Anode-supported solid oxide fuel cell, cell stack and preparation method thereof

A solid oxide and anode support technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve the problems of weak battery structure, difficult current collection, high preparation cost, etc., and achieve high battery strength and compact structure , the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

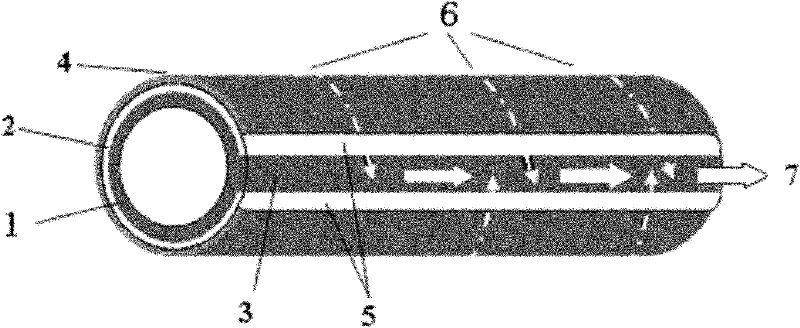

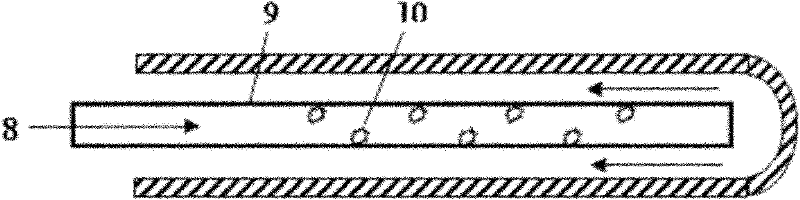

[0046] The preparation of a tubular SOFC single cell includes the following steps:

[0047] 1. Preparation of double-layer ceramic connector slurry:

[0048] First, several lanthanum-doped strontium titanates (La 0.4 Sr 0.6 TiO 3 ) powder. Lanthanum strontium manganate (La 0.8 Sr 0.2 MnO 3 ) powder is a commercially available product from Fuel Cell Materials Corporation of the United States. First take 44 grams of lanthanum-doped strontium titanate powder, 100 grams of absolute ethanol, and 1.5 grams of triethanolamine, add 200 grams of zirconia grinding balls, mill on a planetary ball mill for 1 hour, and then add PVB (polyvinyl acetal) 1 gram, continue ball milling for 2 hours, and then vacuum treatment for 2 to 3 minutes to remove the air in the slurry to obtain the lanthanum-doped strontium titanate coating slurry.

[0049] Lanthanum strontium manganate (La 0.8 Sr 0.2 MnO 3 ) powder 20 grams, butanone 20 grams, ethanol 10 grams, triethanolamine 0.6 grams, add 60...

Embodiment 2

[0055] with H 2 Performance test of tubular SOFC single cell for fuel

[0056] According to the tubular single cell prepared in Example 1, the experimental conditions for its power generation performance test are: cathode area: 9cm 2 ;Test gas: H 2 , O 2 , not sealed. h 2 The flow rate is 100ml / min, O 2 The flow rate is 80ml / min.

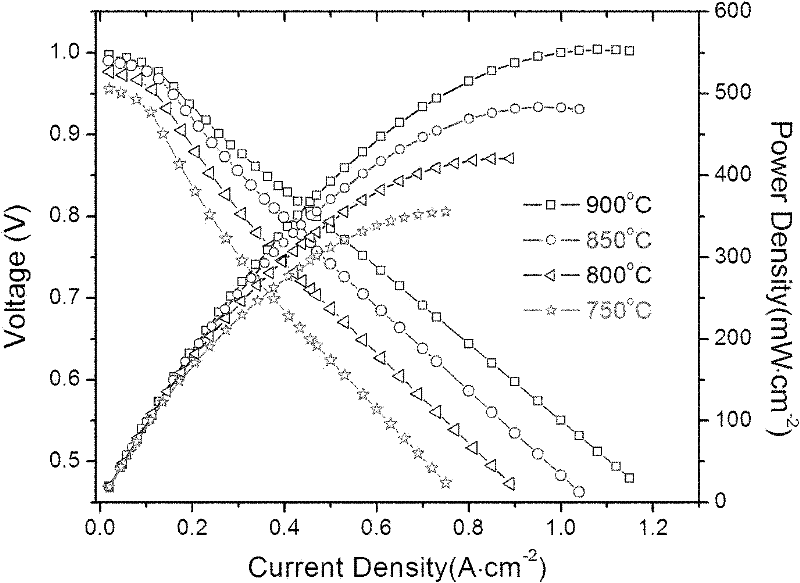

[0057] The test method is the four-terminal method. Use the constant current source in series with the battery, and draw the current-voltage curve (I-V curve) by changing the current test voltage. Then multiply a certain current value by the corresponding voltage value to obtain the power under the current (the power can be divided by the cathode area to obtain the power density). In this way, a current-power density curve (I-P curve) can be obtained. Such as image 3 shown. image 3Indicates the I-V and I-P curves of the battery at different temperatures (900°C, 850°C, 800°C and 750°C). Among them, the open circuit is slightly lower tha...

Embodiment 3

[0059] Performance test of tubular SOFC single cell fueled by ethanol

[0060] A big advantage of SOFC over other types of fuel cells is that it has strong fuel adaptability and can directly use hydrocarbons as fuel. This is because the operating temperature of SOFC is high, and hydrocarbon fuel can be directly oxidized at the anode, or a reforming reaction occurs inside the battery. The possible reforming reactions of alcohol and water vapor are as follows:

[0061] C 2 h 5 OH+H 2 O→2CO+4H 2

[0062] C 2 h 5 OH+3H 2 O→2CO 2 +6H 2

[0063] CO+H 2 O→CO 2 +H 2

[0064] The preparation method of the tubular SOFC single cell is the same as in Example 1. During the performance test, the inner ventilation pipe is made of nickel-plated stainless steel pipe, and the alcohol / H 2 O mixed liquid (volume ratio 2:1) is vaporized and internally reformed to generate electricity. Alcohol / H 2 The O solution was heated in a constant temperature water bath at 70°C, and N 2 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com