Patents

Literature

109results about How to "Good thermal cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS7320832B2Good thermal cycle performanceHigh strengthMaterial nanotechnologyRodsParticulatesChemical composition

Owner:INTEGRAN TECH

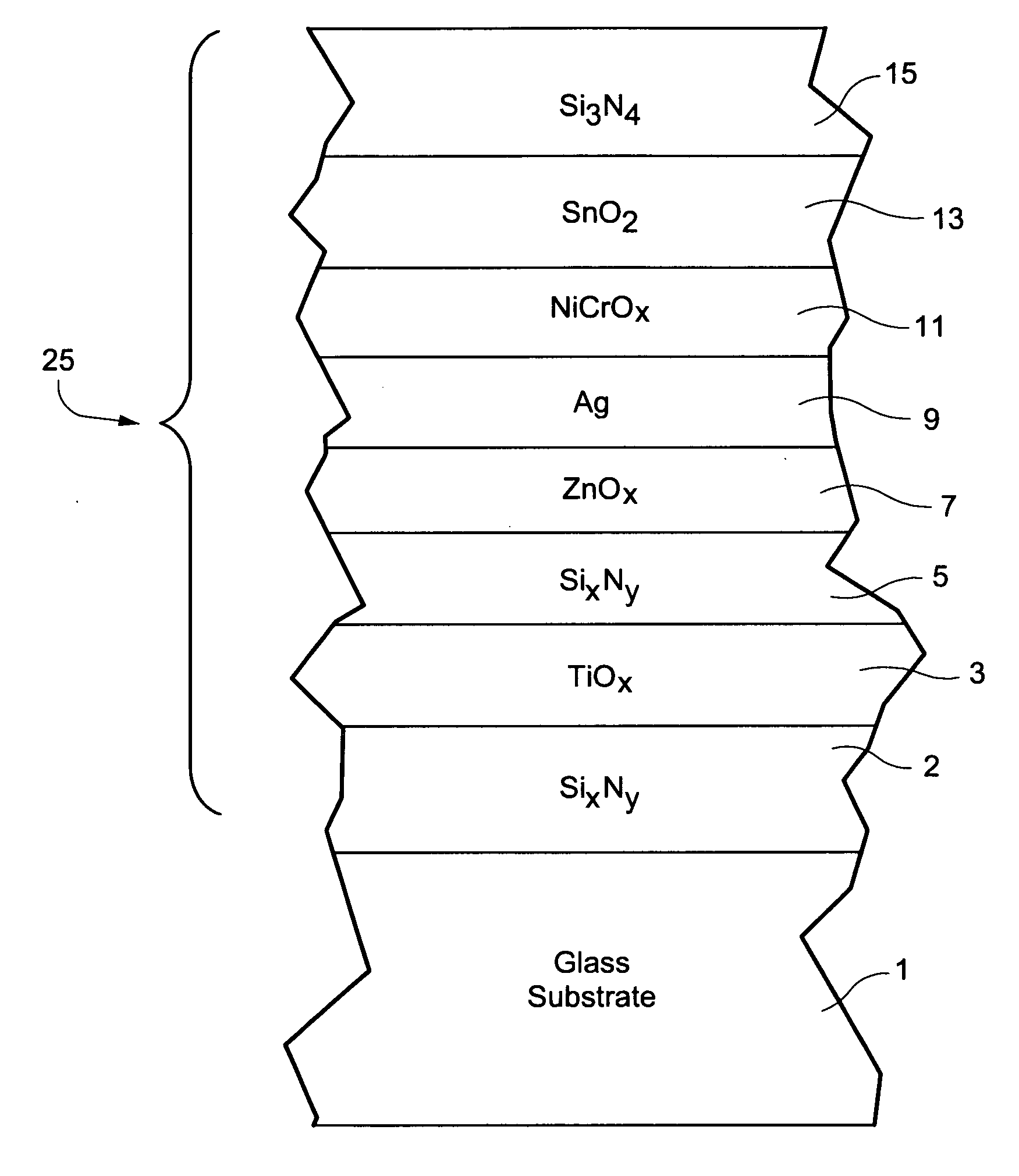

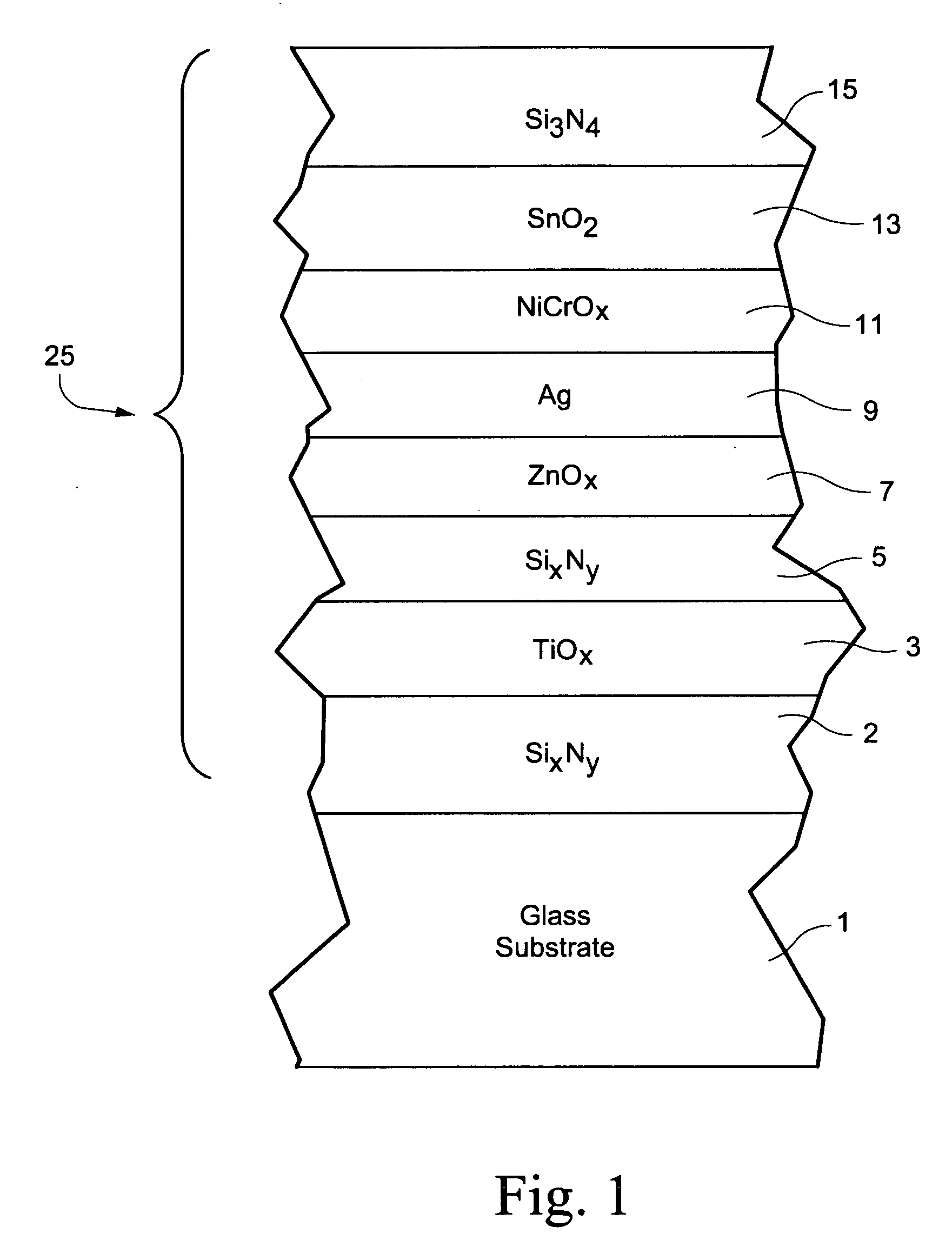

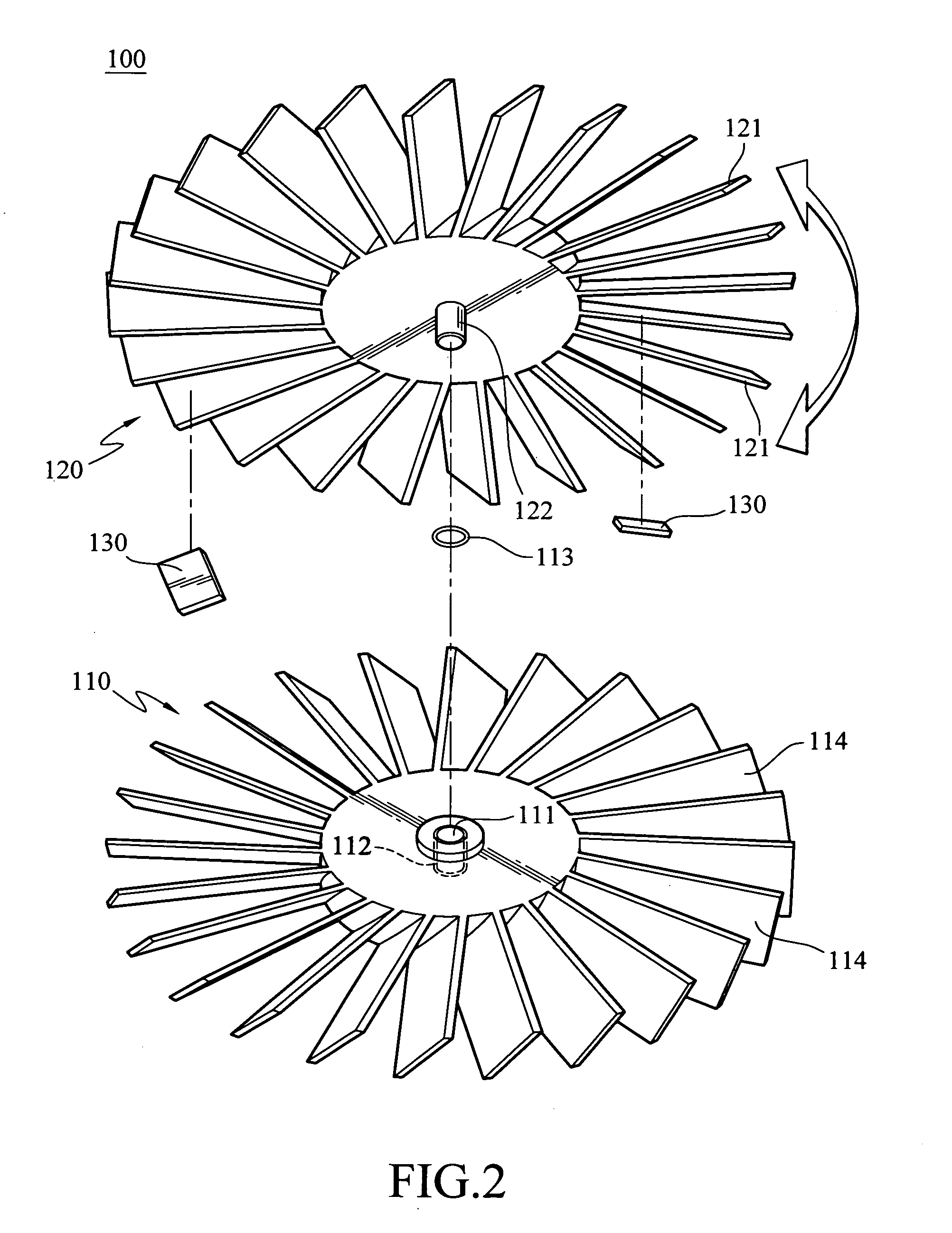

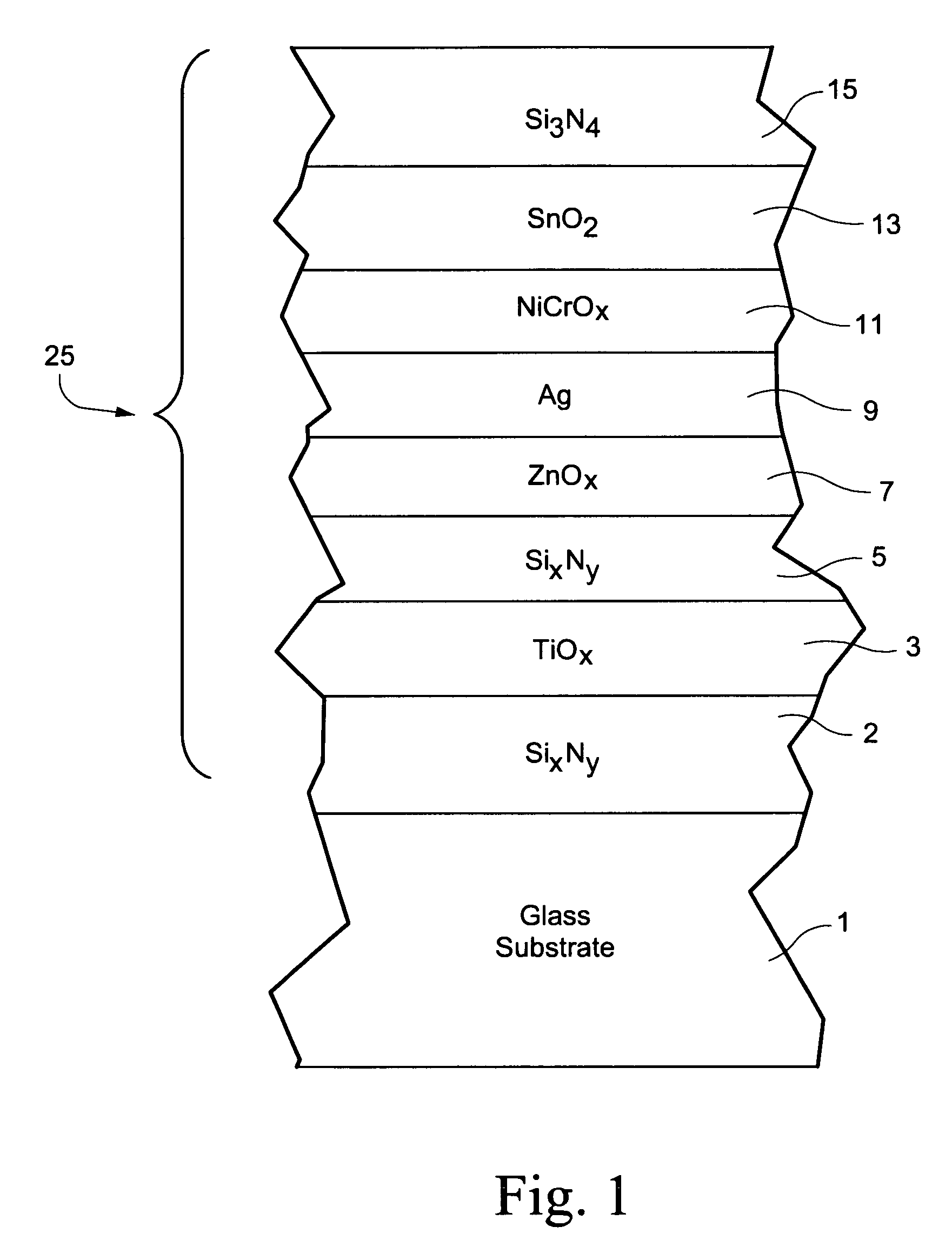

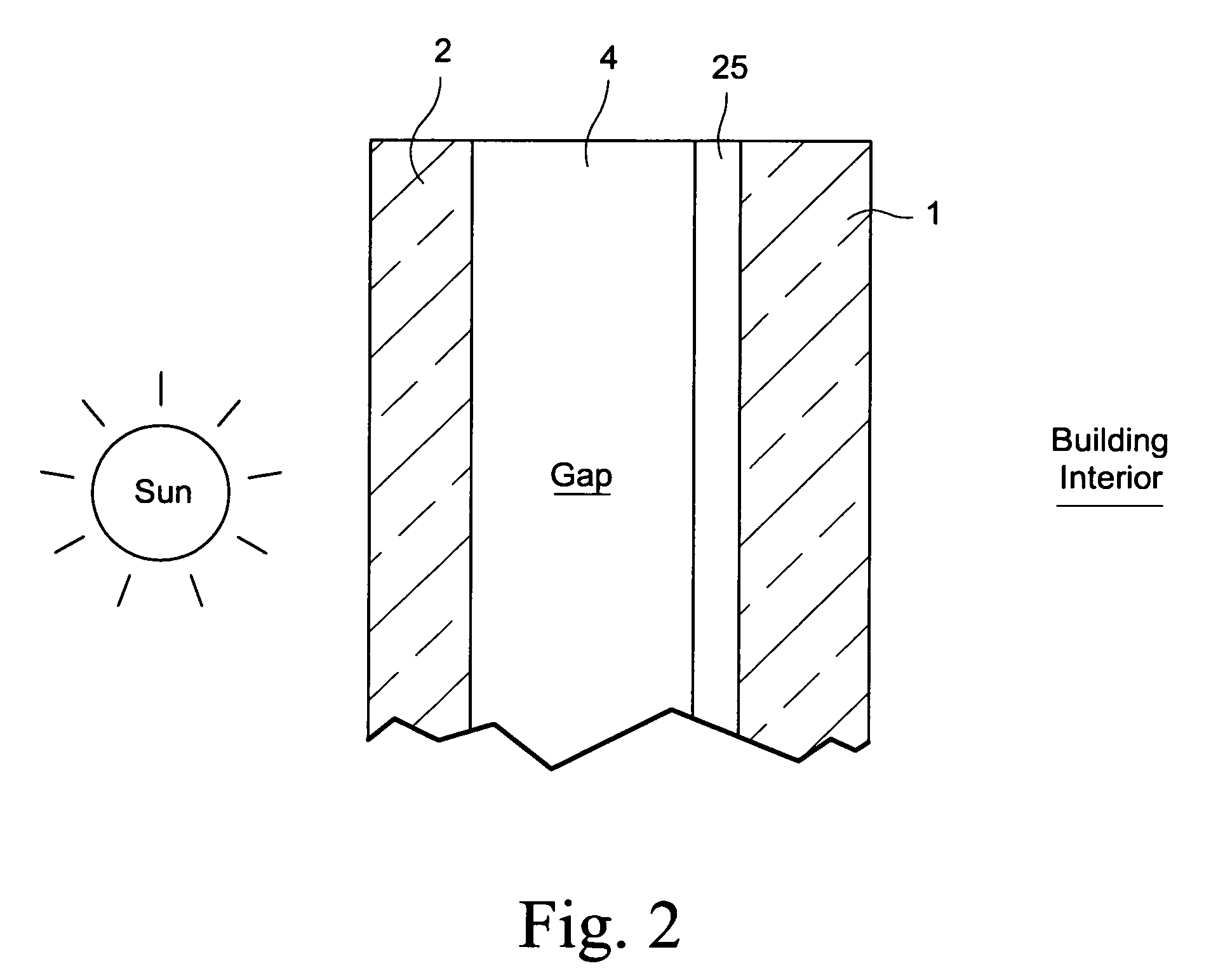

Coated article with IR reflecting layer and method of making same

InactiveUS20090263596A1Low emissivityReduce sheet resistanceVacuum evaporation coatingSputtering coatingMetallurgyNitrogen gas

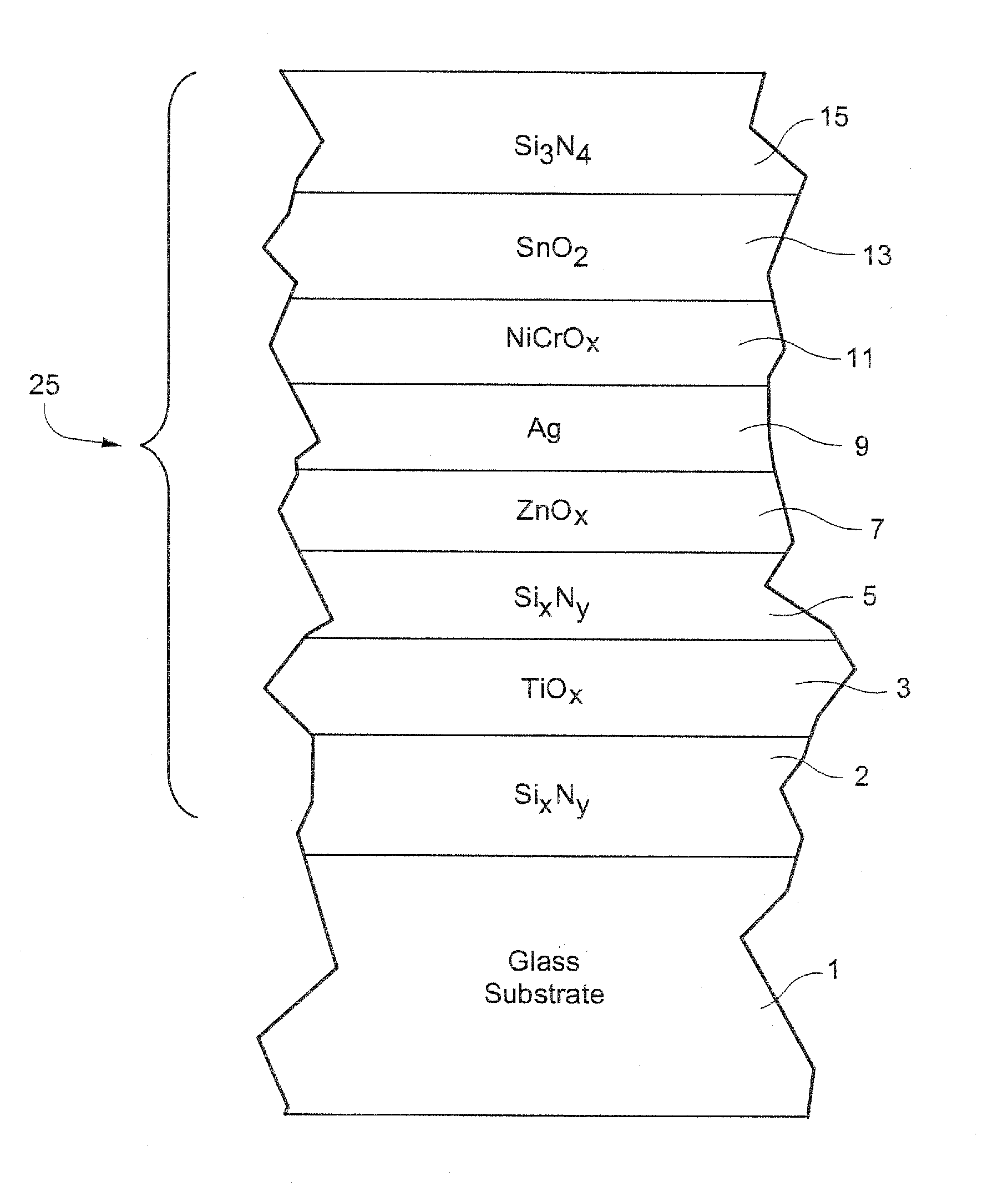

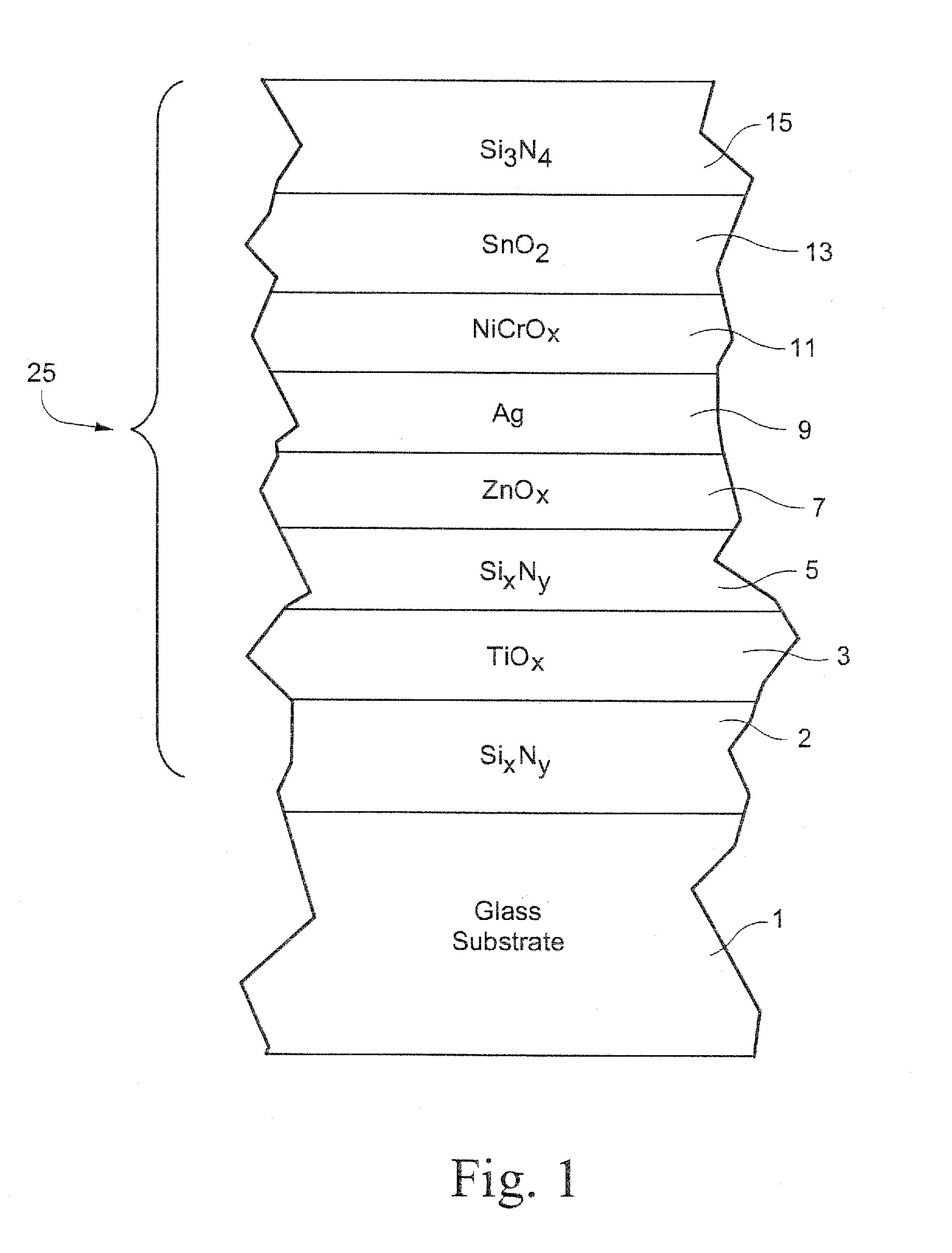

Example embodiments of this invention relate to a coated article including an infrared (IR) reflecting layer of a material such as silver or the like, for use in an insulating glass (IG) window unit for example. In certain example embodiments, the coating is a single-silver type coating, and includes an overcoat including an uppermost layer of or including silicon nitride and a layer of or including tin oxide immediately under and contacting the silicon nitride based overcoat. In certain example embodiments, the thicknesses of the silicon nitride based overcoat and the tin oxide based layer are balanced (e.g., substantially equal, or equal plus / minus about 10%). It has surprisingly been found that such balancing results in an improvement in thermal cycling performance and improved mechanical durability. In certain example embodiments, the coating may realize surprisingly good substantially neutral film side reflective coloration, and may achieve an improved visible transmission, SHGC ratio and low U-values. Moreover, in certain example embodiments, stress in the overcoat of the coating may be reduced by reducing nitrogen gas flow (N2 ml / kW) and cathode power during a sputter-deposition process, thereby further improving thermal cycling performance.

Owner:GUARDIAN EURO S A R L +1

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

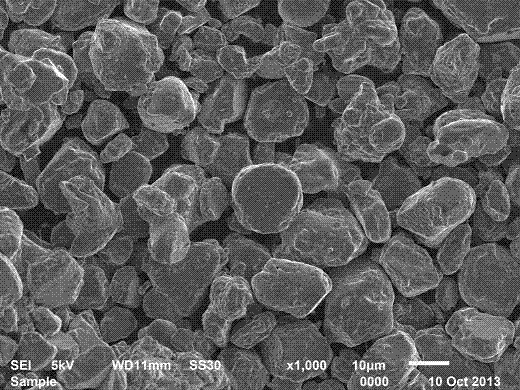

ActiveUS20070281176A1Cost-effective and convenient processIncrease stiffnessMaterial nanotechnologyRodsThermal dilatationMetal coating

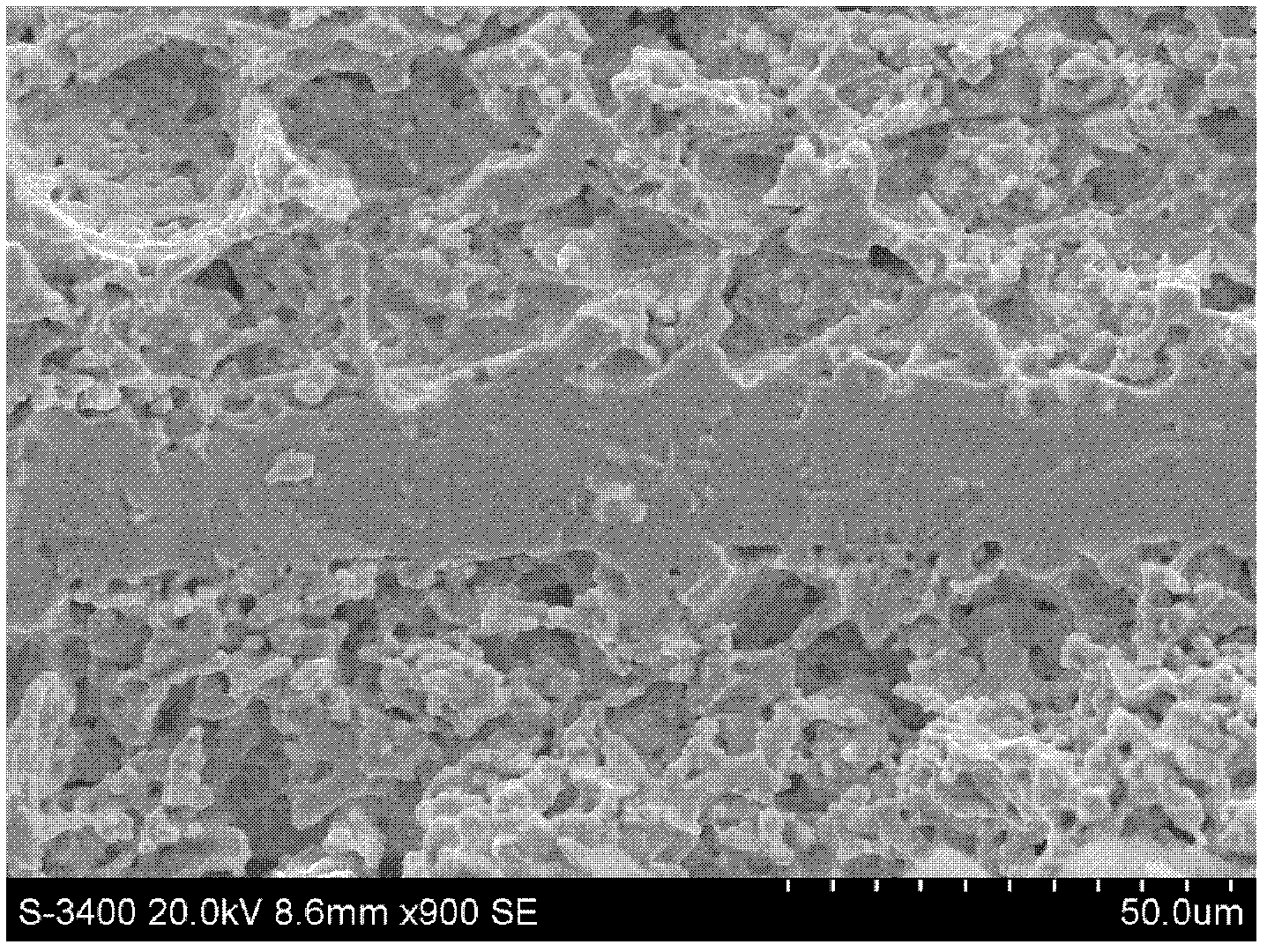

Fine-grained (average grain size 1 nm to 1,000 nm) metallic coatings optionally containing solid particulates dispersed therein are disclosed. The fine-grained metallic materials are significantly harder and stronger than conventional coatings of the same chemical composition due to Hall-Petch strengthening and have low linear coefficients of thermal expansion (CTEs). The invention provides means for matching the CTE of the fine-grained metallic coating to the one of the substrate by adjusting the composition of the alloy and / or by varying the chemistry and volume fraction of particulates embedded in the coating. The fine-grained metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling. The low CTEs and the ability to match the CTEs of the fine-grained metallic coatings with the CTEs of the substrate minimize dimensional changes during thermal cycling and prevent premature failure.

Owner:INTEGRAN TECH

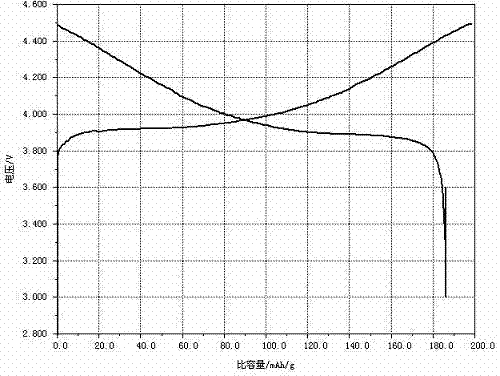

High-voltage high-capacity anode material for lithium ion battery and preparation method of anode material

InactiveCN103618081AGuaranteed stabilityImprove electrochemical performanceCell electrodesSecondary cellsDopantElectrical battery

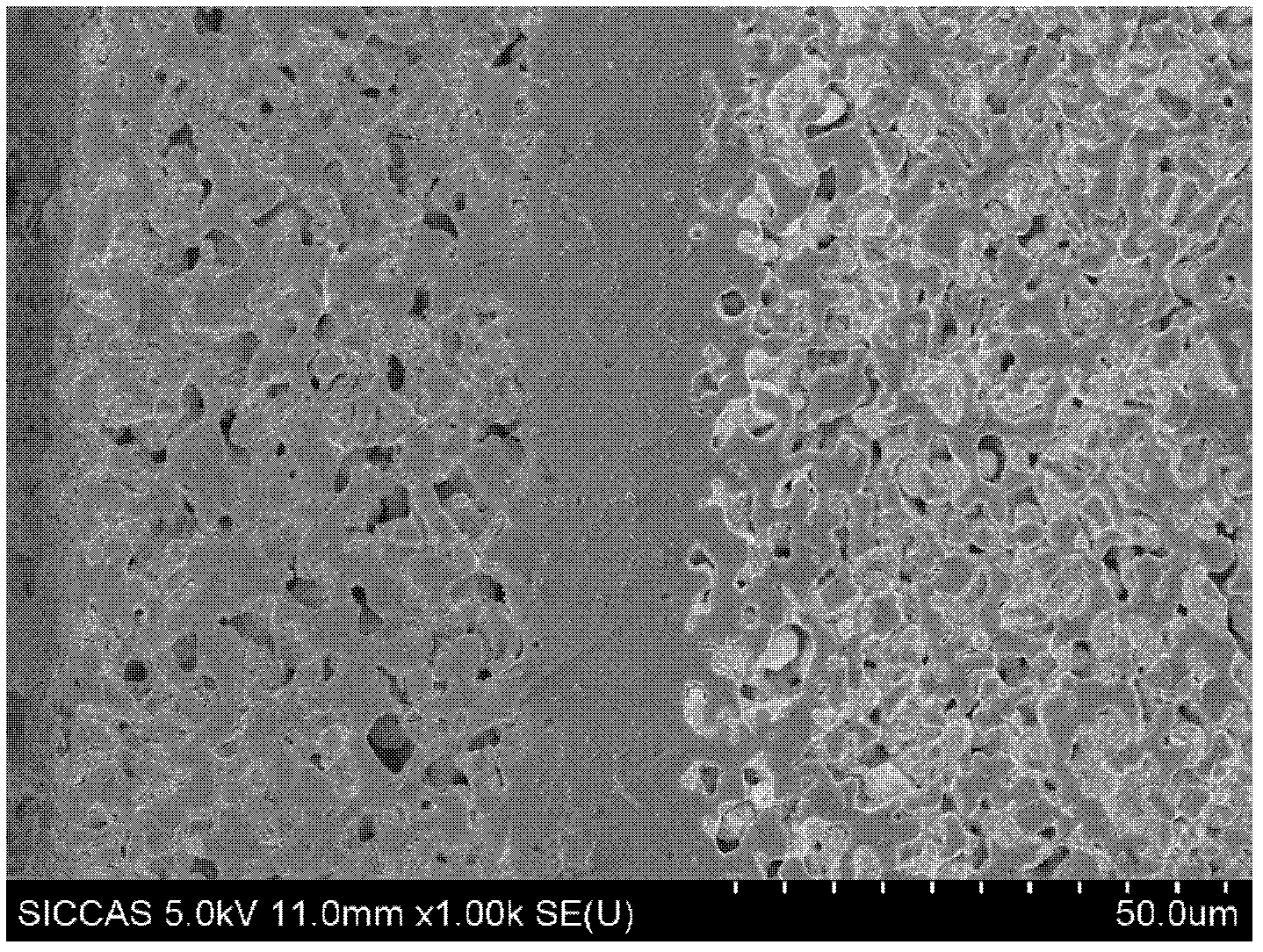

The invention discloses a high-voltage high-capacity anode material for a lithium ion battery. The anode material contains a cobalt source substance, a lithium source substance, a dopant M and a coating material, wherein the molar ratio of Li to Co is 0.95-1.2, the doping amount of the dopant M is 0.01-10wt%, and the total doping amount of the coating material is 0.01-20wt%. The structural stability of lithium cobalt oxide is enhanced by means of doping, the advantages of the lithium cobalt oxide in a base layer and the active material in a coating layer are complemented mutually by means of coating with an active substance, so that the electrochemical performance of the anode material is enhanced; stable cycling can be achieved under the condition of high voltage of 3.0-4.5V and the anode material has excellent electrochemical performance. In a word, the anode material has the advantages of high voltage platform, high reversible specific capacity, excellent thermal cycling performance, stable structure, good safety and the like; the problem that the calcination temperature of the base layer and the coating layer cannot be unified is solved and the anode material has excellent uniformity.

Owner:NANTONG RESHINE NEW MATERIAL

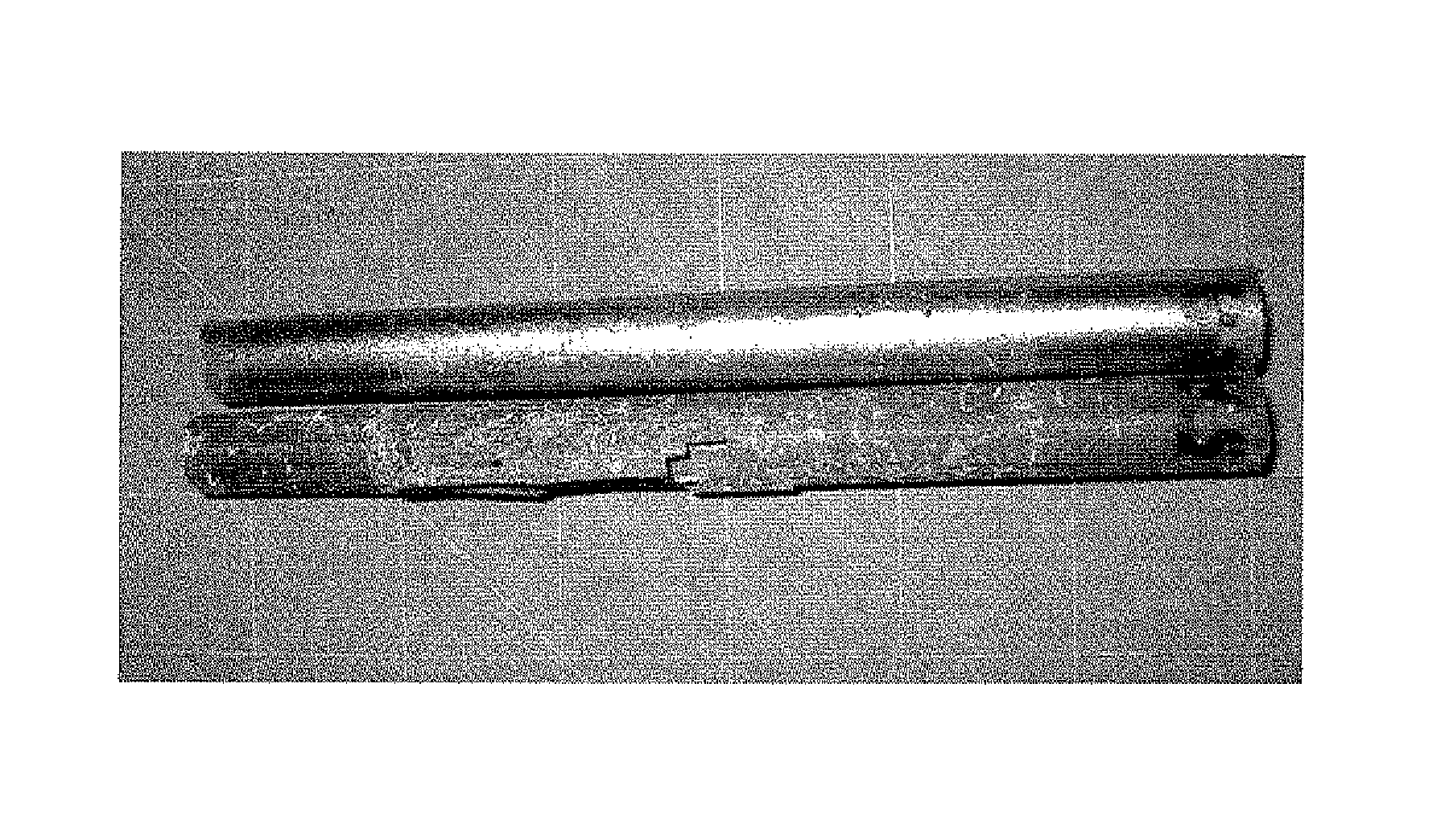

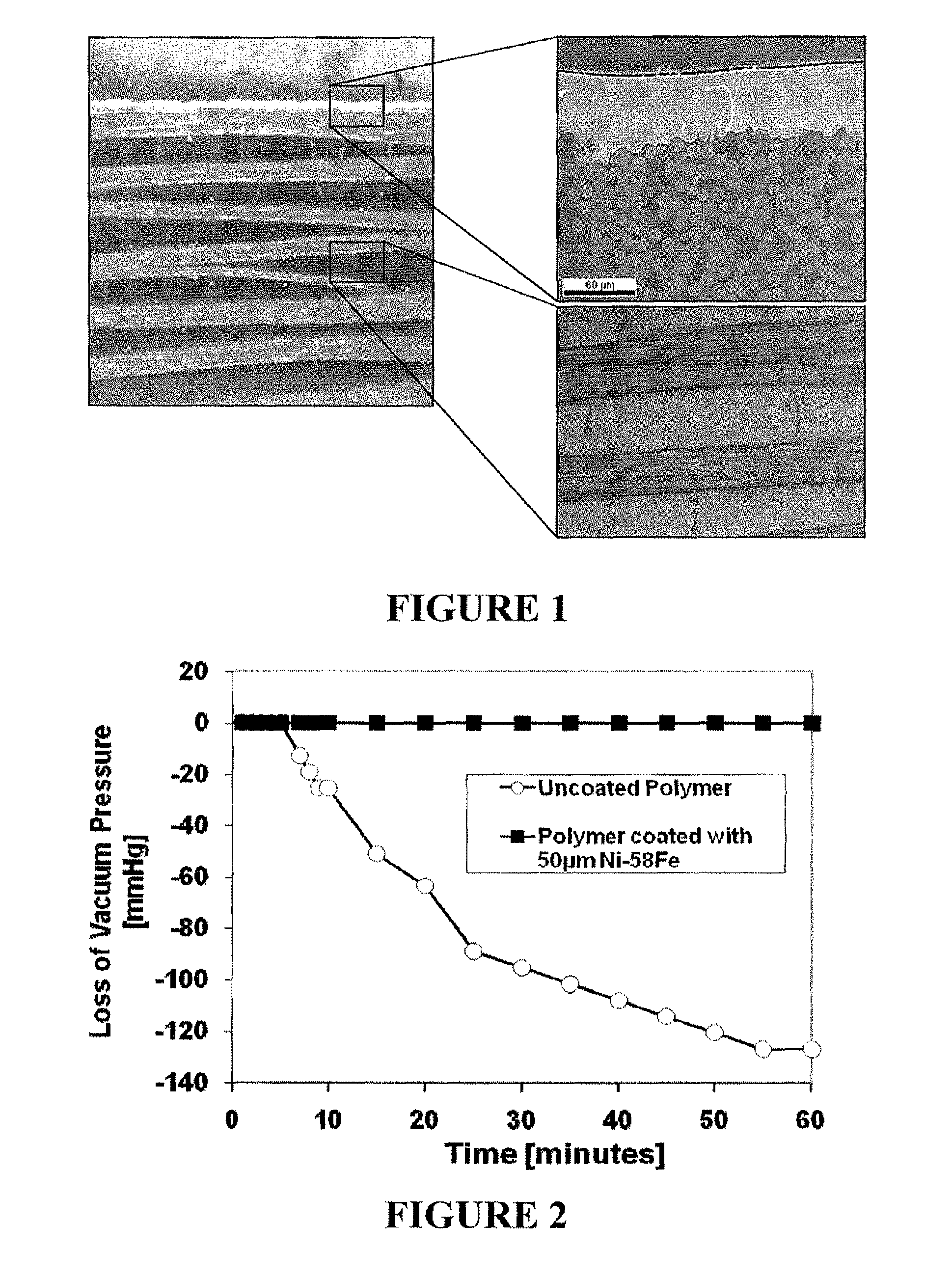

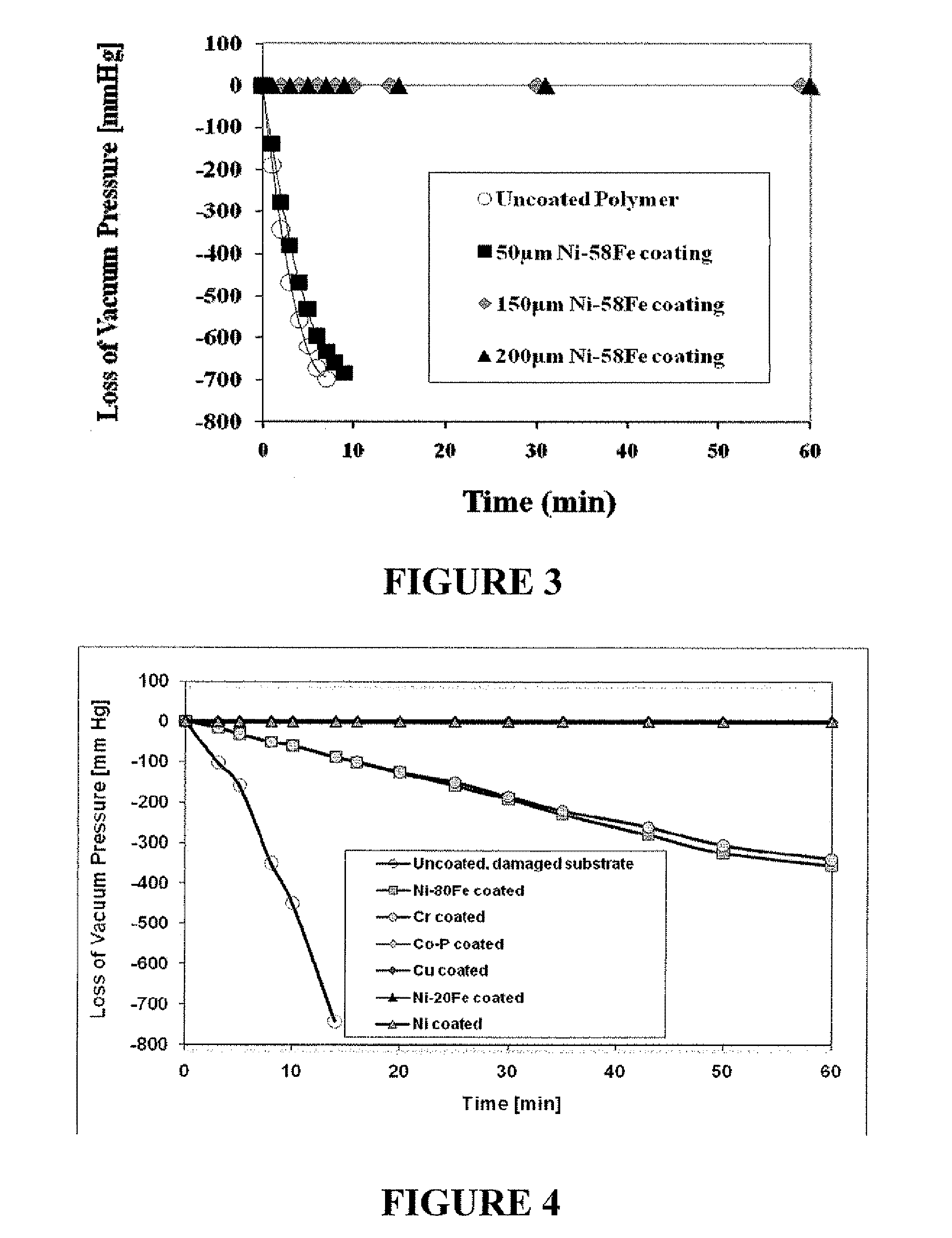

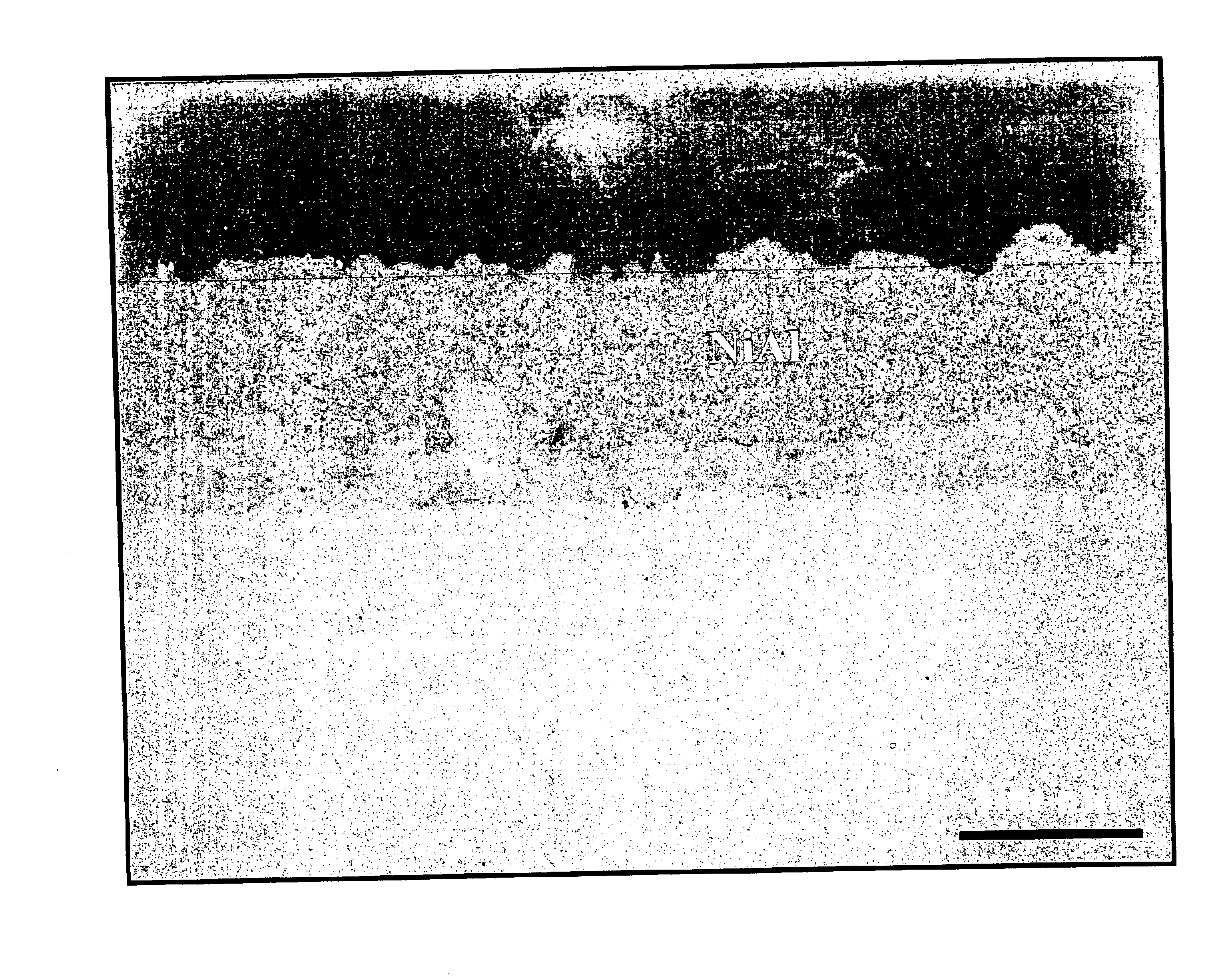

Metal-coated polymer article of high durability and vacuum and/or pressure integrity

InactiveUS8247050B2Increased durabilityImprove integrityEnvelopes/bags making machineryPreformed elementsParticulatesPorosity

Metal-coated polymer articles containing structural substantially porosity-free, fine-grained and / or amorphous metallic coatings / layers optionally containing solid particulates dispersed therein on polymer substrates, are disclosed. The substantially porosity-free metallic coatings / layers / patches are applied to polymer or polymer composite substrates to provide, enhance or restore vacuum / pressure integrity and fluid sealing functions. Due to the excellent adhesion between the metallic coating and the polymer article satisfactory thermal cycling performance is achieved. The invention can also be employed as a repair / refurbishment technique. The fine-grained and / or amorphous metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, aerospace and automotive parts and other components exposed to thermal cycling and stress created by erosion and impact damage.

Owner:INTEGRAN TECH

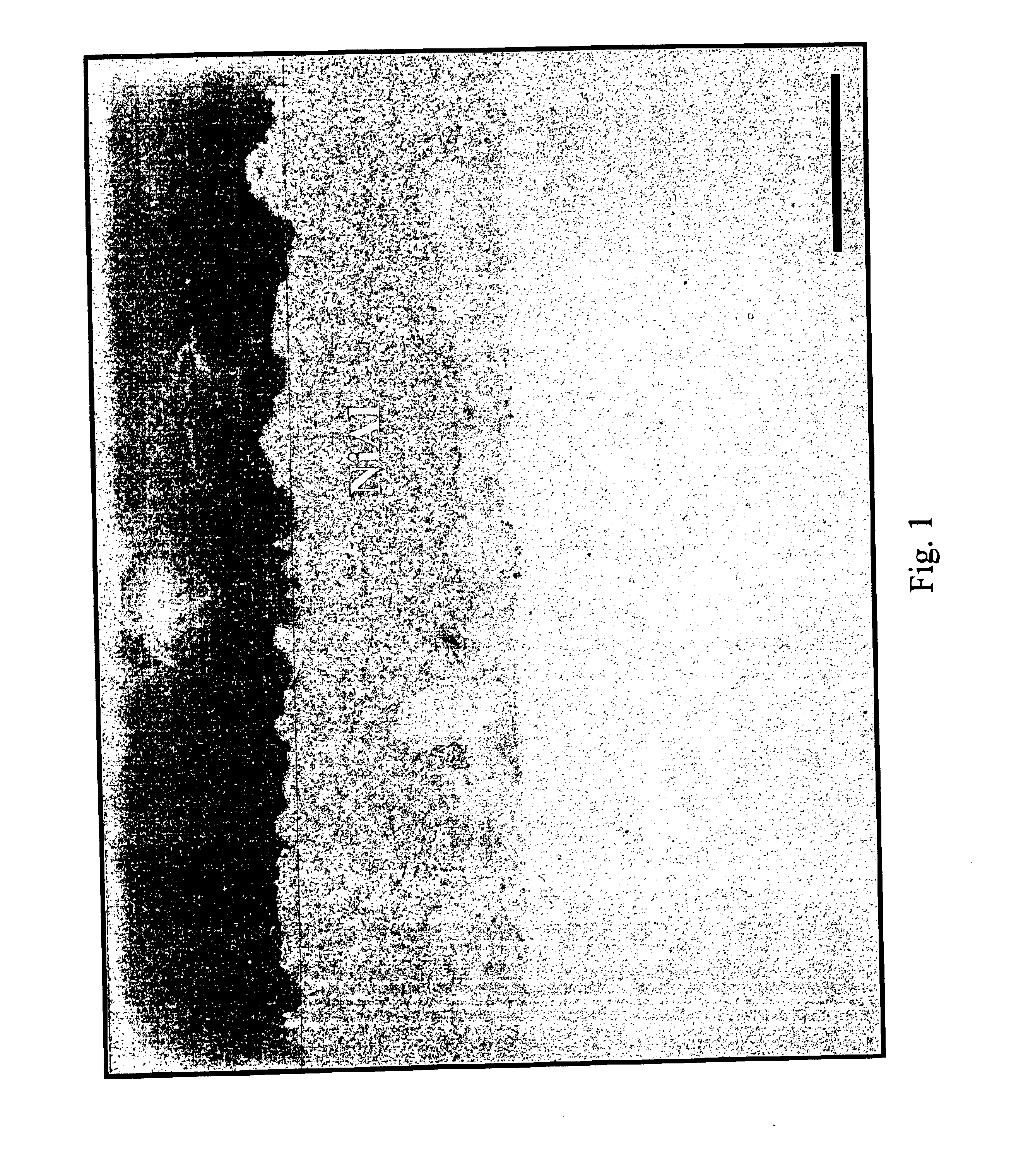

Blanch resistant and thermal barrier NiAl coating systems for advanced copper alloys

InactiveUS6838191B1Good thermal cycle performanceSuitability of coatingMolten spray coatingPretreated surfacesCoating systemBond coat

A method of forming an environmental resistant thermal barrier coating on a copper alloy is disclosed. The steps include cleansing a surface of a copper alloy, depositing a bond coat on the cleansed surface of the copper alloy, depositing a NiAl top coat on the bond coat and consolidating the bond coat and the NiAl top coat to form the thermal barrier coating. The bond coat may be a nickel layer or a layer composed of at least one of copper and chromium-copper alloy and either the bond coat or the NiAl top coat or both may be deposited using a low pressure or vacuum plasma spray.

Owner:NASA

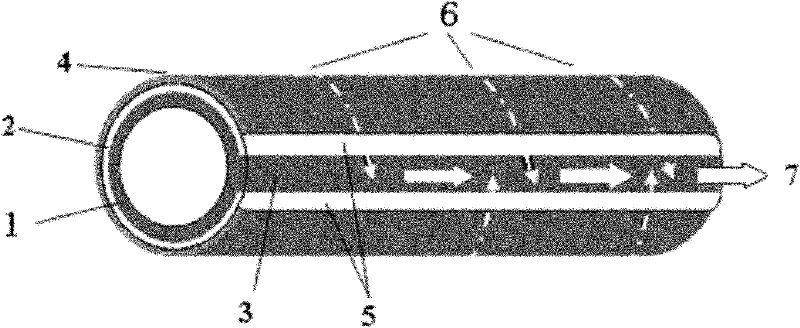

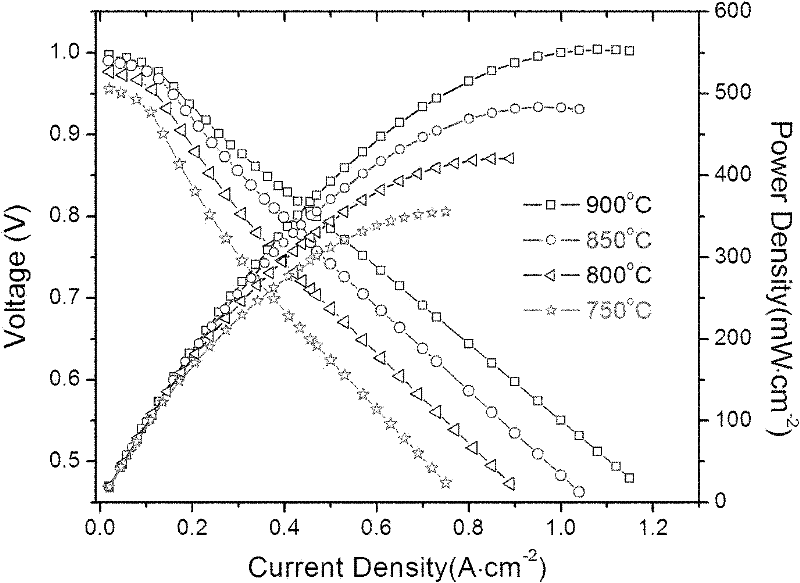

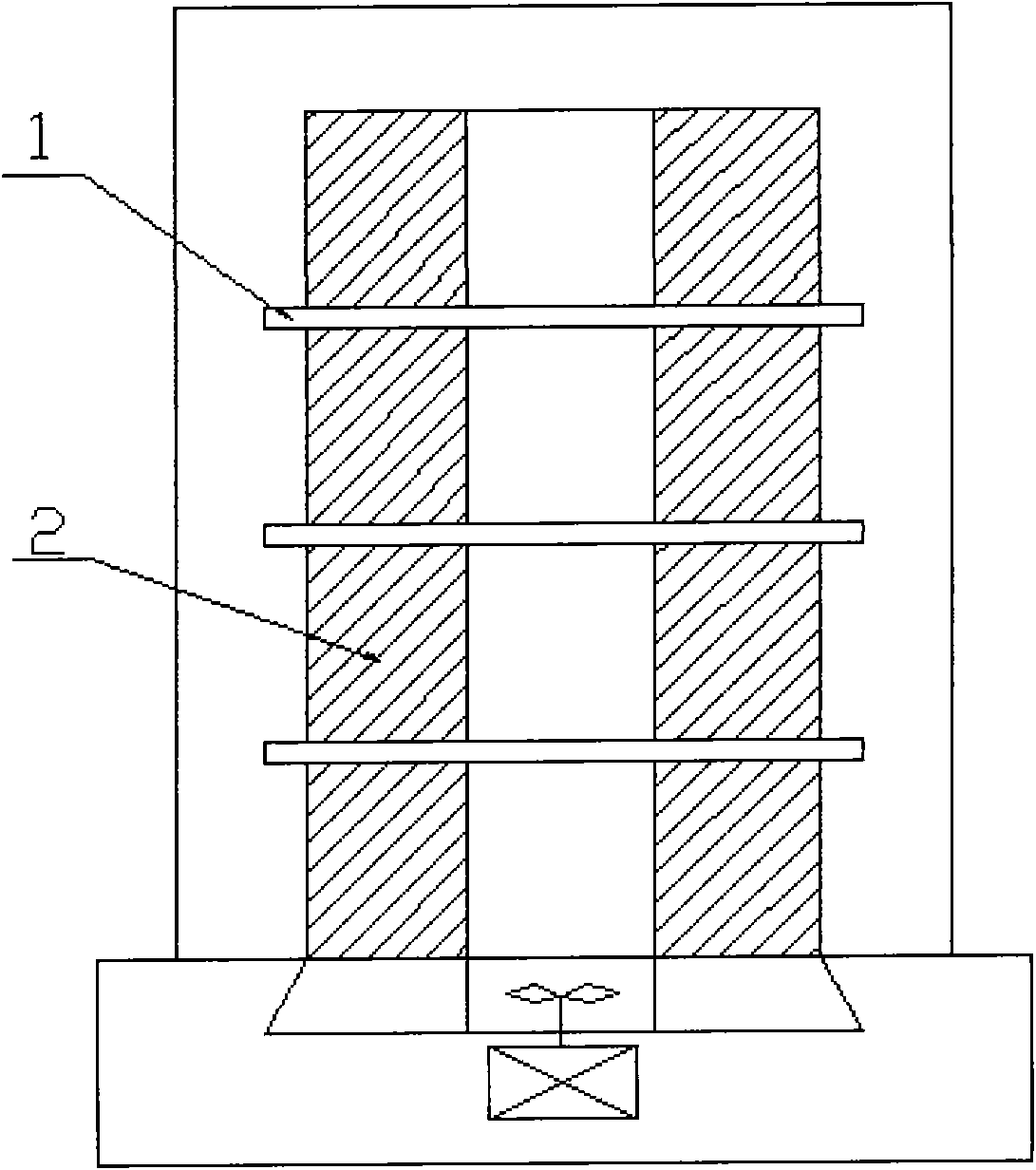

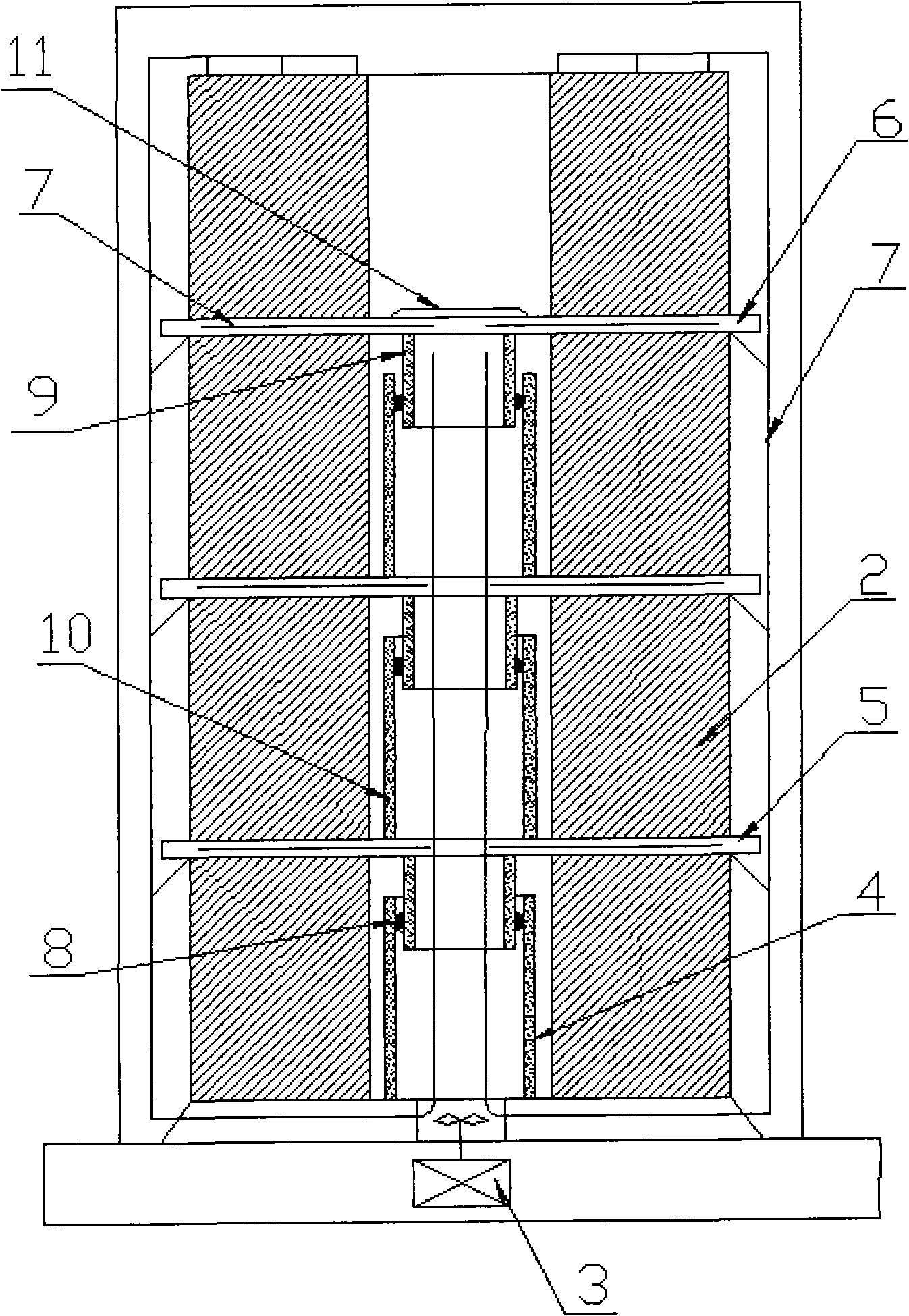

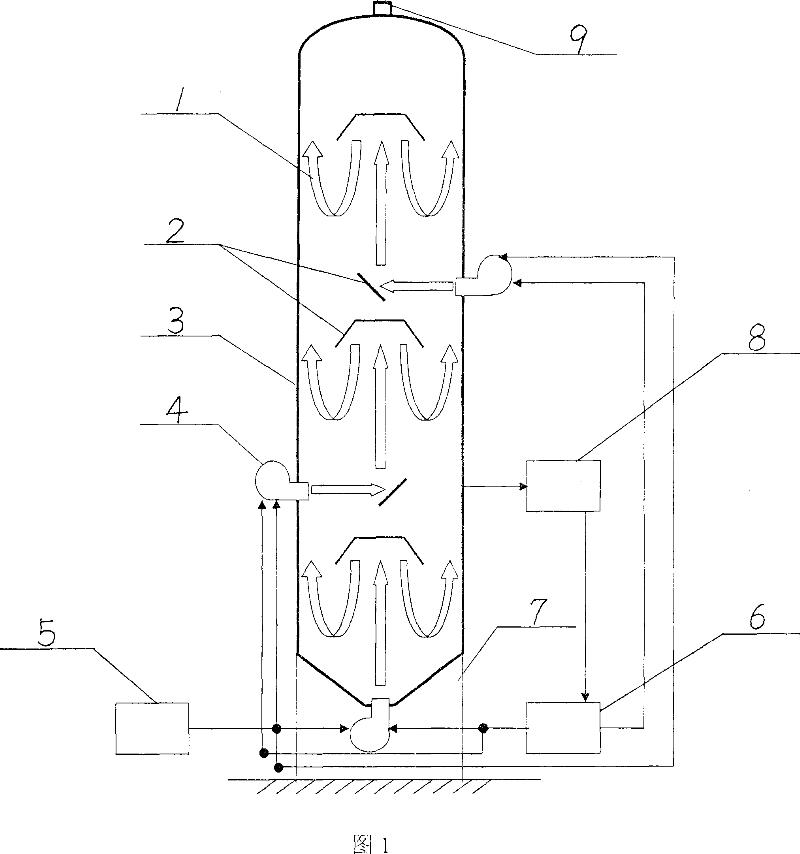

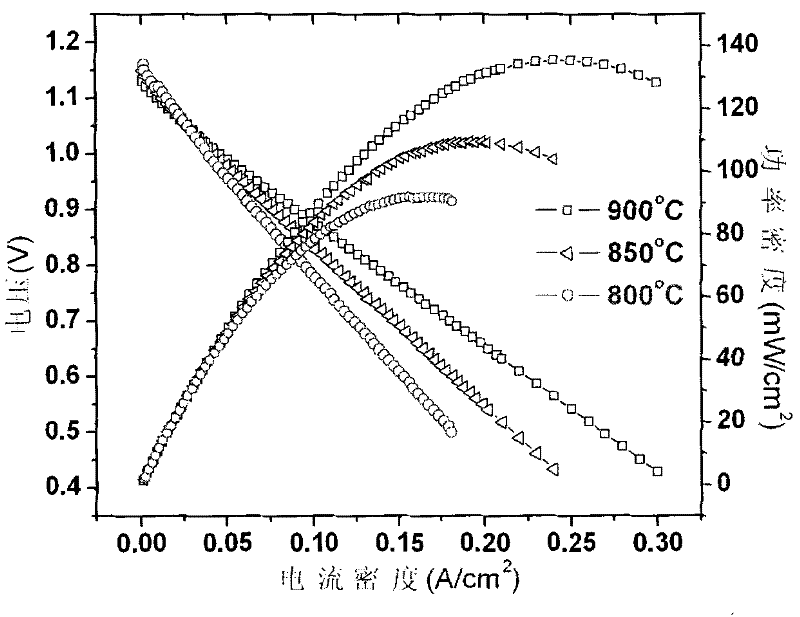

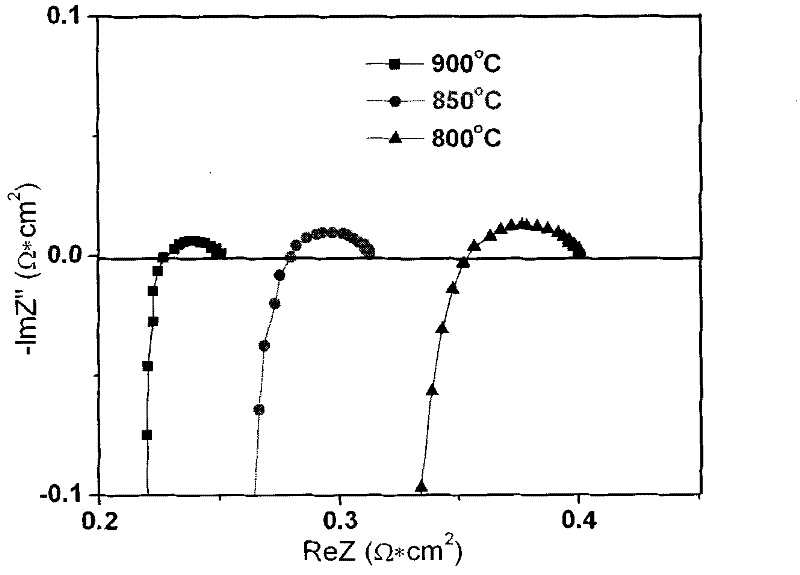

Anode-supported solid oxide fuel cell, cell stack and preparation method thereof

InactiveCN102651480ARaise the sintering temperatureHigh strengthFuel cells groupingSolid electrolyte fuel cellsFuel cellsHigh power density

The invention relates to an anode-supported solid oxide fuel cell, a cell stack and a preparation method thereof, which belong to the field of fuel cell materials. The anode-supported tubular solid oxide fuel cell comprises an anode support tube with one end sealed, wherein a bar-shaped ceramic connector layer is arranged on the outer side surface of the anode support tube; a compact electrolyte layer is arranged at the part of the outer surface of the anode support tube without the ceramic connector layer, and the compact electrolyte layer and the bar-shaped ceramic connector layer are adjacent to each other and completely cover the outer surface of the anode outer surface; the anode support tube, the compact electrolyte layer and the ceramic connector layer are integrated through cofiring; and a cathode layer is further arranged outside the compact electrolyte layer and disconnected with the ceramic connector layer. The anode-supported solid oxide fuel cell is easy for stacking and has high operating temperature and generating efficiency; a connector is stable and reliable and has a long service life; as the connector and the anode support tube biscuit are prepared through cofiring, convenience and low cost are realized; and meanwhile, the cell structure with one end sealed achieves internal reforming of fuel, compact structure and high power density are also realized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

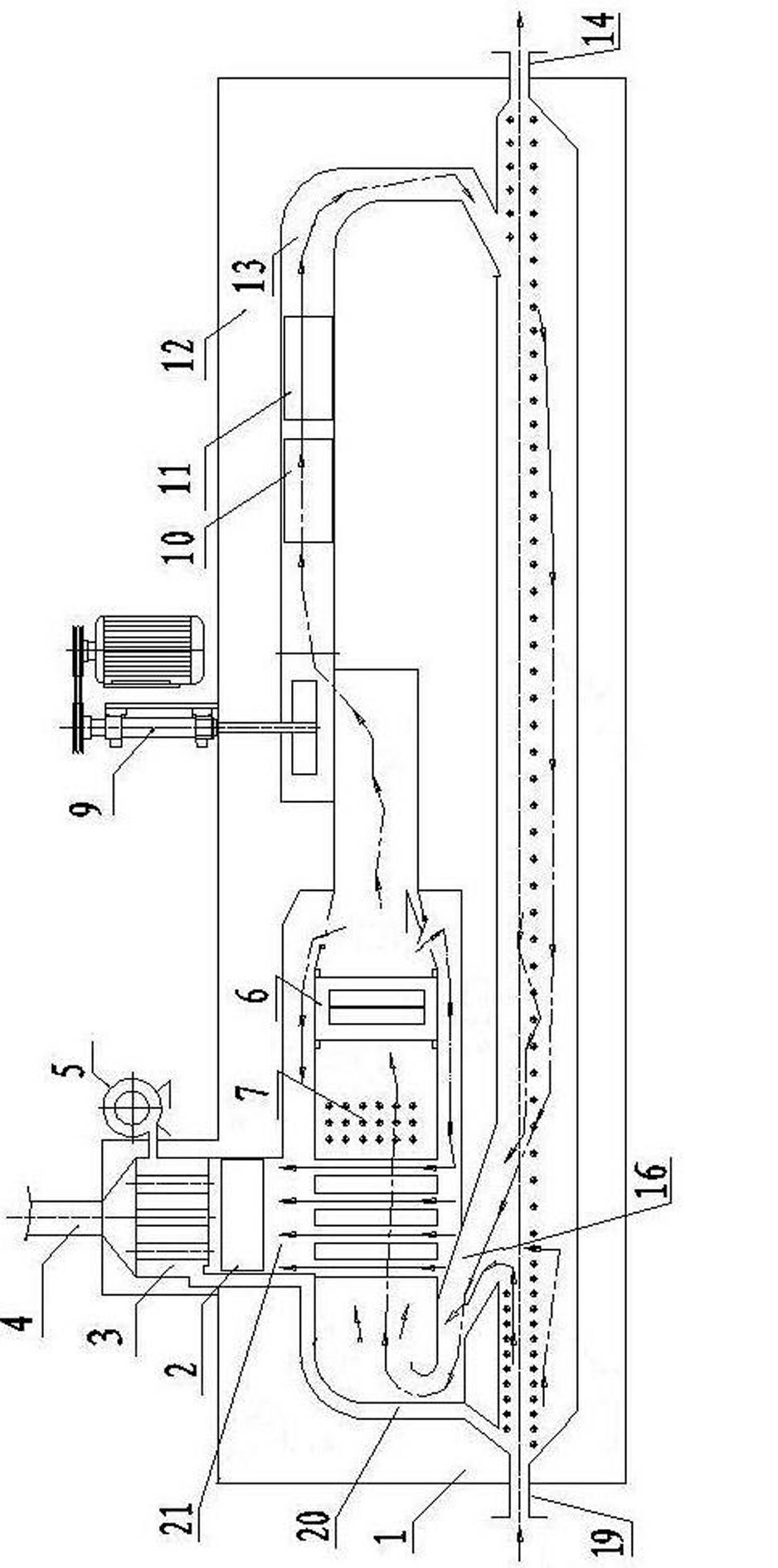

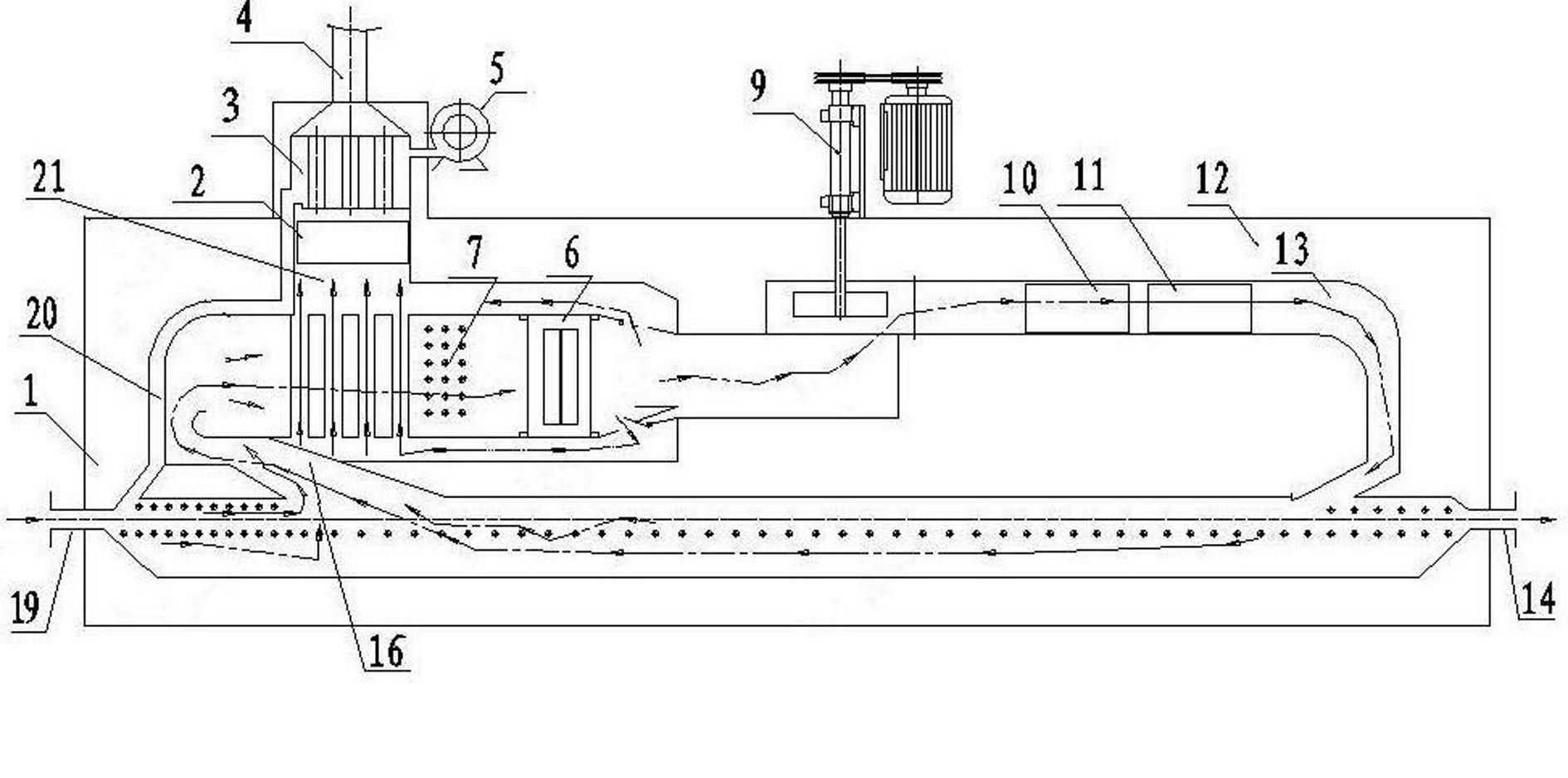

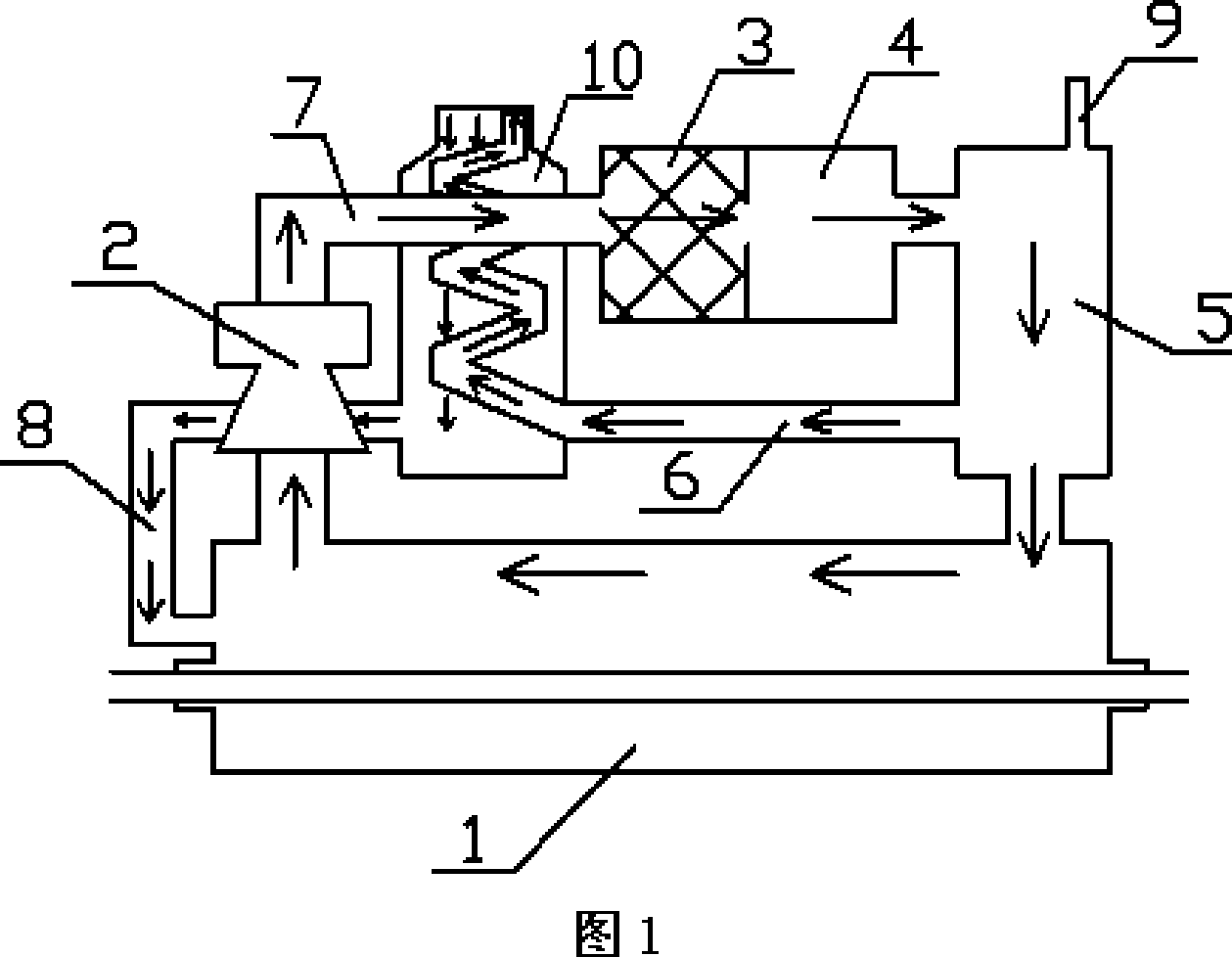

Cyclic baking method of enamelled wire and oven for realizing method

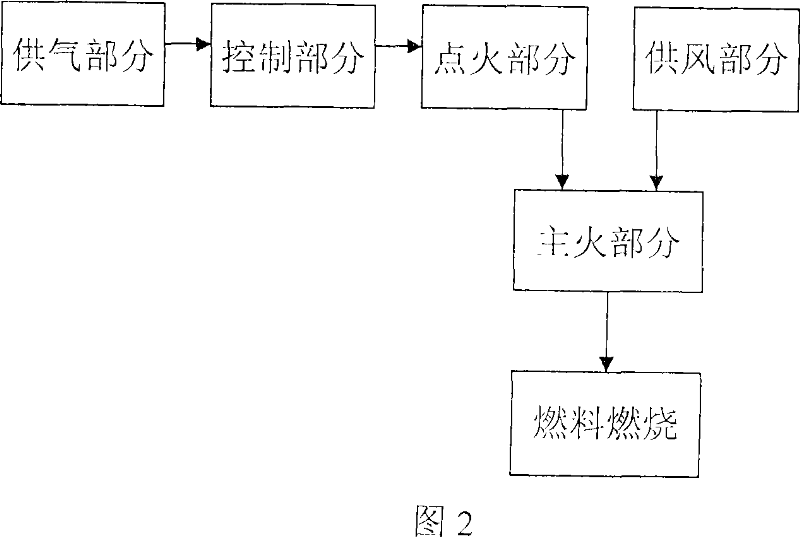

ActiveCN102368412AIncrease in sizeIncrease baking speedFinal product manufactureInsulating conductors/cablesCombustion chamberCombustor

The invention relates to a cyclic baking method of an enamelled wire and an oven for realizing the method. According to the method, after an enamelled wire attached with painted liquid enters a hearth through an inlet entrance of an oven, the painted liquid, which is under the effect of an inner temperature of the oven, starts to be evaporated to generate a certain amount of solvent vapor; the solvent vapor is conveyed to a first level catalytic combustor for combustion so as to generate high temperature airflows, wherein the temperature of the airflows is higher than the temperature that is required by the technology; and one part of high temperature airflows directly pass through an air distribution device and a voltage stabilization device and are conveyed to a baking channel to bake the enamelled wire; and the other part of high temperature airflows are sent to a heat exchanger for heat exchange and then the airflows is discharged from an exhaust gas flue; and the heat exchanger absorbs waste heat of the exhaust gas and the absorbed waste heat is sent to the baking channel at the inlet entrance for baking the enamelled wire. According to the invention, the structures of the devices employed in the invention are simple; an enamelling production efficiency is high; there are no limits for production specifications and varieties; power consumption is reduced; and energy is saved and the environment is protected.

Owner:WUJIANG SHENZHOU MACHINERY

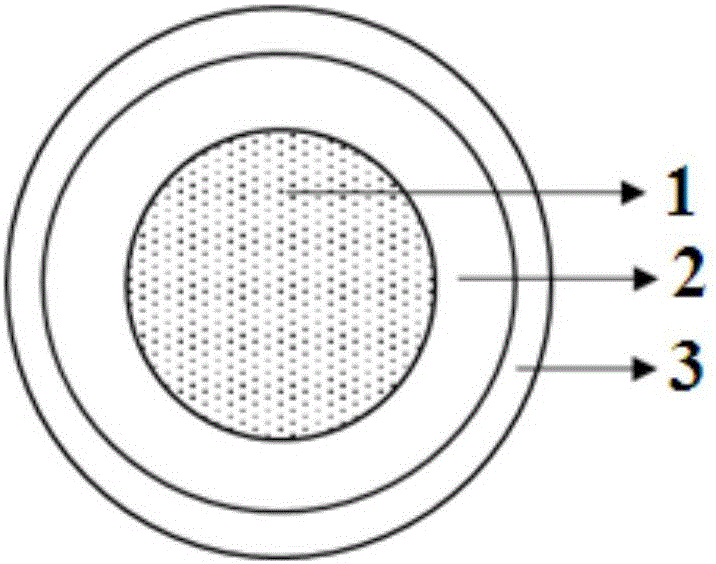

Inorganic nonmetal cladding high-temperature phase change heat storage microcapsule and preparation method thereof

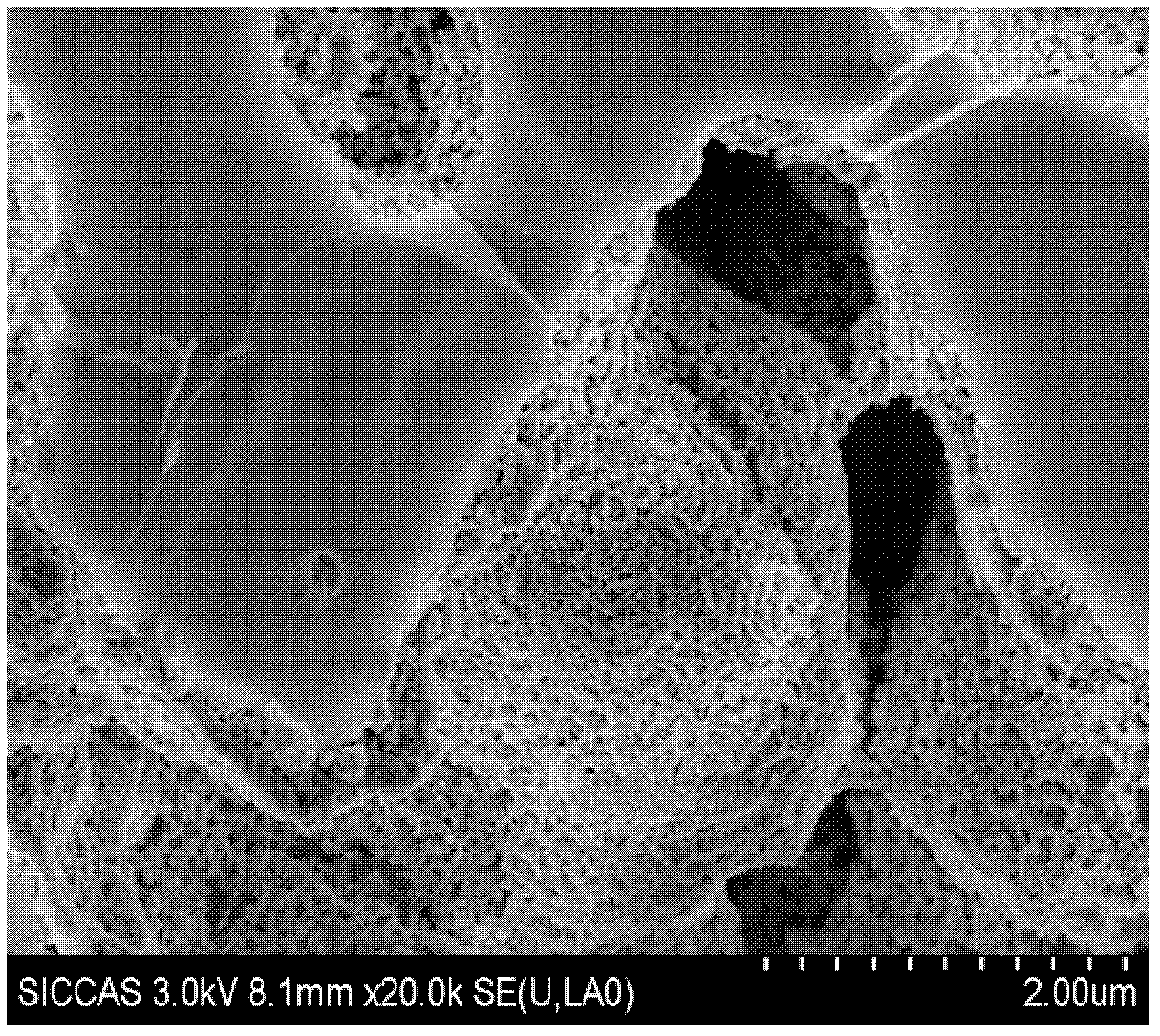

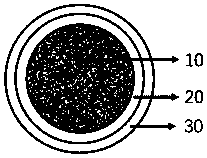

ActiveCN105855537AHigh heat storage densityGood thermal cycle performanceTransportation and packagingMetal-working apparatusMicrospherePyrolytic carbon

The invention relates to an inorganic nonmetal cladding high-temperature phase change heat storage microcapsule. The inorganic nonmetal cladding high-temperature phase change heat storage microcapsule comprises a metal phase change material microsphere, a loose pyrolytic carbon layer and a compact pyrolytic carbon layer. The metal phase change material microsphere is surrounded by the loose pyrolytic carbon layer, and the loose pyrolytic carbon layer is surrounded by the compact pyrolytic carbon layer. The diameter of the metal phase change material microsphere is 500-2000 [mu]m. The density of the loose pyrolytic carbon layer is 0.5-1.5 g / cm<3>. The density of the compact pyrolytic carbon layer is 1.8-2.0 g / cm<3>. The invention further provides a preparation method of the inorganic nonmetal cladding high-temperature phase change heat storage microcapsule. The inorganic nonmetal cladding high-temperature phase change heat storage microcapsule provided by the invention has the advantages of being large in heat storage density, good in heat cycling performance, resistant to high temperature, acid and alkali corrosion and oxidation and the like. According to the provided preparation method of the inorganic nonmetal cladding high-temperature phase change heat storage microcapsule, the product quality is uniform, the yield is high, and the preparation method is suitable for industrial production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Lead-Free Solder Alloy

ActiveUS20140141273A1Excellent drop impact resistanceGood thermal cycle performanceSolid-state devicesWelding/cutting media/materialsDrop impactThermal fatigue

By using a solder alloy consisting essentially of 0.2-1.2 mass % of Ag, 0.6-0.9 mass % of Cu, 1.2-3.0 mass % of Bi, 0.02-1.0 mass % of Sb, 0.01-2.0 mass % of In, and a remainder of Sn, it is possible to obtain portable devices having excellent resistance to drop impact and excellent heat cycle properties without developing thermal fatigue even when used in a high-temperature environment such as inside a vehicle heated by the sun or in a low-temperature environment such as outdoors in snowy weather.

Owner:SENJU METAL IND CO LTD

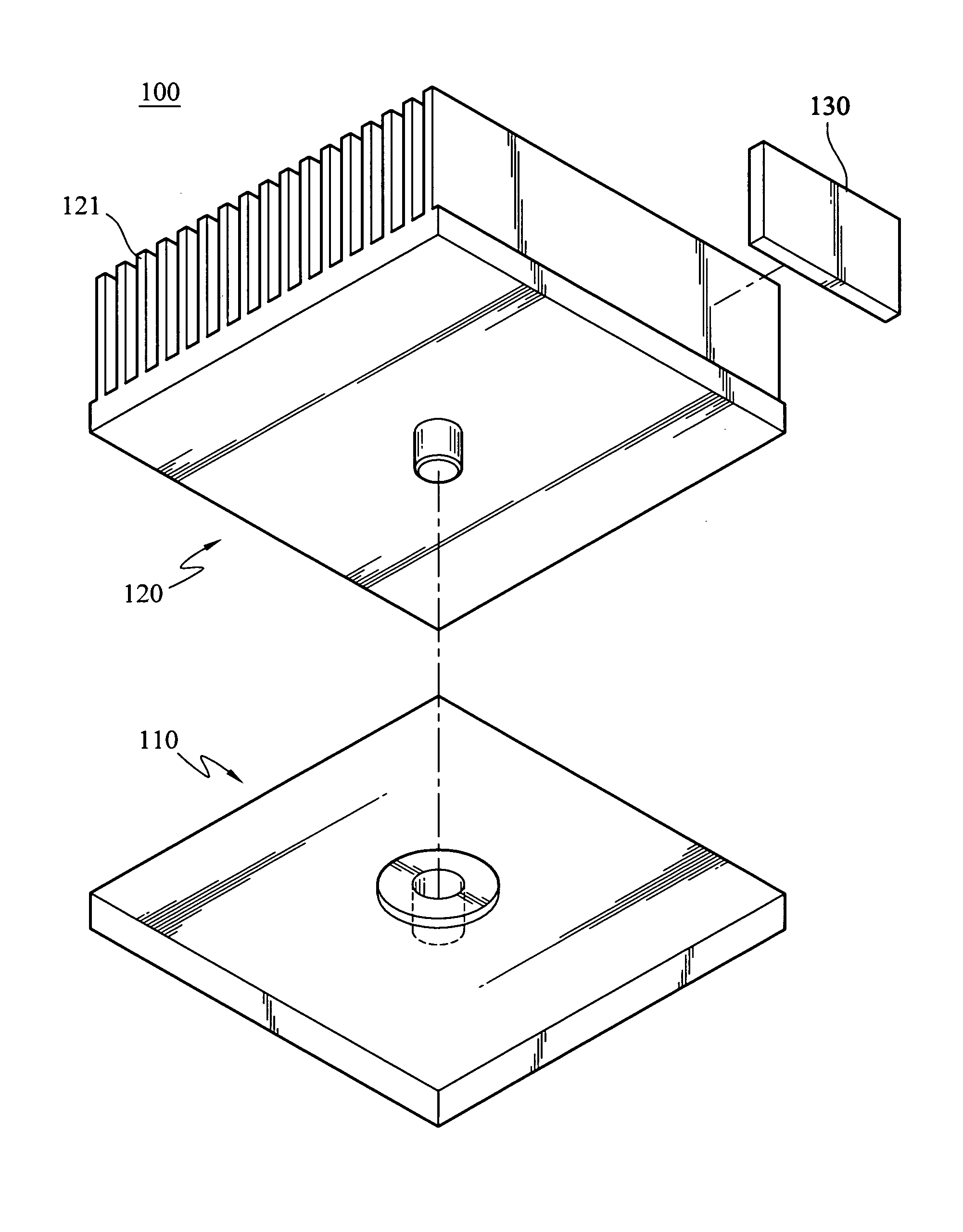

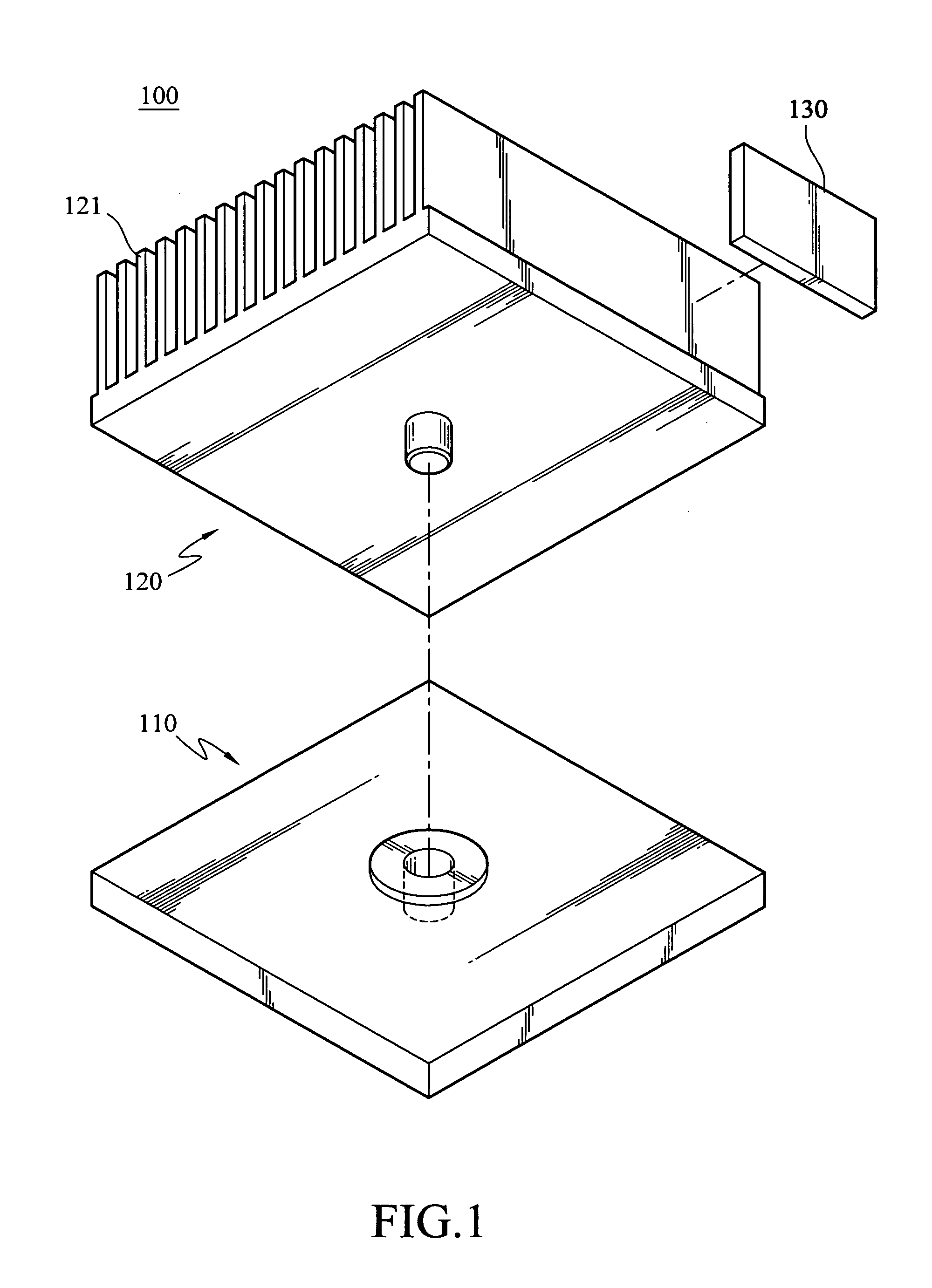

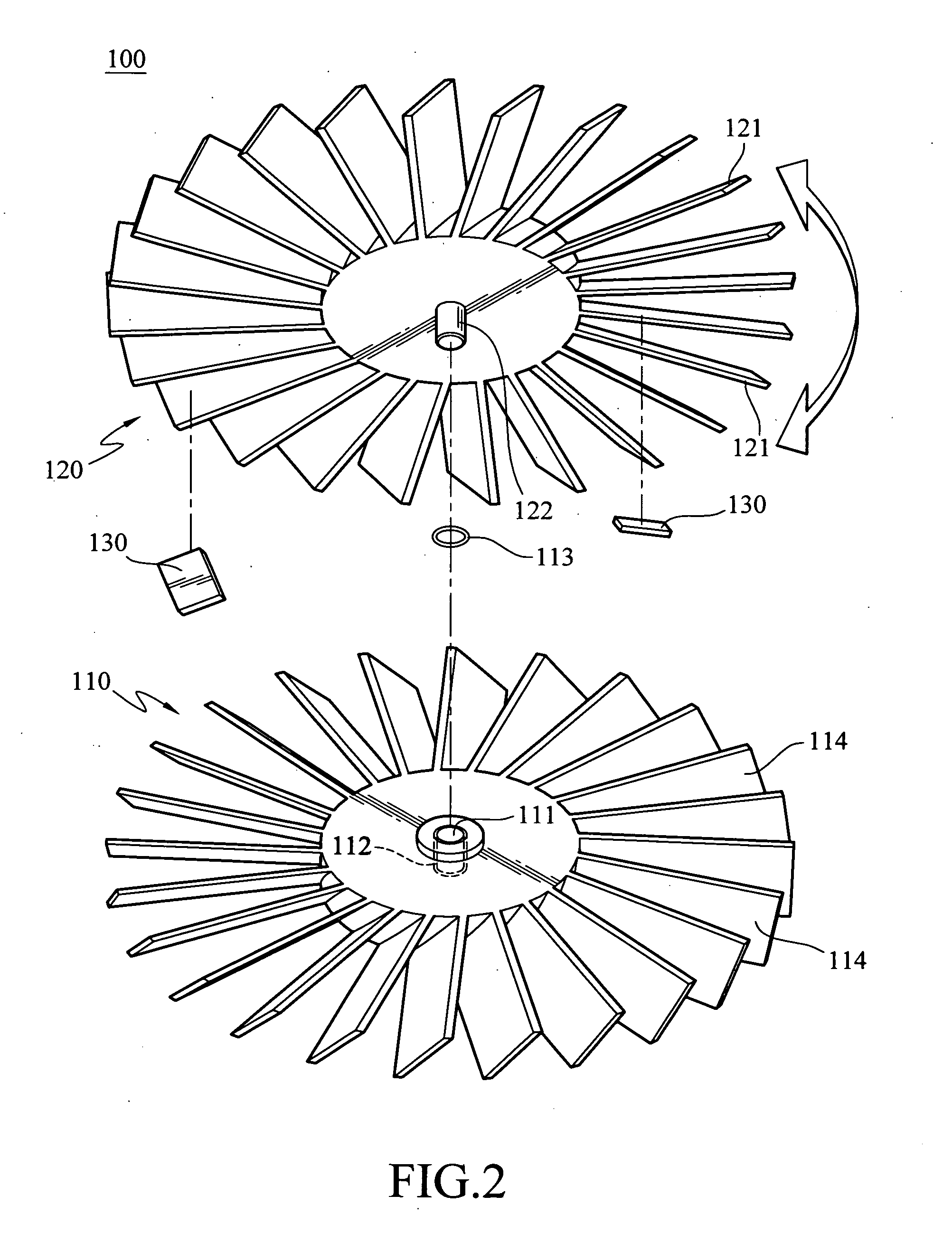

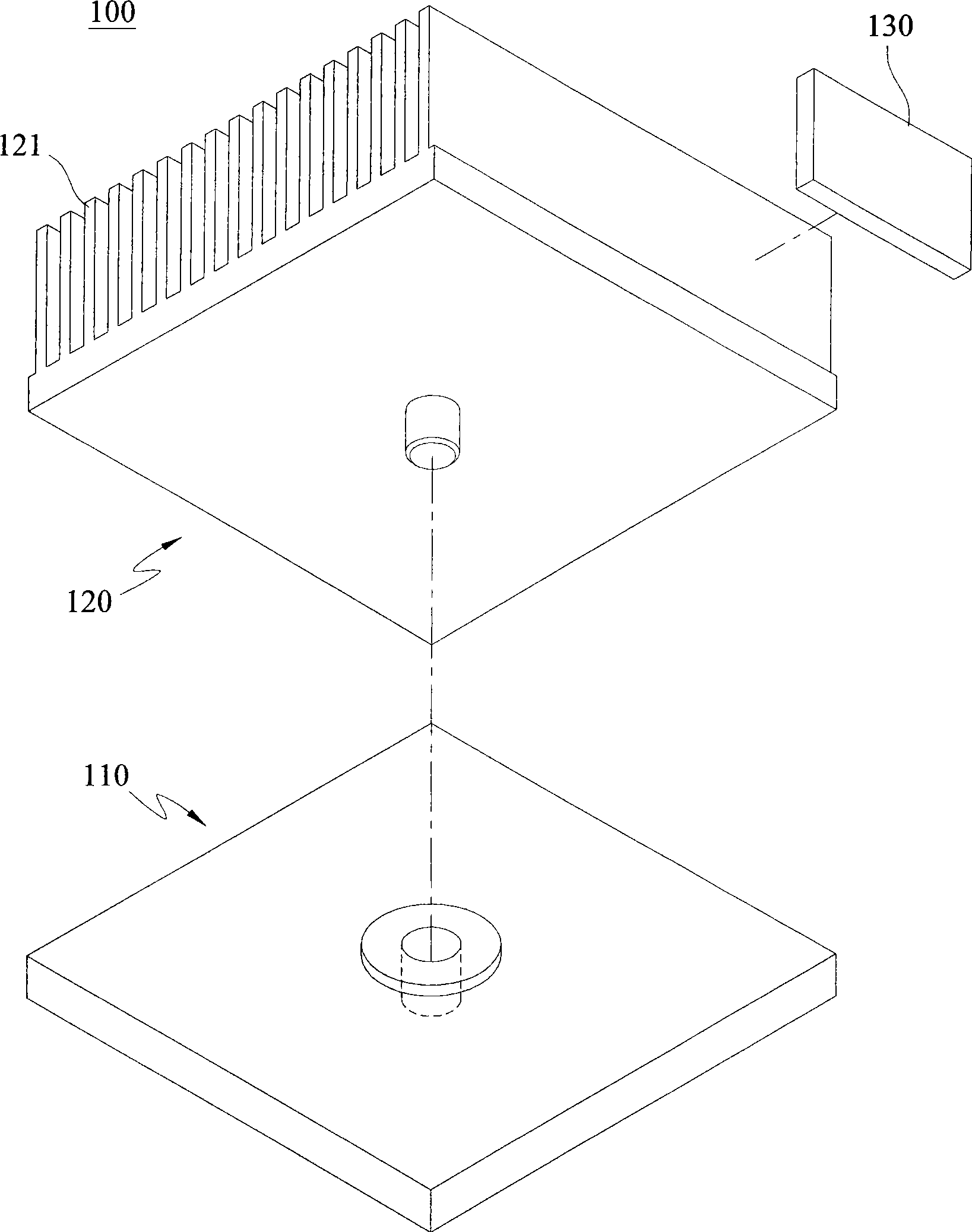

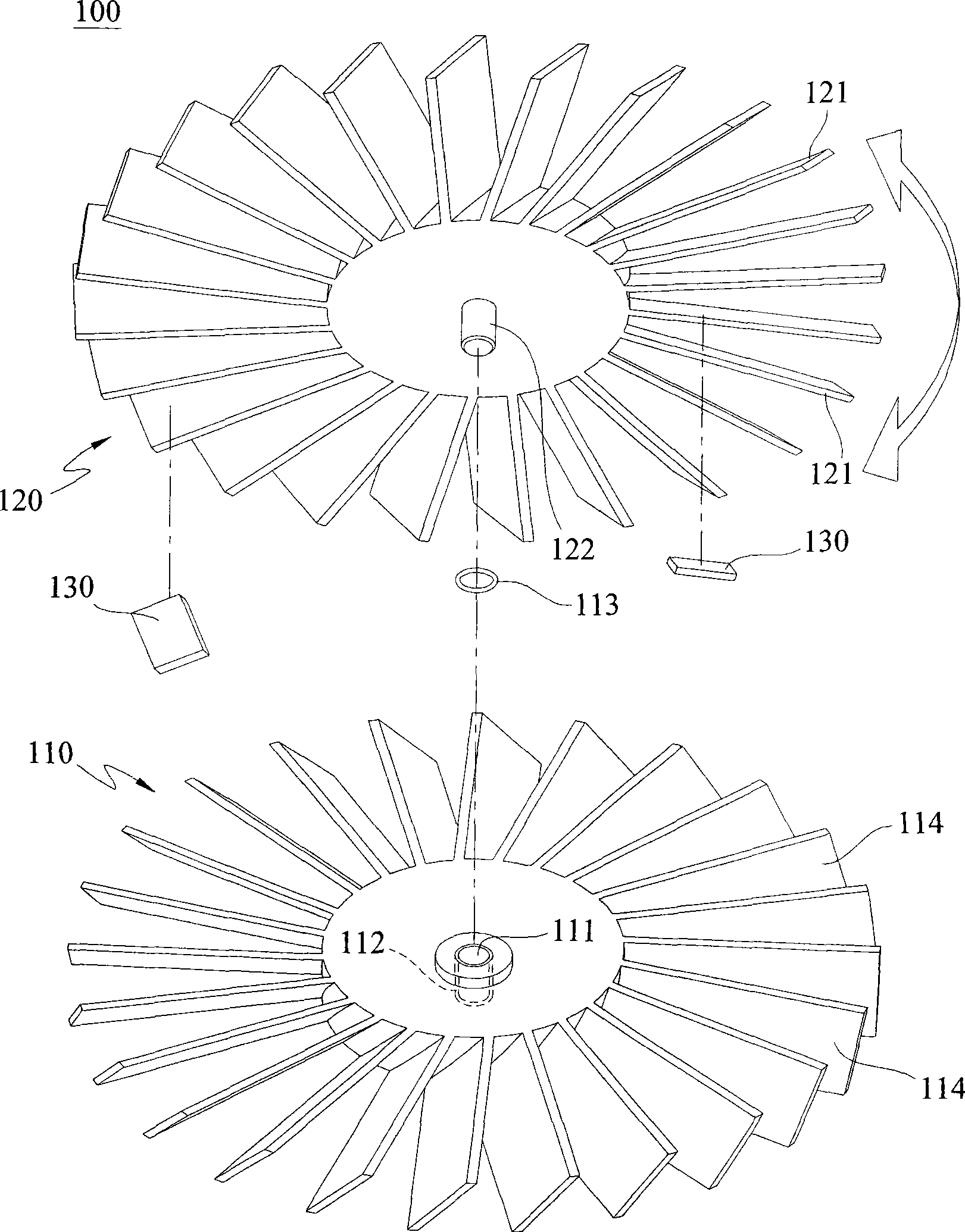

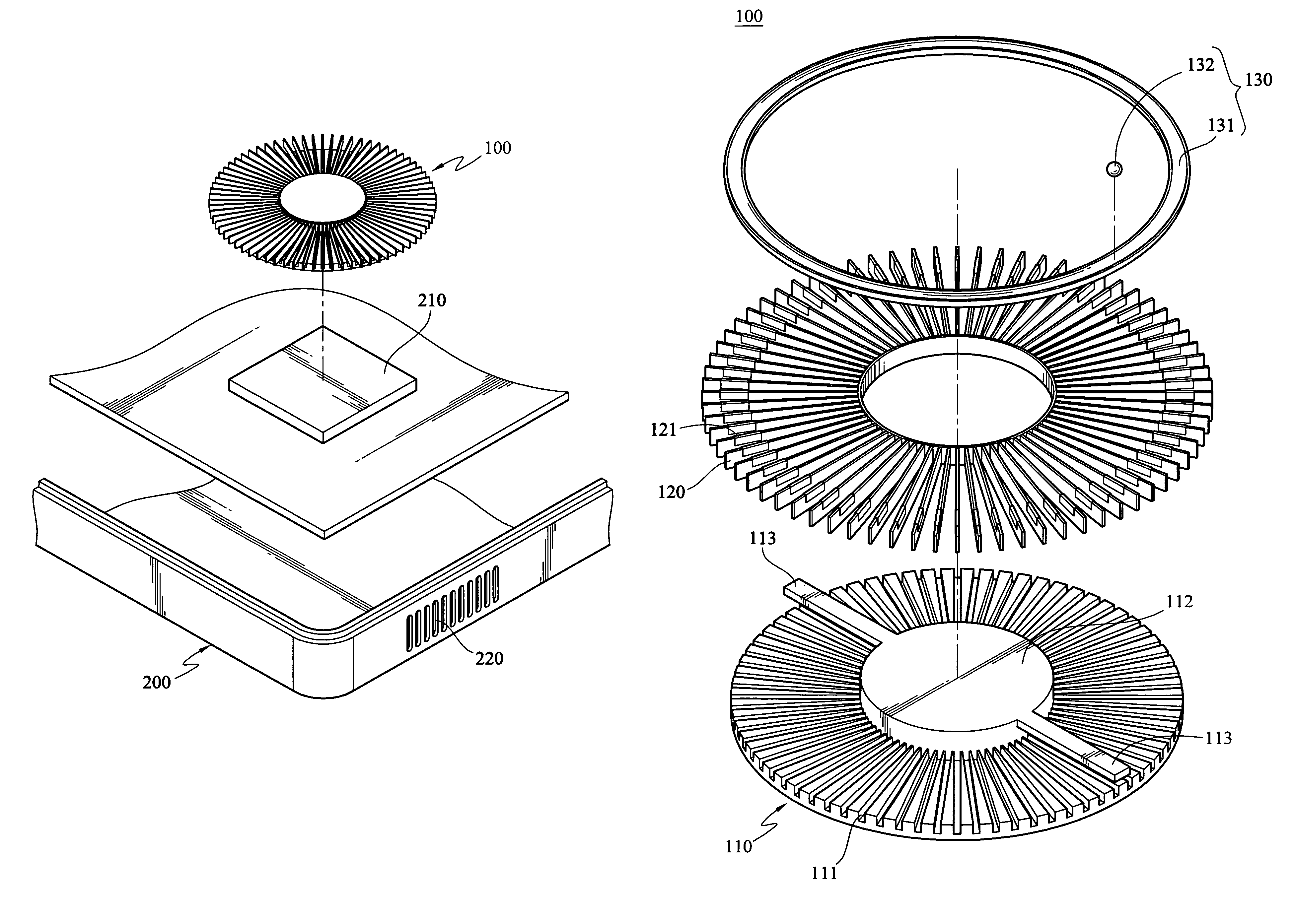

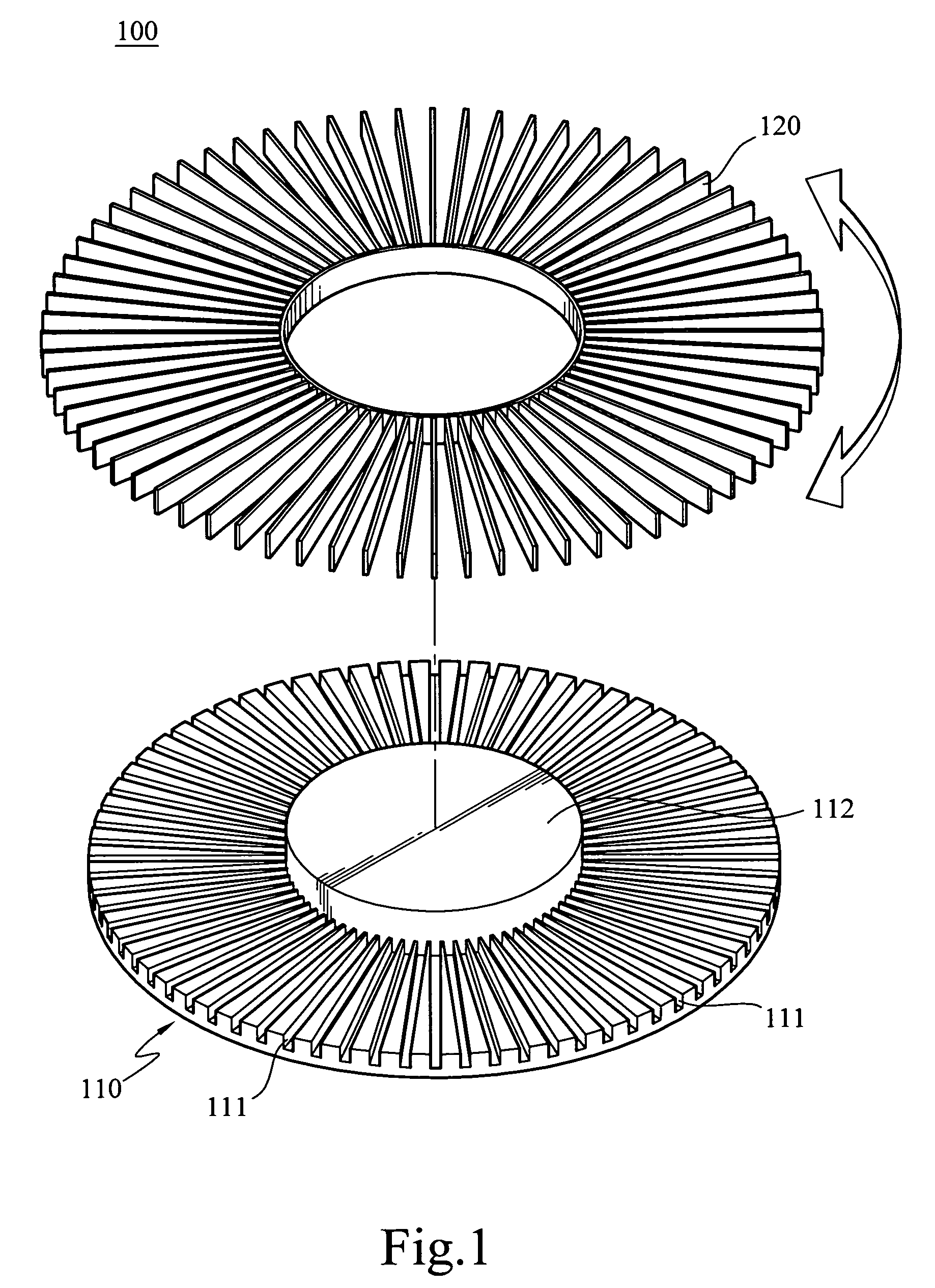

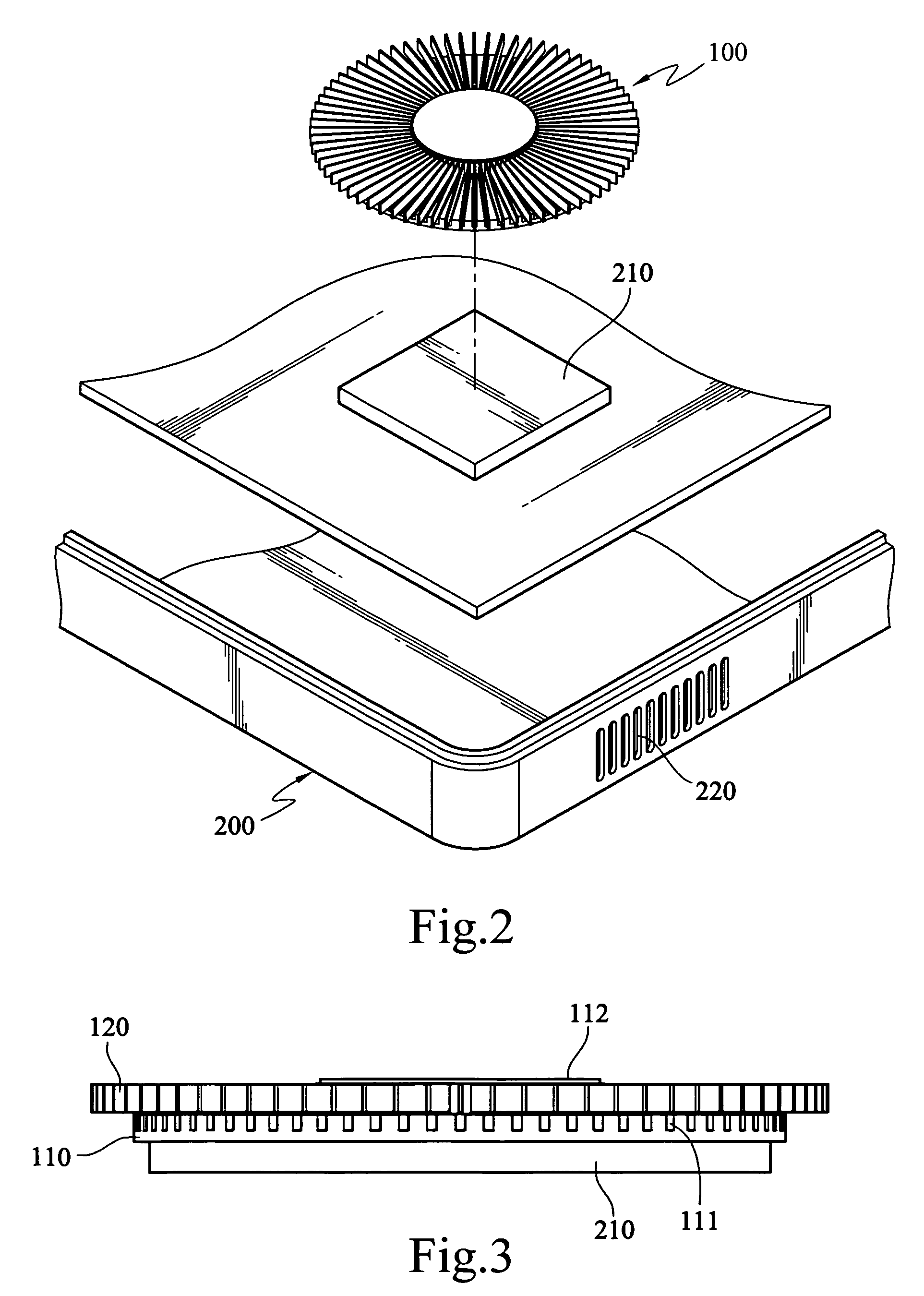

Heat sink structure

InactiveUS7946336B2Good thermal cycle performanceLower performance requirementsSemiconductor/solid-state device detailsSolid-state devicesThermal energyEngineering

Owner:INVENTEC CORP

Coated article with IR reflecting layer and method of making same

InactiveUS8409717B2Quality improvementIncreased durabilityVacuum evaporation coatingLight protection screensInsulated glazingMetallurgy

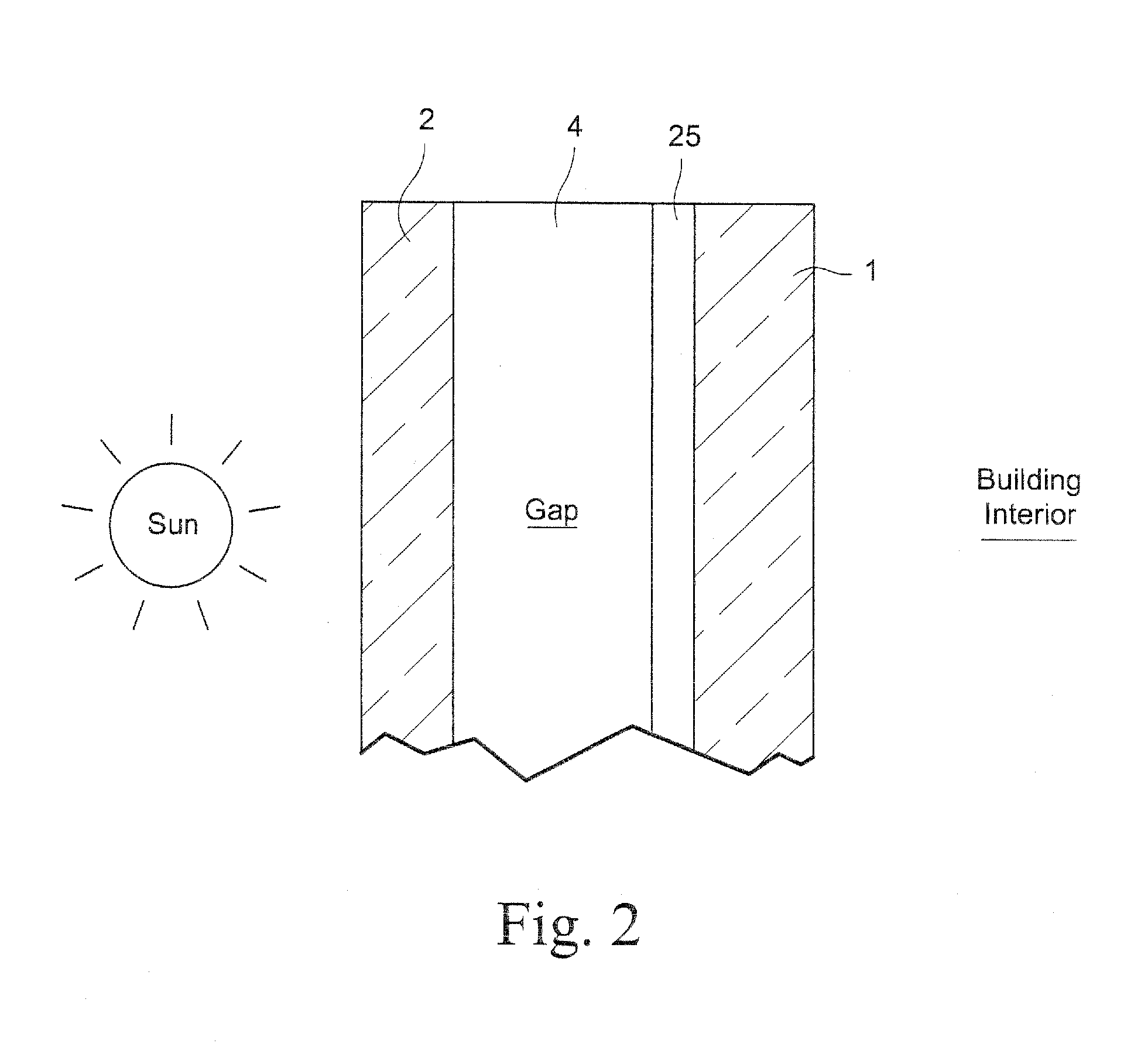

Example embodiments of this invention relate to a coated article including an infrared (IR) reflecting layer of a material such as silver or the like, for use in an insulating glass (IG) window unit for example. In certain example embodiments, the coating is a single-silver type coating, and includes an overcoat including an uppermost layer of or including silicon nitride and a layer of or including tin oxide immediately under and contacting the silicon nitride based overcoat. In certain example embodiments, the thicknesses of the silicon nitride based overcoat and the tin oxide based layer are balanced (e.g., substantially equal, or equal plus / minus about 10%). It has surprisingly been found that such balancing results in an improvement in thermal cycling performance and improved mechanical durability. In certain example embodiments, the coating may realize surprisingly good substantially neutral film side reflective coloration, and may achieve an improved visible transmission, SHGC ratio and low U-values. Moreover, in certain example embodiments, stress in the overcoat of the coating may be reduced by reducing nitrogen gas flow (N2 ml / kW) and cathode power during a sputter-deposition process, thereby further improving thermal cycling performance.

Owner:GUARDIAN EURO S A R L +1

High-efficiency annealing furnace capable of avoiding bonding of cold-rolled strip steel and operating method thereof

InactiveCN101886166AGood thermal cycle performanceEliminate stickingFurnace typesHeat treatment furnacesShielding gasStrip steel

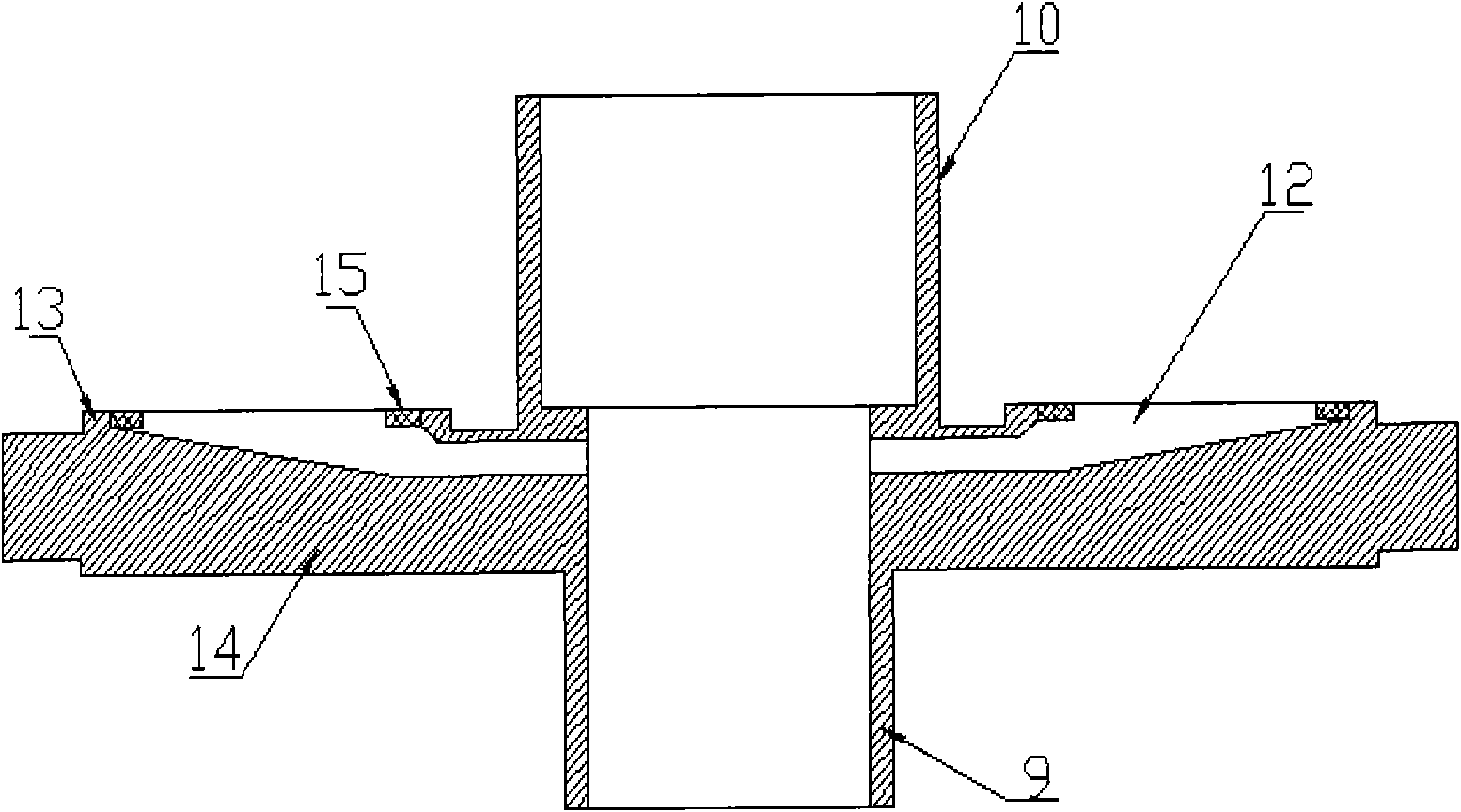

The invention discloses a high-efficiency annealing furnace capable of avoiding bonding of cold-rolled strip steel and an operating method thereof. The high-efficiency annealing furnace comprises a high power blower, a segment of independent flow guide tube, guide plates provided with upper flow guide tubes and lower flow guide tubes, a guide plate only provided with a lower flow guide tube, and a sealing ring. The annealing furnace is characterized in that the independent flow guide tube (4) is positioned at the core of a first cold-rolled steel coil on a furnace platform and sleeves a reserved air port of the blower on the furnace platform in a ring manner; the upper part of the independent flow guide tube (4) is connected with the lower flow guide tubes (9) of the guide plates (5) provided with the upper flow guide tubes and the lower flow guide tubes through the heat resistant sealing ring (8); the upper flow guide tubes and the lower flow guide tubes of the guide plates (5) provided with the upper flow guide tubes and the lower flow guide tubes are sequentially connected through the heat resistant sealing ring (8); and the guide plate (6) at the upmost end is only provided with the lower guide tube (9) and is arranged between two top steel coils. In the invention, the adopted heat cycle path is as follows: a heating mantle (a cooling mantle), an inner cover, protective gas in the furnace after completing warming (cooling) convection in the middle part, outer rings of the steel coils, and heat radiation of the cores of the steel coils, thus strengthening the convection effect in the middle part and reducing the phenomenon of unbalanced inner temperature and outer temperature.

Owner:SHANDONG IRON & STEEL CO LTD

Coated article with ir reflecting layer and method of making same

InactiveUS20130251923A1Quality improvementIncreased durabilityVacuum evaporation coatingSputtering coatingOptoelectronicsZinc

An IG window unit includes a coating supported by a glass substrate. The coating includes at least the following on the glass substrate moving from the glass substrate outwardly: at least one dielectric layer; a layer comprising zinc oxide; an infrared (IR) reflecting layer comprising silver; a layer comprising an oxide of Ni and / or Cr; an overcoat comprising a layer comprising tin oxide located over the oxide of Ni and / or Cr and a layer comprising silicon nitride.

Owner:GUARDIAN GLASS LLC

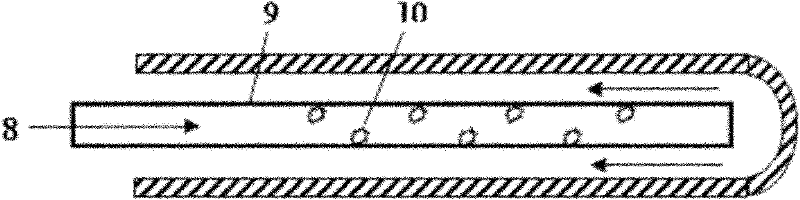

Low-temperature solid oxide fuel cell and making method thereof

ActiveCN103219525ASimple processEasy industrial scale-upFinal product manufactureCell electrodesOxide ceramicFuel cells

The invention relates to a low-temperature solid oxide fuel cell and a making method thereof. The structure of the low-temperature solid oxide fuel cell comprises an anode film deposited on the inner wall of a porous perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta composite film, a cathode film deposited on the inner wall of the porous perovskite structure oxide ceramic La1-xSrxGa1-yMgXO3-delta composite film, and a compact perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta electrolyte film positioned between the anode film and the cathode film, wherein each of x, y and delta is equal to or more than 0 and equal to or lower than 0.2, and the perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta composite film is formed through a porous perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta substrate, the perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta and a porous perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta film. The invention also provides the making method of the low-temperature solid oxide fuel cell.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Gas integral heat treating method and device for large-scale pressure container

InactiveCN101037719AImprove heat treatment construction efficiencyReduce construction costsFurnace typesHeat treatment furnacesChemical industryAutomatic control

A integral heat treatment method of a large pressurized vessel gas, laminated-heating pressurized vessel using plural gas combustors, includes: plural gas combustors for laminated-heating pressurized vessel; an air feed apparatus for providing steady gas source for gas combustors; a guide apparatus for guiding the airflow of the burning gas; an thermometric apparatus for measuring in real time and copying the temperature of each part of the pressurized vessel; A flue apparatus for adjusting in real time the inner pressure of pressurized vessel, a autocontrol apparatus for controlling in real time the output of the gas combustors. The mothod of the invention has good heating power, good internal hot recycle, high autocontrol precision, the quality of integral heat treatment of pressurized vessel is assured. The effect of service performance of the weld joint by the sulfide in the burning process can be effectively reduced using a gas with low-sulfur as a fuel, while it satisfies the special requirement of integral heat treatment after welding a large pressurized vessel in petroleum and chemical industry.

Owner:吉林亚新工程检测有限责任公司

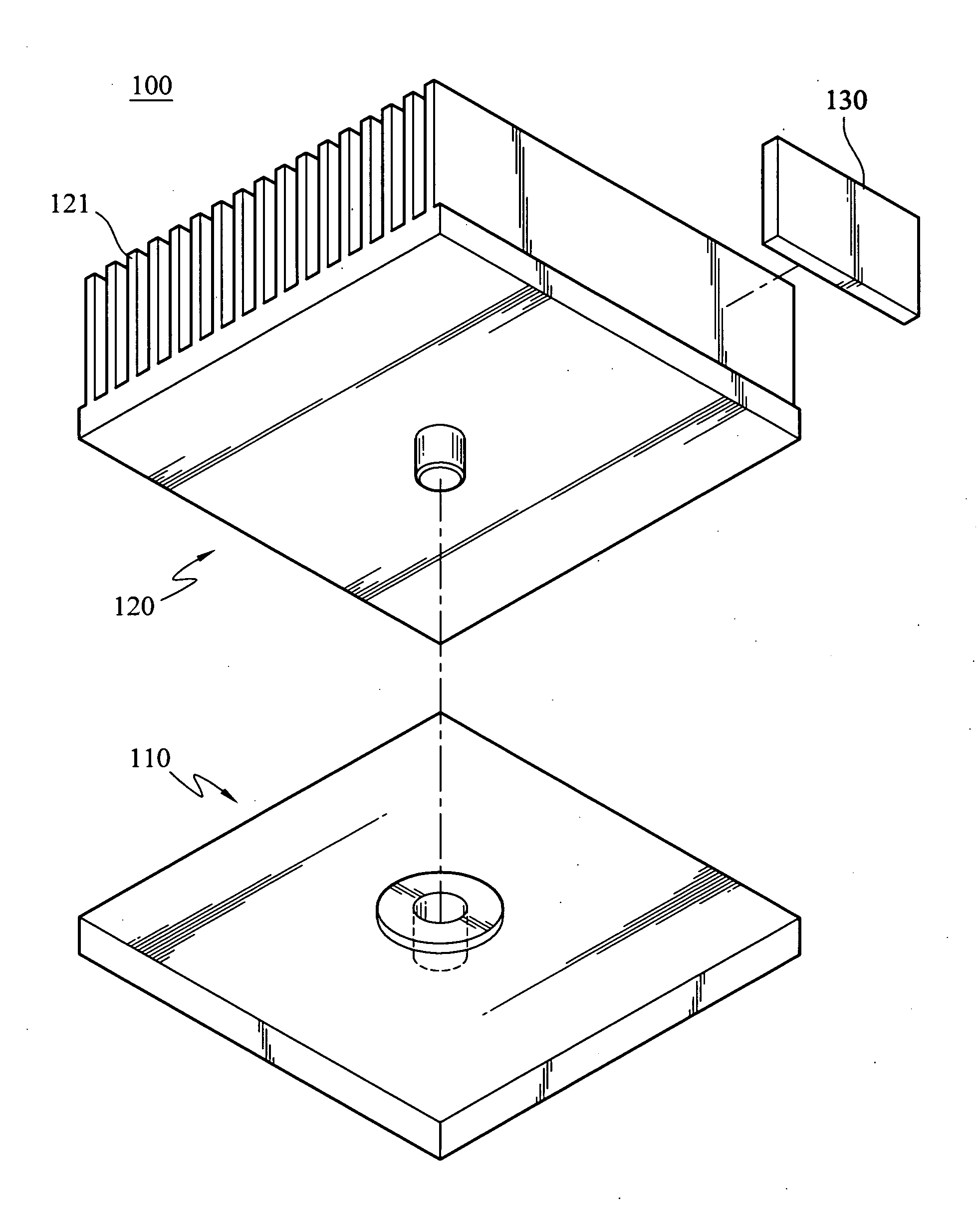

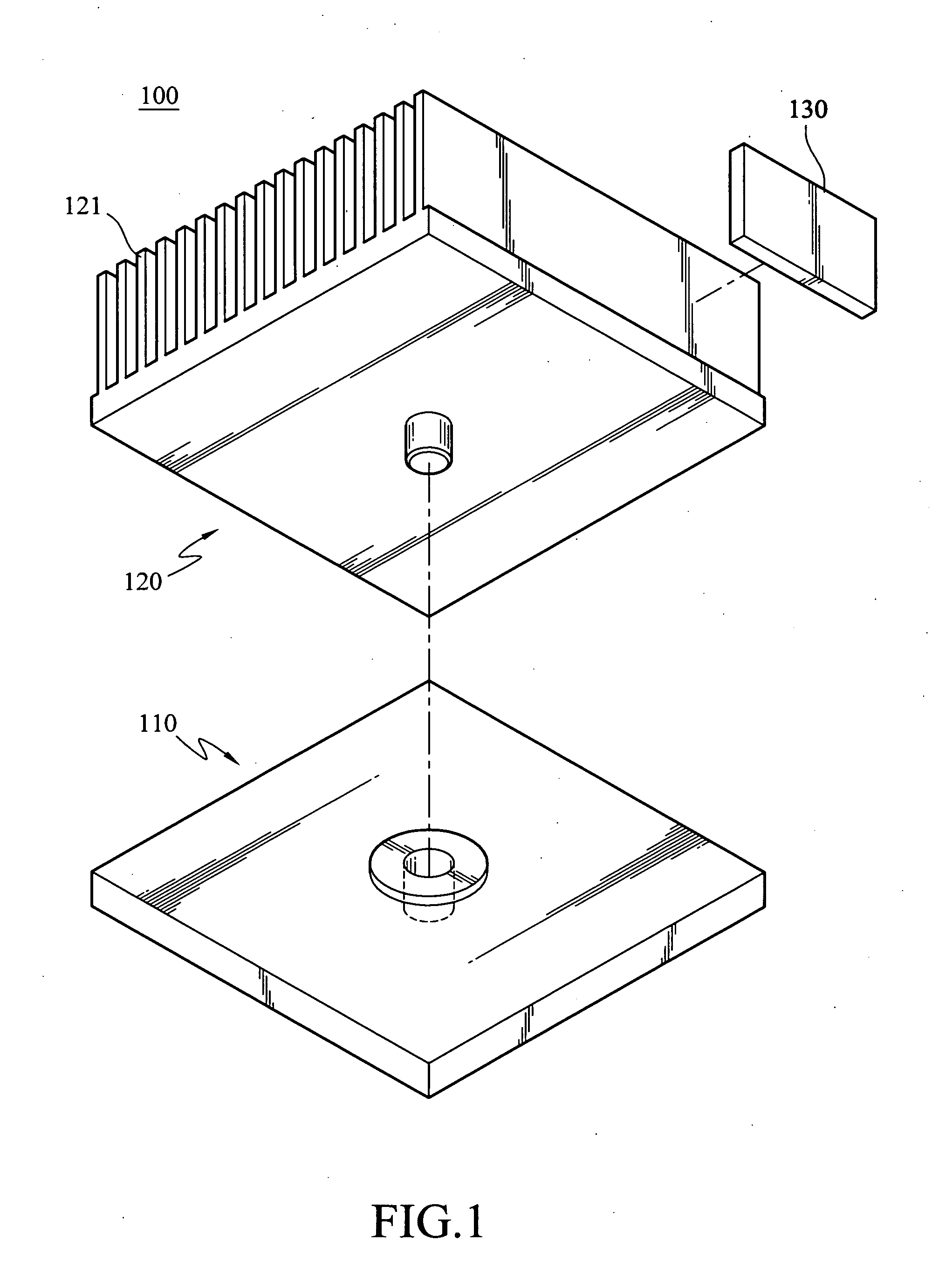

Heat sink structure

InactiveUS20090211729A1Good thermal cycle performanceLower performance requirementsSemiconductor/solid-state device detailsSolid-state devicesThermal energyEngineering

A heat sink is used for dissipating thermal energy generated by an electronic component of an electronic device. The heat sink includes a contact base and a fin base. The contact base is attached on the electronic component to transfer thermal energy, and the fin base is pivotally connected to the contact base to transfer thermal energy with the contact base. The fin base has a plurality of fins, and rotates relative to the contact base. A center of gravity of the fin base deviates from a rotation axis. When the electronic device is moved, due to the deviated center of gravity, the fin base rotates to make the fins disturb the air inside the electronic device.

Owner:INVENTEC CORP

Ternary material, preparation method thereof and battery slurry, positive electrode and lithium battery

ActiveCN108206281AIncrease compaction densityReduce thermal expansion and resistance changeNegative electrodesLi-accumulatorsTemperature cyclingSmall particle

The invention discloses a ternary material and a preparation method thereof and a battery slurry, a positive electrode and a lithium battery. The ternary material is represented by a general formula of LiNi<1-x-y>Co<x> M<y>O<2>, wherein M is Mn or Al, and 0<x<1, 0<y<1, x+y<1. The particulate matter of the ternary material comprises three layers of particles which include primary particles having acrystal structure, middle particles formed by partially fusing multiple primary particles and secondary balls formed by aggregating the intermediate particles. The particulate matter of the ternary material includes the three layers of particles at the same time, so that the material simultaneously has excellent low-temperature performance and rate performance of the small particles and excellenthigh-temperature storage and high-temperature cycling performance of big particles.

Owner:BYD CO LTD

Radiator structure

InactiveCN101424965AEasy to removeGood thermal cycle performanceDigital data processing detailsCooling/ventilation/heating modificationsHeat transmissionEngineering

The invention relates to a radiator structure which is arranged in an electronic device and is used for exchanging heat with an electronic component of the electronic device. The radiator structure comprises a contact socket and a fin socket, wherein the contact socket is clung on the electronic component for the heat transmission. The fin socket is pivoted on the contact socket so as to transmit heat with the contact socket, the fin socket is provided with a plurality of radiating fins and can rotate opposite to the contact socket through using a rotating shaft as the axes, and the gravity center of the fin socket is offset outside the rotating shaft. When electronic device is moved, the fin socket rotates because of the offset gravity center and causes the radiating fins to disturb air at the inner part of the electronic device.

Owner:INVENTEC CORP

Thermal barrier coating on component surface and preparing method thereof

ActiveCN103317787AGood thermal cycle performanceExtended service lifeVacuum evaporation coatingSputtering coatingRepeatabilityThermal barrier coating

The invention relates to a thermal barrier coating on a component surface. The thermal barrier coating has a bonding layer and a ceramic layer, and is characterized by having a thin alumina layer with a thickness of less than 2 microns between the bonding layer and the ceramic layer. The preparation of the thermal barrier coating provided by the invention is characterized in that a dense alumina layer as an oxygen barrier layer is deposited on the surface of the bonding layer by a physical vapor deposition (PVD) method, so as to slow down thermally grown oxides during the use of coating, and thereby improving the thermal shock resistance performance of the thermal barrier coating. The thermal barrier coating has the advantages of being simple in process, low in cost, high in efficiency, good in repeatability, and suitable for large scale production.

Owner:中国科学院上海硅酸盐研究所苏州研究院

Environment-friendly type cryogen for air conditioner

InactiveCN1244663CGuaranteed uptimeGood thermal cycle performanceHeat-exchange elementsEngineeringAir conditioning

The invention discloses a highly effective environment-friendly type cooling agent, which comprises tertiary mixture (R32 / 125 / 152a). As an ideal substitution actuating medium for R22, the cooling agent has similar performance with R22 in terms of whole set refrigerating capacity. The invention realizes good thermodynamic cycling performance, thus can be directly applied to the equipments in refrigeration, air-conditioning low-temperature refrigeration where the original R22 is used.

Owner:XI AN JIAOTONG UNIV

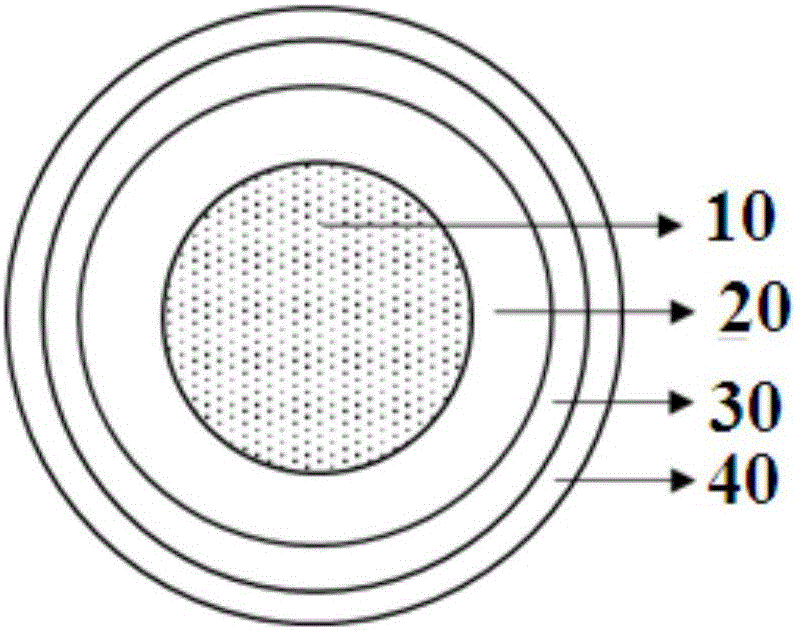

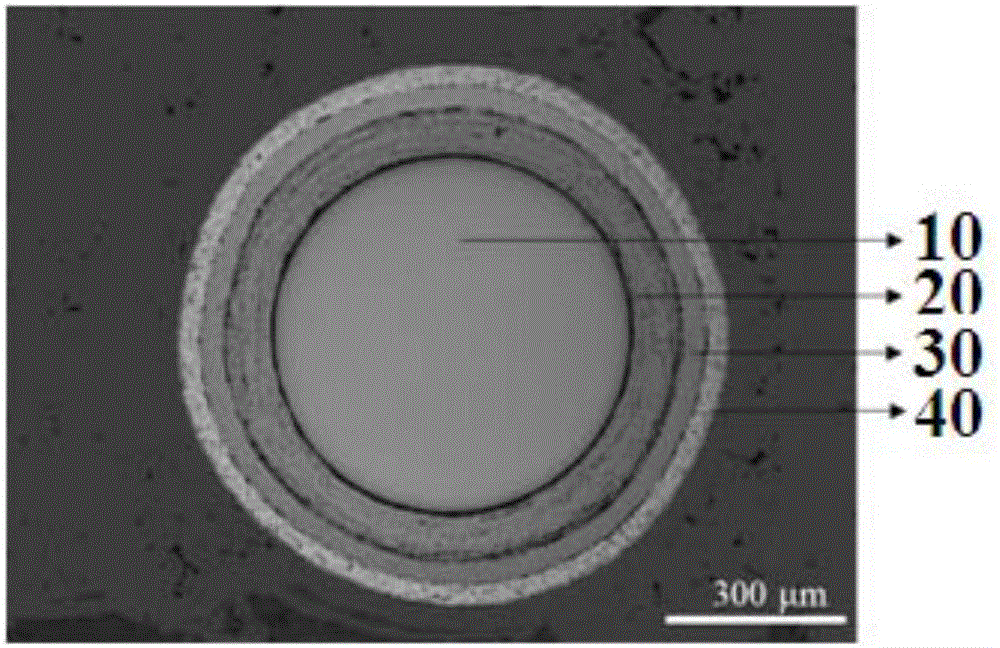

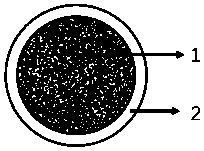

Method for preparing metal cladding high-temperature phase change heat storage microcapsule and heat storage microcapsule obtained by method

ActiveCN109321210AImprove yieldImprove production efficiencyHeat-exchange elementsHydrogenMicrosphere

The invention relates to a method for preparing a metal cladding high-temperature phase change heat storage microcapsule. The method comprises the following steps of providing metal phase change material microspheres with the diameter being 20 to 2000 mu m; charging the metal phase change material microspheres into a reaction pipe of a high-temperature fluidized bed chemical vapor-phase depositiondevice; introducing inert gas so that the metal phase change material microspheres form a stable spouting state; regulating the temperature to a first cracking temperature; switching mixed gas of hydrogen gas and first metal precursors so that the first metal precursors crack under the first cracking temperature so as to form first metal, and the first metal is deposited and coated onto the outersurface of the metal phase change material microspheres to form first metal cladding microspheres; switching the inert gas and lowering the temperature to the room temperature to obtain the metal cladding high-temperature phase change heat storage microcapsule. The invention also provides the metal cladding high-temperature phase change heat storage microcapsule prepared by the method. The methodprovided by the invention has the advantages that the process is simple; the finished product rate is high; the method is suitable for large-scale production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Environmental-protective and energy-saving cryogen

InactiveCN1746257AImprove thermal performanceExcellent thermal parametersChemical industryHeat-exchange elementsEngineeringRefrigerant

An environmental protective and energy-saving refrigerant consists of multiple mixture R152a 20-60wt%, R290 10-30wt%, R32 10-20wt% and R1270 5-20wt%. The process is carried out by proportioning the components, mixing physically and canning. It is safe, energy saving and non-toxic. It has excellent thermal circulation and refrigeration performances and better condensing pressure.

Owner:杨攀峰

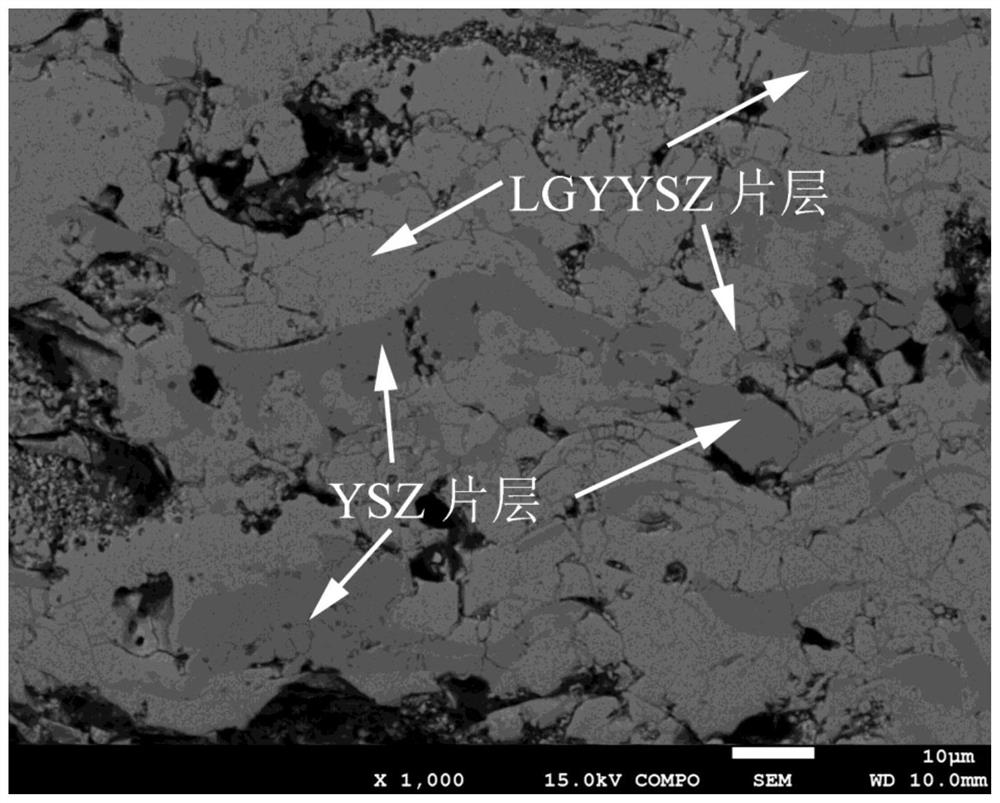

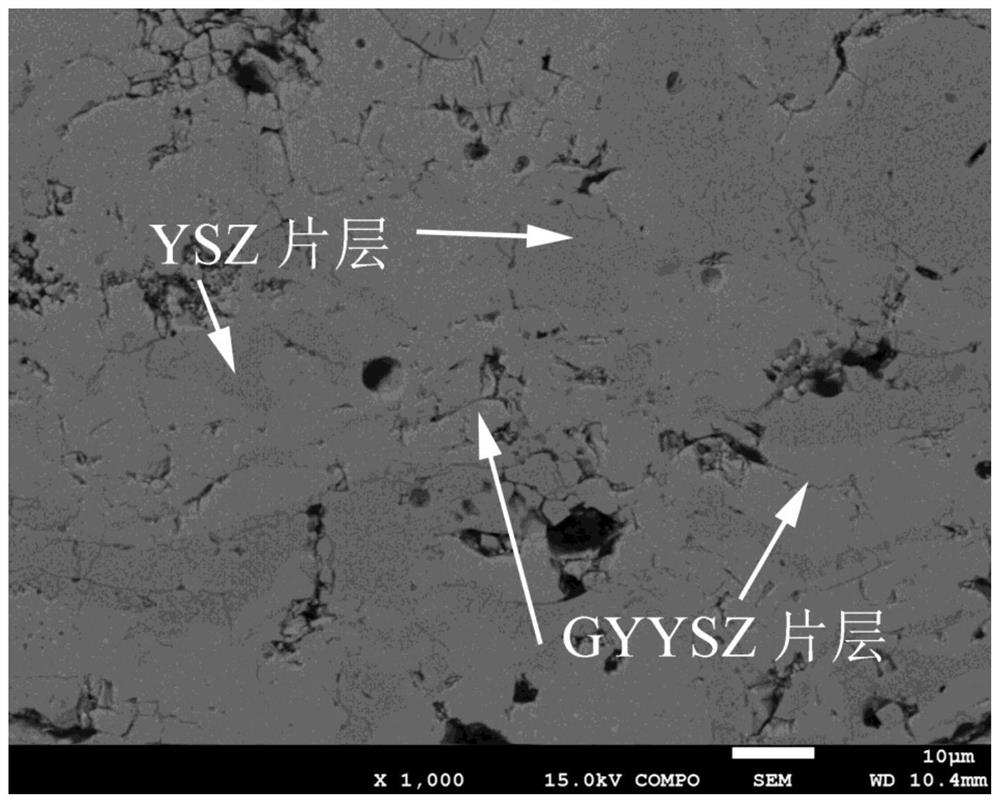

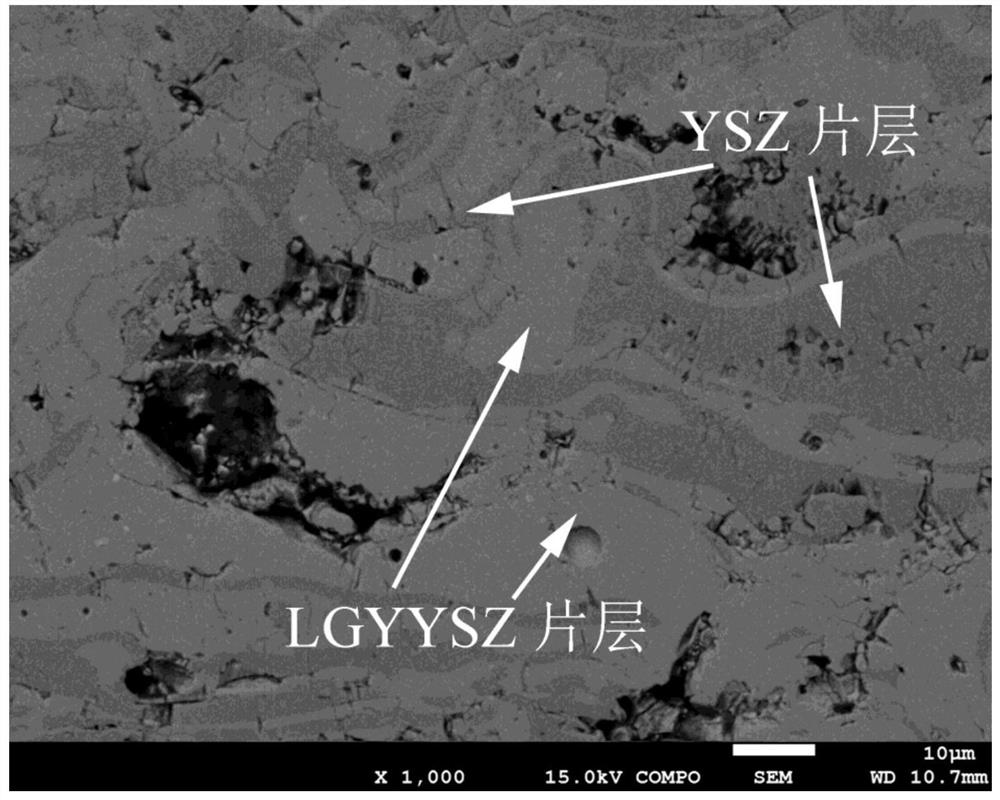

Thermal barrier coating with composite double-ceramic-layer structure and preparation method thereof

PendingCN113388801AHigh thermal conductivityImproved coefficient of thermal expansionMolten spray coatingComposite ceramicThermal barrier coating

The invention relates to a thermal barrier coating with a composite double-ceramic-layer structure and a preparation method thereof, and belongs to the technical field of thermal barrier coating preparation. The thermal barrier coating sequentially comprises a thermal barrier coating bonding layer, a YSZ ceramic layer and a composite ceramic layer from a base body to the top; the composite ceramic layer is composed of a high-toughness ceramic material and a high-rare-earth-content doped zirconium oxide material according to the volume ratio of (1 to 4): (4 to 1); the high-toughness ceramic material is a ceramic material with the fracture toughness being greater than 5MPa. M < 1 / 2 >; and in the high-rare-earth-content doped zirconium oxide material, the sum of the mole fractions of the doped rare earth elements is 16 percent to 30 percent. According to the thermal barrier coating, the thermal barrier coating bonding layer, the YSZ ceramic layer and the composite ceramic layer are sequentially prepared from the base body to the top through a spraying method. The thermal barrier coating can be prevented from cracking in the thermal cycle process, and the service life is long; and cracks are uniformly distributed, the anti-stripping capability is high, and the heat insulation performance is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

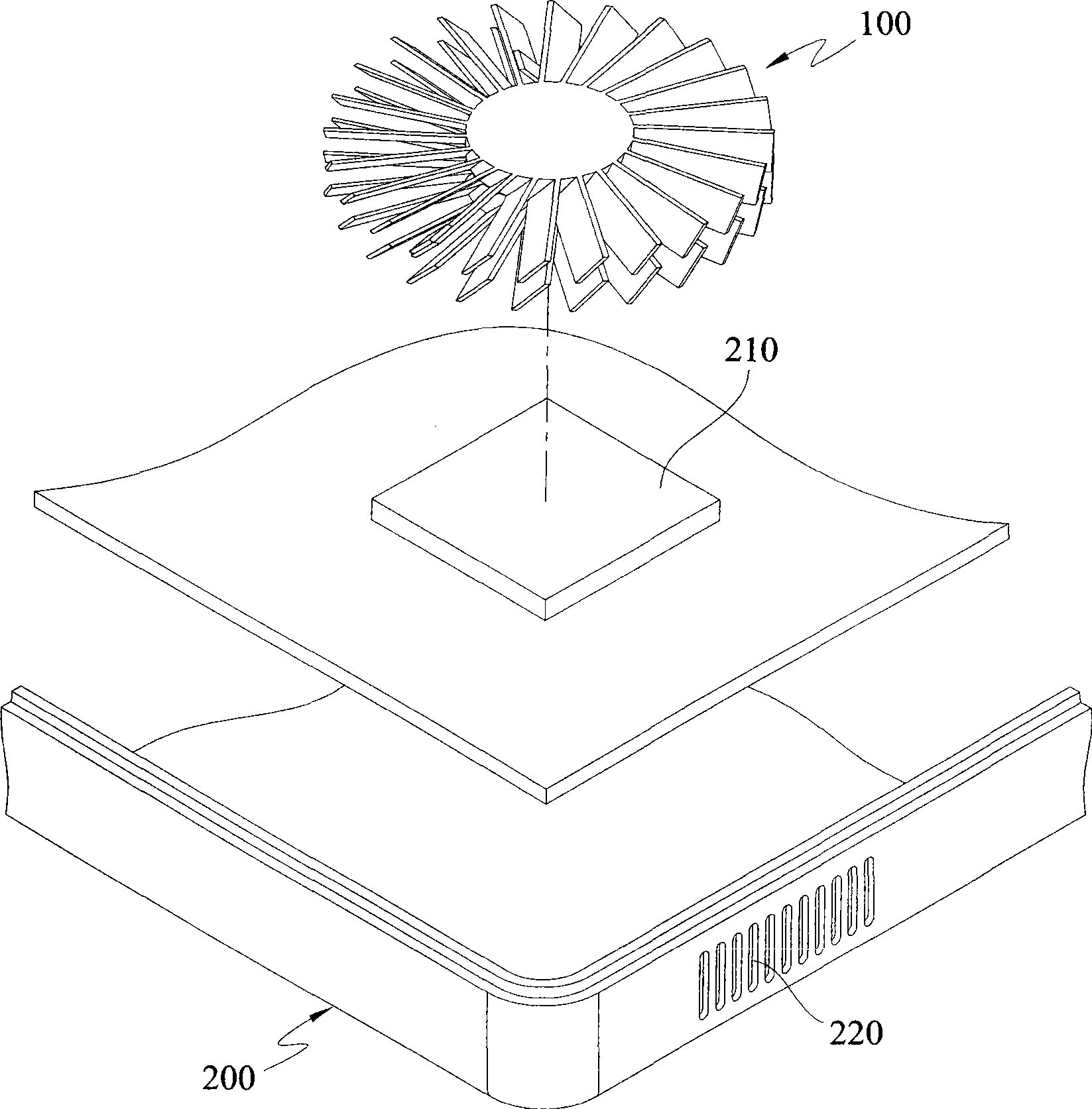

Heat dissipation device

InactiveUS7826227B2Dissipate quicklyGood thermal cycle performanceSemiconductor/solid-state device detailsSolid-state devicesThermal energyEngineering

A heat dissipation device is disposed in an electronic device and performs thermal exchange with an electronic component of the electronic device. The heat dissipation device includes a heat sink and a plurality of fluttering slices. The heat sink is attached on the electronic component to conduct the thermal energy of the electronic component. The fluttering slices are disposed on the heat sink, and the fluttering slices are actuated to generate an airflow when the electronic device is moved, so as to disturb the air inside the electronic device, thereby achieving the purpose of improving the thermal dissipation performance.

Owner:INVENTEC CORP

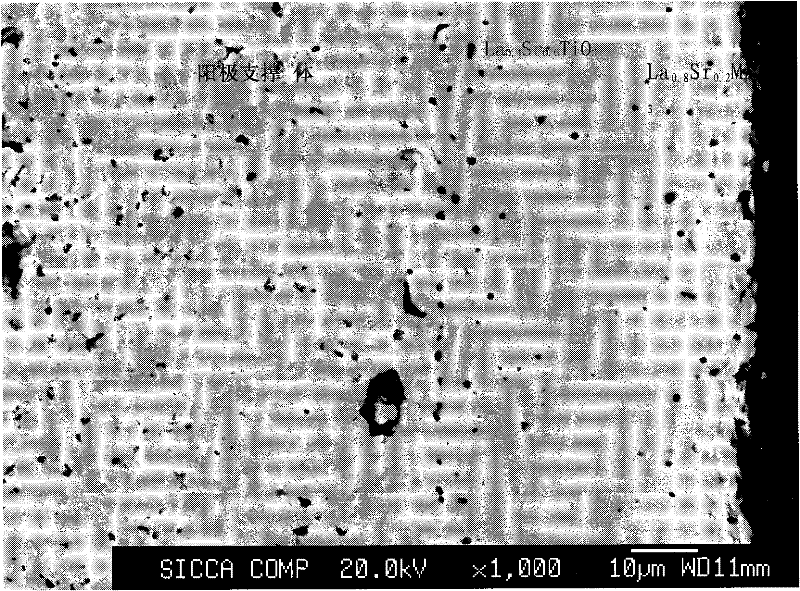

Composite ceramic connector for tubular solid oxide fuel cell and preparation method thereof

ActiveCN102299354ASimple processLow costCeramic layered productsFuel cell detailsTubular solid oxide fuel cellLanthanum

The invention relates to a composite ceramic connector for a tubular solid oxide fuel cell and a preparation method thereof, in particular to a composite ceramic connector for an anode support tubular solid oxide fuel cell and a preparation method thereof, and belongs to the field of fuel cell materials. The composite ceramic connecting body for the tubular solid oxide fuel cell of the present invention is composed of a lanthanum-doped strontium titanate layer and a strontium-lanthanum manganate layer, and the lanthanum-doped strontium titanate slurry is firstly coated with the slurry The material is brushed on the anode, and after drying, the slurry of strontium lanthanum manganate is painted on it, and then co-fired with the anode of the tubular battery to obtain a dense double-layer composite ceramic connector. The invention has the advantages of simple process, low preparation cost, stable and reliable connecting body, firm structure and good combination, and is beneficial to reduce the cost of the tubular SOFC cell stack.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Anti-corrosion environment barrier coating, preparation method and application of anti-corrosion environment barrier coating and engine

ActiveCN108486569AEasy to prepareEasy to operateMolten spray coatingInternal combustion piston enginesGas phaseThin layer

The invention relates to an anti-corrosion environment barrier coating, a preparation method and application of the anti-corrosion environment barrier coating and an engine and belongs to the field ofmaterials. The preparation method comprises the steps that by adopting a plasma spraying-physical vapor deposition method, a Si coating, a mullite coating and a Yb2SiO5 coating are sequentially prepared on the surface of a base body, and the environment barrier coating is obtained; an aluminum thin layer is prepared on the surface of the environment barrier coating, and an aluminum plated sampleis obtained; and vacuum heat treatment is carried out on the aluminum plated sample, and the anti-corrosion environment barrier coating is obtained. The preparation method is simple, operation is easy, and short time is consumed. The prepared anti-corrosion environment barrier coating is good in oxidation resistance and corrosion resistance such as anti-CMAS corrosion performance. The anti-corrosion environment barrier coating is used for preparing the engine, and the using requirement of a heat end component of the engine can be met. According to the engine containing the anti-corrosion environment barrier coating, the reliability and the stability of the heat end structure component in the using process can be guaranteed, the reliability of the engine can be improved, and the service life of the whole engine can also be prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

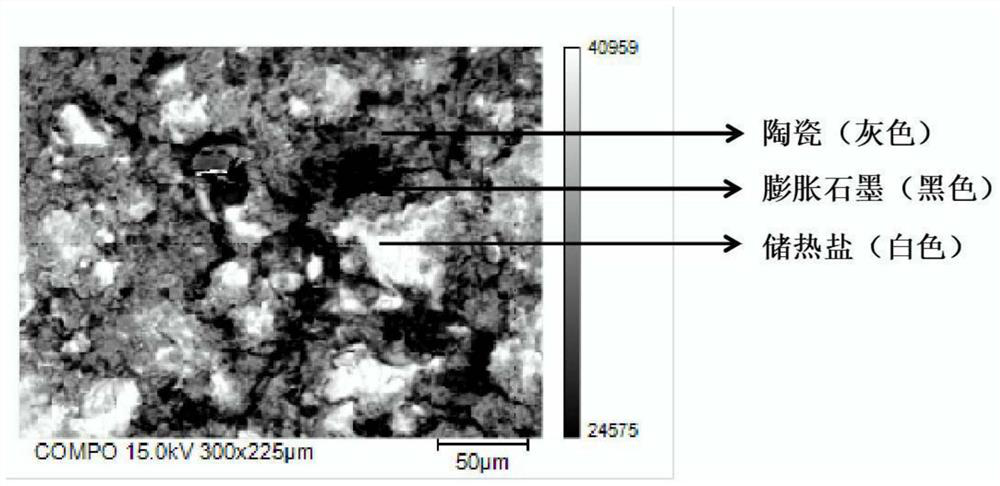

Assembly method of expanded graphite reinforced heat conduction ceramic-based shaped high-temperature phase change heat storage element and heat storage element formed by assembly method

ActiveCN111793474AHigh thermal conductivityImprove heat transfer efficiencyHeat-exchange elementsCompression moldingHeat conducting

The invention relates to an assembly method of an expanded graphite reinforced heat conduction ceramic-based shaped high-temperature phase change heat storage element. The assembly method comprises the following steps: providing an eutectic salt phase change material; providing an expanded graphite heat conducting agent; providing a ceramic powder framework material and a sintering aid; mixing theeutectic salt phase-change material, an expanded graphite heat-conducting agent, a ceramic powder framework material and a sintering aid, putting the mixture into a mold, and performing compression molding at 12-14MPa to obtain a green body; and carrying out heat treatment on the blank to obtain the heat storage element. The invention also relates to a heat storage element formed by the assemblymethod. The heat storage element comprises an eutectic salt phase change material, an expanded graphite heat conduction agent and a ceramic powder framework material. The heat conducting agent expanded graphite material adopted by the high-temperature phase change heat storage element provided by the invention is more resistant to high temperature and corrosion than metal, can be better compatibleand has good thermal cycle performance, and an effective component of the high-temperature phase change material with high heat conductivity and corrosion resistance is provided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Enameled wire baking hot air circulation method and device

InactiveCN101150005AReduce material requirementsExtended service lifeDrying solid materials with heatCable/conductor manufactureCombustion chamberEngineering

This invention relates to a circulating method and a device for hot air baking enamel wires, in which, a fan in front of the baker aspirates hot air in the baker and sends it into a catalyzing device, which sends the hot air to a firebox for heating then the hot air enters into a heat-storage chamber and then is sent to the baker from the back of the baker, which applies a fan to send hot air into a circulation device and then to a baker, since temperature of hot air entering into the fan is low, requirement on the vanes and air vent is low and speed of the hot air entering into the baker is uniform, the thermal circulation result is good.

Owner:何富贵

Oxidation-resistant high energy density magnesium alloy for 500-600 degrees and process thereof

The invention discloses oxidation-resistant high energy density magnesium alloy for 500-600 degrees and a process thereof. The alloy comprises the following components by weight: Li: 2.0-3.0%, Al: 5.0-6.0%, In: 1.0-1.2%, Zn: 2.5-2.8%, B: 0.10.2%, Sn: 1.0-1.2%, Bi: 5.0-6.0%, Sb: 2.4-2.5% and the balance magnesium. A multi-element near-eutectic alloy solution for the oxidation-resistant high energydensity magnesium alloy for 500-600 degrees in the field of alloy energy storage is provided. Alloy melt has excellent oxidation resistance, thermal cycle performance and thermophysical performance. The alloy can effectively overcome the defect of innovation shortage of novel alloy materials in the field of energy storage, and is expected to obtain great market value while solving industrial problems.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com