Silicon carbide based composite microwave-absorbing heating body composition and preparation method thereof

A composite material and microwave absorption technology, applied in the field of composite materials, can solve the problems of easy oxidation at the joint, difficult to form a special atmosphere, consumption, etc., and achieve the effect of improving mechanical properties and improving microwave absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The silicon carbide-based composite material absorbing microwave heating element composition of this embodiment is made of the following mass fractions of raw materials: 90 parts of main agent, 10 parts of modifier; 3 parts of binder, 7 parts of water; Silicon carbide powder with an average particle size of 95 μm, the modifier is 7 parts, a mixture of alumina powder with an average particle size of 40 μm, and 3 parts of silica powder with an average particle size of 50 μm, and the binder is 3 parts of polyethylene Alcohol, the solvent is 7 parts distilled water.

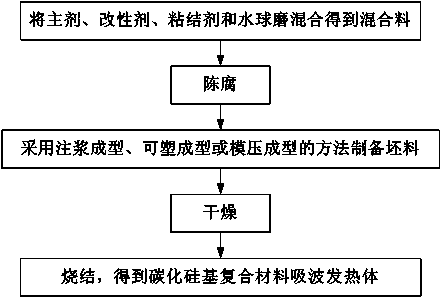

[0045] Reference figure 1 As shown, the preparation method of the silicon carbide-based composite material absorbing microwave heating element composition of this embodiment is carried out in the following steps:

[0046] Step 1. Ball milling: Add the main agent, modifier, binder and water in proportions to the ball mill and mix evenly to obtain a mixture;

[0047] Step two, stale: the mixture described in step ...

Embodiment 2

[0053] In this embodiment, the silicon carbide-based composite material absorbing and heating element is made of raw materials with the following mass fractions: 85 parts of main agent, 15 parts of modifier; 5 parts of binder and 8 parts of water; the main agent is the average particle size It is a 60μm silicon carbide powder, the modifier is a mixture of 9 parts of alumina powder with an average particle size of 40μm and 6 parts of titanium oxide powder with an average particle size of 35μm, the binder is 5 parts of hydroxymethylcellulose, The solvent is 8 parts of distilled water.

[0054] Combine figure 1 , The preparation method of the silicon carbide-based composite material wave-absorbing heating element of this embodiment:

[0055] Step 1. Ball milling: Add the main agent, modifier, binder and water to the ball mill and mix evenly to obtain a mixture;

[0056] Step two, staleness: heat the mixture described in step one at 25°C for 40 hours for staleness treatment;

[0057] Ste...

Embodiment 3

[0062] In this embodiment, the silicon carbide-based composite material absorbing and heating element is made of the following mass fractions of raw materials: 88 parts of main agent, 12 parts of modifier; 6 parts of binder and 28 parts of water; the main agent is the average particle size It is 100 μm silicon carbide powder, the modifier is a mixture of 7 parts of feldspar powder with an average particle size of 50 μm and 5 parts of silica powder with an average particle size of 50 μm, the binder is carboxymethyl starch, and the solvent is distilled water.

[0063] Combine figure 1 , The preparation method of the silicon carbide-based composite material wave-absorbing heating element of this embodiment:

[0064] Step 1. Ball milling: Add the main agent, modifier, binder and water to the ball mill and mix evenly to obtain a mixture;

[0065] Step two, staleness: the mixture described in step one is sealed and kept at a temperature of 25°C for 40 hours for stale treatment;

[0066] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com