Patents

Literature

42results about How to "Limit thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

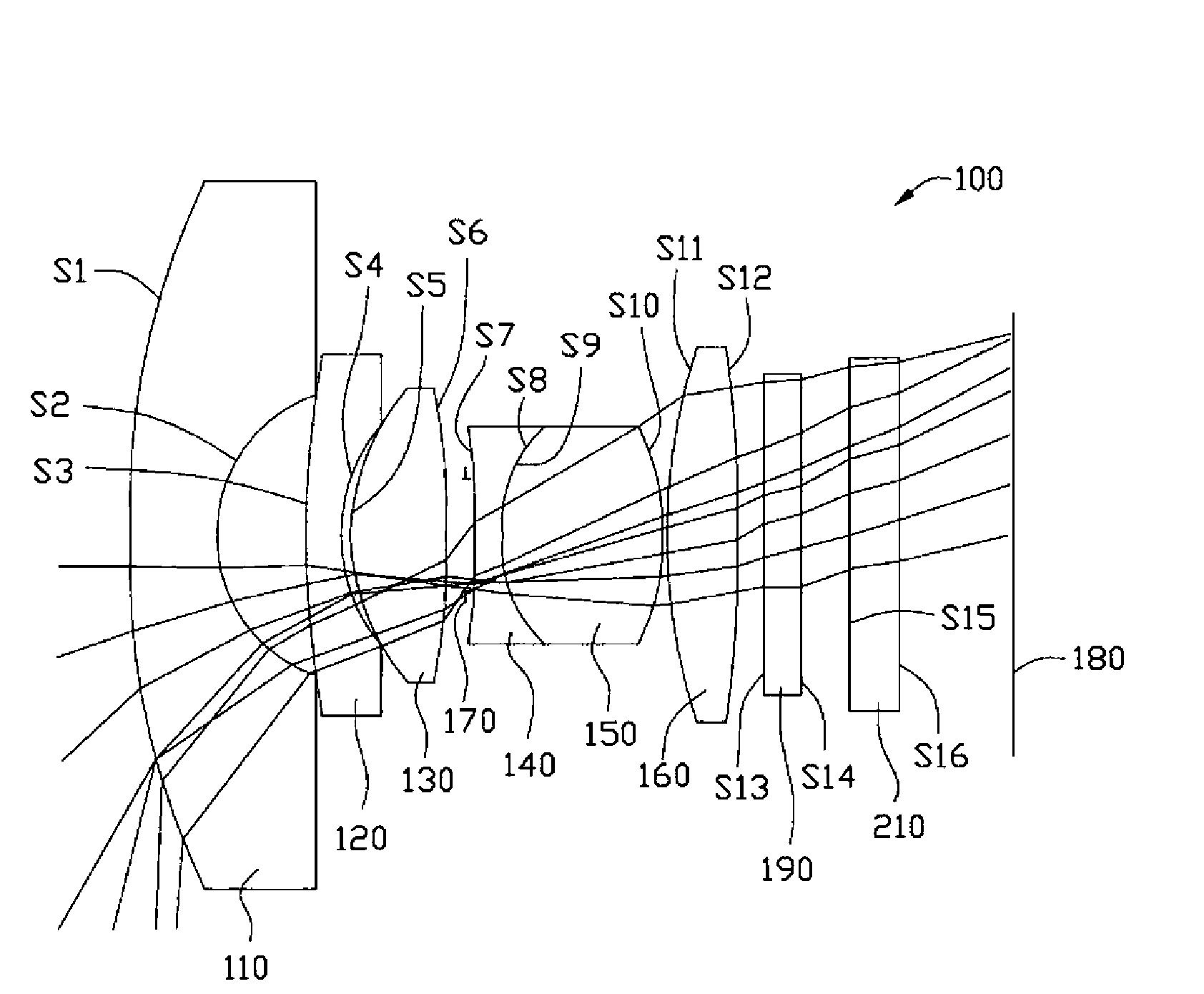

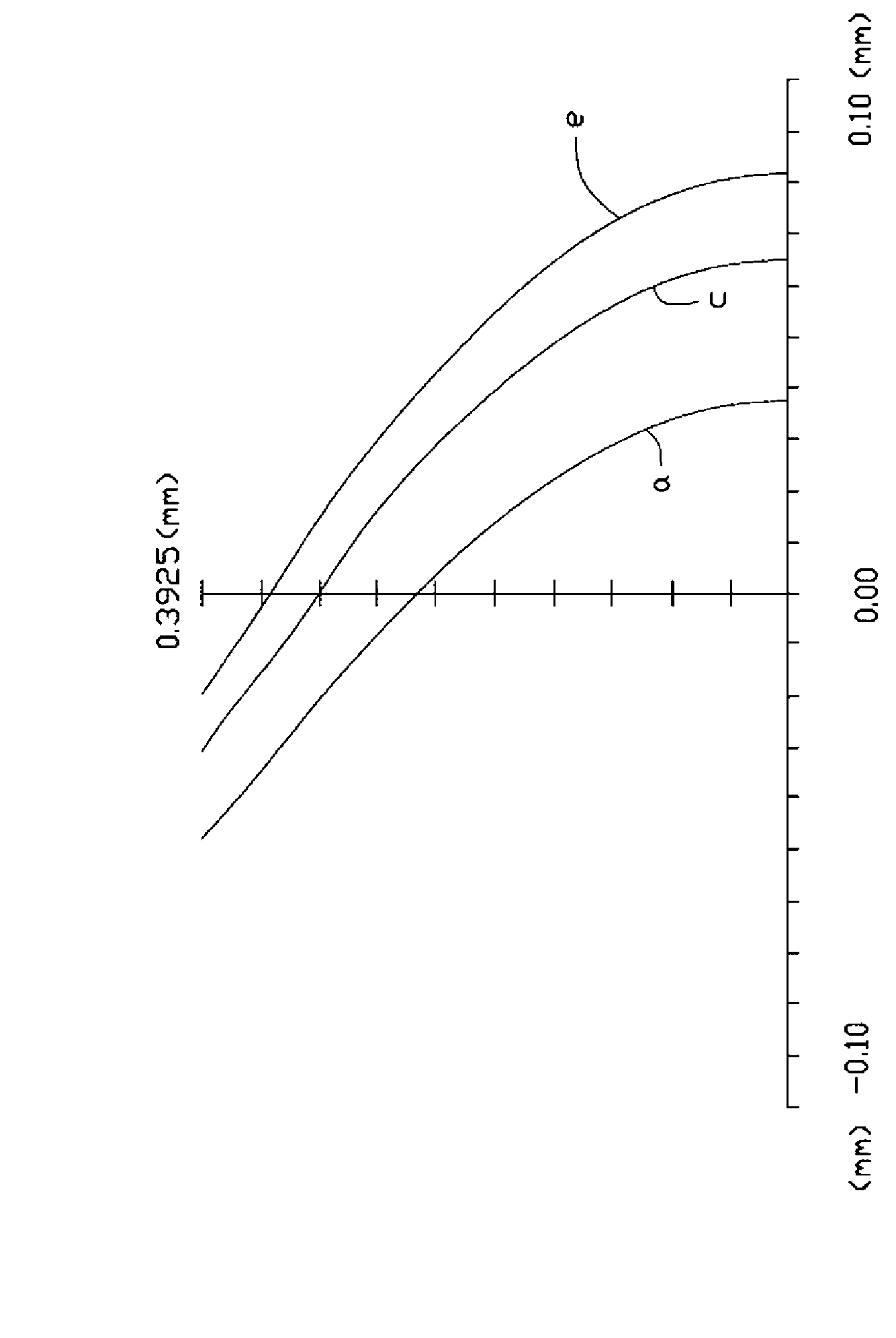

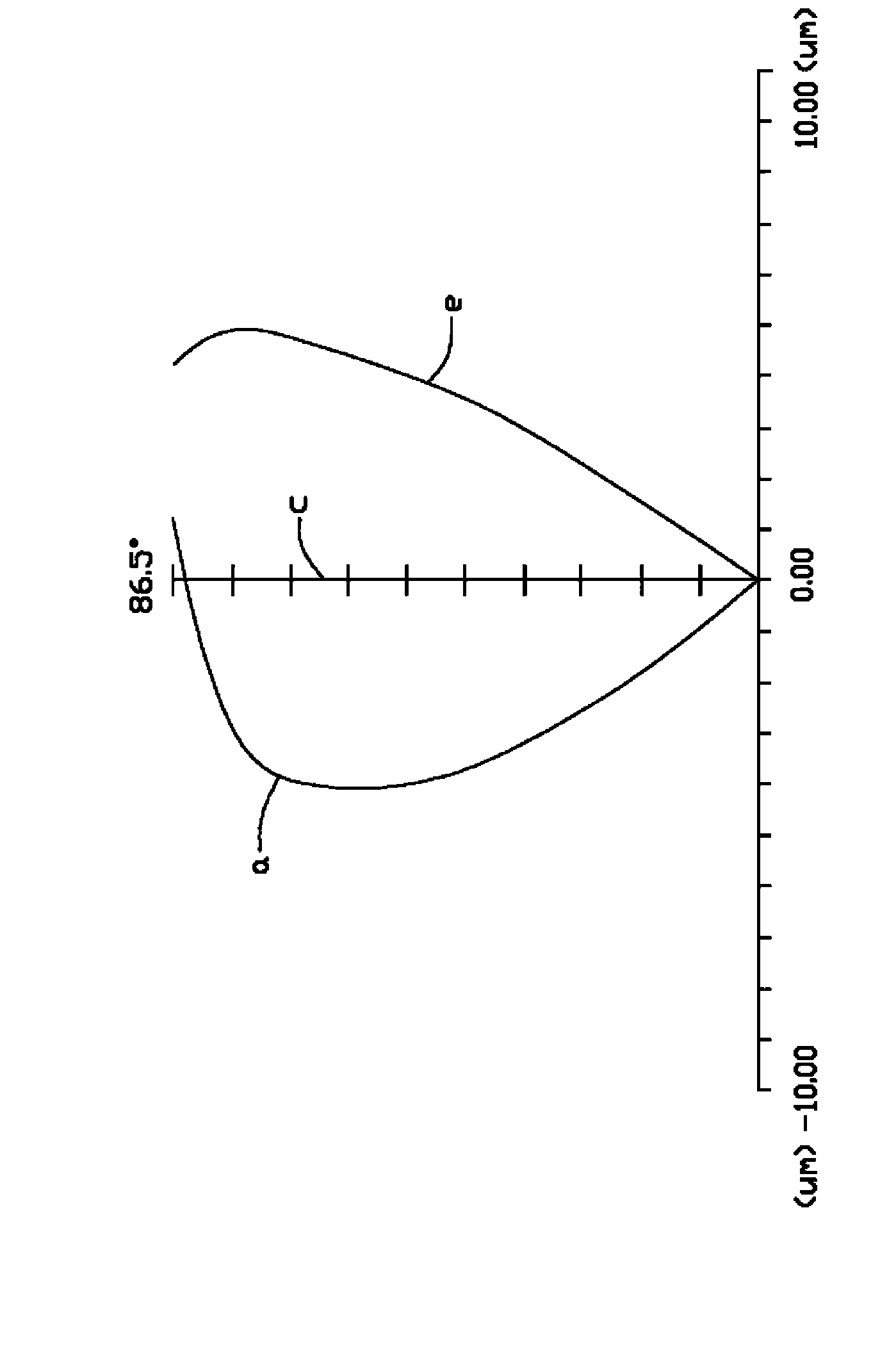

Image-capturing lens

The invention provides an image-capturing lens. The lens comprises a plurality of lenses, wherein, the lenses comprise a first lens with negative power, a second lens with negative power, a third lens with positive power, a fourth lens with negative power, a fifth lens with positive power and a sixth lens with positive power which are sequentially arranged from an object side to an image side; and each lens comprises an object side face arranged towards the object side and an image side face arranged towards the image side. The image-capturing lens meets the following conditional expressions: (1) R1 is more than 8mm and less than 12mm; (2) R2 is more than 1mm and less than 2mm; (3) Nd1 is more than 1.8 and less than 2; (4) vd1 is more than 30 and less than 50; (5) D1 is more than 0.8mm and less than 1.2mm; and (6) -f1 is more than 2 and less than 3, wherein, R1 is curvature radius of the object side face of the first lens; R2 is the curvature radius of the image side face of the first lens; Nd1 is the refractive index of the first lens; vd1 is the Abbe number of the first lens; D1 is the center thickness of the first lens; and f1 is the focal length of the first lens.

Owner:FOSHAN PREMIER SCI & TECH CO LTD +1

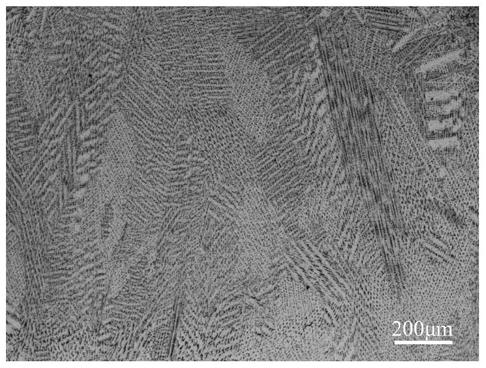

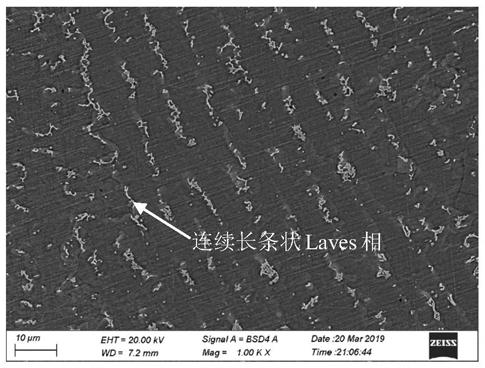

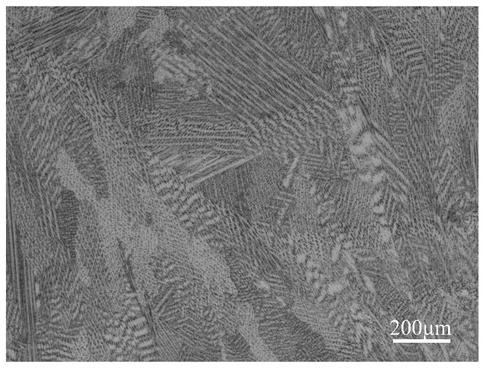

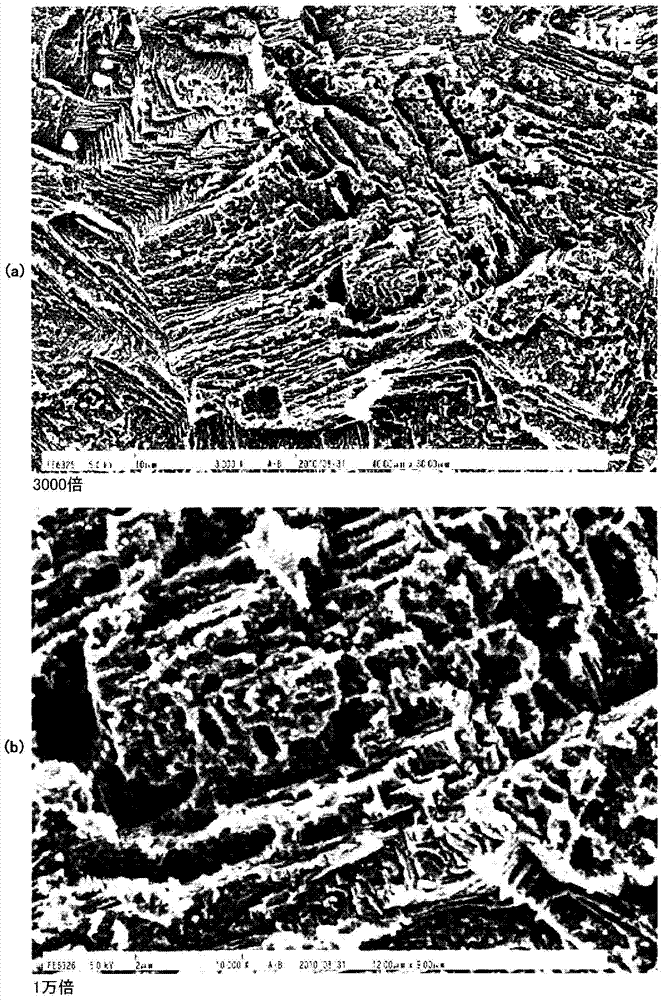

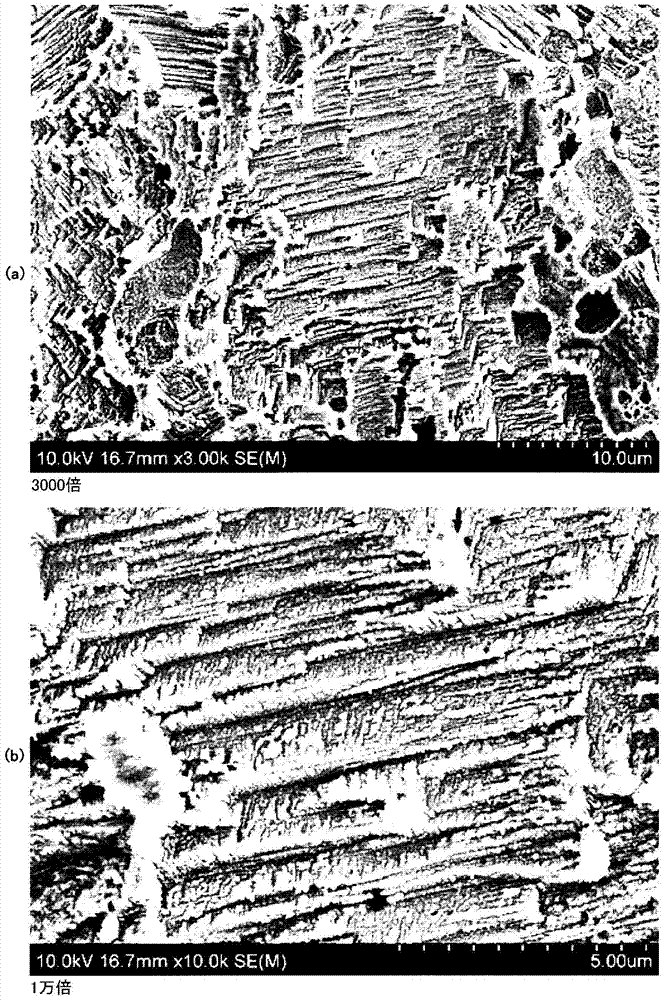

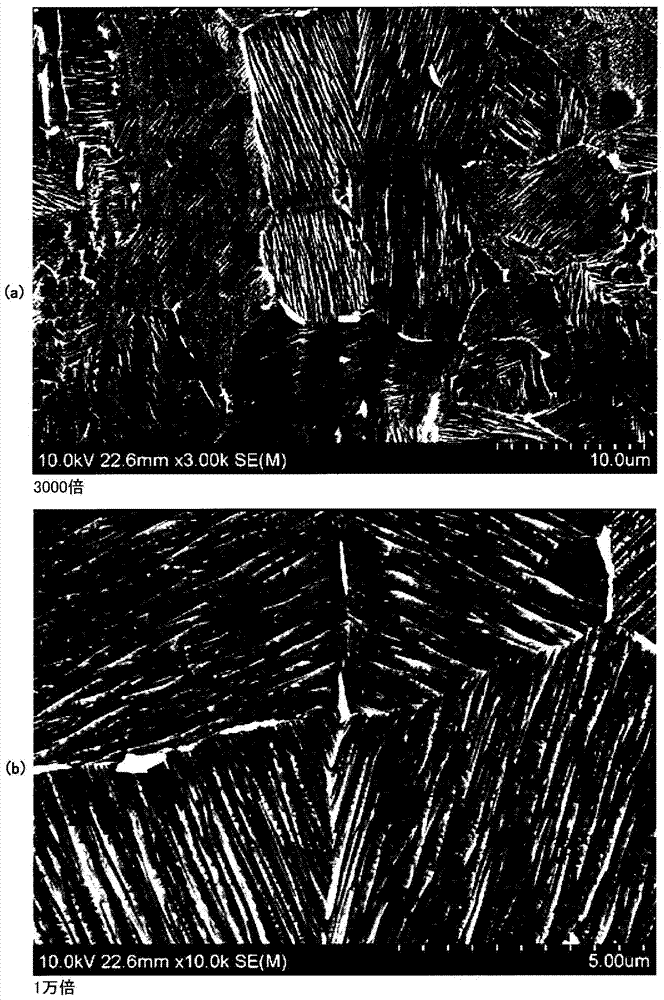

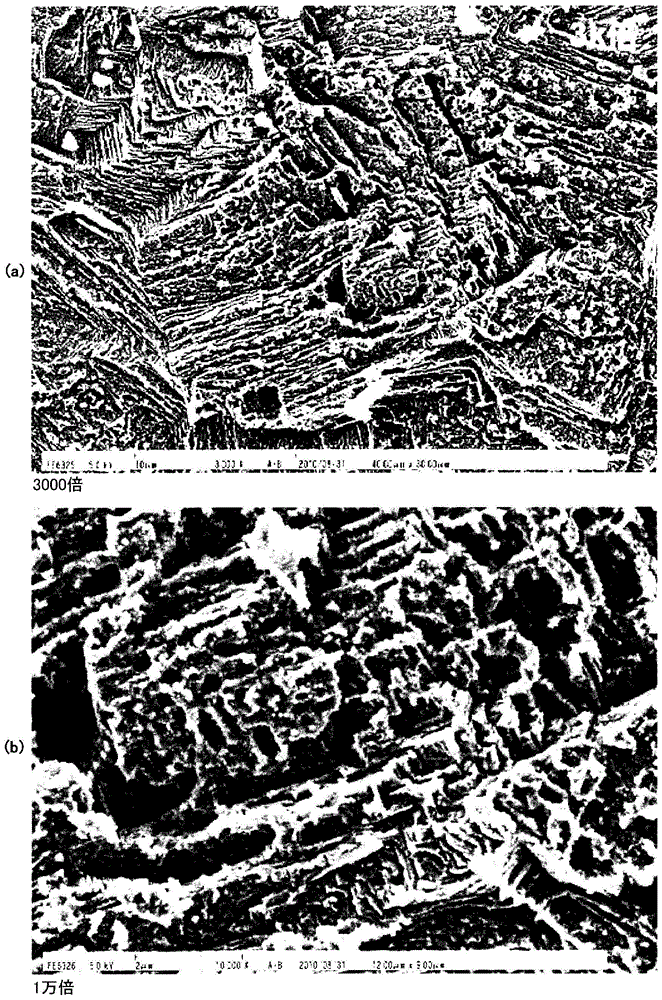

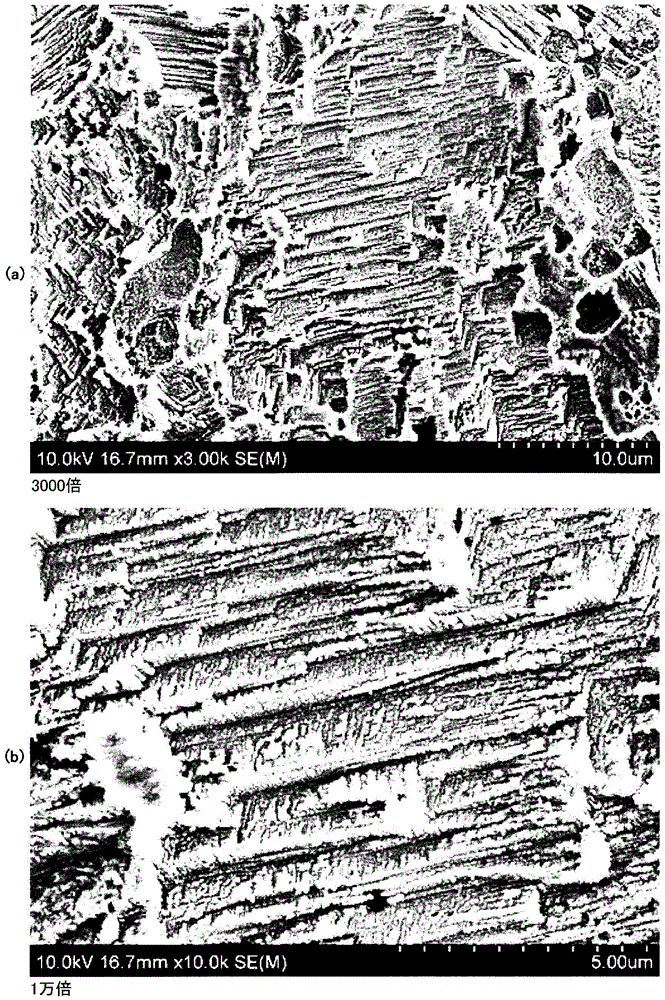

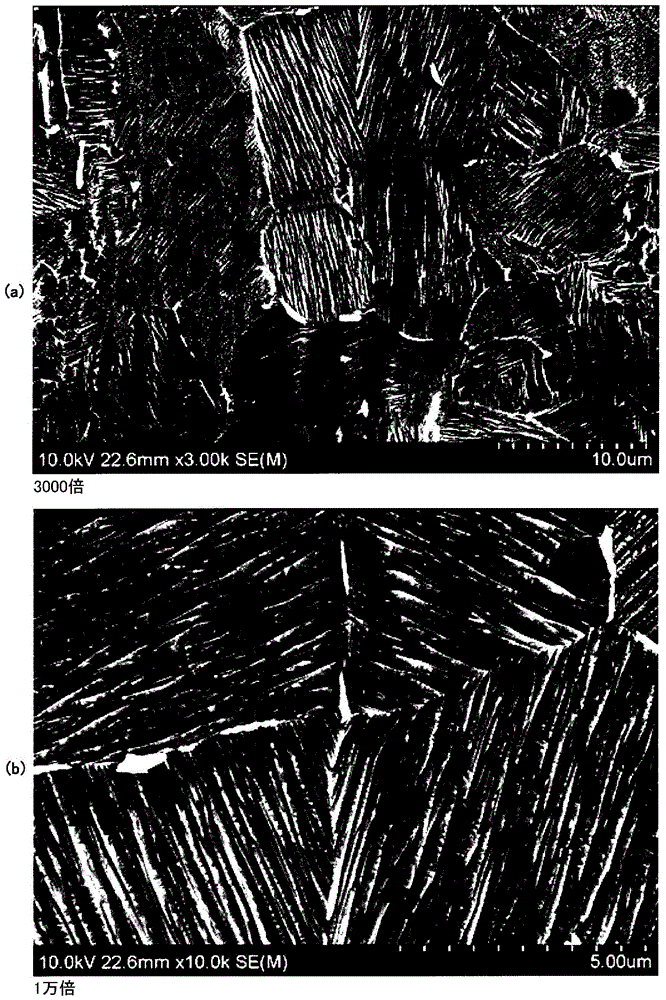

Synchronous laser heat treatment method for laser additive manufacturing nickel-based high-temperature alloy

ActiveCN110315075AImprove coordination and deformation abilityFine and uniform grainAdditive manufacturing apparatusIncreasing energy efficiencyMechanical propertyHeat treated

The invention discloses a synchronous laser heat treatment method for laser additive manufacturing a nickel-based high-temperature alloy. According to the method, morphology size and distribution of Laves phase can be effectively regulated and controlled, the Laves phase is converted into a discrete granular shape from a deposited continuous long strip, and the volume fraction of the Laves phase is obviously reduced along with extension of the laser heat treatment time. According to the laser heat treatment method, synchronous heat treatment in a deposition forming process can be realized, local area Laves phase morphology and distribution can be regulated and controlled under the condition that the tissue performance of a laser repair base material area is not influenced, the granular Laves phase which are fined and dispersion distributed is obtained, so that the overall mechanical property of parts is improved, and effective utilization can be obtained in the repair and remanufacturing of the high-temperature alloy structural member; and in addition, the method can also be applied to the fields of high-temperature alloy material preparation, high-temperature alloy structural member rapid manufacturing and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

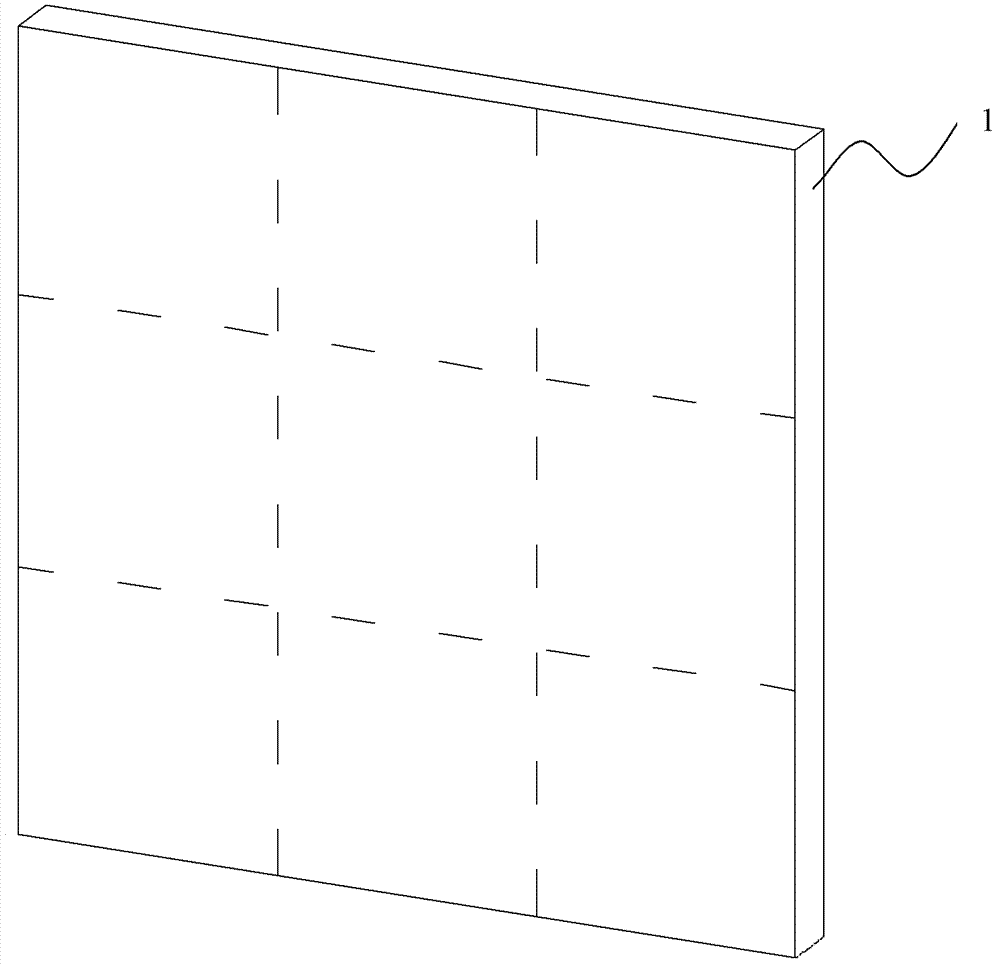

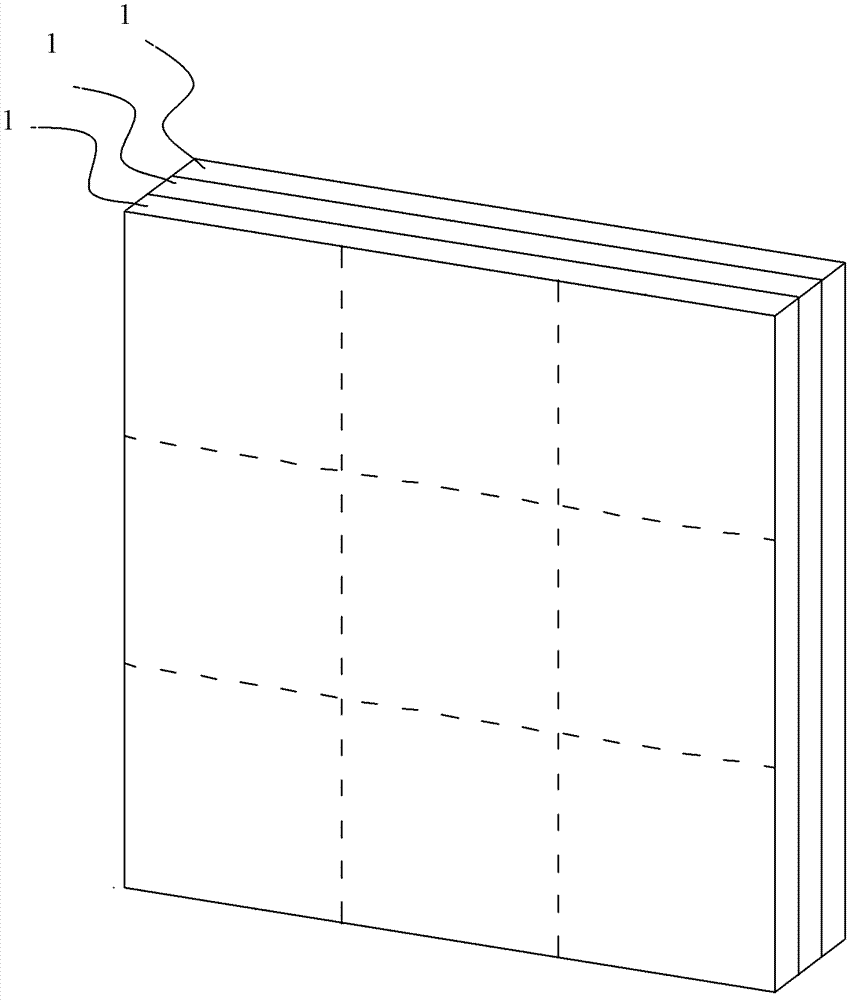

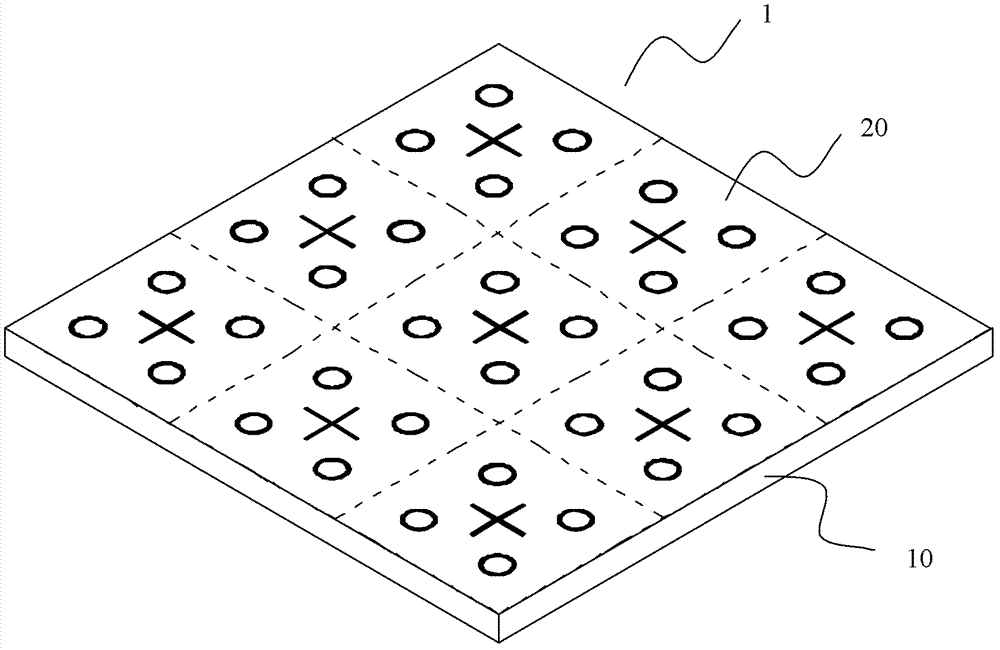

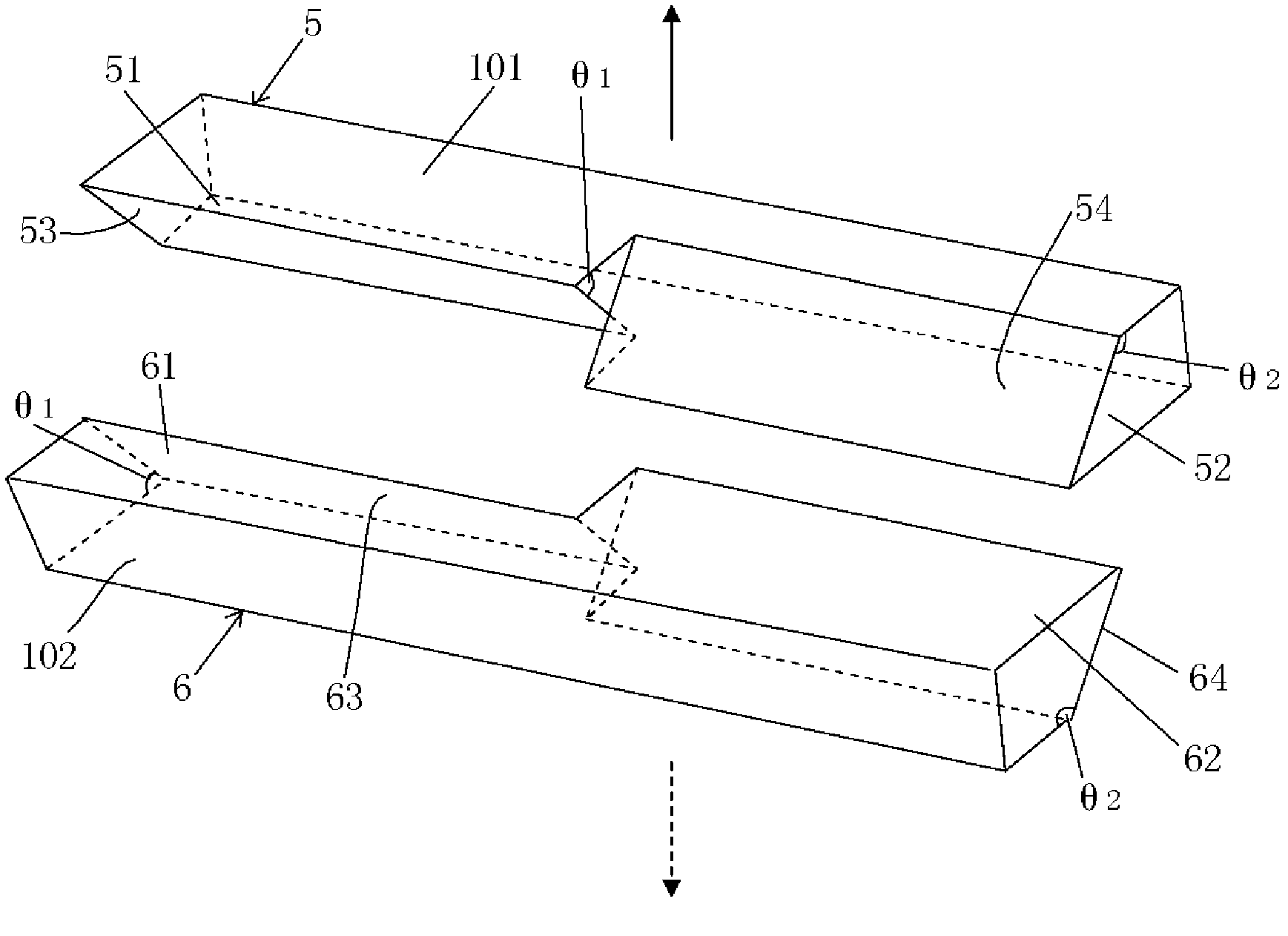

Metamaterial base station antenna housing and antenna system

InactiveCN103367911ALimit thicknessLimiting dielectric constantRadiating element housingsFour quadrantsDielectric

The invention relates to a metamaterial base station antenna housing and an antenna system. The metamaterial base station antenna housing is covered on an antenna and comprises at least one metamaterial sheet layer, wherein each of the metamaterial sheet layer comprises a substrate and a plurality of artificial microstructures arranged on the substrate in an array; the substrate can be divided into a plurality of metamaterial units, and each of the metamaterial units is configured with one artificial microstructure; each of the artificial microstructure comprises a cross-shaped structure arranged at the center of the metamaterial unit and four circular ring structures arranged in four quadrants divided by the cross-shaped structure respectively. According to the invention, the artificial microstructures with special shapes are adhered to the substrate, the relative dielectric constant, the refractive index and the impedance of the material are changed through adjusting the shape and the size of the artificial microstructures, thereby reinforcing transmission of electromagnetic waves, and improving the directivity and the gain of the antenna.

Owner:KUANG CHI INNOVATIVE TECH

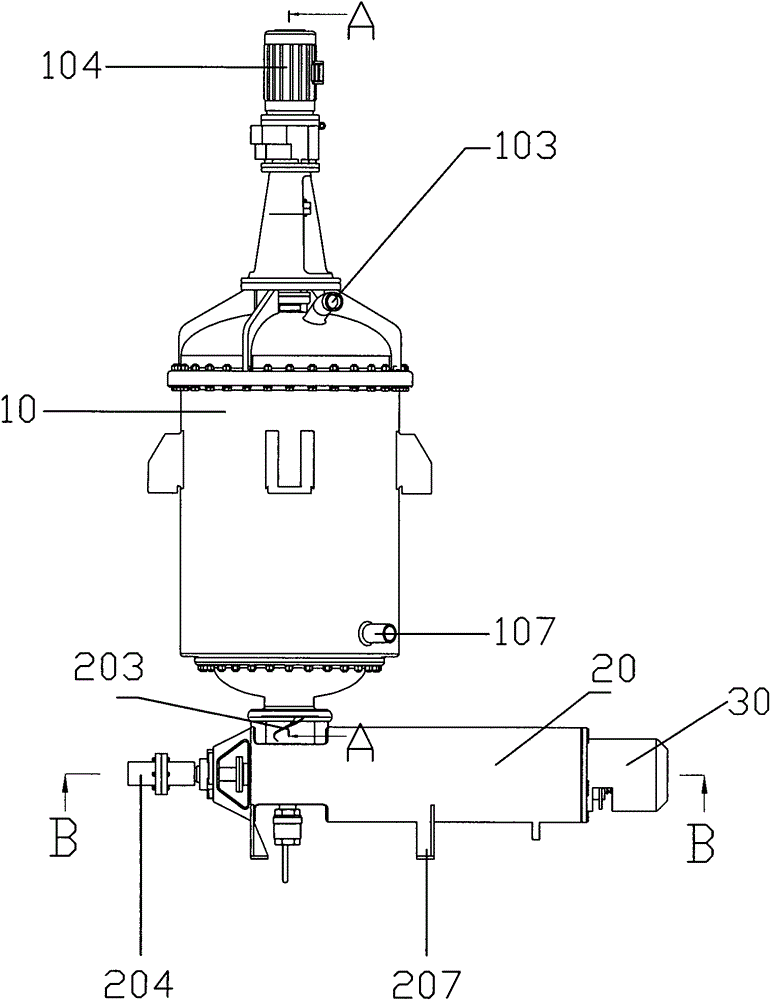

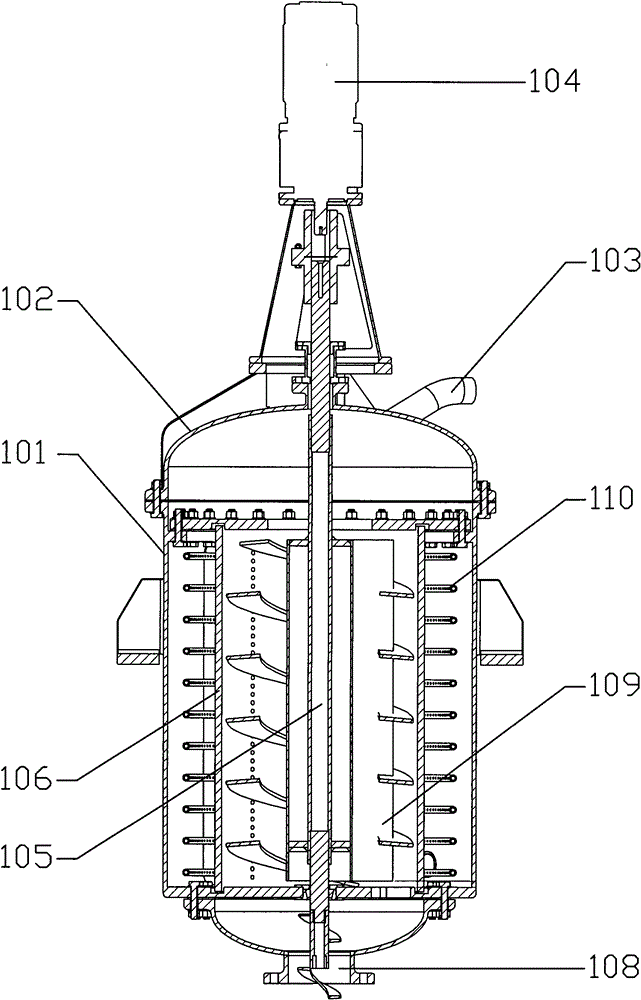

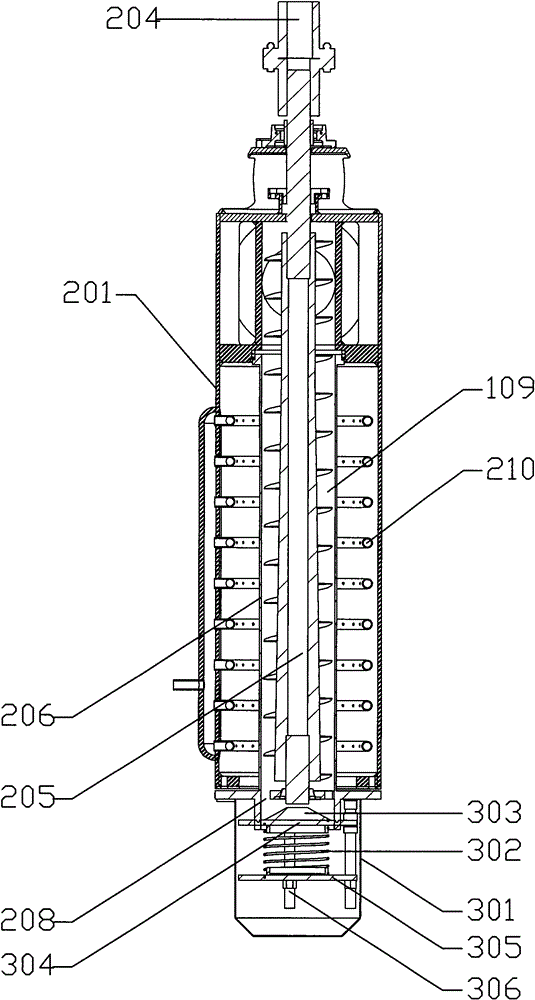

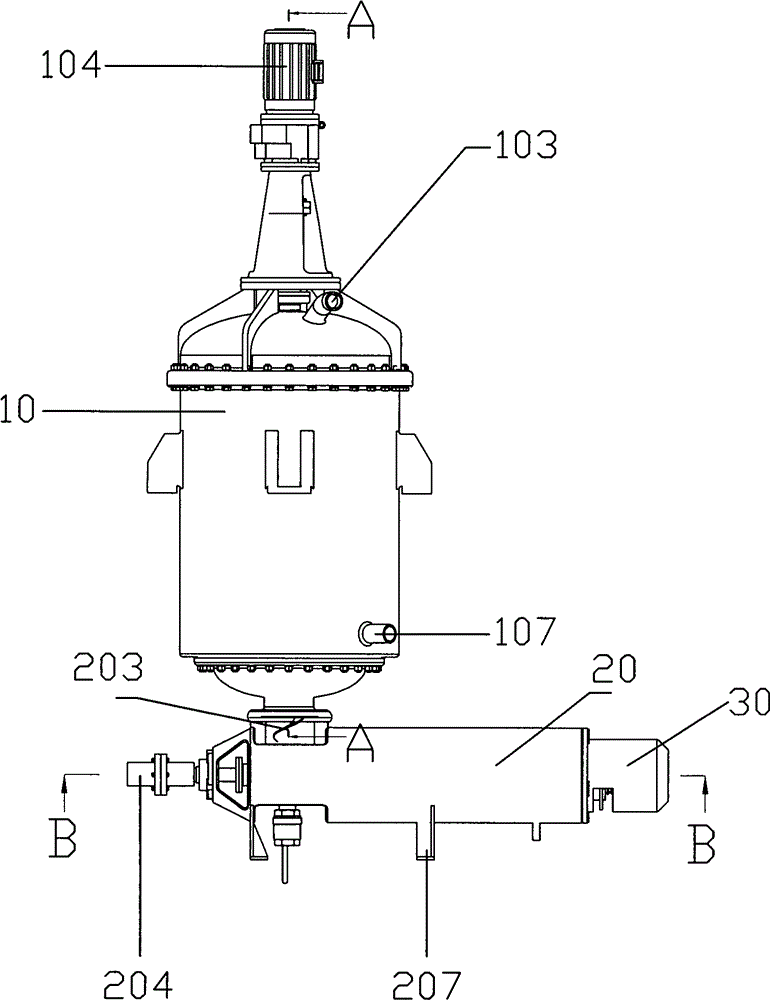

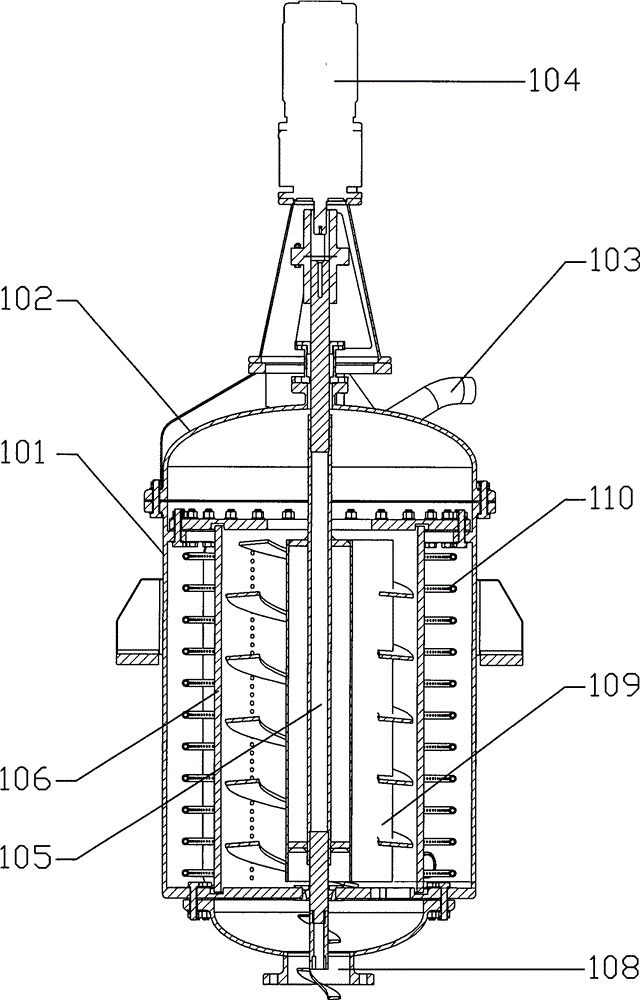

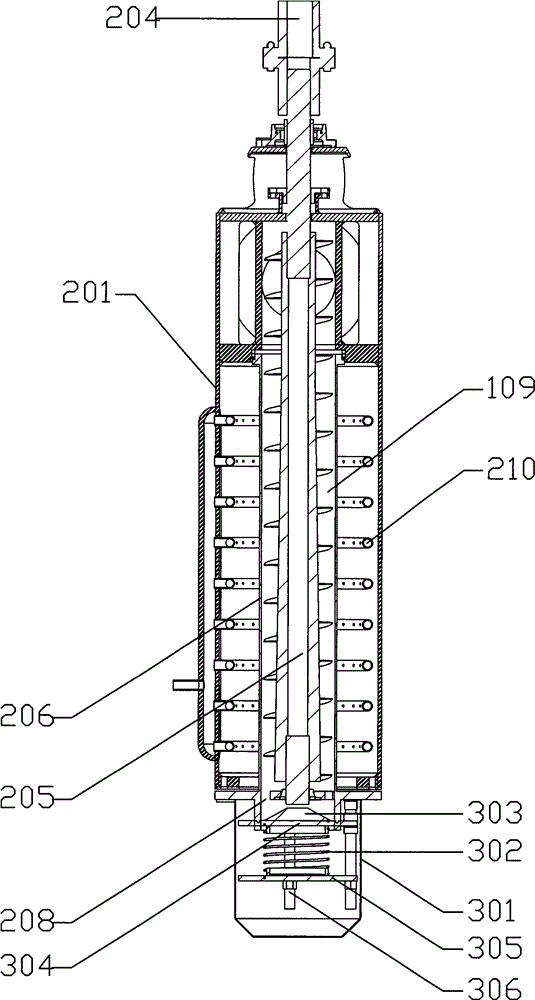

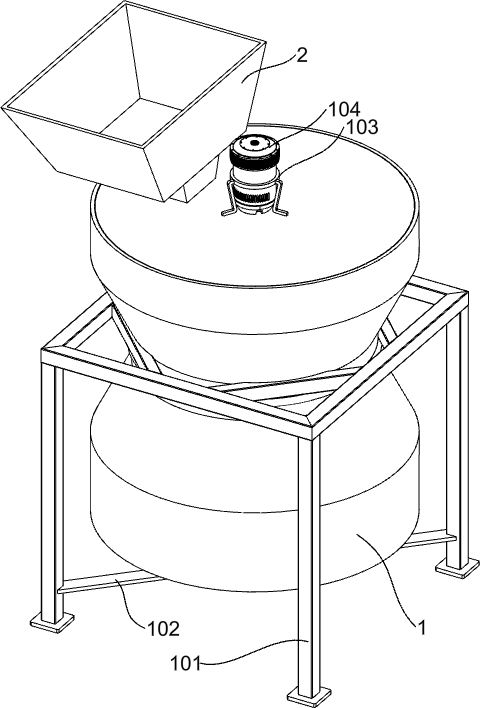

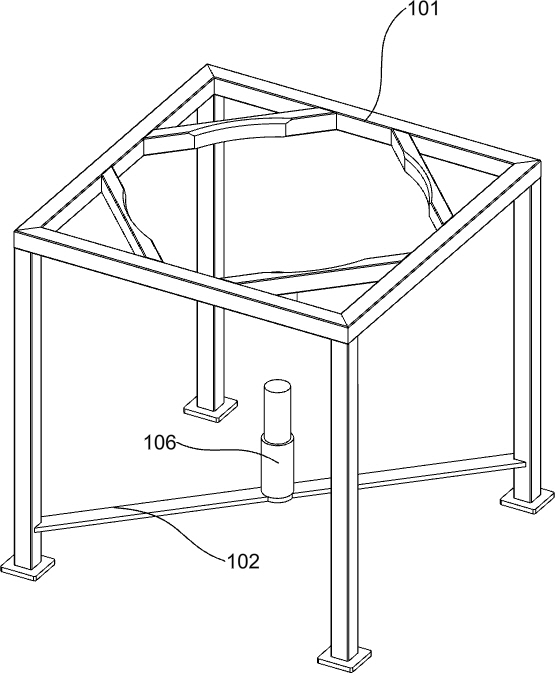

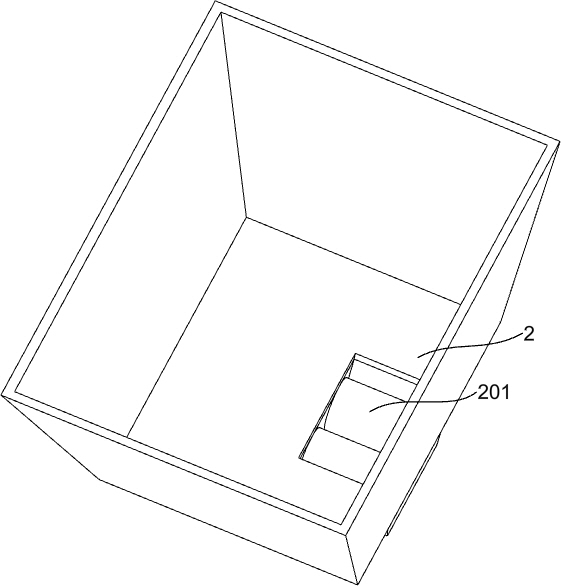

Full-automatic continuous filtering and filter pressing slag unloading machine

The invention relates to a full-automatic continuous filtering and filter pressing slag unloading machine comprising a filtering device, wherein the filtering device comprises a filter cartridge, a filtering stirring shaft and a first filtering medium; a liquid inlet is arranged on the top end of the filter cartridge; the filtering stirring shaft is installed in the filter cartridge through a sealing bearing, and a helical blade is arranged on the filtering stirring shaft; the first filtering medium is arranged between the inner wall of the filter cartridge and the filtering stirring shaft; a liquid outlet is arranged on the bottom end of the filter cartridge; and a press filtering device, the press filtering device comprises a press filter cartridge, a press filtering stirring shaft and a second filtering medium; a slag inlet is arranged on the top end of the press filter cartridge, and the slag inlet is communicated with the liquid outlet; the press filtering stirring shaft is installed in the press filter cartridge through a sealing bearing, and a helical blade is arranged on the press filtering stirring shaft; the second filtering medium is arranged between the inner wall of the press filter cartridge and the press filtering stirring shaft; and a slag outlet is arranged on the bottom end of the press filter cartridge, and an automatic resetting switch is arranged at the slag outlet. The full-automatic continuous filtering and filter pressing slag unloading machine provided by the invention can be conducted with continuous pressure filtration, can automatically feed and automatically discharge and unload slag and is consistently located at a thin layer filtering environment, so that the filtering speed is high, and the machine is operated under a complete sealed state, and the operation environment is excellent.

Owner:王启

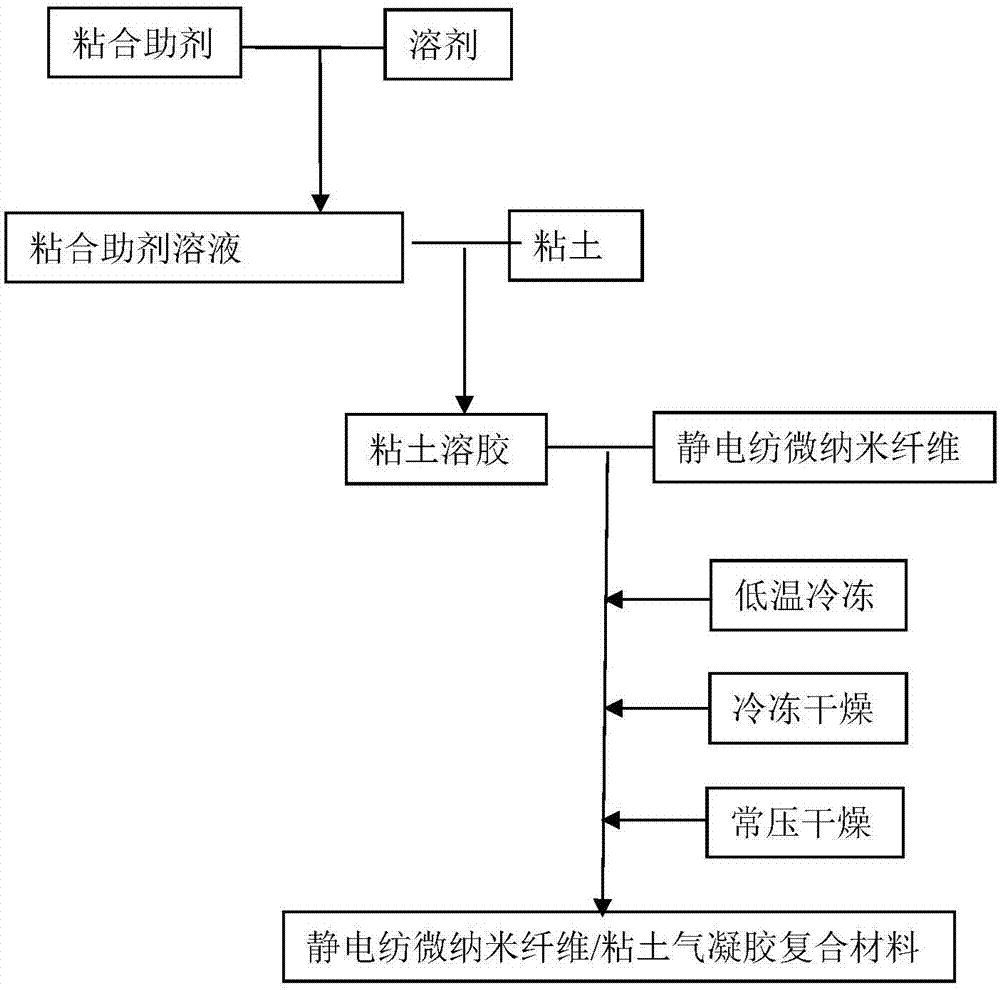

Electrostatic spinning micro-nanofiber/clay aerogel composite material and preparation method thereof

InactiveCN107473627ASimple preparation processGood biocompatibilityCeramicwareMonocomponent halogenated hydrocarbon artificial filamentMicro nanoFreeze-drying

The invention provides an electrostatic spinning micro-nanofiber / clay aerogel composite material and a preparation method thereof. Electrostatic spinning micro-nanofiber is filled in clay / clay additive sol; the electrostatic spinning micro-nanofiber / clay aerogel composite material is prepared through low-temperature freezing drying. The clay aerogel is enhanced by the electrostatic spinning micro-nanofiber in the micro-nano level, so that the composite material has good interface bonding performance and structure completeness; the mechanical property is obviously improved; the weight is light; the environment is protected; the preparation method uses low-temperature freezing drying; the steps of aging, replacement, modification and the like required by the ordinary silicon dioxide aerogel preparation process are not needed; the process is simple; the environment is protected; wide application prospects are realized in the aspects of building, industry, aerospace, heat insulation garments and the like.

Owner:GUANGZHOU UNIVERSITY

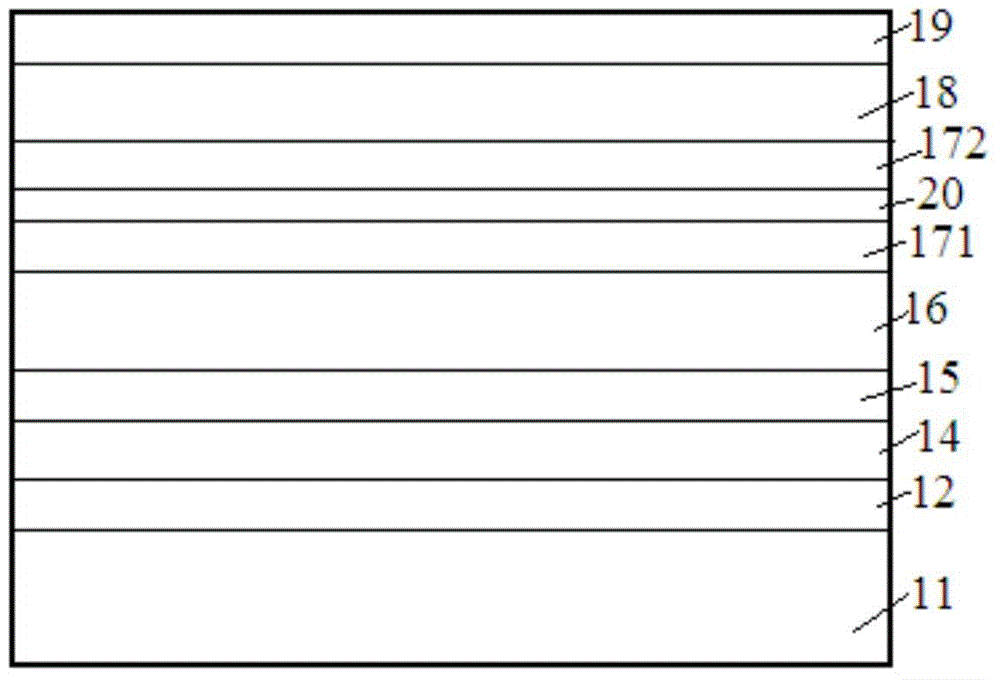

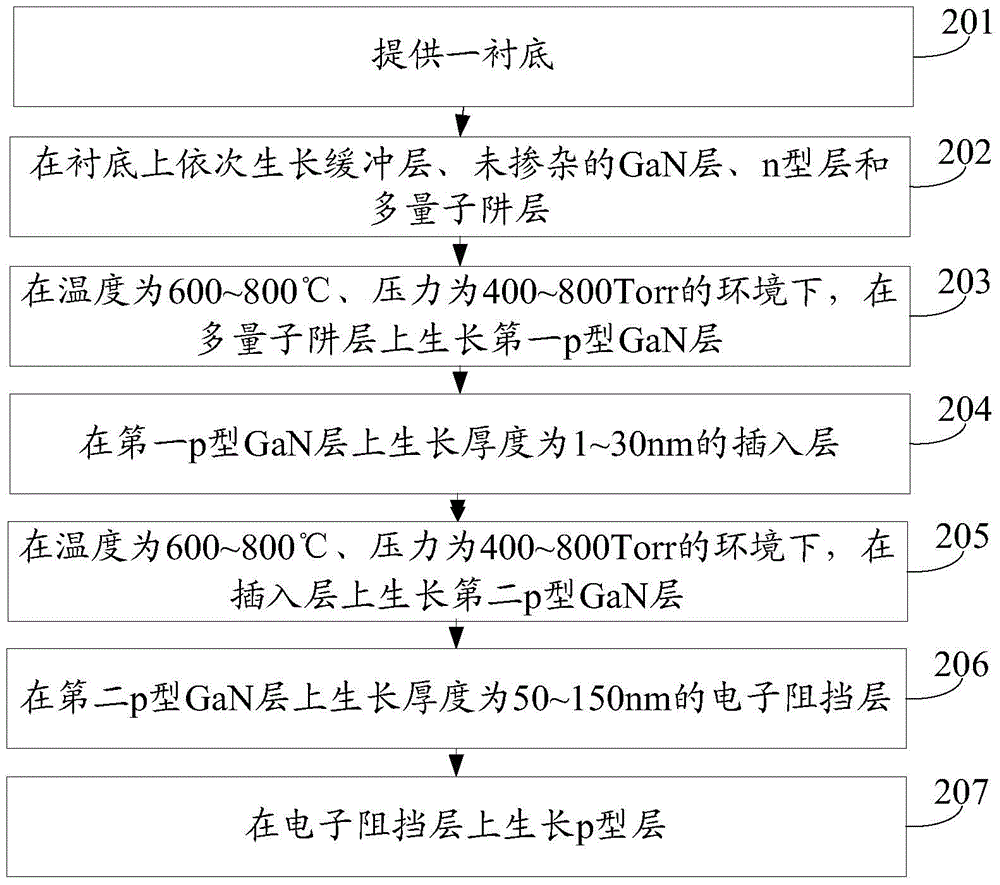

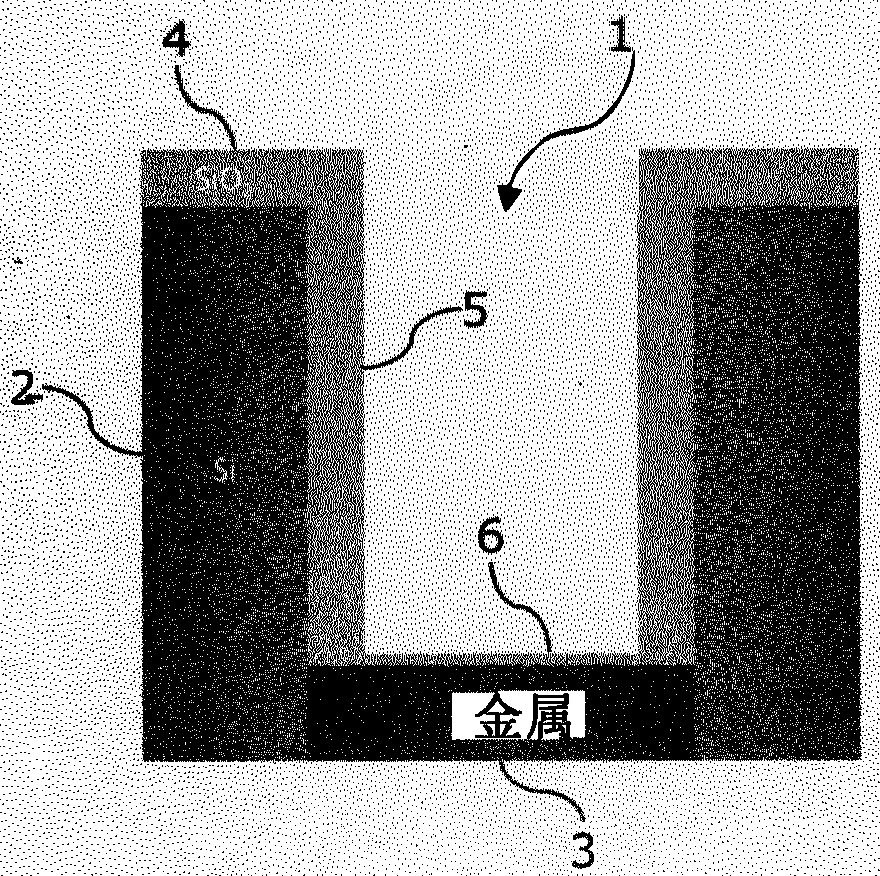

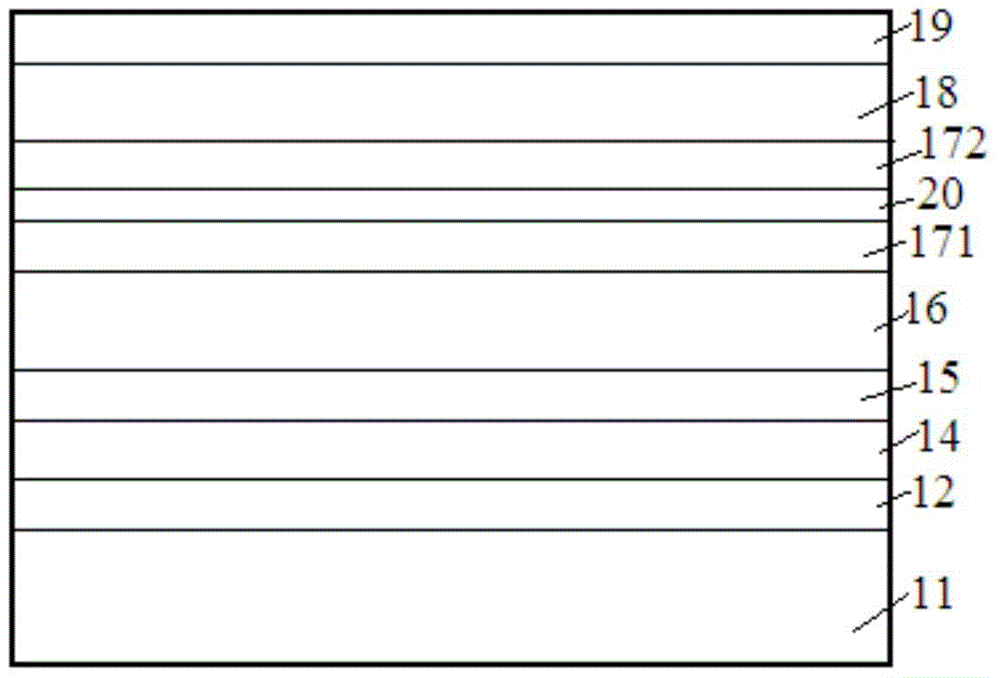

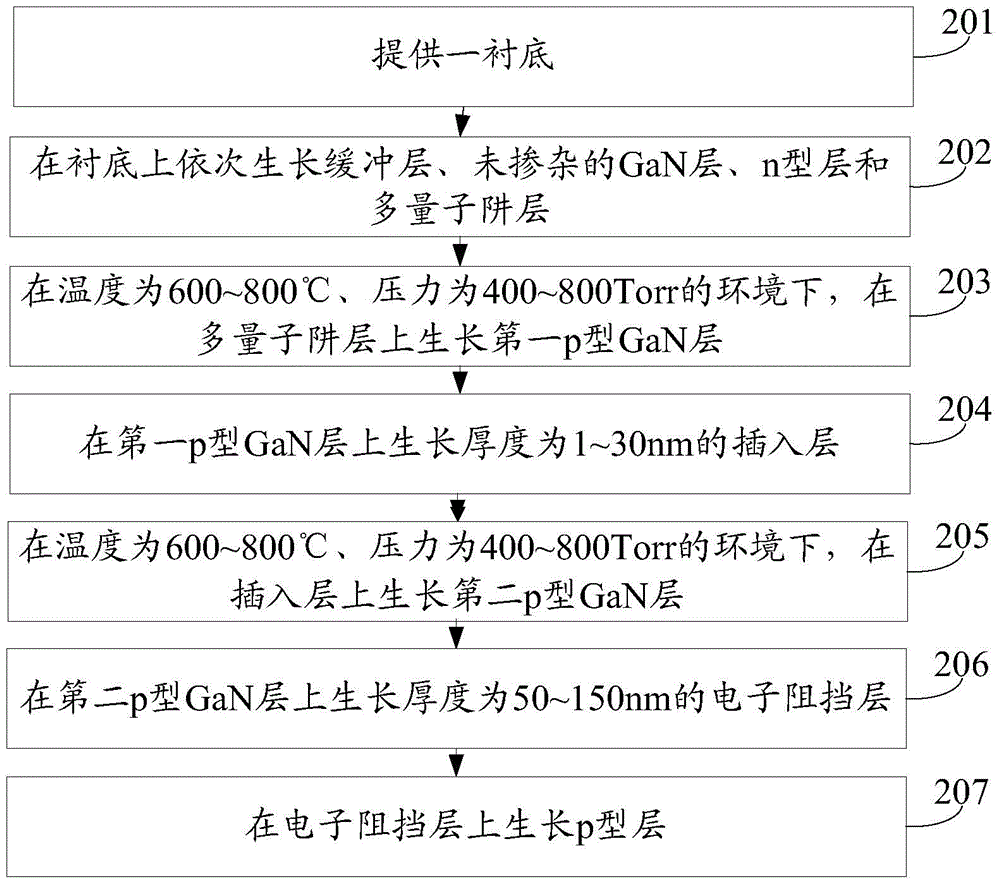

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN104009140AFast vertical growthDoes not affect activitySemiconductor devicesHigh pressureElectron blocking layer

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method of the light emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a nucleating layer, a buffer layer, an undoped GaN layer, an n-type layer, a multiple-quantum-well layer, a first p-type GaN layer, a second p-type GaN layer, an electron barrier layer and a p-type layer, wherein the nucleating layer, the buffer layer, the undoped GaN layer, the n-type layer, the multiple-quantum-well layer, the first p-type GaN layer, the second p-type GaN layer, the electron barrier layer and the p-type layer grow upwards on the substrate. The thickness of the electron barrier layer ranges from 50 nm to 150 nm, the growth temperature of the first p-type GaN layer ranges from 600 DEG C to 800 DEG C, the growth pressure of the first p-type GaN layer ranges from 400 Torr to 800 Torr, the growth temperature of the second p-type GaN layer ranges from 800 DEG C to 1000 DEG C, the growth pressure of the second p-type GaN layer ranges from 50 Torr to 500 Torr. The first p-type GaN layer growing under high pressure and low temperature is arranged, and a hole injection channel is provided, so that hole injection efficiency is improved; through the second p-type GaN layer growing under low pressure and high temperature, crystalline quality is improved, the thickness of the electron barrier layer is limited, and hole injection efficiency is improved.

Owner:HC SEMITEK SUZHOU

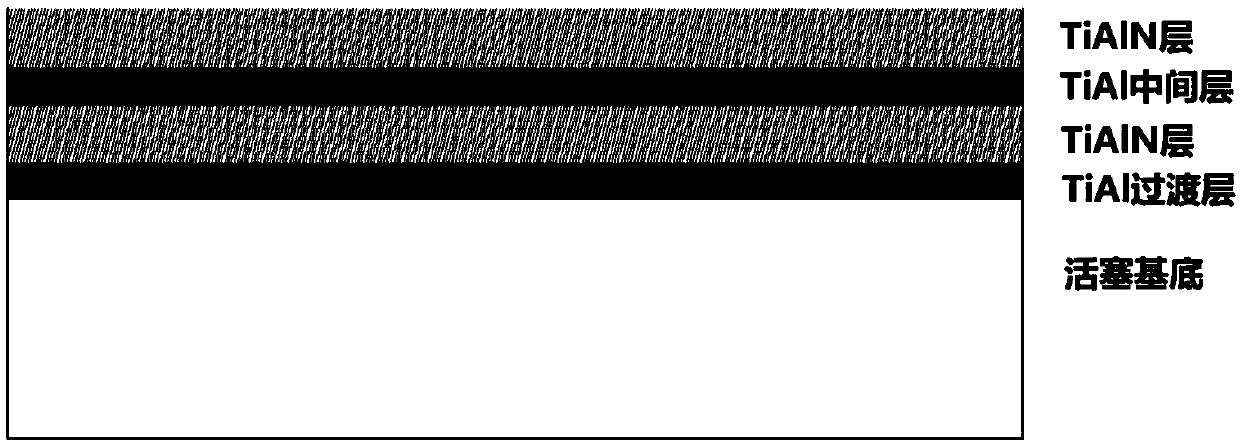

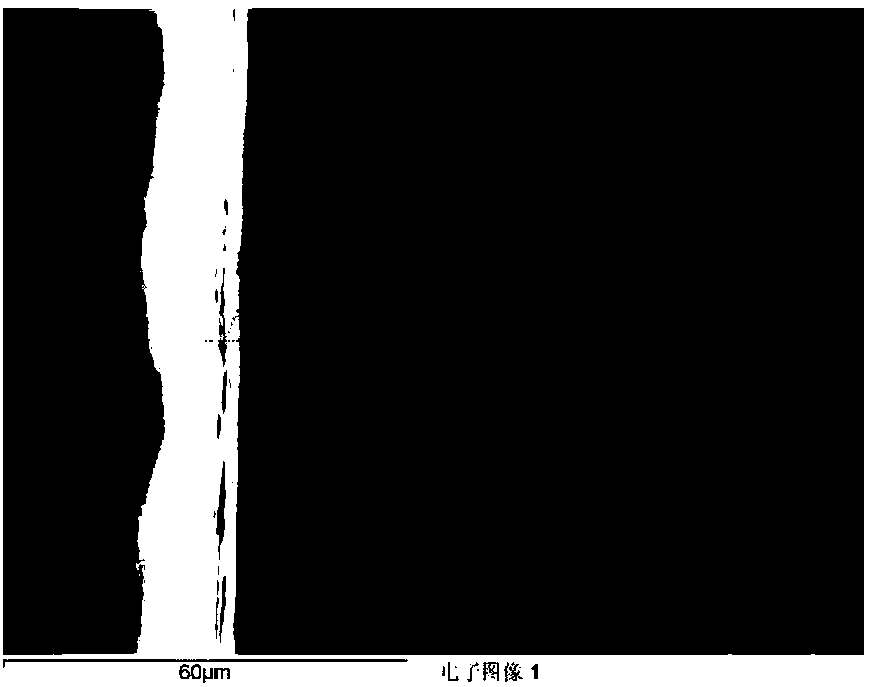

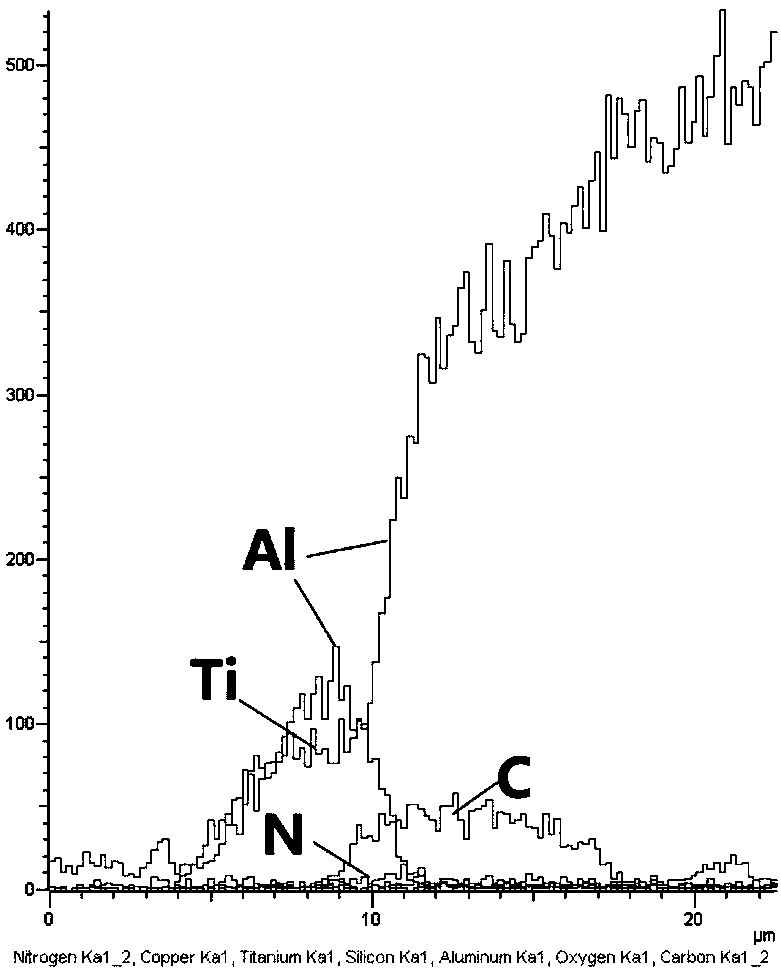

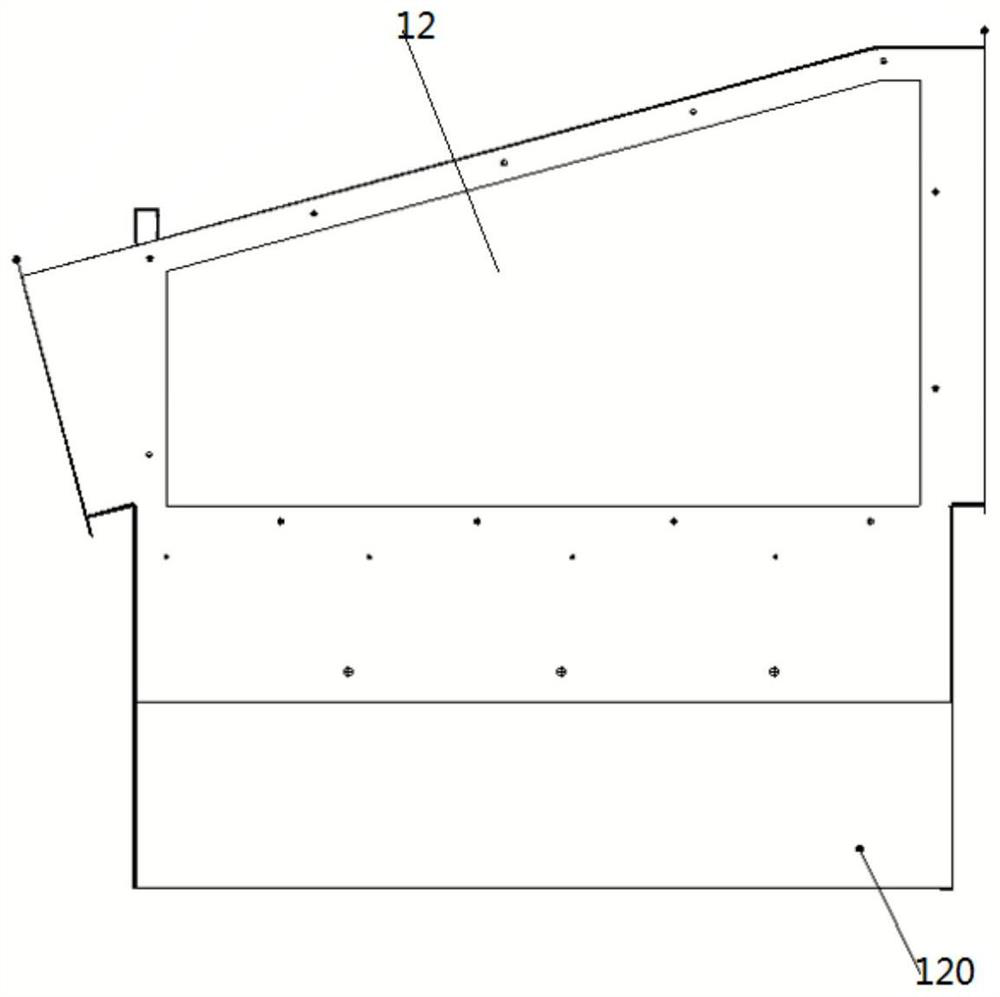

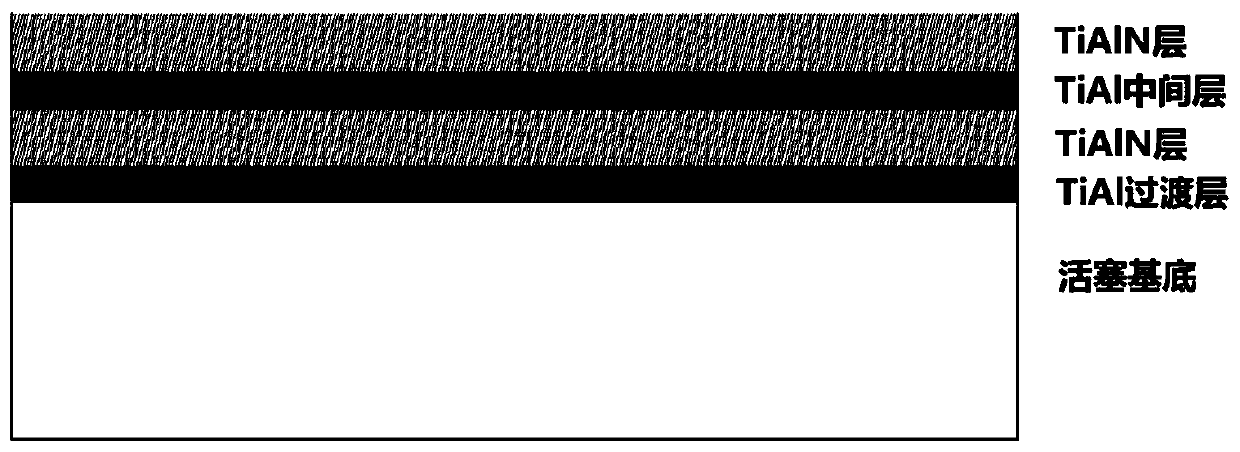

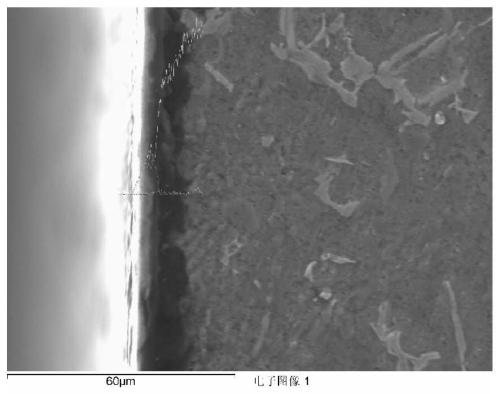

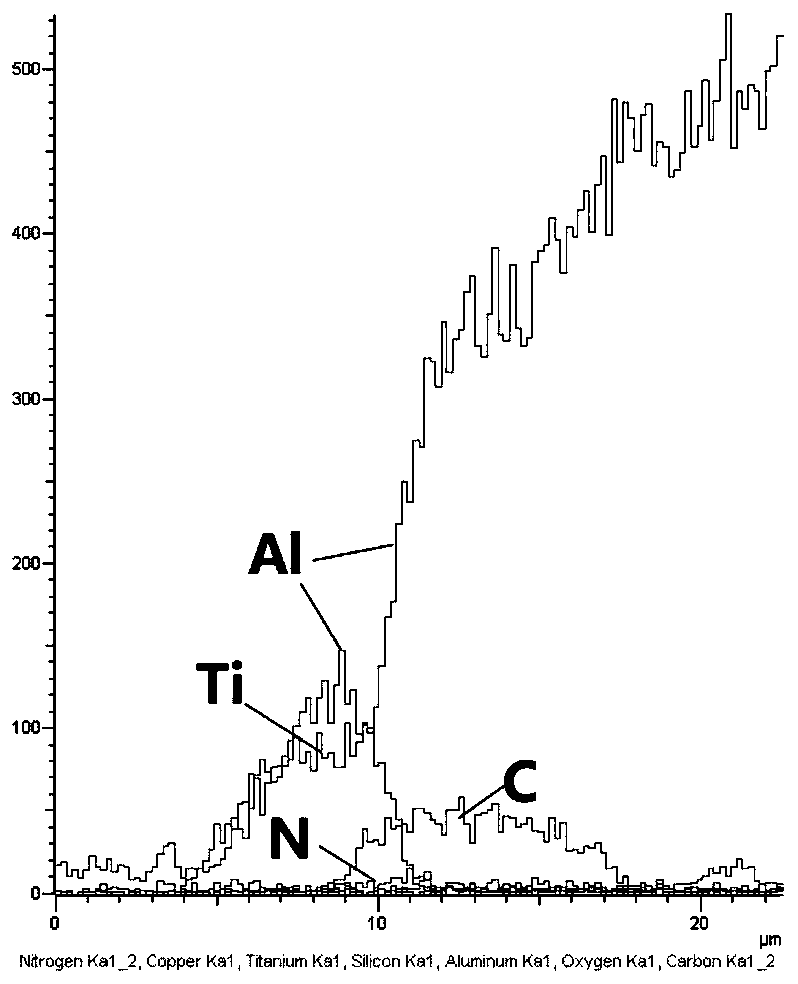

Piston with (Ti, Al)N multilayer heat insulating and wear resisting super-thick coating on surface and preparation method and application of piston

ActiveCN107604312AImprove wear resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingPistonInternal combustion engine

The invention relates to a piston with a (Ti, Al)N multilayer heat insulating and wear resisting super-thick coating on the surface and a preparation technology and application of the piston. The structure of the piston comprises two schemes. According to the first scheme, the piston comprises a base, a TiAl transition layer and a TiAlN clad layer, and the TiAl transition layer evenly wraps the base; and the TiAlN clad layer evenly wraps the TiAl transition layer. According to the second scheme, the piston comprises a base, a first TiAl transition layer, a first TiAlN clad layer, a second TiAltransition layer and a second TiAlN clad layer, and the piston structurally comprises the base, the first TiAl transition layer, the first TiAlN clad layer, the second TiAl transition layer and the second TiAlN clad layer in sequence. According to application of the piston, the piston is used for an internal combustion engine. The designed piston surface has heat insulation performance, wear resistance, oxidation resistance and heat shock resistance, and the service life of the piston is effectively prolonged.

Owner:XIANGTAN UNIV

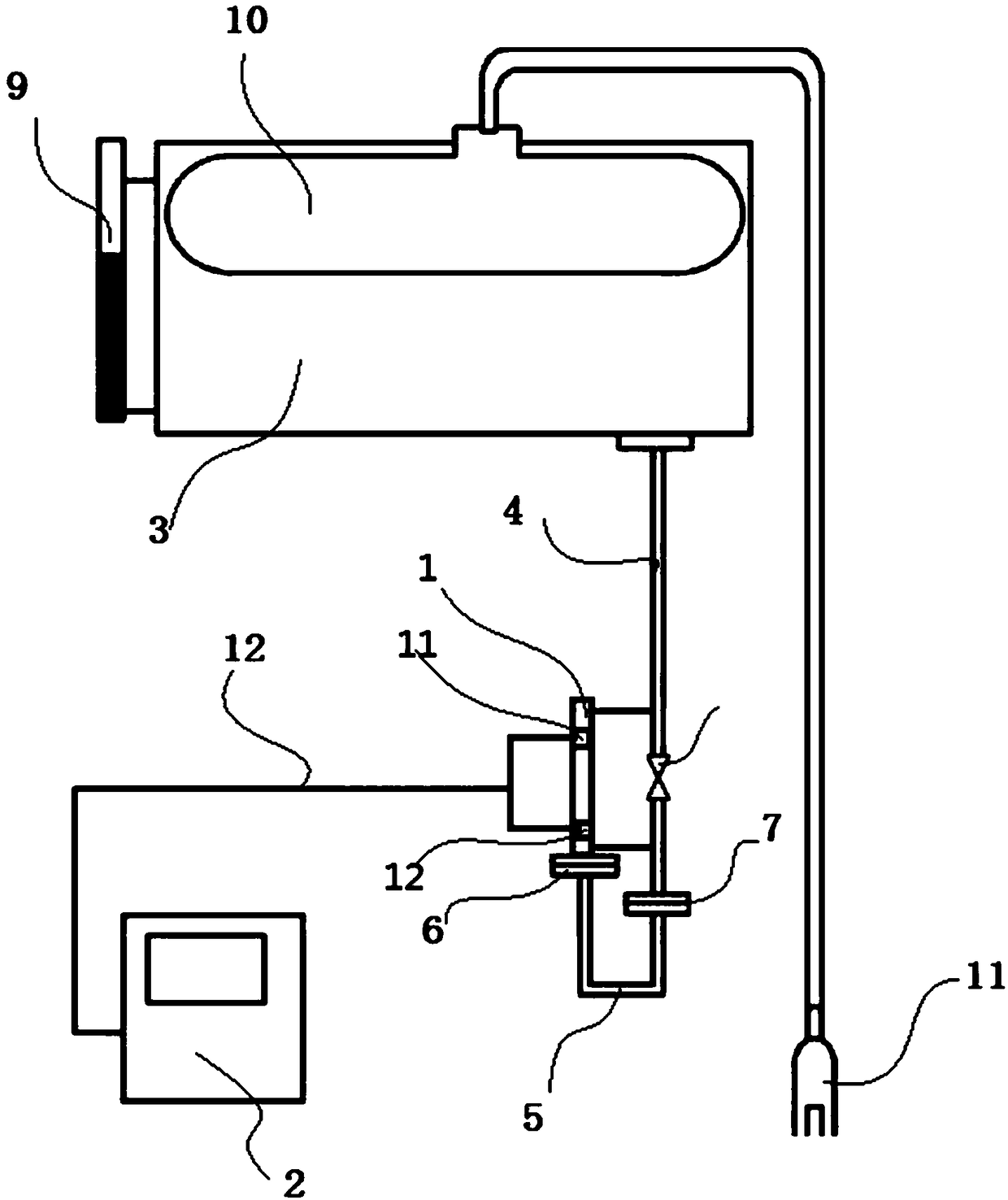

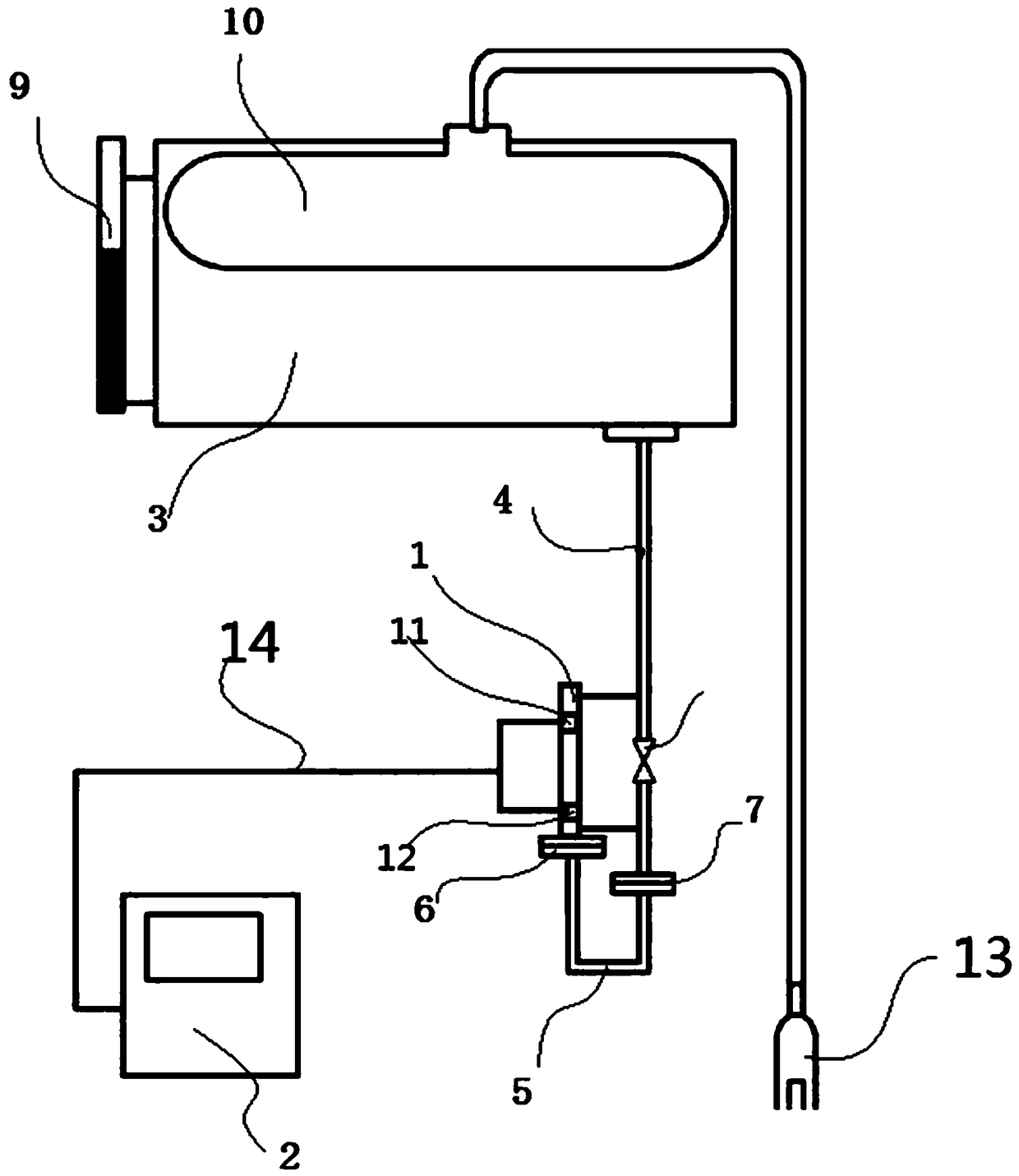

Measuring equipment for liquid level of oil conservator for power transmission and transformation engineering

PendingCN108593043AEliminate densityIncrease known quantityLevel indicators by pressure measurementElectric power transmissionLiquid density

The invention relates to measuring equipment for the liquid level of an oil conservator for power transmission and transformation engineering. The measuring equipment comprises a pressure signal collecting device, a controller and an oil guiding pipeline connected with the oil conservator; the pressure signal collecting device is internally provided with a first pressure sensor and a second pressure sensor which are used for measuring oil pressure of two different vertical heights in the oil guiding pipeline respectively, the first pressure sensor and the second pressure sensor are both connected to the controller, and the first pressure sensor is higher than the second pressure sensor. Compared with the prior art, the measuring equipment has the advantages that through arrangement of thetwo pressure sensors, a known quantity can be added, and the liquid density can be conveniently eliminated by using a ratio of two hydraulic pressure values in the later period so that the measuring equipment can be applied to different liquids.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

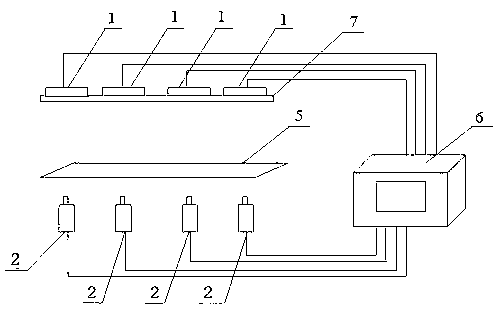

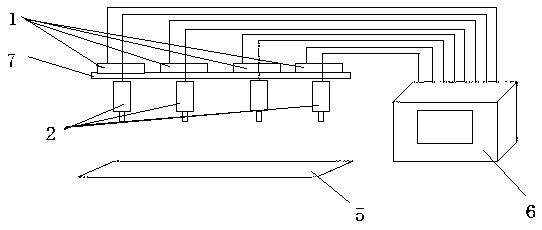

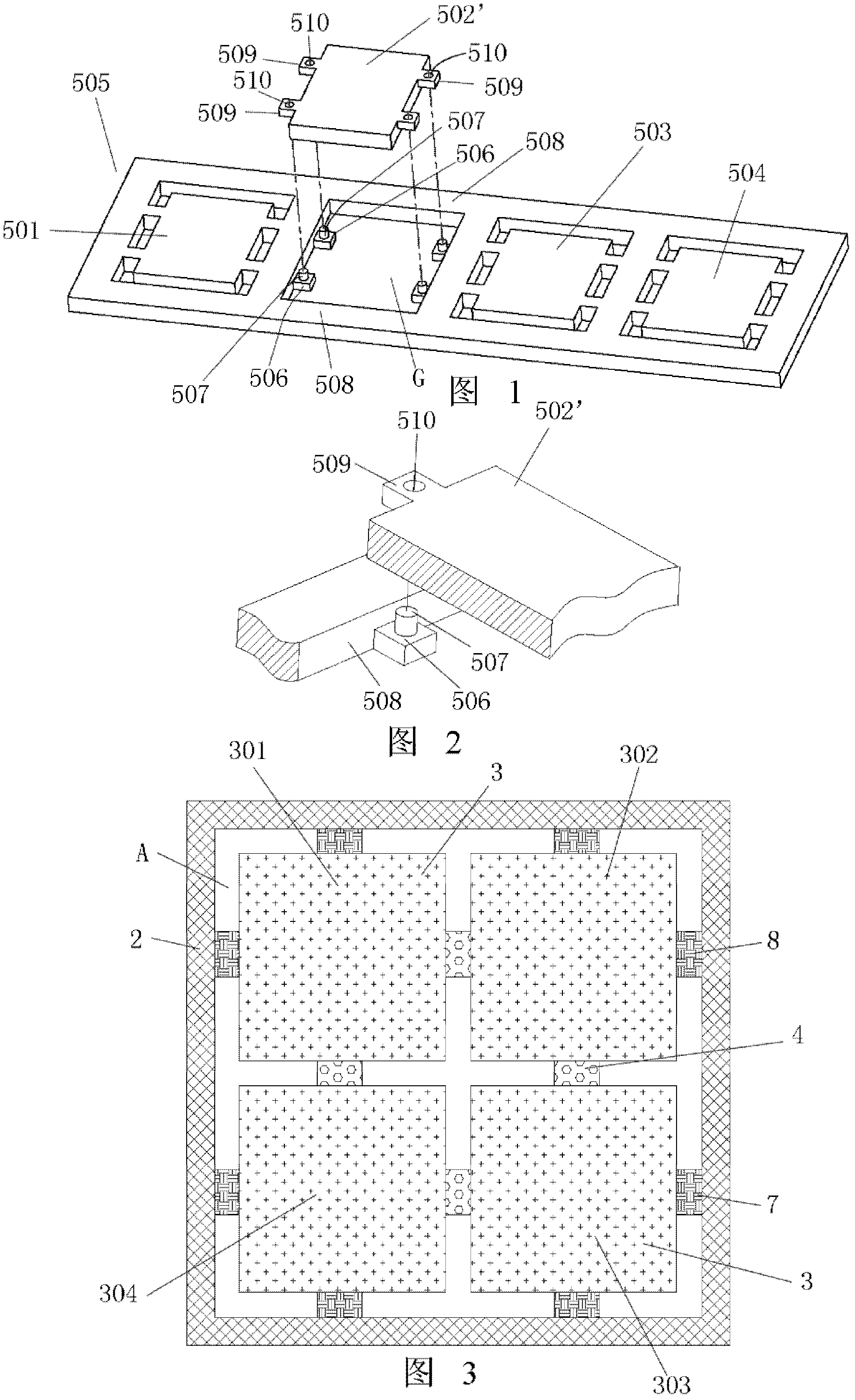

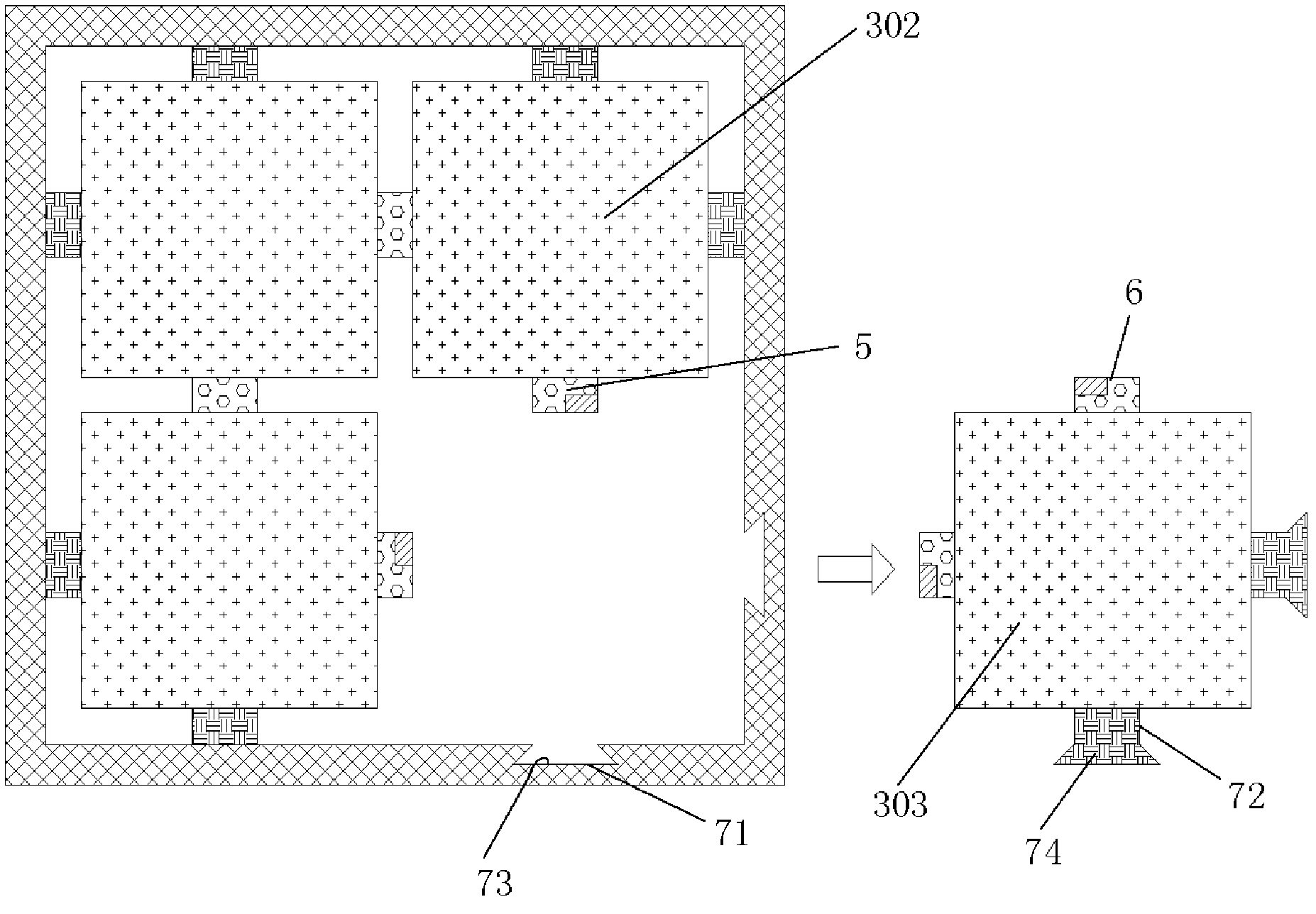

Visual broken line detection system for warp knitting machine

The invention discloses a visual broken line detection system for a warp knitting machine, comprising light sources, an image collecting module and a control module, wherein the image collecting module comprises multiple image collectors, the light sources are arranged corresponding to the image collectors, the image collecting modules collects the image of cloth on the warp knitting machine and transmits the image to the control module, and the control module controls the warp knitting machine according to the collected image information. According to the visual broken line detection system, the image collectors are erected above the cloth, the cloth on the warp knitting machine can be subjected to image collecting, the collected image is processed by an image processing module of the control module, whether the broken yarn situation occurs or not is judged, if the broken yarn situation occurs, a stop signal is transmitted to control the warp knitting machine to stop automatically, the limitations on type and thickness of cloth are overcome due to the strong adaptability of machine vision, the broken yarn automatic stopping is realized completely, so that the working efficiency is greatly improved, and the error judgment rate and miss judgment rate are reduced.

Owner:WUXI XINJIE ELECTRICAL

Blue brick for repairing ancient building wall and preparation method thereof

The invention discloses a blue brick for repairing an ancient building wall. The blue brick comprises a brick blank and coating, wherein the brick blank comprises the following components: plastic clay, an inorganic dispersant, a pigment, a reinforcing fiber, an orange-peel agent, a water reducing agent and aggregate; the coating is petroleum asphalt coating. According to the blue brick for repairing the ancient building wall, after the surface of the brick blank is treated by a liquid petroleum asphalt diluent, on one hand, the attached liquid petroleum asphalt can enhance the anti-acid corrosion and anti-weathering effects, and after use, a time-induced special sense of vicissitudes can be formed on the surface of the brick; the blue brick for repairing the ancient building wall is low in cost, wide in raw material sources, and high in anti-corrosion, wear-resistant and anti-weathering effects; in addition, after restoration, cracks on the surface of an ancient building and the time-induced special sense of vicissitudes can be still maintained, so that a sense of repairing the ancient building as an old building is achieved; the blue brick is an environment-friendly and safe novel building material.

Owner:江门市高新建筑工程有限公司 +2

Multichip typesetting substrate and manufacturing method thereof

ActiveCN103025056AImprove connection strengthLimit thicknessPrinted circuit assemblingPrinted circuits structural associationsEngineeringUltimate tensile strength

Owner:IBIDEN ELECTRONICS BEIJING

Automatic continuous filter press filter slag unloader

The invention relates to a full-automatic continuous filtering and filter pressing slag unloading machine comprising a filtering device, wherein the filtering device comprises a filter cartridge, a filtering stirring shaft and a first filtering medium; a liquid inlet is arranged on the top end of the filter cartridge; the filtering stirring shaft is installed in the filter cartridge through a sealing bearing, and a helical blade is arranged on the filtering stirring shaft; the first filtering medium is arranged between the inner wall of the filter cartridge and the filtering stirring shaft; a liquid outlet is arranged on the bottom end of the filter cartridge; and a press filtering device, the press filtering device comprises a press filter cartridge, a press filtering stirring shaft and a second filtering medium; a slag inlet is arranged on the top end of the press filter cartridge, and the slag inlet is communicated with the liquid outlet; the press filtering stirring shaft is installed in the press filter cartridge through a sealing bearing, and a helical blade is arranged on the press filtering stirring shaft; the second filtering medium is arranged between the inner wall of the press filter cartridge and the press filtering stirring shaft; and a slag outlet is arranged on the bottom end of the press filter cartridge, and an automatic resetting switch is arranged at the slag outlet. The full-automatic continuous filtering and filter pressing slag unloading machine provided by the invention can be conducted with continuous pressure filtration, can automatically feed and automatically discharge and unload slag and is consistently located at a thin layer filtering environment, so that the filtering speed is high, and the machine is operated under a complete sealed state, and the operation environment is excellent.

Owner:王启

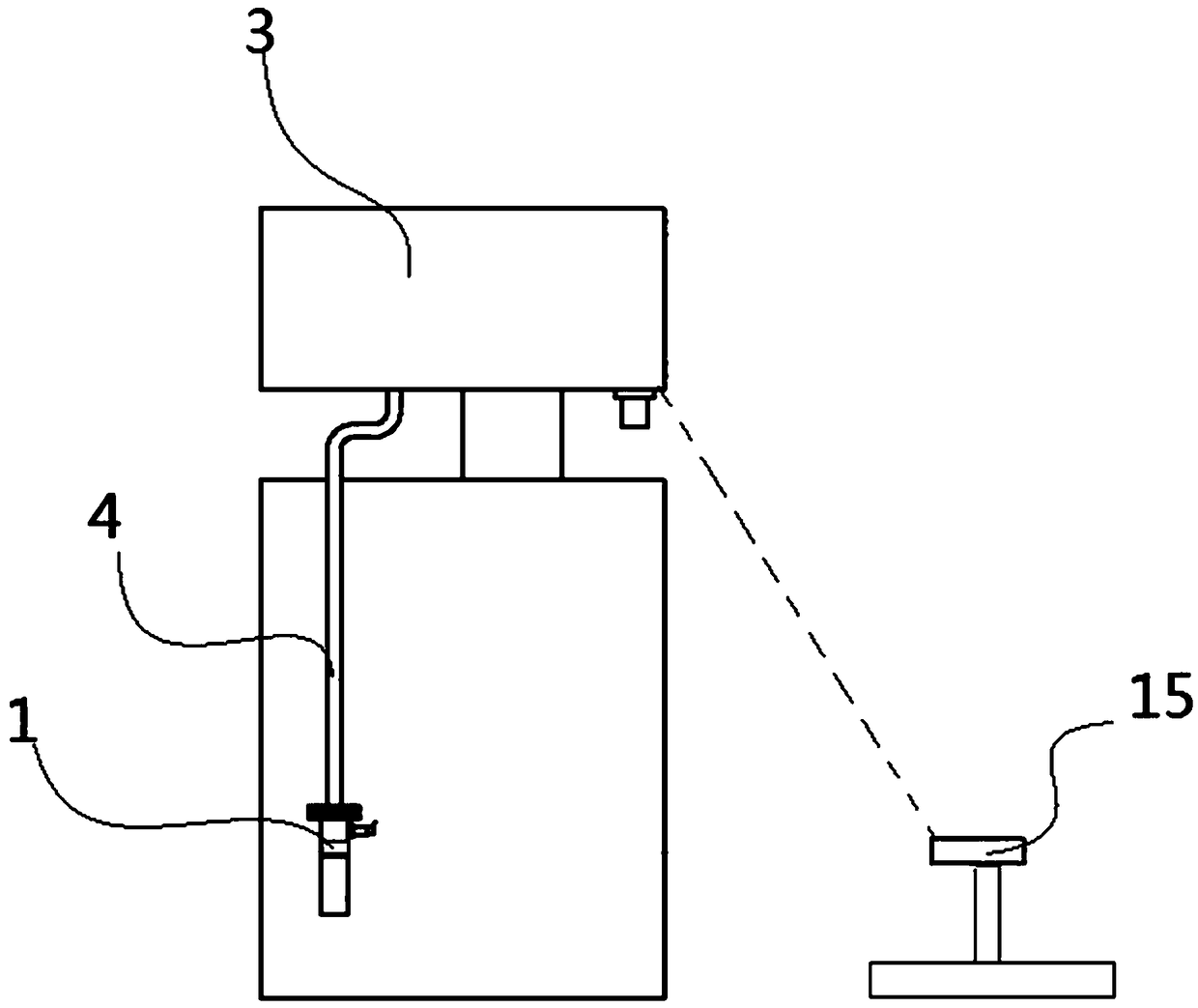

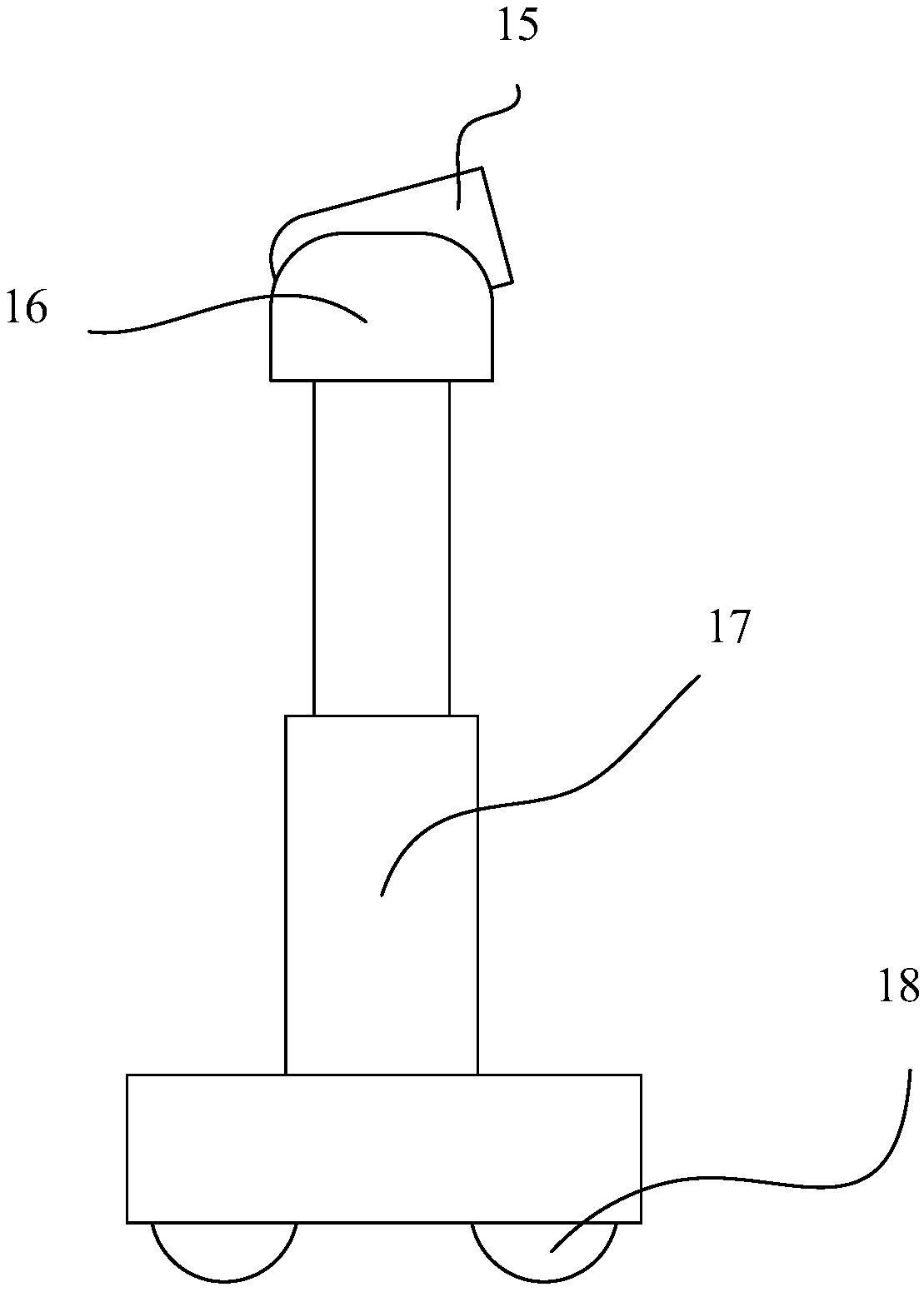

Intelligent transformer oil level detection system based on pressure sensing system

PendingCN109489770AAchieve height differenceImprove accuracyLevel indicators by pressure measurementExpansion tankLaser ranging

The invention relates to an intelligent transformer oil level detection system based on a pressure sensing system, which comprises a pressure signal collection device, a controller and an oil-leadingpipeline connected with an expansion tank. The pressure signal collection device is connected with the oil-leading pipeline and the controller respectively. The system also comprises a laser range finder, a lifting seat for adjusting a height of the laser range finder and a holder for adjusting an angle of the laser range finder, wherein the holder is arranged on the lifting seat, and the laser range finder is arranged on the holder. Compared with the prior art, the intelligent transformer oil level detection system is additionally provided with the laser range finder, and by combining the holder and the lifting seat, a height difference between a pressure sensor and the bottom of the expansion tank can be realized, so that the accuracy of oil level measurement is improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

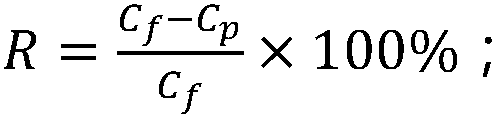

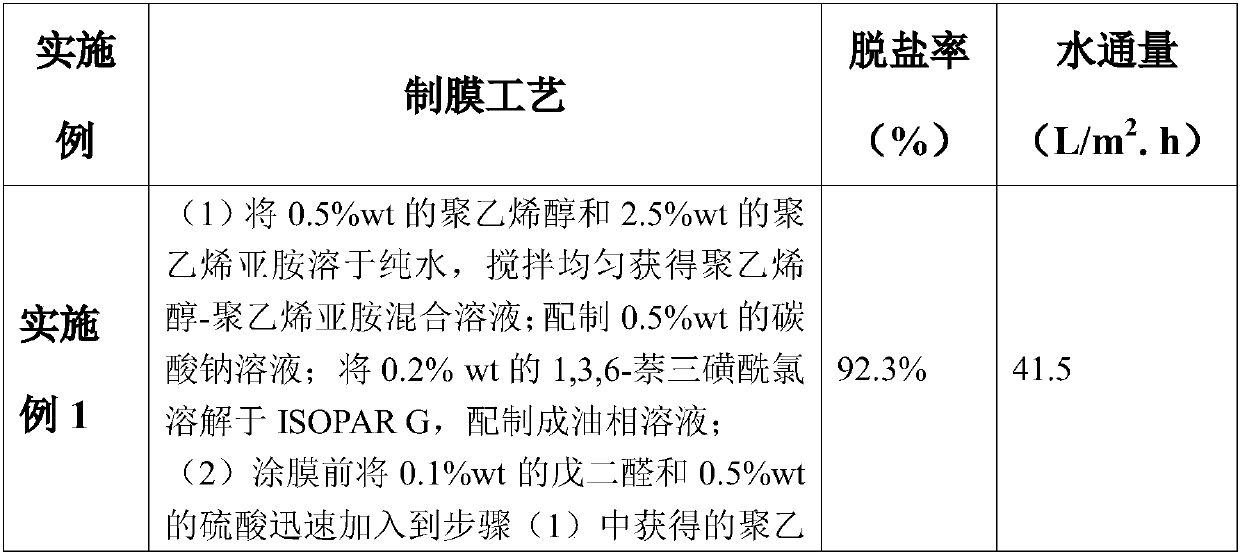

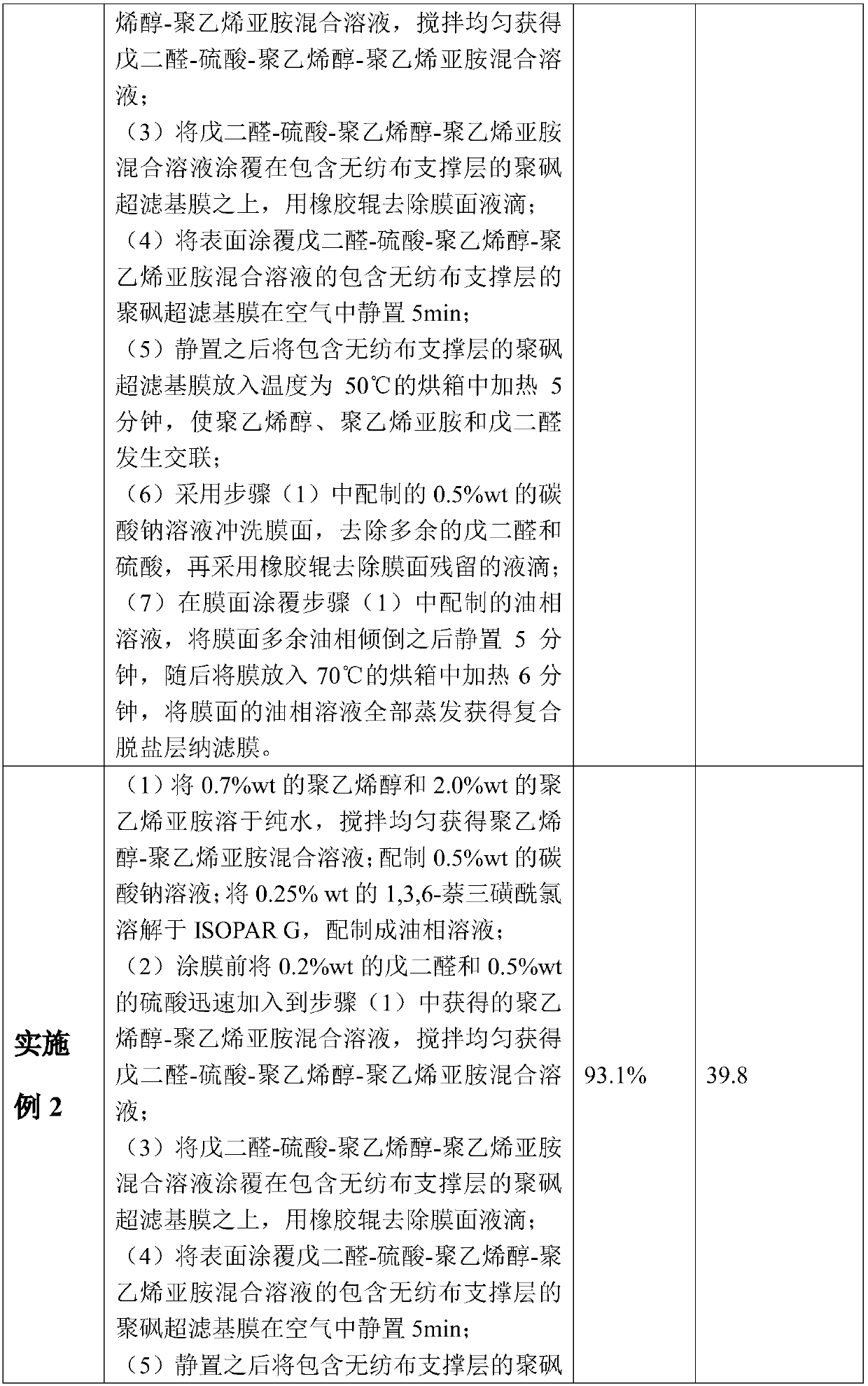

Preparation method of composite desalination layer nanofiltration membrane

ActiveCN110947307AOvercome the problem of larger thickness and lower fluxShorten the diffusion distanceGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisSulfonyl chloridePtru catalyst

The invention relates to a preparation method of a composite desalination layer nanofiltration membrane. The method comprises the following steps of coating a polysulfone ultrafiltration base membranewith a polyvinyl alcohol-polyethyleneimine mixed solution containing a crosslinking agent and a catalyst, and carrying out crosslinking reaction to form a positively charged desalination layer on a surface of the polysulfone ultrafiltration base membrane; cleaning the membrane by using a solution containing an acid absorbent to remove sulfuric acid and glutaraldehyde which does not participate inthe reaction; removing water drops on the surface of the membrane, applying an oil phase solution, and allowing a large number of amine chain segments which do not participate in the cross-linking reaction on a surface of the positively charged desalination layer to react with polyacyl chloride in the oil phase to generate a polysulfonyl chloride desalination layer. According to the technical scheme, a thin polysulfonamide desalination layer can be obtained, meanwhile, the compactness of the polysulfonamide desalination layer can be improved by prolonging the reaction time without worrying about the influence on the flux due to the formation of an over-thick desalination layer, the problems that the reaction speed of polyamine and polyacyl chloride is low, and polyamine molecules penetrate through a loose primary desalination layer to diffuse to an oil phase such that a finally formed desalination layer is large in thickness and low in flux can be solved.

Owner:烟台金正环保科技有限公司

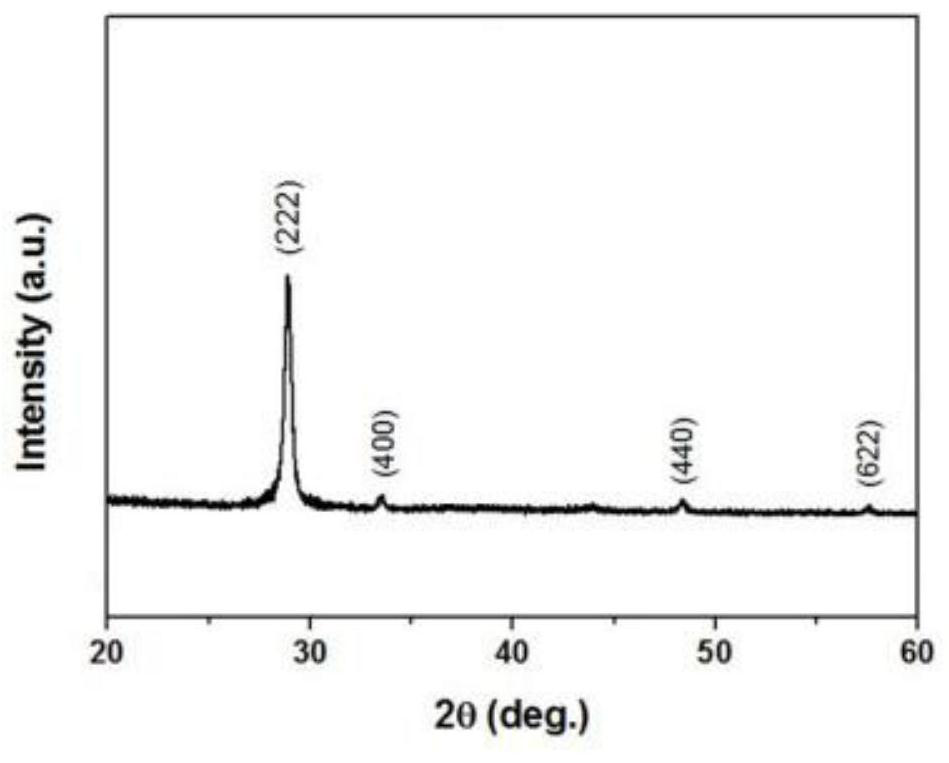

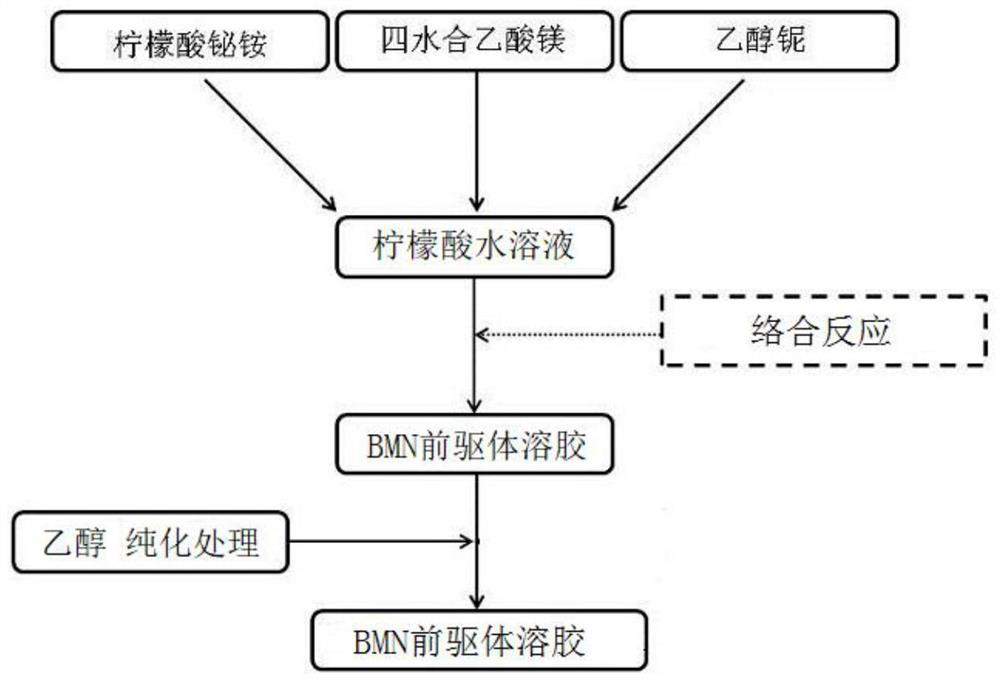

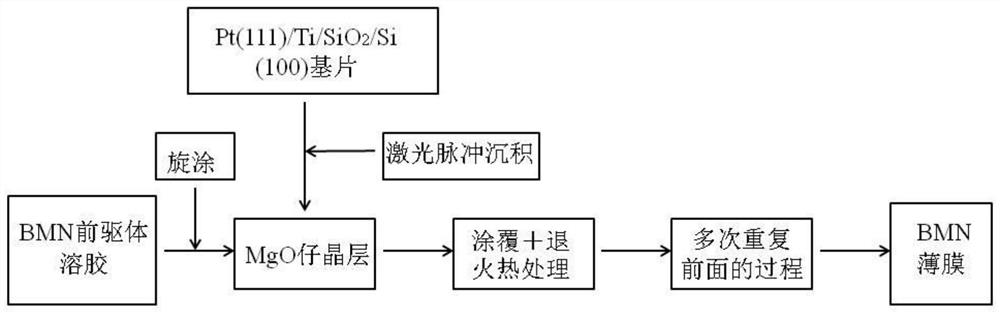

BMN multilayer dielectric film and preparation method thereof

ActiveCN111876756AEvenly heatedLimit thicknessVacuum evaporation coatingSputtering coatingDielectricHydration reaction

The invention provides a Bi1.5MgNb1.5O7 (BMN) multilayer dielectric film and a preparation method thereof, and belongs to the technical field of microelectronics. The preparation method provided by the invention comprises the following steps of mixing ammonium bismuth citrate, magnesium acetate tetrahydrate, niobium ethoxide and a citric acid aqueous solution, and carrying out a complexation reaction to obtain Bi-Mg-Ni precursor sol; carrying out deposition of MgO on the surface of a Pt (111) / Ti / SiO2 / Si (100) substrate through a laser pulse deposition method, and obtaining an MgO seed crystallayer with the orientation being (111); coating the Bi-Mg-Ni precursor sol on the surface of the MgO seed crystal layer with the orientation being (111), and then carrying out annealing heat treatmentto obtain a single-layer film; repeating the coating and annealing heat treatment process on the single-layer film to obtain the BMN multilayer dielectric film with the orientation being (222).

Owner:QILU UNIV OF TECH

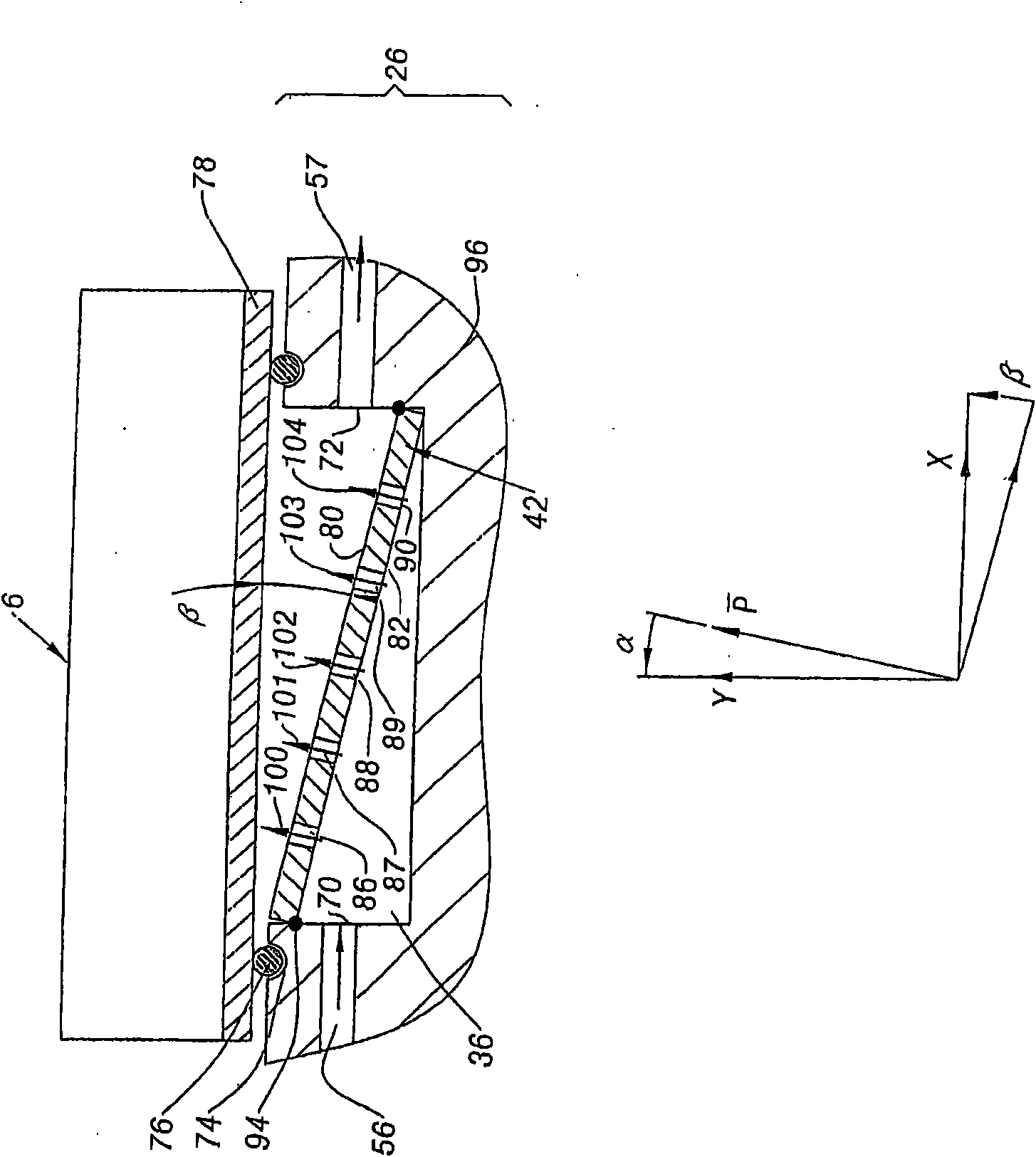

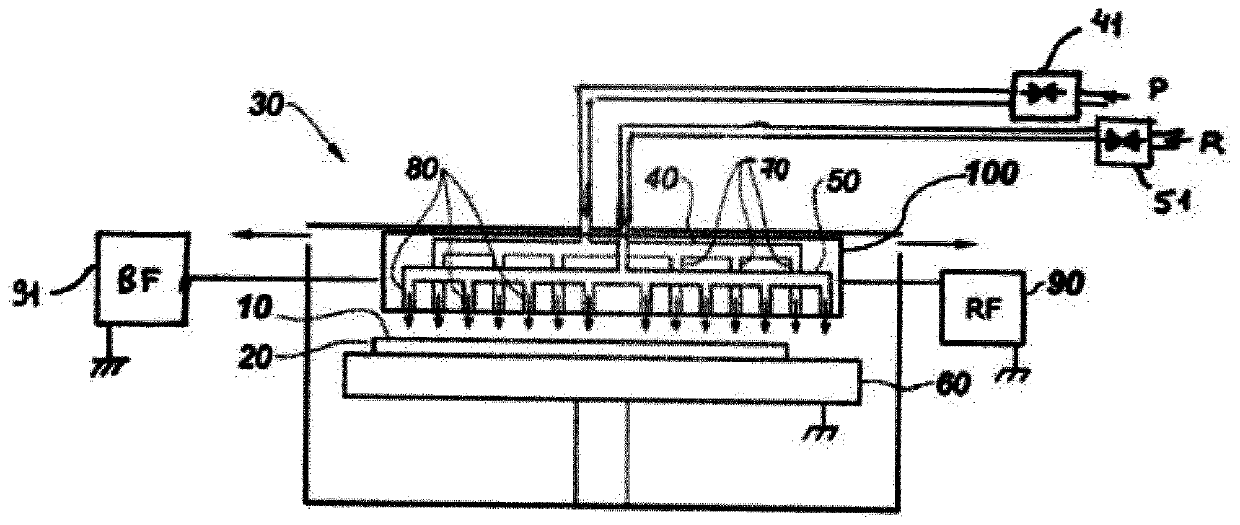

Electronic board and cold plate for said board

InactiveCN101611492AMinimize Cooling DifferencesImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesElectronic circuitEngineering

The board has a cold plate including a projection plate (42) between intake and evacuation holes (70, 72). Rectilinear nozzles (86-90) traverse the plate through and through by following a projection direction. Length of each nozzle along the direction is higher than / equal to width of the nozzle perpendicular to the direction for forming coolant e.g. water, jets (100-104) along the projection direction. The projection direction of each nozzle forms an angle (alpha) with respect to a direction perpendicular to a base plate (78), where the angle ranges between minus 30 to plus 30 degrees.

Owner:SAMES SA MEYLAN FR

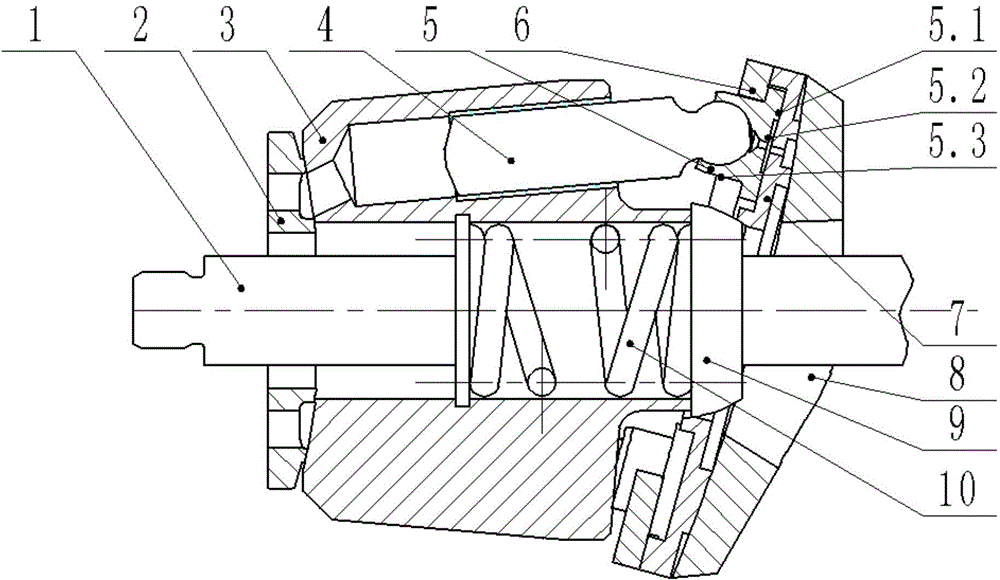

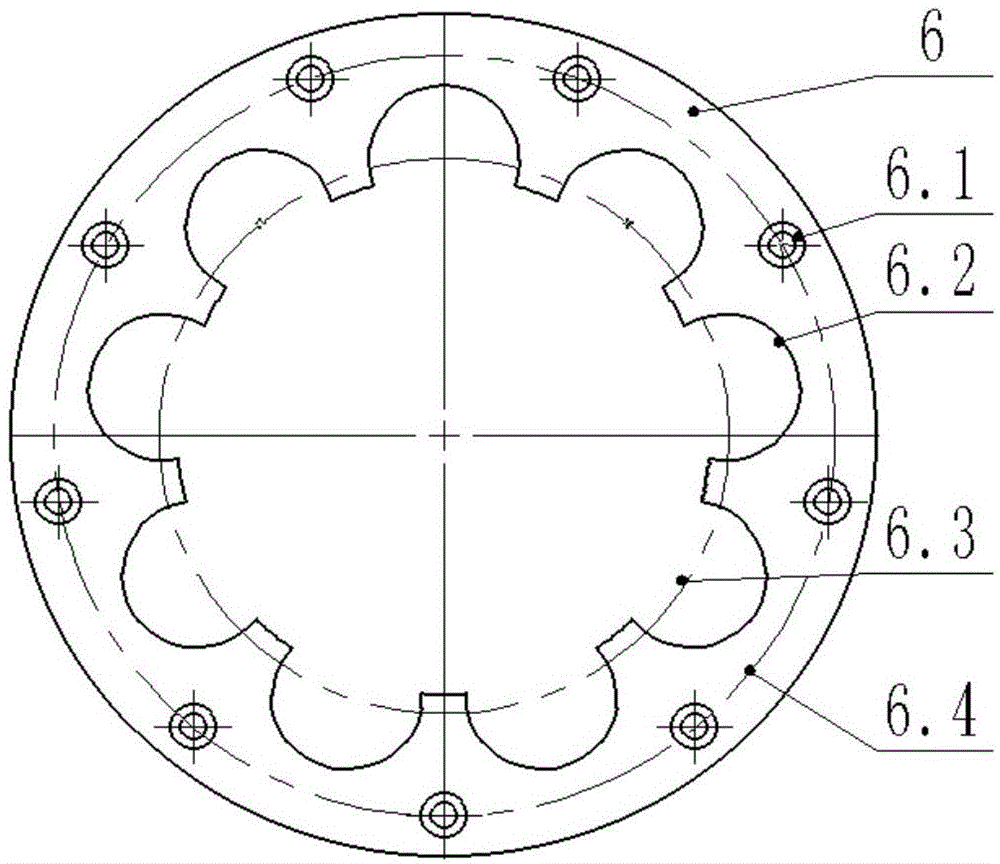

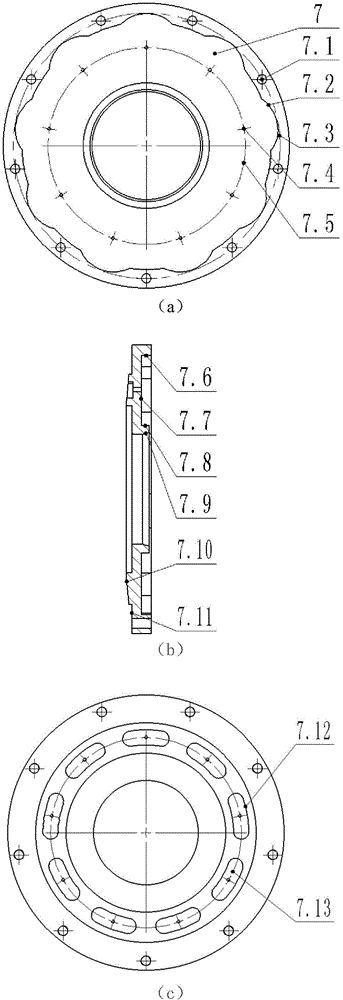

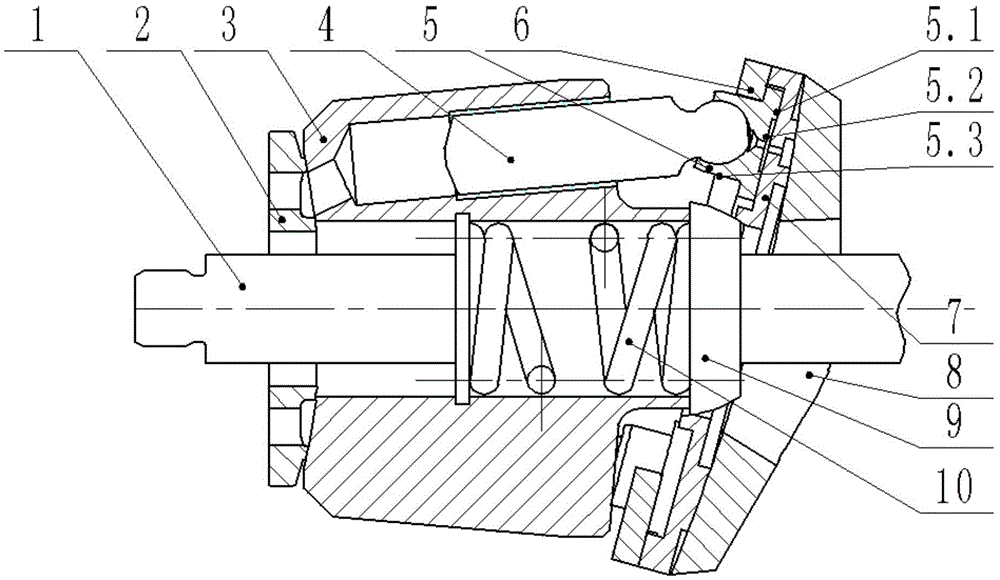

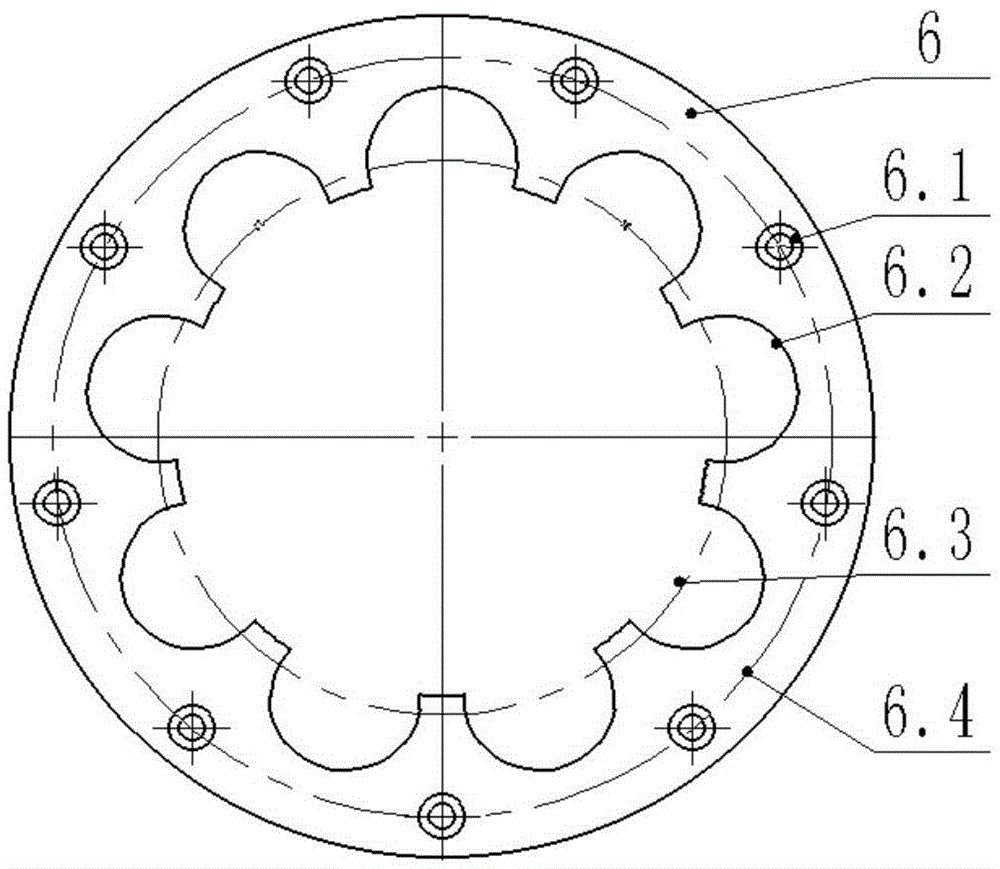

Self-centering and anti-overturning split type return stroke plate

ActiveCN104595141AAvoid direct contactReduced effect and effectPositive displacement pump componentsPositive-displacement liquid enginesEngineeringAxial piston pump

The invention discloses a self-centering and anti-overturning split type return stroke plate, which comprises two concentric discs, where the front end of the lower disc is provided with an enhanced limit boss and a sliding shoe oil film thickness limit boss, a sliding shoe hole of the lower disc is formed by the connection of equal-radian nine inferior arcs which are arranged around a spherical hinge supporting hole axis inside the limit boss, nine equal-radian small kidney-shaped grooves are formed around the spherical hinge supporting hole axis in a spherical arc surface boss at the rear end surface of the lower disc, small kidney-shaped grooves are communicated with an oil chamber on the bottom surface of slid shoe through an oil passing hole; a slide shoe hole is formed by the connection of equal-radian nine major arcs which are arranged around the spherical hinge supporting hole axis of the upper disc. The self-centering and anti-overturning split type return plate can complete the reliable return stroke of an axial piston pump plunger sliding shoe component in an oil absorption area, the return stroke plate is designed to be matched with a spherical surface of a swash plate, so that the force condition of the return stroke plate is good, automatic centering is strong, the split type return stroke plate has a capability of anti-overturning; the structure of the return stroke can effectively avoid the eccentric wear caused by the directly contacting of the sliding shoe and the swash plate, the maximum oil film thickness of a slide shoe pair is limited, and the mechanical efficiency and volume efficiency of a pump can be improved.

Owner:ZHEJIANG UNIV

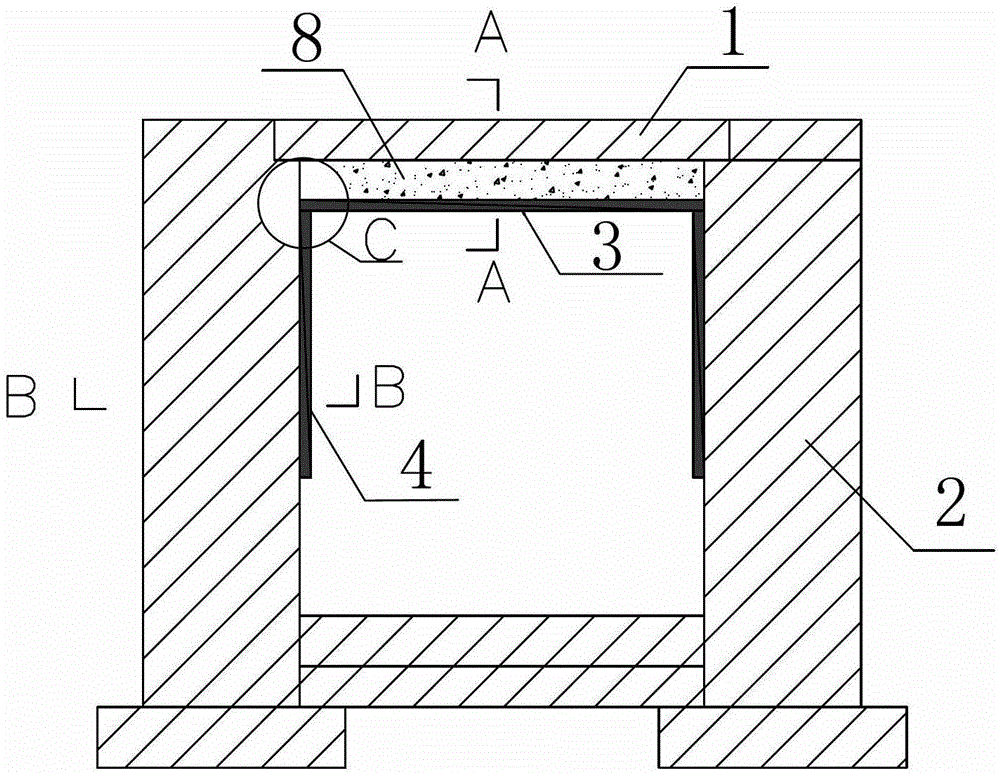

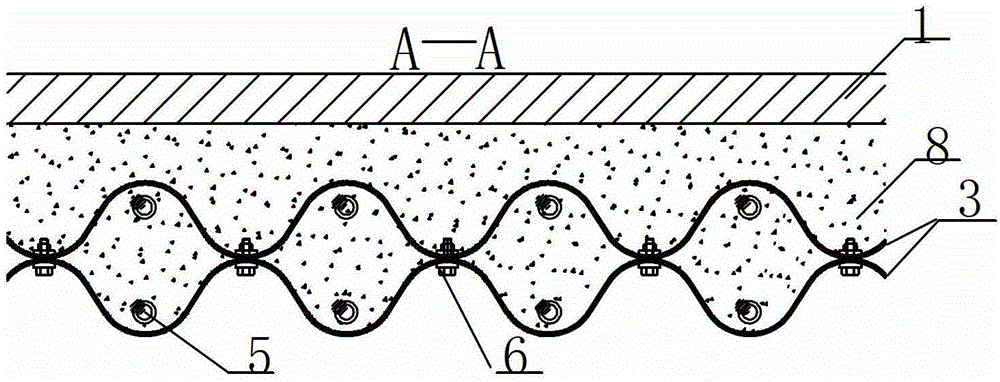

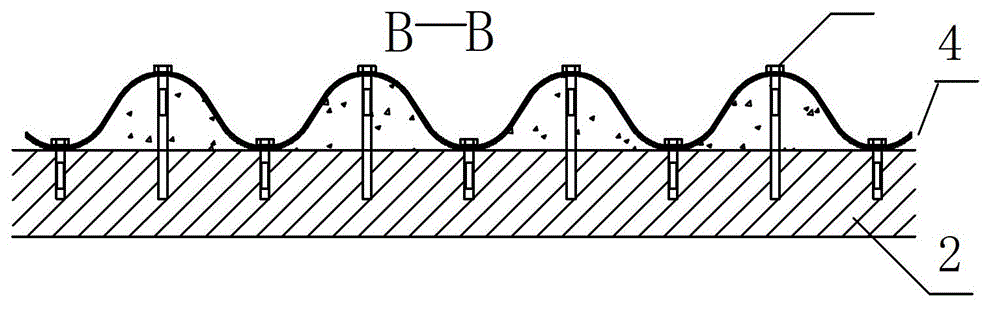

Reinforced culvert

The invention discloses a reinforced culvert. The reinforced culvert comprises a culvert top and side walls. A prestress top plate which is composed of a symmetrically fastened double-layer corrugated steel is arranged at the bottom of the culvert top, single-layer corrugated steels are arranged on the inner sides of left and right side walls, the top plate is installed on the single-layer corrugated steels of the side walls, reinforcing steel bars are arranged in a cavity cylinder formed by the double-layer corrugated steel, the cavity cylinder is filled with concrete, and simultaneously, concrete is filled between the culvert top and the prestress top plate as well as between left and right side walls and the single-layer corrugated steels. The reinforced culvert has the advantages that a corrugated steel rigid support is added on the basis of the original culvert structure, and further expansion of cracks is prevented, so that the internal force and deformation of the original culvert structure are reduced greatly, simultaneously, the original structure is fully utilized, and shared force bearing of new and old structures is guaranteed with the using function of the original culvert unchanged.

Owner:NANJING LIANZHONG CONSTR ENG TECH

Liquid for forming microstructure film on metal surface

ActiveCN103597116ASimple structureExcellent adhesionMetallic material coating processesOrganic acidPhosphoric acid

The purpose of the present invention is to provide a liquid for forming a microstructure film on a metal surface with which, by the simple immersion of a metal product in the liquid or the application or spraying of the liquid onto the metal product, it is possible to completely remove rust from the surface of the metal product, form a microstructure film having crystals or irregularities of 1 µm or smaller on the surface of the metal product such that the surface area is increased, impurities are prevented from penetrating inside the crystals, and the film easily imitates deformation of the metal substrate. The liquid for forming a microstructure film on a metal surface comprises, as the essential components, phosphoric acid, an inorganic acid, a nonionic fluorine surfactant, and water, and contains 2 to 60 mass% of phosphoric acid, 0.02 to 5 mass% of an organic acid, and 0.005 to 0.2 mass% of a nonionic fluorine surfactant.

Owner:盐泽明 +3

A kind of blue brick used for repairing ancient building walls and its preparation method

The invention discloses a blue brick for repairing an ancient building wall. The blue brick comprises a brick blank and coating, wherein the brick blank comprises the following components: plastic clay, an inorganic dispersant, a pigment, a reinforcing fiber, an orange-peel agent, a water reducing agent and aggregate; the coating is petroleum asphalt coating. According to the blue brick for repairing the ancient building wall, after the surface of the brick blank is treated by a liquid petroleum asphalt diluent, on one hand, the attached liquid petroleum asphalt can enhance the anti-acid corrosion and anti-weathering effects, and after use, a time-induced special sense of vicissitudes can be formed on the surface of the brick; the blue brick for repairing the ancient building wall is low in cost, wide in raw material sources, and high in anti-corrosion, wear-resistant and anti-weathering effects; in addition, after restoration, cracks on the surface of an ancient building and the time-induced special sense of vicissitudes can be still maintained, so that a sense of repairing the ancient building as an old building is achieved; the blue brick is an environment-friendly and safe novel building material.

Owner:江门市高新建筑工程有限公司 +2

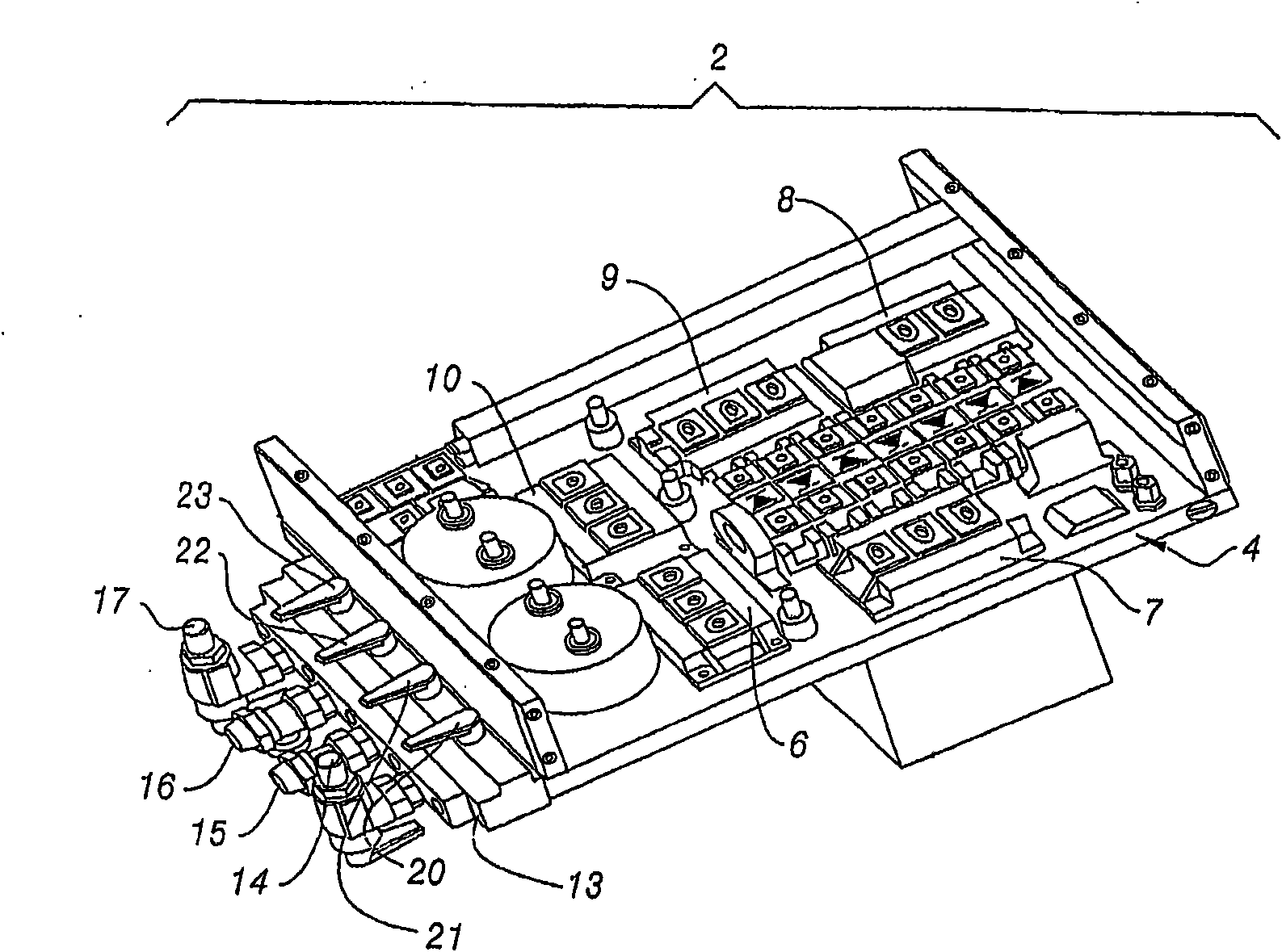

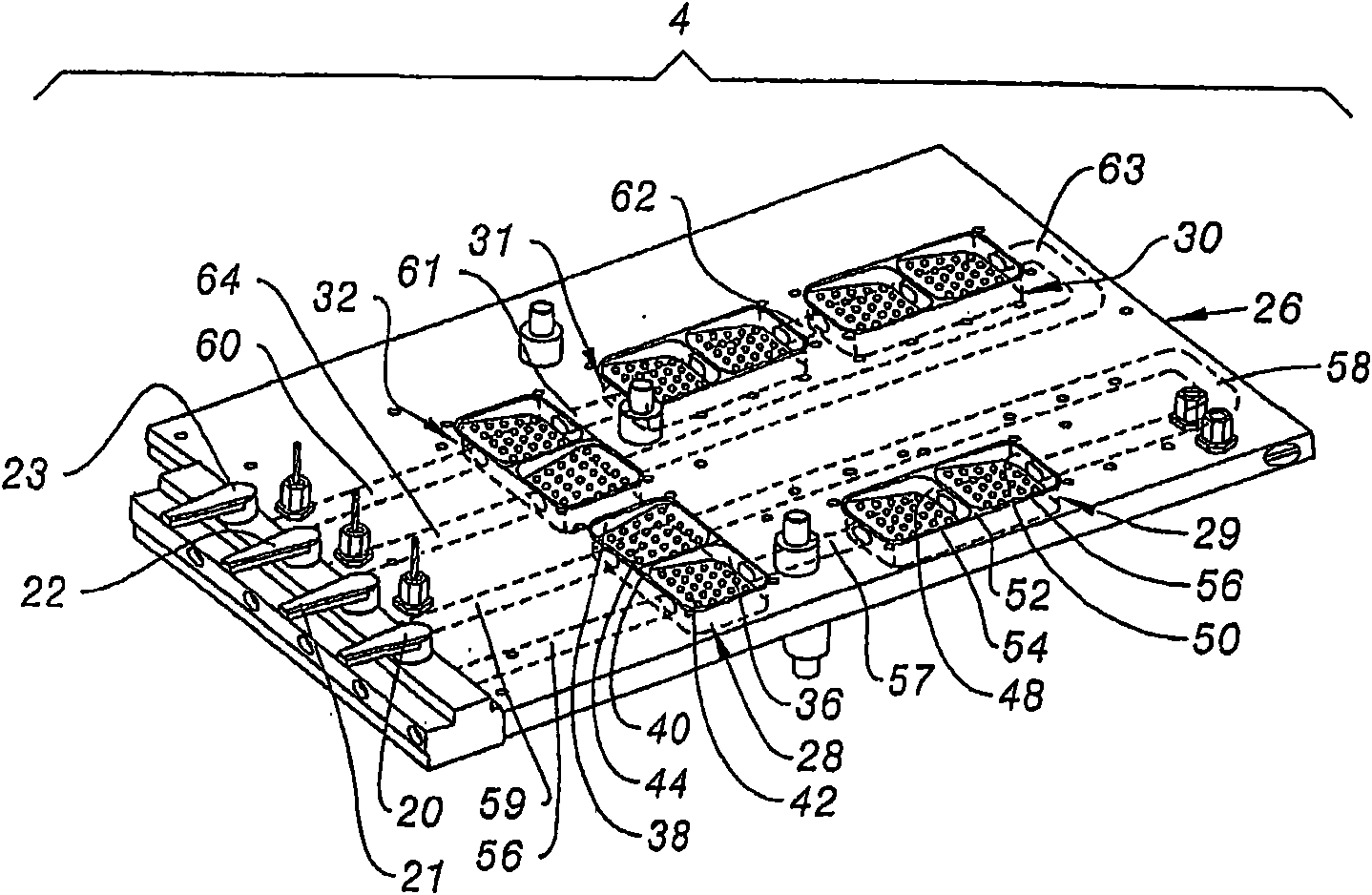

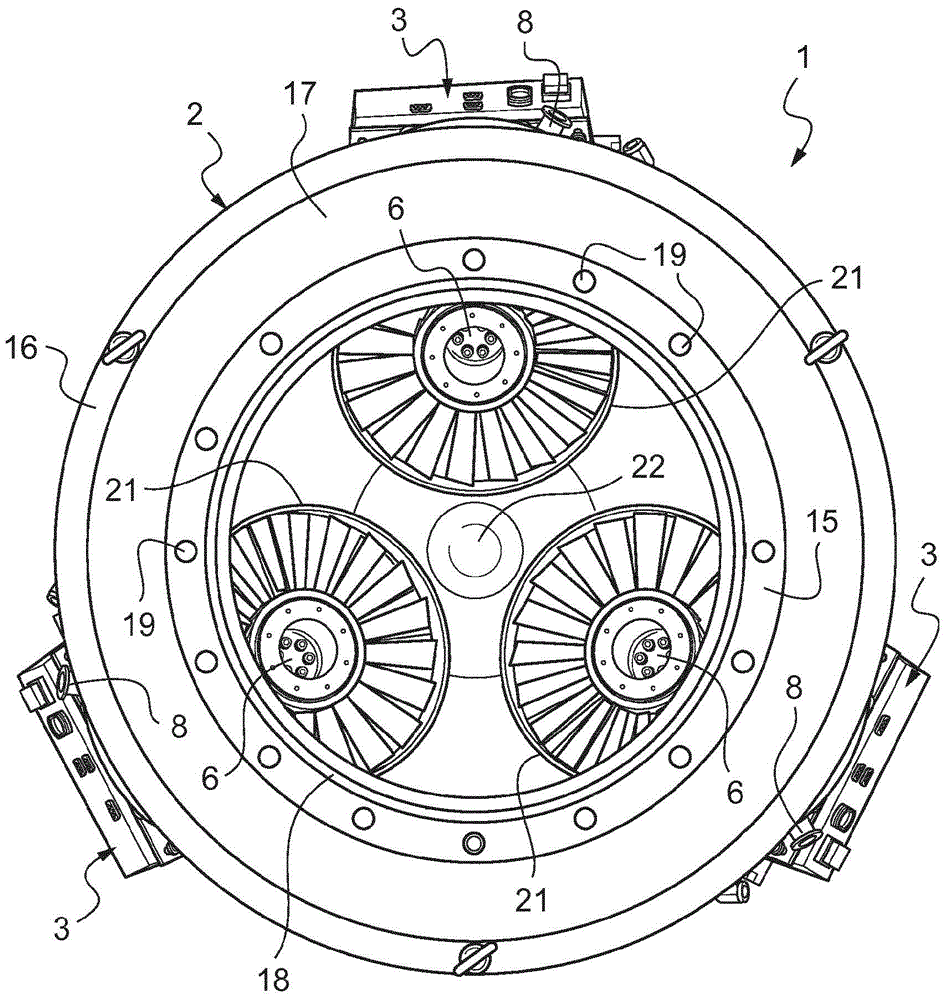

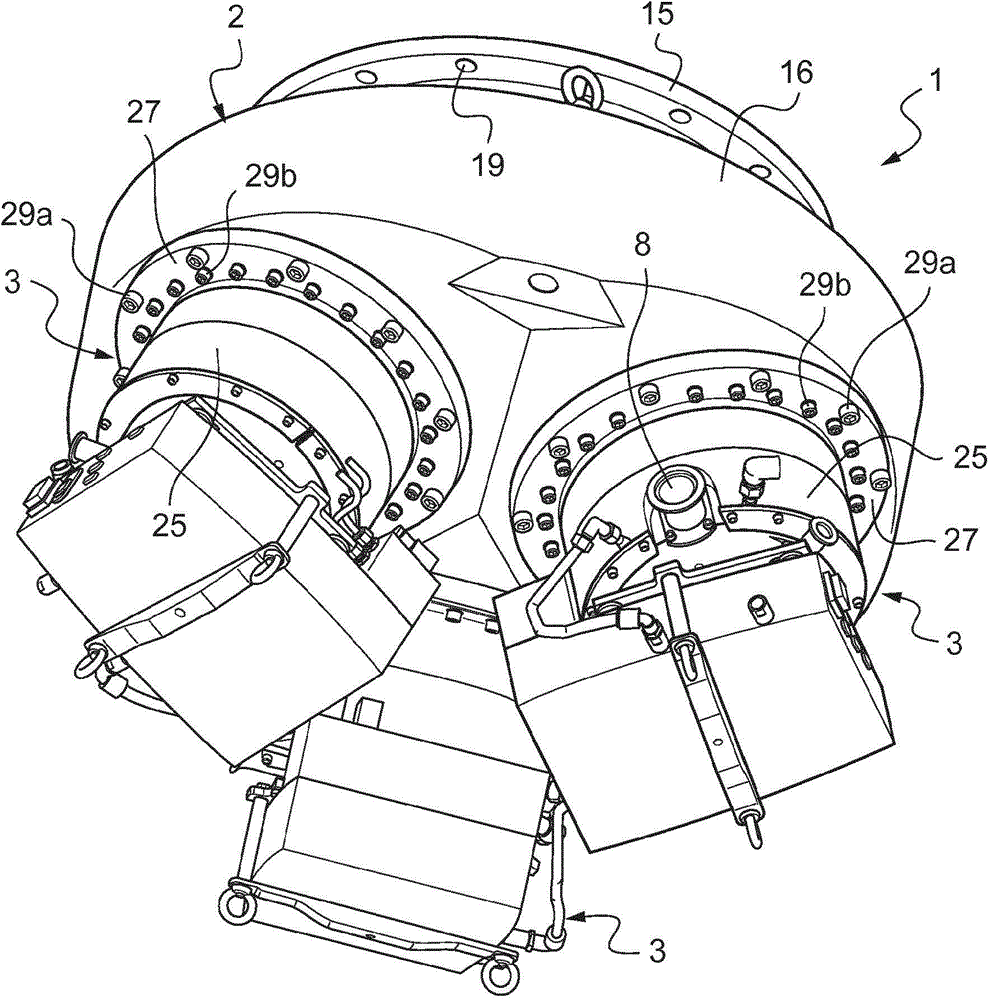

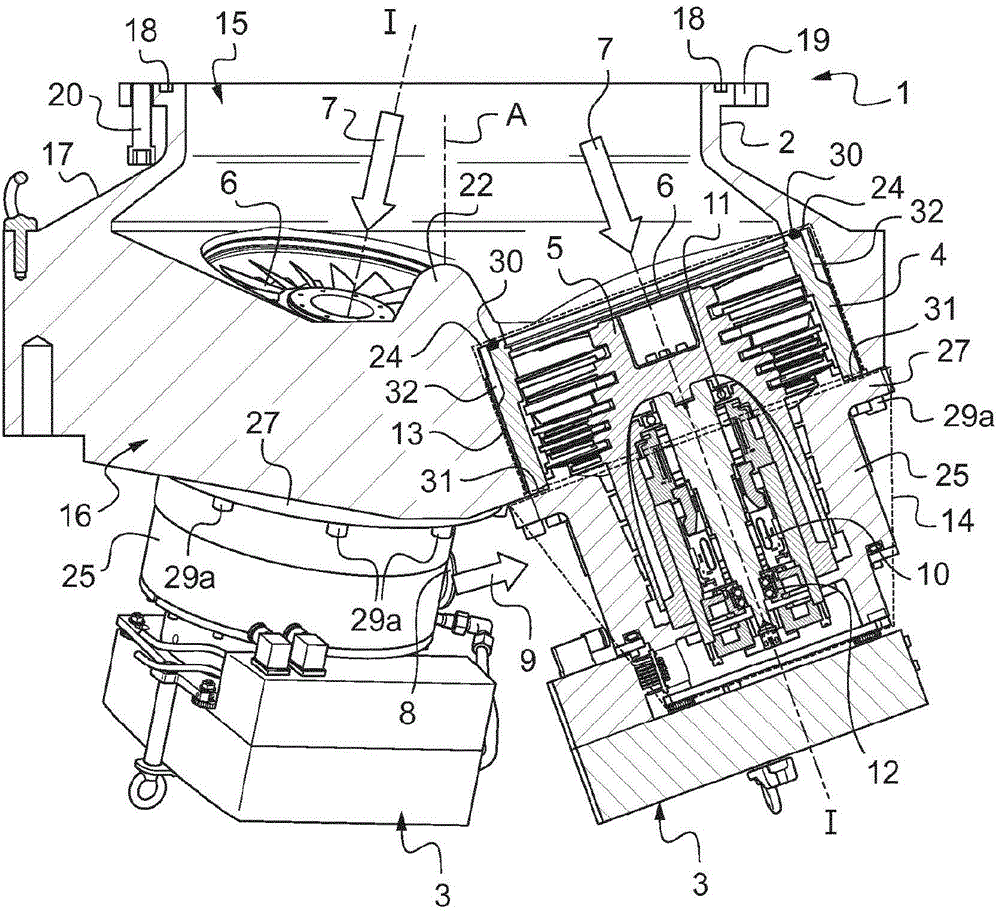

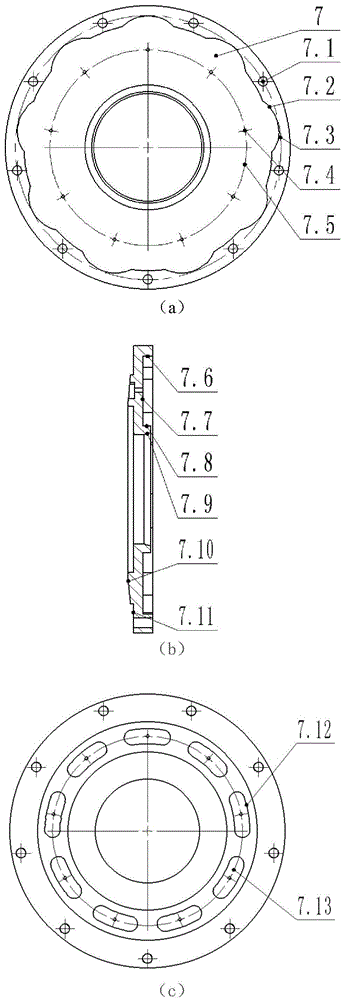

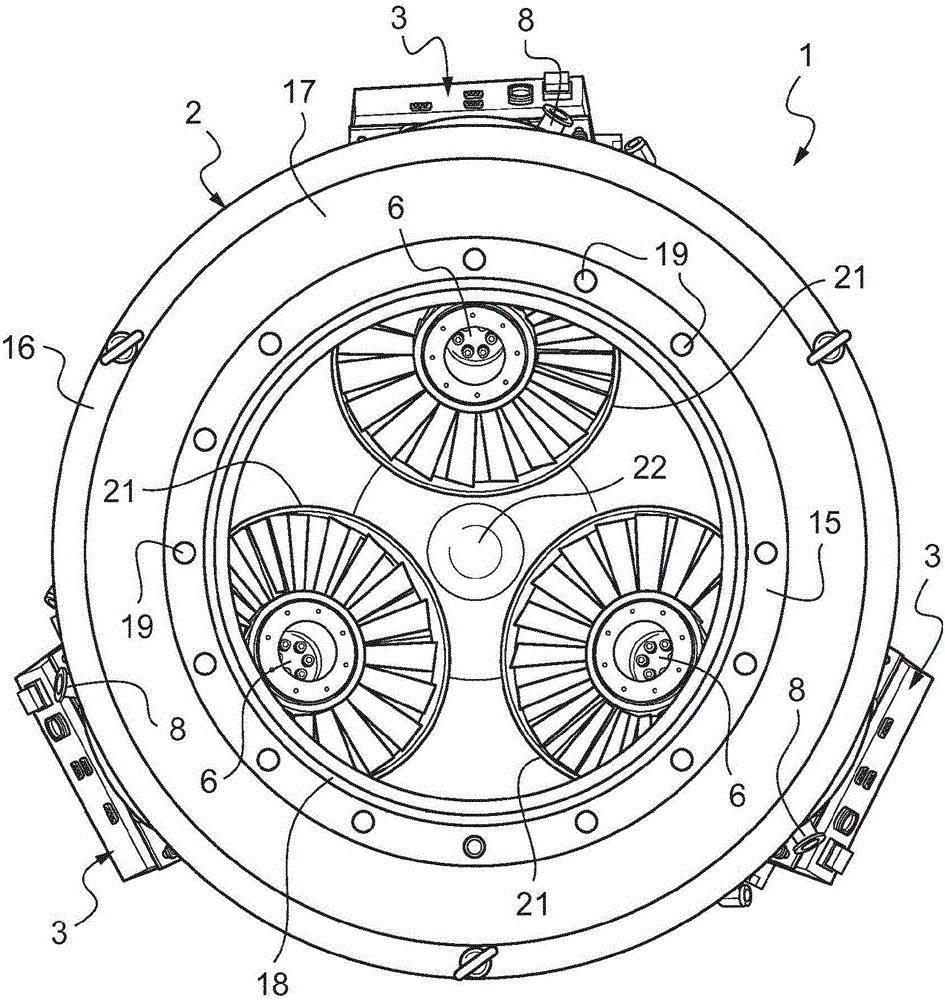

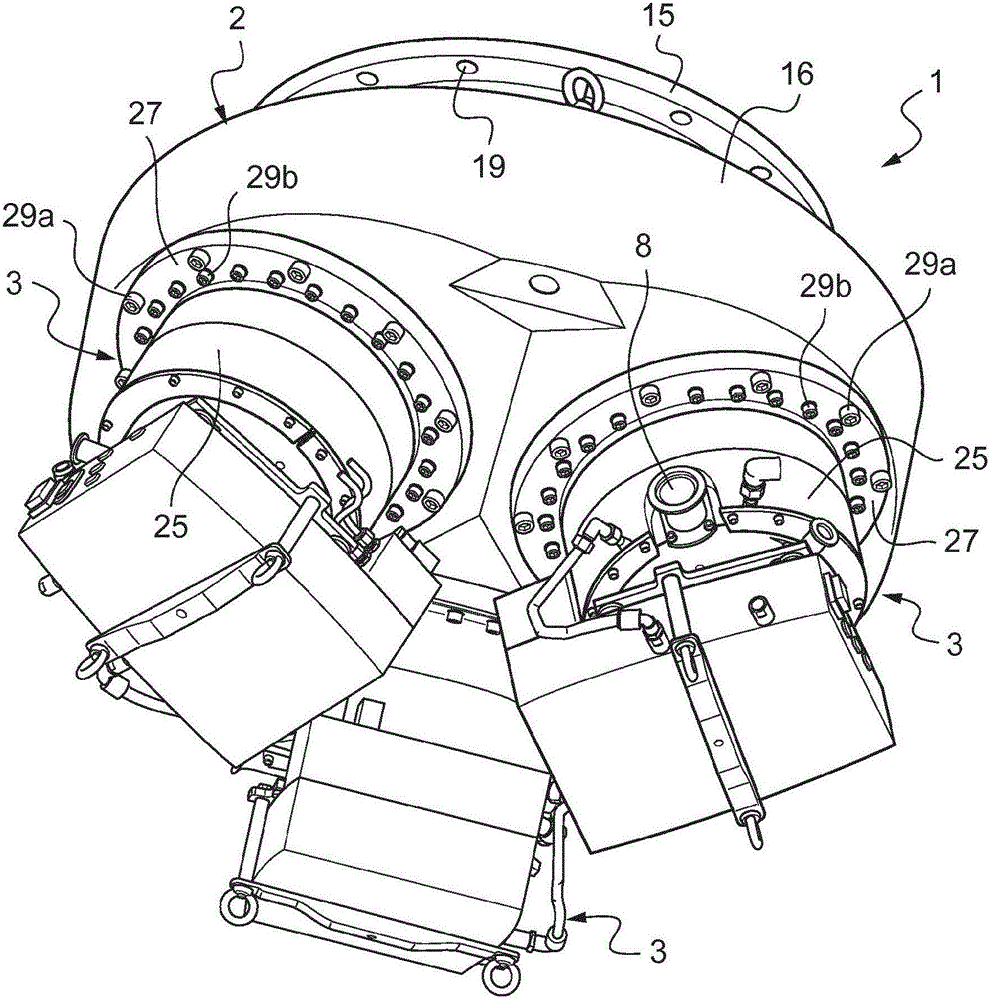

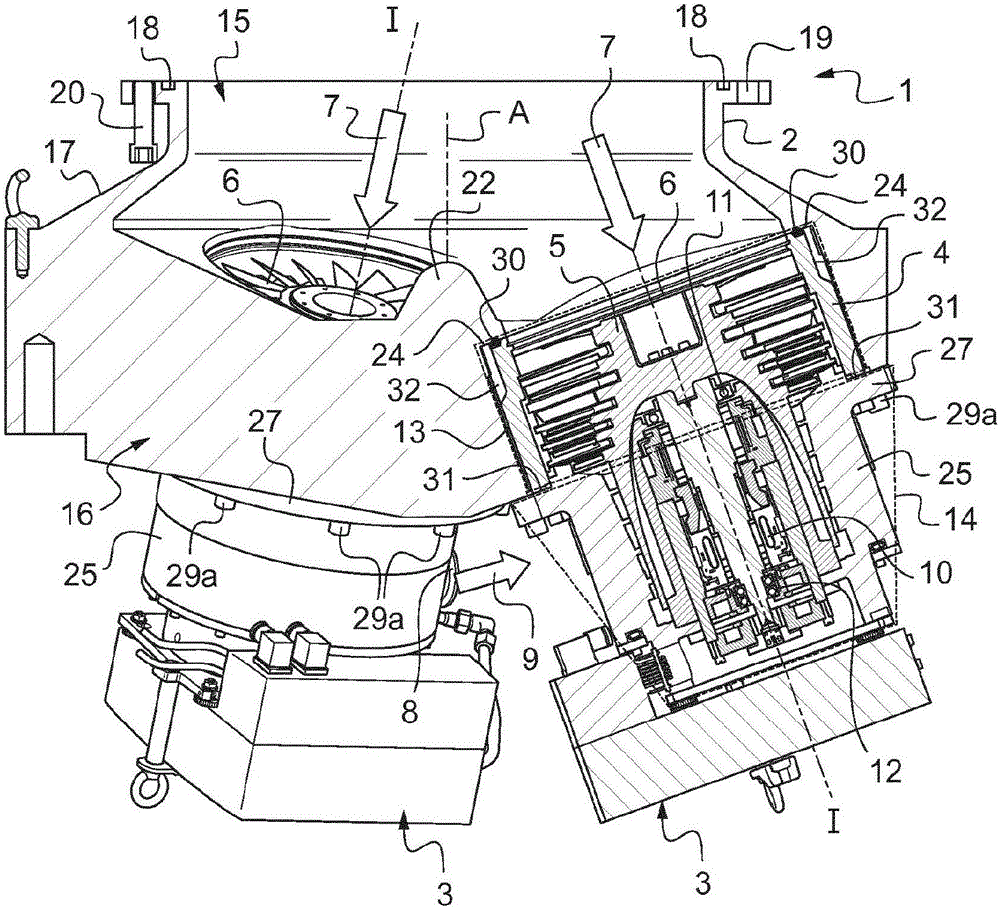

Adapter for vacuum pumps and associated pumping device

ActiveCN104024645ASmall pressure lossImprove pumping uniformityPump componentsPump installationsEngineeringFlange

The invention relates to an adapter for vacuum pumps, characterized in that it comprises an annular inlet flange (15) intended to be coupled to an outlet orifice of a chamber and an outlet coupling (16) comprising at least two cylindrical outlet through-housings (21) and forming an at least partial pump casing for the case (4) of a respective turbomolecular vacuum pump (3), said turbomolecular vacuum pumps (3) being intended to be received in a respective cylindrical outlet housing (21). The invention also relates to a pumping device, characterized in that it comprises an adapter for vacuum pumps (2) as described hereinabove and at least two turbomolecular vacuum pumps (3) housed at least partially in a respective cylindrical outlet housing (21).

Owner:PFEIFFER VACUUM GMBH

Self-centering anti-overturn split return plate

ActiveCN104595141BAvoid direct contactReduced effect and effectPositive displacement pump componentsPositive-displacement liquid enginesCircular discEngineering

The invention discloses a self-centering and anti-overturning split type return stroke plate, which comprises two concentric discs, where the front end of the lower disc is provided with an enhanced limit boss and a sliding shoe oil film thickness limit boss, a sliding shoe hole of the lower disc is formed by the connection of equal-radian nine inferior arcs which are arranged around a spherical hinge supporting hole axis inside the limit boss, nine equal-radian small kidney-shaped grooves are formed around the spherical hinge supporting hole axis in a spherical arc surface boss at the rear end surface of the lower disc, small kidney-shaped grooves are communicated with an oil chamber on the bottom surface of slid shoe through an oil passing hole; a slide shoe hole is formed by the connection of equal-radian nine major arcs which are arranged around the spherical hinge supporting hole axis of the upper disc. The self-centering and anti-overturning split type return plate can complete the reliable return stroke of an axial piston pump plunger sliding shoe component in an oil absorption area, the return stroke plate is designed to be matched with a spherical surface of a swash plate, so that the force condition of the return stroke plate is good, automatic centering is strong, the split type return stroke plate has a capability of anti-overturning; the structure of the return stroke can effectively avoid the eccentric wear caused by the directly contacting of the sliding shoe and the swash plate, the maximum oil film thickness of a slide shoe pair is limited, and the mechanical efficiency and volume efficiency of a pump can be improved.

Owner:ZHEJIANG UNIV

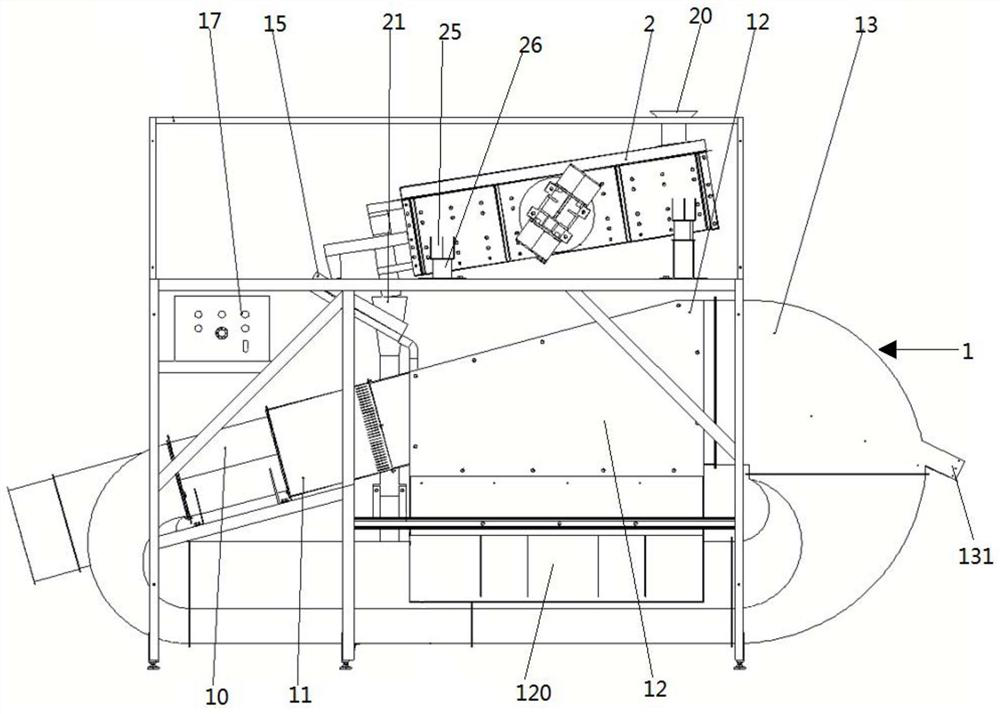

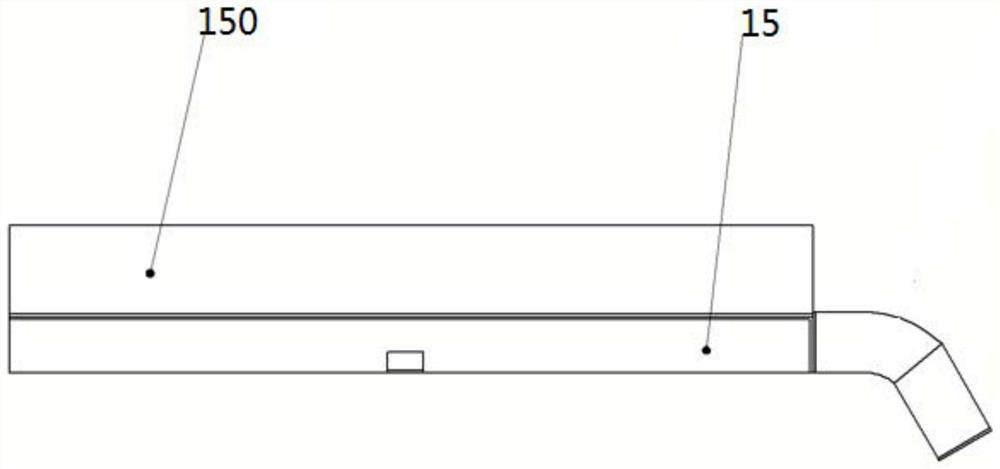

Combined type circulating airflow separation equipment

PendingCN114101060AGuaranteed stabilityEfficient sortingSievingGas current separationSmall footprintMechanics

According to the combined type circulating airflow separation equipment, the vibrating screen on the upper side of the circulating cavity can achieve preliminary screening of materials and clear away large and small impurities, meanwhile, the obliquely-arranged vibrating screen can enable screened materials to fall into the circulating box through gravity, energy can be saved, and the occupied area of the combined type circulating airflow separation equipment can be reduced; the power section provides a certain wind speed for materials to be screened, the rectification section rectifies airflow entering the winnowing section into uniform airflow, the situation that the separation effect is affected due to the fact that the materials interact with one another and a negative pressure area is generated in the winnowing section is avoided, the materials are evenly separated according to different specific gravities of the materials, and therefore the purpose of separation is achieved. The rotary air duct ensures the stability of air flow in the circulating cavity, and meanwhile, dust in the materials can be prevented from being directly discharged, so that environmental pollution is avoided; the device is simple in structure and small in occupied area, meanwhile, materials can be efficiently screened in a high-quality mode, and high applicability and universality are achieved.

Owner:XINGTAI TIANYUANXING FOOD EQUIP

Piston with (ti,al)n multi-layer heat-insulating and wear-resistant ultra-thick coating on the surface, its preparation method and application

ActiveCN107604312BImprove wear resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingInternal combustion engineMaterials science

The invention relates to a piston with a (Ti, Al)N multilayer heat insulating and wear resisting super-thick coating on the surface and a preparation technology and application of the piston. The structure of the piston comprises two schemes. According to the first scheme, the piston comprises a base, a TiAl transition layer and a TiAlN clad layer, and the TiAl transition layer evenly wraps the base; and the TiAlN clad layer evenly wraps the TiAl transition layer. According to the second scheme, the piston comprises a base, a first TiAl transition layer, a first TiAlN clad layer, a second TiAltransition layer and a second TiAlN clad layer, and the piston structurally comprises the base, the first TiAl transition layer, the first TiAlN clad layer, the second TiAl transition layer and the second TiAlN clad layer in sequence. According to application of the piston, the piston is used for an internal combustion engine. The designed piston surface has heat insulation performance, wear resistance, oxidation resistance and heat shock resistance, and the service life of the piston is effectively prolonged.

Owner:XIANGTAN UNIV

Continuous drying device for polyester chips

The invention discloses a continuous drying device for polyester chips. The continuous drying device comprises a drying bin, a fixing frame, a fixing rod, a supporting frame, a power motor and the like. A fixing rod is fixedly connected to the bottom of the fixing frame, a supporting frame is arranged on the top wall of the drying bin, a power motor is installed in the supporting frame, a rotating shaft is rotationally connected into the drying bin, an output shaft of the power motor is connected with the rotating shaft, and a discharging frame is arranged on the top of the drying bin. The multi-layer drying structure is arranged in the drying bin, the polyester chips are rolled into the small polyester chips from the large bonded polyester chips, meanwhile, the polyester chips are continuously dried, water in the polyester chips is completely evaporated, and the drying efficiency is improved. And treating the moistened and bonded polyester chips into dry and mutually dispersed polyester chip particles.

Owner:河南源宏高分子新材料有限公司

Microstructure film forming solution on metal surface

ActiveCN103597116BSimple structureExcellent adhesionMetallic material coating processesFine structureOrganic acid

The purpose of the present invention is to provide a liquid for forming a microstructure film on a metal surface with which, by the simple immersion of a metal product in the liquid or the application or spraying of the liquid onto the metal product, it is possible to completely remove rust from the surface of the metal product, form a microstructure film having crystals or irregularities of 1 µm or smaller on the surface of the metal product such that the surface area is increased, impurities are prevented from penetrating inside the crystals, and the film easily imitates deformation of the metal substrate. The liquid for forming a microstructure film on a metal surface comprises, as the essential components, phosphoric acid, an inorganic acid, a nonionic fluorine surfactant, and water, and contains 2 to 60 mass% of phosphoric acid, 0.02 to 5 mass% of an organic acid, and 0.005 to 0.2 mass% of a nonionic fluorine surfactant.

Owner:盐泽明 +3

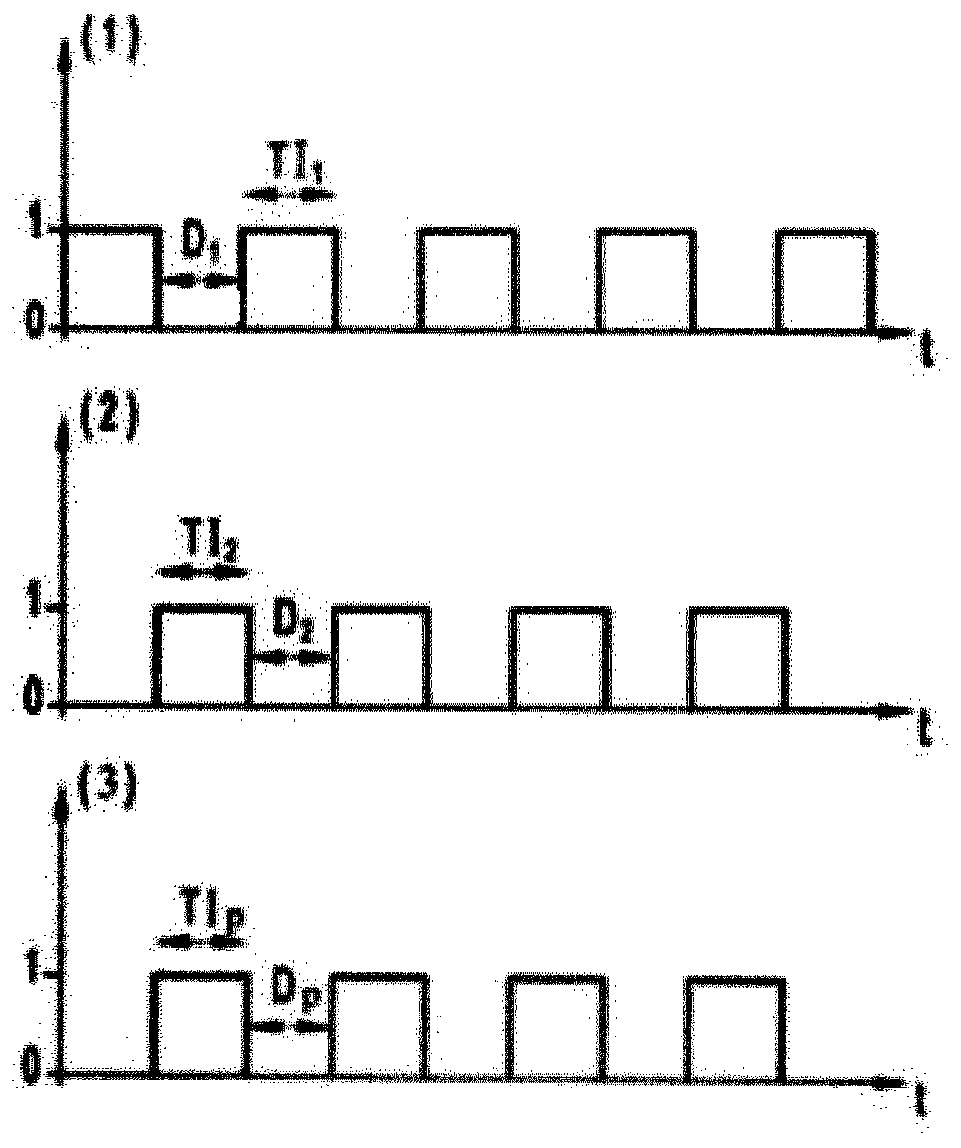

Method for depositing an insulating material into a via

ActiveCN111032909ALimit thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phasePulse sequence

A method for depositing a layer (4, 5, 6) of a material onto a substrate (20), comprising: -one gas-phase injection of a first chemical species with a precursor of such insulating material, into a deposition chamber of a chemical vapor deposition reactor, through a first injection path, according to a first pulse sequence; -one gas-phase injection of a second chemical species with a reactant adapted to react with such precursor, into the deposition chamber, through a second injection path, according to a second pulse sequence which is phase-shifted relative to the first pulse sequence; -one sequential generation of a plasma of the first chemical species and / or the second chemical species during at least one pulse of at least one of the first and second sequences, with such plasma being generated from a high frequency (HF) plasma source and a low frequency (LF) plasma source applied to the first and second injection paths, the low frequency (LF) plasma source power on the high frequency(HF) plasma source power ratio being above 1.

Owner:COOPERS GMBH

Surface treatment method

InactiveCN100473752COxidation rate controlGood removal effectVacuum evaporation coatingSputtering coatingIon bombardmentGas phase

Owner:北京东方新材科技有限公司

A light-emitting diode epitaxial wafer and its manufacturing method

ActiveCN104009140BFast vertical growthDoes not affect activitySemiconductor devicesHigh pressureElectron blocking layer

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method of the light emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a nucleating layer, a buffer layer, an undoped GaN layer, an n-type layer, a multiple-quantum-well layer, a first p-type GaN layer, a second p-type GaN layer, an electron barrier layer and a p-type layer, wherein the nucleating layer, the buffer layer, the undoped GaN layer, the n-type layer, the multiple-quantum-well layer, the first p-type GaN layer, the second p-type GaN layer, the electron barrier layer and the p-type layer grow upwards on the substrate. The thickness of the electron barrier layer ranges from 50 nm to 150 nm, the growth temperature of the first p-type GaN layer ranges from 600 DEG C to 800 DEG C, the growth pressure of the first p-type GaN layer ranges from 400 Torr to 800 Torr, the growth temperature of the second p-type GaN layer ranges from 800 DEG C to 1000 DEG C, the growth pressure of the second p-type GaN layer ranges from 50 Torr to 500 Torr. The first p-type GaN layer growing under high pressure and low temperature is arranged, and a hole injection channel is provided, so that hole injection efficiency is improved; through the second p-type GaN layer growing under low pressure and high temperature, crystalline quality is improved, the thickness of the electron barrier layer is limited, and hole injection efficiency is improved.

Owner:HC SEMITEK SUZHOU

Adapters for vacuum pumps and associated pumping devices

ActiveCN104024645BImprove pumping capacityReduce settingsPump componentsPump installationsEngineeringVacuum pump

The invention relates to an adapter for vacuum pumps, characterized in that it comprises an annular inlet flange (15) intended to be coupled to an outlet orifice of a chamber and an outlet coupling (16) comprising at least two cylindrical outlet through-housings (21) and forming an at least partial pump casing for the case (4) of a respective turbomolecular vacuum pump (3), said turbomolecular vacuum pumps (3) being intended to be received in a respective cylindrical outlet housing (21). The invention also relates to a pumping device, characterized in that it comprises an adapter for vacuum pumps (2) as described hereinabove and at least two turbomolecular vacuum pumps (3) housed at least partially in a respective cylindrical outlet housing (21).

Owner:PFEIFFER VACUUM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com