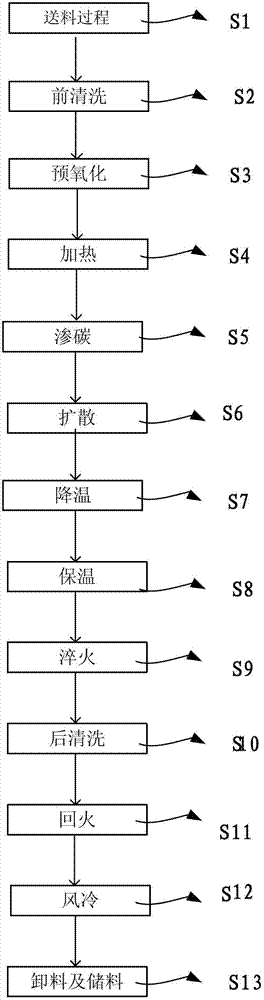

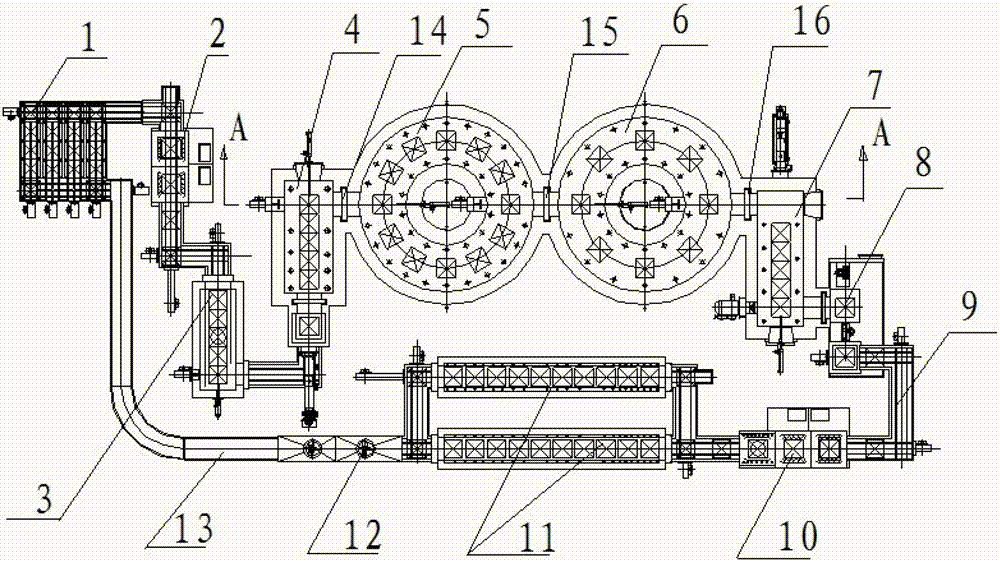

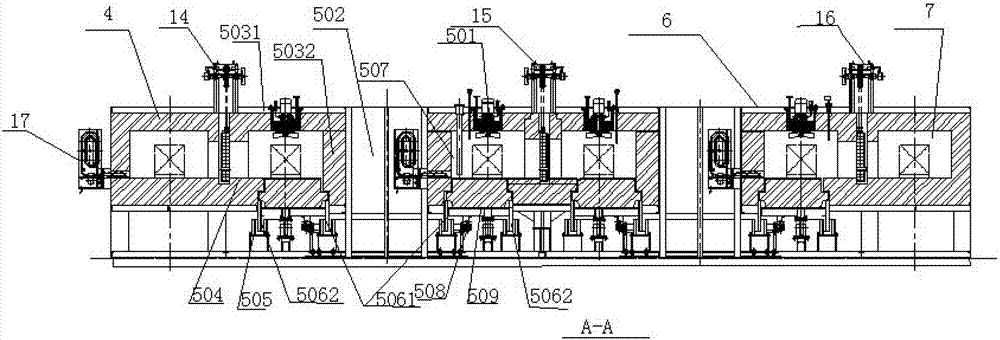

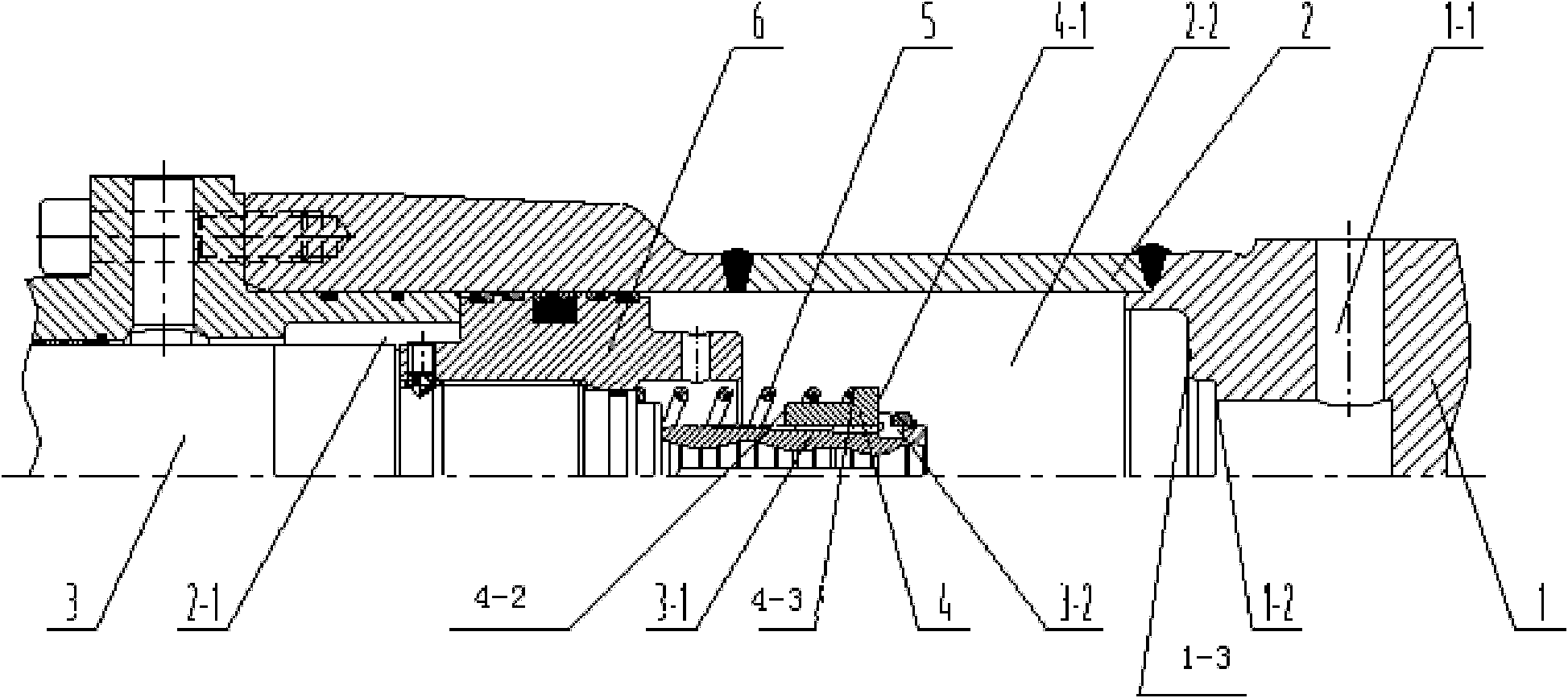

The invention relates to a surface chemico-thermal treatment method for mechanical parts and equipment used by the surface chemico-thermal treatment method. The equipment comprises a material feeding and storing platform, a front washing machine, a pre-oxidizing furnace, a heating furnace, a rotary health carburizing furnace, a rotary bottom type diffusion furnace, a quenching cooling furnace, a quenching heat insulating chamber, a quenching oil tank, a rear washing machine, a low-temperature tempering furnace, an air cooling platform and a discharging platform. The devices are relatively independent, and integrally connected with transmission mechanisms to achieve the production technology of feeding material and preparing material-primarily washing-pre-oxidizing- heating-carburizin-diffusing-cooling-preserving temperature-quenching-finally washing-tempering-cooling with air-discharging and storing material. According to the devices, the forcible carburizing and diffusing in the carburizing technology are decomposed and individually carried out through an individual forcible carburizing chamber and an individual diffusion chamber, and the forcible carburizing and diffusing are combined based on different processing times, so that the requirements on mass production of the same furnaces different in requirements on layer depth and different in materials and parts are achieved; and the efficiency of the equipment is exerted to the maximum.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

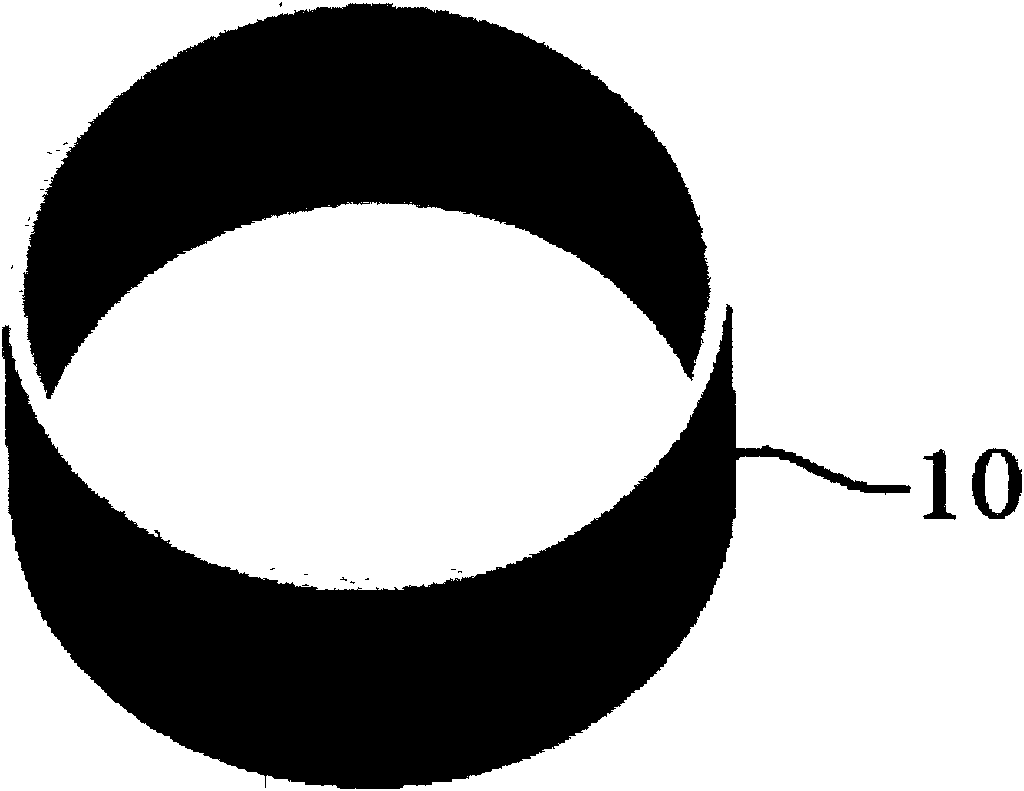

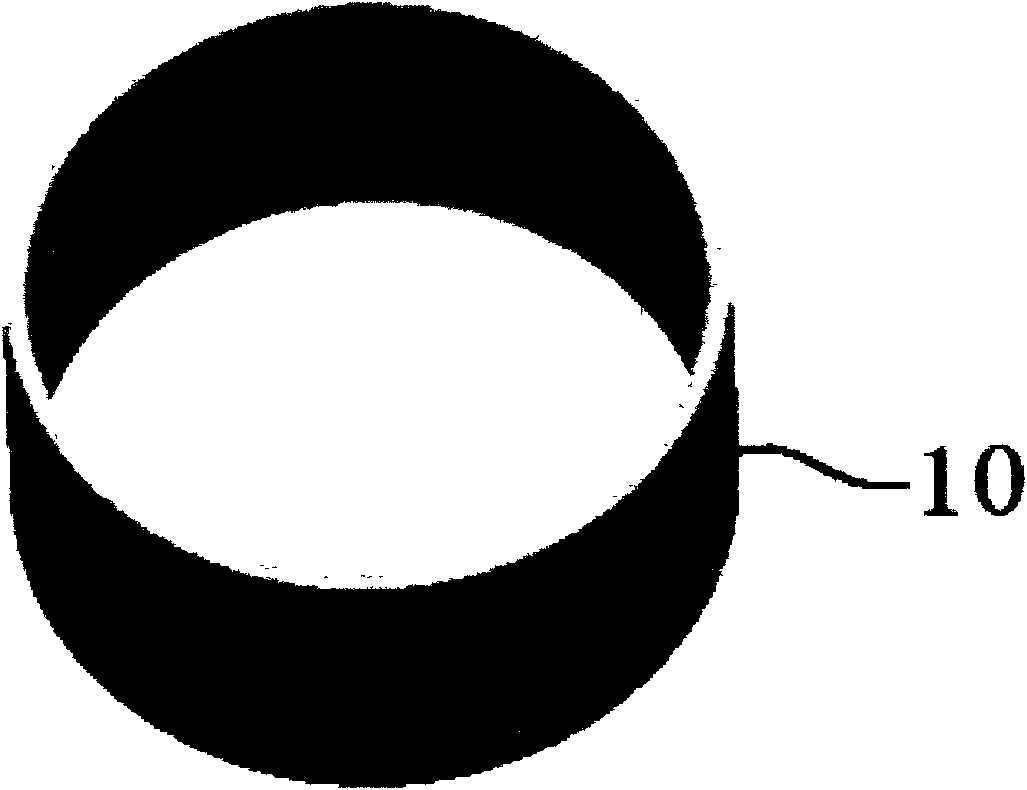

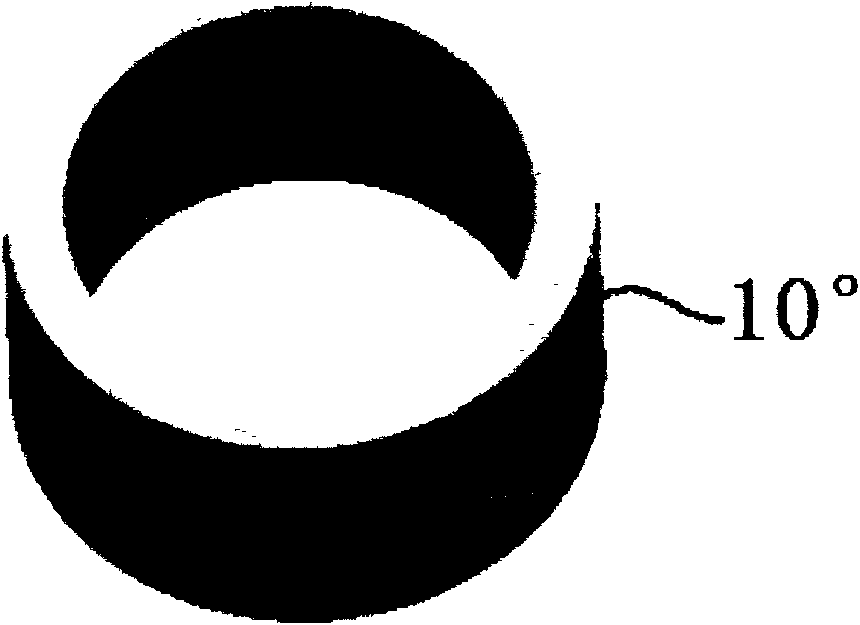

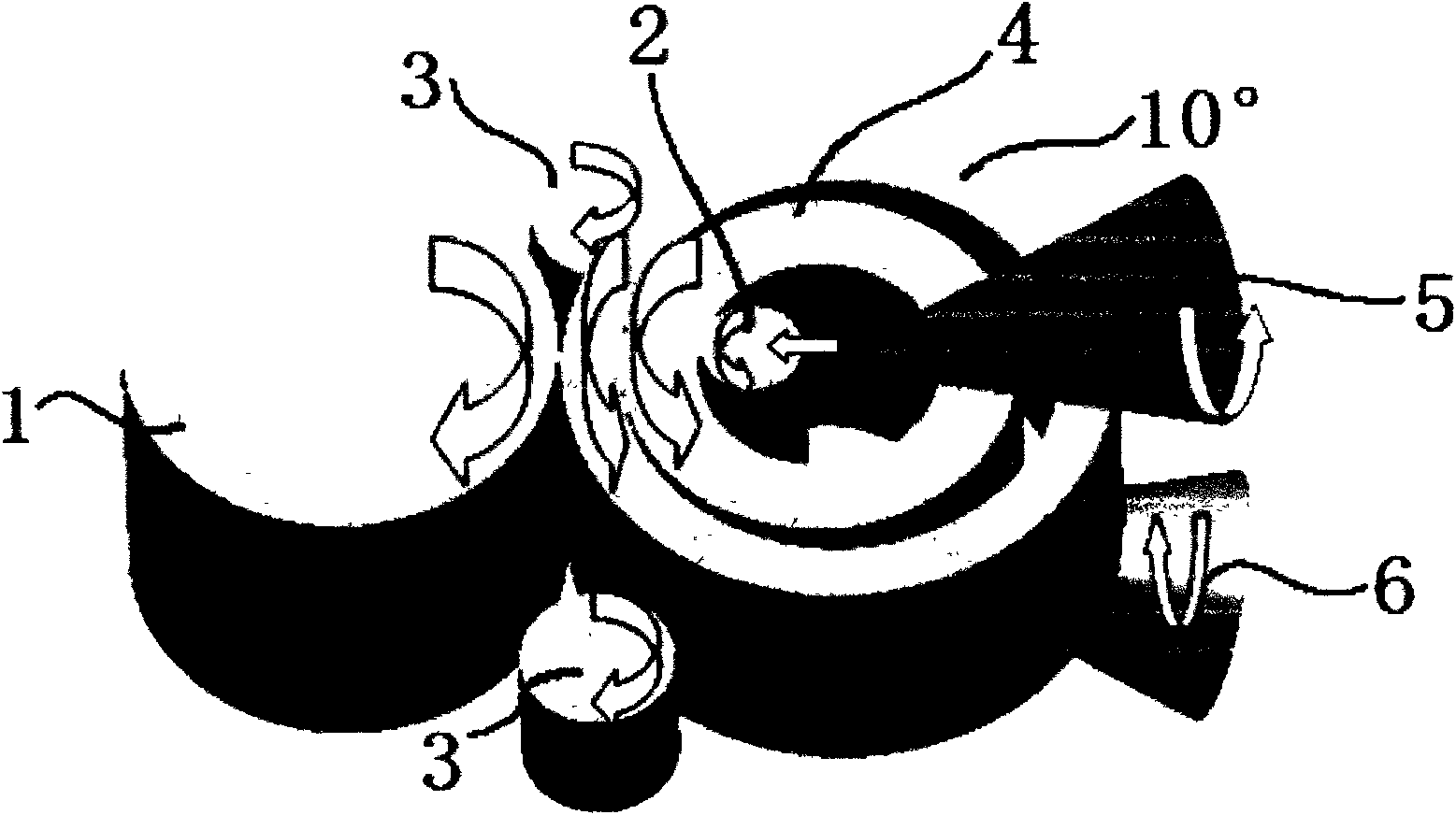

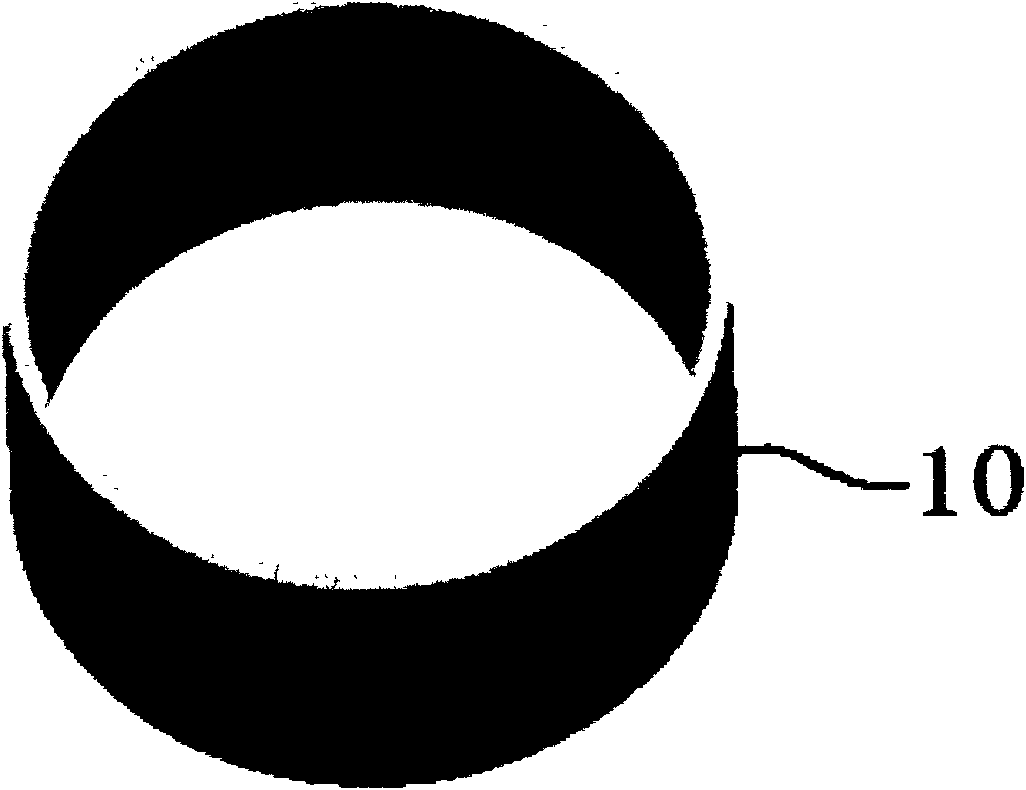

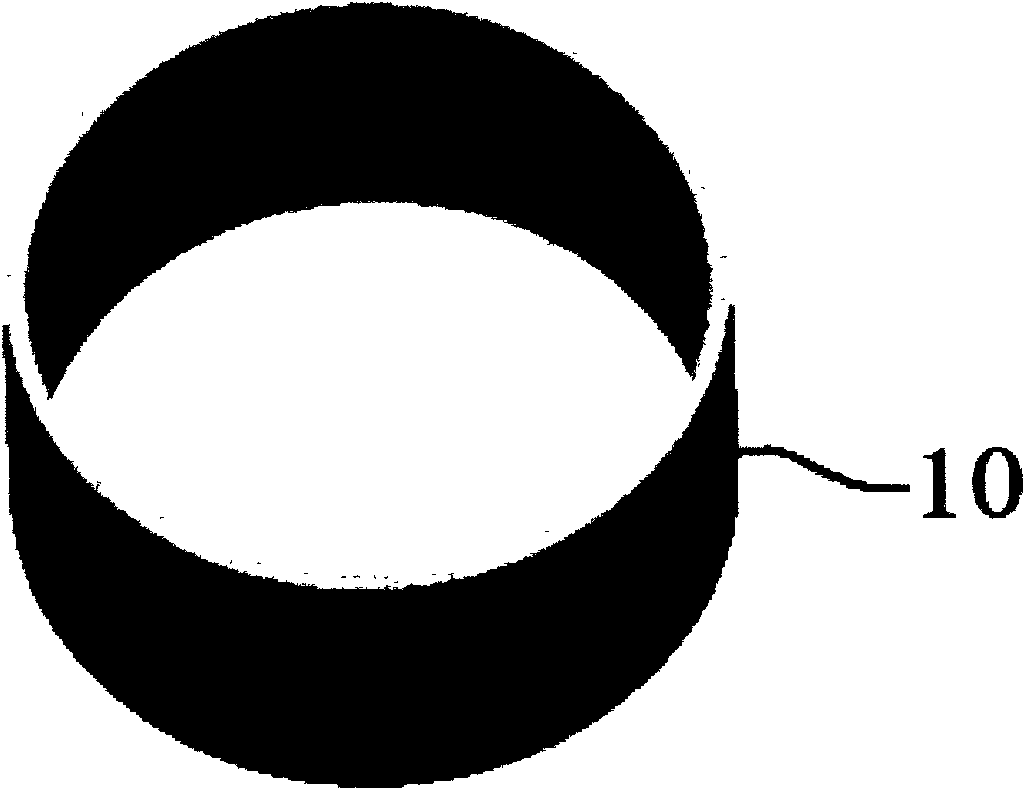

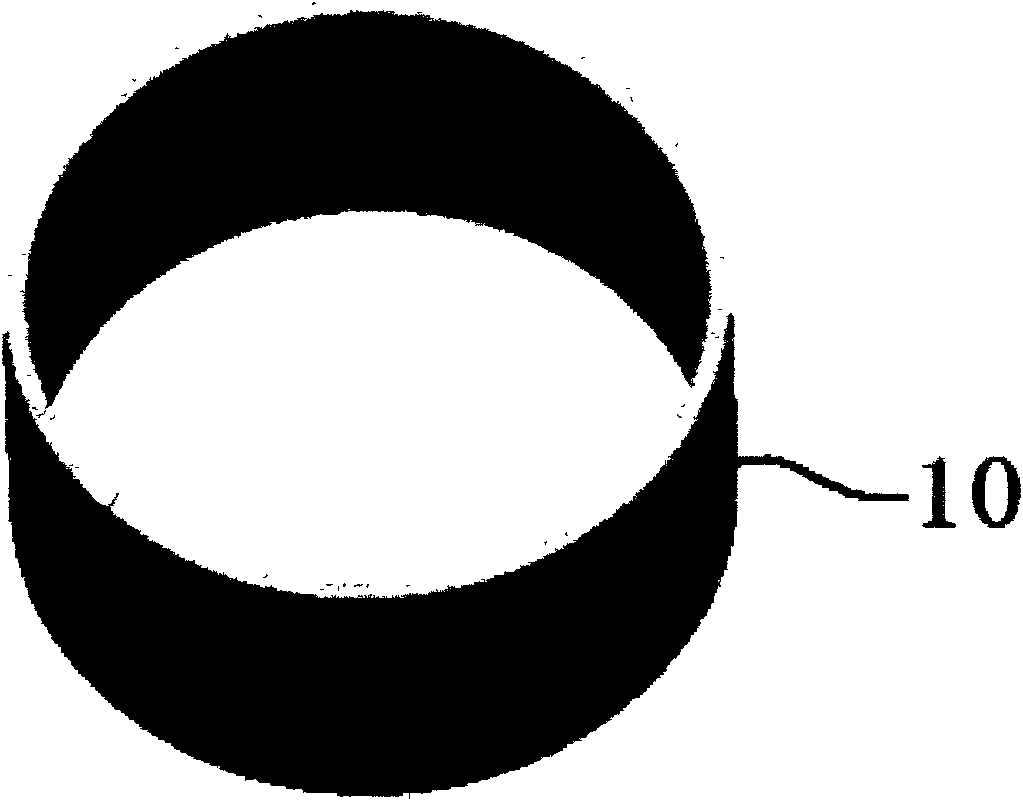

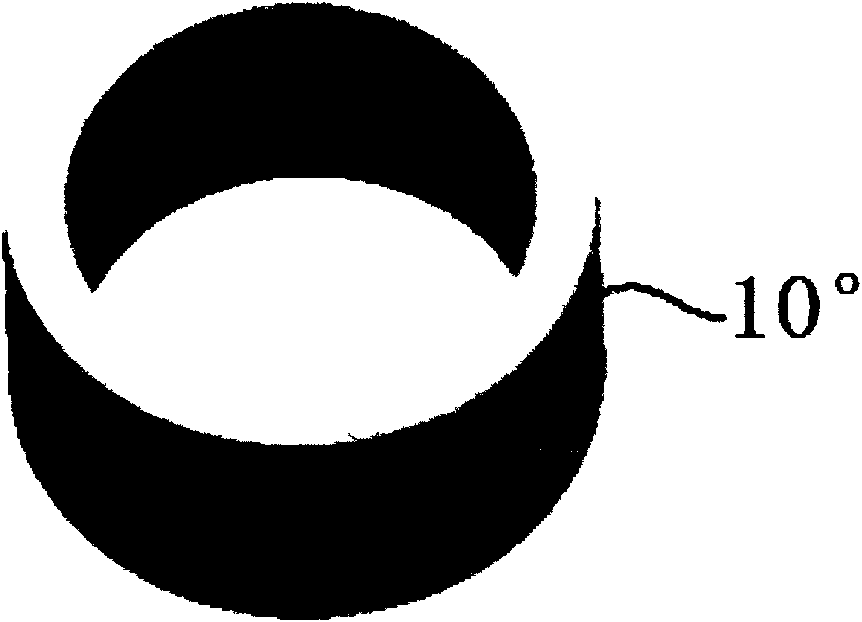

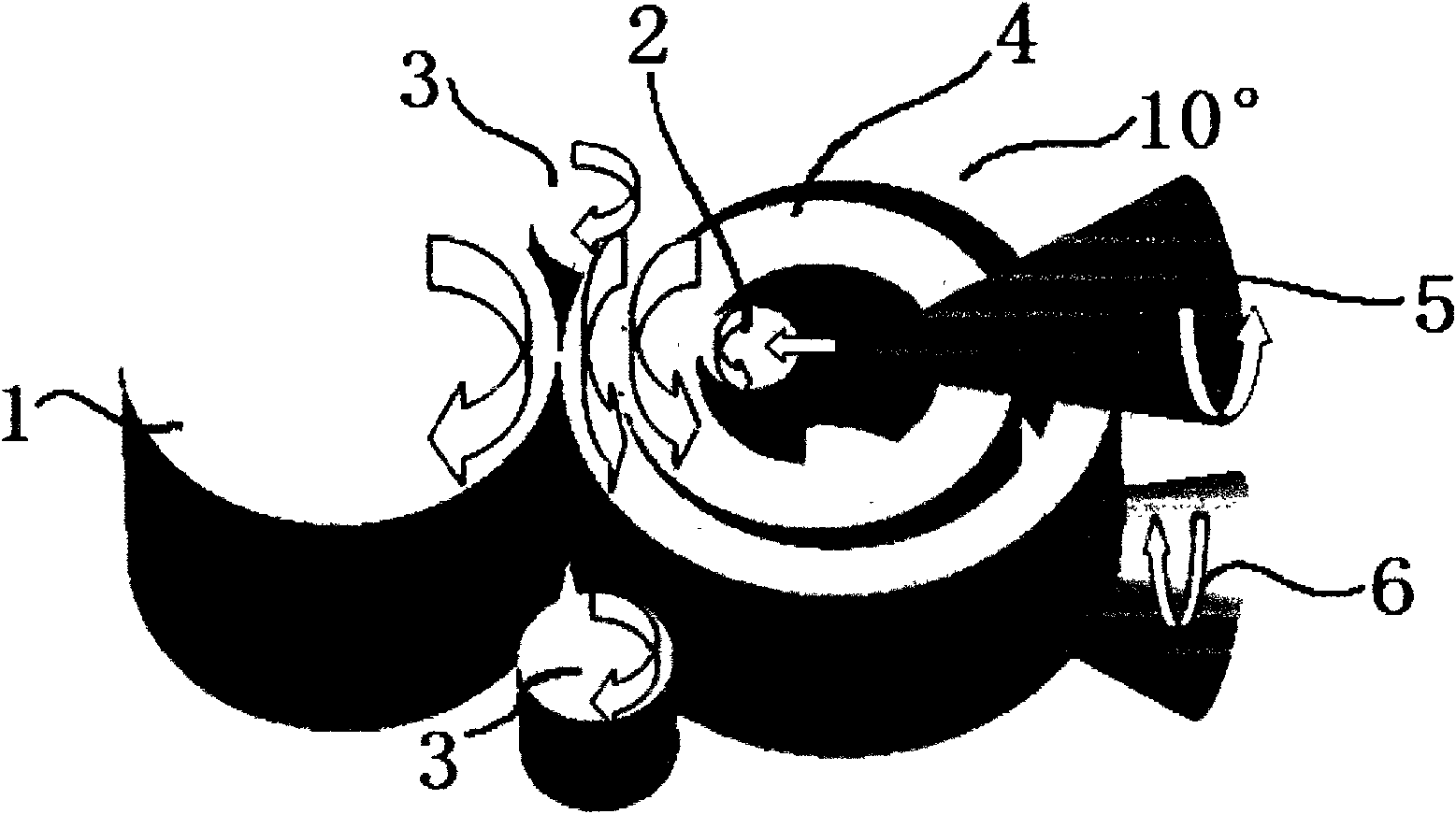

Roll forming method of TC25 titanium alloy thin-walled ring forging

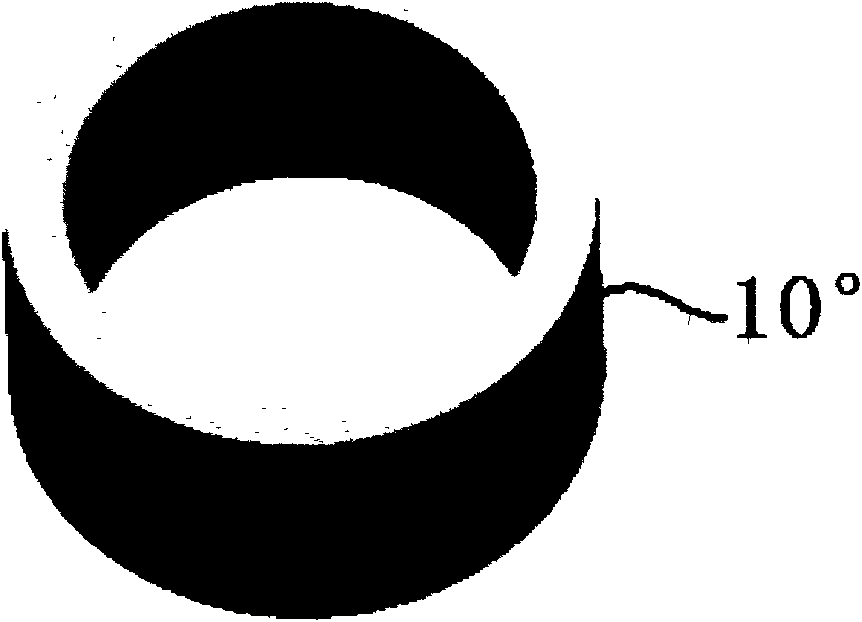

The invention discloses a roll forming method of a TC25 titanium alloy thin-walled ring forging. In order to roll-form a thin-walled ring forging with high dimensional precision and excellent tissue and performance, the technical scheme comprises the steps of: firstly, sleeving a preheated follower die sleeve and a titanium alloy pre-rolled blank heated to a deformation temperature in a ring rolling mill, sleeving the follower die sleeve in the pre-rolled blank, and positioning the two workpieces by using a main roll, a core roll, clutching rolls, an upper cone roll and a lower cone roll of the ring rolling mill; and starting the ring rolling mill, making a feeding motion by the core roll towards the direction of the main roll along the radial direction and rolling the pre-rolled blank at a rolling force of 200-4000KN under the support of the follower die sleeve by the core roll together with the main roll to ensure that the pre-rolled blank expands radially at a speed of 5-10mm / s, wherein the wall thickness is gradually reduced, and the pre-rolled blank is rolled into the thin-walled ring forging when the deformation reaches 25-45 percent. The minimum value of the wall thickness of the titanium alloy thin-walled ring forging roll-formed by adopting the method is 25mm, the maximum value of the height-thickness ratio is 25mm, and the ring forging is mainly used for gyrorotor parts, such as a cylindrical shell and the like used in the fields, such as aerospace and the like.

Owner:GUIZHOU AVIATION TECHN DEV

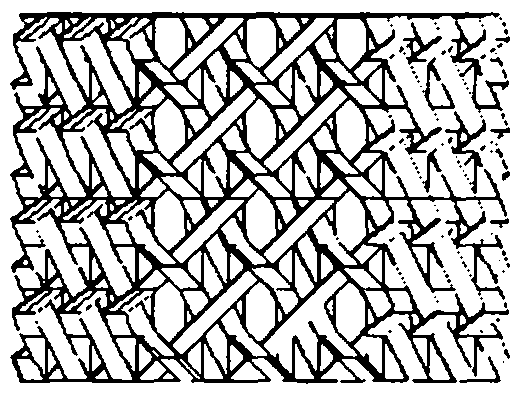

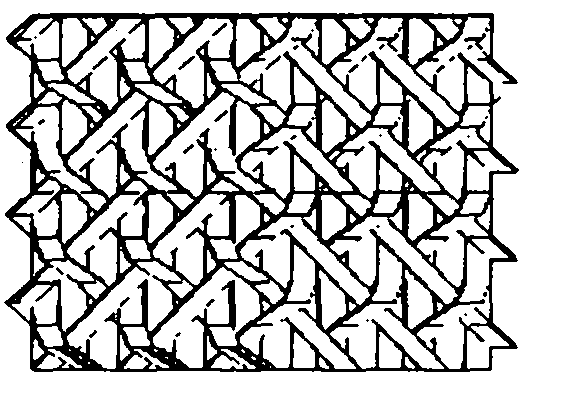

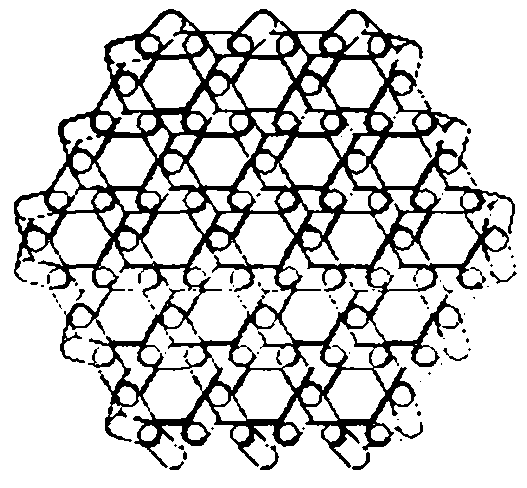

Three-dimensional woven material based on space group P*

The invention relates to a three-dimensional woven material based on symmetry of a space group, the woven geometric structure of the woven material is the structure which extends and is woven in three-dimensional space in the form of continuous yarns, the yarn section in a representative volume unit in the woven geometric structure can meet the symmetry of points described in a space point group,and the woven structure integrally shows three-dimensional woven fabric, which is mutually interwoven in the three-dimensional space and obtained by using translation symmetrical operation described by the space group to carry out translation on the representative volume unit. The new three-dimensional woven geometric structure which meets the symmetry of the space group is deduced via the woven material by taking the representative volume unit capable of meeting the symmetry of the point group as a basic structure unit, and a new three-dimensional woven material type with excellent geometricstructure and performance can be obtained by studying the process feasibility and predicting the fiber content, by volume percentage, of the corresponding three-dimensional woven fabric. An array of the woven material adopts the shape of a regular hexagon, so that the motion trajectory of a yarn carrier is convenient to realize, and the production is easy to organize.

Owner:HENAN UNIV OF SCI & TECH

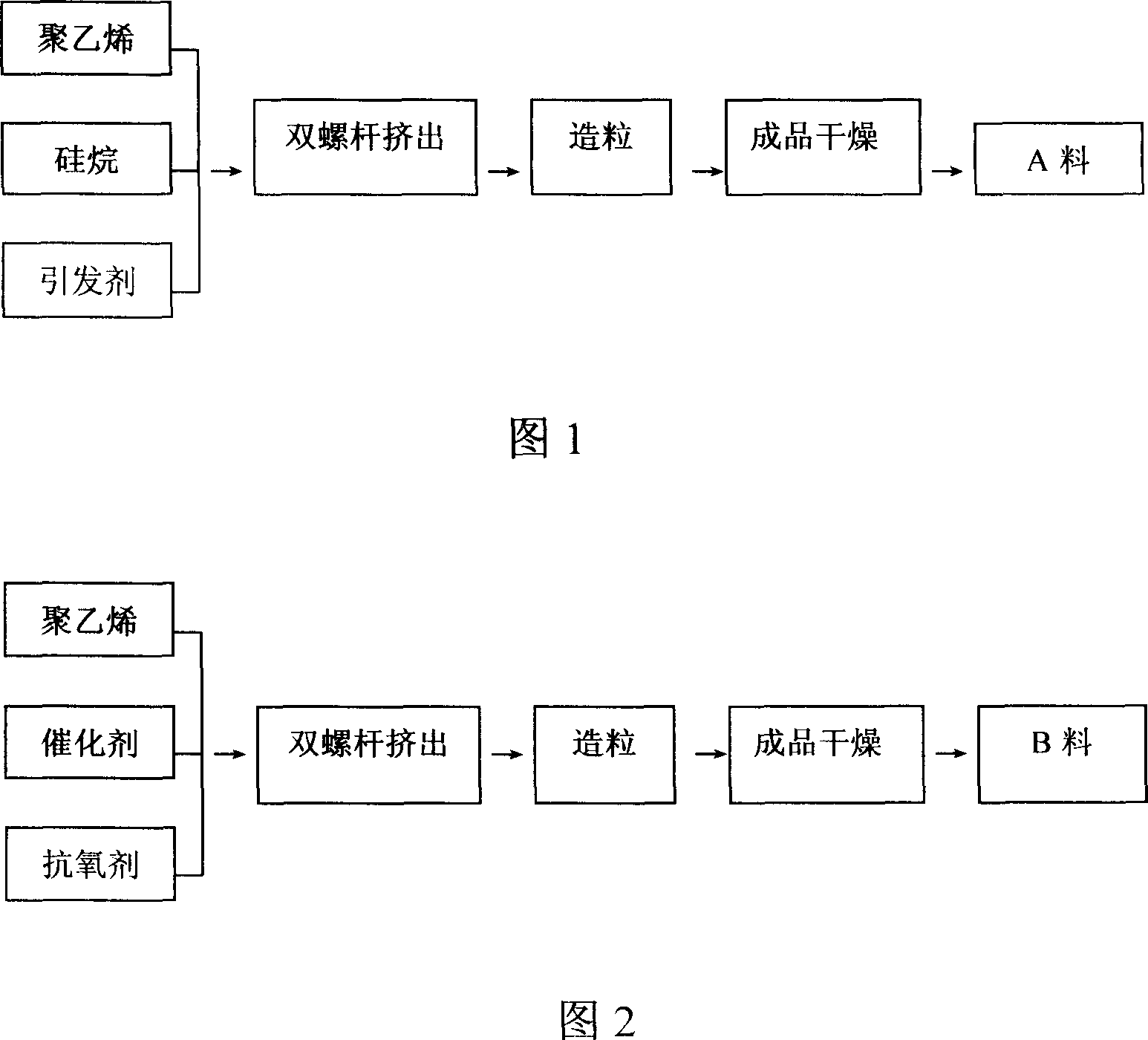

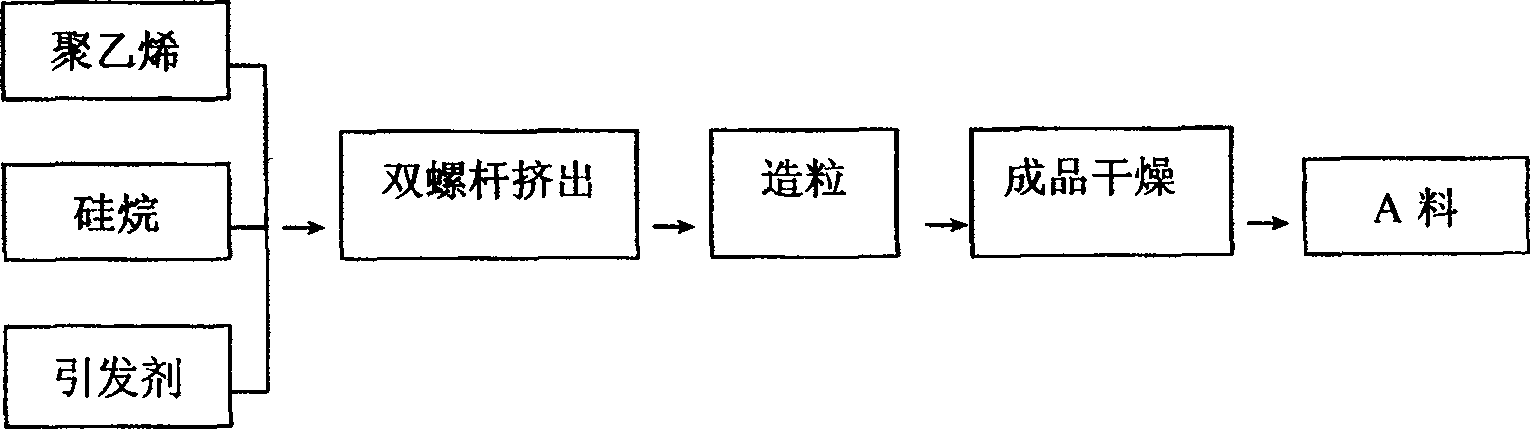

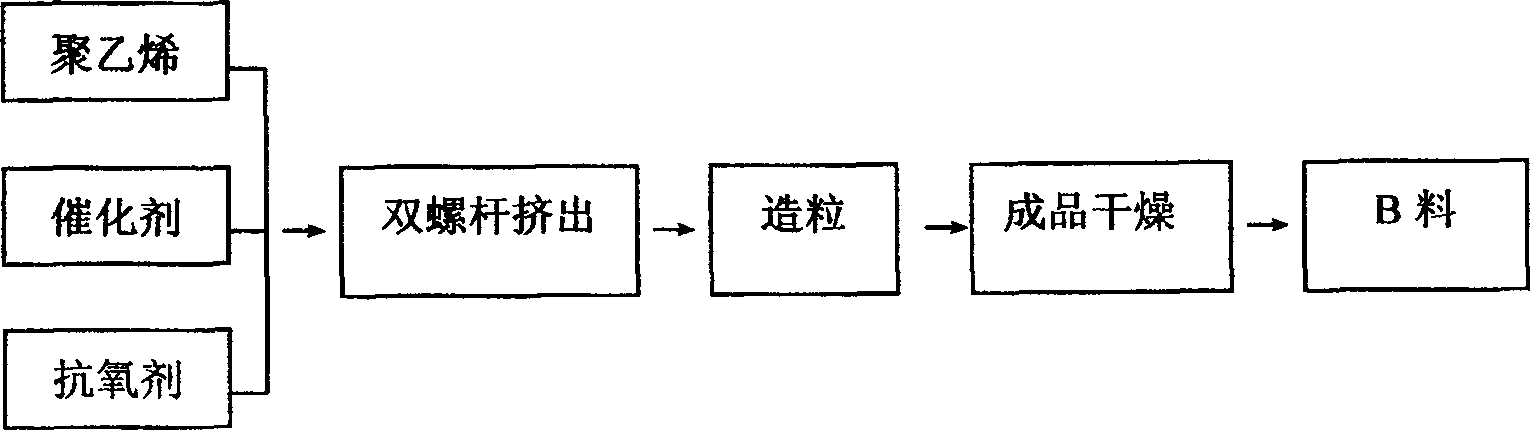

Silane natural-crosslinked polyethylene cable insulating material and its production process

InactiveCN1995120AReduce production processReduce investmentInsulated cablesInsulated conductorsSilanesCross-linked polyethylene

The invention discloses a natural crosslinking polyethylene cable insulating material of silane, which consists of material A and material B with weight rate at 85-955- 15, wherein the material A is composed of 100g polyethylene resin, 0.5-3. 5g silane and 0.02-0.2g initiator; the material B is composed of 100g polyethylene resin, 5-20g anti-oxidant and 0.5-5g catalyst. The invention also provides the manufacturing method of natural crosslinking polyethylene cable insulating material of silane, which adopts natural crosslinking polyethylene cable insulating material of silane without immersing in the heat bath after squeezing to crosslink under natural condition.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

Method for extracting fucoidan for brown seaweed

The invention relates to a fucoidan extract method, in particular to a method for extracting fucoidan for brown seaweed, comprising the following steps: 1. desalting: adopting fresh brown seaweed or unfreezed frozen brown seaweed to soak in pure water to remove salt; 2. enzymolysis: adding enzyme in the desalted brown seaweed to perform enzymolysis at 40-60 DEG C for 1-3h; 3. abstraction: adding calcium chloride in enzymatic hydrolyzate obtained by enzymolysis, and heating the solution to 90-100 DEG C for 1-4h to obtain the fucoidan extract. The invention is characterized of simple operation, high application security, high extraction efficiency, high extraction purity and the like and the extraction process is applicable to factory mass production.

Owner:大连海宝生物技术有限公司

Core-making sand composition of warm core box and sand making method

InactiveCN104439041AWide variety of sourcesLow priceFoundry mouldsMoulding machinesSilicon oxideAtmospheric pressure

The invention discloses a core-making sand composition of a warm core box and a sand making method. The composition comprises an inorganic binding agent, raw sand and non-crystallization type silicon oxide. According to the preparation method, a sand mixing machine is used for mixing, preferably a continuous sand mixing machine is adopted; the raw sand, sodium silicate and the non-crystallization type silicon oxide are automatically controlled by a pc to be fed; after the core-making sand composition is mixed, and is added into a core shooting machine sand bucket; a core-making mold is heated to 145-155 DEG C in advance to prepare the core-making sand composition; the core-making sand composition is shot into a mold cavity by a core shooting machine under the air pressure of 0.4Mpa-0.7Mpa; hot air of 120-160 DEG C is blown into a core-making cavity for 20-200 seconds; a thin core is blown for 20-40 seconds and the air blowing time is properly prolonged by a thick core; after the sand core is hardened, the box is opened and the sand core is ejected out; and the sand core can be poured on the day by assembling the box, and also can be poured by assembling the box after being stored for 3-5 days. The composition has a wide source, a high mechanical property and cheap price; and popularization and application are facilitated, the composition has no toxin and odor, and the environment protection is facilitated.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Roll forming method of 2A70 aluminum alloy thin-walled ring forging

The invention discloses a roll forming method of a 2A70 aluminum alloy thin-walled ring forging. In order to roll-form a thin-walled ring forging with high dimensional precision and excellent tissue and performance, the technical scheme comprises the steps of: firstly, sleeving a preheated follower die sleeve and an aluminum alloy pre-rolled blank heated to a deformation temperature in a ring rolling mill, sleeving the follower die sleeve in the pre-rolled blank, and positioning the two workpieces by using a main roll, a core roll, clutching rolls, an upper cone roll and a lower cone roll of the ring rolling mill; and starting the ring rolling mill, making a feeding motion by the core roll towards the direction of the main roll along the radial direction and rolling the pre-rolled blank at a rolling force of 100-2500KN under the support of the follower die sleeve by the core roll together with the main roll to ensure that the pre-rolled blank expands radially at a speed of 4-11mm / s, wherein the wall thickness is gradually reduced, and the pre-rolled blank is rolled into the thin-walled ring forging when the deformation reaches 35-55 percent. The minimum value of the wall thickness of the aluminum alloy thin-walled ring forging roll-formed by adopting the method is 25mm, the maximum value of the height-thickness ratio is 25mm, and the ring forging is mainly used for gyrorotor parts, such as a cylindrical shell and the like used in the fields, such as aerospace and the like.

Owner:GUIZHOU AVIATION TECHN DEV

Ultra-thick steel plate with high strength and high low-temperature toughness and production method thereof

InactiveCN102127707AReasonable designIncrease productivityTemperature control deviceMetal rolling arrangementsChemical compositionUltimate tensile strength

The invention relates to a method for producing an ultra-thick steel plate with high strength and high low-temperature toughness by adopting a controlled rolling process, in particular to a process for producing a hot rolling steel plate with high strength and high low-temperature toughness in the specification of 40-100mm by utilizing a continuous casting blank with the thickness of 250-300mm. The steel comprises the following chemical components in percentage by weight: 0.10-0.20% of C, 0.15-0.40% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of S, less than or equal to 0.015% of P, 0.010-0.050% of Nb, 0.25-0.50% of Ni, 0.01-0.02% of Ti and the balance of Fe and trace impurities. The product in the invention is reasonable in chemical composition design, the production process is simple, and the ultra-thick (maximum thickness can reach 100mm) high-quality hot rolled steel plate with high strength (tensile strength is more than 490MPa) and high low-temperature toughness (impact power at the temperature of minus 40 DEG C is more than 100J) can be produced by adopting a reasonable controlled rolling process.

Owner:SHANDONG IRON & STEEL CO LTD

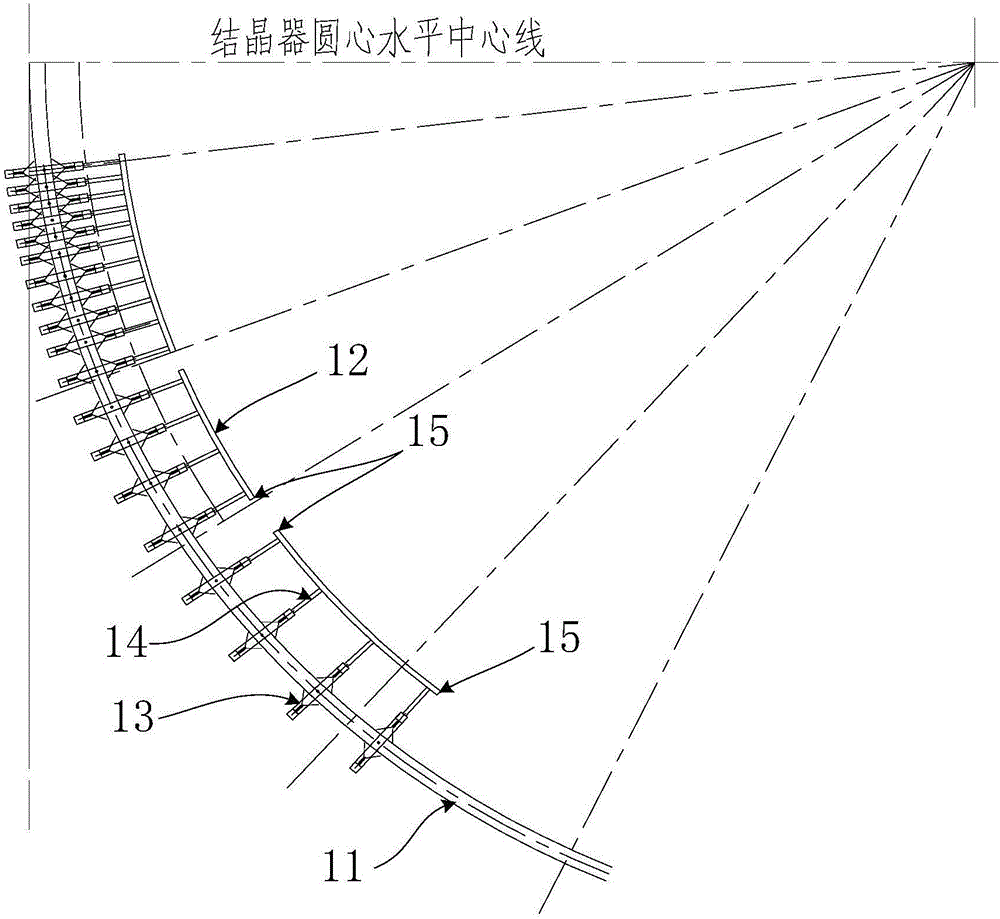

Wire rod continuous casting billet heating-free direct rolling system and method

ActiveCN106180191AReduce temperature lossReduce temperature dropMetal rolling arrangementsWire rodRolling mill

The invention provides a wire rod continuous casting billet heating-free direct rolling system and method. The wire rod continuous casting billet heating-free direct rolling system comprises a continuous casting machine, a rapid hydraulic shear, a cut roller bed, a casting billet stream gathering roller bed, a transportation hot delivery roller bed and a wire rod rolling mill which are closely arranged in sequence. The casting billet stream gathering roller bed gathers casting billets on each stream onto the transportation hot delivery roller bed. A gate mechanism used for blocking the casting billets from entering and releasing the casting billets is arranged between the cut roller bed and the casting billet stream gathering roller bed. According to the wire rod continuous casting billet heating-free direct rolling system and method, efficient continuous casting of the continuous casting machine is conducted, and the casting billets are high in pull-out temperature, regular in shape, low in temperature loss, rapid in shearing and high in initial temperature; by means of the gate mechanism, the sheared casting billets sequentially enter the high-speed casting billet stream gathering roller bed in order, operation is easy and convenient, and production is easy to organize; and when the casting billets reach an inlet of the rolling mill, the temperature of the casting billets is high, and the casting billets can be directly rolled in a heating-free mode, so that the damage to the rolling mill is small.

Owner:CISDI ENG CO LTD

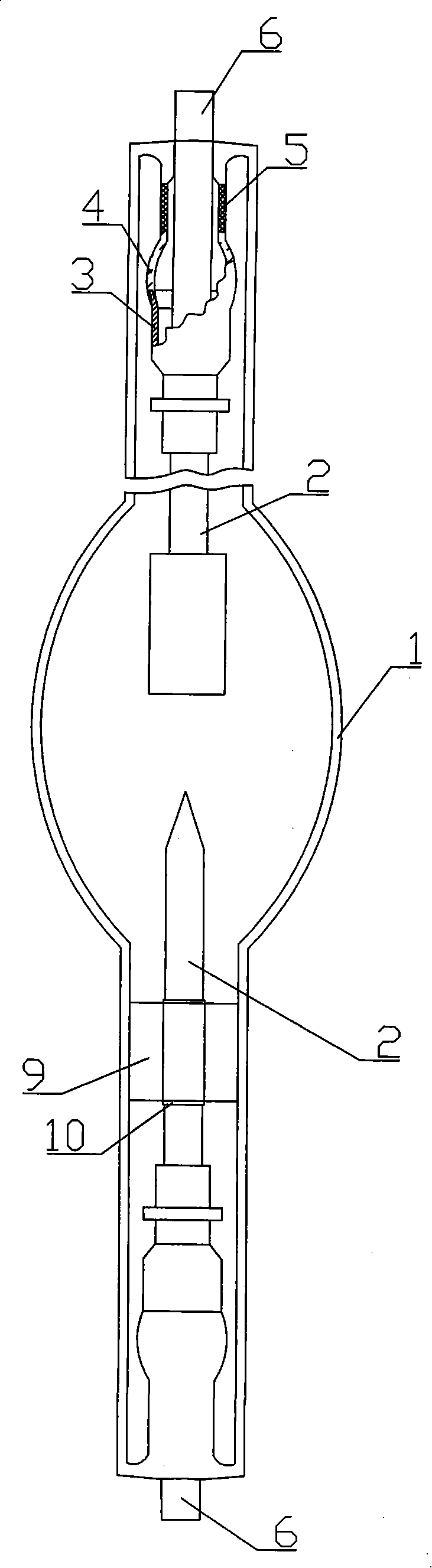

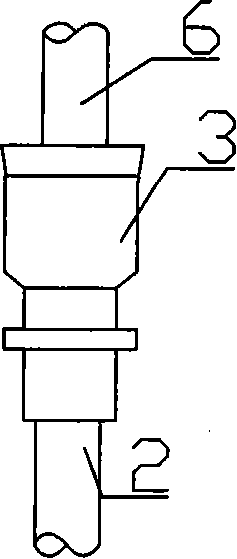

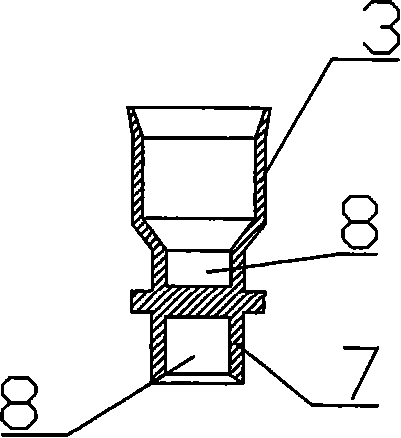

Transition sealing-in type xenon lamp

ActiveCN101246800AStable structureReduce production efficiencyGas discharge lamp detailsEngineeringKovar

The invention relates to the field of high-powder xenon lamp technology, particularly to an intermediate sealing xenon lamp, comprising a quartz glass casing and an electrode in the quartz glass casing, the electrode is provided with a Kovar ring connected with the quartz glass casing by Kovar glass and intermediate sealing connector, the Kovar ring and the Kovar glass are matchedly sealed and have same swell factor, therefore gas leakage phenomena hardly occurs. Compared with the old structure in which bubble, molybdenum foil and quartz glass casing are unmatchedly sealed, the air outlet of the xenon lamp can be arranged on a tail tube, so that the casing of the xenon lamp is kept smooth. The smooth spherical casing is uneasy to generate stress when the xenon lamp glows, thus to avoid lamp explosion.

Owner:CHANGZHOU YUYU ELECTRIC LIGHT APPLIANCE

6063 aluminium alloy made by fine grained aluminium ingot and preparation method thereof

This invention provides a 6063 aluminum alloy made by cryptomere aluminium ingot. It is constituted by Al, Si, Mg, RE, B elements, quality portion is that Si 0.20~0.6%, Mg 0.45~0.9%, REíœ0.35%, Bíœ0.01%. It also provides a method of preparing the 6063 aluminum alloy, aluminum oxide and titanium oxide compound is added into aluminum electrolyte tank, cryptomere aluminium ingot with titanium quality portion is 0.01~0.20% is generated, alloy element is added to cryptomere aluminium ingot directly from electrolyte tank or by cryptomere aluminium ingot melting to melted 6063 aluminum alloy. Because of its special titanium adding mode, production cost is cheap, as-cast grain is little and uniform, its tensile strength is equal to 6063 aluminum alloy thinned by aluminium titanium boron hardner, and extensibility is increased 20% and better surface capability can get. 6063 aluminum alloy after pressure has good ageing characteristic, it can reach high intension in short time and keep high intension long time, it is hard overaging.

Owner:ZHENGZHOU UNIV

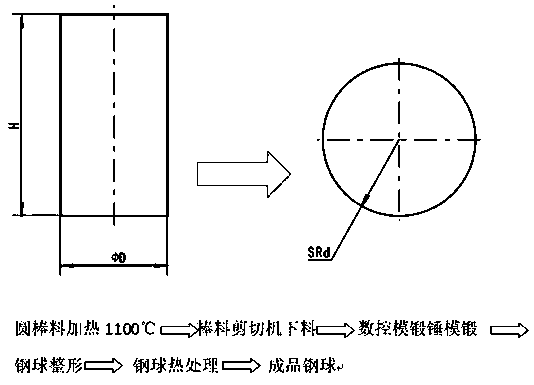

Manufacturing device and production process of forged steel balls

PendingCN108188316AWide range of sizesExtended service lifePower hammersForging/hammering/pressing machinesNumerical controlEngineering

The invention provides a manufacturing device and production process of forged steel balls. A numerical control die forging hammer is mainly used; the numerical control die forging hammer comprises ahammer head, a machine body, a sliding block, an upper anvil block, a lower anvil block, a refrigerating machine and a steel ball die; the steel ball die comprises an upper clamping tire, a lower clamping tire, an upper die core, a lower die core, an ejector rod and a discharging rod; the steel ball die is a closed type die forging steel ball die. A production line mainly comprises a heating furnace, a bar shearing machine, a transferring device, the numerical control die forging hammer, a rounding machine and an isothermal quenching machine. The forged steel balls produced by the numerical control die forging hammer and the equipment of the production line device have the advantages of being good in steel ball roundness, high in steel ball quality, high in production efficiency and the like.

Owner:安阳锻压数控设备有限公司

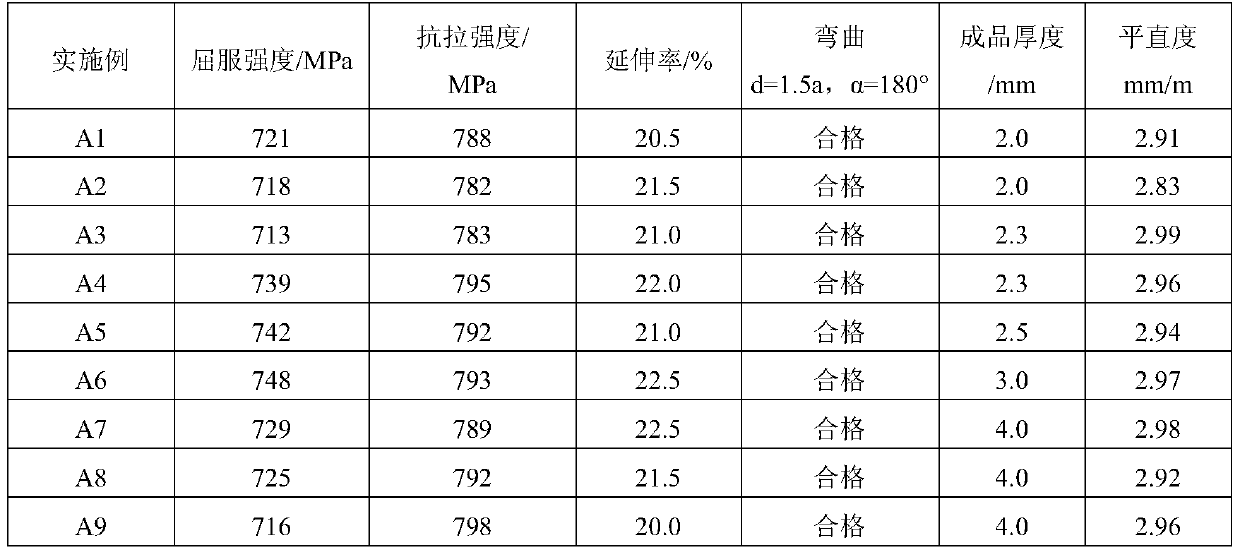

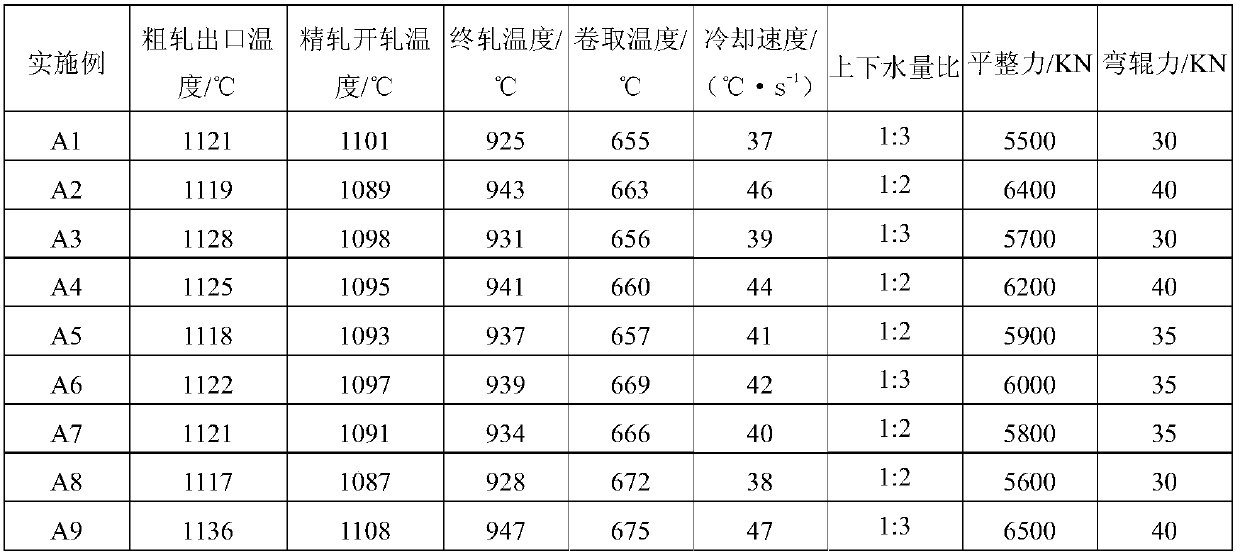

Wide weather-resistant steel for 700 MPa-level hot-rolled container and manufacturing method thereof

ActiveCN111424211AImprove corrosion resistanceAccelerated corrosionMetal rolling arrangementsProfile control deviceBending forceWeathering steel

The invention discloses wide weather-resistant steel for a 700 MPa-level hot-rolled container and a manufacturing method thereof. The steel contains C: 0.058%-0.078%, Si: 0.65%-0.75%, Mn: 0.65%-0.85%,P: 0.035%-0.045%, S: less than or equal to 0.006%, Al: less than or equal to 0.040%, Cr: 0.22%-0.31%, Cu: 0.11%-0.19%, Ti: 0.060%-0.075%, RE: 0.021%-0.035%, N: less than or equal to 0.005%, and the balance Fe and inevitable impurities. The outlet temperature of a billet soaking section is 1283-1300 DEG C, the holding time is 27-41 min, and the total in-furnace time is less than or equal to 178 min. Rough rolling outlet temperature is greater than or equal to 1100 DEG C, finish rolling start temperature is 1087-1108 DEG C, finish rolling finish temperature is 925-947 DEG C, a billet is cooledto 655-675 DEG C for taking up at a cooling rate of 37-47 DEG C / s, flattening force is 5500-6500 KN, and bending force is 30-40 KN. The flatness of a finished steel sheet after flattening is less thanor equal to 3 mm / m.

Owner:ANGANG STEEL CO LTD

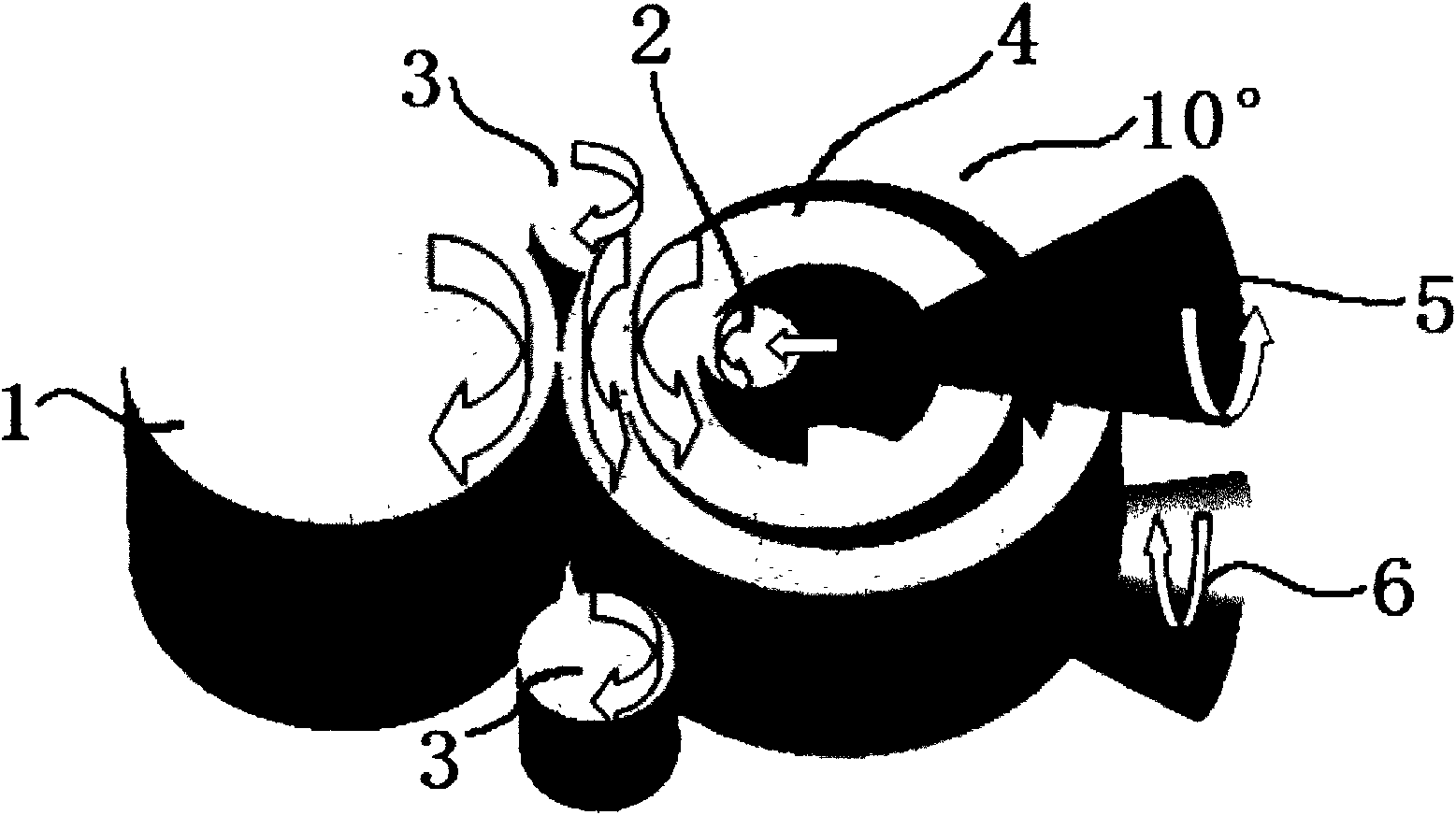

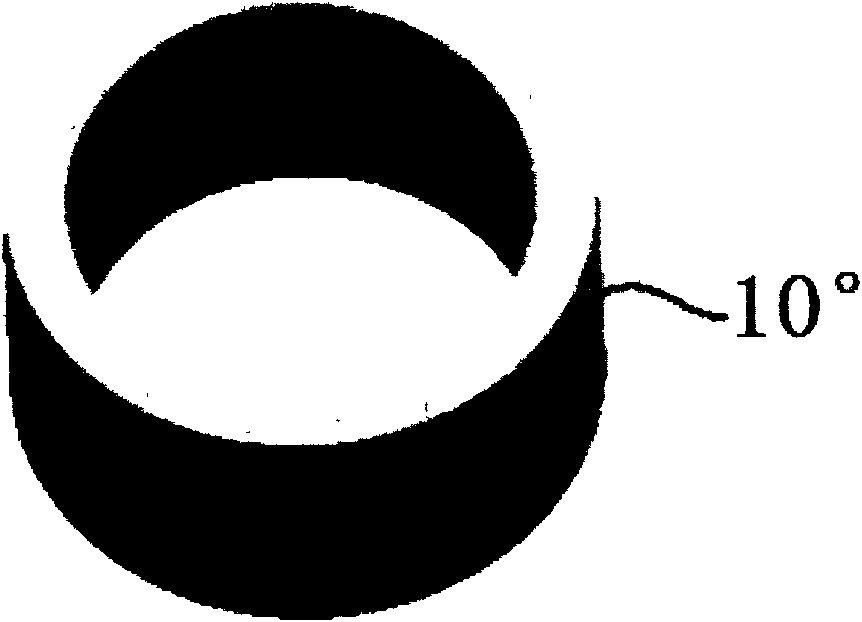

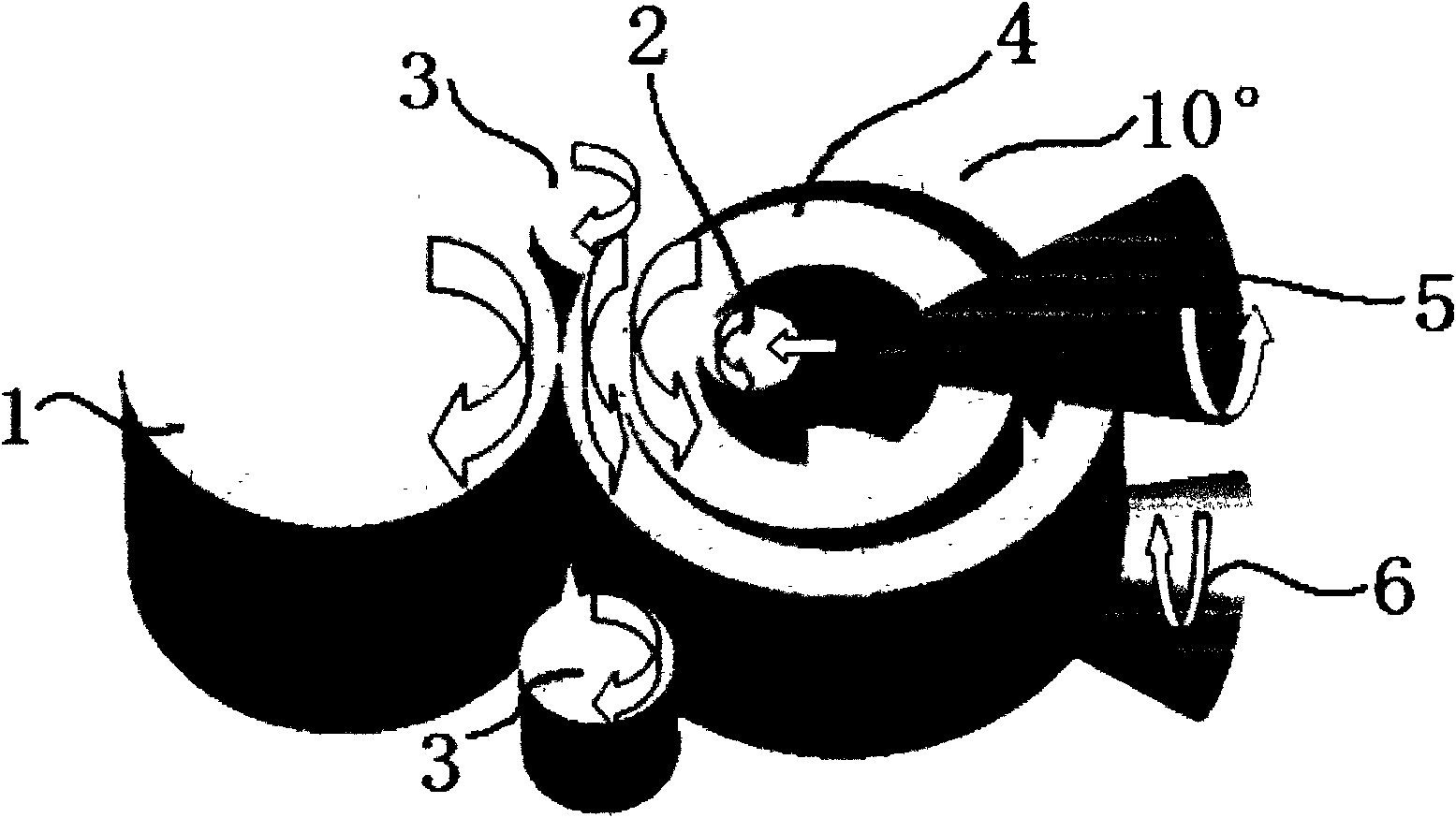

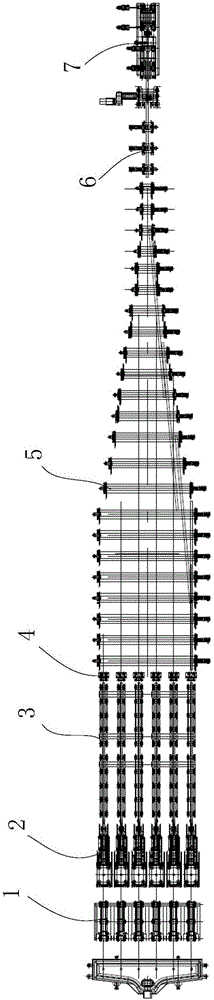

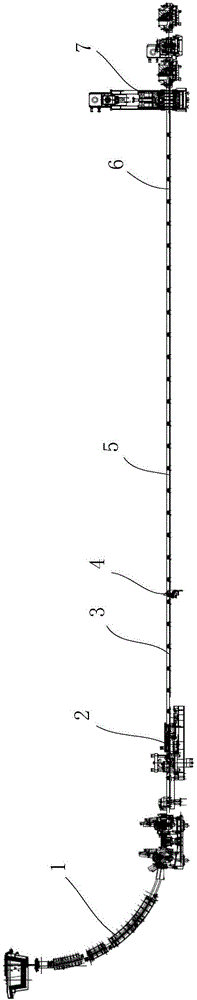

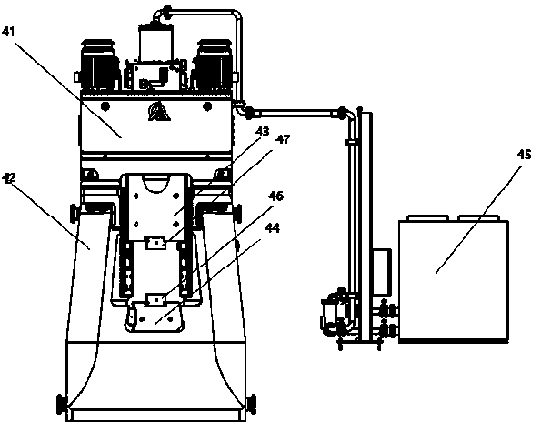

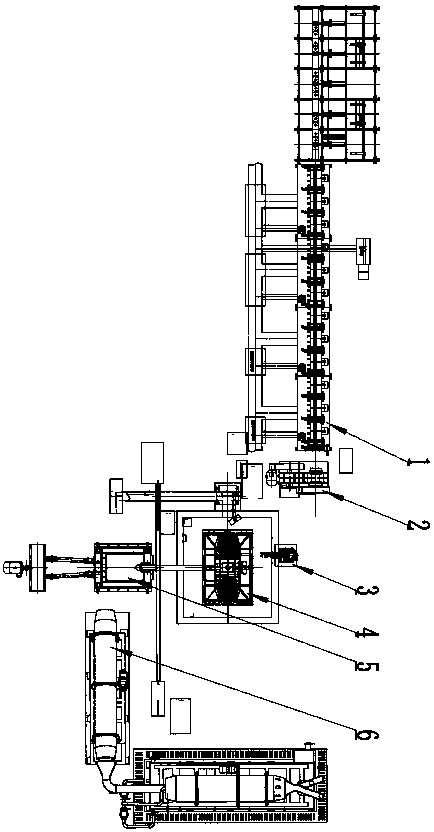

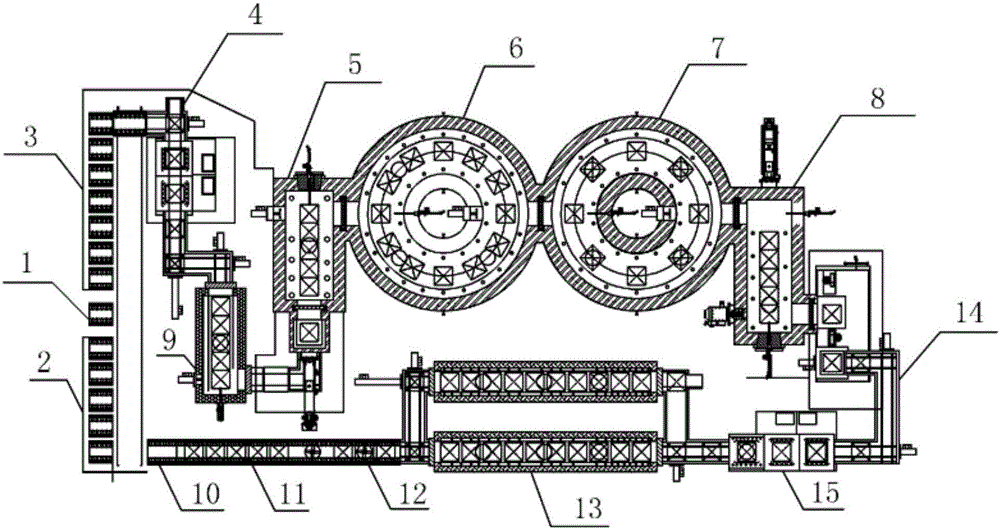

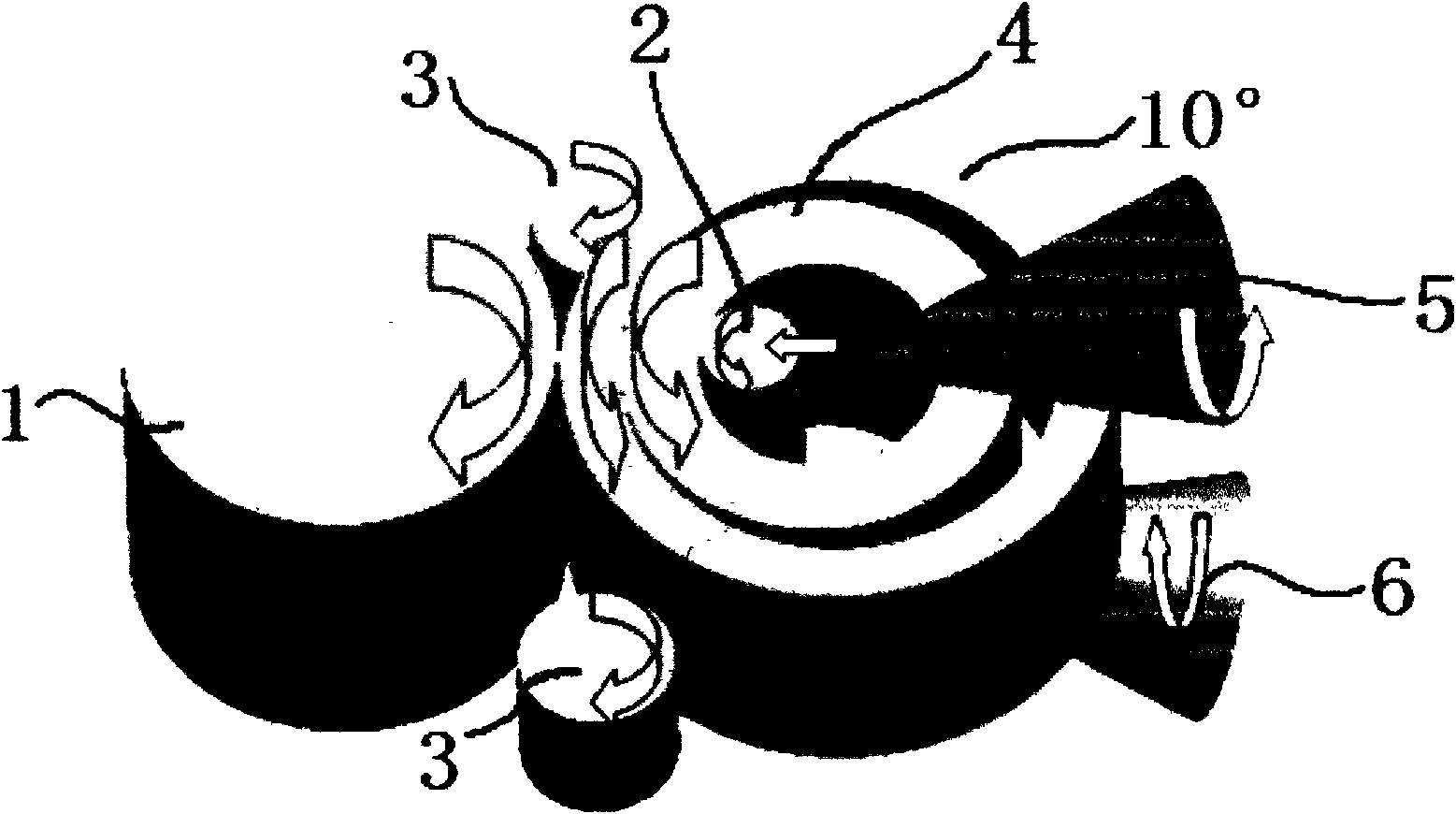

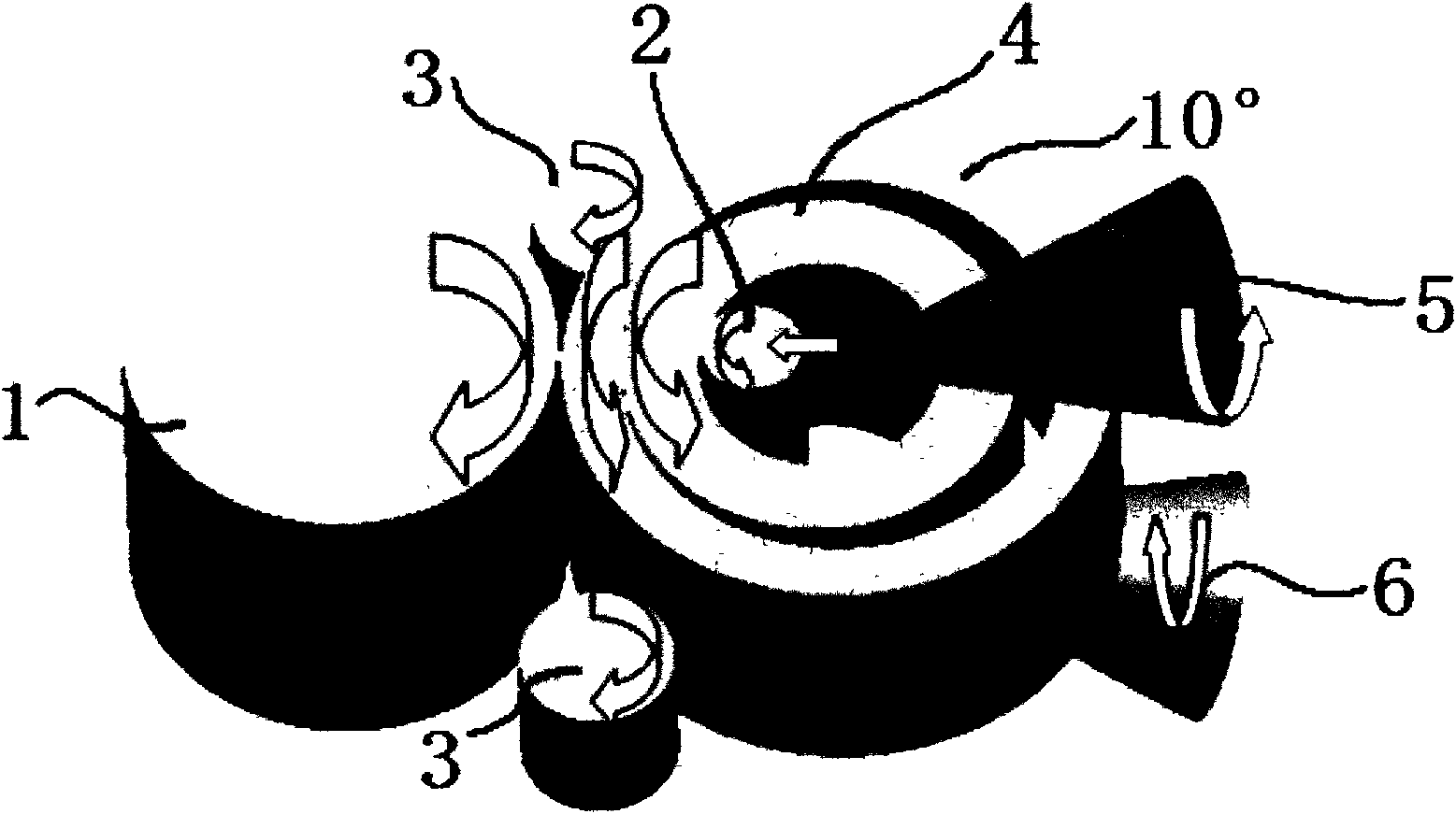

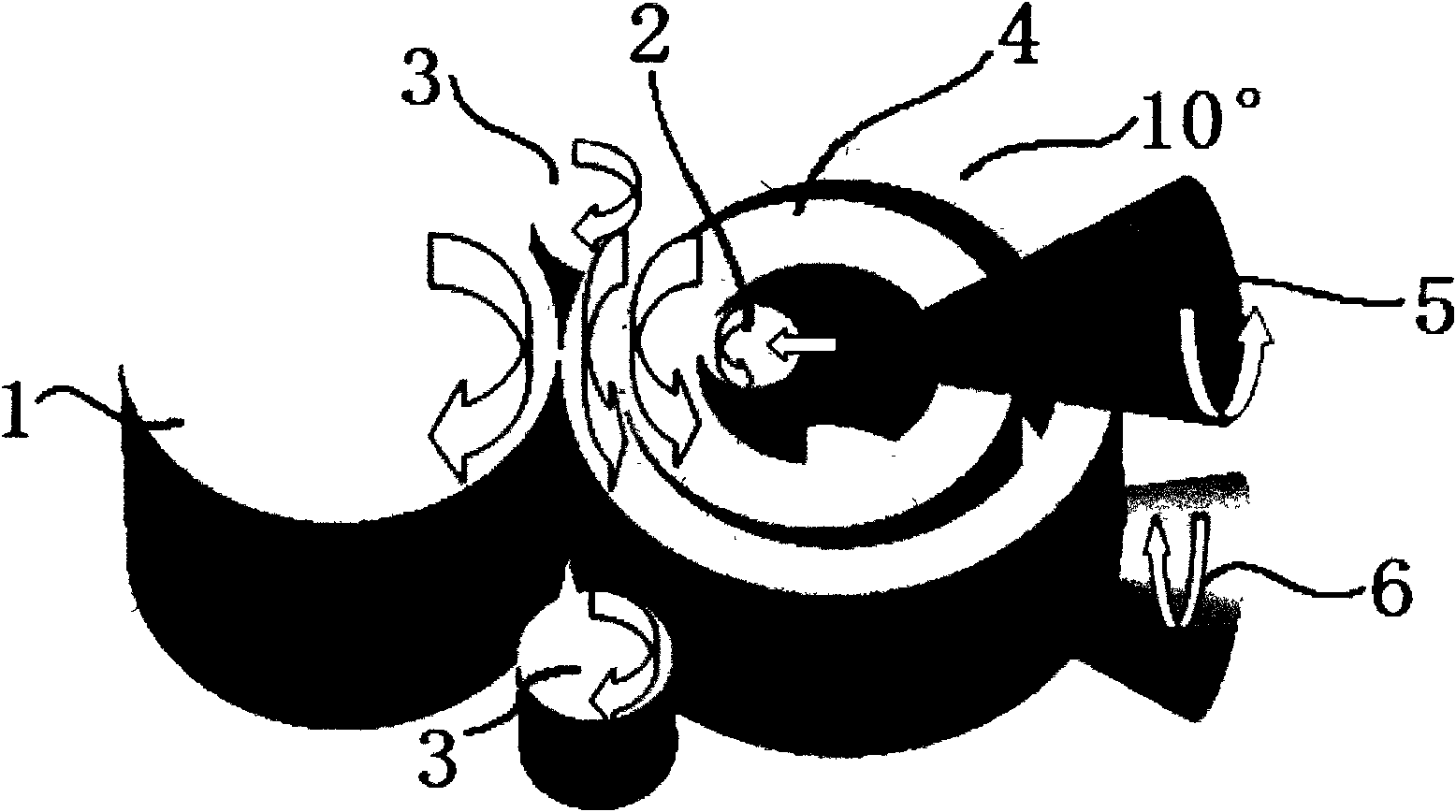

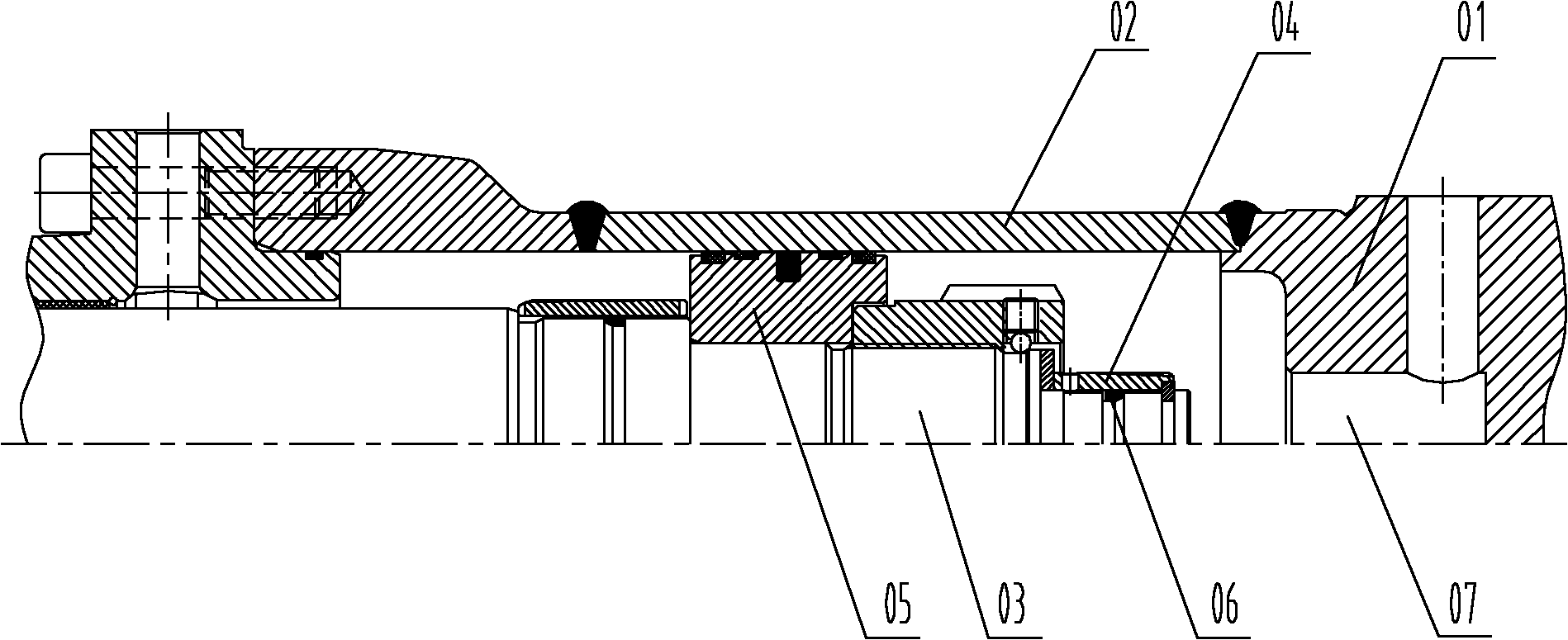

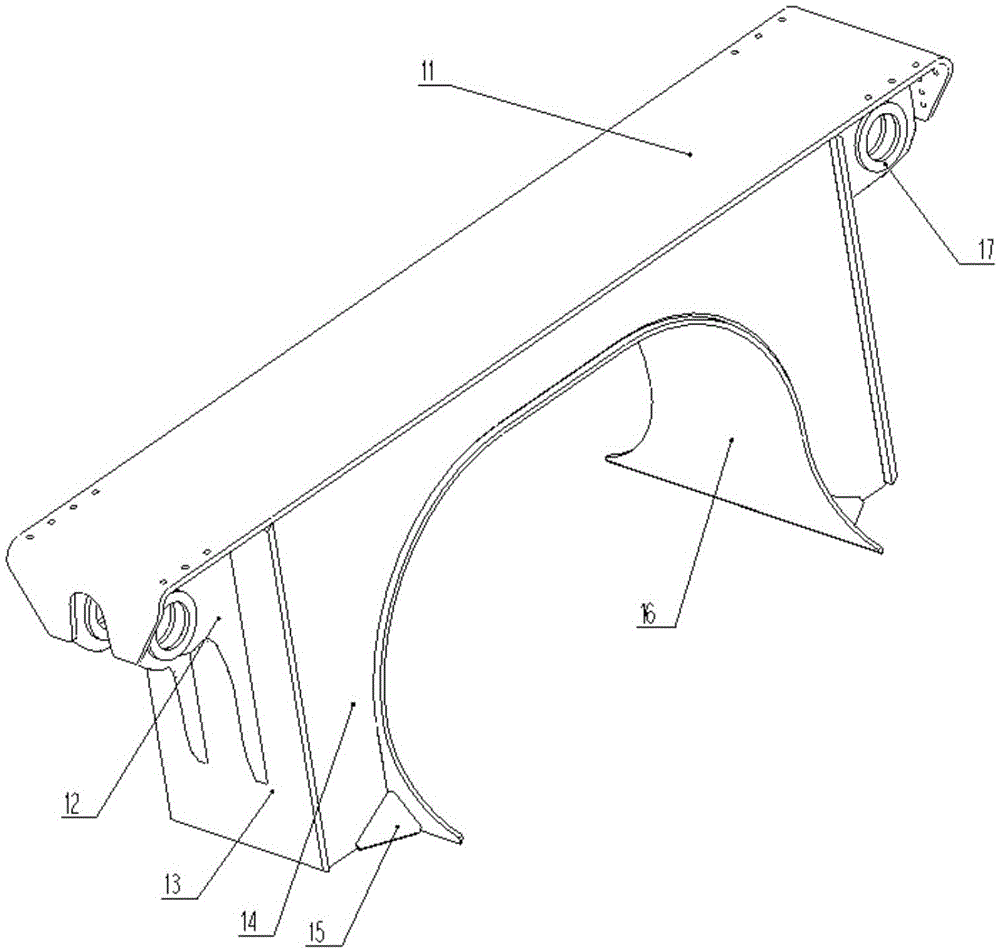

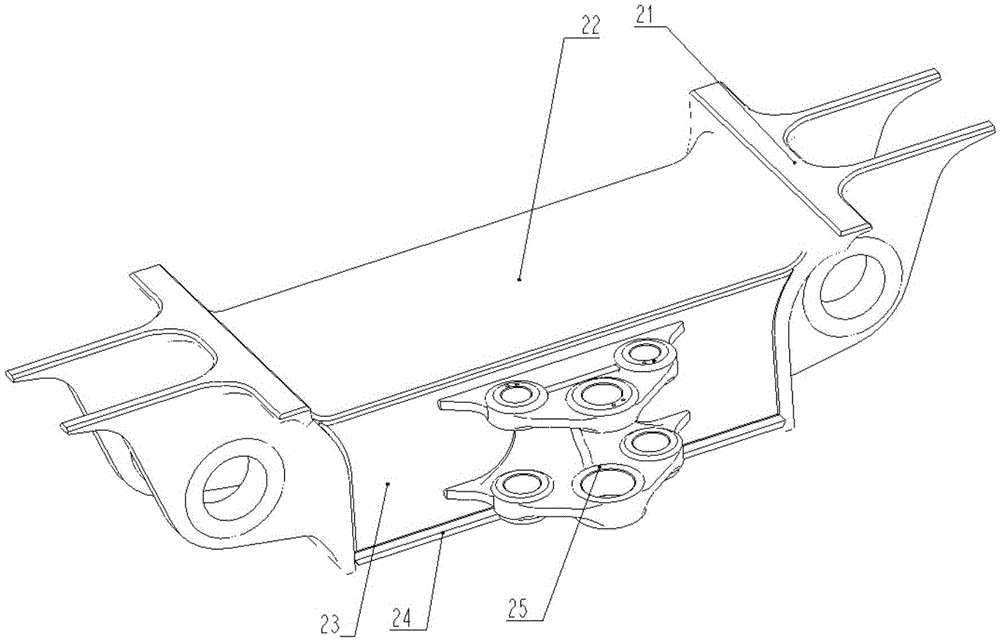

Ring rotary hearth flexible heat treatment production line and heat treatment method thereof

ActiveCN106222673AFlexibleEasy to organize productionSolid state diffusion coatingProduction linePush pull

The invention discloses a ring rotary hearth flexible heat treatment production line and a heat treatment method of the ring rotary hearth flexible heat treatment production line. The ring rotary hearth flexible heat treatment production line comprises a feeding table. The upper end and the lower end of the feeding table are correspondingly and symmetrically provided with a feeding material storage platform and conveying device and a discharging material storage platform and conveying device. A two-station front cleaning machine is arranged on the top of the feeding material storage platform and conveying device. A three-station rear cleaning machine is arranged at the bottom of a double-station oil quenching tank and lifting device. The left side of the three-station rear cleaning machine is connected with a push-rod type low-temperature tempering furnace through a pawl type push-pull chain mechanism, a discharging transition platform is connected to the left side of an air cooling station, and a lifting platform is mounted on the left side of the discharging transition platform. By the adoption of the ring rotary hearth flexible heat treatment production line and the heat treatment method, a variety of products with different depths can be produced at the same time, and the ring rotary hearth flexible heat treatment production line has the very flexible production characteristic; very convenient conditions are provided for organization production; and empty disc push is not needed for process replacement during process shift, and the equipment efficiency is played to the maximum.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

Preparation method for coix seed oil microemulsion

InactiveCN101862423AIncrease fuel capacityProcess operating temperature is lowEmulsion deliveryImmunological disordersDistilled waterBioavailability

The invention discloses a preparation method for a coix seed oil microemulsion. The coix seed oil microemulsion is a coix seed oil microemulsion system which consists of coix seed oil, composite emulsifiers, emulsifier aids, distilled water and the like. Each 100 milliliters of coix seed oil microemulsion contains 5 to 13 grams of coix seed oil, 20 to 30 grams of composite emulsifiers, 1 to 2 grams of emulsifier aids, 0 to 10 grams of dispersants and the balance of water. The microemulsion is prepared by uniform magnetic stirring at 40 DEG C. The preparation method for the coix seed oil microemulsion has the advantages of small addition amount of the emulsifiers, simple process, high oil load, high bioavailability and the like.

Owner:NANCHANG UNIV

Roll forming method of GH4033 high-temperature alloy thin-wall ring piece

The invention discloses a roll forming method of a GH4033 high-temperature alloy thin-wall ring piece, wherein the thin-wall ring piece is roll-formed and has high size precision and excellent structure and performance. The technical is as follows: sleeving a titanium alloy pre-rolled blank which is heated to a deforming temperature and a pre-heated follow-up mould sleeve into a ring rolling mill; sleeving the follow-up mould sleeve in the pre-rolled blank; positioning the two workpieces by utilizing a main roller, a core roller, holding rollers and upper and lower conical rollers of the ring rolling mill; and starting the ring rolling mill, wherein the core roller of the ring rolling mill performs radial feed motion toward the main roller and rolls the pre-rolled blank together with the main roller under the support of the follow-up mould sleeve with a rolling force of 220-4,200 KN so that the pre-rolled blank is widened radially at a speed of 5-8 mm / s and the wall thickness is gradually reduced; and after the deformation of the pre-rolled blank reaches 25-45%, the pre-rolled blank is rolled into a thin-wall ring piece. The minimum of the wall thickness of the titanium alloy thin-wall ring piece roll-formed by the method is 25 mm, and the maximum of the height-thickness ratio is 25 mm; and the ring piece is mainly applied to the rotational parts such as a cylindrical shell and the like used in the fields of aerospace and the like..

Owner:GUIZHOU AVIATION TECHN DEV

Rolling and forming method for 0Cr25Ni20 stainless steel thin-wall ring

The invention discloses a rolling and forming method for a 0Cr25Ni20 stainless steel thin-wall ring, aiming to roll and form the thin-wall ring with high forming size precision and good tissue and performance. The invention has the technical scheme that the method comprises the following steps of: firstly, sheathing a 0Cr25Ni20 stainless steel pre-rolled blank which is heated to deformation temperature and a preheated follow-die die into a ring rolling machine, sheathing the follow-die die into the pre-rolled blank, and positioning the two workpieces by using a home roll, a core roll, a snubber roll and upper and lower cone rolls of the ring rolling machine; then starting the ring rolling machine, and enabling the ring rolling machine to make the feed movement along the radial direction towards the direction of the home roll and roll the pre-rolled blank together with the home roll by a rolling force of 150KN-3000KN under the support of the follow-up die to make the pre-rolled blank broadened along the radial direction at the speed of 6mm / s-13mm / s so that the wall thickness of the pre-rolled blank is gradually reduced; and rolling the pre-rolled blank into the thin-wall ring after the deformation of the pre-rolled blank reaches 40-60 percent. The wall thickness minimum value of the 0Cr25Ni20 stainless steel thin-wall ring rolled and formed by the method is 25mm, and the maximum value of height-thickness ratio is 25mm. The ring is mainly used for a revolving body part used in oil gas field and the like.

Owner:GUIZHOU AVIATION TECHN DEV

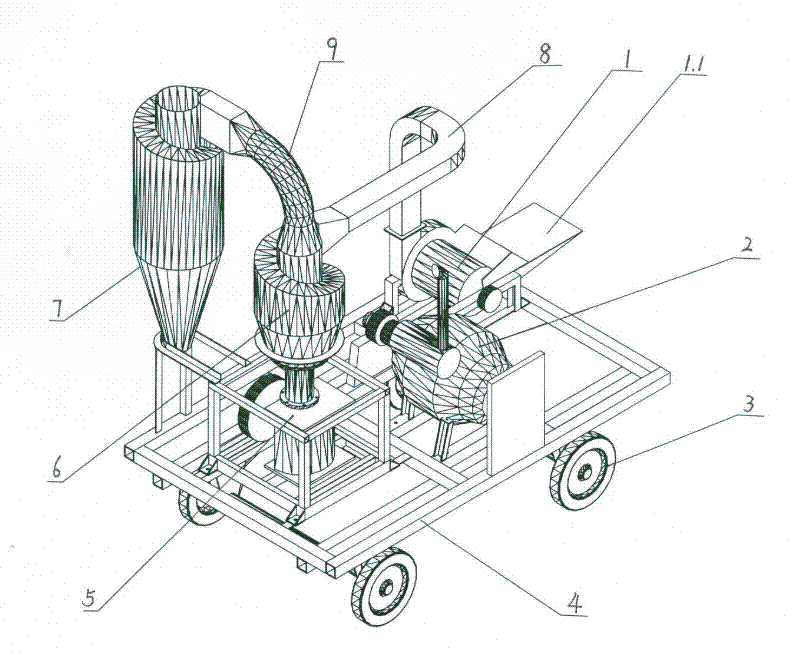

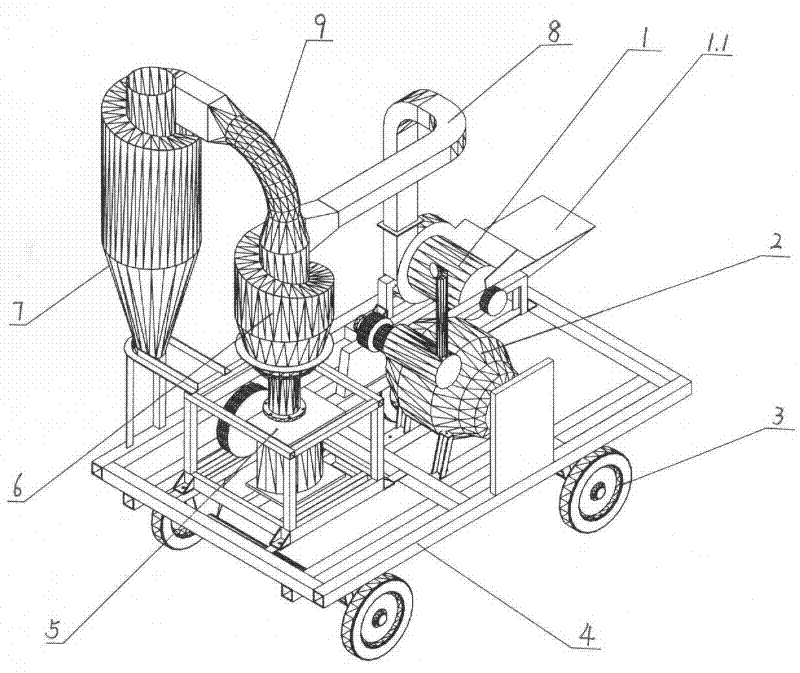

Movable straw solidification device

InactiveCN102173080AReduce shipping costsReduce areaShaping pressPulp and paper industryInternal combustion engine

The invention discloses a movable straw solidification device which comprises a cracking knead machine, an internal-combustion engine, wheels, a frame, a briquetting machine, a depressor, a dust catcher, a feed pipe and a duct, wherein the frame equipped with the wheels can be moved, the middle part of the upper plane of the frame is provided with the internal-combustion engine, the two sides of the upper plane of the frame are respectively provided with the cracking knead machine and the briquetting machine, and the internal-combustion engine, the cracking knead machine and the briquetting machine are driven by a belt transmission mechanism; the inlet end of the briquetting machine is upwards connected with the outlet end of the upper depressor, and the feed pipe is connected with the outlet of the cracking knead machine and the inlet of the depressor, so that falling cracked straws are briquetted into densified straw materials, then the densified straw materials are sequentially discharged from the lower outlet of the device; and the vertical dust catcher is arranged at one side of the depressor, and the dust-laden waste gas discharged from the outlet of the depressor is guided into the dust catcher by virtue of the duct so as to carry out purification and exhaust on the dust-laden waste gas. The movable straw densification briquetting device disclosed by the invention integrates the functions of shredding, kneading and briquetting, and can be moved so as to complete the solidification of straws nearby, thereby reducing the costs for transporting and storing purchased straws. The small integral device is simple in structure, easy to manufacture and easy to use, therefore, the device is beneficial for wide promotion and application.

Owner:江苏爱能洁新能源有限公司

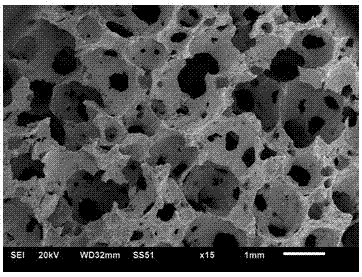

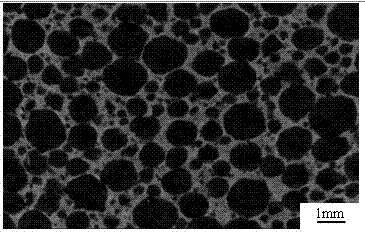

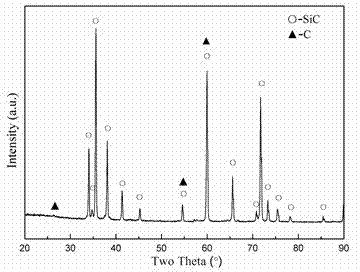

Method for preparing large-aperture three-dimensional network SiC ceramic material

The invention belongs to the technical field of ceramic materials, and in particular relates to a method for preparing a large-aperture three-dimensional network SiC ceramic material. The method comprises the following steps of: mixing SiC powder and B4C powder; adding ammonia hydroxide, sugar, acrylamide, N,N-methylene bisacrylamide and water in a ball milling manner to form a SiC mixed slurry; adding a surfactant, a foaming agent hydrogen peroxide and an adhesive into the SiC mixed slurry, uniformly stirring, and adding an initiator gel for foaming to obtain foaming gel; insulating and sintering the foaming gel for 0.5-1 hour at 1,950-2,040 DEG C in an inert atmosphere to obtain the large-aperture three-dimensional network SiC ceramic material. According to the method, a macropore three-dimensional network silicon carbide can be prepared, the size of apertures can be controlled by controlling the concentration and dosage of polyvinyl alcohol, and the porosity and aperture can be controlled by controlling the dosage of the hydrogen peroxide solution, and the communication performance of macropores can be effectively improved by using the surfactant. The method is simple and reliable, does not need high fixed investment, and has an excellent application prospect.

Owner:山东东大新材料研究院有限公司

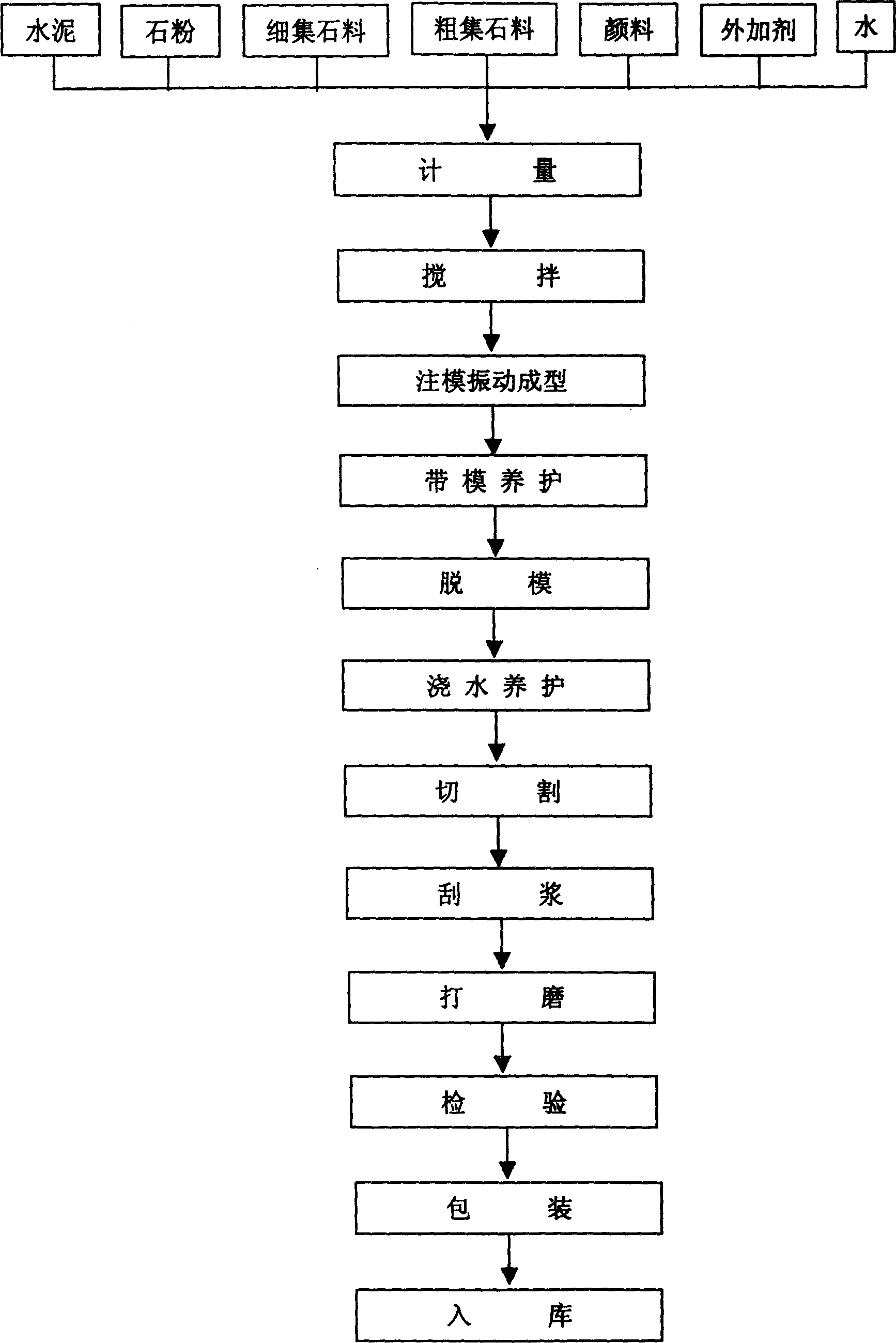

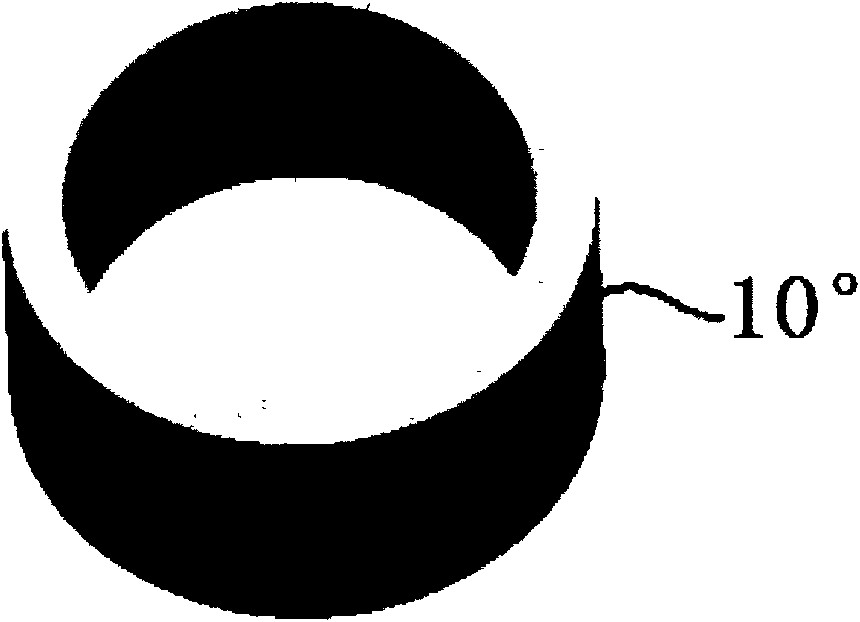

Unitary decorative blocks cut from concrete blanks and their production

InactiveCN1583652AOutstanding advantagesOutstanding effectCovering/liningsCeramic shaping apparatusComposite constructionBrick

The invention is about decorative brick used in indoor-outdoor wall face and ground ornament which is acted as the overall structure and produced through dressing after the dimidiate concrete body. Compared with the existing concrete complex structure decorative brick, it's shrinkage breakup is difficult, service life is long, technology is simple, production cycle is short and cost is low. The decorative surface is shaped through dressing to the dimidiate cement body. Therefore the colorful stone cross-section in the concrete body open naturally. The external appearance is like the crude 'zimu stone'. It is simple and natural. The decorative impression is novel. It is the perfect decorative stuff of wall face and ground.

Owner:成都市新宿墙体材料应用发展公司

Method for rolling and forming TC11 titanium alloy thin-walled rings

The invention discloses a method for rolling and forming TC11 titanium alloy thin-walled rings, which is used for rolling and forming thin-walled rings with high size precision and good organization and performance. The method comprises the following steps: firstly, nesting a pre-rolled titanium alloy billet which is heated to a deformation temperature and a preheated follow-up die sleeve into a ring rolling mill, and positioning the two workpieces by a main roller, a core roller, a holding roller, an upper cone roller and a lower cone roller of the ring rolling mill, wherein the follow-up die sleeve is nested in the pre-rolled billet; and then, starting up the ring rolling mill to enable the core roller to make a feed motion radially towards the direction of the main roller and roll the pre-rolled billet together with the main roller by the rolling force of 200KN-4000KN under the support of the follow-up die sleeve, so that the width of the pre-rolled billet is expanded radially at a speed of 5-10mm / s, the wall thickness of the pre-rolled billet is gradually reduced, and after the deformation of the pre-rolled billet reaches 25%-45%, the pre-rolled billet is rolled into a thin-walled ring. The minimum value of the wall thickness of the titanium alloy thin-walled ring rolled by the method is 25 mm, and the maximum value of the height-to-thickness ratio thereof is 25 mm. The ring is mainly used for components of revolved bodies such as cylindrical shells and the like used in the fields of aviation and the like.

Owner:GUIZHOU AVIATION TECHN DEV

Rolling and forming method for 0Cr25Ni20Mo2 stainless steel thin-wall ring

The invention discloses a rolling and forming method for a 0Cr25Ni20Mo2 stainless steel thin-wall ring, aiming to roll and form the thin-wall ring with high forming size precision and good tissue and performance. The invention has the technical scheme that the method comprises the following steps of: firstly, sheathing a 0Cr25Ni20Mo2 stainless steel pre-rolled blank which is heated to deformation temperature and a preheated follow-up die sleeve into a ring rolling machine, sheathing the follow-up die sleeve into the pre-rolled blank, and positioning the two workpieces by using a home roll, a core roll, a snubber roll and upper and lower cone rolls of the ring rolling machine; then starting the ring rolling machine, and enabling core roll to make the feed movement along the radial direction towards the direction of the home roll and roll the pre-rolled blank together with the home roll by a rolling force of 150KN-2,900KN under the support of the follow-up die sleeve to make the pre-rolled blank broadened along the radial direction at the speed of 7mm / s-13mm / s so that the wall thickness of the pre-rolled blank is gradually reduced; and rolling the pre-rolled blank into the thin-wall ring after the deformation of the pre-rolled blank reaches 40-60 percent. The minimum wall thickness value of the 0Cr25Ni20Mo2 stainless steel thin-wall ring rolled and formed by the method is 25mm, and the maximum value of height-thickness ratio is 25mm. The ring is mainly used for a revolving body part used in oil gas field and the like.

Owner:GUIZHOU AVIATION TECHN DEV

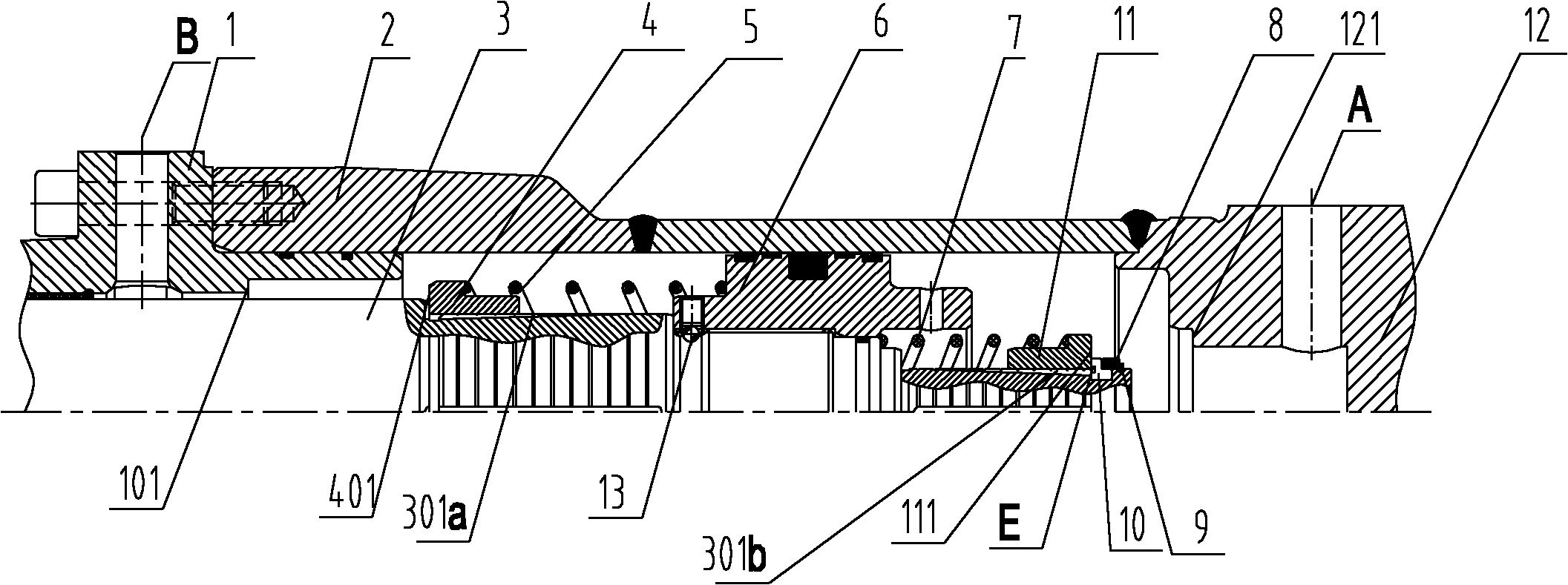

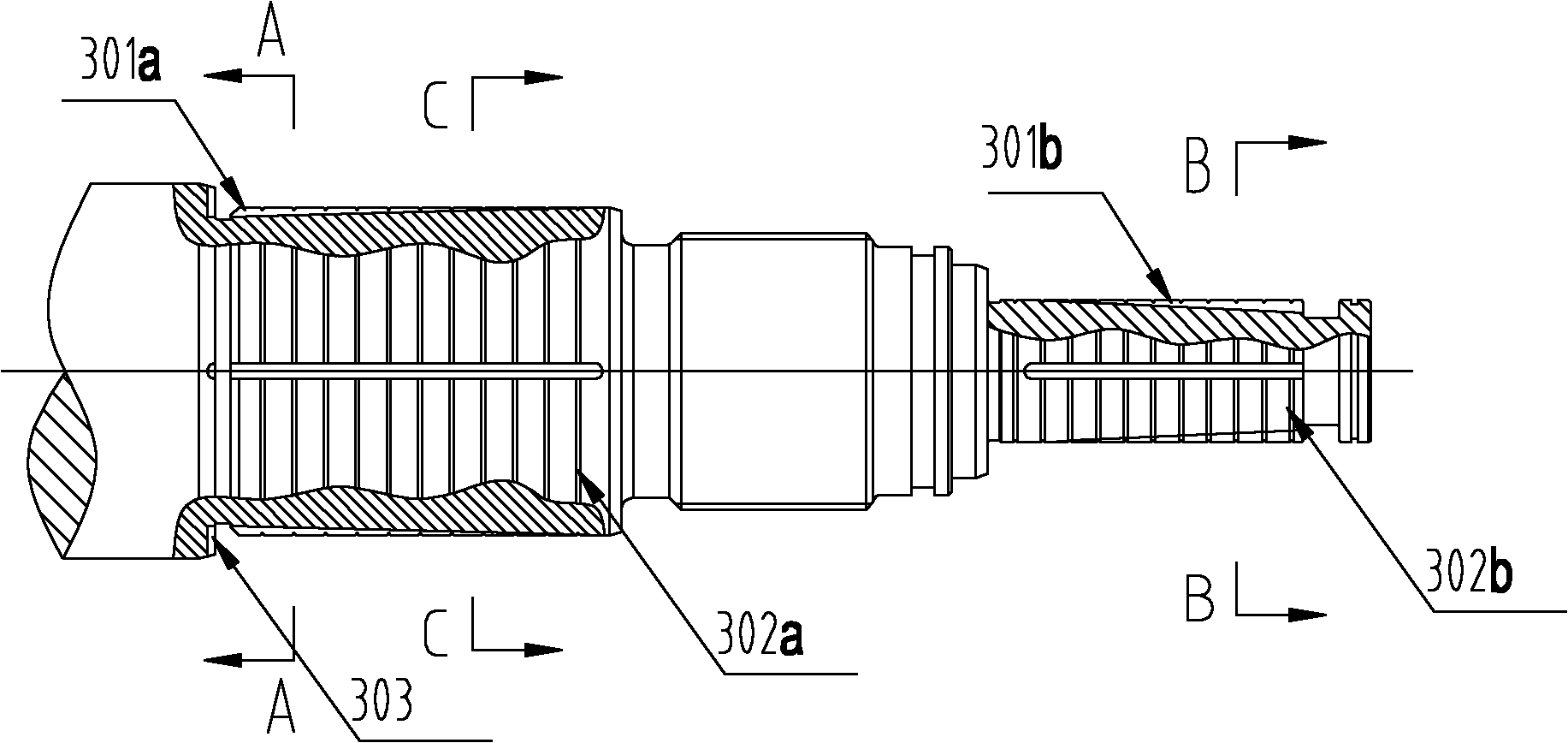

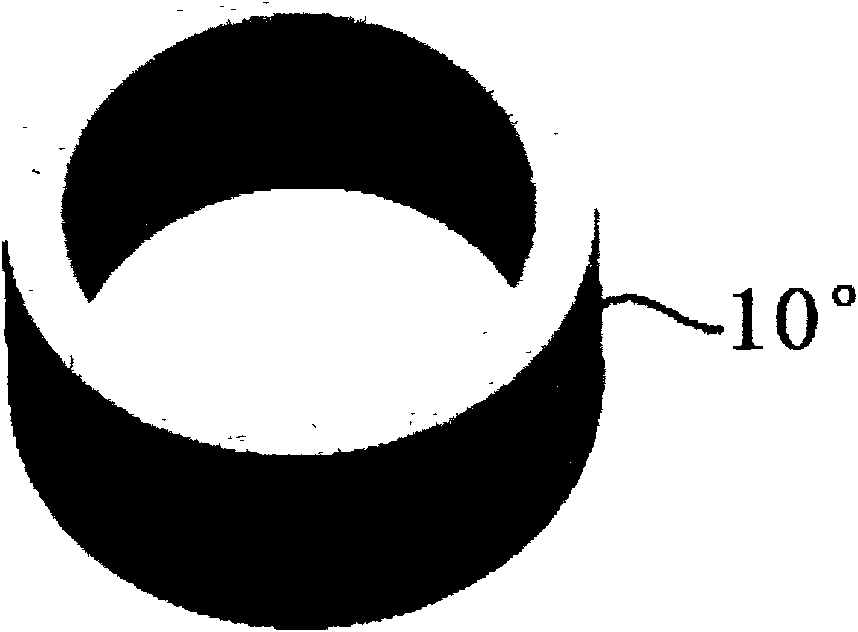

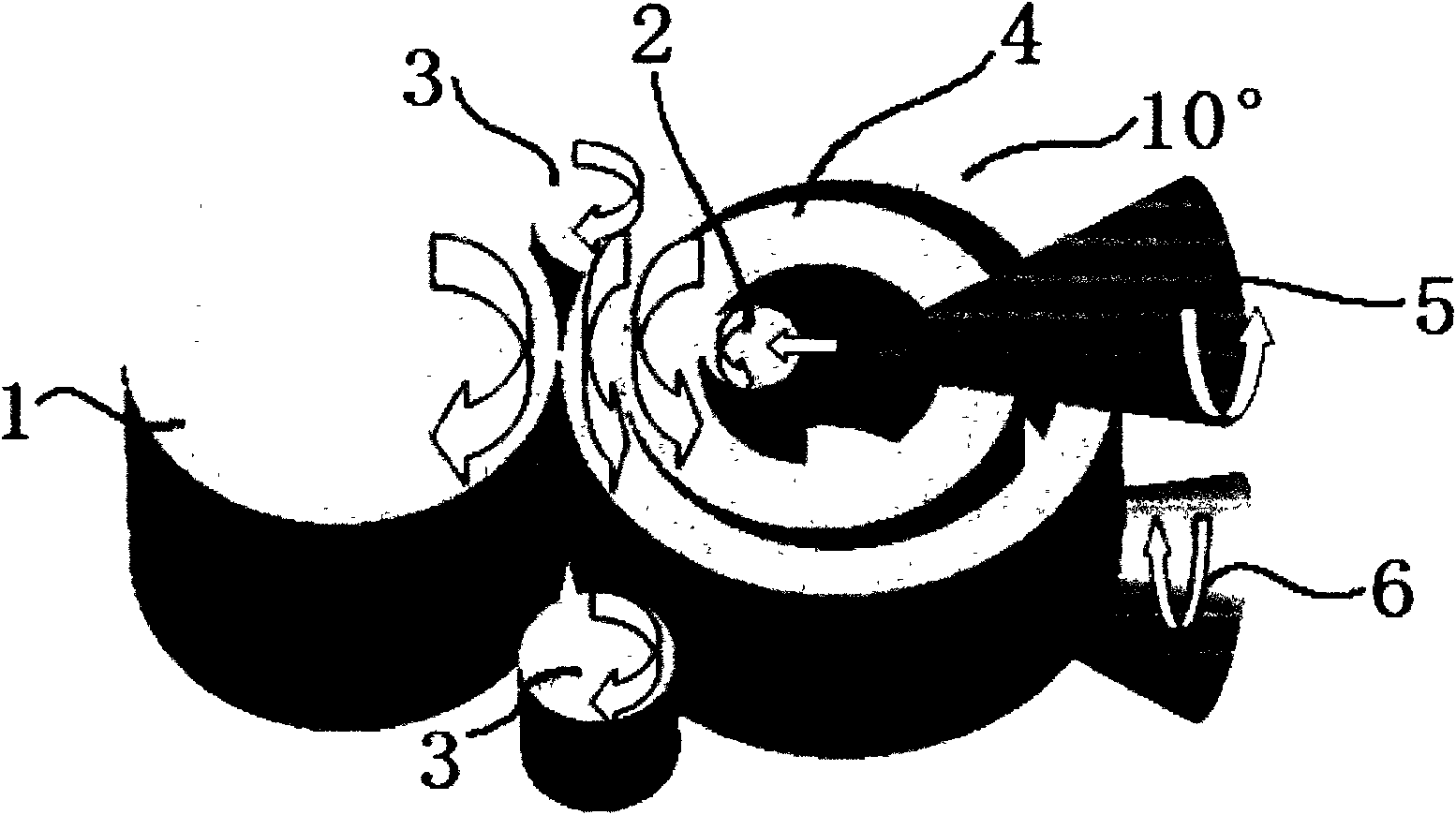

Hydraulic oil cylinder and relevant device thereof, hydraulic buffer system, excavator and concrete pump truck

ActiveCN102155462AManufacturing precision requirements are lowRealize the buffering effectFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a hydraulic oil cylinder. A buffer sleeve capable of sliding along the axial direction of a piston rod additional section is sleeved on the piston rod additional section in a rodless cavity; a rodless cavity hermetic end face which can be used for blocking the buffer sleeve and can be jointed with the first end face of the buffer sleeve to form a sealing surface is arranged in an oil cylinder cavity between a rodless cavity oil flow hole and a final position of the piston rod in retracting movement in a piston rod-free end face; at least one throttling oil channel is formed; and in the retracting movement process of the piston rod, hydraulic oil on one side of the sealing surface close to a piston can flow towards the rodless cavity oil flow hole through the throttling oil channel from the moment when the first end face of the buffer sleeve is jointed with the rodless cavity hermetic end face and the sealing surface is formed to the moment when the piston rod retracts to the final position in the retracting movement. The hydraulic oil cylinder has the advantages of easiness in machining of a buffer structure and good effect. The invention also provides a hydraulic buffer system using the hydraulic oil cylinder, an excavator and a concrete pump truck.

Owner:SANY HEAVY IND CO LTD (CN)

Silane natural-crosslinked polyethylene cable insulating material and its production process

InactiveCN100513470CReduce production processReduce investmentInsulated cablesInsulated conductorsWater bathsAntioxidant

The invention discloses a silane natural cross-linked polyethylene cable insulation material, which is composed of A material and B material in a weight ratio of 85-95:5-15; the component name of A material and the weight ratio of each component are: polyethylene 100 parts by weight of resin; 0.5-3.5 parts by weight of silane; 0.02-0.2 parts by weight of initiator; the name and weight ratio of the components of material B are: 100 parts by weight of polyethylene resin; 5-20 parts by weight of antioxidant; 0.5-5 parts by weight of the catalyst. The invention also discloses a production method for preparing silane natural cross-linked polyethylene cable insulation material. The silane natural cross-linked polyethylene insulation material is produced by the above-mentioned process. After extrusion, it does not need to be soaked in a hot water bath, and can be produced under natural conditions. crosslinking. This can reduce the production process for the cable manufacturing enterprise, reduce the production cost, improve the production efficiency, it is very convenient to organize production, and the equipment investment is small.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

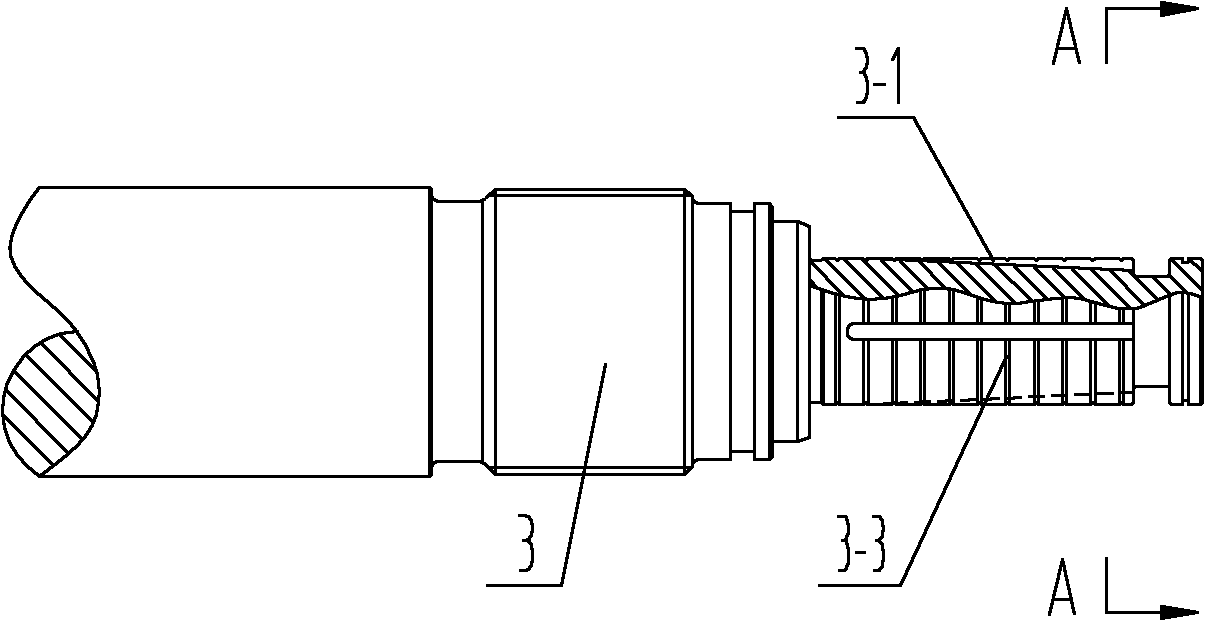

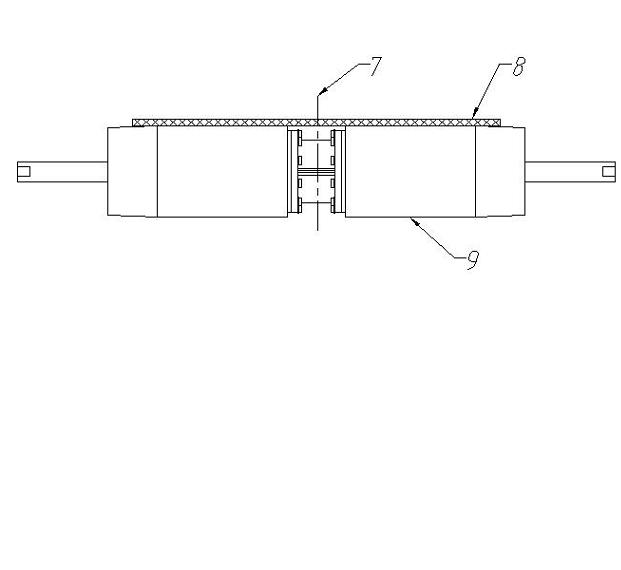

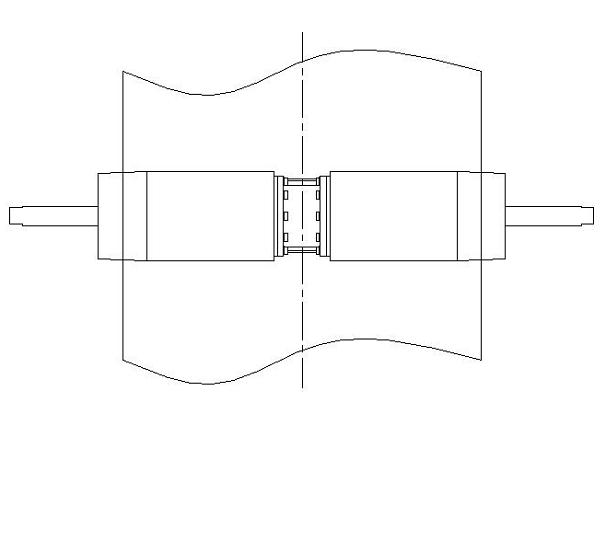

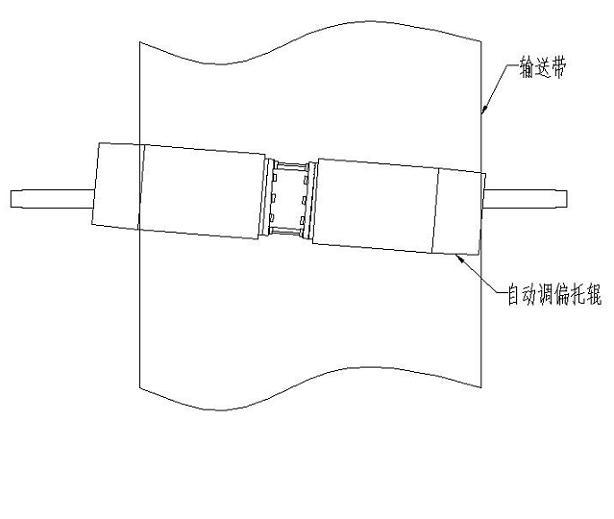

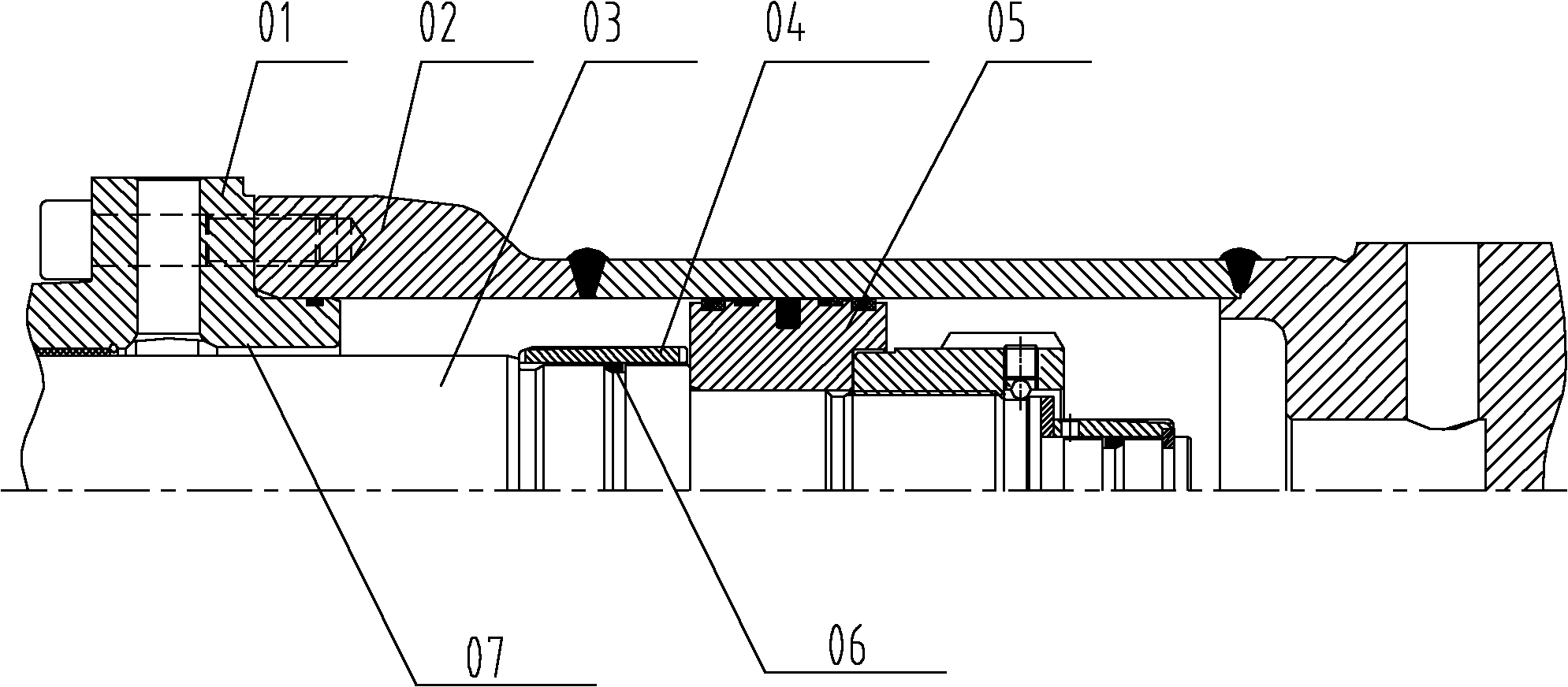

Novel automatic aligning roller of belt conveyer

ActiveCN102114965AReliable dustproofWaterproof and reliableConveyorsRollersRolling-element bearingStructural engineering

The invention discloses a novel automatic aligning roller of a belt conveyer, which comprises two rubber rollers (1), a rubber sleeve (2) and a wabbler mechanism (3), wherein the two robber rollers (1) are symmetrically arranged on the left and on the right, the wabble mechanism (3) is positioned between the two rubber rollers; and the wabbler mechanism (3) consists of a screw (31), a bearing cover (32), a sealing ring (33), an antifriction bearing (34), an inner sleeve (35), a center sleeve (36), an outer sleeve (37), a cylindrical pin (38) and a central pendulum shaft (39). In the novel automatic aligning roller, as a key movement mechanism is concentrated in the wabbler mechanism, and due to the action of the seal ring and the rubber sleeve, the dust-proof and the water-proof effects are more reliable. So that the automatic aligning roller can be used in occasions with severe environment; requirements of different specifications of the belt conveyer can be met by only changing the rubber rollers; and the wabbler mechanism is convenient to maintain, replace and organize production.

Owner:HERMAN NANJING TECHN & ENG PTE

Hydraulic oil cylinder, hydraulic buffering system, excavator and concrete pump truck

ActiveCN102155457AManufacturing precision requirements are lowExtended service lifeFluid-pressure actuatorsHydraulic cylinderExcavator

The invention discloses a hydraulic oil cylinder which comprises a rod cavity end closure, a cylinder barrel, a piston rod, a piston and a rodless cavity end closure, wherein the inner chamber of the hydraulic cylinder barrel is divided into a rod cavity and a rodless cavity by the piston rod and the piston; the piston rod is provided with a buffering sleeve which comprises a first buffering sleeve and / or a second buffering sleeve; the buffering sleeve can slide along the axial direction of the piston rod; an axial throttling oil passage is arranged between the buffering sleeve and the piston rod; the first buffering sleeve is provided with a sealing end surface; a sealing end surface is arranged on the rod cavity end closure; hydraulic oil in the rod cavity is discharged to an oil passage through the throttling oil passage; the end surface of the second buffering sleeve is in contact with the sealing end surface of the rodless cavity end closure to form a sealing; and the hydraulic oil in the rodless cavity is discharged to the oil passage through the throttling oil passage. The invention provides a buffering mechanism of the hydraulic oil cylinder; and the buffering mechanism has longer service life, has lower requirement on the accuracy of manufacturing and is convenient for organizing production.

Owner:SANY HEAVY IND CO LTD (CN)

Rolling forming method for 5CrNiMo steel thin-wall ring

ActiveCN102029340AAvoid flatteningAvoid phenomena such as horn mouthMetal rollingRoll formingHigh dimensional

The invention discloses a rolling forming method for a 5CrNiMo steel thin-wall ring, which is used for rolling and forming a thin-wall ring with high dimensional precision and good texture and properties. In the technical scheme of the method, a 5CrNiMo steel pre-rolled compact heated to a deformation temperature and a preheated following-up die sleeve are firstly sleeved into a ring rolling mill, the following-up die sleeve is sleeved into the pre-rolled compact, and the two workpieces are positioned through a main roller, a core roller, a holding roller, an upper cone roller and a lower cone roller of the ring rolling mill; the ring rolling mill is started again, the core roller of the ring rolling mill does a feed motion toward the direction of the main roller along a radial direction, and the core roller and the main roller roll the pre-rolled compact with rolling force of 180KN-3800KN under the support of the following-up die sleeve together so that the pre-rolled compact is broadened along the radial direction at the speed of 6mm / s-12mm / s, and the wall thickness of the pre-rolled compact is gradually decreased; and the pre-rolled compact is rolled into a thin-wall ring after the deformation reaches 30%-50%. The minimum of the wall thickness of the 5CrNiMo steel thin-wall ring rolled and formed by adopting the method is 25mm, and the maximum of the depth to thickness ratio is 25mm. The ring is mainly used for rotor parts used in the field of special vehicles, and the like.

Owner:GUIZHOU AVIATION TECHN DEV

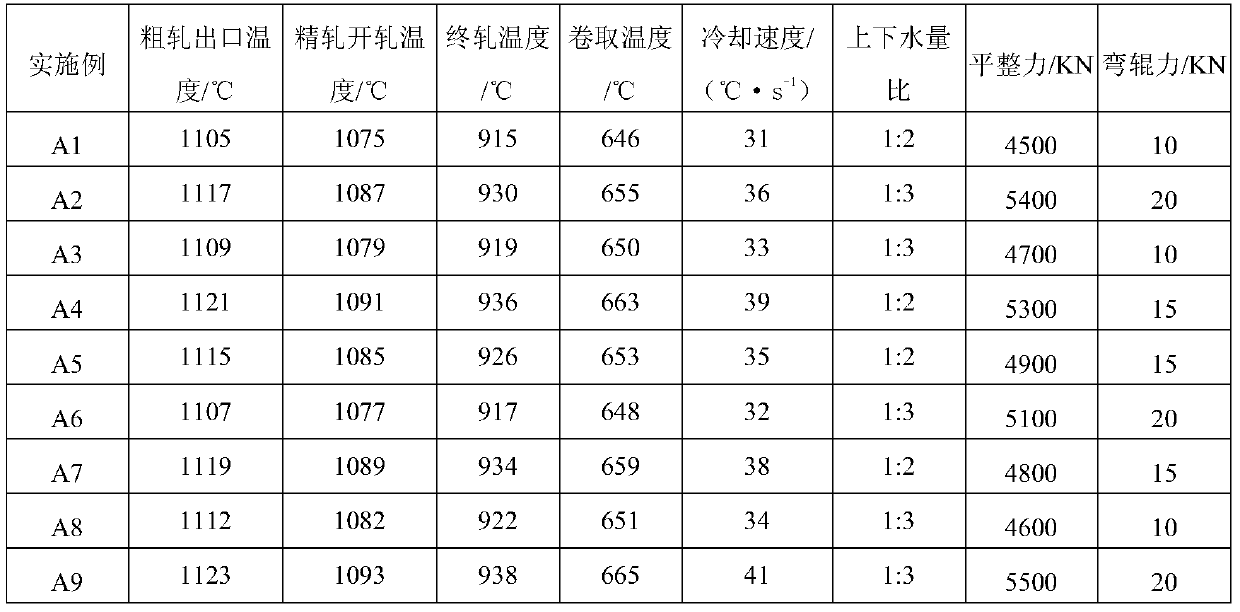

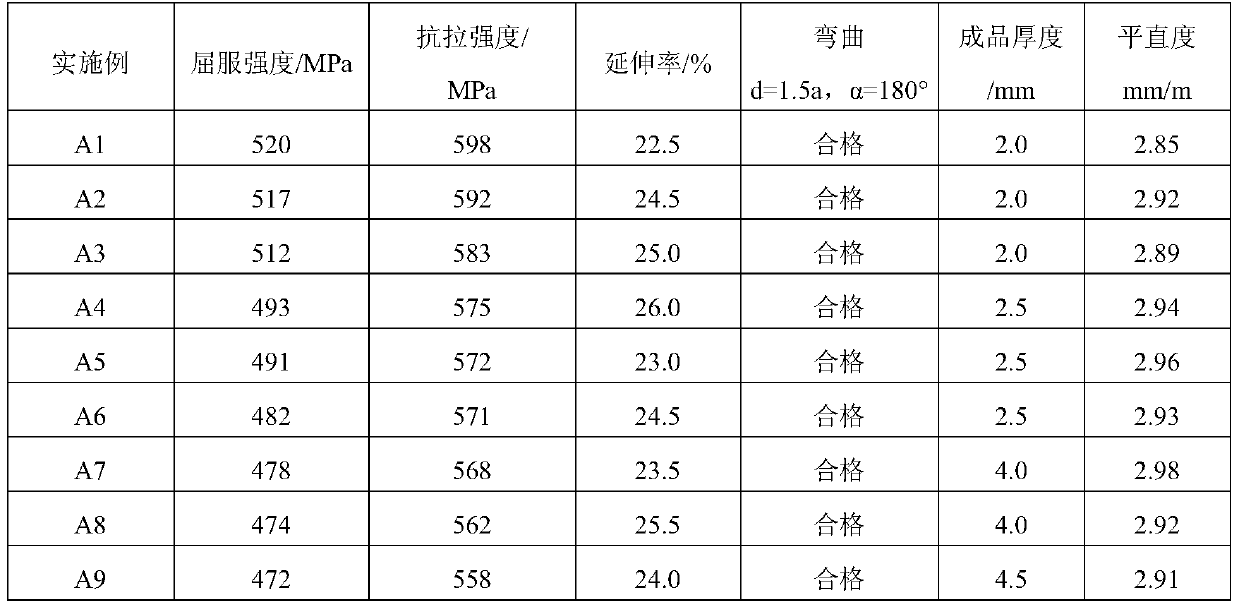

Weather-resistant steel for hot-rolled container with width of 450 MPa and manufacturing method of weather-resistant steel

The invention discloses weather-resistant steel for a hot-rolled container with the width of 450 MPa and a manufacturing method of the weather-resistant steel. The steel contains 0.048%-0.065% of C, 0.61%-0.70% of Si, 0.35%-0.45% of Mn, 0.075%-0.085% of P, smaller than or equal to 0.006% of S, smaller than or equal to 0.040% of Al, 0.20%-0.29% of Cr, 0.11%-0.19% of Cu, 0.035%-0.050% of Ti, 0.010%-0.025% of RE, smaller than or equal to 0.004% of N and the balance iron and inevitable impurities. The outlet temperature of a soaking section of the casting blank is 1278-1298 DEG C, the heat preservation time of the soaking section is 23-37 min, and the total in-furnace time is smaller than or equal to 170 min; the rough rolling outlet temperature is larger than or equal to 1100 DEG C, the finish rolling initial rolling temperature is 1075-1093 DEG C, the finish rolling final rolling temperature is 915-938 DEG C, cooling is conducted to 646-665 DEG C at the cooling speed of 31-41 DEG C / s, coiling is conducted, the leveling force is 4500-5500 KN, and the roll bending force is 10-20 KN.The straightness of the steel strip is smaller than or equal to 3 mm / m. good corrosion resistance is achieved.

Owner:ANGANG STEEL CO LTD

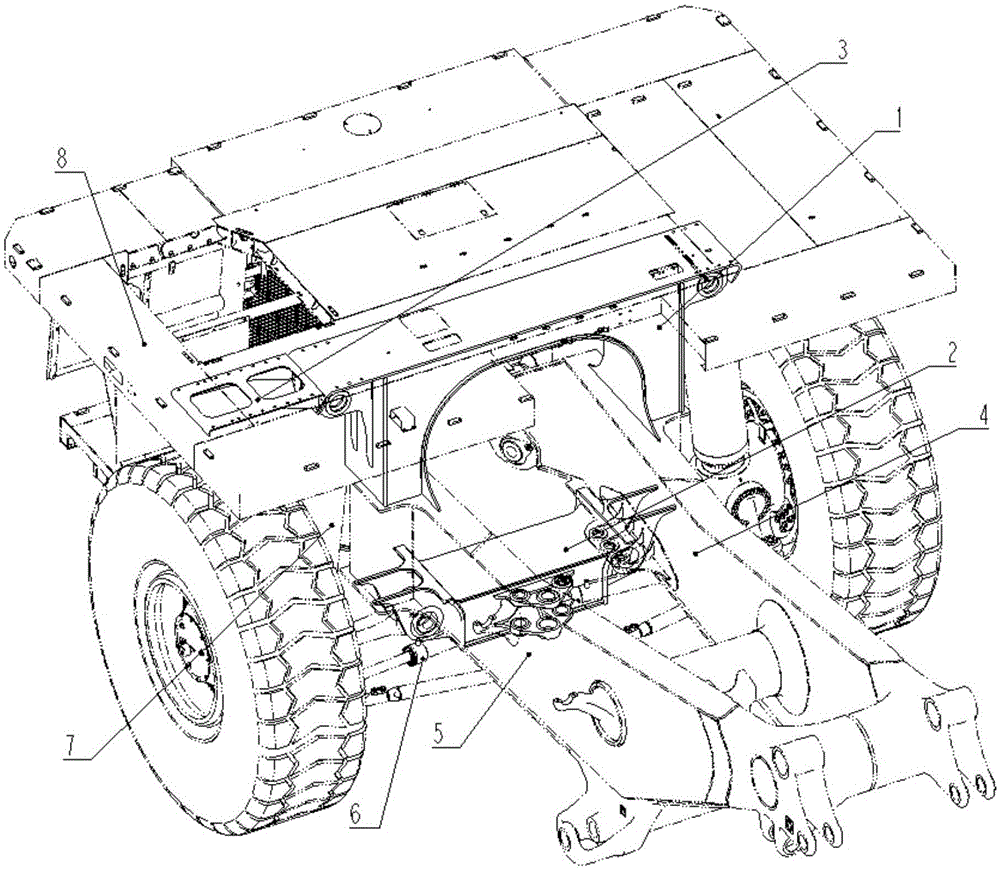

Split type gantry beam for electric drive mining-use dumper frame

ActiveCN105539593AEasy to adjust fitGuaranteed positionUnderstructuresStress concentrationVehicle frame

The invention discloses a split type gantry beam for an electric drive mining-use dumper frame and belongs to the technical field of dumper frames. A split structure of an upper gantry beam body, a lower gantry beam body and a deck support is adopted. The gantry beam structure is simple in positioning and point splicing process, welding formation is easy to control, the attachment situation between the gantry beam and a corresponding longitudinal beam is easy to adjust, and a mounting process is simplified to a great degree; front suspension supports, pull rod seats and steering middle seats are assembled, welded and then machined, and the relative position of a hole is easy to guaranteed, so that positioning parameters of a front axle main pin and a steering trapezoid can be strictly guaranteed; medium machining and finish machining are adopted for small assemblies, machining is easy to conduct, the cycle is short, cost is low, and production is easy to arrange; a casting structure is adopted for the complex stressed position, and a swallow-tail form structure or a stiffened plate is adopted to reduce structural sudden change, so that the gantry beam can bear a large bending load, a twisting load and an impact load, stress concentration of a stress concentrated area is reduced, breakage and damage of a structural piece are avoided, and meanwhile various functional requirements are met.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

Roll forming method of 0Cr19Ni9 stainless steel thin-walled ring forging

The invention discloses a roll forming method of a 0Cr19Ni9 stainless steel thin-walled ring forging. In order to roll-form a thin-walled ring forging with high dimensional precision and excellent tissue and performance, the technical scheme comprises the steps of: firstly, sleeving a preheated follower die sleeve and a 0Cr19Ni9 stainless steel pre-rolled blank heated to a deformation temperature in a ring rolling mill, sleeving the follower die sleeve in the pre-rolled blank, and positioning the two workpieces by using a main roll, a core roll, clutching rolls, an upper cone roll and a lower cone roll of the ring rolling mill; and starting the ring rolling mill, making a feeding motion by the core roll towards the direction of the main roll along the radial direction and rolling the pre-rolled blank at a rolling force of 140-2800KN under the support of the follower die sleeve by the core roll together with the main roll to ensure that the pre-rolled blank expands radially at a speed of 7-14mm / s, wherein the wall thickness is gradually reduced, and the pre-rolled blank is rolled into the thin-walled ring forging when the deformation reaches 40-60 percent. The minimum value of the wall thickness of the 0Cr19Ni9 stainless steel thin-walled ring forging roll-formed by adopting the method is 25mm, the maximum value of the height-thickness ratio is 25mm, and the ring forging is mainly used for gyrorotor parts used in the fields, such as oil gas and the like.

Owner:GUIZHOU AVIATION TECHN DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com