Patents

Literature

341results about How to "Raise the sintering temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

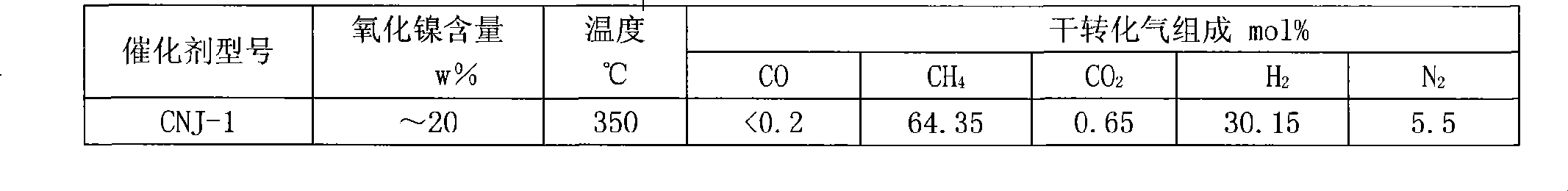

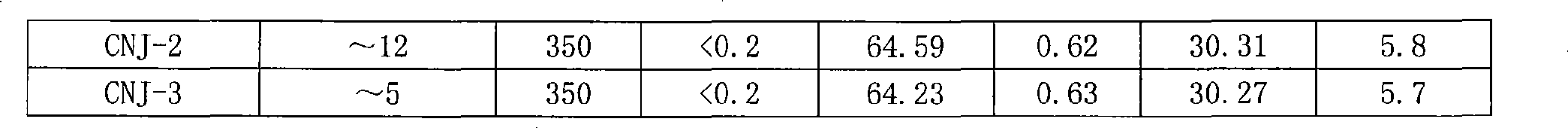

Coke-oven gas methanation catalyst and preparation method thereof

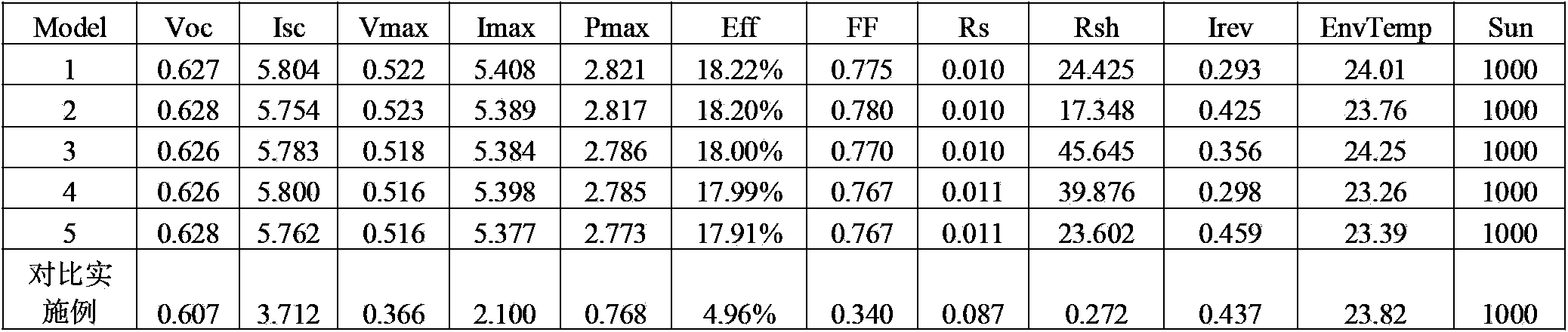

ActiveCN101391218AHigh activityImprove carbon resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationActive component

The invention discloses a coke oven gas methanation catalyst, which takes Al2O3 as a carrier, nickel as a main active component, and MgO as an auxiliary agent; wherein: the active component nickel exists in the catalyst in the form of NiO, and the carrier Al2O3 and the auxiliary agent MgO form a carrier structure of magnesia-alumina spinel; the main components respectively include, by weight percentage: 5 percent to 20 percent of NiO, 30 percent to 80 percent of Al2O3, and 1 percent to 50 percent of MgO. The catalyst has the advantages of high strength, good activity, good thermal stability, excellent anti-coking performance and good low temperature activity, and also has the properties of transforming high hydrocarbon and good anti-oxidation. The invention also discloses a preparation method of the coke oven gas methanation catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

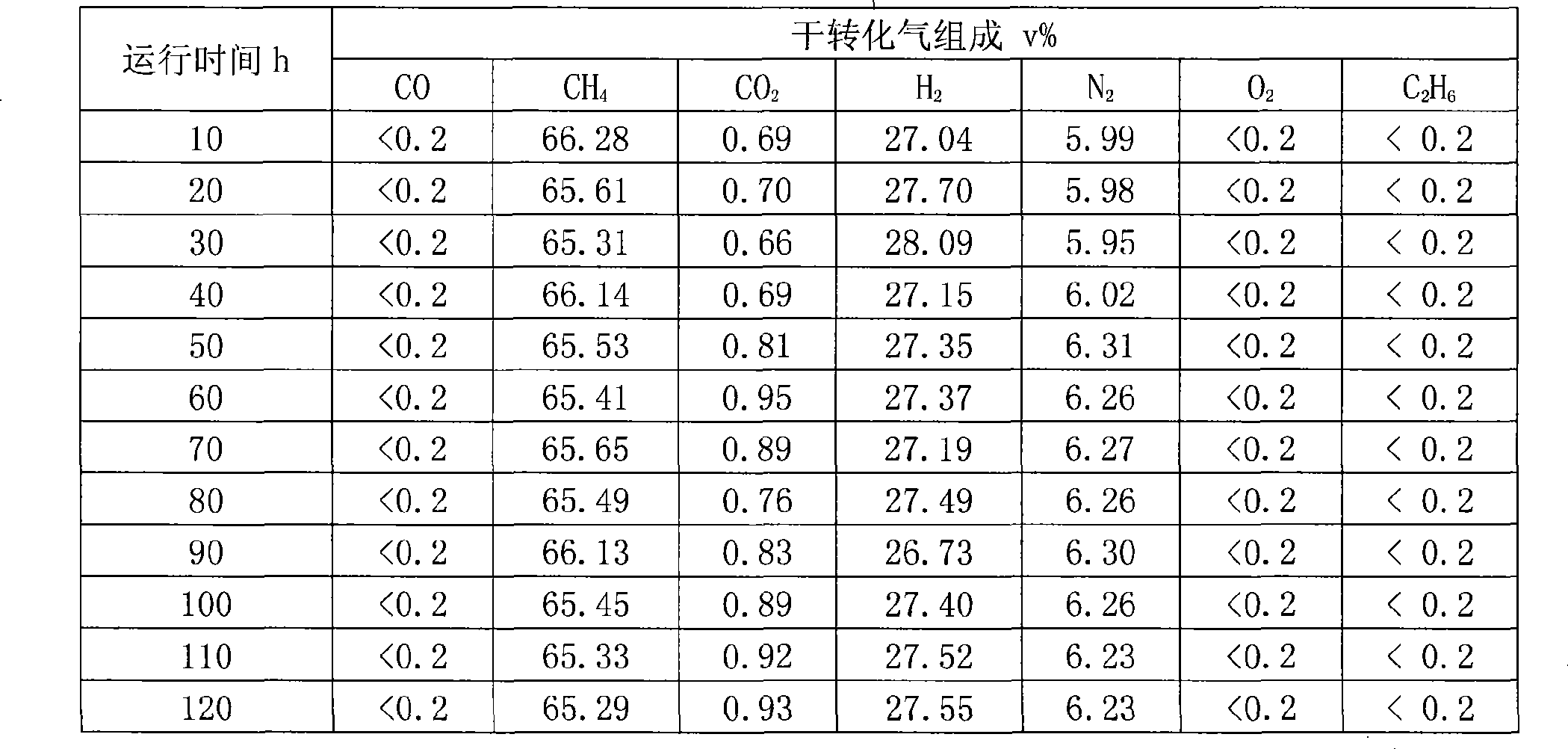

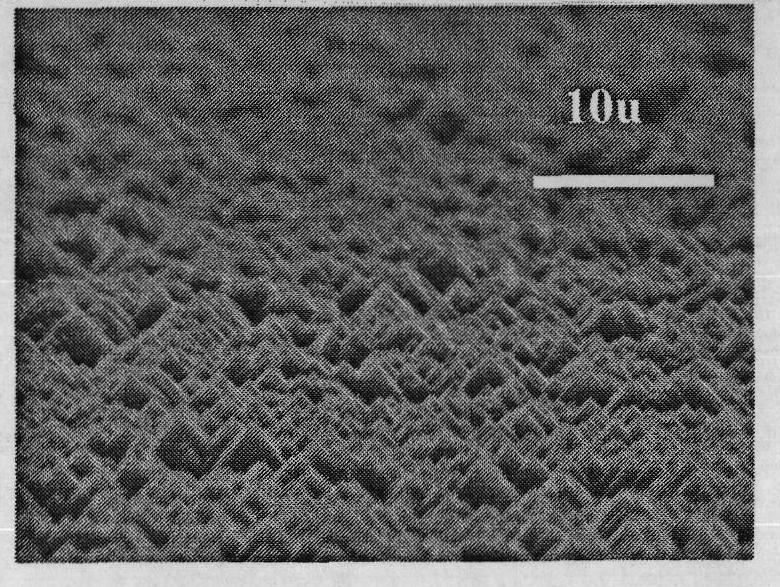

Velvet manufacturing solution of monocrystalline silicon additive

InactiveCN101818378AUniform sizeGuaranteed efficient growthAfter-treatment detailsOrganic acidSurface-active agents

The invention discloses a velvet manufacturing solution of a monocrystalline silicon additive, which comprises an alkaline etching solution, a surface active agent and organic acid or salt, wherein the mass of the surface active agent is 0.05% to 0.5% of the mass or volume of the alkaline etching solution, and the mass of the organic acid or salt is 0.1% to 10.0% of the mass or volume of the alkaline etching solution. The velvet manufacturing solution enables the pyramid size of a velvet surface of monocrystalline silicon to be uniform without blaze or obvious impression. Under a proper temperature condition, the velvet surface is quickly and effectively formed and is matched with traditional production equipment.

Owner:HANWHA SOLARONE QIDONG

Sintered water permeable brick and preparation method thereof

ActiveCN106087631AImprove water permeabilityLittle tortuousnessSingle unit pavingsPaving detailsBiomass fuelsSurface layer

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

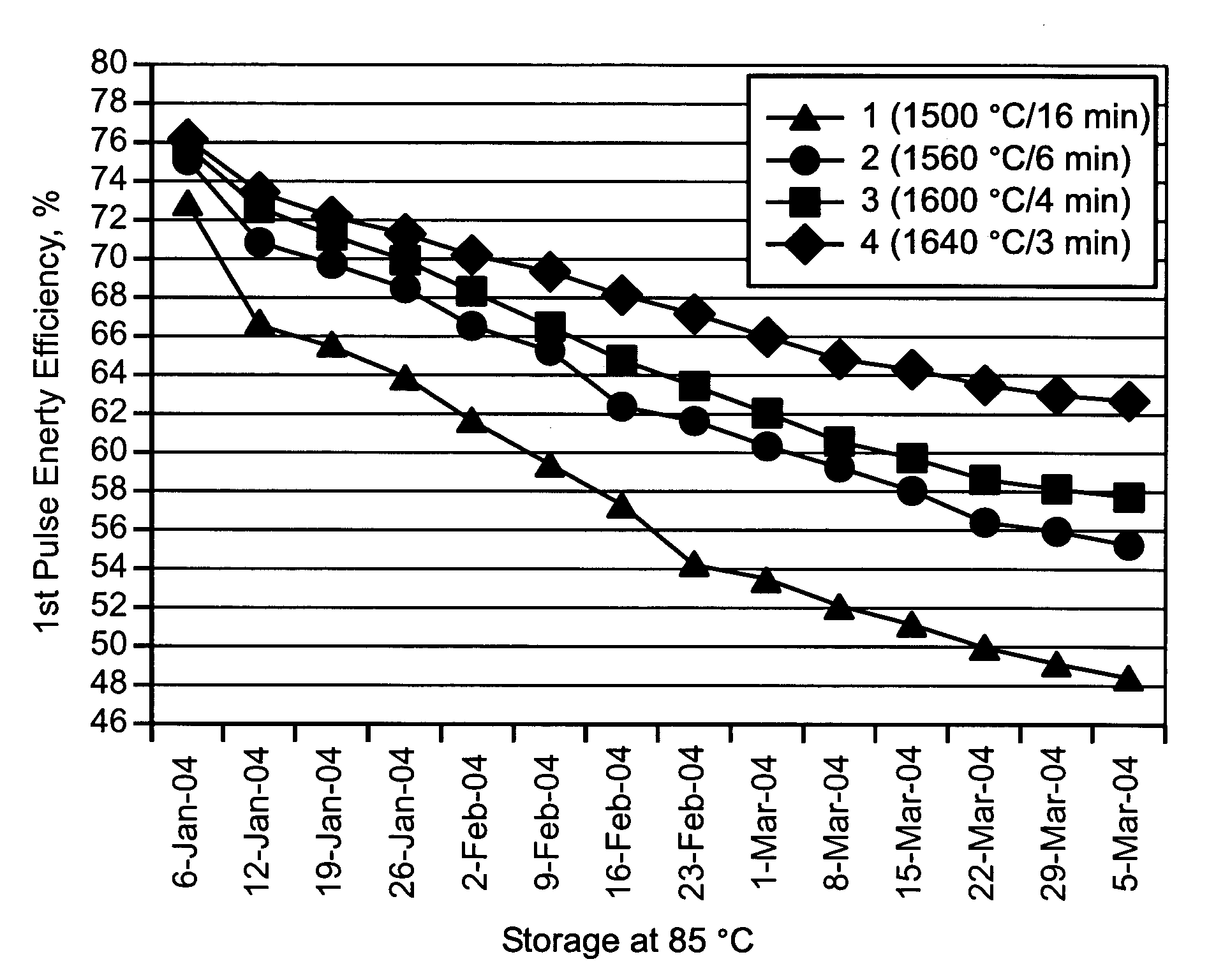

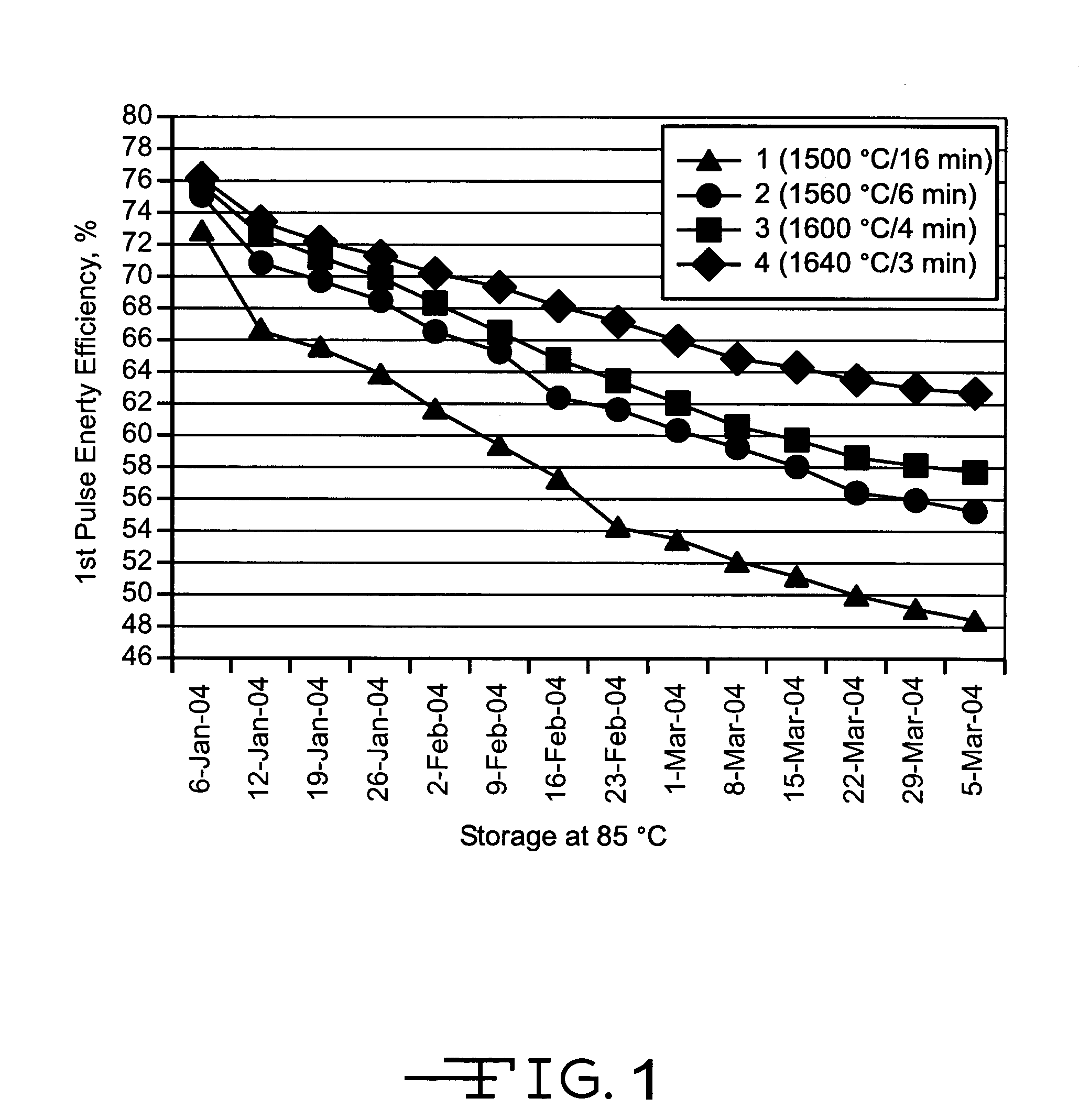

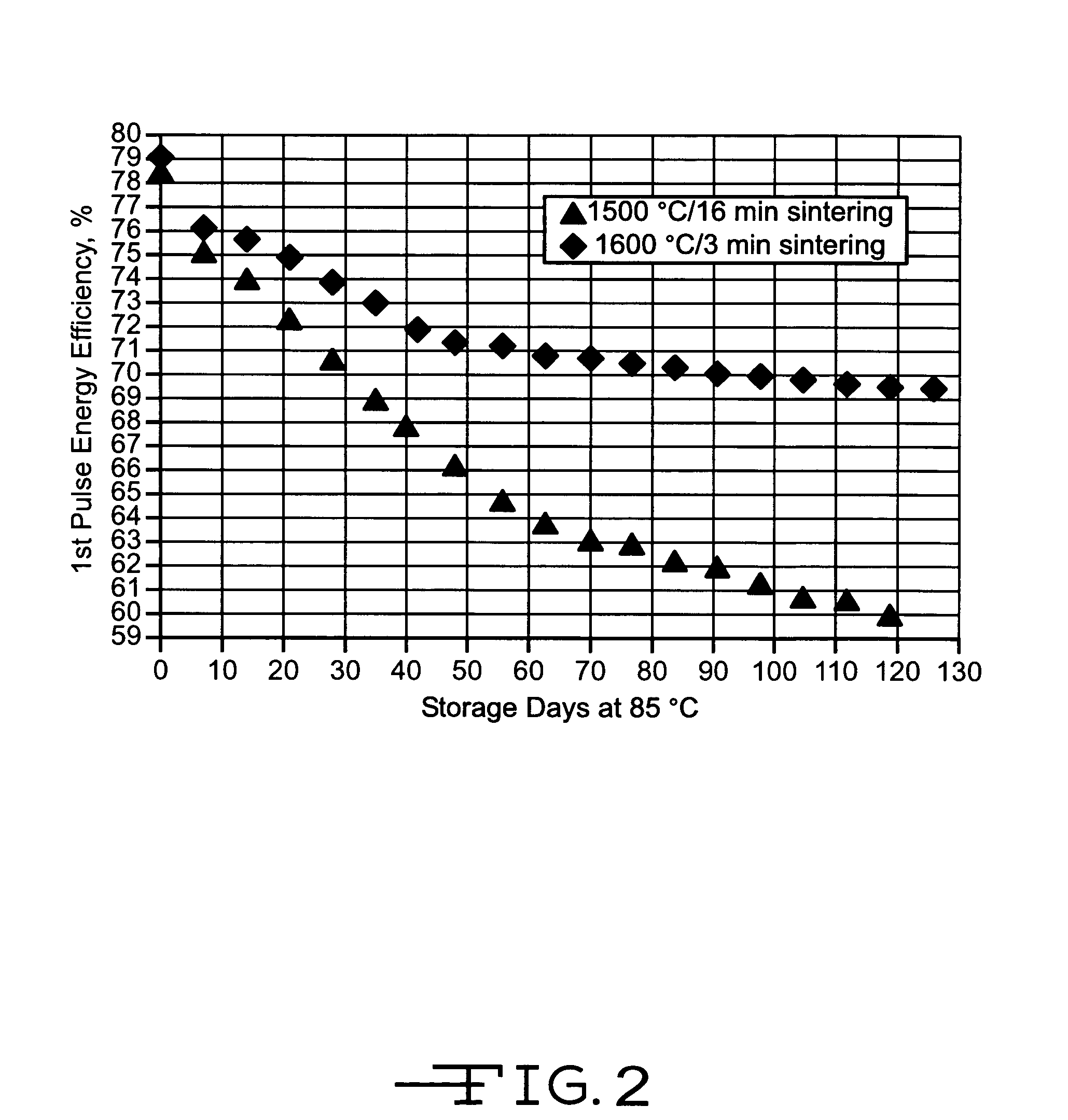

Sintered valve metal powders for implantable capacitors

ActiveUS6965510B1Short timeIncrease temperatureLiquid electrolytic capacitorsCapacitor electrodesNiobiumTitanium

A sintering method for valve metal powders, such as tantalum, niobium, aluminum, titanium, and their alloys, is described. The valve metal powders are pressed into a pellet and sintered at a relatively high temperature, but for a relatively short time. The anodized valve metal structure is then useful as an anode in an electrolytic capacitor.

Owner:WILSON GREATBATCH LTD

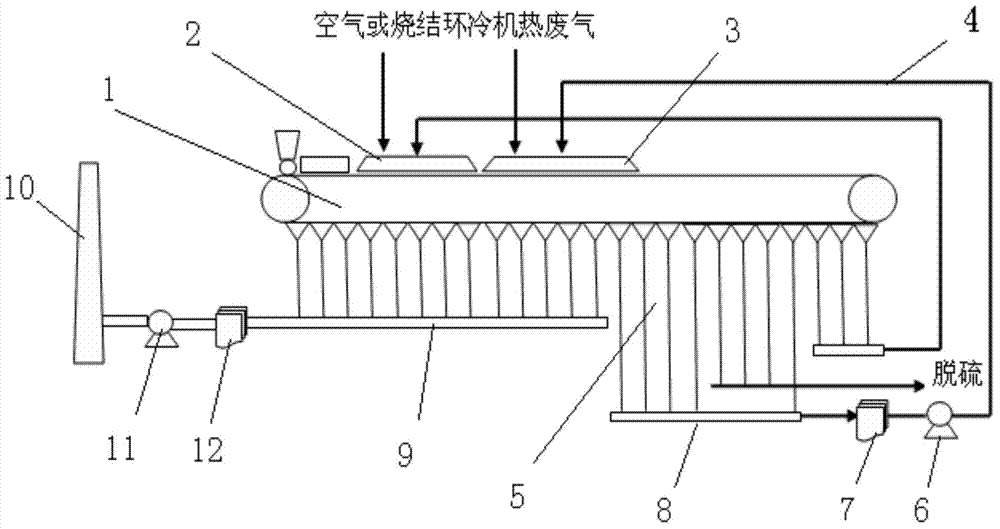

Iron mine sintering flue gas segmented circulation method

ActiveCN103499216AGuaranteed emission reductionAvoid enrichmentIncreasing energy efficiencyWaste heat treatmentFlue gasDust emission

The invention discloses an iron mine sintering flue gas segmented circulation method. Sintering flue gas high in O2 content on the tail portion of a sintering machine is circulated to the interior of a head flue cover of a sintering feed surface of the head portion of the sintering machine, flue gas of two to three bellows highest in SO2 content in a bellow on the tail portion of the sintering machine is conveyed to a desulfurization system to be desulfurized, and flue gas in other bellows is circulated to a middle flue cover of a sintering feed surface of the middle portion of the sintering machine. After segmented flue gas circulation is adopted, SO2 will not be accumulated in sintering ore, dust emission is reduced by 20-40%, NOx emission is reduced by 20-40%, dioxin emission is reduced by 50-80%, and CO2 emission is reduced by 20-45%.

Owner:CENT SOUTH UNIV

Sintering preparation method of boron carbide ceramic

The invention discloses a sintering preparation method of boron carbide ceramic, which comprises the following steps: 1. sintering: carrying out mixing and ball milling on boron carbide powder, carbon powder, metal powder, a dispersant, an adhesive and deionized water to make a slurry, carrying out spray granulation, pressing into a biscuit, presintering for debonding, and carrying out thermal-insulation sintering at lower sintering temperature (slightly higher than the melting point of metal), thereby implementing primary shrinkage sintering of the product by utilizing the surface tension of the molten metal in the system; and 2. sintering: continuing enhancing the sintering temperature, carrying out in-situ reaction to generate metal carbide, metal boride or metal boro-carbide and nano B4C which have higher sintering activity, and forming a solid solution with boron carbide granules by using the metal carbide, metal boride or metal boro-carbide and nano B4C as sintering assistants to promote the further shrinkage sintering of the system, thereby obtaining the high-performance boron carbide ceramic. The method has the advantages of both the normal-pressure sintering technique and the reactive sintering technique.

Owner:NINGBO VULCAN TECH CO LTD

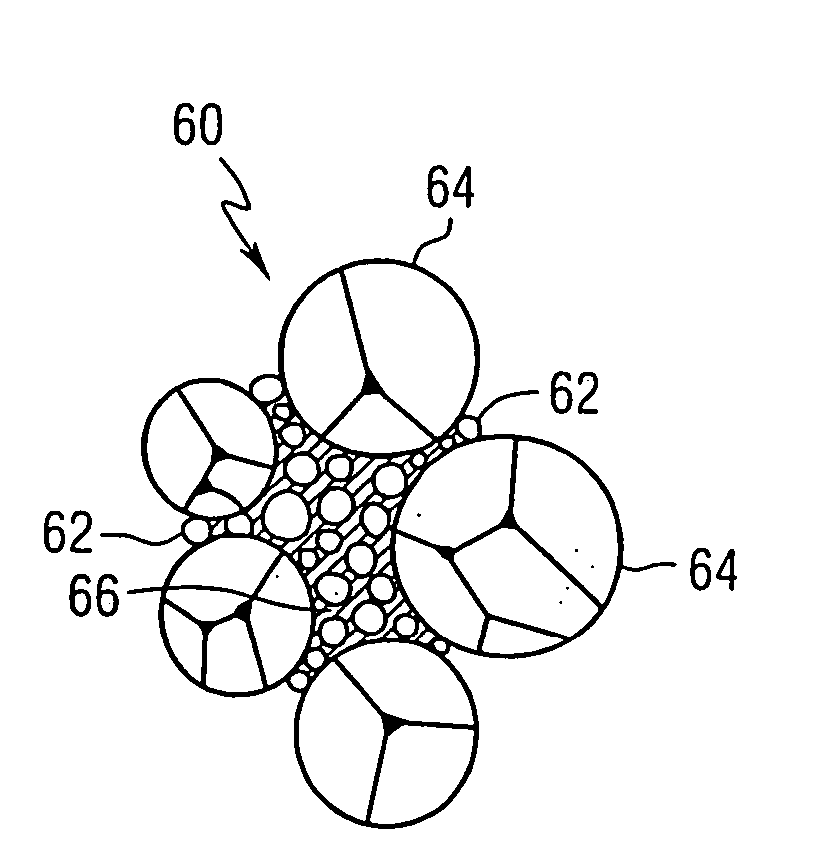

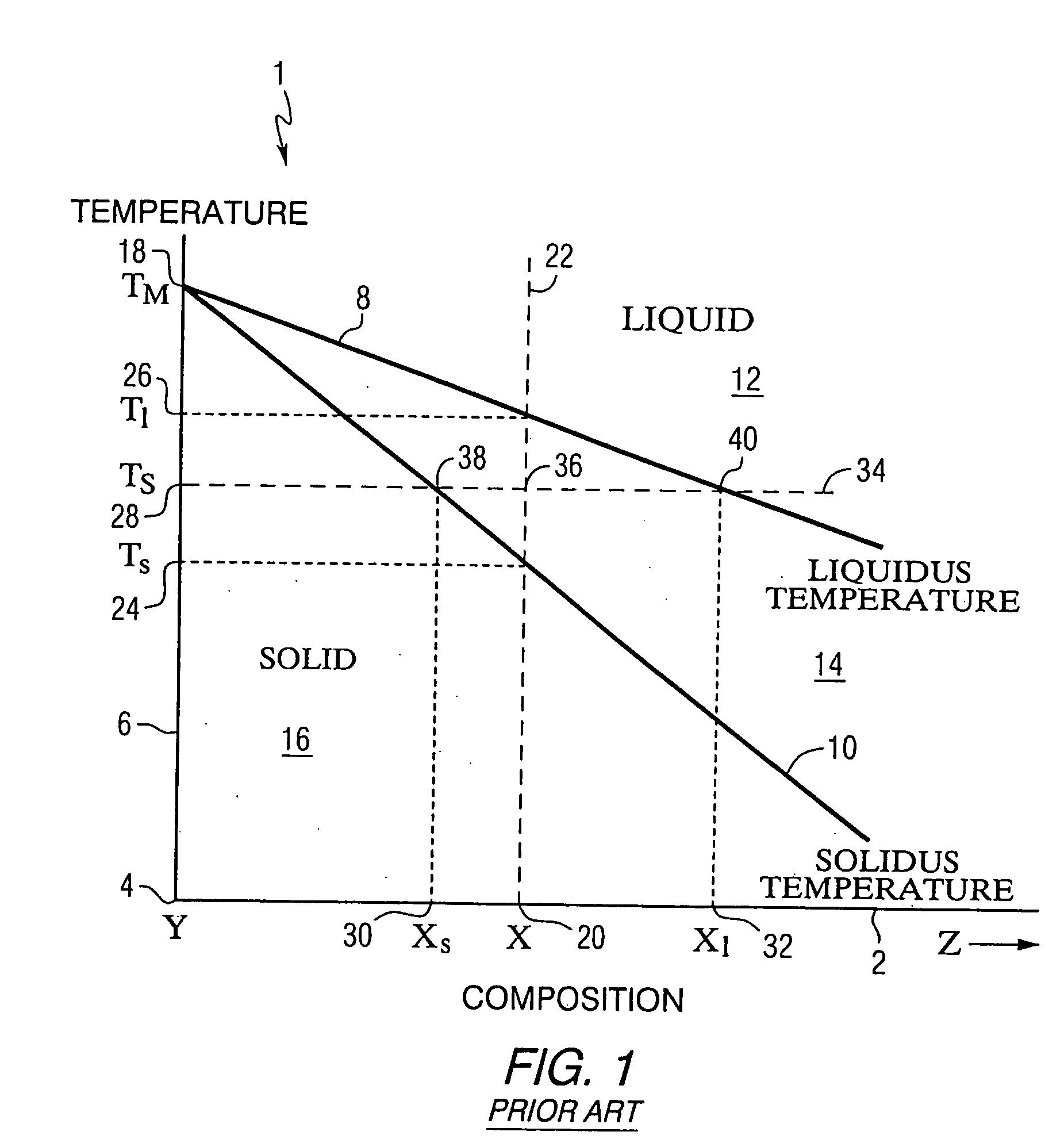

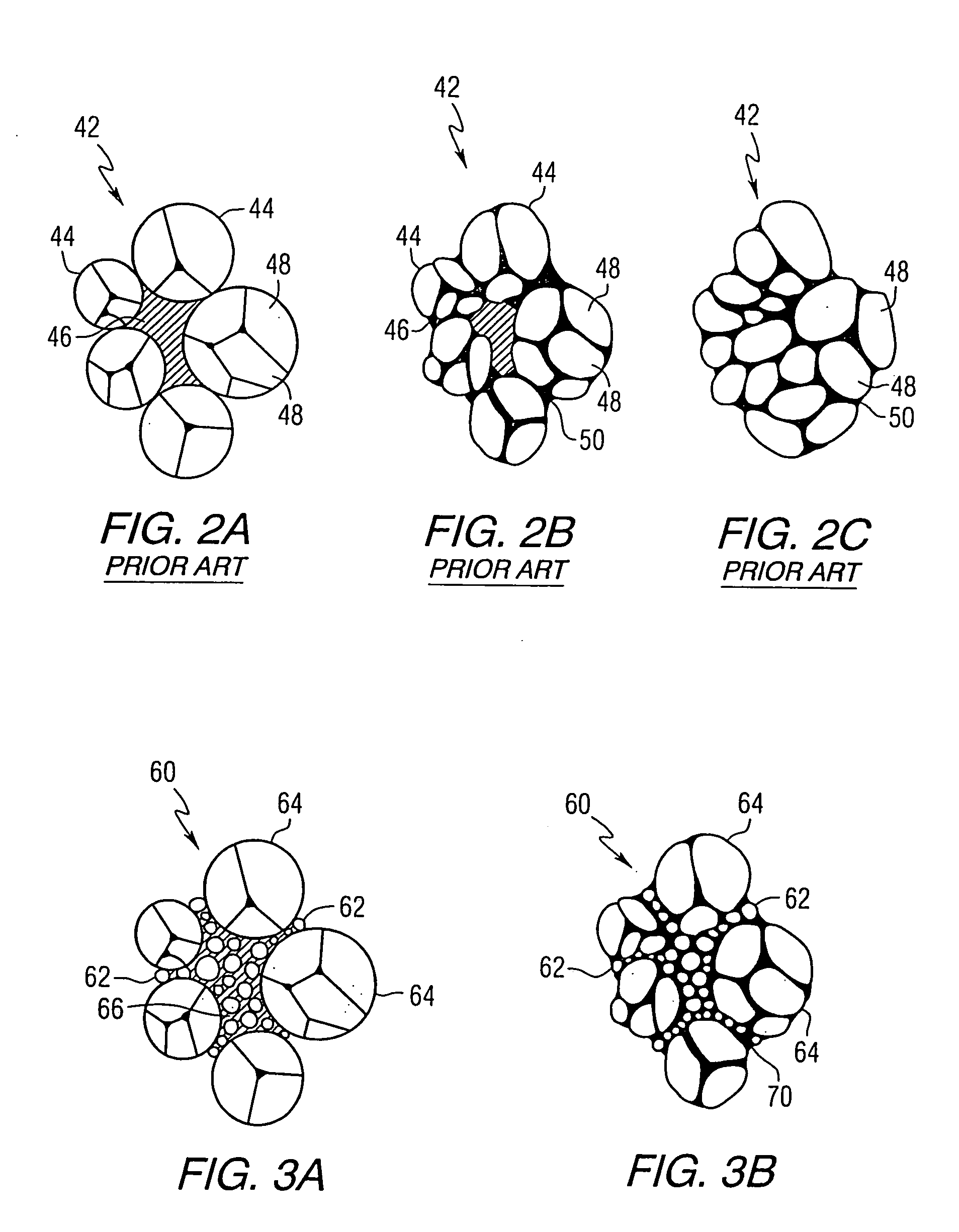

Blended powder solid-supersolidus liquid phase sintering

InactiveUS20060083652A1Deleterious effectHigh densityAdditive manufacturing apparatusTransportation and packagingPowder mixtureAlloy

A green article comprising an A-B powder mixture and methods of manufacturing such green articles and corresponding sintered articles are disclosed. The A-B powder mixture consists of a minor volume fraction of a relatively fine powder A and a complementary major volume fraction of a relatively coarse prealloyed powder B wherein the A-B powder mean particle size ratio is at least about 1:5. Metal powder A consists of one or more elemental metals or alloys which has a melting or solidus temperature above the highest sintering temperature at which the A-B powder mixture may be sintered without slumping. Prealloyed metal powder B consists of one or more alloys which are amenable to supersolidus liquid phase sintering. Green articles made from the A-B powder have a wider sintering temperature window than do articles made from prealloyed metal powder B alone.

Owner:THE EX ONE

Method for manufacturing silicon solar cell

InactiveCN101783374ALow sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesMetallic electrodeOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the purpose of industrialized production better.

Owner:SUN EARTH SOLAR POWER

Front silver paste for high sheet resistance silicon-based solar cell and preparing method of front silver paste

ActiveCN103915127AReduce contentCorrosivity controlFinal product manufactureNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention provides a front silver paste for a high sheet resistance silicon-based solar cell and a preparing method of the front silver paste. The front silver paste is composed of, by weight, 80% to 90% of silver powder, 0.5% to 6% of glass powder and 5% to 15% of organic carriers. The glass powder is composed of, by weight, 25% to 75% of TeO2, 20% to 55% of PbO and 1% to 20% of Na2O. The organic carriers include resin and organic solvents. The silver paste is suitable for the high sheet resistance silicon-based solar cell and can make good ohmic contact with the high sheet resistance silicon-based solar cell, and therefore the conversion efficiency of the solar cell is greatly improved; meanwhile, the silver paste can keep welding pulling force obtained after high-lead silver paste is sintered on the solar cell by adjusting the content of Na2O, the sintering temperature range is effectively widened, and stability of product performance is ensured.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

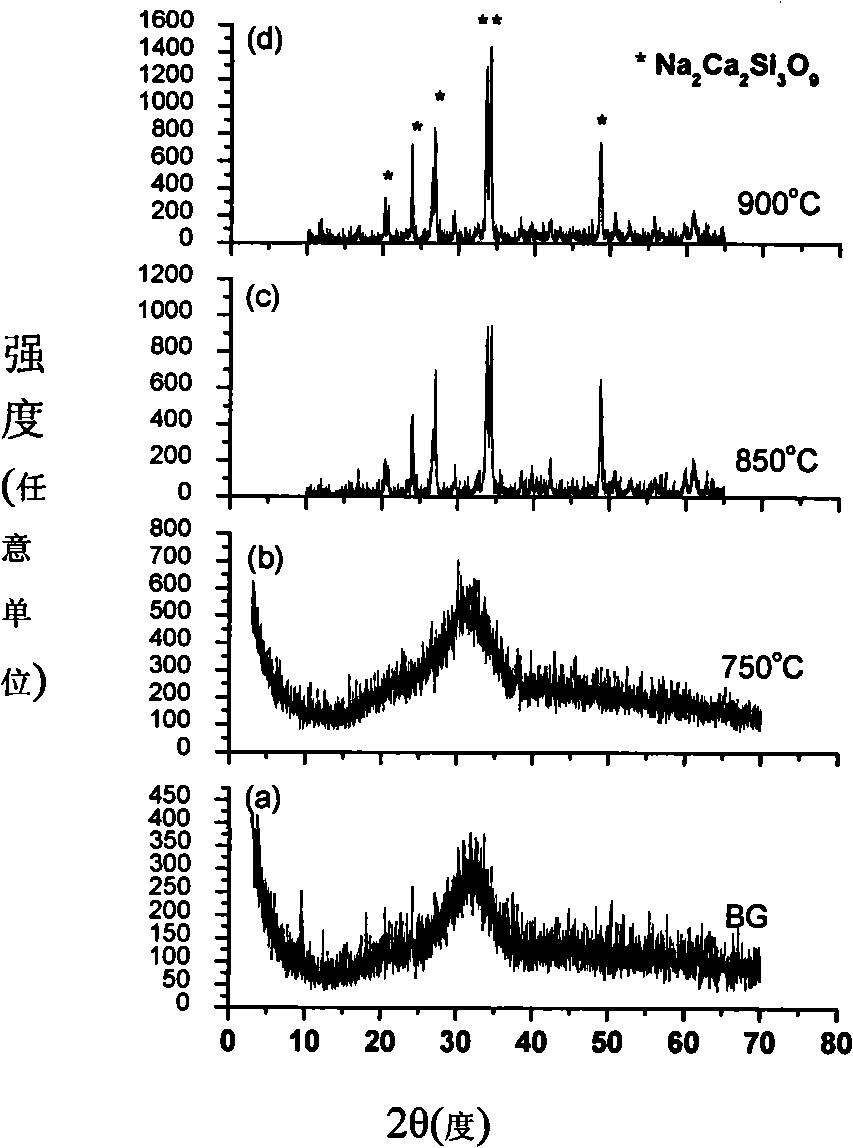

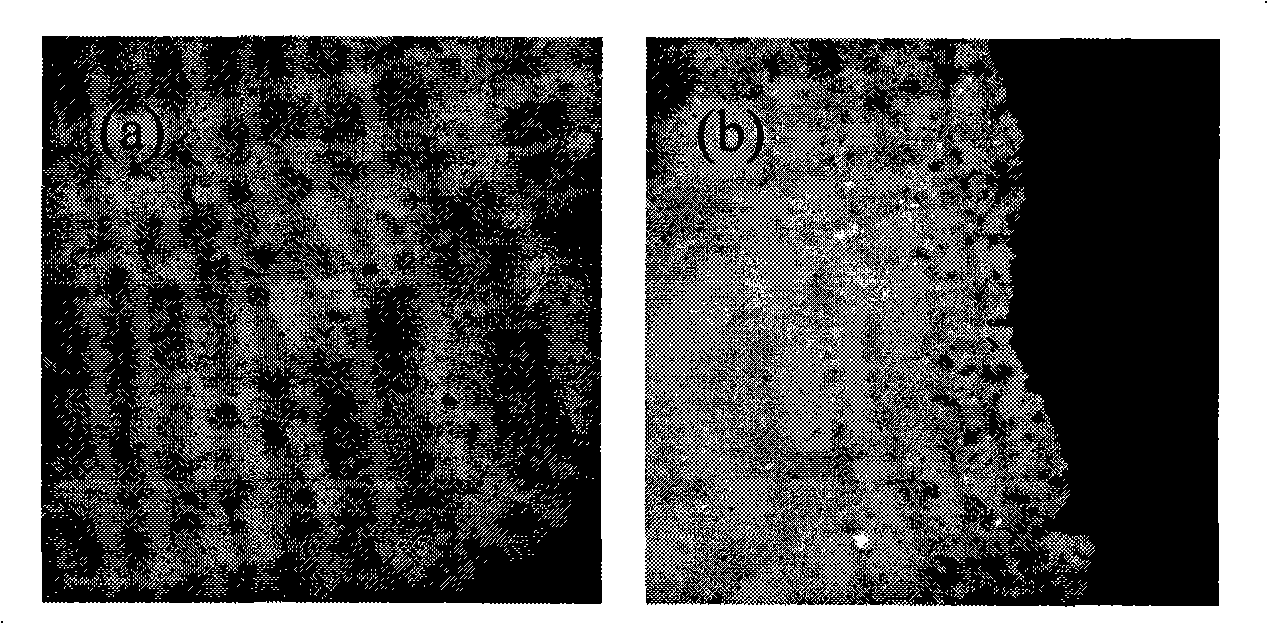

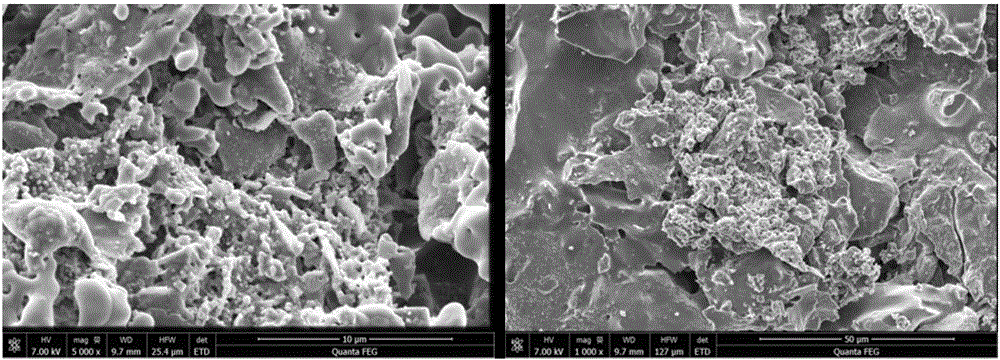

Degradable dynamics enhancement type bioglass radical porous composite material and preparation method thereof

InactiveCN101288780ARaise the sintering temperatureHigh compressive strengthBone implantStress concentrationCell-Extracellular Matrix

The invention relates to a biological glass base porous composite material of a degradable mechanical enhanced type and a preparation method thereof. The material takes a biological glass porous stent which comprises macroporous channels and mediated pore channels as matrix. Adjacent macroporous channels are mutually communicated. The internal and external surfaces of the macroporous channels and mediated pore channels are provided with gel layers which are assembled layer-to-layer by the biomolecules with positive and negative charges alternatively. The biological glass matrix is made from the components with the following weight percentage of 16-38 percent of CaO, 0-10 percent of P2O5, 45-80 percent of SiO2, 0-0.1 percent of SrO and 0-22.5 percent of Na2O. The releasing speed of the biological active ions of the biological glass base porous composite material which is similar to the extracellular matrix and is decorated by the layer-to-layer assembly of the charges of different polarity of the biomolecules can be effectively cut and controlled. The walls of the pore channels are beneficial to the adhesion growth of cells. The mechanical strength, the fracture toughness and the machinability are good. And the application of the regeneration treatment on the bone gear injury home position of a stress concentrated part can be satisfied.

Owner:ZHEJIANG UNIV

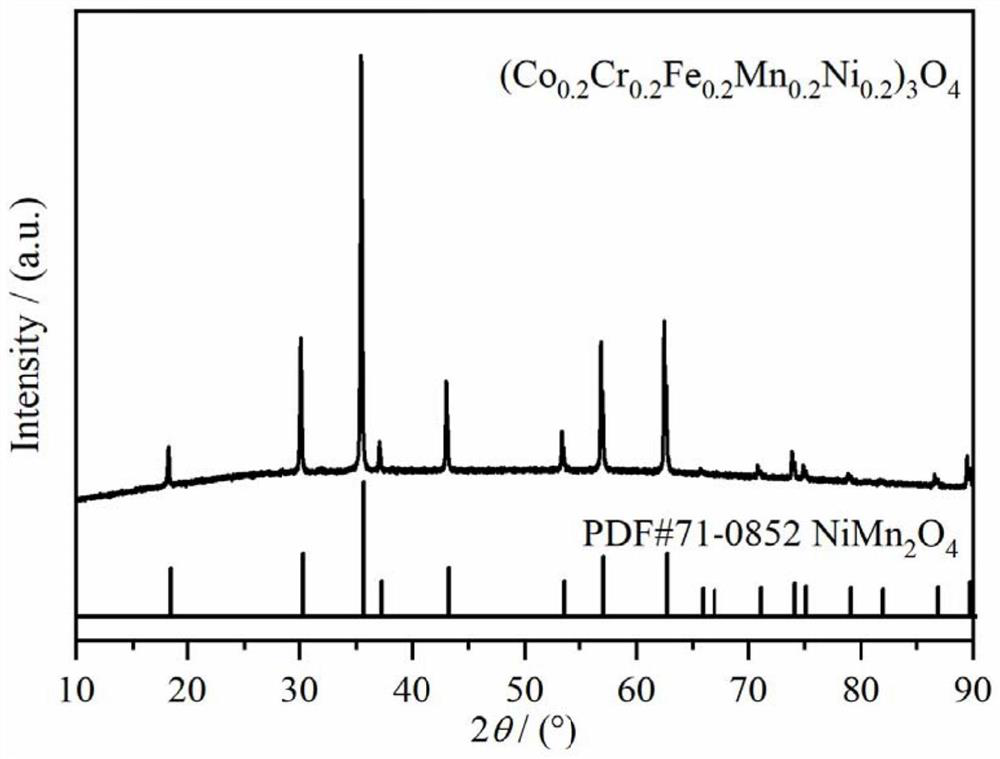

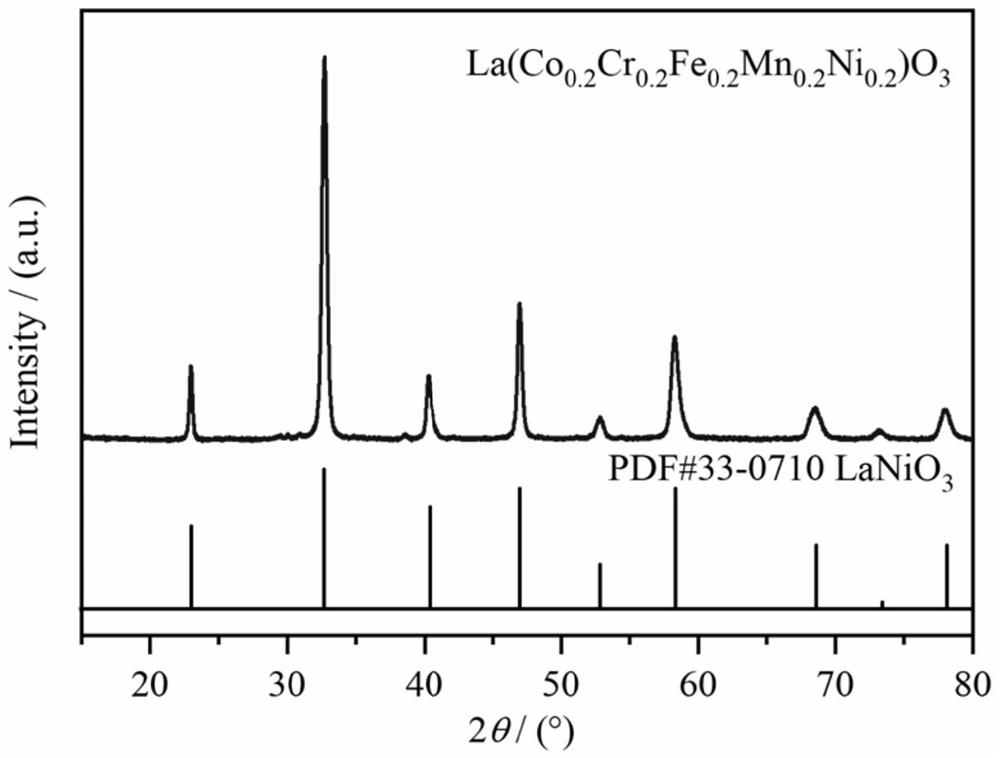

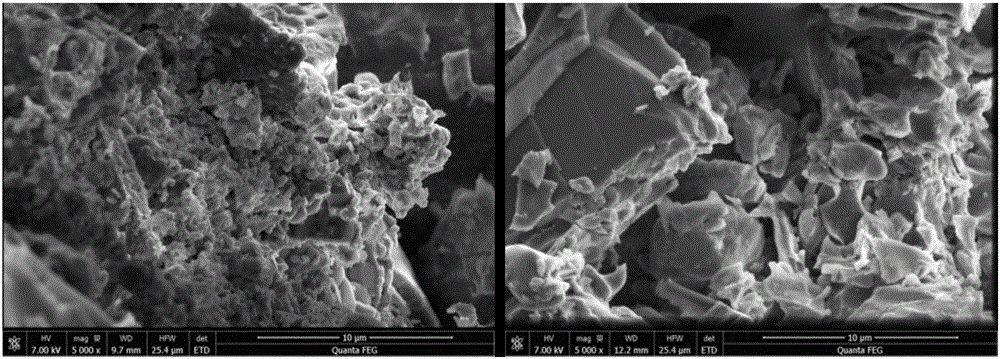

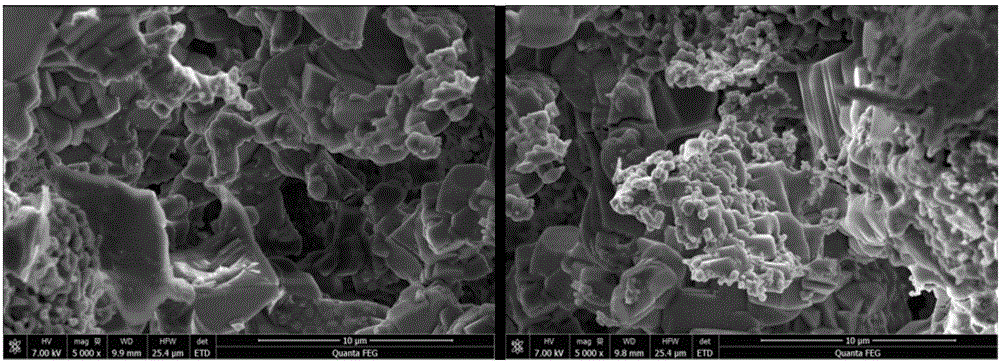

The method for preparing high-entropy oxide ceramic material is simple and low in consumption

ActiveCN112723862AThe primary particle size is fine and uniformHigh activityOxide ceramicPlasma activation

The invention relates to the technical field of high-entropy ceramic preparation, and discloses a simple and low-consumption method for preparing a high-entropy oxide ceramic material, which comprises the following steps: S1, weighing raw materials: weighing the raw materials required for preparation according to a set ratio; s2, performing particle refinement: adding the raw materials weighed in the step S1 and a dispersing agent into a ball milling tank of a planetary ball mill together for particle refinement grinding to prepare uniformly mixed slurry, then drying the slurry, and grinding again to obtain refined powder; s3, performing spark plasma treatment: performing spark plasma activation on the refined powder obtained in the step S2 to obtain a ceramic raw material; and S4, performing microwave sintering: carrying out microwave sintering on the ceramic raw material obtained in the step S3 to obtain the high-entropy oxide ceramic material.

Owner:TAIYUAN UNIV OF TECH

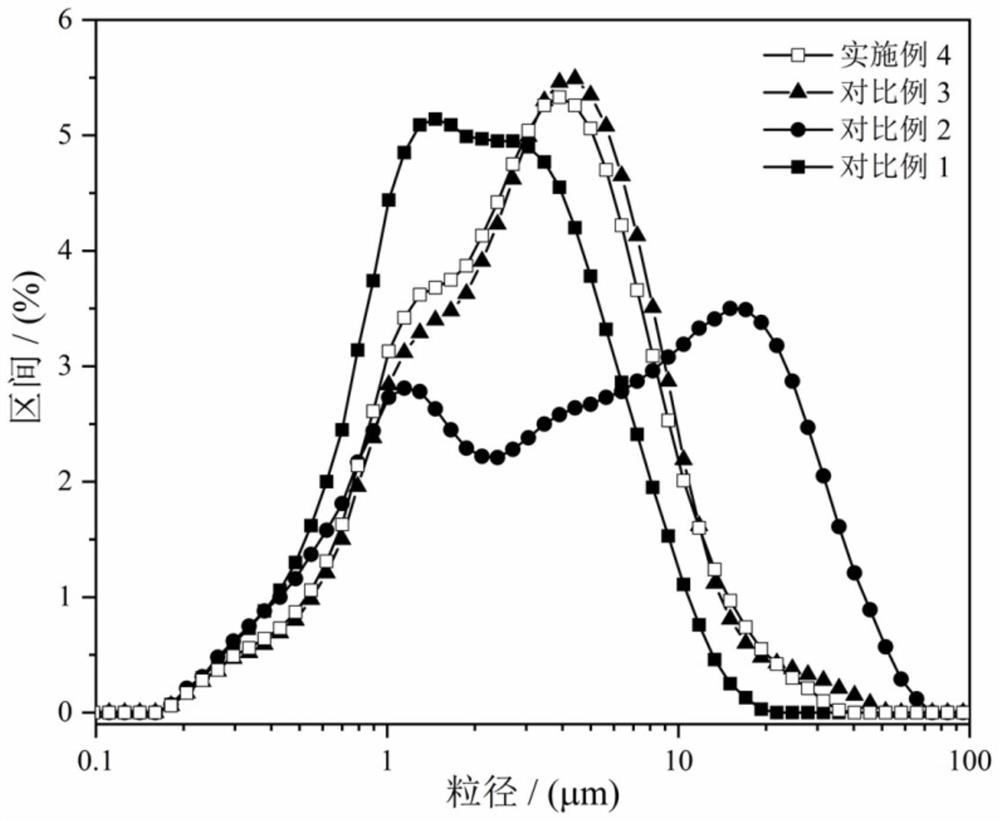

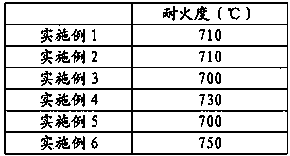

Ceramic bond, preparation method thereof and manufacturing method of ceramic bond grinding tool

ActiveCN103624696ALow refractorinessHigh strengthAbrasion apparatusGrinding devicesLithium carbonateSilicon dioxide

The invention relates to a ceramic bond with low refractoriness and high strength. The ceramic bond comprises the following components in percentage by weight: 25%-45% of silicon dioxide, 15%-25% of ultrafine silicon dioxide with the particle size of not more than 5 microns, 14%-20% of sodium tetraborate, 8%-13% of aluminum oxide, 4%-8% of lithium carbonate, 5%-10% of zinc oxide, 1%-2% of magnesium oxide, 0%-1% of barium carbonate and 3%-5% of titanium oxide. As the ultrafine silicon dioxide is introduced into the component, the strength of the ceramic bond is improved and the refractoriness is simultaneously reduced. In addition, the invention further provides a preparation method of the ceramic bond and a method for manufacturing a ceramic bond grinding tool by utilizing the ceramic bond.

Owner:ZHUHAI JUXIN TECH DEV

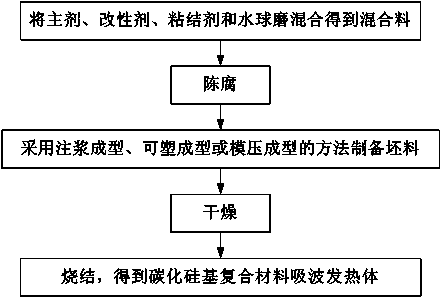

Silicon carbide based composite microwave-absorbing heating body composition and preparation method thereof

The invention discloses a silicon carbide based composite wave-absorbing heating body composition and a preparation method thereof. The heating body composition is prepared from the raw materials in parts by mass: 75-95 parts of main agent, 5-25 parts of modifier, 1-6 parts of additive binder and 5-50 parts of water; the preparation method of the silicon carbide based composite wave-absorbing heating body composition comprises the following steps: carrying out ball milling to mix the materials; ageing; molding; drying; and sintering. The silicon carbide based composite wave-absorbing heating body composition disclosed by the invention has good microwave absorbing and rapid heating performance in the civilian band (2.45GHz). The wave-absorbing heating body composition can be processed into various shapes according to the needs of sintered products, is simple in production process, low in production cost, wide in use temperature range, good in high-temperature oxidation resistance, extensive in use and easy in the forming of different atmospheres, can meet the requirements of products of different types on sintering and is extensively used as heating elements of various high-temperature furnaces.

Owner:XIAN UNIV OF SCI & TECH

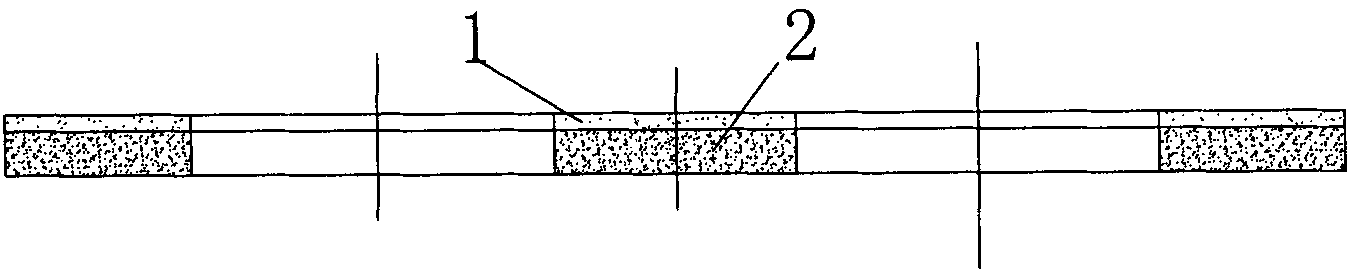

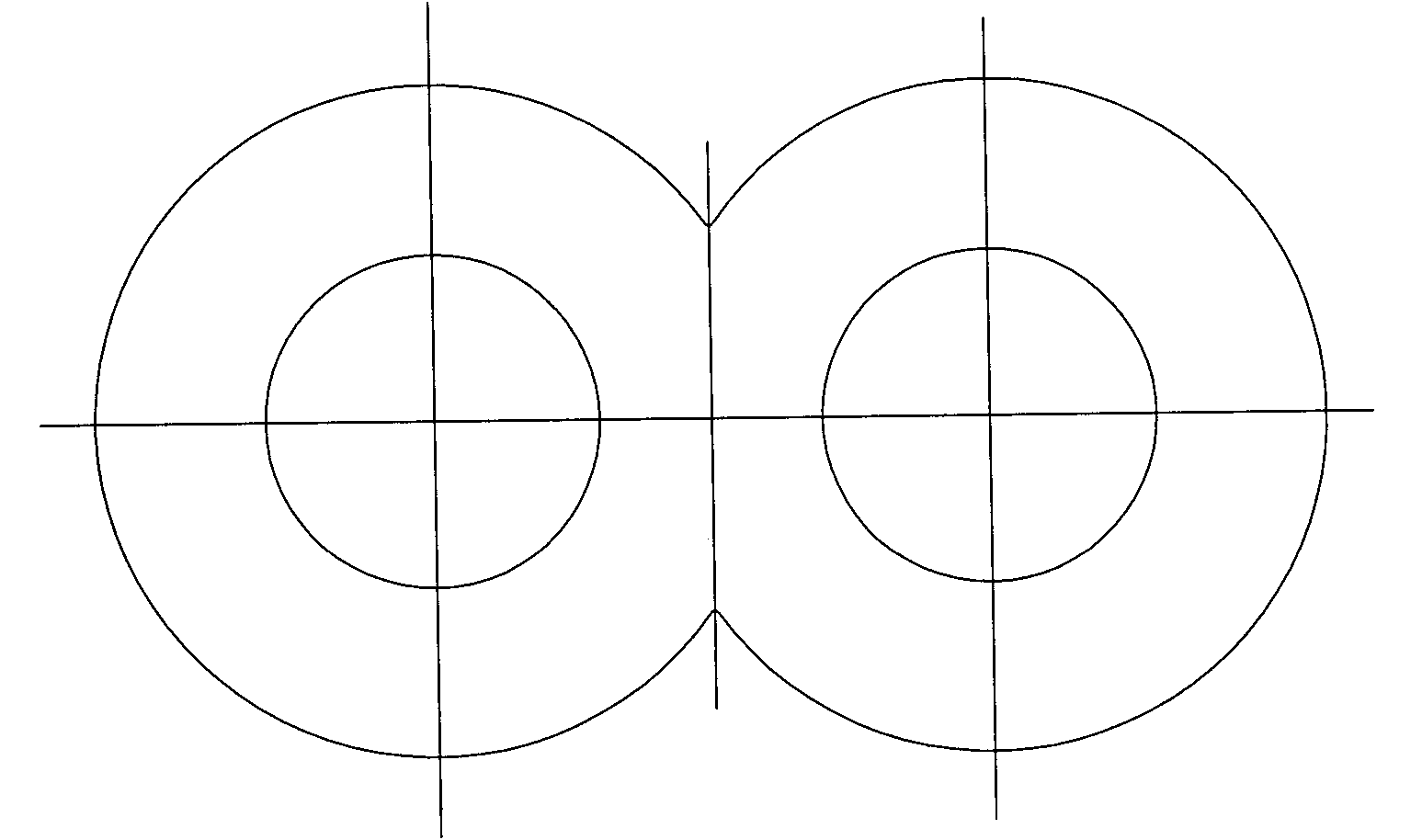

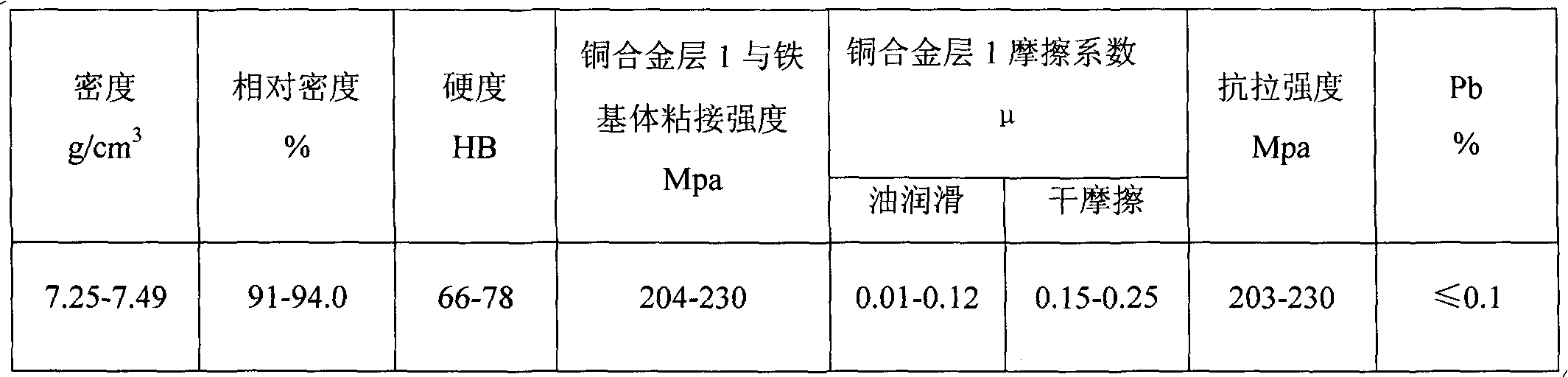

High strength self-lubricating iron-copper powder composite material and preparation method thereof

The invention relates to a high strength self-lubricating iron-copper powder composite material, a preparation method and application thereof. The composite material is characterized by comprising an iron alloy base body and a copper alloy base body as a surface layer, wherein the iron alloy base body contains Cu, C, Sn, Pb and Fe, and the copper alloy base body contains Ni, C, MoS2, Sn, Fe, Pb and Cu. The preparation method comprises the following steps of: respectively preparing copper alloy layer warm-pressing powder and iron alloy base body warm-pressing powder; filling the warm-pressing powder into a mould and then pressing once to form a green compact; sintering the green compact in the protection atmosphere; and shaping the sintered sintering compact in the mould so that the composite material is prepared. By the invention, the cost of parts can be greatly reduced on the basis of ensuring the use performance of the parts.

Owner:合肥波林新材料股份有限公司

Lightweight foamed ceramics and preparation method thereof

The invention relates to lightweight foamed ceramics and a preparation method of the lightweight foamed ceramics. The lightweight foamed ceramics are prepared by the steps as follows: mechanically agitating raw material, curing agent and foam based on a certain ratio, so as to obtain uniform ceramic size; moulding the ceramic size by casting; and curing and drying same at a certain temperature; and finally sintering the dried blank body to obtain the lightweight foamed ceramics. The lightweight foamed ceramics are important for efficiently utilizing the solid waste, reducing the pollution of the industrial solid waste to the environment, and reducing the production cost; the produced lightweight ceramics have the advantages of being more in closed air pores, relatively low in heat conductivity, relatively high in strength, and relatively low in sintering temperature; and the lightweight foamed ceramics are suitable to be applied to the fields of lightweight decorative material, building insulation wall material, sound insulating material, fireproof material and sinking preventing material.

Owner:GANSU WANTE TECH DEV

Production method of ecologic permeable ceramic bricks

The invention provides a production method of ecologic permeable ceramic bricks. The method comprises the following steps: 1, taking 5-10% of construction waste micro-powder, 5-15% of construction waste fine aggregates, 30-45% of construction waste coarse aggregates, 15-20% of dried sludge, 15-40% of modified mud, 0.075-0.2% of alum and 0.5-1% of borax; and 2, uniformly mixing, molding a test block under a molding pressure of 10-20Mpa through adopting a pressure molding process, naturally drying after molding, heating to 300-350DEG C at a rate of 2-3DEG C / min, keeping the temperature at 300-350DEG C for 2.5-3.5h, heating to 1050-1150DEG C at a rate of 3-8DEG C / min, sintering for 3-4h, and cooling. The method has the advantages of high waste utilization rate and effective solving of the contradiction between mechanical performances and the water permeability.

Owner:WUHAN UNIV OF TECH

Preparation method for preparing low-density oil well cementing cement briquettes by vermiculites

The invention provides a preparation method for preparing low-density oil well cementing cement briquettes by vermiculites. The preparation method comprises vermiculite balling treatment, high-temperature expanding and sintering, dosing, mixing, stirring and size-mixing, die testing and strength test, and is characterized by carrying out stirring and size-mixing for 40s to 50-70wt% of G-grade oil well cement, 20-40wt% of blind-hole hollow glass microspheres with particle size of 10-80mu m, 5 to 7wt% of fly ash with loss on ignition of 1.1%, 1.5 to 2wt% of calcium oxide with purity of 99.9%, 0.5 to 1.0wt% of sodium sulfate and 1 to 3wt% of micro-silicon in a stirrer according to a water cement ratio of 0.5-0.7 (W / C), pouring into two test molds in one group, wherein length, width and height of each test mold are 53mm, 53mm and 53mm respectively, curing for 24h and 48h in a water-bath curing box at the constant temperature of 52 DEG C, immersing for 1h in cold water after de-molding, and then carrying out strength test. Therefore, the performance of the low-density oil well cementing cement briquettes is better than that of floating microspheres.

Owner:HAIAN KEHAO TEXTILE CO LTD

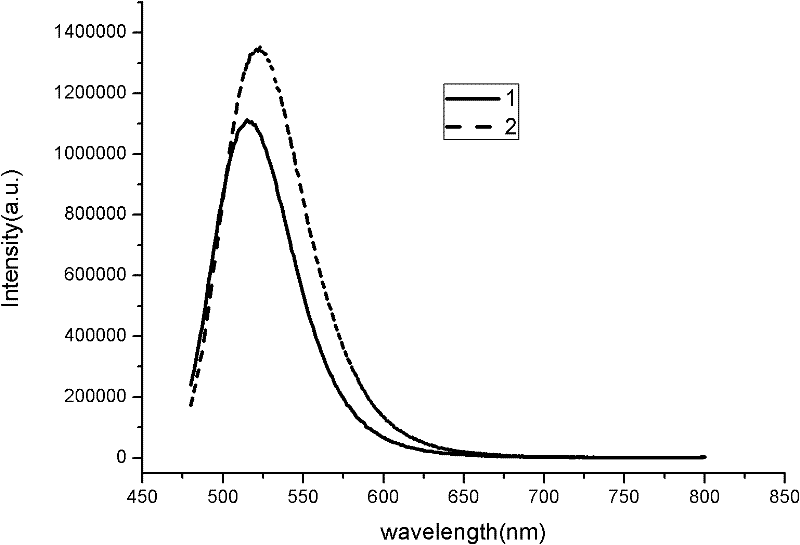

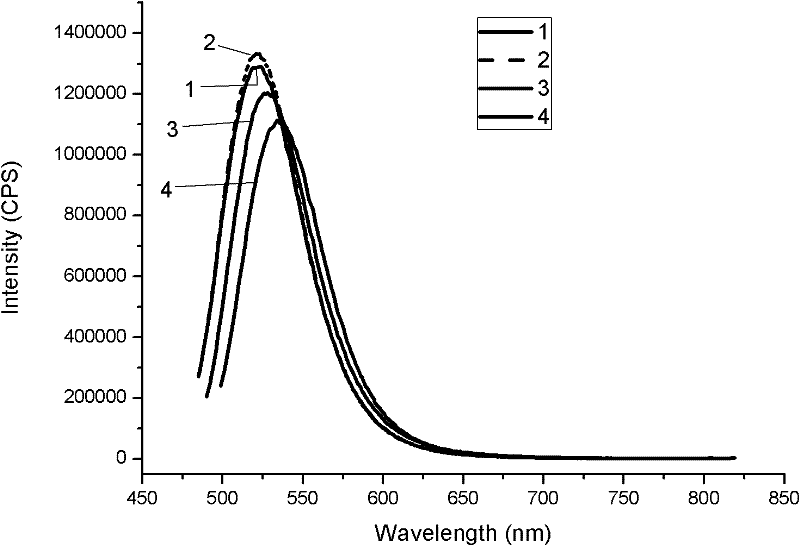

Method for optimizing crystalline form of silicate green fluorescent powder material

InactiveCN102191057AOptimizing Sintering TemperatureRaise the sintering temperatureLuminescent compositionsLuminosityCrystallinity

The invention discloses an optimized silicate green fluorescent powder material and an optimizing method thereof. The silicate green fluorescent powder material has a chemical general formula of (Ba,A)1-xSiO4:xEu, wherein x is more than 0 and less than 1.0, and A is an element Ca or Sr. The method comprises the following steps of: 1, synthesizing a precursor A2SiO4 of the silicate green fluorescent powder; 2, doping an element Ba in a matrix structure provided by the precursor A2SiO4 to synthesize the silicate green fluorescent powder material; and 3, optimizing a crystalline form of the silicate green fluorescent powder material. A crystallinity degree of the green fluorescent powder obtained with the optimizing method disclosed by the invention is greatly improved; the luminosity of the green fluorescent powder of the system is greatly strengthened; the crystalline form of the green fluorescent powder is greatly optimized, and the thermal stability of the green fluorescent powder of the system is improved.

Owner:IRICO

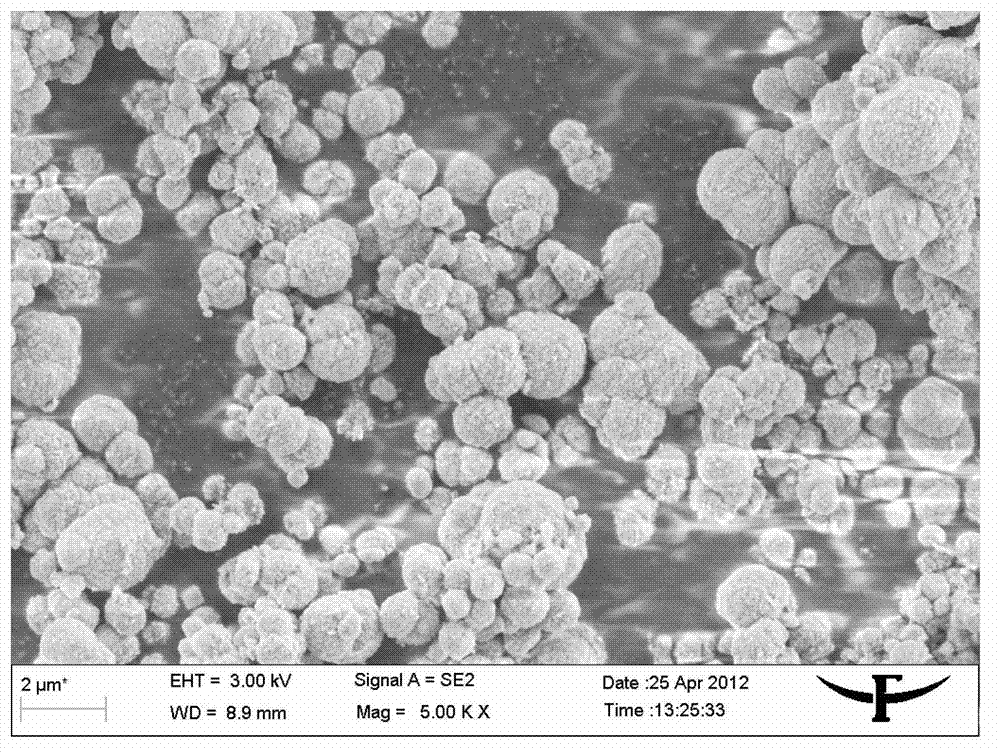

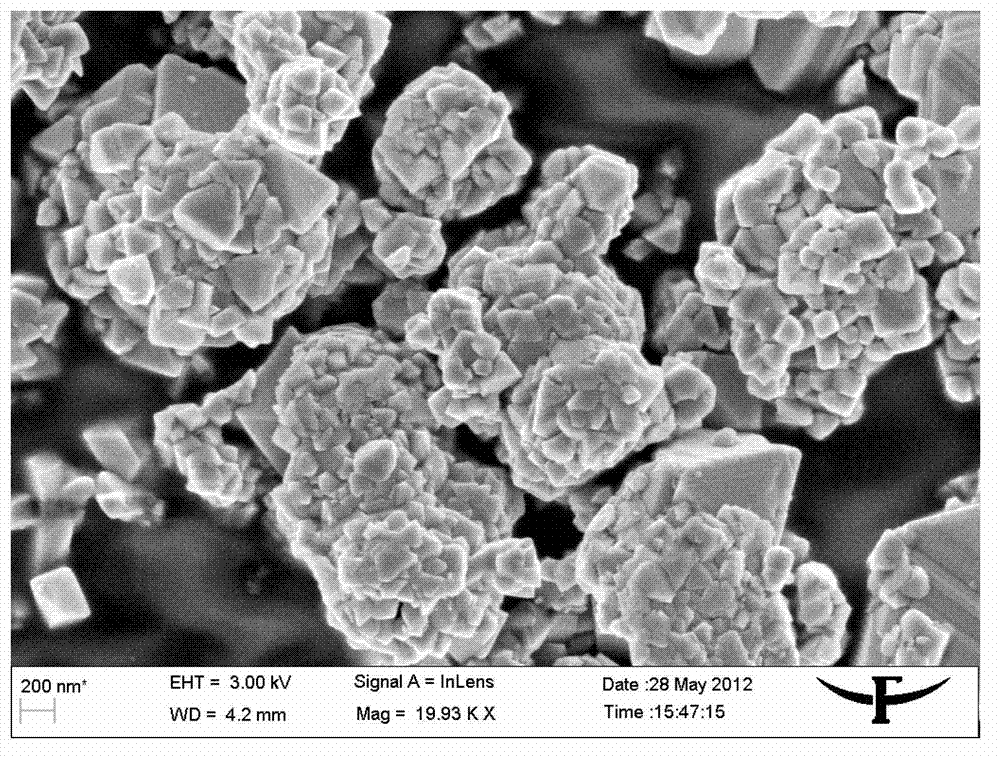

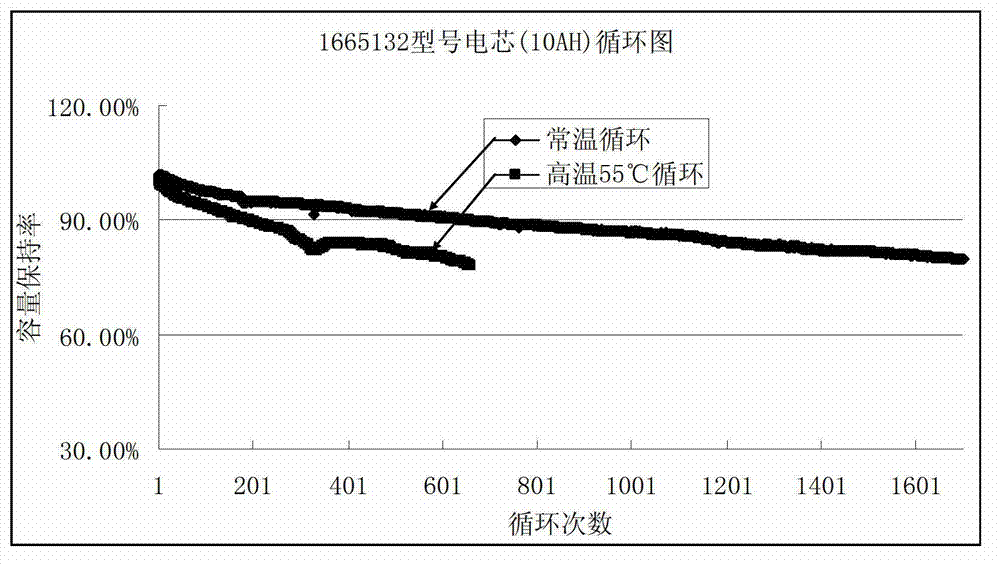

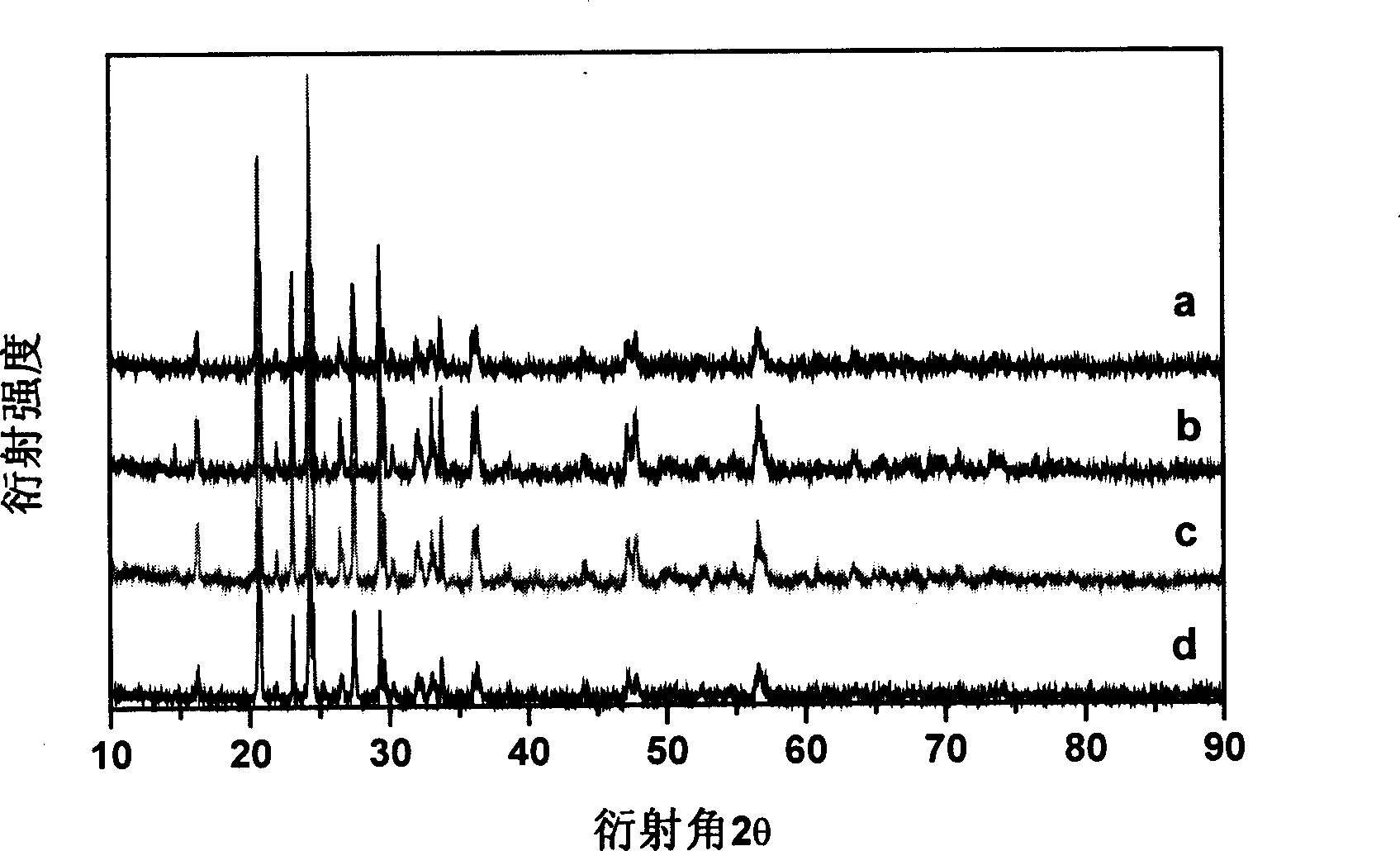

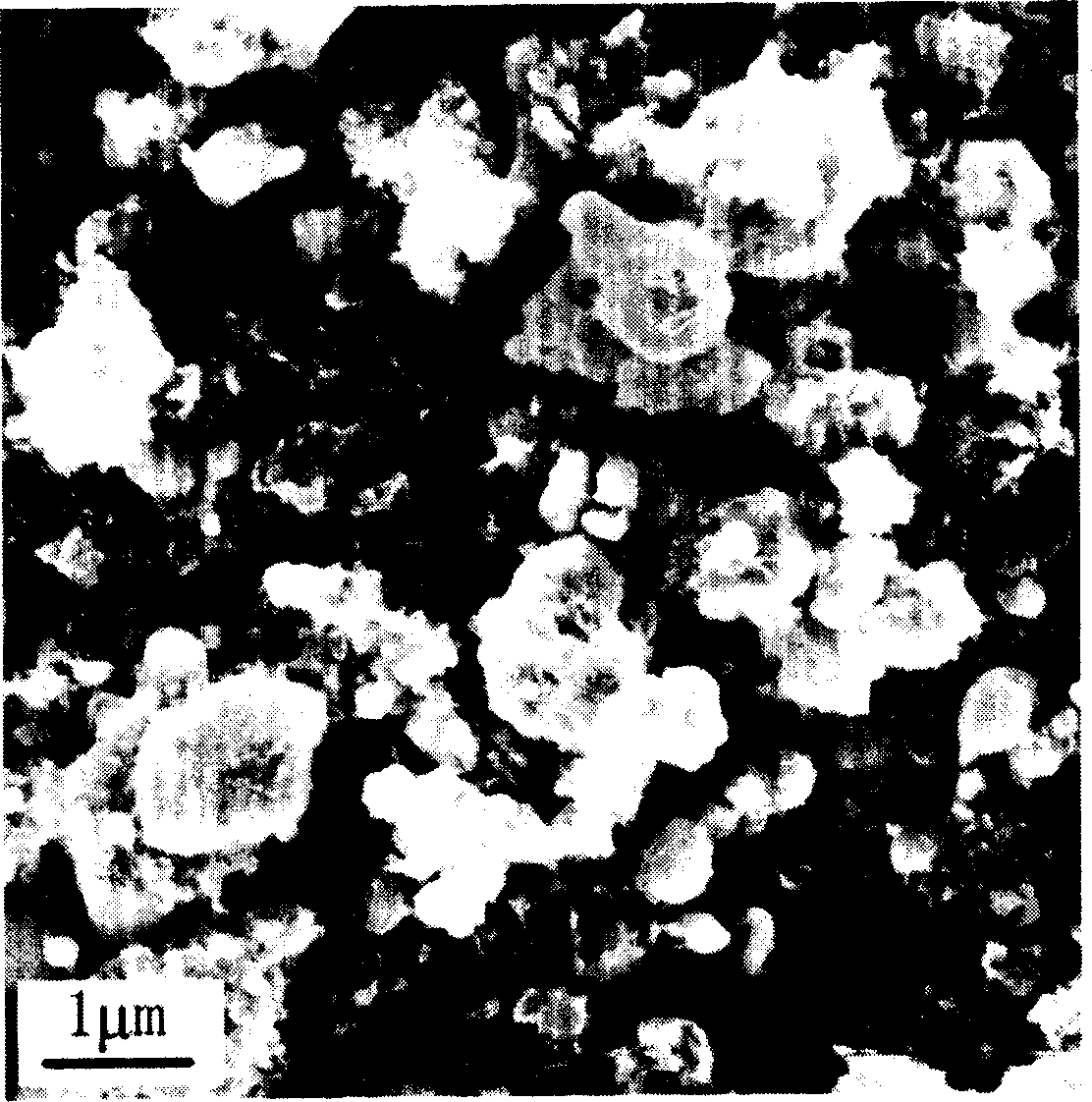

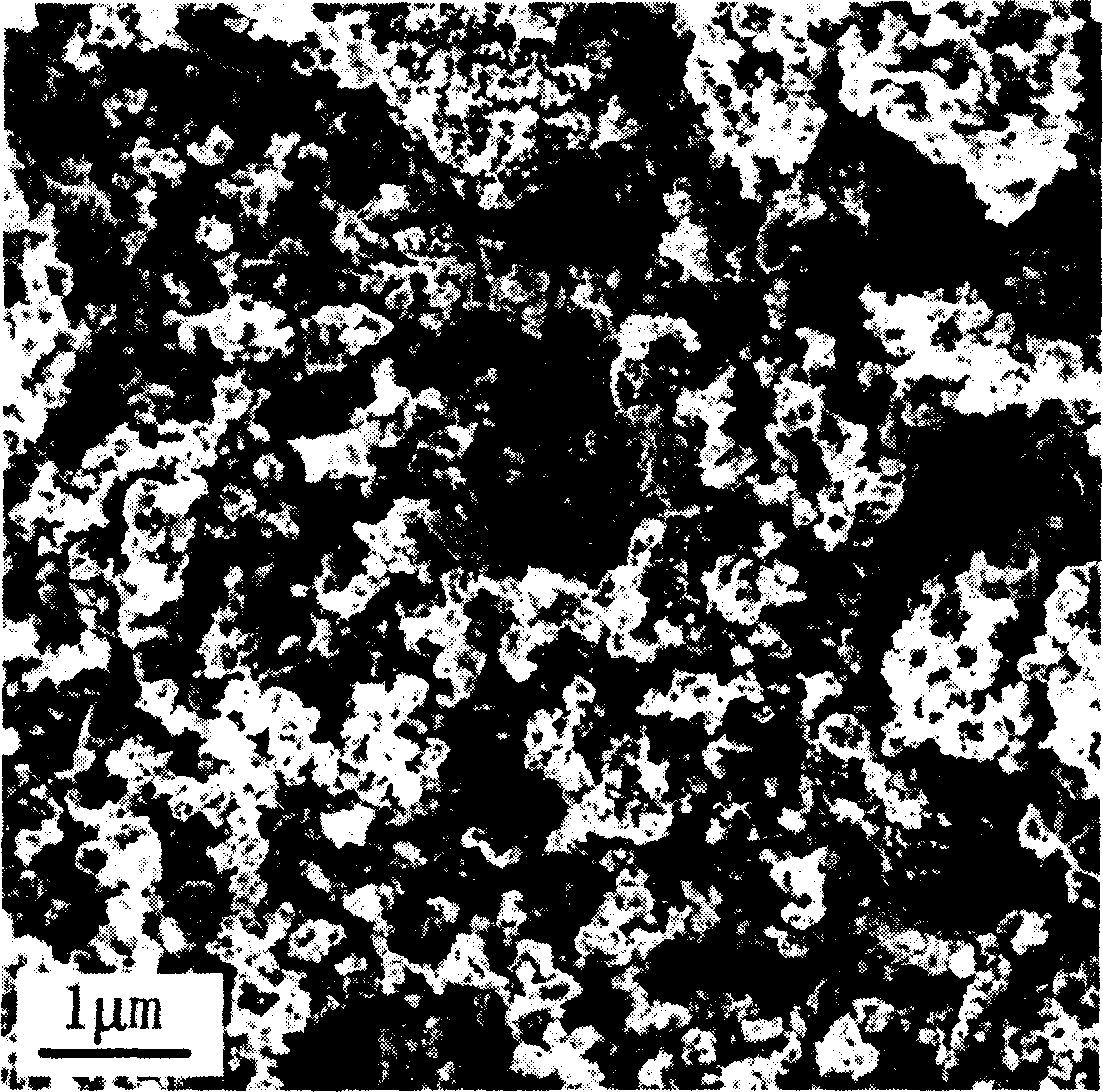

Doping type spinel lithium manganate electrode material and preparation method thereof

The invention discloses a doping type spinel lithium manganate electrode material and a preparation method of the doping type spinel lithium manganate electrode material, wherein the molecular formula of the doping type spinel lithium manganate electrode material is LiMn2-x-yMxNyO4; and in the formula, M and N are doping elements and selected from any two of Al, Mg, Cr and Co, and x+y is greater than 0 and less than 0.6. According to the doping type spinel lithium manganate electrode material, two metal elements M and N are used as epiphase dopants for remarkably improving the structure of pure lithium manganate, so that the proportion of trivalent Mn is further reduced, the stability of the structure is increased and the Jahn-Teller effect is restricted, and at the same time, the metal elements M and N are capable of restricting the dissolution of the Mn on the surface of the lithium manganate, so that the cycle performance and the high / low-temperature performance of the lithium manganate are improved; and at the same time, the epiphase doping has the effect of decreasing the doping amount under the condition with same doping effect, so that benefit is brought to reduce the material cost. The spinel lithium manganate electrode material provided by the invention is characterized by being suitable for the high-power lithium cells of electric tools and electric vehicles.

Owner:焦作伴侣纳米材料工程有限公司

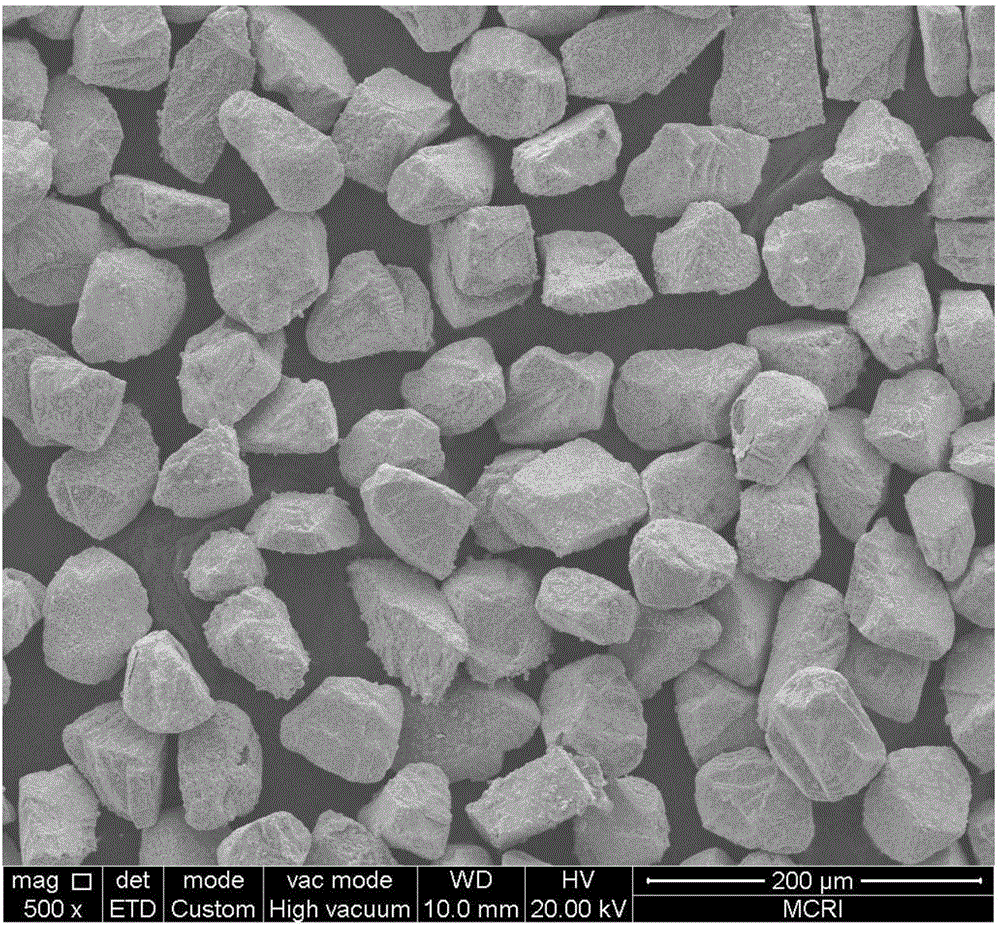

Manufacturing method for diamond honing oilstone

ActiveCN105772730AExcellent grinding efficiencyImprove bindingGrinding devicesReducing atmosphereHardness

The invention relates to the technical field of superhard honing, in particular to a manufacturing method for tungsten-plated diamond honing oilstone. The manufacturing method is characterized in that diamond subject to surface metallization treatment serves as an abrasive material to prepare the honing oilstone. The manufacturing method includes the steps that diamond particles are subject to tungsten-plated pretreatment, and the pretreated diamond particles and a metallic bond are mixed according to a certain proportion to be subject to ball milling; and ball-milled mixing powder is placed into a graphite die to be subject to hot pressing sintering, or arranged in a steel die to be pressed into a green body, and pressureless sintering is carried out in a reducing atmosphere. The diamond honing oilstone manufactured through the method has the beneficial effects of being high in intensity, hardness, grinding efficiency and self-sharpening performance, long in service life, low in process cost, easy and convenient in process and the like.

Owner:ZHENJIANG N E T DIAMOND

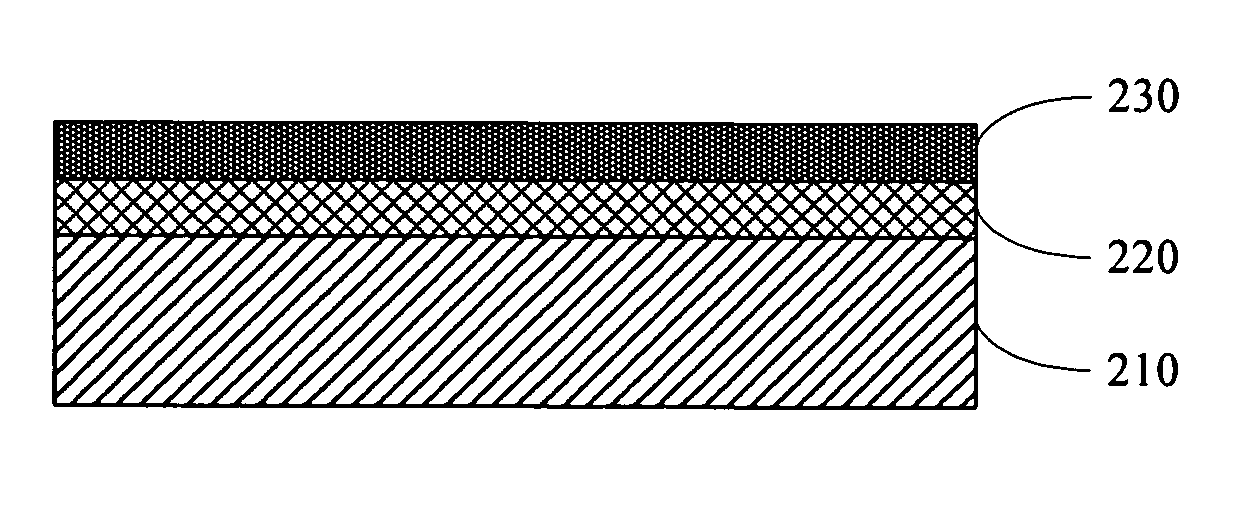

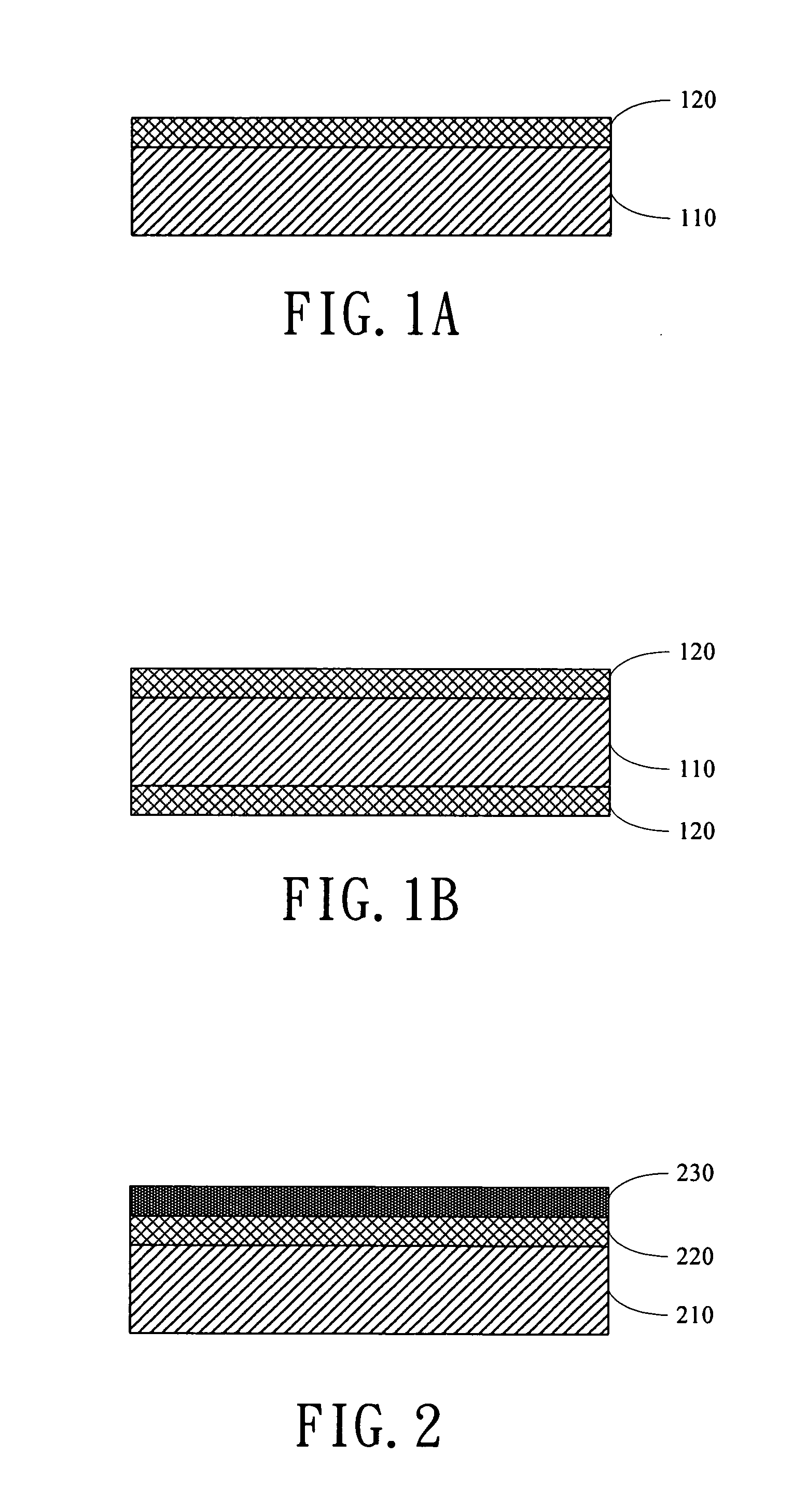

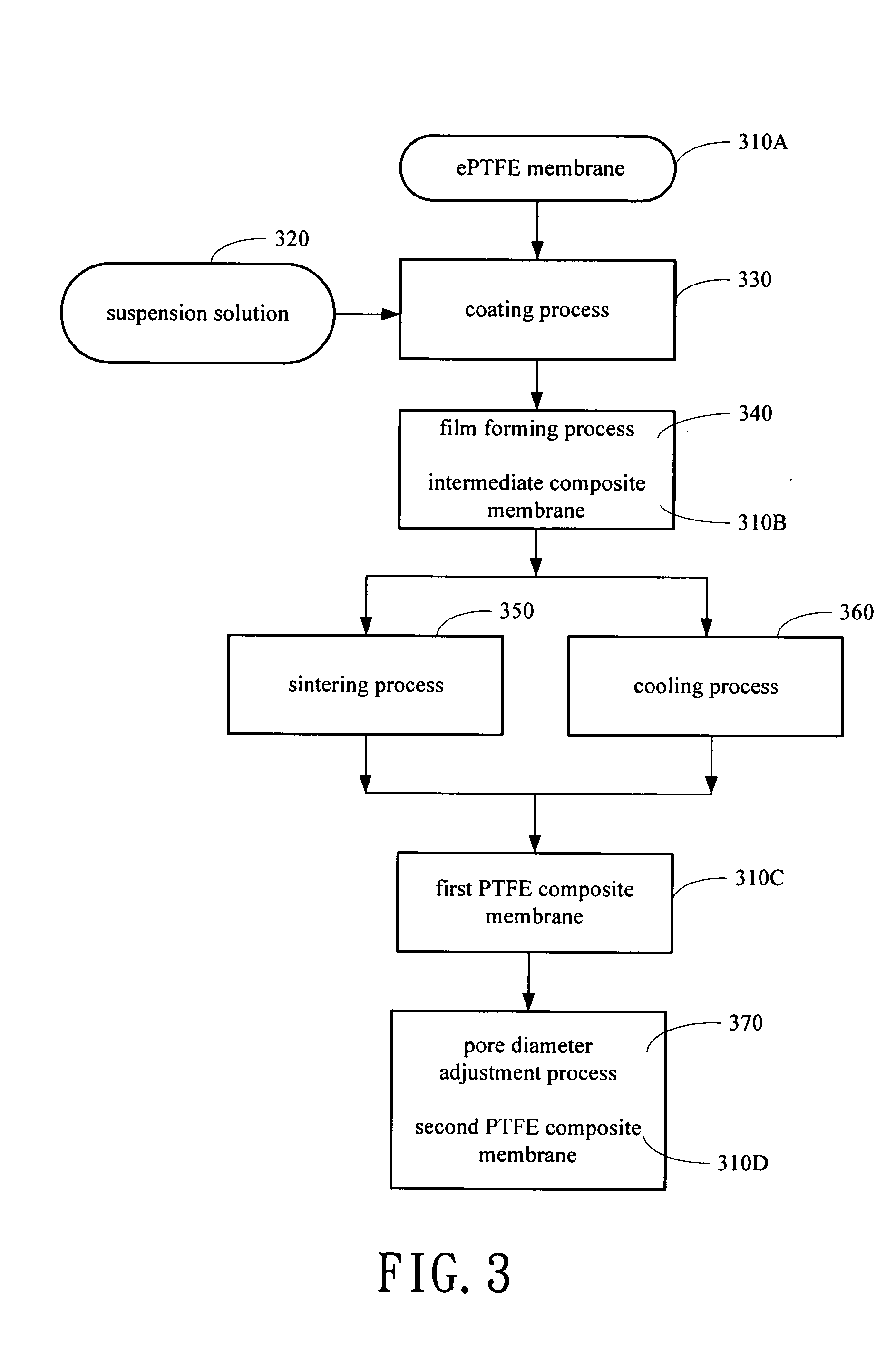

Composite membrane and method for forming the same

ActiveUS20060269735A1Shorten the sintering timeBroaden applicationMembranesSemi-permeable membranesExpanded PTFEMembrane configuration

The present invention discloses discloses a composite PTFE membrane comprising an expanded PTFE membrane as substrate and a sintered porous PTFE membrane on top of it. The porous PTFE membrane on top has porous structure with interconnected channels formed with a sintering process that fuses the PTFE fine powders coated on the ePTFE membrane. Furthermore, the present invention discloses a method for forming the composite PTFE membrane.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Preparation method of metallic bond tool bit and diamond saw web comprising metallic bond tool bit

ActiveCN108097972AEvenly distributedImprove gripTransportation and packagingMetal-working apparatusGraphiteTemperature difference

The invention relates to diamond tools and provides a preparation method of a metallic bond tool bit and a diamond saw web comprising the metallic bond tool bit. The metallic bond tool bit prepared through the method is high in diamond mechanically holding force and acquires appropriate wearing resistance to meet the market development requirements and the cutting requirements of various marble slabs; meanwhile, the sintering temperature range of the metallic bond tool can be expanded, adverse effects caused by sintering conditions such as non-uniform thermal conduction and edge-center temperature difference of graphite molds can be reduced, the sintering temperature can be increased, the material wastage rate can be reduced, and the quality of sintered tool bits can be improved; the welding tolerance temperature can be increased, the selecting range of welding materials can be expanded, and swelling and foaming of matrixes during secondary welding heating of the tool bit can be avoided; besides, the preparation method of the metallic bond tool bit is easy to implement, applicable of large-scale production and high in practicality.

Owner:FUJIAN QUANZHOU HUAZUAN DIAMOND TOOLS CO LTD

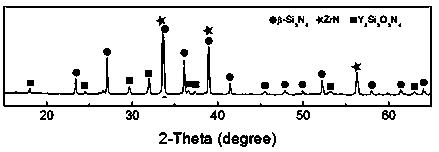

Method for rapidly preparing high heat conduction Si3N4 ceramic with low cost

The invention discloses a method for rapidly preparing high heat conduction Si3N4 ceramic with low cost. The method is characterized in that Si powder is taken as a raw material, ZrO2 powder is taken as a nitridation catalyst, ZrO2-MgO-Re2O3 is taken as a sintering aid, wherein Re2O3 is taken as a rare earth oxide, Si, ZrO2 and MgO-Re2O3 are mixed according to mass fraction and then dried to obtain a Si-ZrO2-MgO-Re2O3 mixing powder; the mixing powder is subjected to a two-step insulation method and a pressureless sintering process to obtain the high heat conduction Si3N4 ceramic; According to the ceramic material, the relative density is higher than 95%, hardness is 8-20 GPa, fracture toughness is 3-8MPa.m<1 / 2>, bending strength is 200-1000Mpa, and the thermal conductivity is 20-100W.m<-1>,K<-1>. By introducing a ZrO2 catalyst, Si powder nitridation IS accelerated, the introduction of ZrO2-MgO-Re2O3 can improve the densification of Si3N4, and the high heat conduction Si3N4 ceramic can be rapidly prepared with low cost.

Owner:GUANGDONG UNIV OF TECH

NdFeB magnet and preparation method thereof

ActiveCN104064301ARefine the grain sizeRaise the sintering temperaturePermanent magnetsInductances/transformers/magnets manufactureIngotCopper

The invention provides an NdFeB magnet which comprises, by mass, 29% to 33% of Pr-Nd, 0.97% to 1.5% of B, 0.4% to 0.6% of Dy, 0.2% to 0.8% of Al, 0.6% to 0.8% of Co, 0.01% to 0.5% of Cu, 0.01% to 0.2% of Zr and the balance Fe. The invention further discloses a preparation method of the NdFeB magnet. The method includes the steps that firstly, Pr-Nd alloy, Zr-Fe alloy, B-Fe alloy, Dy-Fe alloy, aluminum, cobalt, copper and iron are molten to prepare an NdFeB cast ingot; secondly, the obtained NdFeB cast ingot is milled into NdFeB powder; finally, the NdFeB powder is sintered into the NdFeB magnet. The NdFeB magnet prepared through the method has a more refined magnet grain size and higher magnet stability.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

Reinforced iron-base alloy and method for preparing same

The invention discloses a reinforced iron-base alloy and method for preparing same, wherein the powder metallurgy iron-copper alloy (FTG70Cu3-35) is added with alloy elements Cr, which is in the form of high carbon ferro-chrome (CR-Fe) alloy powder.

Owner:HEFEI UNIV OF TECH

Method for preparing lithium vanadium phosphoric acid of anode material of lithium ion battery under high pressure

InactiveCN1872671ASimple processAvoid cumbersome preprocessing stepsCell electrodesEnergy inputAluminium-ion batteryReaction temperature

This invention relates to a high-pressure method for preparing vanadium lithium phosphate used as the anode material for lithium ion batteries. The method comprises: (1) mixing lithium salt, vanadium salt and phosphate uniformly, and ball-milling for 7-24 h; (2) preheating in the air at 200-500 deg.C for 2-12 h to obtain vanadium lithium phosphate. The method has such advantages of simple process, abundant raw materials, no need for reductive gas protection during reaction, short reaction time and low reaction temperature. The product has high capacity and good recycling property, and can be used as the anode material for lithium ion batteries.

Owner:广州鸿森材料有限公司

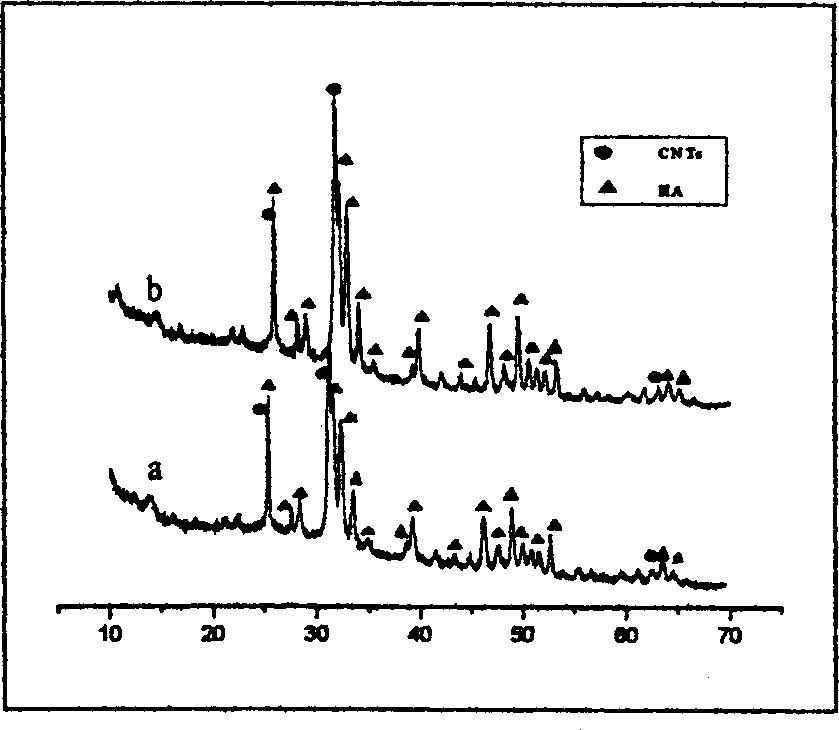

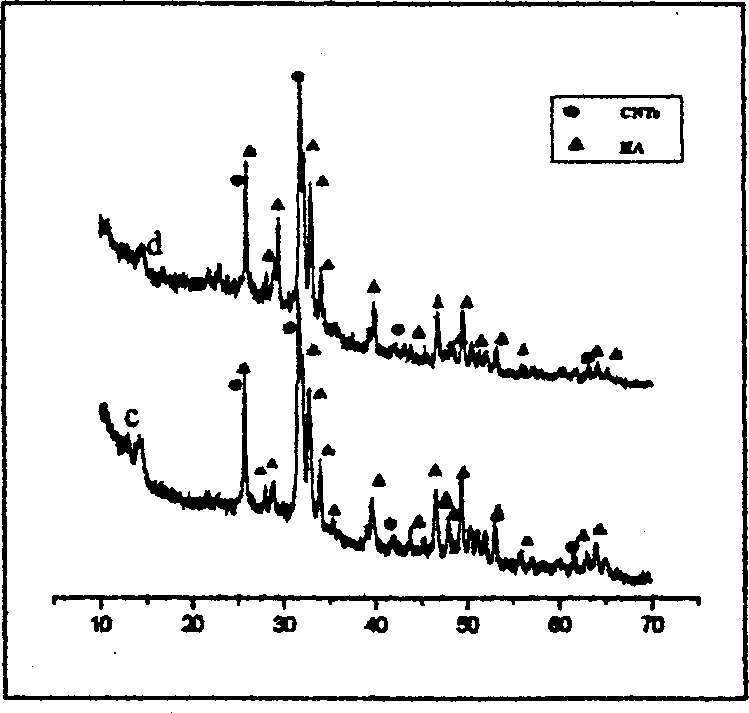

Process for producing nan-hydroxyl kietyoite/carbon nano-pipe compound coating

InactiveCN1772969AAvoid destructionImprove toughnessElectrophoretic coatingsProsthesisArgon atmosphereCarbon nanotube

The present invention provides a method for preparing nano hydroxyapatite / carbon nano tube composite coating by adopting electrophoresis deposition process. Said method includes the following steps: base pretreatment, preparing nano-grade HA and CNTs electrophoresis deposition soliquoid, making the electrophoresis deposition soliquoid undergo the processes of standing still, ultrasonic treatment and centrifugal separation, removing upper layer suspended liquor, making electrophoresis deposition treatment and sintering under the argon atmosphere so as to obtain the invented target product.

Owner:XIAMEN UNIV

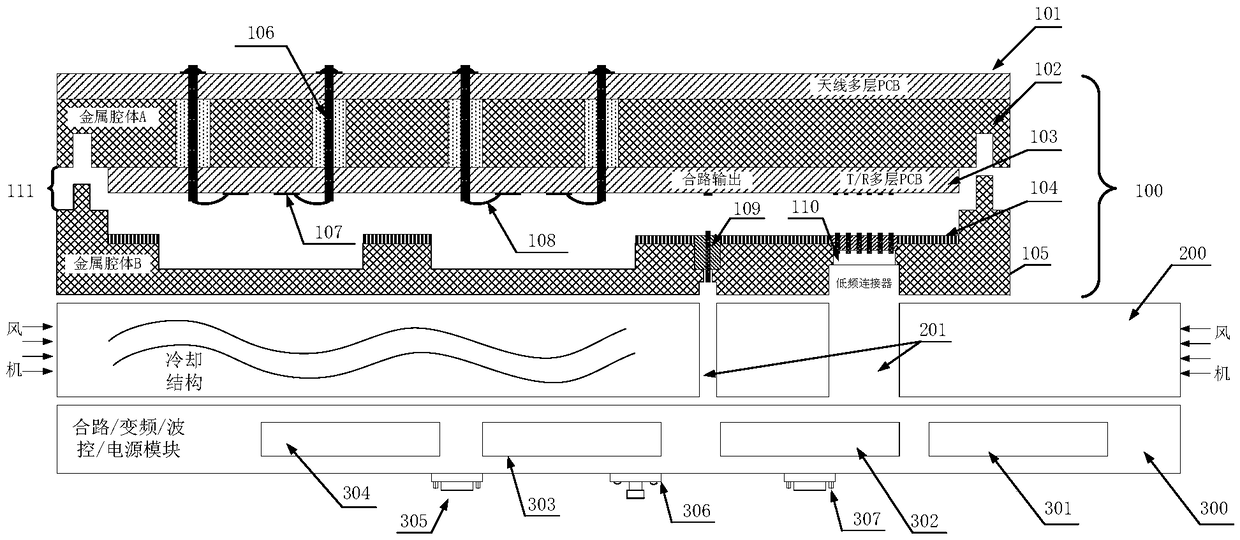

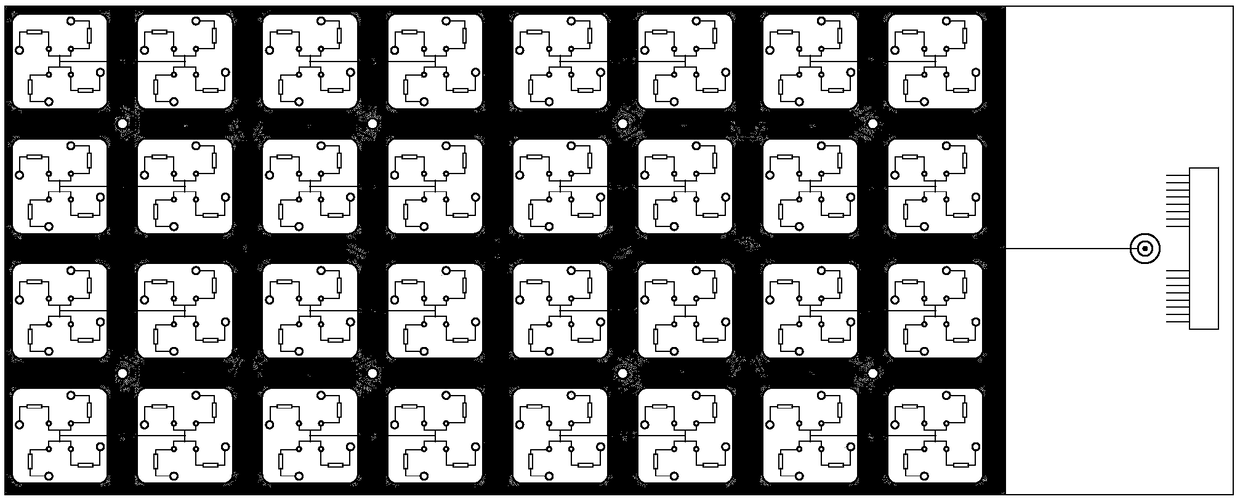

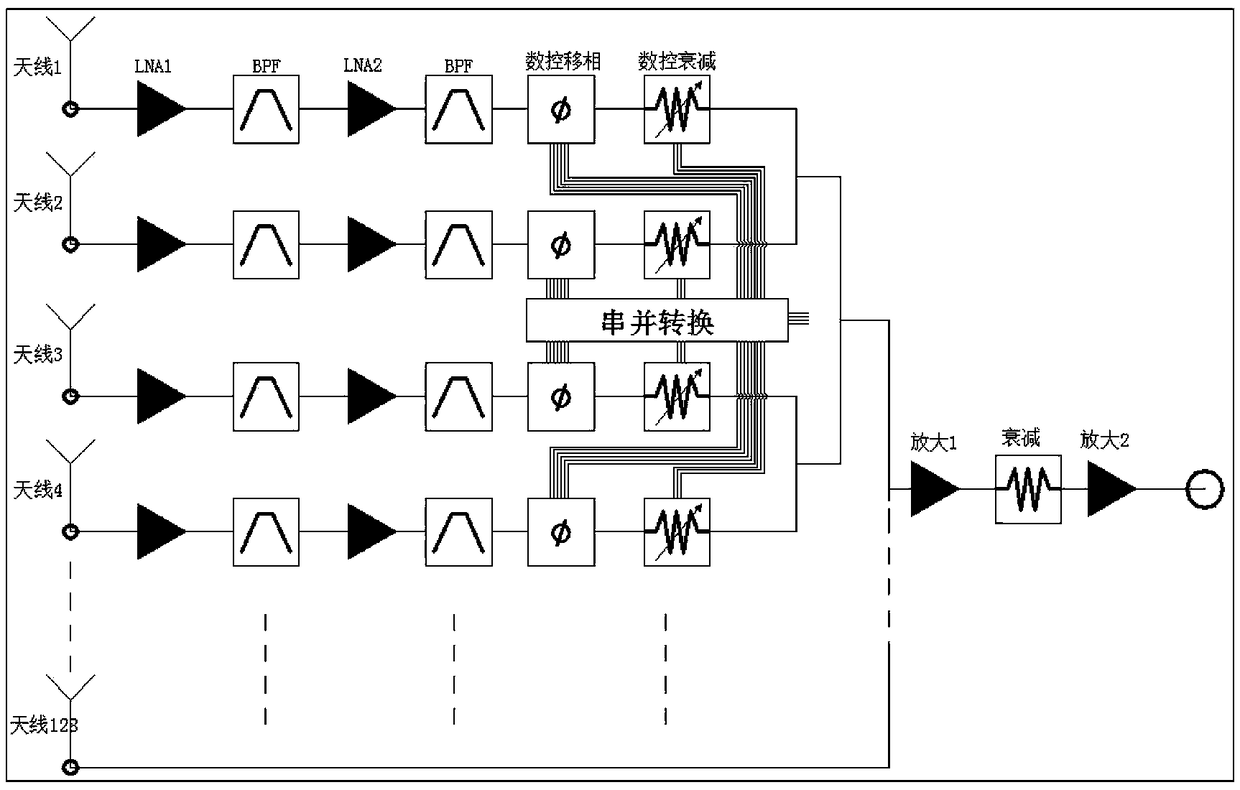

Multi-channel tile-type phased-array transceiver array and manufacturing method thereof

The invention discloses a multi-channel tile-type phased-array transceiver array and a manufacturing method thereof, and belongs to the technical field of phased arrays. The array of the invention comprises a sub-array module layer, a heat dissipation layer and a functional circuit layer, and the sub-array module layer comprises a sub-array module. The sub-array module comprises an upper metal shell and a lower metal shell, wherein a closed cavity is formed between the upper metal shell and the lower metal shell. The upper surface of the upper metal shell is provided with an antenna circuit board, and a lower surface of the upper metal shell is provided with a transceiver circuit board. A power distribution / synthesis network and a power supply control interface are disposed on the transceiver circuit board. The lower metal shell is provided with a second RF connector and a low-frequency connector, and the low-frequency connector is mutually connected with the power control interface. The array has the advantages of good heat dissipation and airtightness, high degree of integration, small size, light weight and convenient use, can effectively reduce the profile height of the array,and is beneficial to realize integration and miniaturization of the array.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Diamond grinding wheel for high-speed four-edge grinding and manufacturing method thereof

InactiveCN104440601AHigh hardnessHigh impact strengthAbrasion apparatusGrinding devicesBronzeMachine tool

The invention discloses a diamond grinding wheel for high-speed four-edge grinding and a manufacturing method of the diamond grinding wheel. The diamond grinding wheel comprises a base body and a work layer, and the work layer is composed of, by volume, 75 percent to 93 percent of bronze bond dedicated alloyed powder and seven percent to 25 percent of diamonds. Firstly, the diamonds are dumped into a grinding bowl, and liquid paraffin is added to be fully wetted with the diamonds. Then, the bronze bond dedicated alloyed powder is dumped for even mixing, and mixtures are obtained. The mixtures are dumped into an assembled mold, the mixtures are placed in a dual-body sintering furnace to be sintered after striking and prepressing, and mold unloading is carried out after sintering and cooling. An obtained semi-finished product is ground and finished, and the diamond grinding wheel for high-speed four-edge grinding is obtained. The diamond grinding wheel for high-speed four-edge grinding has the advantages of being stable in performance, sharp in grinding, high in efficiency, low in cost and the like, and the machining requirement that sheet glass machined by imported and domestic high-speed four-edge grinding machine tools is 30 m / min to the maximum degree can be fully met.

Owner:河南新源超硬材料有限公司

Nano-titania-toughened high-density aluminum nitride-silicon carbide composite circuit board substrate material and preparation method therefor

The invention discloses a nano-titania-toughened high-density aluminum nitride-silicon carbide composite circuit board substrate material. According to the material, aluminum nitride powder and silicon carbide powder are used in a mixed manner, so that the material has high heat conduction and environment-friendliness; a mixed solvent prepared from quaternary ammonium salt ionic liquid, anhydrous ethanol and the like has better wettability to composite powder compared with the traditional organic solvents, and the compatibility among powders is good, so that a stable interpenetrating network structure can be formed, and the utilization ratio of raw materials is increased; slurry is good in fluidity and easy to shape, so that the sintering temperature and thermal stability of prepared preforms are better; nano-titania has good affinity, so that the material has the effects of certain reinforcing and toughening, sintering temperature lowering, substrate density improving and the like; and due to sintering auxiliaries and other raw materials, prepared substrates are better in heat conductivity, easy in sintering shaping and high in finished product rate, are thin, tough and durable and can be extensively used as a variety of circuit board substrates.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com