Microstructure film forming solution on metal surface

A technology of microstructure and metal surface, applied in the direction of metal material coating process, etc., can solve the problems of insufficient coating performance and rust prevention effect, and achieve the effects of excellent electrical characteristics, improved adhesion, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] 20% by mass of the above-mentioned aqueous phosphoric acid solution, 0.1% by mass of the above-mentioned malic acid, 0.03% by mass of the above-mentioned perfluoroalkyl ethylene oxide adduct (nonionic fluorine-based surfactant), and the remaining amount of water were mixed, and These are mixed to prepare a film-forming liquid.

[0118] Next, among the above-mentioned steel members, a member having rust on its surface was immersed in the obtained film-forming solution (40° C.) for 20 minutes. Rust on the surface of the steel member is removed, and a microstructure coating is formed on the surface of the steel member.

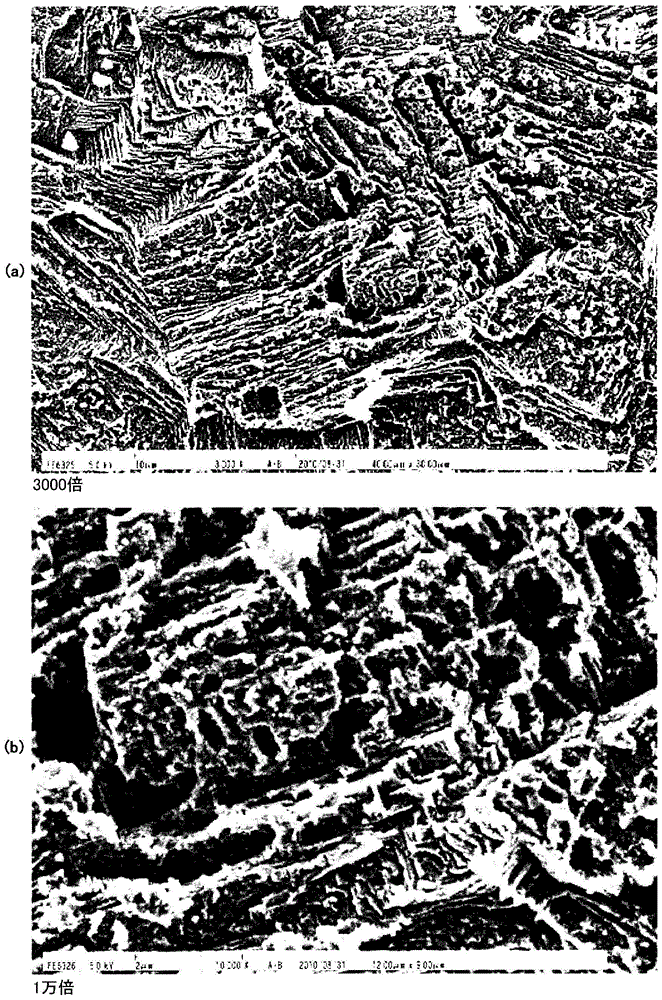

[0119] SEM was carried out on the surface of the steel member with this coating at 3,000 magnifications and 10,000 magnifications using a high-resolution field emission scanning electron microscope model ERA-8900 (manufactured by ELIONIX INC. / Electron beam three-dimensional roughness analysis device with EDX) shooting, and the results are shown in fig...

Embodiment 2

[0122] Use the above-mentioned oligomers (nonionic fluorosurfactants) containing fluorine-containing groups / hydrophilic groups / lipophilic groups instead of the aforementioned perfluoroalkyl oxirane adducts (nonionic Fluorine surfactant), except that it was carried out similarly to Example 1, and this steel member which rusted was immersed in the film formation solution. Rust on the surface of the steel member is removed, and a microstructure coating is formed on the surface of the steel member.

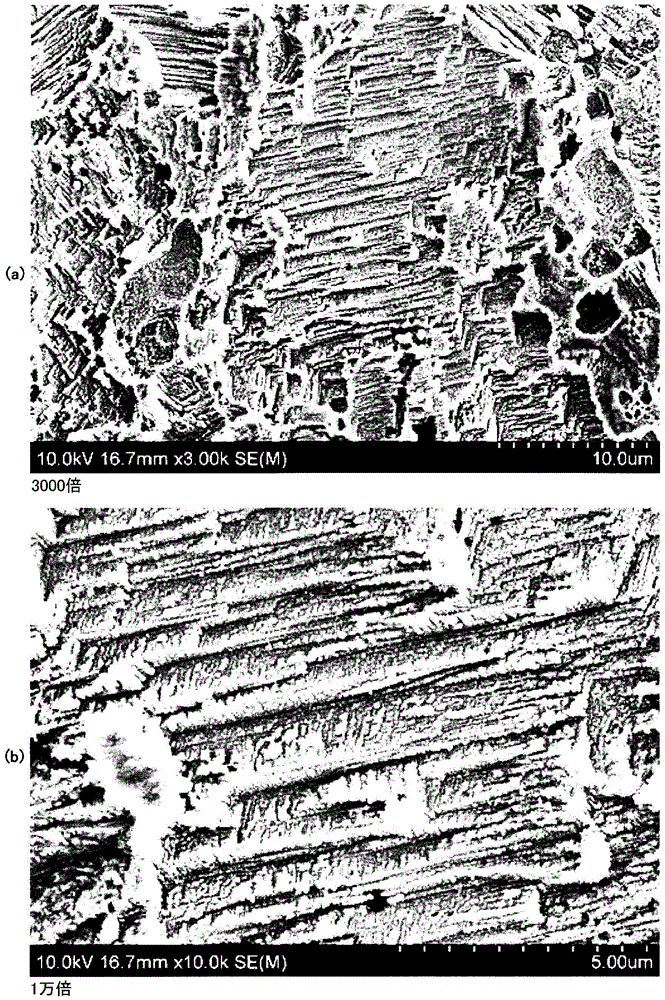

[0123] Using a high-resolution field emission type scanning electron microscope model S-4800 (manufactured by Hitachi, Ltd.), SEM photographs were carried out at 3000 times and 10,000 times the surface of the steel member with the coating, and the results are shown in figure 2 (a) and figure 2 (b).

[0124] It was found that the obtained fine structure had an uneven shape of about 1 μm.

Embodiment 3

[0126] Except having used the above-mentioned tartaric acid instead of the above-mentioned malic acid, it carried out similarly to Example 1, and immersed this steel member which rusted in the film formation solution. Rust on the surface of the steel member is removed, and a microstructure coating is formed on the surface of the steel member.

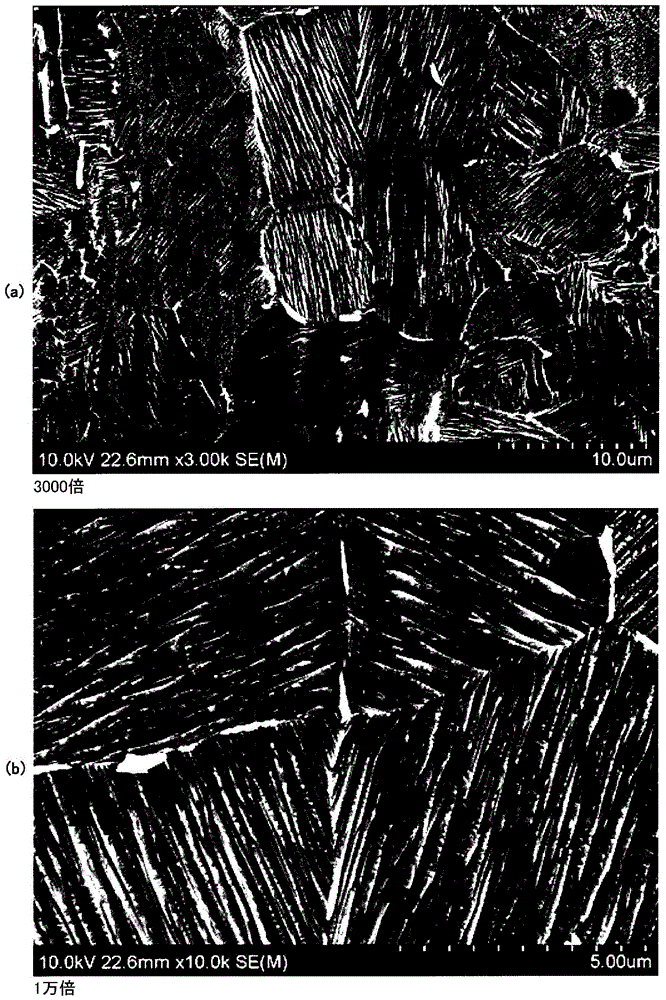

[0127] Operate in the same manner as in Example 2, take SEM photographs of the microstructure, and the results are shown in image 3 (a) and image 3 (b). It was found that the obtained fine structure had an uneven shape of about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com