Hydraulic oil cylinder and relevant device thereof, hydraulic buffer system, excavator and concrete pump truck

A hydraulic cylinder and buffer sleeve technology, applied in the field of hydraulic cylinders, can solve the problems of limited production capacity, difficult to achieve manufacturing level, failure of buffer sleeve buffer mechanism, etc., and achieve the effects of easy organization of production, low manufacturing precision requirements, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The first embodiment of the present invention provides a hydraulic cylinder, the hydraulic cylinder is provided with a buffer device on one side of the rodless cavity.

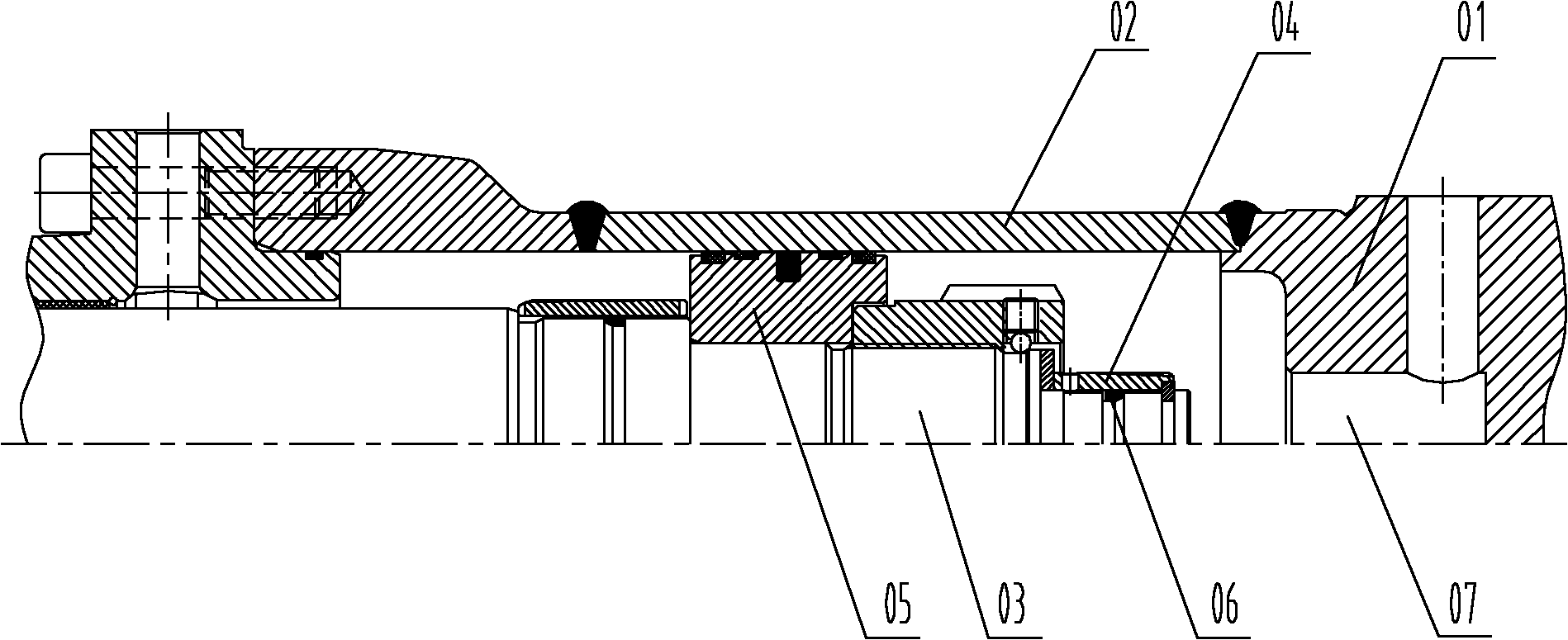

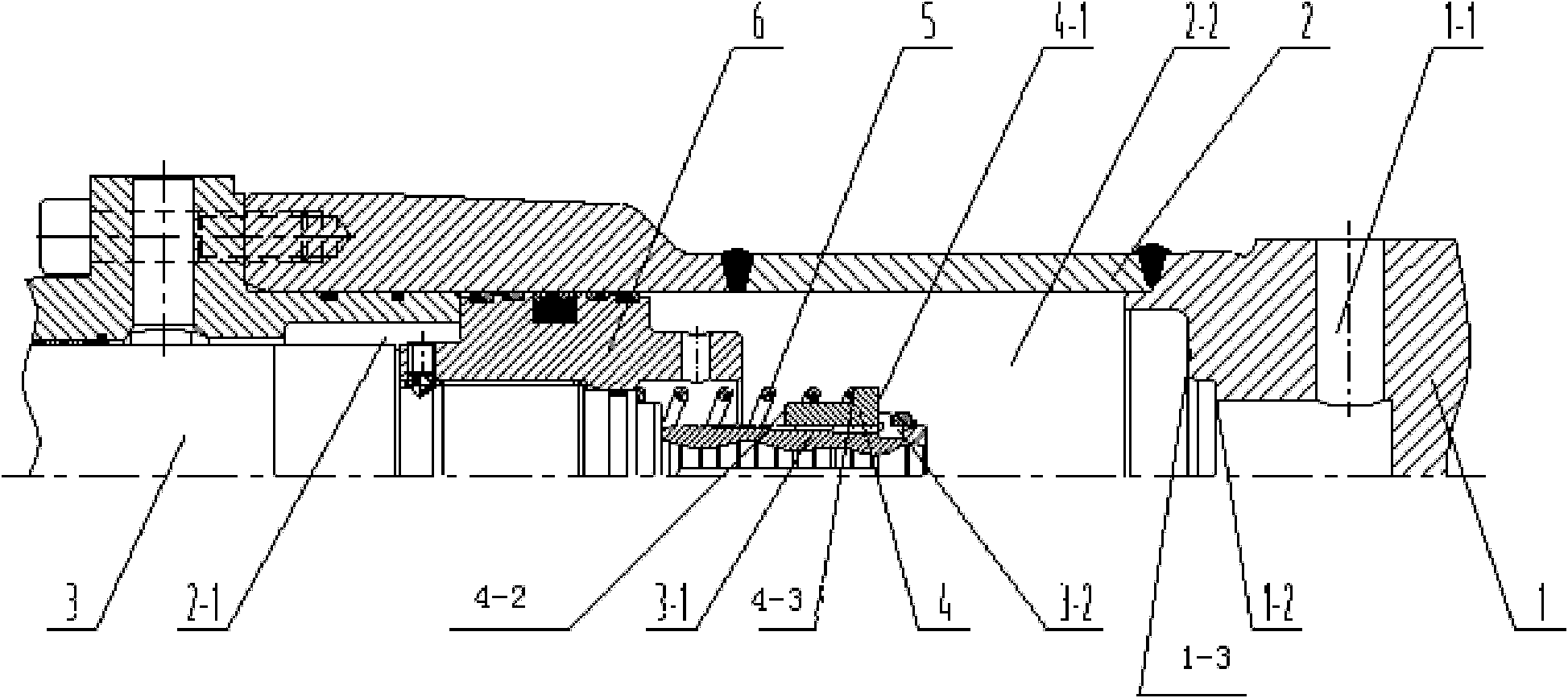

[0058] Please see figure 2 , which is a mechanical structure diagram of the hydraulic cylinder provided by the first embodiment of the present invention. In this figure, the piston has not been retracted to the rodless chamber buffer position.

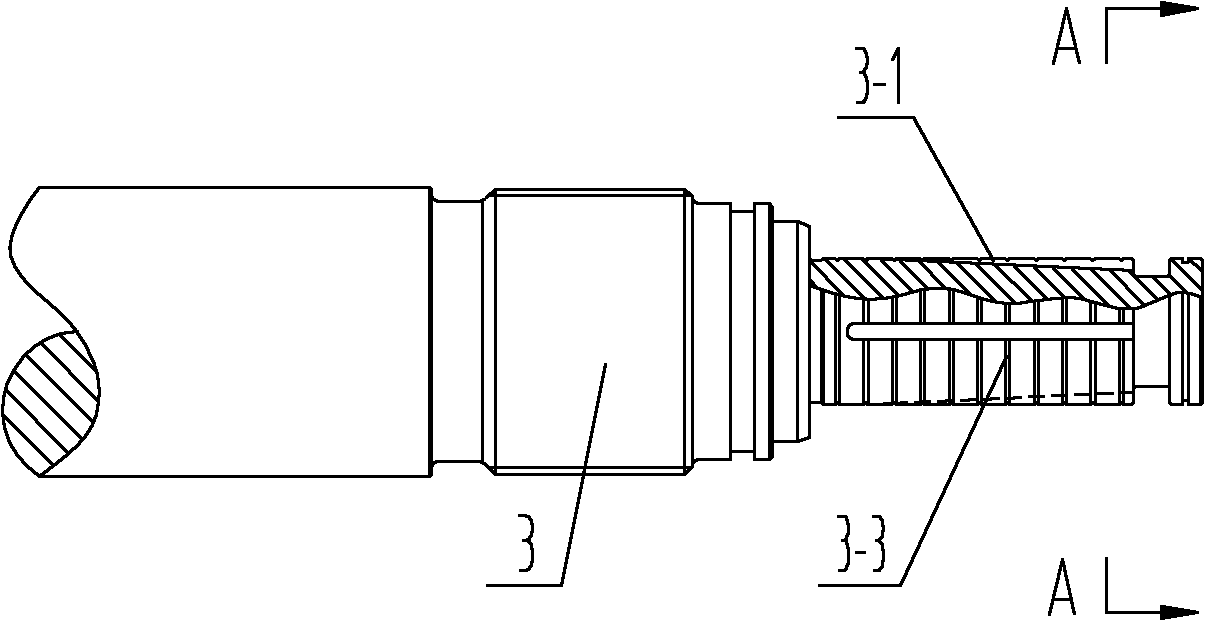

[0059] like figure 2 As shown, the hydraulic cylinder includes a rodless cavity end cover 1, a cylinder barrel 2, a piston rod 3, a buffer sleeve 4, a spring 5, a piston 6, and the like.

[0060] The cylinder 2 provides a sealed hydraulic oil space for the hydraulic cylinder, and the inner cavity of the cylinder 2 is divided into a rod cavity 2-1 and a rodless cavity 2 by a piston 6 that can move axially along the inner cavity. -2, the cavity where the main body of the piston rod 3 is located is the rod cavity 2-1. The outer diameter surface of the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com